Craftsman 917242484 Owner’s Manual

Owner's Manual

ICRRFTSMRN I

8.0 HP

30 INCH TINE WIDTH

SLEEVE HITCH

TILLER ATTACHMENT

Model No.

917.242484

CAUTION:

Read and follow all Safety

Rules and Instructions

before operating this

equipment.

• Safety

• Assembly

• Operation

• Maintenance

• Repair Parts

[_ This product has a low emission engine which operates differentlyfrom previously built engines. Before you start the engine, read

Sears, Roebuck and Co., Hoffman Estates, II 60179

Visit our Craftsman website:www.sears.com/craftsman

PRINTED IN U.S.A. 179021 3.7.01 TR

and understandthis Owner's Manual.

SAFETY RULES

Safe Operation Practices for Tiller Attachments.

TRAINING

• Read the operating and service

carefully. Be thoroughly familiar with the controls and

the proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

o.

Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

Keep the area of operation clear of all persons, particu-

larly small children, and pets.

PREPARATION

• Thoroughly inspect the area where the equipment is to

be used and remove allforeign objects.

• Disengage all clutches and shift into neutral before

startingthe engine (motor).

• Do notoperate theequipment withoutweadng adequate

outergarments. Wear footwear thatwill improvefooting

on slippery surfaces.

• Handle fuel with care; it is highly flammable.

• Use an approved fuel container.

• Never add fuel to a runningengine or hot engine.

• Fillfuel tankoutdoorswithextreme care. Never fillfuel

tank indoors.

• Replace gasoline cap securely and clean up spilled

fuel before restarting.

Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by manufacturer).

OPERATION

• Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when operating on orcrossing

gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry passengers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

the tiller forany damage, and repair the damage before

restarting and operating the tiller.

• Exercise caution to avoid slipping or falling.

• If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

• Stop the engine (motor) when leaving the operating

position, before unclogging the tines, and when making

any repair, adjustments, and inspections.

• Take all possible precautions when leavingthe machine

unattended. Disengage the power take-off, lower the

attachment, shift into neutral, stop the engine, and

remove the key.

• Before cleaning, repairing, or inspecting, shut off the

engine and make certain allmoving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting.

• Do not run the engine indoors; exhaust fumes are

dangerous.

• Never operate the tiller without proper guards, plates, or

other safety protective devices in place.

• Keep children and pets away.

instruction manual

• Do notoverload the machine capacity by attempting to

till too deep at too fast a rate.

• Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

• Lift tiller out of the ground when turning corners.

• Do not put tractor in reverse gear while tiller is in the

ground.

• Never allow bystanders near the unit.

• Useonly attachments and accessories approved by the

manufacturer of the tiller (such as wheel weights,

counterweights, cabs, etc.

• Never operate the tiller without good visibility or light.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

working condition.

• Check shear bolts, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be sure

the equipment is in safe working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters, clothes dryers, etc. Allow

the engine to cool before storing in any enclosure.

• Always refer to the operator's guide instructions for

important details if the tiller is to be stored for an

extended period.

- IMPORTANT -

CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS

OF ATTRACTING ATTENTION TO IMPORTANT OR

CRITICAL INFORMATION IN THIS MANUAL.

IMPORTANT: USED TO ALERT YOU THAT THERE ISA

POSSIBILITY OF DAMAGING THIS EQUIPMENT.

NOTE: Gives essential information that will aid you to

better understand, incorporate, or execute a particular set

of instructions.

Look forthis symbol to point outimportant

safety precautions. It mean CAUTION!!!

BECOME ALERT!!! YOUR SAFETY IS

INVOLVED.

CAUTION: Always disconnect spark

plug wire and place wire where it cannot

contact spark plug in order to prevent

accidental starting when setting up,

transporting, adjusting or making re-

pairs.

WARNING

The engine exhaust from this product con-

tains chemicals known to the State of Califor-

nia to cause cancer, birth defects, or other

reproductive harm.

2

PRODUCT SPECIFICATIONS

GASOLINE CAPACITY: 1 Gallon

Unleaded Regular

OIL : SAE 30W (Above 32°F)

(Capacity: 22 oz.) SAE 5w-30 (Below 32°F)

TRANSMISSION OIL : SAE 30W

(Capacity: 40 oz.)

SPARK PLUG : Champion

(GAP: .030") RJ19LM or J19LM

CONGRATULATIONS on your purchase of a Sears tiller

attachment. It hasbeen designed, engineered and manufac-

tured to give you the best possible dependability and

performance.

Should you experience any problems you cannot easily

remedy, please contact a Sears or other qualified service

Center, which has competent, well trained technicians and

the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain yourtillerattachment

properly. Always observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Followa regular schedule inmaintaining, caringfor and

using yourtiller attachment.

• Followthe instructionsinthe Customer ResponsibiliUes

and Storage sections ofthisOwner's Manual.

IMPORTANT= THIS UNIT IS EQUIPPED WITH AN

INTERNAL COMBUSTION ENGINE AND SHOULD NOT

BE USED ON OR NEAR ANY UNIMPROVED FOREST-

COVERED, BRUSH-COVERED OR GRASS COVERED

LAND UNLESS THE ENGINE'S EXHAUST SYSTEM IS

EQUIPPED WITH A SPARK ARRESTER MEETING

APPLICABLE LOCAL OR STATE LAWS (IF ANY). IF A

SPARK ARRESTER IS USED, IT SHOULD BE MAINTAINED

iN EFFECTIVE WORKING ORDER BY THE OPERATOR.

