Page 1

Operator's Manual

19.0 HR* 42" Mower

Electric Start

Automatic Transmission

Model No.

917.25081

• EspaSol, p. 33

I_ his product has a low emission engine which operates

IMPORTANT:

Read and follow atl Safety

Rules and Instructions before

operating this equipment.

Sears Brands Management Corporation, Hoffman Estates, tL 60179 U.S.A.

Visit our Craftsman website: www,craftsman.com

* The powet r_ing as desiared bythe engine manufacturer is the * La potenc_a nominaJ declareda por el fabr_cacte del motor es la

average gross power output at the specked RPM ofa typical ealida medla do potencia brata a los RPM espectficadas de un

production engine for the engine model measured using SAE motor do eerie tfptco pare el modelo de motor, medida eag/,n

Standards for engine gross power. Please refer to the engine los no_mas SAE sob_e potencie br,Jta de motor. Pa,,a m&s

mentJfacturer for details, informacl6n, consu_teal fabdcante del motor.

differently from previously built engines. Before you start the

engine, read and understand this manual.

For answers to your questions

about this product, call:

1-888-331-4569

Craftsman Customer Help Line

588134349

Page 2

Warranty .................................................. 2

Safety Rules ............................................ 3

Product Specifications ............................. 6

Assembly/Pre-Operation ......................... 7

Operation ................................................. 9

Maintenance ........................................... 16

Service and Adjustments ....................... 21

Storage .................................................. 27

Troubleshooting ..................................... 28

Sears Service ......................... Back Cover

Maintenance Schedule .......................... 16

CRAFTSMAN LIMITED WARRANTY

FOR TWO YEARS from the date of purchase, all non-expendable parts of this riding equipment are

warranted against any defects in material or workmanship. With proof of purchase, a defective non-

expendable part will receive free in-home repair or replacement at option of seller.

BATTERY LIMITED WARRANTY

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of this riding equipment is

warranted against any defects in material or workmanship. Wffh proof Of purchase, a new battery will be

supplied free of charge. You are responsible for the labor cost of battery installation,

ADDITIONAL LIMITED WARRANTIES

In the following additional warranties, you are responsible for the tabor cost of part installation after the

second year from the date of purchase.

FOR FIVE YEARS from the date of purchase, the frame of this riding equipment is warranted against any

defects in material or workmanship. With proof of purchase, a new frame wilt be supplied free of charge,

FOR TEN YEARS from the date of purchase, the front axle of this riding equipment is warranted against any

defects in material or workmanship. With proof of purchase, a new front axle will be supplied free of charge.

FOR AS LONG AS IT !S USED by the original owner after the tenth year from the date of purchase, the

cast iron front axle (if equipped) of this riding equipment is warranted against any defects in material or

workmanship. With proof of purchase, a new cast iron front axle will be supplied free of charge.

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, call 1-888-331-4569 or visit the web

page: www.craftsman.com/warranty

In ali cases above, if part repair or replacement is impossibie, the riding equipment will be replaced free of

charge with the same or an equivalent model.

All of the above warranty coverage isvoid if this dding equipment is ever used while providing commercial

services or if rented to another person,

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT

include:

• Expendable parts (except battery) that can wear out from normal use within the warranty period, including

but not limited to blades, spark plugs, air cleaners, belts, and oil _ters.

• Standard maintenance servicing, oi] changes, or tune-ups.

• Tirerep_a_ement_rrepaircausedbypuncturesfr_m_utside_bjects_suchasnai_s_th_ms's_umps__rg]ass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or

maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by towing

objects beyond the capability of the riding equipment, impacting obiects that bend the frame, axle

assembly or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electricaI and mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, failure

to keep the deck clear of flammable debris, or failure to maintain the riding equipment according to the

instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized

(stale). tn general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warrantygivesyou specific legal dghts, andyoumay alsohaveother rightswhichvaryfromstatetostate.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

Page 3

_DANGER: This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death.

A(_WARNING: Inorderto prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_WARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

_WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Too heavy ofa load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

_WARNING: Engine exhaust, some of

itsconstituents, and certain vehicle compo-

nents contain or emit chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

_IbWARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals knownto the State of

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling.

I. CHILDREN

_(_WARNING! CHILDREN CAN BE IN-

JURED BYTHIS EQUIPMENT. TheAmeri-

can Academy of Pediatrics recommends

that children be a minimum of t2 year of

agebefore operating a pedestrian controlled

lawn mower and a minimum of 16 years of

age before operating a riding lawnmower.

_WARNING! CHILDREN CAN BE

SERIOUSLY INJURED OR KILLED BY

THIS EQUIPMENT. Carefully read and

follow all of the safety instructions below.

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are oftenattracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

• Keep children out of the mowing area

and inthe watchfulcare of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carry children, even with the

blades shut off. They may fall off and

be seriously injured or interfere with safe

machine operation. Children who have

beengiven ridesinthe past may suddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

• Never allow children to operate the ma-

chine.

• Use extreme caution when approaching

blind corners, shrubs, trees, or other

objects that may block your view of a

child,

IL GENERAL OPERATION

- Read, understand, andfo]low all instruc-

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine, Keep clear

of the discharge opening at all times.

• Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clearthe area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

• Ensure the area is clear of bystanders

beforeoperating. Stopmachine ifanyone

enters the area.

• Never carry passengers.

• Do not mowin reverse unless absolutely

necessary. Always look down andbehind

before and while backing,

• Never direct discharged materialtoward

anyone, Avoid discharging material

against a wall or obstruction, Material

may ricochet back toward the operator.

Stop the blades when crossing gravei

surfaces.

• Donot operate machine withoutthe entire

grass catcher, discharge chute, or other

safety devices in place and working.

Page 4

• Slowdown beforetuming.

• Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

• Disengage blades when not mowing.

Shut off engine and wait for all parts to

come to a complete stop before cleaning

the machine, removing the grass catcher,

or unclogging the discharge chute.

• Operate machine onlyin daylightorgood

artificial light.

• Do not operate the machine while under

the influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Use extreme caution when loading or

unloading the machine into a trailer or

truck.

• Always weareye protection when operat-

ing machine.

• Use ear protectors to avoid damage to

hearing.

• Data indicates that operators, age 60

years and above, are involved ina large

percentage of riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

• Followthe manufacturer's recommenda-

tionfor wheel weights or counterweights.

• Keep machine free of grass, leaves or

other debris build-upwhich cantouch hot

exhaust/engine parts and burn. Do not

allow the mower deck to plow leaves or

other debris which can cause build-up

to occur. Clean any oil or fuel spillage

before operating or storing the machine.

Allow machine to coot before storage.

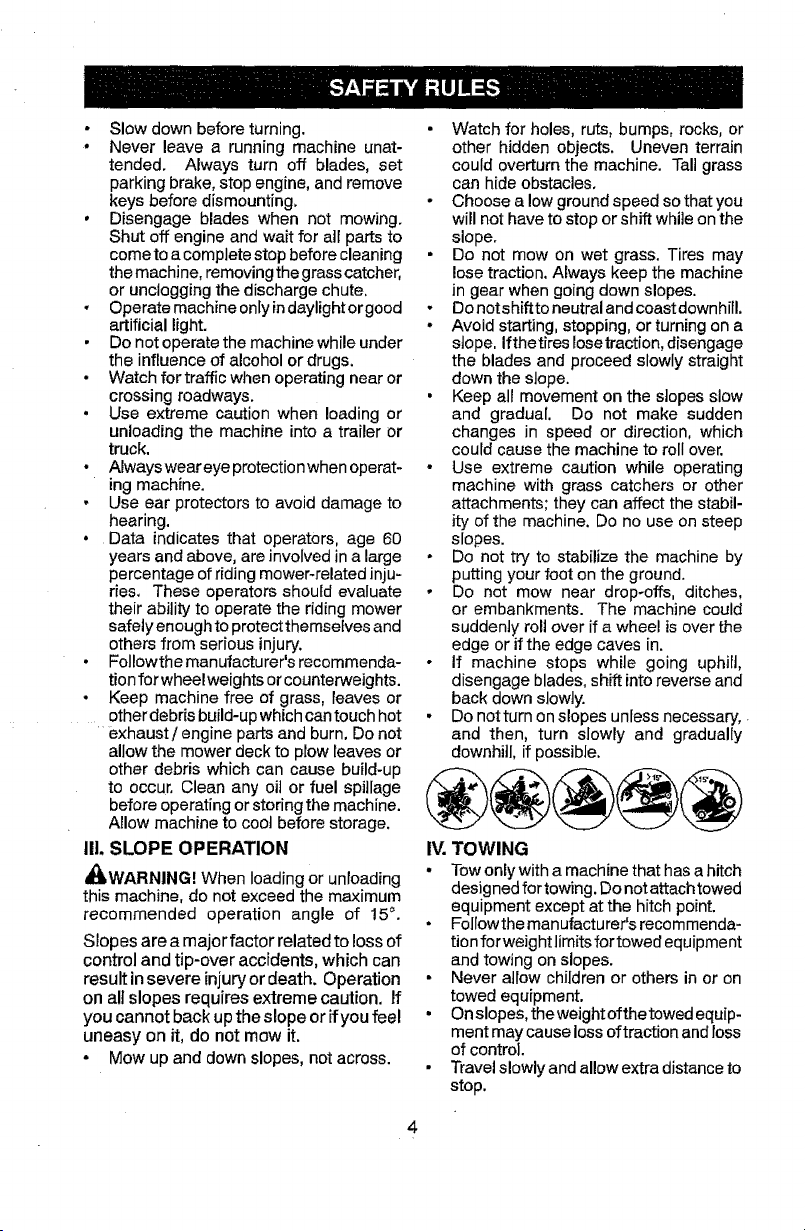

Iil. SLOPE OPERATION

_WARNING! When loading or unloading

this machine, do not exceed the maximum

recommended operation angle of 15°.

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation

on all slopes requires extreme caution. If

you cannot back up the slope or ifyou feel

uneasy on it, do not mow it.

- Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

• Choose a low ground speed sothat you

will not have to stop or shift while on the

slope.

• Do not mow on wet grass. Tires may

lose traction. Always keep the machine

in gear when going down slopes.

, Do notshiftto neutral andcoastdownhitl.

• Avoid starting, stopping, or turning on a

slope. Ifthetires Iosetraction, disengage

the blades and proceed slowly straight

down the slope.

• Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

• Use extreme caution while operating

machine with grass catchers or other

attachments; they can affect the stabil-

ity of the machine. Do no use on steep

slopes.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

• If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

• Do not turn onslopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

IV. TOWING

• Towonly with a machine that has a hitch

designed for towing. Donot attach towed

equipment except at the hitch point.

• Follow the manufacturer's recommenda-

tion forweight limits for towed equipment

and towing on slopes.

• Never allow children or others in or on

towed equipment.

• On slopes, the weight ofthetowed equip-

ment may cause loss of traction and loss

of control.

• Travel slowly and allow extra distance to

stop.

Page 5

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, useextreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

• Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

• Use only approved gasoline container,

• Never remove gas cap or add fuel with

the engine running.

• Allow engine to cool before refueling.

• Never fuel the machine indoors,

• Neverstorethe machineorfuelcontainer

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

• Never fil! containers inside a vehicle or

on a truck or trailer bed with plastic liner.

Always place containers on the ground

away from your vehicle when filling.

- Remove gas-powered equipment from

the truck or trailer and refuel it on the

ground. Ifthis isnot possible, then refuel

such equipmentwith aportable container,

rather than from a gasoline dispenser

nozzle.

• Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times untilfueling iscomplete. Do not

use a nozzle lock-open device.

• Iffuelis spilled onclothing, change cloth-

ing immediately,

• Never overfill fuel tank. Replace gas cap

and tighten securely.

GENERAL SERVICE

• Never operate machine ina closed area.

• Keep allnutsandbotts tighttoensurethe

equipmentis in safe working condition,

o Nevertamperwithsafe'_tdevices. Never

interferewiththe intendedfunctionof a

safety device or reduce the protection

providedby asafetydevice.Check there

properoperation regularly.NEVER oper-

ate a machine with a safety devicethat

does not function properly.

• Keep machine free of grass, leaves, or

other debris build-up, Clean oil or fuel

spillage and remove any fuel-soaked

debris, Allow machine to cool before

storing.

