Craftsman 917254740 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

9I 7.254740

Caution:

Read and follow

atl Safety Rules

and instructions

Before Operating

This Equipment

CRRFTSMRN®

18.0 P TRACTOR

ELECTRIC START

38" MOWER ECK

AUTOMATIC TRANSAXLE

®

Assembly

®

Operation

®

Maintenance

®

Service and Adjustmem

®

Repair Parts

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

LOOK FOR THIS SYMBOL TO POINT 1

OUT iMPORTANT SAFETY PRECAU-

TIONS. iT MEANS - ATTENTION! BE-

COME ALERT! YOUR SAFETY IS iN-

______.__J

CAUTION: LQQK_.FQR .THI_WQRD_ TO POINT Ot

IM_bBzA=NT_ Q _ii PM &i4_ PRECAUTION

NOTE: LOOK_FOh:_i:Ht_ N_R_6_TC) _POINT OUT li

PORT*NT NFORMATIONABOUTT,eOPERATmC

AND PERFORMANCE OF YOUR TRACTOR.

RULES FOR SAFE OPERATION

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest:covere--_"'

brush covered or grass covered land unless the engine s exhaust system is equipped with a spark arrester meetingapplicable local or an

taws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator. (See REPAIR PARTS for p4

number identification),

Inthe State of California the above is required by law (Section 4442 of the California Public Resources Code). Other States may have simil

taws, Federat laws apply on federal lands,

1. Know the controls and how to stop quickly, READ THIS

OWNER'S MANUAL. and instructions furnished with attach-

ments.

2. Do not allow children to operate the machine. Do not allow

adults to operate it without proper instruction,

3. Do not car_ passengers. Do not mow when children and

others are around.

4. Always wear substantial footwear. Do not wear loose fitting

clothing that could get caught in moving parts.

5. Keep your eyes and mind on your tractor, mower, and the

area being cut. Do not let other interests distract you.

6. Do not attempt to operate your tractor or mower when not in

the driver's seat.

7. Always get on or off your tractor from the operator's left hand

side.

8. Clear the work area of objects (wire, rocks, etc.) which might

be picked up and thrown.

9. Disengage all attachment clutches before attempting to start

the engine.

10. Disengage power to attachments and stop the engine before

leaving the operator's position.

11. Disengage power to mower, stopthe engine, and disconnect

sparkplugwire(s)from_; sparkptug(s) beforecteaning making

an adjustment_ 0r _;epair. 8e careful to avoid touching hot

muffter or engine components.

12. Disengage_zer to attachments when transporting or not in

USe,

t3. Take all possible precautions when leaving the vehicle

unattended. Disengage the power take-off, lower the attach-

ments, shift into neutral, set the parking brake, stop the

engine, and remove the key.

14. Do not stop or start suddenly when going uphill or downhill.

Mow up and down the face of slopes (not greater than 15°),

never across the face. Refer to page 55.

t 5, Red uce speed on slopes and make turns grad unity to prevent

tipping or toss of control. Exercise extreme caution when

changing direction on slopes.

16. While going up or down slopes, place gear shift control lever

in 1st gear position to negotiate the slope w_thout stopping.

17. Never mow in wet or slippery grass, when traction is unsure,

or at a speed which could cause a skid.

18. Stay alert for holes in the terrain and other hidden hazards.

Keep away from drop-offs ....

19, Do not drive too' close to creeks, ditches, and public high-

ways.

20, Exercise special care when mowing around fixed objects in

order to prevent the blades from striking them. Never delib-

erately run tractor or mower into or over any foreign objects.

21. Never shift gears until tractor comes to a stop.

22. Never place hands or feet under the mower, in discharge

chute, or near any moving parts while tractor or mower ts

running. Always keep clear of discharge chute.

23. Use care when pulling loads or using heavy equipment.

a. Use only approved drawbar hitch poims.

b. Limit loads to those you can safely control.

c, Do not turn sharply. Use care when backing.

d. Use counterweight or wheel weights when suggested

owner s manual.

24. Watch out for traffic when crossing or near roadways.

25. When using any attachments, never direct discharge

material toward bystanders nor allow anyone near the v.

hicle while in operation.

26. Handle gasoline with care - it is highly flammable.

a. Use approved gasoline containers.

b. Never remove the fuel cap of the fuel tank or ac

gasoline to a running or hot engine or an engine that h_

not been altowed to coot for severat minutes after ru=

ning. Never fil! tank indoors. Atways clean up spi)i_

gasoline.: ......!_::'":_::i="_ ::'-:,:

co Open do_r_:if the er_gtne iSrunin,the garage - exhau:

fumes are d_ngerous D_ nQt run the engine ndoors,

27. Keep the vehicle and attachments in good operating cond

tion. and keep safety devices in place and working.

28. Keep all nuts, bolts, and screws tight to be sure the equi[.

ment is in safe working condition°

29. Never store the equipment with gasoline in the tank inside

buitding where fumes may reach an open flame or spar_

Allow the engine to cool before storing in any enclosure.

30. To reduce fire hazard, keep the engine free of grass, leave:

or excessive grease. Do not clean product while engine i

runntng.

31. Except for adjustments, DO NOToperate engine if airclean_;

or cover directly over carburetor air intake is removec

Removal of such part could create a fire hazard.

32. Do not operate without a muffler, or tamper with exhaut:

system. Damaged muff4ers or spark arresters could create,

fire hazard. Inspect periodically and replace if necessary.

33. The vehicle and attachments should be stopped and in

spected for damage after striking a foreign object, and th_

damage should be repaired before restarting and operatinc

the equipment.

34. Do not change the enginegovernor settings or overspeed th_

engine; severe damage or injury may result.

35. When using the vehicle with mower, proceed as fo]fows:

a. Mow only in daylight or in good artificial light.

b, Shut the engine off when unclogging chute,

c. Check the blade mounting bolts for proper tightness a

frequent intervals.

36. Do not operate the mower without the entire grass catcher

on mowers so equipped, or the deflector shield in place.

37. Disengage power to mower before backing up. Do not mo_

in reverse unless absolutely necessary and then only aftel

careful observation of the entire area 6ehind the mower,

38. Under normal usage the grass catcher bag material issubjec_

to deterioration and wear. ttshould be checked frequently fot

bag replacement Replacement bags should be checked tc

ensure compliance with the original manufacturer's recom

mendations or specifications.

2

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, engineered and manu-

factured to give you the best possible dependability and

performance. Should you experience any problem you

cannot easily remedy, please contact your nearest Sears

Service Department. We have competent, well-trained

technicians and the proper tools to service or repair this

unit.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this

product. See the nearest Sears store or service center

for details.

CUSTOMER RESPONSIBILITIES ........

Read and retain this manual Study and observe the safety rules. Always use care when using your tractor. Always

keep your tractor and mower clean. Follow a regular schedule in maintaining, caring for, and using your tractor. A well

cared for tractor will run better and last longer.

A TTACHMENTS

This unit can use many attachments now available at your Sears store. It can use a tiller, but cannot use other ground

engaging attachments such as a plow, harrow, or cultivator. See page 54 for a list of available attachments.

SERIAL

NUMBER

DATE OF PURCHASE

THE SERIAL NUMBER WILL BE FOUND ON THE

MODEL PLATE UNDER THE SEAT.

YOU SHOULD RECORD THESE NUMBERS AND

KEEP FOR FUTURE REFERENCE.

LmMiTED TWO YEAR WARRANTY

ON ELECTRIC START RIDING EQUIPMENT

For two years from date of purchase, when this tiding equipment is maintained, lubricated, and tuned up according

to ?,heoperating and maintenance instruction in the owner's manual, Sears wilt repair free of charge any defect in

material or workmanship inthis electric start riding equipment.

This warranty excludes blade(s), blade adapter(s), spark plug(s), air cleaner and belt(s), which are expendable and

become worn during normal use.

This warranty does not cover:

o Tire replacement or repair caused by punctures from outside objects (such as nails, thorns, stumps, or

glass); and

• repairs necessary because of operator abuse or negligence, including the failure to maintain the equip-

ment according to instructions contained inthe owner's manual; and

- ridingequipment used for commercial or rental purposes.

FULL 90 DAY WARRANTY ON BATTERY

For 90 days from the date of purchase, if any battery includedwith this riding equipment proves defective in material

or workmanship and our testing determines the battery will not hold a charge, Sears will replace the battery at no

charge.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER DEPART-

MENT IN THE UNITED STATES. This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.

SEARS, ROEBUCK and CO., D/731CR-W, Sears Tower, Chicago, IL 60684

_DO NOT OVERLOAD TRACTOR BY TOWING WEIGHTS GREATER THAN 150 POUNDS (68 KG).

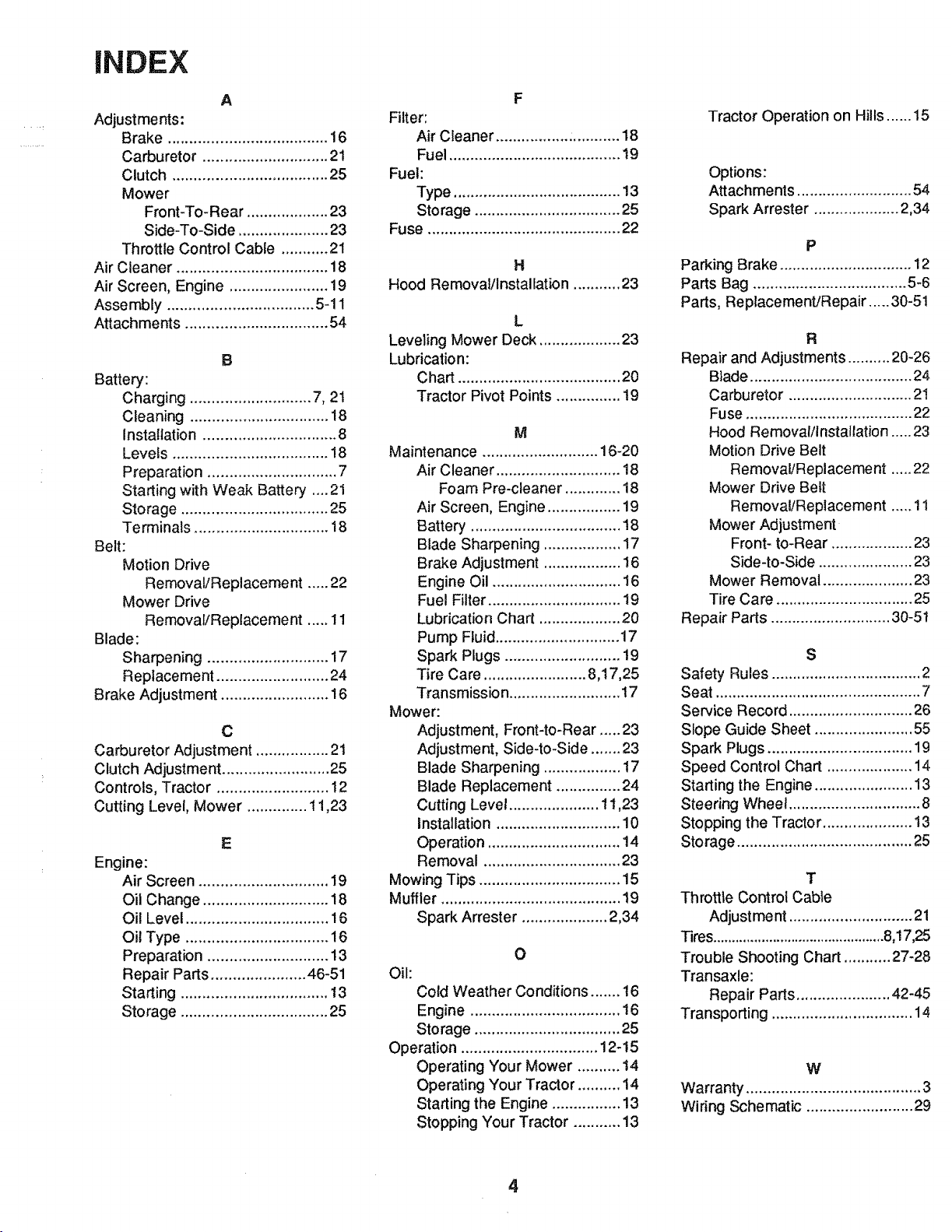

iNDEX

A

Adjustments:

Brake ..................................... 16

Carburetor ............................. 21

Clutch .................................... 25

Mower

Front-To-Rear ................... 23

Side-To-Side ..................... 23

Throttle Control Cable ........... 21

Air Cleaner ................................... 18

Air Screen, Engine ....................... 19

Assembly .................................. 5-11

Attachments ................................. 54

B

Battery:

Charging ............................ 7, 2t

Cleaning ................................ 18

Installation ............................... 8

Levels .................................... 18

Preparation .............................. 7

Starting with Weak Battery ....21

Storage .................................. 25

Terminals ............................... 18

Belt:

Motion Drive

Removal/Replacement ..... 22

Mower Drive

Removal/Replacement ..... 11

Blade:

Sharpening ............................ 17

Replace merit .......................... 24

Brake Adjustment ......................... 16

C

Carburetor Adjustment ................. 21

Clutch Adjustment ......................... 25

Controls, Tractor .......................... 12

Cutting Level, Mower .............. t 1,23

E

Engine:

Air Screen .............................. 19

Oil Change ............................. 18

Oil Level ................................. 16

Oil Type ................................. 16

Preparation ............................ 13

Repair Parts ...................... 46-51

Starting .................................. 13

Storage .................................. 25

F

Filter:

Air Cleaner ............................. 18

Fuel ........................................ 19

Fuel:

Type ....................................... i 3

Storage .................................. 25

Fuse ............................................. 22

H

Hood Removal/Installation ........... 23

L

Leveling Mower Deck ................... 23

Lubrication:

Chart ...................................... 20

Tractor Pivot Points ............... 19

M

Maintenance ........................... 16-20

Air Cleaner ............................. 18

Foam Pre-cleaner ............. I8

Air Screen, Engine ................. 19

Battery ................................... 18

Blade Sharpening .................. 17

Brake Adjustment .................. t6

Engine Oil .............................. 16

Fuel Filter ............................... t9

Lubrication Chart ................... 20

Pump Fluid ............................. 17

Spark Plugs ........................... 19

Tire Care ........................ 8,17,25

Transmission .......................... t7

Mower:

Adjustment, Front-to-Rear .....23

Adjustment, Side-to-Side ....... 23

Blade Sharpening .................. 17

Blade Replacement ............... 24

Cutting Level ..................... t 1,23

Installation ............................. 10

Operation ............................... 14

Removal ................................ 23

Mowing Tips ................................. 15

Muffler .......................................... 19

Spark Arrester .................... 2,34

O

Oil:

Cold Weather Conditions ....... 16

Engine ................................... 16

Storage .................................. 25

Operation ................................ 12-15

Operating Your Mower .......... 14

Operating Your Tractor .......... 14

Starling the Engine ................ 13

Stopping Your Tractor ........... 13

Tractor Operation on Hills ...... 15

Options:

Attachments ........................... 54

Spark Arrester .................... 2,34

P

Parking Brake ............................... 12

Parts Bag .................................... 5-8

Parts, Replacement/Repair .....30-51

R

Repair and Adjustments .......... 20-26

Blade ...................................... 24

Carburetor ............................. 21

Fuse ....................................... 22

Hood Removal/installation .....23

Motion Drive Belt

Removal/Replacement ..... 22

Mower Drive Belt

Removal/Replacement ..... 11

Mower Adjustment

Front- to-Rear ................... 23

Side-to-Side ...................... 23

Mower Removal ..................... 23

Tire Care ................................ 25

Repair Parts ............................ 30-5t

S

Safety Rules ................................... 2

Seat ................................................ 7

Service Record ............................. 26

Slope Guide Sheet ....................... 55

Spark Plugs .................................. 19

Speed Control Chart .................... 14

Starting the Engine ....................... 13

Steering Wheel ............................... 8

Stopping the Tractor ..................... t3

Storage ......................................... 25

T

Throttle Control Cable

Adjustment ............................. 21

Tires ..............................................8,17,25

Trouble Shooting Chart ........... 27-28

Transaxle:

Repair Parts ...................... 42-45

Transporting ................................. 14

W

Warranty ......................................... 3

Wiring Schematic ......................... 29

4

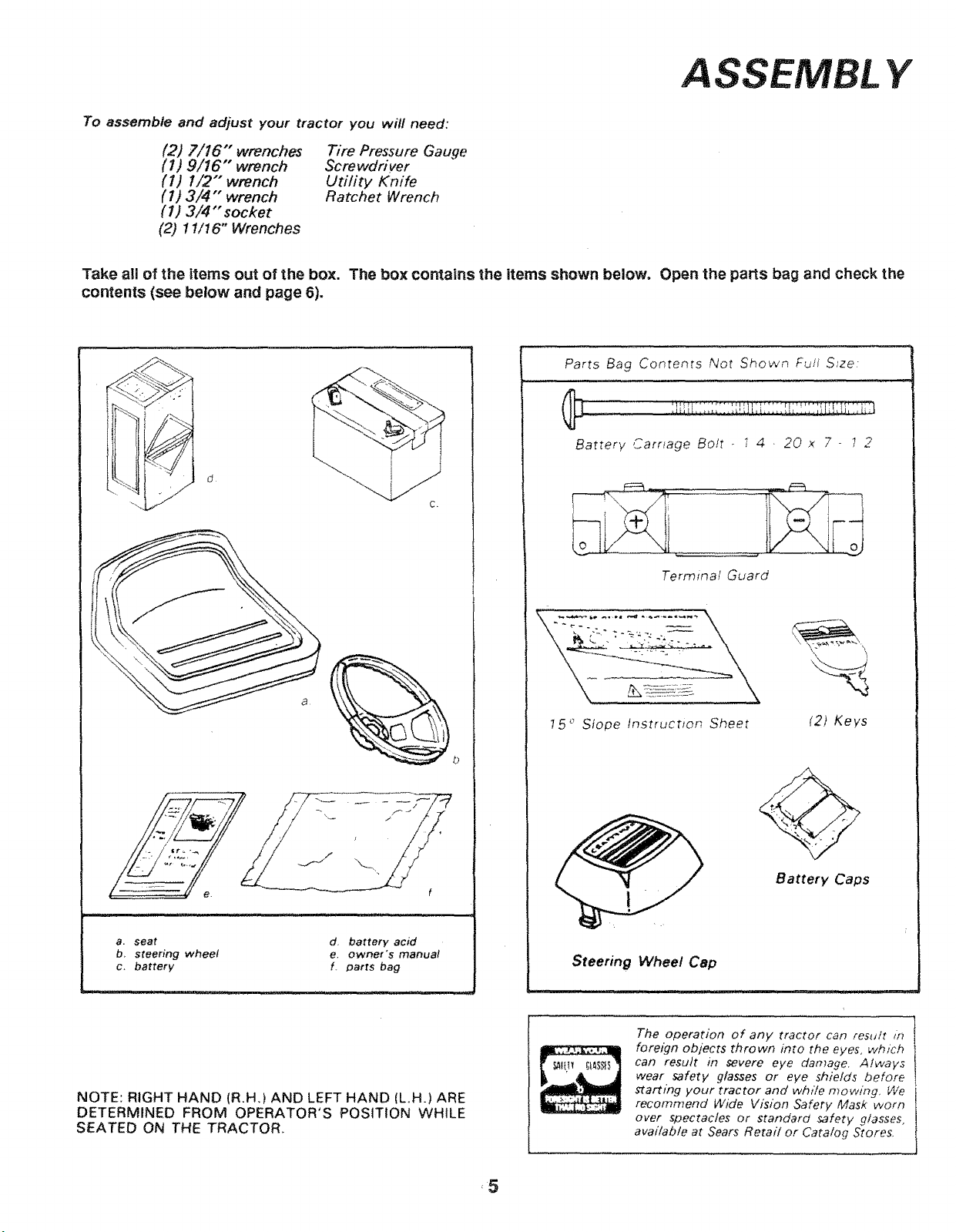

ASSEMBLY

To assemble and adjust your tractor you will need:

(2) 7/16" wrenches

(1) 9/16" wrench

(1) 1/2" wrench

(1) 3/4" wrench

(1) 3/4"'socket

(2) ! 1/16" Wrenches

Take all of the items out of the box. The box contains the items shown below, Open the parts bag and check the

contents (see below and page 6).

d

Tire Pressure Gauge

Screwdriver

Utility Knife

Ratchet Wrench

Parts Bag Contents Not Shown Full S_ze:

Battery Carrfage Bolt . I 4 - 20 x 7- ! 2

C.

a. seat d. battery acid

b, steering wheel e. owner's manual

c. battery f. parts bag

Terminal Guard

b

15 _ Slope Instruction Sheet

Steering Wheel Cap

(2) Keys

Battery Caps

NOTE: RIGHT HAND (R.H,) AND LEFT HAND (L,H.) ARE

DETERMINED FROM OPERATOR'S POSITION WHILE

SEATED ON THE TRACTOR,

The operation of any tractor can result tn

foreign objects thrown into the eyes, which

can result in severe eye damage. Always

wear safety glasses or eye shields before

starting your tractor and while mowing, We

recommend Wide Vision Safety Mask worn

over spectacles or standard safety glasses,

available at Sears Retail or Catalog Stores,

A

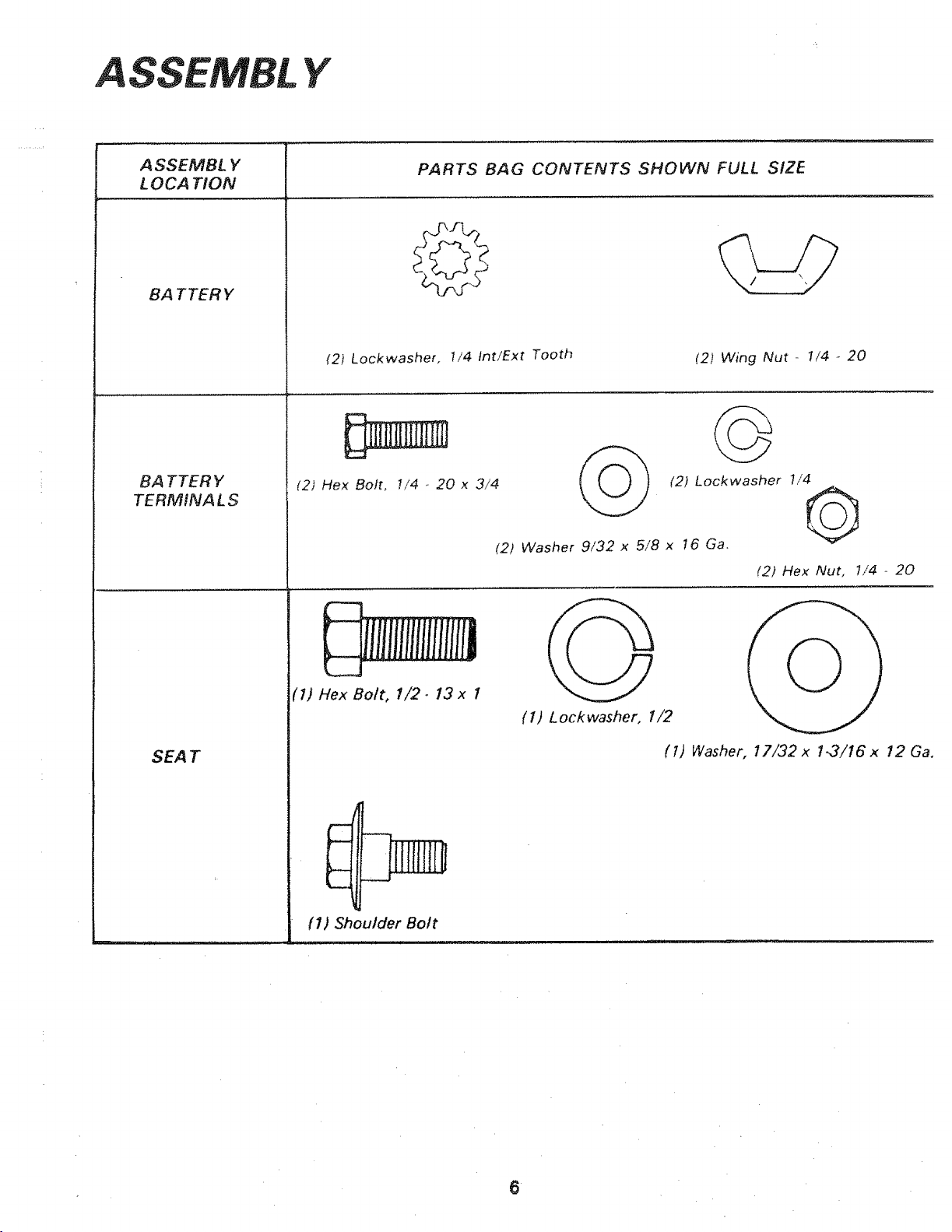

Y

A SSEMBL Y

LOCA TION

BA TTER Y

BA TTER Y

TERMINA L S

PARTS BAG CONTENTS SHOWN FULL SIZE

(2) Lockwasher, t/4 IntiExt Tooth (2) Wing Nut _ I/4 - 20

(2) Hex Bolt, !/4 _ 20x 3/4

(2) Washer 9/32 x 5/8 x t6 Ga,

(2) Lockwasher 1/4

(2) Hex Nut, 1/4 - 20

©

SEAT

(1) Hex Bolt, 1/2- 13 x 1

(1) Lockwasher, 1/2

(1) Washer, 17/32x 1,3/16x 12 Ga.

