Craftsman 917252492 Owner’s Manual

OWNERS

MANUAL

MODEL NO.

917.252492

Caution:

Read Rules for

Safe Operation

and Instructions

Carefully

8 H.R

30" SLEEVE HITCH

T IL LER ATTACHMENT

Assembly

Installation

Operation

Repair Parts

Sears, Roebuck and Co., Chicago, tL60684 U.SA

CONGRATULATIONS on your purchase of a Sears 8 HP

Tiller Attachment. _t has been designed, engineered and manu-

factured to give you the best possible dependability and per-

formance. Should you experience any problem you cannot

easily remedy, please contact your nearest Sears Service De-

partment, They have competent, well-trained technicians and

the proper tools to service or repair this unit,

Please read and retain this manual, The instructions will enable

you to assemble o_erate and maintain your Tiller properly

Always obse_ve the RULES FOR SAFE OPERATION",

WARRANTY

LIMITED ONE YEAR WARRANTY

MQDEL

NUMBER

SERIAL

NUMBER

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON THE MODEL PLATE ATTACHED TO

THE RIGHT HAND SIDE OF THE TRANSMISSION

(FIG. 1)_

YOU SHOULD RECORD BOTH MODEL AND

SERIAL NUMBERS AND KEEPIN ASAFEPLACE

FOR FUTURE REFERENCE,

For one year from the date of purchase, when this attachment is maintained, lubricated, and

tuned up according to the operating and maintenance instructions in the owner's manual, Sears

will repair free of charge any defect in material or workmanship,

This warranty excludes tine(s), spark piL_,;air"cleaner and belt(s) which are expendable parts

and become worn during normal use,,

If the tractor attachment is used for commercial or rental purposes, this warranty applies for

only thirty days from the date of purchaser

WARRANTY SERVICE IS AVAILABLE BY CONTAC_rING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT iN THE UNITED STATES° This warranty applies only while this product

is in use in the United States,

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state,

Sears, Roebuck and Co., D!698-731A, Sears Tower, Chicago, IL 60684

-2_

RULESFORSAFEOPERATION...................................................... BELOW

ASSEMBLYINSTRUCTIONS................................................................ 4

OPERATIONINSTRUCTIONS................................................................ 5

MAINTENANCEINSTRUCTIONS............................................................ 6

REPAIRPARTS......................................................................... 10

RULES FOR SAFE OPERATION

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush,,covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable

local or state laws (if any) If a spark arrester is used, it should be maintained in effective working order by the operator

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may

have similar laws, Federal laws apply on federal lands See your Sears Authorized Service Center for spark arrester Refer to page

17

I., Know the controls and how to stop quickly READ THE

OWNER'S MANUAL.

2. Do not allow children to operate your tractor and Tiller

Attachment Do not allow adults to operate them with°

out proper instruction,

3. Keep children and pets a safe distance away

4_ Clear work area of objects which might be caught in tines.

5. Before starting the engine, be sure Tiller clutch is disen-

gaged and tines are c_ear.

6. Make sure of your footing and stand clear of tines when

starting engine

7_ Do not run engine indoors because the engine exhaust

fumes contain carbon monoxide, which is a tastefess,

odorless, deadly poison°

84 Check fuel supply before each use, Never remove the gas

cap or fill the gasoline tank when engine is running or

while it is hot When filling the fuel tank, leave space for

expansion; do not fill it to the brim and keep in mind

that the heat of the sun can cause the gasoline to expand

Wipe off any spilled gasoline before starting the engine.

Remember, gasoline is highly flammable and must al-

ways be handled with extreme care

9 Stop tractor, disengage Tiller Attachment chJtch and stop

Tiller and tractor engines. Shift tractor to neutral position,

set parking brake and remove ignition key before leaving

operator s posrt_on.

10, Never stand near tines or work on tines when engine is

running,

11. Watch for traffic when crossing or near roadways,

12 Always disengage Tiller clutch, and stop engine when traveF

ing to and from field or when not tilling,

13 Lift Tiller Attachment out of the ground when turning

corners.

