Page 1

Operator's Manual

IH II III

Ic FT=M..°I

IIIIIIII

LAWN TRACTOR

24 HR* 48" Mower

ElectricStart

Automatic Transmission

Model No.

917.20402

• EspaSol, p. 39

I_ his product has a low emission engine which operates I

differently from previously built engines. Before you start the

Iengine, read and understand this manual.

IMPORTANT:

Read and follow all Safety

Rules and instructions before

operating this equipment.

For answers to your questions

about this product, call:

1-888-331-4569

Craftsman Customer Help Line

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

*Thepowerratingasdeclarodbytheenginemanufacturettsthe * La pctensia nominaI dectarada per el fabdcaote d_ rector e.sla

average gross power output at the specked RPM of a typicaJ saJidamedia de po_encia brF_aa Ias RPM espe_ficadas de un

production engine for the engine model measured using SAE motor de eerie tfpi¢o para e! modelo de motor, medida seg_n

Standards for engine gross power, Please refer to the engine _asnormas SAE sobra p_enda bruta de mOtor, Para m_

manufacturer for detaJls, !nformadbn, con,suiteal fabdcante del mOtor,

588807626

Page 2

Warranty .................................................. 2

Safety Rules ............................................ 3

....Product Specifications ............................. 6

Assembly/Pre-Operation ......................... 7

Operation ................................................. 9

Maintenance Schedule .......................... 18

Maintenance .......................................... 18

Service and Adjustments ....................... 23

Storage .................................................. 33

Troubleshooting ..................................... 34

Sears Service ............... _......... Back Cover

CRAFTSMAN LIMITED WARRANTY

FOR "i'WO YEARS from the date of purchase, all non-expendable parts of this riding equipment are

warranted against defects in material or workmanship, With proof of purchase, a defective non-expendable

part will receive free repair or replacement at option of seller,

Battery Limited Warranty

FOR 90 DAYS from the date of purchase, the battery (an expendabie part) of this riding equipment is

warranted against defects in material or workmanship, With proof of purchase, you will receive a new

battery at no charge. You are responsible for the labor cost of batten./installation,

Additional Limited Warranties

In the following additiona; warranties, you are responsible for the labor cost of part installation after the

second year from the date of purchase.

FOR FIVE YEARS from the date of purchase, the frame of this riding equipment is warranted against any

defects in material or workmanship, With proof of purchase, you will receive a new frame at no charge.

FOR TEN YEARS from the date of purchase, the front axle of this riding equipment is warranted against

any defects in material or workmanship. With proof of purchase, you will receive a new axle at no charge.

FOR AS LONG AS IT IS USED by the odginal owner after the tenth year from the date of purchase, the

cast iron front axle (if equipped) of this riding equipment is warranted against any defects in material or

workmanship, With proof of purchase, you will receive a new cast iron front axle at no charge.

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, visit the web page: www.crafteman.com/

warranty

Product Replacement

If part repair or repiaoement is impossible, you will receive a new riding equipment unit of the Same or

equivalent model.

Warranty Restriction

All warranty coverage is void ff this riding equipment is ever used while providing commercial services or ff

rented to another person.

This warranty covers ONLY defects In material and workmanship, Warranty coverage does NOT

include:

• Expendable parts (except battery) that can wear out from normal use within the warranty period, including

but not limited to blades, spark plugs, belts and air, oil or gas filters.

• Standard maintenance servicing, oil changes or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or

glass,

. Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or

maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by towing

objects beyond the capability of the riding equipment, impacting objects that bend the frame, axle

assembly or crankshaft, or over-speeding the engine,

• Repairsne_essarybecause_f_perat_rneg_igence,inc_udingbutn_tlimitedt_'e(ectrica_andmechanica_

damage caused by improper storage, failure to use the proper grade and amount of engine oil, failure

to keep the deck clear of flammable debris, or failure to maintain the riding equipment according to the

instructions contained in the operator's manual.

• Engine (fuet system) cleaning or repairs caused by fuet determined to be contaminated or oxidized

(stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product labeI replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary from stale to state,

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

Page 3

_DANGER:This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death,

A(_WARNING: Inordertopreventacciden-

tal starting when setting up, transporting,

adjusting or making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_t, WARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

A_,WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate onty at the lowest possible speed

when ona slope. Tooheavy of a toad,while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of yourtractor.

_L.WARNING: Engine exhaust, some of

its constituents, and certain vehicle compo-

nents contain or emit chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

_ILWARNING: Battery posts,terminals and

related accessories contain lead and lead

compounds, chemicals knownto the State of

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling.

1,CHILDREN

_WARNING! CHILDREN CAN BE IN-

JURED BYTHIS EQUIPMENT, TheAmeri-

can Academy of Pediatrics recommends

that children be a minimum of 12 year of

age before operatinga pedestriancontrolled

lawn mower and a minimum of I6 years of

age before operating a riding lawn mower.

J_.WARNING! CHILDREN CAN BE

SERIOUSLY INJURED OR KILLED BY

THIS EQUIPMENT. Carefully read and

follow all of the safety instructions below,

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

" saw them.

• Keep children out of the mowing area

and inthewatchfulcare of aresponsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carry children, even with the

blades shut off. They may fall off and

be seriously injuredor interfere withsafe

machine operation. Children who have

beengiven rides inthe past maysuddenly

appear inthe mowing area for another

ride and be run over or backed over by

the machine.

• Never allow children to operate the ma-

chine.

• Use extreme caution when approaching

blind corners, shrubs, trees, or other

objects that may block your view of a

child.

II. GENERAL OPERATION

- Read, understand, andfollowallJnstruc-

tions on the machine and inthe manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine. Keep clear

ofthe discharge opening at all times.

- Only allow responsible adults, who are

familiar with the instructions,to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

• Ensure the area is clear of bystanders

beforeoperating. Stop machine ifanyone

enters the area.

• Never carry passengers,

- Do not mow in reverse unless absolutely

necessary. Always lookdown and behind

before and while backing.

o Never direct discharged materialtoward

anyone. Avoid discharging material

against a watt or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

- Do notoperate machine withoutthe entire

grass catcher, discharge chute, orother

safety devices in place and working.

3

Page 4

• Slow down before turning.

• Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, and stop engine before

dismounting. Manually lock ignition

switch.(See "MANUALUx' LOCKING

THE SmartSwitch TM IGNITION" in the

Operation section of this manual).

• Disengage blades when not mowing.

Shut off engine and wait for all parts to

come to a complete stop before cleaning

the machine, removingthe grass catcher,

or unclogging the discharge chute.

• Operate machine only indaylight or good

artificial light.

• Do not operatethe machine while under

the influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Use extreme caution when loading Or

unloading the machine into a traiJer or

truck.

• Always weareye protectionwhen operat-

ing machine.

• Use ear protectors to avoid damage to

hearing.

• Data indicates that operators, age 60

years and above, are involved in alarge

percentage of riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enoughto pretectthemselves and

others from serious injury.

• Followthemanufacturer'srecommenda-

tienferwheelweights orcounterweights.

o Keep machine free of grass, leaves or

other debris build-upwhich cantouch hot

exhaust/engine parts and burn. Do not

allow the mower deck to plow leaves or

other debris which can cause build-up

to occur. Clean any oil or fue! spillage

before operating or storing the machine.

Allow machine to cool before storage.

III, SLOPE OPERATION

_ILWARNING! When loading or unloading

this machine, do not exceed the maximum

recommended operation angle of 15°.

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result insevere injury or death. Operation

on all slopes requires extreme caution. If

you cannot back up the slope or ifyou feel

uneasy on it, do not mow it.

• Mow up and down slopes, not across.

• Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

• Choose a low ground speed so thatyou

will not have to stop or shift while on the

slope.

° Do not mow on wet grass. Tires may

lose traction. Always keep the machine

in gear when going down slopes.

• Donotshiftto neutral and coast downhill.

• Avoid starting, stopping, or turning on a

slope. Ifthe tires ]osetraction, disengage

the blades and proceed slowly straight

down the slope.

• Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

• Use extreme caution while operating

machine with grass catchers or other

attachments; they can affect the stabil-

ity of the machine. Do no use on steep

slopes.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

• Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

IV. TOWING

• Towenly witha machine thathasahitch

designed fortowing, Do not attachtowed

equipment except at the hitch point.

• Followthe manufacturer's recommenda-

tionfor weight limitsfor towed equipment

and towing on slopes.

• Never allow children or others in or on

towed equipment.

• Onslopes, the weight ofthe towed equip-

ment may cause loss oftraction andloss

of control.

• Travel slowly and allow extra distance to

stop.

Page 5

V,SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care inhandling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

• Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

- Use only approved gasoline container.

• Never remove gas cap or add fuel with

the engine running.

• Allow engine to cool before refueling.

° Never fuel the machine indoors.

• Never storethe machine orfuel container

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

• Never fill containers inside a vehicle or

on atruck or trailer bedwith plastic liner.

Always place containers on the ground

away from your vehicle when filling.

• Remove gas-powered equipment from

the truck or trailer and refuel it on the

ground. Ifthis is not possible, then refuel

such equipmentwith aportablecontainer,

rather than from a gasoline dispenser

nozzle.

- Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until fueling is complete. Do not

use a nozzle lock-open device.

• tffuelis spilled on clothing, changecloth-

ing immediately.

• Never overfill fuel tank. Replace gas cap

and tighten securely.

GENERAL SERVICE

• Never operate machine ina closed area.

• Keep all nuts and boltstighttoensurethe

equipment is in safe working condition.

• Nevertamperwith safetydevices. Never

interfere with the intended function of a

safety device or reduce the protection

provided by a safety device. Check there

proper operation regularly, NEVER oper-

ate a machine with a safety device that

does notfunction properly.

• Keep machine free of grass, leaves, or

other debris build-up. Clean oil or fuel

spillage and remove any fuel-soaked

debris. Allow machine to cool before

storing.

• If you strike a foreign object, stop and

inspectthe machine. Repair,ifnecessary,

before restarting.

• Never make any adjustments or repairs

with the engine running,

• Checkgrass catcher components andthe

discharge chute frequently and replace

with manufacturer's recommended parts,

when necessary.

• Mowerbladesaresharp. Wraptheblade

orwear gloves, and use extreme caution

when servicing them.

• Check brakeoperationfrequently. Adjust

and service as required.

• Maintain orreplace safety and instruction

labels, as necessary, -'

Use ear protectors to avoid damage to hearing.

Always wear eye protectionwhen operatingmachine.

5

Page 6

PRODUCT SPECIFICATIONS

Gasoline Capacity 4.0 Gallons/15,14 L

and type: Regular Unleaded *

Oil Type: SAE30 (above 32°F/0°C

(API: SG-SL) BAE 5W30 (below 32°F/0°C

Oil Capacity: WI Filter: 64 Oz./1,89 L

W/out Filter: 60 Oz./1,77 L

Spark Plug: Champion RC12YC

(Gap: .030"/0,76 ram)

16 Amps,@ 3600 RPM

Amp/Hr: 28

Min. OCA: 230

Case size: UIR

45-55 Ft. LbsJ62-75 Nm

Char,,ging System:

Battery:

Blade Bolt Torque:

*_jLGasoline containing up to 10% ethanol (EIO) _s

acceptable for use in this machine. The use of

any gasoline exceeding 10% ethanol (EtO) will

void the product warranty.

CONGRATULATIONS on your purchase of

a new tractor. It has been designed, engi-

neered and manufactured to give you the best

possible dependability and performance.

Should you experience any problem you can-

not easily remedy, please contact a Sears or

other qualified servicecenter. We havecom-

petent, well-trained representatives and the

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the 'SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow aregular schedule in maintaining,

caring for and using your !ractor.

o Follow instructions under 'Maintenance"

and "Storage" sections of this manual,

• Wear proper Personal Protective Equip-

ment (PPE) while operating this machine,

including(at a minimum) sturdy footwear,

eye protection, and hearing protection,

Do not mow in shorts and/or open toed

footwear,

• Always let someone knowyou areoutside

mowing.

_,WAR NING: This tractor is equipped with

an internal combustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass-

covered land unless the engine's exhaust

system is equipped with a spark arrester

meeting applicable local or state laws (if

any), If a spark arrester is used, it should

be maintained in effective working order by

the operator.

Inthe state ofCalifornia theabove isrequired

bylaw (Section 4442 ofthe California Public

Resources Code). Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

availablethroughyour nearestSears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman@ product is

designed and manufactured for years of

dependable operation. But like all products,

itmay require repairfrom time to time. That's

when having aRepairProtection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here's what's included inthe Agreement:

• Expertservice byour 12,000 professionaI

repair specialists.

• Unlimited service andnocharge forparts

and labor on all covered repairs,

Product replacement if your covered

product can't be fixed,

• Discount of 25% from regular price of

service and service-related parts not

covered bythe agreement; also, 25% off

regular price of preventive maintenance

check.

• Fast help by phone - phone support

from aSears representative on products

requiring in-homerepair, plusconvenient

repair scheduling,

Once youpurchasethe Agreement, asimple

phone call isallthat ittakes for you to sched-

uleservice."Youcan callanytime dayornight,

or schedule a service appointment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories, That's

the kindof professionalism you can count on

to help prolong the life ofyour new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

Forprices andadditional information call

1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional instaflation of home

appliances, garage door openers, water

heaters, and other major home items,in the

U,S.A, call 1-8004-MY-HOME®.