IN THE STATE OF CALIFORNIA THE ABOVE IS REQUIRED

BY LAW (SECTION 4442 OF THE CALIFORNIA PUBLIC

RESOURCES CODE). OTHER STATES MAY HAVE

SIMILAR LAWS. FEDERAL LAWS APPLY ON FEDERAL

LANDS. SEE YOUR SEARS SERVICE CENTER/

DEPARTMENT FOR SPARK ARRESTER. (REFER TO

REPAIR PARTS SECTION OF THIS MANUAL).

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN TILLER ATTACHMENT

Forone year from date of purchase, when this tiller attachment ismaintained, lubricated, and tuned upaccording tothe

operating and maintenance instructions in the owner's manual, Sears will repair free of charge any defect in material or

workmanship.

This warranty does not cover:

• Expendable items which become wom during normal use, such as tines, spark plugs, air cleaners and belts.

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to maintain

the equipment according to the instructions contained in the owner's manual.

• Ifthis Craftsman tiller attachment is used for commercial or rental purposes, this warranty applies for only 30 days

from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THIS CRAFTSMAN TILLER TO THE NEAREST SEARS

SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS

PRODUCT IS IN USE IN THE UNITED STATES.

This Warranty gives you specific legal rights,and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA, HOFFMAN ESTATES, IL 60179

TABLE OF CONTENTS

SAFETY RULES ........................................................ 2

CUSTOMER RESPONSIBILITIES ....................... 3,7-9

WARRANTY ............................................................... 3

PRODUCT SPECIFICATIONS .................................... 3

ASSEMBLY ................................................................ 4

OPERATION ............................................................ 5-6

SERVICE & ADJUSTMENTS ................................... 10

STORAGE ................................................................ 11

TROUBLESHOOTING .............................................. 12

REPAIR PARTS - TILLER ................................... 13-16

REPAIR PARTS - ENGINE .................................. 17-19

3

ASSEMBLY

When R.H., (Right Hand) or L.H. (Left Hand) are used, it

means from a position behind the steering wheel as If you

were seated on the tractor seat and facing forward.

NOTE: Remove mower deck from tractor before mounting

tiller attachment.

• . Remove tiller from carton.

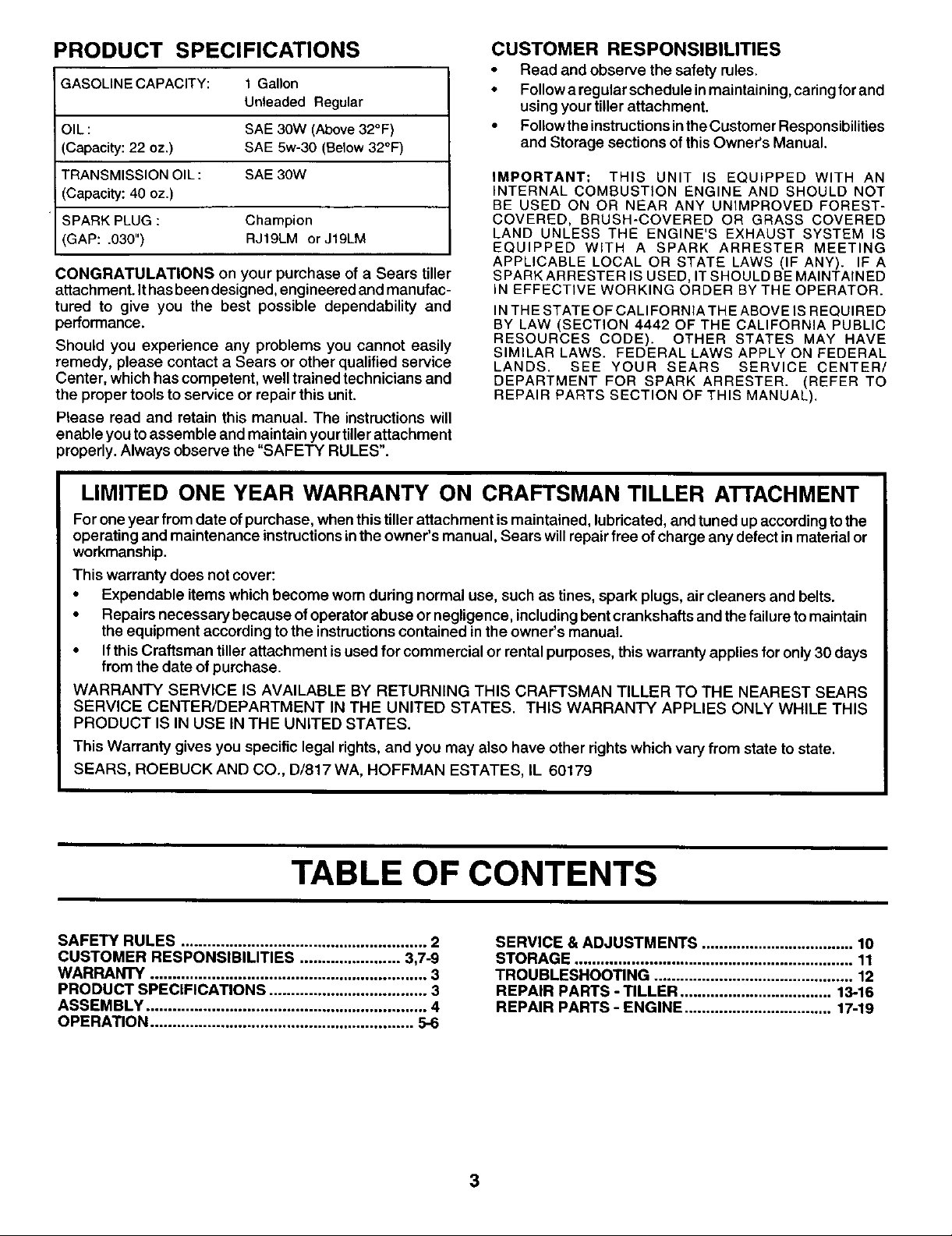

LEVEL TILLER

Place tiller on level ground so that tractor can be backed

up to it for assembly.

