Craftsman 917.255723 Owner's Manual

~010

SEA/RlS

OWNERS

MANUAL

' -

MODEL

917.255723

Read

Safe Operation

and

Instructions

NO.

Caution:

Rules

Carefully

for

I

/.

'

, I

,.,

-

10H.P.

36"

LAWN

ELECTRIC START

RIDING

TRACTOR

·

:;;~·.

~

Sears,

Roebuck and Co

Assembly

Installation

Operation

.,

Chic

Parts

ago,

Repair

IL

60684

.

U.S.A.

CONGRATULATIONS

Tractor.

to

Should you experience any problem you cannot easily reme·

dy,

They

tools

Please

you

Always observe the

It

has

give

you the best possible dependability

please contact

have

to

service

read

to

assemble, operate and maintain

been

competent, well-trained technicians and the proper

or

and retain this manual. The instructions will

on

your

nearest

unit

.

FOR SAFE

purchase

Sear

designed, engineered and manufactured

your

repair this

"RULES

of a Sears

and performance .

s Service Department.

your

Tractor

OPERATION".

properly.

Lawn

enable

MODEL

NUMBER __________

SERIAL

NUMBER

THE

FOUND

THE

YOU

SERIAL

FOR

__________________________

MODEL

FENDER.

SHOULD

FUTURE

AND

ON THE

RECORD BOTH MO

NUMBERS

REFERENCE.

MODEL

AND

____________

SERIAL

NUMBERS

PLATE

KEEP

WILL

ATTACHED

IN

DEL

A SAFE PLACE

__

___

__

BE

TO

AND

LIM~TED

ON

ELECTRIC

For one year

tuned

up

will

repair free

from

according

of

date

of

purchase, when

to

the operating and maintenance instructions in the owner's manual,

charge any defect in material

ment.

This warranty

expendable and become

This warranty

tire

stumps,

repairs

excludes blade(s), blade adapter(s), spark plug{s), air cleaner and belt(s), which

worn

during normal

does

not

cover:

replacement

or

necessary

or

glass); and

because

repair

caused

of

tain the equipment according

· riding equipment

For

90

days from

defective in

Sears

will

material

replace the battery at

WARRANTY

SERVICE

used

FULL

the

date

of

or

workmanship and

IS

AVAILABLE

for

commercial or rental purposes.

90-DAY

purchase,

no

CENTER/DEPARTMENT IN THE

product

is

in

use

in

the

United States.

ONE

START

by

operator

to

instructions contained in the owner's manual; and

WARRANTY

if

our

charge.

UNITED

YEAR

thi

s riding equipment

W~RRANTY

RIDING

EQUIPMENT

is

maintained, lubr icated, and

Sears

or

workmanship

in

this electric start riding equip-

are

use

.

punctures

abuse

any battery included

testing determines the battery

from

outside objects (such

or

negligence, including the failure

ON

BATTERY

with

this riding equipment proves

will

as

nails, thorns,

not

hold a charge,

to

main-

BY CONTACTING THE NEAREST SEARS SERVICE

STATES.

Thi

s warranty applies

only

while this

gives

This warranty

to

state

state.

Sears,

you specific

Roebuck and

•

RULES FOR SAFE OPERATION

ASSEMBLY

INSTRUCTIONS

OPERATION INSTRUCTIONS · TRACTOR .

OPERATION INSTRUCTIONS · MOWER

......

.................

legal

rights, and you may also

Co.,

D/698-731A,

TABLE OF

.

...

....

3

4

....

. 8

.......

11

Sears

Tower;

CONTENTS

MAINTENANCE

MAINTENANCE

TROUBLE

.

REPAIR PARTS

.

2

SHOOTING

have

other rights which vary from

Chicago,

IL

60684

INSTRUCTIONS -MOWER ... . . 12

INSTRUCTIONS·

...

.........

...............

TRACT

.......

............

OR

..

..

14

21

24

RULES FOR

SAFE

OPERATION

WARN lNG: This unit

covered, brush-covered

or

local

In

have similar laws. Federal laws apply on federal lands.

number

10. Disengage power

11. Disengage power

12. Disengage power

13. Take

14. Do

15. Reduce speed

16. While going

17. Never mow in

18.

19. Do

20. Exercise special care when mowing around fixed objects

21. Never shift gears until tractor comes

22. Never place hands

state laws (if any). If a spark arrester

the

State

of

34479.

1. Know

2.

3.

4. Always wear substantial footwear. Do

5.

6.

7. Always get

8. Clear the work area

9. Disengage

the

OPERATOR'S

with attachments.

Do

allow adults

Do

others are around.

clothing

Keep your eyes anq mind

area being

Do

not

hand side.

might be picked

start

fore leaving

spark plug wire(s) from spark plug(s) before cleamng, mak-

ing an adjustment

in use.

attended. Disengage the power-take-off, lower the attach-

ments, shift into neutral,

engine and remove the key.

hill.

150); never across

vent tipping

when changing direction

Lever in 1st gear position

stopping.

sure

Stay alert for holes in the terrain and

Keep away from drop-offs.

ways.

in

deliberately run tractor

object.

chute

running. Always keep clear

controls and how

not

allow children

not

carry passengers. Do

that

cut.

not

attempt

in

the

drivers seat.

all attachment clutches before attempting

the

engine. .

the

all possible precautions when leaving

not

stop

Mow

up

or

at

a speed which could cause a skid.

not

drive

order

to

or

near any moving parts while tractor

is

equipped with an internal combustion engine and should

or

grass-covered land unless the engine's exhaust system

California

to

operate

could get caught

Don t let

on

or

and down the face

on

or

up

too

prevent the blades from striking them. Never

the

above

is

to

MANUAL and instructions furnished

it

other

to

operate

or

off your

of

up

and thrown.

to

attfchments and stop

operators

to

mower,

or

repairs. .

to

attachments when transporting

start suddenly when going uphill

the

face. Refer

slopes and make turns gradually

loss

of

or

down slopes, place Gear Shift Control

wet

or

slippery grass, when traction

close

or

feet under

stop

to

operate the machine. Do

without proper instruction.

not

in

moving parts.

on

your tractor, mower and

interests distract you.

your

tractor

objects (wire, rocks, etc.) which

position.

stop

the

set

the

of

to

control. Exercise extreme caution

on

slopes.

to

negotiate the slope without

to

creeks, ditches and public high-

or

mower i

of

discharge chute.

is

used, it should be maintained

required by law (Section

quickly. READ THIS

mow when children and

not

wear loose fitting

tractor

or

from

the

operators left

the

engine and

the

parking brake,

slopes (not greater

page 43.

other

hidden hazards.

nto

or

over any foreign

to

a stop.

the

mower, in discharge

See

not

the

mower when

engme be-

d~sconnect

or

not

vehicle un-

stop

the

or

down-

than

to

pre-

is

un-

or

mower are

to

not

is

in

effective working order by the operator.

4442

of

the

your

Sears Authorized Service Center for spark arrester muffler

23. Use care when

24. Watch

25. When using any attachments, never direct

26. Hand

27. Keep the vehicle and attachments

28. Keep

29. Never store

30.

31. Except for adjustment;

32. Do

33. The vehicle and attachments should be stopped and

34. Do

35. When using

36.

37.

38. Under normal usage

California Public Resources Code). Other states may

a.

Use

only approved drawbar hitch points.

b. Limit loads

c.

Do n

d.

material toward bystanders nor allow anyone near

hicle while in operation.

a.

ot

Use

coun\erweight

the

owner s manual.

out

le

gasoline with

Use

approved gasoline containers.

b.

Never remove the fuel cap

oline

not

been allowed

ning. Never fill

gasoline.

c.

Open doors if

fumes are dangerous. Do

dition, and keep safety devices

all nuts, bolts and screws tight

ment

is

in

a building where fumes may reach an

Allow

the

To

reduce fire hazard, keep

or

excessive grease. Do

running.

cleaner

moved. Removal

exhaust system. Damaged mufflers

create a fire hazard.

necessary. .

spected for damage after striking a foreign object and

damage should be repaired before restarting and operating

the

the

a. Mow only in daylight

c.

careful observation

or

not

equipment.

not

engine; severe damage

b.

Shut

the

Oleck

frequent intervals.

Do

not

place.

Disengage power

in reverse unless absolutely necessary and

to

deterioration and wear.

for bag replacement. Replacement bags should be checked

to

ensure compliance with

recommendations

be used on

equipped with a spark arrester meeting applicable

pulling loads

to

those

turn

sharply. Use care when backing.

for

traffic when crossing

to

a running

the

the

safe working condition.

the

equipment with gasoline in

engine

to

cool before storing in any enclosure.

cover directly over carburetor air intake

of

operate without a muffler

change the engine governor

the

operate

such part could create a fire hazard.

the

vehicle with mower, proceed as follows:

engine

off

blade mounting bolts for proper tightness

the

to

of

or

or

near any unimproved forest-

or

using heavy equipment.

you

can safely control.

or

wheel weights when suggested

or

near roadways.

care-

it

is

highly flammable.

of

the

or

hot

to

cool for several minutes after run-

tank

indoors, always clean up spilled

engine

is

the

not

clean product while engine

DO NOT operate Engine if air

Inspect periodically and replace if

or

injury may result.

or

in good artificial light.

when unclogging chute.

mower wi

mower before backing up. Do

the entire area behind

the

grass catcher bag material

It

specifications.

fuel

engine

or

an engine

run

in

not

in

thout

should be checked frequently

the

the

run

the

in

good operating con-

place and working.

to

be sure

open

engine free

or

or

spark arresters could

settings

the

deflector shield in

original manufacturer's

part

discharge

the

tank

or

add gasthat

garage - exhaust

engine indoors.

the

equip.

the

tank

flame

of

tamper with

then

the

inside

or

spark.

grass, leaves

is

or

overspeed

not

mow

only after

mower.

is

subject

in

of

ve-

has

is

re-

the

In-

the

at

LOOK FOR THIS SYMBOL TO POINT

PRECAUTIONS.

YOUR SAFETY IS

IT

MEANS-

INVOLVED.

OUT

ATTENTION! BECOME

-3-

IMPORTANT SAFETY

ALERT!