(1) Shoulder Bolt

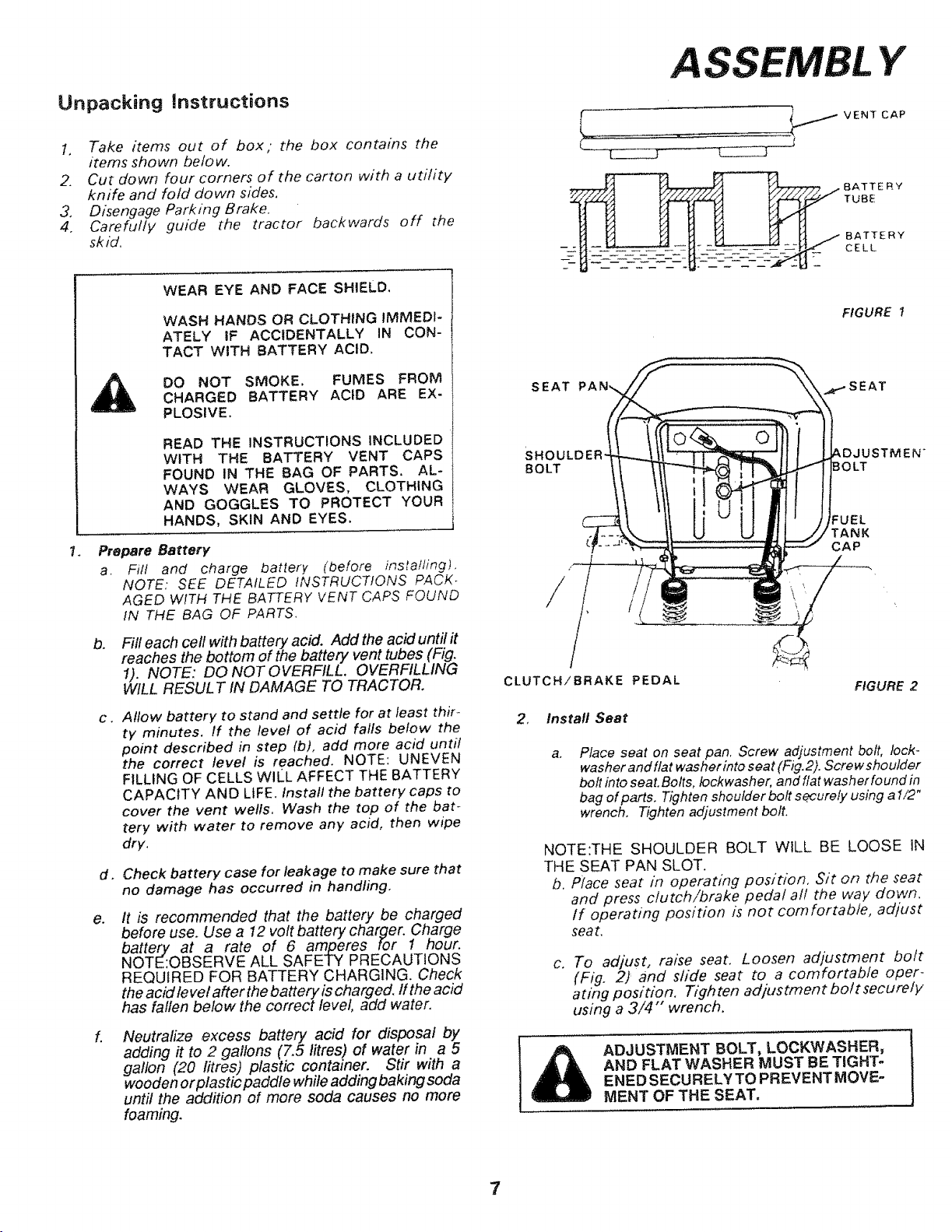

Unpacking instructions

ASSEMBL Y

1, Take items out of box; the box contains the

items shown below.

2. Cut down four corners of the carton with a utility

knife and fold down sides,

3, Disengage Parking Brake.

4. Carefully guide the tractor backwards off the

skid,

WEAR EYE AND FACE SHIELD,

WASH HANDS OR CLOTHING IMMEDI*

ATELY IF ACCIDENTALLY IN CON-

TACT WITH BATTERY ACID,

DO NOT SMOKE. FUMES FROM

CHARGED BATTERY ACID ARE EX-

PLOSIVE.

READ THE INSTRUCTIONS INCLUDED

WITH THE BATTERY VENT CAPS

FOUND tN THE BAG OF PARTS. AL-

WAYS WEAR GLOVES, CLOTHING

AND GOGGLES TO PROTECT YOUR

HANDS, SKIN AND EYES.

T.

Prepare Battery

a. Fill and charge battery (be/ore insta/fingt,

NOTE: SEE DETAILED INSTRUCTIONS PACK-

AGED WfTH THE BATTERY VENT CAPS FOUND

IN THE BAG OF PARTS.

VENT CAP

TUBE

BATTERY

BATTERY

CELL

FIGURE 1

SEAT PAN,,

SHOULDER

BOLT _LT

SEAT

FUEL

TANK

CAP

EN"

b, Fill each cell with battery acid. Add the acid until it

reaches the bottom of the battery vent tubes (Fig,

1), NOTE: DO NOT OVERFILL. OVERFILLING

WILL RESUL T IN DAMAGE TO TRACTOR.

C. Allow battery to stand and settle for at least thir-

ty minutes. If the level of acid falls below the

point described in step (b), add more acid until

the correct level is reached. NOTE: UNEVEN

FILLING OF CELLS WILL AFFECT THE BATTERY

CAPACITY AND LIFE. Install the battery caps to

cover the vent wells. Wash the top of the bat-

tery with water to remove any acid, then wipe

dry.

d_

Check battery case for leakage to make sure that

no damage has occurred in handling.

e.

It is recommended that the battery be charged

before use. Use a 12volt battery charger. Charge

battery at a rate of 6 amperes for 1 hour.

NOTE:OBSERVE ALL SAFETY' PRECAUTIONS

REQUIRED FOR BATTERY CHARGING. Check

the acid level after the battery ischarged, ff the acid

has fallen below the correct level, add water.

Neutralize excess battery acid for disposal by

adding it to 2 gallons (7.5 litres) of water in a 5

gallon (20 fitres) plastic container. Stir with a

wooden or plastic paddle while adding baking soda

until the addition of more soda causes no more

foaming.

1

CLUTCH/BRAKE PEDAL

2, Install Seat

a_

Place seat on seat pan. Screw adjustment bolt, lock-

washer and flat washer into seat (Fig. 2). Screw shoulder

bolt into seat, Bolts, [ockwasher, and flat washer found in

bag of parts. Tighten shoulder bolt securely using a1/2"

wrench. Tighten adjustment bolt.

NOTE:THE SHOULDER BOLT WiLL BE LOOSE IN

THE SEAT PAN SLOT.

b. P/ace seat in operating position, Sit on the seat

and press c/utch/brake pedal a// the way down.

If operating position is not comfortable, adjust

seat.

c, To adjust, raise seat, Loosen adjustment bolt

(Fig, 2) and slide seat to a comfortable oper-

ating position. Tighten ad/ustment bo/t secure/y

using a 3/4"" wrench.

ADJUSTMENT BOLT, LOCKWASHER,

AND FLAT WASHER MUST BE TiGHT-

ENED SECURELY TO PREVENT MOVE-

MENT OF THE SEAT.

FIGURE 2

7

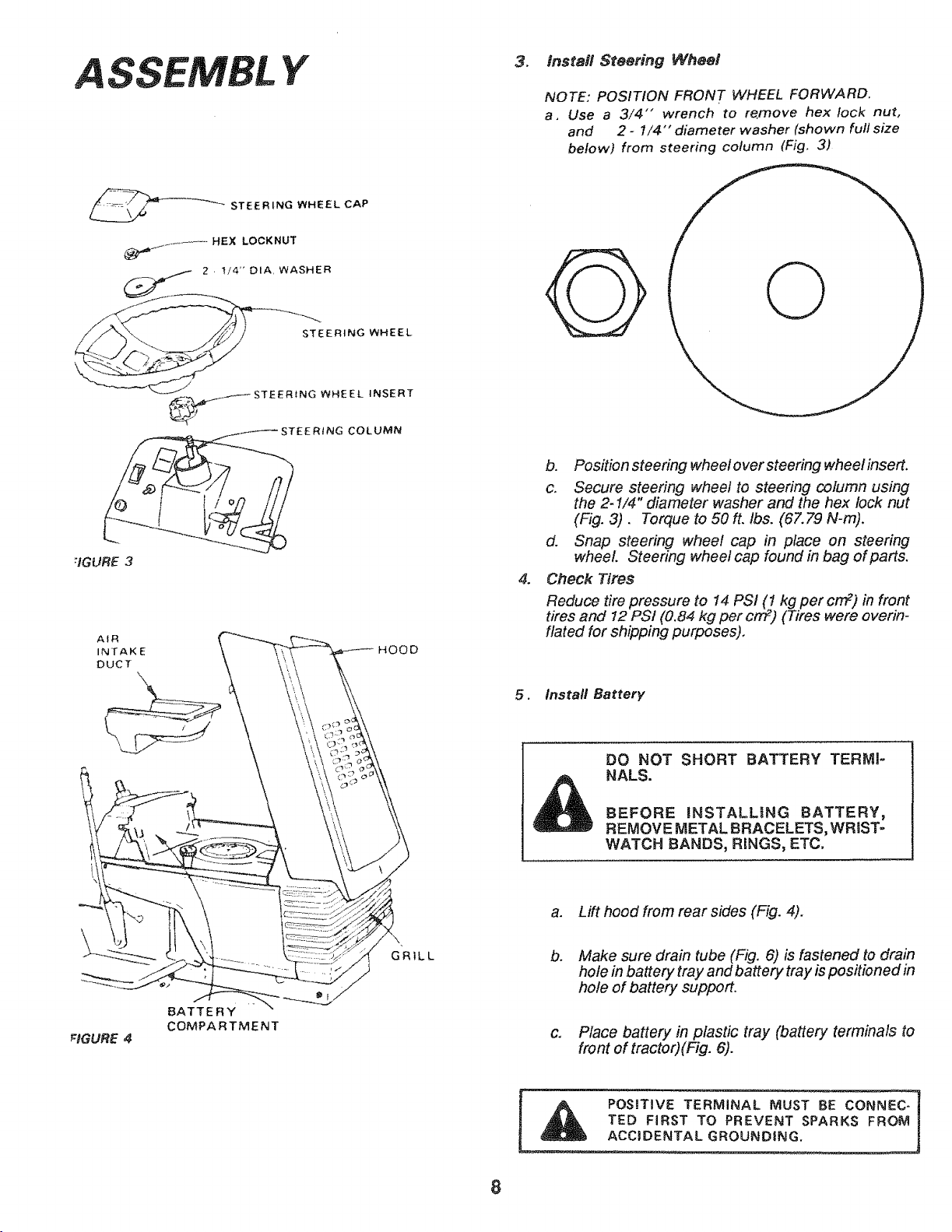

ASSEMBL Y

STEERING WHEEL CAP

......... HEX LOCKNUT

2 . t/4" DIA, WASHER

__'_ .___t'_ _"_'STS T E E R t N O WHEEL

:IGURE 3

AIR

INTAKE

DUCT

HOOD

3. tnstafl Steering Wheel

NOTE: POSITION FRONT WHEEL FORWARD.

a. Use a 3/4" wrench to remove hex lock nut,

and 2 - 1/4" diameter washer (shown full size

below) from steering column (Fig. 3)

b. Position steering wheel over steering wheel insert.

c. Secure steering wheel to steering column using

the 2-1/4" diameter washer and the hex lock nut

(Fig. 3). Torque to 50 ft. Ibs. (67. 79 N-m).

d. Snap steering wheel cap in place on steering

wheel Steering wheel cap found in bag of parts.

