Craftsman 917255470 Owner’s Manual

8EAIRS

®

MODEL NU

oAssembly

oOperation

oCustomer

Responsibilities

oService

IMB

ER 917.255470

OWNER'S MANUAL

IIII I I I IIII 'll'llll'l

oAdjustments

oRepair Parts

Caution:

Read and Follow

all Safety Rules

and Instructions

Before Operating

This Equipment

|1 I I I II1'1111111

Safe Operation Practices for Ride-On Mowers

SAFETY RULES

IMPORTANT: THIS CUTTING MACHIN EISCAPABLE OFAMPUTATtNG HANDS AND FEETAND'THROWING OBJECTS,

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT INSERIOUS INJURY ORDEATH,

I. GENERAL OPERATION

- Read, understand, and follow all instructions in the manual

and on the machine before starting..

• Only allow responsible adults, who are familiar with the

instructions, to operate the machine,.

• Clear the area of objects such as rocks, toys wire, etc.,,

which could be pcked up and thrown by the blade

= Besure the area is clearofother people before mowing. Stop

machine if anyone enters the area,

• Never carry passengers

• Do not mowin reverse unless absolutely necessary Always

took down and behlnd before and while backing.

• Be aware of the mower discharge direction and do not point

it at anyone,. Do not operate the mower without either the

entire grass catcher or the guard in place,

• Slow down before turning.,

• Never leave a running machine unattended. Always turn off

blades, set partdng brake, stop engine, and remove keys

before dismounting,

" Turn off blades when not mowing.

,, Stop engine before removing grass catcher or unclogging

chute°

• Mow only in dayiight or good artificial tight.

° Do not operate the machine while under the influence of

alcohol or drugs

• Watch for traffic when operating near orcrossing roadways.

,, Use extra care when ioading or unloading the machine into

a trailer or truck.

IL SLOPE OPERATION

Slopes are a major factor related to Ioss-of-control and ttpover

accidents, which can result in severe injuryor deathr. A!f s_opes

require extracaution, Ifyou cannot backup the slope orif you feet

uneasy on it, do not mow it.

DO:

= Mow up and down slopes, not across.

° Remove obstacles such as rocks, tree iimbs, etc.

• Watch for holes, ruts, or bumps, Uneven terrain could

overturnthe machine., Tatl grass can hide obstacles.,

• Use slow speed. Choose a low gearso that you will not have

to stop or shift while on the slope.

• Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

• Use extra care with grass catchers or other attachments,

These can change the stability of the machine.

• Keep all movement on the slopes slowand gradual, Do not

make sudden changes in speed or direction,

• Avoid starting or stopping on a slope. If tires iose traction,

disengage the b_adesand proceed slowly straightdown the

slope.,

DO NOT:

• Donor turn on slopes unless necessary, andthen turn slowly

and gradual y downhill, ifpossible.

• Do not mow near drop-offs ditches, or embankments The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in,

• Do not mow on wet grass_ Reduced traction could cause

sliding,,

• Do not try to stabilize the machine by putting yourfoot onthe

ground.

• Do not use grass catcher on steep slopes

II1. CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence ofchildren° Children are often attracted tothe machine

and the mowing acfivity. Neverassume that children will remain

where you Iast saw them,

• Keep children outof themowing area and under the watchful

care of another responsible adult,

• Be alert and turn machine off if children enter the area.

= Before and when backing, look behind and down for small

children,

= Never carry children. They may fall off and be seriously

injuredor interfere with safe machine operation.

• Never allowchildren to operate the machine.

• Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

IV. SERVICE

• Use extracare inhandling gasoline and other fuels, Theyare

flammable and vapors are explosive,

Use only an approved container,,

Never remove gas cap or add fuel with the engine

running. Allow englne to cool before refueling. Do not

smoke,

Never refuel the machine indoors.

Never store the machine or fuel container insidewhere

there is an open flame, such as a water heater.

. Never run a machine inside a closed area.,

• Keep nutsand bolts, especially blade attachment bo_tstight

and keep equ pment in good condition.

o Never tamper with safety dev]ces_ Check their proper

operation regulady,

• Keep machine free of grass, feaves or otherdebflsbuild-up

Clean oil or fuel spillage. Allow machine to cool before

storing

• Stop and inspect the equipment if you strike an object.,

Repair, if necessary, before restarting°

• Never make adjustments or repairs with the engine running°

- Grass catcher components are subject towear, damage, and

deterioration, which could expose moving parts or allow

objects fo be thrown. Frequently check components and

replace with manufacturer's recommendedparts,when nec-

essary.

• Mower blades are sharp and can cUt.rWrap the biade(s) or

wear gloves, and use extra caution when sen/icing them.

o Check brake operation frequently. Adjust and service as

required,

_!IA tent safety precautions. It means

_1_ CAUTIONH! _ECOMEALERT!I! YOUR

I A L°0k';o;'this sYmbo| to point out impor- i

!,, I

SAFETY IS INVOLVED.

ml i mllu ii ii i i

CAUTION: Always disconnect spark

plug wire and place wire where it ca nn ot

contact spark plug in order to prevent

accidental startin 9 when setting up,

transporting, adlusting or making

repairs.

CONGRATULATIONS on your purchase of a Soars

Tractor. It has been designed, engineered and manu*

factured to give you the best possibledependability and

performance°

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Department. We have competent, well-trained techni-

cians and the proper tools to service or repair this unit°

Please read and retain this manual. The instructions will

enable you to assemble and maintain your unit properly_

Always observe the "SAFETY RULES",

MODEL

NUMBER 917.255470

SERIAL

NUMBER

:)ATEOF PURCHASE

THE MODELAND SERIAL NUMBERS WILL BE FOUND

ON A PLATE UNDER THE SEAT°

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

_)ATEOF PURCHASE AND KEEP IN A SAFE PLACE

-'OR FUTURE REFERENCE°

PRODUCT SPECnFnCATDONS

HORSEPOWER; :I4o0

GASOLINE CAPACITY: 5 QUARTS

UNLEADED REGULAR

OIL (3_0PINTS): SAE 30 (Above 32°F)

5W-30 (Below 32°F)

SPARK PLUG.(GAP,0301No); CHAMPION RC12YC

VALVE CLEARANCE: INTAKE .003 - .005 IN.

EXHAUST .003 - .005 IN.

GROUND SPEED: FORWARD

1st 1.0I MPH

2rid 2.08 MPH

3rd 3_12 MPH

4th 3.98 MPH

5th 5.10 MPH

REVERSE: to50 MPH

TIRE PRESSURE: FRONT: 14 PSI

REAR: 12 PSI

CHARGING SYSTEM: 3 AMPS BATTERY

5AMPS HEADLIGHTS

BLADE BOLT TORQUE: 30-35 FT, LBS.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

ucL Contact your nearest Sears store for details.

WARNING= This unit is equipped withan internalcombus-

tionengine and should not be used on or near any unim-

proved forest-covered, brush-covered or grass-covered

land unless the engine*s exhaust system is equipped with

a spark arrestor rnoeting applicable local or state laws (if

CUSTOMER RESPONSIB UTIES

= Read and observethe safety rules.

• Follow a regular schedule in maintai ni ng, caring for and

using your unit.

any). If a spark arresteris used, itshould be maintained in

effectiveworking order by the operator°

In the state of California the above is required by law

(Section 4442 of the California Public Resources Coda)_

Other states may have similar laws. Federal laws apply on

federal lands_ A spark arrestor for the muffler is available

. FOlslOWthe_r_StrrUgCtiOsnSc_indneroCt_SstOornwenreF_r,eSmPOnsiabi'i-

through your nearest Sears Authodzed Service Center

(See REPAIR PARTS section of this manual).

i = i

LIMITED TWO YEAR WARRANTY ON ELECTRIC START RIDIING EQUliPMENT

For two (2) years from the date of purchase, if this tiding equipment is maintained, lubricated and tuned up according to the

instructionsin the owner's manual, Sears will repair or replace, free of charge, any parts found to be defective in material or

workmanship°

This Warranty does not cover:

. Expendable items which become worn during normal use, such as blades, spark plugs, air cleaners and belts.

o Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass°

• Repairs necessary becauee of operator abuse, negligence, improper storage or accident or the failure to maintain the

equipment according to the instructionscontained in the owner's manual.

° Riding equipment used for commercial or rental purposes

UMITED 90 DAY WARRANTY ON BATTERY

For 90 days from date of purchase, if any battery Included with this riding equipment proves defective in material or workmanship

and our testing determines the battery wiil not hold a charge, Sears will replace the battery at no charge°

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE RIDING EQUIPMENT TO THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT IN THE UNITED STATES.

This Warranty gives you specific legal rights, and you may also have other tights which may vary from state to state.

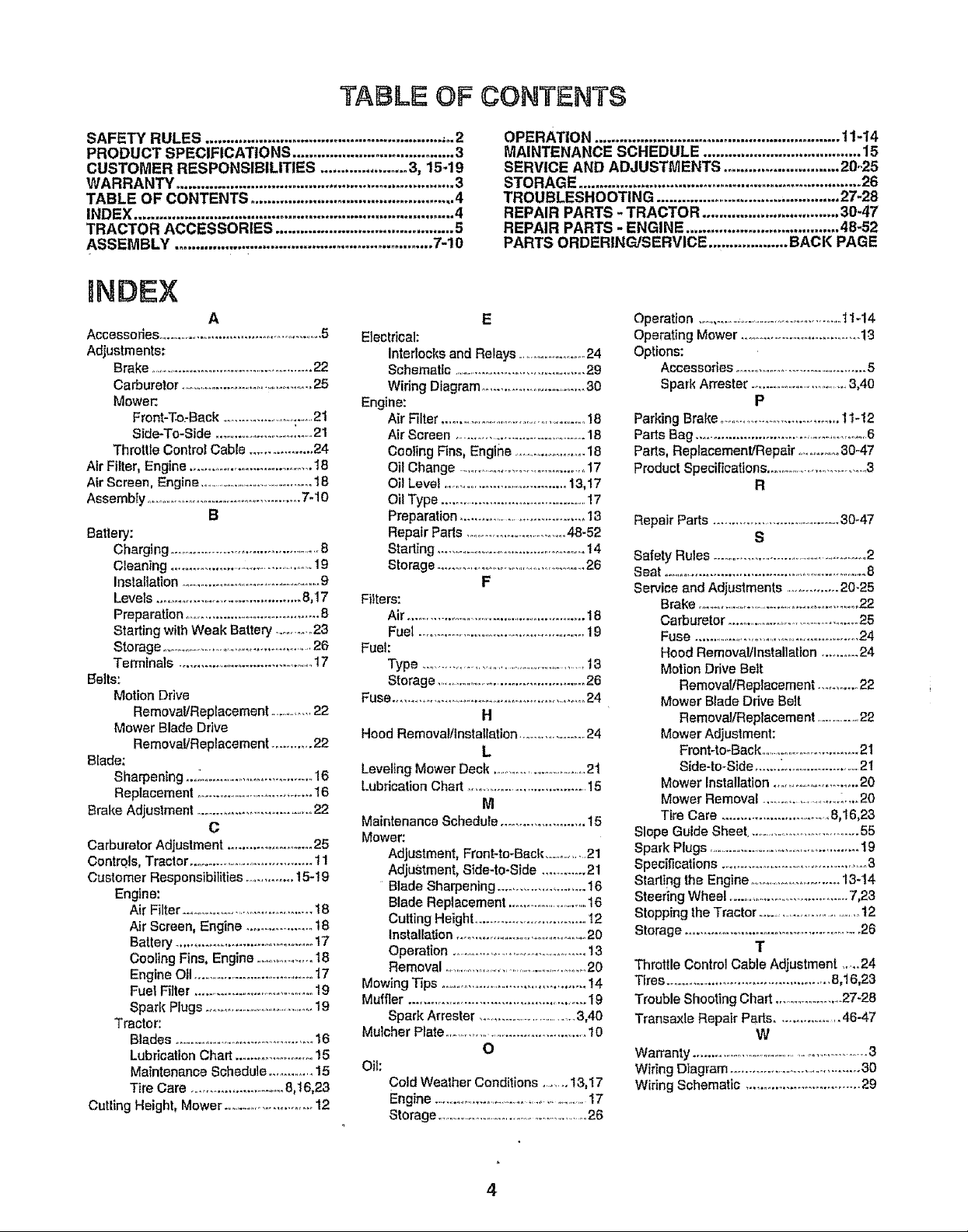

TABLE OF CONTENTS

SAFETY RULES ......................................................... _..2

PRODUCT SPECIFICATIO NS....................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3, 15-19

WARRANTY ................................................................... 3

TABLE OF CONTENTS ................................................. 4

INDEX ............................................................................. 4

TRACTOR ACCESSORIES ........................................... 5

ASSEMBLY .............................................................. 7-10

iNDEX

A

Accessodes .................................................5

Adjustments;

Brake ................................................22

Carburetor ..............................................25

Mower:.