Page 7

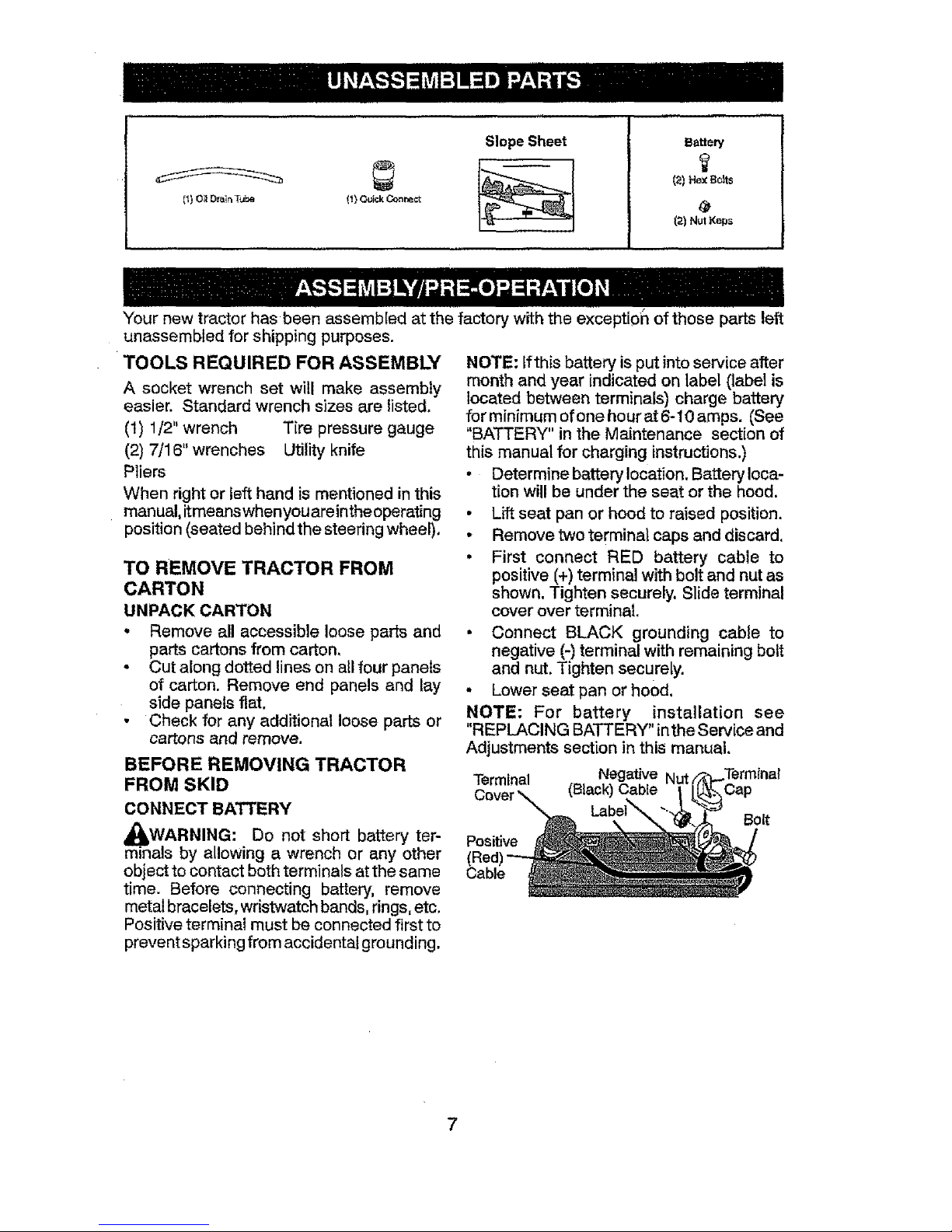

[_) Oil DrainT_e (1} Qu_;k Correct

Slope Sheet Battery

(21 Hex Bolts

12)Nut Keps

Your new tractor has been assembled at thefactory withthe exception of those parts left

unassembled for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) 1/2" wrench Tire pressure gauge

(2) 7/16" wrenches UtUityknife

Pliers

When right or left hand ismentioned inthis

manual,itmeanswhenyouareintheoperating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

• Remove all accessible loose parts and

parts cartons from carton,

° Cut along dotted lines on allfour panels

of carton. Remove end panels and lay

side panels flat.

• Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

CONNECT BATTERY

_It, WARNING: Do not short battery ter-

minals by allowing a wrench or any other

object to contact both terminals atthe same

time. Before connecting battery, remove

metalbracelets, wristwatch bands, rings,etc.

Positive terminal must be connected first to

prevent sparking from accidental grounding.

NOTE: Ifthis battery isput intoservice after

month andyear indicated on label (label is

located between terminals) charge battery

forminimum ofonehourat6-1Oamps. (See

"BATTERY" in the Maintenance section of

this manual for charging instructions.)

• Determine batterylocation, Batteryloca-

tion willbe under the seat or the hood.

• Lift seat pan or hood to raised position.

• Remove two terminal caps and discard.

• First connect RED battery cable to

positive (+) terminal with bolt and nut as

shown. Tighten securely. Slide terminal

cover over terminal.

• Connect BLACK grounding cable to

negative (-) terminal with remaining bolt

and nut.Tighten securely.

- Lower seat pan or hood,

NOTE: For battery installation see

"REPLACING BATTERY" inthe Service and

Adjustments section in this manual.

Terminal Negative Terminal

Cover\_ Cap

BOlt

Positive

Cable

Page 8

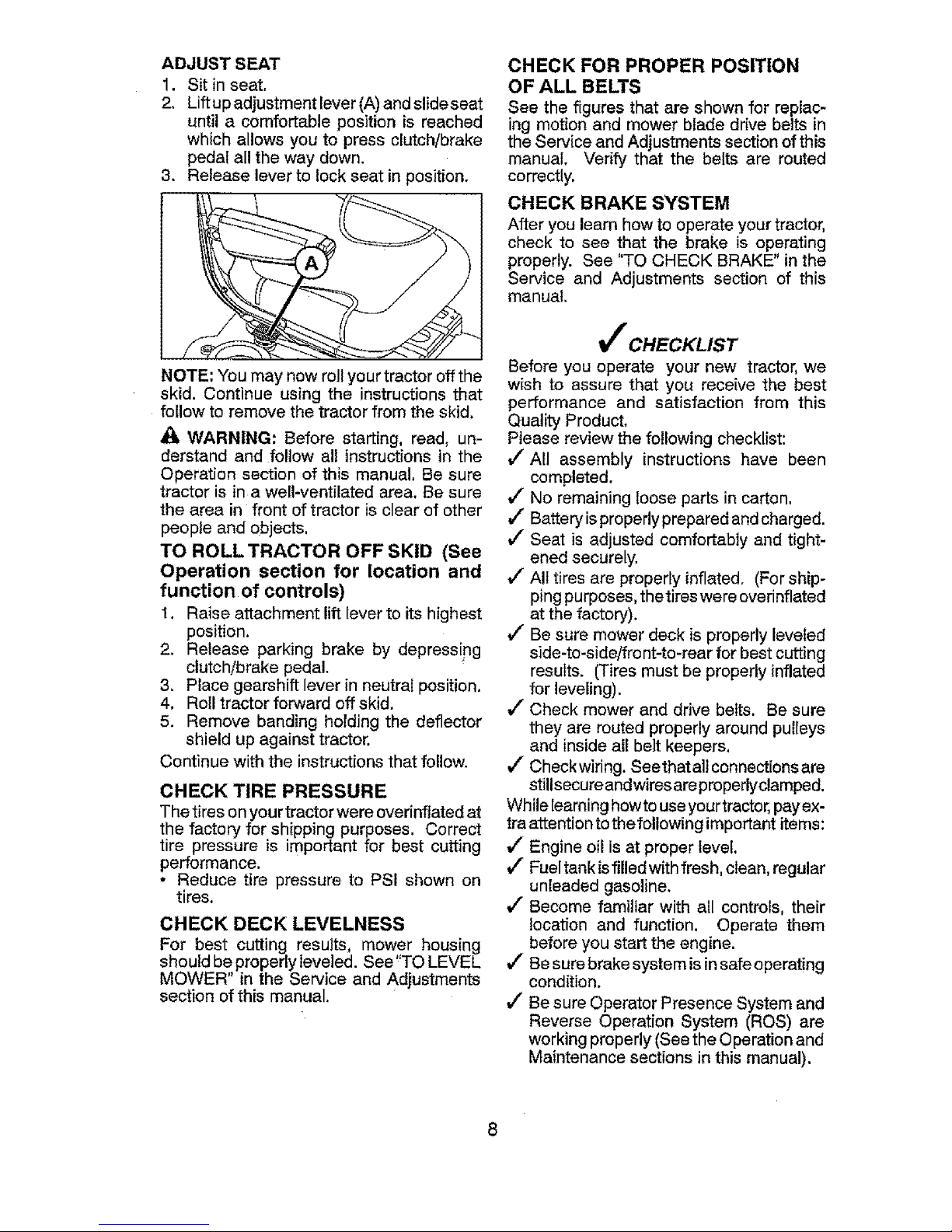

ADJUST SEAT

1. Sit inseat,

2. Liftup adjustment lever (A)and slideseat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

3. Release lever to lock seat in position.

NOTE: You may now rollyour tractor off the

skid. Continue using the instructions that

follow to remove the tractor from the skid.

WARNING: Before starting, read, un-

derstand and follow al! instructions in the

Operation section of this manual, Be sure

tractor is ina well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects,

TO ROLL TRACTOR OFF SKID (See

Operation section for location and

function of controls)

1. Raise attachment lift leverto its highest

position.

2. Release parking brake by depressing

clutch/brake pedal.

3. Place gearshift lever in neutral position.

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Continue with the instructions that follow.

CHECK TIRE PRESSURE

Thetires onyourtractorwere overinflatedat

the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See*'TO LEVEL

MOWER' in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION

OF ALL BELTS

See the figures that are shown for replac-

ing motion and mower blade drive belts in

the Service and Adjustments section of this

manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate yourtractor,

check to see that the brake is operating

properly. See "TO CHECK BRAKE" inthe

Service and Adjustments section of this

manual.

t_ CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product,

Please review the following checklist:

I/All assembly instructions have been

completed,

J" No remaining loose parts in carton,

vF Battery isproperly prepared andcharged.

J" Seat is adjusted comfortably and tight-

ened securely.

_/"All tires are properly inflated. (For ship-

ping purposes, thetires were overinflated

at the factory).

_/"Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling).

J" Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

J Check wiring. Seethata]t connections are

stillsecure andwires areproperlyclamped.

While learninghowto useyourtractor,payex-

traattention tothefollowing important items:

!/Engine oil is at proper level.

_/" Fueltank isfilled with fresh, clean, regular

unleaded gasoline.

J" Become familiar with all controls, their

location and function. Operate them

before you start the engine.

J" Besure brake system isinsafe operating

condition.

_/Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (Seethe Operation and

Maintenance sections in this manual).

8

Page 9

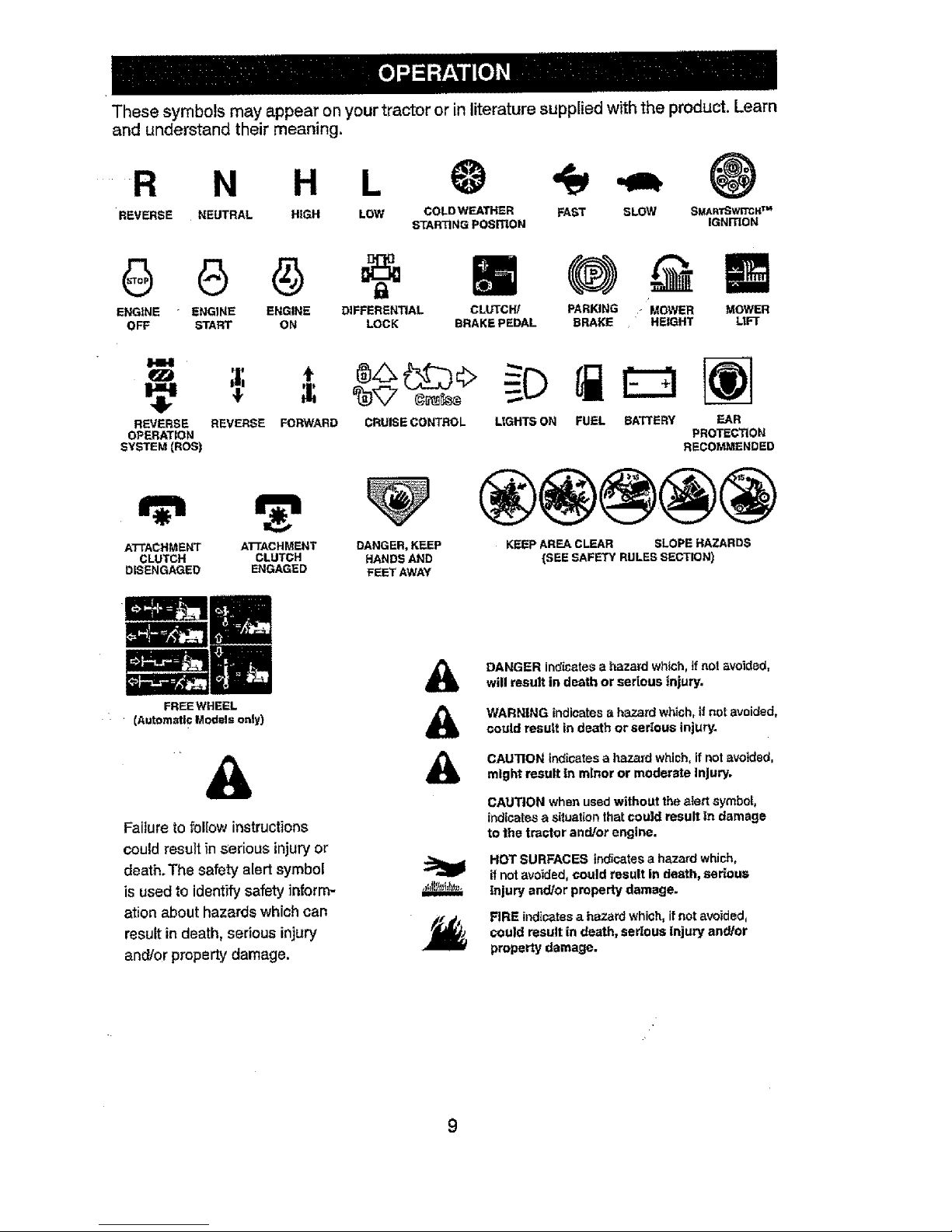

These symbols may appear on your tractor or in literature supplied with the product. Learn

and understand their meaning.

.....R N H

REVERSE NEUTRAL HIGH SLOW SMARISwF_I_ TM

IGNmON

L

LOW COLD WEATHER FAST

STARTING POSITION

ENGtNE ENGINE ENGINE DIFFERENTIAL

OFF START ON LOCK

CLUTCW MOWER

BRAKE PEDAL LtFT

PARKING - MOWER

BRAKE HEIGHT

I.IH

REVERSE

OPERATION

SYSTEM (ROS)

REVERSE FORWARD

CRUISE CONTROL LIGHTS ON FUEL BATTERY EAR

PROTECTION

RECOMMENDED

ATrACHMENT ATTACHMENT DANGER, KEEP

CLUTCH CLUTCH HANDS AND

DISENGAGED ENGAGED FEET AWAY

KEEP AREA CLEAR SLOPE HAZARDS

{SEE SAFETY RULES SECTION)

FREEWHEEL

(Automatic Models only}

Failure to follow instructions

couldresult inserious injuryor

death.The safety alert symbol

is used to identify safety inform-

ation about hazards which can

resultin death, serious injury

and/or property damage.

&

&

&

DANGER indicatesa hazard which, ifnot avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided.

might result In minor or moderate Injury.

CAUTION when used without the alert symbol,

indicatesa situation thatcould result In damage

to the trastor and/or engine.

HOT SURFACES indicates a hazard which,

_fnot avoided, could result in death,serious

injury and/or property damage.

