Craftsman 917257281 Owner’s Manual

MODEL NO,

917.257281

Caution:

Read and follow

all Safety Rules

and instructmns

Before Operating

This Equipment

ERR

12.0 IC

ELECTRIC START

38" MOWER DECK

5 TRANS/_LE

LAWN TRACTO

•Assembly

oOperation

° Customer Responsibilities

° Service and Adjustment

, Repair Parts

Sears, Roebuck and Co., Chicago, iL 60684 U.S.A.

Safe Operation Practices for Ride-On Mowers

SAFETY RULES

IMPORTANT; THIS CUTTtNG MACHINE IS CAPABLE OF AMPUTATING HANDSAND FEETANDTHROWING OBJECTS,

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

Io GENERAL OPERATION

• Read, understand, and follow all instructionsin the manual

and on the machine before starting,

• Only allow responsible adults, who are familiar with the

instructions, tooperate the machine.

• Clear the area of objects such as rocks, toys, wire, etc.,

which could be picked up and thrown by the blade,

• Besure the area isclear ofother people before mowing. Stop

machine ifanyone enters the area°

- Never carp] passengers.

• Do not mow in reverse unless absolutely necessary,. Always

look down and behind before and while backing,

. Be aware ofthe mower discharge direction and do not point

it at anyone. Do not operate the mower without either the

entire grass cat_her or the guard in place.

• Slow down before turning.

. Never leave a running machine unattended. Always turn off

blades, set parking brake, stop engine, and remove keys

before dismounting,.

• Turn offblades when not mowing.

• Stop engine before removing grass catcher or unclogging

chute.

. Mow only in daylight or good artificial lighL

• Do not operate the machine while under the influence of

alcohol or drugs_

• Watch for trafficwhen operating near or crossing roadways.

• Use extra care when loading or unloading the machine into

a trailer or truck.

I1. SLOPE OPERATION

Slopes are a major factor related to loss-of-controland tipover

accidents, which can result in severe injuryor death. All slopes

requireextra caution. Ifyoucannotbackupthes[opeorifyou feel

uneasy on it, do not mow it.

DO:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

° Watch for holes, ruts, or bumps. Uneven terrain could

overturnthe machine° Ta/l grass can hfde obstacles.

• Use slow speed_Choose a lowgear so thatyouwillnothave

to stopor shiftwhile on the slope_

• Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

• Use extra care with grass catchers or other attachrnents_

These can change the stabilityofthe machine.

. Keep allmovement onthe slopes slow and gradual Donot

make sudden changes in speed or direction.

• Avoid starting or stoppingon a slope, If tires lose traction,

disengage the blades and proceed slowtystraight down the

slope.

DO NOT;

• Donot turnon slopes unlessnecessary, and then,turn slowly

and gradua!ly downhill, if possible,

• Do not mow near drop*offs,ditches, or'embankments The

mower couldsuddenly turn over if a wheel is over the edge

of a cliffor ditch, or if an edge caves in

° Do not mow on wet grass_ Reduced traction could cause

sliding.

° Do not try to stabilize the machine by putting your foot on the

ground.

• Do not use grass catcher on steep slopes

I!1. CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence ofchildren_Childrenareoftenattracted tothe machine

and the mowing activity. Never assume that childrenwillremain

where you last saw them,.

° Keep chtldrenout of the mowing area and underthe watchful

care of another responsible adulL

. Be alert and turnmachine offif children enter the area.,

° Before and when backing, look behind and down for small

children_

• Never' carry chiIdrem They may fall off and be seriously

injuredor interferewith safe machine operation.

° Never allow childrento operate the machine_

• Use extra care when approaching blind corners, shrubs,

trees, or other objectsthat may obscure vlsion.

IV. SERVICE

° Use extra care inhandlinggasoline and otherfuels. They are

flammable and vapors are explosive,

Use only an approved container,

Never remove gas cap or' add fuel with the engine

running_ Allow engine to coolbefore refueling, Do not

smoke.

Never refuel the machine indoors.

Never store the machine orfuel container inside where

there is an open flame, such as a water heater,

• Never run a machine insidea closed area.

• Keep nuts andbolts,especially blade attachment bolts,tight

and keep equipment in good condition.

• Never tamper with safety devices,. Check their proper

operation regularly.

. Keep machine free of grass, leaves, or other debris build-up.

Clean oil or' fuel spillage. Allow machine to cool before

storing,.

• Stop and inspect the equipment [f you strike an object.,

Repair, if necessary, before restarting.

° Never make adjustments orrepairs with the engine running_

• Grass catcher componentsare subjecttowear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace withmanufacturer's recommended parts,when nec-

essary.

- Mower blades are sharp and can cut° Wrap tl_eblade(s) or

wear gloves, and use extra caution when servicing them.

- Check brake operation frequently_ Adjust and service as

required.

Look for this symbol to point out impor-

tant safety precautions. It means

CAUTIONH! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED,

CAUTION: Always disconnect spark

plug wire and place wire where itcannot

contact spark plug In order to prevent

accidental starting when setting up,

transporting, adjusting or making

repairs,

CONGRATULATIONSonyourpurchase of a Sears

Tractor. It has been designed, engineered and manu-

factured to give you the best possibledependabilityand

penormanceo

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

CenteriDepartmento We have competent, well-trained

technicians and the proper tools to service or repair this

unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your unit properly°

Always observe the "SAFETY RULES".

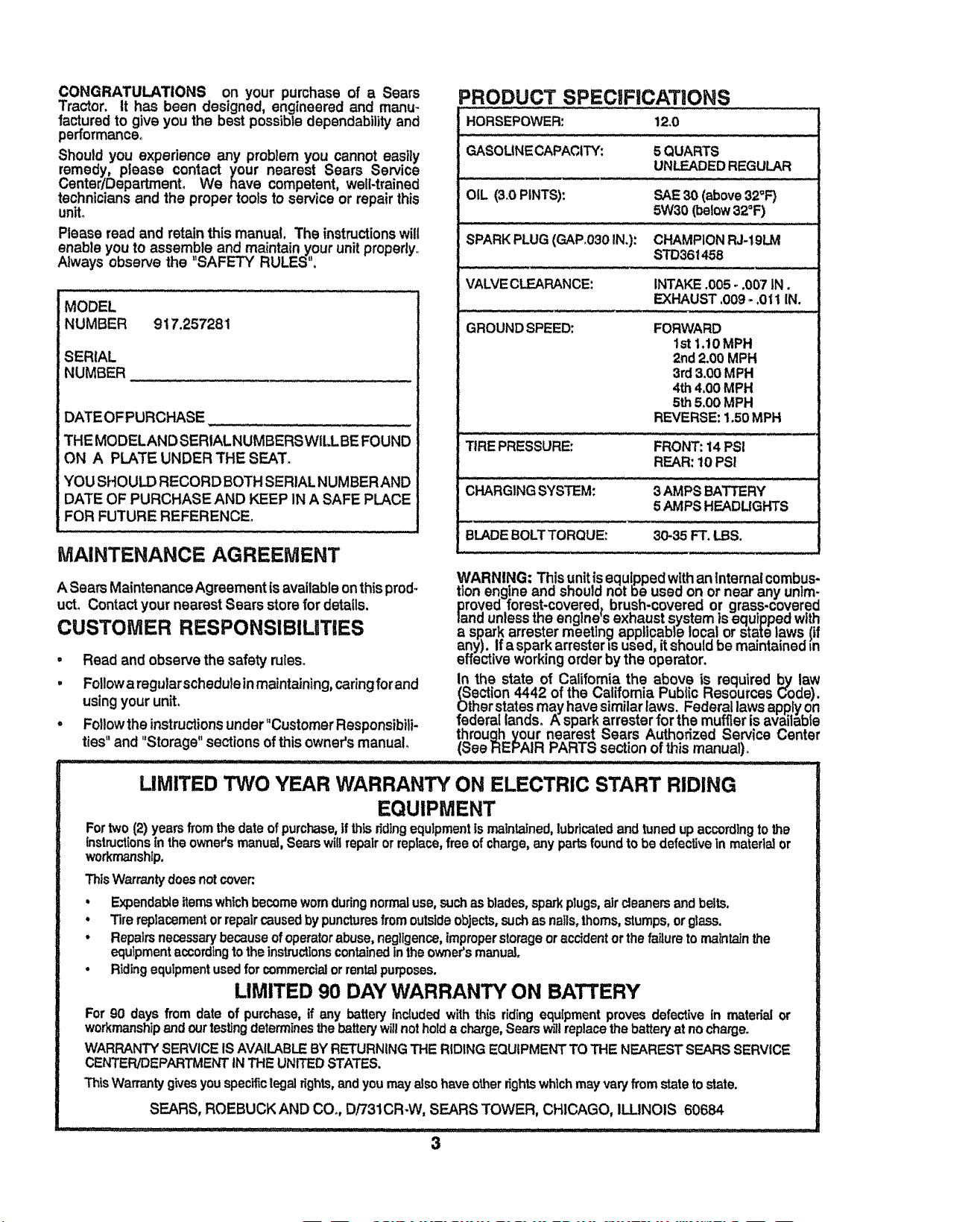

:bRODUCT SPECiFICATiONS

HORSEPOWER: 12.0

.............. H , , ,

GASOLINECAPACITY: 5 QUARTS

UNLEADEDREGULAR

OIL (3.0PINTS): SAE 30 (above32°F)

5W30 (below32°F)

SPARKPLUG(GAP,030IN.): CHAMPIONRJ-lgLM

STD361458

VALVECLEARANCE: INTAKE .005 - .007IN.

MODEL

NUMBER 917.257281

GROUNDSPEED: FORWARD

EXHAUST .009- .01t IN.

1st1.10MPH

SERIAL

NUMBER

2nd2.00 MPH

3rd3.00 MPH

4th4.00 MPH

5th5.00 MPH

DATEOFPURCHASE

THE MODELAND SERIALNUMBERSWILLBE FOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTHSERIAL NUMBERAND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

TIREPRESSURE:

CHARGINGSYSTEM: 3AMPS BATTERY

REVERSE: 1.50MPH

FRONT: 14 PSI

REAR:10 PSi

5AMPS HEADLIGHTS

BLADEBOLTTORQUE: 30*35FT. LBS.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available onthisprod-

uct. Contact your nearest Sears store fordetails.

CUSTOMER RESPONSIBIUTIES

II

Read and observe the safety rules.

0

Followaregularschedutein maintaining, caringfor and

usingyour unit.

Followthe instructionsunder"Customer Responsibili-

ties"and "Storage" sectionsof this owner's manual,

;; ; .............. : .... ;;; ; ; Hi ill ................. ::.... ......... : :

WARNI.NG: This unitisequippedwlth anInternalcomb.us-

on engine ano snould not be usea on or near any unlm:

proved forest-coveredt brush-covered or gras.s-coverea

lana unlessthe engine s exhaust systemis equipped with

a spark arrester meeting applicable local orstate laws lif

any). ira spart_arrester =sused, itshould be maintainea m

effective workingorder bythe operator.

In the state of California the above is required by law

(Section 4442 of the California P,ublic Hesources Code).

Other states may have similarlaws. Federallaws applyon

Teaerallanaso P,spark arres_ermr the muttler isavailable

through your nearest Sears Authorized Service Center

(See REPAIR PARTS section ofthis manual).

LIMITED TWO YEAR WARRANTY ON ELECTRIC START RIDING

EQUIPMENT

Fortwo (2)yearsfrom thedateofpurchase,if thLsridingequipmenttsmaintained,lubricated andtunedupaccordingtothe

instructionsin theowner'smanuaJ,Searswillrepairorreplace,free ofcharge,anypartsfoundtobedefectiveInmaterialor

workmanship.

ThisWarrantydoesnotcover:

• Expendabletternswhichbecomewornduringnormaluse,suchasblades,sparkplugs, aircleanersandbelts.

• Tirereplacementorrepaircausedbypuncturesfrom outsideobjects,suchas nails,thorns,slumps,orglass.

• Repairsnecessarybecauseofoperatorabuse,negligence,improperstorageor accidentorthefailuretomaintainthe

equipmentaccordingtotheinstructionscontainedintheowner'smanual.