To assemble

two 7

/16" wrenches, two 9/

your

Tractor you will need:

16"

wrenches, two 1/2"

wrenches, a 3/4" wrench and a utility knife

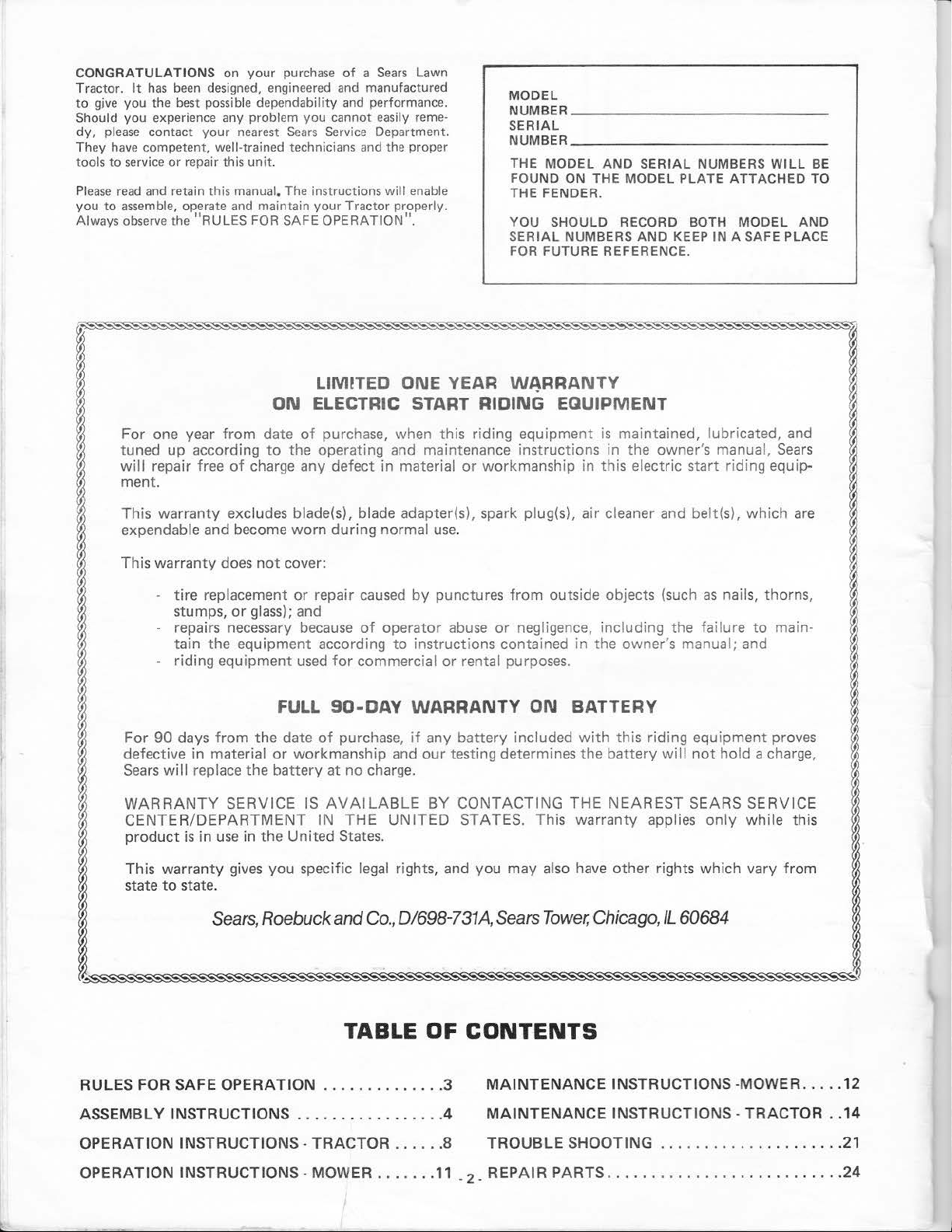

FIGURE

SEAT

FIGURE

1

PAN

2

LOWER

SHAFT

STEERING

FENDER

TUBE

NOTE:

DETERMINED

SEATED

RIGHT

ON

THE

HAND

FROM

TRACTOR.

(R.H.)

AND

LEFT

OPERATOR'S POSITION

HAND

ASSEMBLY

1. Cut

down

carton

at

four

move

Bag

of

Parts.

Slide Upper Steering Shaft over Lower Steering Shaft

2.

bolt

holes line

1).

3.

Use

two

Shaft to Lower Steering Shaft. Tighten securely.

4.

Sl

ide Tube over Stee

Sleeve

Bracket.

5,

Place

Steering Whee

6. With

7,

8.

9. Remove plastic

SEAT

1.

front

Whee

l on

should po

Place

2 · 11

stall a 1 /

Snap Insert

INSTALLATION

Mount

Seat

3/8 - 16 x 3/

two

Crownlock Nuts 3 8 · 16 (Fig. 2).

SHOULD

NUTS. Seat

Bag

of Parts. Tighten Nuts securely.

in

2.

Mount

Seat

Bolts

5/16 • 18 and

of

Bolts

Par

ts. Tighten Nuts securely.

3.

Place Seat on Seat

Lock washer and

Bolt,

Lockwasher and

Tighten finger tight.

4.

Place

Seat in operat ing position.

Clutch-Brake

is

not

comfortable, adjust Seat.

5.

Raise

Seat.

(Fig. 3), When adjusted

Adjustment

up

with

Bolts and

wheels pointed straight ahead, place Steering

Stee

ring

int

straight across tractor.

4"

Dia.

2"

Nut. Tighten

into

Steering

on

Tractor Hood.

Pivot Bracket

4,

two

BE

POS

ITI

P

ivot

Bracket, Bolts,

Pan

to

to

outside). Bolts and Lock Nuts found in

Flat

Pedal

Use

3/

4"

Bolt

securely.

corners,

slots in Lower Steering Shaft (Fig.

two

Locknuts

nng

Shaft Assembly and over Steering

l Adapter on Upper Steering Shaft .

Whee

l Adapter.

Washer

on Upper Steering Shaft and in·

securely.

Whee

to

Washers

ONED

Seat Pivot Bracket using

two Lock

Pan.

Screw Large Adjustment

Washer i

Flat

all the way down.

wrench

for

comfortable operation , tighten

fold

down

to

reta

in

Bars

of

l.

Fender using

13/

32

x 13/16 x 16

UNDER

Nuts 5

nto

Washer found in

to

NOTE:

FENDER

Washers

Seat (Fi

Sit

loosen Adjustment Bo

and Nuts found

/1

6 - 18 (Fig. 2) (head

g.

on the Seat and

If

operating position

Upper Steering

Steering Wheel

two

two

3). Adjustment

Bag

(L.H.)

ARE

WHILE

carton. Re-

unttl

Hex Bolts

Ga.

and

WASHERS

NEXT

TO

Shoulder

Bag

of

Bolt,

of

Parts.

press

lt

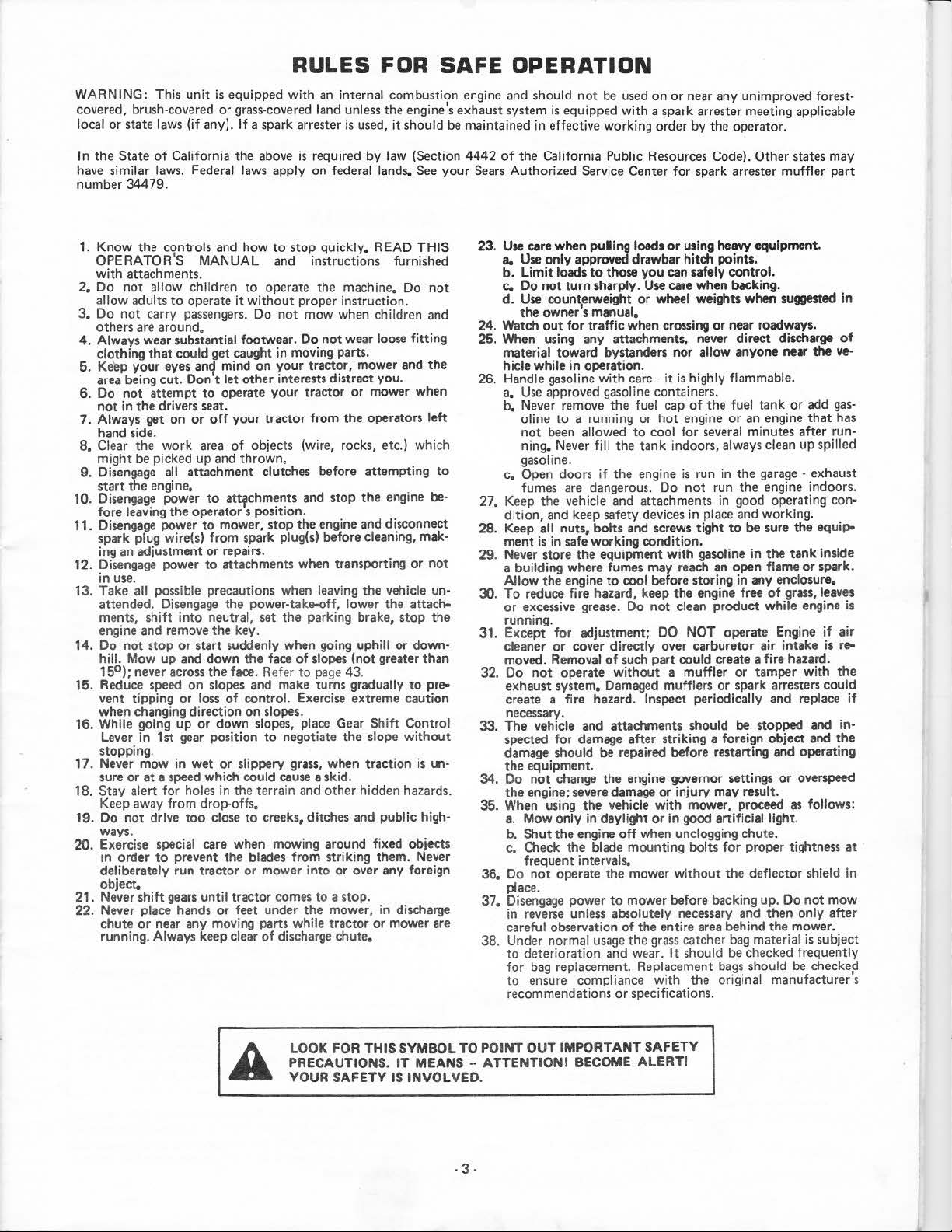

BATTERY

a.

-

4-

INSTALLATION

on

Ttacto

READ

WITH

ALWAYS

TECT

Remove the vent

wtth

actd. Add the

the vent tube (Fig. 4). Do

level

01

tc

the addt ttonal acid

ry

IS

charged.

THE

THE

YOUR

caps

ac•d

INSTRUCTIONS

BATTERY

WEAR

HANDS

ftom

'o

o:

.

;~:

3z::e

y Otepara·

INCLU

ACID

AND

reaches

CONTAINER

TO PRO-

EYES.

the

bottom

out

when the bat

CLOTHING

the battery. Fill each cell

unul

•t

not

add the acid beyond this

can

come

DED

.

of

b. Wait

the level

a,

add more acid

stall

water

c.

Neutralize

to

four

St

ir

ing soda

foaming,

WASH

ATELY

WITH

20

to

of acid falls below the

the vent caps.

to

remove any acid, then wipe

inches

with

until

DO N

ED

HAND

S OR

IF

ACCIDENTALLY

ELECTROLYTE

30

minutes before installing the vent caps.

until

the correct level

Wash

excess

battery acid

of

water in a five gallon plastic container.

a wooden

or

the

OT

ELECTROLYTE

plastic paddle while adding bak-

addition

SMOKE. FUMES

CLOTHING IMM

.

point

as

the

top

of

the

dry.

for

disposal by adding it

of

more

soda

FROM

ARE

EXPLOSIVE.

IN

CONTACT

described

is

reached. In-

battery

causes

CHARG-

no

EDI

in

more

-

step

with

.. :

_.