• If you strike a foreign object, stop and

inspectthemachine. Repair,ifnecessary,

before restarting.

• Never make any adjustments or repairs

with the engine running.

• Checkgrass catchercomponents andthe

discharge chute frequentlyand replace

with manufacturer's recommended parts,

when necessary.

• Mower blades aresharp. Wrapthe blade

orwear gloves, and use extreme caution

when servicing them.

• Checkbrakeoperationfrequently. Adjust

and service as required.

o Maintainor replace safety and instruction

labels, as necessary.

Use ear protectors to avoid damage to hearing.

Always weareye protection when operating machine.

Page 6

PRODUCTSPECIFICATIONS

Gasoline Capacity 2.5 Gallons 19,46 L

and type: Regular Unleaded *

Oil Type: SAE 30 (above 32°F/0°C)

(APt: SG-SL} SAE 5W30 (below 32°F10°C

Oil Capacity: WI Filter: 56 Oz. ! 1,65 L

Spark Plug: Champion RC12YC

Charging ,3Amps Battery

System: 5 Amps Headlights

Battery: AmplHr: 28

Blade Bolt Torque; 45-55 F_. Lbs./62-75 Nm

&Gasoline containing up to 10% ethanol (El0) is

acceptable for use in this machine, The usa of

any gasoline exceed{ng "_0%ethanol (Et0) will

void the productwarranty,

CONGRATULATIONS on your purchase of

a new tractor. It has been designed, engi-

neered and manufactured to gJveyouthe best

possible dependability and performance.

Should you experience any problem you can-

not easily remedy, please contact a Sears or

other qualified service center. We have com-

petent, well-trained representatives and the

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

- Follow a regular schedule in maintaining,

caring for and using your tractor.

- Follow instructions under "Maintenance"

and "Storage" sections of this manuaL.

• Wear proper Personal Protective Equip-

ment _PPE)while operating this machine,

including(at a minimum) sturdy footwear,

eye protection, and hearing protection.

Do not mow in shorts and/or open toed

footwear.

• Always letsomeone knowyou areoutside

mowing.

A(_.WARNING: This tractorisequippedwith

an internal combustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass-

covered land unless the engine's exhaust

system is equipped with a spark arrester

meeting applicable local or state laws (if

any). If a spark arrester is used, it should

be maintained in effective working order by

the operator.

W/out Filter: 48 Oz. / 1,4 L

(Gap: ,030"10,76 mm)

Min, CCA: 230

Case size: U1R

Inthe stateof California the above isrequired

bylaw (Section 4442 ofthe California Public

Resources Code), Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrestor for the muffler is

availablethrough your nearest Sears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman® product is

designed and manufactured for years of

dependable operation. But like all products,

itmay require repairfrom time totime. That's

when havinga Repair ProtectionAgreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourseff from unexpected

hassle and expense.

Herds what's included in the Agreement'.

• Expertservice byour 12,000 professional

repair specialists,

• Unlimited service and no charge for parts

and labor on all covered repairs.

• Product replacement if your covered

product can't be fixed.

• Discount of 25% from regular price of

service and service-related parts not

covered by the agreement; also, 25% off

regular price of preventive maintenance

check.

- Fast help by phone - phone support

from a Sears representative on products

requiring in-home repair, plus convenient

repair scheduling.

Once you #urchasethe Agreement, a simple

phone call is all that it takes for you to sched-

ule service. You can callanytime day or night,

or schedule a service appointment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories. That's

the kind of professionalism you can count on

to help prolong the life of your new purchase

for years to come, Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655,

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in the

U.S.A, call 1-8004-MY-HOME®.

Page 7

Keys

Slope Sheet

(1) Oil Drain Tube

Key(s)

(1) Quick

Connect !

Your new tractor has been assembled at the factory with exception of those parts left

unassembled for shipping purposes.

TOOLS REQUIRED FORASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) 1/2" wrench Tire pressure gauge

(2) 7/t6" wrenches Utility knife

Pliers

When right or left hand is mentioned in this

manual,itmeanswhenyouareintheoperating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

• Remove all accessible loose parts and

parts cartons from carton.

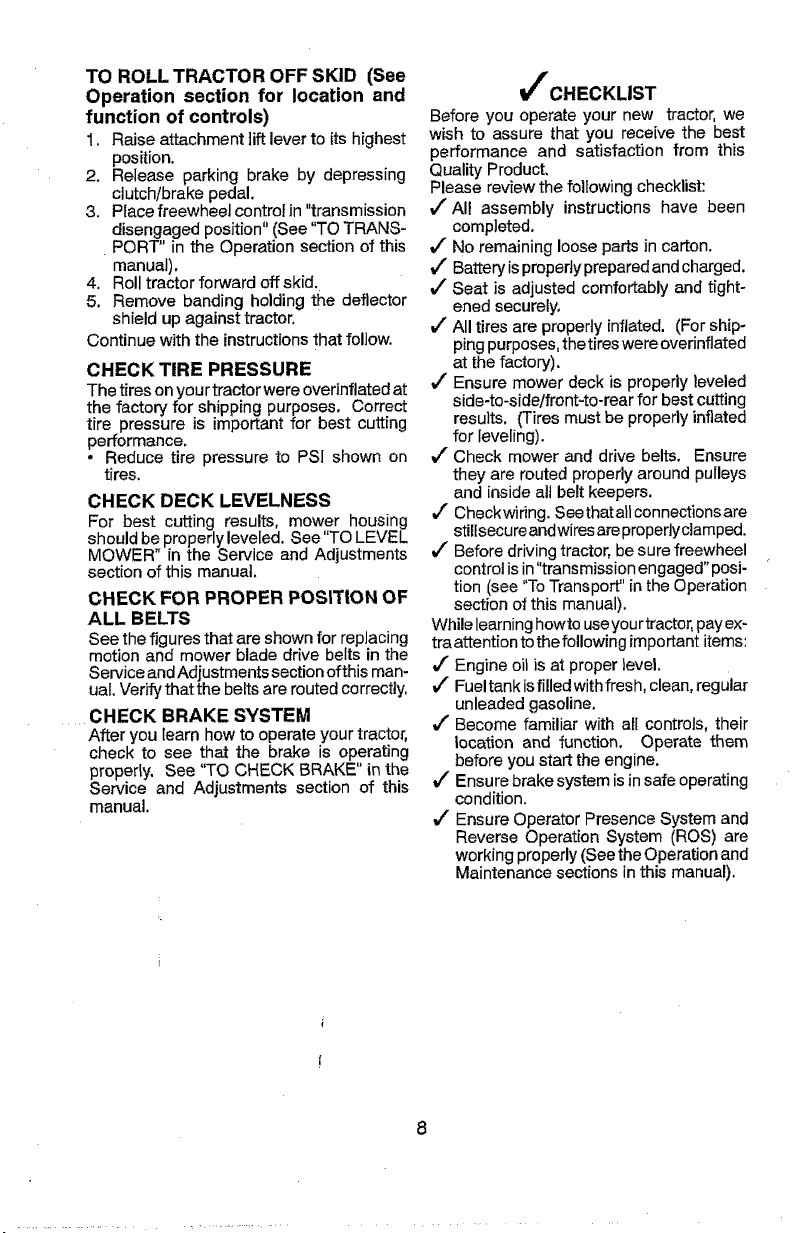

TO ADJUST SEAT

• Sit in seat.

• LAup adjustment lever (A) andslideseat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

• Release lever to lock seat in position,

- Cut along dotted lines on all four panels

of carton. Remove end panels and lay

side panels flat.

• Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

TO CHECK BATTERY

1, Liftseat to raised position.

NOTE: Ifthis battery is put into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of one hour at 6-10 amps. (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

• For battery and battery cable installation

see "REPLACING BATTERY" in the

"Service and Adjustments" section in this

manual.

NOTE: You may now roll your tractor off the

skid. Continue using the instructionsthat

follow to remove the tractor from the skid.

WARNING: Before starting, read, un-

derstand and follow all instructions in the

Operation section of this manual. Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

Page 8

TO ROLL TRACTOR OFF SKID (See

Operation section for location and

function of controls)

1. Raise attachment liftlever to itshighest

position.

2. Release parking brake by depressing

clutch/brake pedal.

S. Place freewheel control Jn"transmission

disengaged position" (See "TO TRANS =

PORT" in the Operation section o1this

manual).

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Continue with the instructionsthat follow.

CHECK TIRE PRESSURE

The tires onyourtractor were overlnflatedat

the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See "TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for replacing

motion and mower blade drive belts in the

Service and Adjustments sectionofthis man-

ual. Veriiy that the belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to see that the brake is operating

properly. See 'q'O CHECK BRAKE" in the

Service and Adjustments section of this

manual.

V(CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product.

Please review the following checklist:

V"All assembly instructions have been

completed.

J" No remaining loose parts in carton.

v/ Battery isproperly prepared andcharged.

J" Seat is adjusted comfortably and tight-

ened securely.

d' All tires are properly inflated. (For ship-

ping purposes,the tires were overinflated

at the factory).

J Ensure mower deck is propedy leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be propedy inflated

for leveling).

J" Check mower and drive belts. Ensure

they are routed properly around pulleys

and inside alt belt keepers.

d" Checkwiring. Seethatall connections are

stillsecureandwiresareproperiyclamped.

J Before driving tractor, besure freewheel

control isin "transmission engaged" posi-

tion (see "ToTransport" in the Operation

section of this manual).

While learninghowto useyourtractor,payex-

traattentiontothe following importantitems:

d" Engine oil is at proper level.

vf Fueltank isfilledwith fresh, clean, regular

unleaded gasoline.

#' Become familiar with all controls, their

location and function. Operate them

before you start the engine.

t/Ensure brake system isin safe operating

condition.

!/Ensure Operator Presence System and

Reverse Operation System (ROS) are

working properly (SeetheOperation and

Maintenance sections in this manual).

Page 9

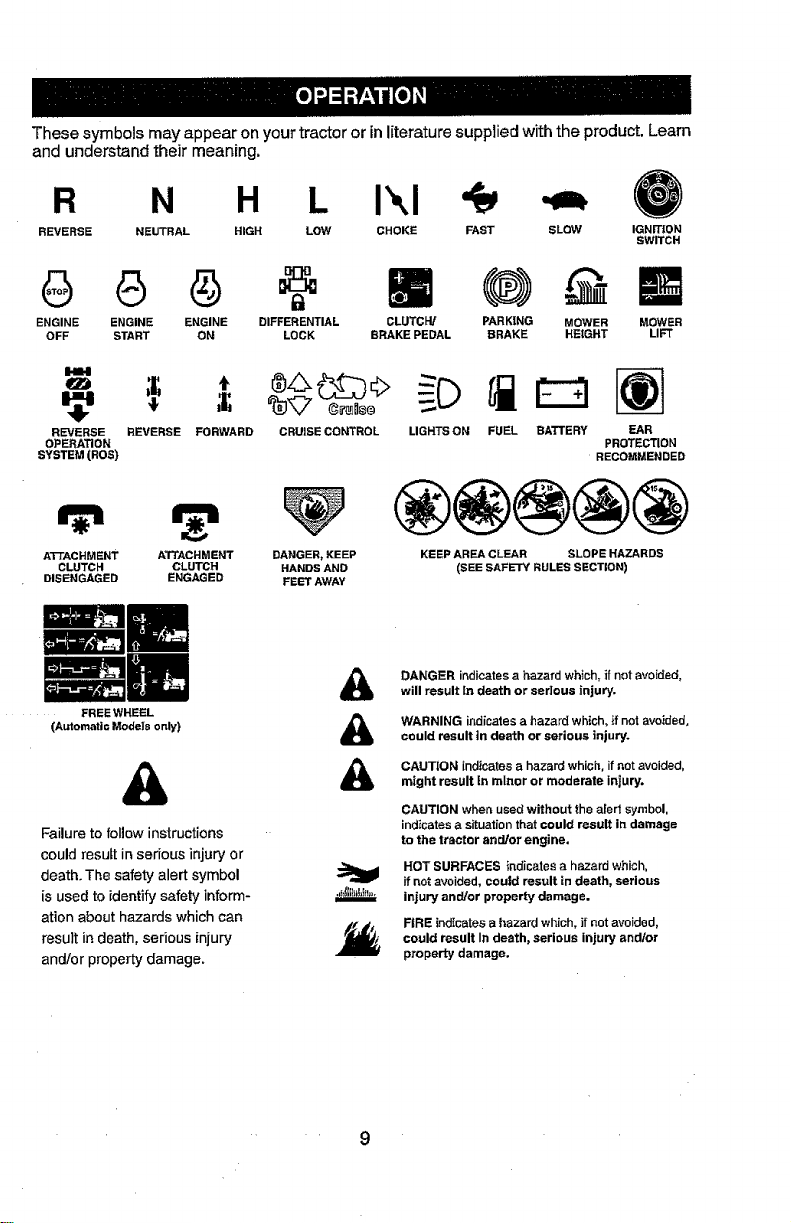

Thesesymbolsmayappearonyourtractororinliteraturesuppliedwiththeproduct.Learn

andunderstandtheirmeaning.