Front-To,Back ...............................21

Side-To-Side ............................_.....21

Throttle Control Cable ................. 24

Air Filter, Engine ...................................18

Air Screen, Engine ...........................................18

Assembly ................................................7-10

B

Batlery:

Charging ............................................ 8

Cleaning ............................................1g

Installation ..........................................9

Levels ..........................................8,17

Preparation ..................................... 8

Starling wilhWeak Battery ...........23

Storage .............................................26

Terminals .........................................17

Belts:

Motion Drive

RemovaVRepfacement.............22

Mower Blade Drive

Remova!/Replace ment ........... 22

Blade:

Sharpening o.o_...................................16

Replacement .....................................16

Brake Adjustment ...................................22

C

Carburetor Adjustment ....................... 25

Contrqls, Tractor ....................................t 1

Customer Responsibilities ...............15-t9

Engine:

Air Filter ........................................18

Air Screen, Engine .................. t8

Battery ...................................... 17

Cooling Fins, Engine ...................18

Engine Oll .......................................t7

FueI Filter .......................................19

Spark Plugs ......................................19

Tractor:

Blades ............................................16

LubricationChart ...................... 15

Maintenance Schedule ............ 15

Tire Care ..............................8,!6,23

Cutting Height, Mower ............................12

Electrical:

Interlocks and Relays .....................24

Schematic .......................................29

Wiring Diagram ...............................30

Engine:

Air Filter ................................................18

Air Screen .........................................18

Cooling Fins, Englne .......................18

Oil Change ....................................... 17

Of! Level .....................................13,17

Oil Type ..........................................17

Preparation .................................... 13

Repair Pads ............................... 48-52

Starting ...................................................14

Storage .................................................26

Fifters:

Air ........................................................18

Fuel ......................................................19

Fuel:

Type .......................................................... 1 3

Storage .............................................. 26

Fuse ..........................................................24

Hood RemovaVtnetailation ...................24

Leveling Mower Deck ................................21

Lubrication Chart ......................................15

Maintenance Schedule ....................... 15

Mower:

Adjustment, Front-to-Back ...............21

Adjustment, Side-to-Side ............ 21

Blade Sharpening ........................ 16

Blade Replacement ............................16

Cutting Height .............................. 12

Installation ............................................20

Operation .........................................13

Removal ................................................... 20

Mowing Tips ......................................... 14

Muffler ................................................. 19

Spark Arrester ..............................3,40

Mulcher Plate ............................................10

Oil:

Cold Weather Conditions ....... 13,17

Engine ......................................................17

Storage ............................................................ 26

OPERATION ........................................................... 11-14

MAINTENANCE SCHEDULE ...................................... 15

SERVICE AND ADJUSTMENTS ............................ 20-25

STORAGE .................................................................... 26

TROUBLESHOOTING ............................................ 27-28

REPAIR PARTS - TRACTOR ................................. 30-47

REPAIR PARTS - ENGINE ..................................... 48-52

PARTS ORDERING/SERVICE ................... BACK PAGE

E

F

H

L

M

0

Operation ....................................................11-14

Operating Mower ................................ 13

Options:

Accessodes ..................................... 5

Spari_ An'ester .................................3,40

P

Parking Brake ................................ 11-12

Pads Bag ................................................. 6

Pads, Replacement/Repair ............30-47

Product Specifications...............................3

R

Repair Parts .......................................30-47

S

Safety Rules ................................................2

Seat .................................................................8

Service and Adjustments ...............20-25

Brake ...........................................................22

Carburetor ............................................25

Fuse ......................................................24

Hood Removal!Installation .......... 24

Motion Drive Sell

Removal/Replacement ........... 22

Mower Blade Drive Beff

Removal/Replacement .................22

Mower Adjustment:

Front-to-Back ................................21

Side-to-Side ......._.......................21

Mower Installation ........................ 20

Mower Removal ..........................._..,.20

Tire Care .................................8,16,23

Slope Guide Sheet..................................55

Spark Plugs .......................................................19

Specifications ..........................................3

Starting the Engine ...............................13-14

Steering Wheel .....................................7,23

Stopping the Tractor ...............................12

Storage .................................................. 26

T

Throttle Control Cable Adjustment .....24

Tires ............................................ 8,16,23

Trouble Shooting Chart .................. 27-28

Transaxle Repair Pads....................46-47

W

Warranty .........................................................3

Wiring Diagram .........................................3D

Wiring Schematic ............................... 29

4

These accessories and atlaohmenls were aval]ai3te when _ne tractor was puronaseo, i nay are also available a_meal: c_eers {e[u_ uu_{_,

catalog and service centers,, Most Sears steres can order these items for you when you provide the model number ef your tractor,,

ENGINE

SPARK PLUG MUFFLER

GAS CAN ENGINEOIL

STABtUZER

MAINTENANCE

BLADES I BELTS

I

PERFORMANCE

Sears offers awldevariety ofattachments thatfit yourtraotoroManyof theseare listedbelow withbdef explanations of howtheycanhelp

you This listwascurrentatthe timeof publication;however, itmay changein future years -more attachments may be added, changes

may be made intheseattachments,or some may no longer be available orfityourmodel. Contact your nearest Sears store for the

accessories and attachments that are available for your tractor,

Mostof these attachments do not requireadd{tiona!hitches or conversionkits(thosethat de are indicated) and are designed for easy

attachingand detaching.

PERMANEX BAGGER lets you coltect grass clippings and

leaves for a healthier, neater looking {awm Two Permanex

containershotd30-gallon plasticbags.

LAWN SWEEPERS let you collect grass clippings and leaves

LAWN VACSforpowerful collectionofheavy grassclippings and

leaves, Wand attachment to pick up debris in hard-to-reach

plaeeSo

CARTSmake hauling easy° Variety ofsizes available°

ROLLER for smoother lawn surface. 36-inch wide, 18cinch

diameterwater-tight drum holdsupto390 Ibs.ofweight. Rounded

edges prevent harm to turf. Adjustable scraper automatically

cleansdrum.

SPREADER/SEEDERS make seeding, fertilizing, and weed

killing easy. Broadcast spreaders are also usefuI for granular

de-icers and sand.

CORING AERATOR takes small plugsout of soil to allow mois-

ture and nutrients to reach grass roots. 36-inch swath, 24

hardened steel coringtips. 150 tb. capacityweight tray°

AERATOR promotes deep root growth for a healthy lawn_ Ta-

pered 2.5-inch steel spikes mounted on 10-inch diameter discs

puncture holes in soil at close intervals to let moisture soak in,

Steel weighttray forIncreased penetration.

MULCH RAKE/D ETHATCHER loosenssoil and ftipsthatchand

matted leavesto lawnsurface fereaey pickup° Twentyspring line

teetheUselulto preparebare areasforseedtngoAvailable forfront

or rear mounting.

SPRAYERS use 12-volt DO electricmotor that connectsto the

tractor battery or other 12-volt source. Includes booms for

automaticspraying when pulling, and hand held wand for spot

spraying. Wand has adjustable spray pattamo For applying

herbicides,insecticides,fungicides, and liquidferlilizerS.r

SNOW BLADE for snow removalontyo 14-inch high, 42-inch

wide blade clears 38-Inchpath whenangted tell or right, Raises,

Eowerswith side lever° Adjustabte skids; replaceable, reversible

scraper bar, (Usewithtire chains,wheelweights, or reardrawbar

weight.)

SNOWTHROWER has40-inchswath. Drum-typeaugerhand[es

powdery and wet/heavy snow° Mounts easily with simple pin

arrangemenL Discharge chute adjustsfrom tractorseat. 6-inch

diameter spout discharges snow 10te 50 feel Lift controlledat

tractor seat. (Use wlth chains, wheat weights, or rear drawbar

weight,)

TIRE CHAINS are heavy duly; closety spaced extra-largecross

linksgive smooth ride, outstanding traction_

WHEEL WEIGHTS for rear wheels provide needed traction for

snowremovalerdozingheavymaferials, thpairs. (301be.each)

TRACTOR CAB has heavy duty vinyl fabricever tubularsteel

frame ABS plastictop;clearplasticwindshieldoffers360degree

visibility.Hingedmeta!doors withcatch, Keeps operatorwarm

and dry. Remove vinyl and windshieldsfor use as sun protector

tn summer_ (Catalog oniy.)

Optional accesserles for tractor cab: tinted/tampered solid

safetyglass windshield wilh handoperated wiper;, 12welt amber

caution light for mounting on cab top. (Catalog only.)

TRACTOR COVER protects tractor from weather.. Made of

Evolution3 fabdc (waler-repetlant, extremely breathable, light

weight, soft, non-abrasive, pliable in all temperatures,durabte,

slaintlear/puncture resistant, will net shrink or stretch,) (Catalog

only.)

TILLER has5hp engineand36-inch swathto prepareseed beds,

cultivate, and compostgardenresidue. Tiller has ttsown buflt-in

lift anddepthcontrolsystem and does NOT require a sleevehitch,

Fits any lawn, yard, or garden tractor. Simply hook up te the

tractor drawbar and go!

,i i1,1

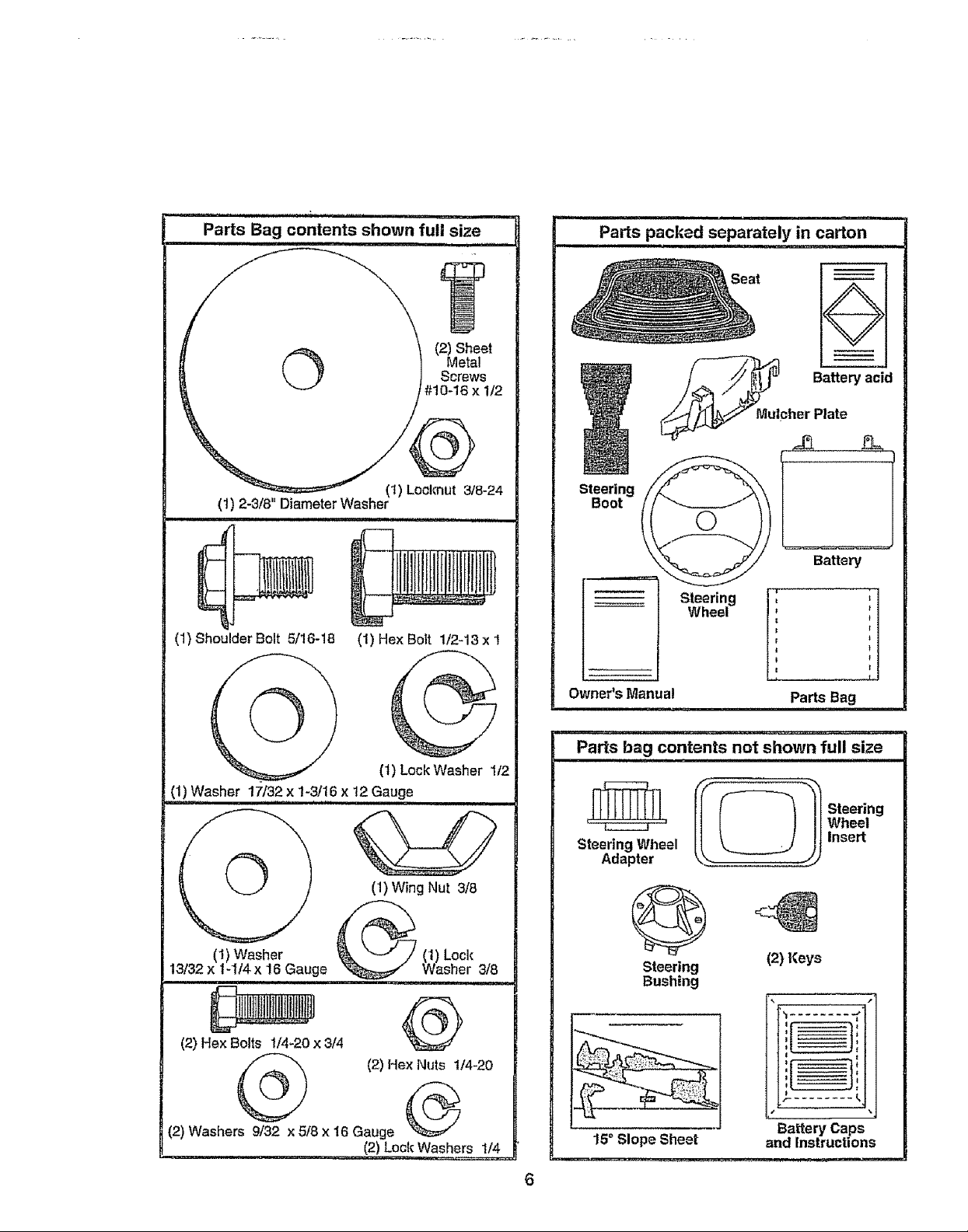

Parts Bag contents shown full size

i ...........

