Page 1

Operator's Manual

I

cRn n#°

II III

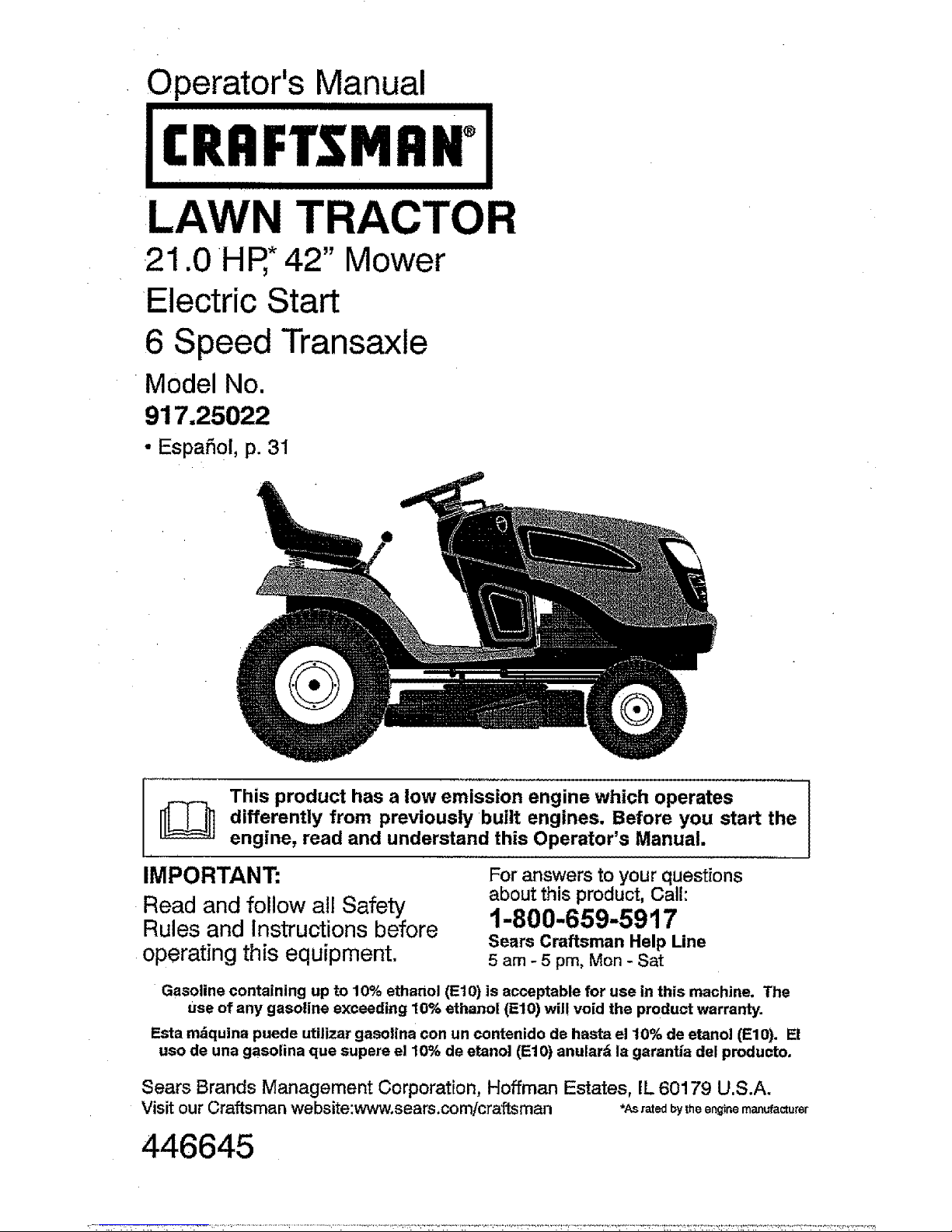

LAWN TRACTOR

21.0 HR*42" Mower

Electric Start

6 Speed Transaxle

Model No.

917.25022

• EspaSol, p. 31

_ This product has a low emission engine which operates

differently from previously built engines, Before you start the

engine, read and understand this Operator's Manual.

IMPORTANT: For answersto yourquestions

Read and follow all Safety about this product, Call:

Rules and Instructions before 1-800-659-5917

Sears Craftsman Help Line

operating this equipment. 5 am - 5 pm, Mon - Sat

Gasoline containing up to 10% ethanol (El0) is acceptable for use in this machine. The

use of any gasoline exceeding 10% ethanol (El0) wil! void the product warranty.

Esta m&quina puede utilizar gasolina con un contenido de haste el 10% de etanol (El0). El

uso de una gasolina qua supere el 10% de etanol (El0) anular6 la garantie del producto,

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website:www.sears.com/craftsman *As rated bytheenginemanufacturer

446645

Page 2

Warranty .................................................. 2

Safety Rules ............................................ 3

Product Specifications ............................. 6

Assembly/Pre-Operation ......................... 7

Operation ................................................. 9

Maintenance .......................................... 15

Maintenance Schedule .......................... t5

Service and Adjustments ....................... 19

Storage .................................................. 25

Troubleshooting ..................................... 26

Sears Service .......................... Back Cover

Craftsman Riding Equipment Warranty

CRAFTSMAN FULL WARRANTY

FOR TWO YEARS from the date of purchase, all non-expendable parts Ofthis ridingequipment are

warranted against any defects in material or workmanship. A defective non-expendable part will

receive free in-home repair or replacement if repair is impossible.

FOR FIVE YEARS from the date of purchase, the frame and front axle of this riding equipment are

warranted against any defects in material or workmanship. A defective frame or front axle will receive

free in-home repair or replacement if repair is impossible.

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of this riding equipment

is warranted against any defects in material or workmanship (our testing proves that it will not hold a

charge). A defective battery will receive free in-home replacement.

ADDITIONAL LIFETIME LIMITED WARRANTY on CAST IRON FRONT AXLE (if equipped)

FOR AS LONG AS IT IS USED by the original owner after the fifth year from the date of purchase, the

cast iron front axle (ifequipped) ofthis riding equipment iswarranted against any defects in mateda] or

workmanship. With proofof purchase, a defective cast front axle will receive free in-home replacement.

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, call 1-800-659-5917 or visit the

web site: www.craftsman.com

In alI cases above, if part repair or replacement is impossible, the riding equipment wilt be replaced

free of charge with the same or an equivalent model.

All of the above warranty coverage is void if this riding equipment is ever used while providing

commercial services or if rented to another person.

This warrantycovers ONLYdefects in material andworkmanship.Warranty coverage does NOTinclude:

• Expendable parts (except battery) that can wear out from normal use within the warranty period,

including but not limited to blades, spark plugs, air cleaners, belts, and oil filters.

- Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns,

stumps, or glass.

• Tire or wheel replacement or repair resultingfrom normal wear, accident, or improper operation or

maintenance.

° Repairs necessary because of operator abuse, including but not limited to damage caused by

towing objects beyond the capability of the riding equipment, impacting objects that bend the

frame, axle assembly or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and

mechanical damage caused by improper storage, failure to use the proper grade and amount

of engine oil, failure to keep the deck clear of flammable debris, or failure to maintain the riding

equipment according to the instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to becontaminated oroxidized

(stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

Page 3

_DANGER: This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death.

_WARNING: Inorder to prevent acciden-

tal starting when setting up, transporting,

adjustingor making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_kWARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

_[_WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Tooheavy of a load,while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor,

_WARNING: Engine exhaust, some of

its constituents, and certain vehicle compo-

nents contain or emit chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm,

,_WARNING: Battery posts,terminals and

related accessories contain lead and lead

compounds, chemicals known tothe Stateof

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling.

I. GENERAL OPERATION

• Read, understand,and followall instruc-

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine. Keep clear

ofthe discharge opening at all times.

° Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

° Clear the area ofobjects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

° Be sure the area is clear of bystanders

beforeoperating. Stopmachine ifanyone

enters the area,

• Never carry passengers.

• Do not mow in reverse unless absolutely

necessary, Always Iookdown andbehind

before and while backing.

• Never direct discharged materialtoward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

• Do not operate machine without the en-

tire grass catcher, discharge chute, or

othersafety devices in placeand working.

• Slow down before turning.

• Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

• Disengage blades when not mowing.

Shut off engine and wait for all parts to

cometo a complete stop before cleaning

the machine, removing the grass catcher,

or unclogging the discharge chute.

° Operate machine only indaylight or good

artificial light.

• Do not operate the machine while under

the influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Useextra carewhen loading orunloading

the machine into atrailer or truck.

• Always wear eye protectionwhen operat-

ing machine.

• Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

othersfrom serious injury.

° Followthe manufacturer's recommenda-

tion forwheelweights orcounterweights.

• Keep machine free of grass, leaves or

other debris build-up which cantouch hot

exhaust / engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc-

cur. Clean any oil or fuel spillage before

operating or storing the machine. Allow

machine to cool before storage.

8

Page 4

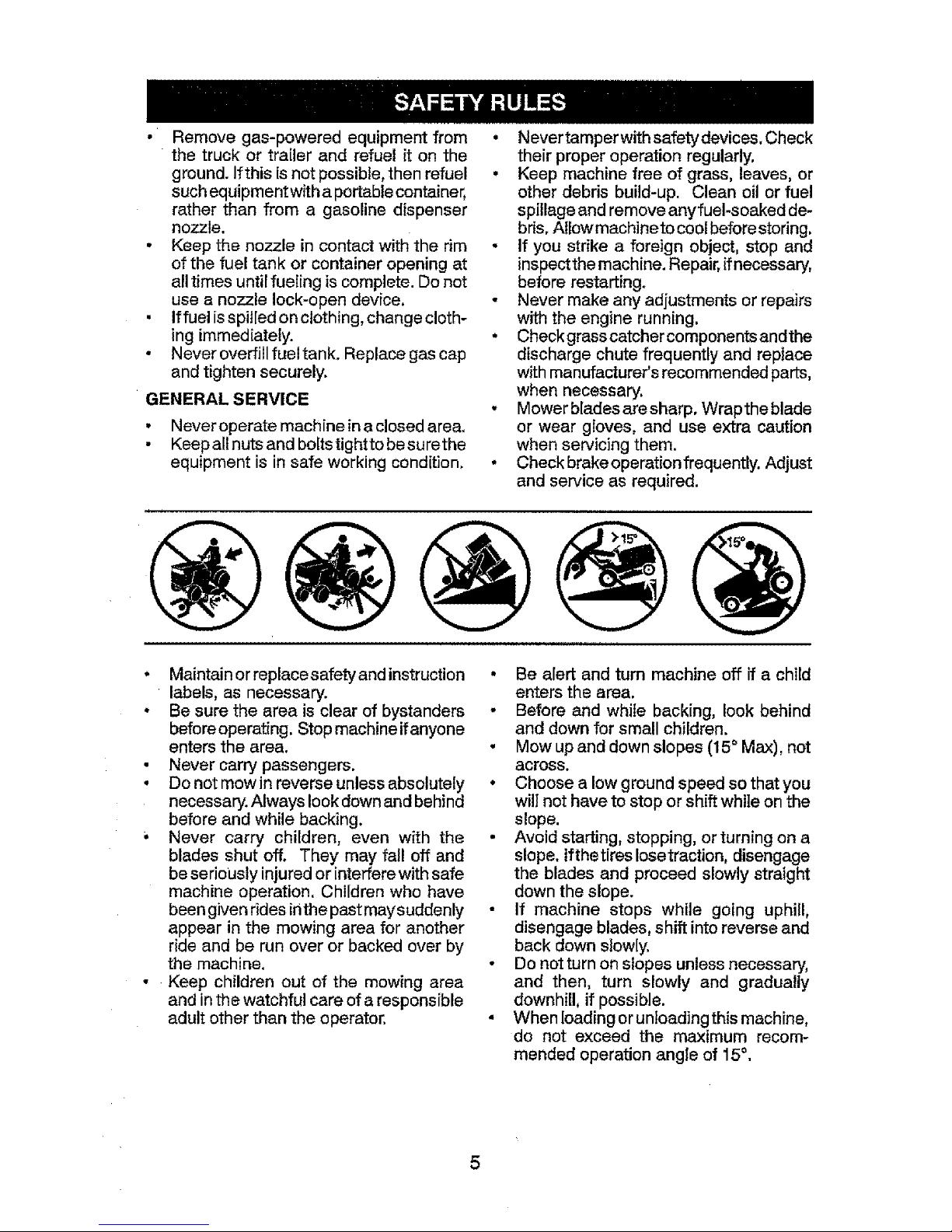

II, SLOPE OPERATION

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation

on all slopes requires extra caution. If you

cannot back upthe slopeor ifyoufeel uneasy

on it, do not mow it.

• Mow up and down slopes, not across,

• Watch for holes, ruts, bumps, rocks, or

other hidden objects, Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

Choose a low ground speed sothat you

will not have to stop or shift while on the

slope.

• Do notmow onwet grass.Tires may lose

traction.