&

Check Tires

Reduce tire pressure to 14 PSI (1 kg per cn'F) in front

tires and 12PSI (0.84 kg per crfP) (Tires were oven'n-

flated for shipping purposes).

\

_IGURE 4

BATTE R Y

COMPARTMENT

\

GRILL

5. Install Battery

DO NOT SHORT BATTERY TERMI-

NALS.

BEFORE INSTALLING BATTERY,

REMOVE METAL BRACELETS, WRIST=

WATCH BANDS, RINGS, ETC,

a. Lift hood from rear sides (Fig. 4).

b. Make sure drain tube (Fig. 6) is fastened to drain

hole in battery tray and battery tray is positioned in

hole of battery support.

c. Place battery in plastic tray (battery terminals to

front of tractor)(Fig. 6).

POSITIVE TERMINAL MUST 8E CONNEC- l

TED FIRST TO PREVENT SPARKS FROM

ACCIDENTAL GROUNDING. ==J

8

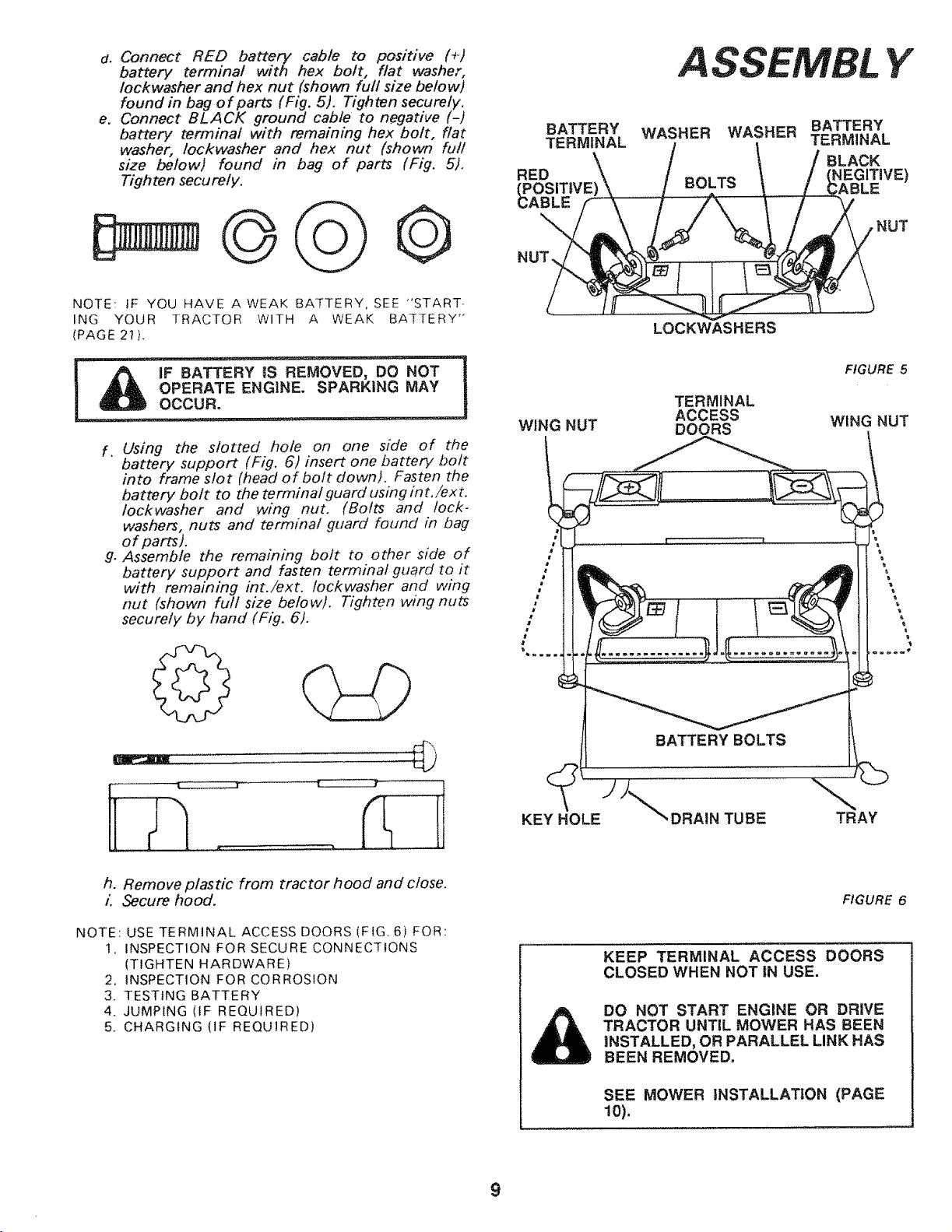

d. Connect RED battery cable to positive (+)

battery terminal with hex bolt, flat washer,

lockwasher and hex nut (shown full size below)

found in bag of parts (Fig. 5). Tighten securely.

e. Connect BLACK ground cable to negative (-)

battery terminal with remaining hex bolt, flat

washer, Iockwasher and hex nut (shown full

size below) found in bag of parts (Fig. 5).

Tighten securely.

BATTERY

TERMINAL

RED

ASSEMBL Y

WASHER WASHER BATTERY

BOLTS

TERMINAL

BLACK

4AEGITIVE)

8LE

NOTE: tF YOU HAVE A WEAK BATTERY, SEE "START-

ING YOUR TRACTOR WITH A WEAK BATTERY"

(PAGE 21 ).

iF BATTERY IS REMOVED, DO NOT

OPERATE ENGINE. SPARKING MAY

OCCUR.

f. Using the slotted hole on one side of the

battery support (Fig. 6) insert one battery bolt

into frame slot (head of bott down). Fasten the

battery bolt to the terminat guard using int./ext.

!ockwasher and wing nut. (Bolts and !ock-

washers, nuts and terminal guard found in bag

of parts).

g. Assemble the remaining bolt to other side of

battery support and fasten terminal guard to it

with remaining int./ext, tockwasher and wing

nut (shown fu!l size below). Tighten wing nuts

securely by hand (Fig. 6).

\

NUT,

WING NUT

LOCKWASHERS

TERMINAL

ACCESS

DOORS

NUT

FIGURE 5

WING NUT

h. Remove plastic from tractor hood and close.

;: Secure hood.

NOTE: USE TERMINAL ACCESS DOORS (FIG. 6) FOR:

1, INSPECTION FOR SECURE CONNECTIONS

(TIGHTEN HARDWARE)

2. INSPECTION FOR CORROSION

3. TESTING BATTERY

4. JUMPING (IF REQUIRED)

5. CHARGING (IF REQUIRED)

9

KEY HOLE

,DRAINTUBE TRAY

FIGURE 6

KEEP TERMINAL ACCESS DOORS

CLOSED WHEN NOT IN USE.

DO NOT START ENGINE OR DRIVE

TRACTOR UNTIL MOWER HAS BEEN

iNSTALLED, OR PARALLEL LINK HAS

BEEN REMOVED.

SEE MOWER INSTALLATION (PAGE

lo).

ASSEMBL Y

\\ "x RETAINER

\\ PARALLEL _ SPRINGS

- LEt

_I _ REAR

FIGURE 7

PiN

FRONT

.

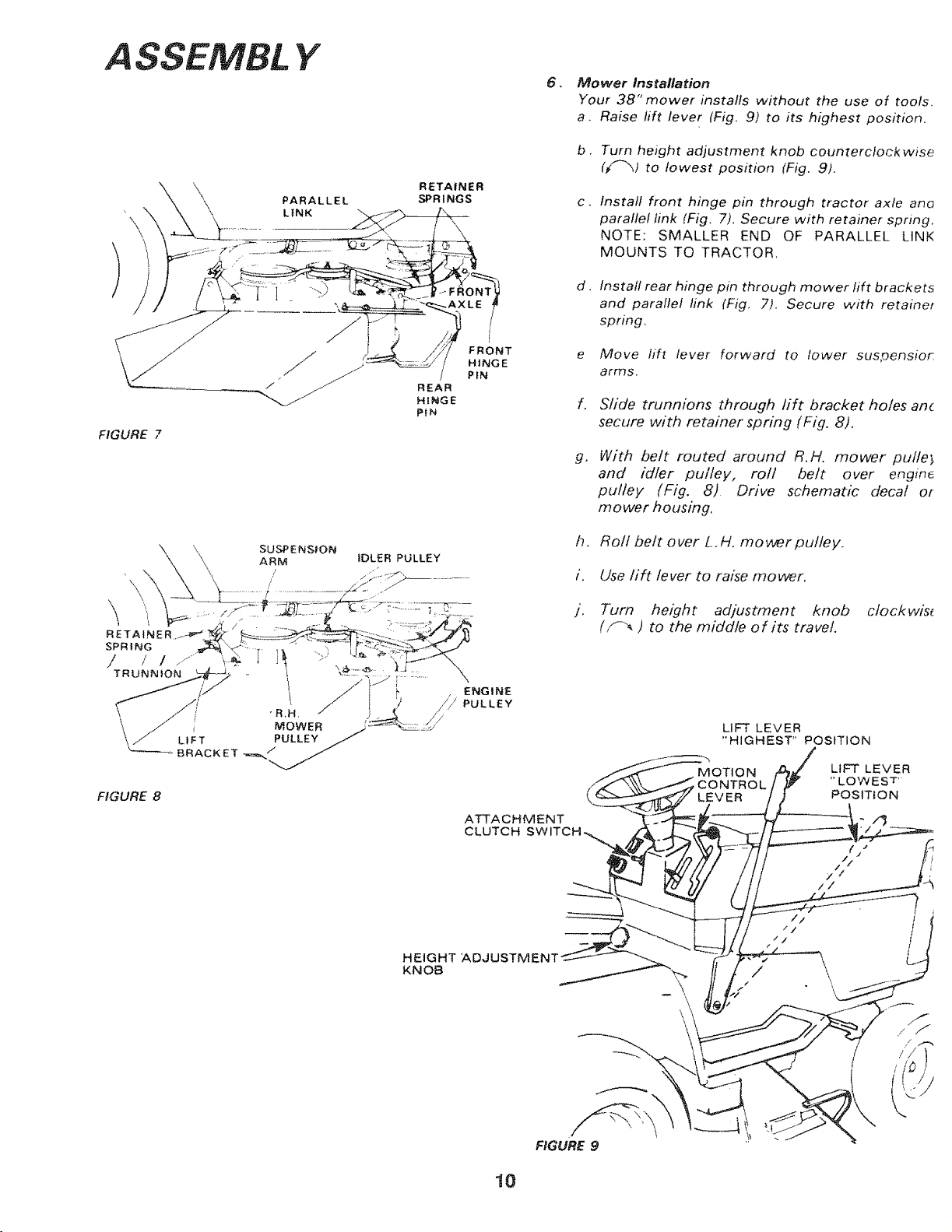

Mower Installation

Your 38"mower installs without the use of tools.

a. Raise lift lever (Fig. 9) to its highest position.

b. Turn height adjustment knob counterclockwise

(f_'J to lowest position (Fig. 9).

C.

Install front hinge pin through tractor axle ano

paraltel fink (Fig. 7), Secure with retainer spring.

NOTE: SMALLER END OF PARALLEL LINK

MOUNTS TO TRACTOR,

d.

Install rear hinge pin through mower lift brackets

and parallel link (Fig, 7), Secure with retainer

spring,

Move lift lever forward to lower suspensior

arms.

f+

Slide trunnions through lift bracket holes an_

secure with retainer spring (Fig. 8).

g,

With belt routed around R.H. mower pufle'_

and idler put/ey, ro// belt over enginc

pulley (Fig. 8) Drive schematic decal or

mower housing.