(2) Sheet

©

Metal

Screws

#10-I6 x 1/2

Ill I I I I I '"1 "1 '1

Parts packed separately in carton

Seat

_ Mulcher Plate

(1) 2-3/8" Diameter Washe_ 1) Locknut 3/8-24

(1) Shoulder Bolt 5/!6-18

(1) Washer 17/32 x 1-3/16 x 12 Gauge

(1) Hex Bolt 1/2-13 x 1

(t) Lock Washer 1/2

(1) Wing Nut 3/8

Steering

Boot

Battery

Steering

Wheel

! U

Owner's Manual

Parts bag contents not shown full size

Steering Wheel

Adapter

Parts Bag

I IWheel

, jJ Insert

(I) Washer __ (1) Lock

13/32 x 1-I/4x 16 Gauge _ Washer 3/8

(2) Hex Bolts I/4-20 x 3/4

i

@

(2) Hex Nuts t/4-20

G

(2) Washers 9/32 x 5/8 x 16 Gauge

(2) Lock Washers 1/4

.....i,,, ..........

Steering (2) Keys

Bushing

........ .j"

15° Slope Sheet and Instructions

Battery Caps

our new _rac[or nas Dean assemDleo at lne "leo'tory WlIR except|on o1" _FIOSe paris lS"K urtassemDteQ lot Snlpptng purpo_e_

To ensure safe andproper operation ofyour tractor all parts andhardware you assemble must betightened securely. Use

the correct tools as necessary to Insure proper tightness.

TOOLS REQUIIRED FOR ASSEMBLY

A socketwrenchsetwill make assemblyeasier° Standard

wrench sizes are listed.

(t) 5/16" wrench

(2) 7/16" wrenches

(1) 3/4" wrench

Tire pressure gauge

Phillips Screwdriver

Utility knife

(1) 9/16" wrench

When right and left hand are mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

o Remove all accessible loose parts and parts cartons

from carton (See page 6),

• Cut along lines on carton, from topto bottom, all four

comers of carton and lay panels fiat.

• Check for any additional loose parts or cartons and

remove_

BEFORE ROLLING TRACTOR OFF SKiD

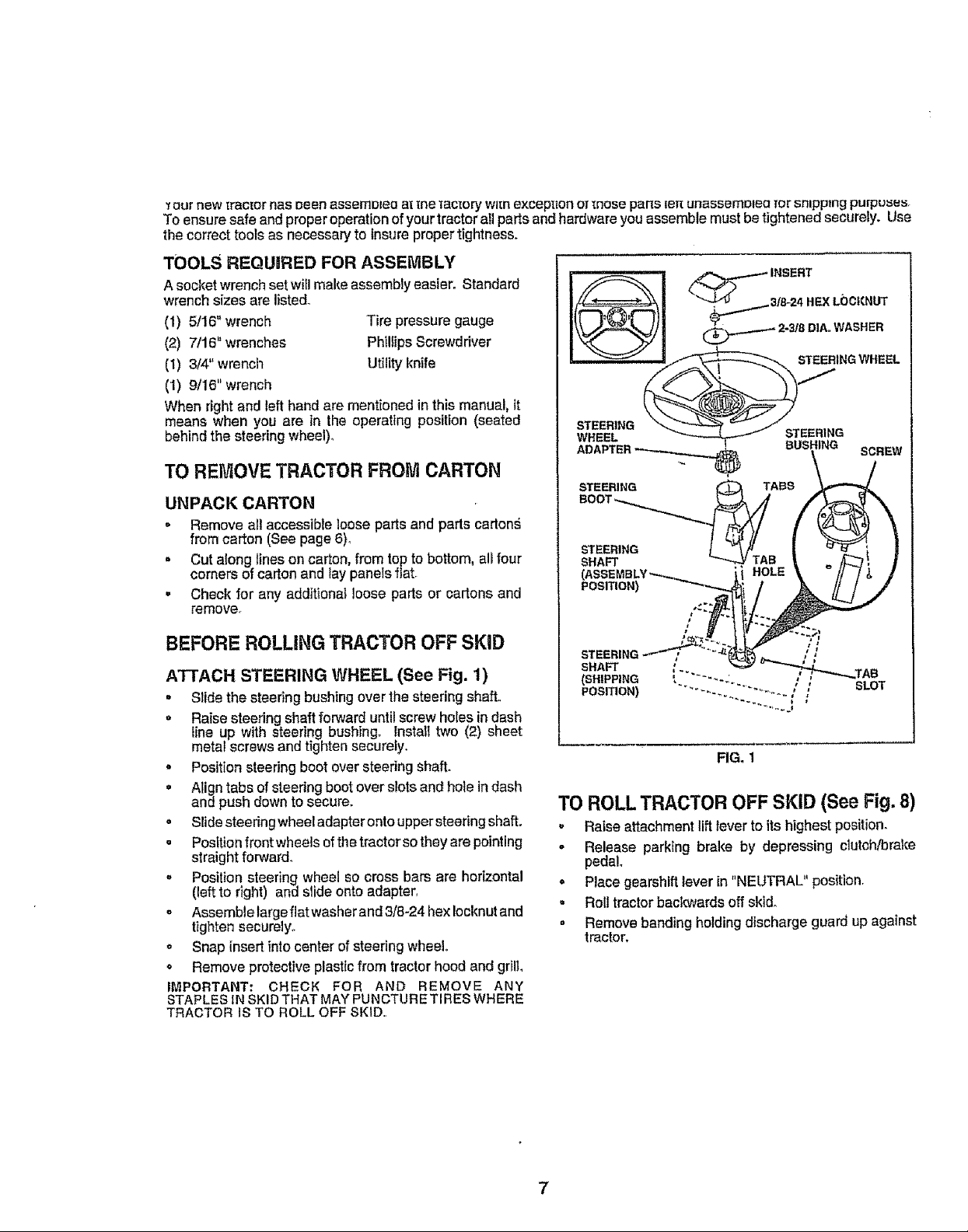

ATTACH STEERING WHEEL (See Fig. 1)

- Slide the steering bushing over the steering shaft,,

. Raisesteering shaft forward until screwholes in dash

tine up with steering bushing° Install two (2) sheet

metal screws and tighten securely.

• Position steeringboot over steering shaft.

= Align tabs ofsteering boot over slotsand hole indash

and push down to secure.

• Slidesteeringwheeladapteronto uppersteeringshaft.

= Position front wheels ofthe tractorso they are pointing

straight forward.

° Position steering wheel so cross bars are horizontal

(left to right) and slide onto adapter,

o Assembletarge flatwasher and 3/8-24 hexIoclmut and

tighten securelyo

o Snap insert into center ofsteering wheel

o Remove protective plasticfrom tractor hood and grill.

IMPORTANT.* CHECK FOR AND REMOVE ANY

STAPLES IN SKID THAT MAY PUNCTURE TIRES WHERE

TRACTOR IS TO ROLL OFF SKID.,

SLOT

FIG. 1

TO ROLL TRACTOR OFF SKID (See Fig. 8)

o Raise attachment lift lever to itshighest position.

- Release parking brake by depressing clutch/brake

pedal.

• Place gearshift lever in "NEUTRAL" position.

= Roll tractor backwards off skid.

- Remove banding holding discharge guard up against

tractor,

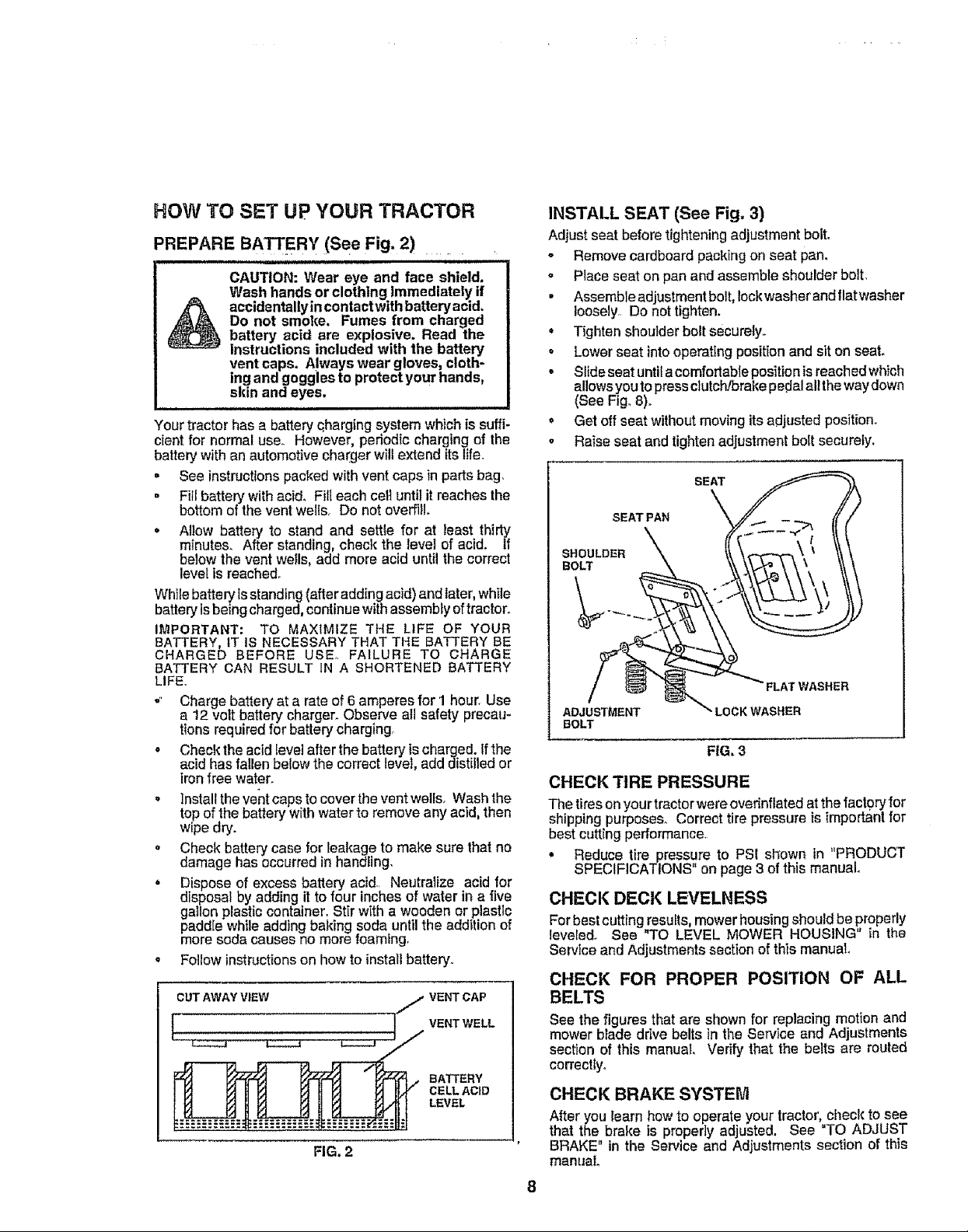

HOW TO SET UP YOUR TRACTOR

PREPARE BATTERY (See Fig. 2) .....

