Craftsman 917255275 Owner’s Manual

ISears ]

OWNERS

MANUAL

MODEL NO,

917.255275

Caution:

Read Rules for

Safe Operation

and Instruction s

Carefully

36" RIDING

LAWN TRACTOR

ELECTRIC START

Assembly

Installation

Operation

Repair Parts

Sears, Roebuck and Co., Chicagor-ffL 60684, USA.

MODEL

NUMBER

SERIAL

NUMBER

THE MODEL AND SERIAL NUMBERS

WILL BE FOUND ON THE MODEL

PLATE ATTACHED TO THE CHASSIS

ASSEMBLY_ (REFER TO PAGE 18L

YOU SHOULD RECORD BOTH MODEL

AND SERIAL NUMBERS AND KEEP

IN A SAFE PLACE FOR FUTURE

REFERENCE_

CONGRATULATIONS on your purchase of a Sears Lawn

Tractor. It has been designed, engineered and manufactured '

to give you the best possib{e dependability and performance_

Should you experience any problem you cannot easily reme-

dy. please contact your nearest Sears, Roebuck and Co. Store_

They have competent, we_-trained technicians and the proper

tools to service or repair this unit.

Please read and retain this manual. The instructions wilt enable

you to assemble, operate and maintain your Tractor properly.

Always observe the "RULES FOR SAFE OPERATION".

_> FULL ONE YEAR WARRANTY

'=_ ON ELECTRBC START LAWN TRACTOR c_

For one year from the date of purchase,when this Lawn Tractor isusedfor persona]household

purposes, Searswill repair any defect in material or workmanship in this Lawn Tractor, except €;_

the battery, at nocharge°

If this Lawn Tractor is usedfor commercial or rentalpurposes,this warranty applies for only 30

daysfrom the dateof purchase.

FULL 90=DAY WARRANTY Ot=_ BATTERY

For 90 days from the date of purchase,if any battery included with the Lawn Tractor proves

defective in material or workmanship and will not hold a charge, Searswilt replace the battery,

at no charge.

UMBTED WARRANTY ON BATTERY

From the 91st day until one year from the date of purchase,if any battery included with the

Lawn Tractor provesdefective in material or' workmanship andwilt not hold acharge,;Searswill

replacethe battery, charging1/12th of the price of the new battery for each full month from the

date of purchase°

Warranty service is available at your home, at no charge, by simply contacting the nearest Sears

store €.r Service Center throughout the United States,,

This warranty gives you specificlegal rights, and you may alsohave other'rights which vary from

state to state.

Sears,Roebuck and Co.

SearsTower

BSC 41-3

Chicago,IL 60684

TABLE OF CONTENTS

RULES FOR SAFE OPERATION ........................ 1 TROUBLE SHOOTING ........................ 11

ASSEMBLY INSTRUCTIONS ................................ 2 OPERATION INSTRUCTIONS - MOWER ............. 14

OPERATION INSTRUCTIONS - TRACTOR ............... 5 MAINTENANCE INSTRUCTIONS - MOWER ......... 15

MAINTENANCE INSTRUCTIONS - TRACTOR ............ 7 REPAI R PARTS .................................. 17

RUILES FOB SAFE OPERATnoN

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engme s exhaust system is equipped with aspark arrester meeting applicable

local or state laws (if any), tf a spark arrester is used, it should be maintained in effective working order by the operator°

in the State of California the above is required by law (Section 4442 of the California Public Resources Code), Other states may

have similar laws, Federal laws apply on federal lands See your Sears Authorized Service Center for spark arrester muffler part

number 673A223.

1, Know the controls and how to stop quickly,, READ THE

OWNER'S MANUAL.

2,. Do not allow children to operate the vehicle. Do not allow

adults to operate it without proper instruction.,

3, Do not carry passengers Keep children and pets a safe dis-

tance away,

4, Always wear substantial footwear. Do not wear loose fitting

clothing that could get caught in moving parts,

5, Keep your eyes and mind on your tractor, mower and the

area being cut Don't let other interests distract you..

6. Do not attempt to operate your tractor or mower when

not in drivers seat,,

Z. Always get on or off your tractor from the operators left

hand side,

8, Clear the work area of objects which might be picked up

and thrown.

9, Disengage all attachment clutches and shift into neutral be-

fore attempting to start the engine.

10, Disengage power to attachments and stop the engine be-

fore leaving the operator's position.

11_ Disengage power to mower, stop the engine and disconnect

spark plug wire(s) from spark plug(s) before cleaning, mak-

ing an adjustment or repairs.

12. Disengage power to attachments when transporting or not

in use.,

13., Take all possible precautions when leaving the vehicle un-

attended, such as disengaging the power-take-off, lowering

the attachments, shifting into neutral, setting the parking

brake, stopping the engine, and removing the key.

14., Do not stop or start suddenly when going uphill or down-

hill. Mow up and down the face of slopes (not greater than

15°); never across the face°

t5_ Reduce speed on slopes and make turns gradually to pre-

vent tipping or loss of control, Exercise extreme caution

when changing direction on slopes..

t6 Do not shift gears while going up or down slopes. Choose

a gear low enough to negotiate the slope without stopping

and shifting gears To reduce speed, move throttle lever

to slow,

17 Never mow in wet or slippery grass, when traction is um

sure or at a speed which could cause a skid.

18o Stay alert for holes in the terrain and other hidden hazards,

19o Do not drive too close to creeks, ditches and public high-

ways_

20, Exercise special care when mowing around fixed objects

in order to prevent the blades from striking them, Never

deliberately run tractor or mower into or over any foreign

object.,

21,, Never shift gears until tractor comes to a stop,.

22, Never place hands or feet under the mower, in the deflector

(discharge chute) or near any moving parts while tractor or

mower are running. Always keep clear of discharge chute,

23, Use care when pulling loads or using heavy equipment_

a, Use only approved drawbar hitch points.

b, Limit loads to those you can safely control,

c. Do not turn sharply,, Use care when backing.,

d Use counterweight or wheel weights when suggested in

this owner's manual,

24. Watch out for traffic when crossing or near roadways_

25 When using any attachments, never direct discharge of

material toward bystanders nor allow anyone near the ve-

hicle while in operation.

26_ Handle gasoline with care - it is highly flammable°

a, Use approved gasoline containers,,

b, Never remove the cap of the fuel tank or add gasoline to

a running or hot engine, or fill the fuel tank indoors.

Wipe up spilled gasoline,

c, Open doors if the engine is run in the garage., exhaust

fumes are dangerous, Do not run the engine indoors_

27, Keep the vehicle and attachments in good operating con-

dition, and keep safety devices in place.

28., Keep all nuts, bolts and screws tight to be sure the equip-

ment is in safe working condition,

29., Never store the equipment with gasoline in the tank inside

a building where fumes may reach an open flame or spark,,

Allow the engine to cool before storing in any enclosure°

30, To reduce fire hazard, keep the engine free of grass, leaves

or excessive grease,

31, Except for adjustment; DO NOT operate Engine if air

cleaner or cover directly over carburetor air intake is re-

moved. Removal of such part could create a fire hazard_

32., DO NOT OPERATE WITHOUT A MUFFLER OR TAM-

PER WITH THE EXHAUST SYSTEM°, Damaged mufflers

or spark arresters could create a fire hazard. Inspect period-

ically and replace if necessary

33, The vehicle and attachments should be stopped and inspect-

ed for damage after striking a foreign object, and the dam-

age should be repaired before restarting and operating the

equipment,

34, Do not change the engine governor settings or overspeed

the engine,

35,, When using the vehicle with mower, proceed as follows:

a,, Mow only in daylight or in good artificial light°

b, Never make a cutting height adjustment while the engine

is running if the operator must dismount to do so.

c Shut the engine off when removing the grass catcher or

unclogging chute,

d. Check the blade mounting bolts for proper tightness at

frequent intervals,

36. Check the grass catcher bags frequently for wear or deterio-

ration Replace with new bags for safety protection,

37 Do not operate the Mower without either the entire grass

catcher, on mowers so equipped, or the deflector shield in

place,

38. Disengage power to mower before backing up, Do not mow

in reverse unless absolutely necessary and then only after

careful observation of the entire area behind the mower,

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS,, IT MEANS - ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED,,