R N H Ikl

REVERSE NEUTRAL HIGH LOW CHOKE IGNITION

FAST SLOW

SWITCH

ENGINE ENGINE ENGINE DIFFERENTIAL

OFF START ON LOCK

1'114

q_

,I;

€

REVERSE

OPERATION

SYSTEM (ROS)

ATTACHMENT ATTACHMENT DANGER, KEEP

CLUTCH CLUTCH HANDS AND

DISENGAGED ENGAGED FEET AWAY

(Automatic Models only)

REVERSE FORWARD CRUISE CONTROL LIGHTS ON FUEL BATTERY EAR

FREEWHEEL

&

Failure to follow instructions

couldresult in serious injure/or

death. The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result indeath, serious injury

and/or property damage.

CLUTCH/ MOWER

BRAKE PEDAL LIFT

PARKING MOWER

BRAKE HEIGHT

RECOMMENDED

®@@@@

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

&

&

&

DANGER indicates a hazard which, if not avoEded,

will result In death or serious injury.

WARNING indicates a hazard which, if not avoided,

could Pesult tn death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate intury.

CAUTION when used without the aled symbol.

indicates a situation that could result in damage

to the tractor and/or engine,

HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious

injury and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result In death, serious injury and/or

property damage.

PROTECTION

• 9

Page 10

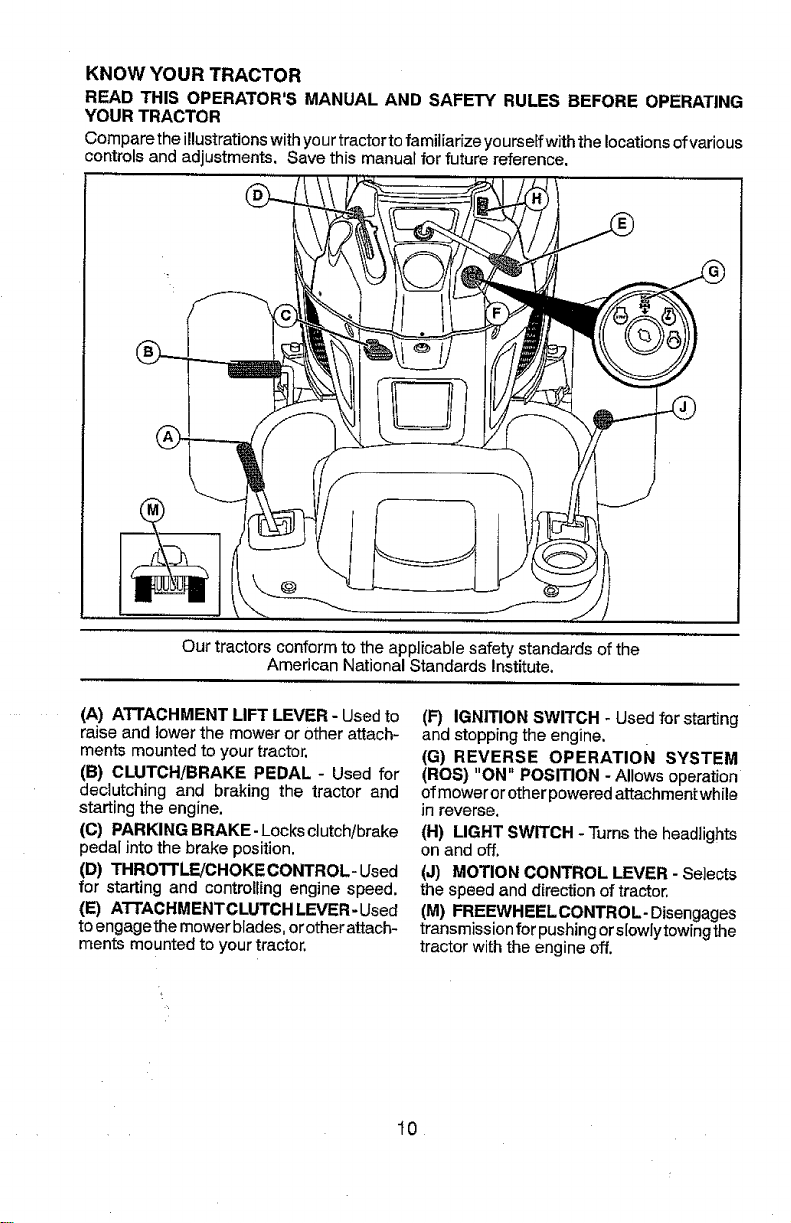

KNOW YOUR TRACTOR

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR TRACTOR

Compare the illustrations withyour tractorto familiarize yourself with the locationsofvarious

controls and adjustments. Save this manual for future reference.

/_ \"_

Our tractors conform to the applicable safety standards of the

American National Standards Institute.

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

merits mounted to your tractor.

(B) CLUTCH/BRAKE PEDAL - Used for

declutching and braking the tractor and

starting the engine.

(C) PARKING BRAKE- Locks dutch/brake

pedal into the brake position.

(D) THROTtLE/CHOKE CONTROL- Used

for starting and controlling engine speed.

(E) ATTACHMENTCLUTCH LEVER- Used

toengagethe mower blades, orother attach-

ments mounted to your tractor.

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION - Allows operation

ofmower orother powered attachment while

in reverse.

(H) LIGHT SWITCH - Turnsthe headlights

on and off.

(J) MOTION CONTROL LEVER - Selects

the speed and direction of tractor,

(M) FREEWHEEL CONTROL- Disengages

transmission for pushing ors[owlytowing the

tractor with the engine off.

t0

Page 11

The operation of any tractor can result in foreign objects thrown into

the eyes, which can result in severe eye damage. Always wear safety

glasses or eye shields while operating your tractor or performing any

adjustments or repairs. We recommend standard safety glasses or a

wide vision safety mask worn over spectacles.

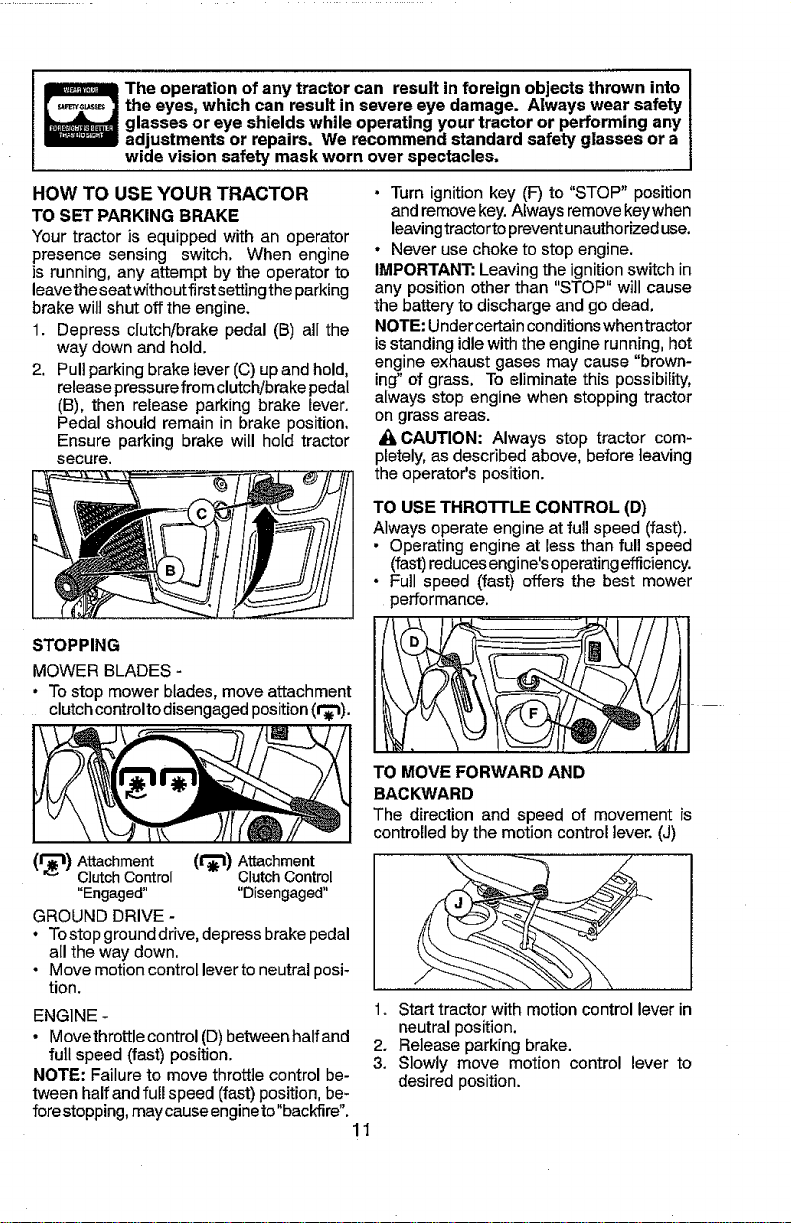

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine

is running, any attempt by the operator to

leavethe seat withoutfirst setting the parking

brake wilt shut off the engine.

1. Depress clutch/brake pedal (B) all the

way down and hold.

2, Pult parking brake lever (C) up and hold,

release pressure from clutch/brake pedal

(B), then release parking brake lever.

Pedal should remain in brake position,

Ensure parking brake will hold tractor

secure.

STOPPING

MOWER BLADES -

• To stop mower blades, move attachment

clutch controlto disengaged position (t_).

(1"_11)Attachment (tr_l) Attachment

Clutch Control Clutch Control

"Engaged .... Disengaged"

GROUND DRIVE -

• To stop ground drive, depress brake pedal

all the way down,

• Move motion control lever to neutral posi-

tion.

ENGINE -

• Movethrottle control (D)between halfand

full speed (fast) position.

NOTE: Failure to move throttle control be-

tween half and full speed (fast) position,be-

forestopping, may causeengineto"backfire".

• Turn ignitionkey (F) to "STOP" position

andremove key.Always remove keywhen

leavingtractorto preventunauthorized use.

• Never use choke to stop engine.

IMPORTANT: Leavingthe ignitionswitch in

any position other than "STOP" will cause

the battery to discharge and go dead.

NOTE: Undercertain conditions whentractor

is standing idle with the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass. To eliminate this possibility,

always stop engine when stoppingtractor

on grass areas.

A CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast)reducesengine'soperating efficiency.

• Full speed (fast) offers the best mower

performance.

TO MOVE FORWARD AND

BACKWARD

The direction and speed of movement is

controlled by the motion control lever, (J)

1. Start tractor with motion control lever in

neutralposition.

2. Release parking brake.

3. Slowly move motion control lever to

desired position.