Always keep the machine in gear when

goingdown slopes. Donotshiftto neutral

and coast downhill,

• Avoid starting, stopping, or turning on a

slope, lfthetireslosetraction, disengage

the blades and proceed slowly straight

down the slope,

• Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

• Use extra care while operating machine

with grass catchers orother attachments;

they can affect the stability of the ma-

chine, Do no use on steep slopes.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or ifthe edge caves in.

!11.CHILDREN

_WARNING: CHILDREN CAN BE INJURED

BY THIS EQUIPMENT. The American Acade-

my of Pediatrics recommends that children

be a minimum of 12 year of age before op-

erating a pedestrian controlled lawn mower

and a minimum of 16 years of age before

operating a riding lawn mower.

Tragic accidents can occur ifthe operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

4

- Keep children out of the mowing area

and in the watchful care ofa responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carrychildren,even withthe blades

shutoff. They mayfaUoffand beseriously

injured or interfere with safe machine

operation. Children who have beengiven

rides inthe past may suddenly appear in

the mowing area for another ride and be

run overor backed over by themachine.

• Never allow children to operate the ma-

chine,

• Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child,

IV. TOWING

• Tow only with amachine that has ahitch

designed for towing. Do notattach towed

equipment except at the hitch point.

• Followthe manufacturer's recommenda-

tion forweight limits for towed equipment

and towing on slopes.

• Never allow children or others in or on

towed equipment.

• On slopes, theweight ofthe towedequip-

ment may cause loss oftraction and loss

of control.

• Travel slowly and allowextra distance to

stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injuryor property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive,

• Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

• Use only approved gasoline container.

• Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

. Never fuel the machine indoors.

• Neverstorethe machine orfue]container

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

• Never fill containers inside a vehicle or

on atruck ortrailer bed with plastic liner.

Always place containers on the ground

away from your vehicle when filling.

Page 5

• Removegas-poweredequipmentfrom

thetruckortrailerandrefuelitonthe

ground.Ifthis[snotpossible,thenrefuel

suchequipmentwithaportablecontainer,

ratherthanfromagasolinedispenser

nozzle.

• Keepthenozzleincontactwiththerim

ofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donot

useanozzlelock-opendevice.

• iffuelisspilledonclothing,changecloth-

ingimmediately.

• Neveroverfillfueltank.Replacegascap

andtightensecurely.

GENERAL SERVICE

• Never operate machine in a closed area,

• Keep all nuts and boltstightto be surethe

equipment is in safe working condition.

• Never tamperwith safety devices. Check

their proper operation regularly.

• Keep machine free of grass, leaves, or

other debris build-up. Clean oil or fuel

spillage and remove anyfuel-soaked de-

bris, Allow machineto coot beforestoring.

• If you strike a foreign object, stop and

inspectthe machine. Repair,ffnecessary,

before restarting.

• Never make any adjustments or repairs

with the engine running.

• Checkgrass catcher components andthe

discharge chute frequently and replace

with manufacturer's recommended parts,

when necessary.

- Mowerbladesaresharp, Wraptheblade

or wear gloves, and use extra caution

when servicing them.

• Check brakeoperationfrequently. Adjust

and service as required.

, Maintain or replacesafety and instruction

labels, as necessary.

o Be sure the area is clear of bystanders

beforeoperating. Stopmachine ifanyone

enters the area,

• Never carry passengers.

• Do not mow inreverse unless absolutely

necessary.Always look downand behind

before and while backing,

• Never carry children, even with the

blades shut off. They may fall off and

be seriously injured or interfere withsafe

machine operation. Children who have

beengiven rides inthe past maysuddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

• Keep children out of the mowing area

and inthe watchful care of aresponsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

° Before and while backing, look behind

and down for small children.

• Mow up and down slopes (15°Max), not

across,

° Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

• Avoid starting, stopping, or turning on a

slope, lfthetires Iosetraction, disengage

the blades and proceed slowly straight

down the slope.

• If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

• Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

• When loading orunloading this machine,

do not exceed the maximum recom-

mended operation angle of 15°,

Page 6

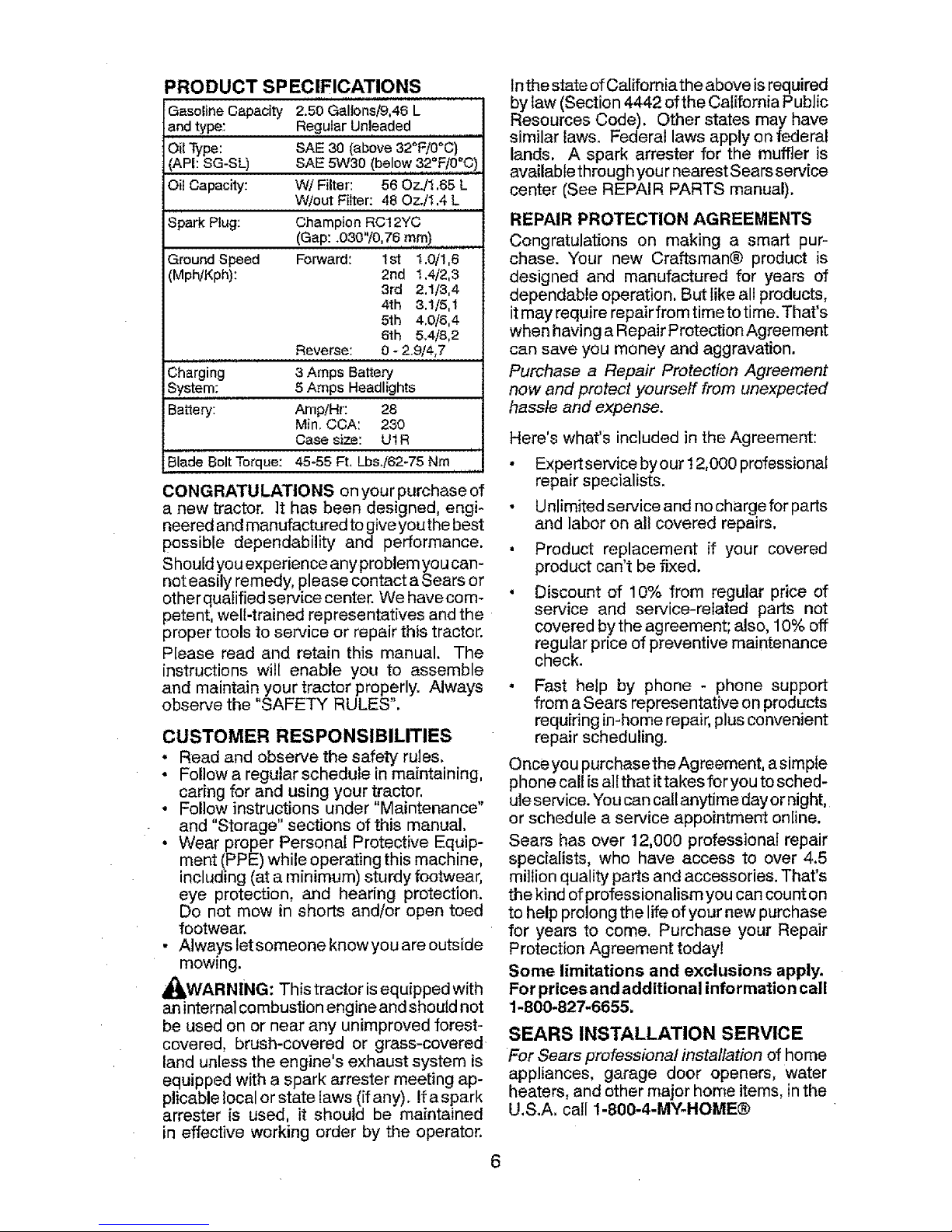

PRODUCTSPECIFICATIONS

Gasoline Capacity 2.50 Galtons19,46 L

and type: Regular Unleaded

Oit Type: SAE 30 (above 32°F/0°C)

_PI: SG-SL) SAE 5W30 (below 32°F/0°C

Oil Capacity: WJ Filter: 56 Oz.!1,65 L

W/out Filter: 48 OzJ1,4 L

Spark Plug: Champion RC12YC

(Gap: .030"/0,75 ram)

Ground Speed Forward: 1st t,0/1,6

(Mph/Kph): 2nd 1,4/2,3

3rd 2,1/3,4

4th 3,1/5,1

5_h 4.0/8,4

6th 5.4/8,2

Reverse: 0 - 2.9/4,7

Charging 3 Amps Battery

System: 5 Amps Headlights

Battery: Amp!Hr: 28

Min. CCA: 230

Case size: U1R

Blade Bolt Torque: 45-55 Ft, LbsJ62-75 Nm

CONGRATULATIONS on your purchase of

a new tractor. It has been designed, engi-

neered and manufactured to give you the best

possible dependability and performance.

Should you experience anyproblem you can-

not easily remedy, please contact a Sears or

other qualified service center. We have com-

petent, well-trained representatives and the

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

o Foliow a regular schedule inmaintaining,

caring for and using your tractor,

• Follow instructions under "Maintenance"

and "Storage" sections of this manual.

° Wear proper Personal Protective Equip-

ment (PPE)while operating this machine,

including (at aminimum) sturdy footwear,

eye protection, and hearing protection.

Do not mow in shorts and/or open toed

footwear.

• Always letsomeone know you are outside

mowing.

_JlLWARNING: This tractor isequipped with

aninternal combustion engine and shouldnot

be used on or near any unimproved forest-

covered, brush-covered or grass-covered

land unless the engine's exhaustsystem is

equipped with a spark arrester meeting ap-

plicable local or state laws (if any). Ifaspark

arrester is used, it should be maintained

in effective working order by the operator.

Inthestate of Ca[ffomiathe aboveis required

bylaw (Section4442 ofthe California Public

Resources Code). Other states may have

similar laws. Federal laws apply onfederal

lands. A spark arrester for the muffler is

availablethrough your nearestSears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman@ product is

designed and manufactured for years of

dependable operation. But like all products,

itmay require repair from time totime. That's

when having a Repair Protection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here's what's included in the Agreement:

• Expertservice byour 12,000 professional

repair specialists.

• Unlimited serviceand no chargefor parts

and labor on all covered repairs.

• Product replacement if your covered

product can't be fixed.

• Discount of 10% from regular price of

service and service-related parts not

covered bythe agreement; also, 10%off

regular priceof preventive maintenance

check.

• Fast help by phone - phone support

from a Sears representative onproducts

requiring in-home repair,plusconvenient

repair scheduling.

Onceyou purchasethe Agreement, asimple

phone calt isall that ittakesfor youto sched-

uleservice. Youcan cattanytime dayor night,

or schedule a service appointment online.

Sears has over 12,000 professionalrepair

specialists, who have access to over 4.5

million quality parts and accessories. That's

the kind ofprofessionalism you cancount on

to help prolong the life ofyour new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For pricesand additional information call

1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, inthe

U.S.A, call 1-800-4-MY-HOME@

Page 7

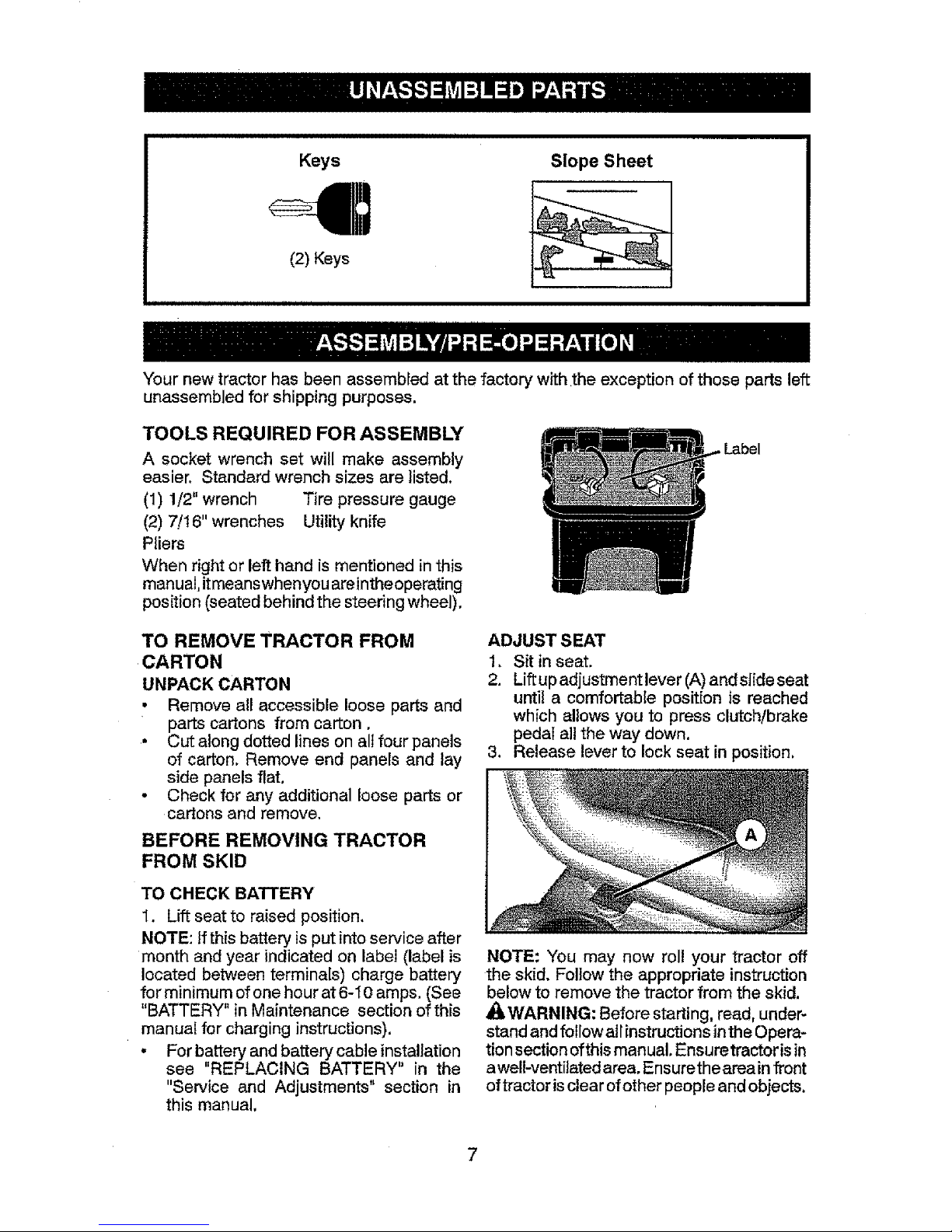

Keys Slope Sheet

(2) Keys

i,iiiL.J.lluJJJlJH ILLuJu,i.JLiii i/i/iLlLI/i H/i/ i1_/ii ill i i

Your new tractorhas been assernbledat the factory with the exception ofthose parts left

unassembled for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) 1/2" wrench Tire pressuregauge

(2) 7/t 6" wrenches Utility knife

Pliers

When right or left hand is mentioned in this

manual,itmeanswhenyou areintheoperating

position (seatedbehind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

• Remove all accessible loose parts and

parts cartons from carton.