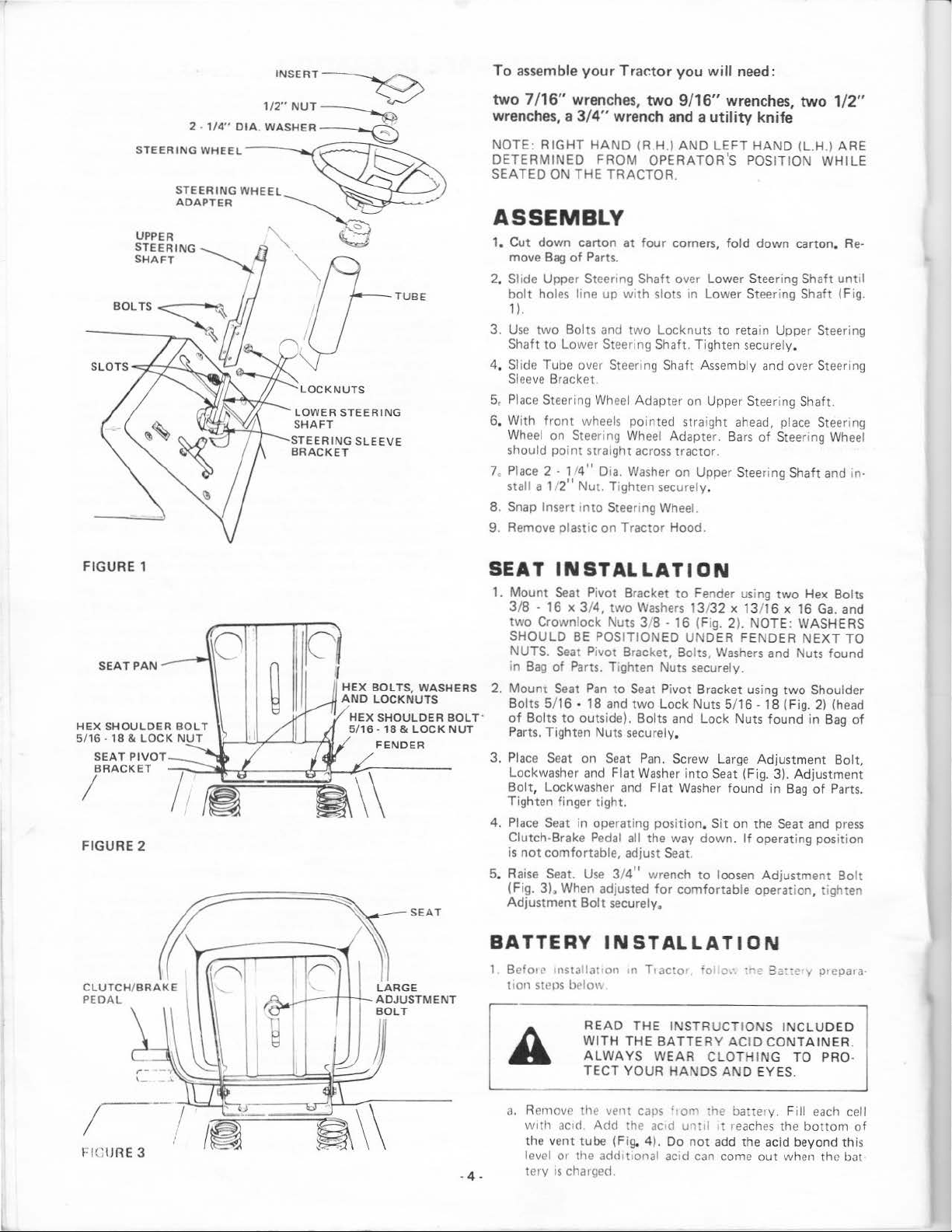

VENT

CA

P

VENT

TUBE

I·

ATTERY

CELL

FI

GURE

4

CUT

AWAY

VIEW

~

I-========<(

If

c:::::::J c:::::::J

~

::...

.::-~~~·

c::::::J

; :

i-

•:

::

~~~-~~~-~-~B

d. Use a 12

of

the battery is charged.

cor

2. Position

a.

Lift

b. Lower Battery

minals

Battery rests

NOTE:

LY

ATTACHED

3. Connect Batter y Cables using: t

Wa

shers,

si

ze

below) found in B

volt

2 amperes

rect level, add water.

Battery

Seat (Fig. 5).

BE

two

battery charge

for 3 to

DO

NOT

SHORT

BEFORE I

MOVE

WATC H

YOUR

to

ward

SURE

POSITIVE

NECTED

FROM

METAL

PERSON.

in

tractor

into

front

in

Battery Tray (Fig. 6).

BATTERY

TO

BATTERY

Lockwashers

ag

FIRST

ACCIDENTAL

BANDS

TERMINAL

4 hours. Chec

If

the acid

BATTERY

NSTALLING

, RINGS

as

follows:

Fender Well

of

tract

DRAIN

and two Hex Nuts (sho

of

Parts.

TO

r.

Charge batte ry

k the acid lev

has

BATTERY

BRACELETS, WRIST

TRAY

, ETC.

with

or

(Fig. 5). Make sure

TUBE

DRAIN

wo

Hex

MUST

P~EVENT

GROUNDING

at

a rate

fallen

TERMINALS

Bolt

el

below

, RE-

FROM

Battery T er·

IS SECURE-

.

s,

two

wn f

BE

CON-

SPA

RKS

.

aft

the

Flat

er

.

-

ull

POSITIVE

TERMINAL

POSITIVE

CABLE

./

(REO)

"

NEGATIVE

TER

MINAL

FIGURE&

NEGATIVE

CABLE (BLACK

)

~~~~

LOCKWASHER

~

a. Connect RED B

minal

with

Nu

t (Fig.

b. Connect

Terminal

washer and Hex Nut (Fig.

attery

Hex

Bolt,

6).

Tighten secure

BLACK

with

remaining Hex

Cable

to

·Flat

Washer,

Ground Cable

ly.

6).

Tighten securely.

Pos

itive(+) Battery

Lockwasher and

to

Negati

Bolt,

Flat

ve

(·) Battery

Wash

er,

Ter

Hex

Lock·

-

BATTERY

.

5.

TRAY

FI

GURE

6

INTERNAL/EXTERNAL

LOCKWASHER

WING

NUT-

INTERNAL/

EXTERNAL~

LOCKWASHER

~

TERMINAL

GUARD

_1/

WING

NUT~

~

(/3!!J

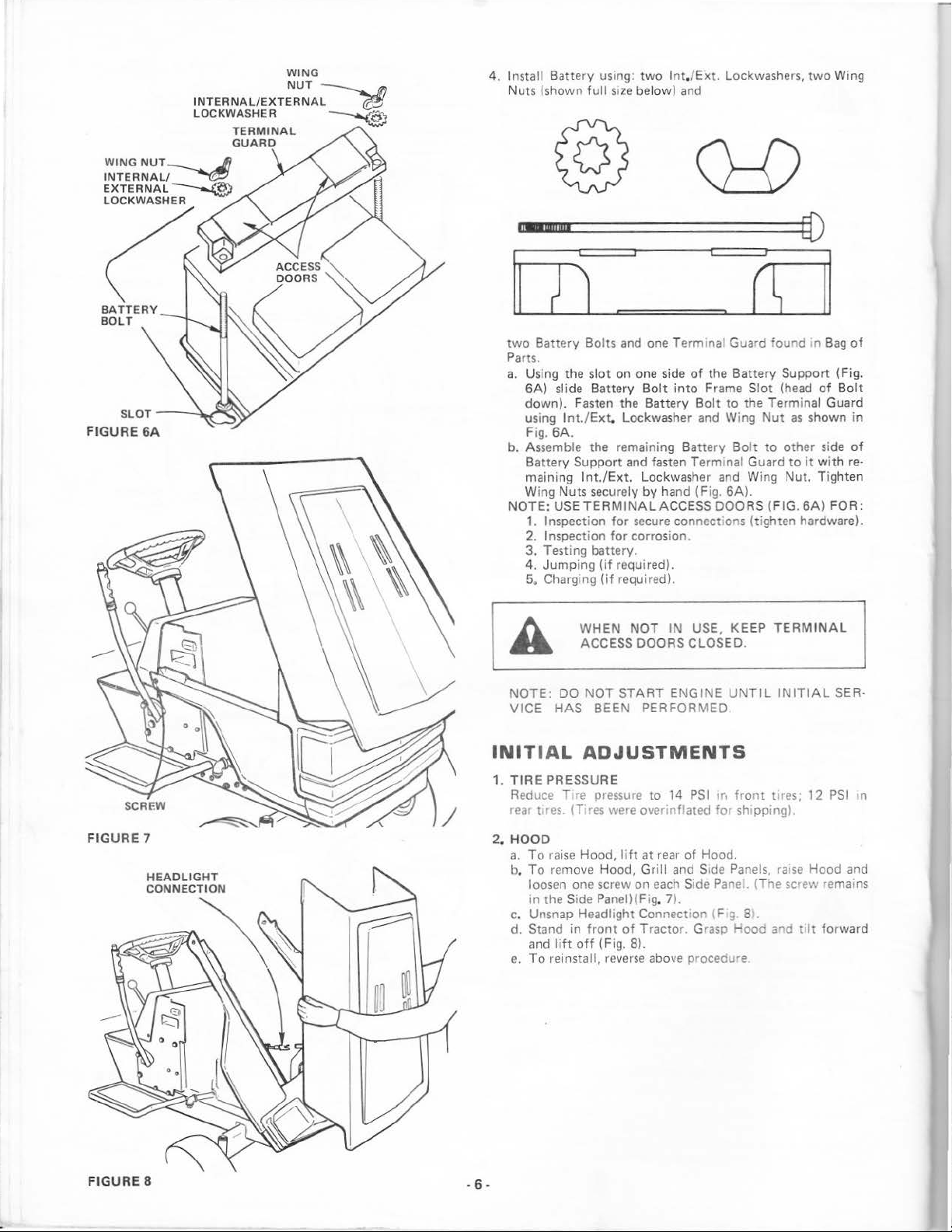

Install Batte

4.

Nuts (shown

ry using:

full

size

two

lnt./Ext.

below) and

Lockwashers,

two

Wing

@

m"IIMIGmmnmm[•::::::::::::::::::::::::::::E[)

SLOT

FIGURE

-

-~_....,~,y

6A

two

Battery Bolts

Parts.

a.

Using the

6A)

slide Battery

down)

. Fasten the Battery

lnt./Ext.

using

Fig.

6A.

b. Assemble the remaining Battery

Battery Support and fasten Terminal Guard

maining

Wing Nuts securely

NOTE: USETER

1. Inspecti

2.

Inspect

and

one Termina Guard 'ound .n

slot

on one side

Bolt

Lockwasher and Wing

lnt./Ext.

on

ion

Lockwash

by

MINALA

for

for

hand (Fig.

secure connect:ons (tighten hardware).

corrosion.

of

into

Frame Slot (head

Bolt

er

CCES

S DOORS (F

3. Testing battery.

4.

Jump

ing

(if

5. Charging

NOTE:

VICE

HAS

INITIAL

1.

TIRE

PRESSURE

Reduce T

res.

rear t

DO

required).

(if

required).

NOT

IN

WHEN

ACCESS DOORS CLOSED.

NOT

START ENGINE UNTIL

BEEN PERFORMED

USE

ADJUSTMENTS

1re

1T1

pressure

res

to

14

were over"nflated

PSI

fs

the Battery Support (Fig.

to

the Terminal Guard

Nut

Bolt

to

and Wing Nut. Tighten

6A).