11

Page 12

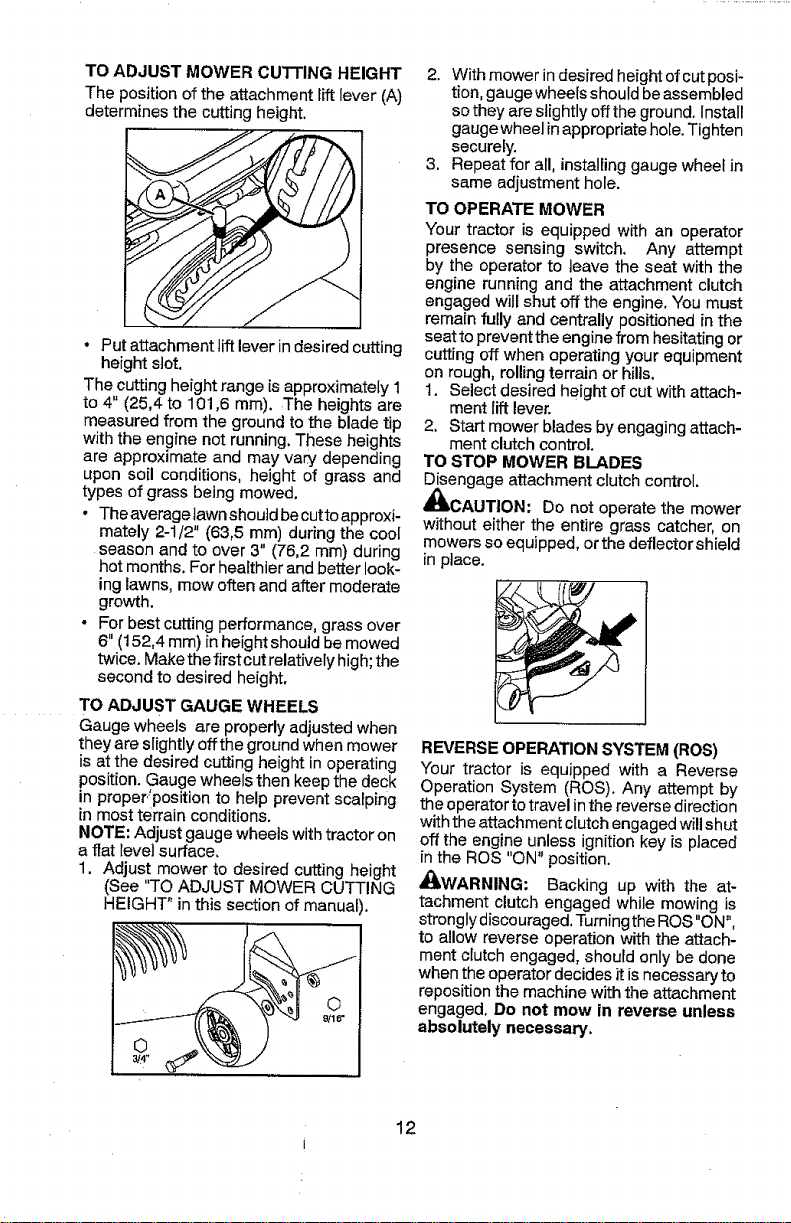

TO ADJUST MOWER CUTTING HEIGHT

The position ofthe attachment liftlever (A)

determines the cutting height.

° Put attachment lift lever in desired cutting

height slot.

The cutting height range is approximately 1

to 4" (25,4 to 101,6 ram)..The heights are

measured from the ground to the blade tip

with the engine not running. These heights

are approximate and may vary depending

upon soil conditions, height of grass and

types of grass being mowed.

• The average lawnshould becutto approxi-

mately 2-1/2" (63,5 mm) during the cool

season and to over 3" (76,2 mm) during

hot months. For healthier and better look-

ing lawns, mow often and after moderate

growth.

• For best cutting performance, grass over

6" (152,4 ram) in height should bemowed

twice. Make the first cut relatively high; the

second to desired height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

theyare slightly offthe ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper/position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a fiat leve_surface,

1. Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

2. With mower indesired height of cutposi-

tion, gauge wheeis shouId be assembled

sothey are slightly off the ground. Install

gauge wheel inappropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Any attempt

by the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine. You must

remain fully and centrallypositioned in the

seatto prevent the engine fTOmhesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills.

1. Select desired height of cut with attach-

ment lift lever.

2, Start mower blades byengaging attach-

ment clutch control.

TO STOP MOWER BLADES

Disengage attachment clutch control.

_CAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, orthe deflector shield

in place.

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel inthe reverse direction

with the attachment clutch engaged will shut

off the engine unless ignition key is placed

in the ROS "ON" position.

all'WARNING: Backing up with the at-

tachment clutch engaged while mowing is

stronglydiscouraged, Turningthe ROS"ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides it is necessary to

reposition the machine w_ththe attachment

engaged, Do not mow in reverse unless

absolutely necessary,

12

Page 13

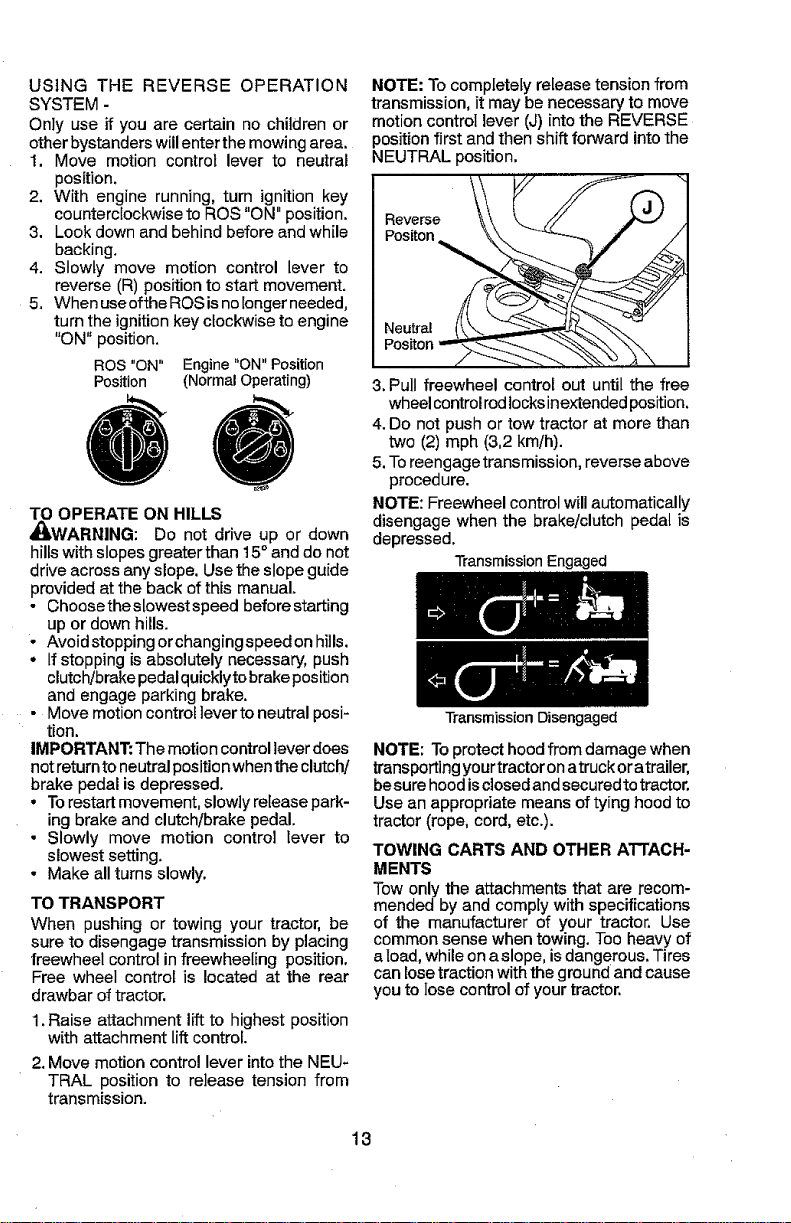

USINGTHEREVERSEOPERATION

SYSTEM-

Onlyuseifyouarecertainnochildrenor

otherbystanderswillenterthemowingarea.

1.Movemotioncontrollevertoneutral

position.

2.Withenginerunning,turnignitionkey

counterclockwisetoROS"ON"position,

3. Lookdownandbehindbeforeandwhile

backing,

4. Slowlymovemotioncontrolleverto

reverse(R)positiontostartmovement.

5,WhenuseoftheROSisnolongerneeded,

turntheignitionkeyclockwisetoengine

"ON"position.

ROS"ON"Engine"ON"Position

Position(NormalOperating)

TO OPERATE ON HILLS

_WARNING: Do not drive up or down

hills with slopes greater than 15° and do not

drive across any slope. Use the slope guide

provided at the back of this manual.

• Choosetheslowestspeed before starting

up or down hills.

- Avoid stopping or changing speed onhills.

• If stopping is absolutely necessary, push

clutch/brake pedalquickly tobrake position

and engage parking brake.

• Move motion control teverto neutral posi-

tion.

IMPORTANT: The motion control lever does

not return toneutral positionwhenthe clutch/

brake pedal is depressed.

• To restart movement, slowly release park-

ing brake and clutch/brake pedal.

• Slowly move motion control lever to

slowest setting,

- Make all turns slowly.

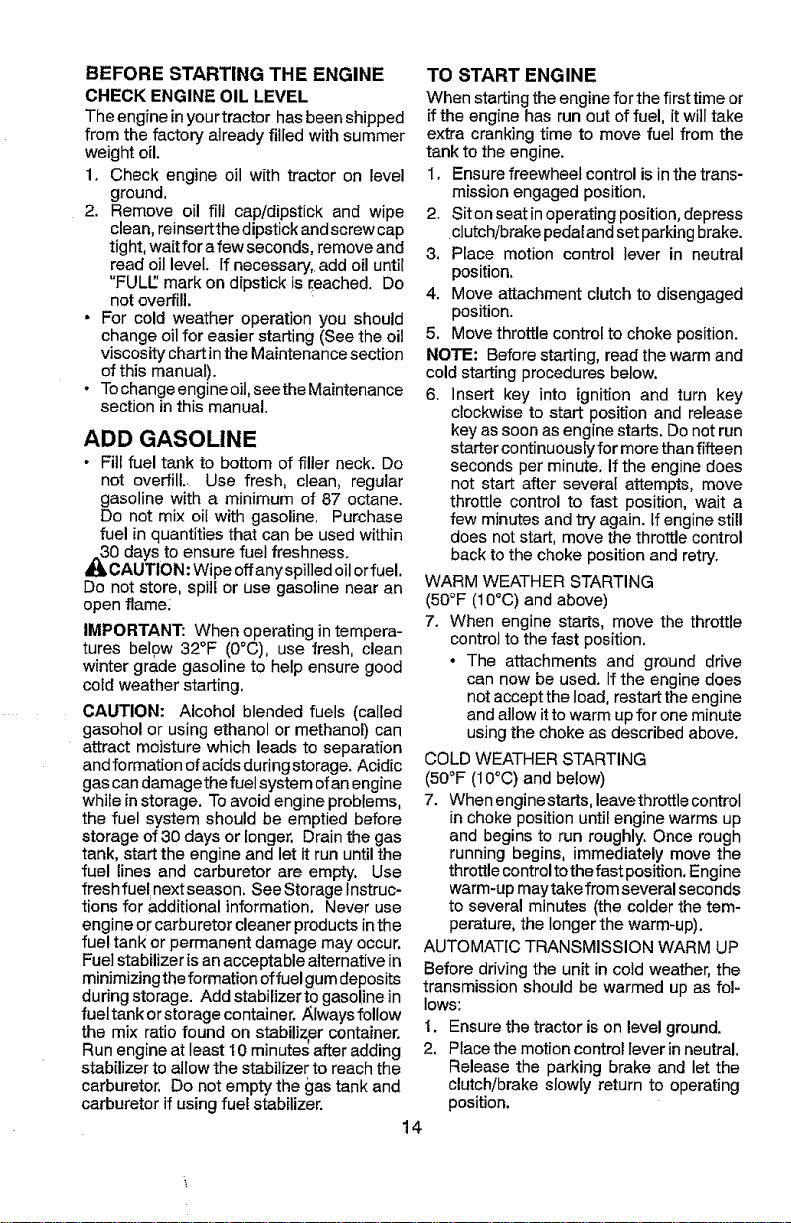

TO TRANSPORT

When pushing or towing your tractor, be

sure to disengage transmission by placing

freewheel control in freewheeling position.

Free wheel control is located at the rear

drawbar of tractor.

1.Raise attachment lift to highest position

with attachment lift control.

2. Move motion control lever into the NEU-

TRAL position to release tension from

transmission.

NOTE: To completely release tension from

transmission,it may be necessary to move

motion control lever (J) into the REVERSE

position first and then shift forward into the

NEUTRAL position.

Neutral (__..zL-...'%.

Pos.o.

3.Pull freewheel control out until the free

wheelcontrolrodlocksinextendedposition.

4.Do not push or tow tractor at more than

two (2) mph (3,2 kin/h).