-I-

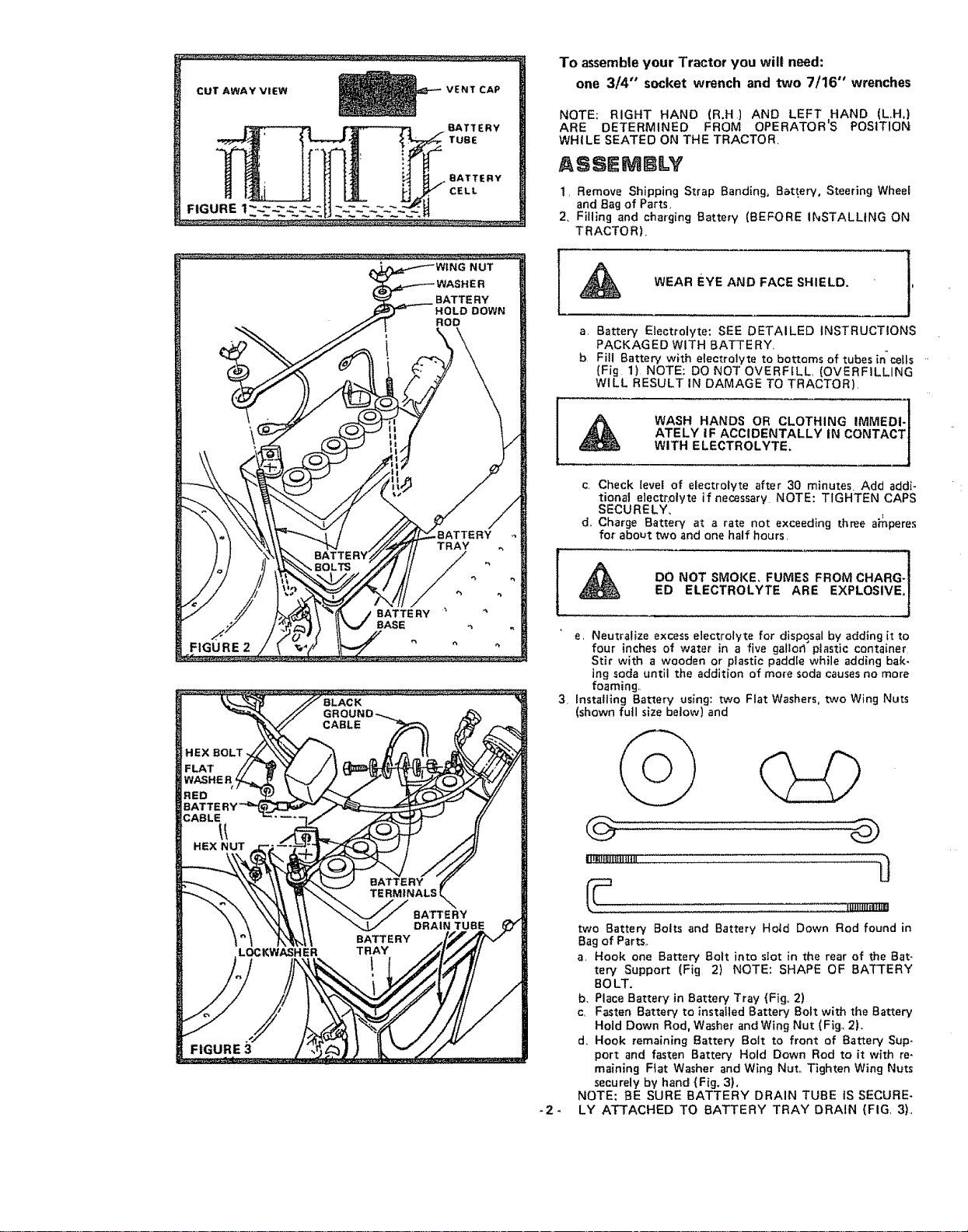

CUT AWAY VIEW VENT CAP

BATTERY

TUBE

To assembleyour Tractor you will need:

one 3/4" socket wrench and two 7/16" wrenches

NOTE: RIGHT HAND (R,H) AND LEFT HAND (L,.H,)

ARE DETERMINED FROM OPERATORS POSITION

WHILE SEATED ON THE TRACTOR.

ASSEMBLY

1_ Remove Shipping Strap Banding, B_ttery, Steering Wheel

and Bag of Parts,

2, Filling and charging Batter,/ (BEFORE I_STALLING ON

TRACTOR),

WEAR EYE AND FACE SHIELD, 1'

a, Battery Electrolyte: SEE DETAILED iNSTRUCTIONS

PACKAGED WITH BATTERY

b Fill Battery with electrolyte to bottoms of tubes incells "

(Fig 1)NOTE: DO NOT OVERFILL, (OVERFILLING

WILL RESULT IN DAMAGE TO TRACTOR),

ATELY IF ACCIDENTALLY tN CONTACT|

WITH ELECTROLYTE. /

c, Check level of electrolyte after 30 mlnutes. Add addi-

tional electrolyte if necessary. NOTE: TIGHTEN CAPS

SECURELY,

d. Charge Battery at a rate not exceeding three a_peres

for' about two and one half hours,

FIGURE 2

FIGURE 3

DO NOT SMOKE, FUMES FROM CHARG-L'!

ED ELECTROLYTE ARE EXPLOSlVE.J

e, Neutralize excess electrolyte for disposal by adding [t to

four inches of water in a five gatlod plastic container

Stir with a wooden or plastic paddle while adding bak-

ing soda until the addition of mo_e soda causesno more

foaming,.

3. Installing Battery using: two Flat Washers, two Wing Nuts

(shown futl size below) and

lii_ligil|{|ltHg .............. L_

two Battery Bolts and Battery Ho_d Down Rod found in

Bag of Parts,.

a, Hook one Battery Bolt into stot in the rear of the Bat-

tery Support (Fig 2) NOTE: SHAPE OF BATI'ERY

BOLT.

b. Place Battery in Battery Tray {Fig_ 2)

c_ Fasten Battery to installed Battery Bolt with the Battery

Hold Down Rod. Washer and Wing Nut (Fig,. 2),.

d_ Hook remaining Battery Bolt to front of Battery Sup-

port and fasten Battery Hold Down Rod to it with re-

maining Fiat Washer and W_ng Nut,, Tighten Wing Nuts

securely by hand {Fig. 3).

NOTE: BE SURE BATTERY DRAIN TUBE iS SECURE-

-2-

LY ATTACHED TO BATTERY TRAY DRAIN (FIG, 3),

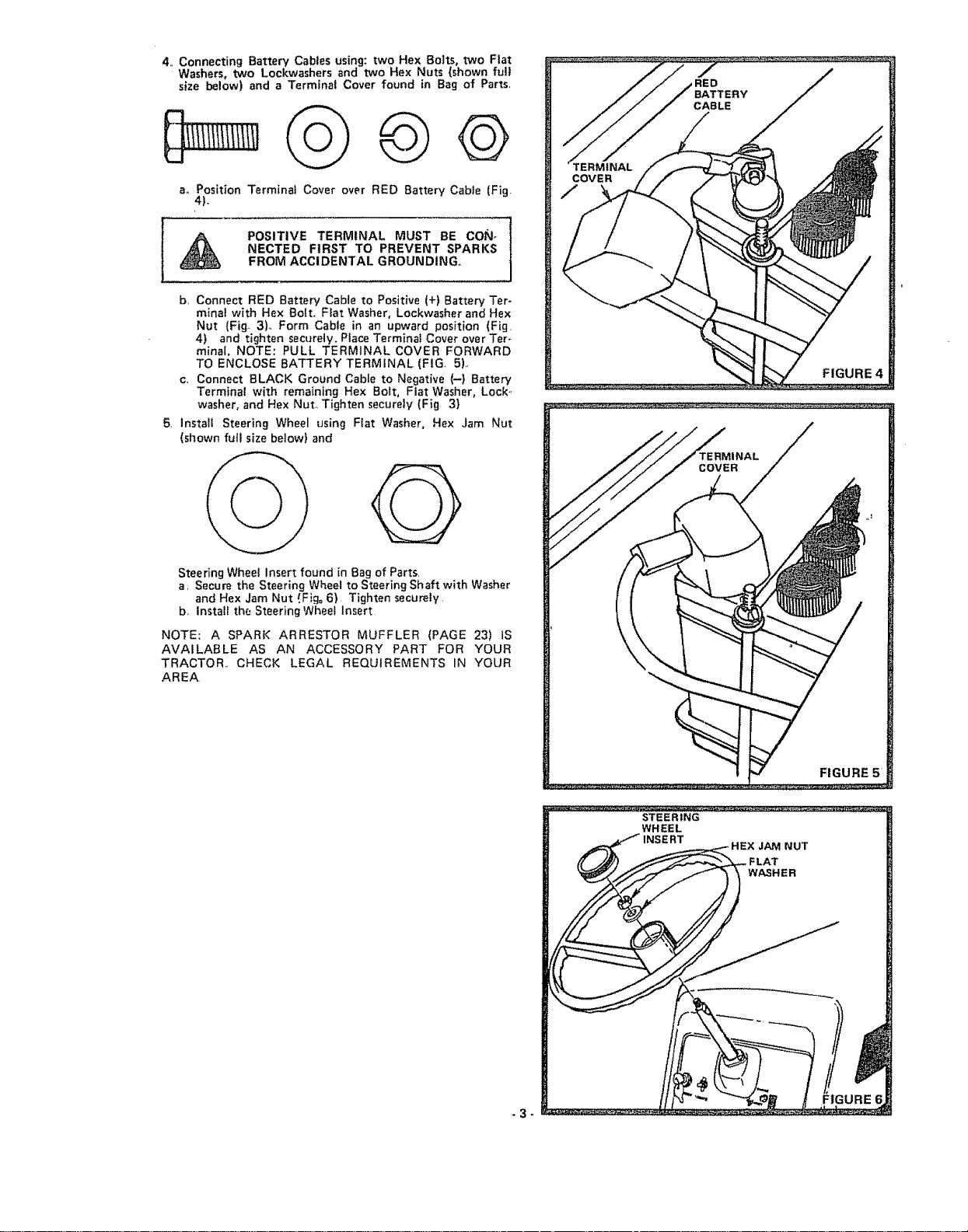

4. Connecting Battery Cables using: two Hex Bolts, two Flat

Washers, two Lockwashers and two He× Nuts (shown full

size below) and a Terminal Cover found in Bag of Parts.

@©

ao Position Terminal Cover over RED Battery Cable (Fig.

4),

POSITIVE TERMINAL MUST BE CON-

NECTED FIRST TO PREVENT SPARKS

FROM ACCIDENTAL GROUNDING°

b, Connect RED Battery Cable to Positive (+) Battery Ter-

minal with Hex Bolt. Flat Washer, Lockwasher and Hex

Nut {Fig_ 3). Form Cable in an upward position (Fig_

4) and tighten securely, Place Terminal Cover over Ter-

minal. NOTE: PULL TERMINAL COVER FORWARD

TO ENCLOSE BATTERY TERMINAL (FIG. 5),

c, Connect BLACK Ground Cable to Negative (-) Battery

Terminal with remaining Hex Bolt, Flat Washer, Lock-,

washer, and Hex Nut° Tighten securely (Fig 3)

