Page 1

Operator's Manual

I

I r s.. i

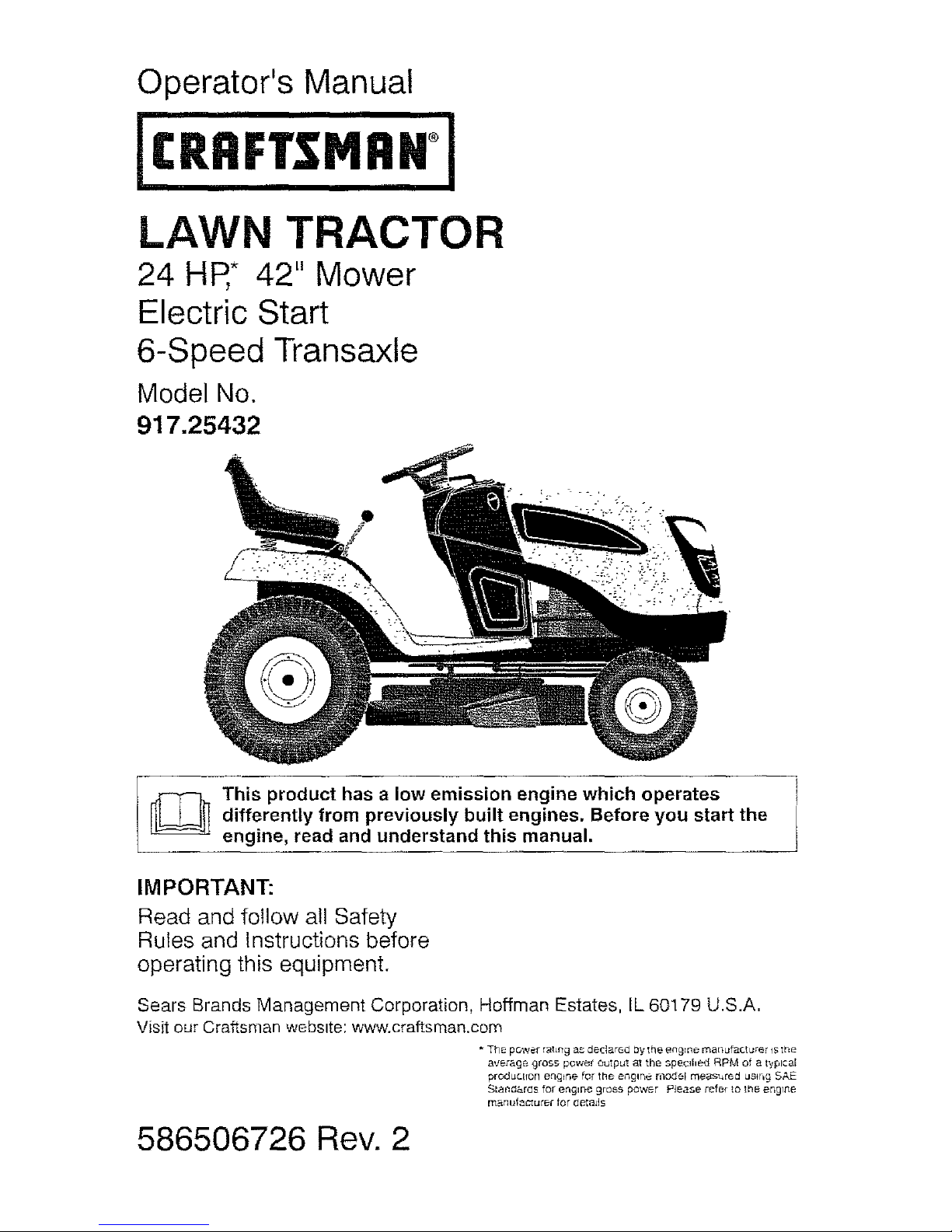

LAWN TRACTOR

24 HP,* 42" Mower

Electric Start

6-Speed Transaxle

Model No.

917.25432

This product has a low emission engine which operates I

[_ ifferently from previously built engines. Before you start the

engine, read and understand this manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

Sears Brands Management Corporation, Hoffman Estates, [L 60179 U.S.A,

Visit our Craftsman webslte: www.craftsman.com

The power r:_ng as declared Dy the engine manufacturer fs the

average gross power output at the spec_hed RRM of a typical

produ&lfon erlqH3e for the et_glr_ model measured us_hg SAE

S[aRd_,rds for engine gross power F_Jease yefer tO t_B eP, gT4he

m_nu|acturel- lor detad£

586506726 Rev. 2

Page 2

Warranty ................................................. 2

Safety Rules ............................................ 3

Product Specifications ............................. 6

AssemblyiPre-Operatlon ......................... 7

OperatEon ................................................. 9

Maintenance .......................................... 16

CRAFTSMAN FULL WARRANTY

TWO YEARS ON RIDING EQUIPMENT

Maintenance Schedule .......................... 16

Service and Adjustments ....................... 2I

Storage ................................................ 27

Troubleshooting ..................................... 28

Sears Service ........................ Back Cover

When operated and maintained according to eli supplied instructlons, Warranty wtll also

cover defects in matenat and workmanship of the Frame and Front Axle for five years from

the date of purchase

This warranty covers ONLY defects in material and workmanship. Sears will NOT

pay for:

• Expendable items that become worn dunng normal use, including but not hm_ted to

blades, spark plugs, air cleaners, belts, and o_1filters.

Standard maintenance servicing, o_1changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as na_ls.

thorns, stumps, or glass.

Tire or wheel replacement or repair resulting from normal wear, accident, or fmproper

operation or matntenance.

Repairs necessary because of operator abuse, including but not limited to damage

caused by towing obiects beyond the capabJhty of the riding equipment, impacting

objects that bend the frame or crankshaft, or over-speeding the engine.

Repairs necessary because of operator negligence, including but not ttmited to, electrical

and mechantcal damage caused by improper storage, failure to use the proper grade

and amount of engine oil, fadure to keep the deck clear of flammable debris, or failure to

malntarn the riding equipment according to the instructions contatned tnthe operator's

manual.

• Engine (fuel system) cleantng or repairs caused by fuel determined to be contaminated

or oxidized (stale]. In general, fuel should be used within 30 days of its purchase date.

Normal deterioration and wear of the exterior ftnishes, or product label replacement.

All rEd,rig equipment and battery warranty coverage _svoid _fth_s product is ever used for

commercial or rental purposes.

This warranty apphes only wh_le thts product _swlthtn the United States.

This warranty gives you specific legal rights, and you may also have other nghts which

vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

Page 3

_DANGER:This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death.

_WARNING: In order to prevent acciden-

tal starting when setting up. transporting,

adjusting or making repairs, always discon-

nect spark ptug wire and place wire where

It cannot contact spark plug.

_WARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

_WARNING; Tow only the attachments

that are recommended by and comply with

spec_hcatlons of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on aslope. Too heavy of a load, wh_le

on a slope, _s dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

_WARNING: Engine exhausL some of

its constituents, and certain vehicle compo-

nents contain or emit chemicals known to

the S_ate of California to cause cancer and

b_rth defects or other reproduchve harm.

_,WARNING: Battery posts, terminals and

related accessories contain tead and lead

compounds, chemicals known tothe State of

Cahforma to cause cancer and b_rth defects

or other reproductive harm. Wash hands

after handling.

I. GENERAL OPERATION

Read, understand, and follow all instruc-

tions on the machine and in the manual

before starting.

De not put hands or feet near rotating

parts or under the machine. Keep clear

of the discharge opening at all times.

Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

Clear the area of objects such as rocks,

toys, wire. etc., which could be Dcked

up and thrown by the blades.

Be sure the area is clear of bystanders

before operating. Stop machine if anyone

enters the area.

Never carry passengers.

Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

Never direct d_scharged material toward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

Do not operate machine without the en-

tire grass catcher, discharge chute, or

other safety devices In place and working,

Slow down before turning.

Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

Disengage blades when not mowing

Shut off engine and walt for all parts to

come to a complete stop before cleamng

the machine, removing the grass catcher,

or unclogging the discharge chute.

Operate machine onty _ndaylig ht or good

artificial light.

Do not operate the machine wMe under

the _nfluence of alcohol or drugs.

Watch for traffic when operahng near or

crossing roadways,

Use extra care when loading or unloading

the machine into a trailer or truck.

Always wear eye protection when operat-

ing machine,

Use ear protectors to avoid damage to

hearing,

Data indicates that operators, age 60

years and above, are involved in a large

percentage of nding mower-related iniu-

nes. These operators should evaiuate

their ability to operate the nd_ng mower

safely enough to protect themselves and

others from serious injury.

Followthe manufacturer's recommenda-

tion for wheel weights or counterweights,

Keep machine free of grass, leaves or

other debris build-up which can to uch hot

exhaust / engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc-

cur, Clean any oil or fuel sDllage before

operating or stenng the machine. Allow

machine to cool before storage.