, KEEP

1ro

for

TERMINAL

front

!Ires;

shipping).

as

shown in

other

to

it with re-

IG.6A)

INITIAL

12

II

Bag

of

side

FOR:

PSI

of

Bolt

of

SER·

n

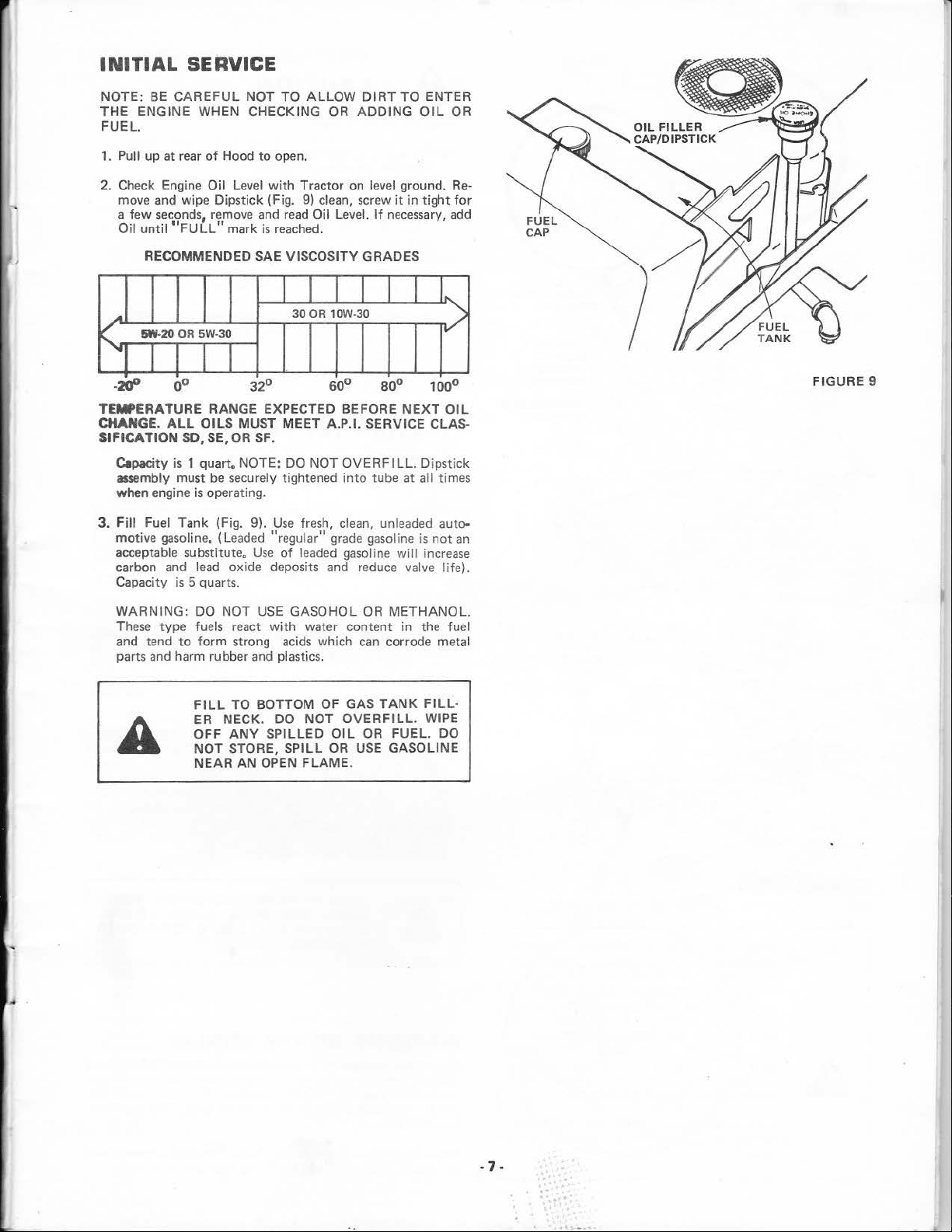

FIGURE

FIGURE

7

8

.

6.

2.

HOOD

a.

To raise

To

b.

loosen one screw on

in the Side Panei)(Fig. 7

c.

Unsnap Headlight Connection (F g 8

d. Stand in

and

e.

To

Hood,

lift

of

(Fig. 8).

reverse

at rear

eac

Tractor. G

above procedu·e

remove Hood, Grill and Side Panels,

front

lift

off

reinsta

ll,

of

Hood.

h Side Panel. (The screw remains

).

rasp

).

Hooc

ra1se

and

Hood and

tIt

forward

INITIAL SERVICE

NOTE:

THE

FUEL.

1.

2. Check Engine

K

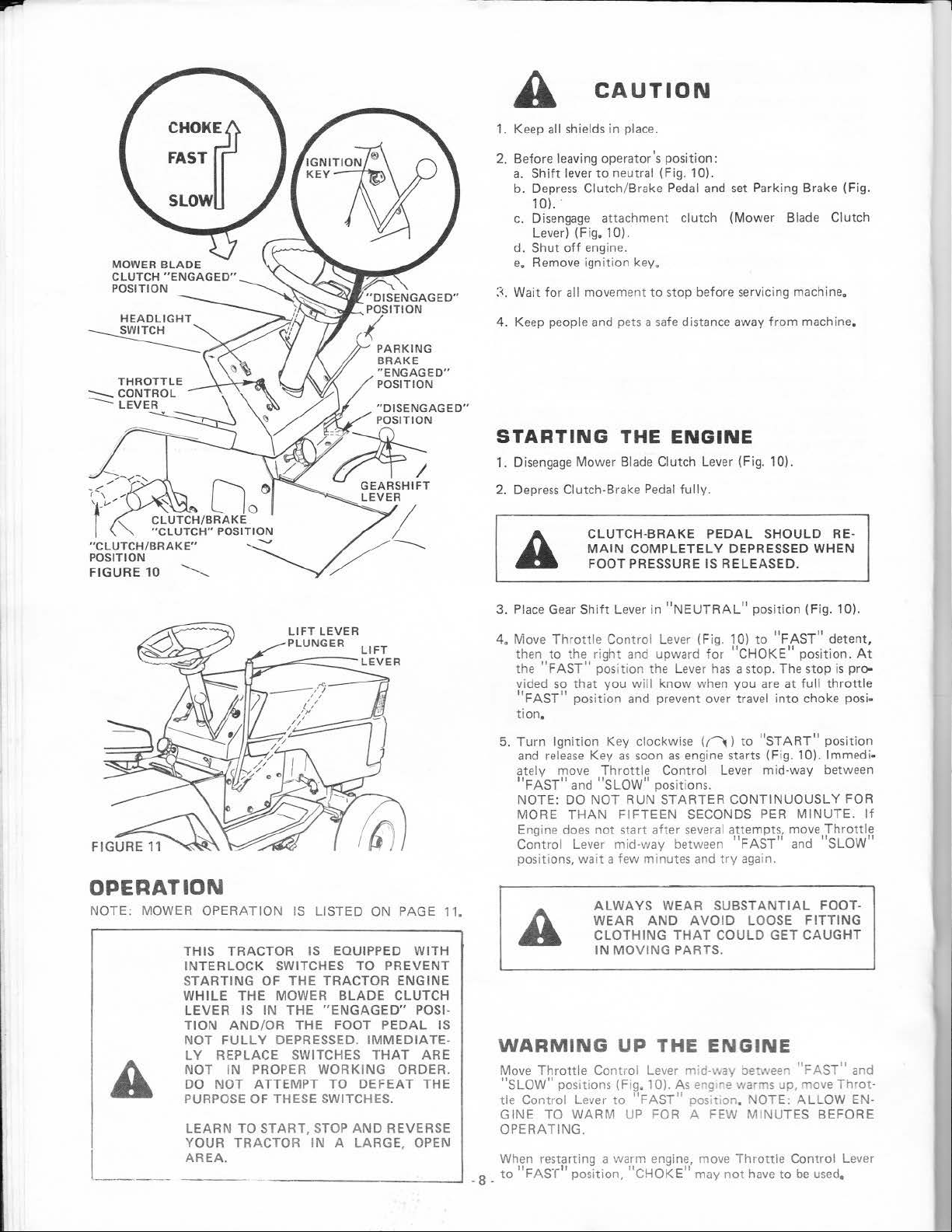

TEWERATURE

CHANGE.

SIFICATION SO, SE,

3.

BE

CAREFUL

ENGINE WHEN CHECKING

Pull up at rear

move and wipe Dipstick (Fig.

a

few

seconds, remove and

Oil

untii"FULL"

RECOMMENDED

.A

!iW-20

OR

5W·30

"""

!

-'l.fP

Capacity

assembly must

when engine

Fill

motive gasoline. (Leaded "regular

acceptable substitute.

carbon and

Capacity

0°

ALL

OILS

is

1 quart. NOTE: DO NOT

is

Fuel Tank (Fig. 9).

lead

is

5 quarts.

NOT TO

of

Hood

to

Oil Level

with

mark

is

SAE VISCOSITY GRADES

32°

RANGE EXPECTED BEFORE

MUST MEET A.P.I. SERVICE CLAS-

OR

SF.

be

securely tightened i

operating.

Use

oxide deposits

ALLOW

open.

Tractor on level ground.

9)

read

Oil Level.

reached.

30

OR

Use

fresh, clean, unleaded auto-

of

leaded gasoline

DIRT

OR

ADDING

clean, screw

11

and

If

lOW-30

60°

grade gasoline

80° 1 00°

OVERFILL.

nto

tube at all times

reduce valve life).

TO

it

necessary,

NEXT

will

ENTER

OIL

in

tight

Dipstick

is

not

increase

OR

Refor

add

I~

v

FIGURE 9

OIL

an

WARNING: DO NOT

These

type fuels

to

and tend

parts and harm rubber and plastics.

,.

.

form

FILL

ER NECK. DO

OFF

NOT

NEAR AN

USE

rea

strong acids which can corrode metal

TO

ANY

STORE, SPILL

GASOHOL

ct

with

water content in the fuel

BOTTOM OF GAS

SPILLED

OPEN

FLAME

NOT

OR

OVERFILL

OIL

OR

OR

USE

.

METHANOL.

TANK

FILL-

. WIPE

FUEL. DO

GASOLINE

-7-

. .

...

..

.....

CHOKf

FAST

SLOW

"CLUTCH/BRAKE"

POSITION

FIGURE

10

'-.....__

A

1.

Keep all shields in place.

2.

Before leaving operator's position:

a.

Shift

b. Depress

10)

c.

Disengage attachment clutch (Mower Blade

lever)

d. Shut

e,

Remove ignition key.

::<.

Wait

for all

4. Keep people and pets a safe distance away

STARTING

1.

Disengage Mower Blade Clutch Lever (Fig. 10).

2.

Depre

A

CAUTION

lever

to

neutral (Fi

Clutch/Bra

..

(Fig. 1

off

engine.

movement

ss

Clutch-Brake Pedal

CLUTCH-BRAKE PEDAL

MAIN

FOOT

ke

0).

to

THE

COMPLETELY

PRESSURE IS

g.

10).

Pedal

and set Parking Brake (Fig.

stop before servicing machine.

ENGINE

fully.

DEPRESSED

RELEASED.

from

machine.

SHOULD

Clutch

RE-

WHEN

OPERATION

NOTE:

l ___ _

MOWER

A

OPERATION

THIS

INTERLOCK

STARTING

WHILE

LEVER

TION

NOT

LV

REPLACE SWITCHES

NOT

DO

NOT

PURPOSE

LEARN

YOUR

AREA.

IS

TRACTOR

FULLY

IN

SWITCHES TO

OF

THE

IS

AND/OR

TO

TRACTOR

THE

MOWER

IN

THE

THE

DEPRESSED.

PROPER

ATTEMPT

OF

THESE SWITCHES.

START,

-------------J

LISTED

IS EQUIPPED

TRACTOR

WORKING

STOP

IN A LARGE,

ON

PREVENT

BLADE

"ENGAGED"

FOOT

TO

PEDAL

IMMEDIATE·

THAT

DEFEAT

AND

REVERSE

PAGE 11.

WITH

ENGINE

CLUTCH

POSI-

IS

ARE

ORDER.

THE

OPEN

3. Place Gear

4.

Move

then

the "

vided

"FAST"

tion.

5.

Turn

and

ately move

"FAST"

NOTE

MORE

Engine does

Control

positions, wait a few minutes and

A

WARMING UP

Move

"SLOW"

tie

Control

GINE

OPERATING.

When restarting a warm engine, move

_

to

"FAST"

.

8

Shif

t Lever in

Throttle

to

FAST"

so

Ignition

release

: DO

Throttle

pos

TO

Con

the

that

pos

and " SLOW" positions.

THAN

Lever m1d·way between

iti

lever

WARM

position,

trol

right

and upward for

position the

you

will

ition

and prevent over travel

Key clockwise (

Key

as

soon

Throttle

NOT

RUN

FIFTEEN

not

start

ALWAYS

WEAR

CLOTHING

IN

MOVING

Contr ol

ons (Fig. 10). As eng

to

"FAST"

UP

"CHOKE"

Lever (Fig. 10)

know

Control

STARTER

after

WEAR

AND

THE

lever

FOR A FEW

"NEUTRAL"

Lever has

when

f'l

as

engine starts (Fig. 10).