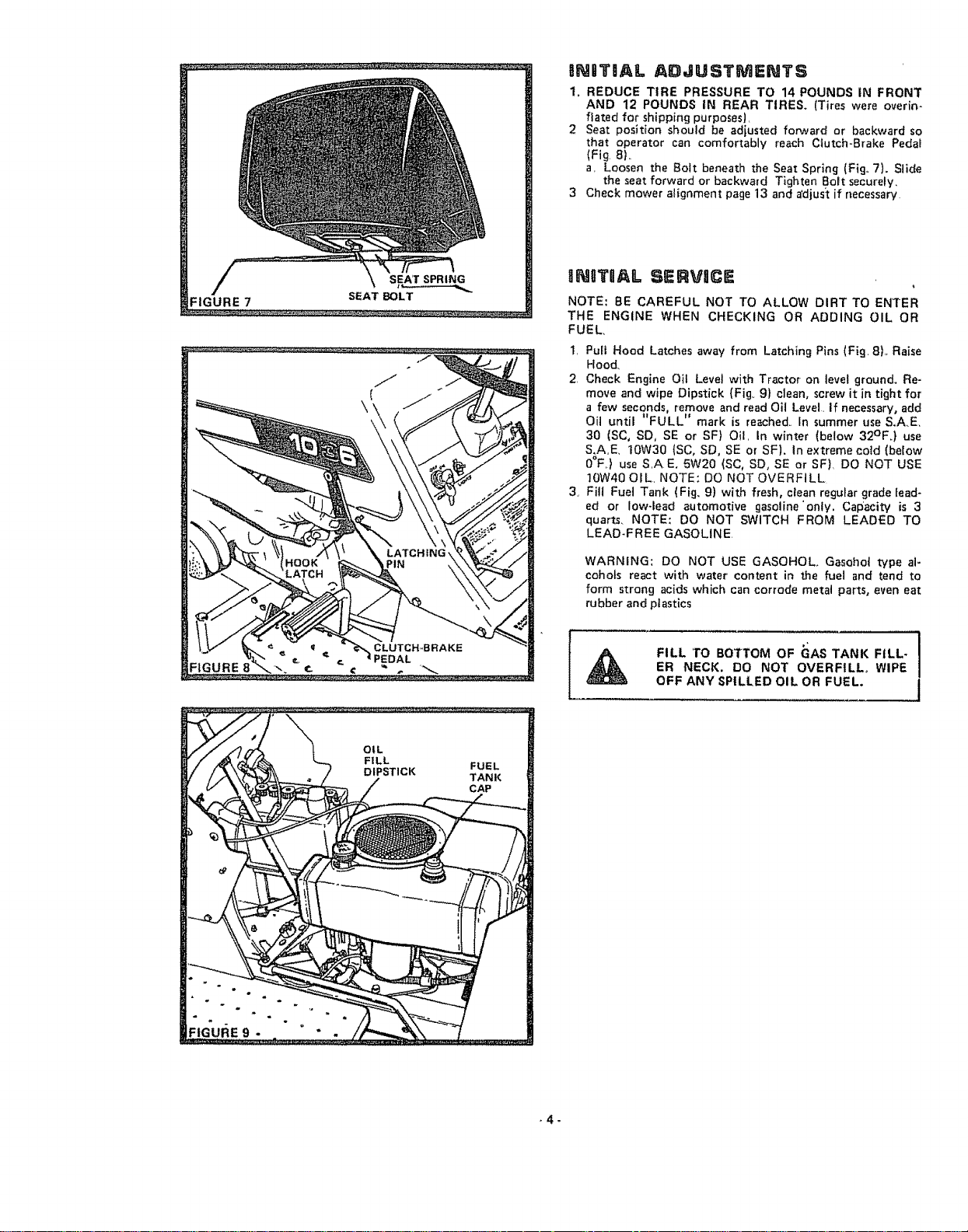

5, Install Steering Wheel using Flat Washer, Hex Jam Nut

(shown full size below) and

TERMINAL

COVER

@

Steering Wheel Insert found in Bag of Parts,

a, Secure the Steering Wheel to Steering Shaft with Washer

and Hex Jam Nut i.Fig=6) Tighten securely,

b, Install the Steering Wheel Insert

NOTE: A SPARK ARRESTOR MUFFLER (PAGE 23) tS

AVAILABLE AS AN ACCESSORY PART FOR YOUR

TRACTOR,, CHECK LEGAL REQUIREMENTS IN YOUR

AREA,

FIGURE

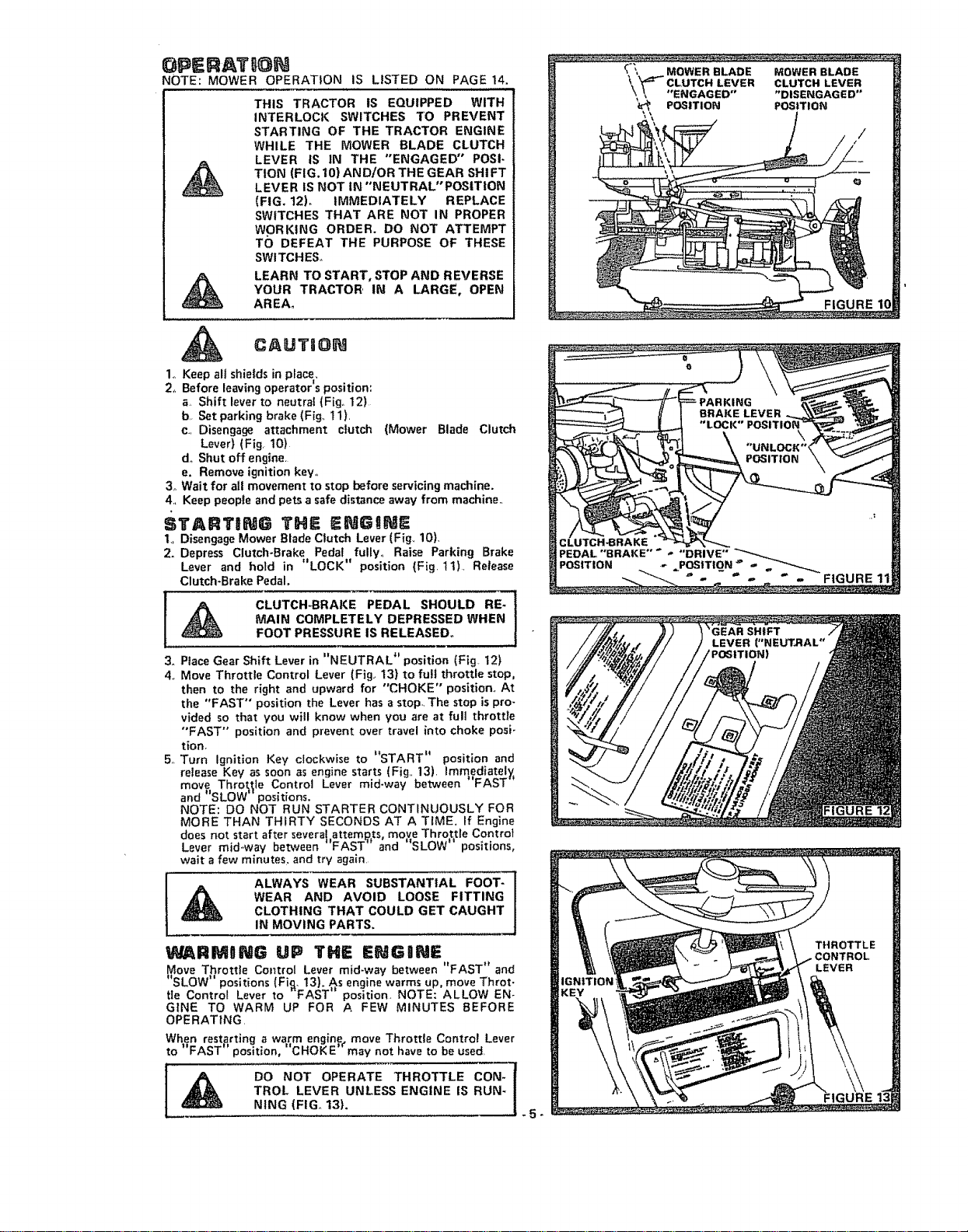

8NITBAL ADaUSTMENTS

1, REDUCE TIRE PRESSURE TO 14 POUNDS IN FRONT

AND 12 POUNDS IN REAR TIRES. (Tires were overin*

flared for shipping purposes)_

2 Seat position should be adiusted forward or backward so

that operator can comfortably reach Ctutch,.Brake Pedal

(Fig 8).

a, Loosen the Bolt beneath the Seat Spring (Fig. 7), Slide

the seat forward or backward Tighten Bolt securely,

3 Check mower alignment page 13 and a'djust if r_ecessary

FIGURE7

SEAT SPRING

SEAT BOLT

s_

IINgTOAL SERVllCE

NOTE: BE CAREFUL NOT TO ALLOW DIRT TO ENTER

THE ENGINE WHEN CHECKING OR ADDING OIL OR

FUEL

t Pu$t Hood Latches away from Latching Pins (Fig 8)+ Raise

Hood.

2 Check Engine Oil Love] with Tractor on tevel ground+ Re-

move and wipe Dipstick (Fig° 9} clean, screw it in tight for'

a few seconds remove and read Oil Level. If necessary, add

Oil untii "FULL mark is reached. In summer use S.A.E+

30 (SC, SO, SE or SF) Oil. tn winter (below 32°F+} use

S,A,E, t0W30 (SC, SD, SE or SF}. in extreme cotd (below

0+F.) use S.A E. 5W20 (SC, SD, SE or SF} DO NOT USE

10W40 OIL. NOTE: DO NOT OVERFILL

3, Flit Fuel Tank (Fig. 9) with fresh, clean regular grade fead-

ed or low-lead automotive gasoline ' only, Cap_acity is 3

quar_s. NOTE: DO NOT SWITCH FROM LEADED TO

LEAD.FREE GASOLINE

WARNING: DO NOT USE GASOHOL. Gasehot type al-

cohols react with water content in the fuel and tend to

form strong acids which can corrode metal parts, even eat

rubber and plastics

FILL 'to BOTTOM OF GAS TANK FILL,

ER NECK. DO NOT OVERFILL, WIPE

OFF ANY SPILLED OIL OR FUEL.