5.Toreengage transmission, reverse above

procedure.

NOTE: Freewheel control will automatically

disengage when the brake/clutch pedal is

depressed.

TransmissionEngaged

Transmission Disengaged

NOTE: Toprotecthoodfrom damage when

transporting yourtractoron atruck oratrailer,

besure hood isclosedand secured to tractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

TOWING CARTS AND OTHER A'rrACH-

MENTS

Tow only the attachments that are recom-

mended by and complywith specifications

of the manufacturer of your tractor, Use

common sense when towing. Tooheavy of

aload, whileona slope, isdangerous.Tires

can losetractionwiththe ground and cause

you tolose controlofyour tractor.

13

Page 14

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine in yourtractor hasbeen shipped

from the factory already filled with summer

weight oil.

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean, reinsertthe dipstick and screw cap

tight, wait for afew seconds, remove and

read oil level, ff necessary,, add oil until

"FULl" mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart inthe Maintenance section

of this manual).

• Tochangeengine oil,seethe Maintenance

section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill.. Use fresh, clean, regular

gasoline with a minimum of 87 octane.

Do not mix oil with gasoline, Purchase

fuel in quantities that can be used within

0 days to ensure fuel freshness.

CAUTION: Wipe offany spilled oil orfuel.

Do not store, spill or use gasoline near an

open flame:

IMPORTANT: When operating intempera-

tures below 32°F (0°C), use fresh, clean

winter grade gasoline to help ensure good

cold weather starting,

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

andformation of acids during storage. Acidic

gas candamagethe fuel system of anengine

while in storage, To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty. Use

fresh fuel nextseason. See Storage Instruc-

tions for additional information. Never use

engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

Fuelstabilizer isanacceptable alternative in

minimizingthe formation offuel gum deposits

during storage. Add stabilizer to gasoline in

fuel tank or storage container. Always follow

the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor. Do not empty the gas tank and

carburetor if using fuel stabilizer.

TO START ENGINE

When starting the engine for the firsttime or

if the engine has run out of fuel, it will take

extra cranking time to move fuel from the

tank to the engine.

1. Ensure freewheel control is in the trans-

mission engaged position,

2. Sitonseat inoperating position, depress

clutch!brake pedal and setparking brake.

3. Place motion control lever in neutral

position.

4. Move attachment clutch to disengaged

position.

5. Movethrottle control to choke position.

NOTE: Before starting, read the warm and

cold starting procedures below.

6. Insert key into ignition and turn key

clockwise to start position and release

key as soon as engine starts. Donot run

starter continuously for more than fifteen

seconds per minute, If the engine does

not start after several attempts, move

throttle control to fast position, wait a

few minutes and try again. If engine still

does notstart, move the throttle control

back to the choke position and retry.

WARM WEATHER STARTING

(50°F (10°C) and above)

7. When engine starts, move the throttle

control to the fast position,

° The attachments and ground drive

can now be used. If the engine does

not accept the load, restart the engine

and allow itto warm upfor oneminute

using the choke as described above.

COLD WEATHER STARTING

(50°F (10°C) and below)

7. When engine starts, leavethrottle control

in choke position until engine warms up

and begins to run roughly. Once rough

running begins, immediately move the

throttle controltothe fast position. Engine

warm-up maytake from several seconds

to several minutes (the colder the tem-

perature, the longer the warm-up).

AUTOMATIC TRANSMISSION WARM UP

Before driving the unit in cold weather, the

transmission should be warmed up as fol-

lows:

1. Ensure the tractor is on level ground.

2. Place the motion control lever in neutral

Release the parking broke and let the

clutch/brake slowly return to operating

position.

14

Page 15

3.AIIowoneminutefortransmissiontowarm

up.Thiscanbedoneduringtheengine

warmupperiod.

• Theattachmentscanalsobeuseddur-

ingtheenginewarm-upperiodafterthe

transmissionhasbeenwarmedup.

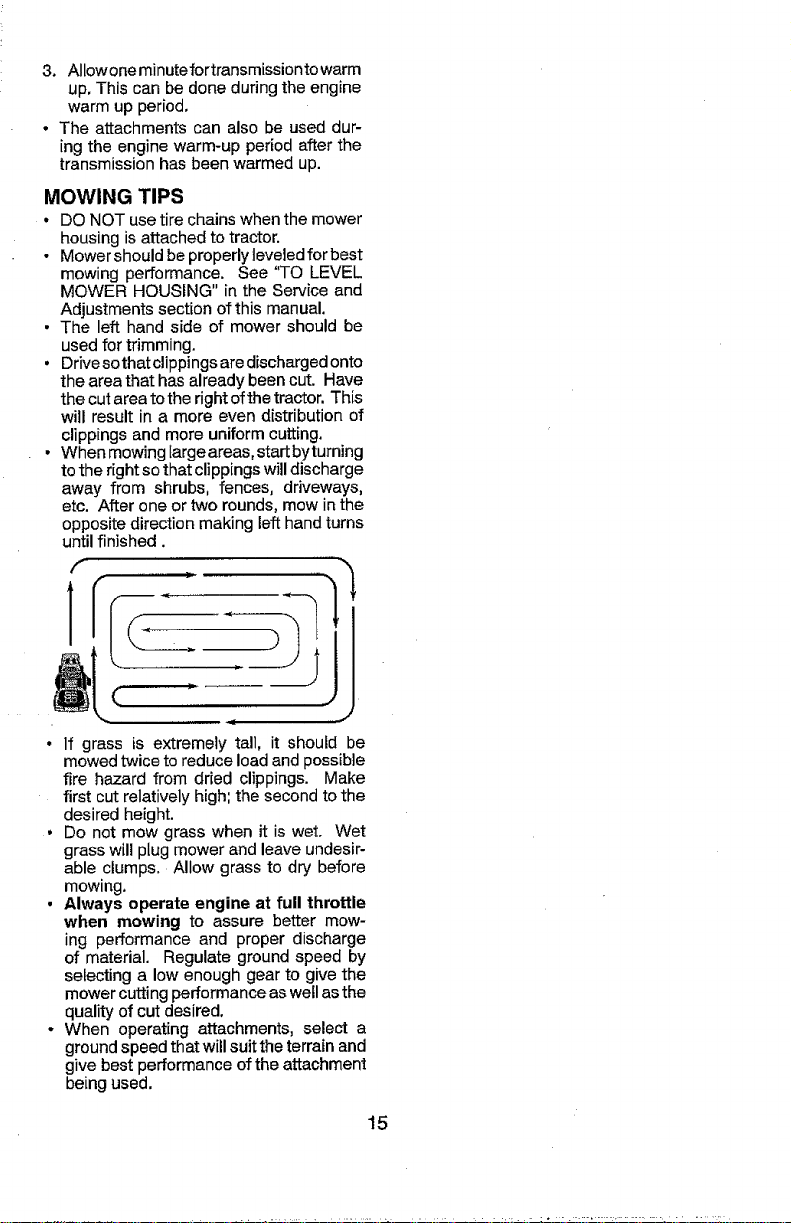

MOWING TIPS

• DO NOT use tire chains when the mower

housing is attached to tractor.

• Mower should be properly leveled for best

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

• The left hand side of mower should be

used fortrimming.

• Drive sothat clippings are discharged onto

the area that has already been cut. Have

the cutarea to the right ofthe tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

• When mowing largeareas, start byturning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

Z"

_ J

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing.

• Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough gear to give the

mower cutting performance as well as the

quality of cut desired.

o When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

15

Page 16

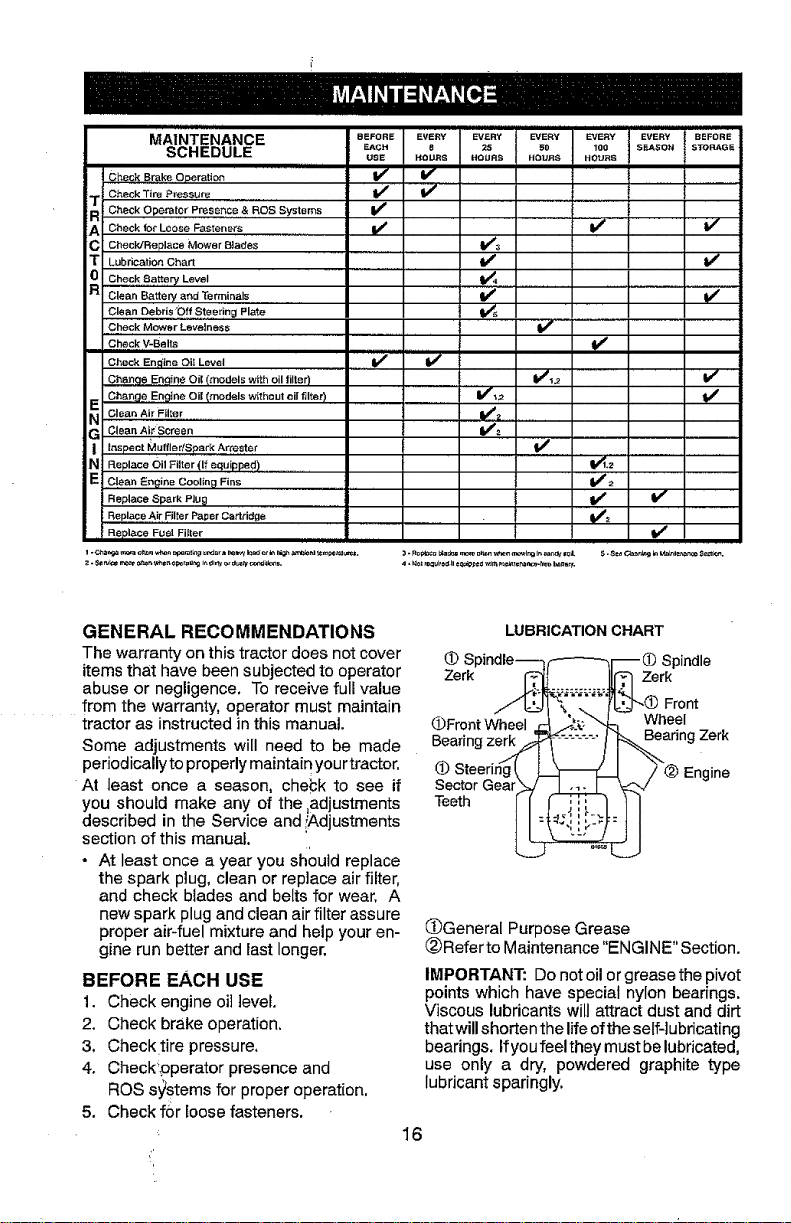

MAINTENANCE eEFOnE

SCHEDULE _c.

Check Brake Op,erafien

Check Tire Pressure ......... V'

T Check Operator Presence & ROS Systems I_'

A Check for Loose Fasteners

C CheeWReplace Mower Blades ......

T Lubrication Chart

0 Check 8attery Level

R Clean Battery and Terminals .........................

ull i i

USE

CleanDebrisO!.!...st_r!ngPla_

.Check Mower Levelness ..............

Check V-Belts

Check Engine eli Level .If

Change Engin # Oil Imodels with oil filter)

Chan£te.Engtne Oil Imodels without oil filter)

_ Clean Air Filt,itr ...............

G risenAl_Screen

I Inspect _luffl_r/Spark Attester .

N Re place Oil Filter (If equipped ) ........

E ,,C!eacEngine Cooling Fins

Replace Spark Plug .............

Replace Air Filter Paper Cartridge

.. R.eplace Fuel Filter ..................................

,lll,l,UHIII,Ul

EVE_ EV_aV _SaY '&_;

8 25 _O 100

_OURS HOSES SOURS SOURS

v

i,,"

V's

V' V'

v' v"

nl v,

v',

v'

V_

EVERY BEFORE

S_.ASON STOOGE

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

items that have been subjected to operator

abuse or negligence, To receive full value

from the warranty, operator must maintain

tractor as instructedin this manual.

Some adjustments will need to be made

periodically to properly maintain your tractor.

At least once a season, chebk to see if

you should make any of the ,adjustments

described in the Service and iAdjustments

section of this manual.