Your tractor has a battery charging system whichis suffi-

cient for normaluser However, periodic charging of the

batterywith an automotive charger will extend its life.

= Seeinstructions packed with vent caps in parts bag,

• Fitl battery with acid. Filleach ceil until it reaches the

° Altow battery to stand and settle for at least thirty

Whilebatteryisstanding (afteradding acid)andlater,while

batteryIsbeing charged,continue withassembly oftractor.

IMPORTANT: TO MAXIMIZE THE LIFE OF YOUR

BATTERY, tT IS NECESSARY THAT THE BATTERY BE

CHARGED BEFORE USE,, FAILURE TO CHARGE

BATTERY CAN RESULT IN A SHORTENED BATTERY

LIFE,,

." Charge battery at a rate of 6 amperes for1 hour. Use

• Check theacid level afterthe battery is charged. Ifthe

o Installthe ventcaps to cover thevent wells, Washthe

o Check battery case for leakage to make sure that no

• Dispose of excess battery acid,, Neutralize acid for

o Follow instructionson how to install battery.

, i,i i

CAUTION: Wear eye and face shield.

Wash hands or clothing Immediately if

_ acciden_allyin contact with batlery acid.

Do not smoke. Fumes from charged

battery acid are explosive. Read the

instructions included with the battery

vent caps. Always wear gloves, cloth-

ingandgoggles to protectyour hands,

skin and eyes.

bottom of the vent welIs, Do not overfill,

minutes_ After standing check the level of acid. If

below the vent wells, add more acid unti the correct

level is reached°

a 12 volt battery charger. Observe all saTetyprecau-

tions required for battery charging,

acid has fallen below the correct level, add distilled or

ironfree water.

top of the batterywith water to remove any acid, then

wipe dry.

damage has occurred in handling.

disposal by adding it to four inches of water in a five

gallon plasticcontainer, Stir with a wooden or plastic

paddle while adding baking soda until the addition of

more soda causes no more foaming,

CUT AWAY VIEW j VENTCAP

I, _ _ L____j ]J VENTWELL

CELL ACID

LEVEL

BATTERY

FIG. 2

INSTALL SEAT (See Fig. 3)

Adjust seatbefore tighteningadjustment bolto

- Remove cardboard packing on seat pan,

o Place seat on pan and assemble shoulder bolt,

• Assembleadjustmentbolt, Iockwasher andflatwasher

toosely Do not tighten.

= Tighten shoulder bolt securely,,

. Lowerseat intooperating position and sit on seat.

• Slideseatuntil acomfodabie position is reachedwhich

allows youto pressclutch/brake pedalallthe waydown

(See Fig.,8).

• Get off seat without moving its adjusted position.

o Raiseseat and tighten adjustment bolt securely,

SEAT

SEAT PAN

SHOULDER

BOLT

FLATWASHER

ADJUSTMENT

BOLT

FtG, 3

CHECK TIRE PRESSURE

Thetireson your tractor wereoverinflated attha factoryfor

shipping purposes. Correct tire pressure isimportant for

best cutting performance.

• Reduce tire pressure to PSI shown in "PRODUCT

SPECIFICATIONS"on page 3 of this manual

CHECK DECK LEVELNESS

Forbestcutting results, mower housing should be properly

leveled. See "TO LEVEL MOWER HOUSING" in the

Service and Adjustments section of this manual

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual Verify that the belts are routed

correctiyo

CHECK BRAKE SYSTEM

After you learn howto operate your tractor, check to see

that the brake is properly adjusted. See =TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual

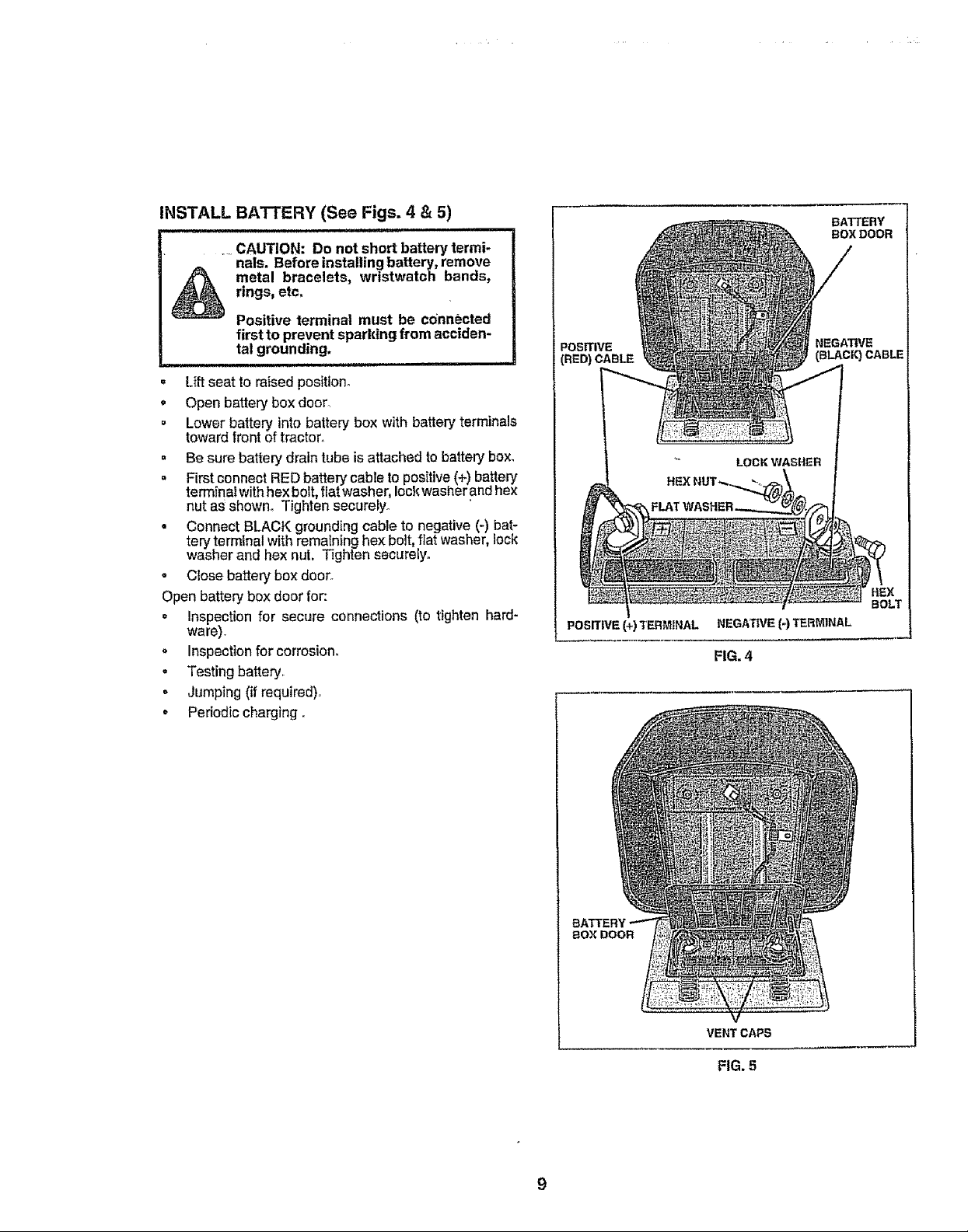

INSTALL BATTERY (See Figs. 4 & 5)

....CAUTION: Donot short battery termi-

nals. Before installing battery, remove

metal bracelets, wristwatch bands,

rings, etc,

Positive terminal must be connected

first to preventsparking from acciden-

tal grounding.

° Liftseat to raised position..

, Openbattery box door

o Lower battery into battery box with battery terminals

toward front of tractor.

. Be sure battery drain tube is attached to battery box_

= First connect REDbattery cable to positive (+) battery

terminal withhexbolt, fiatwasher, lock washerand hex

nut as_shown. Tighten securely_

° Connect BLACK grounding cable to negative (-) bat-

tery terminalwith remaining hex bolt, flat washer, lock

washer and hex nut. Tighten securely_

• Close battery box door.

Open battery box door for.-

Inspection for secure connections (to tighten hard-

ware).

o Inspection for corrosion.