• Cut along dotted lines on all four panels

of carton. Remove end panels and lay

side panels flat.

o Check for any additional loose parts or

cartons and remove,

BEFORE REMOVING TRACTOR

FROM SKID

TO CHECK BATTERY

1. Lift seat to raised position,

NOTE: Ifthis battery is put intoservice after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of onehour at 6-I0 amps. (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

, For battery and battery cable installation

see "REPLACING BATTERY" in the

"Service and Adjustments" section in

this manual.

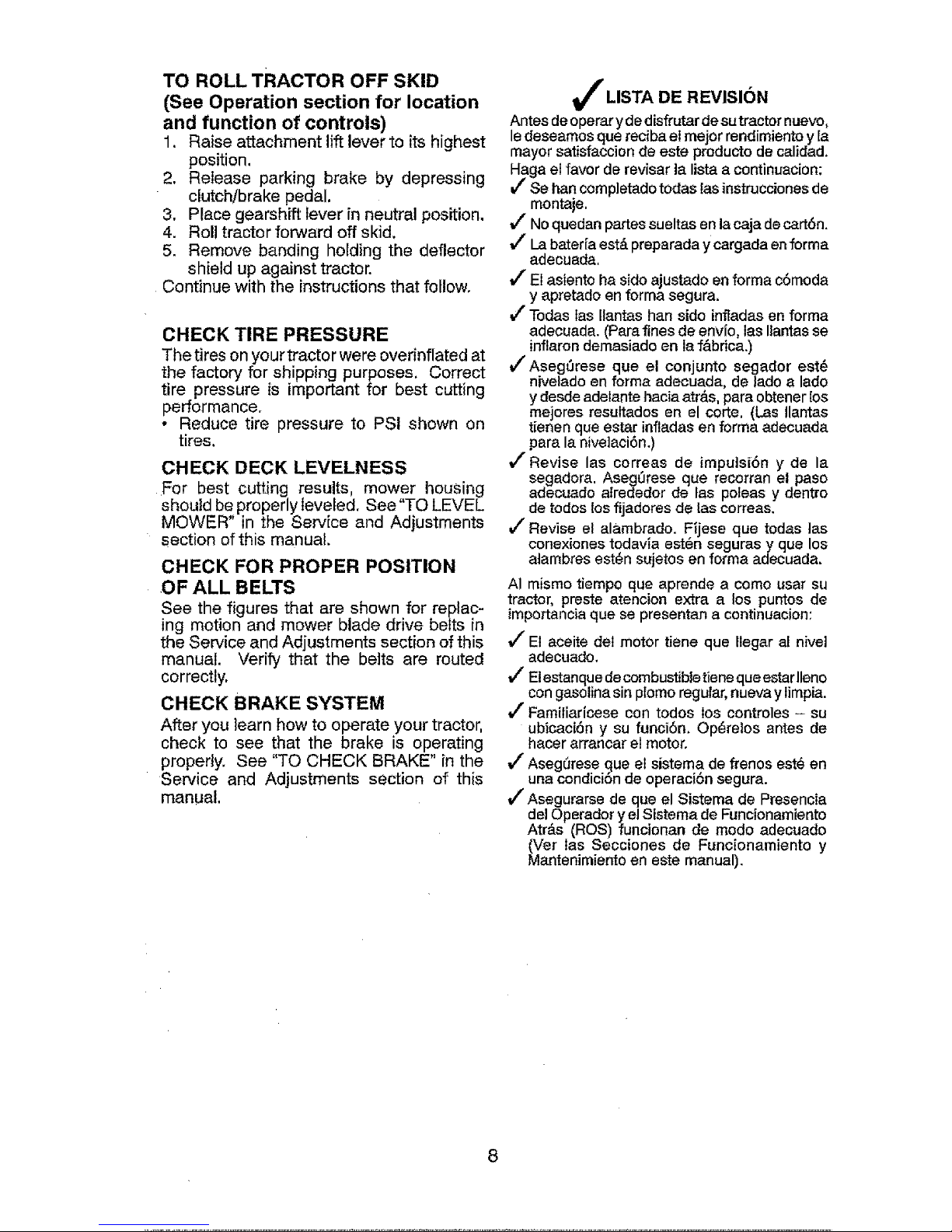

ADJUST SEAT

1, Sit inseat.

2. Liftupadjustment lever(A)andsiide seat

until a comfortable position is reached

which allows you to press clutch!brake

pedal a]]the way down,

3. Release lever to lock seat in position.

NOTE: You may now roll your tractor off

the skid. Foliow the appropriate instruction

below to remove the tractor from the skid.

Al_WARNING: Before starting, read, under-

stand andfollowall instructions inthe Opera-

tionsection ofthis manual. Ensuretractoris in

awell-ventilatedarea, Ensurethearea infront

oftractor isclear ofother people and objects.

7

Page 8

TO ROLL TRACTOR OFF SKID

(See Operation section for location

and function of controls)

1. Raise attachment liftlever to its highest

position.

2. Release parking brake by depressing

clutch/brake pedal.

3. Place gearshift lever in neutral position.

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Continue with the instructionsthat follow.

CHECK TIRE PRESSURE

Thetires on yourtractor were overinflated at

the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See"TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION

OF ALL BELTS

See the figures that are shown for replac-

ing motion and mower blade drive belts in

the Service and Adjustments section of this

manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor.

check to see that the brake is operating

properly. See "TO CHECK BRAKE" in the

Service and Adjustments section of this

manual.

t/f LISTA DE REVISION

Antes de operarydedisfrutar desu tractor nuevo,

le deseamos que reciba el mejor rendimiento y [a

mayor satisfaccion de este preducto de calidad.

Haga el favor de revisar ta lista a continuacion;

J Se ban comp]etado todas las instrucciones de

montaje.

vt Noquedan partessueltas enlacaja decart6n.

J La bater{a est&preparadaycargada enforma

adecuada.

I/El asiento ha side ajustado en forma c6moda

y apretado en forma segura.

,/Todas Ias tlantas han side infladas en forma

adecuada. (Para fines de envio, Ias Ilantasse

inflaron demasiado en Ia f&bdca.)

v( Asegt3rese que el conjunto segador est_

nivelado en forma adecuada, de lade a lade

y desde adelante hacia atr&s, para obtener los

mejores resultados en el corte. (Las ]lantas

tienen que estar infladas en forma adecuada

para la nivelaci6n.)

V_ Revise las correas de imputsi6n y de la

segadora. Asegt_rese que recorran el paso

adecuado alrededor de fas poleas y dentro

de lodes los fijadores de las correas.

J Revise el alambrado. Fijese que todas ]as

conexiones todavia est6n seguras y que los

atambres est6n sujetos en forma adecuada.

A1mismo tiempo que aprende a come usar su

tractor, preste atencion extra a los puntos de

importancia que se presentan a continuacion:

V( El aceite deI motor tiene que ilegar at nive]

adecuado.

_" Elestanque decombustible tiene queestarlleno

con gasolina sin pfomo regular,nueva y Iimpia.

_" Familiaricese con todos los controles - su

ubicaci6n y su funci6n. Op6relos antes de

hacer arrancar el motor.

vf Aseg(Jrese9ue el sistema de frenos est_ en

una condicion de operaci6n segura.

_' Asegurarse de que el Sistema de Presencia

del Operador y el Sistema de Funcionamiento

Atr_.s (ROS) funcionan de mode adecuado

(Vet Ias Secciones de Funcionamiento y

Mantenimiento en este manual).

8

Page 9

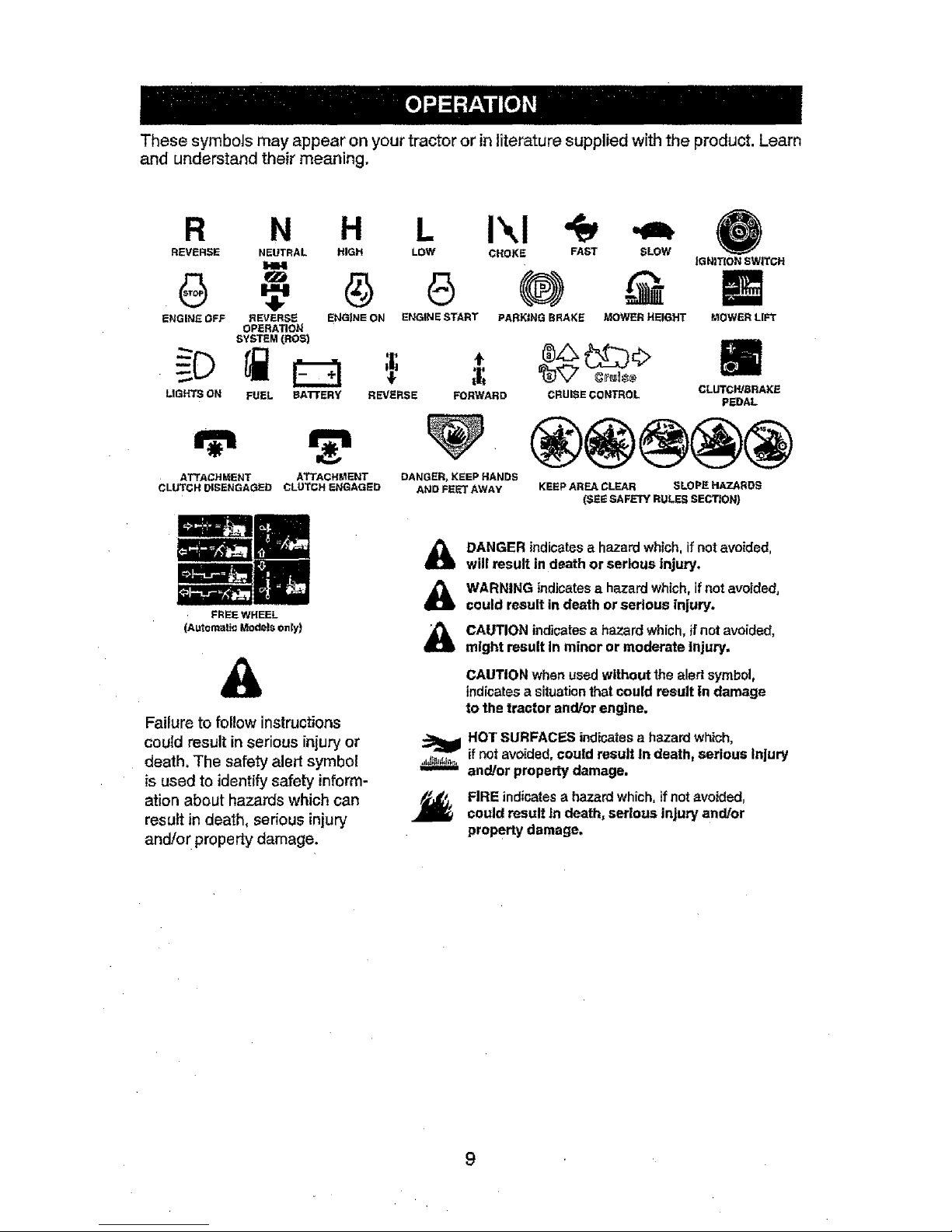

Thesesymbolsmayappearonyourtractororinliteraturesupplied with the product, Learn

and understand their meaning.