CAUTION: Tiller will be heavy when Iperforming the following step.

Adjust tiller gauge wheels so that engine is level (Fig. 1).

• Remove retainer spring from drilled rivet.

• Remove rivet and adjust gauge wheels up or down as

required to level tiller. Replace rivet and retainer spring.

RETAINER

SPRING

MODEL PLATE

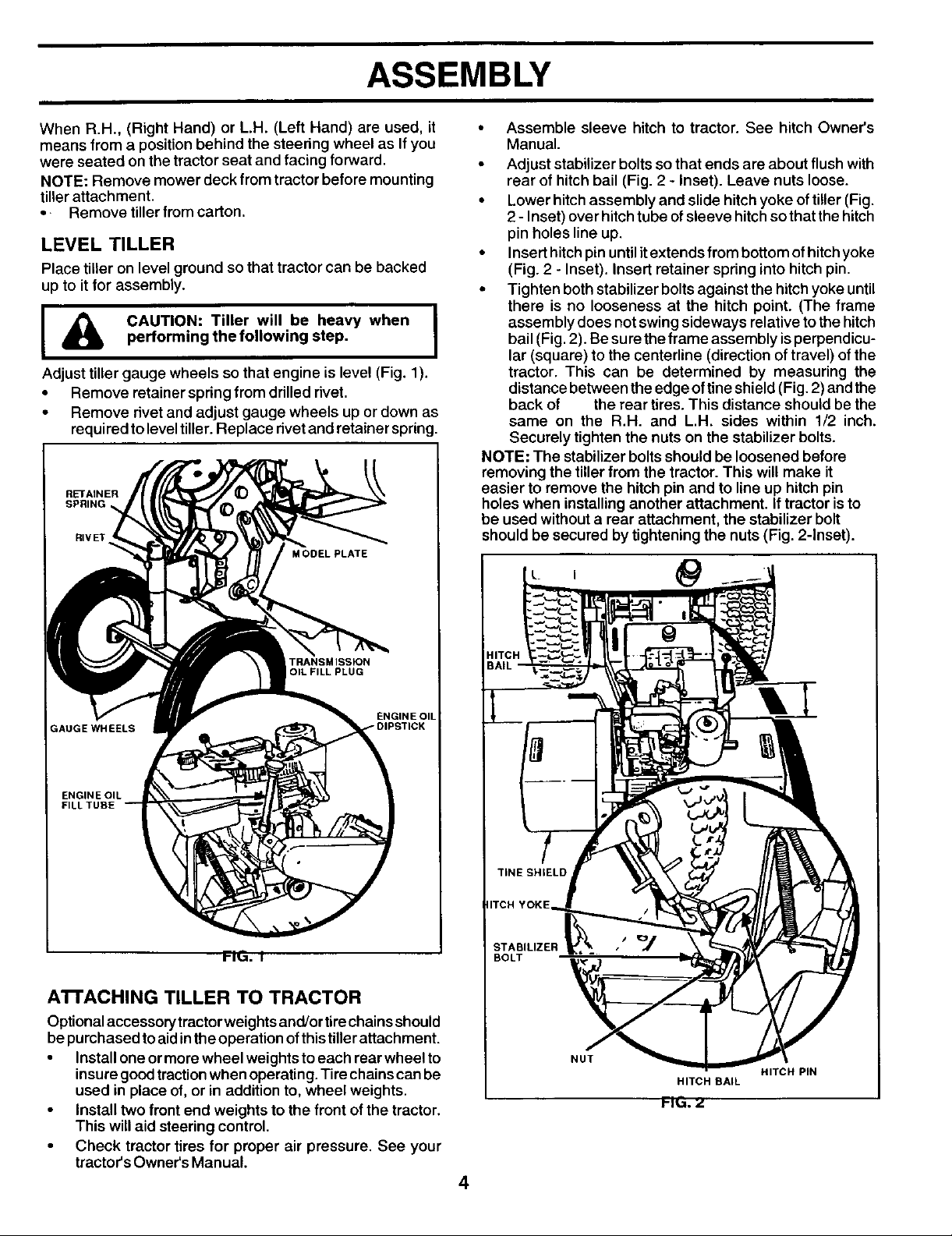

• Assemble sleeve hitch to tractor. See hitch Owner's

Manual.

• Adjust stabilizer bolts so that ends are about flush with

rear of hitch bail (Fig. 2 - Inset). Leave nuts loose.

• Lower hitch assembly and slide hitch yoke of ti!ler (Fig.

2 - Inset) over hitch tube of sleeve hitch so that the hitch

pin holes line up.

• Insert hitch pin until itextends from bottom of hitch yoke

(Fig. 2 - Inset). Insert retainer spring into hitch pin.

