Craftsman 917254791 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

917.254791

CRRFTSMRN

Caution;

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

12.5 HP OHV

ELECTRIC START

38" MOWER

5 SPEED TRANSAXLE

LAWN TRACTOR

• Assembly

• Operation

• Maintenance

• Service and Adjustment

• l_.epair Parts

SAFETY RULES

PLUGTOPREVENTACCIDENTALSTARTINGWHENSETTING_UP,TRANSPORTING,ADJUSTINGORMAKING

CAUTION:ALWAYSDISCONNECTSPARKPLUGWIREANDPLAOEWIREWHEREITCANNOTCONTACTSPARK A

REPAIRS_

IMPORTANT

SAFETYSTANDARDSREQUIREOPERATORPRF..SENCECeNTRe LSTOMINIMIZETHERISKOFINJURY YOURUNil"ISEQUIPPEDWITHSUCH

CONTROLS. DONOTATTEMPTTODEFEATTHEFUNCTIONOF TREOPERATORPRE,SENCECONTROLSUNDERANY CIRCUMSTANCES_

TRAINING:

Know the controlsand howto stop quickly. Readthisowner's

manual and instructionsfurnishedwithattachments:

Do not allow childrento Operate the machine, Do nete_low

edWlsto operate itWitheutpropertnslr00tion.,

De not:carry passengers,Do nat mowwhen cht!drenand

others al:e b:mund., :,:: ' ,.'

Do noi;_ttem_t to ope[aie your vehicle or nlowsrwhennot In

the driver's seat. _:; ' "i';: :! ";.'- _ "." !

Always"gat or_OrOffybur:V_htCe f_'omthb Ope_ai6/'stafthand _

sldeo : ; , "_,," ,:;! '::' _:" ';_, _' '.

The vehlble Bnd aetBchments s_oii],_l:b_ stopped and In;

spooled for damage after strfklng _.foielgn objecl, end the '

carnage should be repaired beloreiieslarting and operat ng

the equipment. <_ ;_' i",

PREPARATION: "_ :_!,__"

* Always wear substantial footwear. Do not wear loose fitting

clo_hJngthat could get caught in moving parts,

Clear the work area of objects (wire, rocks, etc ) which might

be pickedup and thrown_

Disengage all attachment clutchesbefore attempting to start

the engine.

Handle gasolinewith car_-'ll Ishighly flammable.

Use approved gasolin_containers.,

Never removethefu_el:eapoftF_e'fdelta_nkoreddgasoline

to a running or hot b_igidedr an efigi_e that has notbeen

allowed tocoolfoi _:eveta"i_tetJtesafter running,Never

flit tank Indoors Alway_ clead up spilledgasoline.-

Open doors Iflhe engineIsrun Inthe garage - exhaust

fumesere dangerous, De notrun the engine Indoors

Do not operate the mower without the entire grass catehei',

on mowers so equipped or the deflectorshield_nplace:

0 P ERATION;

Keep your eyes and mind on your vehicle mower and the

area beingcut. De not let other tntsres_ distraCtyou.

Disengage power to ettachrae_s aniJs_o'pthe engine before

leaving the operator's position_ ....i ',,

Disengage power to mower,stop the engine, and d_sconnect

spa_kplug wite(s)from spark plug(s)before cleaning, making -

an adjustment,or repair, Be careful to avoidtouchinghot

muffler or engine compononts_

Disengage powerto attachments when transporting or notIn

USe_

, Take all poestble precautions whenleaving the vehicle unat-

tended D{sangage the power take-off,lower the attach_

manta, shift inlo neulret, set the parking brake, stop the

engine, and removethe key.

Do not stop or staff suddenly when golng uphill or downhill,

Mow up end down the faceof slopes (net greater than "_5"},

never across the face.

Reduce speedonslopes and maket0ms gradually top_event

tipping or loss of control. Exercise extreme caution when

changing direction on slopes.

While goingup ordown slopes piecegearshift control lever

in I st gear positionto negotiate the slope without stopping. ',

, Never mow inwet or stippery grass,whentractionis unsure,

orat a speed which could cause a skid.

• Stayalert for holes in the terrain and other hidden h_Lzerdso

Keep away fromdrop.offs.

De not ddve toodose to creeks, ditches, and public high.

ways.

Exercisespecteicarewhen mowingaround fixedobjectsin

orderto preventthe blades from strikingmere. Neverdelib-

erately runvehtde or mower Intoor over any foreign objects.

Never shiftgears un'_lvehiclecomes to a stop

• Never place hands or feet under the mower, in discharge

chute or near any moving partswhile vehtcie or mower is

runnng Always keep clear of discharge chute

Use cam when pulling loads or using heavy equ_pmenL

Use only approved drewbar hitch points.

Umll feeds te those you can safelycontrol

Do not turn sharptyoUsecare when backing

Use counterweight or wheel weights whensuggestedin

owner's manual_

' Watch outfor trafficwhen crossing or near roadways

When using any attachments, never direct discharge of

material towardbystanders nor allow anyone near the ve-

hicle whilelh operation,

Exceptforadjustments,de not operate engine ifair cleaner

d.r,cover directly over carburetor air intake is remeved_

Removalof suchpartcould create a fire hazard.

Do nbt change the engine governor settingsor overspeed

the engine; severe damage orinjury may result.,

When using the vehicle wilhmower, proceed as follows:

s_ow oniy in daylight or Ingood artftictal light.

_ut_e engine off when unelogglng chule.

Check the blade mounting bolls for proper tightnessat

frequenttntewats.

*" Disengage power to mower before backing up, Do not mow

In reverse unless absolutelynecessary and then onlyafter

careful observation of the enUrearea behindthe'mower

MAINTENANCE AND STORAGE

, Keep the vehicle end attachmentstn good operating condi-

tion,and keepsafety devicestn pface and working.

, Keep all nuts, bolL%and screws tightto be sure the equip-

ment is in sate workingcondition.

Never storethe equipment withgasot{nein the tank _nsidea

bulldtng where fumes may reach an open flame or spark

Allow the engine to cool before stodng In any enclosure

, Toreduce fire hazard keep the englne free ofgrassjeaves,

or excessve grease, Do notclean product whileengine is

running,

De not operate without a muftier, or tamper with exhaust

system Damaged mufflers or spark anestare could create a

firehazard inspect periodicallyand replace if necessary.

Under normal usage the grass catcher bag mated_J ts

subject to deterioration and wear, tt should be checked

frequenttyfor bagreplacement Replacement bags should

be checked to ensdre compliance with the orfgfnal

manufacturer's recommendationsor spec_calJens.

I

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT sAFETY PRECAUTIONS,

tT MEANS-ATTENTIONH BECOME ALERTII! YOURSAFETY IS INVOLVED.

CONGRATULATIONSon your purchase of a Sears

Tractor. tt has been designed, engineered ahd manu-

factured to give you the best possible dependabll!ty and

performance.

Shoutd you experience any problem you cannot easily

remedy, please contact your nearest Sears Service

Department. We have competent welt-trained techni-

cians and the proper tools to service or repair this un t,

Please read and retain this manual. The instructions will

enabte you to assemble and maintain your unit properly.

Always observe the "SAFETY RULES"..

MODEL

NUMBER 917254791

SERIAL

NUMBER

DATEOFPURCHASE

THE MODEL AN D SERIAL NUMBERS WILL BE FOUN D

ON A PLATE UNDER THE SEAT

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

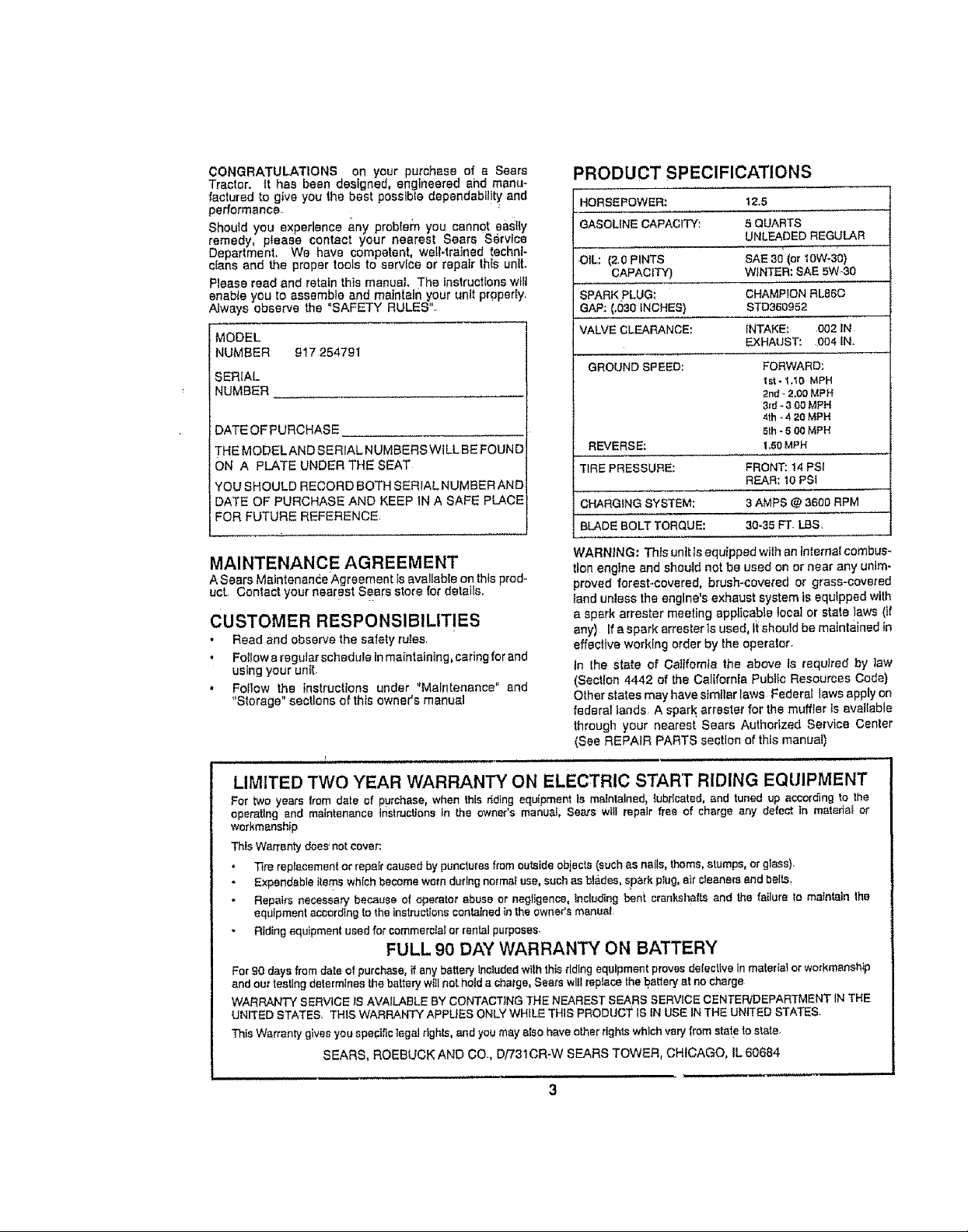

PRODUCT SPECIFICATIONS

HORSEPOWER;

.__

GASOLINE CAPACITY:

OIL: (2,0 PINTS SAE 30 (or t0W-30)

CAPACITY) WINTER: SAE 5W.30

"-SPAR_ CHAMPION RL860

GAP: (,030 INCHES) STD360952

VALVE CLEARANCE: [NTAKE: .002 IN

GROUND SPEED: FORWARD'.

