Craftsman 917250261 Owner’s Manual

rXMaN°

MODEL NUMBER 917.250261

• Assembly

° Operation

° Customer Responsibilities

° Service and Adjustments

=Repair Parts

OWNER'S MANUAL

Safe Operation Practices for Ride-On Mowers

SAFETY RULES &

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

I, GENERAL OPERATION

Read, understand, and follow all instructions in the manual

and on the machine before starting

- Only allow responsible adults, who are familiar with the

instructLons, to operate the machine

Clear the area of objects such as rocks, toys, wire, etc,

which could be picked up and thrown by the blade

Be sure the area isclear of other people before mowing Stop

machine if anyone enters the area

• Never carry passengers

• Do not mow in reverse unless absolutely necessary Always

look down and behind before and while backing

- Be aware of the mower discharge direction and do not point

it at anyone Do not operate the mower without either the

entire grass catcher or the guard in place

Slow down before turnir!g

• Never leave a rurrntng machirje un_ttende.d Always turn off

blades, set park.ing brake, s!op engLne,, and remove keys

before dismountin_

• Turn off blades when n6t mo;,,,4ng

Stop engine before removing grass catcher or unclogging

chute

• Mow only in daylight or good artificial lighL

• Do not operate the machine while under the influence of

alcoho_ or drugs_

Watch for traffic when operating near or crossing roadways

• Use extra care when loading or unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tipover

accidents, which can result in severe injury or death All slopes

require extra caution Ifyou cannot back up the slope or if you feel

uneasy on it, do not mow it

DO:

Mow up and down slopes, not across

• Remove obstacles such as rocks, tree limbs, etc

• Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine Tall grass can hide obstacles

• Use slow speed Choose a low gear so that you will not have

to stop or shift while on the slope

• Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability

• Use extra care with grass catchers or other attachments

These can change the stability of the machine..

Keep all mqvement on the slopes slowand gradual Do not

make sudden changes in speed or direction' "

• - ,_vo:_ stb,_ting c;rstap"p3llg-on ;aslop'e:, It tires lose trb.cti6h, " '.-

• ".._lane-- .'..- ....... . -- =- -.- ...... ...

boN6"r: - ." ' ' - : .... . -':

• Donot turn on slopes unless necessary, and then, turnslgwl_,:

and gradually downhill, if possible

• Do not mow.near drop-errs, ditches, or embankments The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in

• Do not mow on wet grass. Reduced traction could cause

sliding

• Do not tryto stabilize the machine by putting your foot on the

ground

• Do riot use grass catcher on steep slopes

III. CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children Children a_eoften attracted to the machine

and the mowing activity. Never assume that children will remain

where you last saw them

• Keep children out of the mowing area and under the watchful

care of another responsible adult

• Be alert and turn machine off if children enter the area

Before and when backing, look behind and down for small

children

• Never carry children They may fall off and be seriousEy

injured or interfere with safe machine operation

Never allow children to operate the machine

Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision

IV. SERVICE

• Use ektra care m handling g&s611nband other-fuels 1:hey are

flammable and vapors are explosive

Use only an approved container

Never remove gas cap or add fuel w=th the engine

running Allow engine to cool before refueling I3o not

smoke

Never refuel the machine indoors

Never store the machine or fuel container inside where

there is an open flame, such as a water heater

• Never run a machine inside a closed area

• Keep nuts and bolts, especially blade attachment bolts, tight

and keep equipment in good corrdition

Never tamper with safety devices Check their proper

operation regularly

• Keep machine free of grass, [eaves, or other debris build-up

Clean oil or fueI spillage Allow machine to cool before

storing

• Stop and inspect the equipment if you stdke an object

Repair, if necessary, before restarting

• Never make adjustments or repairs with the engine running

• Grass catcher components are subject to wear, damage, and

deterioration, which could expose moving parts or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended parts, when nec-

essary

• Mower blades are sharp and can cut Wrap the blade(s) or

wear gloves, and use extra caution when servicing them

Check brake operation frequentfy Adjust and service as

required

CAUTION: Always disconnect spark

plug wire and place wire where it cannot

contact spark plug in order to prevent

accidental starting when setting up,

transporting, adjusting or making

repairs.