• Tighten both stabilizer bolts against the hitch yoke until

I

there is no looseness at the hitch point. (The frame

assembly does not swing sideways relative to the hitch

I

bail (Fig. 2). Be surethe frame assembly is perpendicu-

lar (square) to the centerline (direction of travel) of the

tractor. This can be determined by measuring the

distance between the edge of tine shield (Fig. 2) and the

back of the rear tires. This distance should be the

same on the R.H. and L.H. sides within 1/2 inch.

Securely tighten the nuts on the stabilizer bolts.

NOTE: The stabilizer bolts should be loosened before

removing the tiller from the tractor. This will make it

easier to remove the hitch pin and to line up hitch pin

holes when installing another attachment. If tractor is to

be used without a rear attachment, the stabilizer bolt

should be secured by tightening the nuts (Fig. 2-Inset).

L ,

TRANSMISSION

OIL FILL PLUG

ENGINE OIL

FILL TUBE

FIG. I

A'n'ACHING TILLER TO TRACTOR

Optional accessory tractorweights and/or tirechains should

be purchased toaidinthe operation ofthistinerattachment.

• Install one ormore wheel weights toeach rear wheel to

insure goodtractionwhen operating. Tire chainscan be

used in place of, or in addition to, wheel weights.

• Install two front end weights to the front of the tractor.

This will aid steering control.

• Check tractor tires for proper air pressure. See your

tractor'sOwner's Manual.

4

STABILIZER

BOLT

NUT

HITCH BAIL

FiG. z

HITCH PIN

OPERATION

IMPORTANT: READ THE =RULES FOR SAFE OPERATION"

CAREFULLY BEFORE OPERATING YOUR TILLER

ATTACHMENT.

HOW TO USE YOUR TILLER

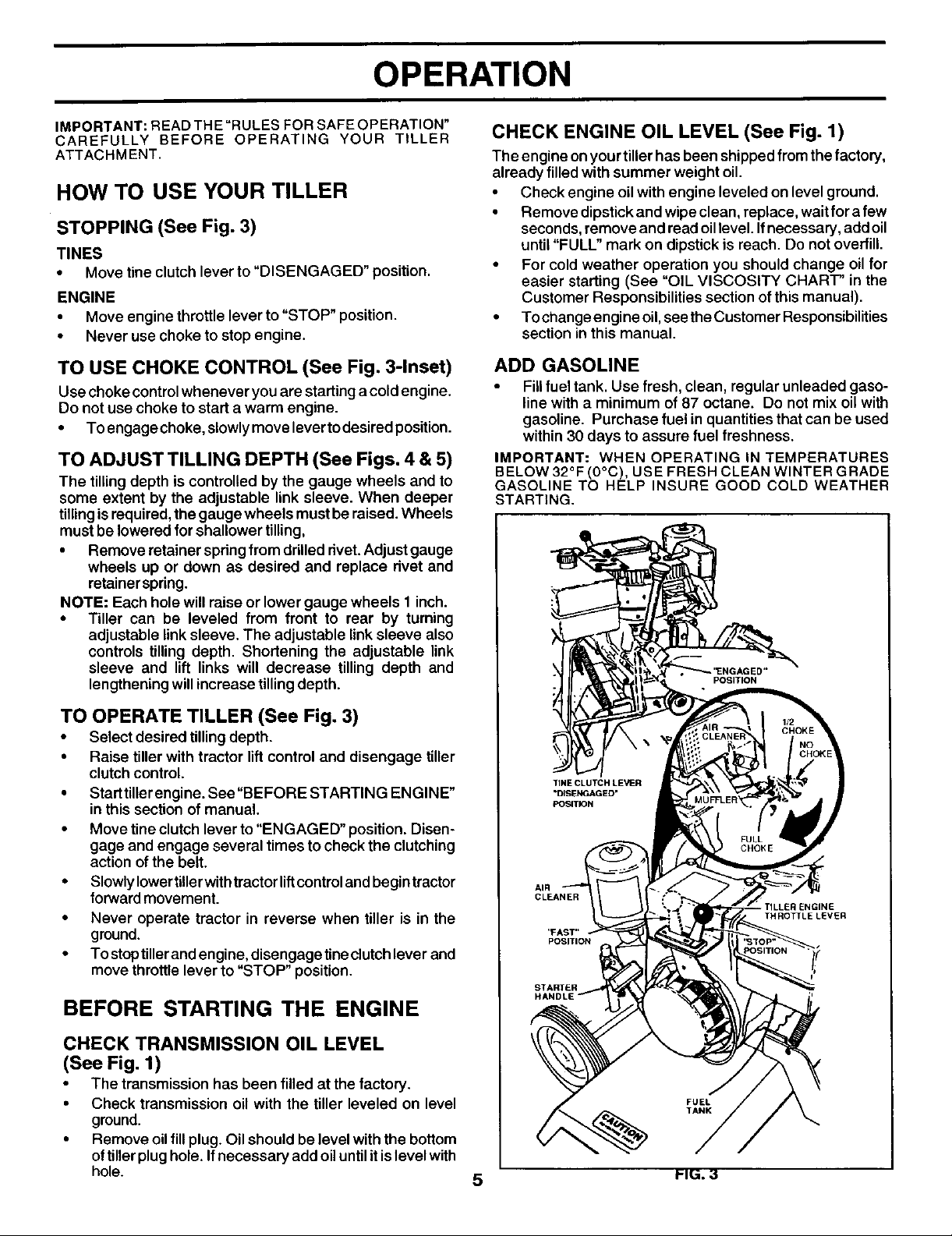

STOPPING (See Fig. 3)

TINES

• Move tine clutch lever to "DISENGAGED" position.