SECONDS PER

several

AVOID

THAT

PARTS

posi

to

"FAST" detent,

"CHOKE"

a stop. The stop is

you

are

into

)

to

"START"

Lever mid-way between

CONTINUOUSLY

a,~tempt~

FAST

try

aga

in.

SUBSTANTIAL

LOOSE

COULD

.

GET

ENGINE

mid

-way bet\veen

ne

warms up, move

positiOn,

may

NOTE:

MINUTES BEFORE

Throttle

not

have

tion

(Fig. 10).

position.

at

full

throttle

choke posi·

position

lmmed

MINUTE.

move

,Throttl~

1

and SLOW

FOOT-

FITTING

CAUGHT

"FAST"

ALLOW

Control

to

be

used.

At

pro-

FOR

and

Throt

EN-

Lever

i·

If

·

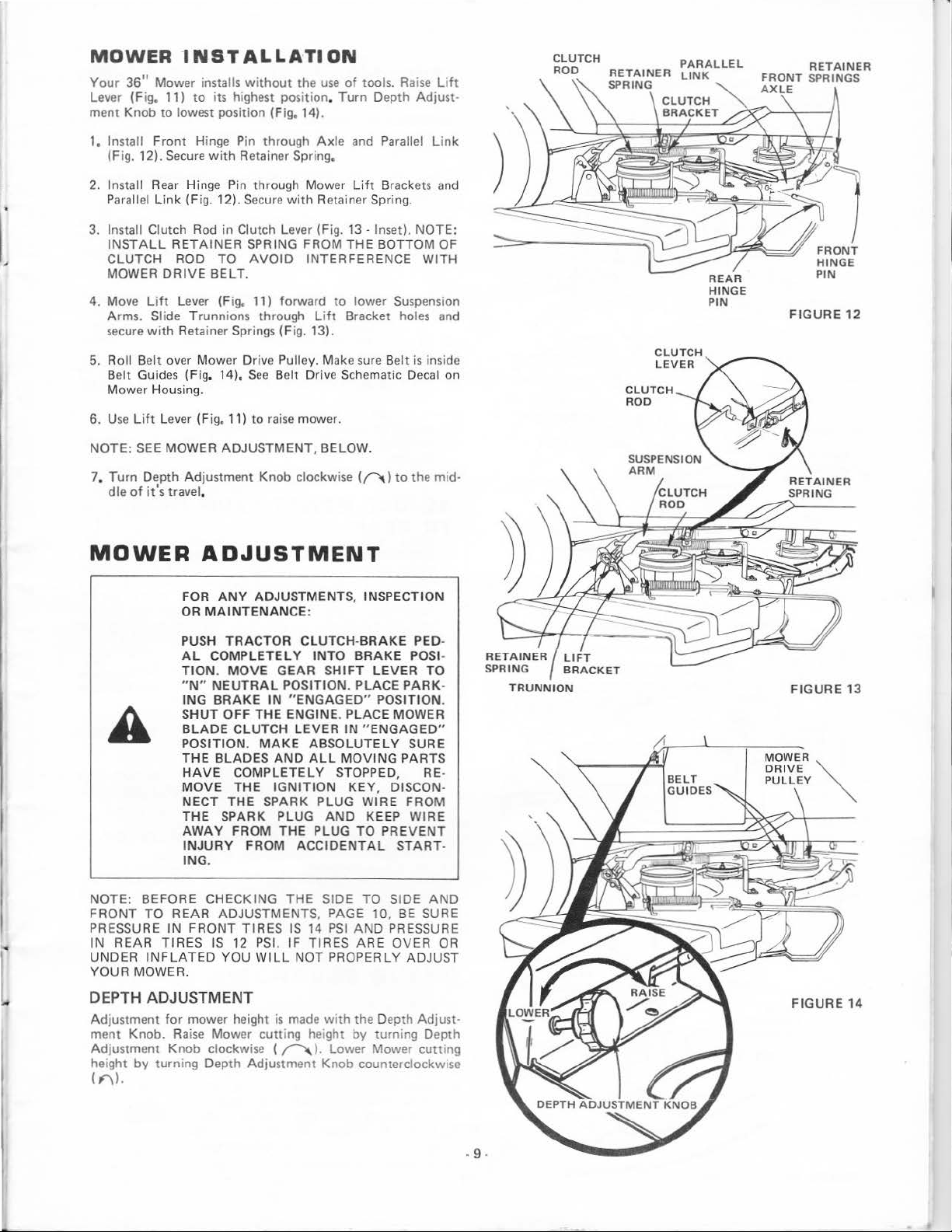

MOWER 'INSTALLATION

Y

our 36" Mower

Lever (F ig. 11) t o its highest position, Turn

ment Knob

In

stall Fr

1,

(Fig. 12). Secure

2.

Install Rear Hinge Pin through Mower Li

Parallel

3.

Insta

INSTALL

CLUTCH ROD TO

MOWER

4.

Move Lift Leve

Ar

se

5.

Roll Belt over Mower Dri

Belt

Mower Housing.

6.

Use Lift

NOTE:

7,

link

ll

Clutch Rod in Clutch Lever (Fig. 13 -

ms. Sli

cure

with

Guides (Fig, 14).

SEE

Turn

Depth

dle

of

it's

installs

witho

ut the

use

of

to

lowest pos

ont

(Fig. 12).

RETAINER

DRIVE

de Trunnions through

Retainer Spri

Lever

MOWER

Adjustment

travel,

iti

on (Fig. 14).

Hinge Pin through

with

Retainer Spring,

Secu

SPRING FROM

AVOID

BELT.

r (F ig. 11) forward to lower Suspension

ngs

ve

See

(Fig.11)

to

rai

ADJUSTMENT,

Knob clockwise ((-"'\)

Axle

and Parallel

re

with

Retainer Spring.

THE

INTERFERENCE WI

Lift Bra

(Fig. 13).

Pulley. Make sure Belt

Belt Drive Schematic Decal on

se

mower.

BELOW.

tools. Rai

ft

cket holes and

se

NOTE:

is ins

to

the mid-

Lift

djust

Lin

TH

Depth A

Brackets and

Inset).

BOTTOM OF

ide

CLUTCH

ROD

-

k

FRONT

HINGE

PIN

FIGURE

12

CL

ROD

CLUTCH

LEVER

UTCH

REAR

HINGE

PIN

MOWER

NOTE: BEFORE CHECKING

FRONT

PRESSURE

IN

UNDER

YOUR

TO

REAR

INFLATED

MOWER.

ADJUSTMENT

FOR

ANY

MAINTENANCE

OR

PUSH

AL

TION. MOVE

"N"

ING

SHUT

BLADE

POSITION.

THE

HAVE

MOVE

NECT

THE SPARK PLUG

AWAY

INJURY

ING

.

REAR

IN

FRONT TIRES

TIR

ES

ADJUSTMENTS, INSPECTION

TRACTOR

COMPLETELY

NEUTRAL

BRAKE

BLADES

ADJUSTMENTS, PAGE 10,

IS

IN

OFF

THE ENGINE. PLACE MOWER

CLUTCH

MAKE

AND

COMPLETELY

THE

THE SPARK PLUG WIRE FROM

YOU

IGNITION

FROM THE PLUG TO

FROM ACCIDENTAL

12 PSI.

WILL

:

CLUTCH-BRAKE

GEAR

POSITION. PLACE

" ENGAG

LEVER IN

ABSOLUTELY

ALL

THE SIDE TO SIDE

IS 14

IF

TIRES

NOT PROPERLY

DEPTH ADJUSTMENT

Adjustment

ment

Adjustment Knob clockwise (

he

i

ght

for

Knob. Rai

by turning Depth Adjustment Knob countercl

mower heig

se

Mower

ht

is

cutting

~

made

hei

(F'\l.

INTO

BRAKE

SHIFT

AND KEE

with

ght

). Lower Mower

LEVER

ED"

POSITION.

"ENGAGE

MOVING

STOPPED, R

KEY,

PSI

by

PARTS

DISCON·

P WIRE

PREVENT

START-

BE

AND

PRESSURE

ARE

OVER

the Depth Adjust-

turn

ing

PED-

POSI-

TO

PARK

-

D"

SURE

E-

AND

SURE

OR

ADJUST

Depth

cutting

ockwise

FIGURE 13

FI

GURE

14

- 9 -

LIFT

LEVER

PLUNGER

LIFT

LEVER

TOP

FLANGE

FIGURE 15

SIDE-

TO-SIDE

ADJUSTMENT

TRUNNION

FIGURE

16

OF

A

-_J_.llio<...._.,.

SIDE-TO-SIDE

ADJUSTMENT

A

I

NUT"B"

LEVEL

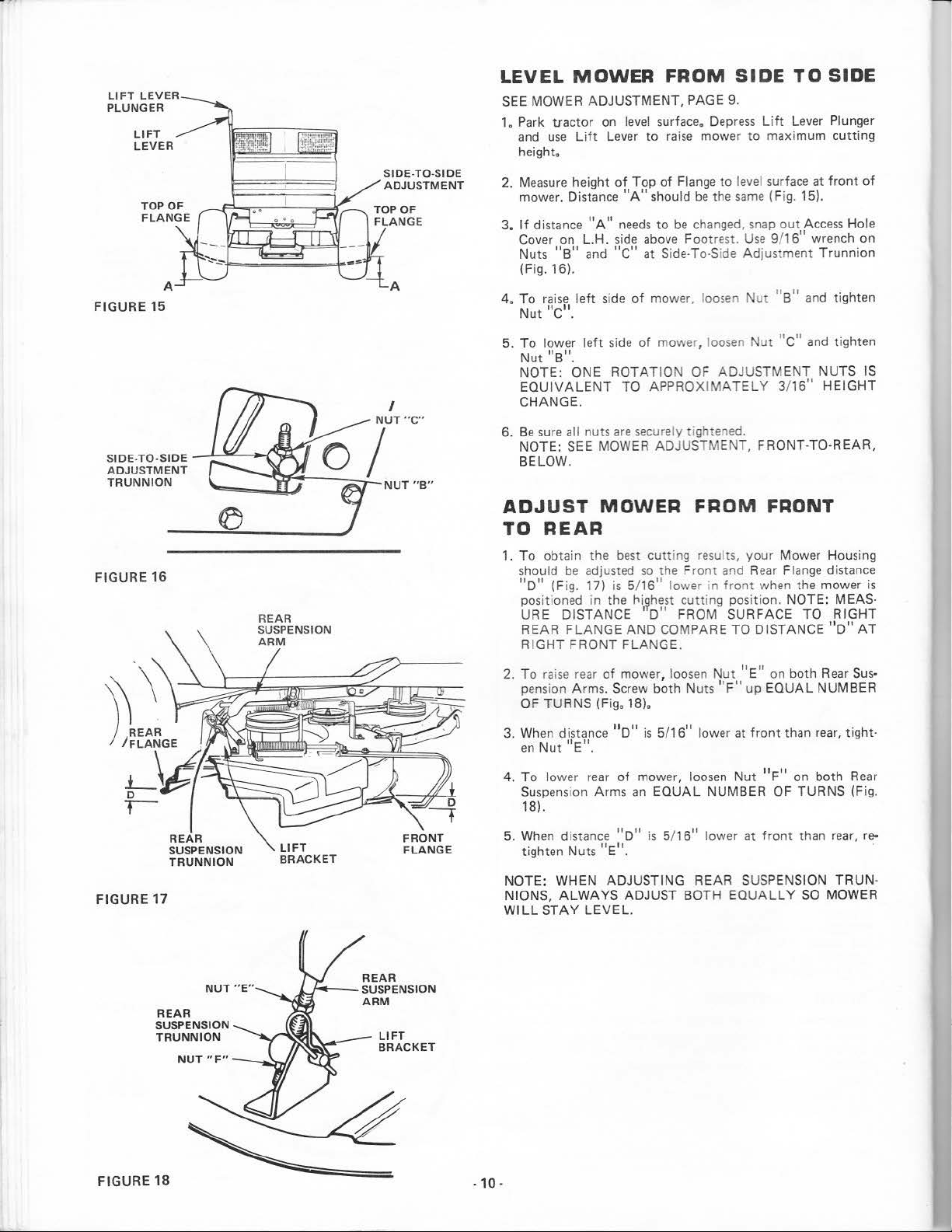

SEE MOWER ADJUSTMENT, PAGE

1.