14 Do not put tractor in reverse gear while Tiller is in the

ground.

t& Keep all nuts, bolts and screws tight in order to be sure

that the tractor and attachment are in safe working con-

dition Be sure the brake and all powered attachment

controls are always in proper adjustment and repair. Check

the attachment and engine mounting bolts at frequent

intervals for proper tightness Before performing any

maintenance, always disengage the power to attachment,

set the parking brake, shift into neutral, shut off the

engine, make absolutely sure the Tiller Attachment and

alt moving parts hove completely stopped, remove ignition

key, disconnect the spark plug wire from the spark plug,

and keep it away from the plug to prevent injury or ac-

cidental starting, The only exception to this rute is car,,

buretor adiustment

16 Keep the engine free from accumulations of grass, leaves

or excessive grease, as these accumulations are combustible

and could result in a fire Always keep your Tiller Attach.,

moot in good operating condition and make sure that alf

shields, guard p|ates and all other protective devices are in

place Give your Tiller Attachment the regular maintenance

it needs and have a competent serviceman make a thorough

inspection of it at least once a year

PRECAUTIONS IT MEANS -.. ATTENTION! BECOME ALERT!

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY

YOUR SAFETY IS INVOLVED.

-3-

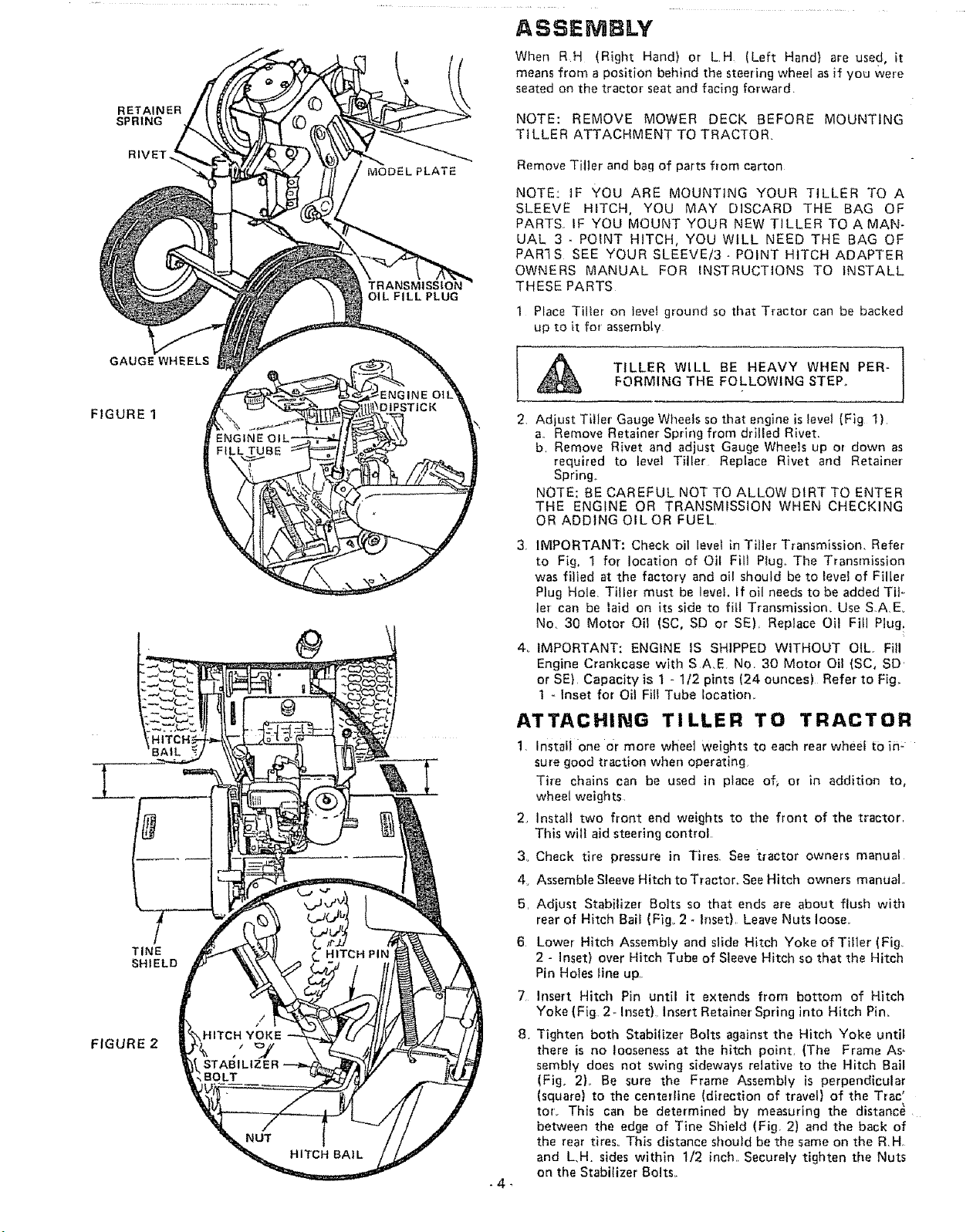

RETAINER

SPIRING

RIVET_

GAUGE WHEELS

OIL FILL PLUG

ASSEMBLY

When R H (Right Hand) or LH (Left Hand) are used it

means from a position behind the steering wheel as if you were

seated on the tractor seat and facing forward.