o Testing battery,

° Jumping (if required)°

• Periodic charging,

BATTERY

BOX DOOR

POSEIVE

(RED) CABLE

POSITIVE(4-)TERMINAL NEGATWE(-)TERMINAL

FIG. 4

(BLACK) CABLE

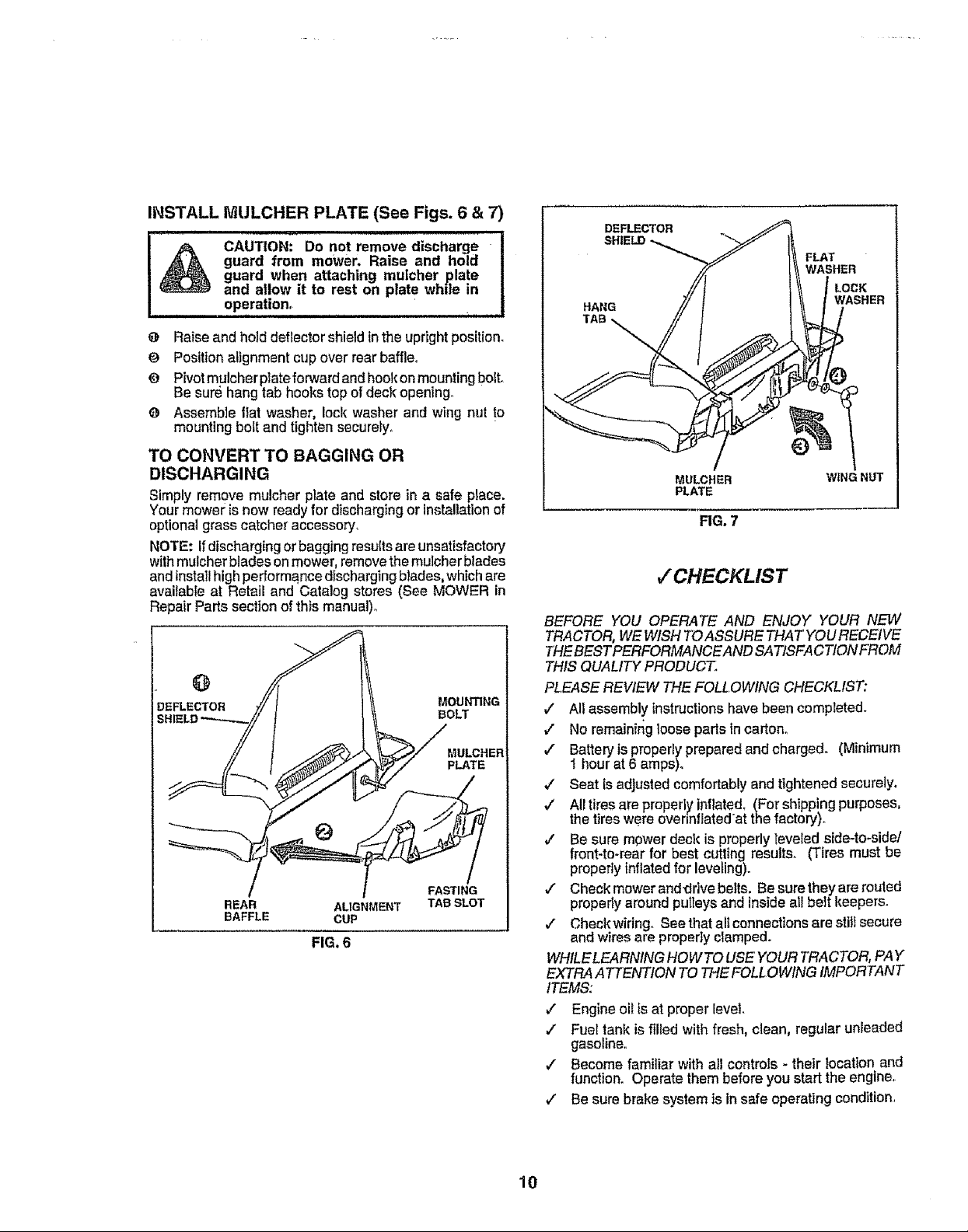

9

BOX DOOR

VENT CAPS

FIG. 5

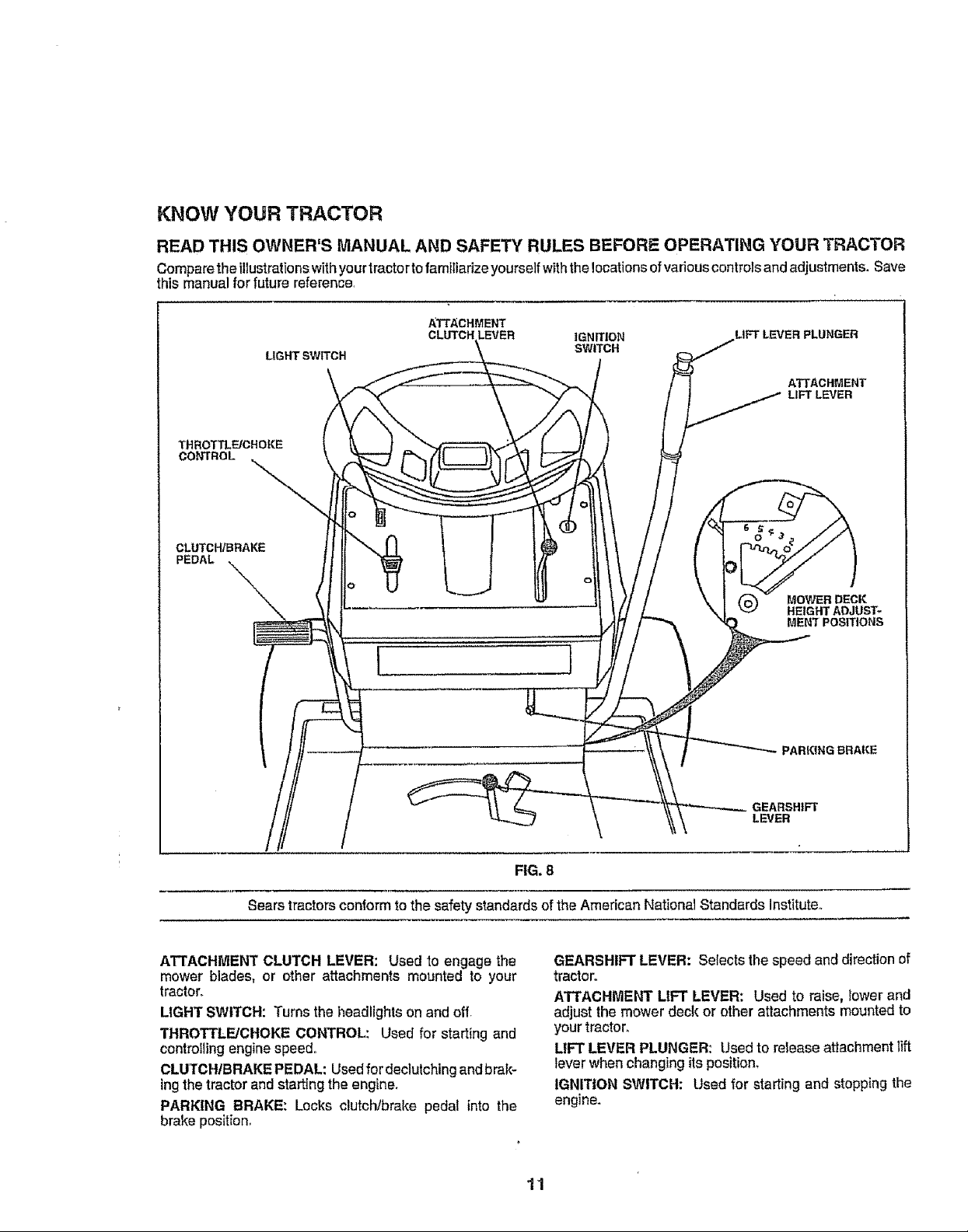

INSTALL IVtULCHER PLATE (See Figs. 6 & 7)

guard from mower. Raise and hold

CAUTION: Do not remove discharge

guard when attaching muicher plate

and allow it to rest on plate whde in

i ill ll,ll.,i .i,i i ,i i IHH "

operation_

O Raiseand holddeflector shieldinthe upright position.

O Position alignment cup over rear baffle°

O Pivotmulcherplateforward and hookon mounting boll

Be sure hang tab hooks top of deck opening,.

O Assemble Slatwasher, loci( washer and wing nut to

mounting bott andtighten securely,

TO CONVERT TO BAGGING OR

DISCHARGING

Simplyremove mulcher plate and stere in a safe place.

Your mower isnow readyfor discharging or installationof

optionalgrass catcher accessory,

NOTE: Ifdischarging orbagging resultsarsunsatisfactory

withmulcherbladeson mower, removethe mulcherblades

andinstallhighperformance discharging blades,whichare

available at Retail and Catalog stores (See MOWER in

Repair Parts section of this manual)°

DEFLEC_TOR MOUNTING

REAR ALIGNMENT

BAFFLE CUP

FIG. 6

BOLT

MULCHER

pLATE

FASTING

TAB SLOT

DEFLECTOR

SHIELD

WASHER

LOCK

HANG

TAB

MULCHER

PLATE

FIG. 7

WASHER

WiNG NUT

v"CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WEWISHTOASSURE THAT YOURECEIVE

THEBESTPERFORMANCEAND SATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ All assembly Instructions have been completed.

,7 No remainirig loose parts incarton_

,/ Batteryis properly prepared and charged. (Minimum

I hour at 6 amps).

•/ Seat {sadjustedcomfortably andtightened securely,

•/ Alltires are properi7 inflated, (Forshipping purposes,

the tires wereovennffated'at the factory).

/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properlyinflatedfor leveling).

,/ Checkmcweranddrivebelts. Besuretheyarerouted

properly around putleys and inside all belt keepers.

/ Checkwiringo See that altconnections are stil_secure

and wires are properly clamped.

WHtLELEARNING HOWTO USEYOUR TRACTOR, PAY

EXTRAATTENTtONTOTHE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil ts at proper level.

,/ FueItank isfilled with fresh, clean, regular unleaded

gasoline,.

v" Become familiar with all controls -their location and

function. Operate them before you start the engine.

,/ Besure brake system is in safeoperating condition..

10

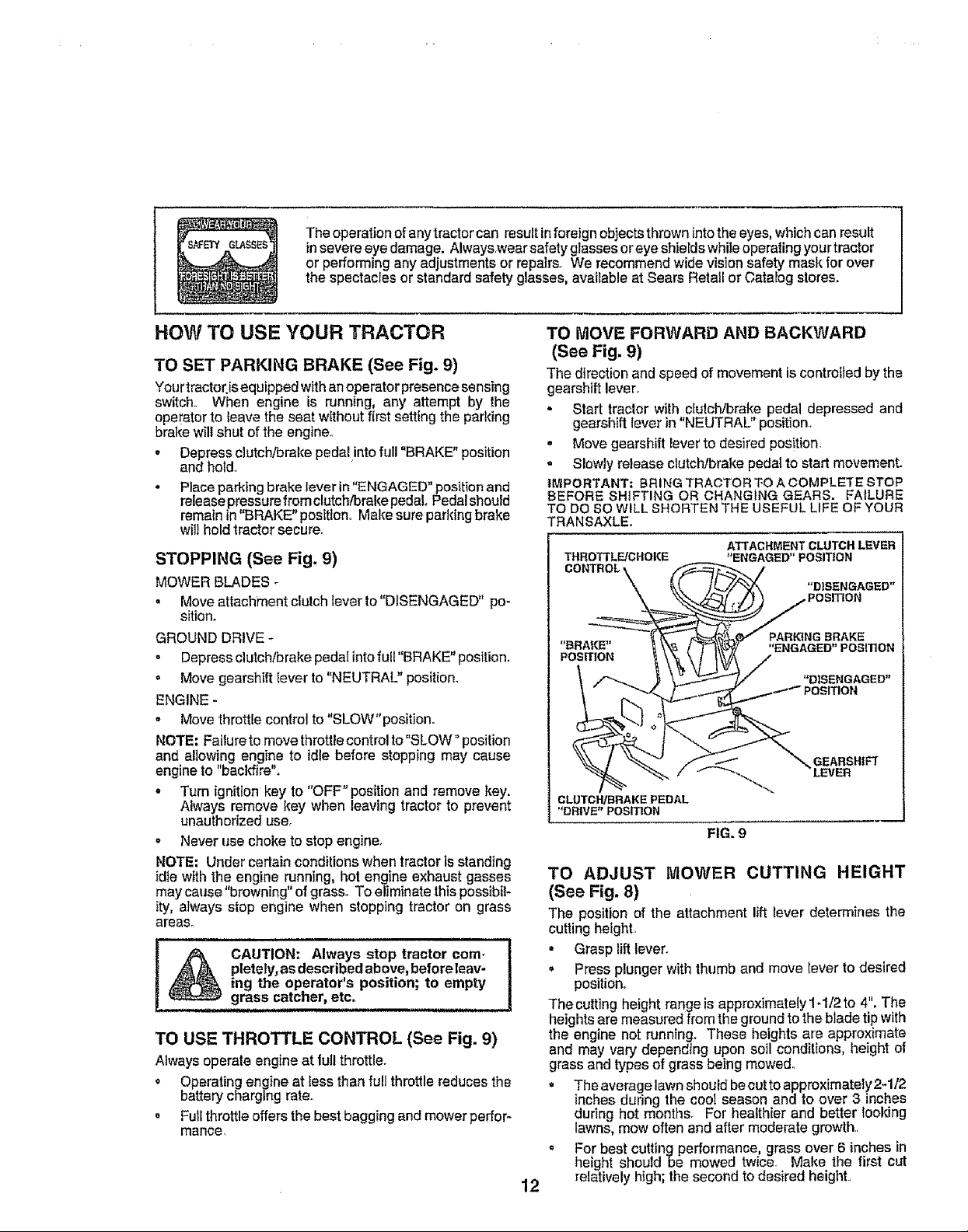

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Comparethe illustrationswithyour tractortofamiliarizeyourselfwiththe !ocationsof various controlsand adjustments. Save

this manualfor future reference,

THROTTLF-JCHOKE

CONTROL

CLUTCH/BRAKE

PEDAL

LIGHT SWITCH

ATTACHMENT

LEVER

l I

IGNITION

SWITCH

LIFT LEVER PLUNGER

ATTACHMENT

LIFT LEVER

MOWER DECK

HEIGHT ADJUST-

MENT POSITIONS

PARKfNG BRAKE

Searstractorsconformtothe safety standards of theAmerican National Standards Institute,,

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turnsthe headlightsonandoff,

THROTTLE/CHOKE CONTROL: Used for start{ng and

controlling engine speed.

CLUTCH/BRAKE PEDAL: Usedfordeclutching andbrak-

ing thetractor and starting the engine.

PARKING BRAKE: Locks clutch/brake pedal into the

brake position.

LEVER

FIG.8

GEARSHIFT LEVER: Selectsthe speed and direction of

tractor.

ATTACHMENT LIFT LEVER: Used to raise, _owerand

adjust the mower deck or other attachments mounted to

your tractor.

LIFT LEVER PLUNGER: Used to release attachment tilt

lever when changing itsposition.

IGNITION SWITCH: Used for starting and stopping the

engine.