Park tractor on

and

height.

2.

Measure

mower. Distance

3.

If

Cover on L.H.

Nuts

(Fig.

4.

To

Nut"c"

5.

To

Nut

NOTE:

EQUIVALENT

CHANGE.

6.

Be

NOTE: SEE MOWER ADJUST MENT, FRONT-TO BELOW.

ADJUST

TO

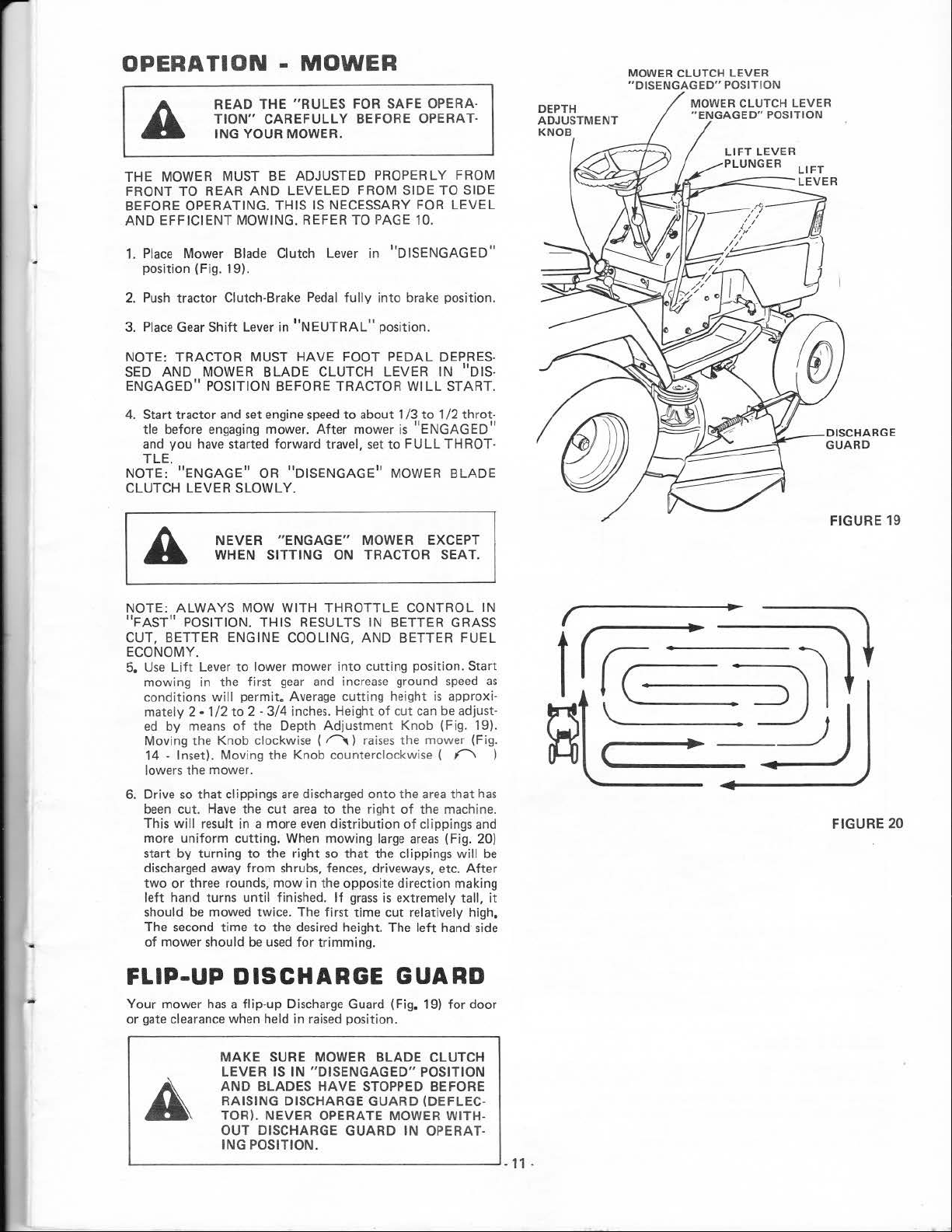

1.

To

should

"D" (Fig

positioned in the

URE DISTANCE 1 D" FROM SURFACE TO

REAR

RIG

MOWER FROM

use

height

distance

"B"

16).

raise l

lower l

"B".

ONE

sure all

Lift

eft

level

Lever

of

Top

"A"

"A"

needs

si

de

and

"c"

s1de of

eft

side

ROTATION OF ADJUSTM

TO APPROXIMATELY 3/

nuts

are

securely

MOWER FROM FRONT

REAR

obtain the best

be adjusted

. 17) is 5

FLANGE AND

HT

FRONT

/1

t>i~hest

FLANGE.

SIDE

9.

surface.

to

of

should

to

above

at Side-To-Side Adjustment

mower, l

of

mower, loosen

cutting

so

the Front and

6" lower in

COMPARE TO DISTANCE

Depress

raise

mower to maximum

Flange

be

the

be

chan

Footrest-

oosen

tightened.

results,

cutt

ing position. NOTE: MEAS-

Lift

to

level surface

same

(Fi

ged, snap

front

out

Use

9/

Nut

"s" and tighten

Nut

"c "

your Mower Housing

Rea

r Fl

when the mower

TO SIDE

Lever Plunger

cutting

at

front

g.

15).

Access

16"

wrench

Trunnion

and

t ighten

ENT

NUTS IS

16"

HEIGHT

REAR,

ange

distance

RIGHT

"D"

of

Hole

on

is

AT

FIGURE

REAR

SUSPENSION

TRUNNION

17

REAR

SUSPENSION

TRUNNION

NUT

"F"

-~

·"--"

2.

To

rai

se rear of

pens

ion Arms. Scre

OF

TURNS

3. When distance "D"

en

Nut

"E".

4.

To

lower rear

Suspens

ion A

mower, loos

w both Nuts '

(Fig. 18).

of

mower, l

rms

an

is

5/16

EQUAL

en

Nut

'F"

" lower at

oosen

Nut

NUMBER OF

''E"

on both Rear

up

EQUAL

front

"F"

than rear, tight-

on

TURNS (Fi

18).

5.

Whe

n distance "D"

tighten Nuts

NOTE: WHEN ADJUSTING REAR SUSPENSION

NIONS,

WILL

STAY

"E".

ALWAYS

LEVEL.

is

5/

16"

lower at

ADJUST BOTH EQ

front

than rear, re-

UALLY SO

Sus·

NUMBER

both

Rear

TRUN-

MOWER

g.

FIGURE

18

-10-

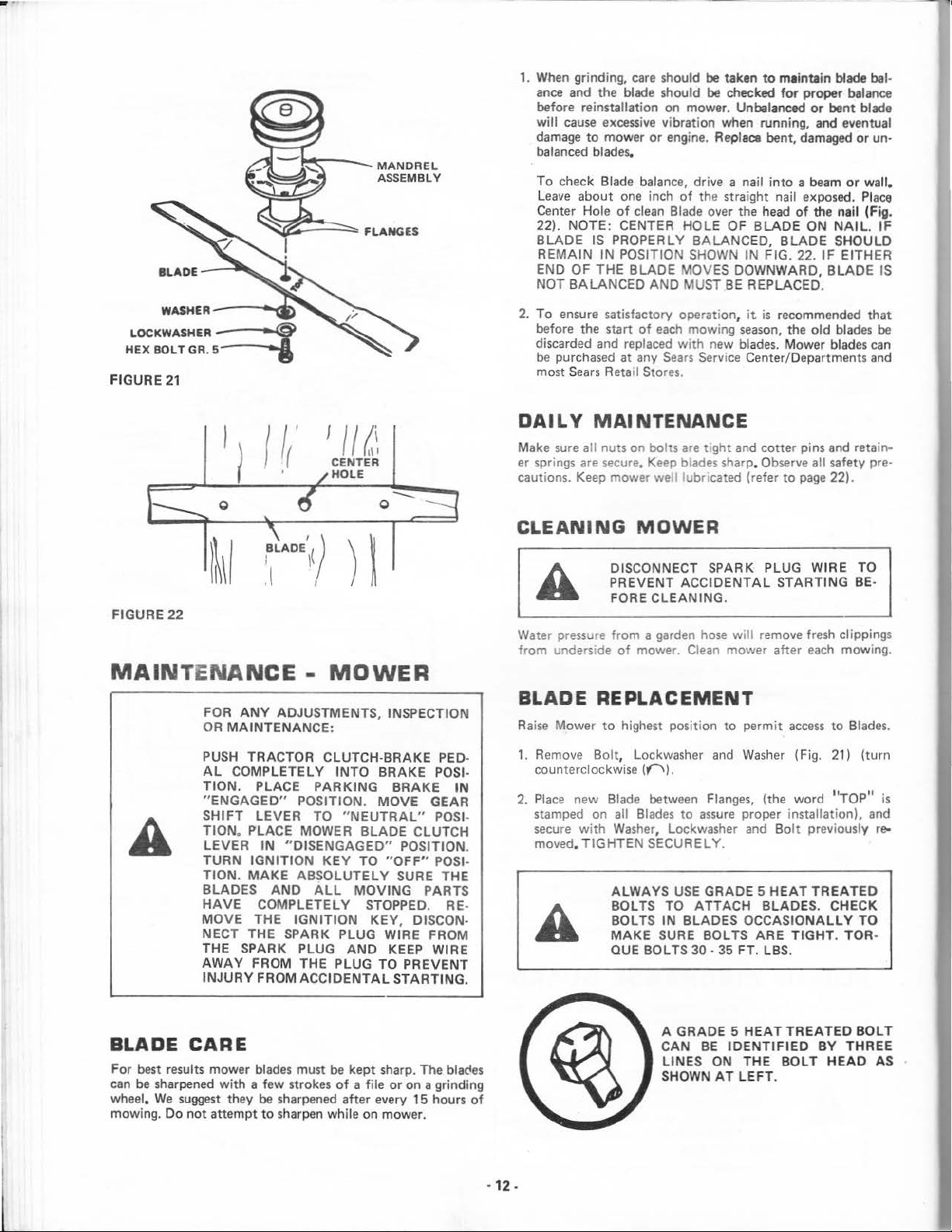

OPERATION

READ THE

TION"

ING

YOUR MOWER.

-

MOWER

"RULES

CAREFULLY

FOR SAFE OPERA-

BEFORE OPERAT-

DEPTH

ADJUSTMENT

KNOB

MOWER

"DISENGAGED"

CLUTCH

MOWER

"ENGAGED"

LEVER

POSITION

CLUTCH

POSITION

LEVER

THE MOWER MUST

FRONT TO

BEFORE OPERATING. THIS IS NECESSARY

AND

1.

Place

position (Fig. 19).

2.

Push

Place

3.

NOTE: TRACTOR MUST HAVE FOOT PEDAL DEPRES-

SED

ENGAGED" POSITION BEFORE TRACTOR

4. Start tractor and set engine

tle before

and

TLE

NOTE:

CLUTCH LEVER SLOWLY .

NOTE:

"FAST"

CUT,

ECONOMY.

5.

Use Lift

mowing in t

conditions w

mately 2 • 1/2 to 2-3/4

ed

Moving the Knob clockwise (

14

lowers the mower.