R N H L

REVERSE NEUTRAL HIGH LOW

ENGINE OFF REVERSE ENG|NE ON ENGINE START

OPERATION

SYSTEM (ROe)

U GHT,3 ON FUEL BATI'ERY REVERSE FORWARD

ATTACHMENT ATTACHMENT DANGER, KEEP HANDS

CLUTCH DISENGAGED CLUTCH ENGAGED AND FEET AWAY

FREE WHEEL

(Automatic Models only)

Failure to follow instructions

could result in serious injury or

death, The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury

and/or proper_ damage.

i\!

CHOKE FAST SLOW

PARKING BRAKE MOWER HEIGHT

IGNITION SWITCH

MOWERLIFT

CRUISE CONTROL CLUTCWBRAKE

PEDAL

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION}

DANGER indicates a hazard which, if not avoided.

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate Injury.

CAUTION when used without the alert symbol,

indicates a situation that could result In damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result In death, serious Injury

and/or property damage.

FIRE indicates a hazard which, if not avoided.

could result In death, serious injury and/or

proPerty damage.

9

Page 10

KNOW YOUR TRACTOR

READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with your tractor to familiarize yourself withthe locations of vari-

ous controls and adjustments. Save this manual for future reference.

03078

Our tractors conform to the applicable safety standards of the

American National Standards Institute,

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor.

(B) CLUTCH/BRAKE PEDAL -Used for

declutching and braking the tractor and

starting the engine,

(C) PARKING BRAKE - Locksclutch/brake

pedal into the brake position,

(D) THROTTLE/CHOKE CONTROL- Used

for starting and controlling engine speed.

(E) ATTACHMENT CLUTCH LEVER- Used

toengagethe mower blades, or otherattach-

ments mounted to your tractor,

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION -Allows operation

ofmower or other powered attachment while

in reverse.

(H) LIGHT SWITCH - Turns the headlights

on and off,

(J) GEARSHIFT LEVER- Selects the speed

and direction of tractor.

10

Page 11

The operation of anytractor can result inforeign objects thrown into the eyes,t

which can result in severe eye damage. Always wear safety glasses or eye{

shields while operating your tractor or performing any adjustments or repairs.I

We recommend standard safety glasses or a wide vision safety, mask wornl

over spectacles. /

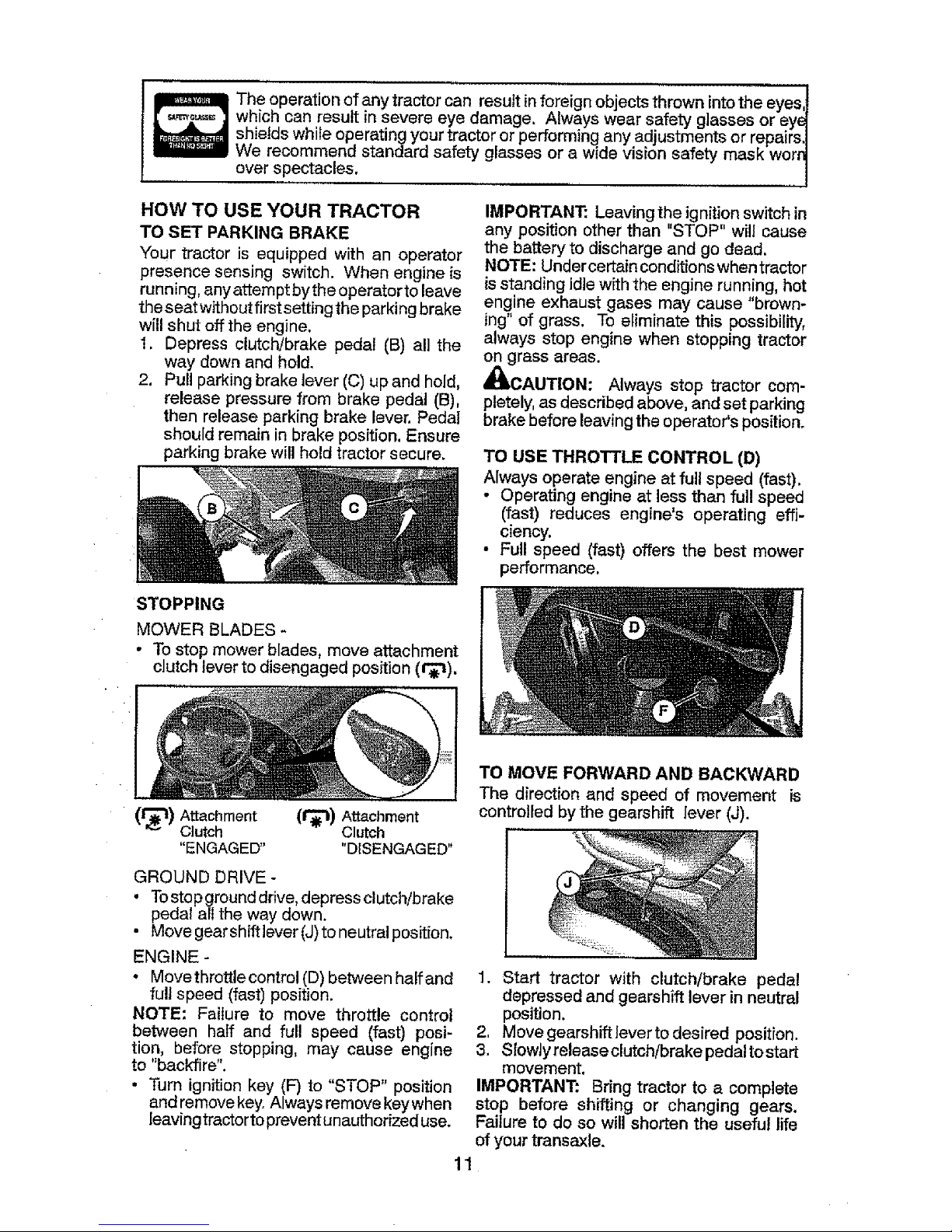

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

running, anyattempt bythe operator toleave

the seat withoutfirst settingthe parking brake

will shut off the engine.

1. Depress clutch/brake pedal (B) all the

way down and hold.

2. Pull parking brake lever (C) up and hold,

release pressure from brake pedal (B),

then release parking brake lever, Pedal

should remain in brake position. Ensure

parking brake will hold tractor secure.

IMPORTANT: Leavingthe ignition switch in

any position other than "STOP" will cause

the battery to discharge and go dead.

NOTE: Undercertain conditionswhen tractor

isstanding idle with the engine running, hot

engine exhaust gases may cause "brown-

ing"of grass. To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

_CAUTION: Always stop tractor com-

pletely,as described above, and set parking

brake before leavingthe operator's position.

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast) reduces engine's operating effi-

ciency.

• Full speed (fast) offers the best mower

performance.

STOPPING

MOWER BLADES -

• Tostop mower blades, move attachment

clutch lever to disengaged position (t_).

(1"_t) Attachment (1_) Attachment

Clutch Clutch

"ENGAGED .... DISENGAGED"

GROUND DRIVE -

• Tostop ground drive, depress clutch!brake

pedal all the way down,

• Move gearshiftlever (J)to neutralposition,

ENGINE -

• Movethrottle control (D) between half and

full speed (fast) position.

NOTE: Failure to move throttle control

between half and full speed (fast) posi-

tion, before stopping, may cause engine

to "backfire",

• Turn ignition key (F) to "STOP" position

and removekey. Always remove keywhen

leavingtractorto preventunauthorized use.

11

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement is

controlledbythe gearshift lever (J).

1. Start tractor with clutch/brake pedal

depressed and gearshift lever inneutral

position.

2, Move gearshift leverto desired position.

3. Slowly release clutch/brake pedalto start

movement,

IMPORTANT: Bring tractor to a complete

stop before shifting or changing gears.

Failure to do so will shorten the useful life

of your transaxle.

Page 12

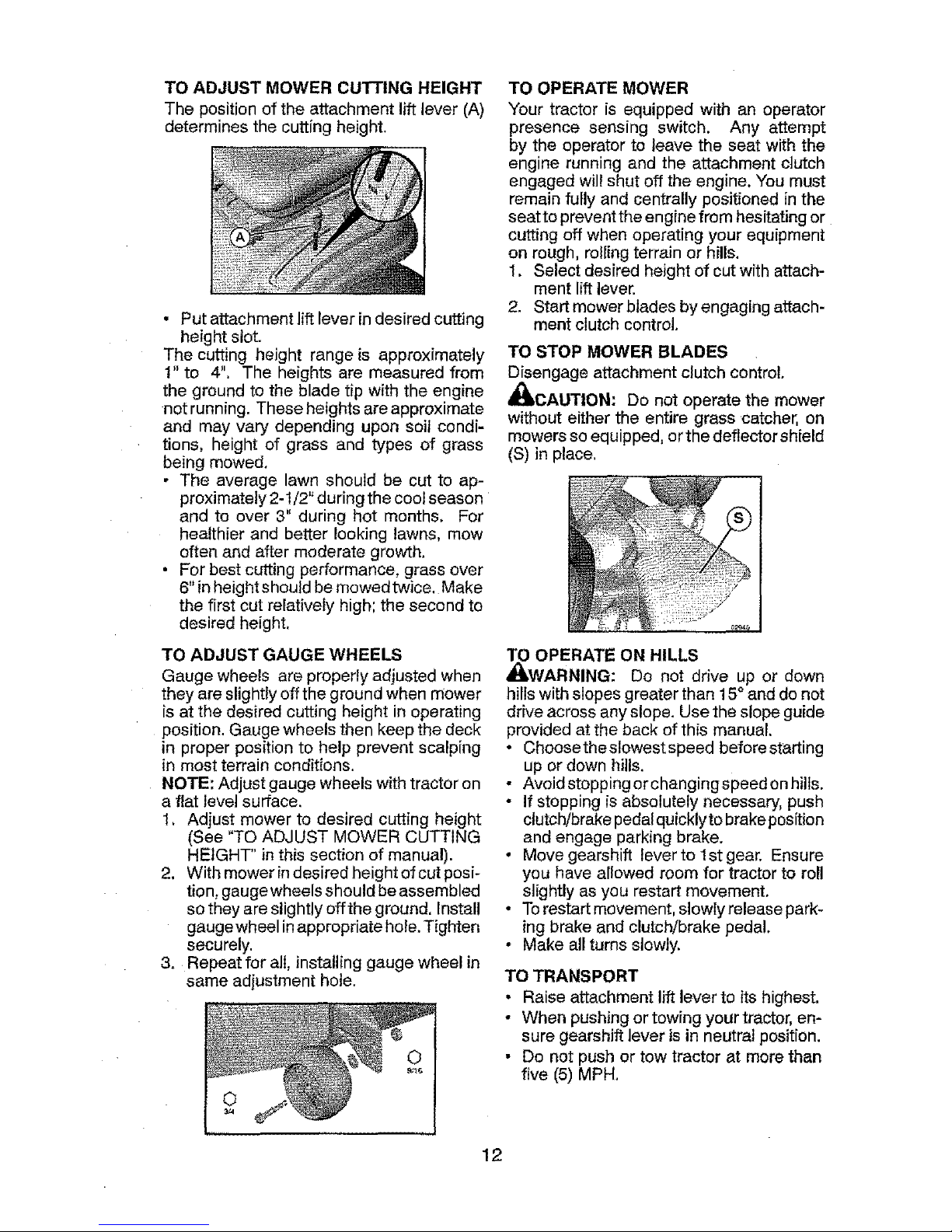

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment liftlever (A)

determines the cutting height.

• Put attachment lift lever indesired cutting

height slot.

The cutting height range is approximately

1" to 4". The heights are measured from

the ground to the blade tip with the engine

not running. These heights areapproximate

and may vary depending upon soil condi-

tions, height of grass and types of grass

being mowed,

• The average lawn should be cut to ap-

proximately 2-1/2" during the cool season

and to over 3" during hot months. For

healthier and better looking lawns, mow

often and after moderate growth.

• For best cutting performance, grass over

6"in heightshouid bemowedtwice. Make

the first cut relatively high; the second to

desired height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly off the ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper position to help prevent scalping

in most terrain conditions.

NOTE; Adjust gauge wheels with tractor on

a flat level surface.

1, Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

2. With mower in desired height of cut posi-

tion, gaugewheels should beassembled

so they are slightly offthe ground. Install

gauge wheel in appropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch, Any attempt

by the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine. You must

remain fully and centrally positioned in the

seat to preventthe engine from hesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills.

1. Select desired height of cut withattach-

ment lift lever.

2. Start mower blades by engaging attach-

ment clutch control.

TO STOP MOWER BLADES

Disengage attachment clutch control.

_kCAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, or the deflector shield

(S) in place.

TO OPERATE ON HILLS

,_kWARNING: Do not drive up or down

hills with slopes greater than 15° and do not

drive across anyslope. Use the slope guide

provided at the back of this manual.

° Choose the slowest speed before starting

up or down hills.

• Avoidstopping or changingspeed onhills.

• If stopping is absolutely necessary, push

clutch/brake pedalquicklyto brakeposition

and engage parking brake.