11

Theoperation ofanytractor can resultinforeign objectsthrown intothe eyes,which can result

in severeeyedamage. Always.wearsafetyglasses oreye shields while operating yourtractor

or performing any adjustments or repalrs_We recommendwide vision safety mask for over

the spectacles or standard safety glasses, available at Sears Retailor Catalog stores.

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE (See Fig. 9)

Yourtractorjs equippedwith anoperator presencesensing

switch.. When engine is running, any attempt by the

operator to leavethe seat without first setting the parking

brake wilt shut of the engine°

• Depress clutch/brake pedaUntofull "BRAKE" position

and hold,,

. Placeparking brake lever in"ENGAGED"positionand

releasepressurefrom clutch/brakepedal. Pedalshould

remainin"BRAKE"position,, Make sureparking brake

will hold tractorsecure.

STOPPING (See Fig. 9)

MOWER BLADES

. Moveattachment clutch leverto"DISENGAGED" po-

sition.

GROUND DRIVE *

= Depress clutch/brake pedal intofuil "BRAKE" position_

. Movegearshift [ever to "NEUTRAL" position.

ENGINE-

- Move throttlecontrol to "SLOW"position°

NOTE: Failureto move throttlecontrol to"SLOW" position

and allowing engine to idle before stopping may cause

engine to"backfire",,

• Turn ignition key to "OFF" position and remove key.

Always remove key when leavingtractor to prevent

unauthorized use°

= Never use choke to stop engine.

NOTE: Under certain conditions when tractor is standing

idte with the engine running,hot engine exhaust gasses

may cause"browning"of grass. To eliminate thispossibil-

ity, always stop engine when stopping tractor on grass

areas°

_k CAUTION: Always stop tractor corn.

_ pletely,asdescribedabove, beforeleav-

! !

TO USE THROTTLE CONTROL (See Fig. 9)

Always operate engine at full throttle.

o Operatingengine at less than full throttle reduces the

batterycharging rate,.

o Fullthrottle offersthe best baggingand mowerperfor-

mance.

ing the operator's position; to empty

grass catcher, etco

TO MOVE FORWARD AND BACKWARD

(See Fig. 9)

The direction and speed of movement iscontrolled by the

gearshift lever,,

- Start tractor with clutch/brake pedal depressed and

gearshift lever in"NEUTRAL" position.,

° Movegearshift leverto desired pos!tion,

o Slowlyrelease clutch/brake pedal to start movement.

IMPORTANT: BRING TRACTOR TO A COMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS. FAILURE

TO DO SO WILL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLE.

THROTI'LFJCHOKE

CONTROL,

CLUTCH/BRAKE PEDAL

"DRIVE" POSITION

TO ADJUST MOWER CUTTING HEIGHT

ATTACHMENT CLUTCH LEVER

"ENGAGED" POSITION

"DISENGAGED"

POSITION

_NG BRAKE

"ENGAGED" POSITION

"DISENGAGED"

,,...,__'*_ POSITION

GEARSHIFT

LEVER

FIG. 9

(See Fig. 8)

The positionof the attachment liftlever determines the

cuttingheight,.

• Grasp lift lever.

. Press plungerwith thumb and move {everto desired

position°

The cutting height range isapproximately 1-1/2to 4", The

heightsare measuredfrom the groundtothe blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The averagelawnshould becutto approximately 2-1/2

inchesduring the cool season and to over 3 inches

dudng hot months. For healthier and better tooldng

lawns, mow often and after moderate growth.,

= For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

12

relatively high; the second to desired height.,

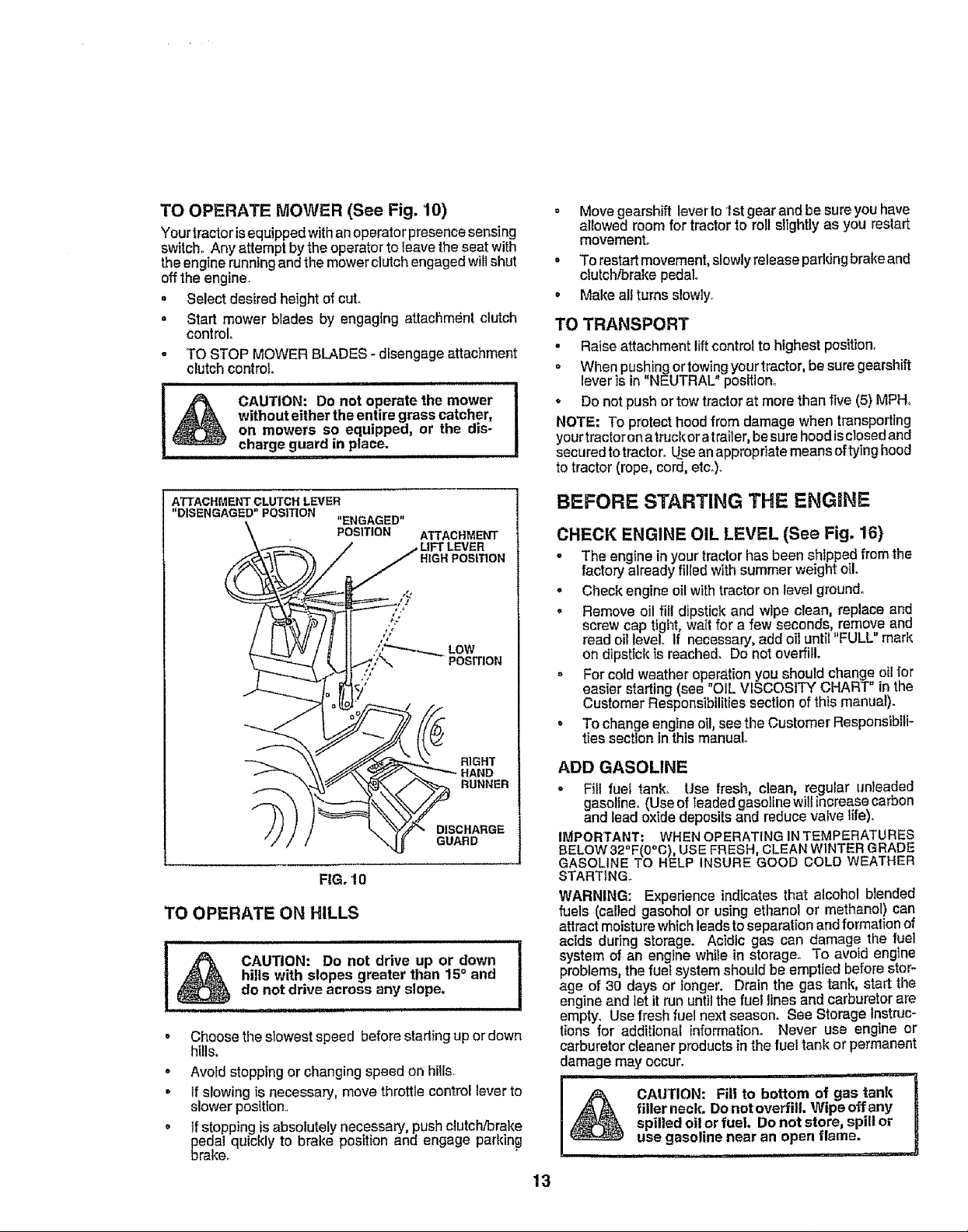

TO OPERATE MOWER (See Fig. 10)

Yourtractor isequippedwithanoperatorpresencesensing

switch° Any attempt by the operator to leavethe seatwith

the engine runningand the mowerclutch engagedwill shut

offthe engine,

. Select desired height of cut.

o Start mower blades by engaging attachment clutch

control°

o TO STOP MOWER BLADES - disengage attachment

clutch control

without eitherthe entire grasscatcher,

CAUTION: Do not operate the mower

on mowers so equipped, or the dis-

charge guard in place.

i, i i1,1,1,i1,111,,H

........................ i

= Movegearshift leverto 1stgearand be sureyou have

allowed room for tractor to roll slightly as you restart

movement.

- To restartmovement,slowly releasepafldng brakeand

clutch/brake peda!.

• Make all turns slowly.

TO TRANSPORT

• Raise attachment lift controlto highest position°

Whenpushing ortowingyour tractor,besuregearshift

lever is in"NEUTRAL" position,

o Do not push or tow tractor at more than five (5) MPH.

NOTE" To protect hoodfrom damage when transporting

yourtractoronatruck or atrailer,besure hoodisclosedand

securedtotractor, Useanappropriate means oftying hood

to tractor (rope, cord, etc,).

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig, 16)

- The engine in yourtractorhas been shipped from the

factory already filledwithsummer weightoil.

= Check engineoilwithtractoronlevel ground.

° Remove oilfii! dipstickand wipe clean, replace and

screw cap tight,wattfor a few seconds, removeand

read oil level If necessary,add oil until' FULL"mark

on dipstickts reached. Do not oveffiIL

• For cold weather operation you should change oil for

easier starling (see "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual).

• To change engine el!,see the Customer ResponsibllF

ties section inthis manual

FIG. f 0

TO OPERATE ON HILLS

hills with slopes greater than 15° and

I & CAUTION: Do notdriveupordown ..... t

.........d° n°tdr! ve acr°ss any sl°pe' I

• Choose the slowest speed beforestading up or down

hills,

• Avoid stoppingorchanging speed on hills,

o if slowing is necessary, move throttle control lever to

slower position.

. Ifstopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

ADD GASOLINE

o Fillfuet tank. Use fresh clean, regular unleaded

gaseline_(Use of teaded gasolinewillincreasecarbon

and lead oxide deposits and reduce valve life),

IMPORTANT; WHENOPERATINGINTEMPERATURES

BELOW32"F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING,,

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisturewhich leadsto separation andformationof

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems,the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine andlet it run untilthe fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage lnstn_c-

tions for additional information° Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

=m

filler neck. Do notoverfill. Wipe off any

spilled oil or fuel, Donot store, spill or R

use gasoline near an open flame. J

13

TO START ENGINE (See Fig. 9)

Whenstarting engine for thefirst timeorif engine hasrun

out offuel,itwill take extra cranking time tomovefuel from

the tank to the engine.

- Depress the clutchlbrake pedal and set the parking

brake..

o Place gearshift lever in "NEUTRAL" position.

,, Move attachment clutchto "DISENGAGED" position°

• Move throttle control lever to "CHOKE" posilion for

coldengine start. Forwarmenginestart, move throttle

control to "FAST" position.

o Turn ignition key c!oclcwiseto "START" position and

release key as soon as engine starts. De not run

starter continuously for'more than fifteen seconds per

minute, If englnedoesnot start afterseveralattempts,

move throttle control to "FAST" position, wait a few

minutes and try again°

• When engine starts, move throttle control to desired

position,

• Allow engine to warm up for a few minutes before

engaging drive or attachment clutch.

NOTE: If at a high altitude (above 3000 feet) or incold

temperatures (below 32° F), the carburetor fuel mixture

mayneedtobe adjustedforbest engine performance. See

"TOADJUST CARBURETOR" inthe Service and Adjust-

mentssection of this manual

MOWING TiPS

. Tire chains cannotbe usedwhen the mower housing

is attached to tractor.

° Mower should be properly leveled for best mowing

performance. See"TOLEVEL MOWER HOUSING"in

the Service and Adjustments section of this manual,.

= The left hand side of mower should be used fortrim-

ming.

° Drive so that clippings are discharged onto the area

thathasbeencut. Havethe cut area to the rightof the

tractor. This will result in a more even distdbution of

clippings and more uniform cutting,.