FIRE indicates a hazard which, it not avoided,

could result in death, serious injury and/or

property damage.

Page 10

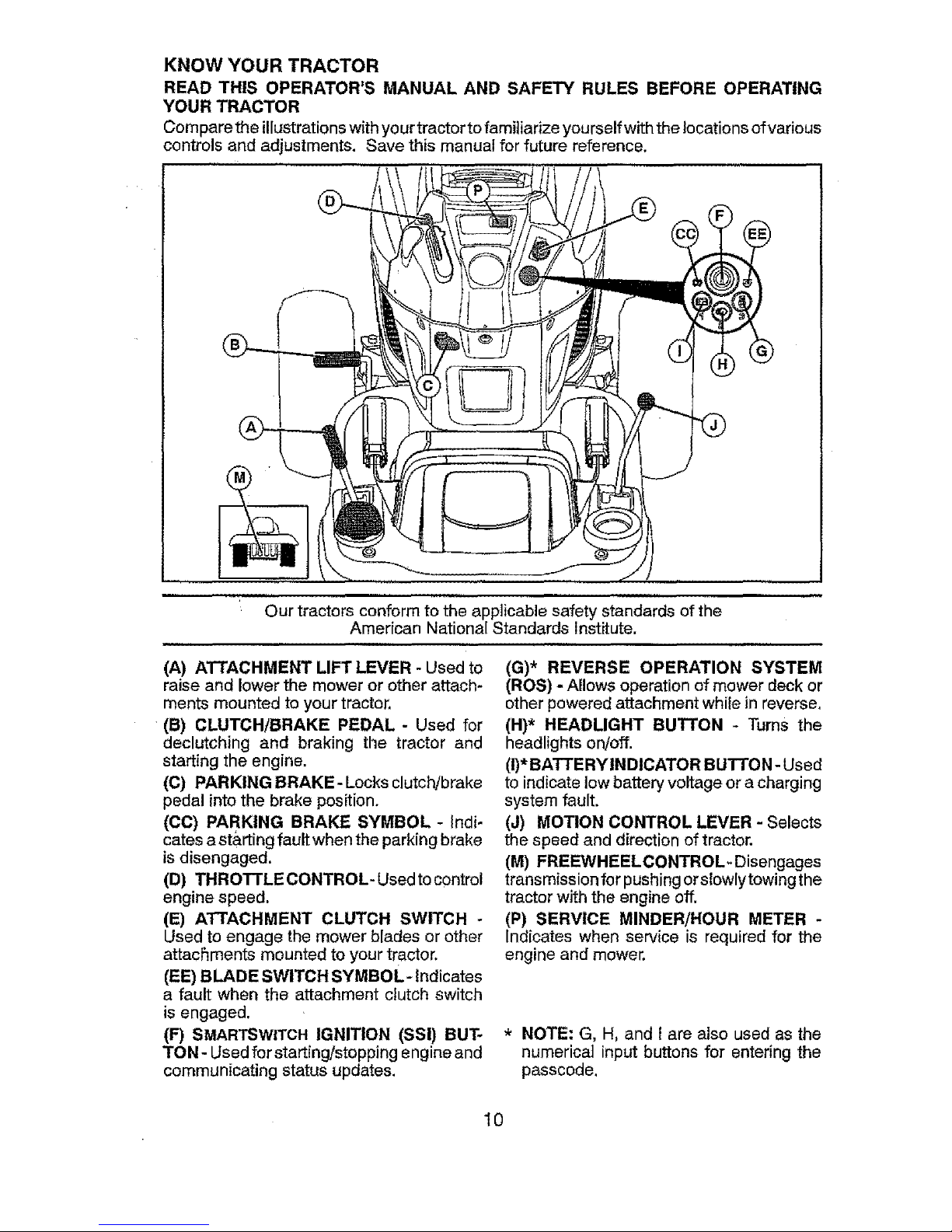

KNOW YOUR TRACTOR

READ THIS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR TRACTOR

Compare the illustrationswithyourtractorto familiarize yourself with the locations ofvarious

controls and adjustments. Save this manual for future reference.

Our tractors conform to the applicable safety standards of the

Amedcan National Standards Institute.

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor.

(B) CLUTCH/BRAKE PEDAL - Used for

declutching and braking the tractor and

starting the engine.

(C) PARKING BRAKE- Locks clutch/brake

pedal into the brake position.

(CC) PARKING BRAKE SYMBOL - Indi-

cates astarting fault whenthe parking brake

is disengaged,

(D) THROTTLE CONTROL- Usedto control

engine speed.

(E) ATTACHMENT CLUTCH SWITCH °

Used to engage the mower blades or other

attachments mounted to your tractor.

(EE) BLADE SWITCH SYMBOL- indicates

a fault when the attachment dutch switch

isengaged.

(F) SMARTSWITCH IGNITION (SSI) BUT-

TON- Usedfor starting/stopping engine and

communicating status updates,

(G)* REVERSE OPERATION SYSTEM

(ROS) - Allows operation of mower deck or

other powered attachment while in reverse,

(H)* HEADLIGHT BUTTON - Turns the

headlights on/off.

(i)*BATTERYINDICATOR BUTTON- Used

to indicate lowbattery voltage or a charging

system fault.

(J) MOTION CONTROL LEVER - Selects

the speed and direction oftractor.

(M) FREEWHEELCONTROL. Disengages

transmission for pushing or slowlytowing the

tractor with the engine off.

(P) SERVICE MINDER/HOUR METER -

Indicates when service is required for the

engine and mower.

* NOTE: G, H, and I are also used as the

numerical input buttons for entering the

passcode,

10

Page 11

The operation of any tractor can result in foreign objects thrown into

the eyes, which can result in severe eye damage. Always wear safety

glasses or eye shields while operating your tractor oFperforming any

adjustments or repairs. We recommend standard safety glasses or a

wide vision safety mask worn over spectacles.

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

running, anyattempt bythe operator to leave

theseatwithout first setting the parking brake

will shut off the engine.

1. Depress clutch/brake pedal (B) all the

way down and hold.

2. Pull parking brake lever (C) up and hold,

release pressure from clutch/brake pedal

(B),then releaseparking brakelever. Ped-

alshould remain inbrake position. Ensure

parking brake will hold tractor secure.

STOPPING

MOWER BLADES -

o Tostopmower blades, moveattachment

clutchcontroltodisengaged position(t_'t).

(t_) Attachment (1"_) A_chment

ClutchControl ClutchControl

"Engaged" "Disengaged'!

GROUND DRIVE -

• Tostop ground drive, depress brake pedal

all the way down.

• Move motion control leverto neutral posi-

tion.

ENGINE -

• Move throttle control (D)to slow position.

NOTE: Failure to move throttle control

to slow position and allowing engine to

idle before stopping may cause engine to

"backfire".

• Press SSl button (F) once to stop engine.

NOTE: Under certain conditions whentractor

is standing idle with the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass. To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

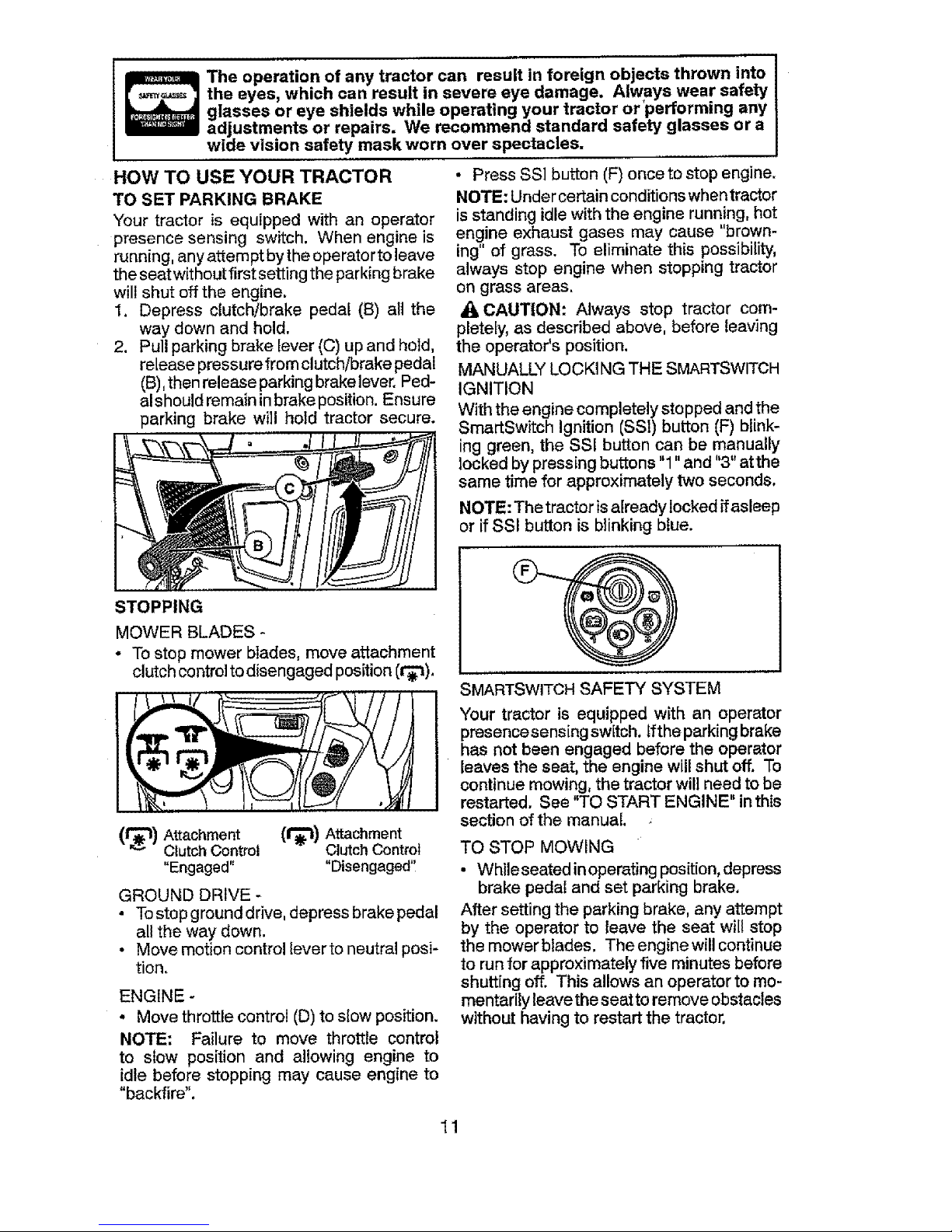

MANUALLY LOCKINGTHE SMARTSWlTCH

IGNITION

With the engine completely stopped and the

SmartSwitch Ignition (SSI) button (F) blink-

ing green, the SSI button can be manually

locked bypressing buttons "1" and "3"atthe

same time for approximately two seconds,

NOTE: Thetractor isalready locked ffasleep

or if SSI button is blinking blue.

SMARTSWITCHSAFETY SYSTEM

Your tractor is equipped with an operator

presencesensing switch, tfthe parkingbrake

has not been engaged before the operator

leaves the seat, the engine will shut off. To

continuemowing, the tractor willneed to be

restarted. See "TO START ENGINE" in this

section of the manual.

TO STOP MOWING

• Whileseated inoperating position,depress

brake pedal and set parking brake,

After setting the parking brake, any attempt

by the operator to leave the seat will stop

the mowerblades. The engine will continue

to run for approximately five minutes before

shutting off. This allows an operator to mo-

mentarily leavethe seatto remove obstacles

without having to restart the tractor.

11

Page 12

TOCONTINUEMOWING

• Returntoseat,

• Placeattachmentclutchswitchfirstin

"DISENGAGED"positionandthenin

"ENGAGED"position.

NOTE:Anyattempttoplaceattachment

....clutchswitchinthe"ENGAGED"position

withouttheoperatorfirstbeingin the seat

will immediately shut off engine.

TO USE THROTTLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast)reducesengine'soperating efficiency.

• Full speed (fast) offers the best mower

performance.

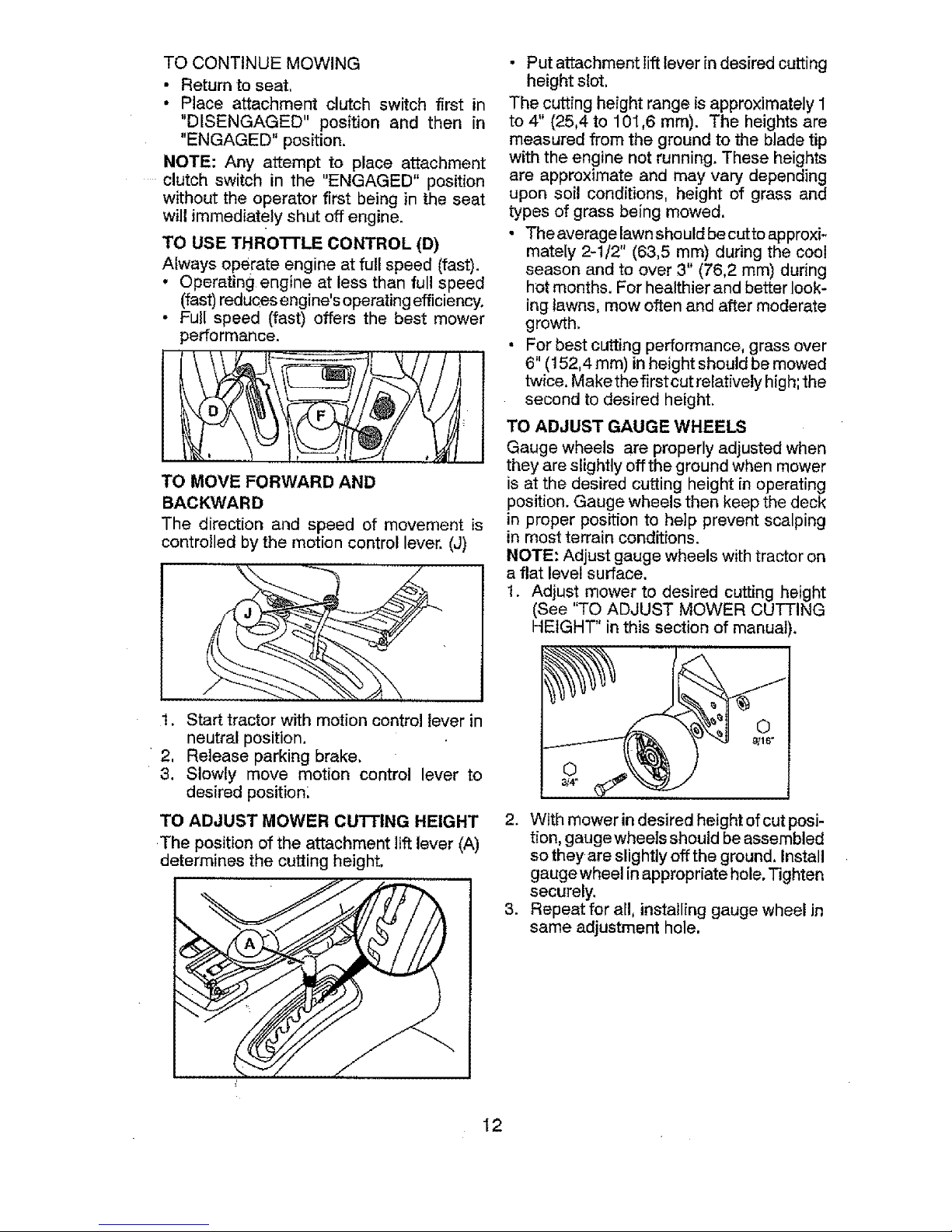

TO MOVE FORWARD AND

BACKWARD

The direction and speed of movement is

controlled by the motion control lever. (J)

• Put attachment lift lever in desired cutting

height slot,

The cutting height range is approximately 1

to 4" (25,4 to 101,6 mm). The heights are

measured from the ground to the blade tip

with the engine not running. These heights

are approximate and may vary depending

upon soil conditions, height of grass and

types of grass being mowed.