Page 4

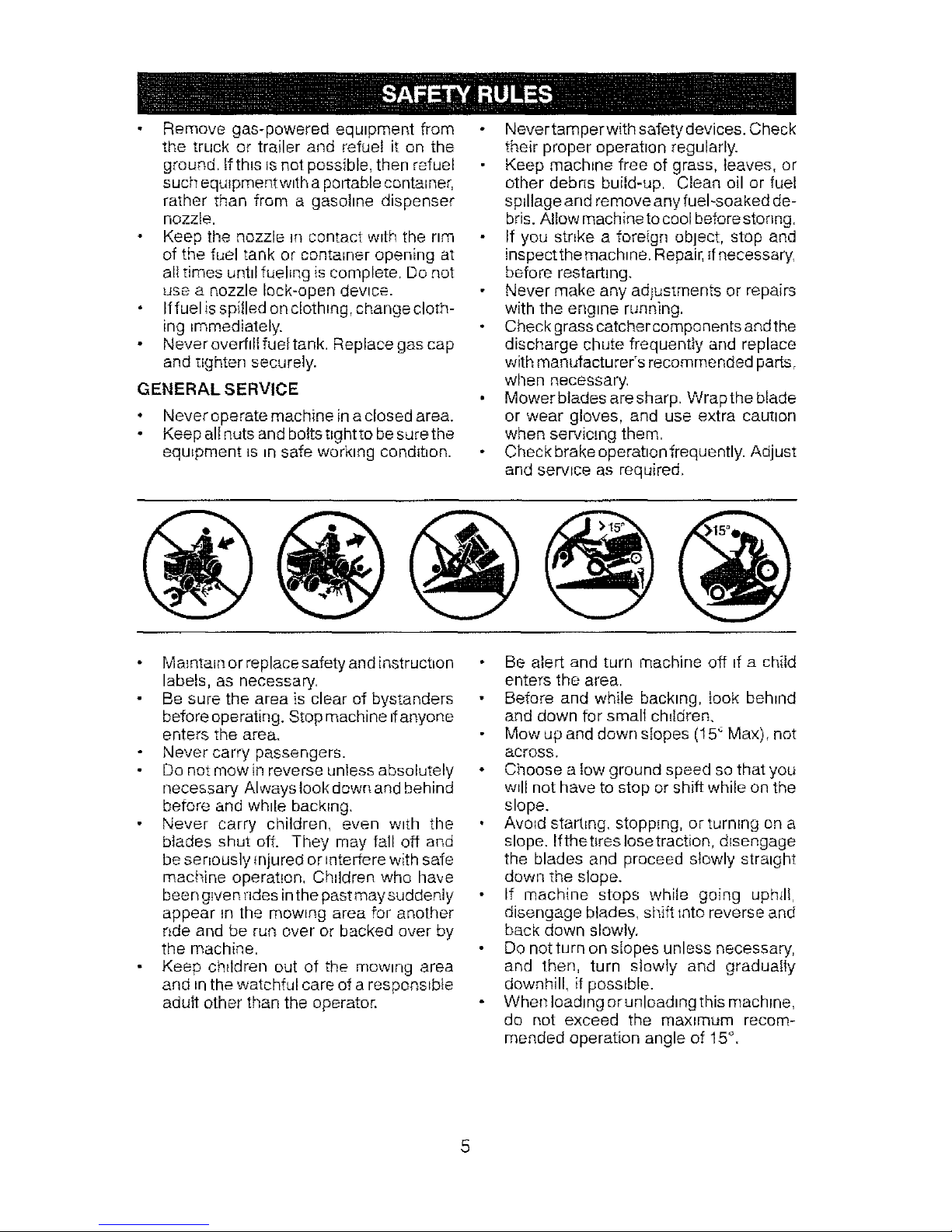

11,SLOPE OPERATION

Slopes are a major factor related to toss of

control and t_p-over accidents, which can

result in severe _njury or death. Operation

on a!l slopes requtres extra caution. If you

cannot back up the slope or _fyou feel uneasy

on _t,do not mow it.

Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine, Tall grass

can hide obstacles.

Choose a low ground speed so that you

will not have to stop or sh_ft white on the

slope,

* Do not mow on wet grass. Tires may !ose

traction.

Always keep the machine in gear when

going down slopes, Do not sh_ftto neutral

and coast downhill.

Avoid starting, stopping, or turning on a

slope, lfthetireslosetractlon, dtsengage

the blades and proceed slowly straight

down the slope.

• Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

Use extra care while operating machine

with grass catchers orother attachments,

they can affect the stability of the ma-

chine. Do no use on steep s{opes.

Do not try to stabilize the machine by

putting your foot on the ground.

Do not mow near drop-offs, ditches,

or embankments. The machine could

suddeniy roll over if a wheel _s over the

edge or if the edge caves in.

i11.CHILDREN

_WARNING: CHILDREN CAN BE INJURED

BY THIS EQUIPMENT The Amencan Acade-

my of Pediatrics recommends that children

be a m_ntmum of 12 year of age before op-

erating a pedestrian con[roiled Fawn mower

and a minimum of 16 years of age before

operatIng a ndmg fawn mower,

Tragic acctden[s can occur if [he operator

is not alert to the presence of children.

Ch_fdren are often attracted to the machine

and the mowing activtty, Never assume

that children will remain where you last

saw them.

Keep chddren out of the mow_ng area

and m the watchful care era responsEble

adult other than the operator.

Be alert and turn machine off if a chdd

enters the area.

Before and while backing, look behind

and down for small children.

Never carry children, even with th e blades

shut off. They may fall off and be seriously

injured or interfere with safe machine

operation. Children who have been given

rides In the past may suddenly appear in

the mowing area for another ride and be

run over or backed over by the machine,

Never allow children to operate the ma-

chine.

Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a chdd.

IV. TOWING

• Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

• Followthemanufacturer'srecommenda-

uonfor weight hm_tsfor towed equipment

and towing on slopes.

Never allow children or others in or on

towed equipment.

Onslopes, the weight ofthe towed equip-

ment may cause loss of tractron and loss

of control.

Travel slowly and allow extra distance to

stop.

V, SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasohne.

Gasohne _s extremely flammable and the

vapors are explosive.

Extinguish alt cigarettes, cigars, p_pes,

and other sources of ignit_on.

• Use only approved gasoline container.

Never remove gas cap or add fuel w_th

the engine running. Allow engine to cool

before refueling.

Never fue! the machine _ndoors.

Never store the machine or fuel container

where there _san open flame, sped<, or

pl{ot light such as on a water heater or

other appliances.

• Never flit containers inside a vehicle or

on a truck or trailer bed with piashc liner.

Always place containers on the ground

away from your vehicle when fiJltng.

Page 5

Removegas-poweredequipmentfrom

thetruckortrailerandrefueiitonthe

ground,ifthisisnotpossible,thenrefuel

suchequlpmentw_thaportablecontainer,

ratherthanfromagasolinedispenser

nozzle.

Keepthenozzle_ncontactw_ththerim

ofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete,Donot

useanozzlelock-opendevice.

Iffuelisspilledonclothing,changecloth-

ing_mmediately.

Neveroverfillfueltank.Replacegascap

andughtensecurely.

GENERALSERVICE

* Neveroperate machine in a closed area.

Keep al! nuts and bolts t_ght to be sure the

equipment is _nsafe working condthon.

Never tamper with safety devices. Check

their proper operation regularly.

Keep machine free of grass, leaves, or

other debris build-up, Clean oil or fuel

spillage and remove any fuel-soaked de-

bris. Allow machine to cool before stonng,

If you stnke a foreign oblect, stop and

inspect the machine. Repair, ifnecessary,

before restarting.

Never make any adiustments or repairs

with the engine running.

Check grass catcher components and the

discharge chute frequently and replace

with manufacturer's recommended parts r

when necessary.

Mower blades are sharp. Wrap the blade

or wear gloves, and use extra caution

when servicing them.

Check brake operation frequently. Adjust

and service as required,

Maintain or replace safety and instruchon

labels, as necessary.

Be sure the area is clear of bystanders

before operating. Stop machine #anyone

enters the area.

Never carry passengers.

Do not mow in reverse unless absolutely

necessary Always look down and behind

betore and while backing.

Never carry children, even with the

blades shut off. They may fall off and

be senously injured or interfere with safe

machine operation, Chddren who have

been g_ven r_desin the past may suddenly

appear _n the mowing area for another

ride and be run over or backed over by

the machine.

Keep children out of the mowing area

and _nthe watchful care of a responsible

adutt other than the operator.

Be alert and turn machine off _fa child

enters the area.

Before and while backing, took behind

and down for small cMdren.

Mow up and down slopes (15" Max), not

across,

Choose a low ground speed so that you

w_ll not have to stop or shift while on the

slope.

Avoid starting, stopping, or turning on a

slope, lfthetlres Iosetraction, d_sengage

the blades and proceed slowly straight

down the slope.

If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

When loading or unloading this machine,

do not exceed the maximum recom-

mended operation angle of 15°.

Page 6

PRODUCT SPECIFICATIONS

Gasohne Capacrty 3 GaIi_ns/t 1,35 L

and type Regular Unleadedl-

Power Rating" t 7 5 K-"W@ 3400 RF'M

eLIType SAE 30 _abeve32_Ft0_C)

(API SG-SLI S_E 5W30 Ibelow 32"F/0"C)

Q_tCapactty W.,Rlter 64 Oz '1.96 L

W/out FEIter 60 Qz/t,77 L

Spark Plug Champion696798

tGap 030" / 0 76 ram)

ChargEng 3 Amps Battery

System 5 Amps HeadlEghts

Battery Amp/Hr 28

Mtn CCA 230

Case s_ze U1R

Blade Bolt Torque 45-55 Ft. Lbs _62-75Nm

The power ratEng as declared by the engine manufac-

turer isthe averagegrosspoweroutputatthespectfJed

RPMofatyptcal production eng¢_eforthe enginemode{

measuredusingSAEStandardsforenginegrosspower.

Pleasereferto the engLnemanufacturerfordeta(_s

"l'_lkGasehne contalmng up to 10%ethanoltel0) _s

acceptable for use in this machine Tr_e use of

any gasohne exceedtng 10% ethanol (EI01 w_ll

vo_d the product warranty.

CONGRATULATIONS on your purchase of

a new tractor. It has been deslgnedr engi-

nee red and manufactured to give you the best

possible dependabih:y and performance.

Should you experience any problem you can-

not easily remedy, please contact a Sears or

other qualified servicecenter, We have com-

petent, well-trained representati,!es and the

proper tools to service or repair th_s tractor.

PIease read and retain this manual. The

instructions w_ll enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES",

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule _nmamta_nlng,

caring for and using your tractor.

• Follow anstructtons under "Maintenance"

and "S_orage" sections of th_s manual.

• Wear proper Personal Protectwe Equip-

ment (PPE) while operahng [hEsmachine,

Including (at a minEmum) sturdy footwear

eye protection, and heartng protechen.

Do not mow in shorts and/or open toed

footwear.

• Always let someone _<nowyou are outside

mow_ng.

