Craftsman 917251520 Owner’s Manual

®

MODEL NUMBER 917.251520 _,OWNER'SMANUAL

o Assembly

Operation

Customer Responsibilities

o Service and Adjustments

Repair Parts

CAUTION: Read and follow all safety rules and instructions before operating this equipment.

FOR CONSUMER ASSISTANCE HOT LINE, CALL THIS TOLL FREE NUMBER: 1-800-659-5917

SAFETY RULES

Safe Operation Practices for Ride_On Mowers &

IMPORTANT: THIS CUTTING MACHINE tS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

L GENERAL OPERATION

• Read, understand, and follow all instructions in the manual

and an the machine before starling

, Only allow responsible adults, who are familiar with the

lnslructions, to operate the machine

. Clear the area of objects such as rooks, Ioys, wire, ele,

which could be picked up and thrown by the blade

• Besure 1hearea fs clearer otherpeople before mowtng Stop

machine if anyone enters the area

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary Always

look down and behind before and wht!e backing

• Be aware of lhe mower discharge direcUon and do not point

il at anyone Do not operate the mower witheul ellher the

entire grass catcher or lhe guard in place

• Stow down before turning

, Never leave a running machine unattended. Always turn off

b_ades, set parking brake, slop engine, and remove keys

before dismounting

• Turn off blades when not mewing

• Stop engine before removing grass catcher or unc!ogging

chute.

• Mow only in daylight or good edifictet tight

• Do not operate the machine while under lhe Inliuence of

alcohol or drags.

• Watctl for traffic when operating near or crossing roadways

, Use extra care when loading or unloadlng the machine into

a trailer or truck

Ilo SLOPE OPERATION

Slopes are a major lector related to loss-of-control and

tipover accidents, which can result in severe injury or

death.. All slopes require extra caution. If you cannot back

up the slope or if you feet uneasy on it, do not mow it.

DO:

• Mow up and down slopes, not across

• Remove obstacles such as rocks, tree limbs, etc

• Watch for holes, ruts, or bumps. Uneven terrain could

ovedum the machine Tall grass can hide obstacles

• Use slow speed Choose a _ow gear so that you witl not have

to stop or shill whi]e on the slope,

• Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability

• Use extra care with grass calchers or other attachments

These can change the stability of the machine

• Keep all movement on the slopes stowand gradua_ Do not

make sudden changes in speed or direolion..

• Avoid starting or slopping on a slope. If tires lose tracl}on

disengage the blades and proceed slowly straight down lha

slope

00 NOT:

• Donottumonslopesunlessnecessery, andthen, tumstowly

and gradually downhill, i{ posstble

• Do not mow near drop-offs, ditches, or embankmenls. The

mower could suddenly turn over if a wheel is over the edge

el a clilt or diloh_ or if an edge caves in

• Do not mow on wel grass Reduced traction could cause

slid{ng

• Do not try to slabi_ize the machine by pulling your foot on the

ground

, Do not use grass catcher on steep slopes

IlL CHILDREN

Tragic accidents can occur {fthe operator is not alert to the

presence of children. Children are often atlracted to the

machine and the mowing aelivity. Never assume that

children wilt remain where you tast saw them.

- Keep children out el the mowing area and under the watchful

care of enolher responsible adult

o Be alert and turn machine off it children enter the area

• Before and when backing, look behind and down {or small

children

• Never carry children. They may fall off and be seriously

injured or inleffere with safe maohlne operation

, Never allow children to operate the machine.

• Use extra care when approaching blind corners, shrubs,

lrees, or other objects lhal may obscure vision

IV. SERVICE

• Use extra care in handling gasoline and olher luels They are

tlemmable and vapors are explosive

Use only an approved container,

Never remove gas cap or add fuel with the engine

running. Allow engine to coot before refuefing Do not

smoke

Never refuel the machine indoors.

Never slots the machine or luel container inside where

there is an open llama, such as a water healer

° Never run a machine inside a closed area,

• Keep nuls and bolts, especially blade attachment bolls, tight

and keep equipment in good condition

. Never lamper with safety devtces Check lheir proper

operation regularly.

, Keep machine free of grass_ leaves, or other debds build-up,

Clean oil or fuel spillage Allow machtne to cool belore

storlng

• Stop and Inspect the equipment if you stdke an objeel.

Repair, {f necessary, before restarting.

. Never make adjuslments or repairs with ihe engine running..

', Grass calcher componenls are subject to wear, damage, and

detedoration_ which could expose moving pads or alIow

objects to be thrown. Frequenlly check components and

replace with manufacturer's recommended paris, when nec-

essary

• Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them

• Check brake operalion frequently Adjust and service as

required.

safety precautions, it means

Look for this symbol to point out important

CAUT!ONIll BECOME ALERT[II YOUR

SAFETY IS INVOLVED,

CAUTION; Always disconnect spark plug

spark plug In order to prevent accidental

wire and plaoewtre wherelt oannotcontact

starting when setting up, transporting,

adjusting or making repairs,,

g WARNING

The engine exhaust from this product contain s

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc-

tive harm,

CONGRATULATIONS on your purchase of a Sears

Tractor [t has been designed, engineered and manufac-

lured to give you the best possible dependability and

performance

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service Center/Department Department We havecom-

petenl, well-trained technicians and the proper too_s to

servtce or repair this tractor

Please read and retain this rnanual The instructions will

enabie you to assemble and maintain your tractor properly

Atways observe the "SAFETY RULES",

NUMBER 917251520

SERlAL

NUMBER

DATE OF PURCHASE

THE MODELAND SERIAL NUMBERS WtLLBE FOUND

OH A PLATE UNDER THE SEAT

YOU SHOULD RECORD BOTH SERIAL NUMBER AN D

])ATE OF PURCHASE AND KEEP SNA SAFE PLACE

-'OR FUTURE REFERENCE,

MAINTENANCE AGREEIVIENT

A Sears Ma}ntenance Agreement Is available on this prod.,

ucf Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules

, Follow a regutar schedule in maintaining, caring for and

using your tractor

• Follow the instructions under "Customer Responsibi]i-

ties" and "Storage" sections of this owner's manual

PRODUCT SPECiFiCATIONS

HORSEPOWER: 20.5

GASOLINE CAPACITY 3 5GALLONS

AND TYPE: UNLEADED REGULAR

OIL TYPE (AP!-SFiSG): SAE 10W30 (above 32_F"}

SAE 5W-30 (below 32'F)

OILCAPACtTY; W/FILTER: ,12 PINTS

W/O FILTER: 3 7 PINTS

SPARK PLUG: CHAMPION RC12YC

(GAP: ,030")

VALVE CLEARANCE: HOT ADJUSTABLE

GROUND SPEED (MPH): FORWARD: 58

REVERSE: 30

TiRE PRESSURE: FRONT: 14 PSI

REAR: 10 PSI

CHARGING SYSTEM: 15 AMPS @ 3600 RPM

BATTERY: AMP/HR: 35

MIN CCA: 280

CASE SIZE: UIR

BLADE BOLT TORQUE: 30-35 FT LBS

WARNING: This lractor is equipped wilh an inlernal

combustion engine and should not be used on or near any

un[rnproved forest-covered, brush-covered or grass-cov-

ered land unless the engine's exhausl system is equipped

with a spark arrestor meeting applicable local or stale laws

(ifany) If a spark arrester is used, it should be maintained

in effective wofldng order by _heoperator

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code),,

O_her states may have stmilar[aws, Federal laws apply on

Iedera[ lands. A spark arrestor for file muffler is available

through your nearesl Sears Authorized Service Center/

Departmenl (See REPAIR PARTS section of this manual

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

For two (2) years lrom the da_.eof purchase_ if this C_a_tsman Riding Equipment is maintained, _ubricated and luned up acco_ding

to the Instructions in the owner's manual, Sears will repair or replace, free el charge, any parts found lo be de_eclive in material

or workmanship

Titis Warranly does not cover,

• Expendable items which become worn during normal use, such as blades_ spark plugs, air cteane_'s, belts, elc

• Tire replacement or repalr caused by punctures from oulsida ebtecls, such as nails. _homs. slumps, or glass

• Repairs necessary because of 0parader abuse, neg!tgence, improper slorage or accident or the Iailure Io mainlain Ihe

equipment accordlng lo the i_'_s_.ruct}onscon'[ained in the owner's manual

• Riding equipment used for commerciaI or rental purposes

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety {90} days from date et puccSase, il any battery included w[fh Ibis riding equipment proves detective in malarial o_"

workmanship and our lestSng determines the battery wil_ not ho_d a charge, Sears will _eplaee lhe battery at no charge

1N-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CHARGE FOR 30

DAYS FROM THE DATE OF PURCHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER. AFTER 30 DAYS

FROM THE DATE OF PURCHASE, WARRANTY SERVICE IS AVAILABLE BY TAK3NG YOUR CRAFTSMAN RIDING EQUIP-

MENT TO YOUR NEAREST SEARS SERVICE CENTER. (IN-HOME WARRANTY SERVICE W_LL STILL BE AVAILABLE

AFTER 30 DAYS FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY ) THIS WARRANTY

APPLIES ONLY WHILE THIS PRODUCT tS 1N THE UNITED STATES

Th_s Warranly gives you specific Iegat rights, and you may also have olher rights which may vary I_'om slate lo stale

SEARS, ROEBUCK AND CO , Di817WA, HOFFMAN ESTATES, IL 60179

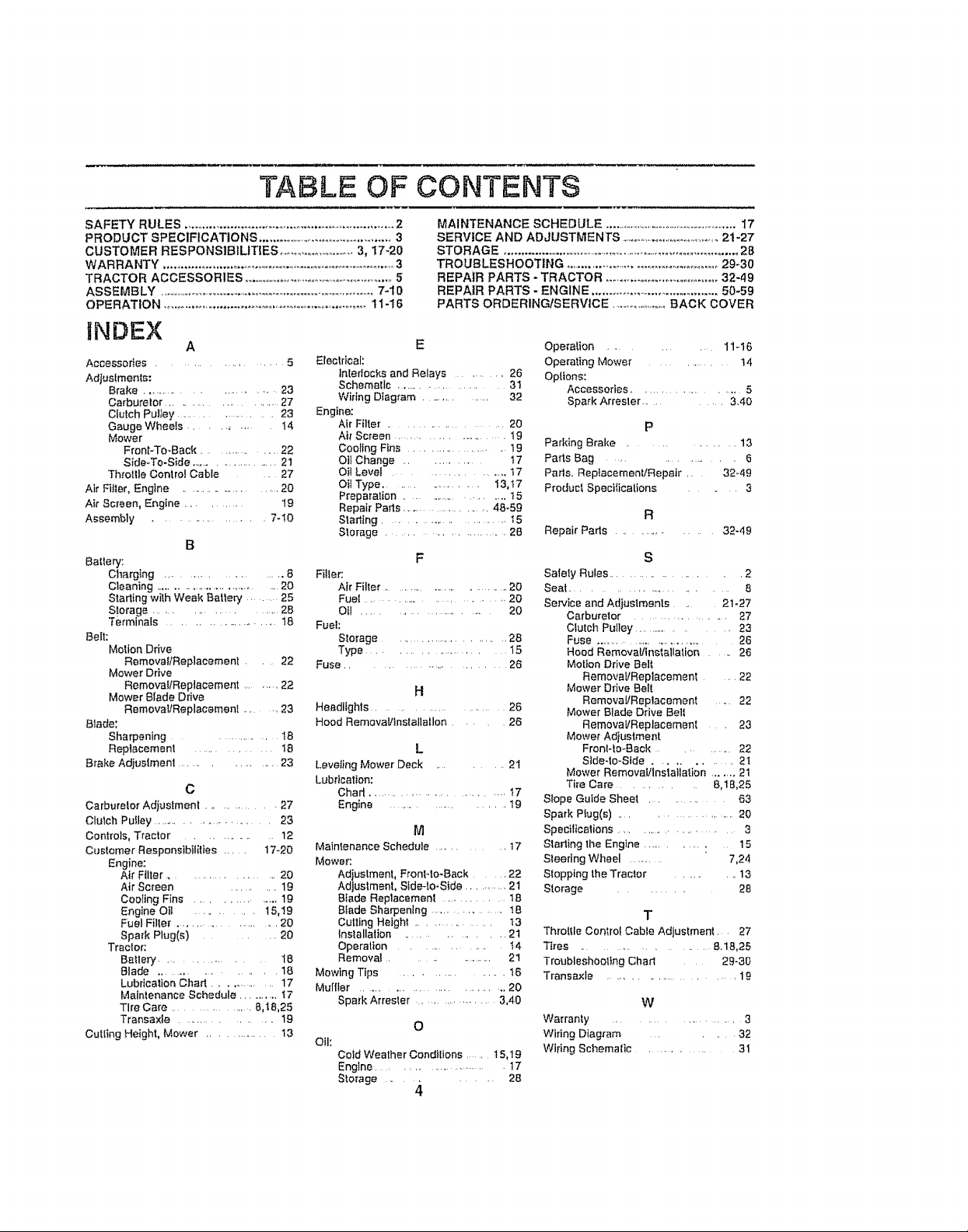

TABLE OF CONTENTS

SAFETY RULES ............................................................... 2

PRODUCT SPECIFICATIONS .................................................3

CUSTOMER RESPONSIBILITIES ...........................3, 17-20

WARRANTY ................................................................................3

TRACTOR ACCESSORIES ..................................................5

ASSEMBLY ..............................................................................7-10

OPERATION ......................................................................11-16

INDEX

A

Accessories .................. 5

Adjuslments:

Brake ......................... 23

Carburetor ....................... 27

Ciulch Pu!ley ..................... 23

Gauge Wheels ........... 14

Mower

Front-To-Back .................22

Side,.To-Side ......................... 21

Throtlle Control Cable . 27

Air niter, Engine ......................... 20

AIr Screen, Engine ............ 19

Assembly ................... 7-I0

B

Battery:

Charging ..................... 8

Cleaning .............................. 20

Starting wi_h Weak Batter,./ .......... 25

S!orage ....................... 28

Terminals ........................ 18

Belt:

Motion Drive

Remova!IReplacement . . 22

Mower Drive

Removal/Replacement ......... 22

Mower Blade Drive

RemovaltReplacemen! ......... 23

Blade:

Sharpening ............... t8

Replacement ............... t8

Brake Adjustment ................ 23

C

Carburetor Adiuslmenl ........... 27

Clulch Pulley ....................... 23

Controls, Tractor ............... 12

Customer Responsibilities ..... 17..20

Engine:

Air Filter ..................... 20

Air Screen ........... 19

Confine Fins ................ 19

Engine Oi_ ............ 15,!9

Fuel Filler ..................... 20

Spark Plug(s) ....... 20

Tractor:

Baltery ................. 18

Blade ............... 18

Lubrication Chart ............. 17

Maintenance Schedule .......... t 7

Tire Care ..................... 8,18,25

Transaxle ................... 19

Cutiing Height, Mower ............... 13

Electrical:

Interlocks and Relays ....... 26

Schemallc ....................... 3I

Wiring Diagram .................. 32

Engine:

Air Filter ....................... 20

Aft Screen ........................ 1g

Coollng Fins ................. Ig

OI1 Change ............ 17

Oil Level .................... 17

Oil Type ................... 13,17

Preparation ...................... t 5

Repair Pads ...................... 48-59

Starling ...................... 15

Storage ....................... 2B

Filler:

Air Filter .............................. 20

Fuel ..................................20

Oil ............................ 20

Fuel:

Storage ............................ 2B

Type ..................... 15

Fuse ................ 26

Headlights ......................... 26

Hood Removathnslallatlon ..... 26

Leveiing Mower Deck ......... 21

Lubrication:

Chad ............................ t7

Engine ........................ 19

Mainlenance Schedule ............ 17

Mower:

Adiuslmenl, Front-to-Back .22

Adjustment, Side-to-Side ......... 21

Blade Replacement ............... 18

B_ade Sharpening .................. !8

Culling Heighl ................ t3

Installation ............... 21

Operation ................ t4

Removal .............. 21

Mowing Tips ................. t6

Muffler ............................... 20

Spark Arrestor ..................... 3,40

Oil:

Cold Weather Condilions ....... 15,1 g

Engine ........................ 17

Storage ......... 28

MAINTENANCE SCHEDULE ........................................................17

SERVICE AND ADJUSTMENTS .......................................21-27

STORAGE .....................................................................................2B

TROUBLESHOOTING ............................................. 29-30

REPAIR PARTS- TRACTOR ................................... 32-49

REPAIR PARTS - ENGINE ..................................... 50-59

PARTS ORDERING/SERVICE .....................BACK COVER

E

Operation ............. 11 -16

Operating Mower .............. 14

Oplions:

Accessories ........................ 5

Spark Arrestor ...... 3,40

P

Parking Brake ................ 13

Parts Bag ............... 6

Paris, Replacemenl/Repair .... 32-4g

Produc| Specitications ...... 3

R

Repair Pads ................. 32-49

F

Salary Rules ....................... 2

Seat ............................. 8

Sew!co and Adjustments .... 21-27

Carburetor ................... 27

Clutch Pulley .................... 23

Fuse ............................... 26

Hood Removal/installaiion .... 26

Motion Drive Belt

RemovaVReplacement . 22

H

L

Mower Drive Belt

Removat/Reptacemenl ,, 22

Mower Blade Drive Belt

Removat!Replacemenl 23

Mower Adiustment

Fronl-lo-Baek .......... 22

Side-to-Side ........... 2t

Mower Removalllnstailaliun ....... 21

Tire Care ........... B,18,25

Slope Guide Sheet ................ 63

Spar]{ Plug(s) ...................... 20

Speciltcations ......................... 3

Starting the Engtne ............... 15

Sleeting Wheel .......... 7,24

Slopping the Traclor .... 13

Storage ......... 28

S

T

Throllle Control Cable AdJustmenl. 27

Tires ....................... 8.18,25

Troubleshooting Char! 2g-30

Transaxle ........................ 19

W

O

Warranty ...................... 3

Wiring Diagram . 32

Wiring Schemalic ............. 31

4

ACCESSORIES AND ATTACH[WENTS

These accessories and attachmenls were available through most Sears telail autlels and service centers when Ihe tractor was purchased

Mosl Sears stores can order these _lems for you when you provide the mode} number of your lractor

ENGINE

SPARK PLUG GAS CAN ENGINE OIL FUEL STABILIZER AIR FILTER

PERFORMANCE

Sears offers a wide variety o! attachments lhaf fit your tractor Manyof these are Itsted below with brief explanations of how [hey can help

you_ This list was current a{ lhe lime el pubJicalton; however, It may change in future years - more attachments may be added, changes

may be made in lhese attachments, or some may no longer be available or tiI your model Contact your nearest Sears store for the

accessories and attachments that are available for your Iractor,

Most oi these aItachments de not require addiIionai hitches or conversion kits (these that do are indicated) and are designed lor easy

attaching and detaching

AERATOR promeles deep reel growth tora heaHhy lawn Tapered

2 5-Inch s_'eet spikes mounled on t04nch diameter d_scs punclure

holesin soil at close intervals to let moisture soak in Slee! weight ltay

tar Increased penetration

BUMPER prolecls Ireful end of tractor from damage

CARTS make hauling easy Variety el sizes available, plus accesso_

ties such as side panel kits, 1oolcaddy, cart cover, protective mat and

dol_y

CORING AERATOR lakes small plugs ou_ o1 soil to allow moislure

and eulrJents {0 reach grass roofs 36-inch swalh 24 hardened steel

co_ng tips f50 lb capacity weight lray

DISC HARROW has 2 gangs of 4 stee! blades that angle from 10 to

20 degrees, 40 inches wide Can hook 2 un!ts in tandem (Requires

sleeve hitch )

DOZER BLADE removes snow; grades dirt, sand and gravel 48

Incheswide, 17tnchesh{gh,clears444nchpathwhenangled Master

_il(control lever for operator ease Spdng ldp for snow removal on

uneven pavemenl; built.in float tor btade to _ollow ground contour.

Revarsibfe, replaceable scraper bar (Use with t_irechains and wheel

weights and/or rear drawbar weighl )

EASY OIL DRAIN VALVE makes oil changes easier, faster

FRONT NOSE ROLLER canlers in front ot mower deck to reduce

chances e{ "scalping" on uneven terrain

GANG BITCH (e_s you low 2 or 3 pelt*bed}ted attachmep.ls al

once, such as sweepers,, delhatchers, aerators (nel for use wlth

rolters, ca_s or other heavy a_tachmenls)

MULCH RAKFJDETHATCRER Ioosens sol{ and flips lhatch and

malted leaves _olawn surface for easy pickup Twenly spdng line

teeth Useful Io prepare bare areas [or seed}rig. Available for {ron_or

rear mount{no. HIGH PERFORMANCE REEL-ACTION SPRING

T;NE DETHA_TCHER covers 36-inch wide path end tosses lhatch tr,l.o

large hopper Mounts behind tractor

PLOW {urns soil 6 inches deep. cuts 104nch furrow Crank adjust-

meet controls depth, 3_pesilion yoke sets width. Heaw steel landside

for straight furrowing (Requires s_eeve hilch }

RAMP TOPS AND FEET Iel you lead and un_oad tractor {tom a

pickup truck Use with 2 x 8 or 2 x 10 lumber

REAR GRADER BLADEis 42_ncheswide and operaled from dhver's

seat Reversible sleet blade can be angled at 30 degrees {orgrading

Reverses for pushing snow backwards (Requires sleeve hitch )

ROLLER for smoother lawn surface. 36-inch wide. 18-inch diameter

walerqight drum holds up to 390 Ibs oI weight. Rounded edges

prevent harm to tud Ad}ustabIe scraper aufomaticaily cleans drum

SLEEVE CULTIVATOR is 43 inches wide, Prepares ground tor

seeding, helps weed control Steel t_'ame holds 5 ._djuslable sweeps.

Adiusls verlically, hodzonlal_y (Requires sleeve bi_ch ) Optiona; _

accessory: steet lurrow opener _or wider openings tot potatoes.

corn, and other deep.seeded crops.

SLEEVE HITCH _or use with master till syslem SirLcle pin couples/

uncouples

SNOWTHROWER has 42..inch swalh Drumdype auger handtr.,s

powdery and wet/heavy snow Mounts eesilywith simpSe pin arrange*

mont. Discharge chute adjusts from tractor seal 64nch diameter

spaul discharges snow 10 to 50 teet Lift controlled al tractor seat

(Use wi_h chains and wheel weights and, or rear drawbar weight )

SPRAYERS use f 2-volt DC electric motor lhai eonnecls _othe tractor

battery or olher t2woll source Includes booms for automatic

spraying and hand held wand for spot spraying Wand has adjuslable

spray pattern For applying herbicides, insecticides, lung[cities and

liquid fert$1izers

SPREADER/SEEDERS make seeding, fedtlizing, and weed Sdlling

easy. Broadcast spreaders ere also uselu_ for granular de-icers and

sand

SWEEPERS let you collect grass dlpp_ngs and leaves

"rILL ER has 8 hp engine [o prepare seed beds, cullivate and compost

garden residue Chain-drive transmission. Six 1t-inchdiameter one

piece heat-treated stee_ tines. Tit[s 30-inch path (Requires sleeve

hitch } Or use 5 hp !ow_behind'TILLER wi_h 36-inch swafl_ to prepare

seed beds, cultivate and compost garden residue, Tiller has ils own

buitt-tn lill and depth conlrcl system and does NO-t require a sleeve

hitch. Fits any lawn, yard or garden tt_actor_ Simply hook up Io Ihe

#actor drawba_'and go! Op_tanal accessories lor 5 !_ptiller convert

unit ]or dethatching aerating, hilling without toOlS

TIRE CHAINS are heavy duty; closely spaced exlra-targe c:oss _inks

glue smoolh ride. oulstanding Iraclion

TRACTOR CAB has heavy duty vinyl tabdc over tubular steel Irame.