6. Drive

been

This

more uniform cutting.

start by turning

discharged away

two

left

should

The second time

of

REAR

EFFICIENT MOWING. REFER

Mower Blade Clutch Lever

tractor Clutch-Brake

Gear

Shift

AND

MOWER

engaging

you

have

.

"ENGAGE"

NEVER "

WHEN

ALWAYS

POSITION. THIS RESULTS IN BETTER GRASS

BETTER ENGINE COOLING, AND BETTER

Lever

by

means

- Inset). Moving the Knob counterclockwise ( 0 )

so

that

cut.

Have

will

result in a more

or

three rounds, mow in the opposite direction making

hand turns

be

mowed twice. The

mower should be

BE

ADJUSTED PROPERLY FROM

AND

LEVELED FROM SIDE TO SIDE

TO

Pedal

fully into

Lever in '

started forward travel,

MOW

to

he first

ill

permit.

of

clippings

the

to

from

until

'NEUTRAL"

BLADE

mower.

OR

SITTING

lower mower into cutting position. Start

the Depth Adjustment Knob (Fig. 19).

cut

the right

to

used

CLUTCH LEVER IN 11DIS-

speed

to

about 1/3

After

mower

set

"DISENGAGE"

ENGAGE"

WITH

gear

and

Average

inches. Height

are

discharged

area

even

When

shrubs, fences, driveways, etc.

finished.

the desired height. The

for

MOWER EXCEPT

ON

TRACTOR SEAT.

THROTTLE

increase

cutting height

~)

raises

onto

to

the right

distribution

mowing large

so

that

If

grass

first

time cut relatively high.

trimming.

FOR

PAGE

10.

in

''DISENGAGED"

brake position.

position.

WILL

to

is

"ENGAGED"

to

FULL

MOWER BLADE

CONTROL IN

ground

of

cut

can

the mower (Fig.

the

area

of

the machine.

of

clippings

areas

the clippings

is

extremely tall,

left

LEVEL

START.

1/2 throt-

THROT

FUEL

speed

is

approxi-

be

adjust-

that

(Fig. 20)

will

Aft

hand side

has

and

as

be

er

-

FI

GURE 19

FIGURE

it

20

FLIP-UP

Your mower

or

gate clearance when held in

~--------------------------------------~

DISCHARGE

has

a flip-up Discharge Guard (Fig. 19)

MAKE

LEVER IS

AND

BLADES

RAISING DISCHARGE

TOR). NEVER OPERATE MOWER WITHOUT DISCHARGE

ING

POSITION.

raised

SURE MOWER BLADE CLUTCH

IN

"DISENGAGED"

HAVE

GUARD

position.

STOPPED BEFORE

GUARD (DEFLEC-

GUARD

POSITION

IN

OPERAT-

for

door

-11-

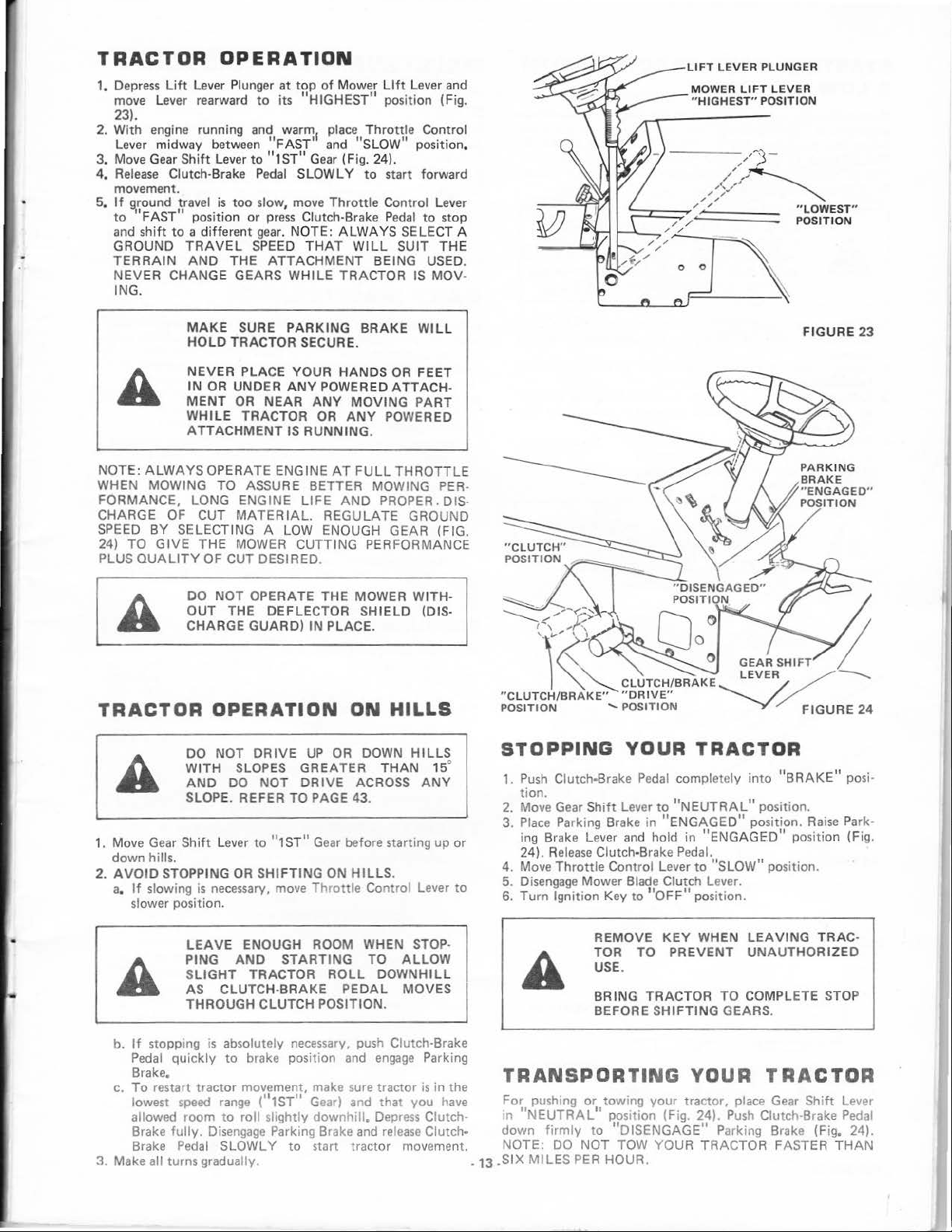

LOCKWASHER

HEX

BOL

FIGURE

WASHER----~:o.

~

T GR.

5---.....

21

'

II~~.

CENTER

HOLE

0

---

1.

When grinding, care should

ance

and the blade should

before reinstallation on mower. Unbalanced

will

cause

damage

balanced blades.

To

leave about one inch

Center Hole

22).

BLADE

REMAIN

END

NOT

2.

To

before the start

discarded and replaced

be

purchased at any

most

excessive

to

mower

or

check Blade balanc

of

NOTE: CENTER HOLE OF

OF

BALANCED

ensure satisfactory operation,

Sea

clean

IS PROPERLY BALANCED,

IN

POSITION SHOWN IN FIG. 22.

THE

BLADE MOVES DOWNWARD, BL

AND

of

each

rs

Reta

il

Stor

be

taken to maintain blade bal·

be

checked

vibration when running, and eventual

engine. Replace bent, damaged

e,

drive a nail

of

the straight nail exposed. Place

Blade over the head

MUST

mowing

with

Sears

Service Center/Departments and

es.

BLA

BE

REPLACED.

it

season,

new blades. Mower blades

DAILY MAl NTENANCE

Make sure a

er sprin

cautions. Keep mower

ll

gs

are secure.

nuts on bolts

Keep

welllubr

are

tight and cotter pins and retain·

blades sharp. Observe all safety pre·

cated (refer

CLEANING MOWER

for

proper balance

or

into a beam

of

the nail (Fig.

DE ON

BLADE

is

recommended

the

old

to

page

bent blade

or

or

wall.

NAIL.

SHOULD

IF

EITHER

ADE

that

blades

22).

un-

IF

IS

be

can

FIGURE

22

MAINTENAN

FOR

ANY

MAINTENANCE:

OR

PUSH

TRACTOR CLUTCH-BRAKE PED·

AL

COMPLETELY INTO BRAKE POSI·

TION.

"ENGAGED"

SHIFT LEVER

TION

. PLACE MOWER BLADE CLUTCH

LEVER

TURN IGNITION

TION.

MAKE

BLADES

HAVE

MOVE

THE SPARK PLUG WIRE FROM

NECT

THE SPARK PLUG

AWAY

INJURY

CE

- MOWER

ADJUSTMENTS, INSPECTI

PLACE

IN

COMPLETELY STOPPED. RE·

THE

FROM THE PLUG TO PREVENT

FROM

PARKING

POSITION. MOVE GEAR

TO

"NEUTRAL"

"DISENGAGED"

KEY

ABSOLUTELY

AND

ALL

IGNITION

AND

ACCIDENTAL

BRAKE

POSITION.

TO

"OFF"

SURE THE

MOVING

KEY, DISCON·

KEEP WIRE

STARTING.

ON

IN

POS

POSI-

PARTS

Water

fr

om

pressure

underside

DISCONNECT SPARK PLUG W

PR

EVENT

FORE

from a garden

of

ACCIDENTAL

CLEANING.

mower. C

hose

will

lean

mower after

STARTING

remove fresh clippings

IRE

each

TO

BE·

mowing.

BLADE REPLACEMENT

Raise

Mower

1.

Remove Bolt, lockwasher

counterclockw

2.

Place

I·

stamped on all Blad

secure

moved.

to

highest position

ise (("\).

new Blade between

with

Was

TIGHTEN

her, lockwasher

SECURELY.

ALWAYS

BOLTS TO

BOLTS IN BLADES

MAKE

QUE BOLTS 30 · 35 FT. LBS.

SURE BOLTS ARE

es

USE

Flanges,

to

assure

GRADE 5

ATTACH

to

permit

access

and

Washer

proper installation). and

and

OCCASIONALLY

(Fig. 21) (turn

(the word

Bolt

previously

HEAT

BLADES. CHECK

TREATED

TIGHT

to

Blades.

''TOP"

TO

. TOR·

is

re-

BLADE CARE

For best results mower blades must

can

be

wheel.

mowing.

sharpened

We

Do

suggest

not

attempt

with

a few strokes

they

be

sharpened after every 15 hours

to

sharpen while on mower.

be

of

kept

a file

sharp. The

or

on

a grinding

blacles

of

.

12.

A GRADE 5

CAN

BE

LIN

SHOWN

IDENTI

ES ON THE

AT

HEAT

LEFT.

TREATEDBO

FIED

BY

BOLT

HEAD

LT

THREE

AS

,__

TRACTOR

1.

Depress

move

23).

2. With engine running and

Lever midway between "FAST'

3. Move

4.

Release

movement.

5.

If

to

and

GROUND

TERRAIN

NEVER CHANGE

ING.

lift

Leve

Gear

Clutch-Brake

9,round travel

'FAST"

shift

to

OPERATION

Lever Plunger

r rearward

Shift

position

a different

TRAVEL

AND

Lever

is

too

THE

GEARS

to

to

Pedal

slow, move

or

gear

SPEED

at

top

of

its

warm1 place

"1ST" Gear (Fig

press Clutch-Brake

. NOTE:

ATTACHMENT

WHILE

Mower

"HIGHEST

Throttle

and "SLOW" position.

SLOWLY

THAT

. 24).

to

Thrott

le Control Lever

ALWAYS

WILL

TRACTOR IS MOV-

Lift

Lever and

11

position (Fig.

Control

start forward

Pedal

to

stop

SELECT A

SUIT THE

BEING USED.