ENGINE

• Move engine throttle lever to "STOP" position.

• Never use choke to stop engine.

TO USE CHOKE CONTROL (See Fig. 3-Inset)

Use choke control whenever you are starting acold engine.

Do not use choke to start a warm engine.

• To engage choke, slowly move lever to desired position.

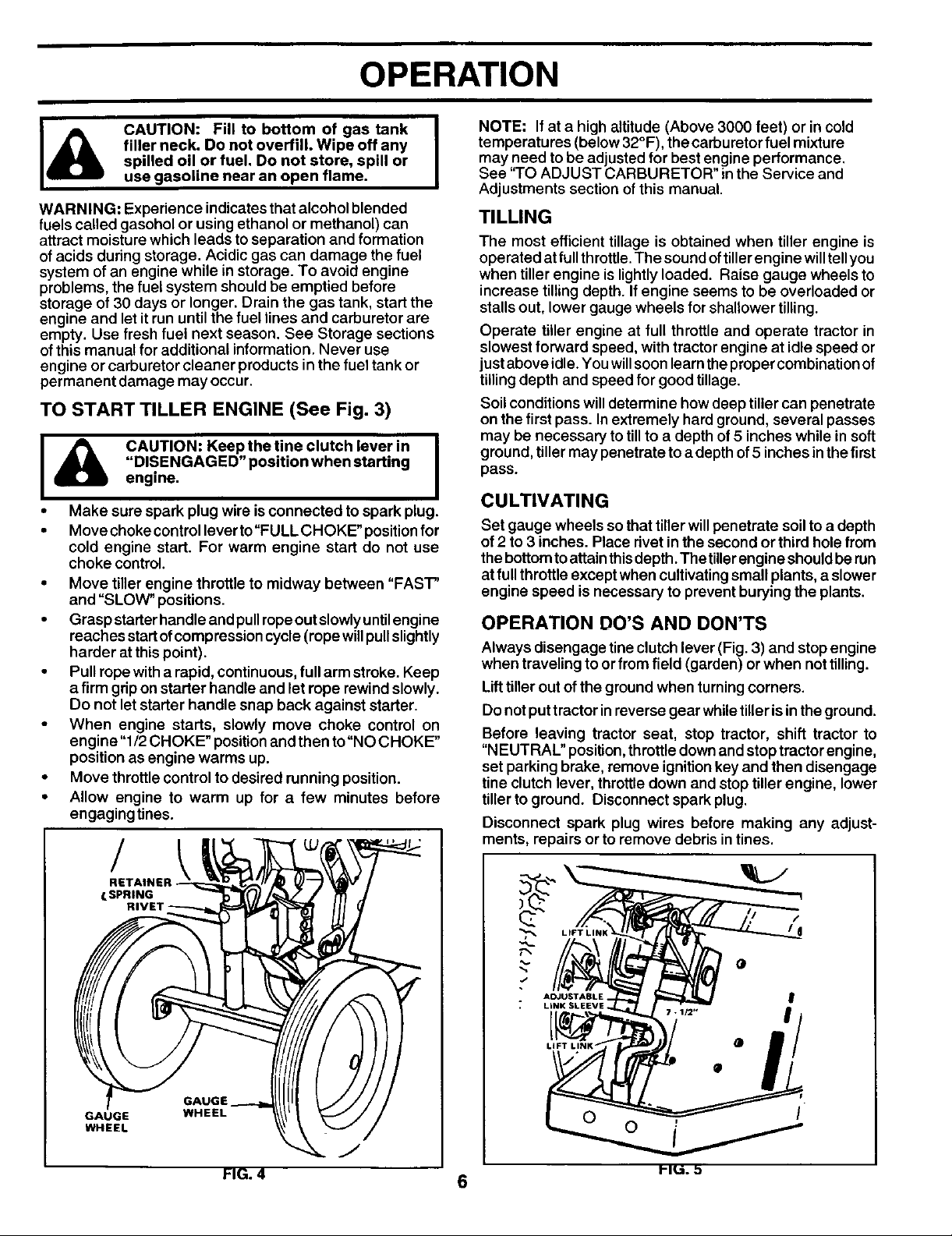

TO ADJUST TILLING DEPTH (See Figs. 4 & 5)

The tilling depth is controlled by the gauge wheels and to

some extent by the adjustable link sleeve. When deeper

tillingisrequired, the gauge wheels mustbe raised. Wheels

mustbe lowered for shallower tilling,

• Remove retainer spring from drilled rivet. Adjust gauge

wheels up or down as desired and replace rivet and

retainer spring.

NOTE: Each hole will raise or lower gauge wheels 1 inch.

• Tiller can be leveled from front to rear by turning

adjustable link sleeve. The adjustable link sleeve also

controls tilling depth. Shortening the adjustable link

sleeve and lift links will decrease tilling depth and

lengthening willincrease tillingdepth.

CHECK ENGINE OIL LEVEL (See Fig. 1)

The engine on yourtiller has been shippedfromthe factory,

already filledwith summer weight oil.

• Check engine oilwith engine leveled on level ground.

• Remove dipstickand wipe clean, replace, wait for a few

seconds, remove and read oil level. Ifnecessary, add oil

until "FULL" mark on dipstick is reach. Do not overfill.

• For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHARr" in the

Customer Responsibilities section of this manual).