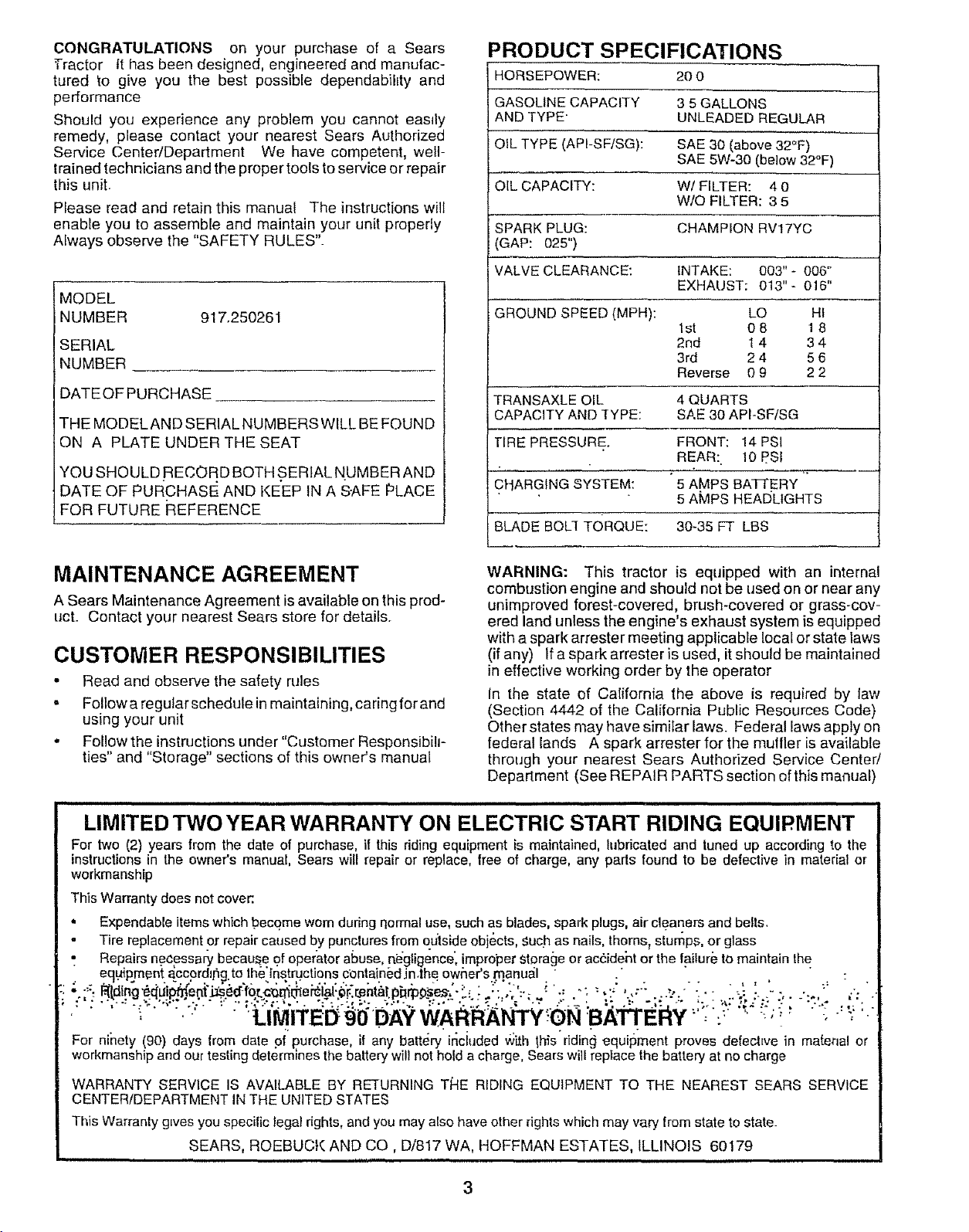

CONGRATULATIONS on your purchase of a Sears

Tractor It has been designed, engineered and manufac-

tured to give you the best possible dependability and

performance

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service Center/Department We have competent, well-

trained technicians and the proper tools to service or repair

this unit

Please read and retain this manual The instructionswili

enable you to assemble and maintain your unit properly

Always observe the "SAFETY RULES"

MODEL

NUMBER

SERIAL

NUMBER

DATEOF PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A PLATE UNDER THE SEAT

YOU SHOULD RECORD BOTH .SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE

917.250261

PRODUCT SPECIFICATIONS

HORSEPOWER: 20 0

GASOLINE CAPACITY 3 5 GALLONS

AND TYPE" UNLEADED REGULAR

OIL TYPE (API-SF/SG): SAE 30 (above 32°F)

SAE 5W-30 (below 32°F)

OIL CAPACITY: W/FILTER: 4 0

W/O FILTER: 3 5

SPARK PLUG: CHAMPION RV17YC

(GAP: 025")

VALVE CLEARANCE: INTAKE: 003" - 006"

EXHALIST: 013"- 016"

GROUND SPEED (MPH): LO HI

TRANSAXLE OIL 4 QUARTS

CAPACITY AND TYPE: SAE 30 API-SF/SG

TIRE PRESSURE.

CI'-IARGINGSYSTEM:

BLADE BOL[ TORQUE:

1st 08 1 8

2nd 1 4 3 4

3rd 2 4 56

Reverse 0 9 2 2

FRONT: 14 PSI

REAR: 10 PSI

5 AMPS BA-!-FERY

5 AMPS HEADLIGHTS

30-35 FT LBS

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement isavailable on this prod-

uct Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules

- Follow a regular schedule in maintaining, caring for and

using your unit

• Follow the instructions under "Customer Responsibih-

ties" and "Storage" sections of this owner's manual

ii

WARNING: This tractor is equipped with an interne!

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov-

ered land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any) If a spark arrester is used, it should be maintained

in effective working order by the operator

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code)

Other states may have similar laws. Federal laws apply on

federal lands A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS section of this manual)

LIMITED TWOYEAR WARRANTY ON ELECTRIC START RIDING EQUIPMENT

For two (2) years from the date of purchase, if this ridingequipment is maintained, lubdcated and tuned up according to the

instructions in the owner's manual, Sears will repair or replace, free of charge, any parts found to be defective in material or

workmanship

This Warranty does not cover:.

', Expendable itemswhich becomeworn duringqormaluse,such as blades,spark plugs,air cleaners and belts.

- Tire replacement.oJ"repair caused by puncturesfrom outside objects, Suc.has nails,thorns_stumps, or glass

- RepairsneCessarybecause of operB_torabuse, r_egligence_impro_per_4orageor aceidentor the failure to maintain the

• ecj.uipm_n{_ccordl_g to the'instructions cbntainedin.the owner's manual " :

• ". l_[din'ge_Li,'l:_ent_sedfor.c_l_e_lai'_r..r.entatpl:Irp_seS',--_ ._'. ,; :.- i .: . .,:. ,,: .,;.• _. .: • 1... " ,'-

"' ......- ' " :;:;;--,IT ' ' -: " ": "; : "

For ninety (90) days from date of purchase, if any battery inciudedv_i.th_h4sridin(}equipment proves defective in matet_alor

workmanship and our testing determlnesthe batterywill not hoida charge, Searswill reptacethebattery at no charge

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE RIDING EQUIPMENT TO THE NEAREST SEARS SERVICE

CENTERfDEPARTMENT iN THE UNITED STATES

This Warranty givesyouspecific legal rights,and you may aJsohave other rightswhich mayvary from state tostate