NOTE: REMOVE MOWER DECK BEFORE MOUNTING

TILLER ATTACHMENT TO TRACTOR.

Remove Tiller and bag of parts from carton

NOTE: IF YOU ARE MOUNTING YOUR TILLER TO A

SLEEVE HITCH, YOU MAY DISCARD THE BAG OF

PARTS. IF YOU MOUNT YOUR NEW TILLER TO A MAN-

UAL 3 - POINT HITCH, YOU WILL NEED THE BAG OF

PARIS SEE YOUR SLEEVE/3. POINT HITCH ADAPTER

OWNERS MANUAL FOR INSTRUCTIONS TO INSTALL

THESE PARTS

1 Place Tiller on level ground so that Tractor can be backed

up to it for assembly

]

TILLER WILL BE HEAVY WHEN PER- |FORMING THE FOLLOWING STEP°

FIGURE I

TINE

SHIELD

FIGURE 2

@

Adjust Tiller Gauge Wheels so that engine is level (Fig 1),

a, Remove Retainer Spring from drilled Rivet,

b, Remove Rivet and adjust Gauge Wheels up or down as

required to level Tiller Replace Rivet and Retainer

Spring,,

NOTE: BE CAREFUL NOT TO ALLOW DIRT TO ENTER

THE ENGINE OR TRANSMISSION WHEN CHECKING

OR ADDINGOILOR FUEL

3, IMPORTANT: Check oil level in Tiller Transmission. Refer

to Fig. I for location of Oil Fill Plug,, The Transmission

was filled at the factory and oil should be to level of Filler

Plug Hole Tiller must be level, if oil needs to be added TiF

let can be laid on its side to fill Transmission, Use S.A,E_

No, 30 Motor Oil (SC, SD or SE), Replace Oil Fill Plug:

4, IMPORTANT: ENGINE IS SHIPPED WITHOUT OIL Fill

Engine Crankcase with SA.E NO, 30 Motor Oil (SC, SD'

or SE)Capacity is 1 - 1/2 pints (24 ounces) Refer to Fig.

1 - Inset for Oil Fill Tube location,.

ATTACHING TILLER TO TRACTOR

1, Install one or more wheel Weights to each rear wheel to in:

sure good traction when operating,

Tire chains can be used in place of; or in addition to,

wheel weights,

2 Install two front end weights to the f_ont of the tractor,

This will aid steering control

3o Check tire pressure in Tires See tractor owners manual

44 Assemble Sleeve Hitch to Tractor. See Hitch owners manual,

5, Adjust Stabilizer Bolts so that ends are about flush with

rear of Hitch Bail (Fig. 2 * Inset), Leave Nuts loose,.

6 Lower Hitch Assembly and slide Hitch Yoke of Tiller (Fig

2 - Inset) over Hitch Tube of Sleeve Hitch so that the Hitch

Pin Holes line up,

7.

Insert Hitch Pin until it extends from bottom of Hitch

Yoke (Fig 2- Inset), Insert Retainer Spring into Hitch Pin,

8.

Tighten both Stabilizer Bolts against the Hitch Yoke until

there is no looseness at the hitch point, (The Frame As _

sembly does not swing sideways relative to the Hitch Bail

(Fig. 2),, Be sure the Frame Assembly is perpendicular

(square) to the centerline (direction of travel} of the Trac'

tor,, This can be determined by measuring the distanc_

bebNeen the edge of Tine Shield (Fig, 2) and the back of

the rear tires° This distance should be the same on the R,H,

and L.H sides within 1/2 inch. Securely tighten the Nuts

on the Stabilizer Bolts_

NOTE:THESTABILIZERBOLTSSHOULDBELOOSENED

BEFOREREMOVINGTHETILLERFROMTHETRACTOR.