_,WARNING: Th_s tractor _sequipped with

at_ internal combustion engine and should

not be usect on or near any unimproved

forest-covered, brush-covered or grass-

covered land unless the engine's exhaust

system is equipped with a spark arrestor

meeting apphcable local or state laws (If

any). [f a spark arrester is used, It should

be maintained tn effective working order by

the operator.

Inthe state of Cahfornia the above is req ulred

by law (Section 4442 of the Caltfornla Pubhc

Resources Code). Other states may have

stmilar taws. Federal laws apply on federal

lands. A spark arrester for the muffler ts

ava ilablethrough your nearest Sears service

center (See REPAIR PARTS manual).

6

Page 7

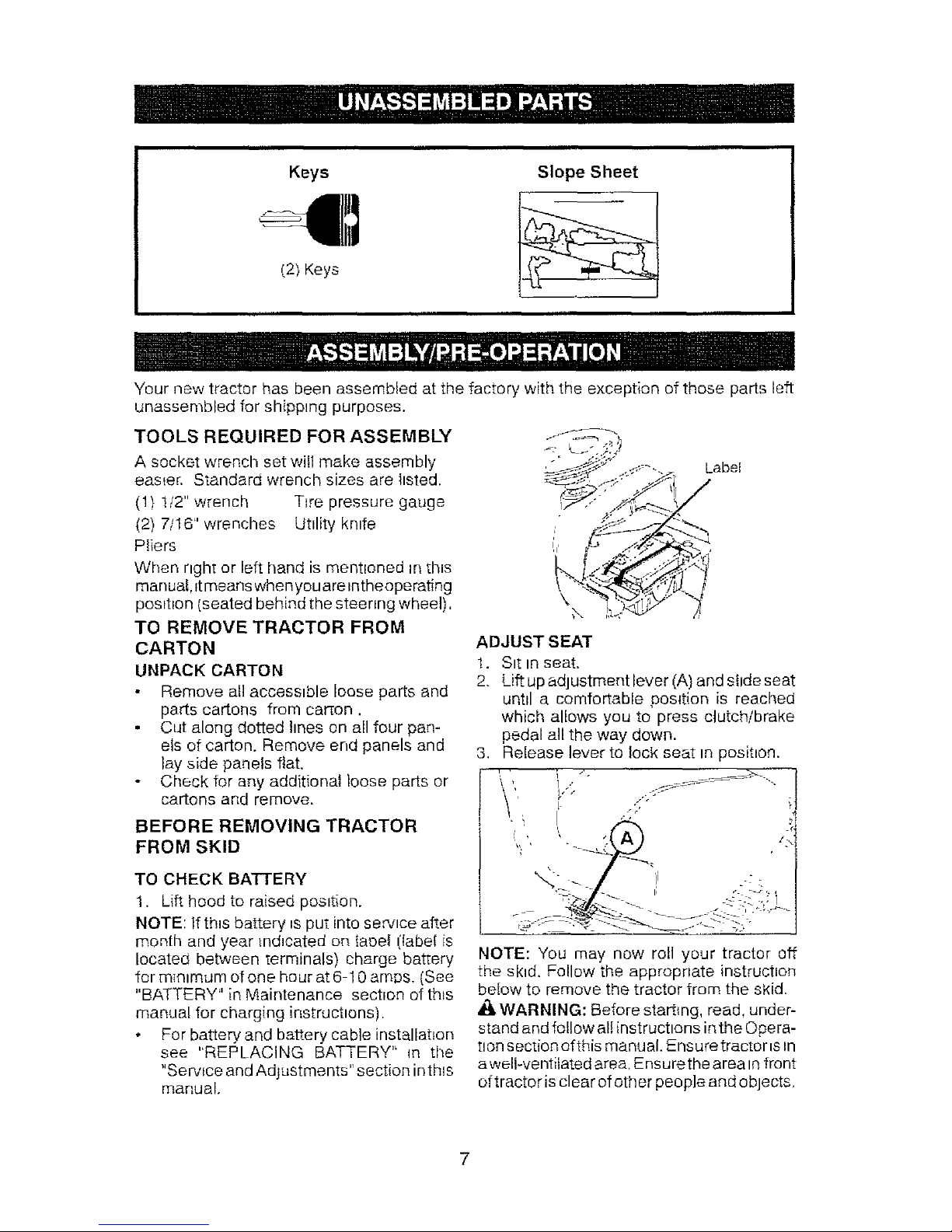

Keys Slope Sheet

(2) Keys

Your new tractor has been assembled at the factory with the exception of those parts left

unassembled for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

eas_er. Standard wrench sizes are l_sted.

(1) 1/2" wrench Tire pressure gauge

(2) 7116" wrenches Utility knife

Pliers

When righ_ or left hand is mentioned in this

manual, itmeans whenyou arelntheoperating

position {seated behind the steering wheel),

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

Remove all accessible loose parts and

parts cartons from carton.

Cut along dotted lines on all four pan-

els of carton. Remove end panels and

lay side panels fiat.

Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

TO CHECK BATTERY

1, Lift hood to raised position.

NOTE: If th_s battery _sput into service after

month and year _nd_cated on taoel (labe{ is

located between _erminals) charge battery

for m_nimum of one hour at 6-10 arabs. (See

"BATTERY" in Maintenance section of this

manual for charging instructions),

* For battery, and battery cable installahon

see "REPLACING BATTERY" _n the

"Service and Adjustments" section in this

manual.

Label

ADJUST SEAT

l. Satin seat.

2. Lift up adjustment lever (A) and slide seat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

3. Release lever to lock seat in posit_on.

l [- <-.

NOTE: You may now roll your tractor off

the skid. Follow the appropnate instruchor_

below to remove the tractor from the skid.

_kWARNING: Before start{ng, read, under-

stand and follow al! instructions inthe Opera-

tlon sec[ion of this manual. Ensure trac_or _sIn

awell-ventilated area, Ens ure the area infront

of tractor is clear of other people and objects,

Page 8

NOTE:Youmaynowrollyourtractoroffthe

skid.Continueustngtheinstructionsthat

followtoremovethetractorfromtheskid.

WARNING:Beforestarting,read,un-

derstandandfollowallinstructionsinthe

Operationsectionofth_smanual.Besure

tractorIS_nawefl-ventdatedarea.Besure

theareainfrontoftractor_sc{earofother

peopleandobjects.

TOROLLTRACTOROFFSKID(See

Operationsectionfor locationand

functionofcontrols)

1, Raiseattachmentliftlevertoitshighest

position.

2. Releaseparkingbrakebydepressing

clutch!brakepedal.

3. PlacegearshiftleverInneutralposition.

4. Rolltractorforwardoffskid.

5, Removebandingholdingthedeflector

shieldupagainsttractor.

Continuewiththeinstructionsthatfollow.

CHECKTIREPRESSURE

Theflresonyourtractorwereevennflatedat

thefactoryfor.shippingpurposes.Correct

tirepressureis _mportant for best cutting

performance,

• Reduce tire pressure to PSI shown on

[ires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See 'TO LEVEL

MOWER" tn the Servtce and Adjustments

section of th_s manual

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for replac-

ing motion and mower blade dnve belts _n

the Service and Adjustments section of this

manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to see that the brake is operating

properly, See "TO CHECK BRAKE" in the

Service and Adjustments section of this

manual,

,!CHECKLIST

Before you operate your new tractor, we

wish to ensure that you receive the best

performance and satisfaction from th_s

Quality Product.

Please rewew the following checkiist:

,/Alt assembly instructions have been com-

pleted,

v" No remaining loose parts _ncarton.

,/Battery is properly prepared and charged.

,/Seat _sadjusted comfortably and tfg hte ned

securely,

¢" All tires are properly inflated. (For shEp-

ping purposes, the tires were overinflated

at the factory).

¢" Ensure mower deck is properly leveled

side-to-sideifront-te-rear for best cueing

results. (Tires must be properly inftated

for levehng).

,/Check mower and dnve belts. Ensure

they are routed properly around pulleys

and inside all belt keepers.

v" Check w_rEng. See that all connections

are stitl secure and w_res are properly

clamped.

Whtle learning how to use your tractor, pay

extra atXent_on to the following important

_tems'

•/ Engine otl is at proper level.

,/Fuel tank _sfilled w_thfresh, clean, reguIar

unleaded gasoline.

,/Become familEar wtth all comrois, [herr Io-

cahon and function. Operate them before

you start the engine.

v' Ensure brake system is tn safe operatHlg

condition.

v" Ensure Operator Presence System and

Reverse Operal:lon System (ROSI are

working properly (See the Operation and

Maintenance secttons in [h_s manual).