• To change engine oil, see the Customer Responsibilities

section inthis manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded gaso-

line with a minimum of 87 octane. Do not mix oil with

gasoline. Purchase fuel in quantitiesthat can be used

within 30 days to assure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F (0°C), USE FRESH CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

POSITION

TO OPERATE TILLER (See Fig. 3)

• Select desired tillingdepth.

• Raise tiller with tractor lift control and disengage tiller

clutch control.

• Start tillerengine. See"BEFORE STARTING ENGINE"

in this section of manual.

• Move tine clutch lever to"ENGAGED" position. Disen-

gage and engage several times to check the clutching

action of the belt.

• Slowly lowertillerwithtractor liftcontroland begintractor

forward movement.

• Never operate tractor in reverse when tiller is in the

ground.

• To stoptillerand engine, disengage tineclutchlever and

move throttle lever to "STOP" position.

BEFORE STARTING THE ENGINE

CHECK TRANSMISSION OIL LEVEL

(See Fig. 1)

• The transmission has been filled at the factory.

• Check transmission oil with the tiller leveled on level

ground.

• Remove oil fillplug. Oil should be level with the bottom

oftillerplug hole. If necessary add oil untilit is level with

hole.

TINE CLUTCH LEVER

"DISENGAGED"

POSITION

AIR

CLEANER

STARTER

5 PI_.

TILLER ENGINE

TH ROT]LE LEVER

OPERATION

CAUTION: Fill to bottom of gas tank I

filler neck. Do not overfill Wipe off any

spilled oil or fuel, Do not store, spill or

use gasoline near an open flame.

WARNING: Experience indicates that alcohol blended

fuels called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation

of acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage sections

of this manual for additional information. Never use

engine or carburetor cleaner products in the fuel tank or

permanent damage may occur.

TO START TILLER ENGINE (See Fig. 3)

"DISENGAGED" position when starting

CAUTION: Keep the tine clutch lever in I

engine.

Make sure spark plug wire isconnected to spark plug,

• Move choke control lever to=FULL CHOKE" positionfor

cold engine start. For warm engine start do not use

choke control.

• Move tiller engine throttle to midway between "FAST'

and "SLOW" positions.

• Grasp starter handle and pull rope out slowly until engine

reaches start ofcompression cycle (rope will pull slightly

harder at this point).

• Pull rope with a rapid, continuous, full arm stroke. Keep

a firm grip on starter handle and let rope rewind slowly.

Do not let starter handle snap back against starter.

• When engine starts, slowly move choke control on

engine "1/2 CHOKE" position and then to"NO CHOKE"

position as engine warms up.

• Move throttle control to desired running position.

• Allow engine to warm up for a few minutes before

engaging tines.

/

RETAINER

{SPRING

NOTE: If at a high altitude (Above 3000 feet) or in cold

temperatures (below 32°F), the carburetor fuel mixture

may need to be adjusted for best engine performance.

I

See "TO ADJUST CARBURETOR" in the Service and

Adjustments section of this manual.

TILLING

The most efficient tillage is obtained when tiller engine is

operated at full throttle. The sound of tiller engine will tellyou

when tiller engine is lightly loaded. Raise gauge wheels to

increase tilling depth. If engine seems to be overloaded or

stalls out, lower gauge wheels for shallower tilling.

Operate tiller engine at full throttle and operate tractor in

slowest forward speed, with tractor engine at idle speed or

just above idle. You willsoon learn the proper combination of

tilling depth and speed for good tillage.

Soil conditions will determine how deep tiller can penetrate

on the first pass. In extremely hard ground, several passes

may be necessary to till to a depth of 5 inches while in soft

ground, tiller may penetrate to a depth of 5 inches in the first

pass.

I

CULTIVATING

Set gauge wheels so that tiller willpenetrate soil to a depth

of 2 to 3 inches. Place rivet in the second or third hole from

the bottom to attain this depth. The tiller engine should beran

at full throttle except when cultivating small plants, a slower

engine speed is necessary to prevent burying the plants.

OPERATION DO'S AND DON'TS

Always disengage tine clutch lever (Fig. 3) and stop engine

when traveling to or from field (garden) or when not tilling.

Lift tiller out of the ground when turning corners.

Do not put tractor in reverse gear while tiller is inthe ground.

Before leaving tractor seat, stop tractor, shift tractor to

"NEUTRAL" position, throttle down and stop tractor engine,

set parking brake, remove ignition key and then disengage

tine clutch lever, throttle down and stop tiller engine, lower

tiller to ground. Disconnect spark plug.

Disconnect spark plug wires before making any adjust-

ments, repairs or to remove debris in tines.

GAUGE

WHEEL

GAUGE

WHEEL

FIG. 4 6

LIFT LINK

ADJUSTABLE

LINK SLEEVE

LIFT LINK _

I

I'IL_. _)