-4+

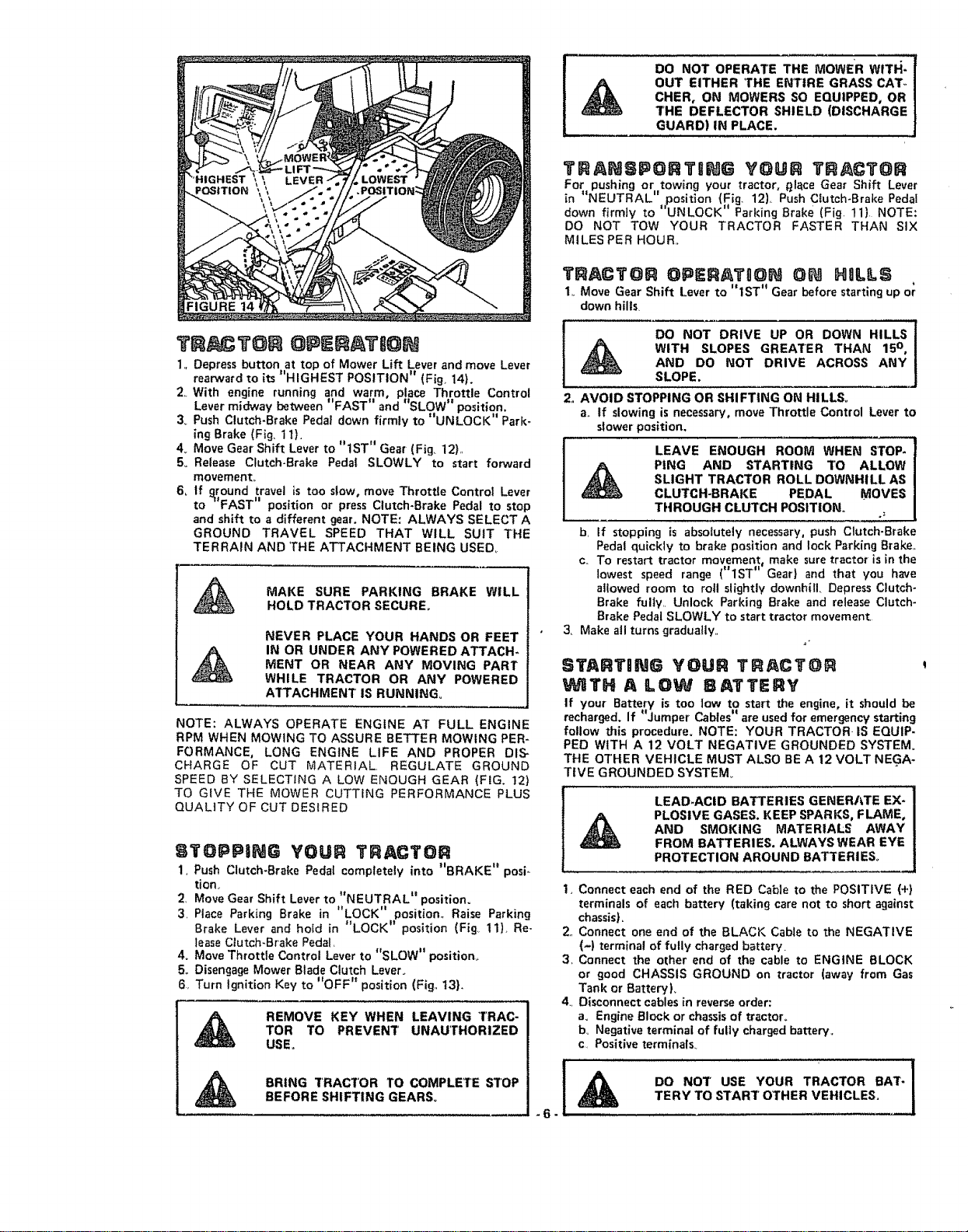

OPERATBON

NOTE: MOWER OPERATION IS LISTED ON PAGE 14,

THIS TRACTOR IS EQUIPPED WITH

INTERLOCK SWITCHES TO PREVENT

STARTING OF THE TRACTOR ENGINE

WHILE THE MOWER BLADE CLUTCH

LEVER IS IN THE "ENGAGED" POSI-

TION (FIG. 10) AND/OR THE GEAR SH! FT

LEVER IS NOT IN "NEUTRAL" POSITION

(FIG. 12), IMMEDIATELY REPLACE

SWITCHES THAT ARE NOT IN PROPER

WORKING ORDER. DO NOT ATTEMPT

TO DEFEAT THE PURPOSE OF THESE

SWITCHES,,

YOUR TRACTOR' IN A LARGE, OPEN

LEARN TO START, STOP AND REVERSE

AREA.

CAUTSON

1o Keep eli shields in place,.

2,, Before leaving operator's position:

a Shift lever to neutra{ (Fig° 12)

b Set parking brake (Fig, 11),

c., Disengage attachment clutch (Mower Blade Clutch

Lever) (Fig 10)

do Shut off engine.

e. Remove ignition key.

3o Wait for all movement to stop before servicing machine.

4., Keep people and pets a safe distance away from machine°

STARTgNG THE ENGINE

1., Disengage Mower Blade Clutch Lever {Fig. 10),

2. Depress Clutch-Brake Pedal fully,, Raise Parking Brake

Lever and hold in "LOCK" position (Fig 11) Release

Clutch-Brake Pedal.

FIGURE

FIGURE

[ _ CLUTCH-BRAKE PEDAL SHOULD RE-

3. Place Gear Shift Lever in "NEUTRAL" position (Fig 12)

4, Move Throttle Control Lever (Fig. 13) to full throttle stop,

then to the right and upward for "CHOKE" position,, At

the "FAST" position the Lever has a stop. The stop ispro_

vided so that you will know when you are at full throttle

"FAST" position and prevent over travel into choke posi-

tion,

5, Turn Ignition Key clockwise to "START" position and

release Key as soon as engine starts (Fig,, 13). immediately,

move Throt,_le Control Lever mid-way between "FAST-

and "'SLOW" positions.

NOTE: DO NOT RUN STARTER CONTINUOUSLY FOR

MORE THAN THIRTY SECONDS AT A TIME. If Engine

does not start after severel,attem_,ts, mo_e Throttle Control

Lever mid,,way between FAST and "SLOW' positions,

wait a few minutes, and try again,

MAIN COMPLETELY DEPRESSED WHEN

FOOT PRESSURE IS RELEASED_

WEARANDAVO,DLOOSEF,TT,NG

CLOTHING THAT COULD GET CAUGHT

ALWAYSWEARSUBSTANT,ALFOOT-

IN MOVING PARTS.

WARMONG UP THE ENGnNE

Move Throttle Control Lever mid-way between FAST and

,t iI ....

SLOW positions (Fig,. 13). As engine warms up, move Throt-

tle Control Lever to -FAST" position NOTE: ALLOW EN-

GINE TO WARM UP FOR A FEW MINUTES BEFORE

OPERATING

When restarting a warm engine_ move Throttle Control Lever

to "FAST" position, "'CHOKE-may not have to be used,

TROL LEVER UNLESS ENGINE IS RUN*

DO NOT OPERATE THROTTLE CON- {

NING (FIG. 13).

:tGURE

5-

DO NOT OPERATE THE MOWER WITI_-

OUT EITHER THE ENTIRE GRASS CATo

CriER, ON MOWERS SO EQUIPPED, OR

THE DEFLECTOR SHIELD (DISCHARGE

GUARD) IN PLACE.

TRANSPORTING YOUR T_ACTOR

For pushing or towing your tractor, _l_ce Gear Shift Lever

in "NEUTRAL" ,position (Fig. 12}, Push Clutch-Brake Peda!

down firmly to UNLOCK Parking Brake (Fig, 11} NOTE:

DO NOT TOW YOUR TRACTOR FASTER THAN SIX

MILES PER HOUR,,

TRACTOR OPERATgON ON HgLILS

1,. Move Gear Shift Lever to "IST" Gear before starting up o;

down hills.

@PERATB@N

1,, Depress button at top of Mower Lift Lever and move Lever

rearward to its "HIGHEST POSITION" (Fig° 14).

Z With engine running and warm, place Throttle Control

Lever m_dway between FAST and SLOW pos=tlon,

3_ Push Clutch-Brake Pedal down firmly to "UNLOCK" Park-

ing Brake (Fig, t t),

4_ Move Gear Shift Lever to "1ST" Gear (Fig_ 12),,

5o Release Clutch-Brake Pedal SLOWLY to start forward

movement_

6_ If ground travel is too slow, move Throttle Control Lever

_tl II , ,

to FAST posnt=on or press Clutch-Brake Pedal to stop

and shift to a different gear, NOTE: ALWAYS SELECT A

GROUND TRAVEL SPEED THAT WILL SUIT THE

TERRAIN AND 'THE ATTACHMENT BEING USED,

MAKE SURE PARKING BRAKE WILL

HOLD TRACTOR SECURE.

NEVER PLACE YOUR HANDS OR FEET

IN OR UNDER ANY POWERED ATTACH-

MENT OR NEAR ANY MOVING PART

WHILE TRACTOR OR ANY POWERED

ATTACHMENT IS RUNNING°

NOTE: ALWAYS OPERATE ENGINE AT FULL ENGINE

RPM WHEN MOWING TO ASSURE BETTER MOWING PER-

FORMANCE, LONG ENGINE LIFE AND PROPER DIS-

CHARGE OF CUT MATERIAL REGULATE GROUND

SPEED BY SELECTING A LOW ENOUGH GEAR (FIG. 12)

TO GIVE THE MOWER CUTTING PERFORMANCE PLUS

QUALITY OF CUT DESIRED

STOPPING YOUR TRACTOR

1, Push Clutch-Brake Pedal completely into "BRAKE" posi-

tiono

2, Move Gear Shift Lever to '*NEUTRAL" position.

3, Place Parking Brake in "LOCK" position., Raise Parking

Brake Lever and hoed in "LOCK'* position (Fig.. 11L Re-

lease Clutch-Brake Pedal,

4o Move Throttle Control Lever to "SLOW" positiom

5. Disengage Mower Blade Clutch Lever.

6, Turn ignition Key to "OFF" position (Fig,, 13}.

TOR TO PREVENT UNAUTHORIZED

REMOVE KEY WHEN LEAVING TRAC-

USEo

BRING TRACTOR TO COMPLETE S3[OP

BEFORE SHIFTING GEARS.

DO NOT DRIVE UP OR DOWN HILLS

WITH SLOPES GREATER THAN 15 ° ,

AND DO NOT DRIVE ACROSS ANY

SLOPE.

2. AVOID STOPPING OR SHIFTING ON HILLS_

a,. tf slowing is necessary, move Throttle Control Lever to

slower position.

LEAVE ENOUGH ROOM WHEN STOP-

SLIGHT TRACTOR ROLL DOWNHILL AS

PING AND STARTING 3['O ALLOW

CLUTCH-BRAKE PEDAL MOVES

THROUGH CLUTCH POSITION.

b, If stopping is absolutely necessary, push Clutch-Brake

Pedal quickly to brake position and lock Parking Brake_

c_ To restart tractor movement, make sure tractor is in the

lowest speed range ( 1ST Gear) and that you have

allowed room to rolt slightly downhill. Depress Clutch-

Brake fully, Unlock Parking Brake and release Clutch-

Brake Pedal SLOWLY to start tractor movement.