SEARS, ROEBUCK AND CO, 1:)/817WA, HOFFMAN ESTATES, ILLINOIS 60179

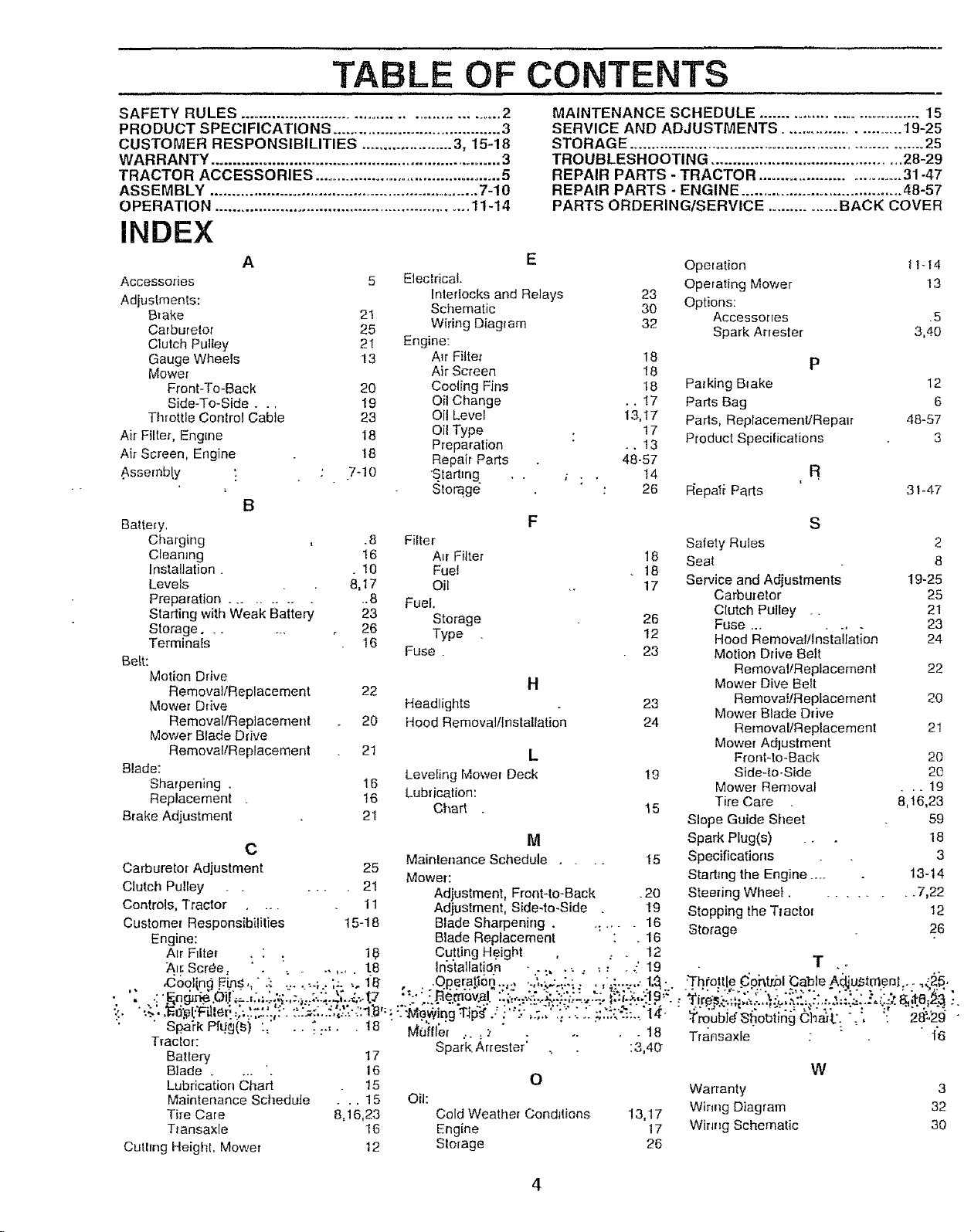

TABLE OF CON!TENTS

SAFETY RULES ....................................................... 2

PRODUCT SPECIFICATIONS ....................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3, 15-18

WARRANTY ................................................................... 3

TRACTOR ACCESSORIES ............................................ 5

ASSEMBLY ............................................................... 7-10

OPERATION .......................................................... 11-14

MAINTENANCE SCHEDULE .................................. 15

SERVICE AND ADJUSTMENTS ......................... 19-25

STORAGE ................................................................... 25

TROUBLESHOOTING ........................................... 28-29

REPAIR PARTS - TRACTOR ............................... 31-47

REPAIR PARTS - ENGINE ..................................... 48-57

PARTS ORDERING/SERVICE ............... BACK COVER

INDEX

A

Accessories

Adjustments:

Blake

Carburelor

Clutch Pulfey

Gauge Wheels

Mower

Front-To-Back

Side-To-Side...

Throttle Control Cable

Air Filter, Engine

Air Screen, Engine

Assembly

7-10 S.tartlng . . ; . . 14

Electrical.

5

Interlocks and Relays 23

21 Schematic 30

25 Wiring Diagram 32

2t Engine:

13 A_rFilter 18

20 Cooling Fins 18

19 Oil Change .. 17

23 Oil Level 13,17

18 Oil Type . 17

! 8 Repair Parts 48-57

Air Screen 18

Preparation .. 13

Stor'a•ge : 26

B

Battery.

Charging

Cleaning

Installation.

Levels

Preparation .........

Starting with Weak Battery

Storage ......

Terminals

Beit:

Motion Drive

Removal/Replacement

Mower Drive

Removal/Replacement

Mower Blade Drive

RemovallReplacement

Blade:

Sharpening ,

Replacement

Brake Adjustment

•8 Filter

16 A_rFilter

• 10 Fuel

8,17 Oil

..8 Fuel.

23 Storage

26 Type

16

Fuse .

22 H

Headlights

20 Hood Removal/tnslalfation

21 L

16 Leveling r,4owerDeck

16 Lubrication:

21

Chart .

C M

Carburetor Adjustment 25

Clutch Pulley ...... 21 Adjustment, Front-to-Back .20

Controls, Tractor ... 11 Adjustment, Side-to-Side 19

Customel Responsibilities 15-18 Blade Sharpening ....... 16

Engine: Blade Replacement " . 16

Air Filter . : . 11_ Cutting Height , ;

_.r. Scree ' " .,. 18 n's'lallatdn - ..,., . : ..-' 19 - _ -° .

•-C6ol(n_) F.[ns, " .:: _..... _.. ;;. ,', 18 , . .qperat,i6n_..,., ..;',,_,.,::,_:" . ,_:.....,': 1,9,-. "T.hfottle do_trbl _3at_le.A_uS_trienI..o _25,

• . ,_ gJ . • . "7,....... ." "'_:: ""." ".° " . .- ...... • -." "1" .-'.-'. :"_':"_' -"_" " .'- --. " " -- _-.:,..,,b,,'_-.=;-.,_...... ;,-..:.-.:--=--- :." - "_. i =_ :.