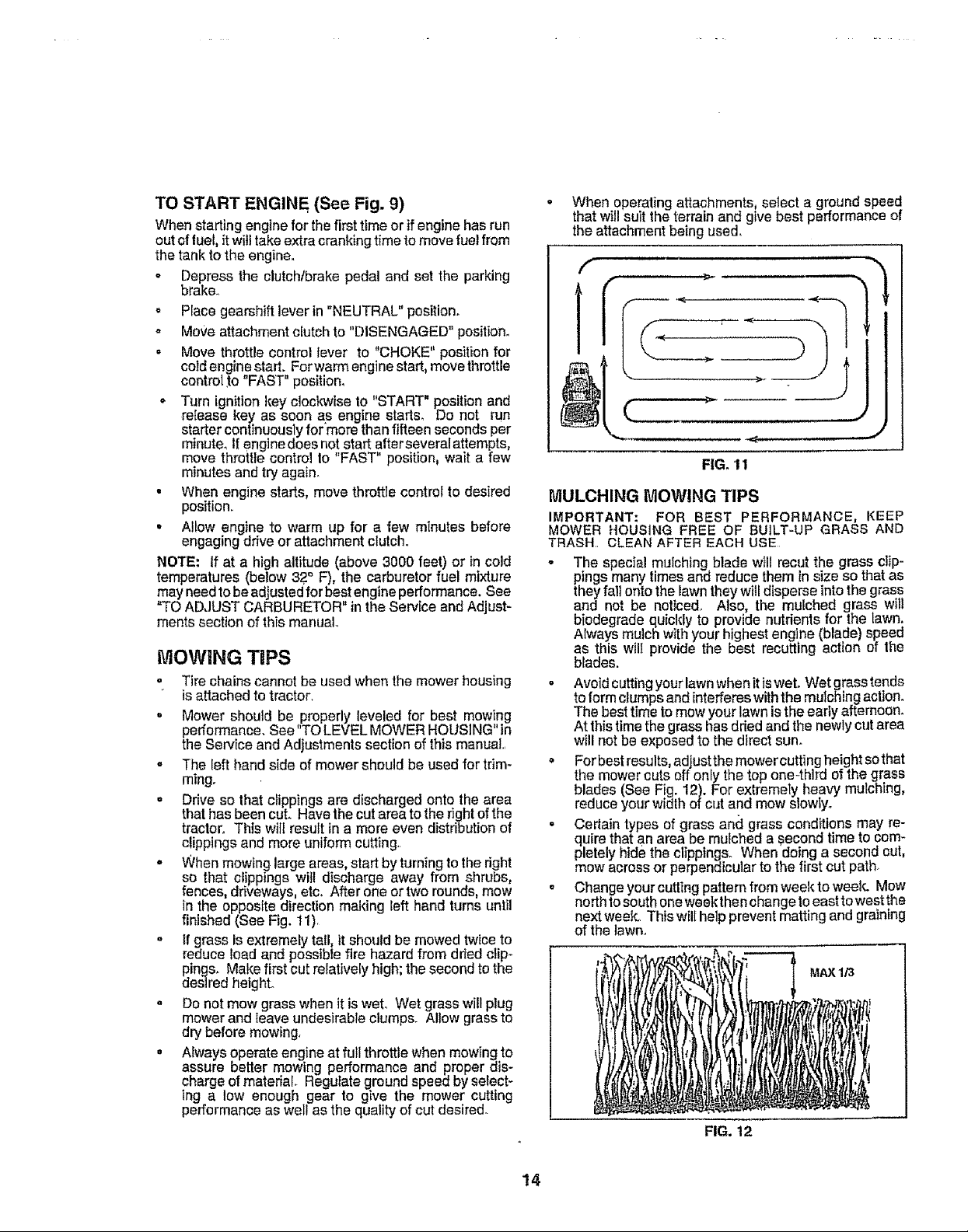

• When mowing large areas, start byturning to the dght

so that clippings wilt discharge away from shrubs,

fences, driveways, etc. After one ortwo rounds, mow

in the opposite direction making left hand turns until

finished (See Fig. 11),

° tfgrass is extremely tall, it should be mowed twice to

reduce load and possibtefire hazard from dded clip-

pings. Make first cut relatively high; the second tothe

desired height°

° Do not mow grass when it is weL Wet grass will plug

mower and leave undesirable clumps. Allow grassto

dry before mowing.

, Always operateengine at fullthrottle when mowing to

assure better mowing performance and proper dis-

charge of material. Regulateground speed by select-

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired.

° When operatingattachments, select a ground speed

that will suit the terrain and give best performance of

the attachmentbeing used.

FIG. 11

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH,, CLEAN AFTER EACH USE

- The special mulching blade will recut the grassclip-

pings many times and reduce them in size so that as

they fall onto the lawnthey will disperse intothe grass

and not be noticed.. Also, the mulched grass wtll

biedegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of the

blades.

o Avoid cuttingyourlawn whenit iswet. Wet grass tends

to formclumpsand interferes withthe mulching action.

The best time to mow your lawnisthe early afternoon.

At thistime the grasshas ddedand the newly cut area

will not beexposed to the direct sun.

° Forbestresults,adjustthe mower cuttingheightsothat

the mower cuts off only the top one-.thirdof the grass

blades (See Fig. 12). For extremely heavy mulching,

reduce your widthof cut and mow slowly.

° Certain typesof grass and grass conditions may re-

quire that an area be muched a second time to com-

pletelyhide the clippings. When'doing a second cut,

mow across or perpendicular to the firstcut path

o Change yourcutting pattern fromweek to week. Mow

northtosouthoneweek then changeto easttowest the

next week..Thiswill help prevent matting and graining

of the lawn..

MAX 1/3

FIG. 12

14

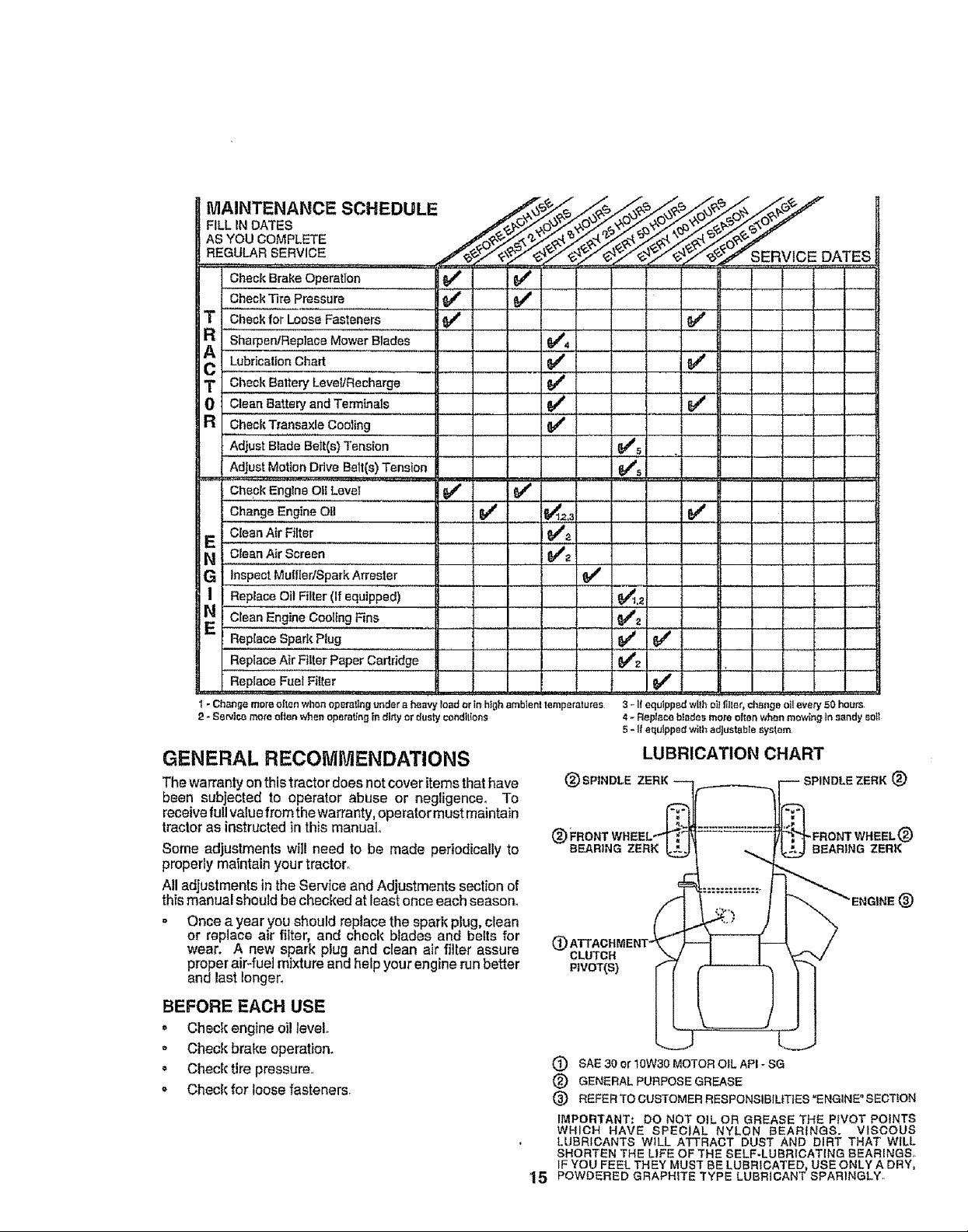

MAINTENANCE SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGU_RSERVICE

Check Brake Op"rai]on ''_ _/

Check Tire Pressure _

T Check for Loose Fasteners

AR'""_he,per,JRepl.eeMo,_;Blaae_R 1 I IV'.

C,,i,Lub;'oa'ionOho", i, I Ii IV, ,

T Check Battery Leve!lRecharge _*

0 Clean Battery and Terminals

R CheckTransaxle Cooling

Adjust Blade Bait(s) Tension

AdJust,_Motion ,DF1v_ Belt(s)rm_n_ioR

Check Englna Oti Level

Change Engine Oil

Clean Air Filter

Clean Air Screen

G Inspect Mut'fledSpark Arrester

Replace Oil Filter (If equipped)

E Clean Engine Cooling Fins

Replace Spad_ Plug

Replace Air Filter Paper Cadddge

Replace Fuel Filter

t - Chen_e more often when operating under a heavy"load or in highambienttemperatures

:2- Semite more often when opetaffngin dirtyor dusty condilior',s

GENERAL RECOMIViENDATIONS

Thewarranty onthistractor does notcoveritems that have

been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

tractor as instructed in this manual.

Some adjustments wilt need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

= Once a year you should replace the spark plug.clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer,

BEFORE EACH USE

o Check engineoil level.

* Check brake operation.

* Check tire pressure..

* Check for loose fasteners.

...............................L,_"

J v'

J _._

.... i

SERVICE DATES

v'

v'

_5 .......... .]

v"

IV"_

v"

3.-Ifequippedwllhoi!filter,changeoi!every50hours

4- Replaceb_adesmoreoftenwSenmov_n9 insandysog

5- Ifequtppodwilhadjustablesystem

LUBRICATION CHART

(_) SPINDt,E SPINDLE ZERK (_

(_ _FRONT WHEEL (_)

BEARING ZERK BEARING ZERK

®

CLUTCH

PIVOT(S)

SAE 30 or 10W30 MOTOR OIL API - SG

(_ GENERAL PURPOSE GREASE

(_ REFER TOCUSTOMER RESPONStBIL|TIES =ENGINE" SECTION

IMPORTANT." DO NOT OiL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS

LUBRICANTS WILL ATTRACT DUST AND DIRT THAT WILL

SHORTEN THE LIFE OF THE SELF*LUBRICATING BEARINGS.

IF YOU FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY,

15 POWDERED GRAPHITE TYPE LUBRICANT SPARINGLY.

®

IIHAfJT{3R

Alwaysobserve safety ruleswhen performing any mainte-

nance,

BRAKE OPERATION

ff tractor requires more than six (6) feet stopping distance

athigh speedtnhighest gear,thenbrake mustbeadjusted°

(See "TO ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

o Maintain proper air pressure in all tires {See "PROD-

UCTSPECIFICATIONS" on page 3 efthis manual).

. Keeptiresfree ofgasoline, oil, or insect controlchemi-

cals which can harm rubber.

. Avoid stumps, stones, deep ruts, sharp objects and

otherhazards that may cause tire damage.