3. Make all turns gradually,,

tl tl

STARTING YOUR TRACTOR

'dVItTH A LOW BATTERY

If your Battery is too tow to start the engine, it should be

recharged. If Jumper Cables are used for emergency starting

follow this procedure. NOTE: YOUR TRACTOR IS EQUIP-

PED WITH A 12 VOLT NEGATIVE GROUNDED SYSTEM.

THE OTHER VEHICLE MUST ALSO BE A 12 VOLT NEGA-

TIVE GROUNDED SYSTEM.

1, Connect each end of the RED Cable to the POSITIVE (+)

terminals of each battery (taking care not to short against

chassis)_

2, Connect one end of the BLACK Cable to the NEGATIVE

(-) terminal of fully charged battery.

3, Connect the other end of the cable to ENGINE BLOCK

or good CHASSIS GROUND on tractor (away from Gas

Tank or Battery),

4., Disconnect cables in reverse order:

a. Engine Block or chassis of tractor_

bo Negative terminal of fully charged battery.

c, Positive terminals_

I

-6-

1| II .

LEAD*ACID BATTERIES GENERi_TE EX-

PLOSIVE GASES. KEEP SPARKS, FLAME,

AND SMOKING MATERIALS AWAY

FROM BATTERIES. ALWAYS WEAR EYE

PROTECTION AROUND BATTERIES°

DO NOT USE YOUR TRACTOR BAT-I

TERY TO START OTHER VEHICLES,

I

1

MAIINTENANCE

MOWER MAINTENANCE tS LISTED ON PAGE t5.,

To keep your tractor running better, longer; perform neces-

saw service using the following Maintenanc_ Schedule..

REFER TO "STOPPING YOUR TRAC-

TOR" PAGE 6 AND DISCONNECT SPARK

PLUG WIRE TO PREVENT ACCIDENTAL

STARTING BEFORE MAKING ANY IN-

SPECTION, ADJUSTMENT OR REPAIR

(EXCEPT CARBURETOR)..

D gLV t ABNTENANCE

Make sure all nuts on bolts are tight and cotter pins are secure.

Observe all safety precautions Keep Tractor well lubricated

(refer to page 12)

FIIRST _ HOURS

1. CHANGE,ENGINE OIL

Changing Oil after the first two hours wilt help e{iminate

break4n residue which might be damaging to your Engine.

NOTE: Be careful not to allow dirt to enter the Enginewhen

changing,, oil. Move Mower Blade Clutch Lever to--EN-

GAGED" position.

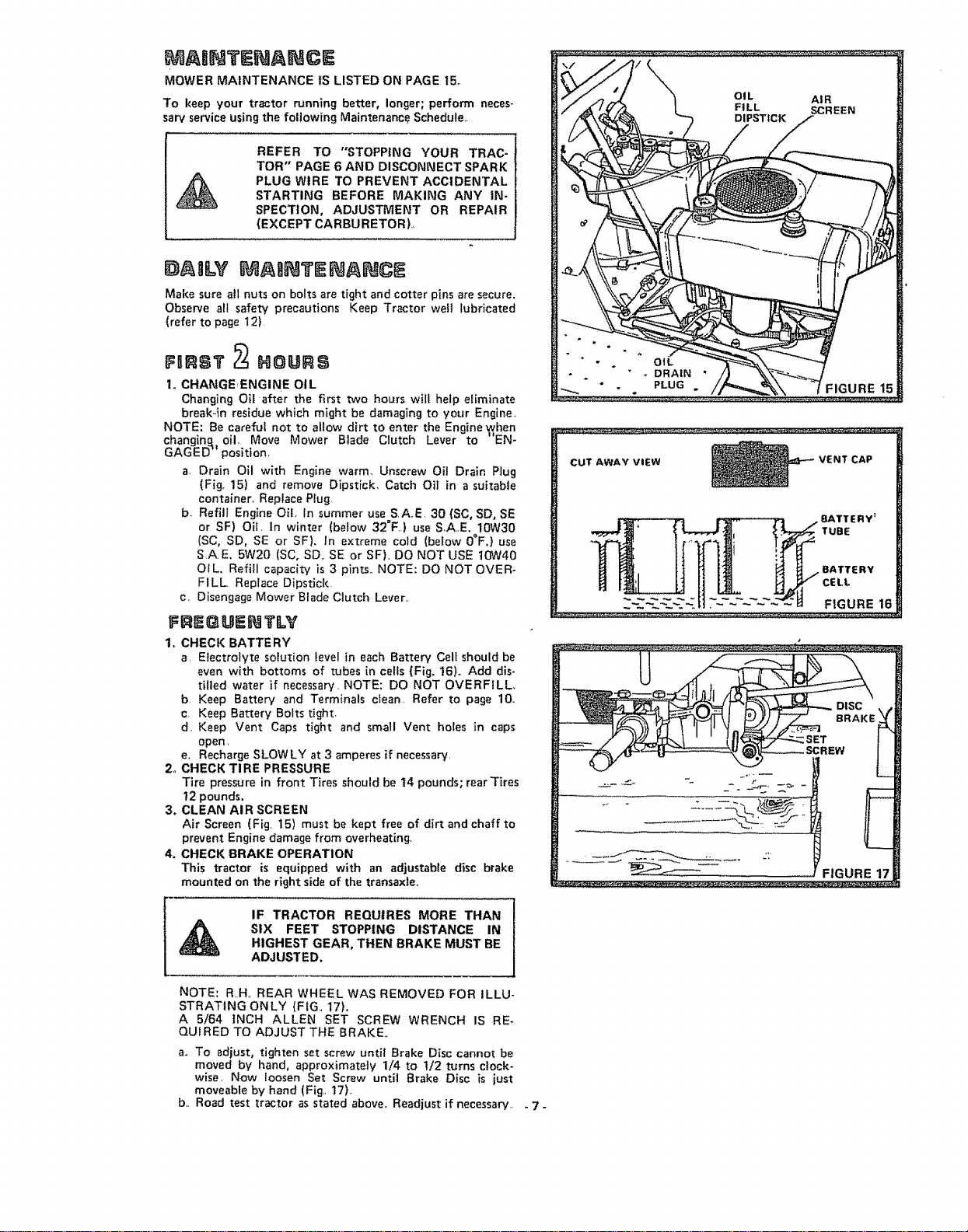

a. Drain Oil with Engine warm. Unscrew Oil Drain Plug

(Fig. 15) and remove Dipstick. Catch Oit in a suitable

container. Replace Ptug

b. Refill Engine Oil. tn summer use S,A.E, 30 (SC, SD, SE

or SF) Oil, In winter (below 32°F.) use S.AE. 10W30

(SC, SD, SE or SF). In extreme cold {below O°F.} use

SAE. 5W20 (SC. SD. SE or SFL DO NOT USE 10W40

Of L. Refill capacity is 3 pints., NOTE: DO NOT OVER-

FILL Replace Dipstick.

c, Disengage Mower Blade Clutch Lever.,

FREQUENTILY

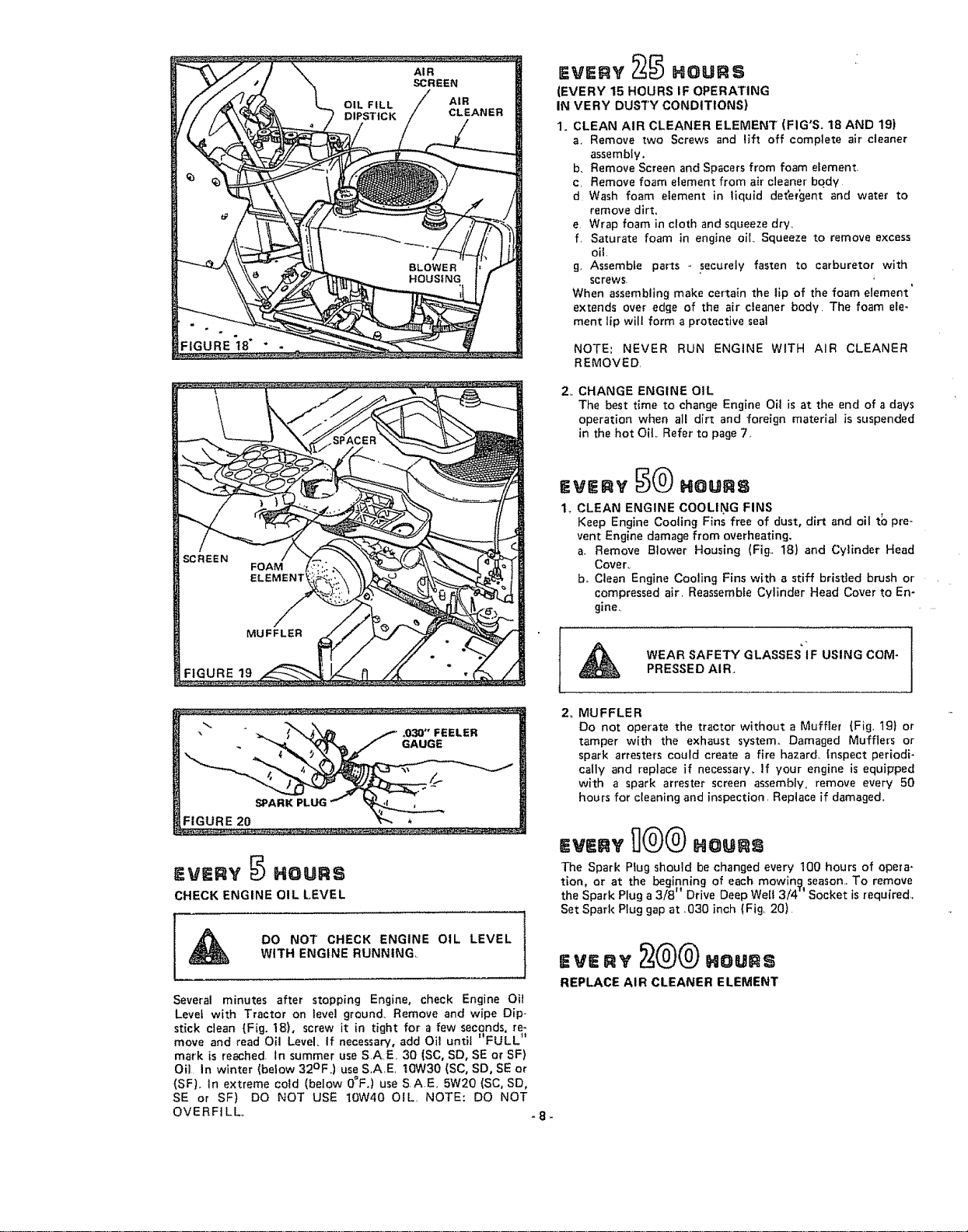

1_ CHECK BATTERY

a. Electrolyte solut{on level in each Battery Cell should be

even with bottoms of tubes in cells (Fig, !6). Add dis-

ti{led water if necessary. NOTE: DO NOT OVERFILL.

b. Keep Battery and Terminals ctean. Refer to page 10.

c Keep Battery Bolts tight_

d, Keep Vent Caps tight and smatl Vent holes in caps

open.

e. Recharge SLOWLY at 3 amperes if necessary.