FIGURE 8

h.

\

Roll belt over L.H. mower pu//ey.

i.

Use lift lever to raise mower.

j*

Turn height adjustment knob ctockwis_

(,F-, ) to the middle of its travel.

ENGINE

PULLEY

LIFT LEVER

"HIGHEST" POSITION

LIFT' LEVER

"LOWEST"

POSITION

ATTACHMENT

CLUTCH

HEIGHT 'ADJUSTMEN_I

KNOB

10

FIGURE 9

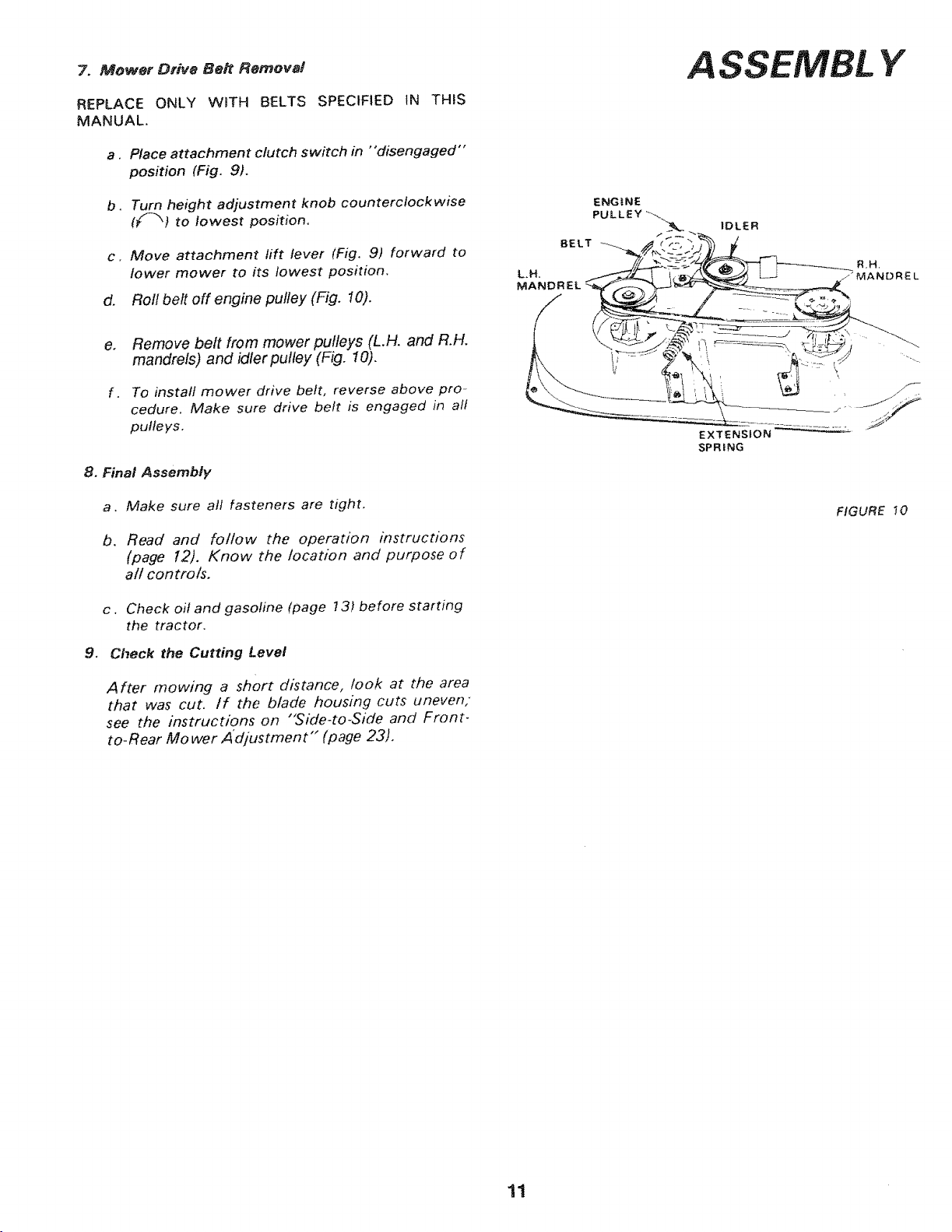

REPLACE ONLY W_TH BELTS SPECIFIED IN THIS

MANUAL.

a, Place attachment clutch switch in "disengaged"

position (Fig. 9),

A SSEMBL Y

b. Turn height adjustment knob counterclockwise

(_-") to lowest position,

c, Move attachment lift lever (Fig, 9) forward to

lower mower to its lowest position,

d. Rofl belt off engine pufley (Fig. 10).

8.

Remove belt from mower pulleys (L.H. and R.H.

mandrels) and idler pulley (Fig. 10).

f .

To install mower drive belt, reverse above pro-

cedure, Make sure drive belt is engaged in all

pulleys.

8. Final Assembly

a, Make sure all fasteners are tight,

b. Read and follow the operation instructions

(page 12). Know the location and purpose of

a// controls.

c . Check oil and gasoline (page 73) before starting

the tractor.

9, Check the Cutting Level

ENGtNE

IDLER

BELT

LH.

MANDREL

SPRING

FIGURE 10

A fter mowing a short distance, look at the area

that was cut. If the blade housing cuts uneven,

see the instructions on "'Side-to-Side and Front-

to-Rear Mower A'djustment'" (page 23),

11

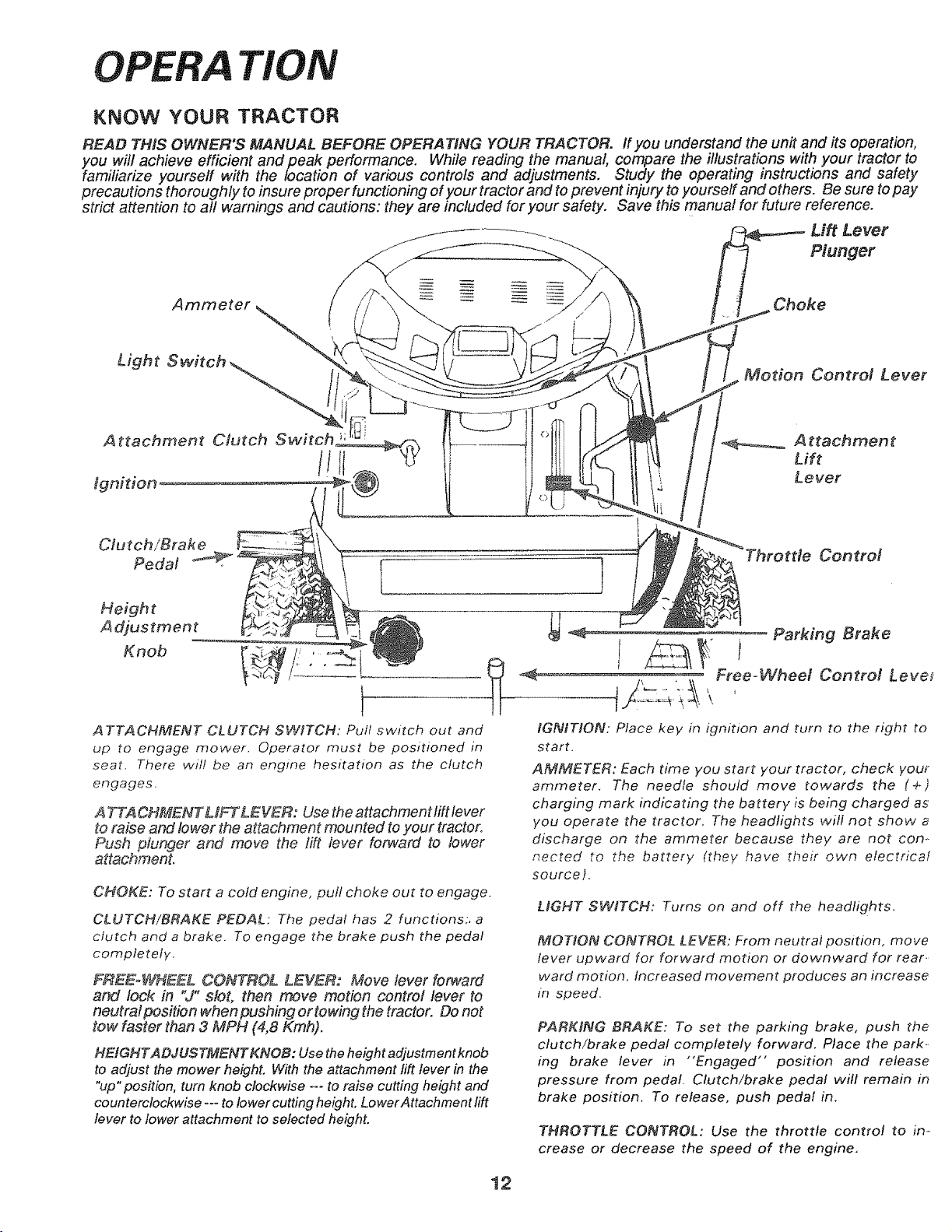

OPERA TION

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL BEFORE OPERATING YOUR TRACTOR. If you understand the unit and its operation,

you will achieve efficient and peak performance, While reading the manual, compare the illustrations with your tractor to

familiarize yourself with the location of various controls and adjustments, Study the operating instructions and safety

precautions thoroughly to insure proper functioning of your tractor and to prevent injury to yourself and others. Be sure topay

strict attention to all warnings and cautions: they are included for your safety. Save this manual for future reference.

Lift Lever

Plunger

Choke

Motion Control Lever

Height

Adjustment

Knob

ATTACHMENT CLUTCH SWITCH; Pull switch out and

up to engage mower. Operator must be positioned in

seat. There will be an engine hesitation as the clutch

engages.

A TTA CHMENTLIFTLEVER: Use the attachmenttift lever

toraise and lower the attachment mounted toyour tractor.

Push plunger and move the lift lever forward to lower

attachment,

CHOKE: To start a cold engine, pull choke out to engage.

CLUTCH/BRAKE PEDAL: The pedal has 2 functions:, a

clutch and a brake. To engage the brake push the pedal

completely.

FREe.WHEEL CONTROL LEVER: Move lever forward

and !ock in "J" s!ot, then move motion control lever to

neutrat position when pushing ertowing the tractor. Do not

tow faster than 3 MPH (4,8 Kmh).

HEIGHTADJUSTMENT KNOB: Use the height adjustment knob

to adjust the mower height. With the attachment lift lever in the

"up" position, turn knob clockwise oo-to raise cutting height and

counterclockwise--- to lower cutting height. Lower Attachment lift

lever to lower attachment to selected height.

_ttle Control

i i Pork,ng ro.o

Free-Wheel Control Leve_

IGNITION: Place key in ignition and turn to the right to

start.

AMMETER: Each time you start your tractor, check you_°

ammeter. The needle should move towards the (+)

charging mark indicating the battery is being charged as

you operate the tractor, The headlights will not show a

discharge on the ammeter because they are not corn

nected to the battery (they have their own efectrieaI

source),

LIGHT SWITCH: Turns on and off the headlights.

MOTION CONTROL LEVER: From neutral position, move

lever upward for forward motion or downward for rear.

ward motion, Increased movement produces an increase

in speed.

PARKING BRAKE: To set the parking brake, push the

clutch/brake pedal completely forward. Place the park-

ing brake lever in "Engaged" position and release

pressure from pedal. C/utch/brake pedal will remain in

brake position, To release, push pedal in.

THROTTLE CONTROL: Use the throttle control to in-

crease or decrease the speed of the engine.

12

,!

1. StOpping Your Tractor

CAUTION:DO NOT CHOKE CARBURETOR TO STOP

THE ENGINE,

NOTE: REMOVE KEY WHEN LEAVING TRACTOR TO

PREVENT UNAUTHORIZED USE.

a. Push clutch!brake pedal into full "BRAKE"

position.

b Move motion control lever to "'NEUTRAL"

position.

c Place parking brake in "'ENGAGED" position and

release pressure from clutch/brake. Pedal should

remain in "'BRAKE"position. NOTE: MAKE SURE

PARKING BRAKE WiLL HOLD TRACTOR

SECURE.

d. Place attachment clutch switch in "DISENGAG-

ED" position.

e. Move throttle control to "'S" (stow) position.

f. Turn ignition key to "OFF" position. Never use

choke to stop engine.