ADS plastic top; croat plastic windshield oilers 360 degree visibility

Hinged metal doors with catch Keeps operalor warm and dry

Remove vinyl sides end windshields [or use as sun protector in

summer Optional accessories Include: tinled/lempered solid

safely glass windshield with hand operated wiper;, 12-volt ember

caution iighl !or mounting on cab lop

VACS for powerful cotleclion el heavy grass clippings and leaves

Optfonalwand attachment to pick u_debris inhard-lo..reach places

VACICHIPPER includes a eh{pper_shredder

WEIGHT BRACKET for drawbar tot snow removal applications. Can

be mounted on trent of Iracter tot plowing applications Uses (t) 55

{b weigh_

WHEEL WEIGHTS for rear wheels provide needed traction for snow

removal e; dozing heavy materials

MAINTENANCE

BLADES BELTS

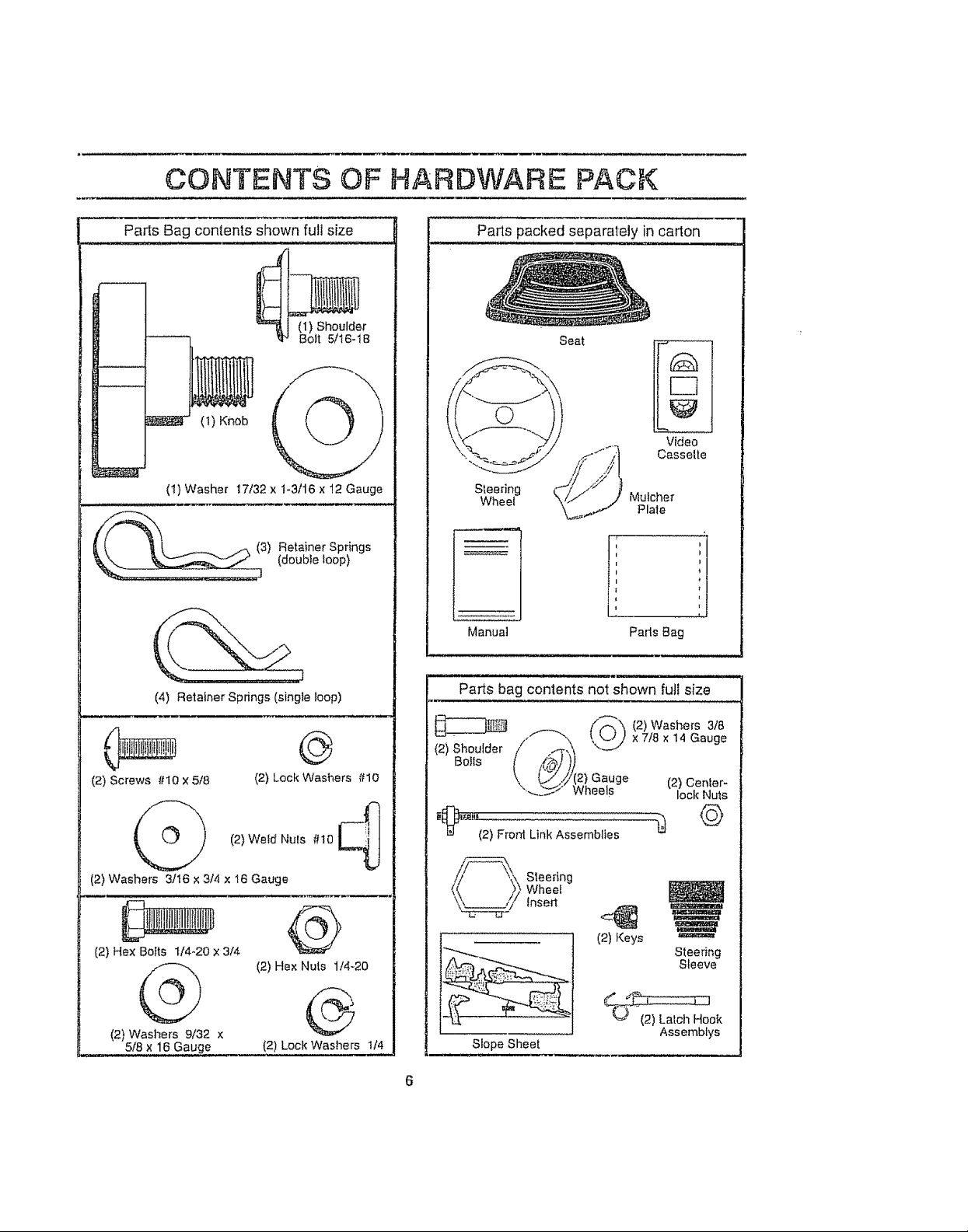

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

r----

r

(I) Knob

(!) Washer 17/32 x I-3/16 x 12 Gauge

3) etainer Springs(double loop)

(1) Shoulder

Bolt 5!16-18

Parts packed separately in carton

Seat

Video

Cassette

Steering

Wheel

Manual

Mutcher

Plate

i i

i I

i I

Pads Bag

t

(4) Retainer Springs (single loop)

(2) Screws #10 x 5t8 (2) Lock Washers #10

(2) Weld Nuts ;H0

(2) Washers 3/t6 x 3/4 x I6 Gauge

@

(2) Hex Bo_ts t14_20 x 3/4

(2) Hex Nuts 1/4-20

(2) Washers 9/32 x

5/8 x 16 Gauge (2) Lock Washers 114

Parts bag conlents not shown full size

,"'-_" x 7/8 x 14 Gauge

(2) Sh°ulder (// C.(_.(Bolls

\"-,.._J'::_._ Wheel_ (2) Center-

_] (2) Front Link Assemblies

Sleedng

Wheel

Insert

Slope Sheet

6

2) Gauge

(2) Keys

_ook

(2) Washers 3/8

lock Nuts

Steering

Sleeve

Assemblys

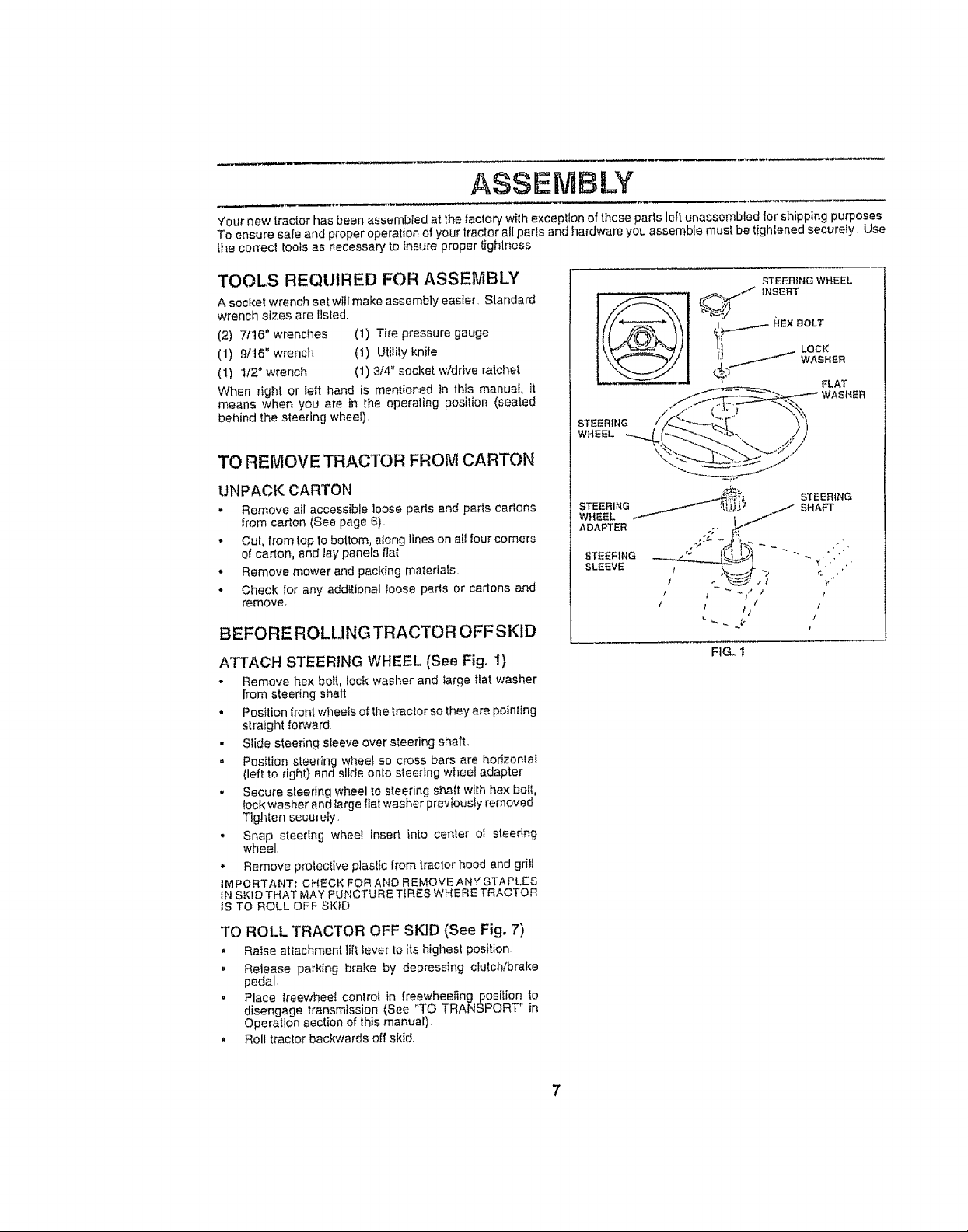

ASSEMBLY

Your new tractor has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

To ensure safe and proper operation of your tractor all parts and hardware you assemble must be tightened securely Use

the correct tools as necessary to insure proper tightness

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier, Standard

wrench sizes are listed.

(2) 7/16" wrenches (t) Tire pressure gauge

(1) 9/16" wrench (t) Utility knife

(1) tt2" wrench (1) 3/4" socket w!drive ratchet

When right or left hand is mentioned In this manual, it

means when you are in the operating position (sealed

behind the steering wheel)

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

. Remove all accessible loose parts and paris cartons

from carton (See page 6)

° Cut, from top 1o bottom, aIong lines on all four corners

of carton, and tay panels fiat.

• Remove mower and packing materials

° Check for any additional foose parts or cations and

remove,

BEFORE ROLLING TRACTOR OFF SK|D

ATTACH STEERING WHEEL (See Fig. 1)

- Remove hex boit, lock washer and Iarge flat washer

from steering shaft

• Position front wheels of the tractor so they are pointing

straight forward

• Slide steering sleeve over steering shaft.

" Position steering whee_ so cross bars are horizonlal

(left to right) andsllde onlo steering wheel adapter

, Secure steedng wheel to steering shaft with hex boit,

rock washer and large fiat washer previousfy removed

Tighten securely.

• Snap steering wheel insert into center el steering

wheel.

• Remove protective plastic from tractor hood and grill

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

tN SKID THAT MAY PUNCTUR E TIRES WHERE TRACTOR

tS TO ROLL OFF SKID

TO ROLL TRACTOR OFF SKID (See Fig, 7)

,, Raise attachment lift lever to its highest position

• Release parking brake by depressing clulchibrake

pedal

• Place freewhee{ conlret in (reewheeiing position to

disengage transmission (See "TO TRANSPORT" in

Operation section of this manual)

• Roll tractor backwards off skid,

STEERING WHEEEL

I_._._......---REXBOLT

l'i _..,,,,.LOCK

_i_ WAs.ER

STE_A_NG / /_"'----_:"r" \'\

STEERING / {t_" _,._, _HA_-_r

WHEEL ./ ...._"/ .....

ADAPTER ,;, '_,"_

/ I _ _ i"// t

/ I l/ I

_" _ _ _._ I"_

FIG,. 1

FLAT

7

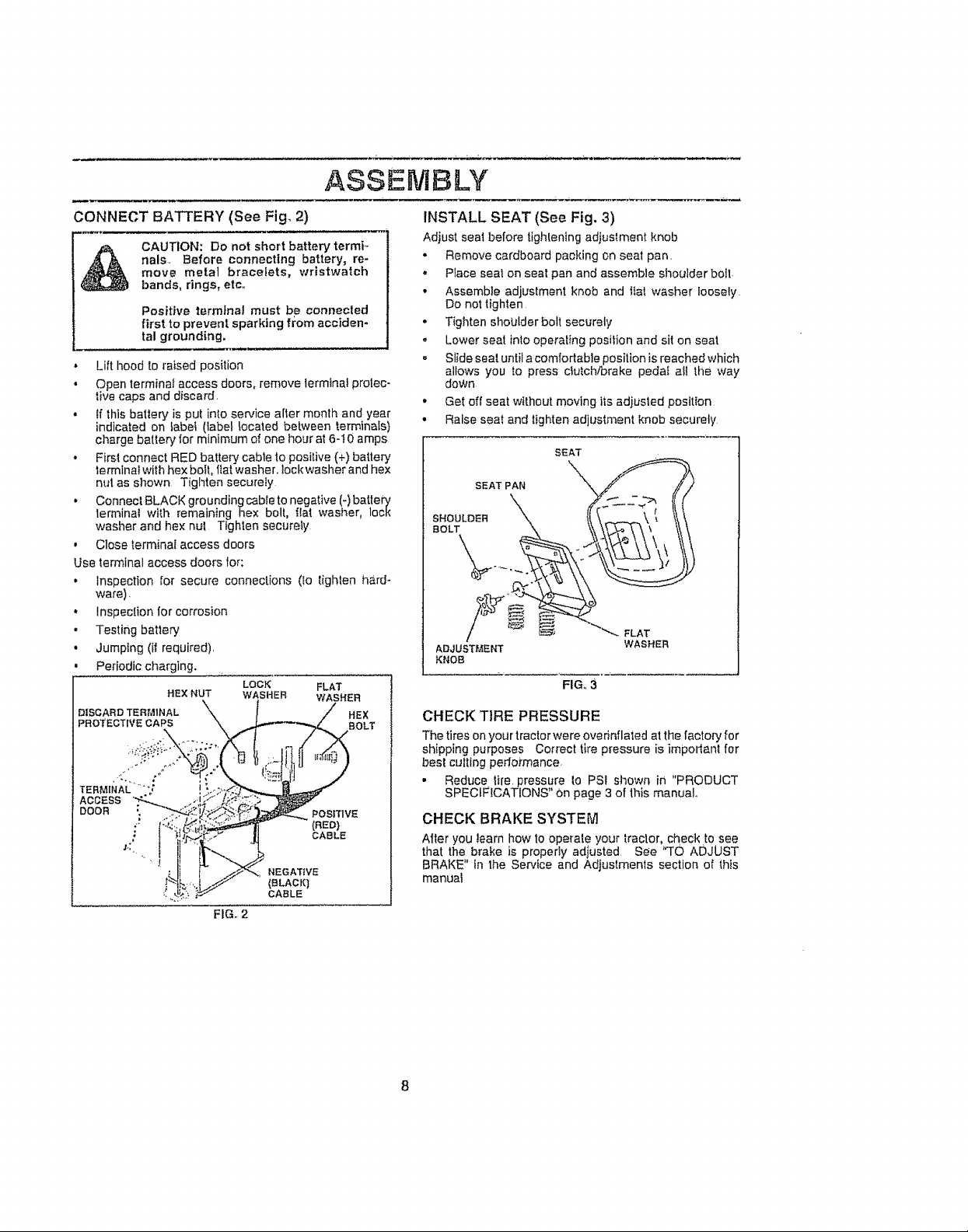

ASSEMBLY

CONNECT BATTERY (See Fig_ 2)

CAUTION: Do not short batten,/termF

nals. Before connecting battery, re-

move metal bracelets, wristwatch

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden-

tal grounding.