• Ridingequipmentusedfor commercialorrentalpurposes.

UMITED 90 DAY WARRANTY ON BATTERY

For90 days from date of purchase,if any batteryincluded withthis ridingequipmentprovesdefectiveIn material or

workmanshipandourtestingdeterminesthebatterywillnotholdacharge,Searswillreplacethe batteryatnocharge.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHE RIDINGEQUIPMENTTO THE NEARESTSEARSSERVICE

CEI_.,rrEFI/DEPARTMENTINTHE UNITEDSTATES.

ThisWarrantygivesyouspecificlegalrights,andyoumayalsohaveotherdghtswhtchmayvaryfromstatetostate.

SEARS, ROEBUCK AND CO, D/731CR-W, SEARS TOWER, CHICAGO, ILLINOIS 60684

.,. ,, .......

3

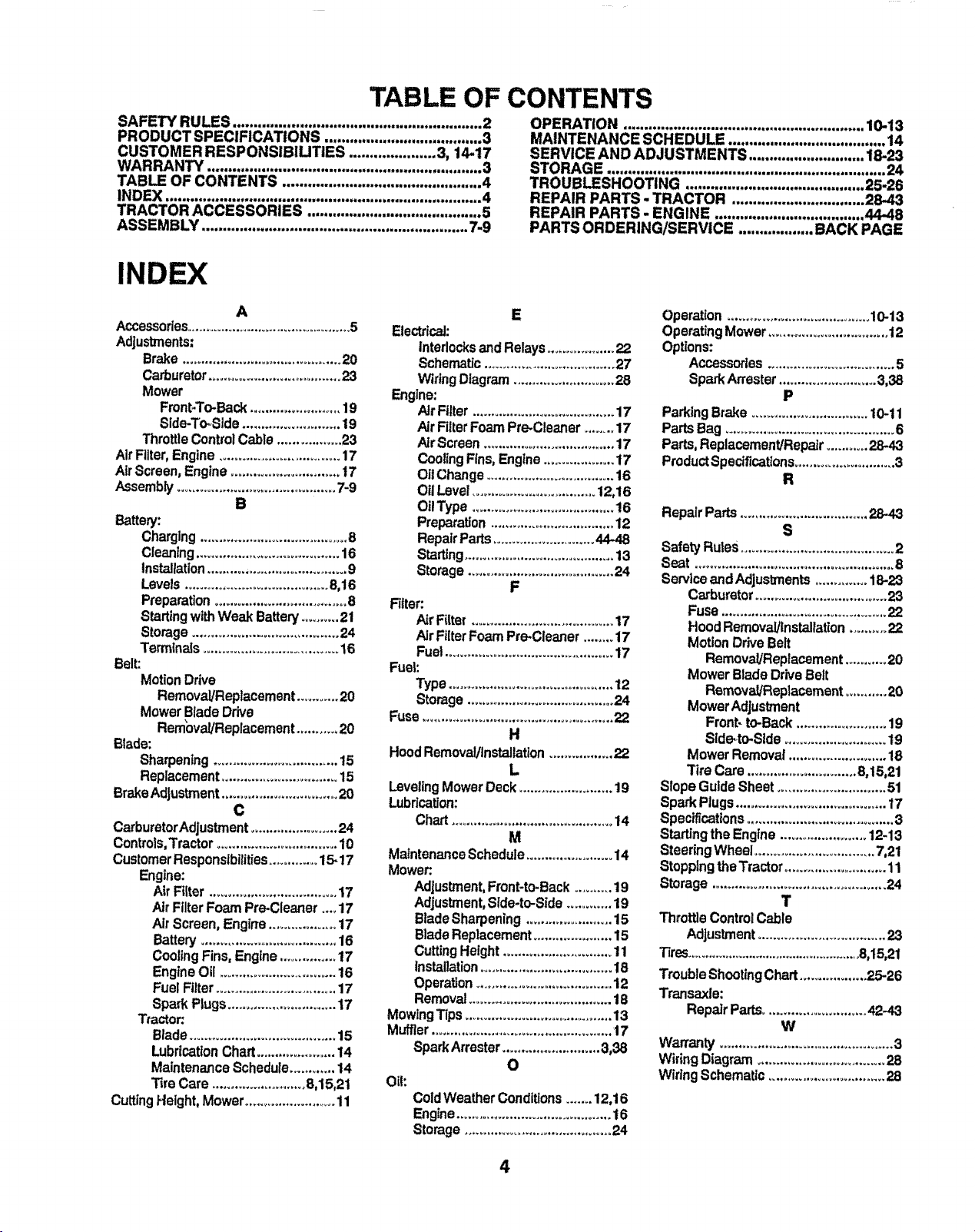

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBIUTIES ..................... 3, 14.17

WARRANTY .................................................................. 3

TABLE OF CONTENTS ................................................ 4

INDEX ............................................................................ 4

TRACTOR ACCESSORIES .......................................... 5

ASSEMBLY ................................................................ 7-9

INDEX

OPERATION .......................................................... 10-13

MAINTENANCE SCHEDULE ...................................... 14

SERVICE AND ADJUSTMENTS ............................ 18-23

STORAGE ................................................................... 24

TROUBLESHOOTING ........................................... 25-26

REPAIR PARTS - TRACTOR ................................ 28-43

REPAIR PARTS - ENGINE .................................... 44-48

PARTS ORDERING/SERVICE .................. BACK PAGE

A

Accessories............................................5

Adjustments:

Brake..........................................20

Carburetor...................................23

Mower

Front-To-Back........................19

Side-To_Slde..........................19

ThrottleControlCable .................23

Air Filter,Engine................................17

AirScreen,Engine.............................t7

Assembly..........................................7-9

B

Battery:

Charging.......................................8

Cleaning......................................16

tnstaJlatton.....................................9

Levels......................................8,16

Preparation...................................8

StartingwithWeakBattery..........21

Storage.......................................24

Term{na_s....................................16

Belt:

MotionDrive

Removal/Replacement...........20

MowerBladeDrive

Rein'oval/Replacement...........20

Blade:

Sharpening ..................................t5

Replacement...............................15

BrakeAdjustment...............................20

C

CarburetorAdjustment.......................24

Controls,Tractor................................10

CustomerResponsibilities.............15-17

Engine:

AirFilter..................................17

AirFilterFoamPre-Cleaner....!7

Air Screen,Engine..................17

Battery....................................16

CoolingFins,Engine...............17

EngineOil ...............................16

FuelFilter................................17

SparkPlugs.............................17

Tractor:.

Blade.......................................15

Lubrication Chart.....................14

MaintenanceSchedule............14

TireCare .........................8,15,21

CuttingHeight,Mower.........................11

E

Electrical:

InterlocksandRelays...................22

Schematic...................................27

WiringDiagram...........................28

Engine:

AirFilter......................................17

Air FilterFoamPre.Cleaner........17

Air Screen...................................17

CoolingFins,Engine...................17

OilChange..................................16

OilLevel.................................12,16

OilType ......................................16

Preparation.................................12

RepairParts...........................44-48

Starting........................................13

Storage.......................................24

F

Filter:

Air Filter......................................17

AirFilterFoamPre-Cleaner........17

Fuel.............................................17

Fuel:

Type............................................12

Storage.......................................24

Fuse...................................................22

H

HoodRemova!/Installation.................22

L

LevelingMowerDeck.........................19

Lubrication:

Chart...........................................14

M

MaintenanceSchedule.......................14

Mower:.

Adjustment,Front-to-Back..........19

Adjustment,Side-to-Side............19

BladeSharpening.......................15

BladeReplacement.....................15

CuttingHeight..............................11

installation....................................18

Operation....................................12

Removal......................................18

MewingTips.......................................13

Muffler................................................17

SparkArrester..........................3,38

O

Oil:

ColdWeatherConditions.......12.16

Engine.........................................16

Storage.......................................24

Operation......................................10-13

OperatingMower................................12

Options:

Accessories..................................5

SparkArrester..........................3,38

P

ParkingBrake ...............................10-11

PartsBag .............................................6

Parts,Replacement/Repair...........28-43

ProductSpecifications...........................3

R

RepairParts..................................28-48

S

SafetyRules.........................................2

Seat ..................................................... 8

ServiceandAdjustments..............t8-23

Carburetor...................................23

Fuse.............................................22

HoodRemoval/Installation..........22

MotionDriveBelt

Removal/Replacement...........20

MowerBladeDriveBelt

Removal/Replacement...........20

MowarAdjustment

Front-to-Back........................19

Side to-Side ...........................19

MowerRemoval..........................18

"TireCare .............................8.15,21

SlopeGuideSheet.............................51

SparkPlugs........................................17

Specifications.......................................3

StartingtheEngine........................12-13

SteeringWheel................................7,21

StoppingtheTractor...........................11

Storage..............................................24

T

ThroffieControlCable

Adjustment..................................2.3

Tires...................................................8,15.21

TroubleBhootingChart..................25-26

Transaxle:

RepairParts...........................42-4.3

W

Warranty..............................................3

WiringDiagram..................................28

WiringSchematic...............................28

4

ACCESSORIES AND ATTACHMENTS

Thoseaccessoriesand attachmentswereavailablewhentheunitwaspurchased.Theyare alsoavailableat mostSearsretailoutlets,

catalogandservicecenters. MostSearsstorescanorderthoseitemsforyouwhenyouprovidethemodel numberofyourtractor.

ENGINE

SP KPLua MUFFLER AIR FILTER

GASCAN

........F.N iNEO,L

STABILIZER

PERFORMANCE

Searsoffersawidevarietyof attachmentsthat fityourvehicle.Manyoftheseare listedbelowwithbrief explanationsof howtheycan

helpyou.Thisllstwascurrentatthetimeofpublloation;hov_evar,itmaychangetnfutumyears-moreattachmentsmaybeadded,changas

may bemade Intheseattachments,orsomemaynolonger beavailableor fit yourmodeL Contactyour nearest Searsstore forthe

accessoriesand attachmentsthatareavailable foryour unit,

Mostoftheseattachmentsdo notrequireadditionalhitchesorconversionkits(thosethatdoare indicated)and are designedforeasy

attachinganddetaching.

MAINTENANCE

BLADES BELTS

PERMANEX BAGGER letsyoucollect grassclippingsand

leaves for a healthier,neater looking lawn. Two Permanex

containershold30-galtonplasticbags.

LAWN SWEEPERSletyoucollectgrassclippingsand leaves.

LAWN VACS for powerfulcollectionof heavygrassclippings

andleaves.Wandattachmenttoplokupdebrtsinhard4o_reash

places,

CARTSmakehaulingeasy. Varietyofsizesavailable.

ROLLER for smootherlawn surface. 36-inchwide,18-inch

diameterwater-ttghtdrumhotdsupto390Ibs_ofweighLRounded

edgespreventharmto turf. Adjustablescraperautomatically

cleansdrum.

SPREADER/SEEDERS make seeding, fertilizing, and weed

kBlingeasy, Broadcastspreaders are also useflJtforgranularde-

Icers and sand,

CORING AERATOR takes small plugsout of sot! to allow

moistureandnutrientstoreachgrass roots_36-1nchswath.24

hardenedsteelcoringtips. 150tb.capacityweighttray.

AERATOR promotesdeep root growthfor a healthylawn,

Tapered2_5-tnchsteelspikesmountedon 104nchdiameter

dtscspunctureholesinsoilatcloseintervalstoletmoisturesoak

in. Steelweighttrayforincreasedpenetration.

MULCH RAKE/DETHATCHER loosenssoiland flipsthatch

and matted leavesto lawnsurfaceforeasy pickup. Twenty

springtinsteeth_ Usefulto preparebare areas for seeding°

Availableforfrontorrearmounting.

SPRAYERSuse 12weltDCelectricmotorthatconnectstothe

tractorbatteryor other 12-vottsource° Includesboomsfor

automaticsprayingwhenpurling,andhandheldwandfor spot

spraying.Wand has adjustable spraypattern_For applying

herbicides,insecticides,fungicides,andliquidfedilizers_

SNOW BLADE forsnowremovalonly. 14-inchhigh,42-inch

widebladeclears38-Inchpathwhenangledleftorright.Raises,

lowerswithsidelever,Adjustableskids;replaceable,reversible

scraperbar° (Use withtirechains,wheel weights,or rear

drawbarweight.)