-!. :.-..,_o,.g!"F_er:-,;.. ,,.;.:,:.... _ ........... 1_ .:-. "Mg,.W[}.gTipS".-... ,.;., .; ..... .:.;....,'.::.,14- -'Trouble"Shobting Cha;'.t'. : ", ': 28:,29 "

_LLLLLLLL.Iparkl--'I_.g(_).... :: .... lid Muffet ... ::, ..... 18 Tra_sax[e : : . " 1"6

Tractor: Spark Attester' :3,40

Battery 17

Blade . 16

Lubrication (Dhad 15

Maintenance Schedule . .. 15

Tire Care 8,16,23

Transaxle 16

Culling HeighL Mower 12

Maintenance Schedule .... 15

Mower:

Oil:

Cold Weather Conditions 13,17 Winng Diagram 32

Engine t 7 Winng Schematic 30

Storage 26

E

Operation t t- t 4

Operating Mower t 3

Options:

Accessories .5

Spark Attester 3,40

Pinking Brake 12

Parts Bag 6

Parts, Replacement!Repair 48-57

Product Specifications 3

,R

Flepat_ Parts 3t-47

F

Safety Rules 2

18 Seat 8

18

17 Service and Adjustments 19-25

26 Fuse ... 23

12 Hood Removal/Instaiiation 24

23 Motion Drive Belt

23 Remova!/Replacement 20

24 Removal/Replacement 21

19 Side-to-Side 20

15 Tire Care 8,16,23

12

O W

Carburetor 25

Clutch Pulley .. 21

Remova]lReplacemenl 22

Mower Dive Bell

Mower Blade Drive

Mower Adlustment

Front-to-Back 20

Mower Removal . .. 19

Slope Guide Sheet 59

Spark Plug(s) .. 18

Specifications 3

Stadmg the Engine .... 13-14

Steering Wheel ......... 7,22

Stepping the Tlactor 12

Storage 26

Warranty 3

P

S

4

ACCESSORIES ATTACHMENTS

These accessories and attachments were available through most Sears retail outlets and service centers when the tractor was purchased

Most Sears stores can order these _tems for you when you provide the model number of your tractor

ENGINE MAINTENANCE

SPARK PLUG GAS CAN ENGINE OIL FUEL STABILIZE

BLADES BELTS

,2

J;

PERFORMANCE

Sears offers a wide variety of attachments that tit your tractor Many of these are listed below with brief explanations of how they can help

you This list was current at the ttme o! puhticat_on; however, it may change in fulure years - more attachments may be added, changes

may be made in these attachments, or some may no longer be availabre or fit your model Contact your nearest Sears store for the

accessories and attachments that are available for your tractor.

Most of these attachments do not require addilional hitches or conversion kits (those that do are indicated) and are designed for easy

attaching and detaching

AERATOR promotes deep reel growth for a healthy lawn Ta-

pered 2 5-inch steel spikes mounted on 10-inch diameter d_scs

punctuCe,holes in soil at close intervals to let moisture soak in

Steel weight tray lor increased, pen'etration

BUMPER protects front end of tractor from damage

CARTS make hauling easy Variety of sizes available, plus

accessories such as side panel kits, tool caddy, cad cover,

protective mat and dolly

CORING AERATOR takes small plugs out of soil to allow mois-

ture and nutrients to reach grass roots 36-inch swath 24

hardened steel coring tips 150 lb capacity weight tray

DISC HARROW has 2 gangs of 4 steel blades that angle from 10

to 20 degrees, 40 inches wide Can riook 2 units in tandem

(Requires sleeve hitch )

DOZER BLADE removes snow; grades dirt, sand and gravel. 48

inches wide, 17 inches high, clears 44-inch path when angled

Master lilt control lever for operator ease Spring trip for snow

removal on uneven pavement; built-in float for blade to follow

ground contour Reversible, replaceable scraper bar (Use with

hre chains and wheel weights and/or rear drawbar weight )

EASY OIL DRAIN VALVE makes oil changes easier, faster

FRONT NOSE ROLLER canters infront of mower deck to reduce

chances of "scalping" on uneven terrain

GANG HITCH lets you tow 2 or 3 pull-behind altachments at

once, such as sweepers, dethatchers, aerators (not for use with

rollers, carts or other heavy attachments)

MULCH RAKF_JDETHATCHER loosens soil and tlips thatch and

matted leaves to lawn sudace for easy pickup Twenty spring fine

teeth Useful to prepare bare areas for seeding. Avatlable for front

or rear mounting. HIGH PERFORMANCE REEL-ACTION

SPRING TINE DETHATCHER covers 36-inch wide path and

tosses thatch into large hopper Mounts behind tractor

PLOW lurns soil 6 inches deep, cuts 10-inch lurrow Crank

adjustment conlrols depth, 3-position yoke sets width Fleav.y " TRACTOR CAB has heavy duty vinyl fabric over tubqlar steef

steel lanBside for straight fuirowlng (Requires s'leeve hitch )_ " frame, ABS plastic.top; Clear plastic windshield.off_r_ 360 degfe_:

SLEEVE CULTIVATOR is 43 inches wLde Prepares ground !or

seeding, helps weed control Steel frame holds 5 adjuslable

sweeps Adlusls vedically, horizontally..(Requires sleeve hitch )

"Optional accessory: .steel furrow opener for wider op.enings fo.r

potatoes, cotn, _(nd other d_epseeded crops

SL'EEVE HITCH for use with master lift system Single pin

couples/uncouples

SNOWTHROWER has 42-inch swath Drum-type auger handles

powdery and web'heavy snow Mounts easily with simple pin

arrangement Discharge chute adjusts from tractor seat 6-inch

diameter spout discharges snow 10 to 50 feet Lilt controlled at

tractor seat. (Use with chains and wheel weights and/or rear

drawbar weight )

SPRAYERS use 12-volt DC electric motor that connects to the

tractor battery or other 12-volt source Includes booms for

automatic spraying and hand held wand for spot spraying Wand

has adjustable spray pattern For applying herbicides, insecti-

cides, fungicides and liquid fertilizers

SPREADER/SEEDERS make seeding, fertilizing, and weed kill-

,nOeasy. Broadcast spreaders are also useful for granular de-

icers and sand

SWEEPERS let you collect grass clippings and leaves

TILLER has 8 hp engine to prepare seed beds, cultivate, and

compost garden residue. Chain-drive transmission. Six 11-inch

diameter one piece heat-treated steel tines Tills 30-inch path

(Requires sleeve hitch.) Or use 5 hptow-behind TILLER with 36-

inch swath to prepare seed beds, cultivate and compost garden

residue. Tiller has its own built-in lift and depth control system and

does NOT require a sleeve h_tch Fits any lawn, yard or garden

tractor Simply hook up to the tractor drawbar and go[ Optional

accessories for 5 hp tiller convert unit for dethatching, aerating,

hilling, without tools

TIRE CHAINS are heavy duty; closely spaced extra-large cross

links give smooth ride, outstanding traction

• ,-,_,,ii_ ;..,;.--,_.... ,;._,.-. __-. ;-: .o _-:..... , prote&lor _n-summer, .Opt_al ac!_es_ories nclt._de. -t_nt

nr-..._T'..,,,,_l"l/-,kU_l"l IclLALIt: tS 'q.2: mcnes .wtoe are op.eraieo lrom - r_,-z_n_r r4--k/_l_[a{'_ t_il=ee _,_r_4ehi_l',4 _'i_tthh=nH'"...... " " " " " " " 'h¢_l_ " " : " ; ;

d'rivei-;sseat" Ri_versibl.e "re .elblade can be angled at 30 Begrees _1_2'_''v_o_ea_mS;eircau_;nUl:g_io"r'moun;_'_';;;; ;_o_; rated

for grading Rev.erses for push_ng snow backwards (Requires

sleeve hitch )