Page 9

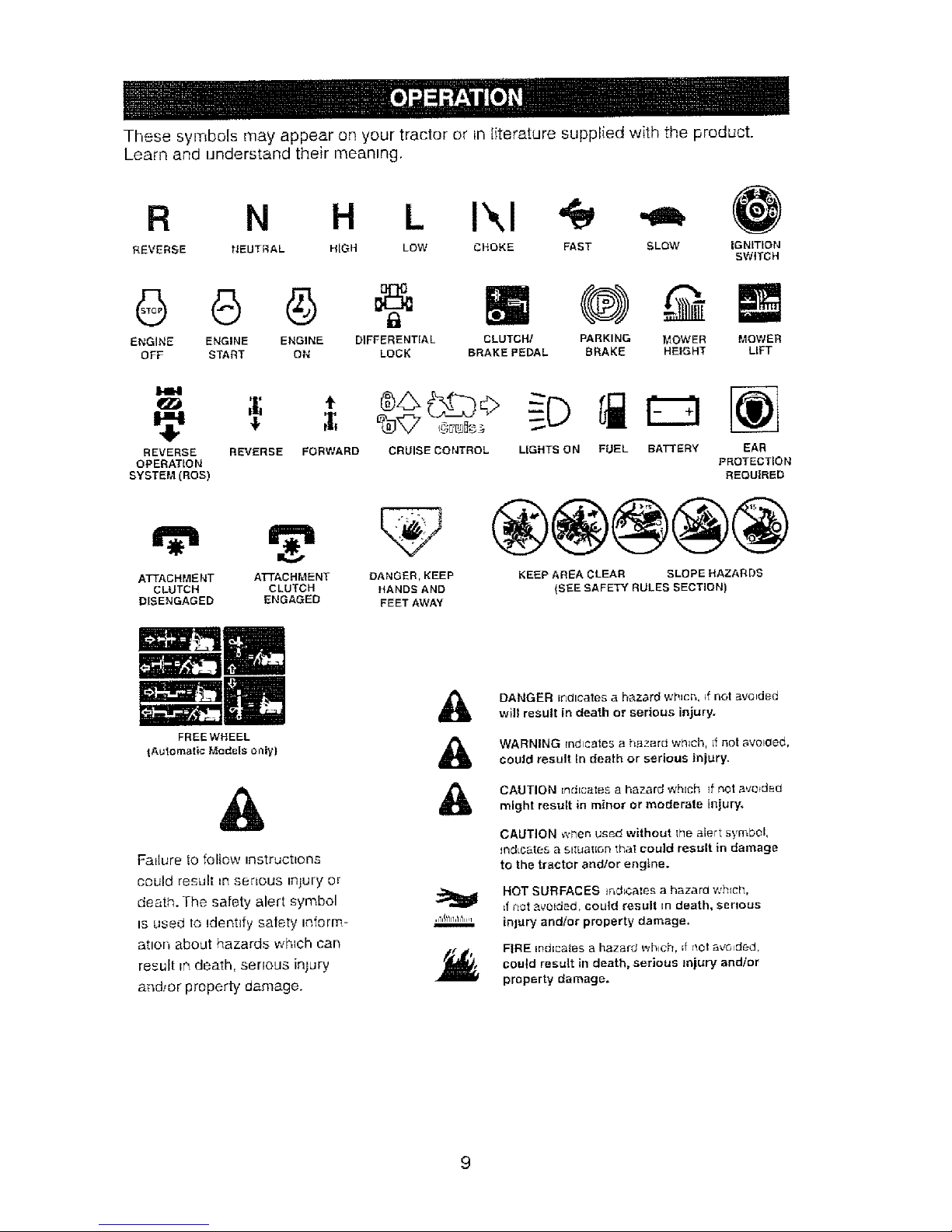

Thesesymbolsmayappearonyourtractororinliteraturesuppliedwiththeproduct.

Learnandunderstandtheirmeaning.

R N H L Ikl

REVERSE NEUTRAL HIGH LOW CHOKE FAST SLOW IGNITION

SWITCH

@

ENGINE ENGINE ENGINE DIFFERENT[AL

OFF START ON LOCK

CLUTCH/ MOWER

BRAKE PEDAL LIFT

@} @

PARKING MOWER

BRAKE HEIGHT

IklH

REVERSE REVERSE FORWARD

OPERATION

SYSTEM (ROS)

®,u o

CRUISE CONTROL LIGHTS ON

ATTACHMENT A'N'ACHMENT DANGER, KEEP

CLUTCH CLUTCH HANDS AND

DISENGAGED ENGAGED FEET AWAY

FREEWHEEL

)Automatic Models only)

Faliure to follow instructions

could result tn senous injury or

death. The safety alert symbol

is used to _dentffy safety inform-

ation about hazards which can

result _ndeath, serious injury

and:or property damage.

FUEL BATTERY EAR

PROTECTION

REOU1RED

®@@@@

KEEP AREA CLEAR SLOPE HAZARDS

{SEE SAFETY RULES SECTION)

&

&

&

,lll_tlll,lllu,I

DANGER indicates a hazard wnlcr=, if not avoided

will result in death or serious injury.

WARNING _ndlcates a hazard wr_leh, if not avmoed,

could result In death or serious injury.

CAUTION _ndlcates a hazard which tf Dot avoided

might result in minor or moderate injury.

CAUTION when used without me alert symbol,

JndLcates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES tnd=cates a hazard wh{cn,

=1ROt avoided, could result In death, serious

inluqi and/or property damage.

FIRE indicates a hazard which, _frxot avoided,

could result in death, serious injury and/or

property damage.

Page 10

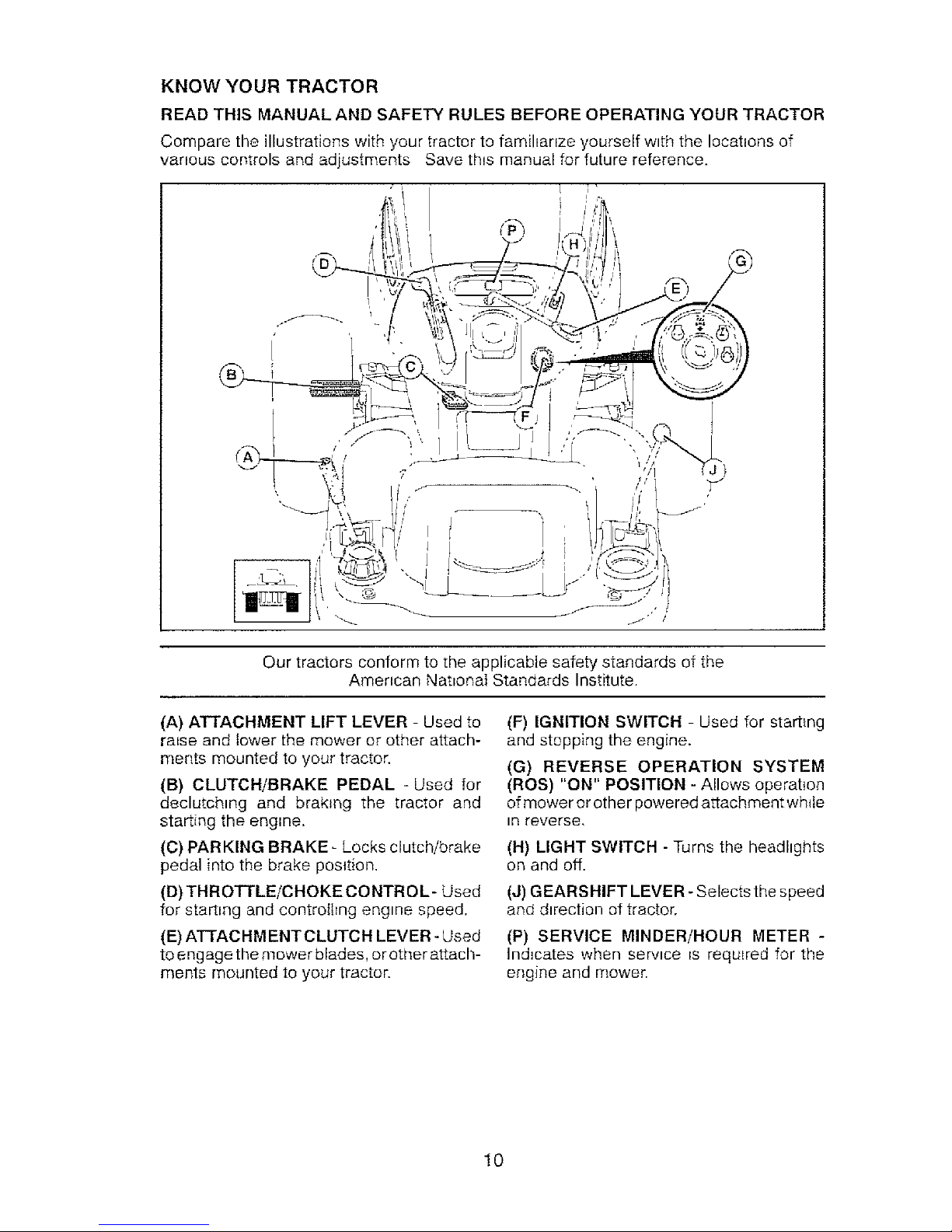

KNOW YOUR TRACTOR

READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of

vanous controls and adjustments Save this manual for future reference.

i ,i

Our tractors conform to the applicable safety standards of the

American National Standards Institute.

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor.

(B) CLUTCH/BRAKE PEDAL -Used for

declutch_ng and braking the tractor and

starting the engine.

(C) PARKING BRAKE _Locks clutch/brake

pedal into the brake posItion.

(D) THROTTLE/CHOKE CONTROL- Used

for starting and controlling engine speed,

(E) ATTACHMENT CLUTCH LEVER - Used

to eng age the mower blades, or other attach-

merits mounted to your tractor.

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

(G} REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION - Allows operation

of mower or other powered attachment white

IR reverse.

(H) LIGHT SWITCH - Turns the headhghts

on and off.

(J) GEARSHIFT LEVER- Selects the speed

and direction of tractor.

(P) SERVICE MINDERiHOUR METER -

Indicates when service _s required for the

engine and mower.

10

Page 11

The operation of any tractor can result in foreign objects thrown into the

eyes, which can result in severe eye damage. Always wear safety glasses

or eye shields while operating your tractor or performing any adjustments

or repa;rs. We recommend standard safety glasses or a wide vision safety

mask worn over spectacles.

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor ts equipped with an operator

presence sensing sw_tch. When engme

is running, any attempt by the operator to

leave the seat wlthoutflrst seltingthe parking

brake w_ll shut off the engine,

1, Depress clutchfbrake pedal (B) a!l the

way down and hold.

2. Pull parkmg brake lever (C) up and hold,

release pressure from clutchlbrake pedal

(B), then release parking brake tever. Ped-

al should remain in brake position. Ensure

parking brake wilt hold tractor secure.

. . t.t__ " ..,.(c)-s

':',;4_',<,J "L - '-"

STOPPING

, Z-:

[/?

MOWER BLADES -

• To stop mower blades, move attachment

clutch control to disengaged position (r_).

J

',i>..."--T._),

(1"_1) Attachment (t_) Attachment

Clutch Contro] Clutch Control

"Engaged .... Disengaged"

ENGINE -

• Move throttle control (D) to slow position.

NOTE; Failure to move throttle control

to slow position and atlowlng engine to

idle before stopping may cause engine to

"backfi re".

* Turn ignition key (F) to "STOP" poslbon

and remove key. Always remove keywhen

leavtng tractor to prevent unauthonzed use.