. Lift hood to raised position

. Open terminal access doors, remove lermlnaf protec-

tive caps and discard,

• If this battery is put into service a{ter month and year

indicated on tabeI (label _ocated between terminals)

charge battery for minimum of one hour at 6-t0 amps

• First connect RED battery cable to positive (+) battery

terminaI with hex bolt, flat washer, lockwasher and hex

nut as shown Tighten secureIy

• Connect BLACK groundingcabte to negative (-)battery

terminal wtth remaining hex bolt, flat washer, lock

washer and he× nut Tighten securely

, Close terminat access doors

Use terminal access doors for:

• inspection for secure connections tic tighten hard°

ware).

• inspection for corrosion

• Testing battery

• Jumping (if required),

Periodic charging.

HE:( NUT WASHER WASHER

DISCARD TERMINAL HEX

PROTECTIVE CAPS BOLT

LOCK FLAT

NEGATIVE

(RLACK)

CABLE

FIG. 2

POSITIVE

{RED)

CABLE

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob

• Remove cardboard packing on seat pan,

. PIace seat on seal pan and assemble shoulder bolt.

• Assemble adjustment knob and flat washer loosely

Do not tighten

. Tighten shoblderbelt securely

,, Lower seat into operating position and sit on seat

,, Slide seat until a comfortable position is reached which

allows you to press clutchforake pedal ai! the way

down

. Get off seat without moving its adjusled position

• Raise seat and tighten adjustment knob securely

SEAT

SEAT PAN __

_'_'_ FLAT

ADJUSTMENT WASHER

KNOB

FIG., 3

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes Correct ttre pressure is impoilant for

best culling pedoi'mance

• Reduce tire, pressure to PSI shown in "PRODUCT

SPECIFICATIONS" On page 3 of this manual

CHECK BRAKESYSTEM

After you learn how to operate your tractor, check to see

that the brake is properiy adjusted See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual

ASSEMBLY

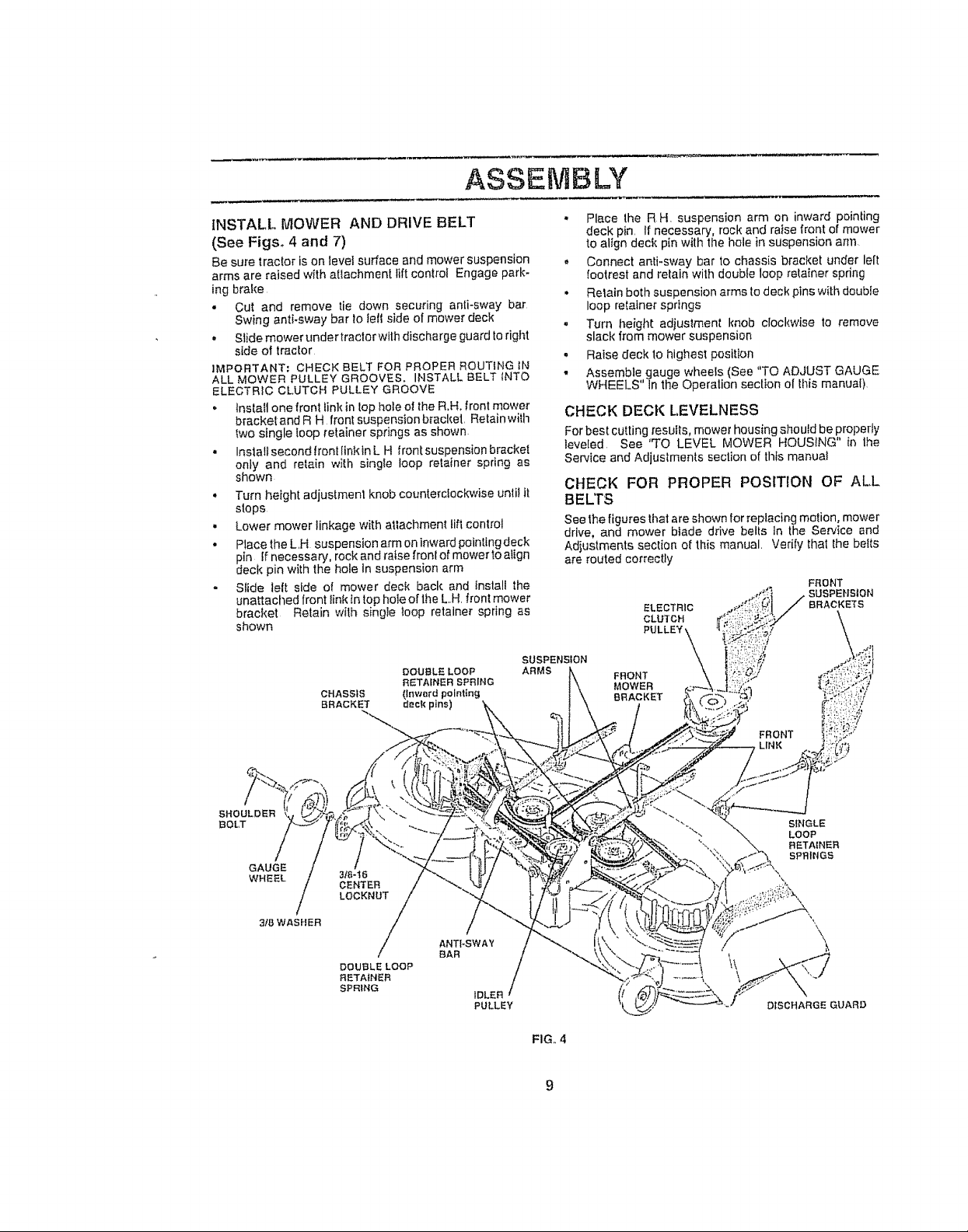

INSTALL MOWER AND DRIVE BELT

(See Figs_ 4 and 7)

Be sure tractor is on level surface and mower suspension

arms are raised with attachment lift control Engage park-

ing brake

• Cut and remove tie down securing anti-sway bar

Swing anti-sway bar 1otell side of mower deck

,, Slide mower under tractor with discharge guard to right

side of tractor

IMPORTANT: CHECK BELT FOR PROPER ROUTING iN

ALL MOWER PULLEY GROOVES. INSTALL BELT INTO

ELECTRIC CLUTCH PULLEY GROOVE

• Install one front link in top hole o! the R.H, front mower

bracket and R H front suspension bracket, Retain with

two single foop retainer springs as shown

° Install second tronf link _nL H front suspension bracket

only and retain with single loop retainer spring as

shown

• Turn height adjustment knob counterclockwise unit! it

stops

• Lower mower linkage with attachment lift control

• Place the LH suspension arm on inward pointing deck

pin if necessary, rock and raise front of mower to align

deck pin with the hole in suspension arm

- Slide lelt side of mower deck back and Install the

unattached front link tn top hole or the LH. front mower

bracket Retain wilh singte _oop retainer spring as

shown

DOUt_LE LOOP

CHASSfS {lnv,_er d pointing

BRACKET d_ck pins)

RETAINER SPRING

,, Place the R H. suspension arm on inward pointing

deck pin, If necessary, rock and raise front of mower

tO align deck pin with the hole in suspension arm

. Connect anti-sway bar to chassis bracket under left

footrest and retain with doubte loop retainer spdng

• Relain both suspension arms to deck pins with doubie

loop retainer springs

. Turn height adjustment knob clockwise to remove

slack from mower suspension

• Raise deck to highest position

,, Assemble gauge wheats (See "TO ADJUST GAUGE

WHEELS" in the Operation section of this manual)

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

leveled See "TO LEVEL MOWER HOUSING" in 1he

Service and Adjustments seclion of this manual

CHECK FOR PROPER POSITION OF ALL

BELTS

See thefigures that are shownforreplacingmotion, mower

drive, and mower biade drive belts In the Service and

Adiustments section o{ this manual, Verify thal the bel_s

are routed correctly

ELECTRIC

CLUTCH

SUSPENSION

ARMS

FRONT

MOWER

BRACKET

FRONT

.SUSPENSION

BRACKETS

SHOULDER

BOLT

GAUGE

WHEEL

3tB WAStlER

3,t8-16

CENTER

LOCKNU/_

DOUBLE LOOP

RETAINER

SPRING

ANTI-SWAY

BAR

IDLER

PULLEY

FIG,, 4

9

FRONT

SINGLE

LOOP

RETAINER

SPRI',NGS

DISCHARGE GUARD

ASSEMBLY

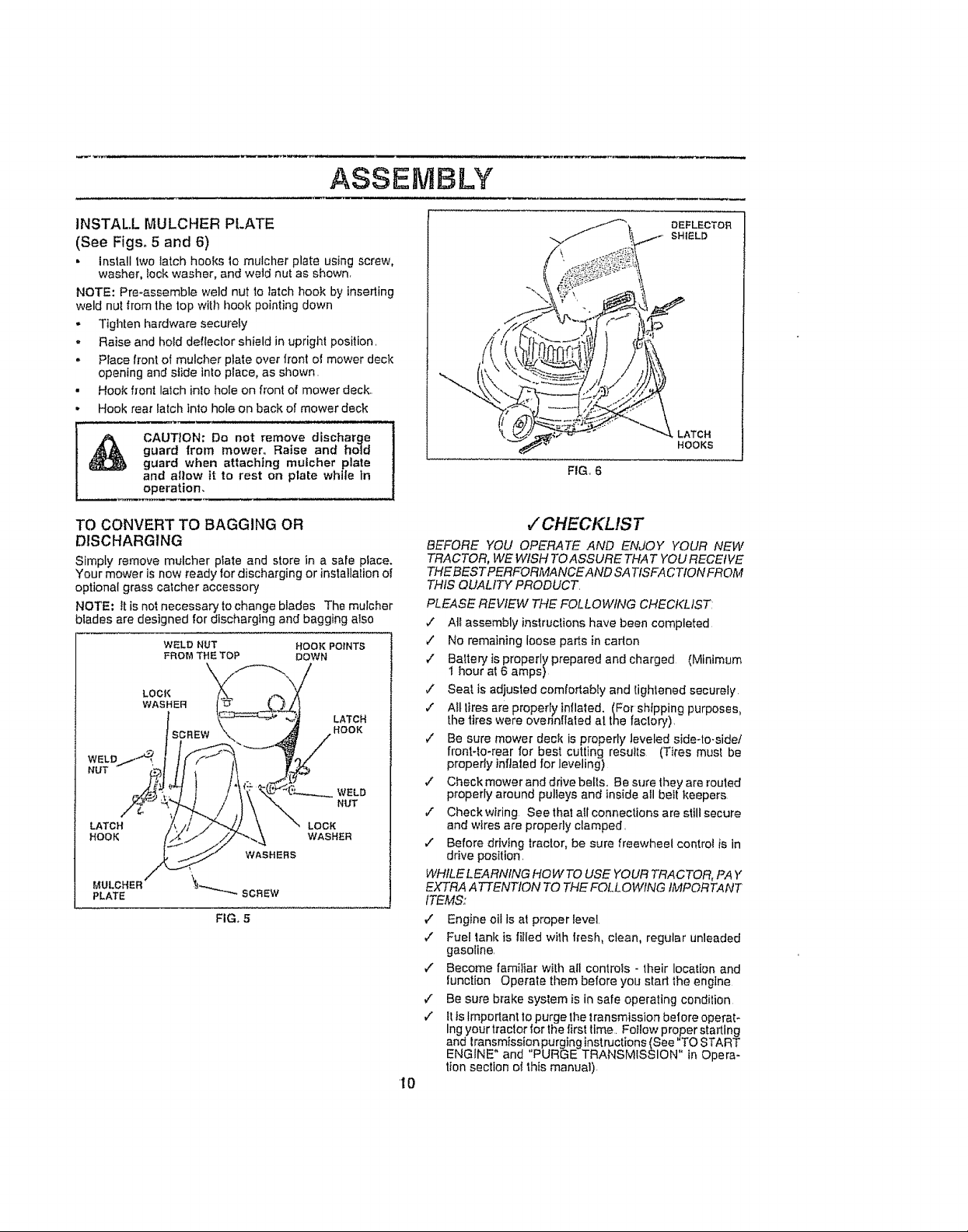

INSTALL MULCHER PLATE

(See Figs° 5 and 6)

• install two latch hooks to mulcher plate using screw,

washer, fock washer, and weld nut as shown,

NOTE: Pro-assemble weld nut to latch hook by inserting

weld nut from the top with hook pointing down

- Tighten hardware securely

. Raise and hold defIector shield in upright position,

. Place front of mulcher plate over front of mower deck

opening and stide into place, as st_own.

• Hook front latch into hole on front of mower deck,.

• Hook rear Iatch into hoie on back of mower deck

CAUTION: Do not remove discharge

&

guard from mower,, Raise and hold

guard when attaching mulcher plate

and allow It to rest on plate while In

operation.

TO CONVERT TO BAGGING OR

DISCHARGING

Simply remove mutcher plate and store in a safe place.