SNOWTHROWERhas40-inchswath.Drum.typeaugerhandles

powderyandwet/heavy snow. Mountseasilywithsimplepin

arrangement°Dischargechuteadjustsfrom tractorseat.6-inch

diameterspoutdischargessnow10to 50feet. LiftcontroUedat

tractorseal (Usewithchains,wheelweights,or reardrawbar

weight,)

TIRECHAINSare heavyduty;closelyspacedextra-largecross

linksgivesmoothride,outstandingtraction.

WHEELWEIGHTSfor rearwheelsprovideneededtractionfor

snowremovalordozingheavymaterials.Inpairs.(30Ibs_each.)

TRACTORCAB hasheavydutyvinylfabric overtubularsteel

frame, ABS plastictop; clear plasticwindshieldoffers360

degreevisibility.Hingedmetaldoorswithcatch. Keepsoperator

warmand dry. Removevinyland wtndshietdsfor useas sun

protectorinsummer,(Catalogonly.)

Optionalaccessories for tractor cab: tinted/temperedsoled

safetyglasswindshieldwithhandoperatedwiper;12-voltamber

cautionlightformounting oncabtop. (Catalogonty.)

TRACTOR COVER protectstractor from weather. Made of

Evolution3 fabric(water-repeUent,extremelybreathable,light

weight,soft,non.abrasive,pliabteinall temperatures,durable,

staln/tear/punctureresistant,willnotshrinkorstretch.)(Catalog

only,)

TILIJ'Rcultivatesandpreparessolllnoneoperatlon_UsesFro

fromtractor; 12counter-rotatingblades_Breaksgroundwith

upper-cutaction,thendeflectsandrattlesitIntoasoft,aerated

soil, Chain*drivetransmission.Tills 21-inch path, 6-inchas

deep. (Usechainsandwheelweights.)

I'ILLER has 5 hpengineand 36-inchswathtoprepareseed

beds,cultivate,and compostgardenresidue.Tillerhasits own

built.in liftanddepthcontrol systemand does NOT requirea

sleevehitch,.Fitsanylawn,yard,orgardentractor.Simplyt_ok

uptothetractordrawbarandgot

iiiiiii1,,, I ................................ ii/!1 .... ii I1'111111"1' i,, i,i I IIII '1 I LI]II!

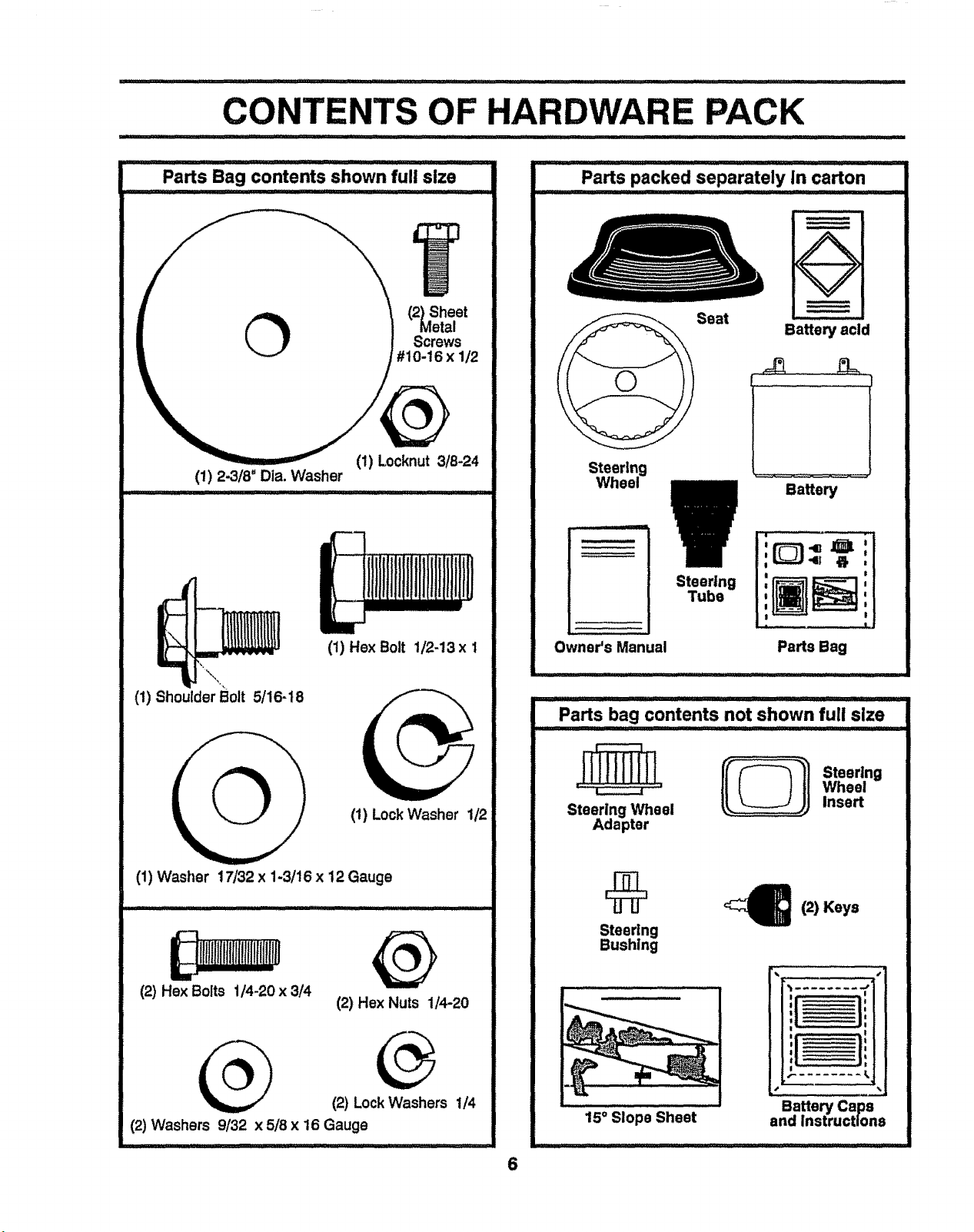

CONTENTS OF HARDWARE PACK

,HWI'II' '= III1' I ................................................................ ..........

iii1,11,ii .. ill ,1[ , L'IJJl

Parts Bag contents shown full size

i,i ..... ii I , iiii1! ii

Parts packed separately In carton

,,!, I,LI

©

(1) 2-3/8" Dia. Washer

(1) Shoulder I_olt 5/16-t8

'\\\/#10.16 x 1_/2

(1) Locknut 3/8-24

(1) Hex Bolt 1/2-13 x 1

Seat

Battery acid

Steering

Wheel

Battery

Steering

Tube

Owner's Manual

........................ _ ,, ,11 iiii 1,1,1,i i'

Parts Bag

Parts bag contents not shown full size

(1) LockWasher 1/2

(1) Washer 17/32 x 1-3/16 x 12 Gauge

(2) Hex Nuts 1/4-20

(2) LockWashers 1/4

(2) Washers 9/32 x 5/8 x 16 Gauge

........_ • Wheel

J'_ I(_ 1 Steering

Steering Wheel Insert

Adapter

<_(2) Keys

Steering

Bushing

% •

,,ll ,.HL I

...... I

15° Slope Sheet

Battery Caps

and Instructions

, L,,,,...............

LY

............r '"'""................ :

"Your newiract0r has been assembled at the factory withexceptionof those partsleft unassembled for shipping purposes.

To ensure safe and proper operation of your tractor, allparts and hardware you assemble must be tlghtened securely. Use

the correct toolsas necessary to insure their propertightness.

TOOLS REQUIRED FOR ASSEMBLY

Asocket wrench setwitlmake assembly easier. Standard

wrench sizes are listed.

(1) 5/16" wrench

(2) 7/16" wrenches

(1) 1/2"wrench

(1) 9/16" wrench

When right and left hand ts mentioned in this manual, it

means when you are In the operating position (seated

behindthe steering wheel).

TO REMOVE UNIT FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 6).

• Cutalong dotted lines oncarton,from toptobottom, all

four comers of carton and lay panelsflat.

• Check for any additional loose parts or cartons and

remove.

(1) 3/4" wrench

Screwdriver

Tire pressure gauge

Utilityknife

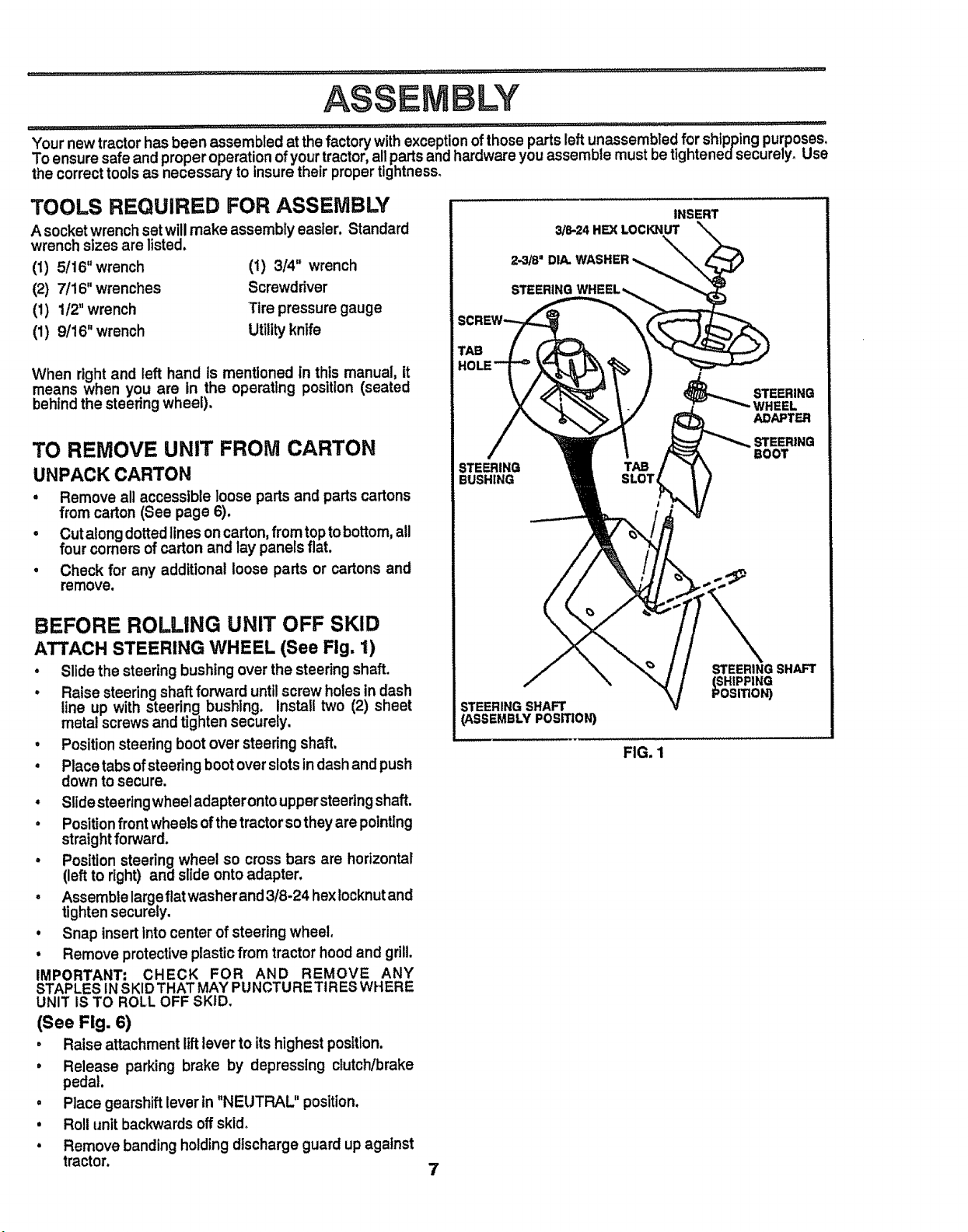

STEERING

BUSHING

STEERING

NHEEL

ADAPTER

STEERING

BOOT

BEFORE ROLLING UNIT OFF SKID

ATTACH STEERING WHEEL (See Fig. 1)

• Slidethe steering bushingover the steeringshaft.