REVERSE:

TIRE PRESSURE:

CHARGING SYSTEM;

BLADE BOLT TORQUE;

t2,5

5 QUARTS

UNLEADED REGULAR

, ,, , ,,

EXHAUST: 004 IN.

tst- t,10 MPH

2nd..2.00MPH

3_d-3 O0MPH

4th*4 _oMPH

5Ih-5 CoMPH

t,50 MPH

FRONT: 14 PSI

REAR: t0 PSI

3 AMPS @ 3600 RPM

30-35 FT_L.BS.

MAINTENANCE AGREEMENT

A Sears Malntenan(_e Agreement Isavailable on this prod_

uct. Conlact your nearest Sears store for details,

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regutar schedule in maintaining, caring for and

using your unit.

Fotlow the instructions under "Malntenance" end

"Storage" sections of this owner's manual

WARNtNG: This unit is equipped wilh an Internal combus_

tlon engine and should not be used on or near any unim-

proved forest-covered, brush-coveted or grass-covered

Iand unless the engine's exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if

any) If a spark arrestor Is used, It should be maintained tn

effecltve working order by the operator.

in Ihe state of California the above is required by law

(Section 4442 of the California Public Resources Code)

Other states may have sire!tar laws Federal laws apply on

federal lands A spark arrestor for the muffler Is available

through your nearest Sears Authorized Service Center

(See REPAIR PARTS section of this manual)

1, ,,,u ,H , 11 , ,. ,,

LIMITED TWO YEAR WARRANTY ON ELECTRIC START RIDING EQUIPMENT

For two years from date of purchase, when this ffding equipment is maintained, lubricated, and tuned up according to the

operating and maintenance instructionsin the owner's manual, Sears wfl! repair free of charge any defect in material or

workmanship

This Warranty does not cover;

Tirereplacement or repair caused by puncturesfrom outside objects (sUchas nails, theme, stumps, or glass).

Expendable items which become worn dudng ne_rna}use, such as blades, spark plug, e}r cleanersand balls,

Repairs necessary because el operator abuse or negligence, includingbent crankshaftsand the failure le matntaln the

equipment according to the instrucllons cenlainedIn the owner's manual

Ridingequipment used for commercial or rentaJpurposes,

FULL 90 DAY WARRANTY ON BATTERY

For g0 days fromdate ofpurchase, if any battery Inoludedwith this riding equipmentproves delectivein material orworkmanship

and our testing determines the battery willnot held a charge, Sears willreptace thebai,lery at ne charge

WARRANT'( SERVICE iS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT INTHE

UNITED STATES. THIS WARRANTY APPUES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

This Warranty givesyou specificlegal rights, and you may also haveother rightswhich v_ry from stats to slate.

SEARS, ROEBUCK AND CO., D/731CR-W SEARS TOWER, CHICAGO, IL 60684

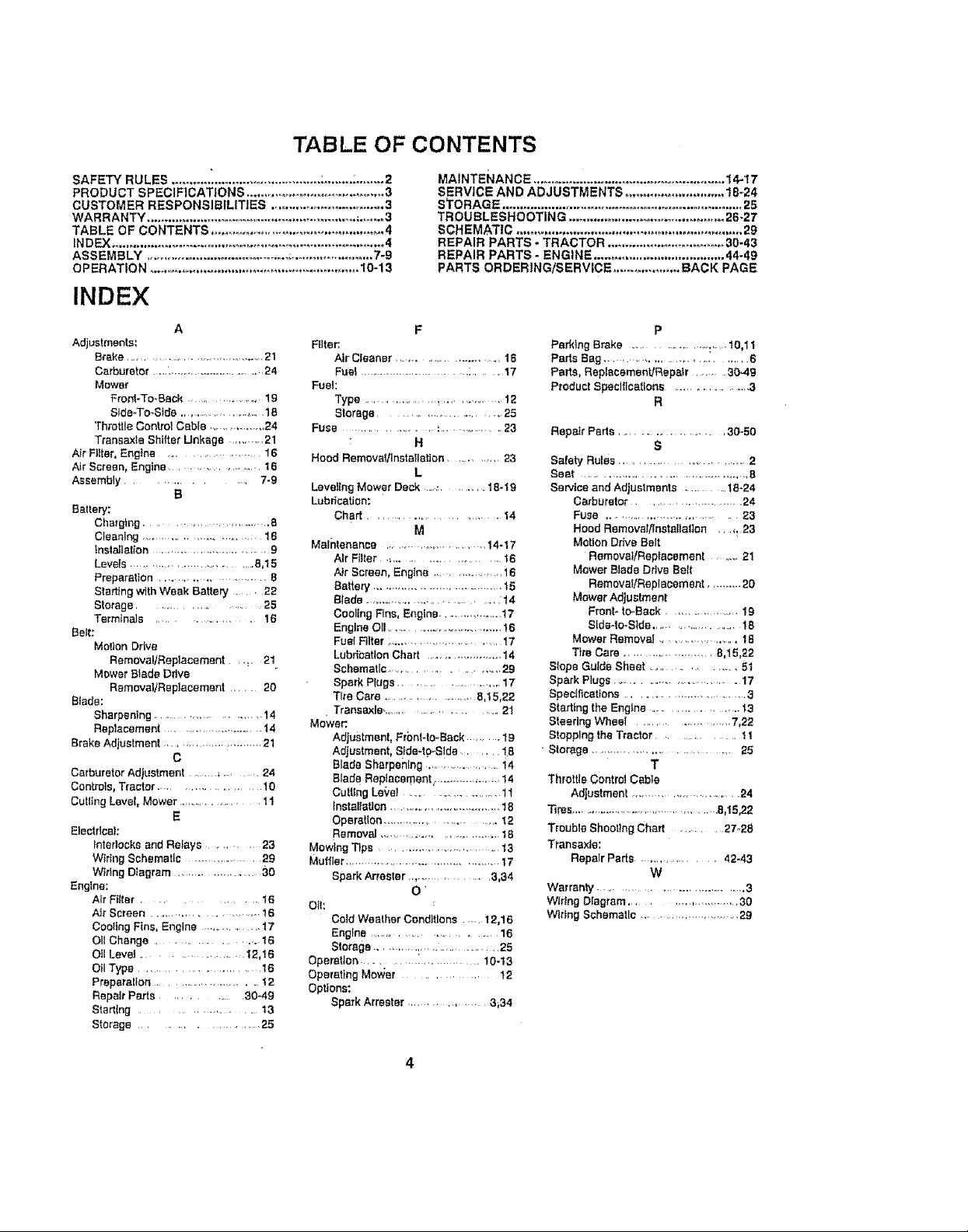

TABLE OF CONTENTS

SAFETY RULES ........... ............................... ;........ ;........ 2

PRODUCT SPECIFICATIONS ........................................ 3

CUSTOMER RESPONSIBILITIES ................................. 3

WARRANTY ............................................................... _........3

TABLE OF CONTENTS .................................................. 4

INDEX .............................................................................. 4

ASSEMBLY ........................................ ;....................... 7-9

OPERATION ............................................................ 10-13

INDEX

A

Adjustments,*

Brake ....................................... 21

Carburetor...L ............................. 24

Mower

Frot_-To-rBack - o ............. 19

Side-To..Side ......................... 1B

ThrottleControlCable ............... 24

Ttansaxle Shifter Unkage ........ 21

Air Fliter,Engine ....................... 16

Air Screen, Engine.................I6

Assembly ........................ 7-9

Battery:

Chmgtng........................8

Cleaning ............................. 16

tnslaltation ...............................g

Levels ............................... B,15

Preparation ............ ., ............. 8

Starting with Weak Battery ...... 22

Storage .................. 25

Terminals ....................16

Belt:

Molton Drive

Removal/Replacement ,,,21

Mower Blade Ddve

Removal/Replacement .....20

Btade:

Sharpening ......... ............... 14

Replacement ..................... 14

Brake Adjustment ............................. 21

Carburetor Adjustment ......._....... 24

Controls, Tractor.................. 10

Cutllng Level,Mower .................... 11

Electrlcah

_nterlocksand Relays ..... , 23

Wlring Schematic ........... ;29

Wiring Diagram ..................... ;_0

Engine:

AIr Filter ............... 16

Air Screen ........................ 16

Cool]ng Fins,Engine .............. 17

OII Change .................. I8

O11Level .............. I2,t6

OilType ........................... 16

Praparaiton ............................. 12

Repair Parts ................ 30.49

Starting .................... 13

Storage ....................... 25

B

C

E

Filter;

Air CIeaner, ,., ................ 16

Fuel .................. ;....... 17

Fuel:

Type ................... _................ 12

Storage ...................... 25

Fuse ................ _.............. 23

: H

Hood RemovafllnstallaUon ............. 23

LevelingMower Deck ..: .......... 18-19

Lubrication:

Chart .......................14

Malhtenance ...................... 14.17

Air Filter, ....................... 16

A_rScreen,Engine ................... 16

Battery ....................................15

Blade .................................... 14

Cooling Fins, Engine ...............17

Engine 011..................................... 16

Fuel Filter ;........................... 17

LubribatlonChart ........................ 14

Schematic ......................... 2g

Spark Plugs ......................17

Tire Care .................... BJ5,22

Tranaaxle_.........................21

Mower:.

Adjustment, Frbnt-tmBack .... 19

Adjustment, Stde-to-S!de...... 18

Blade Sharpening....................... {4

Blade Replacement..................... 14

Cuttlng Level ....................... 11

Installation ...................................18

Operation.............................12

Removal ..........................1B

Mowing Tips . .............................t3

Muffler ........................ ..................... 17

Spark Arreslar ..,.............. 3,34

Oil:

ColdWeather Conditions ...... 12,16

Engine............................ 16

Storage .......... :.................. 25

Operation ....................... 10-13

Operating Mov_er .................... 12

Options:

Spark Arrestor ................... 3_34

MAINTENANCE ........................................................ 14-17

SERVICE AND ADJUSTMENTS ............................ 18-24

STORAGE .................................................................... 25

TROUBLESHOOTING ............................................ 26-27

SCHEMATIC ................................................................ 29

REPAIR PARTS - TRACTOR ................................. 30-43

REPAIR PARTS- ENGINE ..................................... 44-49

PARTS ORDERING/SERVICE ................... BACK PAGE

F

Parking Brake .................. _', 3 " 10,1 t

Parts Bag ................................. 6

Parts, ReplacemenL/Repalr...... 80.49

ProductSpecifications .............. 3

RepairParis ....................... 30-50

L

M

O"

Safety Rules ........................... 2

Seat .......................................... ..8

Service and Adjustments .......... 18-24

Carburetor ................. 24

Fuse ........................................ 23

Hood Removaltlnstallalton .... ff23

Motion Drive Belt

Removal/Replacement ....... 21

Mower Blade Drive Belt

Removal/Replacement .......... 20

Mower Adjuelment

Front-to-Back .................. 19

Side-to*Side ......................... 18

Mower Removal ..................... 18

Tire Care ........................ 8,15,22

SlopeGuide Sheet .................... 51

Spark Plugs ...............................17

Specifications....................... 3

Startingthe Engine ........................ 13

Steering Wheel ....................... 7,22

Stopping the Tractor ............... 1t

, Storage ................................ 25

Throttle ControlCable

Adjustment ............................. 24

33ms..............................................8,15,22

Trouble ShootingChart ........27-28

Transaxle:

Repair Parts.. ............. 42.43

Warranty..............................3

Wiring Diagram ........................ 30

Wiring Schematic .......................... 29

P

R

S

T

W

ACCESSORIES AND ATTACHMENTS

,,, i, ,, ,, ,,i,H ,, ....................