ROLLER for smoother l_wn sudace. 36-inch wide, 18-inch

diameter water-t_ght drum holds up to 3901bs of weight Rounded

edges prevent harm to tuff Adlustable scraper automatically

cleans drum

VACS Ibr powerful collection of heavy grass clippings and leaves:

Optional wand attachment to pick tJp debris in hard-to-reach

places VAC/CHIPPER includes a chipper-shredder

WEIGHT BRACKET for drawbar for snow removal applicaf_ons

Can be mounted on trent of tractor for ptowing apphcations Uses

(1) 55 Ib weight

WHEEL WEIGHTS for rear wheels prowde needed traction for

snow removal or dozing heavy materials

wiper,

5

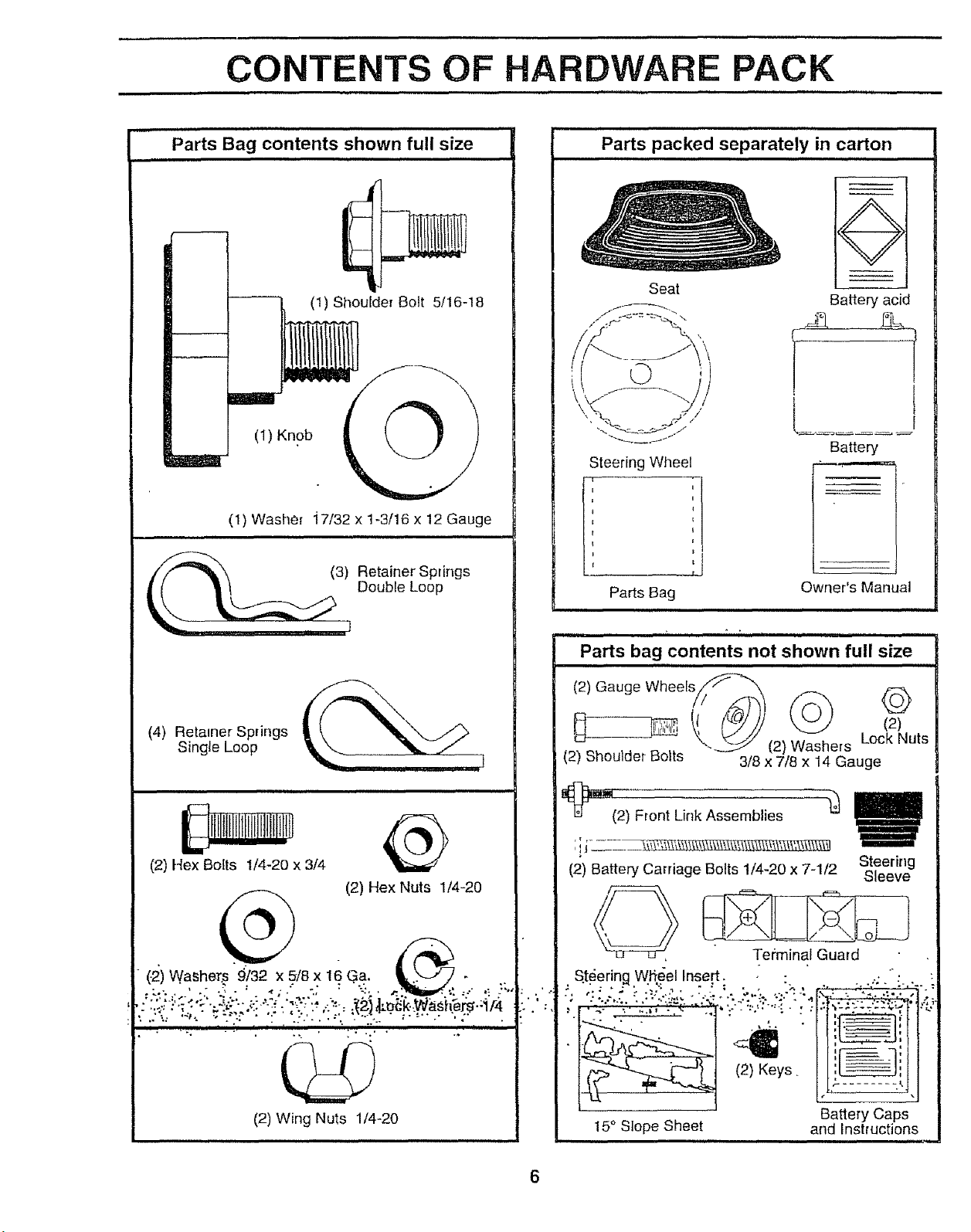

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

,,,,,,,,,, i, u [,

ii, ill,lllli,

Parts packed separately in carton

0

(1) Shoulder Bolt 5t16-18

u_

(1) Knob

(1) Washer "i7/32 x 1-3116 x 12 Gauge

Double Loop

(_ 3) Retainer Springs

(4) Retainer Springs

Single Loop

Seat

Steering Wheel

\

\

Battery acid

Battery

r

J

Parts Bag Owner's Manual

i i ii

Parts bag contents not shown full size

(2) Gauge Wheelsi!j// _

--._J (2) Washers Lock Nits

(2) Shoulder Bolts 3/8 x 7/8 x 14 Gauge

I

©

(2) Hex Bolts 1/4-20 x 3/4

(2) Hex Nuts 114-20

(-;_)Washe_.s"_/32 x 5/8 x 16 Ga.

"= i _ t i r ; ,11

(2) Wing Nuts 114-20

_(2) Front Link Assemblies

,r ,_----

(2) Battery Carriage Bolts 1/4-20 x 7-1/2 Steering

Te#minal Guard

St._erin_lW_.eel Insert. , : " . ,: .": . :

• Q

.. ,... ; .:; .... .._,._ - +.: ...._..:_.,['-.__,.._ -..,_-,..