• Raise steeringshaft forward untilscrew holesin dash

line up with steering bushing. Install two (2) sheet

metal screws and tighten securely.

• Positionsteering boot over steedng shaft.

• Place tabs ofsteeringbootover slotsindash and push

down to secure.

• Slidesteertngwheeladapteronto uppersteeringshaft.

• Positionfront wheels of the tractorsothey are pointing

straightforward.

• Positionsteering wheel so crossbars are horizontal

(leftto right) and slide onto adapter.

• Assemblelarge flatwasher and 3/8-24 hexlocknutand

tighten securely.

, Snap insert into center of steering wheel.

• Remove protective plasticfrom tractor hoodand grill.

IMPORTANT: CHECK FOR AND REMOVE ANY

STAPLES INSKID THAT MAY PUNCTURETtR ESWHERE

UNIT tS TO ROLL OFF SKID.

(See Fig. 6)

• Raise attachment liftlever to itshighest position.

• Release parking brake by depressing clutch/brake

pedal.

, Place gearshiftlever in "NEUTRAL" position.

• Rollunit backwardsoffskid°

° Remove banding holdingdischarge guard up against

tractor.

STEERINGSHAFT

(ASSEMBLYPOSITION)

7

STEERING SHAFT

$oHIPPING

snlON)

FIG. 1

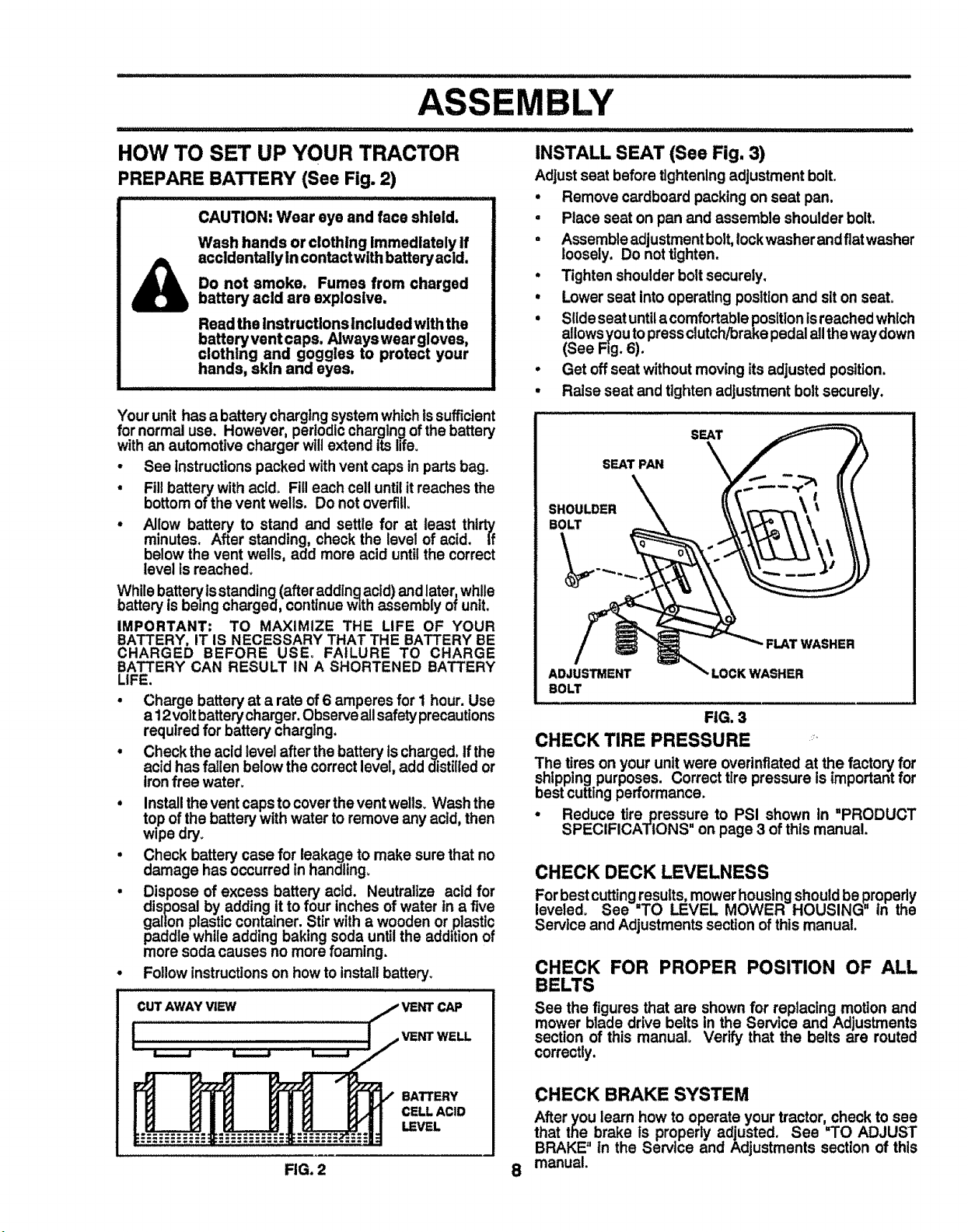

HOW TO SET UP YOUR TRACTOR

PREPARE BATTERY (See Fig. 2)

I II I I , ii , i,ii,i,1,ii,ii,iiiii,iiii,ii,iiii, I, III, , L !LLLIJLI

CAUTION: Wear eye and face shield.

Wash hands or clothing immediately If

accidentally In contactwlth batteryacid.

Do not smoke, Fumes from charged

battery acid are explosive,

Read the lnstrucUons Included with the

battery vent caps. Always wear gloves,

clothing and goggles to protect your

hands, skin and eyes,

Yourunit has a battery chargtngsystem whtch ts sufficient

for normal use, However, periodiccharging ofthe battery

with an automotive charger will extendits life.

• See instructionspacked withvent caps inparts bag.

• Fill battery with acldo Fill each cell untilit reaches the

bottomof the vent wells. Do not overfill.

• Allow battery to stand and settle for at least thirty

minutes. After standing, check the level of actd. tf

below the vent wells, add more acid untilthe correct

level Is reached.

While batterytsstanding (afteraddlng acid) and later,while

battery isbeing charged, continuewith assembly of unit,

iMPORTANT: TO MAXIMIZE THE LIFE OF YOUR

BATTERY, IT IS NECESSARY THAT THE BATTERY BE

CHARGED BEFORE USE° FAILURE TO CHARGE

BATTERY CAN RESULT IN A SHORTENED BATTERY

LIFE.

• Charge battery at a rate of 6 amperes for t hour. Use

a 12volt batterycharger, Observe all safety precautions

required for battery charging.

. Check the acid level after the battery ts charged, if the

acid has fallen below the correctlevel, add distilled or

Iron free water,

. Installthe ventcaps tocoverthe vent wells. Wash the

top ofthe battery withwater to remove any acid, then

wipe dry.

. Check battery case for leakage to make sure that no

damage hasoccurred in handling_

• Dispose of excess battery acid. Neutralize acid for

disposal by adding it to four inches of water in a five

gallon plastic container. Stir with a wooden or plastic

paddle while adding baking soda untilthe additionof

more soda causes no more foaming.

• Follow instructionson how toinstall battery.

CUT AWAY VIEW jVEWr CAP

!

I _ _ _ ........._

INSTALL SEAT (See Fig. 3)

Adjust seat beforetightening adjustment bolt.

• Remove cardboard packing on seat pan,

• Place seat on pan and assemble shoulder bolt.

• Assembleadjustment bolt,lockwasher andflatwasher

loosely. Do notttghten.

• Tighten shoulderbolt securely.

• Lower seat into operating position and siton seat.

• Slide seat untila comfortablepositionisreachedwhich

allowsyoutopressclutch/brake pedalallthe waydown

(See Fig. 6).

• Get offseat without movingits adjusted position.

• Raise seat and tighten adjustmentboltsecurely.

SEAT

S_TP_

SHOULDER

BOLT

!

FLAT WASHER

ADJUSTMENT LOCK WASHER

BOLT

FIG. 3

CHECK TIRE PRESSURE

The tires on your unit were overinflated at the factoryfor

shipping purposes. Correct tire pressure Is importantfor

bestcuttingperformance.

• Reduce tire pressure to PSI shown In "PRODUCT

SPECIFICATIONS" on page 3 of this manual.

CHECK DECK LEVELNESS

Forbestcutting.:esults,mower housingshould bepropedy

leveled. See TO LEVEL MOWER HOUSING" in the

Service and Adjustmentssection of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts In the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

BATTERY

CELL ACID

_VEL

FIG. 2 8

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted, See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual.

ASS SLY

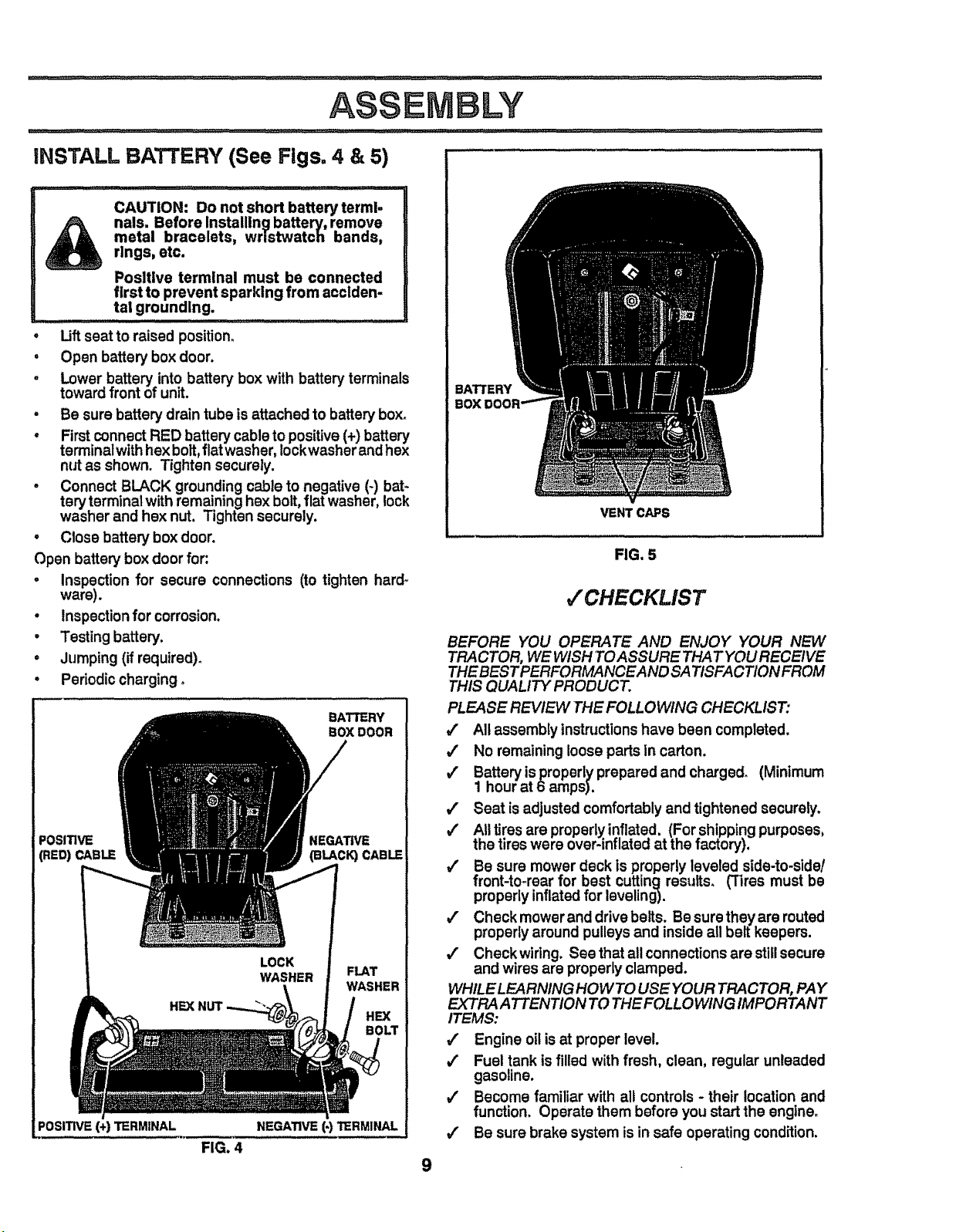

iNSTALL BATTERY (See Figs, 4 & 5)

CAUTION: Do not short batten=/termi-

nals, Before Installing battery, remove

metal bracelets, wristwatch bands,

rings, etc.