• Theaverage lawn should becutto approxi-

mately 2-1/2" (63,5 mm) during the cool

season and to over 3" (76,2 mm) during

hot months. For healthier and better look-

ing lawns, mow often and after moderate

growth.

• For best cutting performance, grass over

6" (t52,4 ram) inheight should be mowed

twice, Makethe first cut relatively high;the

second to desired height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly offthe ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a flat level surface.

1. Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

1. Start tractor with motion control lever in

neutral position.

2, Release parking brake.

3. Slowly move motion control lever to

desired position,

TO ADJUST MOWER CUTTING HEIGHT

The positionof the attachment liftlever(A)

determines the cuttingheight.

2. With mower in desired height of cut posi-

tion, gauge whee|s should be assembled

so they are slightly off the ground, install

gauge wheel in appropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

I2

Page 13

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. While engine

is running, any attempt by the operator to

leave the seat without first setting the park-

ing brake will shut off the engine. You must

remain fully and centrally positioned in the

Seatto prevent the engine from hesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills.

1, Select desired height of cut with attach-

merit lift lever.

2, Start mower blades by engaging attach-

ment clutch control,

TO STOP MOWER BLADES

Disengage attachment clutch control.

_I_CAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, orthe deflector shield

in place,

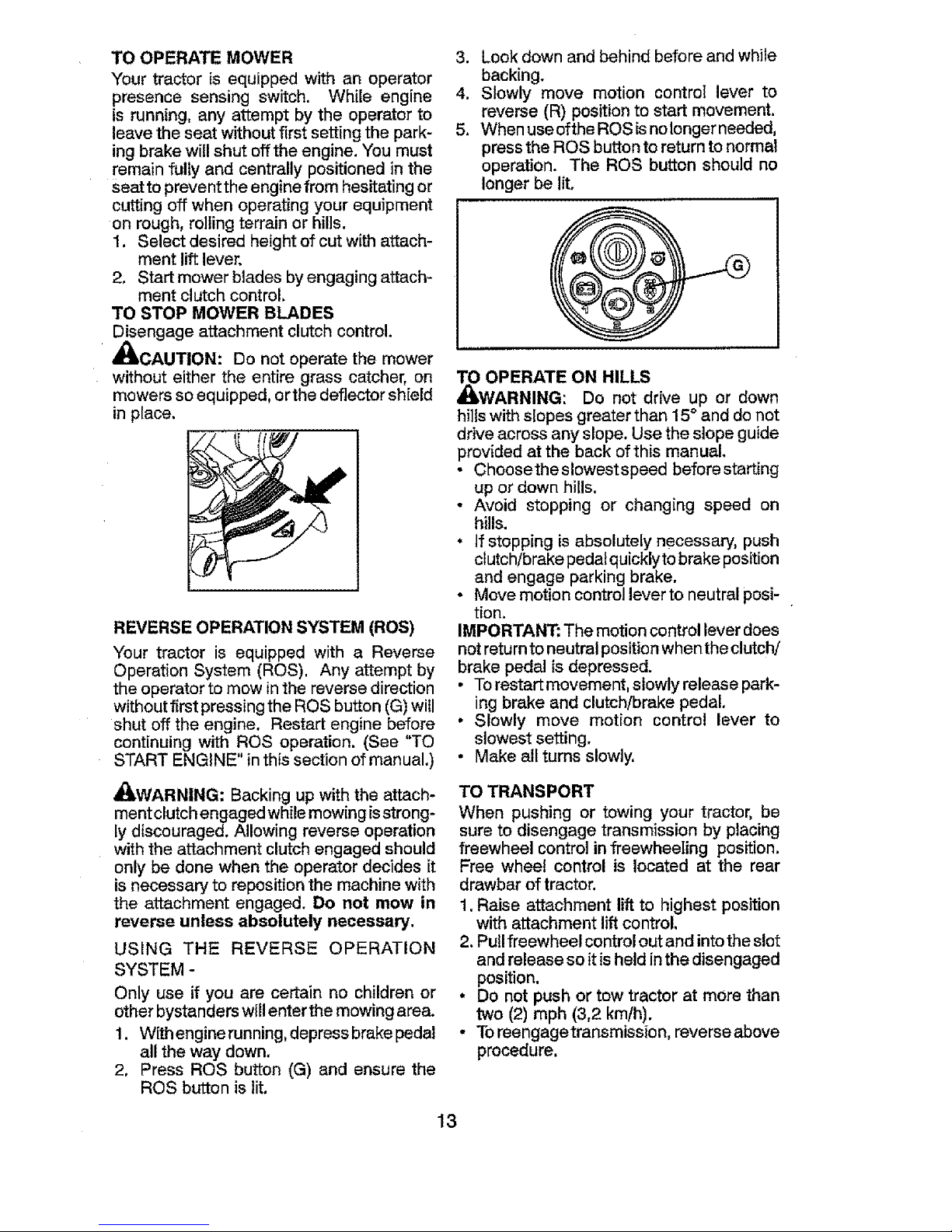

REVERSE OPERATIONSYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS), Any attempt by

the operator to mow in the reverse direction

without first pressing the ROS button (G)will

shut off the engine. Restart engine before

continuing with ROS operation. (See "TO

START ENGINE" in this section of manual.)

_ILWARNING: Backing up with the attach-

ment clutchengaged whilemowing isstrong-

[ydiscouraged, Allowing reverse operation

with the attachment clutch engaged should

only be done when the operator decides it

is necessary to reposition the machine with

the attachment engaged. Do not mow in

reverse unless absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM -

Only use if you are certain no children or

other bystanders willenter the mowing area.

1, With engine running, depress brakepedal

all the way down,

2, Press ROS button (G) and ensure the

ROS button is lit,

3. Look down and behind before and while

backing.

4. Slowly move motion control lever to

reverse (R) position to start movement.

5, When useofthe ROSisnolonger needed,

press the ROS button toreturn to normal

operation. The ROS button should no

longer be lit.

TO OPERATE ON HILLS

_I_WARNING: Do not drive up or down

hi]Iswith slopes greater than 15° and do not

drive across any slope, Use theslope guide

provided at the back of this manual.

* Choosethe slowest speed before starting

up or down hills,

o Avoid stopping or changing speed on

hills.

. If stopping isabsolutely necessary, push

clutch/brake pedalquicklyto brake position

and engage parking brake.

- Move motion control lever to neutral posi-

tion.

IMPORTANT: The motion control lever does

not returnto neutral positionwhenthe clutch/

brake pedal is depressed.

. Torestart movement, slowly release park-

ing brake and clutch!brake pedal

. Slowly move motion control lever to

slowest setting,

* Make all turns slowly,

TO TRANSPORT

When pushing or towing your tractor, be

sure to disengage transmission by placing

freewheel control in freewheeling position,

Free wheel control is located at the rear

drawbar of tractor.

1, Raise attachment lift to highest position

with attachment lift control,

2. Pullfreewheel control out and into the slot

andrelease soit isheld inthe disengaged

position.

* Do not push or tow tractor at more than

two (2) mph (3,2 km/h).

- Toreengagetransmission, reverse above

procedure.

13

Page 14

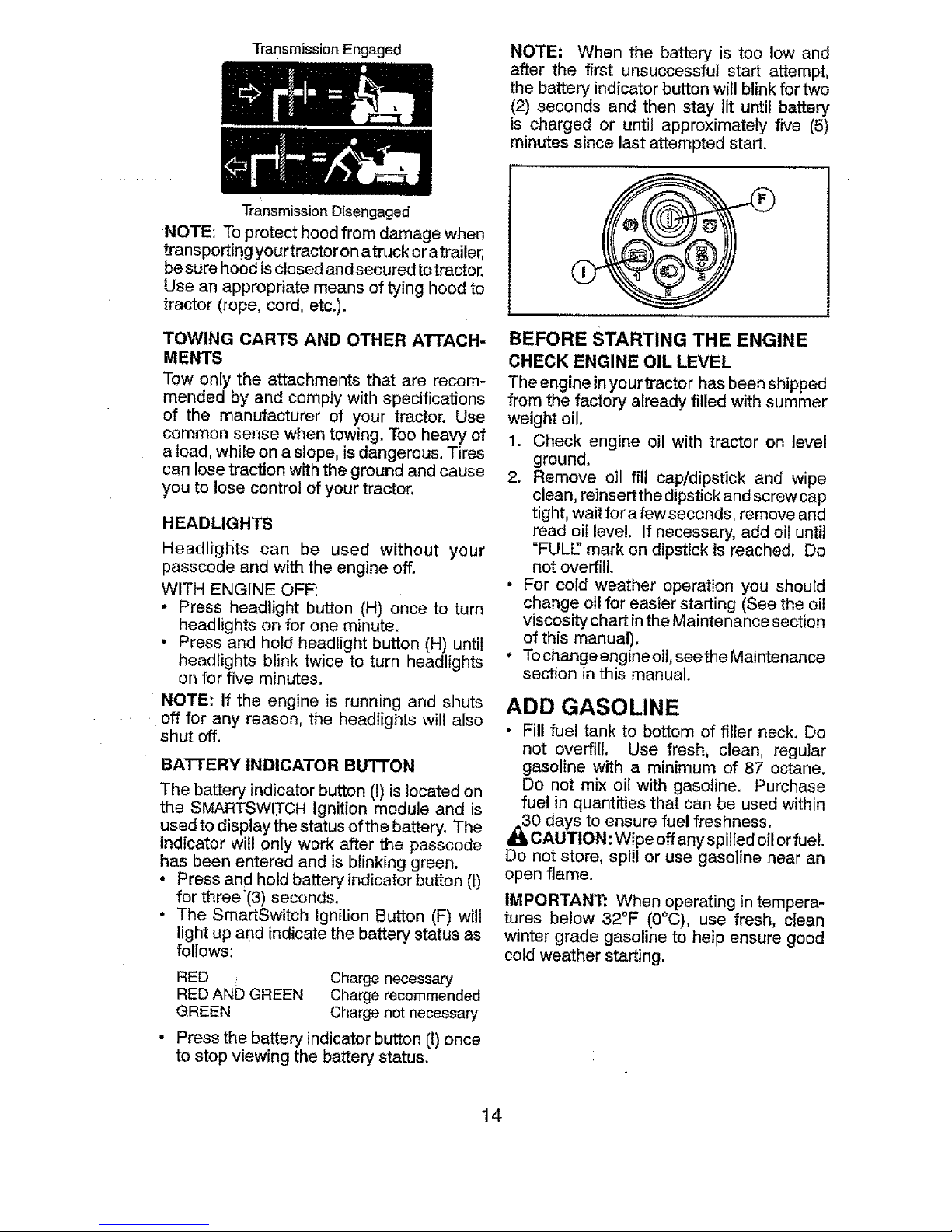

Transmission Engaged

Transmission Disengaged

NOTE: When the battery is too low and

after the first unsuccessful start attempt,

the battery indicator button will blink for two

(2) seconds and then stay tit until battery

is charged or until approximately five (5)

minutes since last attempted start.

NOTE: Toprotect hood from damage when

transporting yourtractoron atruck oratrailer,

be surehood isclosed and secured totractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.),

TOWING CARTS AND OTHER ATTACH-

MENTS

Tow on[y the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on a slope, is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

HEADLIGHTS

Headlights can be used without your

passcode and with the engine off.

WITH ENGINE OFF:

• Press headlight button (H) once to turn

headlights on for one minute.

• Press and hold headlight button (H) until

headlights blink twice to turn headlights

on for five minutes.

NOTE: If the engine is running and shuts

off for any reason, the headlights will also

shut off.

BATTERY INDICATOR BUTTON

The batter>, indicator button (!) is located on

the SMARTSWITCH ignition module and is

used to display the status ofthe battery. The

indicator will only work after the passcode

has been entered and is blinking green.

• Press and hold battery indicator button (t)

for three'(3) seconds.