Battery Caps

15° Slope Sheet and Instructions

Sleeve

i I

--- i

ASSEMBLY

iiiiii J, i iiiiiiii iiiiiiiiiiii , i i I,IIIIIIl,lI,JUJIJl,ll,lll,I

Your new tractor has been assembled at thefactory with the exception of those parts left unassembted for shipping purposes,.

To ensure safe and proper operation of your tractor all parts and hardware you assemble must be tightened securely Use

the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set wilt make assembly easier. Standard

wrench sizes are listed.

(2) 7/16" wrenches Tire pressure gauge

(I) 1/2" wrench Utility knife

(1) 9/16" wrench

(t) 3/4" socket with drive ratchet

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel),

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON,

• ,R(_move ali acces.sible Io0se parts and parts car;tons

from .carton(See #age 6),," "

- Cut, fron:l top io bottor_, al6ng lines on _II four corners

of carton, and lay panels flat.

• Remove mower and packing materials

• Check for any additional loose parts or cartons and

remove,,

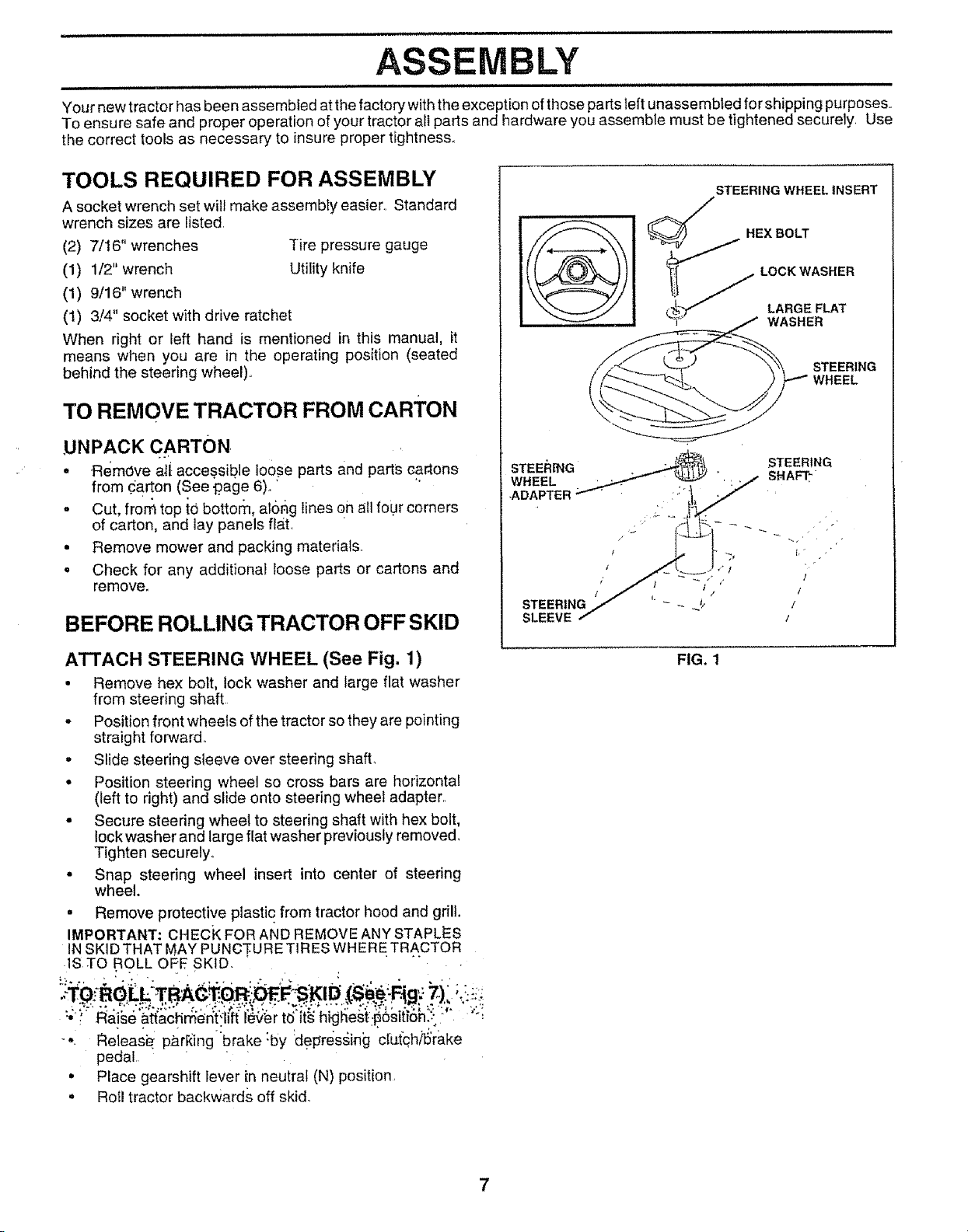

BEFORE ROLLING TRACTOR OFF SKID

STEERING WHEEL INSERT

i __ _ HEX BOLT

' STEERING - _I STEERING

STEERINGY ,I - - t_ /

SLEEVE / /

/ l I/' f

ATTACH STEERING WHEEL (See Fig. 1)

• Remove hex bolt, lock washer and large flat washer

from steering shaft

- Position front wheels of the tractor so they are pointing

straight forward,

• Slide steering sleeve over steering shaft.

• Position steering wheel so cross bars are horizontal

(left to right) and slide onto steering wheel adapter,;

• Secure steering wheel to steering shaft with hex bolt,

lock washer and large flat washer previously removed.

Tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective plastic from tractor hood and grill•

IMPORTANT: CHECI< FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCT.URE TIRES WHERETRACTOR

1S.TO ROLL OFF. SKID.

-" Releas_ p_.r_ing brake :by delsres_ing c[u_tchi15rake

pedal

• Place gearshift lever _nneutral (N) position

° Rotl tractor backwards off skid.