• Move gearshift lever to 1st gear. Ensure

you have allowed room for tractor to roll

slightly as you restart movement.

. Torestart movement, slowly release park-

ing brake and clutch!brake pedal,

• Make all turns slowly.

TO TRANSPORT

• Raise attachment lift lever to its highest.

• When pushing or towing your tractor,en-

sure gearshift lever isin neutral position.

• Do not push or tow tractor at more than

five (5) MPH.

12

Page 13

NOTE: To protect hood from damage when

transporting yourtractor on atruckor atrailer,

ensure hood is closed and secured to tractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

TOWING CARTS AND OTHER ATTACH-

MENTS

Tow only the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when tow=ng. Too heavy of

a load, while on a slope, is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

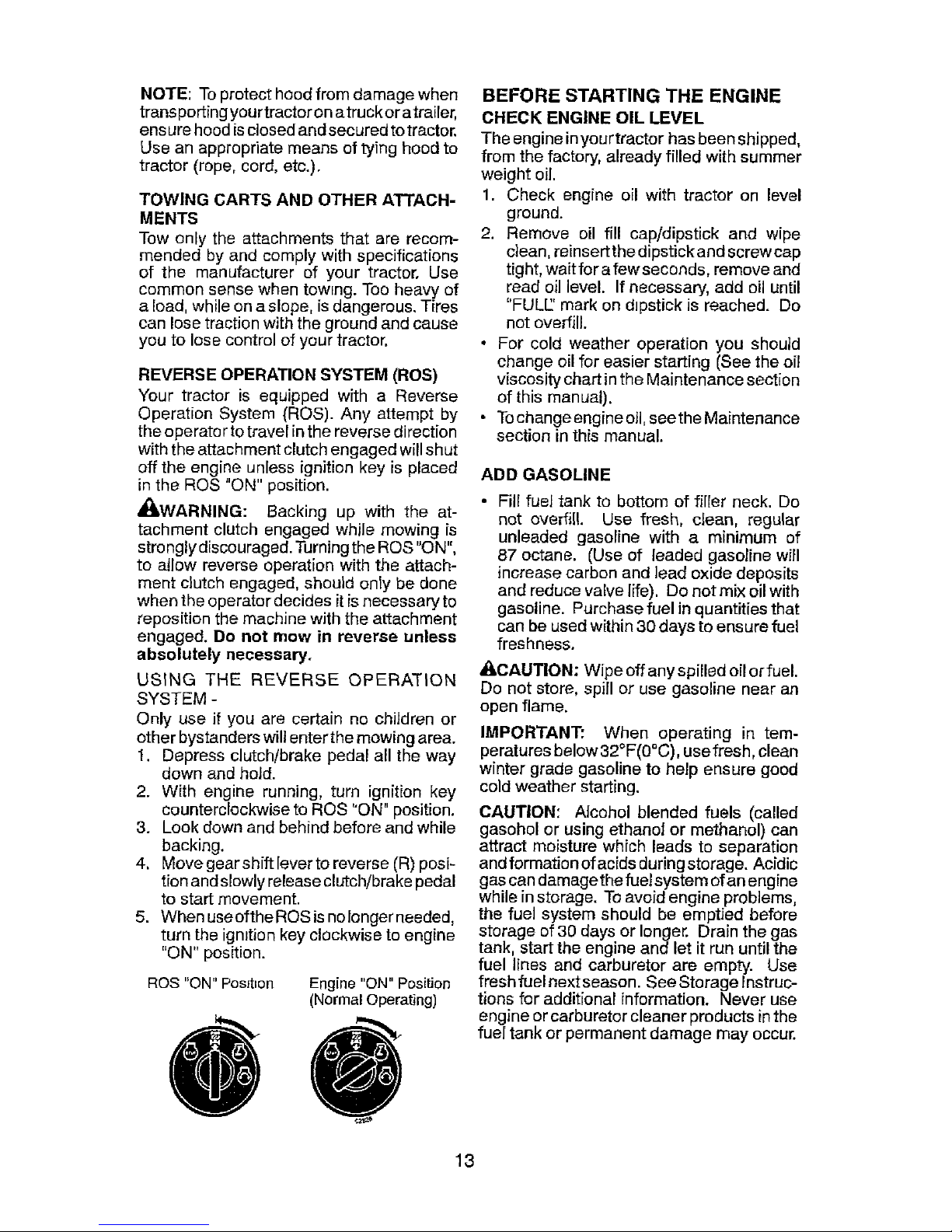

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direction

with the attachment clutch engaged will shut

off the engine unless ignition key is placed

in the ROS "ON" position.

_kWARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discouraged. Turning the ROS "ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides it is necessary to

reposition the machine with the attachment

engaged. Do not mow in reverse unless

absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM -

Only use if you are certain no children or

other bystanders will enter the mowing area.

1. Depress clutch/brake pedal all the way

down and hold.

2. With engine running, turn ignition key

counterclockwise to ROS "ON" position.

3. Look down and behind before and while

backing.

4. Movegearshiftleverto reverse (R) posi_

tion and slowly release clutch!brake pedal

to start movement.

5. When useofthe ROS is nolonger needed,

turn the ignition key clockwise to engine

"ON" position.

ROS "ON" PosJt_on Engine "ON" Position

(Normal Operating)

ee

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine inyourtractor has beenshipped,

from the factory, already filled with summer

weight oil.

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean, reinsert the dipstick and screw cap

tight, wait for afew seconds, remove and

read oil level. If necessary, add oil until

"FULE' mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (Seethe oi_

viscosity chart inthe Maintenance section

of this manual).

• Tochange engine o11,see the Maintenance

section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane. (Use of leaded gasoline will

increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil with

gasoline. Purchase fuel in quantities that

can be used within 30 days to ensure fuel

freshness.

&CAUTION: Wipe off any spilled oil or fuel.

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tem-

peratures below 32°F(00C), usefresh, clean

winter grade gasoline to help ensure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

and formation of acids during storage. Acidic

gas can damage the fuel system of an engine

while instorage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty. Use

fresh fuel next season. See Storage Instruc-

tions for additional information. Never use

engine or carburetor cleaner products inthe

fuel tank or permanent damage may occur.

13

Page 14

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel. it will take

extra cranking time to move fuel from the

tank to the engine.

1. Sit on seat in operating position, depress

clutch/brake pedal and set parking brake.

2. Place gear shift lever in neutral position.

3. Move attachment clutch to disengaged

position.

4. Move throttle control to choke position.

NOTE: Before starting, read the warm and

cold starting procedures below.

5, Insert key into Ignition and turn key

clockwise to start position and release

key as soon as engine starts. Do not run

starter contin uously for mo rethan fifteen

seconds per minute. If the engine does

not start after several a_empts, move

throttle control to fast position, wait a

few minutes and try again. If engine still

does not start, move the throttle control

back to the choke position and retry.

WARM WEATHER STARTING

(50 ° F/10 ° C and above)

6. When engine starts, move the throttle

control to the fast position.

• The attachments and ground drive can

now be used. If the engine does not accept

the load, restart the engine and allow itto

warm up for one minute using the choke

as described above,

COLD WEATHER STARTING

(50 _ F/10 ° C and below)

7. When engine starts, reave throttle control

in choke position until engine warms up

and begins to run roughly. Once rough

running begins, immediately move the

throttle control to the fast position. Engine

warm-up may take from several seconds

to several minutes (the colder the tem-

perature, the longer the warm-up).

• The attachments can also be used during

the engine warm-up period,

NOTE: Ifat a high altitude (above 3000 feet)

or in cold temperatures (below 32°F/0°C)

the carburetor fuel mixture may need to be

adjusted for best engine performance (see

"TO ADJUST CARB URETO R" in the Service

and Adjustments section of this manual).

MOWING TIPS

• Tire chains cannot be used when the

mower housing is attached to tractor.

• Mowershould be properly leveledforbest

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

, The left hand side of mower should be

used for trimming,

• Dnve sothat clippings are discharged onto

the area that has already been cut, Have

the cut areato the right of the tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

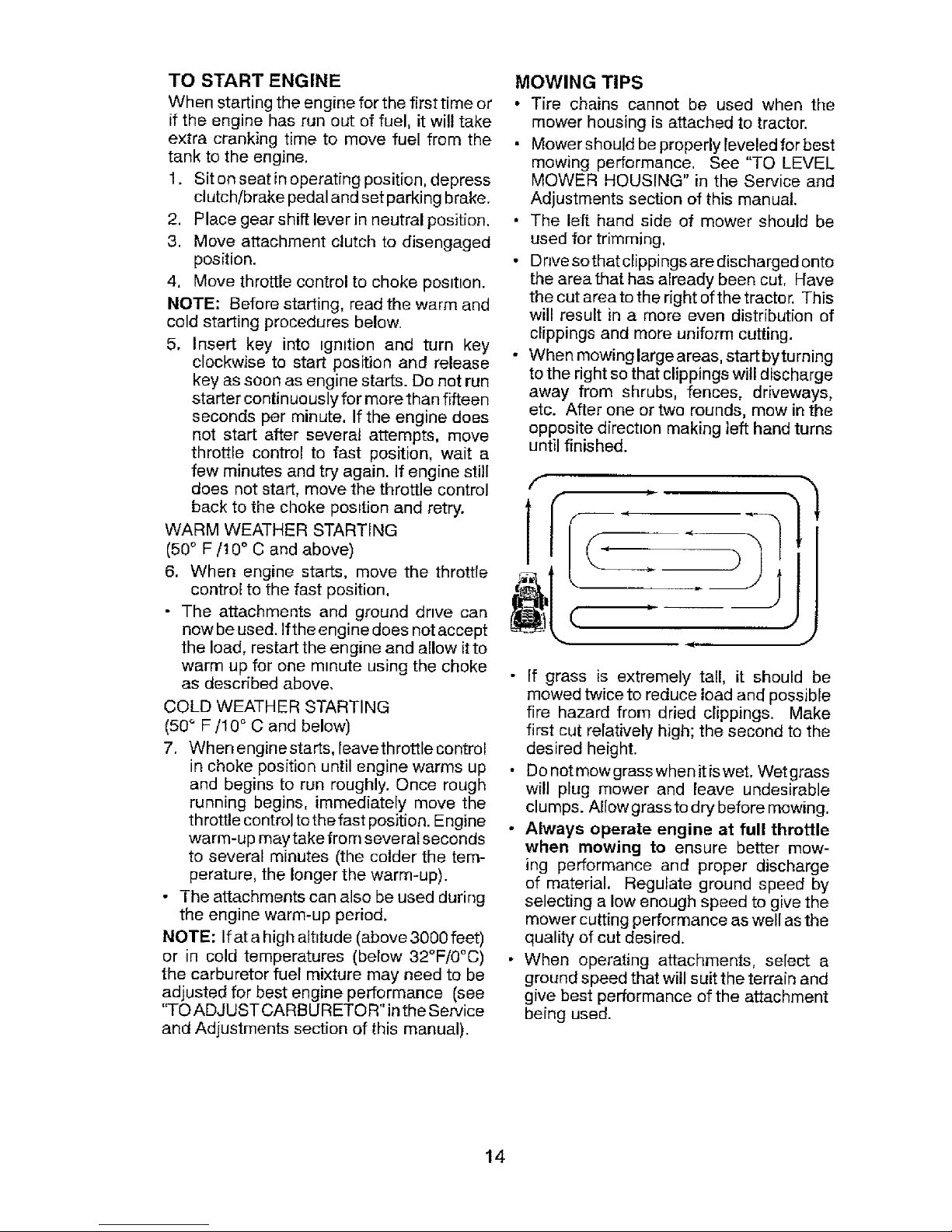

• When mowing large areas, start bytu rning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

f

JJ

J

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet grass

will plug mower and leave undesirable

clumps. Allow grass to dry before mowing.

• Always operate engine at full throttle

when mowing to ensure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough speed to give the

mower cutting performance as well as the

quality of cut desired.

• When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

14

Page 15

MAINTENANCE

SCHEDULE

9EFORE

_a_C:H

USE

Check Brake IOpe.ratten

ohe.ok ,e.P....... ,,"

Check Operatar Presence & NON Systems V"

iA Check fe.rLoe.se Fasteners V'

C Ch_cWRe.p[ace Mower B[ade.e

T Lubr=cation Chz, rt

0 Check B_t;e.ry Level

R Clean Batten/andTermma_s

Ore.an Debris Off Steering Plate

Cheek Traes,,axle Ce.e.hng

Check Mowe.r Levelness

Cheek V-Be.Its

i

Check Enqlne O=[ Level

Chz_C.qe. Eni,}ine. O=| (WLth e.zlh_ter)

Chancle En_l_e Od (wFthout o_ filter)

E Clean Air Filter

G Cle.an ALr ScTee.n

| Inspect Muter/SPark Armorer

U' Replr_ce Oil F=lter !If eClu_ppB_ )

E Cl_an En_me Co_ln 9 Fins

Re.p_aee. Spark Plug

Replace Atr Filter Paper C_r_r_d_ie

Rep|a_ce Fur:l Fdter

I_VERY

B

HOURS

EV£RY EVERY EVERY EVERY BEFORE

2_ 50 100 sEASO_ STORAGE

_OURS HQURS HOURS

v',

v'

i| i m If H i|1

v',_ v"

V',, is'

v" . V

Lv',

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

items that have been subjected to operator

abuse or negligence. To receive full value

from the warranty, operator must ma=ntain

tractor as instructed in this manual

Some adjustments wilt need to be made

pe riodically to properly maintain your tractor.