Positive terminal must be connected

first to prevent sparking from acclden-

tat grounding.

Liftseat to raised position_

, Open battery box door.

, Lower battery intobattery box with battery terminals

toward front of unit.

, Be sure battery drain tube isattached to battery box°

• Firstconnect RED batter_jcableto positive (+)battery

terminalwith hex bolt, flatwasher, Iockwasher and hex

nut as shown. Tighten securely.

° Connect BLACK grounding cable to negative (-) bat-

tery terminal with remaining hex bolt, flat washer, lock

washer and hex nut. Tighten securely.

• Close battery box door.

Open battery box door for:

, inspection for secure connections (to tighten hard-

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required)°

° Periodic charging.

BATTERY

BOX DOOR

POSITIVE _IEGATIVE

(RED) CAB_ (BLACK) CABLE

FLAT

WASHER

POSITIVE (+) TERMINAL NEGATIVE (.) "tERMINAL

FIG. 4

BATTERY

VENT CAPS

FIG. 5

,/'CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WEW/SH TOASSURE THATYOU RECEIVE

THE BEST PERFORMANCE AND SAT/SFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

_/ All assembly instructions have been completed.

,/ No remaining loose parts in carton.

/ Battery isproperly prepared and charged. (Minimum

1 hour at 6amps).

4" Seat isadjusted comfortably and tightened securely.

#' All tires are properlyinflated. (For shippingpurposes,

the tires were over-inflatedatthe factory).

v" Be sure mower deck is properly leveled side-to-side/

front-to.rear for best cutting results. (Tires must be

properly inflated forleveling).

#" Check mower and drivebelts. Be surethey are muted

properlyaround pulleys and inside all belt keepers.

4" Check wiring. See that all connectionsare stillsecure

and wires are properly clamped.

WHILE LEARNING HOWTO USE YOUR TRACTOR, PAY

EXTRA A TTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

v" Engine oil is at proper level.

#" Fuel tank isfilled with fresh, clean, regular unleaded

gasoline.

€" Become familiar with all controls - their location and

function. Operate them before you startthe engine.

4" Be sure brake system is in safe operating condition.

9

i .... iiiii1,,i........... _ ii ,i ii iii , ii ii1,111,111111111 i I i i i, ,11, II'H :

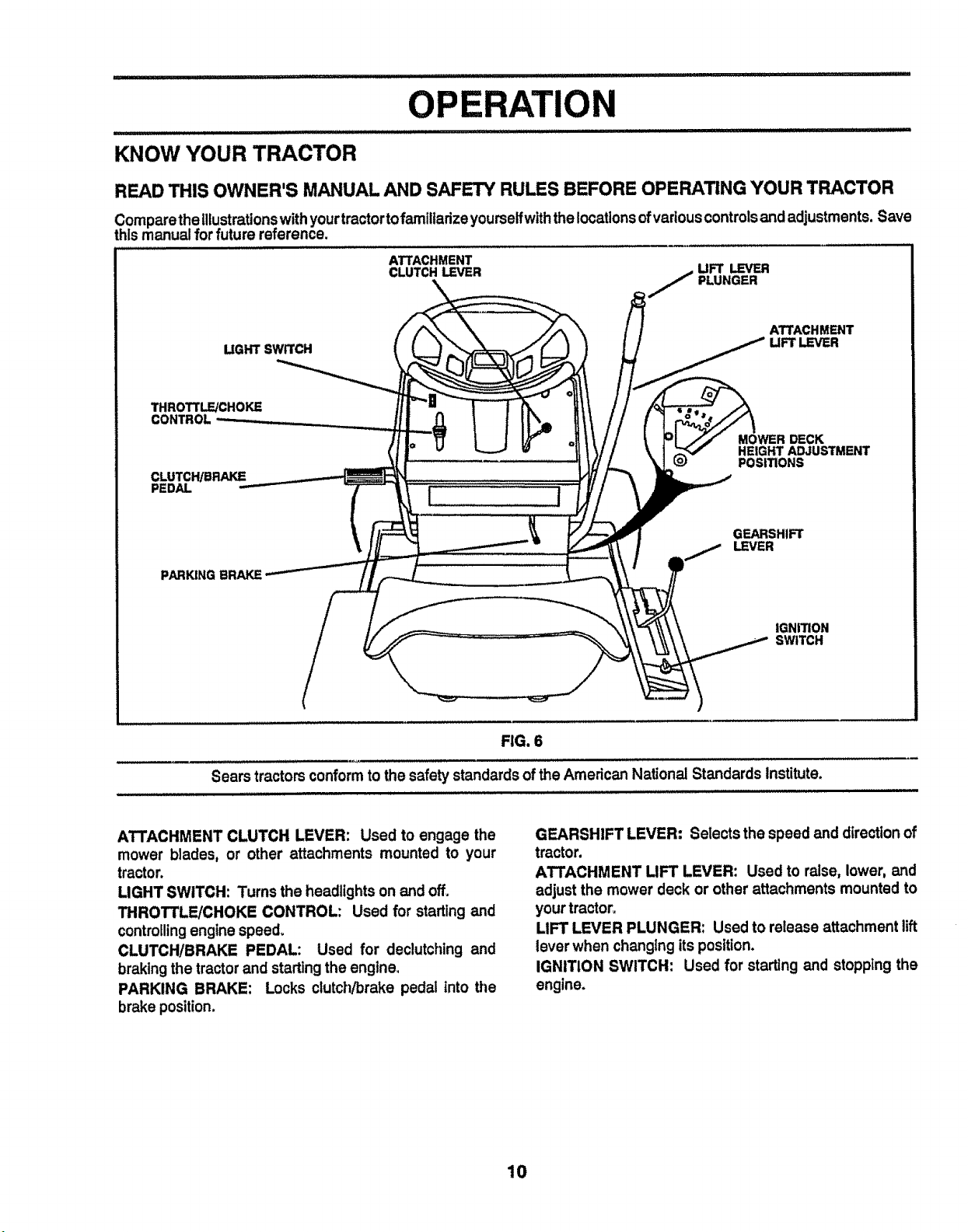

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Comparethe,tustrations withyour tractortofamiltadze yourselfwiththe locations ofvariouscontrolsand adjustments. Save

thismanual for future reference,

ATTACHMENT

UGHT SWITCH

THROTTLEJCHOKE

CONTROL

CLUTCH/BRAKE

PEDAL

CLUTCH LEVER LIFT LEVER

PLUNGER

ATTACHMENT

UFT LEVER

MOWER DECK

HEIGHT ADJUSTMENT

POSITIONS

PARKING BRAF,E

Sears tractors conform tothe safety standardsof the American National Standards Institute,

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor,

LIGHT SWITCH: Turns the headlights on andoff,

THROTTLE/CHOKE CONTROL: Used for starting and

controllingengine speed,

CLUTCH/BRAKE PEDAL: Used for declutching and

brakingthe tractorand startingthe engine,

PARKING BRAKE: Locks clutch/brake pedal into the

brake position.

GEARSHIFT

LEVER

IGNmON

SWITCH

)

FIG. 6

GEARSHIFT LEVER: Selects the speed and directionof

tractor,

ATTACHMENT LIFT LEVER: Used to raise, lower, and

adjust the mower deck or other attachments mounted to

yourtractor=

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changingitsposition.

IGNITION SWITCH: Used for starting and stopping the

engine.

10

The operation of any tractor can resultin foreign objectsthrown intothe eyes, which can

result in severe eye damage, Always wear safety glasses or eye shields while operating

your tractor or performingany adjustments or repairs. We recommend wide vision safety

mask for over the spectacles or standard safety glasses, available at Sears Retail or

Catalog stores.

HOW TO USE YOUR TRACTOR

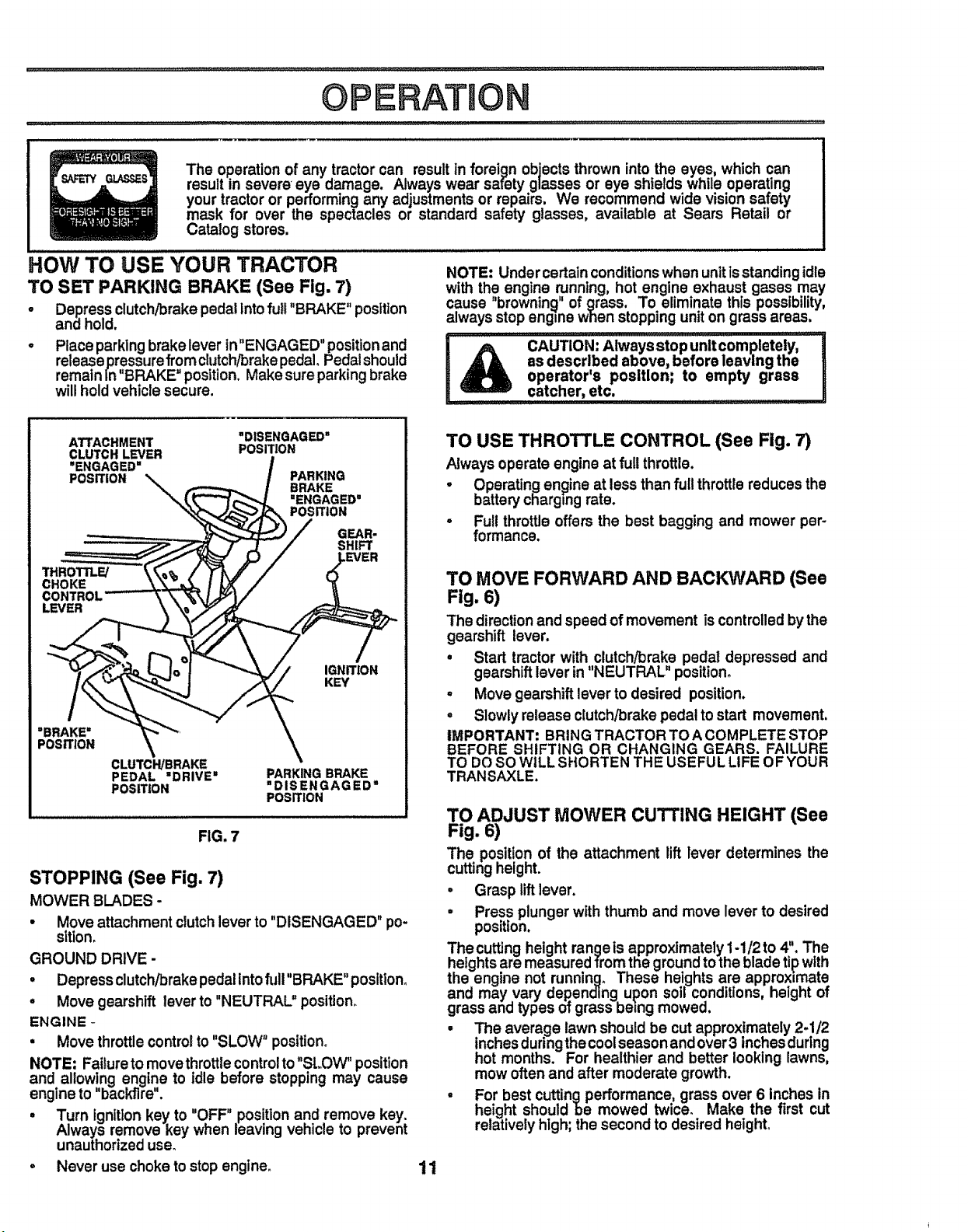

TO SET PARKING BRAKE (See Fig. 7)

• Depress clutch/brake pedalintofult"BRAKE"position

and hold,

- Placeparking brakelever tn"ENGAGED" positionand

releasepressurefrom clutch/brakepedal, Pedalshould

rematn|n"BRAKE"posttion, Make sure parkingbrake

willhold vehicle secure.