These accessories and attachments were available when the unitwas purchased They are also available at most Sears ral_li outlets,

catalogand service centsrs M_stSearsst_rascan_rder_heseitemsf_ry_uwh_ny_upt_vld_themodeinumb____yo_rtract_r

ENGINE

SPARKPLUG MUFFLER

AIRFTLTER

GASCAN [ ENGINEOIL

STABILIZER

PERFORMANCE

Sears offema w_devarletyofattachments that ftt yourvehicle Many of theseare listedbelowwith bdef explanations of how they canhelp

you This iist wascurrentat the timeof publication; however,Itmay changeIn future years - mars attachments maybe added, changesmay

bemade In these attachments, orsome may notongarbeeva|tableorfityour mode! Contsctyour nearest Sears store for the accessories

and attachments that ere available for your unlL

Most of these attachments do notrequire additional hitches ar conversionkits (those that do are thdIcated) and are designedfor easy

at_ch[ng and de|achthg.

PERMANEX BAGGER lets you collect grass c_tpptngsand

leaves for a healthier, nearer {0ekinglawn. Two Permanex

containersherd 30-go!IonpiasUcbags,

LAWN SWEEPERS let you coltsotgrass cflppthgsand ]eaves

LAWN VACS forpowerfulcollection of heavygrass clippings and

tsavas. Wand attachment to pick up debds in hard-to-reach

places

CARTS make hauling easy Variety of sizes available

ROLLER for smoother lawn surface. 36-thch wide, 18 Inch

diameterwater-tight drumholds upto3B01be.of weight.Rounded

edges prevent harm to turf Adjustabte scraper automaUcally

cleansdrum

SPREADER/SEEDERS make seeding, fertl!lzthg, endweed klil-

fng easy. Broadcastspreaders are also asafui tot granularde-

icersand sand

CORING AERATOR takes email plugsout of _oll to allow robin-

lure and nutrients |o reach grass roots 36-thch swath 24

hardened steel codngtips. 150 Ib cepasItyweight tray

AERATOR promotesdeep root growth for a heaithy lawn. To-

pared 2,5" sisal spikes mounted on '_O-th.diameter d{scs punc-

ture holesin soilat close inferrersto tst moisture soak In. Steel

weight tray for Increased penetration.

DE'THATCHERtoosansso_{and flipsthatchand matted leaves to

lawn surface fat easy pickup Twentyspringline teeth. Usefulto

prepare bare areas for seeding. Available for front or rear

mounting

SPRAYERS use 12-volt DO electric motet that connects to the

traclor battery or other 12-vett source. Incfudes booms for

automatic spraying when pulling,end hand held wand for spot

spraying, Wand hasadjustable spray pattern. For applying

herbicides, Insecticides,fungicides, and liquid fertilizers

SNOW BLADE forsnowremovalonly. 14-inchhigh,42-Inch wide

blade clears38 tnchpathwhen angled leftor right Ratsas,lower_

with sidelever. Adjusfable skids;replaceable,reversiblescraper

bat (Usewith Urechatha,wheel weights,or rear drawbar weight)

SNOW'rHROWER has 404nch swath. Drum-typeaugerhandtes

powderyand weVheavy snow Mounts easItywith simple ptn

arrangement., Dischargechuteadiusts from tractorseat. 6-thch

dlametetspoutdtschargessnow lOtoSOfeet Uftcontrolled at

tractor seat. (Use with chains, wheel weights,or rear drawbar

weight)

TIRE CHAINS are heavy duty;closely spaced extraqarge cross

links give smoothride, outstanding traction

WHEEL WEIGHTS for rearwheels provideneeded tractionfor

snowremovalor dozing heavy materials. Inpatm. (30 [bs.each )

TRACTOR CAB has heavy duty vthyl fabric over tubular stset

frame,ABS plastictop; steerplasticw_ndshleldoffers360 degree

Vtstbltl_ Hinged metaldoors withcatch, Keeps operatorwarm

and dry Remove vinyland windshieldsfor use assun protector

In summer.

Optional accessories for traolor cab: lintsdi'Iamperod solid

safetyglass windshieldwithhand operated Wiper;12-vol! amber

caugonlighttar mounting on cab top.

TRACTOR COVER protects tractor from weather. Made of

Evolution3 fabric (water-repellent, extremely breathable, ltght

walght,soft, non-abrasive, pIfab{ein all temperatures, durable,

stathltsar[puncttJre resistant, wilt notshdnk or stretch)

MAINTENANCE

BLADES BELTS

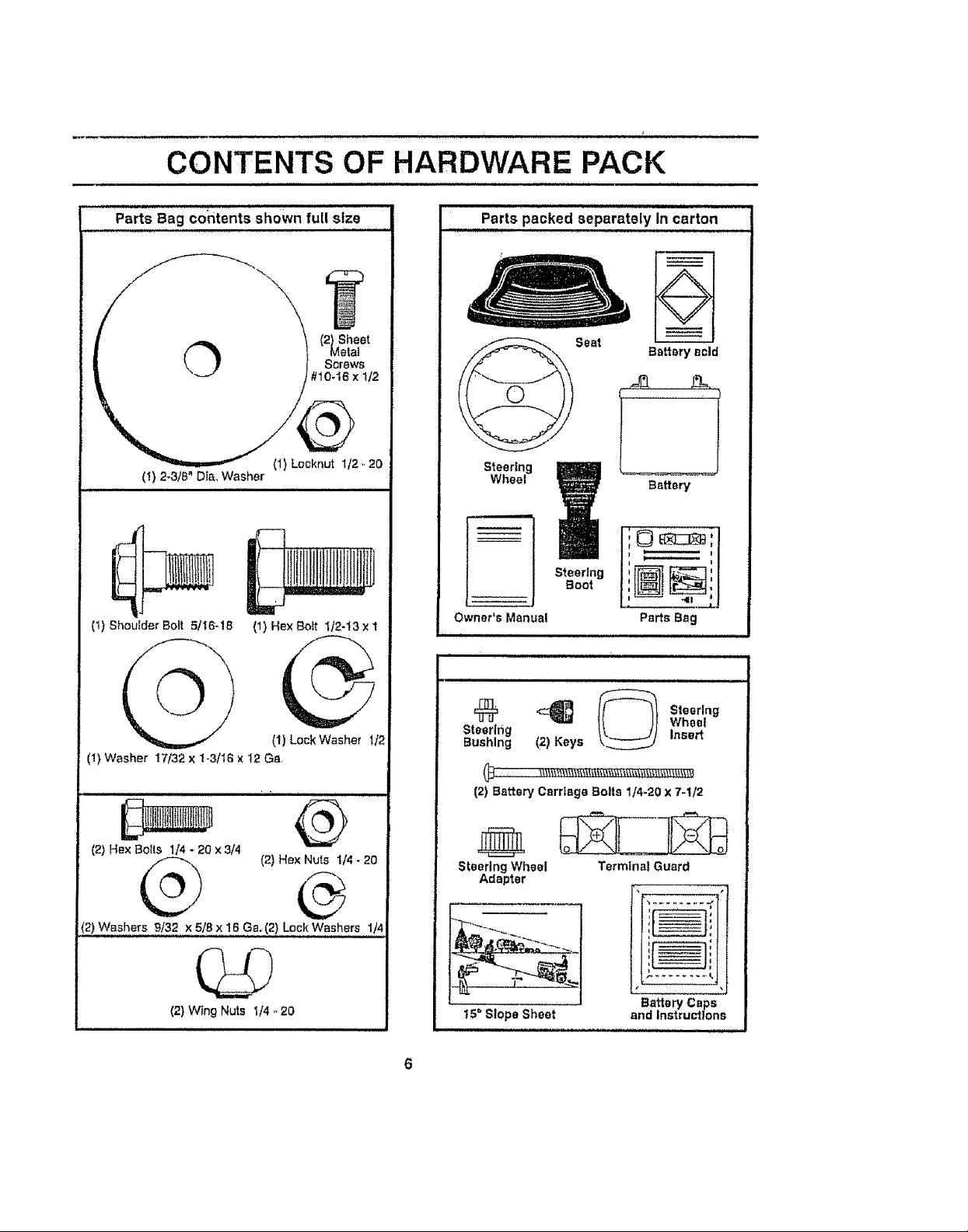

CONTENTS OF HARDWARE PACK

, L = J, ii i

Parts Bag contents shown full size

Parts packed separately In carton

,,=u,,i = =, i

(2) Sheet

Metal

©

(I) Shoulder Bolt 5/16-18 (1) Hex Bolt I/2-13 x I

(1) Washer 17/32 x 1-3/16 x 12 Ga,

Screws

#10-16 x 1/2

Seat

Steering

Wheel

Steering

Boot

Owner's Manual

Steering

% _ _ Steer,og

Bushing (2) Keys Insert

(2) Battery Carriage Bolts 1/4-20 X 7-I/2

Battery acid

I

Parts Bag

Wh0al

(2) Hex Baits 1/4 - 20 x 3/4

(2) Hex Nuts 1/4 - 20

®

12)Washers 9/32 x 5/8 x 16 Ga. (2) Lock Washers 1,!4,

121Wing Nuts I/4 ° 20

Steering Wheel Terminal Guard

Adapter

I i

i i

, 1

15=Slope Sheet and Instructions

Battery Caps

1

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set wi[f make assembly easier, Standard

wrench sizes are listed°

(I) 5/16" wrench (I) 3f4" wrench

(2) 7/16" wrenches Tire pressure gaugD

(1) t/2" wrench Screwdriver

(I) 9/16 =wrench Utility knife

When right or left hand Is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheei).

TO REMOVE UNIT FROM CARTON

UNPACK CARTON

Remove all accessible loose parts and parts cartons

from carton (See page 6)

, Cut along dotted lines on the carton, from top to

bottom, alt four comers of carton and lay panels fiat.