2o CHECK TIRE PRESSURE

Tire pressure in front Tires should be 14 pounds; rear'Fires

t2 pounds.

3. CLEAN AIR SCREEN

Air Screen (Fig. 15) must be kept free of dirt andchaff to

prevent Engine damage from overheating.

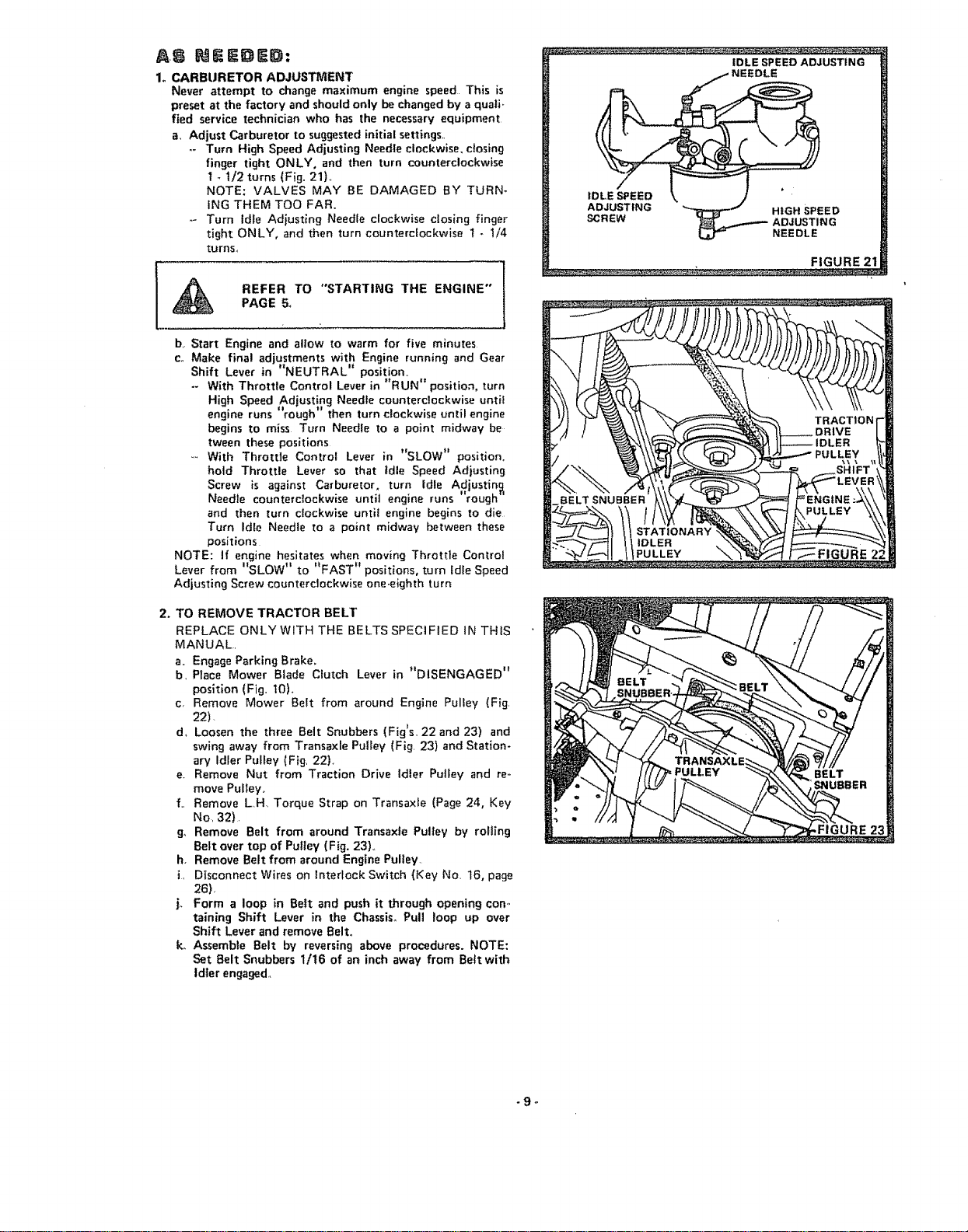

4. CHECK BRAKE OPERATION

This tractor is equipped with an adjustable disc brake

mounted on the right side of the transaxle..

CUT AWAY VIEW VENT CAP

_ /BATTERY'

i BATTERY

.'t'

FIGURE 17

IF TRACTOR REQUIRES MORE THAN

SIX FEET STOPPING DISTANCE INHIGHEST GEAR, THEN BRAKE MUST BE

ADJUSTED,

NOTE; R,H, REAR WHEEL WAS REMOVED FOR ILLU-

STRATING ONLY (FIG., 17).

A 5/64 INCH ALLEN SET SCREW WRENCH IS RE-

QUI RED TO ADJUST THE BRAKE.,

a. To adjust, tighten set screw until Brake Disc cannot be

moved by hand, approximately 1/4 to t/2 turns clock-

wise, Now loosen Set Screw until Brake Disc is just

moveable by hand (Fig,, 17).

b., Road test tractor as stated above. Readjust if necessary... 7 -

.ou.s

(EVERY 15 HOURS IF OPERATING

IN VERY DUSTY CONDITIONS)

1. CLEAN AIR CLEANER ELEMENT (FIG'S. 18 AND 19)

a, Remove two Screws and lift off complete air cteaner

assembly.

b. Remove Screen and Spacers from foam element

c, Remove foam element from air cleaner bqdy

d Wash foam element in liquid de_'er_ent and water to

remove dirt,

e. Wrap foam in cloth and squeeze dry,

f. Saturate foam in engine oiL. Squeeze to remove excess

FIGURE 19

HOUSING

g, Assemble parts - securely fasten to carburetor with

screws_

When assembling make certain the lip of the foam element'

extends over edge of the air cleaner body. The foam ele-

ment lip will form a protective seal

NOTE', NEVER RUN ENGINE WITH AIR CLEANER

REMOVED.

2,_CHANGE ENGINE OIL

The best time to change Engine Oil is at the end of a days

operation when all dirt and foreign material is suspended

in the hot Oit_ Refer to page 7,

=vE.v .ou.s

1,. CLEAN ENGINE COOLING FINS

Keep Engine Cooling Fins free of dust, d_rt and oil t_ pre-

vent Engine damage from overheating,

a. Remove Blower Housing (Fig,, 18) and Cylinder Head

Cover_

b,_Clean Engine Cooling Fins with a stiff brisded brush or

compressed air, Reassemble Cylinder Head Cover to En-

gine,

WEARSAFETYGLASSESUSINGCOM-

PRESSED AIR.

2, MUFFLER

Do not operate the tractor without a Muffter (Fig, 19) or

tamper with the exhaust system., Damaged Mufflers or

spark arrestors could create a fire hazard, Inspect periodi-

cally and replace if necessary_ if your engine is equipped

with a spark arrestor screen assembly, remove every 50

hours for cleaning and inspection, Replace if damaged,,

EVERY HOURS

CHECK ENGINE OIL LEVEL

DO NOT CHECK ENGINE OIL LEVEL

WITH ENGINE RUNNING,.

Several minutes after stopping Engine, check Engine Oit

Level with Tractor on tevel ground. Remove and wipe Dip-

stick ctean (Fig. 18), screw it in tight for a few seconds re-

move and read Oil Level. If necessary, add Oil until _ FULL

mark is reached, In summer use SA.E, 30 (SC, SD, SE or SF)

Oil In winter (below 32°F,) use S,A,E. t0W30 (SC, SD, SE or

(SF),. In extreme cold (below O=F,) use S.A.E, 5W20 (SC, SD,

SE or SF) DO NOT USE 10W40 OIL NOTE: DO NOT

OVERFILL,. -8-

The Spark Plug should be changed every 100 hours of opera-

tion or at the beginning of each mowing season,.To remove

the Spark Plug a 3/8 Drive Deep Well 3/4 Socket is required,,

Set Spark Plug gap at 030 inch {Fig. 20)

It /!

=v=.v

REPLACE AIR CLEANER ELEMENT

A+S NEEDED:

1+ CARBURETOR ADJUSTMENT

Never attempt to change maximum engine speed This is

preset at the factory and should only be changed by a quali-

fied service technician who has the necessary equipment

a. Adjust Carburetor to suggested initial Settings+

-- Turn High Speed Adjusting Needle clockwise, closing

finger tight ONLY, and then turn counterclockwise

I ..1/2 turns (Fig. 21}_

NOTE: VALVES MAY BE DAMAGED BY TURN-

ING THEM TOO FAR,

-+ Turn Idle Adiusting Needle clockwise closing finger

tight ONLY, and then turn counterclockwise ! + 1/4

turns,,

REFER TO "STARTING THE ENGINE"

PAGE 5_

b. Start Engine and aliow to warm for five minutes

c. Make final adjustments with Engine running and Gear

Shift Lever in "NEUTRAL" position..