2. Starting The Engine

LEARN TO START, STOP AND REVERSE

YOUR TRACTOR iN A LARGE, OPEN AREA.

THiS TRACTOR iS EQUIPPED WiTH IN-

TERLOCK SWITCHES TO PREVENT STAR-

TING OF THE TRACTOR ENGINE WHILE

THE ATTACHMENT CLUTCH SWITCH iS iN

THE "ENGAGED" POSITION AND/OR THE

FOOT PEDAL IS NOT FULLY DEPRESSED. /

IMMEDIATELY REPLACE SWITCHES THAT

ARE NOT IN PROPER WORKING ORDER.

DO NOT ATTEMPT TO DEFEAT THE PUR-

POSE OF THESE SWITCHES.

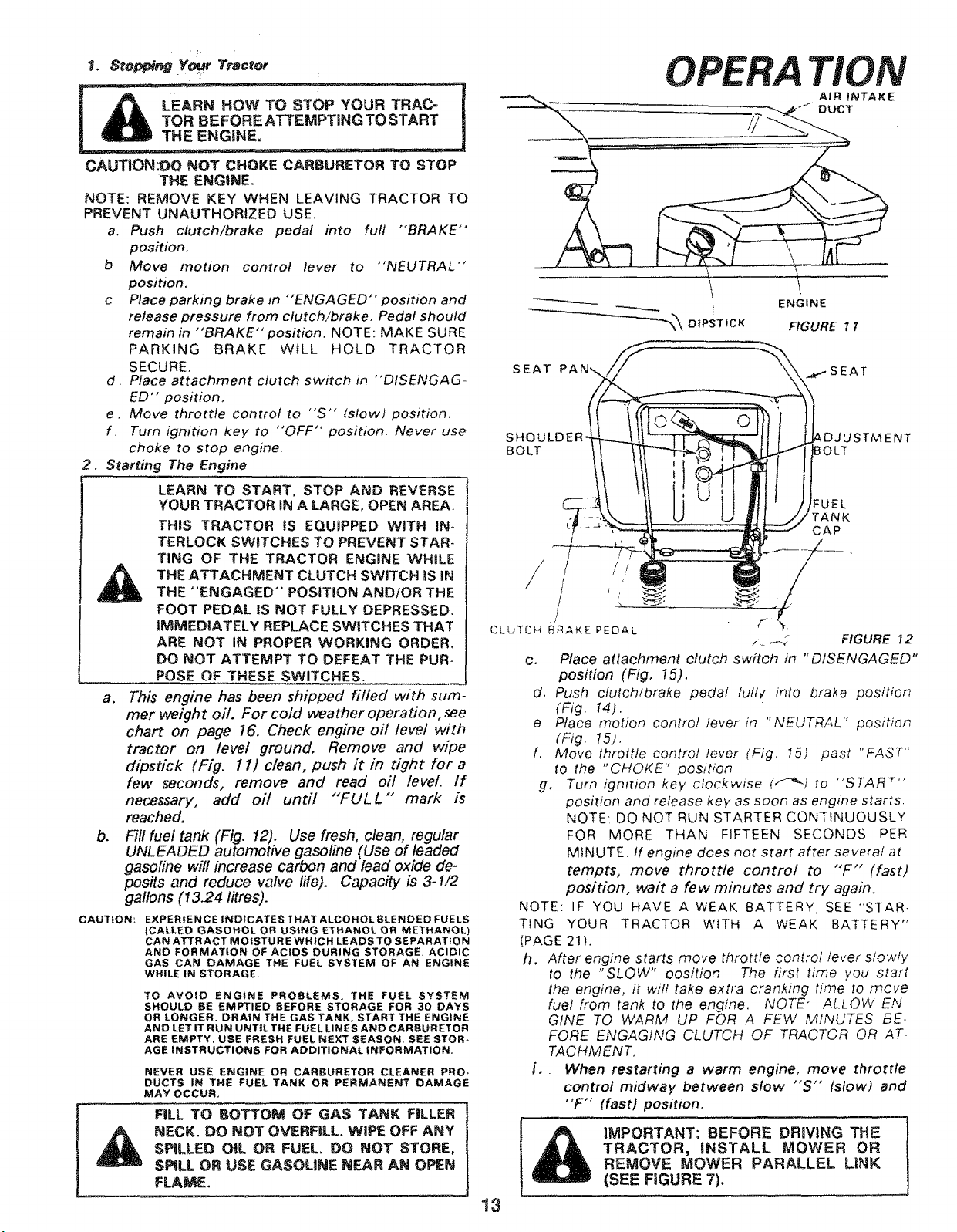

a,

This engine has been shipped filled with sum-

mer weight oil. For cold weather operation, see

chart on page 16. Check engine oil level with

tractor on level ground, Remove and wipe

dipstick (Fig. 11) clean, push it in tight for a

few seconds, remove and read oil level. If

necessary, add oil until "FULL" mark is

reached,

b.

Fill fuel tank (Fig. 12). Use fresh, clean, regular

UNLEADED automotive gasoline (Use of leaded

gasoline will increase carbon and lead oxide de-

posits and reduce valve life). Capacity is 3-1/2

gallons (13.24 litres).

CAUTION', EXPERIENCE INDICATES THAT ALCOHOL SLENDED FUELS

|CALLED GASOHOL OR USING ETHANOL OR METHANOL)

CAN ATTRACT MOISTURE WHICH LEADS TO SEPARATION

AND FORMATION OF ACIDS DURING STORAGE, ACIDIC

GAS CAN DAMAGE THE FUEL SYSTEM OF AN ENGINE

WHILE IN STORAGE,

TO AVOID ENGINE PROBLEMS, THE FUEL SYSTEM

SHOULD BE EMPTIED BEFORE STORAGE FOR 30 DAYS

OR LONGER. DRAIN THE GAS TANK, START THE ENGINE

AND LET IT RUN UNTILTHE FUEL LINES AND CARSURETOR

ARE EMPTY, USE FRESH FUEL NEXT SEASON. SEE STOR-

AGE INSTRUCTIONS FOR ADDITIONAL iNFORMATION,

NEVER USE ENGINE OR CARBURETOR CLEANER PRO+

DUCTS IN THE FUEl TANK OR PERMANENT DAMAGE

MAY OCCUR,

FiLL TO BOTTOM OF GAS TANK FILLER

NECK, DO NOT OVERFILL. WiPE OFF ANY

SPILLED OIL OR FUEL. DO NOT STORE,

SPILL OR USE GASOLINE NEAR AN OPEN

FLAME.

SEAT _ISEAT

SHOULDER.

BOLT

CLUTCH BRAKE PEDAL

J

c, Place attachment clutch switch in "DISENGAGED"

d, Push clutchtbrake pedal fully into brake position

e. Place motion control lever in "NEUTRAL" position

f. Move throttle control lever (Fig, I5) past "FAST"

g. Turn ignition key' clockwise (,f'_) to "START'*

NOTE: IF YOU HAVE A WEAK BATTERY, SEE "STAR-

TING YOUR TRACTOR WITH A WEAK BATTERY"

(PAGE 21 ).

h, After engine starts move throttle control lever slowly'

i,. When restarting a warm engine, move throttle

13

OPERA TION

- _DUCT

.! r x

position (Fig, 15),

(Fig. 14),

(Fig. 15).

to the "CHOKE" position

position and release key as soon as engine starts.

NOTE: DO NOT RUN STARTER CONTINUOUSLY

FOR MORE THAN FIFTEEN SECONDS PER

MINUTE. tf engine does not start after several at-

tempts, move throttle control to "F'" (fast)

position, wait a few minutes and try again.

to the "SLOW" position. The first time you start

the engine, it wi!t take extra cranking time to move

fuel from tank to the engine, NOTE: ALLOW EN-

GINE TO WARM UP FOR A FEW MINUTES BE-

FORE ENGAGING CLUTCH OF TRACTOR OR AT-

TACHMENT,

control midway between slow "S'" (slow) and

"F'" (fast) position.

IMPORTANT: BEFORE DRIVING THE

TRACTOR, INSTALL MOWER OR

REMOVE MOWER PARALLEL LiNK

(SEE FIGURE 7).

./ AIR iNTAKE

:UEL

TANK

CAP

/ ......._ FIGURE 12

OPERA TION

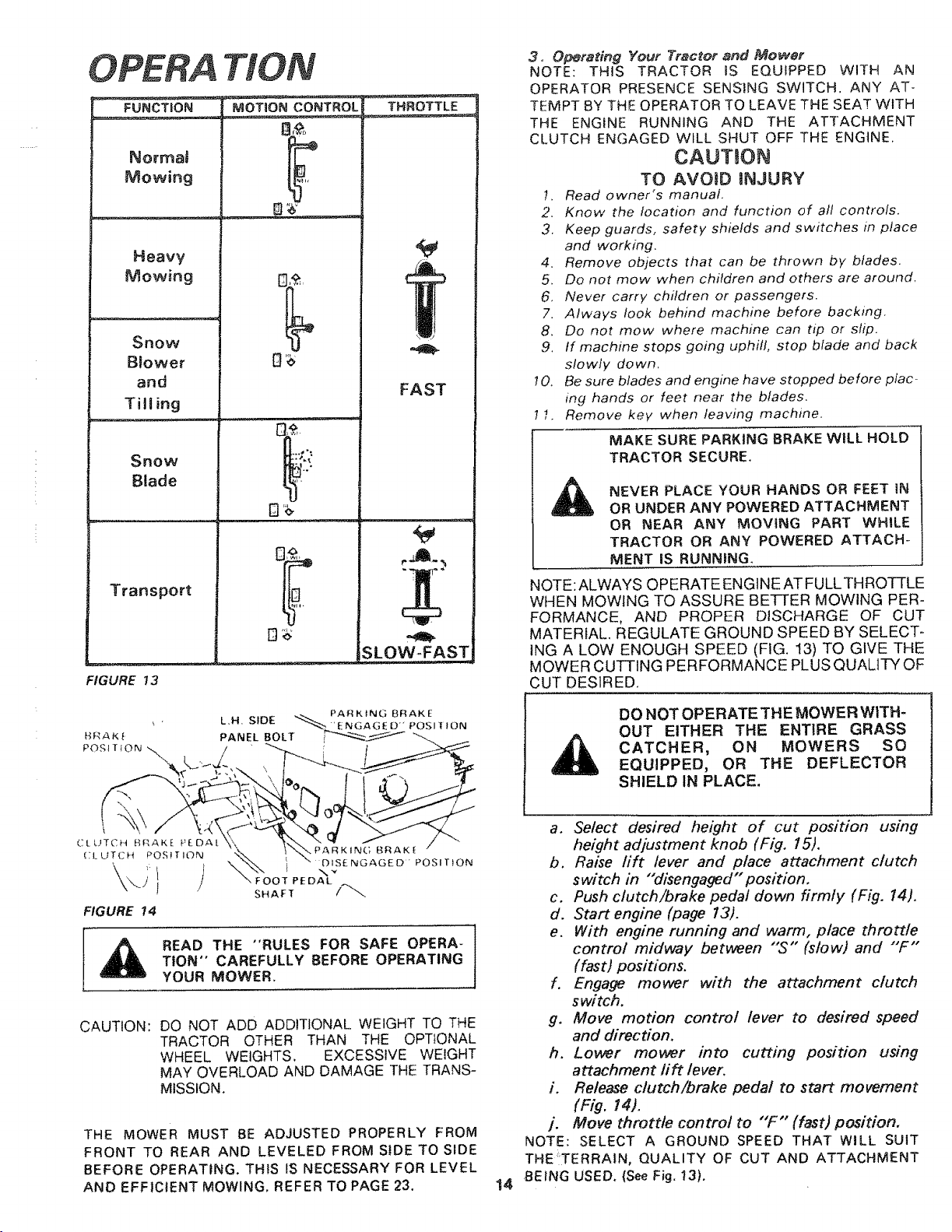

FUNCTtON

Normat

Mowing

Heavy

Mowing

Snow

Blower

and

Tilling

Snow

Blade

Transport

MOTION CONTROL

8,co

7

FIGURE 13

THROTTLE

FAST

SLOW-FAST

3. Operating Your Tractor _nd Mower

NOTE: THIS TRACTOR IS EQUIPPED WITH AN

OPERATOR PRESENCE SENSING SWITCH. ANY AT-

TEMPT BY THE OPERATOR TO LEAVE THE SEAT WITH

THE ENGINE RUNNING AND THE ATTACHMENT

CLUTCH ENGAGED WILL SHUT OFF THE ENGINE.