Your mower isnow ready fordischarging or installation of

optional grass catcher accessory

NOTE: It is not necessary to change blades The mulcher

blades are designed for discharging and bagging also

WELD NUT HOOK POINTS

FROM THE TOP DOWN

LATCH

NUT

LATCH LOOK

HOOK WASHER

WASHERS

PLATE

DEFLECTOR

SHIELD

HOOKS

FIG, 6

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, !'VEWISH TOASSURE THAT YOU RECEIVE

THE BEST PERFORMANCE AND SA TISFA CTION FROM

THIS QUALITY PRODUCT,

PLEASE REVIEW THE FOLLOWING CHECKLIST:

./ Atl assembly instructions have been completed

/ No remaining loose parts in carton

,/ Battery is properly prepared and charged (Minimum

1 hour at 6 amps)

/ Seat is adjusted comfortably and tighfened securely

#' AItlires are properly inflated. (For shipping purposes,

the tires were ovennffaled at the factory).

/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results (Tires must be

properly inflated for leveling)

v' Check mower and drive botts. Be sure they are fouled

properly around pulleys and inside all belt keepers

/ Checkwtring See that a!r connections are still secure

and wires are properly clamped.

,/ Before driving tractor, be sure freewheel control is in

driveposition.

WHtLE LEARNING HOWTO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

V' Engine oil is at proper level

/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline,

/ Become familiar with alt controls - their location and

function Operate them before you stad the engine

v" Be sure brake system is in safe operating condition

v" It tsImportant to purge the transmission before operat-

Ing your tractor for the first time. Follow proper starting

and transmission purging tnstructions (See "TO START

ENGINE" and "PURGE TRANSMISSION" in Opera-

tion section of this manual).

10

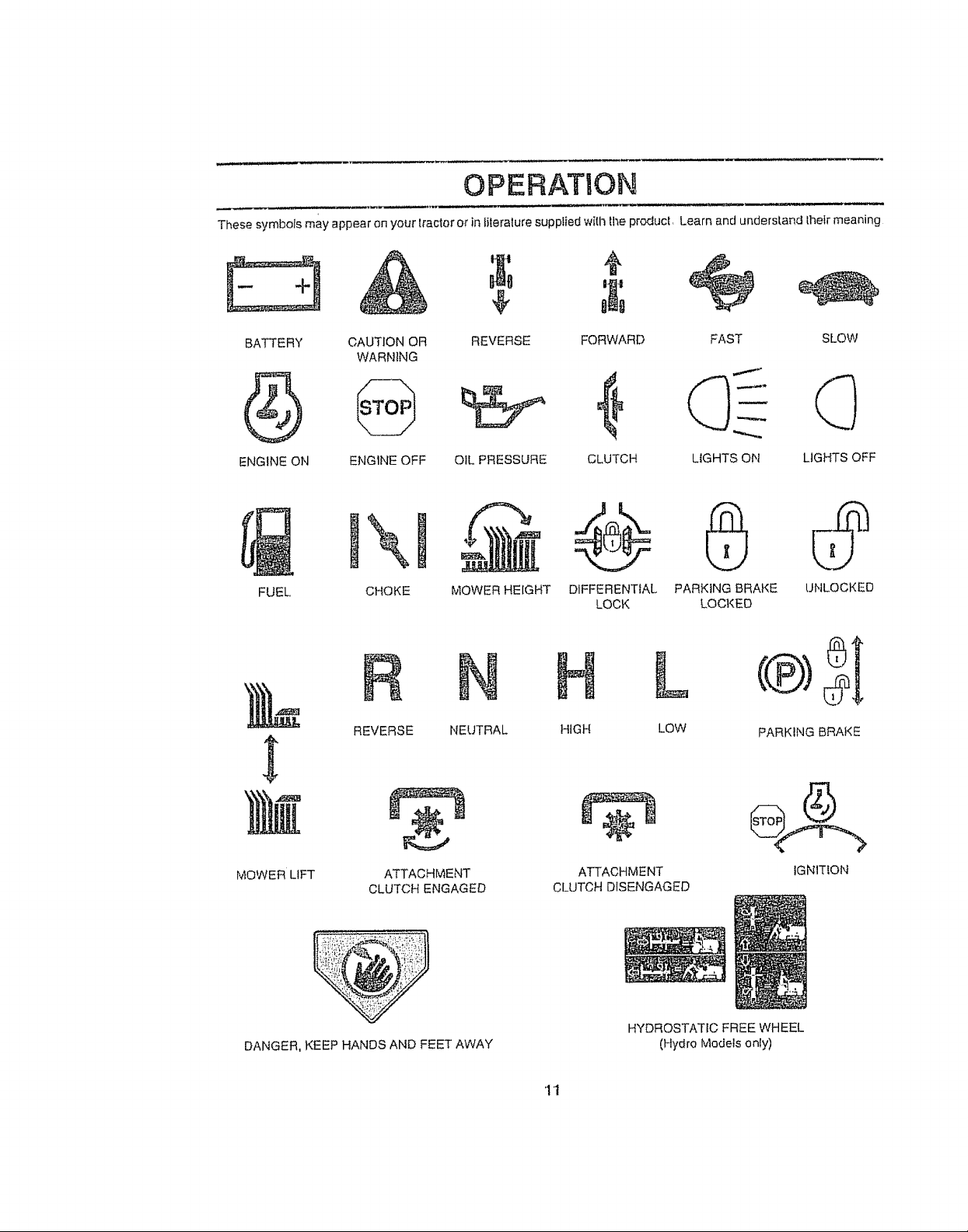

OPERATION

These symbols may appear on your tractor or in literature supplied with Ihe producL Learn and understand lhetr meaning

C3

BATTERY

ENGINE ON

FUEL.

k

!

CAUTION OR

WARNING

ENG1NE OFF

REVERSE FORWARD FAST SLOW

OIL PRESSURE CLUTCH LIGHTS ON LIGHTS OFF

H\

CHOKE

R N

REVERSE NEUTRAL

MOWER HEIGHT

DIFFERENTIAL PARKING BRAKE UNLOCKED

LOCK LOCKED

H L

HIGH LOW PARKING BRAKE

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

ATTACHMENT

CLUTCH DISENGAGED

HYDROSTATIC FREE WHEEL

'1t

IGN1TION

(Hydro lvlodels only)

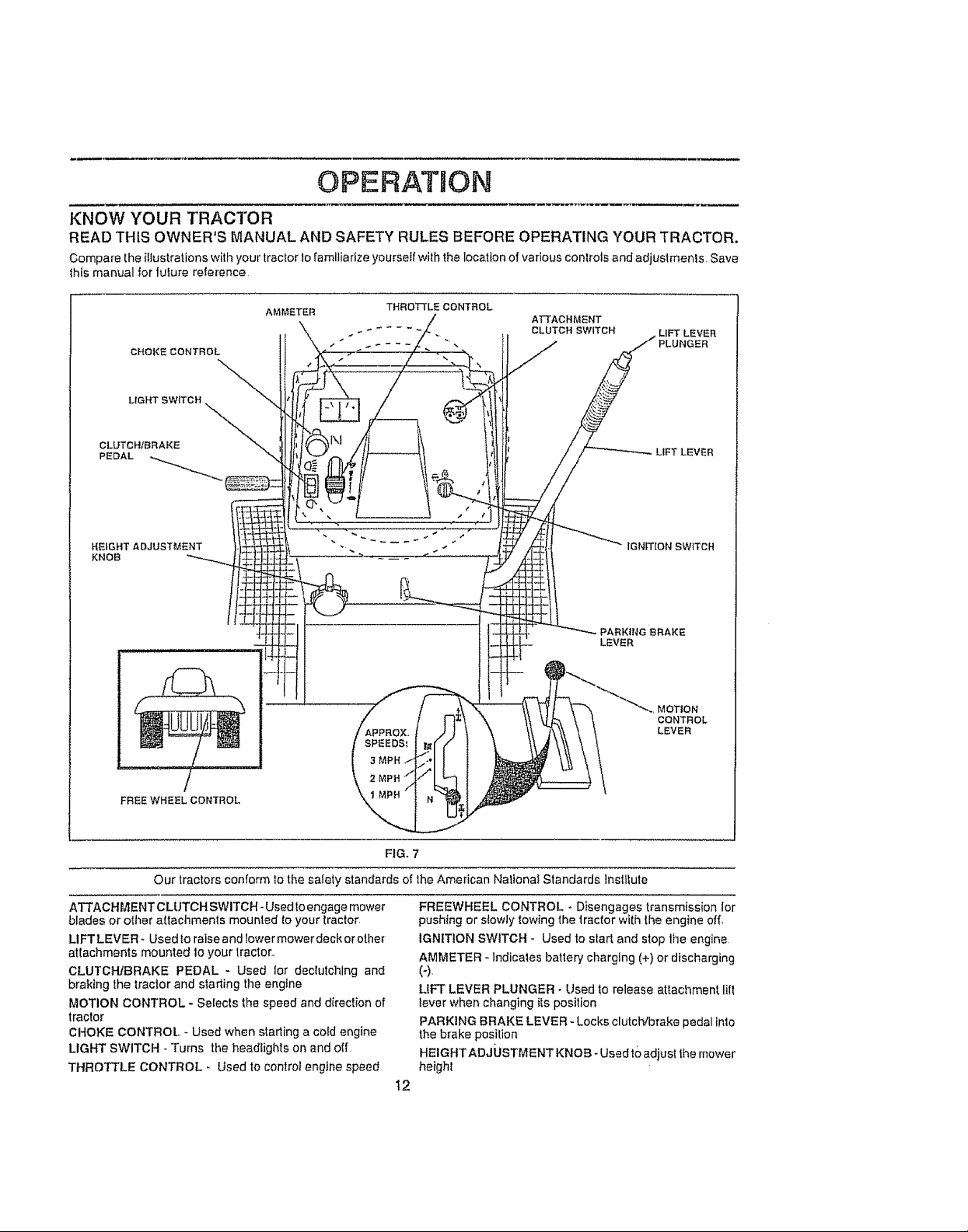

OPERATNON

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR.

compare the illustrations with your tractor Io famllia dze yourself with the location of various controls and adjustments, Save

this manual for tulure reference

CHOKE CONTROL

CLUTCH/BRAKE

PEDAL

HEIGHT ADJUSTMENT

KNOB

AMMETER

THROTTLE CONTROL

.... CLUTCH SWITCH LIFT LEVER

ATFACHMENT

L;FT LEVER

IGNITION SWITCH

PARKING BRAKE

LEVER

MOTION

CONTROL

LEVER

FREE WHEEL CONTROL

Our tractors conform to the satoty standards of the American NatIonaI Standards lnslitute

ATTACHMENT CLUTCH SWITCH- Used toengage mower

blades or ofl'_er a_.tachments mounted to your tractor

LIFTLEVER - Used toraise and lower mowerdeck or othe_

attachments mounted 1oyour tractor_

CLUTCH/BRAKE PEDAL - Used for declutchlng and

braking the tractor and starling the engine

MOTION CONTROL - Selects the speed and direction of

tractor

CHOKE CONTROl.,, - Used when starling a cold engine

LIGHT SWITCH - Turns the headlights on and off,

THROTTLE CONTROL - Used to contro; engine speed

FIG. 7

FREEWHEEL CONTROL - Disengages transmission lor

pushing or slowly towing the tractor with the engine off,

IGNITION SWITCH - Used to start and stop tile engine

AMMETER - lndicales battery charging (+) or discharging

(-).

LIFT LEVER PLUNGER - Used to release attachment li!_

tever when changing its position

PARKING BRAKE LEVER - Locks clutch!brake pedal into

the brake position

HEIGHT ADJUSTMENT KNOB - Used to adjust the mower

height

12

OPERATKON

The operation of any tractor can result in foreign oblecls thrown into the eyes, which can result

in severe eye damage Always wear safety glasses or eye shields while operating your tractor

or performing any adjustments or repairs We recommend a wide vision safety mask over the

spectacles or standard safety glasses_

HOW TO USE YOUR TRACTOR NOTE: Under certain conditions when unit is slanding idle