THISW1LLMAKEIT EASIERTOREMOVETHEHITCH

PINANDTOLINEUPHITCHPINHOLESWHENINSTALL,,

INGANOTHERATTACHMENTtFTRACTORISTOBE

USEDWITHOUTAREARATTACHMENT,THESTABILIZ-

ERBOLTSSHOULDBESECUREDBYTIGHTENINGTHE

NUTS(FIG,2- INSET)

OPERATOON

READ THE "RULES FOR SAFE OPERA-

TION" CAREFULLY BEFORE OPERAT-

ING YOUR TILLER. THE ENGINE HAS

BEEN SHIPPED WITHOUT OIL,

1 Be sure that you have complied with steps 3 and 4 at top of

page 4,,

2, F_II Fuef Tank with clean, fresh, unleaded gasoline. Capa-

city is 1 gallon.. WARNING: DO NOT USE GASOHOL,

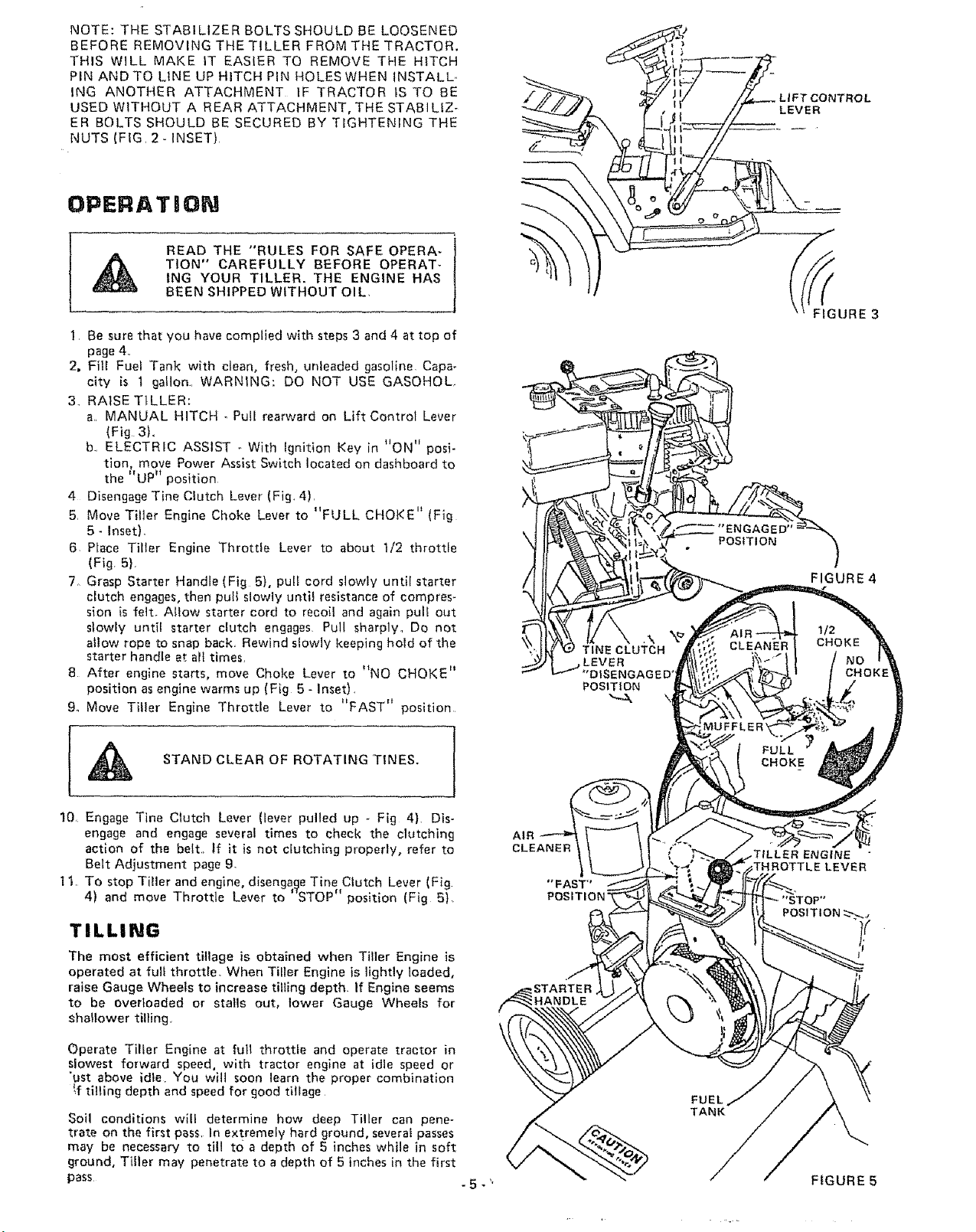

3. RAISE TILLER:

a,, MANUAL HITCH . Pu!l rearward on Lift Control Lever

{Fig 3),

b,, ELECTRIC ASSIST - With Ignition Key in "ON" pos]-

tion¢ move Power Assist Switch located on dashboard to

the _LJP_ position

4 Disengage Tine Clutch Lever (Fig, 4),

5, Move Tiller Engine Choke Lever to "FULL CHOKE" (Fig

5- Inset),

6 Place Tiller Engine Throttle Lever to about 1/2 throttle

(Fig, 5),

7 Grasp Starter Handle (Fig 5), pull cord slowly until starter

clutch engages, then pull slowly until resistance of compres-

sion is felt, Allow starter cord to recoil and again pull out

slowly until starter clutch engages Pull sharply,, Do not

allow rope to snap back, Rewind slowly keeping hold of the

starter handle at all times,

8 After engine starts, move Choke Lever to _NO CHOKE"

position as engine warms up (Fig 5 - Inset),