• Never use choke to stop engine.

IMPORTANT: Leavmg the _gnition switch in

any positaon other than "STOP" will cause the

battery to discharge and go dead,

NOTE: Under certain conditions when tracto r

ts standing tdlewith the engme runmng, hot

engine exhaust gases may cause "brown-

mg'' of grass. To eliminate this poss_bihty,

always stop engine when stopping tractor

on grass areas.

_i_ CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than ful! speed

(fast) reduces engine's operating efficiency.

• Full speed (fast) offers the best mower

performance.

l .. iI :iii

GROUND DRIVE -

• To stop ground dnve, depress brake pedal

all the way down.

• Move gearshift lever to neutral posmon.

1!

Page 12

TO MOVE FORWARD AND BACKWARD

The d{rectlon and speed of movement is

controlled by the gearshift lever (J},

"-_L

_--J2"- "- <

Start tractor with clutch/brake pedal

depressed and gearshift lever =nneutral

(N) posiuon.

2. Move gearshift leverto desired pos_tion,

3, Slowly release clutch/brake pedalto start

movement.

IMPORTANT: Bnng tractor to a complete

stop before shifting or changing gears.

Fadure to do so will shorten the useful life

of your transaxle.

TO ADJUST MOWER CUFFING HEIGHT

The position of tile attachment hft _ever (A)

determines the cutting height.

I ._. "° ]

• Put attachment hft _ever _ndesired cutting

height slot.

The cutting height range is approxtmately 1

to 4" (25,4 to 101,6 mm), The heights are

measured from the ground to the blade tip

with the engine not running, These heiglqts

are approximate and may vary dependtng

upon soil conditions, height of grass and

types of grass being mowed.

, The average lawn should be cut to approxi-

mately 2-1/2" (63,5 mm) during the cool

season and to over 3" (76,2 ram) during

hot months. For heakh[er and better look-

ing tawns, mow often and after moderate

growth.

• For best cutttng performance, grass over

6" (152,4 ram) in height should be mowed

[w_ce. Make the first cut rela[wely hEgh,the

second to desired Iqelght,

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

_hey are shghtly off the ground when mower

ts at the desired CUttEng height _noperating

posit_on. Gauge wheels then keep the deck

_nproper posttton to help prevent scalping

in most terrain conditions,

NOTE: Adjust gauge wheels with tractor on

a flat lave] surface,

1. Adjust mower to desired cu_ng height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this sectton of manuall.

2. W_th mower tndesired height of cut posi-

t_on,gauge wheels should be assembled

so they are stightly oflthe ground, install

gauge wheel in appropriate hoie, Tighten

secureiy.

3. Repeat for all, installing gauge wheel in

same adjustment hole_

r

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch, Any attempt

by the operator to leave the seat with [he

engine running and the attachment clutch

engaged wtli shut off the engine. You must

remain fully and centrally positioned tn the

seat to preven[the engtne from hes_tahng or

cutting off when operating your equipment

on rough, rolling terrain or hills.

1 Select destred height of cut with attach-

ment hfl lever.

2. Start mower blades by engagtng attach-

merit clutch control,

!2

Page 13

TO STOP MOWER BLADES

D_sengage attachment clutch control.

_kCAUTION: Do not operate the mower

without e_ther the entire grass catcher, on

mowers so equipped, orthe deflector shield

in place.

i , ,,- "/' "q

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direction

with the attachment clutch engaged wdl shut

off the engine unless tgnit{on key is placed

in _he ROS "ON" position.

_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discouraged. Turning the RQS "ON",

to allow reverse operation with the attach-

ment clutch engaged, shoutd only be done

when the operator dec_des it_snecessary to

reposlt_on the machtne w_th the attachment

engaged Do not mow in reverse unless

absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM -

Only use ff you are certain no children or

other bystanders will enter the mowing area.

l. Depress clutch/brake pedal aif the way

down and hold.

2. W_th engtne running, turn _gnit_on key

counterclockwise to ROS "ON _'pos_t_on.

3. Look down and behind before and while

backing.

4. Move gear shift lever to reverse (R}

posit{on and siowly release clutch/brake

pedal to start movemen:.

5. When use of the RQS is no longer

needed, wrn the ignition key clockwise

to engine "ON" position.

ROS "ON" Poskt_on Engine "ON" Position

(Normal Operating}

TO OPERATE ON HILLS

_,WARNING: Do not dnve up or down

hills with slopes greater than 15° and do

not drive across any slope, Use the slope

guide provided at the back of this manual.

• Choosetheslowestspeed beforestarting

up or down hills,

• Avoid stopping or changing speed on hills.

• If stopping is absolutely necessary, push

clutch/brake pedal quickly to brake posi-

tion and engage parking brake.

• Move gearshift lever to 1st gear. Ensure

you have allowed room for tractor to roll

shghtty as you restart movement.

* To restart movement, slowly release park-

ing brake and clutch/brake pedal.

• Make all turns slowly.

TO TRANSPORT

1. Raise attachment lift lever to its highest.

2. When pushing or towing your tractor, be

sure gearshift lever is in neutra{ posttion.

• Do not push or tow tractor at more than

five (5) mph (8 kmih}.

NOTE. To protect hood from damage when

transporting your tractor on atruck or atrailer,

be sure hood isclosed and secured totractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

TOWING CARTS AND OTHER ATTACHMENTS

Tow only the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on a slope, Is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

SERVICE MINDERiHOUR METER

Service Minder shows the total number of

hours the engine has run and indicates when

the engine or mower needs servicing, After

every 50 hours of operation the olf can icon

will stay on for 2 hours or until a manual reset

occurs, To reset the display manually turn

the ignition switch to the on posit_on, then

the off position five times (l second on, I

second off). To service engine and mower,

see the Maintenance section of this manual.

NOTE: Service M[nder runs when the ignition

key is in any posttion but "STOP". For ac-

cu rate reading, ensure the key remains tnthe

"STOP" position when engine is not running,

13

Page 14

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine in your tractor has been shipped

from the factory already filled w_th summer

weight oil,

1. Check engrne otl wtth tractor on level

ground.

2. Remove etl fiTI cap!dipstick and wipe

clean, re_nsert the dtpstEck and screw cap

tight, wa_t for a few seconds, remove and

read oi! level. If necessary, add oil unttl

"FULL' mark on d_pstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the o_1

viscosity chart in the Maintenance sechon

of this manual).

• To change engine oil, see the Maintenance

section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

gasoltne wtth a mtnimum of 87 octane.

Do not mix oil wrth gasohne. Purchase

fuel in quamitles that can be used wtth_n

0 days to ensure fuel freshness.

CAUTION: Wipe off any spilled oil orfuel.

Do not store, sp_ll or use gasohne near an

open flame.

IMPORTANT: When operating Lntempera-

tures below 32°F (0°C), use fresh, clean

winter grade gasoline to help ensure good

cofd weather starting,

_IbCAUTION: Alcohol blendedfuels (called

gasohel or us{rig ethanol or methanol) can

attract moisture which leads to separatton

and formation of acids dunng storage. Acidic

gas can damage the fuel system of an engine

while instorage. To avoid engine problems.

the fuel system should be emptied before

storage of 30 days or longer, Dram the gas

tank, start the engine and let _t run unttt the

fuel Itnes and carburetor are empty. Use

fresh fuel nextseason. See Storage Instruc-

ttons for additional _nformatlon. Never use

engine or carburetor cleaner products in the

fuef tank or permanent damage may occur,

Fuel stabihzer is an acceptab{e alternative _n

mtnlmizt ngthe fo rmarton of fuel gum deposits

dunng storage. Add stabd_zer to gasoline in

fuel tank or storage container. Always follow

the mix ratio found on stabihzer container.

Run engine a_least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor. Do not empty the gas tank and

carburetor if using fuel s_ab_lizer.

TO START ENGINE

When starting the engine for the first hme or

if the engine has run out of fuel, _tw_ll take

extra cranking time to move fuel from the

tank to the engine.

1. Sit on seat In operating pos_hon, depress

clutch/brake pedal and set parking brake.

2. Place gearshift lever _nneutral posttion.

3. Move attachment clutch to disengaged

positron.

4. Move throttle control to dqoke pos_uon

NOTE: Before starting, read the warm and

cold starting procedures below.

5, insert key _nto fgnition and turn key

clockwise to start posklon and release

key as soon as engine starts. Do not run

starter continuously for more than f_fteen

seconds per minute. If the engine does

not start after several attempts, move

throttle control to fast position, watt a

few minutes and try again, If engine sttll

does not start, move the throttle control

back to the choke positron and retry.

WARM WEATHER STARTING

(50°F (10°C) and above)

6. When engine starts, move the throttle

control to the fast position.

• The attachments and ground drive

can now be used. If the engine does

not accept the load, restart the engine

and aliow it to warm up for one m_nute

using the choke as described above.

COLD WEATHER STARTING

(50°F (I0°C) and below)

6. When engine starts, leave throttle control

_nchoke poslt_on until engine warms up

and begins to run roughly. Once rough

running begins, immediately move the

throttle controito the fast posttlon. Engine

warm-up may take from several seconds

to severat m_nutes (the colder the tem-

perature, the longer the warm-up).

• The attachments can also be used

during the engtne warm-up period

14

Page 15

MOWING TIPS

• Tire chains cannot be used when the

mower housing is attached to tractor.

• Mower should be properly leveled for best

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

• The left hand side of mower should be

used for trimming,

• Drivesothatctipptngs are dischargedonto

the area that has already been cut. Have

the cut area to the right of the tractor. Th_s

will result m a more even d_stribution of

chppings and more uniform cutting.

• When mowing large areas, start by turning

to the right so that chppings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow m the

opposite direction making left hand turns

untJt ftntshed.

f

p

J

J

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dned chppings. Make

first cut relatively hgh; the second to the

desired height.

• Do not mew grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing.

• Always operate engine at full throttle

when mowing to ensure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a tow enough speed to gtve the

mower cutttng performance as well as the

quahty of cut desired.