LIFT

LEVER

MOWER

" HIGHEST"

PLUNGER

LIFT

POSITION

LEVER

MAKE

HOLD

NEV

IN OR UND ER

MENT

W

ATTACHMENT

PLUS

ALWAYS

BY

TO

GIVE

QUALITY

SELECTING A LOW ENOUGH GEAR (FIG.

DO

OUT

CHA

NOTE:

WHEN MOWING

FORMANCE, LONG ENG INE

CHARGE OF CUT

SPEED

24)

SURE

TRACTOR SECURE.

ER

OR

HILE

OPERATE ENGINE

TO

MATERIAL.

THE

MOWER CUTTING PERFORMANCE

OF CUT DESIRED.

NOT

THE DEFLECTOR

RGE

PARKING

PLACE YOUR HANDS

ANY

NEAR

TRACTOR OR

ASSURE BETTER MOWING PER-

OPERATE THE MOWER WITHGUARD)

ANY

IS RUNNING.

LIFE

IN PLACE.

BRAKE

POWERED ATTACH-

MOVING

ANY

AT

FULL

AND

REGULATE GROUND

PROPER. DIS-

SHIELD

WIL

OR

FEET

PART

POWERED

THROTTLE

(DIS-

TRACTOR OPERATION ON HILLS

1.

Move Gear

down hills.

2.

AVOID

a.

If

slower position.

DO NOT

WITH SLOPES GREATER

AND

SLOPE. REFER

Shift

STOPPING

slowing

is necessary,

Lev

DO

er

OR

DRIVE

to

UP

OR DOWN

NOT

DRIVE

TO

PAGE 43.

"1ST " Gear

SHIFTING ON

move

Throttle Control Lever

HILLS

THAN

ACROSS

before starting up

HILLS.

15°

ANY

L

STOPPING

1.

2.

3.

or

4.

to

5.

6.

Push

Clutch·Brake

tion.

Move

Gear

Place Parking Brake in

i

ng

Brake Lever

24).

Release

Move

Throttle

Disengage

Turn

Ignition Key to 1'0FF"

YOUR TRACTOR

Pedal

complete

Shift

Lever to 1'NEUTRAL"

"ENGAGED"

and

hold in

Clutch-Brake Pedal.

Control Lever

Mower Blade Clutch Lever.

ly

"ENGAGED"

to

"SLOW"

pos

ition.

into

position.

"BRAKE"

position.

position (Fig.

pos

ition.

FIGURE

posi-

Raise Park-

23

LEAVE

PING

SLIGHT

AS CLUTCHTHROUGH CLUTCH POSITION.

b.

If

stopping

Pedal

quickly

Brake.

c.

To

restart tractor movement, make sure tractor

lowest

speed

allowed room to roll slightly

Brake

fully.

Brake

3. Make all turns gradually

Pedal

ENOUGH ROOM WHEN STOP-

AND

is

absolutely

to

range

Disengage

SLOWLY

STARTING

TRACTOR

BRAKE

brake position

t1ST"

Parking Brake

ROLL

necessary,

Gear)

downhill.

to

start tractor movement. NOTE: DO

TO

ALLOW

DOWNHILL

PEDA L MOVES

push

Clutch-Brake

and

engage

and

Depress

and

Parking

is

that

release

in

you

ClutchClutch· down

have

the

REMOVE

TOR TO

USE

BRING

BEFORE SHIFTING GEARS.

TRANSPORTING

For

1n

-13 .SIX

pushing

"NEUTRAL

MILES

or

towing

1

'

firmly

position (Fig. 24).

to 11DISENGAGE"

NOT

PER HOUR.

KEY

WHEN

.

PREVENT

TRAC

TOR

YOUR

your

tractor, place Gear

TOW YOUR TRACTOR FASTER

LEAVING

UNAUTHORIZ

TO

COMPLETE STOP

TRAC-

TRACTOR

Push

Parking Brake (Fig. 24).

Shift

Clutch-Brake

ED

Lever

Pedal

THAN

STARTING

A

LOW

If

your

recharged.

follow

PED

THE

TIVE

1. Connect each end

2. Connect one end

3. Connect the

4.

Battery is

If

this procedure.

WITH

A 12

OTHER

GROUNDED

terminals

chassis).

H terminal

or

good CHASSIS

Tank

or

Battery).

Disconnect cables in reverse order·

a.

Engine

b. Negative terminal

c.

Positive terminals.

YOUR

BATTERY

too

"Jumper

VEHICLE

LEAD

PLOSIVE GASES.

AND

FROM

PROTECTION

of

each

of

Block

low

Cables" are

NOTE:

VOLT

SYSTEM.

-ACID

SMOKING

BATTERIES.

of

battery

of

the

fully

charged battery.

other

end

GROUND

or

chassis

of

NEGATIVE

MUST

the RED Cable

of

fully

to

BATTERIES

BLACK

TRACTOR

start the engine,

used

YOUR

ALSO

AROUND

(taking care

the cable

of

charged

for

TRACTOR

GROUNDED

BE A 12

KEEP SPARKS,

MATERIALS

ALWAYS

BATTERIES.

to

Cable

to

on

tractor

tractor.

battery.

WITH

it

emerge11cy

should be

,s

SYSTEM

VOLT

GENERATE

not

to

FLAME

AWAY

WEAR

the POSITIVE

to

short against

the

NEGATIVE

ENGINE

(away

from

starti

ng

EQUIP-

NEGA

EX-

,

EYE

(+-)

BLOCK

Gas

MAINTENANCE-

\/lOWER

-o

sary service using the

DAILY

Make sure all nuts on bolts

er spn

tor

FIRST~

1.

NOTE:

THE

MAINTENANCE

keep

your

tractor

REFER TO "STOPP

TOR"

SPARK

CIDENTAL

ANY

REPAIR

MAINTENANCE

ngs

are secure. Observe al safety precautions. Keep trac-

well lubricated (refer

HOURS

CHANGE

Changing

break-in

ENGINE

Oil

aher

res1due

BE

EI\IGII\IE WHEN

wh1ch m•ght

CAREFUL

IS LISTED

running better, onger,

following

PAGE 13

PLUG WIRE TO

STARTING

INSPECTION,

(EXCEPT

are:

to

page

OIL

the f1rst

NOT

TO

CHANGING

TRACTOR

ON

PAGE 12.

Maintenance Schedule.

ING

AND

ADJUSTMENT

CARBURETOR).

gnt and

22).

two

hours

be

damaging

ALLOW

OIL.

perform

YOUR

DISCONNECT

PREVENT AC·

BEFORE

cotter

MAKING

pins and retain·

will

help eliminate

to

your

DIRT

TO

neces·

TRAC-

OR

Engine.

ENTER

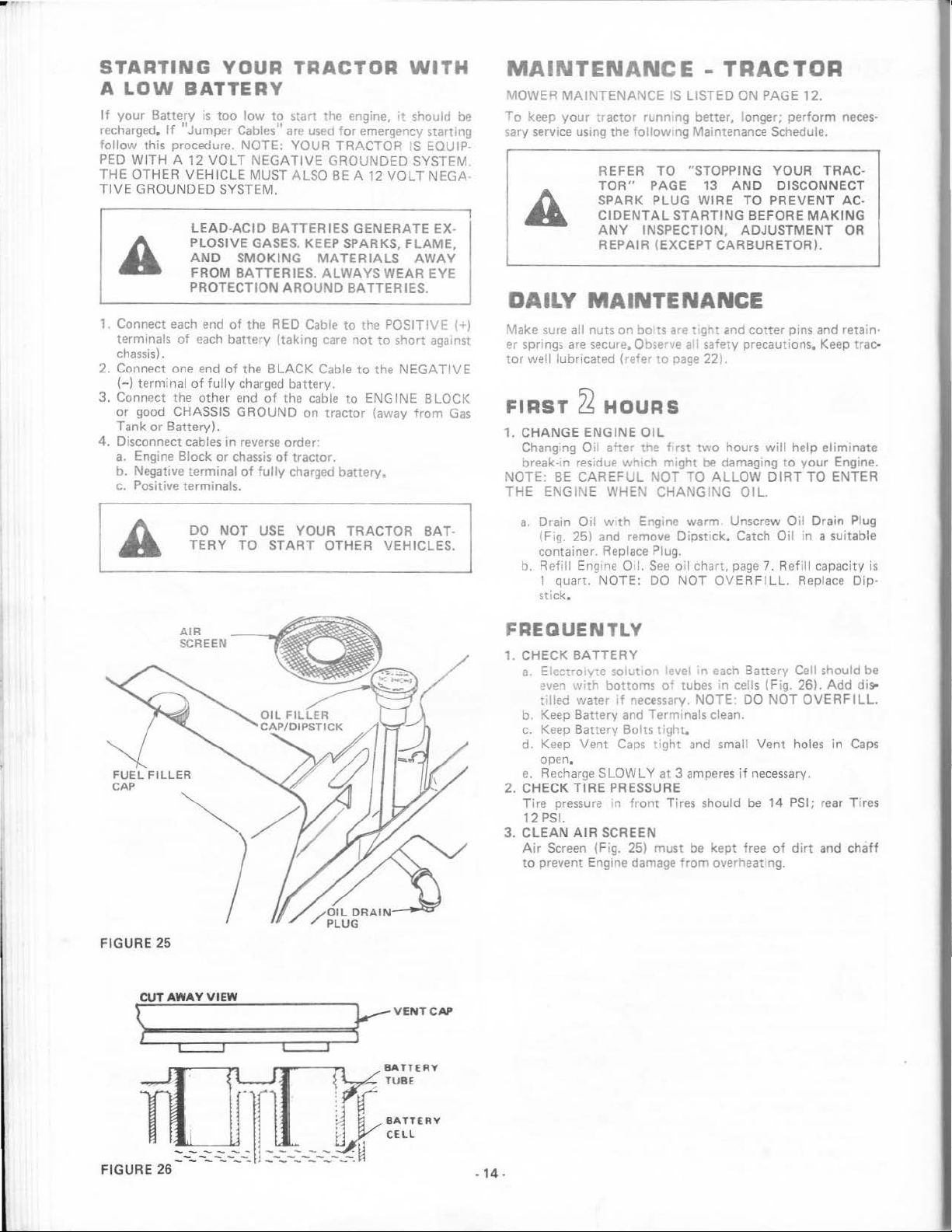

FIGURE

25

DO

TERY

AIR

SCREEN

NOT

TO

USE

START

YOUR

OTHER

TRACTOR

VEHICLES.

BAT·

a Drain

b. Refill Eng

Oil

w•th

me

Oil.

NOTE:

Engme

See

DO

(F1g.

25) and remove

container. Replace Plug.

1 quart.

stick,

warm

Dipstick.

oil

chart,

NOT

fREQUENTLY

1.

CHECK

a E ectro

b Keep Battery and Termmals clean.

c.

d. Keep Vent

e.

2. CHECK

Tire

12 PSI.

3.

CLEAN

Air

to

BATTERY

v:e

so

ut

with

even

t

1.ed

water

Keep

Battery

open.

Recharge

TIRE

pressur<? m front

AIR SCREEN

Screen {Fig. 25) must

prevent Engine damage

o 1 level ·n !!ach

bottoms

SLOWLY

PRESSURE

of

if

necessary. NOTE. DO

Bolts

tight.

Caps

ight and small

at

Tires should

tubes

3 ampe

be

from

Unscrew

Catch

page

OVE

kept free

overheat'ng.

7.

RFILL.

Battery

•n

cells (Fig. 26).

NOT

Vent

res

if

necessary.

be

14 PSI; rear Tires

of

Oil

Drain Plug

Oil

in a suitable

R

efill

capacity

Replace Dip-

Cell should be

Add

OVERFILL.

holes in

dirt

and

is

di9'

Caps

chaff

\}oU•T-==A=W=A=Y=V=I=E

c:::=:J

=W=====

=~r-

c::::::::J

V

ENT

CAP

-14.

Loading...

Loading...