• The SmartSwitch Ignition Button (F) will

light up and indicate the battery status as

follows:

RED _ Charge necessary

RED AND GREEN Charge recommended

GREEN Charge not necessary

Press the battery indicator button (1)once

to stop viewing the battery status,

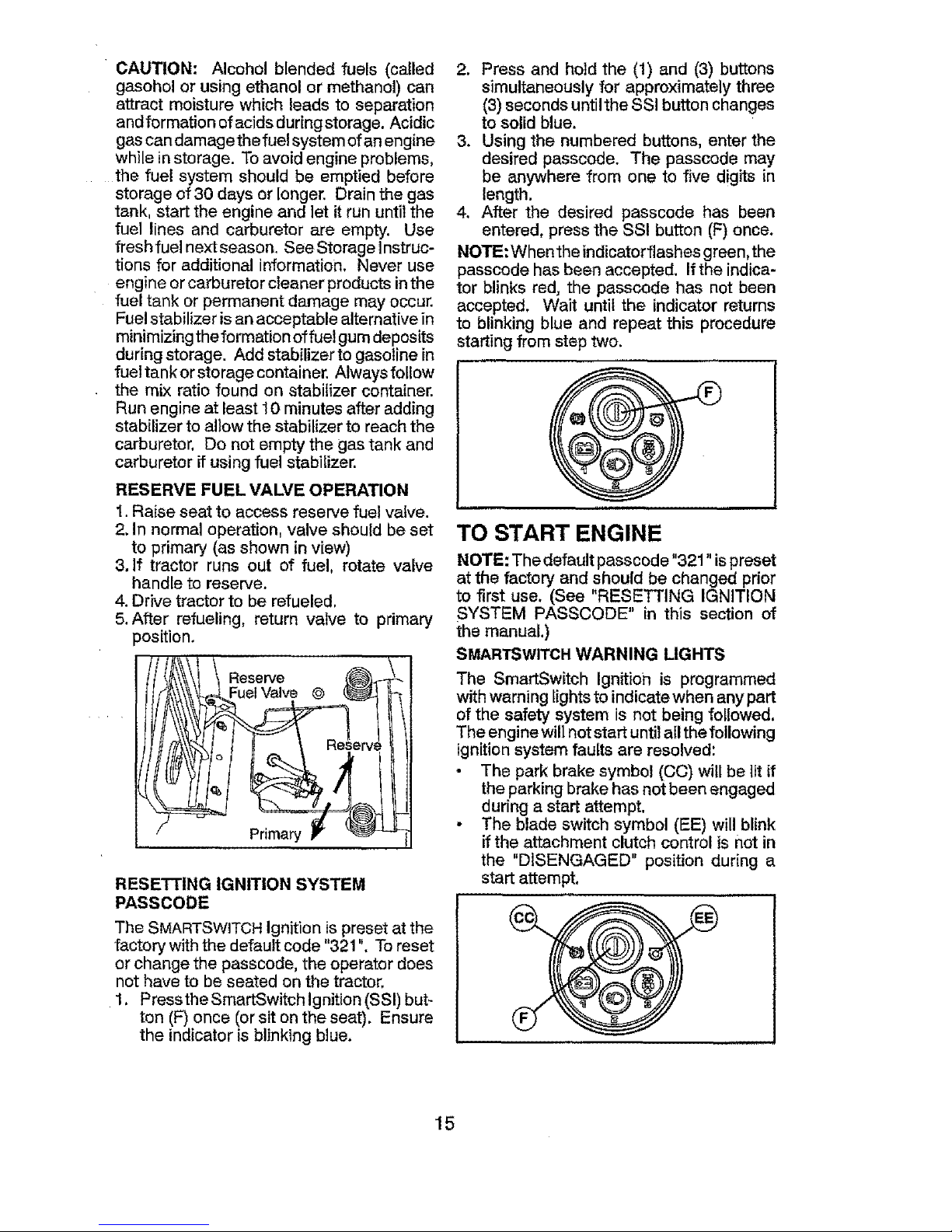

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine inyourtractor has been shipped

from the factory already filled with summer

weight oil.

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean,reinsertthe dipstick and screwcap

tight,wait for afewseconds, remove and

read oil level. If necessary, add oil until

"FULE'mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (Seethe oil

viscosity chart inthe Maintenance section

of this manual).

• Tochangeengine oil, seethe Maintenance

section inthis manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

gasoline with a minimum of 87 octane.

Do not mix oil with gasoline. Purchase

fuel in quantities that can be used within

0 days to ensure fuel freshness.

CAUTION: Wipe offany spilled oilorfueL

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tempera-

tures below 32°F (0°C), use fresh, clean

winter grade gasoline to help ensure good

cold weather starting.

14

Page 15

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

andformation ofacids duringstorage. Acidic

gas candamagethe fuel systemofan engine

while instorage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty. Use

freshfuel nextseason. SeeStoragelnstruc-

tions for additional information. Never use

engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

Fuelstabilizer isan acceptable alternative in

minimizing theformation offuel gum deposits

during storage. Add stabilizer to gasoline in

fuel tank orstorage container. Always fotlow

the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor, Do not empty the gas tank and

carburetor ff using fuel stabilizer.

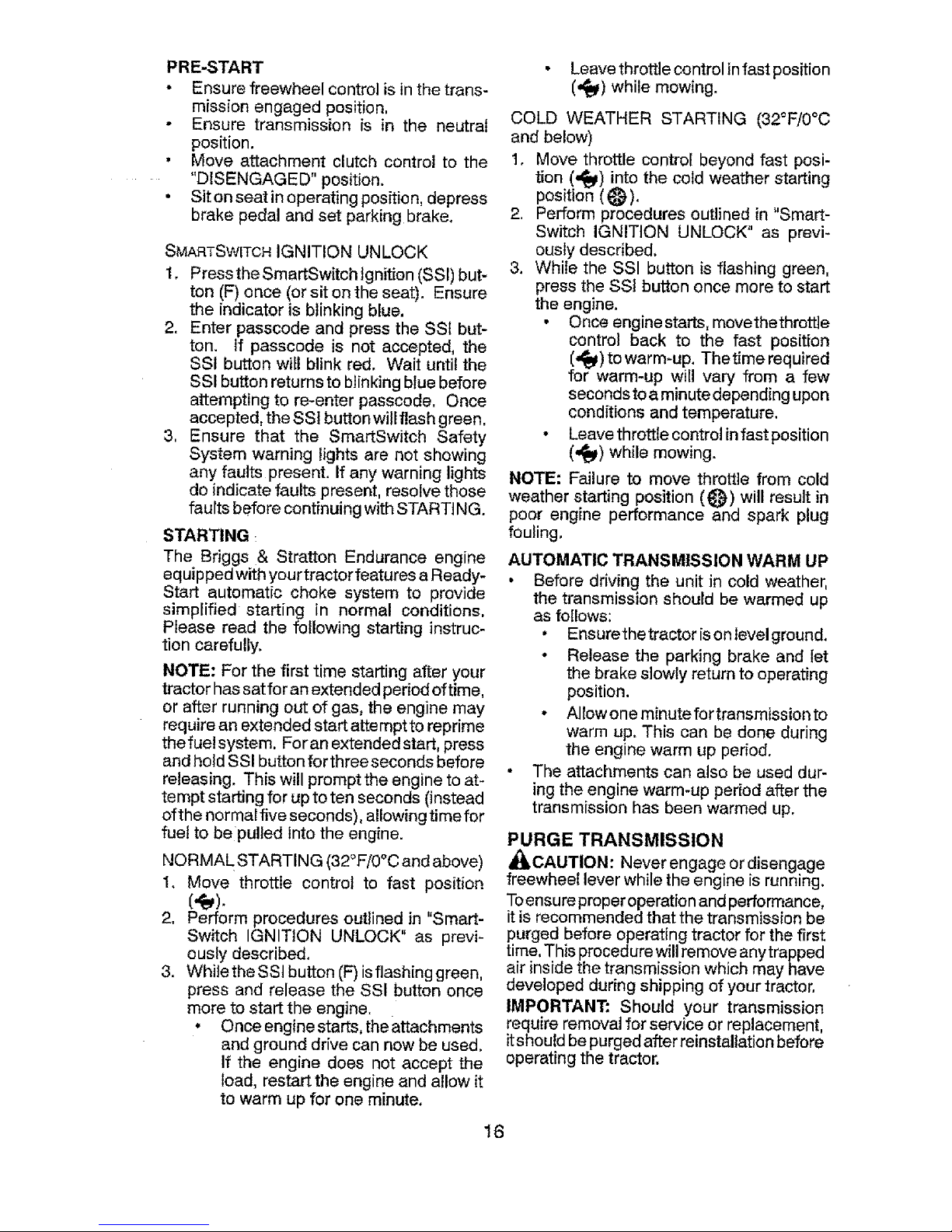

RESERVE FUEL VALVE OPERATION

1,Raise seat to access reserve fuel valve.

2. In normal operation, valve should be set

to primary (as shown in view)

3, If tractor runs out of fuel, rotate valve

handle to reserve.

4. Drive tractor to be refueled,

5.After refueling, return valve to primary

position.

Reserve

Fuel Valve @

Primary

RESETTING IGNITION SYSTEM

PASSCODE

The SMARTSWITCHIgnition ispreset at the

factory with the default code "321". To reset

or change the passcode, the operator does

not have to be seated on the tractor,

1. Pressthe SmartSwitch ignition (SSI)but-

ton (F)once (or sit on the seat). Ensure

the indicator is blinking blue.

2, Press and hold the (1) and (3) buttons

simultaneously for approximately three

(3)seconds untilthe SSI button changes

to solid blue.

3. Using the numbered buttons, enter the

desired passcode. The passcode may

be anywhere from one to five digits in

length.

4. After the desired passcode has been

entered, press the SSI button (F) once.

NOTE: Whenthe indicatorflashes green, the

passcode has been accepted. If the indica-

tor blinks red, the passcede has not been

accepted. Wait until the indicator returns

to blinking blue and repeat this procedure

starting from step two.

TO START ENGINE

NOTE: The default passcode "321" ispreset

at the factory and should be changed prior

to first use. (See "RESETTING IGNITION

SYSTEM PASSCODE" in this section of

the manual.)

SMARTSWITCHWARNING LIGHTS

The SmartSwitch Ignition is programmed

with warning lights to indicate when any part

of the safety system is not being followed.

The engine will notstart until all the following

ignition system faults are resolved:

• The park brake symbol (CC) will be lit if

the parking brakehas not been engaged

during a start attempt.

• The blade switch symbol (EE) will blink

if the attachment clutch control is not in

the "DISENGAGED" position during a

start attempt.

15

Page 16

$

PRE-START

• Ensure freewheel control is in the trans-

mission engaged position,

• Ensure transmission is in the neutral

position.

Move attachment clutch control to the

"DISENGAGED" position.

Siton seat inoperating position, depress

brake pedal and set parking brake,

SMARTSWITCHIGNITION UNLOCK

1, Press the SmartSwitch Ignition (SSI) but-

ton (F) once (or sit on the seat). Ensure

the indicator is blinking blue.

2. Enter passcode and press the SSI but-

ton. If passcode is not accepted, the

SSI button wifl blink red. Wait until the

SSI button returns to blinking btuebefore

attempting to re-enter passcode. Once

accepted, the SSi buttonwill flash green.

3, Ensure that the SmartSwitch Safety

System warning lights are not showing

any faults present. Ifany warning lights

do indicatefaults present, resolve those

faults before continuing withSTARTtNG.

STARTING :

The Briggs & Stratton Endurance engine

equipped with yourtractor features a Ready-

Start automatic choke system to provide

simplified starting in normal conditions.

Please read the following starting instruc-

tion carefully.

NOTE: For the first time starting after your

tractor has satfor anextended period oftime,

or after running out of gas, the engine may

require an extended start attempt to reprime

thefuel system. Foran extended start, press

andhold SSI button for three seconds before

releasing. This will promptthe engine to at-

tempt starting for upto ten seconds (instead

ofthe normal five seconds), allowing time for

fuel to be pulled into the engine.

NORMAL STARTING (32°F/0°Cand above)

1. Move throttle control to fast position

(,_).

2, Perform procedures outlined in "Smart-

Switch IGNITION UNLOCK" as previ-

ously described.

3. WhiletheSSt button (F)isflashinggreen,

press and release the SSI button once

more to start the engine.

o Once enginestarts, theattachments

and ground drive can now be used.

If the engine does not accept the

load, restart the engine and allow it

to warm up for one minute.

• Leave throttle control in fast position

(,_) while mowing.

COLD WEATHER STARTING (32°F/0°C

and below)

t. Move throttle control beyond fast posi-

tion (-t/_) into the cold weather starting

position (@).

2, Perform procedures outlined in "Smart-

Switch IGNITION UNLOCK" as previ-

ously described.

3. While the SSI button is flashing green,

press the SSt button once more to start

the engine,

• Once enginestarts, movethethrottte

control back to the fast position

(._) towarm-up. Thetime required

for warm-up will vary from a few

secondsto a minute depending upon

conditions and temperature.

• Leave throttle control infast position

(._) while mowing.

NOTE: Failure to move throttle from cold

weather starting position (@) will result in

poor engine performance and spark plug

fouling.

AUTOMATIC TRANSMISSION WARM UP

• Before driving the unit in cold weather,

the transmission should be warmed up

asfollows:

• Ensurethe tractor ison levelground.

. Release the parking brake and let

the brake slowly return to operating

position.

• Allow one minute fortransmission to

warm up. This can be done during

the engine warm up period.

• The attachments can atso be used dur-

ing the engine warm-up period after the

transmission has been warmed up.

PURGE TRANSMISSION

_CAUTION: Never engage or disengage

freewheel lever while the engine is running.

Toensureproper operation andperformance,

it is recommended that the transmission be

purged before operating tractor for the first

time,This procedure will removeanytrapped

air inside the transmission which may have

developed during shipping of your tractor.

IMPORTANT: Should your transmission

require removal for service or replacement,

itshould bepurged after reinstallation before

operating thetractor.

16

Page 17

1. Place tractor safely on a level surface -

that is clear of objects and open - with

engine off and parking brake set.

2. Disengage transmission by placing

freewheel control in disengaged position

(See "TO TRANSPORT" in this section

of manual).

3. Sitting in the tractor seat, start engine.

After the engine is running, move throttle

control to slow position. With motion

control lever in neutral position, slowly

disengage ciutchJbrake pedal.

,I_CAUTION: At any time, during step 4,

there maybe movement of the drive wheels.

4. Move motion control lever tofull forward

position and hold for five (5) seconds.

Move lever to full reverse position and

hold for five (5) seconds. Repeat this

procedure three (3) times,

5. Move motion controlleverto neutral posi-

tion.Shutoff engine andset parkingbrake.

6. Engage transmission by placing free-

wheel control in engaged position (See

"TO TRANSPORT" in this section of

manual),

7. Sitting in the tractor seat, start engine.

After the engine is running, move throttle

control to half (1/2) speed. With motion

control lever in neutral position, slowly

disengage clutch/brake pedal.

8. Slowly movemotioncontrol leverforward,

after the tractor moves approximately

five (5)feet (t ,5 m), slowly move motion

control lever to reverse position. After

the tractor moves approximately five (5)

feet (1,5 m) return the motion control

lever to the neutral position. Repeat this

procedure with the motion control lever

three (3)times,

Your transmission is now purged and now

ready for normal operation.

SERVICE MINDER!HOUR METER

Service minder shows the total number of

hours the engine hasrun andindicates when

the engine or mower needs servicing. After

every 50 hours of operation the oil can icon

will stay on for 2 hours. To service engine

and mower, see the Maintenance section

of this manual.

NOTE: The service minder runswhen either

the engine is running or the SmartSwitch is

active (unlocked).