CAUTION

TO AVOtD tNJURY

1. Read owner's manual•

2. Know the location and function of all controls.

3. Keep guards, safety shields and switches in place

and working.

4. Remove objects that can be thrown by blades.

5. Do not mow when children and others are around,

6, Never carry children or passengers•

7. Always look behind machine before backing,

8, Do not mow where machine can tip or slip.

9. tf machine stops going uphill, stop blade and back

slowly down>

10. Be sure blades and engine have stopped before plac-

ing hands or feet near the blades.

I. Remove key when leaving machine.

MAKE SURE PARKING BRAKE WILL HOLD

TRACTOR SECURE.

NEVER PLACE YOUR HANDS OR FEET iN

OR UNDER ANY POWERED ATTACHMENT

OR NEAR ANY MOVING PART WHILE

TRACTOR OR ANY POWERED ATTACH-

MENT IS RUNNING,

NOTE: ALWAYS OPERATE ENGINE AT FULLTHRO-rTLE

WHEN MOWING TO ASSURE BETTER MOWING PER-

FORMANCE, AND PROPER DISCHARGE QF CUT

MATERIAL. REGULATE GROUND SPEED BY SELECT _

ING A LOW ENOUGH SPEED (FIG. 13) TO GIVE THE

MOWER CUTTING PERFORMANCE PLUS QUALITY OF

CUT DESIRED.

\

FIGURE !4

TION" CAREFULLY BEFORE OPERATING

READ THE "RULES FOR SAFE OPERA-

YOUR MOWER.

CAUTION: DO NOT ADD ADDITIONAL WEIGHT TO THE

THE MOWER MUST BE ADJUSTED PROPERLY FROM

FRONT TO REAR AND LEVELED FROM SIDE TO SIDE

BEFORE OPERATING. THIS IS NECESSARY FOR LEVEL

AND EFFICIENT MOWING, REFER TO PAGE 23.

TRACTOR OTHER THAN THE OPTIONAL

WHEEL WEIGHTS. EXCESSIVE WEIGHT

MAY OVERLOAD AND DAMAGE THE TRANS-

MISSION.

DO NOT OPERATE THE MOWER WITH-

OUT EITHER THE ENTIRE GRASS

CATCHER, ON MOWERS SO

EQUIPPED, OR THE DEFLECTOR

SHIELD IN PLACE.

a. Select desired height of cut position using

height adjustment knob (Fig. 15).

b. Raise rift lever and place attachment clutch

switch in "disengaged'position.

c. Push clutch/brake pedal down firmly (Fig. 14).

d. Start engine (page 13).

e. With engine running and warm, place throttle

control midway between "S'" (slow) and "F'"

(fast) positions.

f. Engage mower with the attachment clutch

switch.

g. Move motion control lever to desired speed

and direction.

h. Lower mower into cutting position using

attachment rift lever.

i. Release clutch/brake pedal to start movement

(Fig. 14).

j. Move throttle control to ,;c,, (fast) position.

NOTE: SELECT A GROUND SPEED THAT WILL SUIT

THE TERRAIN, QUALITY OF CUT AND ATTACHMENT

BEING USED. (SeeFig. 13),

14

CAUTION:NEVERRUN THE ENGINE WITHOUT AIR

iNTAKE DUCT INSTALLED (FIGURE 11),

4. Mowing Tips

NOTE: TIRE CHAINS CANNOT BE USED WITH THE

MOWER HOUSING ATTACHED.

READ THE "SAFETY RULES" CAREFULLY ]

BEFORE OPERATING YOUR MOWER.

REFER TO PAGE 2,

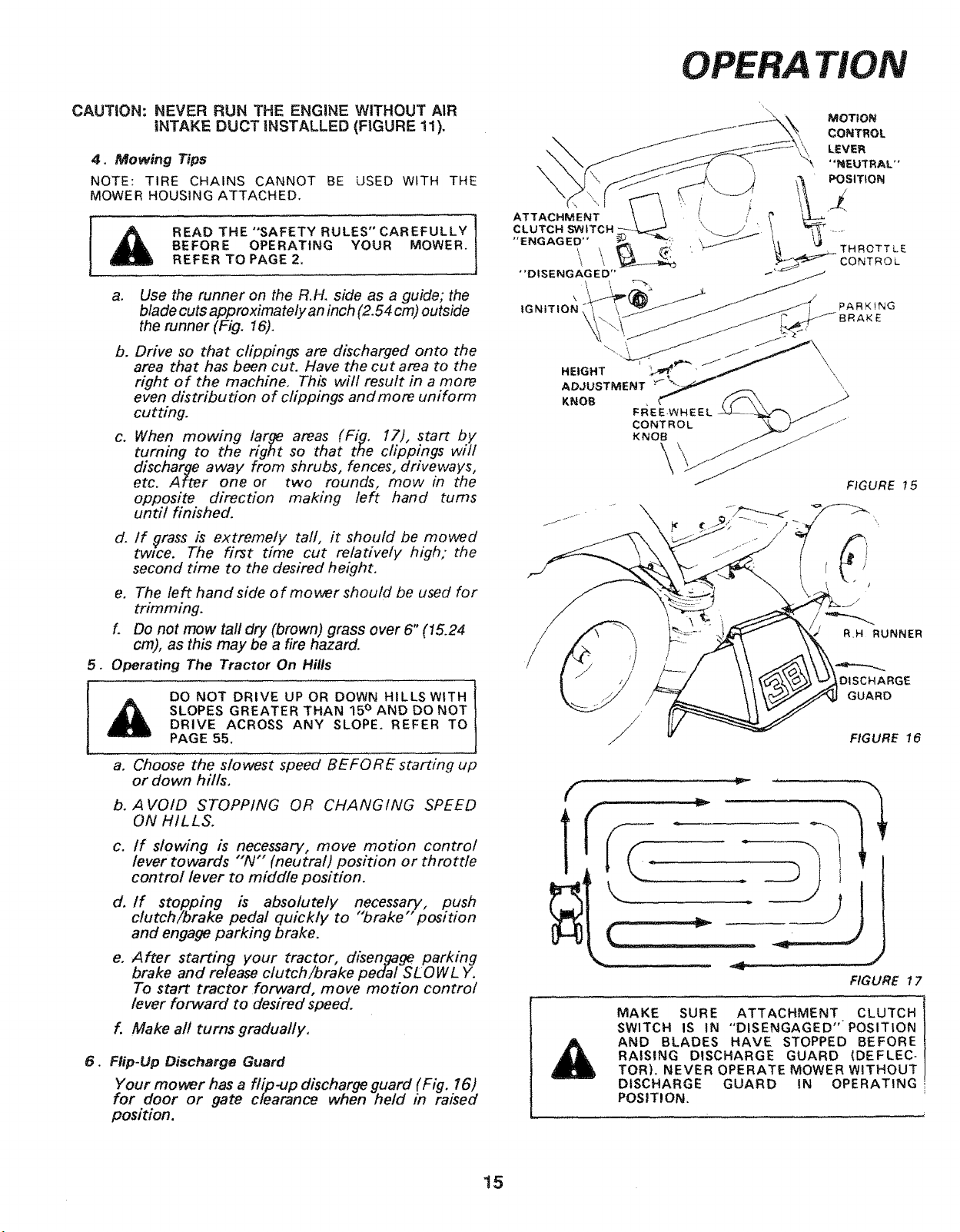

a.

Use the runner on the R.H. side as a guide; the

blade cuts approximately an inch (2.54 cm)outside

the runner (Fig. 16).

b. Drive so that clippings are discharged onto the

area that has been cut. Have the cut area to the

right of the machine. This will result in a more

even distribution of clippings and more uniform

cutting.

c. When mowing lar_le areas (Fig. 17), start by

turning to the right so that the clippings witl

discharge away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

und/ finished.

TION

i

i

FREE.WHEEL

CONTROL

KNOB

\,

FIGURE t 5

d. If (irass is extremely tall, it should be mowed

twice. The first time cut relatively high," the

second time to the desired height.

e. The left hand side of mower shoutd be used for

trimming.

f. Do not mow tall dry (brown) grass over 6" (15.24

cm), as this may be a fire hazard.

5. Operating The Tractor On Hills

DO NOT DRIVE UP OR DOWN HILLS WITH

SLOPES GREATER THAN 15° AND DO NOT

DRIVE ACROSS ANY SLOPE. REFER TO

PAGE 55.

a. Choose the slowest speed BEFORE starting up

or down hills.

b. AVOID STOPPING OR CHANGING SPEED

ON HILLS.

C_

If slowing is necessary, move motion control

lever towards "N'" (neutral) position or throttle

control lever to middle position.

d.

if stopping is absolutely necessary, push

clutch/brake pedal quickly to "brake"position

and engage parking brake.

e.

After starting your tractor, disengage parking

brake and release clutch/brake pedal St OWL Y.

To start tractor forward, move motion control

lever forward to desired speed.

f. Make aft turns graduafly.

,

Flip-Up Discharge Guard

Your mower has a flip-up discharge guard (Fig. 16)

for door or gate clearance when held in raised

position.

K

1

R,H RUNNER

DISCHARGE

GUARD

FIGURE 16

t;

FIGURE 17

MAKE SURE ATTACHMENT CLUTCH 1

SWITCH IS tN "DISENGAGED'"POSITtON

AND BLADES HAVE STOPPED BEFORE

RAISING DISCHARGE GUARD (DEFLEC-

TOR). NEVER OPERATE MOWER WITHOUT

DISCHARGE GUARD IN OPERATING I

POSITION.

i

15

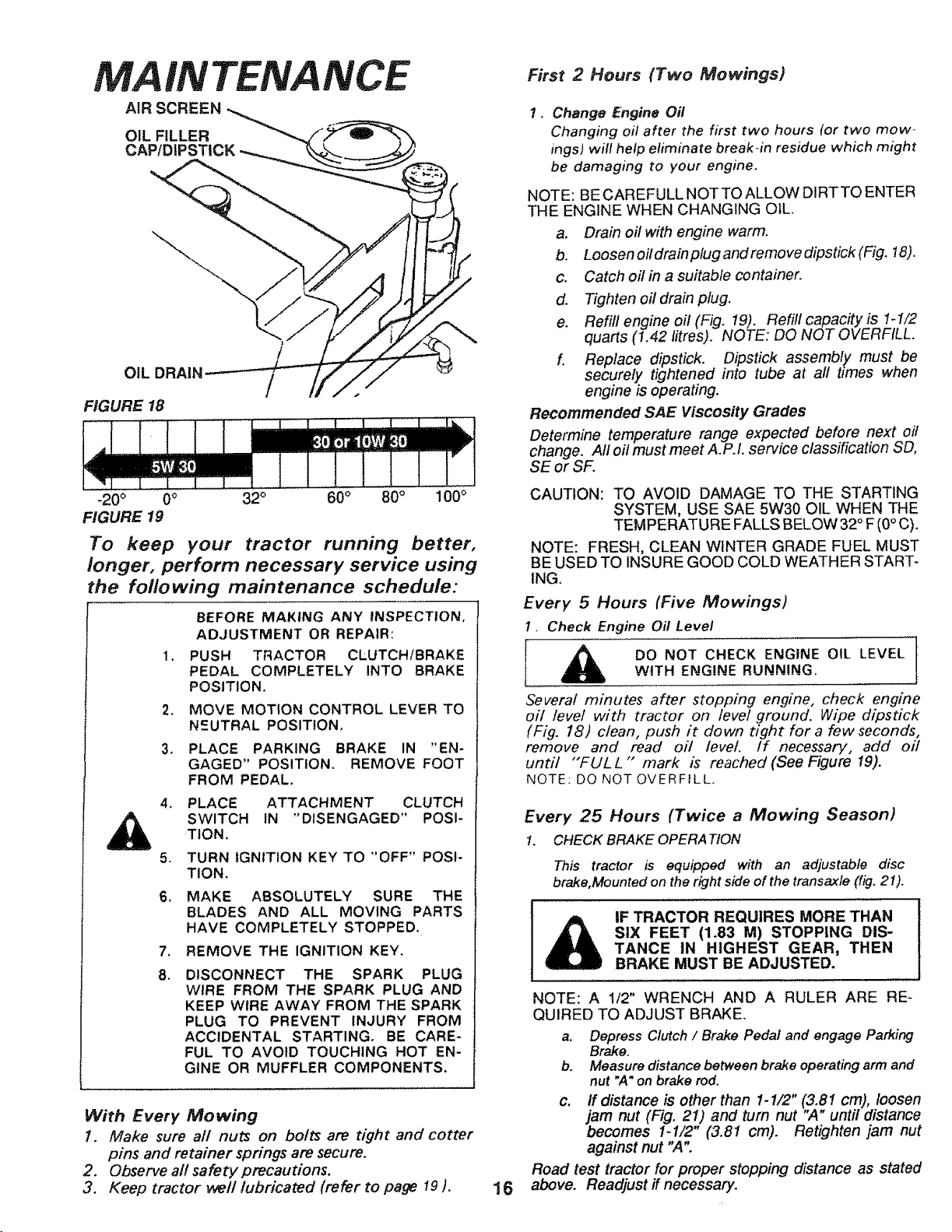

INTENANCE

First 2 Hours (Two Mowings)

AIR SCREEN

OIL FILLER

CAP!DIPSTICK

OiL DRAIN /

FIGURE 18

.20 ° 0° 32 ° 60° 80° 100°

FIGURE 19

To keep your tractor running better,

longer, perform necessary service using

the following maintenance schedule:

BEFORE MAKING ANY INSPECTION,

ADJUSTMENT OR REPAIR:

1. PUSH TRACTOR CLUTCH/BRAKE

PEDAL COMPLETELY INTO BRAKE

POSITION,

2. MOVE MOTION CONTROL LEVER TO

N=.UTRAL POSITION.