• When operating attachments, select a

ground speed that will suit the terrain and

gwe best performance of the attachment

betng used.

15

Page 16

GENERAL RECOMMENDATIONS

The warranty on th_s tractor does not cover

items that have been subiected to oper&tor

abuse or negligence. To recewe full value

from the warranty, operator must maintain

tractor as _nstructed _nthis manual.

Some adlus[ments wilt need to be made

periodicallyto properly maintain your tractor.

At least once a season, check to see if

you should make any of the adjustments

described _nthe Service and Adlustments

section of this manual.

, At least once a year you should replace

the spark plug, clean or replace a_r filter,

and check blades and belts for wear. A

new spark plug and clean a_rfilter assure

proper air-fuel m_xture and help your en-

gine run better and fast longer.

BEFORE EACH USE

l, Check engine oil level.

2, Check brake operation.

3. Check tire pressure.

4. Check operator presence and

ROS systems for proper operabon.

5. Check for loose fasteners,

LUBRICATION CHART

"_; Spindle_--__-'lr---_ Spindle

Zerk ,'::_ ...... _['_ Zerk

Front _-_J'_=_="_" "_,_<2"_ Front Wheat

Wheel ,-__ _ Bearing Zerk

Beanna _'_f ........... _ _.-'."_

zerk _ " i _ :_ ,I i "-_"X Engine

?""iP

......... Pivots

@,SAE 30 or 10w30 motor o_I

,_)General Purpose Grease

L_3}Refer_o Maintenance "ENGINE" Section.

IMPORTANT: Do not oil or grease tt_e pivot

points which have special nylon beanngs.

Viscous lubricants wd/attract dust and dirt

that wilt shorten the life of the self-lubncatmg

bearings. If you feelthey must be lubricated,

use only a dry, powdered graphite type

lubncant spanngly.

16

Page 17

TRACTOR

Always observe safety rules when perform-

ing any maintenance.

BRAKE OPERATION

If tractor requires more than 5 feet (1,5 m)

to stop at highest speed in highest gear on

a level, dry concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" _n the Service and Adjustments

section of this manual).

TIRES

• Maintain proper a_r pressure in all tires

(See the side of tires for proper PSi.)

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal hre punctures and preven[

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

T_re sealant aJso prevents t_re dry rot and

corrosion

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operatton systems are working properly, If

your tractor does not function as descnbed,

repair the problem _mmedlately.

• The eng=ne should not start un{ess the

brake pedal is fully depressed, and the

attachment dutch control is in the dtsen-

gaged position,

CHECK OPERATOR PRESENCE SYSTEM

• When the engine _srunning, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engtne.

• The attachment clutch should never oper-

ate unless the operator is in the seat.

CHECK REVERSE OPERATION (ROS)

SYSTEM

• When the engine is running with the lgnttion

switch in the engine "Q N" position and the

attachment clutch engaged, any attempt

by the operator to dnve in reverse shouid

shut off the engine.

• Whentheeng_ne_s running wtththe ignition

switch in the RQS "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive _nreverse shoutd

NOT shut off the engine.

Ros "On" Engtne "On" Posttton

Pos_t_on (Normal Operating}

BLADE CARE

For best res ul;s mower b{ades mus_ be sharp.

Replace worn, bent or damaged blades.

_CAUTION: Use onIy a replacement blade

approved bythe manufacturer of your tractor.

Using a btade not approved by the manu-

facturer of your tractor is hazardous, could

damage your tractor and void your warranty.

BLADE REMOVAL

I Raise mowerto highest position to allow

access to biades.

NOTE: Protect your hands with gloves and,"

or wrap blade w_th heavy cloth,

2. Remove blade bolt by turntng counter-

clockwise.

3. Install new blade with stamped "GRASS

SIDE" facing the ground,

IMPORTANT: To ensure proper assembly,

center hole _nblade must ahgn with star on

mandrel assembly.

4. Install and tighten bfade bolt securely

(45-55 Ft. Lbs,i62-75 Nm).

IMPORTANT Special b{ade bolt is heat

treated

Star

Center Hole \ i-, ,._

"_ '_' I-_ 71

o.o0o°o....... I oo..o,

B ade _'_'_'"J-- ['..

BATTERY

Your tractor has a battery charging system

which is sufficient for normal use. However,

periodic charging of the battery with an au-

tomotwe charger will extend its life,

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-I0 amperes for 1 hour

NOTE; The orlgtnal equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of elec[roiyte is

not necessary.

17

Page 18

TO CLEAN BATTERY AND TERMINALS

Co rrosion and dtrton the battery and terminals

can cause the battery to "leak" power.

1. Remove temlinal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

3. Rinse the battery w_th plain water and

dry.

4. Clean terminals and battery cable ends

wIth wire brush until bright.

5. Coat terminals with grease or petroleum

ielly.

6. Remstalf battery (See "REPLACING

BATTERY" in the Service and Adjust-

ments section of this manuall.

TRANSAXLE MAINTENANCE

Keep transaxle free from bu_ld-up of dirl and

chaff wh=ch can restrict cootng.

Do not attempt to clean transaxle while

engine is running or while the transaxle {s

hot. To prevent possible damage to seals,

do not use high pressure water or steam to

clean transaxle.

V-BELTS

Check V-baits for deterioration and wear after

t00 hours of operation and replace if neces-

sary. The belts are net adjustable, Replace

belts _fthey begin to slip from wear.

ENGINE

LUBRICATION

Only use high quality detergent eelrated with

API servtce classification SG-SL. Seiectthe

oil's SAE viscosity grade according to your

expected operat=ng temperature,

I__ I SAE VfSCOSITI GRADES

J

NOTE: Although mulh-wscoslty ells (5W30.

10W30 etc.) treprove starttng Er_coId weather

they will result in increased oil consumption

when used above 32_F/0°C. Check your

engine oitlevel more frequentiyto avoid pos-

sible engine damage from runntng low on oil.

Changethe eit after every 50 hours of opera-

tton or at least once a year If the tractor is

not used for 50 hours _none year.

Check the crankcase otl level before starting

the engine and after each eight (8) hours

of operation. Tighten oil flit cap/dipshck

securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL,

• Be sure tractor is on level surface.

• QEIwill drain more freely when warm,

• Catch eel in a sultab{e container.

1 Remove oil fill capidipsttck, Be careful

not to allow dirt to enter the engine when

changing oil.

2. Shdeoil dram extension from the dock_ng

pos_t_on on the engtne blower housing

and extend outward from engtne,

Docking

Posit{on Oii Dratn

Extension

Cap

3, To open, twist cap counter-clockwise

4. After oil ts drained completely, replace

cap and twist clockwise until it stops.

5, Re-attach oil drain extension to engine

blower housing.

6. Refilt engtne with oil through o_Ifill dtpst_ck

tube. Pour slowly. Do not overNi. For ap-

proximate capacity see "PRODUCT SP-

ECIFICATIONS" section of this manual.

7. Use gauge on oil fill cap/dipstick for

checktng level. For accurate reading,

tighten d_pshck cap securely onto the

tube before removing dipstick. Keep o_1

at "FULE' line on d_pstick. T_ghten cap

onto the tube securely when finished,

ENGINE OIL FILTER

Replace the engine od filter every season or

every ether od change _f[he tractor _sused

more than 100 hours in one year

AIR FILTER

Your engine w=ll not run properly using a

d_rtya_rNter, Service atr cteaner more often

under dusty cendftions. See engine manual.

CLEAN AIR SCREEN

The a_rscreen _sover the a_r _ntake blower

located on top of engine The azr screen

must be kept free of d_r[ _nd chaff to prevent

engine damage from overheating. C{ean w_th

a w_re brush or compressed air to remove

d_rt and stubborn dned gum fibers.

18

Page 19

ENGINE COOLING SYSTEM

To ensure proper coohng, make sure the

grass screen, cooling fins, and other exter-

nal surfaces of tile engine are kept clean

at all t_mes.

Every 100 hours ef operahon (more often

under extremely dusty, dirty conditions),

remove the blower housing and other cooling

shrouds. Clean the cooling fins and externa{

surfaces as necessary. Ensure _he cooling

shrouds are reinstalled.

NOTE. Operating the engine w_th a blocked

grass screen, dirty or plugged cooling fins,

and/or cooling shrouds removed will cause

engine damage due to overheating.

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could cre-

ate a fire hazard and/or damage.

SPARK PLUG(S)

Replace spark plug(s) at the beginning of

each mowing season or after every !00

lTours of operation, whichever occurs f_rst.

Spark plug type and gap setting are shown

in "PRODUCT SPECIFICATIONS" section

el this manual.

IN-LINE FUEL FILTER

The fuei filter should be replaced once each

season, if fuel filter becomes clogged, ob-

struchng fuel flowto carburetor, replacement

is required,

1. With engine cool, remove filter and plug

fuel line sections.

2. Place newfuel filter in position in fuet hne

with arrow pointing towards c_rburetor,

3, Ensure there are no fuel line leaks and

clamps are property positioned.

4, Immed_atetywipe up any spilled gasotme.

CIamp_ ,"_'_,-._'--_ Clam

Fuel Fitter_j[-"__-_ J

CLEANING

Cfean engine, battery, seat, finish, etc.

of all foreign matter.

* Clean debnsfromsteermg plate. Debris

can restrict clutch/b rake pedal shaft: move-

ment, causing belt slip and toss of dnve.

_1,CAUTION: Avoid all pinch points and

movable parts

Clutch/brake pedal _ , ,'

-../- / '

Clean ' _: . . /-

top side , _ -.:- _..../

"1

Plate _, _'__

Steering System, Dash, Fender

and Mower Not Shown

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

Protect painted s uriaces with auto motive

type wax.

Except ?or the washout port (if equipped),

we do not recommend using a garden hose

or pressure washer to clean the outside of

your tractor unless the engine and transmis-

sion are covered to keep water out. Water

m engine or transmission will shorten the

useful hfe of your tractor. Use compressed

air or a leaf blower to remove grass, leaves

and trash from outside tractor and mower.