-- With Throttle Control Lever in ++RUN" position, turn

High Speed Adjusting Needle counterclockwise until

+ ii t! , , .

engine runs rough then turn clockwise unt+l end+no

begins to miss Turn Needle to a point midway be

tween these positions

With Throttle Control Lever in "SLOW ++position.

hold Throttle Lever so that Idle Speed Adiusting

Screw is against Carburetor, turn Idle Adjusting

Needle counterclockwise until engine runs "rough"

and then turn clockwise until engine begins to die

Turn Idle Needle to a point midway between these

positions

NOTE: tf engine hesitates when moving Throttle Control

Lever from "SLOW" to "FAST Hpositions, turn Idle Speed

Adjusting Screw counterclockwise one-eighth turn

IDLE SPEED ADJUSTING

• FIGURE 21

2. TO REMOVE TRACTOR BELT

REPLACE ONLY WITH THE BELTS SPECIFIED IN THIS

MANUAL.

a,, Engage Parking Brake,

b, Place Mower Blade Clutch Lever in "DISENGAGED"

position (Fig,, 10)+

c, Remove Mower Belt from around Engine Pulley (Fig

22)

d+ Loosen the three Belt Snubbers (Fig's, 22 and 23) and

swing away from Transaxle Pulley (Fig, 23) and Station-

ary Idler Pulley (Fig, 22}+

e, Remove Nut from Traction Drive Idler Pulley and re,.

move Pulley,

f., Remove LH, Torque Strap on Transaxte (Page 24, Key

No, 32).

g+ Remove Belt from around Transaxle Pulley by rolling

Belt over top of Pulley (Fig. 23),,

h, Remove Belt from around Engine Pulley,

i, Disconnect Wires on Interlock Switch (Key No+ 16, page

26),

j+ Form a loop in Belt and push it through opening con+,

raining Shift Lever in the Chassis° Pull loop up over

Shift Lever and remove Belt.

k. Assemble Belt by reversing above procedures. NOTE:

Set Belt Snubbers 1/16 of an inch away from Belt with

Idler engaged+

-9+

FIGURE 23A

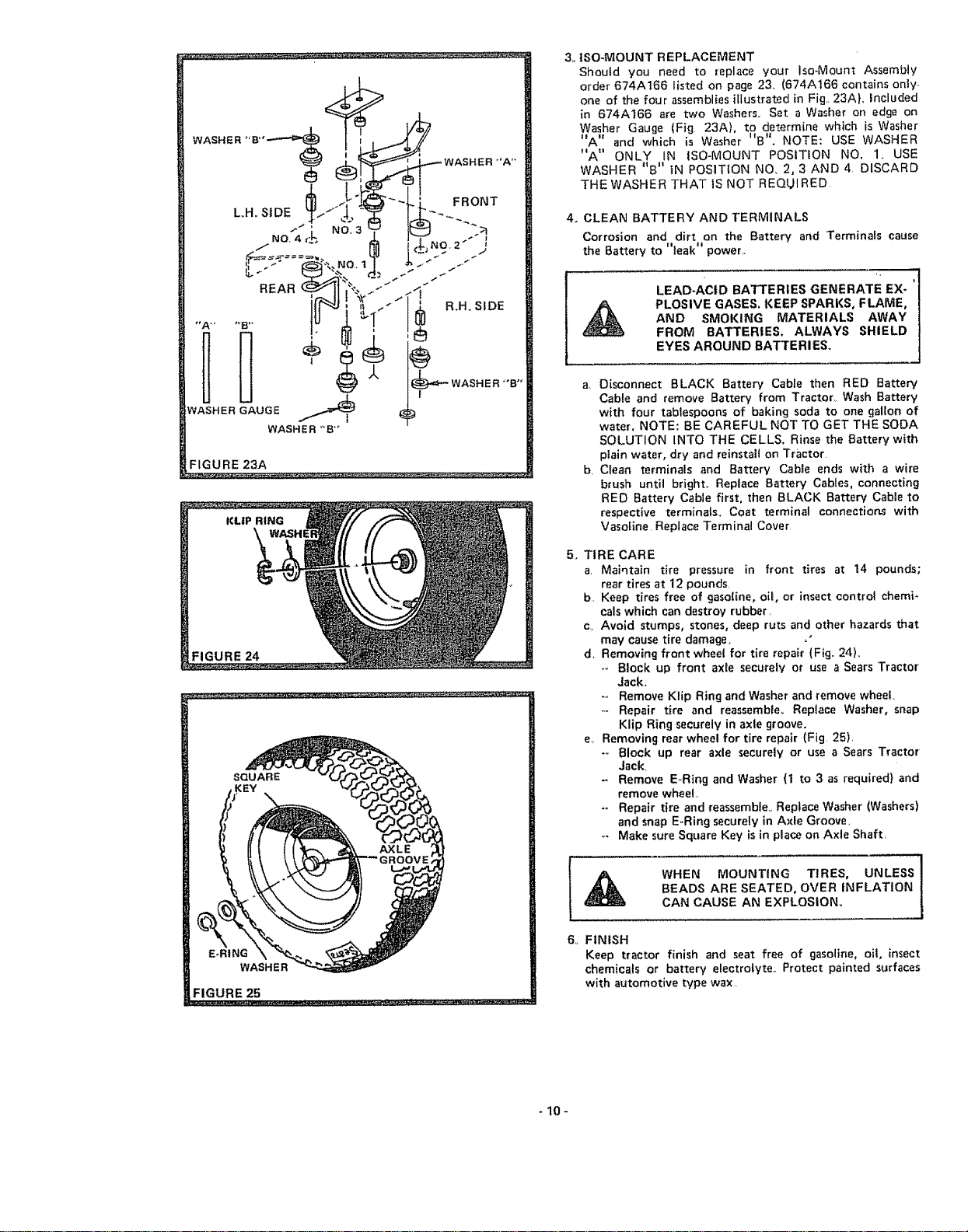

3. ISO-MOUNT REPLACEMENT

Should you need to replace your Iso-Mount Assembly

order 674A166 listed on page 23, (674A166 contains only,,

one of the four assemblies illustrated in Fig,. 23AL Included

in 674A166 are two Washers,. Set a Washer on edge on

Washer Gauge (Fig 23A), to determine which is Washer

"A" and which is Washer "B". NOTE: USE WASHER

"A" ONLY IN tSO-MOUNT POSITION NO. 1. USE

WASHER "B" iN POSITION NO, 2,3 AND4 DISCARD

THE WASHER THAT IS NOT REQUIRED

4. CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the Battery and Terminals cause

the Battery to "leak"power,,

LEAD-ACID BATTERIES GENERATE EX-

PLOSIVE GASES. KEEP SPARKS, FLAME,

AND SMOKING MATERIALS AWAY

FROM BATTERIES. ALWAYS SHIELD

EYES AROUND BATTERIES.

a Disconnect BLACK Battery Cable then RED Battery

Cable and remove Battery from Tractor. Wash Battery

with four tablespoons of baking soda to one gallon of

water, NOTE: BE CAREFUL NOT TO GET THE SODA

SOLUTION INTO THE CELLS. Rinse the Battery with

plain water, dry and reinstall on Tractor

b, Clean terminals and Battery Cable ends with a wire

brush until bright,. Replace Battery Cables. connecting

RED Battery Cable first, then BLACK Battery Cabte to

respective terminals° Coat terminal connections with

Vasofine, Replace Terminal Cover

SQUARE

E.RING

WASHER

FIGURE 25

5. TIRE CARE

a Maintain tire pressure in front tires at 14 pounds;

rear tires at 12 pounds,

b Keep tires free of gaso{ine, o11,or insect controt chemi-

cals which can destroy rubber

c Avoid stumps, stones, deep ruts and other hazards that

may cause tire damage, ,"

d. Removing front wheel for tire repair (Fig,. 24),

,.-Block up front axle securely or use a Sears Tractor

Jack.

-,. Remove Klip Ring and Washer and remove wheel.

-- Repair tire and reassemble_ Replace Washer, snap

Klip Ring securely in axle groove.

e, Removing rear wheel for tire repair (Fig 25)

.,. Block up rear axle securely or use a Sears Tractor

Jack.

- Remove E, Ring and Washer (1 to 3 as required} and

remove wheel,.

-- Repair tire and reassemble., Replace Washer (Washers)

and snap E,,Ring securely in Axle Groove,

-- Make sure Square Key is in place on Axle Shaft,

BEADS ARE SEATED, OVER INFLATION

WHEN MOUNTING TIRES, UNLESS

CAN CAUSE AN EXPLOSION.