* At least once a year you should replace

the spark plug, clean or replace air filter,

and check blades and belts for wear. A

new spark plug and clean air filter assure

proper air-fuel mixture and help your en-

gine run better and lastlonger.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3, Checktire pressure,

4. Check!pperator presence and

ROS sy'stems for proper operation,

5. Check for loosefasteners.

LUBRICATION CHART

Spindle---_ F----'--ql_ _ Spindle

Zerk _'_. __._,:_:_Zerk

//]__J_;_"%--L --f 'ij"-(_ Front

l_FrontWheel r_ _5:'_ Wheel

Steering[ _ / @ Enaine

SectorGear_ -,_L:_z:_L-'_',/

Teeth _!_,! i!_._

TRACTOR

Always observe safety rules when perform-

ing any maintenance.

BRAKE OPERATION

if tractor requires morethan 5 feet (1,5 m)

to stop at highest speed inhighest gear on

a level, dry concrete or paved surface, then

brake must be serviced. _See"TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

• Maintain proper air pressure in all tires

(See the side of tires for proper PSL)

o Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

fiat tires due to slow leaks, tire sealant may

be purchased from yourlocal parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation systems are workingproperly. If

your tractor does not function as described,

repair the problem immediately.

• The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE SYSTEM

• When the engine is running, anyattempt

by the operator to leavethe seat without

first settingthe parking brake should shut

off the engine.

- When the engine is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shutoff the engine.

• The attachment clutch should never oper-

ate unless the operator is inthe seat.

CHECK REVERSE OPERATION (ROS)

SYSTEM

• When the engineisrunning withthe ignition

switch in the engine"ON" position and the

attachment clutch engaged, anyattempt

bythe operator to drive in reverse should

shut off the engine,

• When the engineisrunningwiththe ignition

switch in the ROS "ON" position and the

attachment clutch engaged, any attempt

bythe operator to drive in reverse should

NOT shut off the engine.

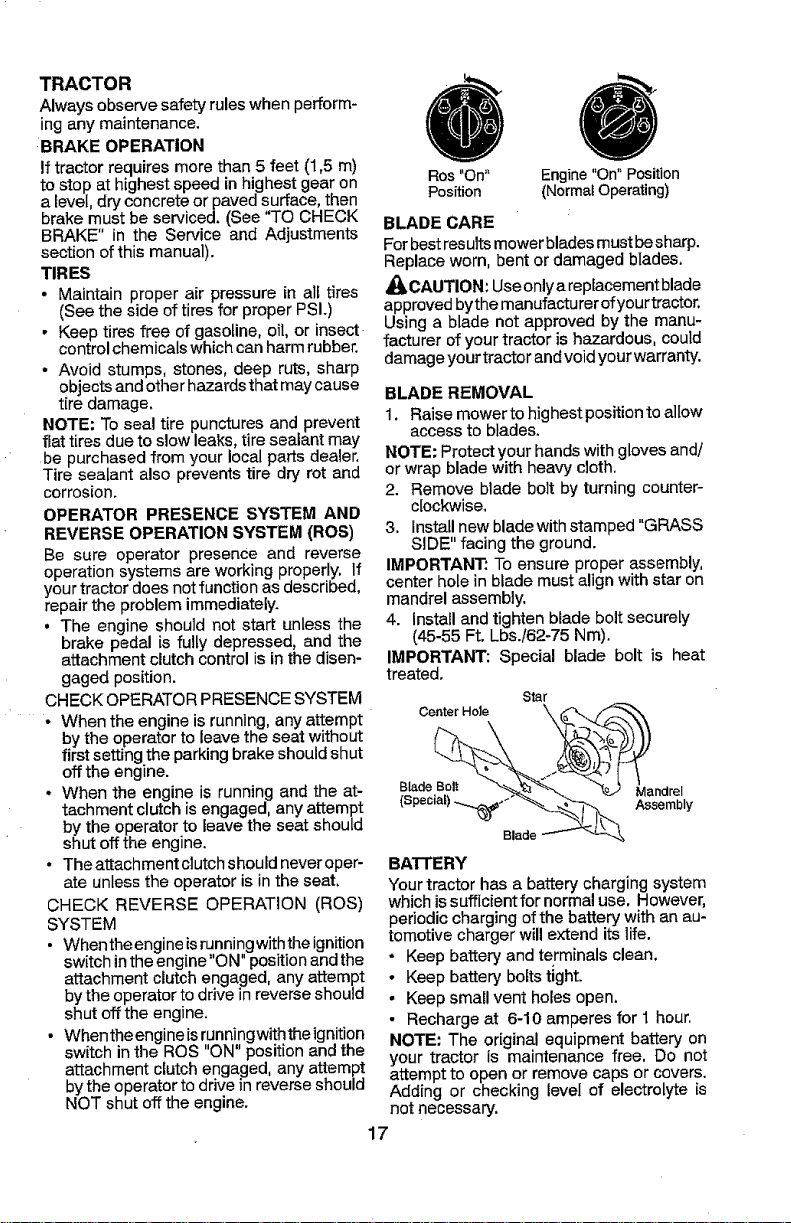

Ros "On" Engine "On" Position

Position (Normal Operating)

BLADE CARE

Forbest resultsmower blades must besharp.

Replace worn, bent or damaged blades.

_IbCAUTION: Use onlya replacement blade

approvedbythe manufacturer ofyourtractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage your tractor and void your warranty.

BLADE REMOVAL

1. Raise mower to highest position to allow

access to blades.

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth,

2. Remove blade bolt by turningcounter-

clockwise.

3. Install new blade with stamped "GRASS

SIDE" facing the ground.

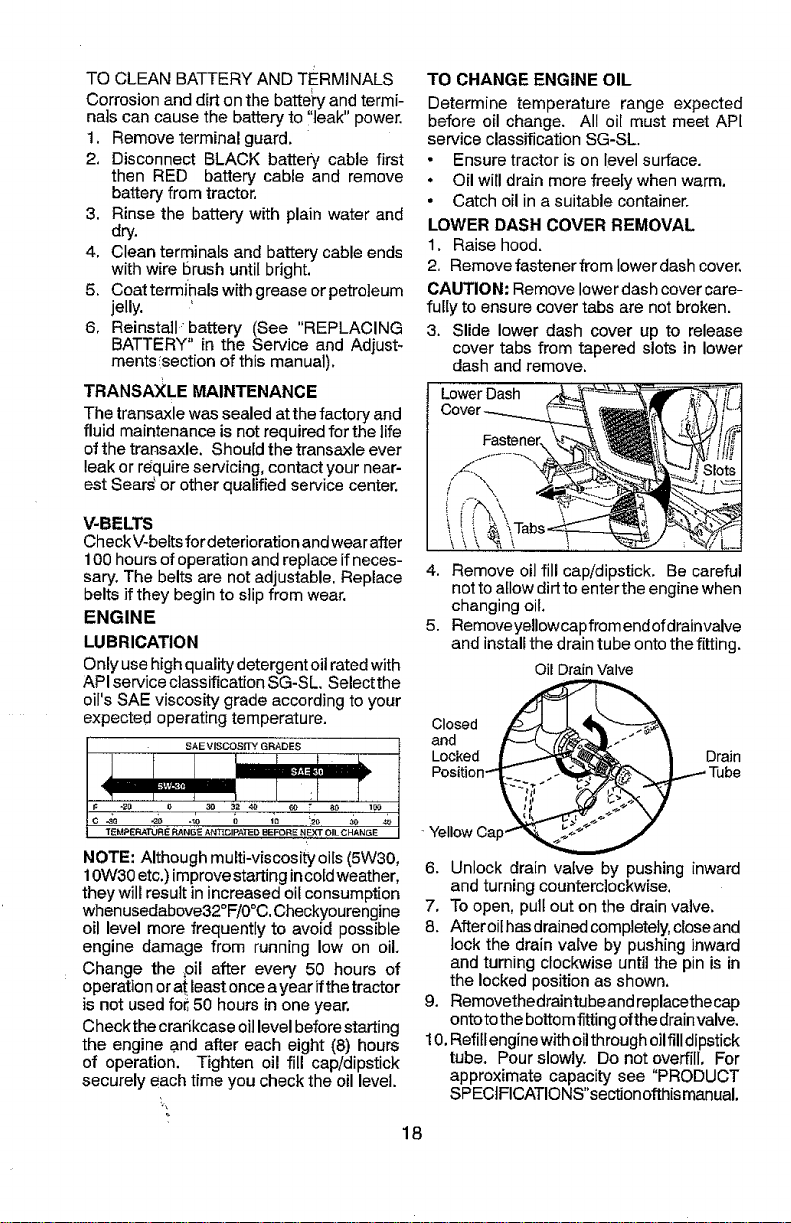

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. Install and tighten blade bolt securely

(45-55 Ft. Lbs./62-75 Nm).

IMPORTANT: Special blade bolt is heat

treated.

Canter Hole

Star

BATTERY

Your tractor has a battery charging system

which issufficient for normal use. However,

periodic charging of the battery with an au-

tomotivecharger will extend its life.

- Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for I hour.

NOTE: The original equipment battery on

your tractor is maintenance free, Do not

attempt to open or remove capsor covers.

Adding or checking level of electrolyte is

not necessary.

17

Page 18

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battei'y and termi-

nals can cause the battery to ,leak" power.

1, Remove terminal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

3, Rinse the battery with plain water and

dry.

4. Clean terminals and battery cable ends

with wire brush until bright.

5. Coat termihals with grease or petroleum

jelly.

6, Reinstallbattery (See "REPLACING

BATTERY" in the Service and Adjust-

ments !section of this manual).

TRANSAXLE MAINTENANCE

The transaxlewas sealed at the factory and

fluid maintenance is not required for the life

ofthe transaxle. Should the transaxle ever

leak or require servicing, contact your near-

est Sears or other qualified service center.

V-BELTS

Check V-beltsfor deterioration andwearafter

100hours ofoperation and replace if neces-

sary, The belts are not adjustable. Replace

belts if they begin to slip from wear.

ENGINE

LUBRICATION

Only use high quality detergent oilrated with

API service classification SG-SL. Selectthe

oil's SAE viscosity grade according to your

expected operating temperature.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet AP[

service classification SG-SL

• Ensure tractor is on level surface.

• Oil will drain more freely when warm,

• Catch oil in a suitable container.

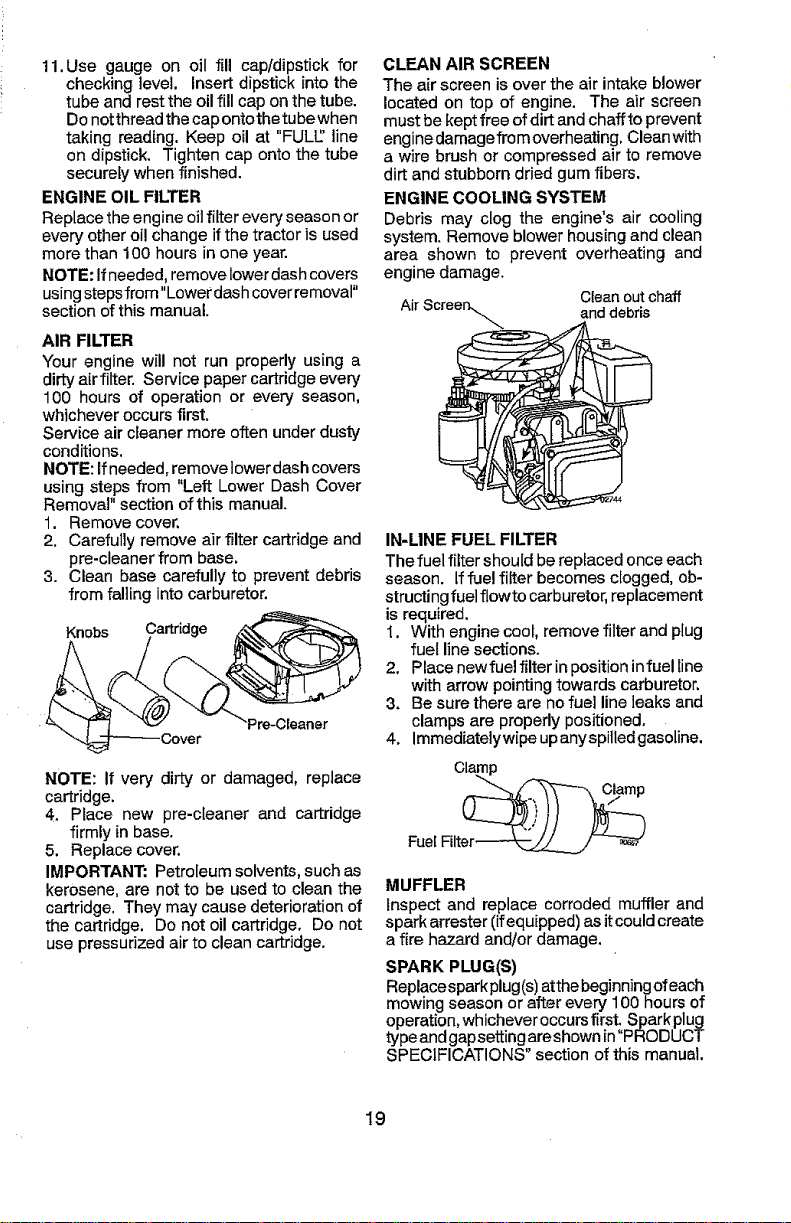

LOWER DASH COVER REMOVAL

1. Raise hood.

2. Remove fastener from lower dash cover,

CAUTION: Remove lower dash cover care-

fully to ensure cover tabs are notbroken.