ATTACHMENT "DISENGAGED"

CLUTCH LEVER POSITION

"ENGAGED =

POSITION \_-\._ BRAKEPARKING

THROTTLE/

CHOKE

LEVER

"BRAKE =

POSITION

CLUTCH]BRAKE

PEDAL =DRIVE"

POSITION

FIG. 7

STOPPING (See Fig. 7)

MOWER BLADES -

• Move attachment clutchlever to "DISENGAGED" po-

sition,

GROUND DRIVE -

• Depress clutch!brakepedalIntofuIi"BRAKE"posltlon_

• Move gearshift leverto "NEUTRAL" positlon_

ENGINE -

• Move throttle controlto "SLOW" position°

NOTE: Failureto movethrottle controlto"SLOW" position

and allowing engine to idle before stopping may cause

engine to "backfire".

• Turn ignitionkey to "OFF" positionand remove key,

Always remove key when leaving vehicle to prevent

unauthorized use°

• Never use choke tostopengine.

"ENGAGED"

POSITION

GEAR-

SHIFT

IGNITION

KEY

\

PARKING BRAKE

"DISENGAGED"

POSITION

NOTE: Undercertain conditionswhen unit isstanding idle

with the engine Panning,hot engine exhaust gases may

cause "browning" of grass., To eliminate this possibility,

always stop eng=newnen stopping unit on grass areas.

i i i , i ...... ,J_,..,:L.......

as aescrlbea above, before leaving the

operator's position; to empty grass

CAUTION: A.lwpysstopunltcompletely, !

................. ca,tcher, ate,

TO USE THROTTLE CONTROL (See Fig. 7)

Always operate engine at full throttle.

• Operating en_]ineat less than full throttlereduces the

battery charging rate.

o Full throttle ofters the best bagging and mower per-

formance,

TO MOVE FORWARD AND BACKWARD (See

Fig. 6)

The directionand speedof movement iscontrolledbythe

gearshift lever.

, Start tractor with clutch/brake pedal depressed and

gearshift lever in "NEUTRAL" position.

• Move gearshift lever to desired position.

• Slowly release clutch/brake pedal to start movement.

IMPORTANT; BRtNGTRACTORTOACOMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS. FAILURE

TO DO SO WILL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLE.

TO ADJUST MOWER CUTTING HEIGHT (See

Fig, 6)

The positionof the attachment lift lever determines the

cuttingheight.

• Grasp liftlever.

• Press plunger with thumb and move lever to desired

position.

The cuffingheight range is approximately 1-1/2 to 4". The

heights are measured from the ground to the blade tip with

the engine not n,nning. These heights are approx=mate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut approximately 2-1/2

!nches during the coolseason and over3 inchesduring

hot months. For healthier and better Iooklng lawns,

mow often and after moderate growth.

• For best cuttingperformance, grass over 6 Inches in

height shouldbe mowed twice, Make the first cut

relatively high; the second to desired height,

11

OPERATION

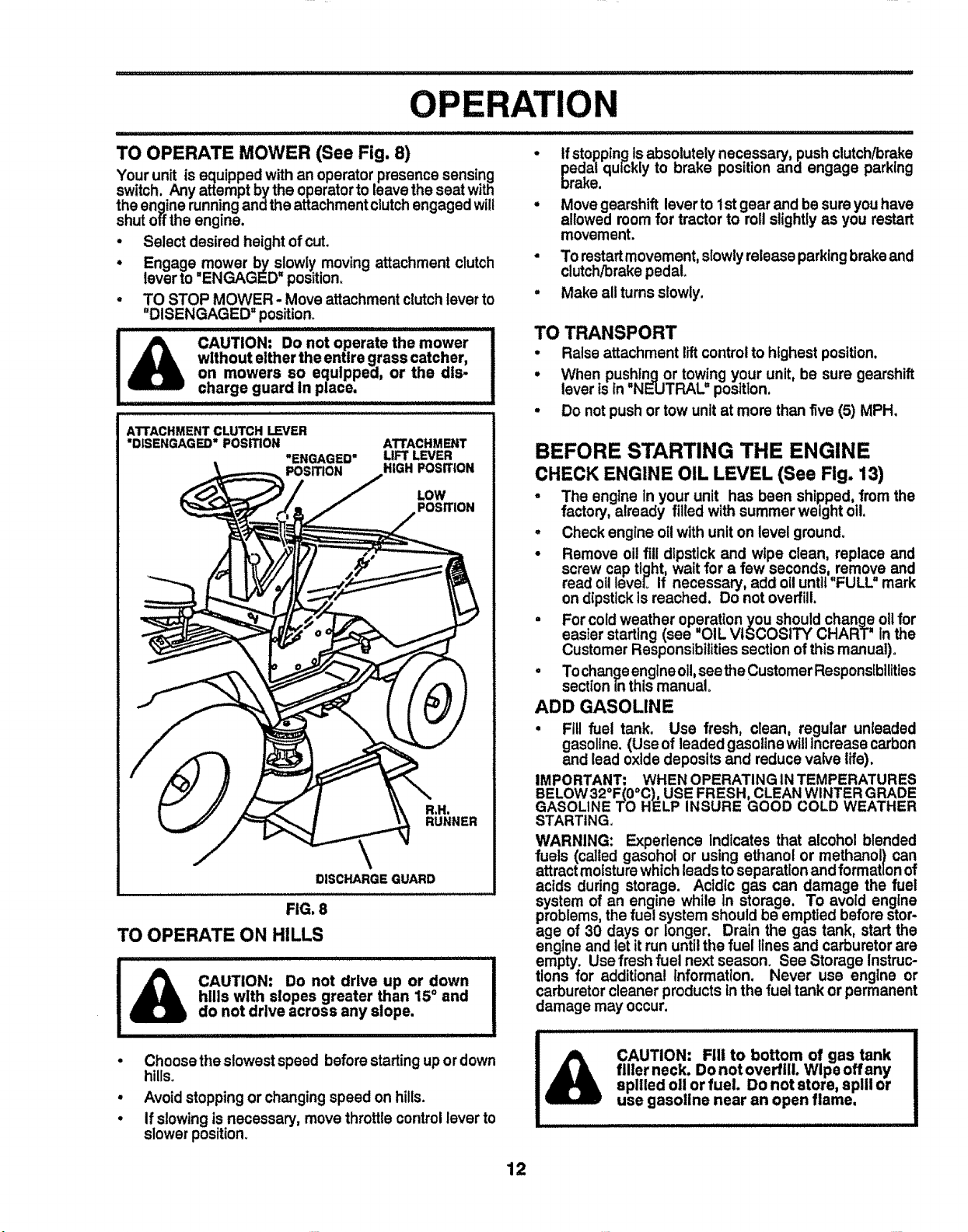

TO OPERATE MOWER (See Fig. 8)

Your unit is equipped with an operator presence sensing

switch. Any attempt bythe operatorto leave the seatwith

the eng!ne runningand the attachmentclutch engaged will

shut offthe engine.

• Select desired height of cut.

• Engage mower by slowly moving attachment clutch

lever to "ENGAGED" position_

• TO STOP MOWER- Move attachment clutchlever to

"DISENGAGED" positton_

CAUTION: Do not operate the mower

without either the entire grass catcher,

on mowers so equipped, or the dis-

charge guard In place.

ATTACHMENT CLUTCH LEVER

"DISENGAG _n. PosmoN

"ENGAGED"

POSITION

DISCHARGE GUARD

FIG. 8

ATTACHMENT

LIFT LEVER

HIGH POSITION

LOW

POSITION

R_HI

RUNNER

TO OPERATE ON HILLS

CAUTION: Do not drive up or down

&

L -_ ................................................ i i Ill I II Ill

hills wlth slopes greater than 15 and

do not drive across any slope.

o

• If stoppingIs absolutely necessary, push clutch/brake

pedal quickly to brake positionand engage parking

brake.

• Move gearshift leverto1st gear and be sureyouhave

allowed roomfor tractor to roll slightly as you restart

movement.

To restartmovement,slowly release parkingbrakeand

clutch/brakepedal.

°

Make all turns slowly.

TO TRANSPORT

• Raiseattachment rift control to highest position.

• When pushing or towing your unit, be sure gearshift

lever istn "NEUTRAL" position.

• Do notpush or tow unitat more than five (5) MPH.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 13)

- The engine In your unit has been shipped, from the

factory, already filled with summer weight oil

° Check engine oil with uniton level ground.

• Remove oil fill dipstick and wipe clean, replace and

screw cap tight, wait for a few seconds, remove and

read 011level If necessary, add oiluntil"FULL" mark

on dipstickls reached. Do not overfill.

• For cold weather operationyou should change oil for

easier starting (see "OIL VISCOSITY CHART" Inthe

Customer Responsibilitiessection of this manual).

• Tochangeenglneoil,seethe CustomerResponstbUities

sectionin this manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasoline. (Use of leaded gasolinewillincrease carbon

and lead oxide deposits and reduce valve life).

IMPORTANT; WHEN OPERATING INTEMPERATURES

BELOW32°F(0°C), USE FRESH, CLEANWINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience Indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attractmoisturewhich leads toseparationand formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while In storage. To avoid engine

problems, thefuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run untilthe fuel linesand carburetor are

empty. Use fresh fuel next season. See Storage Instruc-

tions for additional Information. Never use engine or

carburetor cleaner products inthe fuel tank or permanent

damage may occur.

o

Choose theslowest speed before starting upor down

hills_

•&.voidstopping or changingspeed on hills.

ifslowing is necessary, movethrottle control lever to

slower position.

CAUTION: Fill to bottom of gas tank

filler neck. Do not overfill. Wipe off any

spilled oli or fuel. Do not store, spill or

use gasoline near an open flame,

12

OPERATnO

TO START ENGINE (See Fig. 7)

When starting engine for the first time or if engine has

run out of fuel, it will take extra cranking time to move

fuel from the tank to the engine.

• Depress the clutch!brake pedal and set the parking

brake.

• Place gearshift lever in "NEUTRAL" position_

o Move attachment clutchto "DISENGAGED" position.

• Move throttle controllever to "CHOKE" positionfor

cold engine start. For warm engine start, move

throttle control to "FAST" position.

attempts, move h o on o to FAS pos""on,

wait a few minutes and try again.

° When engine starts, move throttle controlto desired

position.

° Allow engine to warm up for a few minutes before

engaging drive or attachment clutch.

NOTE: tf at a high altitude (above 3000 feet) or in cold

temperatures (below 320 F), the carburetor fuel mixture

may need to be adjusted for best engine performance.

See "TO ADJUST CARBURETOR" in the Service and

Adjustments section of this manual

MOWING TIPS

° Tire chains cannot be used when the mower hous-

ing is attached to unit.

• Mower should be properly leveled for best mowing

performance. See "TO LEVEL MOWER HOUSING"

m the Service and Adjustments section of this

manual.

, Use the runner on the right hand side of mower as

a guide, The blade cuts approximately an inch

outside the runner (See Fig,8),

• The left hand side of mower should be used for trim-

ming,

° Drive so that clippingsare discharged onto the area

that has been cut. Have the cut area to the rightof

the machine. This will result in a more even distri-

bution of clippings and more uniform cutting.