6., FINISH

Keep tractor finish and seat free of gasoline, oit, insect

chemicals or battery e}ectrolvte Protect painted surfaces

with automotive type wax

-10-

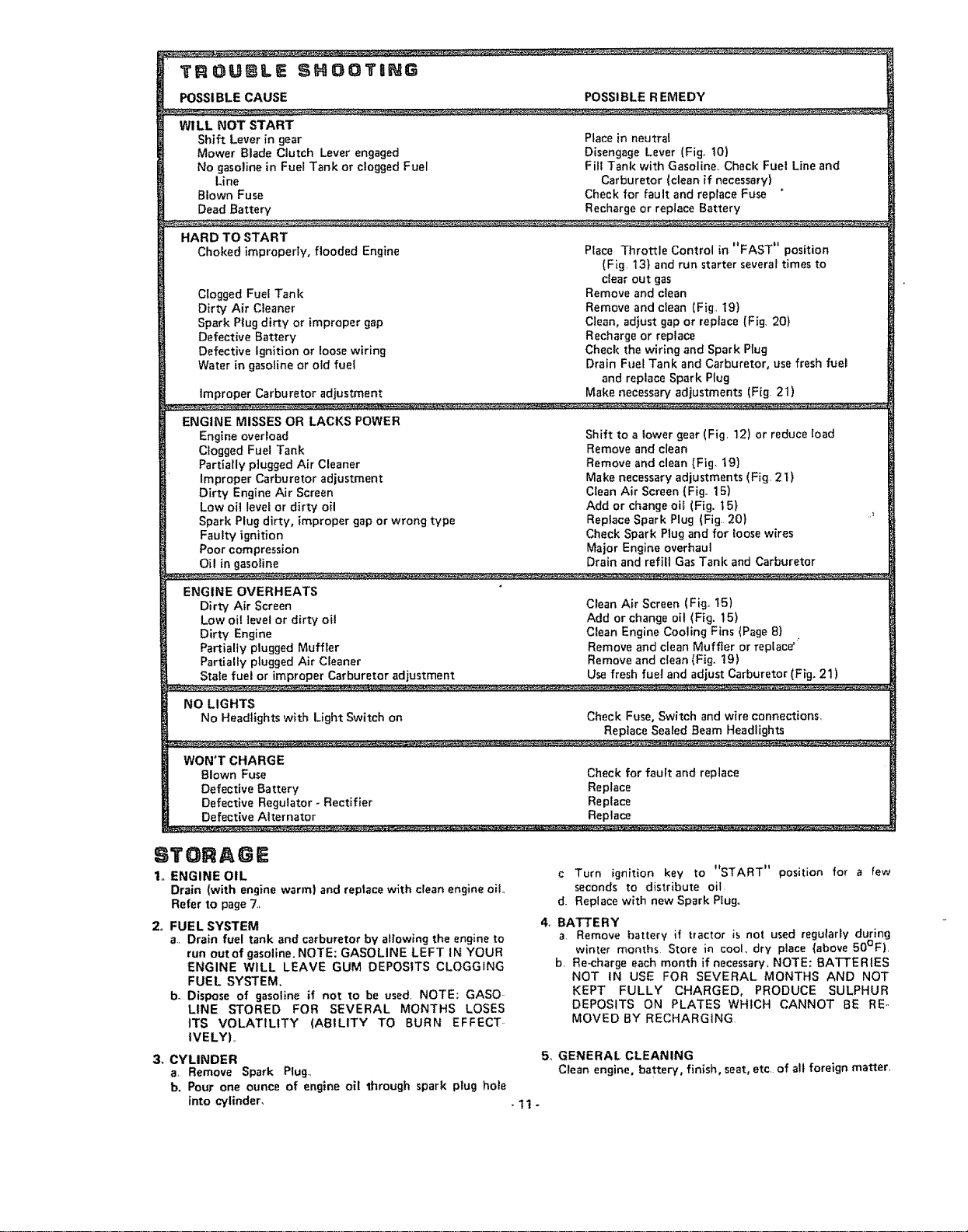

TROUBLE SHOOTaNG

POSSI BLE CAUSE POSSIBLE R EMEDY

WILL NOT START

Shift Lever in gear

Mower Blade Clutch Lever engaged

No gasoline in Fuel Tank or clogged Fuel

Line

Blown Fuse

Dead Battery

HARD TO START

Choked improperly, flooded Engine

Clogged Fuel Tank

Dirty Air Cleaner

Spark P|ug dirty or improper gap

Defective Battery

Defective ignition or loose wiring

Water in gasoline or old fuel

improper Carburetor adjustment

ENGINE MISSES OR LACKS POWER

Engine overload

Clogged Fuel Tank

Partially plugged Air Cleaner

Improper Carburetor adjustment

Dirty Engine Air Screen

Low oil level or dirty oil

Spark Plug dirty, improper gapor wrong type

Faulty ignition

Poor compression

Oil in gasoline

ENGINE OVERHEATS

Dirty Air Screen

Low oil level or dirty oil

Dirty Engine

Partially plugged Muffler

Partially plugged Air Cleaner

Stale fuel or improper Carburetor adjustment

NO LIGHTS

No Headlights with Light Switch on Check Fuse, Switch and wire connections

Place in neutral

Disengage Lever {Fig t0)

Fill Tank with Gasoline. Check Fuet Line and

Carburetor (clean if necessary1

Check for fault and replace Fuse

Recharge or replace Battery

Place Throttle Control in "FAST" position

(Fig 131 and run starter several times to

clear out gas

Remove and clean

Remove and clean (Fig 19)

Clean, adjust gap or replace (Fig, 20}

Recharge or replace

Check the wiring and Spark Plug

Drain Fuel Tank and Carburetor, use fresh fuet

and replace Spark Plug

Make necessary adjustments (Fig 21)

Shift to a lower gear (Fig 12) or reduce load

Remove and clean

Remove and clean (Fig, t9}

Make necessary adjustments (Fig 21)

Clean Air Screen (Fig 15)

Add or change oil (Fig. t51

Replace Spark Plug (Fig 201

Check Spark Ptug and for loose wires

Major Engine overhaul

Drain and refill Gas Tank and Carburetor

Clean Air Screen (Fig, 15)

Add or change oil (Fig. 15)

Clean Engine Cooling Fins (Page 81

Remove and clean Muffler or replace'

Remove and clean (Fig_ 19)

Use fresh fuel and adjust Carburetor (Fig. 21)

Replace Sealed Beam Headlights

WON'T CHARGE

Blown Fuse Check for fault and replace

Defective Battery Replace

Defective Regulator _Rectifier Replace

Defective Alternator Replace

ETORAGE

1. ENGINE OIL

Drain (with engine warm) and replace with clean engine oi!.,

Refer to page 7,

2. FUEL SYSTEM

a. Drain fuel tank and carburetor by allowing the engine to

run outof gasoline. NOTE: GASOLINE LEFT IN YOUR

ENGINE WILL LEAVE GUM DEPOSITS CLOGGING

FUEL SYSTEM,

b. Dispose of gasoline if not to be used. NOTE: GASO..

LINE STORED FOR SEVERAL MONTHS LOSES

ITS VOLATILITY (AStLITY TO BURN EFFECT..

tVELYI,.

3, CYLINDER

a, Remove Spark Plug.,

b. Pour one ounce of engine oil through spark plug hole

into cylinder,

c Turn ignition key to "START" position fo_ a few

seconds to distribute oil

d. Replace with new Spark Plugo

4, BATTERY

a, Remove battery if tractor is not used regularly during

winter months Store in cool. dry place (above 50°F),

b, Re-charge each month if necessary, NOTE: BATTERIES

NOT IN USE FOR SEVERAL MONTHS AND NOT

KEPT FULLY CHARGED, PRODUCE SULPHUR

DEPOSITS ON PLATES WHICH CANNOT BE RE-,

MOVED BY RECHARGING

5. GENERAL CLEANING

Clean engine, battery, finish, seat, etc, of all foreign matter,

-!1-

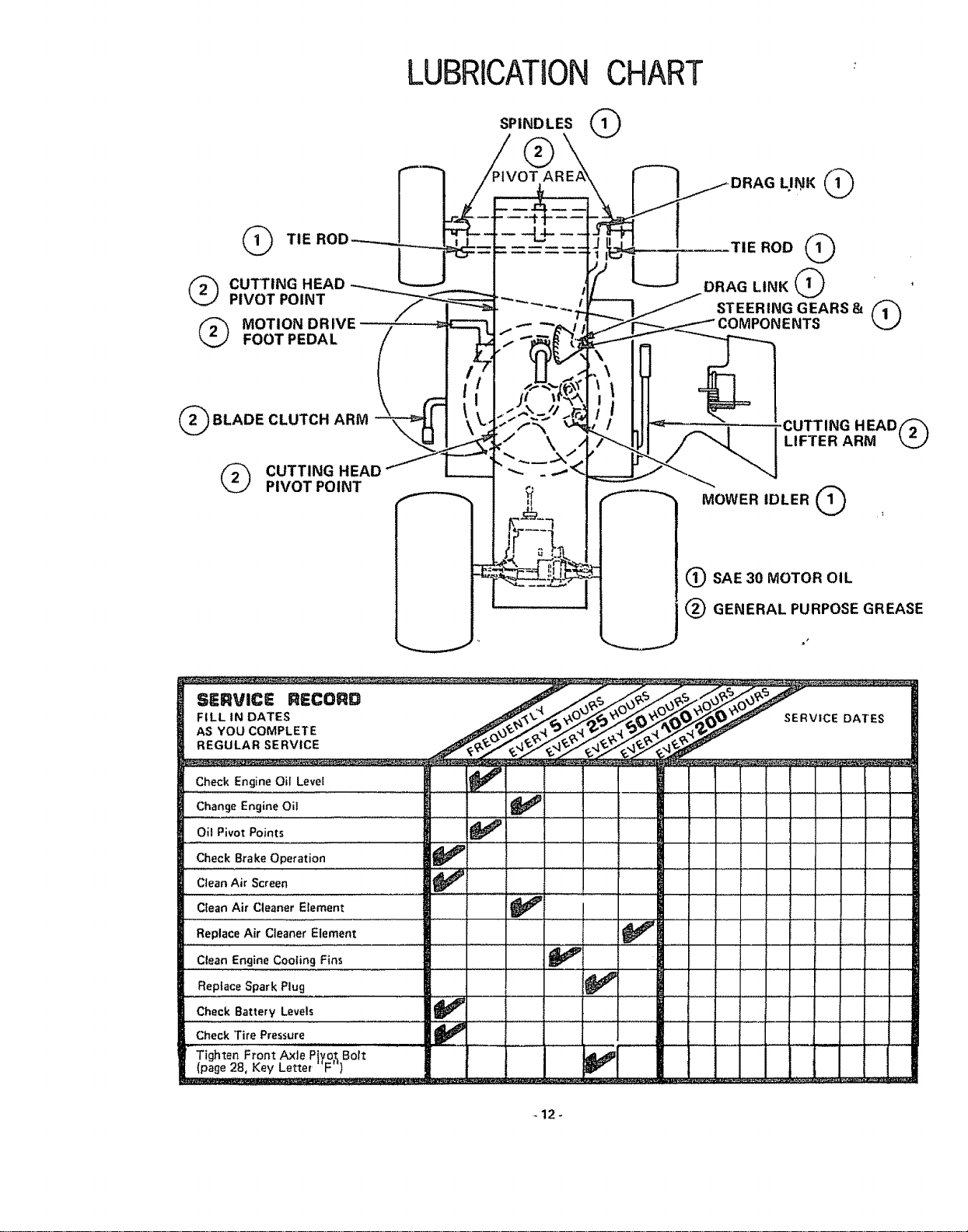

LUBRICATIONCHART

SPINDLES @

(_ TIE

(_ CUTTING HEAD --_--..._

PIVOT POINT

@ MOTION DRIVE .

TIE ROD @

DRAG LINK @

STEERING GEARS 8= 1/'_1

COMPONENTS

't \ t"

_"_ MOWER IDLER @

@ SAE 30 MOTOR OIL

@ GENERAL PURPOSE GREASE

v

I

SERVICE RECORD

FILL tN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check Engine OIlLevel ,

Change Engine Oil

OIl Pivot Points

.... ,,, , _ . _ ,,,

Check Brake Operation _iP

Clean Air Screen .......... _ ...........

Clean Air Cleaner Element _ ....

Replace Air Cleaner Element

Clean Engine Cooling Fins

Replace Spark Plug _!_

Check Battery Levels

Check '[ire Pres,_ure _l_ ]

Tighten Front Axle Pjyo_Bolt _ _ _i_I

o(pane28,KeyLe_e,'F") ......

12-

SERVICE DATES

Loading...

Loading...