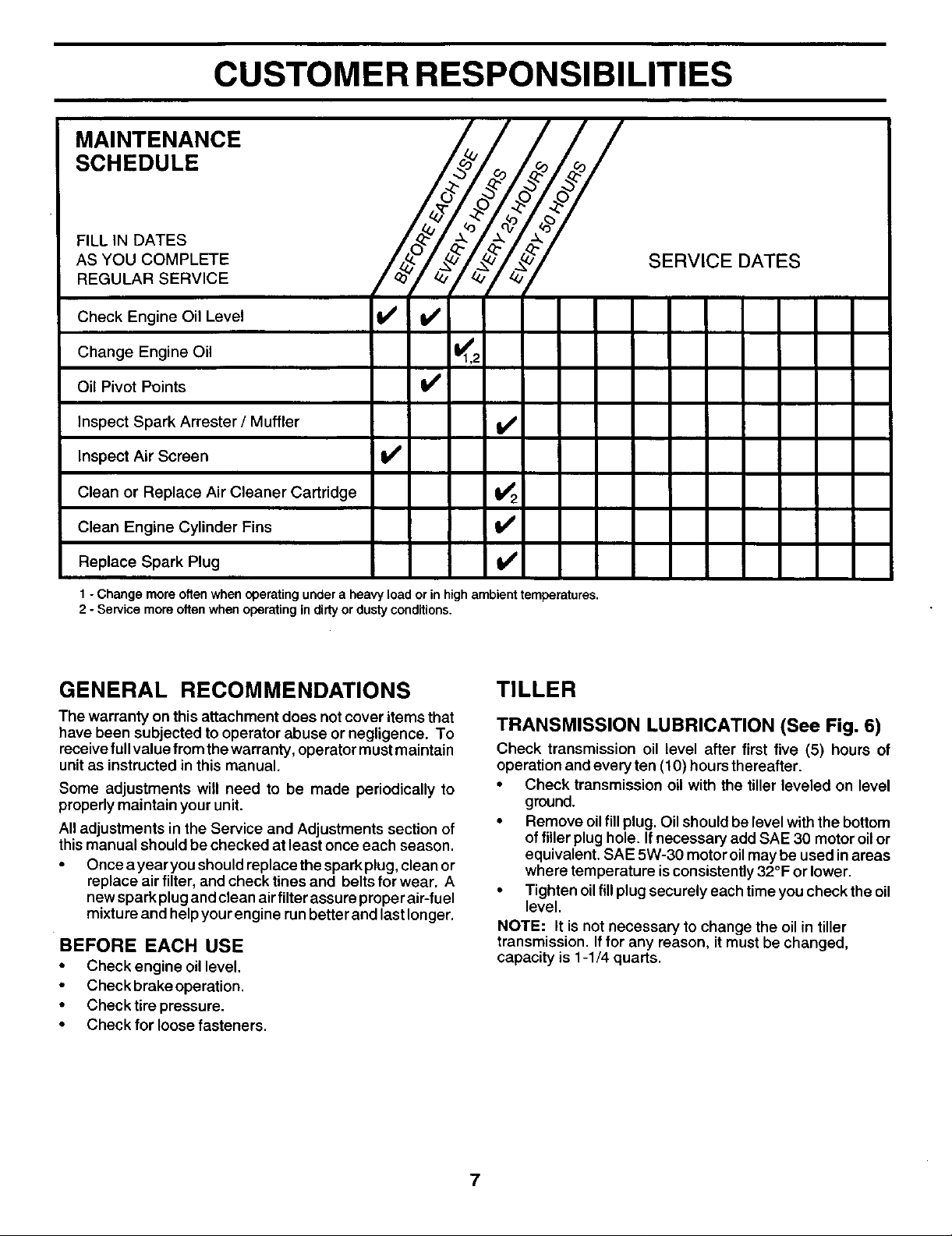

CUSTOMER RESPONSIBILITIES

MAINTENANCE

SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check Engine Oil Level If If

Change Engine Oil _1,2

Oil Pivot Points V'

Inspect Spark Arrester/Muffler If

Inspect Air Screen I_

Clean or Replace Air Cleaner Cartridge I_ 2

Clean Engine Cylinder Fins I/

SERVICE DATES

Replace Spark Plug I/

1- Change moreoften whenoperatingundera heavy load or inhigh ambienttemperatures.

2 - Service more oftenwhen operatingin dirtyor dusty conditions.

GENERAL RECOMMENDATIONS

The warranty on this attachment does not cover items that

have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

unit as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your unit.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season.

• Once ayear you should replace the spark plug, clean or

replace air filter, and check tines and belts for wear. A

new spark plug and clean air filterassure proper air-fuel

mixture and help your engine run better and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check for loose fasteners.

TILLER

TRANSMISSION LUBRICATION (See Fig. 6)

Check transmission oil level after first five (5) hours of

operation and every ten (10) hours thereafter.

• Check transmission oil with the tiller leveled on level

ground.

• Remove oilfill plug. Oil should be level with the bottom

of filler plug hole. Ifnecessary add SAE 30 motor oilor

equivalent. SAE 5W-30 motor oilmay be used in areas

where temperature isconsistently32°F or lower.

• Tighten oilfill plug securely each time you check the oil

level.

NOTE: It is not necessary to change the oil intiller

transmission. If for any reason, it must be changed,

capacity is 1-1/4 quarts.