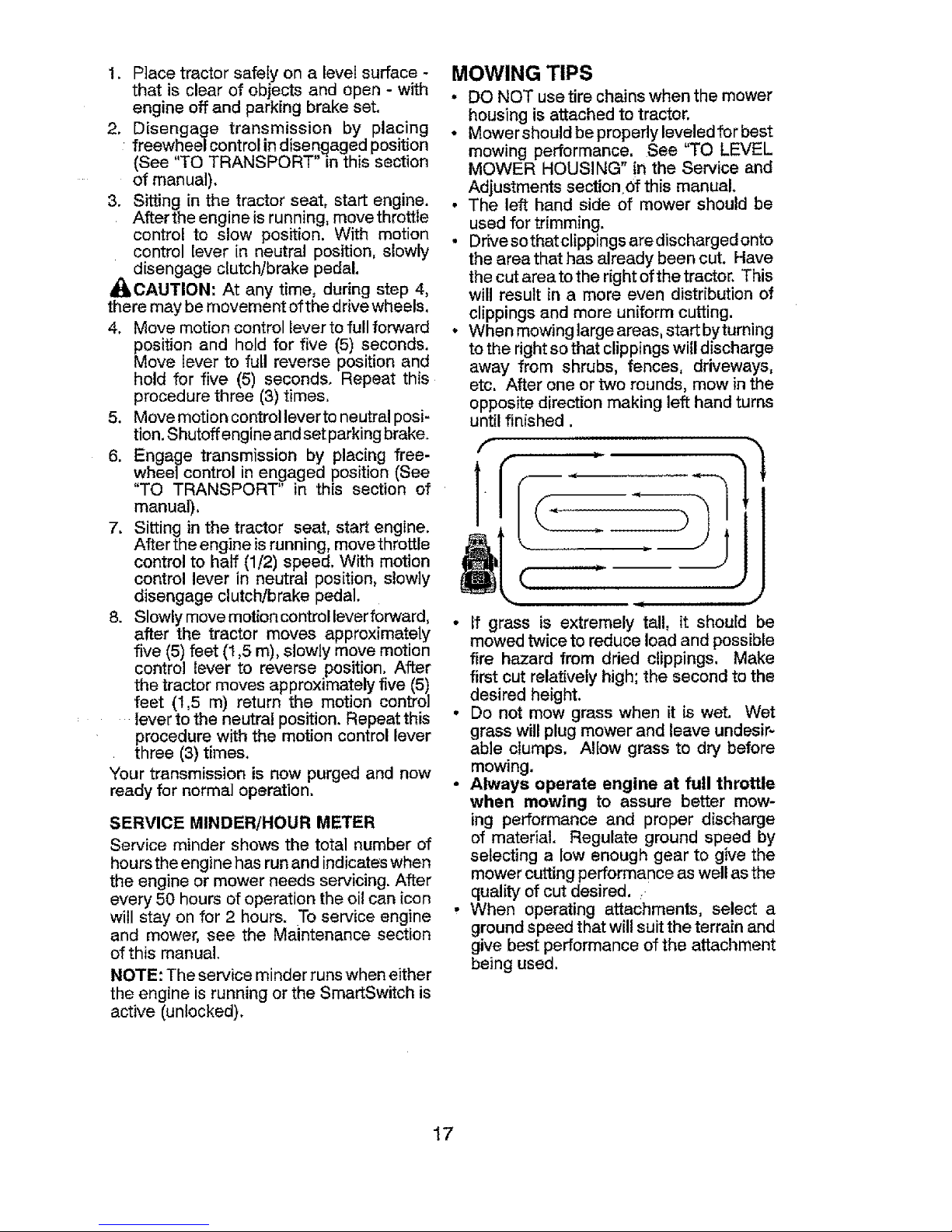

MOWING TIPS

• DO NOT usetire chains when the mower

housing is attached to tractor.

• Mower should be properly leveledfor best

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments sectionof this manual.

• The left hand side of mower should be

used for trimming.

• Drivesothat clippings are discharged onto

the area that hasalready been cut. Have

the cut area tothe right of the tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

• When mowing large areas,start byturning

to the right sothat clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow inthe

opposite direction making left hand turns

until finished.

f

(.

(

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet, Wet

grass willplug mower and leave undesir-

able clumps. Allow grass to dry before

mowing.

• Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough gear to give the

mower cutting performance as well as the

quality of cut desired.

• When operating attachments, select a

ground speed that will suitthe terrain and

give best performance of the attachment

being used.

17

Page 18

SCNEOULE o =o. o,..Y %. .,., ..... o .o

MAINTENANCE _c. _ re _o_ s_soN sTo_4,_

USE HOURS tlOURS HOURS HOU_S

' ,,,,,,,,,,,,,,,,,,,,,, ii

,,,,,,,,,,,,,,,,,,,,, i

Cheek Brake Oper,_lio n If V _

Che_ k Tits Pless ure .......i If , V"

T Ch=o'k'bpn_ato_ Prese_nce =nd"ROS SyStems V f,,,, '...........

R Cheok_o_ Lo_l_eFaste_ .... If V'

A ,,,,,,ChecP4R_pl=ce MOWer Blade_ ..... _ ......

.................................................. =

T Oheck 8artery Level _ I

O Clean Bakery a nd Terminals ........... ................

Cie_ Debds off Steedag Plate ....... _,,

Check T_'e_ e_Ie Ceot!r_g.................. tf

Check Mower Leveirtess V j ,,

........c_=okv-Bo,_, .......v"

Cheek Engine O;I L_VeI I_ If

Change Er_glne Oil (mods_s without eli filter) _,_ V e

E ¢|een Air Fitter

Oleni1,Air ........

Scle_

inspec_ Muffler/Spark Al'i-est et V _

N_ Replace Oil Filter (It e_.uippe_ _,_ ......

E Glean Engine CooEng Fins ..... V_=

Replac_ Spar_ Plug _

Replaca A{; Figer P_per ¢ar_idge

Rep_ce Fuel Fillet !1##

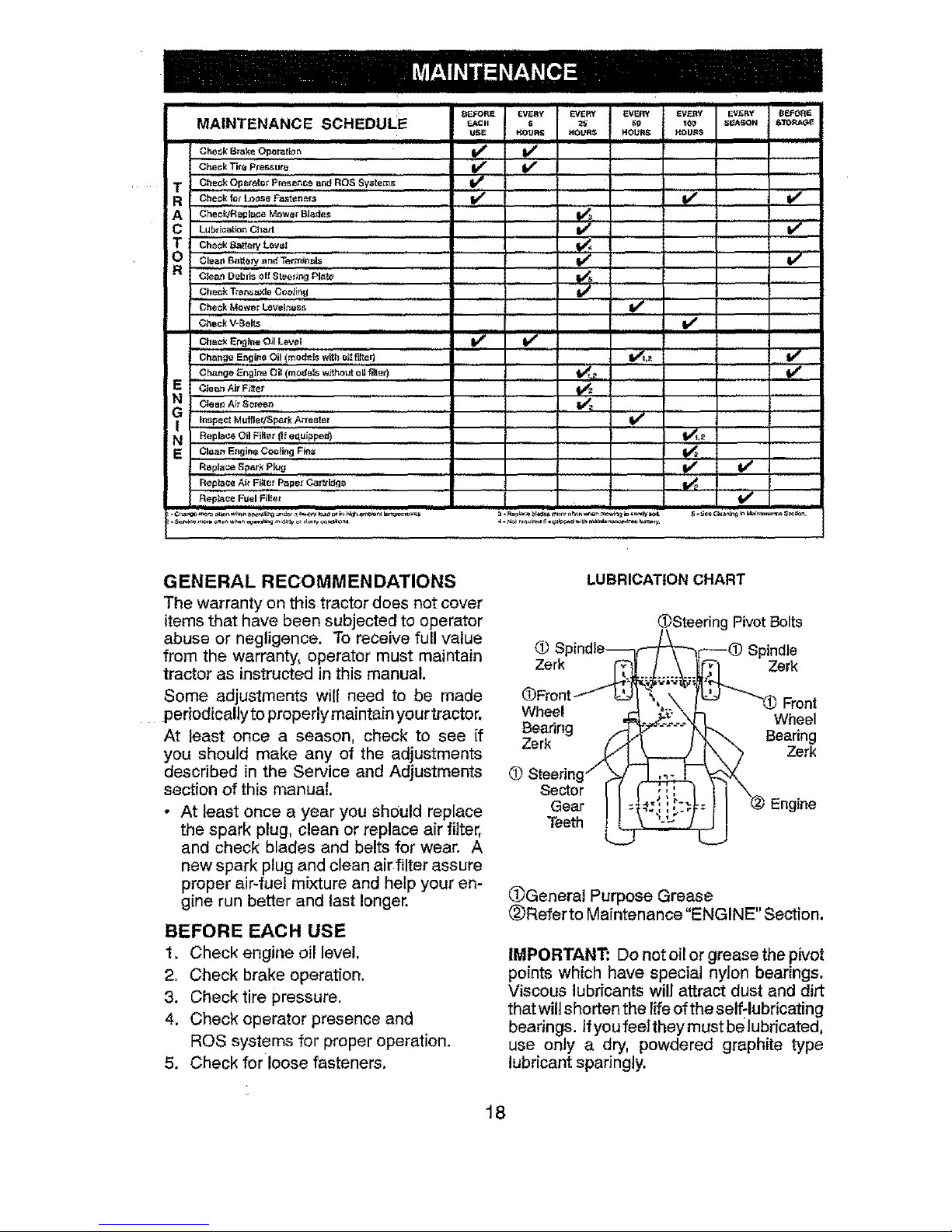

GENERAL RECOMMENDATIONS

The warrantyon thistractordoes notcover

itemsthat have been subjectedto operator

abuse or negligence. Toreceivefull value

fromthe warranty, operatormust maintain

tractor as instructedin this manual.

Some adjustments wil{ need to be made

periodicallyto properlymaintain yourtractor,

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual,

- At least once a year you should replace

the spark plug, clean or replace air filter,

and check blades and belts for wear. A

new spark plug and clean air filter assure

proper air4uel mixture and help your en-

gine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3. Check tire pressure.

4, Check operator presence and

ROS systems for proper operation.

5. Check for loose fasteners.

LUBRICATION CHART

(l_Steering Pivot Bolts

1_ Spindle_t,_--_r_---(_) Spindle

Zerk _._.;_ Zerk

(DFront---" _-41 k, _., fl_.tg- "_Front

Wheel 4_. _.'_ .":-,_I _VVheel

_eanng

. ,'_ ...... N _'_. Bear,ng

z.er_ _"\:_ - Zerk

(_ Steering / _/ _ 'y_-':/,,.

S_eC__ ',i_-t= }t \@ Engine

@_)Generat Purpose Grease ,

Relerto Maintenance ENGINE' Section.

IMPORTANT: Do not oil or grease the pivot

points which have special nylon bearings.

Viscous lubricants willattract dust and dirt

thatwilt shorten the lifeof the self:lubricating

bearings, tfyou feelthey must be lubricated,

use only a dry, powdered graphite type

lubricant sparingly.

18

Page 19

TRACTOR

Always observe safety ruIes when perform-

ing any maintenance,

BRAKE OPERATION

if tractor requires more than 5 feet (1,5 m)

to stop at highest speed in highest gear on

a level, dry concrete or paved surface, then

brake must be serviced, (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

- Maintain proper air pressure in all tires

(See the side of tires for proper PSI.)

- Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects andother hazards that may cause

tire damage,

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM

AND REVERSE OPERATION SYSTEM

(ROS)

Ensure operator presence and reverse

operation systems are working properly. If

your tractor does notfunction as described,

repair the problem immediately.

• The engine should not start unless the

parking brake is engaged, and the attach-

ment clutch control is in the disengaged

position.

CHECK OPERATOR PRESENCE SYSTEM

• While the engine is running, any attempt

bythe operator to leave the seat without

first setting the parking brake should shut

off the engine,

• With the engine running, the parking

brakeengaged, andthe attachment clutch

engaged, any attempt by the operator to

leave the seat should shut off the attach-

ment clutch,

. The attachment clutch should never oper-

ate unless the operator is in the seat.

CHECK REVERSE OPERATION (ROS)

SYSTEM

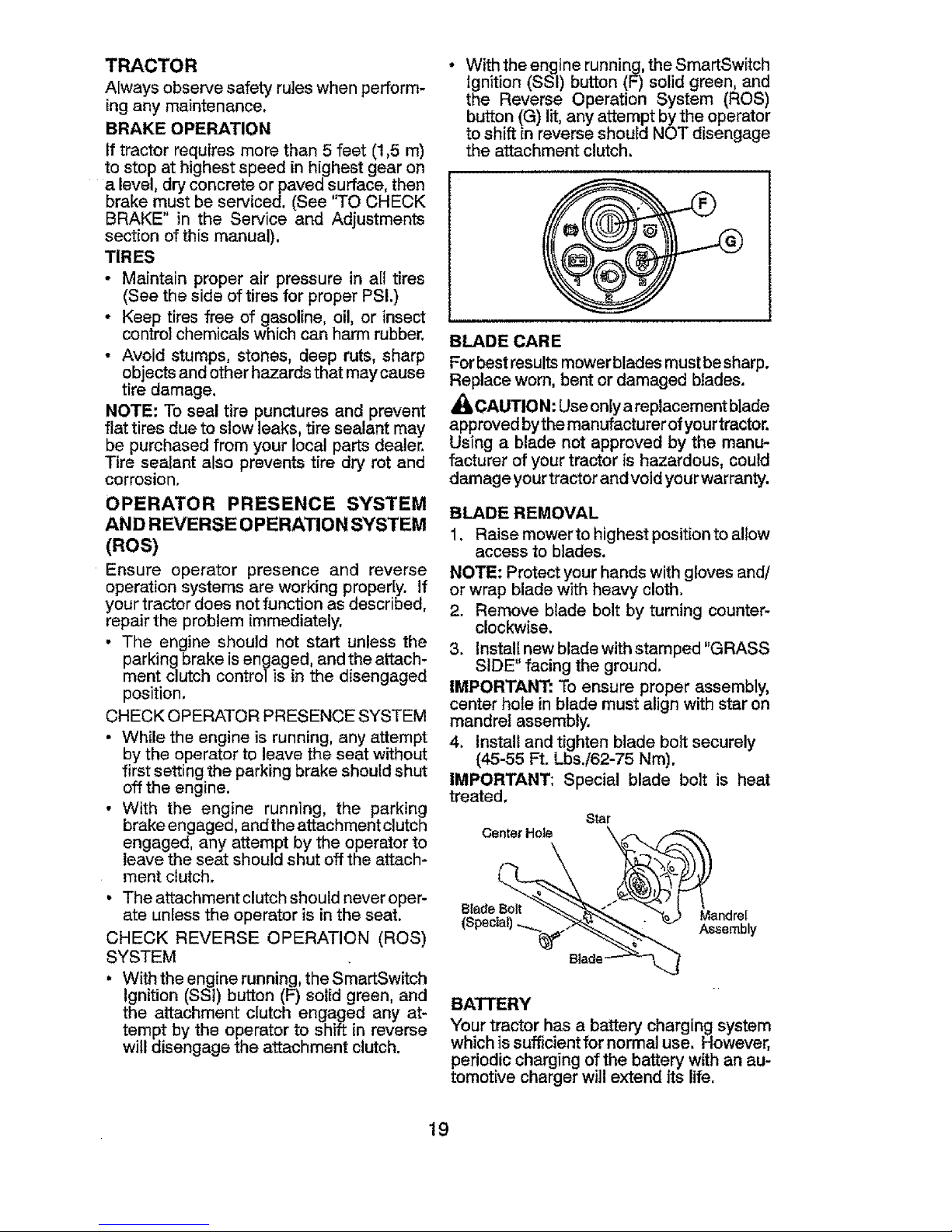

• With theengine running, the SmartSwitch

Ignition (SSi) button (F) solid green, and

the attachment clutch engaged any at-

tempt by the operator to shift in reverse

will disengage the attachment clutch.