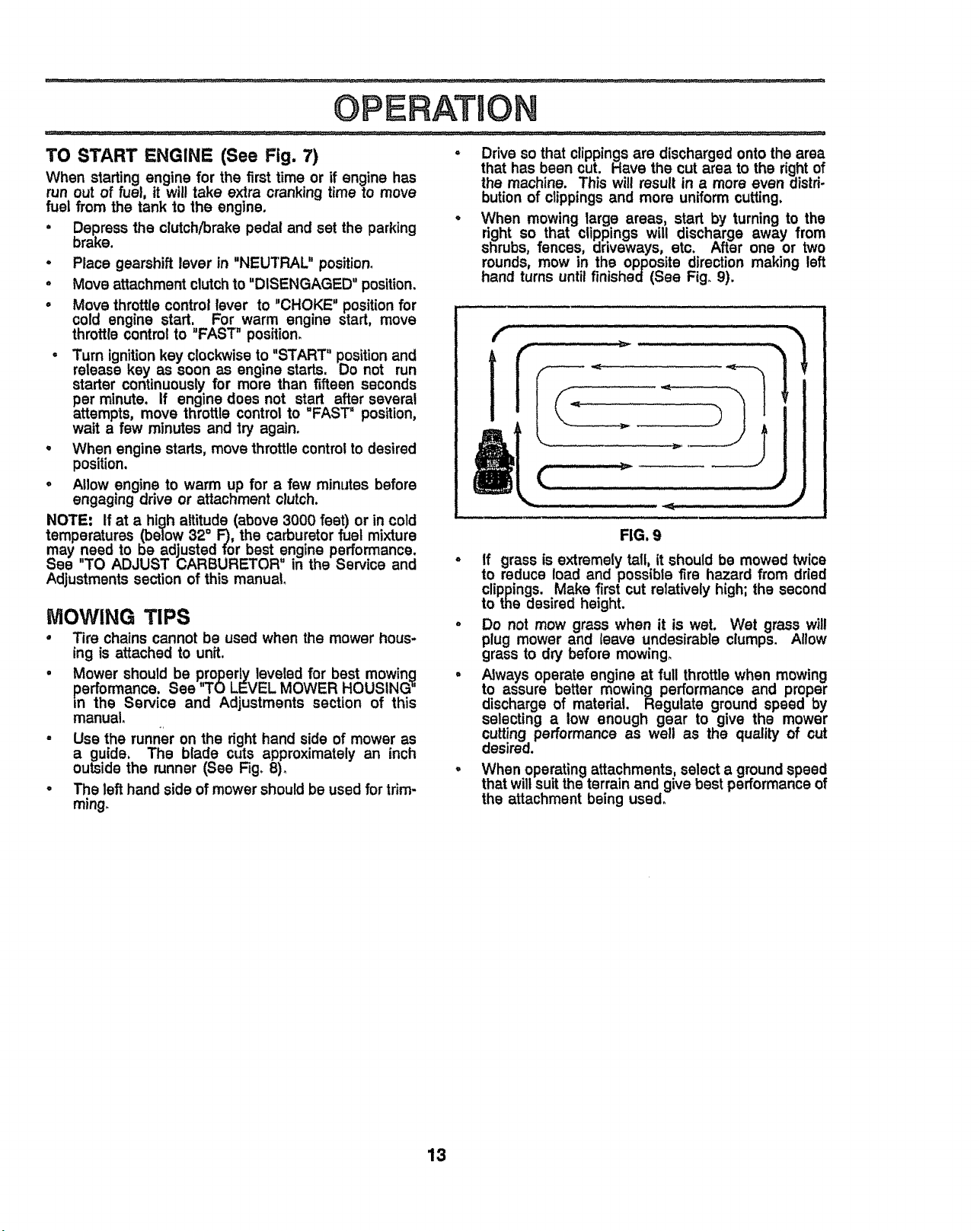

• When mowing large areas, start by turning to the

right so that clippings will discharge away from

shrubs, fences, driveways, etc. After one or two

rounds, mow in the opposite direction making left

hand turns until finished(See Fig. 9).

FIG. g

° if grass is extremely tall, it should be mowed twice

to reduce load and possible fire hazard from dried

clippings. Make first cut relatively high; the second

to the desired height.

° Do not mow grass when it is wet. Wet grass will

plug mower and leave undesirable clumps. Allow

grass to dry before mowing.

• /_ways operate engine at full throttle when.mowing

to assure better mowing penormance ana proper

discharge of material. Regulate ground speed by

selecting a low enough gear to give the mower

cutting performance as welt as the quality of cut

desired.

, When operating attachments, select a ground speed

that wiltsuit the terrain and give best performance of

the attachment being used.

13

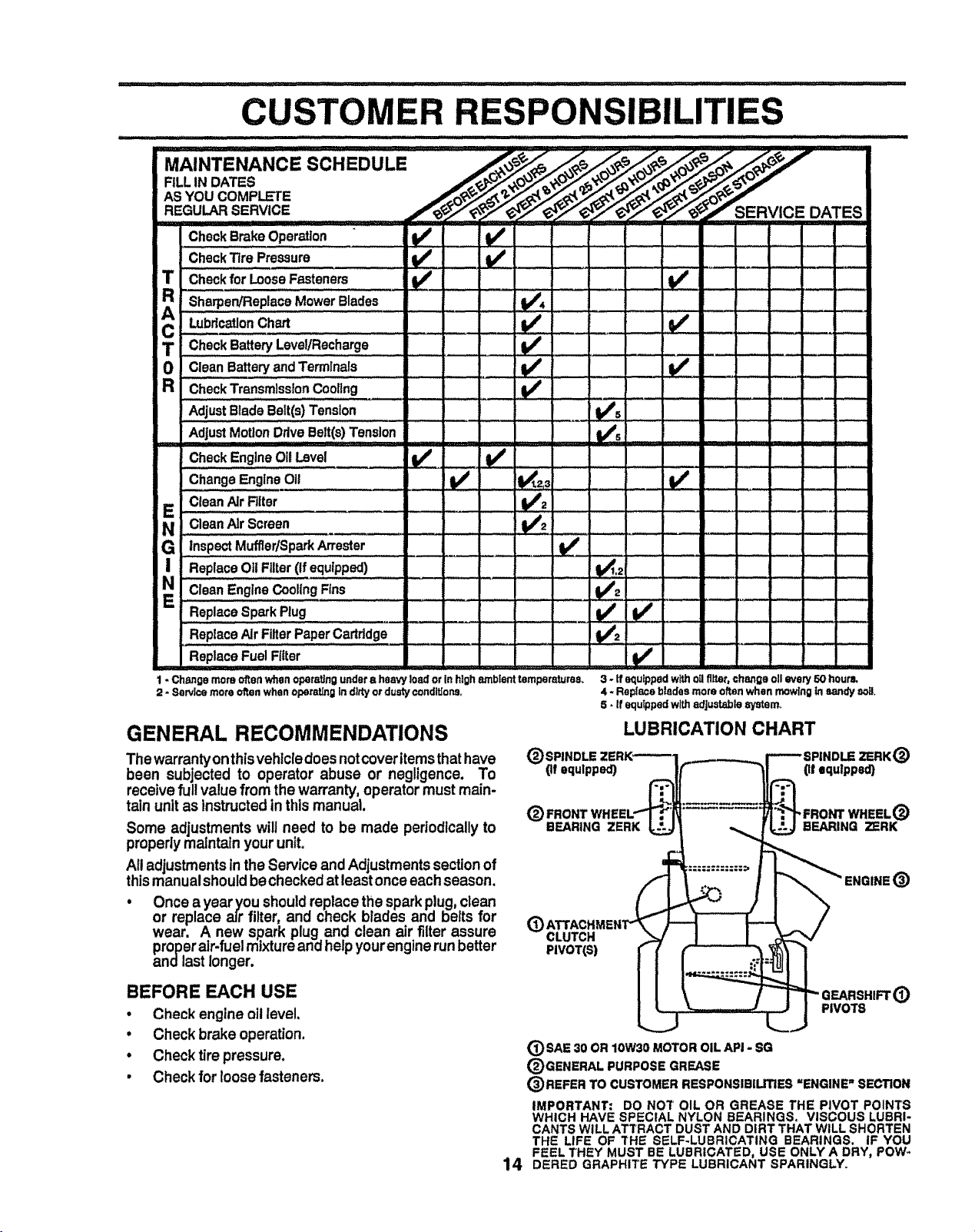

RESPONSIBILITIES

ASYOUCOMPLETE _, _€ _

REGULARSERVICE /_/_/_.,_ERVICE DATES

.................. III1'11'11I'

CheckBrakeOperation Ii# # !k/

C,eck',roP.e=ura IV v' " +. " " "

T Checker_0SeFasteners

R Sha_ervl:leplace MowerBlades tj_4

c m+<8o.;_L,;vom_h;;_o V' ...... --

0 CleanBatteryandTerminals

R Check Transmission Cooling

.....,_djUS,Stad_,,olti;+)Tens,on . _ _,_+V',, ......

Adjust Motion Drive Belt(s) Tension I_s

CheckEngineO11Level If _ :_21_

ChangeEngineOII l/ i '" :1/

CteanAirmite, ,, V'_I __

NE Clean Air Screen....................... IkIP21....................

G I InspectMuffler/Spaf_An'ester

I_l Replace Oil Filter(if equipped) . !_,2

CleanE.glneCoolingFtns !V'_!

._,.,

E '"ReplaceSp_kPing .............. !V"1I/

ReplaceAir FilterPaperCartridge................ _#+

ReplaceFuelFitter '

1 - Change more often when operating under s heavy load or In high ambient temperatures+ 3 + ff equipped with oil fl_tet, change oll every 60 houri+

2 - Service mote often when operating In dirty or dusty conditJons_ 4 - Repine blades more often when mowing in aandy aoiL

GENERAL RECOMMENDATIONS

The warrantyonthisvehicledoesnotcoveritems thathave

been subjected to operator abuse or negligence. To

receive fullvalue from the warranty, operator must main-

tain unitas instructedin this manual.

Some adjustments wilt need to be made periodicallyto

properlymaintain your unit+

All adjustments inthe Service and Adjustments sectionof

thismanual shouldbecheckedat leastonce each season+

, Once a yearyou should replace the sparkplug,clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

properair-fuelmixture an_ help yourengine runbetter

andlast longer.

BEFORE EACH USE

• Check engine oillevel.

• Check brake operation.

• Check tirepressure.

• Check for loose fasteners.

(_)SPINDLE ZERK_I _..__.-..._._ F----'SPINDLIE ZERK (_)

(If equipped) _Jl[ ..... _ (If equlppsd)

(_) FRONT WHEEL'"I_='r'_N: _._t _FRONT WHEEL (_)

BEARING ZERK _ | __ BEARING _RK

®

CLUTCH

PIVOT(S)

(_) SAE 30 OR 10W30 MOTOR OIL API - SG

_GENERAL PURPOSE GREASE

(_)REFER TO CUSTOMER RESPONSIBILITIES =ENGINE" SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS, VISCOUS LUBRI-

CANTS WtLL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF "tHE SELF-LUBRICATING BEARINGS, IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

14

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

6 - if equipped with adjustable system+

LUBRICATION CHART

|

PWOTS

®

d)

CUSTO E TIES

TRACTOR

AZwaysobserve safety rules when performingany matnte-

n_ce,

BRAKE OPERATION

If unit requiresmore than six (6) feet stopptngdistanceat

highs_eed in highest gear, than brakemustbe adjusted.

(See 'TO ADJUST BRAKE" in Service and Adjustments

sectionof this manual).

TIRES

, Maintain proper air pressure In alltires (See "PROD-

UCT SPECIFICATIONS" on page 3 ofthis manual),

. Keeptires free of gasoline, oil, orinsect control chemi.

caiswhich can harm rubber.

- Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

BLADE CARE

For best results mower blades must be kept sharp_ The

blades canbe sharpened withafile or on agrindingwheel.

We suggest they be sharpened or replacedafter every 25

hours of mowing. Check blades more often if mowing in

sandy conditions.

, Do notattempt tosharpen blades whilethey areonthe

mower,

- Replace bent or damaged blades.