Check for any additional loose parts or cations and

remove

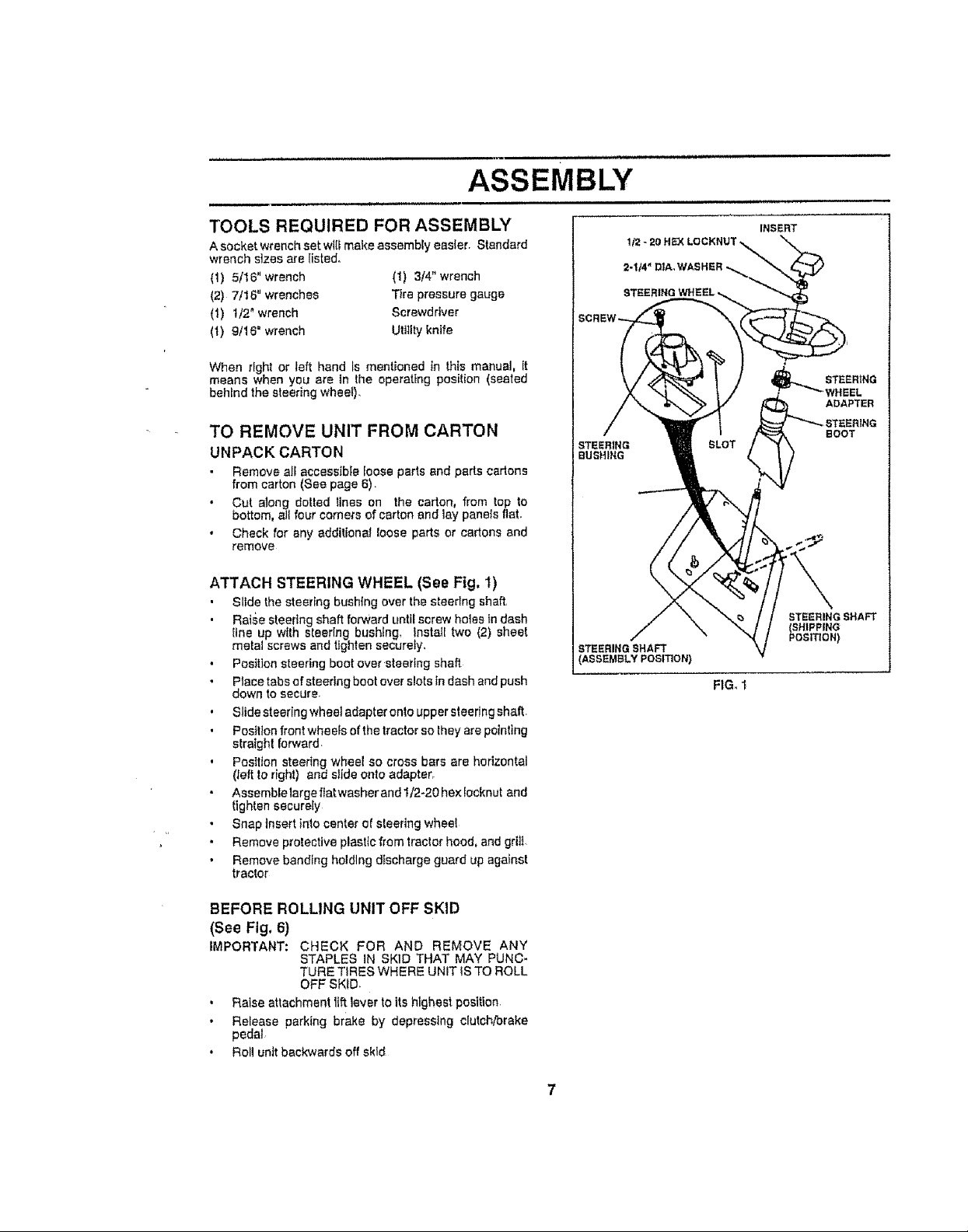

ATTACH STEERING WHEEL (See Fig, 1)

Slide the sleeting bush{ng over the steering shaft.

Raise steering shaft forward until screw holes in dash

tine up with steering bushtng, install two (2) sheet

metal screws and tighten securely,

Posii]on steering boot over steertng shaft

Ptace tabs af steering boot over slots in dash and push

down to secure.

Slide steering wheel adapter onto upper steering shaft.

Position front wheels of the tractor so lhey are pointing

straight forward.

, Position steering wheel so cross bars are horizontal

(left to right) and slide onto adapter,

Assemble large flatwasher and 1/2-20 hex [ocknut and

tighten securely

Snap insert into center of steering wheel

Remove protective plastic from tractor hoed, and grill

Remove banding holding discharge guard up against

tractor

STEERING SHAFT

(ASSEMBLY POSITION)

FIG_1

INSERT

STEERING SHAFT

=SHIPPING

OSITION)

BEFORE ROLLING UNIT OFF SKID

(See Fig. 6)

IMPORTANT: CHECK FOR AND REMOVE ANY

, Raise attachment Itft lever to itshlghBsl position,

Release parking brake by depressing clutch/brake

pedal

Roll unit backwards off skid

STAPLES IN SKID THAT MAY PUNC.

TURE TIRES WHERE UNiT iS TO ROLL

OFF SKID.

ASSEMBLY

HOW TO SET UP YOUR TRACTOR

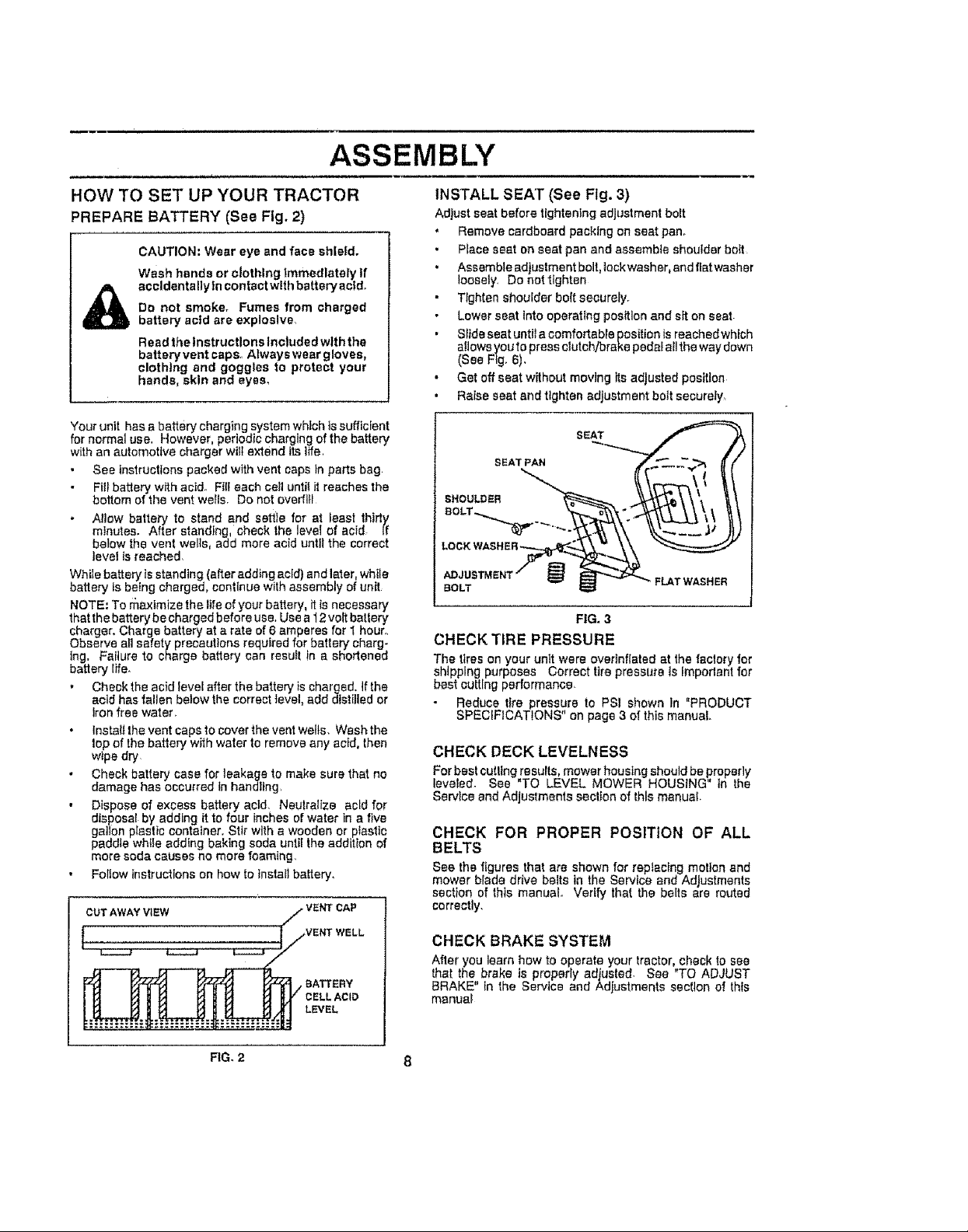

PREPARE BATTERY (See Fig. 2)

CAUTION: Wear eyeand face shield.

wash hands orclothing immedlatefy If

_i_l accidentally In contact with battery actd'

Do not smoke. Fumes from charged

battery acid are explosive

ReadtheInstructions Includedwith the

batteryvent caps. Atwayswear gloves,

clothing and goggles to protect your

hands, skin and eyes,

Your unit has a battery charging system which is sufficient

for normal use. However, periodic charging of the battery

with an automotive charger wilI extend its I_fe

See instructions packed with vent caps in parts bag

Flit battery with acid. Fill each cell until it reaches the

bottom of the vent wells. Do not overfill

Allow battery to stand and settle for at _east thldy

minutes. After standing, check the leve| of acid ff

below the vent wells, add more acid until the correct

level _sreached.

While battery isstanding (after adding acid) and later, while

battery is being charged, continue with assembly of unit

NOTE" To n_axlmize the ltfe of your battery, it is necessary

that the battery be charged before use, Usea 12volt battery

charger. Charge battery at a rate of 6 amperes for 1 hour.

Observe all safety precautions required for battery charg-

ing. Faiture to charge battery can result in a shortened

battery life.

* Check the acid level after the battery is charged, tfthe

acid has fallen below the correct level, add distilled or

iron free water,

Instal{ lhe vent caps to cover the vent wells, Wash the

top of the battery with water to remove any acid, then

wtpe dry

Check battery case for leakage to make sure that no

damage has occurred tn handling,

Dispose of excess battery acid. Neutralize acid for

disposal by adding it to four inches of water in a five

gallon plastic container. Stir with a wooden or plastic

paddle while adding baking soda until the addition of

more soda causes no more foaming.

Follow instructions on how to install bsltery.

CUTAWAYVIEW / VENTCAP

I J/VENT WELL

_/eAI-fERY

9 _ IIB _1I__ _1B,f" CELLAClO

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment bolt

. Remove cardboard packing on seat pan.

Place seat on seat pan and assemble shoulder bolt

Assembte adjustment bolt, lock washer, and flstwasher

loosely, Do not tighten

Tighten shoulder bolt securely.

Lower seat into operating position and sit on seat.

Slide seat uoti_a comfortable position isreachedwhlch

allows you to press dutch/brake pedal allthe way down

(See Fig. 6).

Get off seat without moving its adjusted position

, Raise seat end ttghten adjustment boil securely,

SEAT

SEATPAN

SHOULDER

BOLT

BOLT

FIG. 3

CHECK TIRE PRESSURE

The tires on your unit were over_nfIaled at the taclory for

shipping purposes Correct tire pressure is important for

best cutting performance_

Reduce ttre pressure to PSI shown tn "PRODUCT

SPECIFICATIONS" on page 3 of this manual.