- With the enginerunning, the SmartSwitch

Ignition (SSI) button (F) solid green, and

the Reverse Operation System (ROS)

button (G) lit, any attempt by the operator

to shift in reverse should NOT disengage

the attachment clutch.

BLADE CARE

For bestresultsmower bladesmust besharp.

Replace worn, bent or damaged blades.

_I=CAUTION: Use onlya replacement blade

approved bythe manufacturer ofyourtractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage yourtractor and void your warranty.

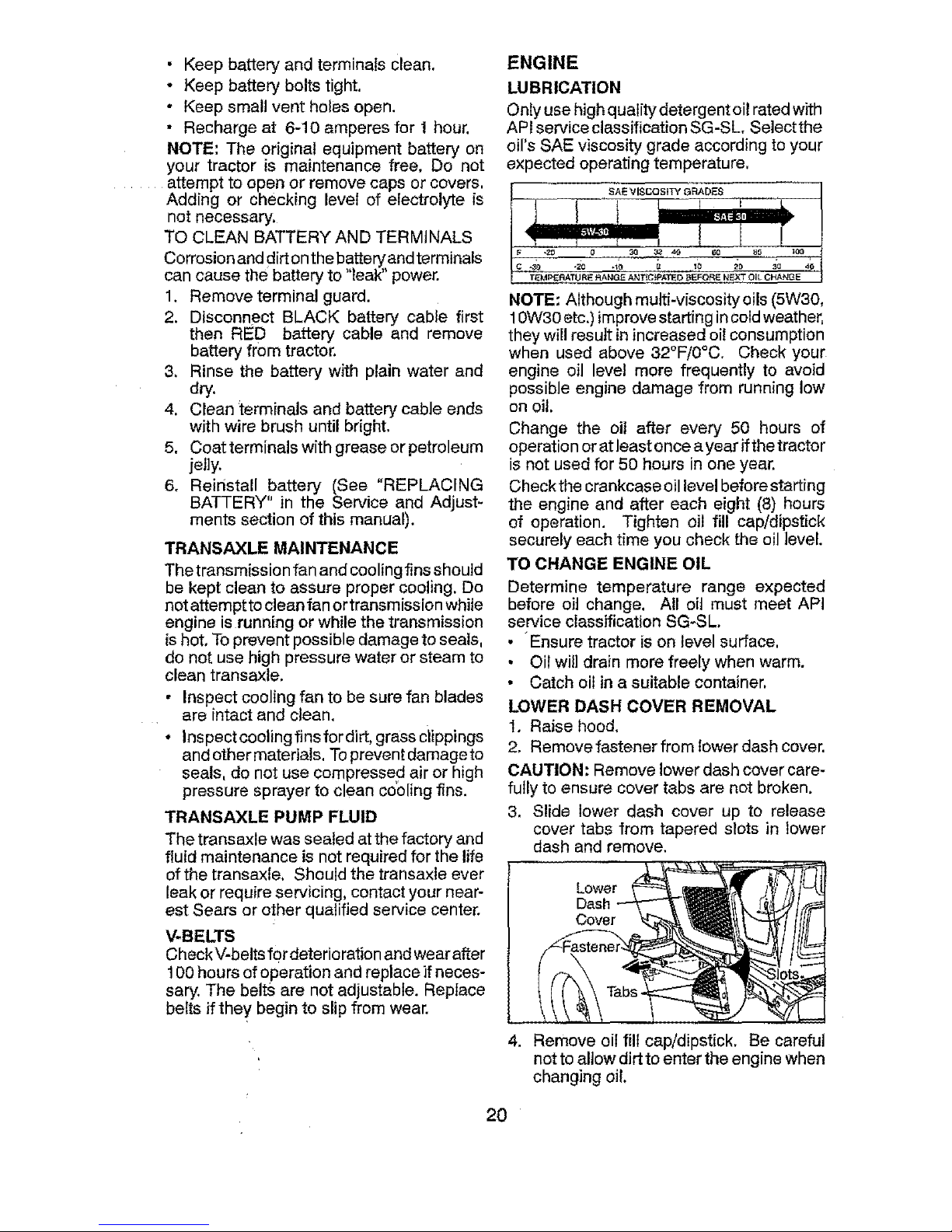

BLADE REMOVAL

1. Raise mowerto highest position to allow

access to blades,

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth.

2. Remove blade bolt by turning counter-

clockwise.

3. Instalt newblade with stamped "GRASS

SIDE" facing the ground.

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly,

4. Install and tighten blade bolt securely

(45-55 Ft. LbsJ62-75 Nm).

IMPORTANT: Special blade bolt is heat

treated.

Star

center Hole \i__

BATTERY

Your tractor has a battery charging system

whichis sufficientfor normaluse, However,

periodicchargingof the battery withan au-

tomotivechargerwill extendits life.

19

Page 20

• Keep batten/and terminals clean.

. Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for ! hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

TO CLEAN BATTERY AN DTERMt NALS

Corrosionanddirtonthe batte_and terminals

can cause the battery to "leak' power.

1. Remove terminal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

3. Rinse the battery with plain water and

dry.

4. Clean terminals and battery"cable ends

with wire brush until bright.

5. Coat terminals with grease or petroleum

jelly.

6. Reinstall battery (See "REPLACING

BATTERY" in the Service and Adjust-

ments section of this manual).

TRANSAXLE MAINTENANCE

The transmission fan and coolingfinsshould

be kept clean to assure proper cooling. Do

not attempt toclean fan ortransmission while

engine is running or while the transmission

ishot. Toprevent possible damage to seals.

do not use high pressure water or steam to

clean transaxle.

• Inspect cooling fan to be sure fan blades

are intact and clean.

• Inspectcoolingfinsfordirt, grass clippings

andother materials. To preventdamage to

seals, do not use compressed air or high

pressure sprayer to clean co'01ingfins.

TRANSAXLE PUMP FLUID

The transaxle was sealed atthe factory and

fluid maintenance is not required for the life

ofthe transaxle. Should the transaxle ever

leak or require servicing, contact your near-

est Sears or other qualified service center.

V-BELTS

CheckV-belts for deterioration andwear after

t O0hours of operation andreplace if neces-

sary. The belts are not adjustable. Replace

belts if they begin to slip from wear.

ENGINE

LUBRICATION

Onlyuse high quality detergent oil rated with

APIservice classification SG-SL. Selectthe

oil's SAE viscosity grade according to your

expected operating temperature,

NOTE: Although multi-viscosityoils (5W30,

10W30etc.) improvestarting incold weather,

they will result inincreased oi!consumption

when used above 32°F/0°C. Check your

engine oil level more frequently to avoid

possible engine damage from running low

onoil.

Change the oil after every 50 hours of

operation oratleast once ayearif thetractor

is not used for 50 hours in one year.

Checkthe crankcase oil level beforestarting

the engine and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick

securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

, "Ensure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

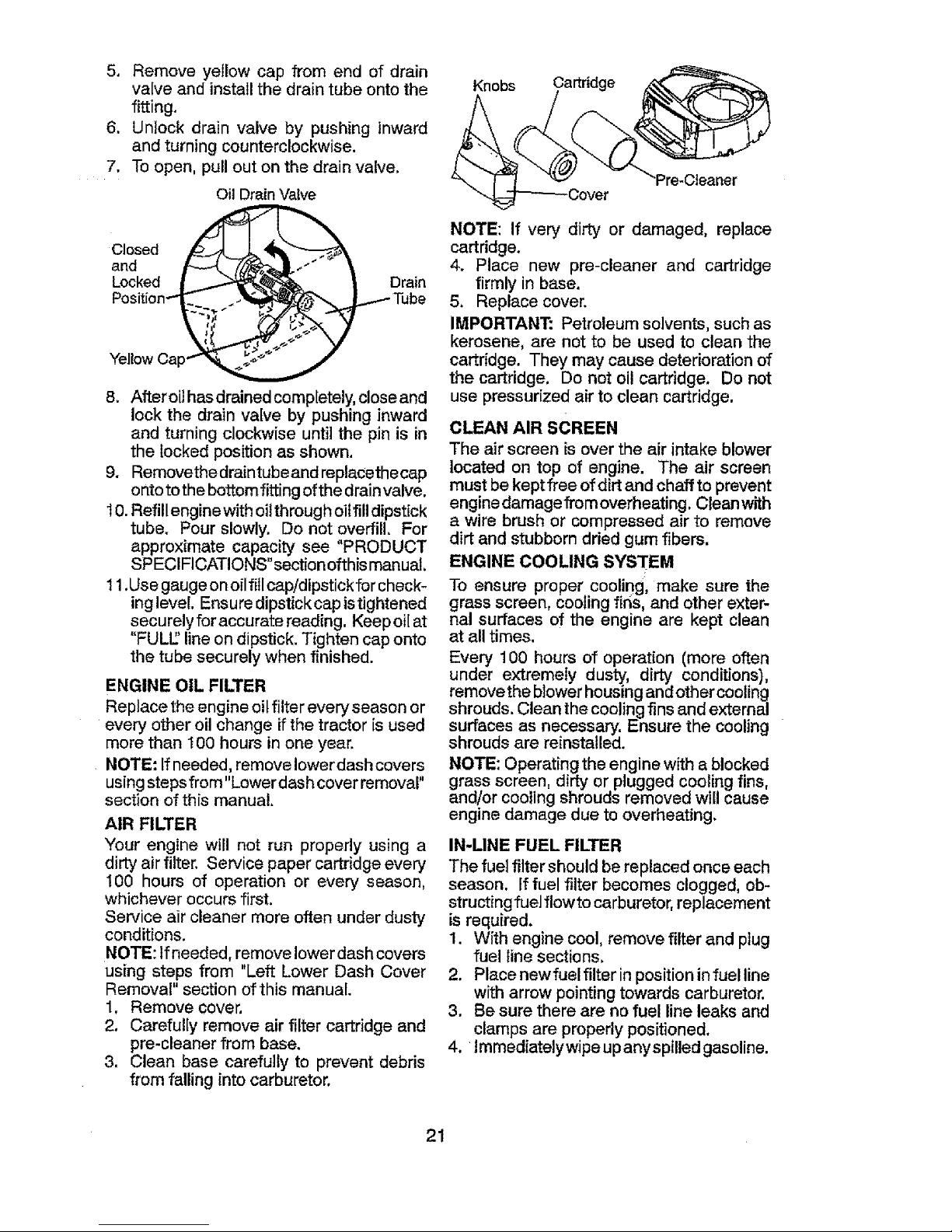

LOWER DASH COVER REMOVAL

1. Raise hood,

2. Remove fastener from lower dash cover.

CAUTION" Remove lower dash cover care-

fully to ensure cover tabs are not broken.

3. Slide lower dash cover up to release

cover tabs from tapered slots in lower

dash and remove.

Lower

Dash

4. Remove oil fill cap/dipstick. Be careful

not to allow dirtto enter the engine when

changing oil.

20

Page 21

5. Remove yellow cap from end of drain

valve and install the drain tube onto the

fitting.

6. Unlock drain valve by pushing inward

and turning counterclockwise.

7. To open, pull out onthe drain valve.

OilDrainValve

Ye,ow

8. After oilhasdrained completely, closeand

lock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked position as shown.

9. Removethedraintubeand replacethecap

ontotothe bottomfitting ofthe drainvalve.

10.Refillenginewith oilthrough oilfill dipstick

tube. Pour slowly. Do not overfill. For

approximate capacity see "PRODUCT

SPECIFICATIONS"sectionofthismanual,

11.Usegauge onoilfillcap/dipstick for check-

ing level. Ensuredipstick cap istightened

securely for accurate reading. Keepoil at

"FULL' lineon dipstick. Tighten cap onto

the tube securely when finished.

ENGINE OIL FILTER

Replacetheengine oilfilter everyseason or

every other oil change ifthe tractor is used

more than 100 hours inone year.

NOTE: Ifneeded, removelowerdashcovers

usingsteps from"Lowerdashcoverremoval"

section ofthis manual.

AIR FILTER

Your engine will not run properly using a

dirtyairfilter. Service paper cartridgeevery

100 hours of operation or every season,

whichever occursfirst.

Service air cleaner more oftenunder dusty

conditions.

NOTE: Ifneeded, removelowerdashcovers

using steps from "Left Lower Dash Cover

Removal" section of this manual.

1. Remove cover,

2. Carefully remove air filter cartridge and

pre-cleaner from base.

3. Clean base carefully to prevent debris

from falling into carburetor.

Knobs Cartridge

"Pre-Cteaner

NOTE: If very dirty or damaged, replace

cartridge.

4. Place new pre-cleaner and cartridge

firmly in base,

5. Replace cover.

IMPORTANT: Petroleum solvents, such as

kerosene, are not to be used to clean the

cartridge. They may cause deterioration of

the cartridge. Do not oil cartridge. Do not

use pressurized air to clean cartridge.

CLEAN AIR SCREEN

The air screen is over the air intake blower

located on top of engine. The air screen

mustbe keptfree ofdirt and chaffto prevent

engine damagefrom overheating.Cleanwith

a wire brushor compressed air to remove

dirtand stubborndried gum fibers.

ENGINE COOLING SYSTEM

To ensure proper cooling, make sure the

grass screen, cooling fir_s,and other exter-

nal surfaces of the engine are kept clean

at all times.

Every 100 hours of operation (more often

under extremely dusty, dirty conditions),

removethe blower housing and other cooling

shrouds. Clean thecooling fins and external

surfaces as necessary. Ensure the cooling

shrouds are reinstalled.

NOTE: Operating the engine with ablocked

grass screen, dirty or plugged cooling fins,

and/or cooling shrouds removed will cause

engine damage due to overheating.

IN-UNE FUEL FILTER

The fuelfiltershould be replaced once each

season. If fuelfilter becomes clogged, ob-

structing fuel flowtocarburetor,replacement

is required.

1. With engine cool, remove filter and plug

fuel line sections.

2. Place newfuel filter inposition infuel line

with arrow pointing towards carburetor.

3. Be sure there are no fuel line leaks and

clamps are properly positioned.

4. lmmediatelywipeupanyspilled gasoline.