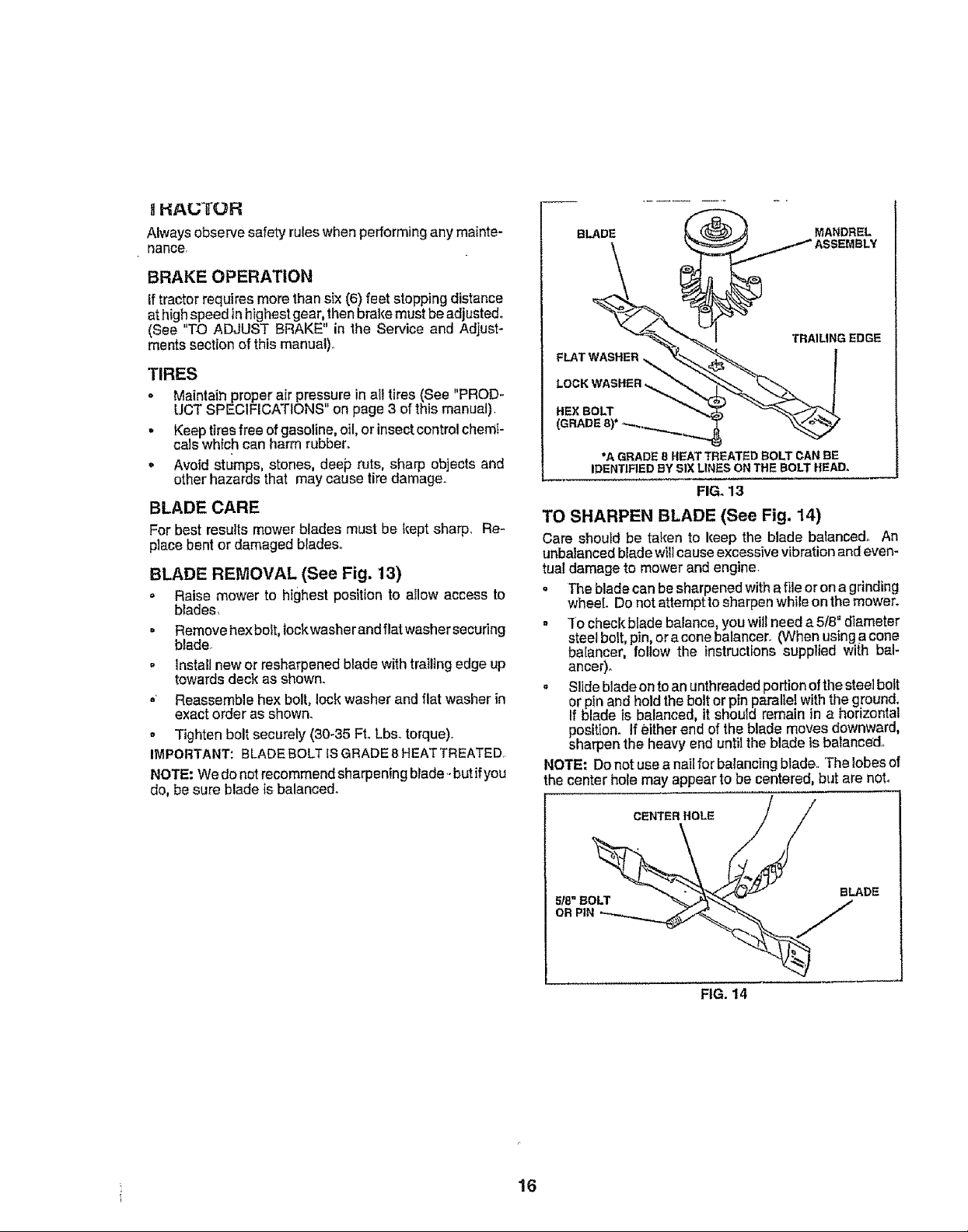

BLADE CARE

For best results mower blades must be kept sharp. Re-

p]ace benter damaged blades°

BLADE REMOVAL (See Fig. 13)

o Raise mower to highest position to allow access to

blades,

, Removehexbolt, lockwasher and flat washersecuring

blade

o Installnew orresharpenedbladewithtrailingedge up

towards deck as shown.

, Reassemble hex bolt, lock washer and flatwasher in

exact order as shewn.

o Tighten bolt securely (30-35 FroLbs.torque).

IMPORTANT: BLADE BOLT IS GRADE 8 HEAT TREATED

NOTE: Wedonetrecommendsharpening blade*-butifyou

do, be sure blade is balanced.

BLADE

FLATWASHEB

LOCK WASHER.._

HEXBOLT

"A GRADE B HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX LINES ON THE BOLT HEAD.

FIG. 13

MANDREL

TRAILING EDGE

TO SHARPEN BLADE (See Fig. 14)

Care should be taken to keep the blade balanced,. An

unbalanced bladewillcause excessive vibration andeven-

tual damage to mower and engine.

o The blade canbe sharpenedwith af_leor onagrinding

wheel. Donot attemptto sharpenwhile en the mower.

o "[e check blade balance, yeu wtllneed a 5/8 dlamete

steel bolt,pin oraconebalancer. (When using a cone

baIancer, follow the instructions supplied with bal-

ancer).

• S!Idebladeon toan unthreadedpoflion ofthe steelbolt

or pinand holdthe bolt or pin parallel with the ground.

If blade is balanced, it shouId remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end untilthe blade is balanced.

NOTE=Do not use anailfor balancingblade,.The lobes of

the center hole may appear to be centered, but are not,

CENTER HOLE / /

518"BO_ BLADE

FIG. 14

16

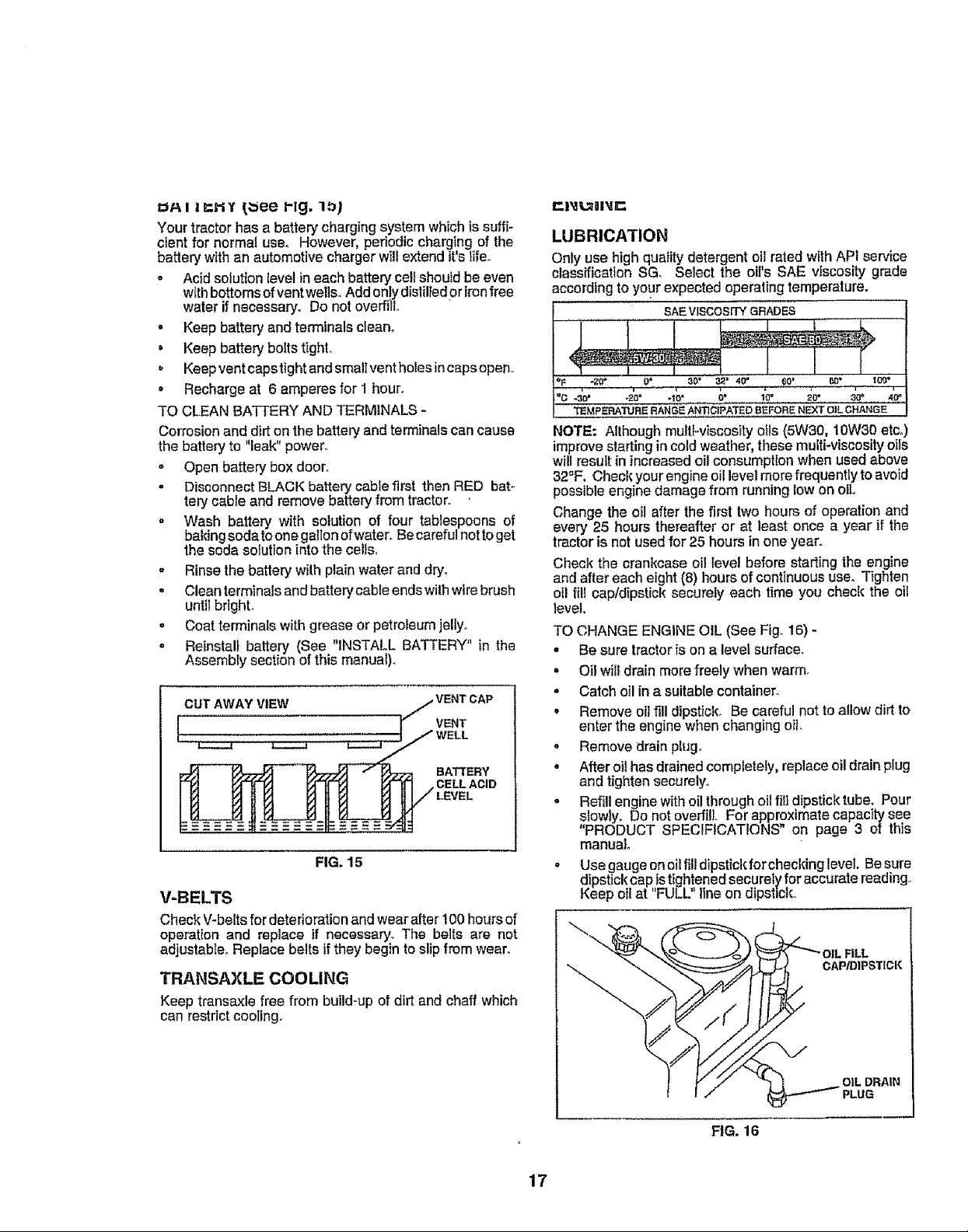

Your tractor has a battery charging system which is suffi-

cient for norma{ use. However, periodiccharging of the

battery with an automotive charger will extend it'slife_

o Acid solution level ineach battery cell should beeven

withbottoms ofvent wells. Addon!ydistilledor ironfree

water if necessary. Do not overfill°

o Keepbattery and terminals clean°

= Keep battery bolts tight.

, Keepventcapstight andsmallvent holes incapsopen.

= Recharge at 6 amperes for 1 hour.

TO CLEAN BATTERY ANDTERMINALS -

Corrosion and dirton the battery andterminals can cause

the battery to "leak" power.

= Open battery box door.

- Disconnect BLACK battery cable first then RED bat-

tery cable and remove battery from tractor.

, Wash battery with solution of four tablespoons of

bakingsodatoone gallonofwater°Becarefulnottoget

thesoda solution into the cells.

= Rinse the battery with plain water anddry.

- Clean terminalsand batterycable endswith wirebrush

untilbright.

= Coat terminals with grease or petroleum jelly°

• Reinstall battery (See "INSTALL BATTERY" in the

Assembly section of this manual)_

CUTAWAYVIEW ./VENT CAP

_ VENT

I,,,,,_ _ L__J_ WELL

_ _ __7_ BATTERY

_ ]_J-_{-'_ r_., CELL ACID

/

FIG. 15

V-BELTS

Check V-belts for deterioration and wear after 100 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin toslip fromwear.

TRANSAXLE COOLING

Keep transaxle free from build-up of dirt and chaff which

can restrictcooling.

LUBRICATION

Only use high quality detergent oil rated with API service

classification SG. Select the eli's SAE viscosity grade

according to your expected operating temperature.

SAE V[SCOSFFY GRADES

_'F , -;tO* 9* _0" _2 _ 40" _0' P_" 10_

TEMPERATURE RANGEANTICIPATED BEFORE NF._T OIL CHANGE

NOTE: Although mult[oviscosityoils(5W30, 10W30 etco

improvestarting incoldweather,thesemulti_viscosityoils

willresult in increased oil consumptionwhen usedabove

32_F, Checkyourengineoil levelmorefrequently toavoid

possible enginedamage from running low on oil

Change the oi! after the first two hours of operation and

every 25 hours thereafter er at least once a year if the

tractor is not usedfor 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours ofcontinuous use. Tighten

otl fill cap/dipstick securely each time you check the oil

level.

TO CHANGE ENGINE OIL (See Fig. 16) -

• Be sure tractor is ona lever surface.

• Oil willdrain more freely when warm.

= Catch oil ina suitable container.

, Remove oil filldipstick.. Be careful not to allow dirt to

enter the engine when changing oil.

° Remove drain phJgo

, Afteroil has drainedcompletely, replace oildrainplug

and tightensecurely°

• Refill engine with oil through oil filldipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

"PRODUCT SPECIFICATIONS" on page 3 of this

manual°

= Usegauge onoil filidipstick forchecking level. Be sure

dipstick cap istigh!enedsecurely foraccurate reading..

Keep oil at FULL line on dipstick°

FILL

CAP/D|PSTICK

17

OIL DRAIN

PLUG

FIG. 16

Loading...

Loading...