CHECK DECK LEVELNESS

Forbest cuttingresults,mowerhousing should beproperly

leveled- See "TO LEVEL MOWER HOUSING" tn the

Service and Adjustments section of this manual,

CHECK FOR PROPER POSITION OF ALL

BELTS

See thefigures that are shownfor replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adiueted See TO ADJUST

BRAKE" In the Service and Adjuslments section of this

manual

FIG. 2 8

ASSEMBLY

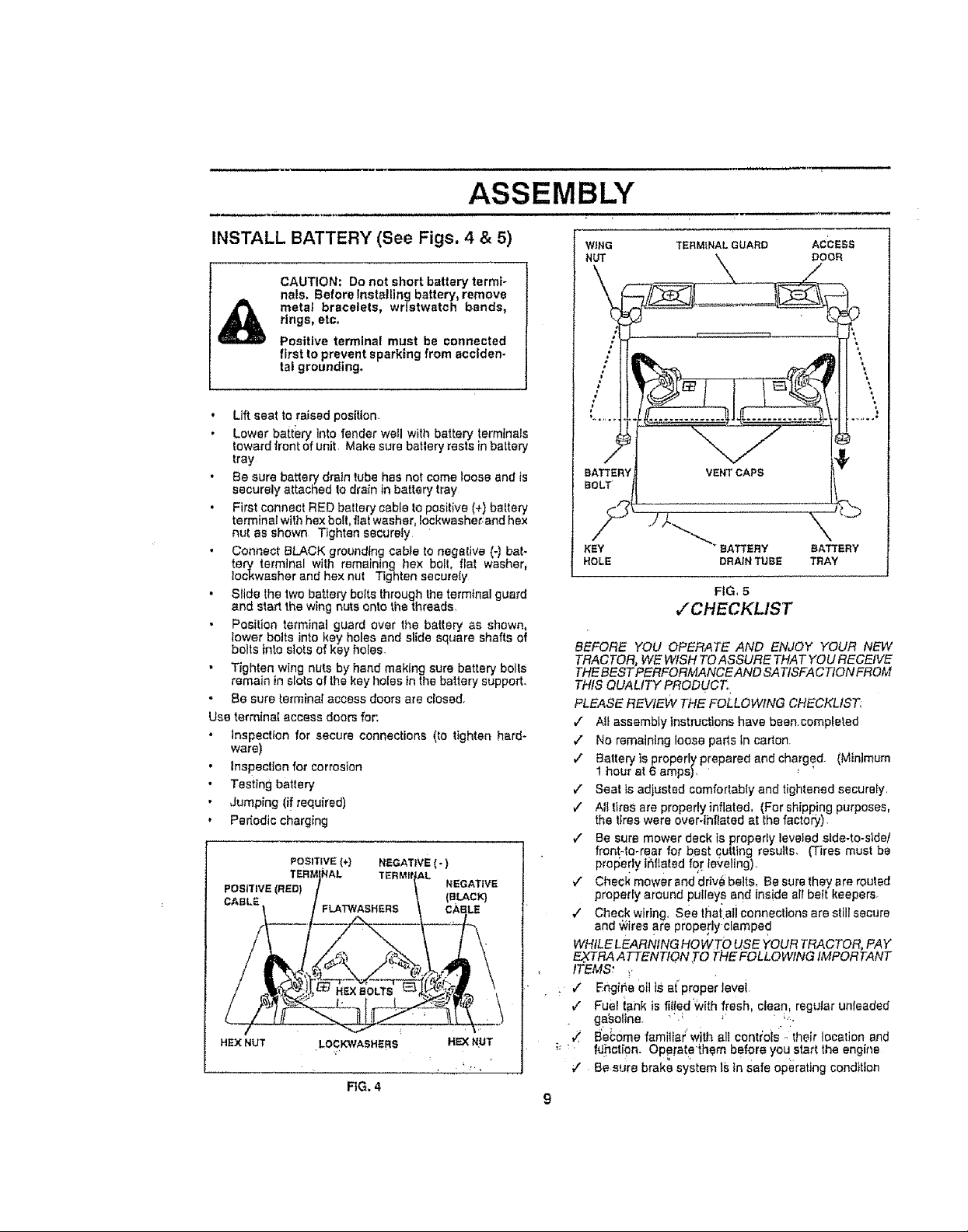

INSTALL BATTERY (See Figs, 4 & 5)

CAUTION: Do not short battery termi-

nals. Before Installing battery, remove

metal bracelets, wristwatoh bends_

rings, etc0

Positive terminal must be connected

firstto prevent sparking from acciden-

tal grounding.

, Lift seat to raised position.

Lower battery into fender wslI with battery terminals

toward front of unit Make sure battery rests inbattery

tray

Be sure battery drain tube has not come loose and is

securely attached to drain in battery tray

First connect RED battery cable to posilive (+) flaltery

terminal with hex boIt, flat washer, lockwasherand hex

nut as shown Tighten securely '

Connect BLACK grounding eabte to negative (-) bat-

tery terminal with remaining hex boil, fiat washer,

Iockwasher and hex nut Tighten secure{y

, Slide the two battery bolts through the terminal guard

and start the wing nuts onto the threads

Position terminal guard over the battery as shown,

lower bolts into key holes and slide square shafts of

bolts into slots of key holes.

Tighten wing nuts by hand making sure battery bolls

remain in slots of the key holes in the battery support.

Be sure terminal access doors are ctosed.

Use termina{ access doors for:

inspection for secure connections (Io tighten hard-

ware)

, Inspection for corrosion

, Testing battery

Jumping (if required)

, Periodic charging

POSITivE t*) NEGATIVE( -)

POSITIVE(RED) NEGATIVE

"fERMttIAL

(BLACK)

WING TERMINAL GUARD ACCESS

NUT DOOR

KEY BATTERY BATTERY

HOLE DRAIN TUBE TRAY

FIG, 5

,."CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRAGTOR, WE WfSH TO ASSURE THAT YOU RE CEfVE

THE BEST PERFORMANCE AND SA TISFA CTION FROM

THIS QUALITY PRODUCT,

PLEASE REVIEW THE FOLLOWING CHECKLIST,

,/ Alf assembly instructi_:,nshave been. completed

v" No remainEng loose parts in carton.

,/ Battery is properly prepared and charged. (Minimum

1 hour at 6 stops). _ '

,/ Seat is adjusted comfortab{y and tightened securely.

,/ All tkes are properly inflated. (For shipping purposes,

the tires were over-inflated at the factor).

,,/ Be sure mower deck is proper_y leveled side-to-side/

front-to-rear fo_' best cutting results. (Tires must be

prol::;eriy ir_tlalsdfor tee'sling).

v" Check mower and drive'belts, Be sure they are routed

properly around pulleys and inside air bert keepers.

V' Check wiring. See that all connections are still secure

and *ires are propedy clamped

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

_RA A TTENTION.T ° THE FOLLO WING IMPORTANT

fTEMS_ _.

: ,/ Engir_e ell is a{ proper levet

,/" Fuel iank is fi{ted'with fresh, clean, regular un(eaded

HEX NUT LOCKWASHERS HEXNUT

FIG. 4

BeCome familia(with eli contiois .their location and

;_ fdhot[on. Opec'atethem before YoU start the engine

v" Besure brake system ls tn safe operating cond_tlon

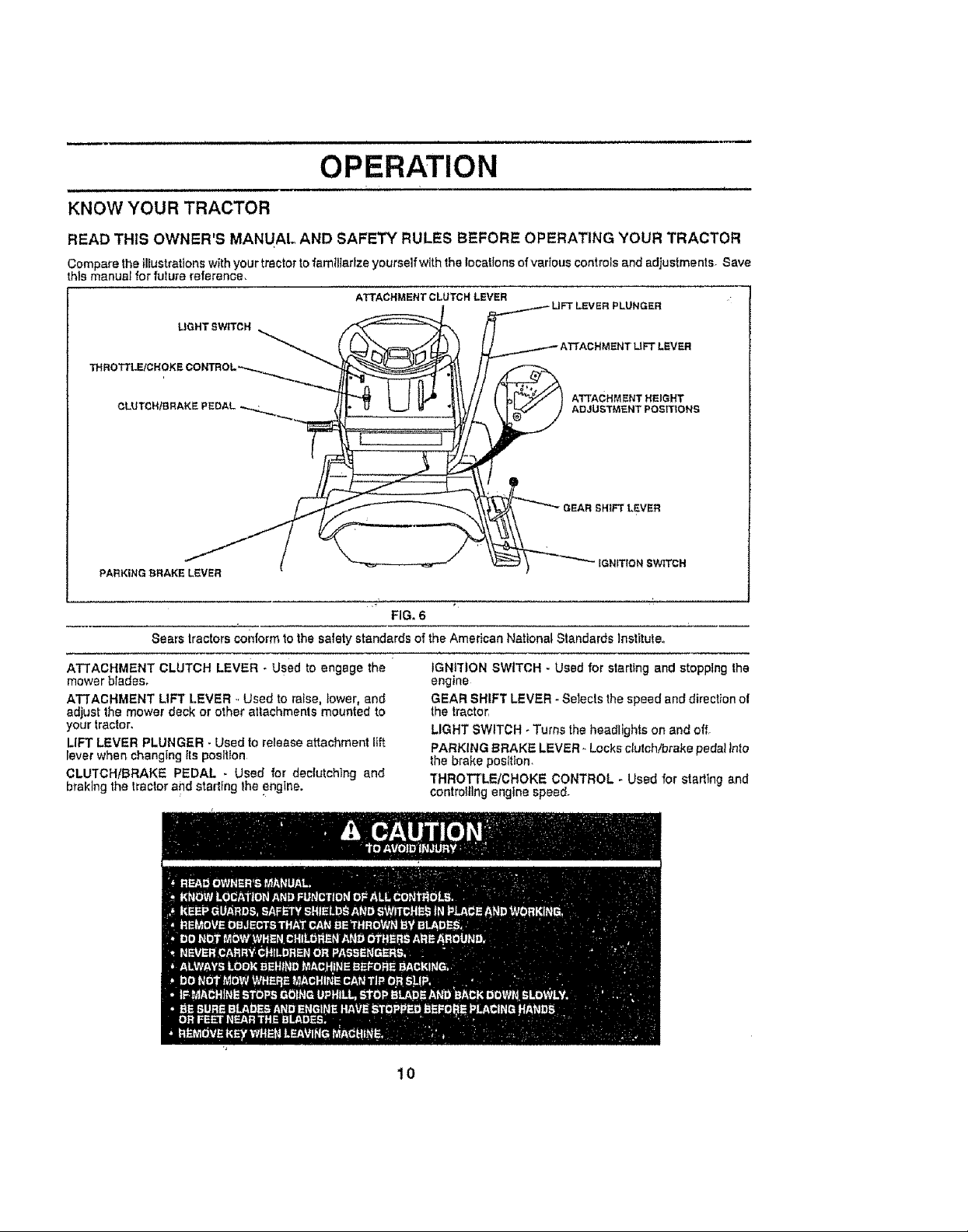

LIGHT SW_CH

OPERATION

CLUTCHiBRAKE PEDAL

PARKING BRAKE LEVER

Sears Iractors conform to the safety standards of the American National Standards institute,,

ATTACHMENT CLUTCH LEVER - Used to engage the '

mower blades,

ATTACHMENT LIFT LEVER - Used to raise, lower, and

adjust the mower deck or other attachments mounted to

your tractor.

LIFT LEVER PLUNGER - Used to release attachment lift

tever when changing Its position

CLUTCH/BRAKE PEDAL _ Used for declutchlng and

braking the tractor and starling the engine.

ATTACHM ENT HEIGHT

ADJUSTMENT POSITIONS

IGNITION SW_TCH

FIG. 6

tGNI'rION SWITCH - Used for starting and stopping the

engine

GEAR SHIFT LEVER - Setects the speed and direction of

the traeto_

LIGHT SWITCH - Turns the headlights on and off

PARKING BRAKE LEVER - Locks clutch!brake pedal into

the brake position

THROTTLE/CHOKE CONTROL o Used for starting and

contre}llng engine speed.

10

OPERATION

The operat on of any ractor can result inforeign objects thrown into the Byes which can resull

in severe eye damage_ Afways wear safety glasses or eye shields while operating your tractor

or performing any ad ustments or repairs We recommend Wide Vision Safety Mask for over

the spectacles or standard safety g asses, available at Sears Retail or Catalog Stores.