19

Page 20

DECK WASHOUT PORT

Your tractor's deck is equipped with a wash-

out port on _tssurface as part of its deck wash

system, it should be uN_zed after each use.

1. Drive the tractor to a level, clear spot

on your lawn, near enough to a water

spigot for your garden hose to reach,

IMPORTANT: Make certain the tractor's

discharge chute is dErected AWAY from your

house, garage, parked cars, etc. Remove

bagger chute or mulch cover if attached.

2. Make sure the attachment clutch control

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Ensure your garden hose is fitted w_th a

standard t 2ram female hose connector

(at the opposite end from the tap con-

nect_on).

4. Pull back the lock collar of the hose

connector and push the connector onto

the deck washout port at the left end of

the mowerdeck Refeasethe tockcoltar

to lock the connector on the nozzle.

10. Move the tractor to a dry area, prefer-

ably a concrete or paved area. Place

the attachment clutch control in the

"ENGAGED" position to remove excess

water and to help dry before putting the

tractor away.

Aid,WAR NING: A broken or missing washout

fitting could expose you or others to thrown

objects from contact with the blade.

Replace broken or missing washout fitting

immediately, prior to using mower again.

Plug any holes in mower with bolts and

Iocknuts.

Hose _"i:

Hose CoRoector ...._,__t',, _.&tashout POF'.

(t 2rr_m Female) J ,:_

€,

IMPORTANT: Tug hose ensuring connec-

tion Jssecure.

5. Turn the water on.

6. While setting in the operator's position

on the tractor, re-start the engine and

place the throttle lever in the Fast ",_"

positEon.

IMPORTANT: Recheck the area making

certain the area is clear.

7, Move the tractor's attachment clutch

control to the "ENGAGED" poslhon

Remain in the operator's posit_on w_th

the cutting deck engaged until the deck

is cleaned.

8. Move the tractor's attachment clutch

control to the "DISENGAGED" posi-

tion. Turn the ignition key to the STOP

position to turn the tractor's engine off.

Turn the water off.

9. Pull back the lock collar of the hose

connector to disconnect the connector

from the nozzle washout port.

2O

Page 21

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANYSERVICE OR ADJUSTMENTS:

1. Depress clutch/brake pedal fully and set parktng brake.

2, Place gearshift lever In neutral poslt_on.

3, Place attachment clutch in "DISENGAGED" position.

4, Turn ignition key to "STOP" and remove key.

5. Ensure the blades and all moving parts have completely stopped.

6. O_sconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug,

TO REMOVE MOWER

1. Place attachment clutch in 'DISEN-

GAGED" posrtfon.

2. Lower attachment hft lever to its lowest

position.

3, Roll belt off engine pulley (M) and belt

keepers (G).

4. Remove retafner spring (K), slide collar

(L) off and push housing guide (P} out

of bracket.

5. Remove clutch cable spring (Q) from

idler arm (R).

6. Disconnect fronl link (E) from mower -

remove retainer spring and washer.

7. Go to either s_de of mower and discon-

nect mower suspension arm (A) from

chassis pin (B) and rear lift link (C) from

rear mower bracket (D) - remove retainer

springs and washers.

CAUTION: After rear lift hnks are discon-

nected, the attachment lift lever will be spring

loaded. Have a tight grip on lift lever when

changing position of the lever,

8, Slide mower out from under nght side of

tractor.

IMPORTANT: If an attachment other than

the mower is to be mounted on the tractor,

remove the front link (E) and rear lift hnks

(C) from tractor and hook the clutch spring

(Q) into the cable guide on front edge of

lower dash.

TO INSTALL MOWER

Ensure tractor fs on leve! surface and engage

parking brake.

1. Lower attachment lift [ever to 1Is Iowest

pos_t_on.

_IL CAUTION: Lift lever is spnng loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position.

NOTE: Ensure mower side suspensron arms

(A) are pointing forward before sliding mower

under tractor.

2 Slide mower under tractor unhl it is cen-

tered under tractor.

03042te_

21

Page 22

3. ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS - Position hole

in arm over pin (B) on outside of tractor

chassis and secure w_th retainer spr_ng.

4. Repeat on opposite stcie of tractor.

5. ATTACH REAR LIFT LINKS (C) o Lift

rear corner of mower and position slot

in hnk assembly over pin (D) on rear

mower bracket and secure wEth washer

and retainer spnng,

7. Insert end of link /E) into hole in front

mower bracket (H) and secure w_th

washer and retainer spring /J).

8, Hook end of clutch cablespr;ng (Q) into

hole In tdler arm (R).

9 Push clutch cable housing guide IP) _nto

bracket, slide collar (L) onto gu{de and

secure wtth retainer spring (K).

10. Install belt onto eng}ne pulley (M) and belt

keepers (G).

6. ATTACH FRONT LINK (E) - Work from

left stde of tractor. Insert rod end of link

assembly through front hole in tractor

front suspension bracket (F).

IMPORTANT: Check beit for proper rout=ng

in all mower pulley grooves.

11,Raise attachment ttft lever to h=ghest

pos=fion.

12, If necessary, adiust gauge wheels before

operattng mower as shown inthe Opera-

tion section of thEs manual.

/

D)

03042te_

22

Page 23

TO LEVEL MOWER

Ensure tires are properiy inflated to the PSi

shown on tires, if ttres are over or under

inflated, it may affect the appearance of your

lawn and Iead you to th_nk the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. W_th all tires properly _nflated and ffyour

lawn appears unevenly cut, determine

which side of mower is cutting lower.

2. W_th a 3/4" or adjustable wrench, turn

lift link adjustment nut (A) to the left to

lower LH side of mower, or, to the right

to raise LH side of mower.

Turn nut Turn nut

rsght to left to

raise _ lower

mower mower

NOTE: Each full turn of adjustment nut w_ll

change mower height about 3/16" (4,7 ram).

3. Test your adjustment by mowing some

uncut grass and visually ci_eckmg the

appearance. Readjust, if necessary, untif

you are sat{stied with the resuits.

PRECISION SIDE-TO-SIDE ADJUSTMENT

1. Wtth all ttres properly inflated, park tractor

on level ground or driveway.

A01LCAUTION: Blades are sharp. Protect

your hands w_th gloves and/or wrap blade

w_th heavy cloth

2. Raise mower to its highest posit_on.

3. At both sides of mower, posltLon blade

at side and measure d_stance "A" from

bottom edge of blade to ground. The dis-

tance should be the same en both sides.

4. If adjustment _snecessary, see steps in

V_sual Adiustment instructions above.

5. Recheckmeasurements, adjustifneces-

sary until both sides are equal.

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-side.

To obtain the best cutting results, the mower

blades should be adjusted so the front tip

is 1i8 to 1/2" (3,1 to t2,7 ram) (iower than

the rear tip when the mower Is in its h_ghest

posibon.

A(_CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

w_th heavy cloth.

• Raise mower to h_ghest position.

• Position any blade so the tip is pointing

straight forward. Measure distance "B'Lto

the ground at front and rear hp of blade

• If front tip of blade is not 1/8 to I/2" (3,1

to ! 2,7 ram) lower than the rear tip, go to

the front of tractor.

• With an 11/16" or adjustable wrench,

loosen jam nut "A" several turns to clear

adjustment nut "B".

• With a 3/4" or adjustable wrench, turn

fro nt link adjustment nut "B" clockwise (,_)

(t_ghten) to raise the front of mower_ or.

counterclockwise (¢',) (loosen) to lower

the front mower.

®

T_grtten adjust Loosen adjust

nut "B" to nut "B" to

-- --- lower mower

raise mower

Loosen jam nut "A" first

NOTE: Each full turn of adiustment nut will

change mower height about 1,._8'' [3,1 mm).

• Recheck measurements, adjust if neces-

sary until front tip of blade is 1/8 to ti2"

(3,1 to I2,7 ram) lower than the rear tip.

• Hotd adjustment nut in positBon w_th

wrench and tighten jam nut securely

against adjustment nut.

23

Page 24

TO REPLACE MOWER BLADE DRIVE

BELT

The mower blade drwe belt may be replaced

w_thout teoJs. Park the tractor on level sur-

face. Engage parking brake.

BELT REMOVAL -

1. Remove mower from tractor (See "TO

REMOVE MOWER" in this section of

manual).

2. Work belt off both mandrel pulleys and

idler pulleys,

3. Pull belt away from mower,

BELT INSTALLATION -

l. Work belt around both mandrel pulleys

and idler pulleys

2, Ensure belt _s in all pulley grooves and

inside all belt guides.

3, Instal! mower (See "To Install Mower" in

this section of this manual),

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parF,mg brake. For assistance, there is a

belt mstallabon guide decal on bottom s_de

of {eftfootrest.

BELT REMOVAL-

1. Remove mower (See '%O REMOVE

MOWER 'r In this section of manual).

NOTE: Observe enbre motion dove belt

and position of all belt guides and keepers.

2. Remove beltfromstationary idler (A) and

clutching idler CB).

3. Pull belt slack toward rear of tractor.

Remove belt upwards from transaxle

toput pulley (D),

4. Remove belt downward from engine

pulley (E).

5. Shde belt toward rear of trac_or, off the

steering plate (F) and remove from tractor.

TO CHECK BRAKE

tf tractor requires more than five (5) feet (1,5

m) to stop at highest speed m h_ghest gear

on a level, dry concrete or paved surface,

then brake must be serviced.

You may also check brake by

1. Park tractor on a level, dry concrete or

paved surface, depress clutch/brake

pedal all the way down and engage

parking brake

2. Place gear shift lever _nneutral posEbon.

The rear wheels must lock and skid when

you try to manually push the tractor forward.

If the rear wheels rotate, then t_qe brake

needs to be serviced. Contact a Sears or

other quahfJed service center,

BELT INSTALLATION -

1. Install new belt from tractor rear to front,

over the steering plate (F) and above

clutch brake pedal shaft (G).

2. Pull belt toward front of tractor and roll

belt onto engine pulley (E).

3. Pull belt toward rear of tractor. Carefully

work belt down around transaxle input

pulley (D), Ensure belt is reside the belt

keeper.