with the engine running, hot engine exhaust gases may

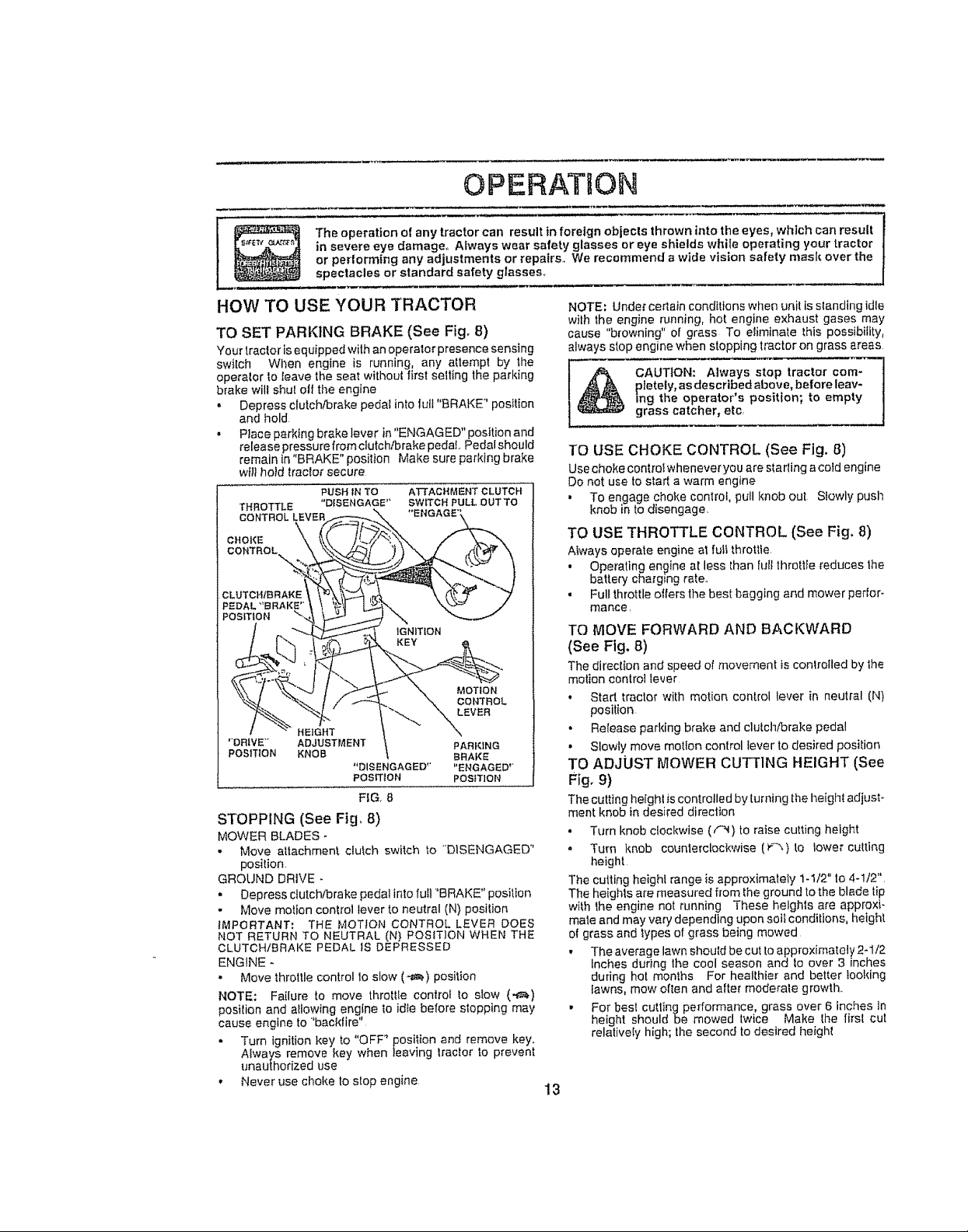

TO SET PARKING BRAKE (See Fig. 8)

Your tractor is equipped with an operator presence sensing

switch When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake will shut off the engine

• Depress clutch/Drake pedal into lull "BRAKE' posWon

and hold

. Place parking brake lever in "ENGAGED" position and

release pressure from clutch/brake pedal Pedalshould

remain In "BRAKE" position Make sure parking brake

wilt holdtracfor secure

THROTTLE "DISENGAGE" SWITCH PULL OUT TO

CONTROL LEVER

CLUTCH/BRAKE !

_OSITtON

"ORIVE "_ ADJUSTMENT PARtr, tNG

POSITION KNOB BRAKE

PUSH IN TO A'ITFACHMENT CLUTCH

IGNITION

KEY

HEIGHT

"DISENGAGED" "ENGAGED'"

POSITION POSITiON

MOTION

CONTROL

LEVER

FIG, 8

STOPPING (See Fig, 8)

MOWER BLADES -

* Move attachment clutch switch to DISENGAGED"

position

GROUND DRIVE -

. Depress clutc!_tbrake pedal into full 'BRAKE" position

. Move motion control lever to neutral (N) position

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITiON WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED

ENGINE -

. Move throttle control 1ostow (_) position

NOTE: Failure to move throtlle control 1o slow (._)

posilion and aIIowing engine _o idle before stopping may

cause engine to 'backfire"

. Turn ignition key to "OFF' position and remove key.

Always remove key when leaving lractor to prevent

unauthorized use

, Never use choke to slop engine

cause "browning" of grass To eliminate this possibility,

always stop engine when stopping tractor on grass areas

pletely, asdescribed above, before leav-

CAUTION: Always stop tractor com-

ing the operator's position; to empty

grass catcher, etc

TO USE CHOKE CONTROL (See Fig. 8)

Use choke control whenever you are starting a co_d engine

Do not use to stad a warm engine

• To engage choke control, pull knob out Slowly push

knob in to disengage,

TO USE THROTTLE CONTROL (See Fig. 8)

Aiways operate engine at ful_ throttle

• Operating engine at less Ihan lull lhrotlte reduces the

battery charging rate

• Full throttle offers the best bagging and mower perfoF

marco,

TO MOVE FORWARD AND BACKWARD

(See Ftg. 8)

The direclton and speed ot movement is controlled by the

motion eontrot lever

• Stud tractor with motion control lever in neutral (N)

position

• Release parking brake and clutchforake pedal

. Slowly move motion control lever to desired position

TO ADJUST MOWER CUTTING HEIGHT (See

Fig, 9)

The cutting height is controlled by turning Ihe heigh_ adjust-

ment knob in desired direction

• Turn knob clockwise (f4 } to raise cutting height

- Turn knob counlerclockwise (_'_'_} to lower cutting

height

The cutting height range is approximately 1-1/2" to 4-1/2",

The heighls are measured from Ihe ground to the blade tip

wi_h 1he engine not running These helghls are approxi-

male and may vary depending upon soil conditions, height

of grass and types of grass being mowed

• The average lawn should be cut to approximately 2-1/2

Inches during the cool season and Io over 3 inches

during hot months For healthier and better looking

lawns, mow often and after moderate growth,

,, For best cutling performance, grass over 6 inches in

height should be mowed lwice Make lhe first cut

relatively high; the second to desired heigh[

13

OPERATION

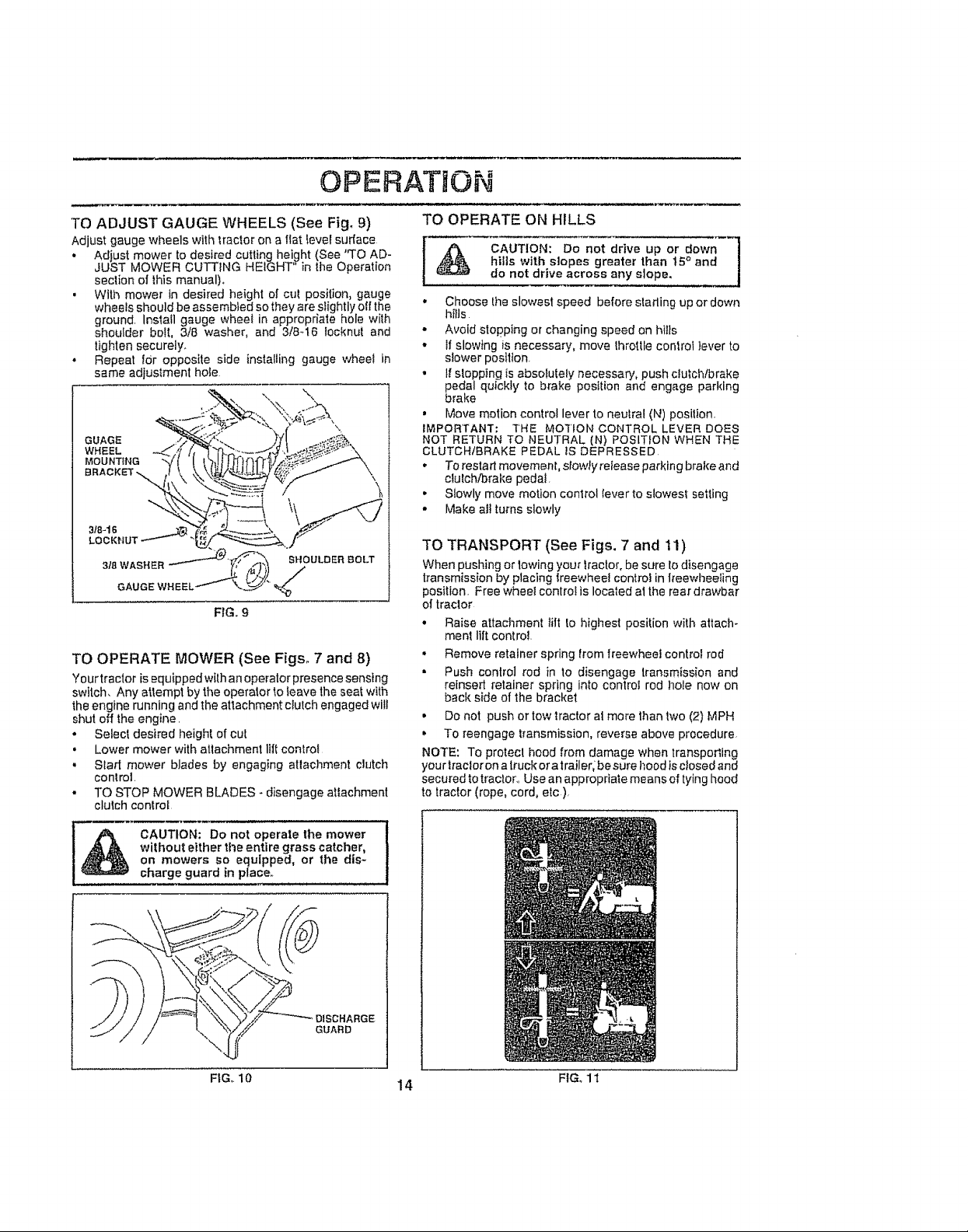

TO ADJUST GAUGE WHEELS (See Fig. 9)

Adjust gauge wheels with tractor on a fiat level surface

• Adjust mower to desired cutting height (See 'q'O AD-

JUST MOWER CUTTING HEIGHT" in the Operation

section of this manual).

, With mower in desired height of cut position, gauge

wheels should be assembled so they are slightly off the

ground. Instatl gauge wheel in appropriate hole with

shoulder bolt, 3/8 washer, and 3!8..16 Iocknut and

tighten securely.

• Repeat for opposite side installing gauge wheel in

same adjustment hole

LOOKNUT-'-'-'

318 WASHER _'t_. __1 SHOULDER eOLT

FIG. 9

TO OPERATE MOWER (See Figs. 7 and 8)

Yourtractor is equipped with an operator presence sensing

switch, Any attempt by tf_e operator _oleave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

- Select desired height of cul

• Lower mower with attachment lilt conlrol

• Slart mower blades by engaging atlachment clutch

control.

- TO STOP MOWER BLADES- disengage attachment

clutch control

TO OPERATE ON HILLS

& CAUTION: Do not drive up or down /

• Choose the slowest speed before starling up or down

• Avoid stopping or changing speed on hitls

• if slow}ng is necessary, move throttle control lever to

• If slopptng is absofutely necessary, push clutch/brake

, Move motion control lever to neutral (N) position.

IMPORTANT: ]'HE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL iS DEPRESSED

,' To restart movement, stowly reiease parking brake and

, Stowly move motion control lever to slowest setting

• Make al! turns slowly

hills with slopes greater than 15° and

do not drive across any slope.

htIls

slowerposition.

edal quickly to brake position and engage parking

rake

clutch/brake pedal,

TO TRANSPORT (See Figs. 7 and tl)

When pushing or lowing youz lractor, be sure 1odisengage

transmission by placing freewheel control in treewheeting

position. Free wheet centrot is located at the rear drawbar

of traclor

• Raise attachment !ill Io highest position with attach _

ment lift control.

• Remove retainer spring from freewheel cont_'ol rod

• Push conffoI rod in lo disengage transmission and

reinsed retainer spring into controf rod hole now on

back side of the bracket

• Do not push or tow tractor at more than two (2) MPH

To reengage transmission, reverse above procedure

NOTE: To protect hood from damage when transporting

your Iracloron a truck or a trailer, besure hood is c_osed and

secured to traclor:. Use an appropriate means of tying hood

to tractor (rope, cord, etc),

1

1

without either tile entire grass catcher,

CAUTION: Do not operale the mower

on mowers so equipped, or the dis_

charge guard in place..