7

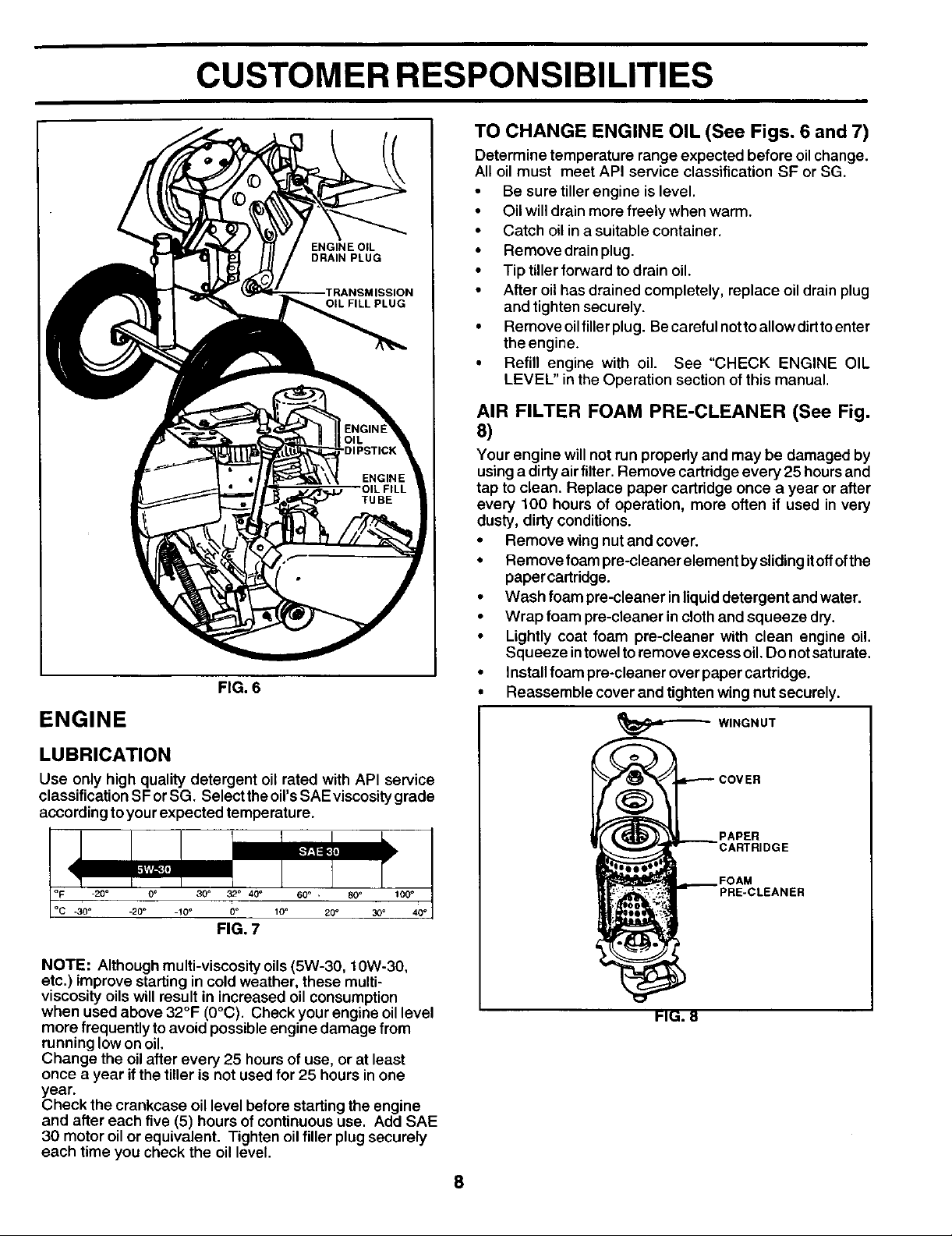

CUSTOMER RESPONSIBILITIES

FIG. 6

ENGINE

LUBRICATION

Use only high quality detergent oil rated with API service

classification SF orSG. Select the oil's SAE viscosity grade

according to your expected temperature.

TO CHANGE ENGINE OIL (See Figs. 6 and 7)

Determine temperature range expected before oilchange.

All oil must meet API service classification SF or SG.

• Be sure tiller engine is level.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove drain plug.

• Tip tiller forward to drain oil.

• After oil has drained completely, replace oil drain plug

and tighten securely.

• Remove oilfiller plug. Becareful notto allow dirt to enter

theengine.

• Refill engine with oil. See "CHECK ENGINE OIL

LEVEL" in the Operation section of this manual.

AIR FILTER FOAM PRE-CLEANER (See Fig.

8)

Your engine willnot run properly and may be damaged by

using a dirty air filter. Remove cartridge every 25 hours and

tap to clean. Replace paper cartridge once a year or after

every 100 hours of operation, more often if used in very

dusty, dirty conditions.

• Remove wing nutand cover.

• Remove foam pre-cleaner element by sliding itoff of the

paper cartddge.

• Wash foam pre-cleaner in liquid detergent and water.

• Wrap foam pre-cleaner in cloth and squeeze dry.

• Lightly coat foam pre-cleaner with clean engine oil.

Squeeze intowel to remove excess oil. Do not saturate.

• Install foam pre-cleaner over paper cartridge.

Reassemble cover and tighten wing nut securely.

-_ WINGNUT

COVER

PAPER

-20 ° 0= 30_ 32 o 40_ 60 ° . 80 _ 100 °

-30 o -20 o -10 o 0 ° 10 _ 20 ° 30 ° 40 °

FIG. 7

NOTE: Although multi-viscosity oils (5W-30, 10W-30,

etc.) improve starting in cold weather, these multi-

viscosity oils will result in increased oil consumption

when used above 32°F (0°C). Check your engine oillevel

more frequently to avoid possibleengine damage from

running lowon oil.

Change the oil after every 25 hours of use, or at least

once a year ifthe tiller is not used for 25 hours in one

year.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use. Add SAE

30 motor oil or equivalent. Tighten oil filler plug securely

each time you check the oil level.

FOAM

PRE-CLEANER

PIG. 8

8

Loading...

Loading...