At [east once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

• At least once a year you should replace

the spark plug, clean or replace air filter,

and check blades and belts for wear. A

new spark plug and clean air filter assure

proper a=r-fuel mixture and help your en-

gine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3, Check tire pressure.

4. Check operator presence and

ROS systems for proper operation.

5. Check for loose fasteners.

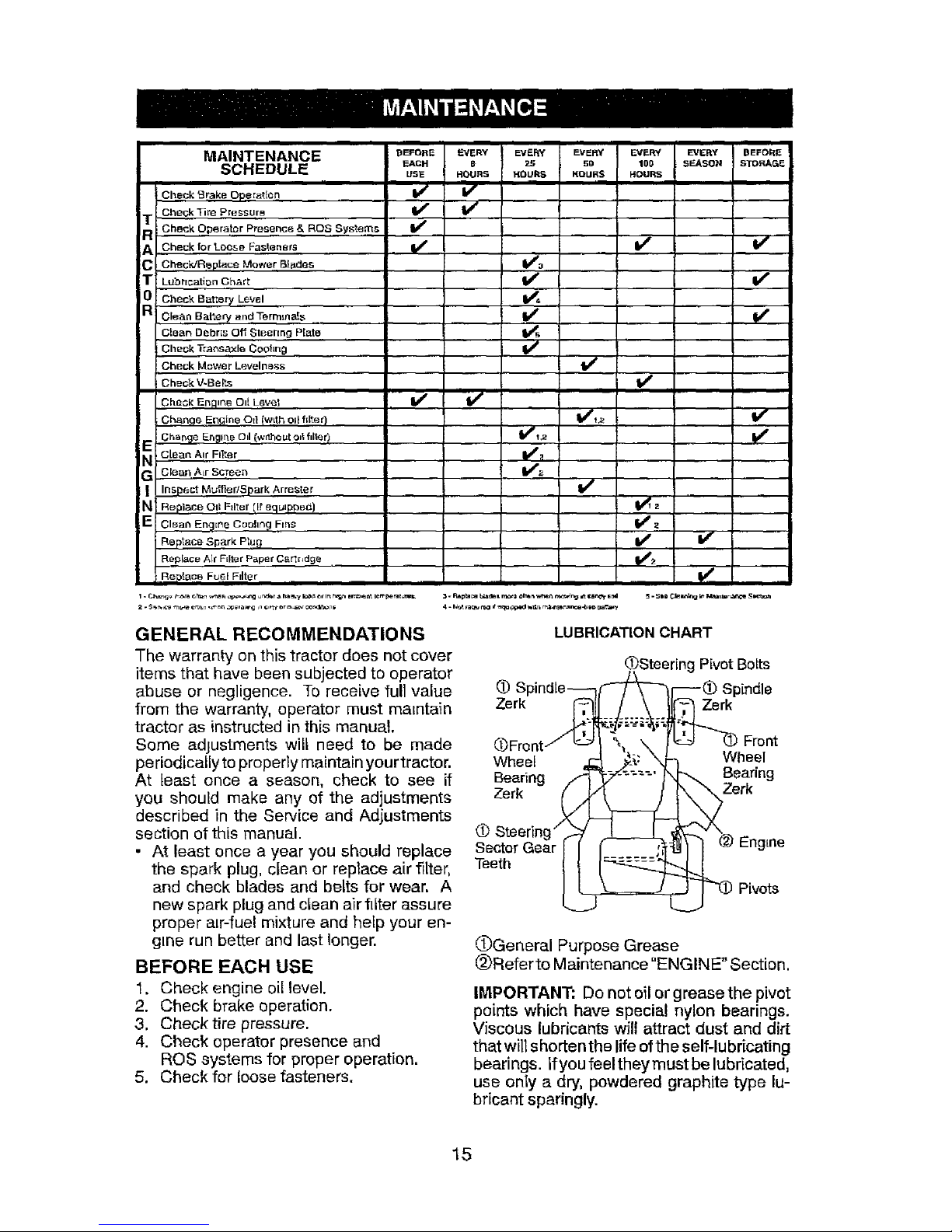

LUBRICATION CHART

(f_)SteeringPivot Botts

Spindie__l_--_ Spindle

(_Front! _Lc2__ %; \ I _ _ Front

__;: X_ Wheel

Wheet 4;

_- ....._ Bearing

Bearing

_erk

Zerk /(_

(1).Steering"

Sector Gear I I Engine

Teeth _ Pivots

OGeneral Purpose Grease

@Refer to Maintenance"ENGINE" Section.

IMPORTANT: Do net oilor grease the pivot

points which have special nylon bearings.

Viscous lubricants will attract dust and dirt

thatwill shorten the lifeofthe self-lubricating

bearings. Ifyou feel they must be lubricated,

use only a dry, powdered graphite type lu-

bricant sparingly.

15

Page 16

TRACTOR

Alwaysobservesafetyruleswhenperform-

inganymaintenance.

BRAKE OPERATION

If tractor requires more than five (5) feet to

stop at highest speed in htghest gear on a

level, dry concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

• Maintain proper air pressure in all tires

(See PSI on tires).

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow Ieaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Ensure operator presence and reverse

operation systems are workmg properly. If

your tractor does not function as described,

repair the problem immediately.

• The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE SYSTEM

• When the engine is running, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine Is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engine.

• The attachmentclutch should neveroper-

ate unless the operator is in the seat.

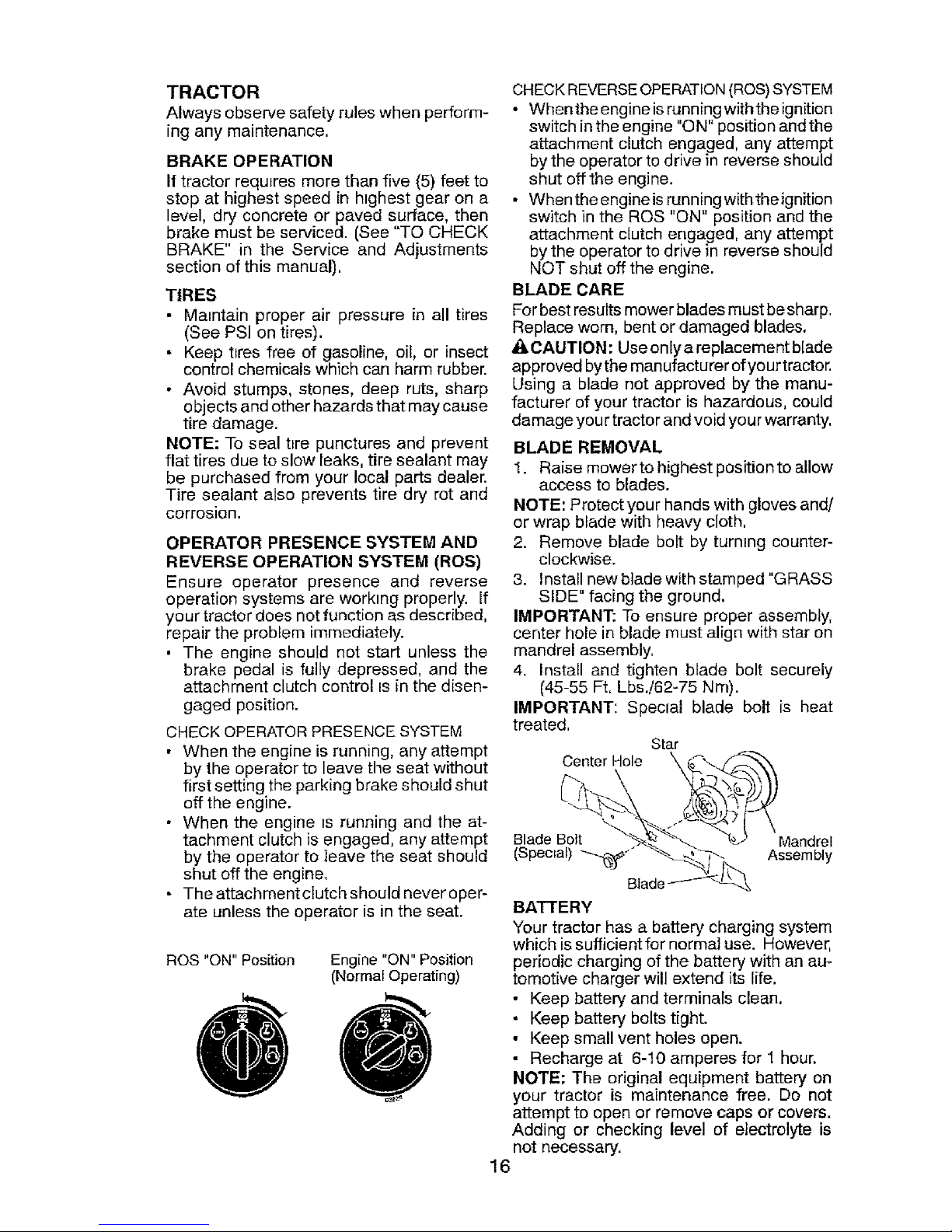

ROS "ON" Position Engine "ON" Position

(Normal Operating)

CHECK REVERSE OPERATION (ROS) SYSTEM

• Whenthe engine is running with the ignition

switch in the engine "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

shut offthe engine.

• When the engineis running withtheignition

switch in the ROS "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

NOT shut off the engine.

BLADE CARE

For best results mower blades must be sharp.

Replace worn, bent or damaged blades.

_kCAUTION: Use only a replacement blade

approved bythe manufacturer ofyourtractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage your tractor and void your warranty.

BLADE REMOVAL

I. Raise mowerto highest positionto allow

access to blades.

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth,

2. Remove blade bolt by turning counter-

clockwise.

3. Install newblade with stamped "GRASS

SIDE" facing the ground.

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly,

4. Install and tighten blade bolt securely

(45-55 Ft, Lbs.!62-75 Nm).

IMPORTANT; Special blade bolt is heat

treated,

Star

Center Hole

\

Blade Bolt Mandrel

(Special) "_'" Assembly

BA'f-I'ERY

Your tractor has a battery charging system

which is sufficient for normal use. However,

periodic charging of the battery with an au-

tomotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

16

Page 17

TOCLEANBATTERYANDTERMINALS

Corrosionanddirtonthebatteryandterminals

cancausethebatteryto"leak" power.

1. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

2. Rinse the battery with plain water and dry.

3. Clean terminals and battery cable ends

with wire brush until bright.

4. Coat terminals w{th grease or petro{eum

jelly.

5. Reinstall battery (See "REPLACING

BATTERY" in the SERVICE AND AD-

JUSTMENTS section of this manual).

TRANSAXLE MAINTENANCE

Keep transaxte free from build-up of dirt and

chaff which can restrict cooling.

Do not attempt to clean transaxle while

engine is running or while the transaxle is

hot. To prevent possible damage to seals,

do not use high pressure water or steam to

clean transaxle.

V-BELTS

Check V-belts for deterioration and wear after

100 hours of operation and replace if neces-

sary. The belts are not adjustable. Replace

belts if they begin to slip from wear.

ENGINE

LUB RICATION

Only use high quality detergent oil rated with

AP[ service classification SG-SL. Selectthe

oil's SAE viscosity grade according to your

expected operating temperature.

£AE V_SCOSR'Y GRADES

NOTE: Although multi-viscosityoils (5W30,

] 0W30 etc.) improve starting in cold weather,

they will result in increased oil consumption

when used above 32°F/0°C. Check your

engine oil level more frequently to avoid pos-

sible engine damage from running low on oil

Change the oil after every 50 hours of opera-

tion or at {east once a year if the tractor is

not used for 50 hours in one year,

Check the crankcase oil level before starting

the engine and after each eight (8) hours

of operation. Tighten oil fill cap[dipstick

securely each time you check the oil level.