3. Slide lower dash cover up to release

cover tabs from tapered slots in lower

dash and remove.

LowerDash

4. Remove oil fill cap/dipstick. Be careful

nottoallow dirt to enter the engine when

changing oil.

5. RemoveyeUowcapfromendofdrainvalve

and install the drain tube ontothe fitting.

OilDrainValve

NOTE: Although multi-viscosity oils (5W30,

10W30 etc,) improvestarting incoldweather,

they will result in increased oil consumption

whenusedabove32°F/0°C.Checkyourengine

oil level more frequently to avoid possible

engine damage from running low on oil.

Change the ,oil after every 50 hours of

operation orat..least oncea year ifthe tractor

isnot used fo_50 hours inone year,

Checkthe crarikcase oillevel before starting

the engine .and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick

securely each time you check the oil level.

Tube

6. Unlock drain vafve by pushing inward

and turning counterclockwise.

7, To open, putl outon the drain valve.

8. After oilhasdrained completely,closeand

tock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked position as shown,

9, Removethedraintubeand replacethecap

ontoto the bottomfitting ofthe drainvalve.

10, Refilfengine with oilthrough oilfilldipstick

tube. Pour slowly. Do not overfill, For

approximate capacity see "PRODUCT

SPECIFICATIONS"sectIonofthismanual,

18

Page 19

11.Use gauge on oil fill cap/dipstick for

checking level. Insert dipstick into the

tube and restthe oil fill cap on the tube.

Do notthread the capontothe tube when

taking reading. Keep oil at "FULL' line

on dipstick. Tighten cap onto the tube

securely when finished.

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the tractor is used

more than 100 hours in one year.

NOTE: If needed, remove lower dashcovers

using stepsfrom"Lowerdash cover removal"

section of this manual.

AIR FILTER

Your engine will not run properly using a

dirty airfilter. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

NOTE: If needed, remove lower dash covers

using steps from "Left Lower Dash Cover

Removal" section of this manual.

1. Remove cover,

2, Carefully remove a_irfilter cartridge and

pre-cleaner from base.

3. Clean base carefully to prevent debris

from falling into carburetor.

NOTE: If very dirty or damaged, replace

cartridge.

4. Place new pre-cleaner and cartridge

firmly in base.

5. Replace cover.

IMPORTANT: Petroleum solvents, such as

kerosene, are not to be used to clean the

cartridge. They may cause deterioration of

the cartridge. Do not oil cartridge, Do not

use pressurized air to clean cartridge.

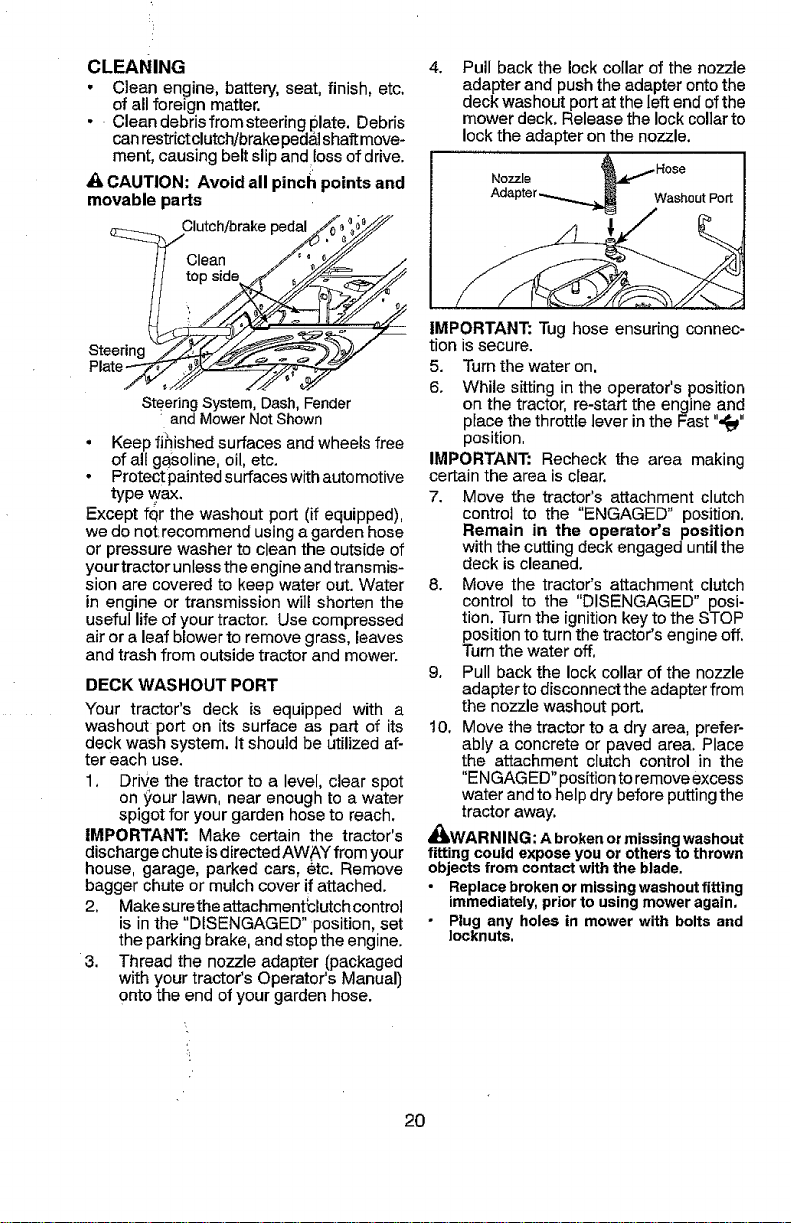

CLEAN AIR SCREEN

The air screen is over the air intake blower

located on top of engine. The air screen

must be kept free ofdirt and chaffto prevent

engine damagefrom overheating. Cleanwith

a wire brush or compressed air to remove

dirt and stubborn dried gum fibers.

ENGINE COOLING SYSTEM

Debris may clog the engine's air cooling

system. Remove blower housing and clean

area shown to prevent overheating and

engine damage.

AirScree Cleanout chaff

IN-LINE FUEL FILTER

The fuel filter should be replaced onceeach

season. If fuel filter becomes clogged, ob-

structing fuelflowto carburetor, replacement

is required.

I. With engine cool, remove filter and plug

2, Place newfuel filter in position infuel line

3. Be sure there are nofuel line leaks and

4. Immediatelywipe upanyspilledgasoline.

MUFFLER

Inspect and replace corroded muffler and

spark arrester (ifequipped) asit could create

a fire hazard and/or damage.

SPARK PLUG(S)

Repl.acesparkplug(s)atthebeginningofeach

mowing season or after every 100 hours of

operation, whichever occursfirst. Sparkplug

typeand gapsettingareshown in"PRODUCT

SPECIFICATIONS" section of this manual.

r_.\ anddebris

fuel line sections.

with arrow pointing towards carburetor,

clamps are properly positioned,

Clamp

FuelFilter__.__j/

19

Page 20

CLEANING

• Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Clean debris from steering plate. Debris

canrestrictclutch/brakepeda.lshaft move-

ment, causing belt slip and toss of drive.

S

A CAUTION: Avoid all pinch points and

movable parts

Clutch/brakepedal

top

Steering

SteeringSystem,Dash,Fender

andMowerNot Shown

° Keep finished surfaces and wheels free

of all gasoline, oil, etc.

• Protectpainted surfaces with automotive

type wax.

Except fQrthe washout port (if equipped),

we do not recommend using agarden hose

or pressure washer to clean the outside of

your tractor unlessthe engine and transmis-

sion are covered to keep water out. Water

in engine or transmission will shorten the

useful life of your tractor. Use compressed

air or aleaf blower to remove grass, leaves

and trash from outside tractor and mower.

DECK WASHOUT PORT

Your tractor's deck is equipped with a

washout port on its surface as part of its

deck wash system. It should be utilized af-

ter each use.

1, Drive the tractor to a level, clear spot

on your lawn, near enough to a water

spigot for your garden hose to reach.

IMPORTANT: Make certain the tractor's

discharge chute is directed AWAY from your

house, garage, parked cars, etc. Remove

bagger chute or mulch cover if attached.

2. Makesurethe attachment_clutchcontrol

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Thread the nozzle adapter (packaged

with your tractor's Operator's Manual)

onto the end of your garden hose.

4, Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the left end ofthe

mower deck. Release the lock collar to

lock the adapter on the nozzle.

Washout Port

IMPORTANT: Tug hose ensuring connec-

tion is secure.

5. Turn the water on,

6. While sitting in the operator's position

on the tractor, re-start the engine and

place the throttle lever in the Fast ",t_"

position.

IMPORTANT: Recheck the area making

cerbainthe area is clear.

7. Move the tractor's attachment clutch

control to the "ENGAGED" position.

Remain in the operator's position

with the cutting deck engaged until the

deck is cleaned.

8. Move the tractor's attachment clutch

control to the "DISENGAGED" posi-

tion. Turnthe ignition keyto the STOP

position to turn the tractor's engine off.

Turnthe water off,

9, Pull back the lock collar of the nozzle

adapter to disconnec_theadapter from

the nozzle washout port.

10. Move the tractor to a dry area, prefer-

ably a concrete or paved area. Place

the attachment clutch control in the

"ENGAGED" positionto removeexcess

water and to help dry before putting the

tractor away.

AI_WARNING: Abrokenormissingwashout

fittingcouldexposeyouor otherstothrown

objectsfromcontactwiththe blade,

Replacebrokenor missingwashoutfitting

immediately,priorto usingmoweragain,

Plug any holes in mowerwith bolts and

Iocknuts,

>i

20

Page 21

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

1. Depress clutch/brake pedal fullyand set parking brake.

2. Place motion control lever in neutral position,

3. Place attachment clutch in "DISENGAGED" position.

4, Turn ignition key to "STOP" and remove key.

5. Ensure the blades andall moving parts have completely stopped.

6. Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug.

TO REMOVE MOWER

1. Place attachment clutch in "DISEN-

GAGED" position,

2. Lower attachment lift lever to its lowest

position.

3. Roll belt off engine pulley (M).

4. Remove retainer spring (K), slide collar

(L) off and push housing guide (P) out

of bracket.

5. Remove clutch cable spring (Q) from

idler arm (R).

6, Disconnect front link (E) from mower -

remove retainer spring and washer.

7. Go to either side of mower and discon-

nect mower suspension arm (A) from

chassis pin (B) and rear lift link (C) from

rear mower bracket (D) -remove retainer

springs and washers,

8. Goto othersideof mowerand disconnect

the suspension arm and rear lift link.

d_l CAUTION: After rear lift tinksarediscon-

nected, the attachment liftleverwiil be spring

9. Slide mower outfrom under right sideof

tractor.

IMPORTANT: lfan attachment otherthanthe

mower isto be mounted on the tractor, re-

movethe frontlink (E) andrearliftliks (C)from

tractor and hook the clutch spring (Q) into

the cable guide on front edge of lower dash.

TO INSTALL MOWER

Ensuretractor isonlevelsurface and engage

parking brake,

1. Lower attachment lift lever to it's lowest

position.

_, CAUTION: Lift lever is spring loaded,

Have a tight grip on lift lever, lower it slowly

and engage in lowest position.