FIG. 1

7

ASSEMBLY

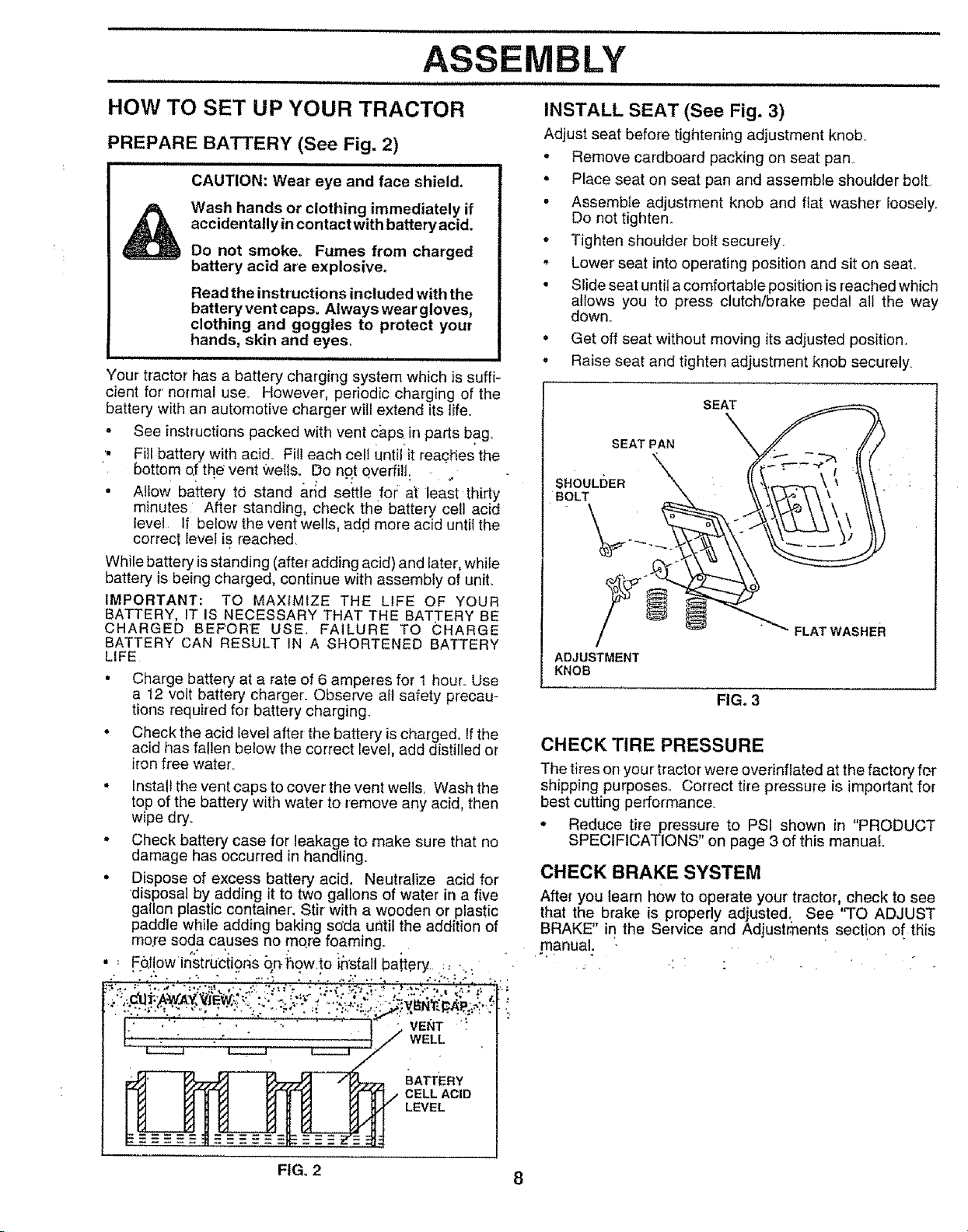

HOW TO SET UP YOUR TRACTOR

PREPARE BATTERY (See Fig. 2)

,NN,mm,ll II

CAUTION: Wear eye and face shield.

Wash hands or clothing immediately if

acc identally in contact with battery acid.

Do not smoke. Fumes from charged

battery acid are explosive.

Read the instructions included with the

battery vent caps° Always wear gloves,

clothing and goggles to protect your

hands, skin and eyes•

,i,1,1,,ill i mira ii

Your tractor' has a battery charging system which is suffi-

cient for' no{real use. However, periodic charging of the

battery with an automotive charger' will extend its life.

• See instructions packed with vent caps. in parts bag,

'- Fill battery with acid. Fill each celt until it reaches the

Bottom o.fthe vent Wells. Do not overfill,

- Allow battery to stand a,nd settle for; at least thirty

minutes After standing, check the battery cell acid

level If below the vent wells, add more acid until the

correct Ievel is reached.

While battery is standing (after adding acid) and later, while

battery is being charged, continue with assembly of unit.

IMPORTANT: TO MAXIMIZE THE LIFE OF YOUR

BATTERY, IT IS NECESSARY THAT THE BATTERY BE

CHARGED BEFORE USE. FA1LURE TO CHARGE

BATTERY CAN RESULT IN A SHORTENED BATTERY

LIFE

• Charge battery at a rate of 6 amperes for 1 hour.• Use

a 12 volt battery charger. Observe all safety precau-

tions required for battery charging.

• Check the acid level after the battery is charged. Ifthe

acid has fallen below the correct level, add distilled or

iron free water_.

• Install the vent caps to cover the vent wells. Wash the

top of the battery with water to remove any acid, then

wipe dry.

• Check battery case for leakage to make sure that no

damage has occurred in handling.

• Dispose of excess battery acid. Neutralize acid for

disposal by adding it to two gallons of water in a five

gallon plastic container, Stir with a wooden or plastic

paddle while adding baking soda until the addition of

rno.re soda causes no more foaming.

• Fb.llow in'structior_s 6r_how to _'sfall ba'.ttery. : : ..:

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob_

° Remove cardboard packing on seat pan..

° Place seat on seat pan and assemble shoulder boll

o Assemble adjustment knob and flat washer loosely.

Do not tighten.

" Tighten shoulder bolt securely.

', Lower' seat into operating position and sit on seat°

• Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

° Get off seat without moving its adjusted position

• Raise seat and tighten adjustment knob securely.

SEAT

ADJUSTMENT

KNOB

FIG. 3

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes,, Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in "PRODUCT

SPECIFICATIONS" on page 3 of this manual,,

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See "TO ADJUST

BRAKE" in the Service and Adjustments section o! this

manual.