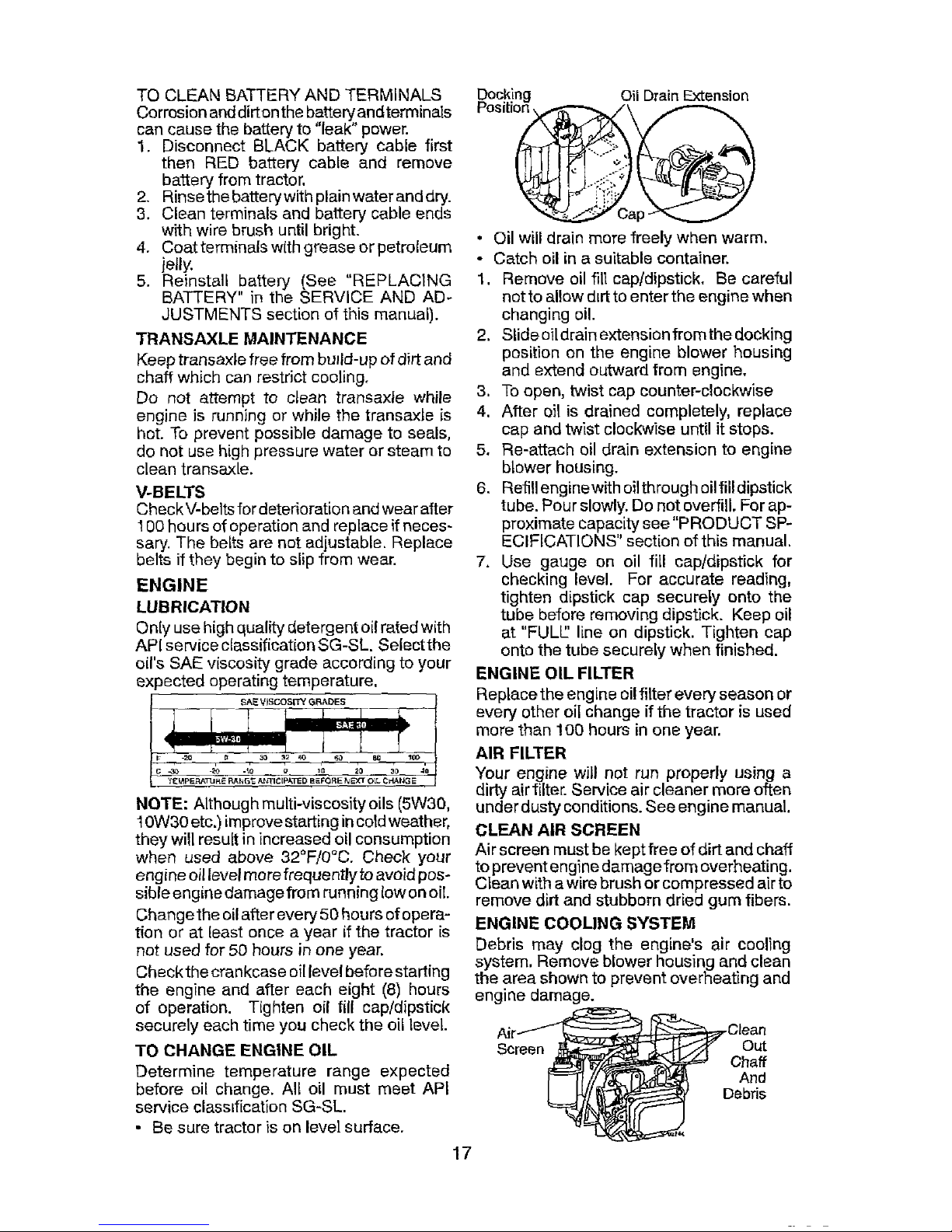

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classLfication SG-SL.

• Be sure tractor is on level surface.

17

Docking Oil Drain Extension

• Oil will drain more freely when warm.

* Catch oil in a suitable container.

1. Remove oil ill] capldipstick, Be careful

not to allow dirt to enter the engine when

changing oil.

2. Stide oil drain extension from the docking

position on the engine blower housing

and extend outward from engine,

3, To open, twist cap counter-clockwise

4. After oil is drained completely, replace

cap and twist clockwise until it stops.

5. Re-attach oil drain extension to engine

blower housing.

6, Reffil enginewith oil through oilfill dipstick

tube. Pour slowly, Do not overfill, For ap-

proximate capacity see "PRODUCT SP-

ECIFICATIONS" section of this manual.

7. Use gauge on oil fill cap/dipstick for

checking level. For accurate reading,

tighten dipstick cap securely onto the

tube before removing dipstick. Keep oil

at "FULL_ line on dipstick. Tighten cap

onto the tube securely when finished.

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the tractor is used

more than 100 hours in one year.

AIR FILTER

Your engine will not run properly using a

dirty air filter. Service air cleaner more often

under dusty conditions. See engine manual.

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff

to prevent engine damagefrom overheating.

Clean with a wire brush or compressed air to

remove dirt and stubborn dried gum fibers.

ENGINE COOLING SYSTEM

Debris may clog the engine's air cooling

system. Remove blower housing and clean

the area shown to prevent overheating and

engine damage.

Air--Clean

/_ Debris

Page 18

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as itcould create

a fire hazard and/or damage.

SPARK PLUG(S)

Replace spark plug(s) at the beginning of

each mowing season or after every 100

hours of operation, whichever occurs first.

Spark plug type and gap setting are shown

in "PRODUCT SPECIFICATIONS" section

of this manual.

IN-LINE FUEL FILTER

The fuel filter should be replaced once each

season, If fuel filter becomes clogged, ob-

structing fuel flow to carburetor, replacement

is required.

1. With engine cool, remove filter and plug

fuel line sections.

2. Place newfuel filter in position in fuel line

with arrow pointing towards carburetor.

3. Ensure there are no fuel line leaks and

clamps are properly positioned.

4. Immediatelywipe up any spilled gasohne.

amp

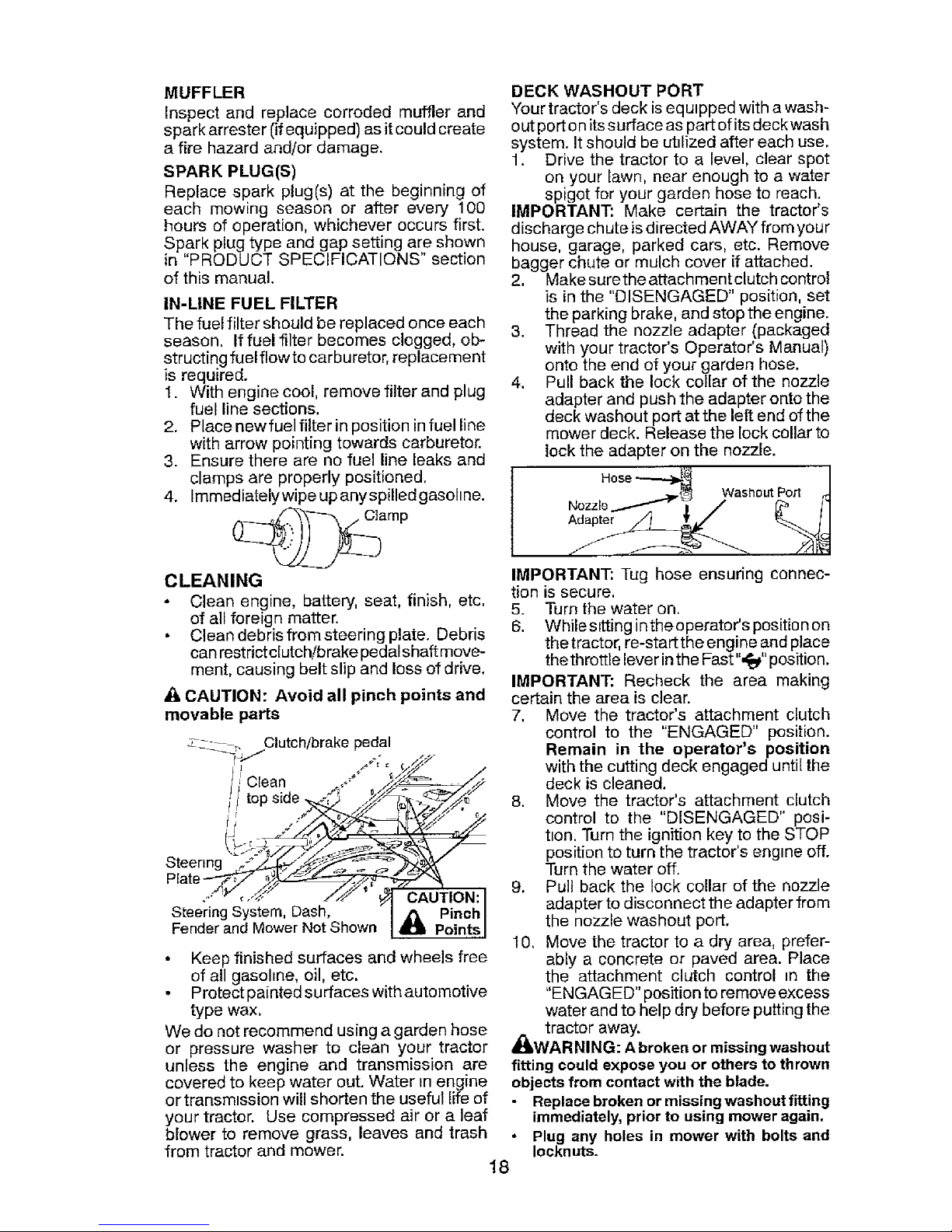

CLEANING

• Clean engine, battery, seat, finish, etc,

of all foreign matter.

• Clean debrisfromsteering plate. Debris

can restrictclutch!brake pedal shaft move-

ment, causing belt slip and loss of drive.

/i, CAUTION: Avoid all pinch points and

movable parts

_- _. Clutch/brake pedal

4/ ."

f,' Clean _o_+

I/ topside _ ._//-."

Steerlngplate_,.-;" "_ ....

Steering System, Dash,

Fender and Mower Not Shown

/i"" ¢

CAUTION: I

Pinch I

41_ Points I

• Keep finished surfaces and wheels free

of all gasohne, oil, etc.

• Protect painted surfaces with automotive

type wax.

We do not recommend using a garden hose

or pressure washer to clean your tractor

unless the engine and transmission are

covered to keep water out. Water in engine

or transmission will shorten the useful life of

your tractor. Use compressed air or a leaf

blower to remove grass, leaves and trash

from tractor and mower.

DECK WASHOUT PORT

Your tractor's deck is equipped with a wash-

out port o nits surface as part of its deck wash

system. It should be utilized after each use.

1. Drive the tractor to a level, clear spot

on your fawn, near enough to a water

spigot for your garden hose to reach.

IMPORTANT: Make certain the tractor's

discharge chute is directed AWAY from your

house, garage, parked cars, etc. Remove

bagger chute or mulch cover if attached.

2. Make surethe attachment clutch control

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Thread the nozzle adapter (packaged

with your tractor's Operator's Manual)

onto the end of your garden hose.

4. Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the left end of the

mower deck. Release the lock collar to

lock the adapter on the nozzle.

Hose_ /

_._._ WashoutPort 4-1

Nozzlo/_ "i / r_ _1

IMPORTANT: Tug hose ensuring connec-

tion is secure.

5. Turn the water on.

6. While sitting inthe operator's position on

the tractor, re-start the engine and place

thethrottle lever in the Fast",_" position.

IMPORTANT: Recheck the area making

certain the area is clear.

7, Move the tractor's attachment clutch

control to the "ENGAGED" position.

Remain in the operator's position

with the cutting deck engaged until the

deck is cleaned.

8. Move the tractor's attachment clutch

control to the "DISENGAGED" posi-

tion. Turn the ignition key to the STOP

position to turn the tractor's engine off.

Turn the water off.

9. Pull back the lock collar of the nozzle

adapter to disconnect the adapter from

the nozzle washout port.

10. Move the tractor to a dry area, prefer-

ably a concrete or paved area. Place

the attachment clutch control _n the

"ENGAGED" position to remove excess

water and to help dry before putting the

_ll tractor away.

WARNING: A broken or missing washout

fitting could expose you or others to thrown

objects from contact with the blade.

• Replace broken or missing washout fitting

immediately, prior to using mower again.

* Plug any holes in mower with bolts and

Iockn uts.

18

Page 19

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANYSERVICE OR ADJUSTMENTS:

1. Depress clutch/brake pedal fully and set parking brake.

2. Place gearshift lever in neutral position,

3. Place attachment clutch in "DISENGAGED" position.

4. Turnignitionkey to "STOP" and remove key.

5. Ensure the blades and all moving parts have completely stopped,

6. Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug.

TO REMOVE MOWER

1, Place attachment clutch in "DISEN-

GAGED" position.

2, Lower attachment lift lever to its lowest

position.

3. Roll belt off engine pulley (M) and belt

keepers ((3).

4. Remove retainer spring (K), slide collar

(L) off and push housing guide (P) out

of bracket.

5. Remove clutch cable spring (Q) from

idler arm (R).

6. Disconnect front link (E) from mower -

remove retainer spring and washer.

7. Go to either side of mower and discon-

nect mower suspension arm (A) from

chassis pin (B) and rear lift link (C) from

rear mower bracket (D) -remove retainer

springs and washers,

A_kCAUTION: After rear lift links are discon-

nected, the attachment li_ leverwill be spring

loaded. Have a tight grip on lift lever when

changing position of the lever,

8. Slide mower outfrom underrights!de of

tractor.

IMPORTANT: If an attachment other than

the mower is to be mounted on the tractor,

remove the front link (E) and rear lift links

(C) from tractor and hook the clutch spring

(Q) into the cable guide on front edge of

lower dash.

TO INSTALL MOWER

Ensure tractor ison level surface and engage

parking brake.

I. Lower attachment lift lever to its lowest

position.

CAUTION: Lift lever is spring loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position.

NOTE: Ensure mower side suspension arms

(A) are pointing forward before sliding mower

under tractor,

2. Slide mower under tractor until it is cen-

tered under tractor.