NOTE: Ensure mowersidesuspension arms

(A)arepointing forward beforesliding mower

under tractor.

2. Slide mower undertractoruntil it iscen-

tered under tractor.

loaded, Have a tight grip on lift lever when

changing position of the lever.

21

O3042

Page 22

3. ATTACH MOWER SIDE SUSPENSION

ARMS (A),TO CHASSIS - Position hole

in arm over pin (B) on outside of tractor

chassis arid secure with retainer spring.

4. Repeat on opposite side of tractor.

8. Insert end of link (E) into hole in front

mower bracket (H) and secure with

washer and retainer spring (J),

5, ATTACH REAR LIFT LINKS (C) - Lift

rear corner of mower and position slot

in link assembly over pin on rear mower

bracket (D)and secure with washer and

retainer spring.

6. Repeat on opposite side of tractor.

7, ATTACH FRONT LINK (E) - Work from

left side of tractor, insert rod end of link

assembly through front hale in tractor

front suspension bracket (_,

9. Push clutch cabte housing guide (P) into

bracket, slide collar (L) onto guide and

secure with retainer spring (K).

10. Hook end of clutch cable spring (Q) into

hole in idler arm (R),

11. Install belt onto engine clutch pulley (M),

IMPORTANT: Check belt for proper routing

in all mower pulley grooves.

12. Raise attachment lift lever to highest

position.

13, If necessary, adjust gauge wheels before

operating mower as shown inthe Opera-

tion section of this manual.

22

Page 23

TO LEVEL MOWER

Ensuretires are properly inflated to the PSI

shown on tires. If tires are over or under

inflated, it may affect the appearance of your

lawnand lead you to think the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. With all tires properly inflated and ifyour

lawn appears unevenly cut, determine

which side of mower is cutting lower.

NOTE: As desired, you can raise the low

side of mower or lower the high side.

2, Go to side of mower you wish to adjust.

3. With a 3/4" or adjustable wrench, turn

lift link adjustment nut (A) to the left to

lower the mower, or, to the right to raise

the mower.

Turn nut Turn nut

right to left to

raise lower

mower mower

NOTE: Each full turn of adjustment nut will

changemower height about 3/16" (4,7mm).

4. Test your adjustment by mowing some

uncut grass and visually checking the

appearance. Readjust, ifnecessary, until

you are satisfied with the results.

PRECISION SIDE-TO-SIDE ADJUSTMENT

1, With aUtiresproperly inflated, parktractor

on level ground or driveway,

_,CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth,

2. Raise mower to its highest position.

3. At both sides of mower, position blade

at side and measure distance "A" from

bottom edge of bladeto ground,The dis-

tance should bethe same on both sides.

4. If adjustment is necessary, see steps in

Visual Adjustment instructions above,

5. Recheck measurements; adjust ffneces-

sary until both sides are equal.

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-side.

To obtain the best cutting results, the mower

blades should be adjusted so the front tip

is 118to 1/2" (3,1 to 12,7 ram) (Iower than

the reartip when the mower is in its highest

position.

_JlkCAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heaw/cloth.

• Raise mower to highest position,

- Position any blade so the tip is pointing

straightforward, Measure distance "B"to

the ground at front and rear tip of blade,

• If front tip of blade is not 1/8 to 1/2" (3,1

to 12,7 mm) lower than the rear tip, go to

the front of tractor,

• With an 11/16" or adjustable wrench,

loosen jam nut "A" several turns to clear

adjustment nut "B".

• With a 3/4" or adjustable wrench, turn

front linkadjustment nut"B" clockwise (f'_)

(tighten) to raise the front of mower, or,

counterclockwise (_'_) (loosen) to lower

the front mower,

Tighten adjust Loosen adjust

nut "B" to nut "El" to

raise mower lower mower

Loosen jam nut "A" first

NOTE: Each full turnof adjustment nut will

change mower height about 1/8" (3,1 mm),

• Recheck measurements, adjust if neces-

sary until front tip of blade is 1/8 to 1/2"

(3,1 to 12,7 mm) lower than the reartip.

• Hold adjustment nut in position with

wrench and tighten jam nut securely

against adjustment nut.

23

Page 24

TO REPLACE MOWER BLADE DRIVE

BELT

The mower blade drive belt may be replaced

without tools. Parkthe tractor on level sur-

face. Engage parking brake.

BELT REMOVAL-

1, Remove mbwerfromtractor (See"TO RE-

MOVEMOWER"inthissectionofmanual).

2, Work belt off both mandrel pulleys and

idler pplleys.

3. Pull beltaway from mower.

BELT INS_FALLAT1ON-

1. Work belt around both mandrel pulleys

and idler pulleys

2. Ensure belt is in all pulley grooves and

inside all belt guides.

31 Instaliimower (See "To Install Mower" in

this section of this manual).

Mandrel Idler

Pulleys

Mandrel

TO CHECK BRAKE

Iftractor requires morethan fiv_ (5)feet (1,5

m) to stop at highest speed in,highest gear

on a level, dry concrete or paved surface,

then brake must be serviced.

You may also check brake by:

1. Park tractor on a level, dry concrete or

paved surface, depress brake pedal all

the waydown and engage parking brake.

2. Disengage transmission by placing

freewheel,control in'_ransmission disen-

gaged" p_sition. Pull freewheel control

out and into the slot and release so it is

held inthe' disengaged position.

The rear wheels must lock and skid when

you try to manually push the tractor forward.

if the rear wheels rotate, then the brake

needs to be serviced. Contact a Sears or

other qualified service center.

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface, Engage

parking brake. For assistance, there is a

belt installation guide decal on bottom side

of ]eft footrest.

BELT REMOVAL-

1. Remove mower (See "TO REMOVE

MOWER" inthis section of manual).

NOTE: Observe entire motion drive belt

and position of all belt guides and keepers.

2. Remove beltfrom stationary idler(A) and

clutching idler (B).

3. Remove belt from centerspan idler (C).

4. Pull belt slack toward rear of tractor.

Carefully remove belt upwards from

transmission input pulley and over cool-

ing fan blades (D).

5. Remove belt downward from engine

pulley (E).

6. Slide belt toward rear of tractor, off the

steering plate (F)andremovefrom tractor.

BELT INSTALLATION -

1, Install new belt from tractor rearto front,

over the steering plate (F) and above

clutch brake pedal shaft (G).

2. Pull belt toward front of tractor and roll

belt onto engine pulley(E).

3. PulI belttoward rear of tractor. Carefully

work belt down around transmission

cooling fan and ontothe input pulley (D).

Be sure belt is inside the belt keeper.

4. Install belt on centerspan idler (C),

5. Install belt through stationary idler (A)

and clutching idler (B).

6. Make sure belt is in all pulley grooves

and inside all belt guides and keepers.

7. Install mower (See "TO INSTALL MOW-

ER" in this section of manual).

24

Page 25

TRANSAXLE MOTION CONTROLLEVER

NEUTRAL ADJUSTMENT

The motion control lever has been preset

at the factory and adjustment should not

be necessary.

1. Engage the freewheel control lever. (See

TO TRANSPORT in the Operations

section of this manual.)

2, Move the motion control lever until the

unit rolls freely.

3. While holding motion control lever in

place, loosen the adjustment bolt.

4. Move motion control lever to the neutral

(lock gate) position.

5. Tighten adjustment bolt securely.

Motion Control Lever Neutral Lock Gate

olt

NOTE: Ifadditional clearance is needed to

get to adjustment bolt, move mower deck

height to the lowest position,

After above adjustment ismade, tithe tractor

does not reach full forward orreverse speed

at the furthest motion control lever location

for forward and reverse, follow these steps,

1. Lower attachment lift lever to it's lowest

position.

2, Move the shift plate on front of transmis-

sion so that the extruded area centedine

is in line with the dynamic brake arm.

3, While holding motion control lever in

place, loosen the adjustment bolt,

4. Move motion control lever to the neutral

(lock gate) position,

5, Tighten adjustment bolt securely.

Transmission __

Shift Plate ___" _"

Extrusion .... DynamicBrakeArm -

TO REMOVE WHEEL FOR REPAIRS

1. Block up axle securely.

2, Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheels have asquare key- Do notlose).

3. Repairtire and reassemble.

NOTE:On rearwheels only: align grooves in

rear wheel hub and axle. !nsert square key,

4. Replacewashers andsnap retaining ring

securely in axle groove.

5. Replace axle cover.

NOTE: To seal tire puncturesand prevent

flat tires due to stow leaks, purchase and

use tire sealantfrom Sears, Tire sealant also

prevents tire dry rot and corrosion.

Washers

Retaining

Axle

Cover_\

Square

Key_

(Rear Wh_ _

FRONT WHEEL TOE-IN/CAMBER

Your new tractor front wheel toe-in and

camber is set at the factory and is normal.

The front wheel toe-in and camber are not

adjustable. If damage has occurred to

affect the factory set front wheel toe-in or

camber, contact a Sears or other qualified

service center.

TO STARTENGINE WITH WEAKBATTERY

_WARNING: Lead-acid batteries gener-

ate explosive gases. Keep sparks, flame

and smoking materials away from batteries,

Always wear eye protection when around

batteries.

Ifyour batteryistoo weakto start the engine,

it should be recharged. (See "BATTER'{" in

the MAINTENANCE section ofthis manual).

if "jumper cables" are used for emergency

starting, follow this procedure:

IMPORTANT: Yourtractoris equipped with

a12volt system. The othervehicle must also

be a 12volt system. Do not use your tractor

battery to start other vehicles.

TO ATTACH JUMPER CABLES -

1. Connect oneend ofthe RED cable tothe

POSITIVE (+)terminal ofeachbattery(A-

B),taking care notto short against tractor

chassis.

2. Connect one end of the BLACK cable

to the NEGATIVE (-) terminal (C) of fully

charged battery.

3. Connect the other end of the BLACK

cable (D)to good chassis ground, away

from fuel tank and battery.

25

Page 26

TO REMOMECABLES, REVERSEORDER-

1. BLACk,cab ef rstfrom chassis andthen

from the fully charged battery.

2, RED Cable last from both batteries,

/

Weakor _ h_rFtt_2_Dead C

Battery

REPLACING BATTERY

_,WARNING: Do notshortbatteryterminals

byallowing a wrench or any other object to

contact both terminals at the same time.

Before connecting battery, remove metal

bracelet s, wristwatch bands, rings, etc.

Positive terminal must be connected first to

prevent sparking from accidental grounding.

1. Lift seat pan to raised position.

Seat

2. DisconnectBLACK batterycable firstthen

RED battery cable and carefully remove

battery fr0m tractor.

3. ]nstall new batterywith terminals insame

positionas old battery,

4. First connect RED battery cableto posi-

tive (+) terminal with hex bolt and keps

nut as shown. Tighten securely, Slide

terminal cover over terminal

5. Connect BLACK grounding cable to

negative (-) terminal with remaining hex

bolt and keps nut. Tighten securely.

Terminal

-_. Hex

Bolt

(Red)

Cable Negative(Black)

Cable

TO REPLACE HEADLIGHT BULB

I. Raise hood.

2, Remove bulb holderfromthe hole inthe

backside of the grill,

J

3. Replace bulb in holder and install bulb

holder securely back into the hole in the

backside of the grill.

4. Close hood,

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poorly, stoprunning, or prevent

it from starting,

• Check wiring.

TO REPLACE FUSE

Replacewith20 amp automotive-typeplug-

in fuse. The fuse holder is located behind

the dash.

TO REMOVE HOOD & GRILL ASSEMBLY

1. Raise hood.

2. Unsnap headlight wire connector.

3. Remove retainer clip and washer from

right hand pivot pin.

4. Stand in front of tractor. Grasp hood at

sides and slide left removing hood from

pivot pins and lift hood off of tractor.

5. When replacing hood, reconnect the

headlight wire connector, and reinstall

the washer and retainer clip on the

right hand pivot pin,

LeftPivot Pin

___R! sher

Retainer

Clip

ght Pivot

Headlight Wire

Connector

__ Pin

ENGINE

TO ADJUST THROTTLE CONTROL

CABLE

The throttle control has been preset at

the factory and adjustment should not be

necessary Check adjustment as described

below before loosening cable. Ifadjustment

is necessary, see engine manual.

TO ADJUST CHOKE CONTROL

The choke control has been preset at