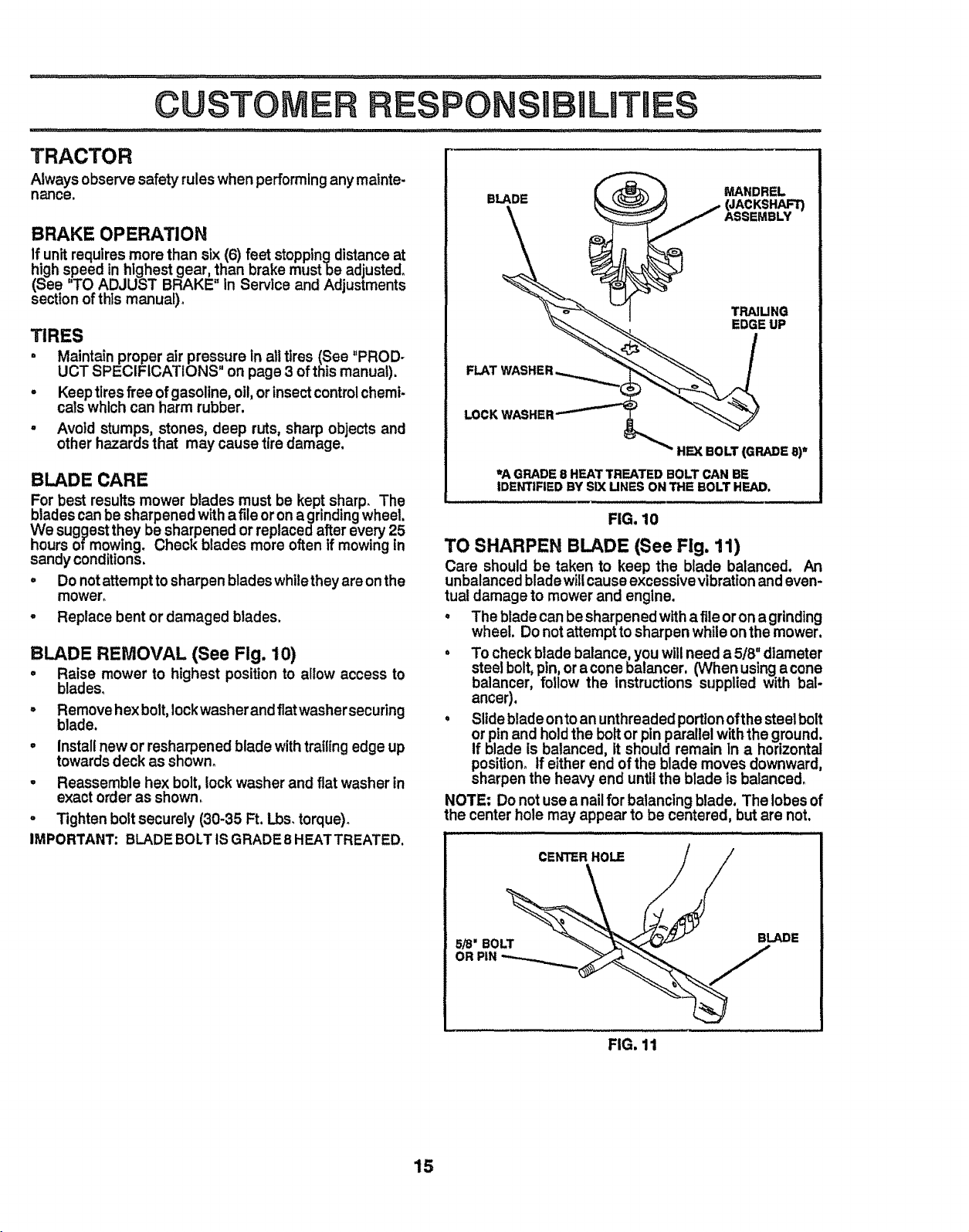

BLADE REMOVAL (See Fig. 10)

• Raise mower to highest positionto allow access to

blades_

= Removehexbolt, lockwasherandflatwashersecuring

blade.

• installnew or resharpened blade withtrailingedgeup

towardsdeck as shown.

. Reassemble hex bolt, lockwasher and fiat washer in

exact order as shown.

- Tighten bolt securely (30-35 Ft. Lbs.torque).

IMPORTANT: BLADEBOLTIS GRADE8HEATTREATED.

"t

222

NED( BOLT (GRADE 81"

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX UNES ON THE BOLT HEAD.

FIG, 10

TO SHARPEN BLADE (See Fig. 11)

Care should be taken to keep the blade balanced. An

unbalanced bladewill causeexcessive vibration andeven-

tual damage to mower and engine.

. The blade can be sharpened witha file oron a grinding

wheel. Do not attemptto sharpen while on the mower.

• To check blade balance, you willneed a 5/8" diameter

steel bolt, pin. ora cone batancer. (When usingacone

balancer, follow the instructions supplied with bal-

ancer),

• Slideblade onto an unthreaded portion ofthe steel bolt

or pin and holdthe bolt or pin parallel with the ground.

If blade Is balanced, it should remain In a horizontal

position, tfeither end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

NOTE: Do not use anailfor balancing blade. The lobes of

the center hole may appear to be centered, but are not,

11

15

5/8" BOLT

OR PIN

BLADE

FIG. 11

CUSTOMER RESPONSIBILITIES

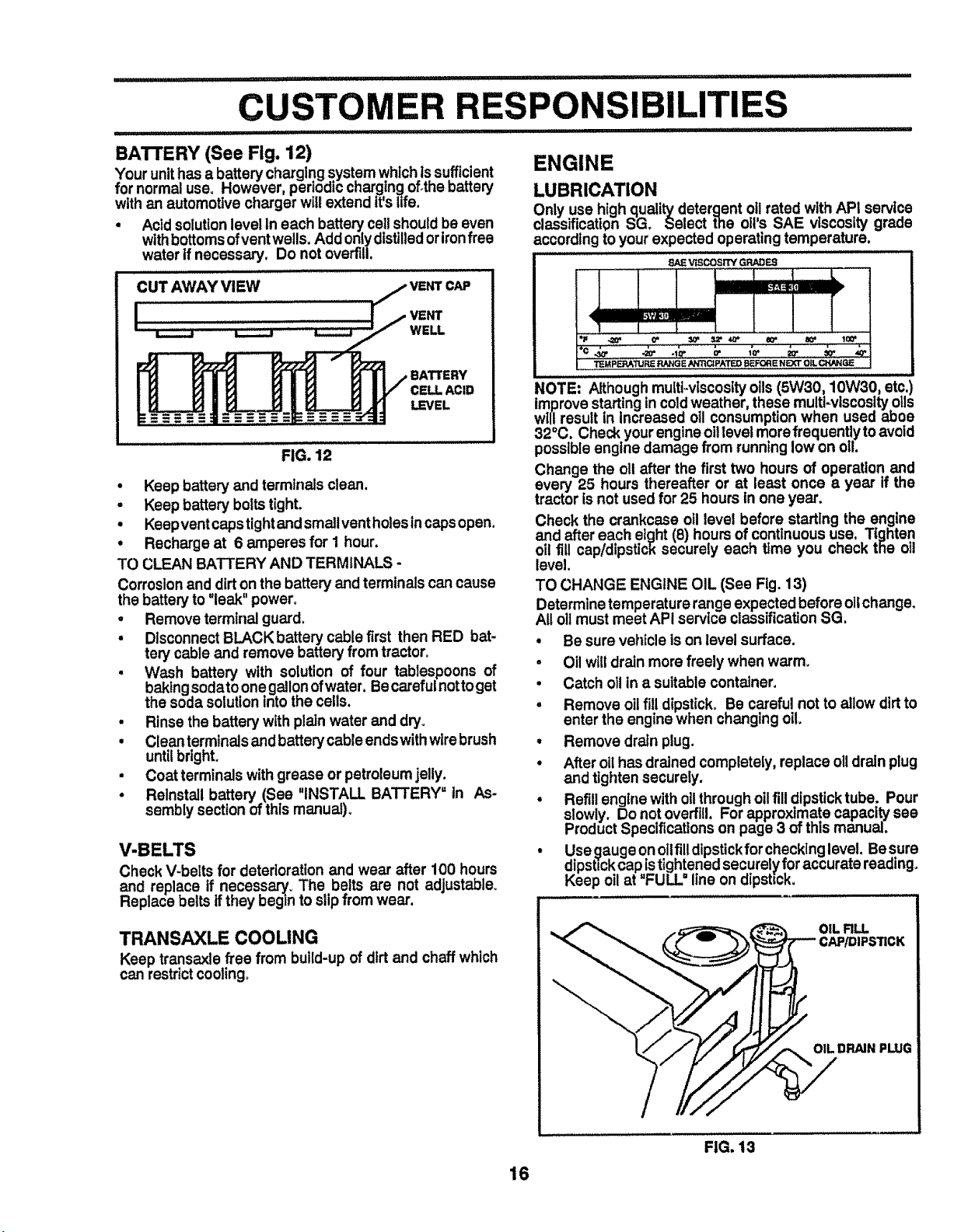

BATTERY (See Fig. 12)

Your unithas a battery charging system whlchis sufficient

for normal use° However. periodiccnargmg of.thebattery

withan automotive charger will extend it'slife.

• AcidsolutionlevelIneach battery cel!should be even

withbottoms ofventwalls. Add onlydistilledorironfree

water if necessary. Do not overfill.

CUT AWAY VIEW / VENTCAP

! r

WELL

! !:1 I:'JI l_ _ I _ _1lY CELl.ACID

FIG. 12

* Keep battery and terminals clean.

, Keep battery boltstight.

, Keepvent capstightand smallventholesincaps open.

* Recharge at 6 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS -

Corrosionand dirton the battery and terminals can cause

the battery to "leak" power°

, Remove terminal guard.

, DisconnectBLACK battery cable first then RED bat-

tery cable and remove battery from tractor.

, Wash battery with solution of four tablespoons of

baklngsodato onegallon ofwater. Becarefulnottoget

the soda solution into the cells.

, Rinse the battery with plain water and dry.

, Clean terminalsandbatterycable ends withwirebrush

untilbright.

. Coat terminals with grease or petroleum jelly.

, Reinstall battery (See "INSTALL BATTERY" in As-

sembly section Ofthis manual).

V-BELTS

Check V-belts for deterioration and wear after 100 hours

and replace if necessary. The belts are not adjustable.

Replace belts if they begin to slipfrom wear.

TRANSAXLE COOLING

Keep transaxie free from build-up of dirt and chaff which

can restrictcooling°

ENGINE

LUBRICATION

Only use high quality detergent oll rated with API service

classification SG. Select the oil's SAE viscosity grade

according to your expected operatingtemperature.

SAE%qscosn%,GRAOES

4IBm

TE,M P_:_ATURE RANGE ANltC_PATI_3 BEFORE NEXT OL CHANGE

NOTE: ARhoughmultt_vtscosttyoils (5W30, 10W30, etc,)

improve startingin coldweather, these multtLvlscosity otis

wlll result in Increased oli consumptionwhen used _ooe

32°C. Check yourengine oillevel morefrequentlytoavoid

possibleengine damage from running low on oil.

Change the oll after the firsttwo hours of operation and

every 25 hours thereafter or at least once a year if the

tractor isnot used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of continuous use, Tighten

oil fill cap/dipstick securely each time you check the otl

level,

TO CHANGE ENGINE OIL (See Fig.13)

Determine temperature rangeexpected before ollchange.

Alloil mustmeet API service classificationSG,

* Be sure vehicle Is on level surface.

= Oil willdrain more freely when warm.

. Catch oilina suitable container.

o Remove oilfill dipstick_ Be careful not to allow dirt to

enter the engine when changing oil.

. Remove drain plug.

• After oilhas drained completaly, replace oll drain plug

and tighten securely.

* Refillenginewithoilthroughoil filldipsticktube. Pour

slowly. Do notoverfill. For approximate capacity see

Product Specificationson page 3 of this manual.

, Usegaugeonollfilldipstickforchecktnglevel. Besure

dipstickcap istightenedsecurelyfor accurate reading.

Keep oilat "FULL" line on dipstick.

OIL RLL

CAP/DIPS'riCK

16

OIL DRAIN PLUG

FIG. 13

Loading...

Loading...