HOW TO USE YOUR TRACTOR

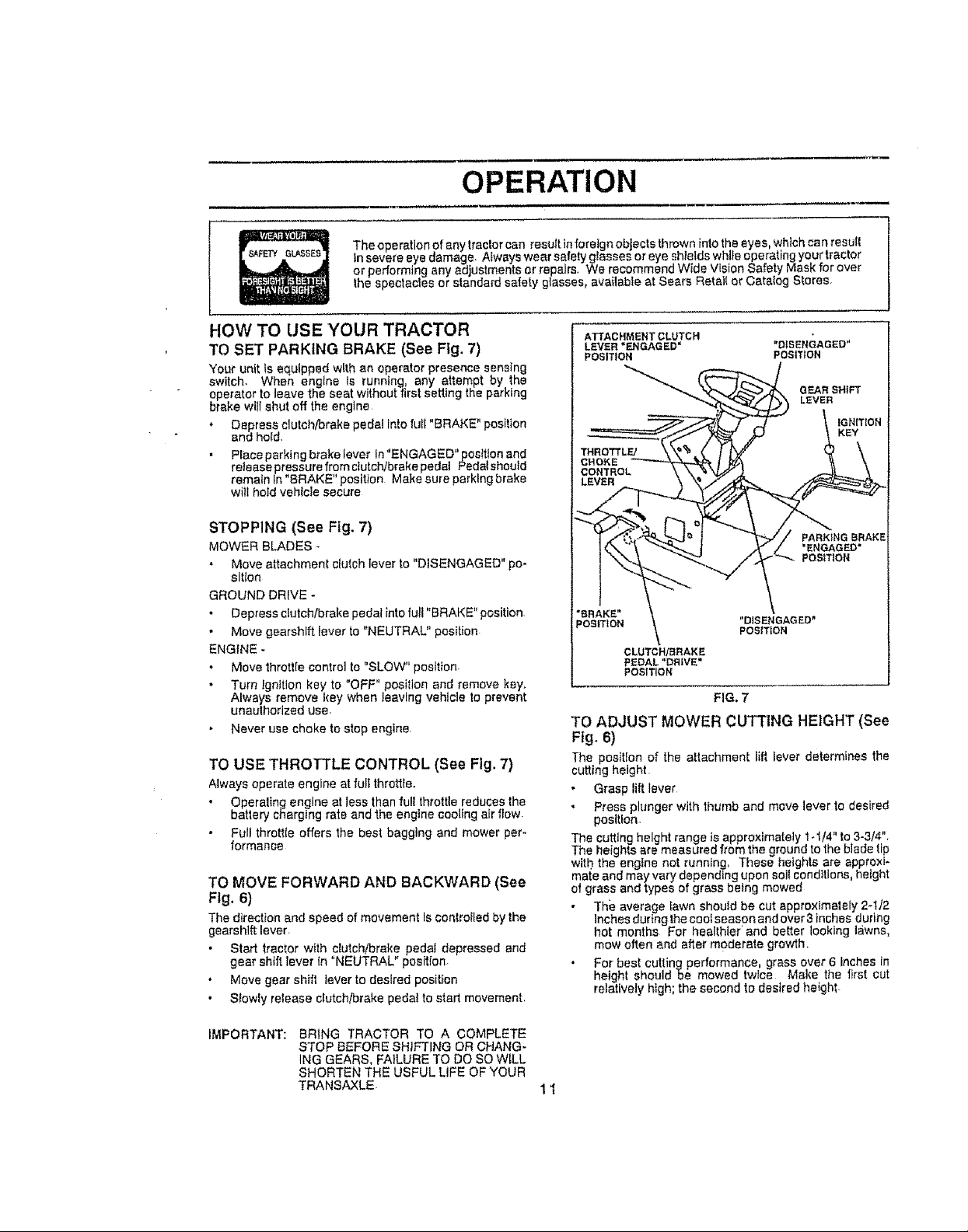

TO SET PARKING BRAKE (See Fig. 7)

Your unit Is equipped with an operator presence sensing

switch. When engine ts running, any attempt by the

operator to leave the seat without first setting the parking

brake will shut off the engine

* Depress clutch/brake pedal Into fuI[ "BRAKE" position

end hold.

Place park!ng brake lever In"ENGAGED" position and

retease pressure from dutch/brake pedal Pedat should

remain In BRAKE position Make sure parking brake

will hold vehicle secure

STOPPING (See Ftg, 7)

MOWER BLADES

Move aftachment clutch lever to "DISENGAGED" po-

sition

GROUND DRIVE -

Depress dutch/brake pedal into futl "BRAKE" position

Move gearshift lever to "NEUTRAL" position

ENGINE -

Move throtlIe controJ to "SLOW" posit}on

Turn ignition key to "OFF" posilion and remove key.

Always remove key when leaving vehicle to prevent

unauthorized use.

Never use choke to stop engine,

TO USE THROTTLE CONTROL (See Fig. 7)

Always operate engine at full throttled

Operating engine at less than full throttlereducesthe

battery charging rate and the enginecooling air flow

Full throttle offers the best bagging and mower per-

formance

TO MOVE FORWARD AND BACKWARD (See

Fig, 6)

The direction and speed ofmovement Iscontrolled by the

gearshift lever,

Start tractor with clutch/brake pedal depressed and

gear shift lever in"NEUTRAL" position,

Move gear shift leverto desired posiUen

SIowly release clutch/brake pedalto start movement,

ATTACHMENT CLUTCH

LEVER "ENGAGED _ "DISENGAGED"

POSITION POSITION

GEAR SHIFT

LEVER

PARK}NG BRAKE

'ENGAGED"

"DISENGAGED"

POSITION

CLUTCH/BRAK E

PEDAL "DRIVE"

POSITION

FIG. 7

TO ADJUST MOWER CUTTING HEIGHT (See

Fig. 6)

The position of the attachment lift lever determines the

cutting height,

Grasp lift lever

Press plunger with thumb and move lever to desired

position-

The cutting height range is approximately 1ol/4" to 3-3/4".

The heights are measured from the ground to the blade tip

with the engine not running, These heights are approxi-

ma{e and may vary depending upon soil condltlons, height

of grass and types of grass being mowed

The average _awn should be cut approximately 2-!/2

Inches during the cool season and over 3 inches during

hot months For healthier and better looking lawns,

mow often and after moderate growth.

For best cutting performance, grass over 6 Inches In

height should be mowed twice Make the first cut

relatively high; the second to desired height.

IMPORTANT: BRING TRACTOR TO A COMPLETE

STOP BEFORE SHIFTING OR CHANG-

ING GEARS, FAILURE TO DO SO WILL

SHORTEN THE USFUL LIFE OF YOUR

TRANSAXLE.

11

OPERATION

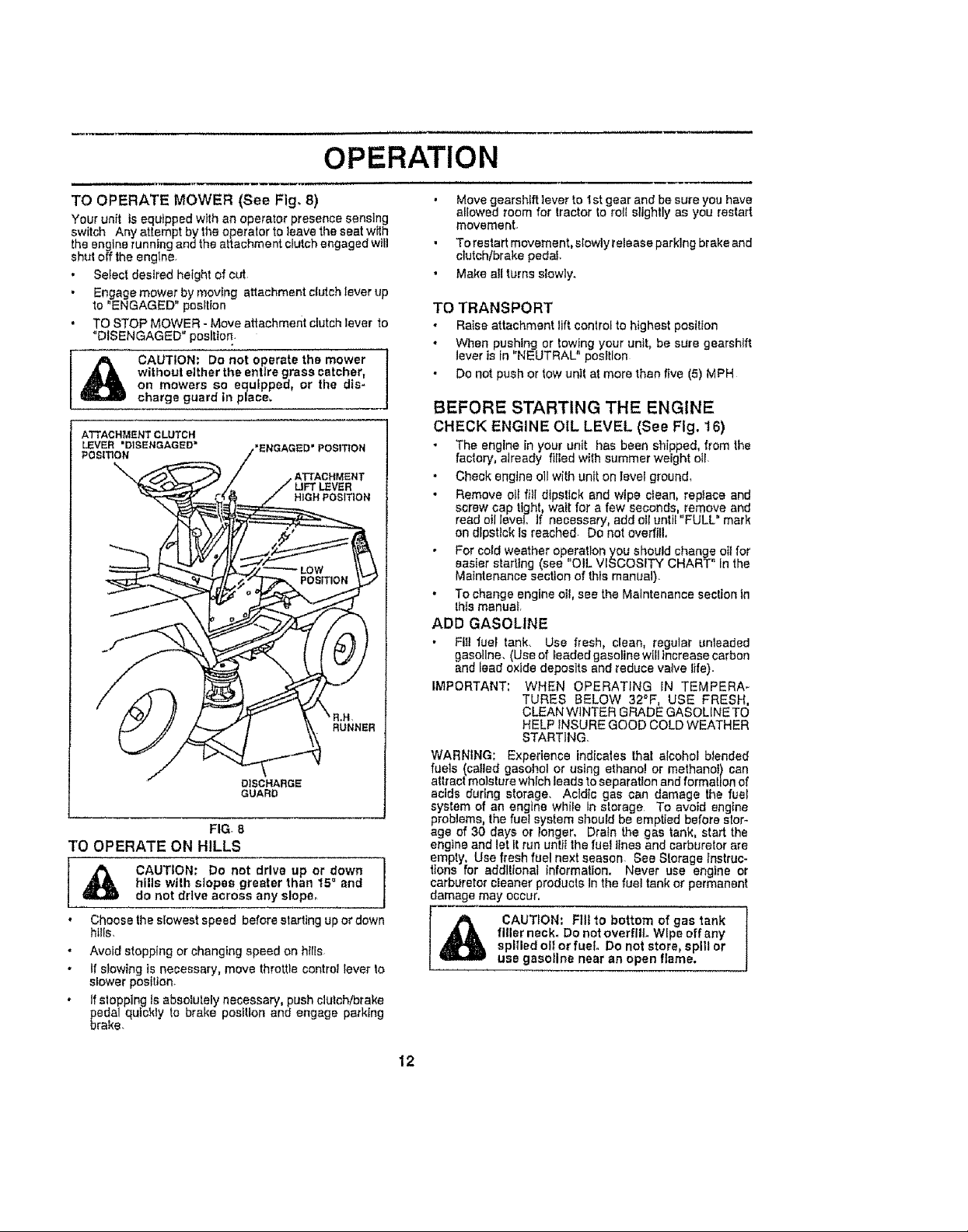

TO OPERATE MOWER (See Fig 8)

Your unit is equipped with an operator presence sensing

switch Any attempt by the operator to leave the seat w_th

the engine running and the attachment clutch engaged will

shut off the englne.

Setect desired height of cut

Engage mower by moving attachment clutch lever up

to ENGAGED posttion

, TO STOP MOWER - Move attachment clutch laver to

*'DISENGAGED" position:

without either the entire grass catcher,

I /_, CAUTION; Do not operate the mower

ATTACHMENTCLUTCH

LEVER "DISENGAGED"

POSITION

on mowers so equipped, Dr the dis-

charge guard in place,

"x,

FIG 8

DISCHARGE

GUARD

ATTACHMENT

LIFT LEVER

HtGH POSITION

RUNNER

TO OPERATE ON HILLS

I Z% CAUTION, Do not drive up or downdlt

' Choose the slowest speed before starting up or down

hills with slopes greater than 15_ and

do not drive across any sloper

htlls,

Avoid stopping or changing speed on hi{is

If slowing is necessary, move throttle control Fever Io

stower position_

if stopping iS absolutely necessary, push dutch/brake

pedal qutckly to brake position and engage parking

brake,

Move gearshift lever to ist gear and be sure you have

allowed room for tractor to rotl slightly as you restarf

movemenL

TOrestart movement, slowly release parking brake and

clutch/brake pedal

Make all turns stowly.