9,, Move Tiller Engine Throttle Lever to "FAST" position

/ LIFTCONTROL

LEVER

FIGURE 3

"ENGAGED" -=

POSITION

FIGURE 4

%

TINE CLUTCH

LEVER

,,01._

POSITION

CLEANER CHOKE

I12

)

NO

CHOI

STAND CLEAR OF ROTATING TINES.

1

I0, Engage Tine Clutch Lever (lever pulled up - Fig 4), Dis-

engage and engage several times to check the clutching

action of the belt,, If it is not clutching properly, refer to

Belt Adjustment page 9,

11, To stop Tiller and engine, disengage Tine Clutch Lever (Fig

4) and move Throttle Lever to "STOP" position (Fig 5)

TILLING

The most efficient tillage is obtained when Tiller Engine is

operated at full throttle. When Tiller Engine is lightly loaded,

raise Gauge Wheels to increase tilling depth If Engine seems

to be overloaded or stalls out, lower Gauge Wheels for

shallower tilling,

Operate Tiller Engine at full throttle and operate tractor in

slowest forward speed, with tractor engine at idle speed or

"ust above idle You will soon learn the proper combination

_f tilling depth and speed for good tillage

Soil conditions will determine how deep TilLer can pene-

trate on the first pass, In extremely hard ground, several passes

may be necessary to till to a depth of 5 inches while in soft

ground, Tiller may penetrate to a depth of 5 inches in the first

pass - 5 -"

AIR

CLEANER

;STARTER

!HANDLE

'" FAST"