FIG,. 10 14 FIG. 11

OPERATUON

BEFORE STARTING THE ENGINE

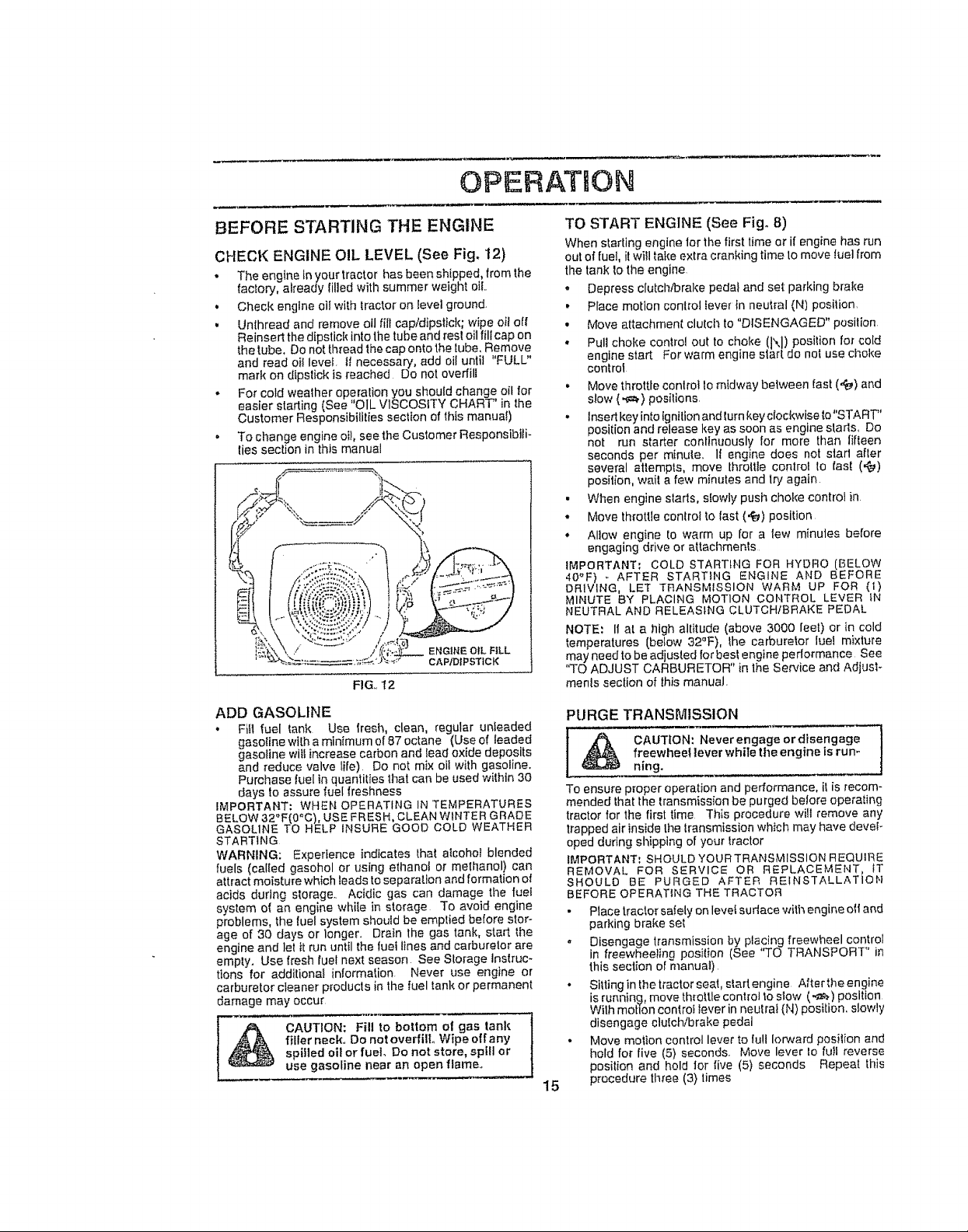

CHECK ENGINE OIL LEVEL (See Fig, t2}

,, The engine lnyour tractor has been shipped, from the

factory, already filled with summer weight oil

• Check engine oil with tractor on level ground.

. Unthread and remove otl fill cap/dipstick; wipe oil off

Reinsert the dipstick into the tube and resl oil fill cap on

the tube. Do net thread the cap onto the Lube,Remove

and read oil level, if necessary° add oil until "FULL"

mark on dipstick is reached Do not overfill

. For cold weather operation you should change o11for

easier starting (See "OIL VISCOSITY CHART' in the

Customer Responsibilities section of this manua0

• To change engine oil, see the Customer Responsibt{i-

ties section in this manual

ENGINE OIL FiLL

CAPIDfPSTiCK

FIG. t2

ADD GASOLINE

. Fitl fuel tank Use fresh, clean, regular untended

gasorine with a minimum of 87 octane (Use of leaded

gasoline witl increase carbon and Iead oxide deposits

and reduce valve life) Do not mix oii with gasoline.

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOL1NE TO HELP INSURE GOOD COLD WEATHER

STARTING

WARNING: Experience indicates that aicohet blended

fuels (ca!{ed gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage.. Acidic gas can damage the fuel

system of an engine whiie in storage To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel ltnes and carburetor are

empty. Use fresh fuel next season See Storage Instruc-

tions for additional informalion Never use engine or

carburetor cIeaner products in the fuel tank or permanent

damage may occur

filler neck,, Do not overfill Wipe off any

CAUTION; Fill to bottom el gas tank

spllled oil or fuel. Do not store, spill or

use gasoline near an open flame,,

TO START ENGINE (See Fig. 8)

When s_arting engine lor the first time or if engine has run

out of fuet, it will take extra cranking time to move tuel from

the tank Io the engine

,, Depress clutch/brake pedal and set parking brake

* Place motion control tever in neutral (N] position.

. Move attachment clutch to "DISENGAGED" position

,, Pull choke control out to choke (1\) position for cold

engine start For warm engine slat[ do not use c'_o _e

control

. Move throttle conlrot 1omidway between tast (z__)and

slow (._.) positions,

. Insert key into _gni[tonand turn key clockwise to "START"

position and release key as soon as engine starts, Do

not run starter conllnuously lor more than fifleen

seconds per minute,, If engine does not slam after

several attempts, move throttle control to !as! (_)

position, wait a few minutes and lry again

. When engine starts, sEowly push choke control in

,, Move throttle conlrol to fast (,,_) position

. Allow engine to warm up for a low minutes before

engaging drive or attachments,

Ir4PORTANT: COLD STARTING FOR HYDRO (BELOW

40_'F) _ AFTER STARTING ENGINE AND BEFORE

DRIVING, LET TRANSMISSION WAR# UP FOR (1)

MINUTE BY PLACING MOTION CONTROL LEVER _N

NEUTRAL AND RELEASING CL,UTCH/BRAKE PEDAL

NOTE: it at a high altitude [above 3000 feet) or in cold

temperatures [below 32"F), Lhe carburetor luel mixture

may need to be adjusted for best engine performance See

"TO ADJUST CARBURETOR" in 1he Service and Adjusl-

ments section of this manual.

PURGE TRANSMISSION

freewheel lever while the engine is run-

ning.

To ensure proper operation and performance, il is recom-

mended that the transmission be purged beJare operating

tractor for the first time This procedure will remove any'

trapped air inside the lransmission which may have deveF

aped during sl)ipping of youJ"Iraclor

IMPORTANT: SHOULD YOURTRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR

• Place tractor safely on levef surtace with engine off and

parking brake set

Disengage transmission by placing freewheel control

in freewheeling position (See "TO TRANSPORT" in

this section ofmanual)

• Si_tinginthetractor seal, sladengine After!he engine

is running, move throttle control _oslow (,.'_) position

With mohon controt Iever in neutrat iN) position, slowly

disengage clulchibrake pedal

. Move motion control lever to full Iorward posilion and

hold for five (5) seconds, Move lever Io full reverse

position and hold for five (5) seconds Repeal this

procedure three (3) times

15

OPERATnON

NOTE: Dudng this procedure there will be no movement of

drive wheefs, The air isbeing removed from hydraulic drive

system

,, Move motion control lever to neutral (N) posilion. ShuF

off engine and set parking brake..

• Engage transmission by p_acing freewheel control in

driving position (See "TO TRANSPORT' in this section

of manuat)

, Sitting in the tractor seat, start engine, After the engine

is running, move throttle control to half (1/2) speed

With motion contrei lever in neutral (N) position, slowly

disengage clutch/brake pedal,

• Slowly move molten control iever forward, after the

tractor moves approximately five (5) feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately five(5) feet return the

motion control lever to the neutral (N) position. Repeat

this procedure with the motion controI lever three (3)

times

• Your tractor is now purged and now ready for normal

operation

MOWING TIPS

• Tire chains cannot be used when lhe mower housing is

attached to tractor.,

• Mower should be properly leveled for best mowing

performance. See"TO LEVELMOWER HOUSING"in

the Service and Adjustments section Of lhis manual

. The left hand side of mower should be used for trim-

ming

• Drive so thai clippings are discharged onto the area

that has been cut Have lhe cut area to the right of the

tractor- This wiI_ result in a more even distribution of

clippings and more uniform culting

. When mowing large areas, start by turning to the fight

so that clippings will discharge away from shrubs,

fences, driveways, etc, After one or two rounds, mow

in the opposite direction making left hand turns until

linished (See Flg 13)

• If grass is extremely tai!, it should be mowed twice to

reduce load and possible fire hazard from dried clip-

ings,, Make first cut relalbely high; the second to the

esired height

f

P

Do not mow grass when it is wet Wet grass will plug

mower and leave undesirable clumps Allow grass to

dry be!ore mowing.

Always operate engtne at full throttle when mowing to

assure betler mowing peflormance and proper dis-

charge of material. Regulate ground speed by select-

ing a low enough gear to give lhe mower cutting

performance as well as the quality of cut desired

When operating atlachments, select a ground speed

that will suit the terrain and give best pedormance of

the aflachmenl being used

I_IULCHING IVIOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH CLEAN AFTER EACH USE