• • BATTERY

-]_ _ _ r__/CELL ACID

FIG. 2 8

i,ii ill,,llll i iiiii , __

ASSEMBLY

iii i i Ill IIIIII

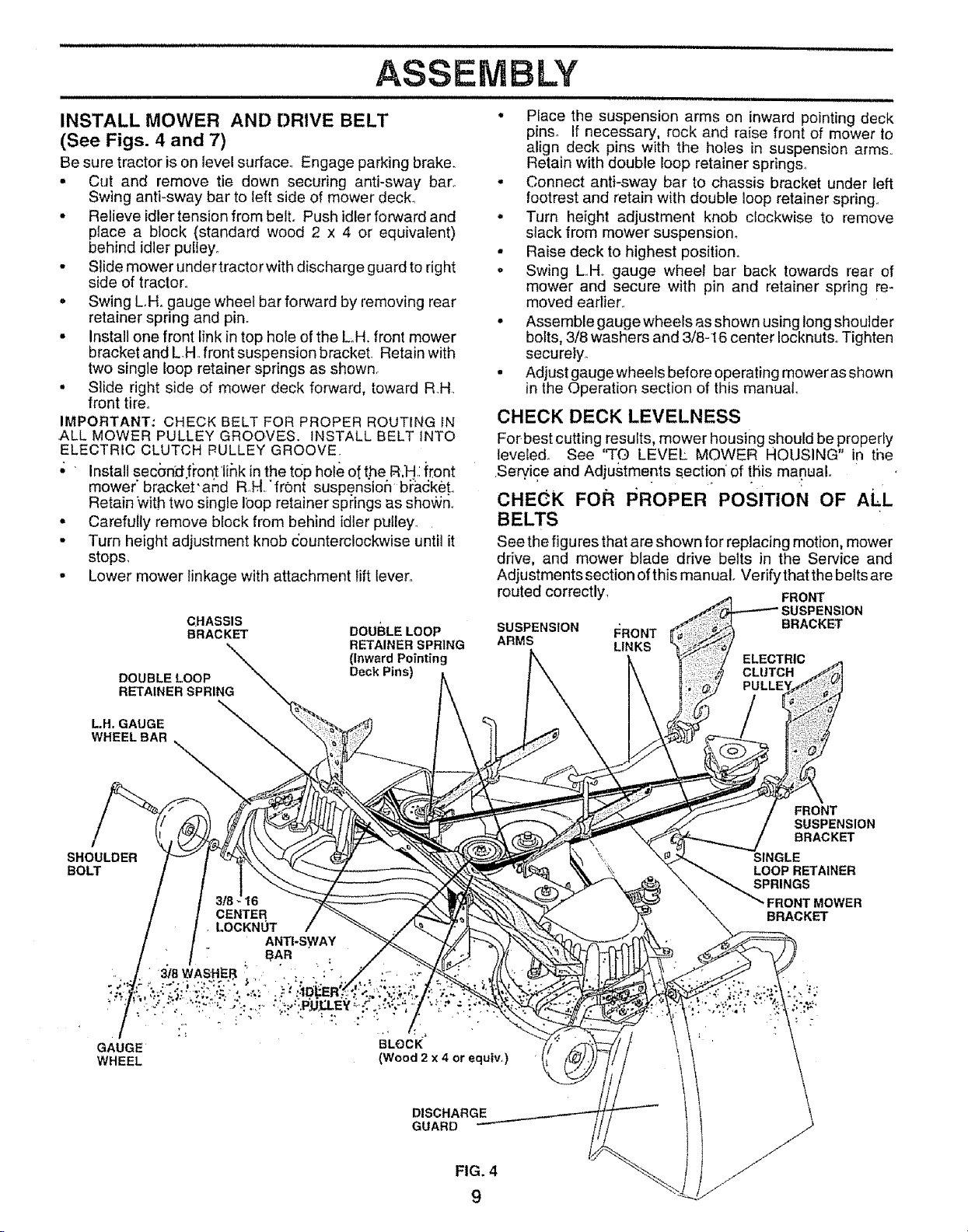

INSTALL MOWER AND DRIVE BELT • Place the suspension arms on inward pointing deck

(See Figs. 4 and 7') pins° If necessary, rock and raise front of mower to

Be sure tractor is on level surface_ Engage parking brake. Retain with double loop retainer springs,,

• Cut and remove tie down securing anti-sway bar. ° Connect anti-sway bar to chassis bracket under left

Swing anti-sway bar to left side of mower deck footrest and retain with double loop retainer spring.,

• Relieve idlertension from belt. Push idler forward and • Turn height adjustment knob clockwise to remove

place a block (standard wood 2 x 4 or equivalent) slack from mower suspension_

behind idler pulley,, • Raise deck to highest position°

• Slide mower undertractorwith discharge guard to right o Swing LH,, gauge wheel bar back towards rear of

side of tractor,, mower and secure with pin and retainer spring re-

. Swing L.H. gauge wheel bar forward by removing rear moved earlier,,

retainer spring and pin. • Assemble gauge wheels as shown using long shoulder

• Install one front link intop hole of the LH. front mower bolts, 3/8 washers and 3/8-16 center Iocknutso Tighten

bracket and LH• front suspension bracket, Retain with secure3y,

two single loop retainer springs as shown. • Adjust gauge wheels before operating moweras shown

• Slide right side of mower deck forward, toward R.H, in the Operation section of this manual,

front tire,,

IMPORTANT: CHECK BELT FOR PROPER ROUTING IN

ALL MOWER PULLEY GROOVES. INSTALL BELTINTO

ELECTRIC CLUTCH PULLEY GROOVE

-" " Install second'fi'ont link inthe top hole of.the R_,Hr: f_ont

mower" bracket'and RN.'frOnt suspenson bi'ackeL

Retain With two single loop retainer springs as shown,

• Carefully remove block from behind idler pulley,

• Turn height adjustment knob counterclockwise until it

stops,

• Lower mower linkage with attachment lift tever,

CHASSIS

BRACKET DOUI_LE LOOP

DOUBLE LOOP

RETAINER SPRING

RETAINER SPRING

(Inward Pointing

Deck Pins)

align deck pins with the holes in suspension arms,,

CHECK DECK LEVELNESS

Forbest cutting results, mower housing should beproperfy

leveled, See 'q'O LEVEl' MOWER HOUSING" in the

Service and Adju.stments section' of this manual.

CHECK FoR PROPER POSITION OF ALL

See the figures that are shown for replacing motion, mower

drive, and mower blade drive belts in the Sewice and

Adjustments section of this manualo Verifythat the betts are

routed correctly, FRONT

SUSPENSION

SUSPENSION F_RONT BRACKET

ARMS LINKS

ELECTRIC

CLUTCH

WHEEL BAR

L.H. GAUGE

/

SHOULDER

BOLT

GAUGE

WHEEL

CENTER

t.OCKNUT

FRONT

SUSPENSION

BRACKET

SINGLE

LOOP RETAINER

SPRINGS

FRONT MOWER

BRACKET

ANTI-SWAY

BAR

BLOCK"

(Wood 2 x 4 or equiv,)

DISCHARGE

GUARD

FIG. 4

9

Loading...

Loading...