21

Page 22

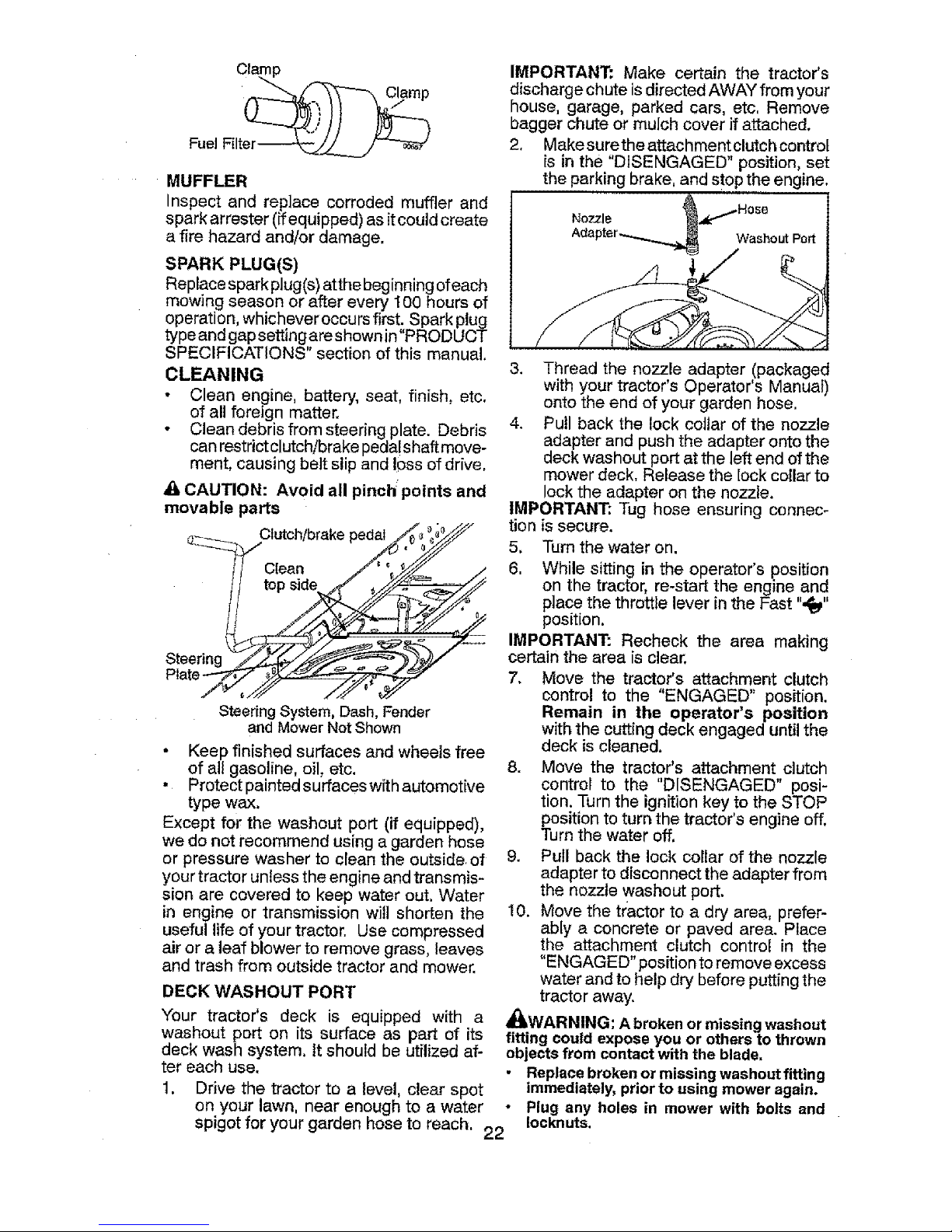

Clamp

Fuel Filter__"---_g

MUFFLER

Inspect and replace corroded muffler and

spark arrestor (ifequipped) as itcould create

afire hazard and/or damage.

SPARK PLUG(S)

Replacespark plug(s)atthe beginning ofeach

mowing season or after every I00 hours of

operation, whicheveroccurs first. Spark plug

type andgap settingareshownin"PRODUCT

SPECIFICATIONS" section of this manual,

CLEANING

• Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Clean debris from steering plate. Debris

canrestrictclutch/brake peda!shaftmove-

ment, causing belt slipand loss of drive.

_&CAUTION: Avoid all pinch points and

movable parts

&____CIutch!brake ped_ey

tl c[_a. /' °,,y/f_ /.

Steer____j--

Steering System, Dash, Fender

andMowerNotShown

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

. Protect paintedsurfaces withautomotive

type wax,

Except for the washout port (if equipped),

we do not recommend using a garden hose

or pressure washer to clean the outside of

yourtractor unless the engine and transmis-

sion are covered to keep water out, Water

in engine or transmission will shorten the

useful life of your tractor. Use compressed

air or a leafblower to remove grass, leaves

and trash from outside tractor and mower.

DECK WASHOUT PORT

Your tractor's deck is equipped with a

washout port on its surface as part of its

deck wash system, tt should be utilized af-

ter each use,

1. Drive the tractor to a level, clear spot

on your lawn, near enough to a water

spigot for your garden hose to reach,

IMPORTANT: Make certain the tractor's

discharge chute isdirected AWAYfrom your

house, garage, parked cars, etc, Remove

bagger chute or mulch cover if attached,

2, Makesurethe attachment clutch controt

is in the "DISENGAGED" position, set

the parking brake, and stop the engine,

Nozzle ]

Washout Port

3. Thread the nozzle adapter (packaged

with your tractor's Operator's Manual)

onto the end of your garden hose,

4, Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the left end of the

mower deck, Release the lock collar to

lock the adapter on the nozzle.

IMPORTANT.* Tug hose ensuring connec-

tion is secure.

5, Turn the water on.

6, While sitting in the operator's position

on the tractor, re-start the engine and

place the throttle lever in the Fast ",_"

position.

IMPORTANT: Recheck the area making

certain the area is clear.

7. Move the tractor's attachment clutch

control to the "ENGAGED" position.

Remain in the operator's position

with the cutting deck engaged until the

deck is cleaned.

8. Move the tractor's attachment clutch

control to the "DISENGAGED" posi-

tion, Turn the ignition key to the STOP

position to turn the tractor's engine off,

Turn the water off.

9. Pull back the lock collar of the nozzle

adapter to disconnect the adapter from

the nozzle washout port.

10. Move the tractor to a dry area, prefer-

ably a concrete or paved area. Place

the attachment clutch control in the

"ENGAGED" position to remove excess

water and to help dry before putting the

tractor away.

_WARNING: A broken or missing washout

fitting could expose you or others to thrown

objects from contact with the blade,

Replace broken or missing washout fitting

immediately, prior to using mower again.

• Plug any holes in mower with bolts and

Iocknuts.

22

Page 23

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY SERVICE OR

ADJUSTMENTS:

3.

4,

5.

6.

in contactwith plug,

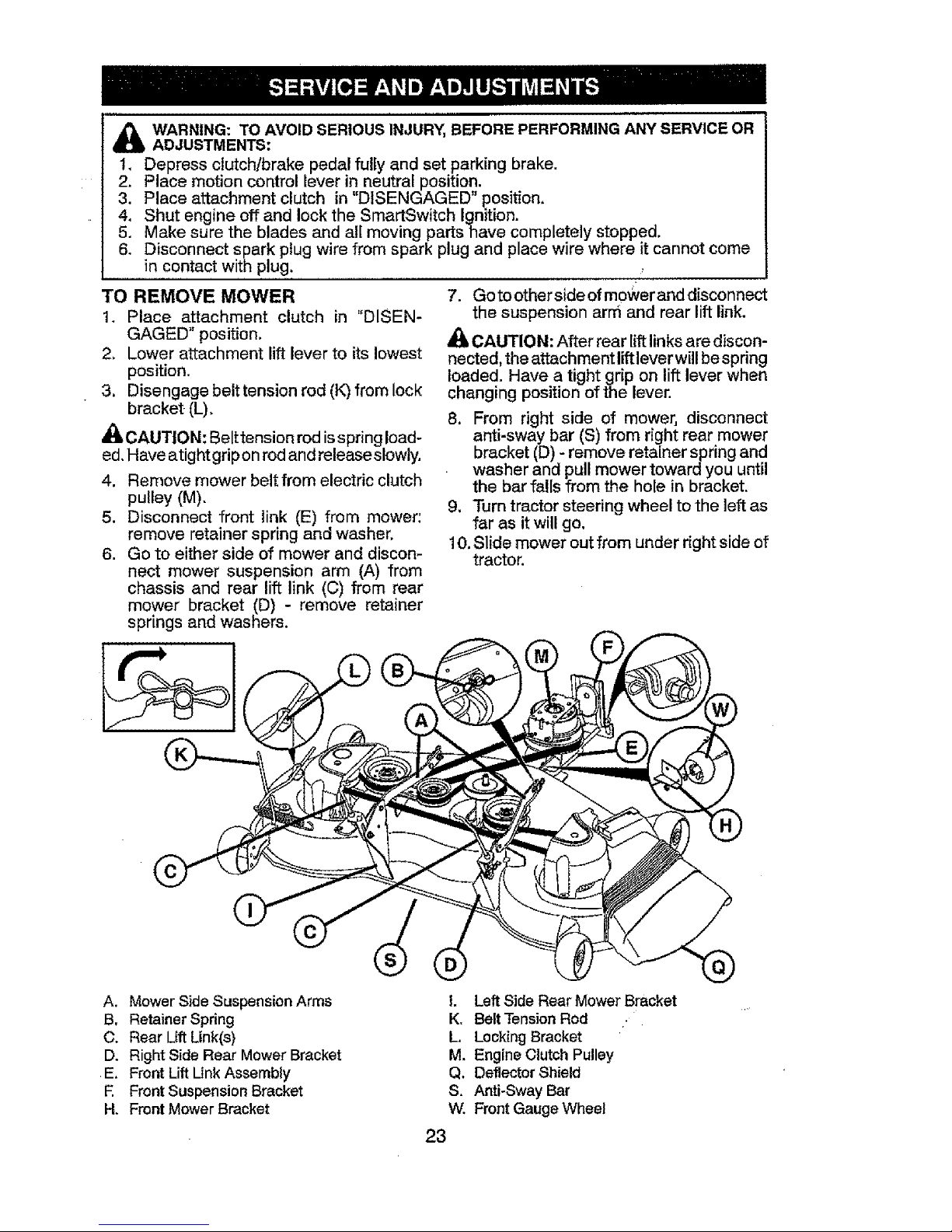

TO REMOVE MOWER

1. Place attachment clutch in "DISEN-

GAGED" position.

2, Lower attachment lift lever to itslowest

position.

3. Disengage belt tension rod (K)from lock

bracket (L),

_,CAUTION: Belttension rod isspring load-

ed.Have atightgrip onrodand releaseslowly.

4. Remove mower belt from electric clutch

5.

6.

Depress clutch/brake pedal fully and set parkingbrake.

Place motion control lever in neutral position.

Place attachment clutch in "DISENGAGED" position,

Shut engine offand lock the SmartSwitch Ignition.

Make sure the blades and all moving partshave completely stopped.

Disconnect spark plugwire from spark plug and placewire where it cannot come

pulley(M).

Disconnect front link (E) from mower:

remove retainer spring and washer.

Go to either side of mower and discon-

nect mower suspension arm (A) from

chassis and rear lift link (C) from rear

mower bracket (D) - remove retainer

springs and washers,

0!

7. Gotoother sideofm0wer anddisconnect

the suspension arm and rear lift link.

CAUTION: After rear lift linksarediscon-

nected, the attachment liftleverwill bespring

loaded. Have a tight grip on lift lever when

changing position of the lever.

8. From right side of mower, disconnect

anti-sway bar (S) from right rear mower

bracket (D)- remove retainer spring and

washer and pull mower toward you until

the bar falls from the hole in bracket.

9, Turn tractor steering wheel to the left as

far as it will go.

10,Slide mower out from under right side of

tractor.

A. Mower Side Suspension Arms

B. Retainer Spring

C. Rear Lift Link(s)

D. Right Side Rear Mower Bracket

E, Front Lift Link Assembly

E Front Suspension Bracket

H. Front Mower Bracket

I, Left Side Rear Mower Bracket

K, Belt Tension Rod

L, Locking Bracket

M, Engine Clutch Pulley

Q. Deflector Shield

S. Anti-Sway Bar

W. Front Gauge Wheel

23

Page 24

TO INSTALL MOWER

1. SET PARKING BRAKE LEVER AND

LOWER ATTACHMENT LiFT LEVER

• Depress clutch/brake pedal all the way

down and hold.

• Pull parking brake lever up and hold,

release pressure from clutch/brake

pedal, then release parking brake lever.

Pedal should remain in brake position.

Ensure parking brake will hold tractor

secure.

_CAUTION: Lift lever is spring loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position. Lift lever is

located on left side of fender.

Lift

Lever

2. ASSEMBLE FRONT GAUGE WHEEL

(W) TO FRONT OF MOWER

H. Front Mower Bracket

W. Front Gauge Wheel

X. Shoulder Bo]t

Y, 1-1/40.D. Washer

Z. 3/8-16 Locknut

3. TURN STEERING WHEEL LEFT AND

POSITION MOWER

° Turn steering wheel to the left as far as it

will go andposition mower onrightside of

tractorwith deflectorshield (Q)tothe right.

Front

fEngine

'_ Transaxle

Q. Deflector Shield

4. SLIDE MOWER UNDER TRACTOR

° Bring belt forward and check be[tfor pro-

per routing in all mower pulley grooves,

NOTE: Ensure mower side suspension arms

(A) are pointing forward before sliding mower

under tractor,

• Slide mower under tractor until it is

centered under tractor.

j

A. Mower Side Su_ }ension Arms

Q. Deflector Shield

24

Page 25

5, INSTALL ANTI-SWAY BAR (S)

(IF EQUIPPED)

ANTI-SWAY BAR (S)

.,_ Towards Towards

Transaxle MowerDeck_'_

90" End integrated Washer End

• From right side of mower, first insert

90° end of anti-sway bar (S) into hole in

transaxIe bracket (_, located near left

rear tire infront of transaxfe.

NOTE: Flashlight may be helpful.

TransaxleBracket(T)

LocatedBetweenRearTires

NOTE: Depending on model, bracket(T) may

be different than shown but hole for anti-sway

bar will be in same position/location,

• Pivot the integrated washer end of anti-

sway bar (S) towards mower deckbracket

on right side of mower. Insert integrated

washer end of bar into hole inrear mower

bracket (D), Move mower as needed to

insert integrated washer end of bar into

rear mower bracket (D).

• Secure with small washer and small

retainer spring as shown.

D. RightSideRear MowerBracket

S. Anti-SwayBar

"11.TransaxJeBracket

l 1

6. ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS

, Positionfront hole inside suspension arm