3. PLACE PARKING BRAKE IN "EN-

GAGED" POSITION. REMOVE FOOT

FROM PEDAL.

4. PLACE ATTACHMENT CLUTCH

SWITCH IN "DISENGAGED" POSI-

TION.

5. TURN IGNITION KEY TO "OFF" POSI-

TION.

6. MAKE ABSOLUTELY SURE THE

BLADES AND ALL MOVING PARTS

HAVE COMPLETELY STOPPED.

REMOVE THE IGNITION KEY.

7_

8.

DISCONNECT THE SPARK PLUG

WIRE FROM THE SPARK PLUG AND

KEEP WIRE AWAY FROM THE SPARK

PLUG TO PREVENT INJURY FROM

ACCIDENTAL STARTING. BE CARE-

FUL TO AVOID TOUCHING HOT EN-

GINE OR MUFFLER COMPONENTS.

With Every Mowing

1. Make sure all nuts on bolts are tight and cotter

pins and retainer springs are secure.

2. Observe all safety precautions.

3. Keep tractor well lubricated (refer to page 19). 16

1. Change Engine Oil

Changing oil after the first two hours (or two mow _

ings) will help eliminate break-in residue which might

be damaging to your engine.

NOTE: BE CAREFULL NOT TO ALLOW DIRTTO ENTER

THE ENGINE WHEN CHANGING OIL.

a. Drain oil with engine warm,

b. Loosen oil drain ptug and remove dipstick (Fig. 18).

c. Catch oil in a suitable container.

d. Tighten oi! drain plug.

e. Refill engine oil (Fig, 19). Refill capacity is 1-1/2

quarts (1.42 litres). NOTE: DO NOT OVERFILL.

L Replace dipstick. Dipstick assembf_, must be

securely tightened into tube at all times when

engine is operating.

Recommended SAE Viscosity Grades

Determine temperature range expected before next oil

change. All oil must meet A.P.I. service classification SD,

SE or SF.

CAUTION: TO AVOID DAMAGE TO THE STARTING

SYSTEM, USE SAE 5W30 OIL WHEN THE

TEMPERATURE FALLS BELOW 32° F(0°C).

NOTE: FRESH, CLEAN WINTER GRADE FUEL MUST

BE USED TO INSURE GOOD COLD WEATHER START-

ING.

Every 5 Hours (Five Mowings)

I, Check Engine Oil Level

WITH ENGINE RUNNING.

Several minutes after stopping engine, check engine

oil level with tractor on level ground. Wipe dipstick

(Fig. 18) clean, push it down tight for a few seconds,

remove and read oil level If necessary, add oil

until "FULL" mark is reached (See Figure 19).

NOTE: DO NOT OVERFILL,

Every 25 Hours (Twice a Mowing Season)

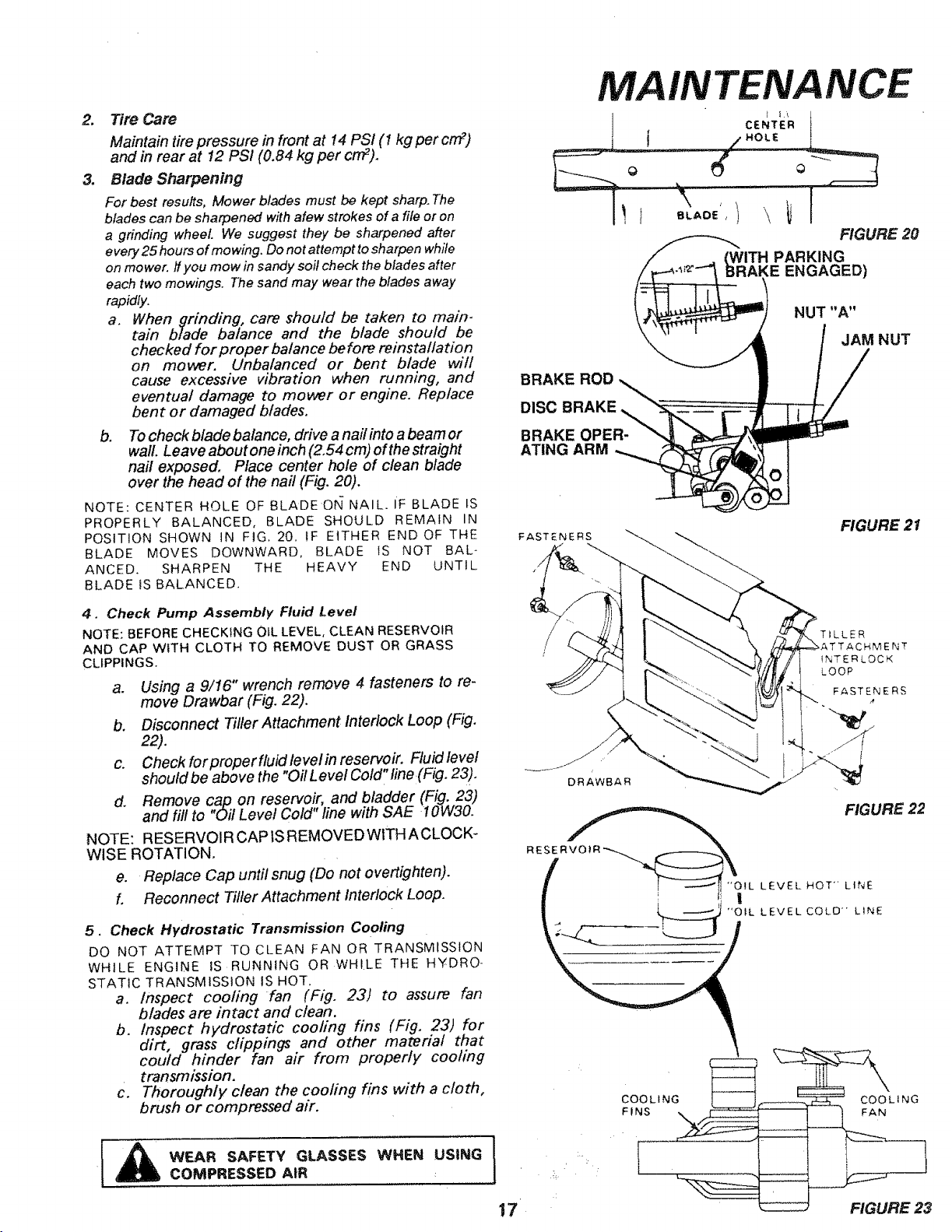

1. CHECK BRAKE OPERAT/ON

This tractor is equipped with an adjustable disc

brake,Mountedon theright sideofthe transax/e(fig.21).

IF TRACTOR REQUIRES MORE THAN

SIX FEET (1.83 M) STOPPING DIS-

TANCE IN HIGHEST GEAR, THEN

BRAKE MUST BE ADJUSTED.

NOTE: A 1/2" WRENCH AND A RULER ARE RE-

QUIRED TO ADJUST BRAKE.

a. Depress Clutch / Brake Pedal and engage Parking

Brake.

b, Measure distance between brake operating arm and

nut "A" on brake rod.

C. ff distance is other than 1-1/2" (3.8t cm), loosen

jam nut (Fig. 21) and turn nut "A" until distance

becomes 1-1/2" (3.81 cm), Retighten jam nut

against nut "A"

Road test tractor for proper stopping distance as stated

above. Readjust if necessary.

2. Tire Cam

Maintain tire pressure in front at 14 PSI (1 kg per crr£)

and in rear at 12 PSI (0.84 kg per crrP).

3. Blade Sharpening

For best results, Mower blades must be kept sharp.The

blades canbe sharpened with afew strokesof a fife oron

a grinding wheel We suggest they be sharpened after

every25hoursof mowing. Donot attempttosharpen while

on mower, ffyou mow in sandy soilcheck theblades after

each two mowings. The sand may wear the blades away

rapidly.

a. When grinding, care should be taken to main-

tain blade balance and the blade should be

checked for proper balance be fore reinstallation

on mower. Unbalanced or bent blade will

cause excessive vibration when running, and

eventual damage to mower or engine. Replace

bent or damaged blades.

b. Tocheck blade balance, drive anail into a beam or

wall. Leave about one inch (2.54 cm) of the straight

nail exposed. Place center hole of clean blade

over the head of the nail (Fig. 20).

NOTE: CENTER HOLE OF BLADE ON NAIL. IF BLADE IS

PROPERLY BALANCED, BLADE SHOULD REMAIN IN

POSITION SHOWN IN FIG, 20, IF EITHER END OF THE

BLADE MOVES DOWNWARD, BLADE IS NOT BAL-

ANCED, SHARPEN THE HEAVY END UNTIL

BLADE iS BALANCED.

BRAKE ROD

DISC BRAKE,_

BRAKE OPER-

ATING ARM

FASTENERS

INTENANCE

l

t

CENTER

FIGURE 20

WITH PARKING

RAKE ENGAGED)

NUT "A"

JAM NUT

_GURE21

4. Check Pump Assembly Fluid Level

NOTE: BEFORE CHECKING OIL LEVEL, CLEAN RESERVOIR

AND CAP WITH CLOTH TO REMOVE DUST OR GRASS

CLIPPINGS.

a. Using a 9/16" wrench remove 4 fasteners to re-

move Drawbar (Fig. 22).

b. Disconnect Tiller Attachment Interlock Loop (Fig.

22).

c. Check for proper fluid level in reservoir. Fluid level

should be above the "Oil Level Cold, line(Fig. 23).

d. Remove cap..on reservoir, and bladder (Fig. 23)

and fill to Oil Level Cold line with SAE 10W30.

NOTE: RESERVO1R CAP IS REMOVED WITH ACLOCK-

WISE ROTATION.

e. Replace Cap until snug (Do not overtighten).

f. Reconnect Tiller Attachment Interlock Loop.

5. Check Hydrostatic Transmission Cooling

DO NOT ATTEMPT TO CLEAN FAN OR TRANSMISSION

WHILE ENGINE IS RUNNING OR WHILE THE HYDRO-

STATIC TRANSMiSSiON IS HOT.

a. Inspect cooling fan (Fig. 23) to assure fan

blades are intact and clean.

b. Inspect hydrostatic cooling fins (Fig. 23) for

dirt, grass clippings and other material that

could hinder fan air from properly cooling

transmission.

c. Thoroughly clean the cooling fins with a cloth,

brush or compressed air.

WEAR SAFETY GLASSES WHEN USING

COMPRESSED AIR

DRAwBAR

COOLH_G

FiNS

TILLER

INTERLOCK

LOOP

FASTENERS

tNG

!7

FIGURE 23

Loading...

Loading...