POSITIOt _

FUEL

TANK

FULL _

CHOKE

FIGURE 5

RETAINER

L_RING

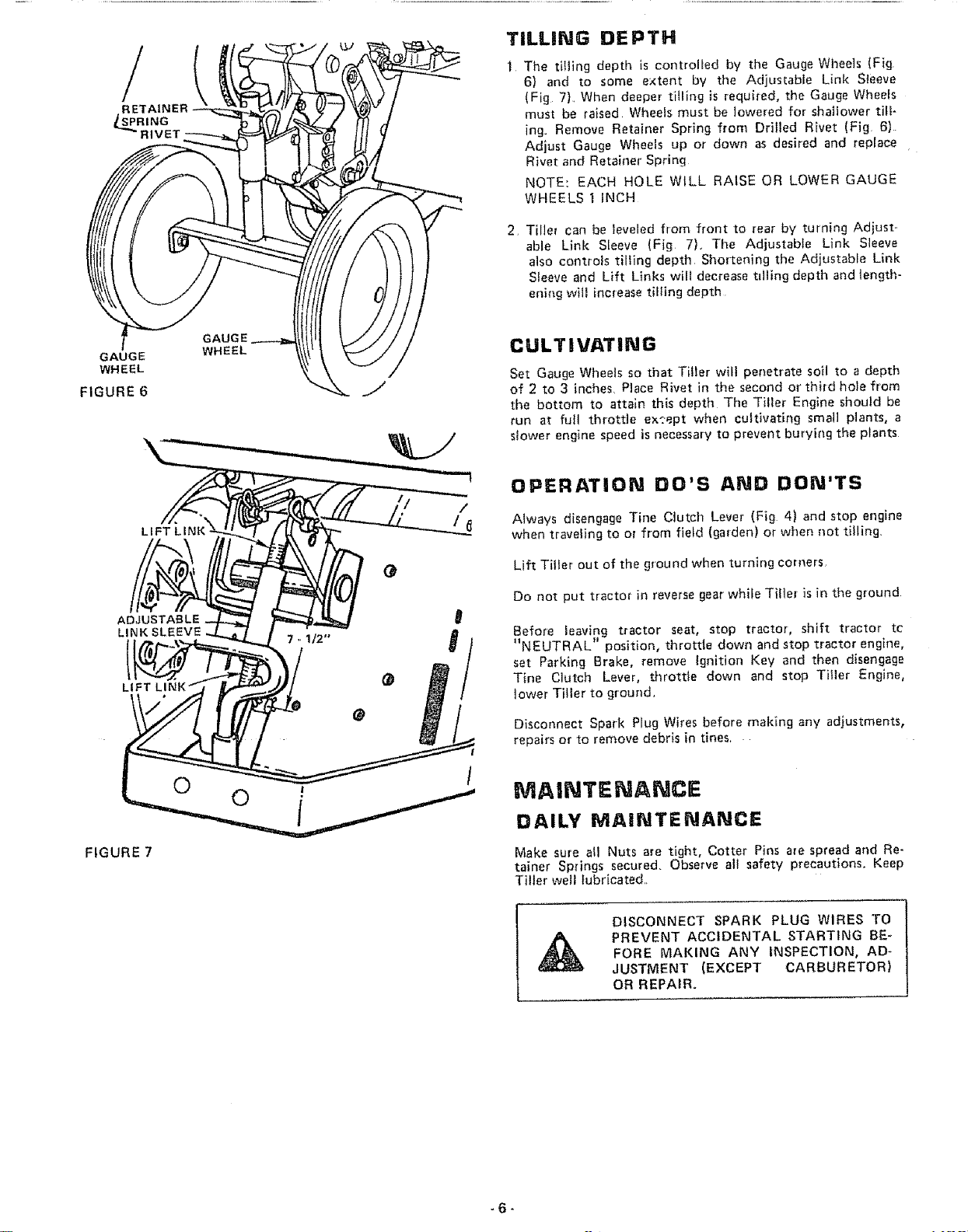

TILLING DEPTH

The tilling depth is controlled by the Gauge Wheels (Fig

6) and to some extent by the Adjustable Link Sleeve

(Fig 7).. When deeper titling is required, the Gauge Wheets

must be raised Wheels must be lowered for shallower tilt-

ing. Remove Retainer Spring from Drilled Rivet (Fig 6).

Adjust Gauge Wheels up or down as desired end reptace

Rivet and Retainer Spring

NOTE: EACH HOLE WILL RAISE OR LOWER GAUGE

WHEELS 1 INCH

2,

Tiller can be leveled from front to rear by turning Adjust..

able Link Sleeve (Fig 7). The Adjustable Link Sleeve

also controls tilling depth Shortening the Adjustable Link

Sleeve and Lift Links will decrease tilling depth and length-

ening will increase tilling depth

GAUGE WHEEL

WHEEL

FIGURE 6

LIFT LINK

ADJUSTABLE

LINK SLEEVE

LIFT

GAUGE

7 ,, 112"

CULTIVATING

Set Gauge Wheels so that Tiller wilt penetrate soil to a depth

of 2 to 3 inches, Place Rivet in the second or third hole from

the bottom to attain this depth The Tiller Engine should be

run at full throttle ex:'ept when cultivating small plants, a

slower engine speed is necessary to prevent burying the plants

OPERATION DO'S AND DON'TS

/

Always disengage Tine Clutch Lever (Fig 4) and stop engine

when traveling to or from field (garden) or when not tilling.

Lift Tifier out of the ground when turning corners.

Do not put tractor in reverse gear while Tiller is in the ground

Before leaving tractor seat, stop tractor shift tractor tc

NEUTRAL posit=on, throttle down and stop tractor engine,

set Parking Brake, remove Ignition Key and then disengage

Tine Clutch Lever, throttle down and stop Tiller Engine,

lower Ti!ler to ground.

Disconnect Spark Plug Wires before making any adjustments,

repairs or to remove debris in tines.

FIGURE 7

MAINTENANCE

DAILY MAINTENANCE

Make sure all Nuts are tight, Cotter Pins are spread and Re-

tainer Springs secured. Observe all safety precautions., Keep

Tiller welt lubricate&

DISCONNECT SPARK PLUG WIRES TO

PREVENT ACCIDENTAL STARTING BE-

FORE MAKING ANY INSPECTION, AD-

JUSTMENT (EXCEPT CARBURETOR)

OR REPAIR°

-6-

Loading...

Loading...