03042te×

19

Page 20

3. ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS - Position hole

in arm over pin (B) on outside of tractor

chassis and secure with retainer spring.

4. Repeat on opposite side of tractor.

5. ATTACH REAR LIFT LINKS (C) - Lift

rear corner of mower and position slot

in link assembly over pin (D) on rear

mower bracket and secure with washer

and retainer spring.

7. Insert end of link (E) into hole in front

mower bracket (H) and secure with

washer and retainer spnng (J).

8. Hook end of clutch cable spring (Q) into

hole in idler arm (R).

9. Push clutch cable houstng guide (P) into

bracket, slide collar (L) onto guide and

secure with retainer spnng (K).

t0. install belt onto engine pulley (M) and belt

keepers (G).

6. ATTACH FRONT LINK (E) - Work from

left side of tractor. Insert rod end of link

assembly through front hole in tractor

front suspension bracket (F).

IMPORTANT: Check belt for proper routing

tn all mower pulley grooves.

11. Raise attachment lift lever to htghest

position.

12. Ifnecessary, adjus_ gauge wheels before

operating mower as shown in the Opera-

tion section of this manual.

03042[ex

2O

Page 21

TO LEVEL MOWER

Make sure tires are properly inflated to the

PSI shown ontires. If tires are over or under

inflated, it may affect the appearance of your

lawn and lead you to think the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. With all tires properly inflated and if your

lawn appears unevenly cut, determine

which side of mower is cutting lower.

2. With a 3/4" or adjustable wrench, turn lift

link adjustment nut (A) to the left to lower

LH side of mower, or, to the right to raise

LH side of mower.

NOTE: Each full turn of adjustment nut wilt

change mower height about 3/16".

Turn nut ri Turn nut left

to raise mower to lower mower

3. Test your adjustment by mowing some

uncut grass and visually checking the

appearance. Readjust, ifnecessary, until

you are satisfied with the results.

PRECISION SIDE-TO-SIDE ADJ USTMENT

1. With all tires properly inflated, park tractor

on level ground or driveway.

CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

2. Raise mower to its highest position.

3. At both sides of mower, position blade at

side and measure the distance (A) from

bottom edge of blade to the ground. The

distance should be the same on both

sides.

4. If adjustment is necessary, see step 2 in

V_sual Adjustment instructions above.

5. Recheck measurements, adjust if neces-

sary until both sides are equal.

At

21

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-side.

To obtain the best cutting results, the mower

blades should be adjusted so the front tip is

1/8" to 1/2" lower than the rear tip when the

,_ower is in its highest position.

CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap btade

with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing

straight forward, Measure distance (13)

to the ground at front and rear tip of the

blade.

• If front tip of blade is not 1/8" to 1/2" lower

than the rear tip, go to the front of tractor.

• With an 11/16" or adjustable wrench,

loosen jam nut A several turns to clear

adjustment nut B.

• With a 3/4" or adjustable wrench, turn

front link adjustment nut (B) clockwise

(tighten) to raise the front of mower, or,

counterclockwise (loosen) to lower the

front mower.

Tighten adjust nut Loosen adjust

B to raise mower nut B to lower

mowel"

Loosen jam nut A first

NOTE: Each full turn of the adjustment nut

willchange mower height about 1/8%

• Recheck measurements, adjust ifneces-

sary until front tip of blade is 1/8" to t/2"

bowerthan the rear tip.

• Holdadjustment nutin positionwith wrench

and tighten jam nut securely against ad-

justment nut.

Page 22

TO REPLACE MOWER BLADE DRIVE

BELT

The mower blade drive belt may be replaced

without tools, Park the tractor on level sur-

face. Engage parking brake.

BELT REMOVAL -

1. Remove mower from tractor (See "TO

REMOVE MOWER" in this section of

manuat).

2. Work belt off both mandrel pulleys and

idler pulleys.

3. Pull belt away from mower.

BELT tNSTALLATIO N -

1. Work belt around both mandrel pulleys

and idler pulleys

2. Ensure belt is in all pulley grooves and

inside all belt guides.

3. Install mower (See "To Instal] Mower" in

this section of this manual).

Idler

Pulleys

Mandrel

,Pulley

TO REPLACE MOTION DRIVE BELT

Park the tractor on level su#ace. Engage

parking brake. For assistance, there is a

belt installation guide decal on bottom side

of left footrest,

BELT REMOVAL -

1. Remove mower (See "TO REMOVE

MOWER" in this section of manual).

NOTE: Observe entire motion drive belt

and position of all belt guides and keepers.

2. Remove beltfrom stationary idler (A) and

clutching idler (B).

3. Pull belt slack toward rear of tractor.

Remove belt upwards from transaxle

input pulley (D).

4. Remove belt downward from engine

pulley (E).

5. Slide belt toward rear of tractor, off the

steering plate (F) and remove from tractor.

TO CHECK BRAKE

If tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced.

You may also check brake by:

1. Park tractor on a Jevel, dry concrete or

paved surface, depress clutch/brake

pedal all the way down and engage

parking brake,

2, Place gear shift lever in neutral position.

The rear wheels must lock and skid when

you try to man ualiy pus h the tractor forward.

If the rear wheels rotate, then the brake

needs to be serviced. Contact a Sears or

other qualified service center.

BELT INSTALLATION -

1. Install new belt from tractor rear to front,

over the steering plate (F) and above

clutch brake pedal shaft (G).

2, Pull belt toward front of tractor and roll

belt onto engine pulley (E).

3. Pull belt toward rear of tractor. Carefully

work bell down around transaxle input

pulley (D). Ensure belt is inside the belt

keeper.

4. Install belt through stationary idler {A)

and clutching idler (B).

5. Ensure belt is in all pulley grooves and

inside all belt guides and keepers.

6. Install mower (See "TO INSTALL MOW-

ER" in this section of manual).

22

Page 23

TRANSAXLE GEAR SHIFT LEVER NEU-

TRAL ADJUSTMENT

The transaxle should be in neutral when the

gear shift lever is in neutral (N) (lock gate)

position. The adjustment is preset at the

factory; however, if adjustment is needed,

proceed as follows:

1. Ensure transaxle is in neutral (N).

NOTE: When the tractor rear wheels move

freely, the transaxle is in neutral.

2. Loosen adjustment bolt in front of the

right rear wheeL.

3. Position the gear shift lever in the neutral

(N) position.

4. Tighten adjustment bolt securely.

NOTE: If additional clearance is needed to

get to adjustment bo]t, move mower deck

height to the lowest position.

Gearshift Lever

Neutral

Lock

Adjustment Bolt Gate

TO REMOVE WHEEL FOR REPAIRS

1. Block up axle securely.

2. Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheels have a square key - Do net lose).

3. Repair tire and reassemble.

NOTE: On rearwheels only: align grooves in

rearwheel hub and axle. Insert square key.

4. Replace washers and snap retaining ring

securely in axle groove.

5. Replace axle cover.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, purchase and

use tire sealant from Sears. Tire sealant also

prevents tire dry rot and corrosion.

Retaining

#

AxleCover "_8qu;_re Key (Rear

Wheel On]y)

FRONT WHEEL TOE-IN/CAMBER

Your new tractor front wheel toe-in and

camber is set at the factory and isnormal,

The front wheel toe-in and camber are not

adjustable. If damage has occurred to

affect the factory set front wheel toe-in or

camber, contact a Sears or other qualified

service center.

TO START ENGINE WITH A WEAK BAT-

"FIERY

_WARNING: Lead-acid batteries gener-

ate explosive gases. Keep sparks, flame

and smoking materials away from batteries.

Always wear eye protection when around

batteries.

Ifyour battery istoo weak to start the engine,

it should be recharged. (See "BATTERY" in

the MAINTENANCE section ofthis manual).

If "jumper cables" are used for emergency

starting, follow this procedure:

IMPORTANT: Your tractor is equipped with

a 12volt system. The other vehicle must also

be a 12 volt system. Do not use your tractor

battery to start other vehicles.

TO ATTACH JUMPER CABLES -

1. Connectoneend ofthe RED cabletothe

POSITIVE (+) terminal of each battery(A-

B), taking care notto short againsttractor

chassis.

2. Connect one end of the BLACK cable

to the NEGATIVE (-) terminal (C) of fully

charged battery.

3. Connect the other end of the BLACK

cable (D) to good chassis ground, away

from fuel tank and battery.

TO REMOVECABLES, REVERSEORDER-

1. BLACK cabIe first from chassis and then

from the fully charged battery.

2. RED cable last from both batteries,

Weak or Dead Fully Charged

Battery Battery

23

Page 24

REPLACING BA'I-I'ERY

n_asWARNING: Do not short battery termi-

by altowi nga wrench or any other object

to contact both terminals at the same time.

Before connecting battery, remove metal

bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected first to

prevent sparking from accidental grounding.

1. Lift seat pan to raised position.

2. Remove terminal cover,

3, Disconnect BLACK battery cable then

RED battery cable and carefully remove

battery from tractor,

4. Install new battery with termtnals _nsame

position as old battery.

5. Reinstall terminal cover.

6. First connect RED battery cable to posi-

tive (+) battery terminal wtth bolt and nut

as shown, Tighten securely.

7. Connect BLACK grounding cable to

negative (-) batteryterminal with remain-

ing bolt and nut. Tighten securely

8. Lower seat pan.

Terminal

Ceverx Negative

(Black)

Nut

Bolt

Positive

(Red)

TO REPLACE FUSE

Replace with30 amp automotive-type plug-

in fuse, The fuse holder is located behind

the dash.

TO REMOVE HOOD AND GRILL

ASSEMBLY

1. Raise hood.

2. Unsnap headlight wire connector.

3. Stand in front of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor.

4. When replacing hood, ensure to recon-

nect the headlight wire connector.

Headlight Wire

Connector

ENGINE

TO ADJUST THROTI-LE CONTROL

CABLE

The throttle control has been preset at

the factory and adjustment should not be

necessary Check adjustment as described

below before loosening cable. Ifadjustment

is necessary, see engine manual.

TO REPLACE HEADLIGHT BULB

1. Raise hood.

2. Remove bulb holder from the hole in the

backstde of the grill.

3. Replace bulb m holder and install bulb

holder securely back into the hole in the

backside of the grill.

4. Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poorly, stop running, or prevent

it from starting.

• Check wiring.

TO ADJUST CHOKE CONTROL

The choke control has been preset at

the factory and adjustment should not be

necessary. If adjustment is necessary, see

engine manual.

TO ADJUST CARBURETOR

You r carburetor has been preset at the factory

and adjustment should not be necessary.

However, m=nor adjustment may be required

to compensate for differences in fuel, tem-

perature, altitude or load. If the enginedoes

need adjustment, see engine manual.

24

Page 25

immediatelyprepareyourtractorforstorage

attheendoftheseasonorifthetractorwill

notbeusedfor30daysormore.

A_, WARNING: Never store the tractor with

gasoline in the tank inside a building where

fumes may reach an open flame or spark.

Allow the engine to cool before storing in

any enclosure,

TRACTO R

Remove mower from tractor for winter stor-

age. When moweristo bestored foraperiod

of time, clean it thoroughly, remove all dirt,

grease, leaves, etc. Store in aclean, dry area.

1, Clean entire tractor (See"CLEANING" in

the Maintenance section of this manuaf).

2. Inspect and replace belts, ff necessary

(See belt replacement instructions in the

Service and Adjustments section of this

manual).

3. Lubncate as shown in the Maintenance

section of this manual.

4, Be sure that all nuts, bolts and screws

are securely fastened. Inspect moving

parts for damage, breakage and wear.

Replace if necessary.

5. Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

BATTERY

• Fully charge the battery for storage.

• After a period of time in storage, battery

may require recharging.

• To help prevent corrosion and power

leakage during long periods of storage,

battery cables should be disconnected

and battery cleaned thoroughly (see "TO

CLEAN BATTERY AND TERMINALS" m

the Maintenance section of this manual).

• Aftercleaning, leave cables disconnected

and place cables where they cannot come

in contact with battery terminals.

• If battery is removed from tractor for

storage, do not store battery directly on

concrete or damp surfaces.

ENGINE

FUEL SYSTEM

IMPORTANT: It is important to prevent

gum deposits from forming in essential fuel

system parts such as carburetor, fuel hose,

or tank duringstorage. Also, alcoholblended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads

to separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage.

• Emprythe fuel tank by starting the engine

and letting it run until the fuel lines and

carburetor are empty.

• Never use engine or carburetor cleaner

products in the fuet tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE: Fuei stabilizer is an acceptable al-

ternative in minimizing the formation offuel

gum deposits during storage. Add stabilizer

to gasoline in fuel tank or storage container.

Alwaysfollow the mixratiofound onstabilizer

container. Run engine at least 10 minutes

afteradding stabilizer toal[owthestabilizer to

reach the carburetor. Do not empty the gas

tank and carburetor if using fuel stabilizer,

ENGINE OIL

Drain oil (with engine warm) and replace

with clean engine oil (See "ENGINE" inthe

Maintenance section of this manual).

CYLINDER(S)

1. Remove spark plug(s).