• The special mulching blade will recur the grass clip-

pings many times and reduce fhem in size so that as

lhey fall onto the lawn they wit!disperse into the grass

and not be noticed. Also, the mulched grass will

biodegrade quickly to provide nutrients for the lawn,

Atways mulch with your highesl engine (blade) speed

as this wilt provide the best recuUing action of the

blades,

o Avoid culling your lawn when il is wet, Wet grass lends

1oform clumps and Interferes with the mulching action

The best time lo mow your lawn is the early afternoon

At this time the grass has dried and the newly cut area

wilt not be exposed to 1he direct sun,

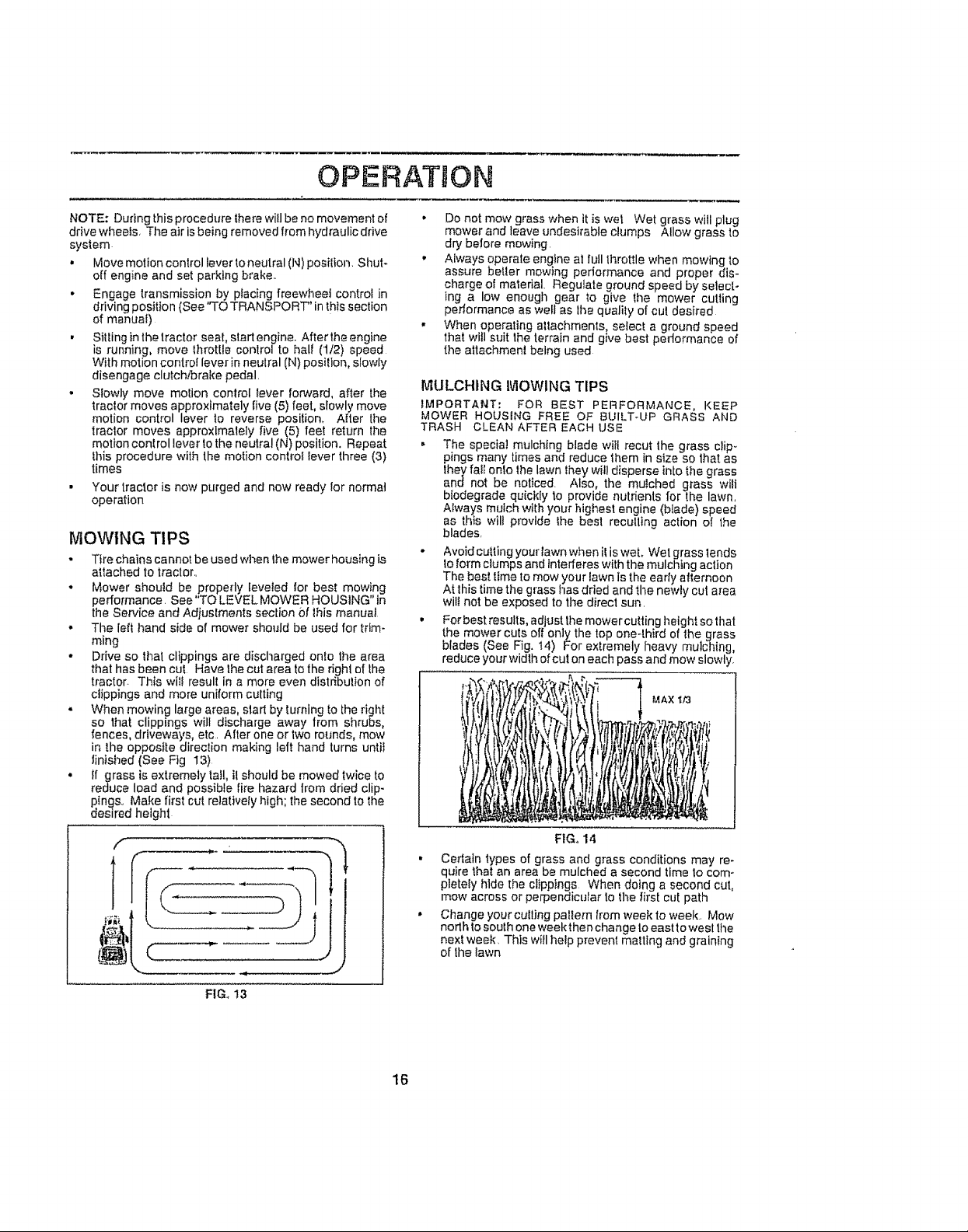

. For best results, adjust the mower cuffing height so that

the mower cuts off only the lop one4hird of the grass

blades (See Fig. 14) For extremely heavy mulching,

reduce your width ofcut on each pass and mow slowly,

FtG. 14

• Cedatn types of grass and grass conditions may re-

quire that an area be mulched a second time Io com-

pletely htde the clippings When doing a second cut,

mow across or perpendicular to the first cut path

" Change your cutting pattern from week to week, Mow

norlh to soulh one week then change toeast towe st the

next week, This will help prevent matting and graining

of ti_elawn

FIG., 13

16

CUSTOMER RESPONSIIB LJT ES

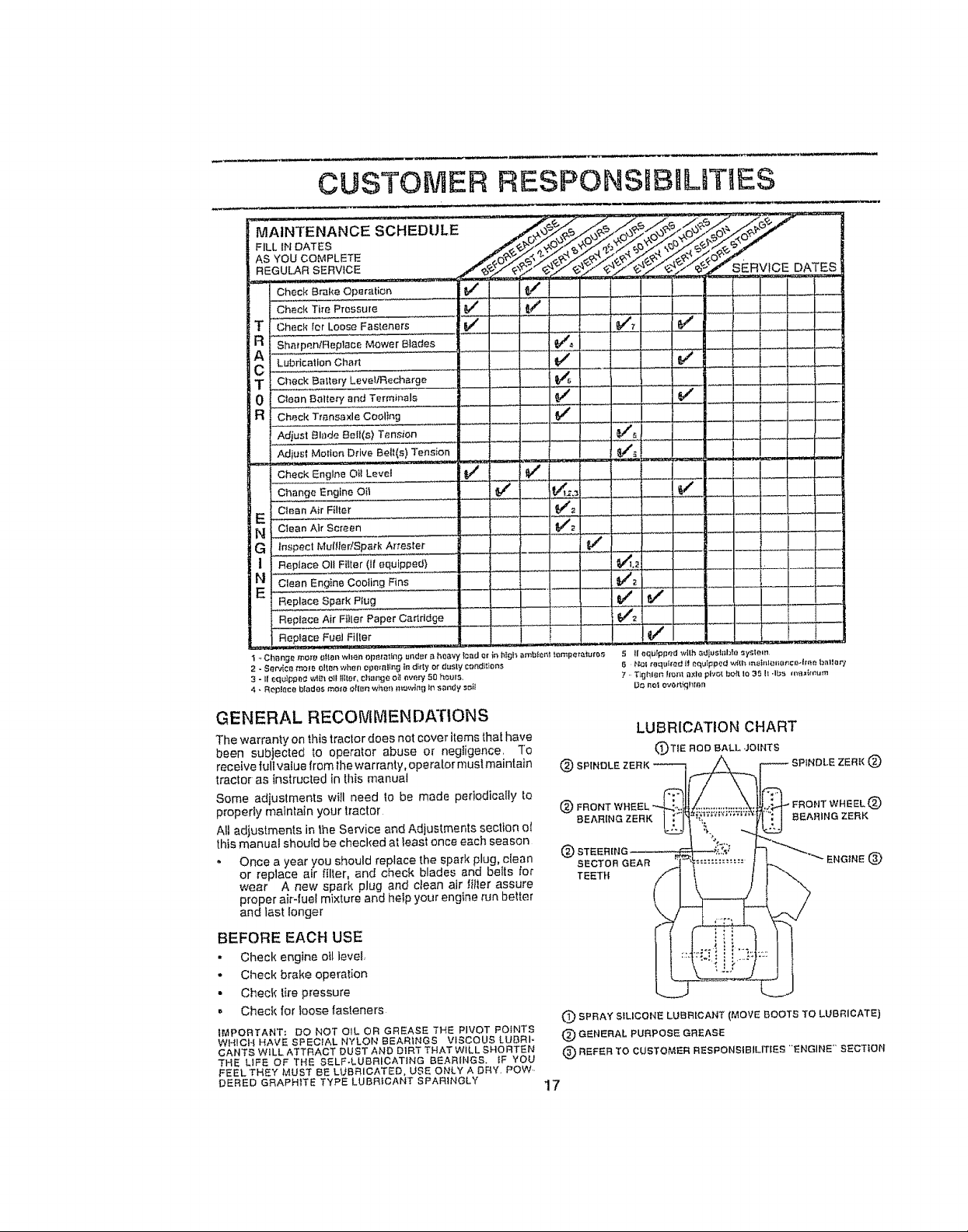

'I., ChangQ rr,o_e otten when opm, atFn9 undl_r_,h0_,vytoad or i_*i_t{tt'ternbi.,ar,t tompera._uiD_

2 - S_.RCa mole ell0n wi_ee epe_riltng tn d_tly of dusly condl;ions

3 - It equ]ppl)_ wl_t_,oll filler, change OEInvnri 50 hoL_l,_,

4 "Rept_:ta btado.s mole _l{]rt whe_ i:_owing tf_sandy so,it

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence, 30

receive fullvafua from lhewarranty, opera[or must maintain

tractor as instructed in this manual

Some adjustments wifl need to be made periodically to

properly maintain your tractor

All adjustments in the Service and Adjustments section o!

this manual shouid be checked at least once each season

" Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear A new spark plug and clean air Jiller assure

proper air-luel mixture and help your engine run better

and last longer

BEFORE EACH USE

- Check engine oil level,

• Check brake operation

• Check life pressure

• Check for loose fasteners

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT PO_NTS

WHICH HAVE SPECIAL NYLONBEARtNGS VISCOUSLUBRI-

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHO RTEN

THE LIFE OF THE SELF,LUBRICATING BEARINGS, SF YOU

FEELTHEY MUST BE LUBRICATED, USE ONLY A DRY. POW-.

DERBD GRAPHITE TYPE LUBRICANT SPARINGLY

5 It eql_ppe{l wilh _d_uslable system,

6 t'tol roquI__UIt eqo_ppecl w_r,h ma_len0f_c[)÷/r_e l_Iter/

7 - 'Tighler_ liD.n'{ a_lo pivbt boil Io 35 It .Ib+ m_:=i+mim

D_ nol OvOr_l(jllten

LUBRICATION CHART

(I"_TIE ROD BALL .JOINTS

(_) SPINDLE ZERK

(_)FRONTWHEEL

BEAR[NG ZERK

(_STEERIr

SECTOR GEAR

TEETH

SPRAY SILICONE LUBRICANT (MOVE BOOTS TO LUBRICATEJ

(_ GENERAL PURPOSE GREASE

I_) REFER TO CUSTOMER RESPONSIBILITIES -ENGINE" SECTtOH

17

CUSTO[ ER RESPONSIBILiTiES

TRACTOR

Aiways observe safety rules when performing any mainte-

nance

BRAKE OPERATION

tf tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted

(See "TO ADJUST BRAKE" in the Service and Adjust-

ments section o! this manual)

TIRES

• Maintain proper air pressure in all tires (See "PROD-

UCT SPECIFICATIONS" on page 3 of this manual)

• Keep tires free of gasoline, oil, or insect controt chemi-

cals which can harm rubber

• Avoid stumps, stones, deep ruts, sharp objects and

olher hazards that may cause tire damage

BLADE CARE

For best resufts mower blades must be kept sharp Re-

place bent or damaged blades

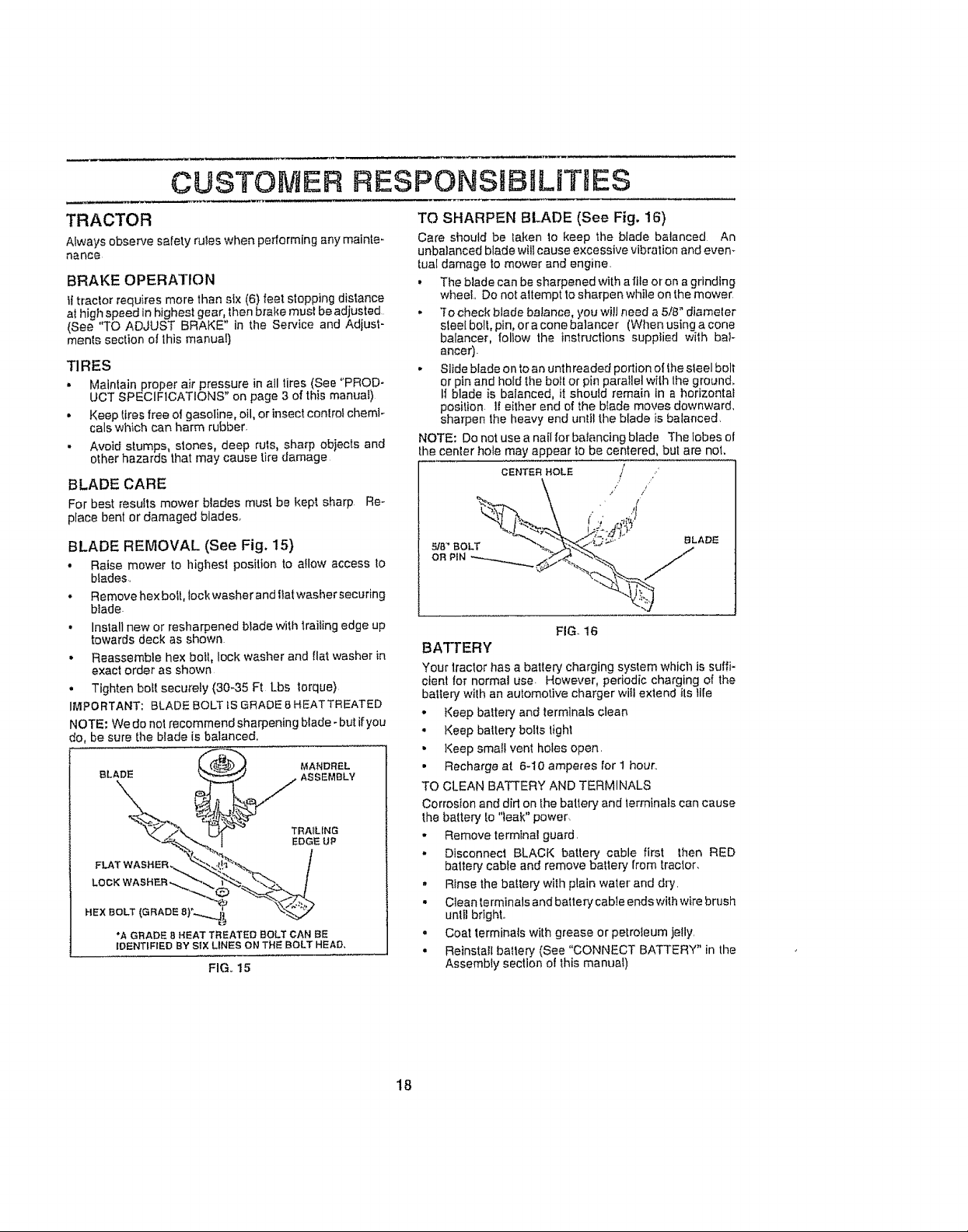

BLADE REMOVAL (See Fig. 15)

• Raise mower to tlighest position to aflow access to

blades,

• Remove hex boll, fock washer and flat washersecuring

btade

. Install new or resharpened blade with traiIing edge up

towards deck as shown

• Reassemble hex boil, lock washer and flat washer in

exact order as shown

• Tighten bolt securely (30_35 Ft Lbs torque)

IMPORTANT: BLADE BOLT IS GRADE BHEATTREATED

NOTE: We do not recommend sharpening blade -but ifyou

do, be sure the blade is balanced

BLADE _ MANDREL

• X.__ . ASSEMBLY

x_ "_, EDGE UP

FLAT WASHERs..._ :_ <,_,!'__%,... /

LOOK WASHER,_ ". "_. "_'b.

• A GRADE 8 HEAT TREATED BOLT CAN BE

IOENTfFIED BY SIX LINES ON THE BOLT HEAD,

"i ,,. %,.. 1

FIG., 15

TO SHARPEN BLADE (See Fig. 16)

Care should be taken to keep the blade balanced An

unbalanced blade wiil cause excessive vibration and even*

tual damage to mower and engine,

. The blade can be sharpened with a file or on agrinding

wheel Do not attempt to sharpen while on the mower

. To check blade balance, you wi!l need a 5/8" diameter

steel boll, pin, or a cone balancer (When using a cone

balancer, follow the instructions supplied with bal-

aRcer)

• Slide blade on to an unthreaded portion ofthe sleel bolt

or pin and hold the bolt or pin parailel with lhe ground.

If blade is balanced, it should remain in a horizontal

position 11either end of the blade moves downward,

sharpen the heavy end until the blade is balanced,

NOTE: Do not use a nail for balancing blade The lobes of

the center hole may appear Io be centered, but are not.

CENTER HOLE / , ."

BOLT ..... B'ADE

FIG 16

BATTERY

Your tractor has a battery charging syslem which is suffi-

cient for normal use. However, periodic charging of the

battery with an automotive charger will extend its life

• Keep battery and terminals clean

', Keep battery bolts tight

• Keep smaIlvent holes open.

• Recharge at 6-10 amperes Ior 1 hour..

TO CLEAN BATTERY AND TERMINALS

Corrosion and did on the battery and terminals can cause

the battery [o "leak" power,,

• Remove terminal guard,

. Disconnect BLACK battery cable first lhen RED

battery cable and remove battery from traclor.

,, Rinse the battery with plain water and dry.

• Cleanterminatsandbatterycable endswithwire brush

until brtghL

• Coat terminals with grease or petroleum jelly,

° Reinstall battery (See "CONNECT BATTERY" in the

Assembly section of this manual)

18

Loading...

Loading...