4. install belt through stabonary idier (A_

and ctutchmg idler (B).

5. Ensure belt is _nall pulley grooves and

inside all belt guides and keepers.

6. Install mower (See "TO INSTALL MOW-

ER" In this secbon of manual),

24

Page 25

TRANSAXLE GEAR SHIFT LEVER NEU-

TRAL ADJUSTMENT

The transaxte should be in neutral when the

gear shift lover ts in neutral (N) (lock gate)

position. The adjustment _s preset at the

factory, however, if adjustment is needed,

proceed as follows:

1. Make sure transaxle is tnneutral (N).

NOTE: When the tractor rear wheels move

freely, the transaxie ts in neutral.

2, Loosen adjustment bolt in front of the

right rear wheel.

3, Position the gear shift lever _nthe neutral

(N) position.

4. Tighten adjustment bolt securely.

NOTE: If additional clearance _sneeded to

get to adjustment bolt, move mower deck

hetght to the lowest position,

Gearshift Adjustment Bolt

Lever ..- _ __

2_:., 5:-

Lock Gate

TO REMOVE WHEEL

1. Block up axle securely.

2. Remove axte cover, retaining ring and

washers to atlow wheel removal Irear

wheels have a square key -Do not tose)

3. Repair tire and reassemble,

NOTE: On rear wheels only. ahgn grooves in

rear wheel hub and axle, Insert square key.

4. Replacewashers andsnap retaining ring

securely _naxle groove.

5. Replace axle cover.

NOTE: To seal fire punctures and prevent

flat tires due to slow leaks, purchase and

use ttre sealant from Sears. T_re sealant atso

prevents tire dry rot and corrosion.

Washers

Retaining

Axle Ring.

Cover\ \

'\

'\\

Square

(Rear Wheel Only)

FRONT WHEEL TOE-IN/CAMBER

Your new tractor front wheel toe-in and

camber is set at the factory and _snormal.

The front wheet toe-in and camber are Rot

adjus[able. If damage has occurred to

affect the factory set front wheel toe-in or

camber, contact a Sears or other qualified

service center.

TO START ENGINE WITH A WEAK BAT-

TERY

_WARNING: Lead-acid batteries gener-

ate explosive gases. Keep sparks, flame

and smoking materials away from batteries.

Always wear eye protection when around

batteries.

If your battery _stoo weak to star_ the engine,

it should be recharged. (See "BATTERY" in

the MAINTENANCE section of this manual).

If "jumper cables" are used for emergency

starting, follow th_s procedure

IMPORTANT' Your tractor is equipped with

a 12 volt system. The other vehicle must also

be a 12 vott system, bo not use your tractor

battery to start other vehicles.

TO ATTACH JUMPER CABLES -

I. Connect one end of the RED cabIe to the

POSITIVE (+) terminal of each battery(A-

B), taking care not to short against tractor

chassis.

2, Connect one end of the BLACK cable

to the NEGATIVE (-) terminal (C) of fully

charged battery.

3. Connect the other end of the BLACK

cable (D) to good chassts ground, away

from fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER

1 BLACK cable f{rst from chass{s and then

from the fully charged battery,

2. RED cable last from both batteries,

A +A

Weak or Dead Fully Charged

Battery Battery

25

Page 26

REPLACING BATI'ERY

n_asWARNING: Do not short battery termi-

by a{Iowf ng a wrench or any other object

to contact both term_nNs at the same time.

Before connecting battery, remove metal

bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected first to

prevent sparkff_g from accidental grounding.

1. Lift hood to ratsed posit_on.

2. Removeterm_nal cover.

3. Disconnect BLACK battery cable then

RED battery cable and carefully remove

battery from tractor.

4. Install new battery w_thtermEnals _nsame

pos_hon as old battery.

5. RemstNt terminal cover.

6. First connect RED battery cable to pose-

tire (+} battery terra,nat with bolt and nut

as shown. Tighten securely.

7. Connect BLACK grounding cable to

negative (-) battery termt halwath re main-

ing bolt and nut. T_ghten securely

8. Close hood.

Negatwe

Cable

TO REPLACE HEADLIGHT BULB

1. Raise hood.

2. Remove bulb holder from the hole _nthe

backside of the grill.

3. Reptace bulb in holder and _nstall bulb

holder securely back _ntothe hole _nthe

backside of the gnll.

4. Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poorly, stop running, or prevent

it from starting.

• Check winng.

TO REPLACE FUSE

Replace w_th30 amp automotwe-type plug-_n

fuse. Thefuseholderistocatedbehindthedash.

TO REMOVE HOOD AND GRILL

ASSEMBLY

I. Raise hood.

2. Unsnap headlight wtre connector.

3. Stand in front of tractor, Grasp hood at

stdes, t_lttoward engine and hffoff oftractor.

4. When replacing hood, ensure to recon-

nect the headlight w_re connecter.

ENGINE

TO ADJUST THROTTLE CONTROL

CABLE

The throttle control has been preset at

_he factory and adIustment should not be

necessary Check adjustment as descnbed

below before Ioosentng cable. If adjustment

_snecessary, see engine manual.

TO ADJUST CHOKE CONTROL

The choke control has been preset at the

factory and adjustment shoutd not be neces-

sary. If adjustment is necessary, see engine

manual.

26

Page 27

Immediately prepare your tractor for storage

at the end of the season or if the tractor will

not be used for 30 days or more.

WARNING: Never store the tractor with

gasohne in the tank inside a butldlng where

fumes may reach an open flame or spark

Atlow the engine to cool before storing _n

any enclosure.

TRACTOR

Remove mower from tractor for w_nter stor-

age. When mower is to be stored for a period

of brae, clean It thoroughly, remove atl dwt,

grease, teaves, etc. Storein aclean, dryarea,

1. Clean entlretractor (See"CLEANfNG" in

the Maintenance section of this manual).

2, Inspect and replace belts, if necessary

(See belt replacement instructions in the

Service and Adjustments section of this

manual).

3. Lubncate as shown in the Maintenance

secbon of _h_smanual.

4. Ensure that alf nuts, bolts and screws

are securely fastened. Inspect movtng

parts for damage, breakage and wear.

Replace if necessary.

5. Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

BATTERY

• Fully charge the battery for storage.

• After a penod of time tn storage, battery

may require recharging.

• To help prevent corrosion and power

leakage during long periods of storage,

battery cables should be disconnected

and battery cleaned thoroughly (see "TO

CLEAN BATTERY AND TERMINALS" in

the Maintenance section of th_s manual).

• After cleaning, leave cables disconnected

and place cables where they can not come

m contact w_th battery terminals.

• If battery _s removed from tractor for

storage, do not store battery dwectly on

concrete or damp surfaces.

• If unit is equipped with battery tndlcatori

charging plug, an opbonal charging unit

may be purchased and connected to the

unit to charge the battery dunng long term

storage. Inspect and clean the battery

terminals as needed prior to long term

storage w_th charger connected.

ENGINE

FUEL SYSTEM

IMPORTANT. It is important to prevent

gum deposits from forming in essential tuel

system parts such as carburetor, fuel hose,

or tank dunng storage. Also, alcohol blended

fuels (called gasohol or using ethanol or

methanoi) can attract moisture which feNdS

to separation and formabon of acids dunng

storage. Acidic gas can damage the fuel

system of an engine while in storage.

• Empty the fuel tank by starting the engine

and le_lng it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner

products =n the fuel tank or permanent

damage may occur.

• Use fresh fuel next season,

NOTE: Fuel stabihzer is an acceptable al-

ternattve in minimtz_ng the formation of fuel

gum deposits during storage. Add stabilizer

to gasoline _nfuel tank or storage container.

Always followthe mix raUo found on stabdizer

container, Run engine at least 10 minutes

after add_ng stab ilize r to al low the stabilizer to

reach _he carburetor. Do not empty the gas

tank and carburetor tf using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace

with clean engine oi!. (See "ENGINE" in the

Maintenance section of this manual).

CYLINDER(S)

1, Remove spark plug(s),

2. Pour one ounce (29.5 mL) of oil through

spark plug hole(s) into cylinder(s).

3. Turn ignition key to "START" position for

a few seconds to dtstribute off.

4, Replace with new spark plug(s).

OTHER

• Do not store gasoline from one season to

another.

• Replaceyourgasoline can tfyourcan starts

to rust, Rust and/or dirt in your gasohne

will cause problems.

• if possible, store your tractor tndoors and

cove r_tto give protection from dust and dirt.

• Cover your tractor wtth a suitable protec-

tive cover that does not retaIn moisture,

Do not use plastic, Piastic cannot breathe

which allows condensation to form and wtll

cause your tractor to rust.

IMPORTANT' Never cover tractor while

engine and exhaust areas are stdl warm.

27

Page 28

TROUBLESHOOTING CHART:

See appropriate section in manual unless directed to Sears service center

PROBLEM

Will not start

Hard to start

Engine witl not

turn over

I

2

Engine clicks but

will not start

CAUSE

Out of fuel

Engine not CHOKED' 13roperly

Engine flooded

4 Bad spark plug

5 Dirty air filter

6 Dirty fuel filter

7 Water Jnfuel.

8

9

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

1

2

3

4

Loose or damaged w_nng.

Engine valves out of adjustment 9

DErtyair filter

Bad spark plug

Weak or dead battery'.

Dirty fuel filter

Stale or dErtyfuel.

CORRECTION

1 FJilfuel lank

2 See "TO START ENGINE' in

Operation £ectlon

3 Watt several mLnutes before

attempting to start

4 Replace spark pIug

5 Clean, replace a_rfilter

6 Replace fuel filter

7 Empty fuel tank and carburetor.

refdl tank wrth fresh gasoline and

replace fuel filter

8 Check all w_nng

Contact a Sears or other quaIff_ed

service center

I Clean/_eplace air filter

2 Replace sparV, plug

: 3 Recharge or replace battery"

4 Replace fuel filter

5 Empty fuel tank and reNI tank w_tk-

i fresh, clean gasoline.

Check all wlnng.

Contact a Sears or ether qualified

service center

Depress clutch/brake pedal