TO TRANSPORT

Raise attachment lift control to highest position

• When pushing or towing your unit, be sure gearshift

lever is In "NEUTRAL" position

Do not push or tow unit at more than five (5) MPH

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 16)

The engine [n your unit has been shipped, from the

factory, already tilted with summer weight e_l

Check engine o11with unit on level ground,

Remove oil fill dipstick and wipe dean, replace and

screw cap tight, wait for a few seconds, remove and

read oil level. If necessary, add oil unlit "FULL" mark

an dipstick Is reached Do not overfill.

For cold weather operation you should change oil for

easier starting (see "OIL VISCOSITY CHART" In the

Maintenance section of this manual).

• To change engine oli, see the Maintenance section in

lhts manual,

ADD GASOLINE

Ftlt fuel tank Use fresh clean regular unleaded

gasoline. (Use of leaded gasoline will increase carbon

and lead oxide deposits and reduce valve life).

IMPORTANT; WHEN OPERATING IN TEMPERA-

WARNING; Experience indicales {hal alcohol blended

fuels (called gasollol or using ethane! or methanol ! csn

attract moisture which leads to separation and forma!ion el

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer, Dra_n the gas tank, start the

engine and let it run untII the fuel lines and carburetor are

empty, Use fresh rue! next season See Storage Instruc-

tions for addllional information. Never use engine or

carburetor cleaner products In the fuel tank or permanent

damage may occur.

I& CAUTION; FIllto bottom of gas tank

TURES BELOW 32°F, USE FRESH,

CLEAN WINTER GRADE GASOLINETO

HELP iNSURE GOOD COLD WEATHER

STARTING.

filler neck. Do not overfill Wipe off any

spilled oil or fuel. Do not store spill or

use gasoline near an open fame.

12

OPERATION

TO START ENGINE (See Fig. 7)

When starting engine for the first time or if engine has run

out of fuel_ ttwilt lake extra cranking time to move fuel from

the tank to the engine

Depress the clutch/brake pedat and set the parking

brake

Place gearshift lever In "NEUTRAL" position.

Move attachment clutch to "DISENGAGED" position,

Move throltta control lever to"CHOKE" position for cold

engine start, For warm engine start, move throttle

control to =FAST" position,

• Turn Ignition key clockwise to "START" position and

release key as soon as engine starts, Do not run

starter continuously for more than fifteen seconds per

minute. If engine does not start after severalaltempls,

move throttle control to "FAST' position, wait a few

minutes and try agath

. When engine starts, slowly move throttle control iever

to desired running speed

Allow engine to warm up for a few minutes before

engaging drive or attachment ciulch

NOTE: If at a high altitude (above 3000 feet or .9I

kilometers) or In cotd temperatures (below 32"F), the

carburetor fuel mixture may need to be adjusted for best

engine performance See 'TO ADJUST CARBURETOR"

in the Service and Adlustments section of this manuat

MOWING TIPS

Tire chains cannot be used when the mower housing

is attached to unit,,

• Mower should be properly leveled for best mow!,ng

performance, See "TO LEVEL MOWER HOUSING In

the Service and Adtustments section of this manual,,

Use the runner on the right hand side of mower as a

tghuide,The blade cuts approximately an Inch outside

s runner (See Fig. 8) r

• The left hand side of mower should be used for trim-

mlng

Drive so that clippings are discharged onto the area

that has been cut. Have the cut area to the right of the

machine. This will result in a more even distribution of

clippings and more uniform cutting.

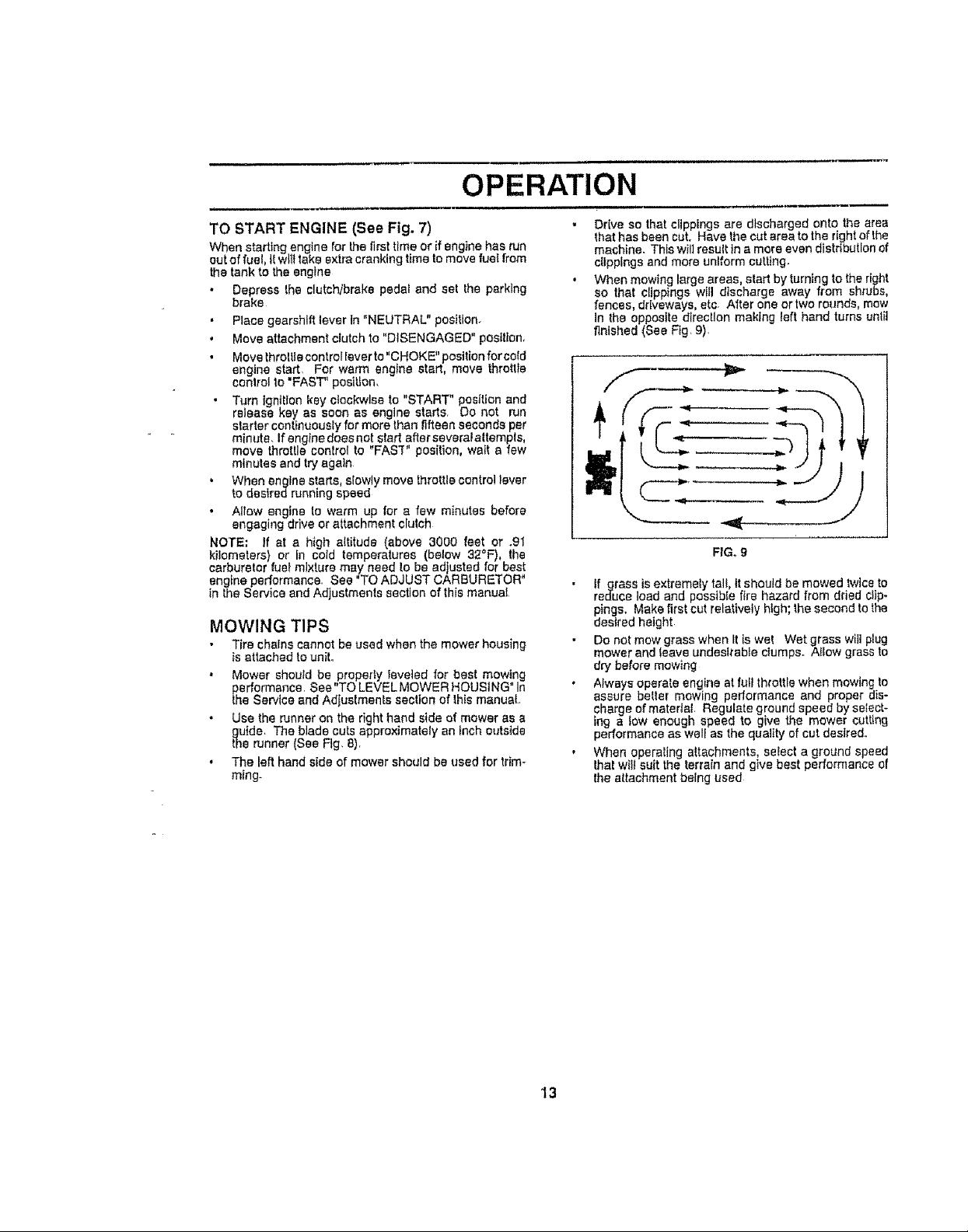

When mowing large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

In the opposite direction maklng left hand turns until

finished (See Fig, 9),

FtG. g

tf grass ise×tremety tall it shouJd be mowed twice to

reduce load and possible fire hazard from dr ed c p.

pings. Make first cut relatively high; the second to the

desired height

Do not mow grass when It Is wet Wet grass will plug

mower and leave undes#abta dumps. Atlow grass to

dry before mowing

A_ways operate engine at ful! throttlewhen mowing to

assure better mowing performance and proper dis-

charge of material, Regulate ground speed by select-

ing a low enough speed to give the mower cutting

performance as well as the quality of cut deslred.

When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used

'I3

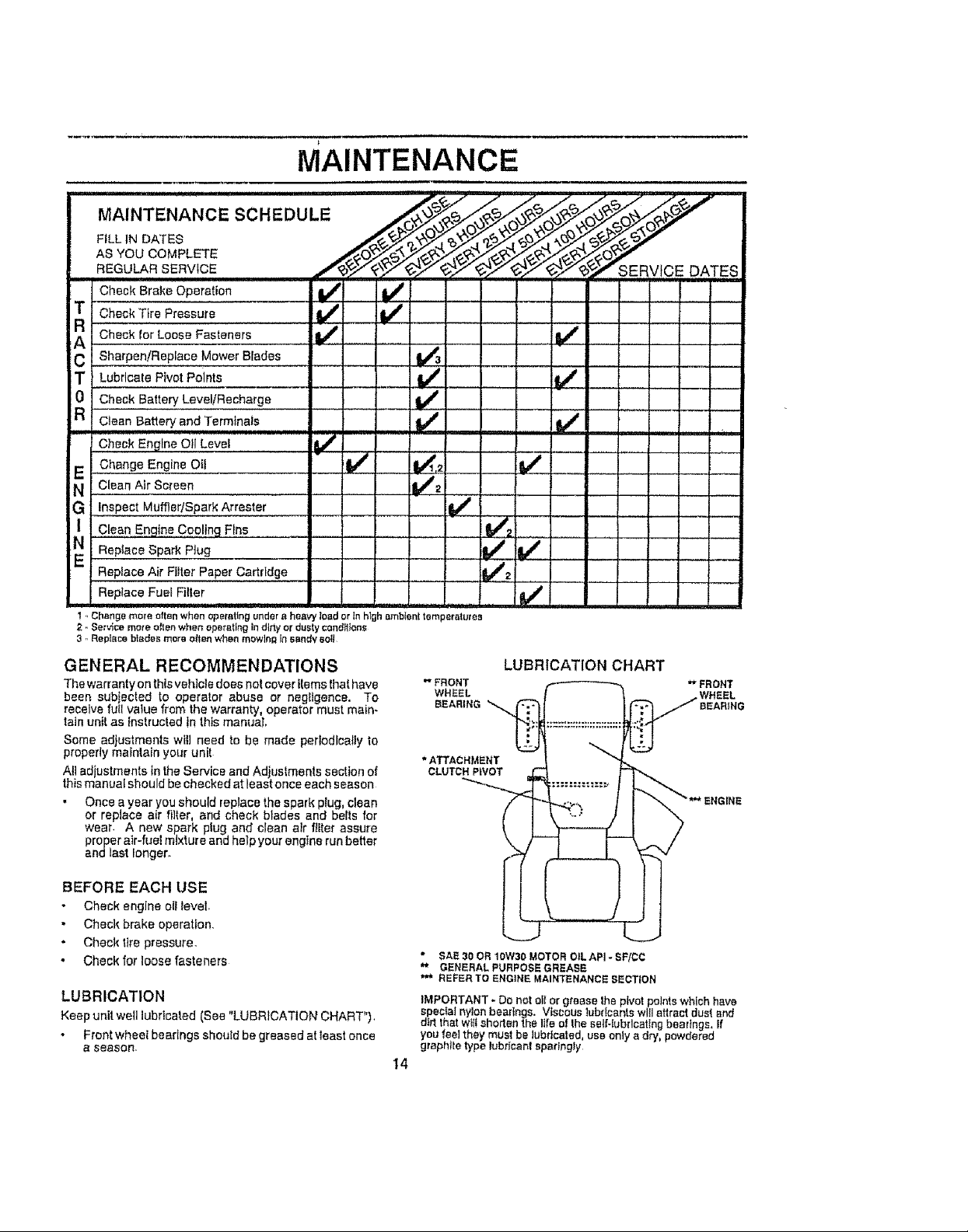

MAINTENANCE

F,LL,=OAT=S °

O=eckBrakeOpe=t,ooiJ !"' 'V,'

T C=.ckT_rePrese=rer_ !I/

I Check for Loose Fasteners li_

C SharpenlReplace Mower Blades _ =

T Lubrlca,e Pivot Points if _ l

0 Check Battery Level/Recharge V e

a Clean Battery and Terminals V # ......... V f

Check Engine OII Level

E Cha.0eE_gineO, V" -._.2 V'

Clean Air Screen V#2i

N

G Inspect MUffler/Spark Attester V _'

I C!ean F-ri!!no Co01tng Fins _ . .

I Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

I"r Changemoreoftenwhen operatingunder,aheavyloadatin highambienttemperatuteB

2. Serv;cemeteoJtenwhenoperatingindirtyor dustycondt_ens

3,,Repl_ceblades moree/tenwhenmowing[nsandysot

GENERAL RECOMMENDATIONS

The warranty on this vehicle does not cover ilems that have

been subjected to operator abuse or neglgence, To

receive full value from the warranty, operator must main-

tain unit as instructed in this manual

Some adjustments will need to be made pertodlcaly to

properly maintain your unl

All ad ustments In the Service and Adjuslments section of

this manua[ shou d be checked at least once each season

Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear. A new spark ptug and clean air filer assure

proper air-fue! mixture and help your engine run better

andlast longer.

* ATTACHMENT

CLUTCHPIVOT

iv' V,

LUBRICATION CHART

FRONT _ *"FRONT

WHEEL ; - WHEEL

.............. C_

BEFORE EACH USE

Check engine el level,

Check brake operation,

Check tire pressure,

Check for loose fasteners

LUBRICATION

Keep unit wei lubricated (See "LUBRICATION CHART"),

Front wheel bearings should be greased at feast once

a season.

" SAE 30 OR 10W30 MOTOR OiL API - SF/CC

** GENERAL PURPOSEGREASE

REFER TO ENGINE MAINTENANCE SECTION

IMPORTANT. Do not ot or grease Ihe pivot points which have

special nylon bearings. Viscous lubricants wil attract dustand

d_rtthat wit shorten the life of Ihe set-lubrlcatlng bearings, if

you feel they must be lubricated, use onlya dry, powdered

graphite type lubricant sparingl)'

14

MAINTENANCE

TRACTO R

Always observe safety ru_es when performing any maim

tenance,

TIRES

Maintain proper err pressure in atl tires (See "PROD-

UCT SPECIFICATfONS on page 3 of thts manual).

Keep tires free of gasol.rne, oi!, or Jnsect control chemi-

cals which can harm rubber-

Avoid stumps, stones, deep ruts, sharp oblects and

other hazards that may cause tire damage,

BLADE CARE

For best results mower blades must be kept sharp. The

blades can be sharpened with afile or ona gdnd_ng wheel.

We suggest they be sharpened or replaced after every 25

hours of mowing Check blades more often if mowing in

sandy conditions

Do not attempt to sharpen blades while they are on the

mower

Replace bent or damaged blades.

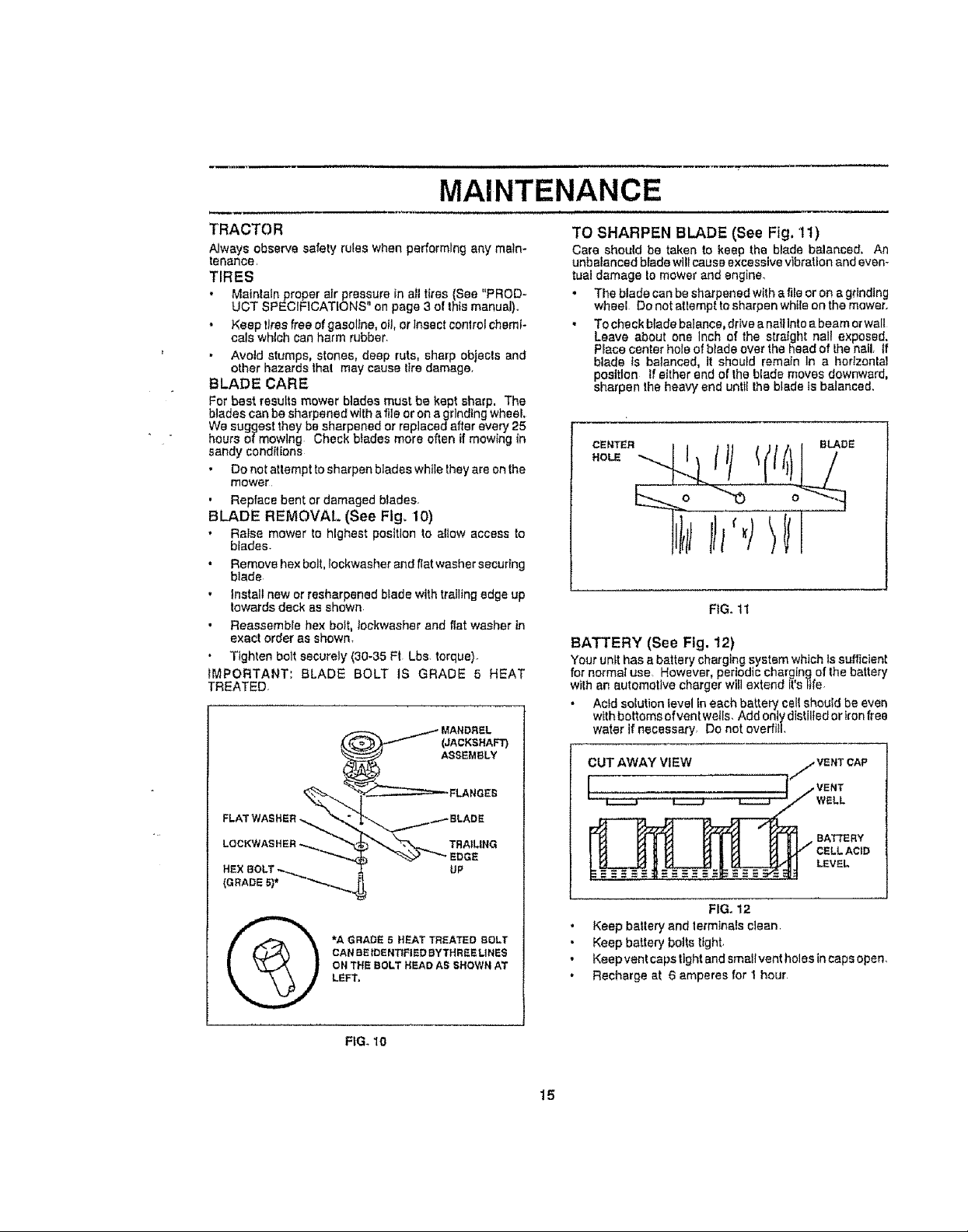

BLADE REMOVAL (See Fig, 10)

Ralse mower to highest position to allow access to

blades.

Remove hex bolt, lockwasher and flat washer securing

blade

install new or resharpened b_ade with trail}ngedge up

towards deck as shown

Reassemble hex bolt, $ockwasher and flat washer in

exact order as shown.

Tighten belt securely (30-35 Ft Lbs, torque),

iMPORTANT: BLADE BOLT IS GRADE 5 HEAT

TREATED.

TO SHARPEN BLADE (See Fig. 11)

Care should be taken to keep the blade balanced, An

unbalanced b_ade will cause excessive vibration and even-

tual damage io mower and engine_

. The blade can be sharpened with a file or on a grinding

wheel Do not attempt to sharpen whtle on the mowaro

TOcheck blade balance, drive a naillnto a beam or wall

Leave about one inch of the straight nail exposed.

Place center hole of blade over the head of the nail. tf

blade is balanced, it should remain In a horizontal

position If either end of the blade moves downward,

sharpen the heavy end untie the blade _s balanced.

CENTER

HOLE

FIG. 11

BATTERY (See Fig. 12)

Your unit has a battery charging system which Issufficient

for normal use However, periodic charging of the battery

wi{h an automotive charger will extend it's _ife

Acid solution level in each ba_,terycol{ sheuEd be even

w{th bottoms of ventwetls_ Add only distilled oriron free

water if necessary. Do not overfit!.

FLANGES

TRAILING

UP

*A GRADE 5 HEAT TREATED BOLT

CAN BE tOENTtFIED BYTHREELtNES

ON THE BOLT HEAD AS SHOWN AT

LEFT,

FtG_10

CUT AWAY VIEW

BATTERY

LEVEL

FIG. 12

Keep battery and term}rials clean

Keep battery botts tight,

Keep vent caps tight and smaflvent holes in caps open.

Recharge st 6 amperes for 1 hour.

15

MAINTENANCE

i,, J ,Ll

TO CLEAN BATTERY AND TERMINALS -

Corrosion and dirt on the battery and terminals can cause

the battery to "leak" power

Remove term{hal guard

Disconnect BLACK battery cable first then RED bat-

lery cable and remove battery from tractor.

Wash battery with solulfon of four tablespoons of

baking soda to one gallon ofwater Be carefulnot teget

the soda solution Into the celiso

Rinse the battery with plain water and dry.

Clean terminals and battery cable ends with wire brush

until bright

Coat terminals with grease or petroleum jeIly,

, Reinslall battery (See "INSTALL BATTERY" tn as,,

sembty section of 1his manual).

After oil has drained completely, replace olt drain plug

and tighten securely.

Refill engine wlth oil through oil ftll dipstick tube. Pour

slowly. D=onot overfill. For approximate capacity see

Proauct Speciacatlons on page 3 of this manual.

Use gauge on ofi lilt dtpstiok for checking leveL Be sure

dipstick cap Is ttgh!ened securely for accurate reading.

Keep ofl at "FULL line on dipstick,

RECOMMENDED SAE VISCOSITY GRADES

o20_ 0'= 32° 60'_ 80Q 100"

FIG. 13

ENGINE

LUBRICATION

Change the oil after the first two hours of operation and

every 25 hours thereafter or at least once a year if the

traclor Is not used for 25 hours tn one year

Check the crankcase ott level before starting the Engine

and after each eight (8) hours of continuous use. Add SAE

30W motor oil or equivalent, Tighten ott lilt cap/dipstick

securely each ttme you check the oil level SAE 5W-30

motor oi! may be used to make starting easier in areas

where temperature ts consislenfty 32" F or lower

TO CHANGE ENGINE OIL (See Figs 13 & 14)

Determine temperature range expected before oil change.

All oil must meet API service classification SD, SE or SF.

Be sure vehicle is on level surface

Oit wt{l drain more |reely when warm

Catch oil in a su[tab!e conlalner

Remove oil f{]] dipstick Be careful not to ar!ow dlrt to

enter the engine when changing o1_

Remove drain plug

AIR FILTER (See Fig, 14)

Your engine wltl not run properly and may be damaged by

using a dirty air fftter. Replace paper cartridge once a year

or after every 100 hours of operation, more often If used In

very dusty, dirty condltLons.

Remove knobs and cover

. Replace cartridge

Reassemble and tighten securely

NOTE: Do not attempt to clean or oi! the paper cartridge.

AIR SCREEN (See Fig. 14)

The engine air screen must be kept #ee of dirt and chaffto

prevent engine damage from overheating. Clean with a

wire brush or compressed air to remove dirt and stubborn

dried gum fibers,

AIR

ENGINE O1LFILLER

CAP AND DIPSTICK

COVER

AIR

BODY

16

"OIL DRAINPLUG

FIG. 14

Loading...

Loading...