Page 1

Operator's Manual

i

iCR.FT .nN°I

LAWN TRACTOR

22 HP,* 48" Mower

Electric Start

Automatic Transmission

Model No.

917.20392

• EspaSol, p. 35

I

This product has a low emission engine which operates I

differently from previously built engines. Before you start the

iengine, read and understand this manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

For answers to your questions

about this product, call:

1-888-331-4569

Craftsman Customer Help Line

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

* The power rating as dectared bythe engine manufacturer is the * L_ potenc_enomlnaJdeclarada per el febncaote del motor es re

average gross power output at the specked RPM of a typlc_ sal;da media de potencia brute _ las RPM ospecificadas de on

production engine for the engine model measured using SAE motor de serie t[plco paza el modolo de motor, medlda seg_n

Stand_ds for engine gross power, please refer to the engine las aortaes SA_ sobre petenc_a brute de motor Pa,'a m_.s

ntenufaoturer for details. Jnformaci_, consulte al fabriea.nte del motor,

588807326

Page 2

Warranty ................................................ 2

Safety Rules .......................................... 3

Product Specifications ........................... 6

Assemb]y/Pre-Operation ....................... 7

Operation ............................................... 9

Maintenance Schedule ........................ 16

Maintenance ........................................ 16

Service and Adjustments ..................... 2I

Storage ................................................ 29

Troubleshooting ................................... 30

Espa5ol ................................................ 35

Sears Service ........................ Back Cover

CRAFTSMAN UMITED WARRANTY

FOR TWO YEARS from the date of purchase, aJl non-expendable parts of this haling equipment are

warranted against defects inmaterial or workmanship. With proof of purchase, a defective non-expendable

part wiJl receive free repatr or replacement at option of seller.

Battery Limited Warranty

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of thjs riding equipment is

warranted against defects in matenal or workmanshtp. WFth proof of purchase, you will receive a new

batten! at no charge. You are responsible for the labor cost of battery installation.

Additional Limited Warranties

In the following additional warranties, you are responsible for the labor cost of part installation after the

second year from the date of purchase.

FOR FiVE YEARS from the date of purchase, the frame of this riding equtpment is warranted agmnst any

defects in matenal or workmanshtp. With proof of purchase, you will receive a new frame at no charge.

FOR TEN YEARS from the date of purchase, the front axle of this riding equipment is warranted against

any defects in material or workmanship. With proof of purchase, you will receive a new axle at no charge.

FOR AS LONG AS IT IS USED by the oNgmal owner after the tenth year from the date of purchase, the

cast tron front axle (if equtpped) of this riding equipment is warranted against any defects in material or

workmanship. With proof of purchase, you wiFI receive a new cast iron front axJe at no charge.

WARRANTY SERVICE

For warranty coverage details to ebtmn free repair or replacement, v=s=tthe web page: www.craftsman.eomi

warranty

Product Replacement

If part repair or repracement is tmpossible, you wttl receive a new ndlng equipment unit of the same or

equivalent model

Warranty Restriction

All warranty coverage is yard if this riding equipment isever used while providing commercial services or if

rented to another person.

This warranty covers ONLY defects In material and workmanship. Warranty coverage does NOT

include:

" Expendable parts (except batten!) that can wear out from normal use within the warranty pened, including

but not hmited to blades, spark plugs, belts and air, oil or gas filters.

• Standard maintenance servicing, oil changes or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or

glass.

•Ttre or wheel replacement or repatr resulting from normal wear, accident, or improper operation or

maintenance.

• Repairs necessary because of operator abuse, tncJudlng but not limited to damage caused by towing

objects beyond the capability of the riding equipment, impacting objects that bend the frame, axle

assembty or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not tlmited to, electrica! and mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, failure

to keep the deck clear of flammable debris, or failure to maintain the riding equipment according to the

instructions contained Jnthe operator's manual.

• Engine (fuel system) cleaning or repairs caused by fue! determined to be contaminated or oxidized

(stale). In general, fue_ should be used within 30 days of its purchase date.

• Normal detedoratton and wear of the exterior finishes, or product label replacement.

This warranty gives you specific legal rights, and you may also have other nghts which van! from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

Page 3

_DANGER: This cutting machine is capable of amputating hands and feet and

throwing objects, Failure to observe the following safety instructions could result

in serious injury or death.

_WARNING: Inorderto preventacciden-

tal starting when setting up, transporting,

adjusting or making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_IbWARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

_IbWARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Too heavy of a load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

_(_WARNING: Engine exhaust, some of

its constituents, and certain vehicle compo-

nents contain or emit chemicals known to

the State of California to cause cancer and

birth detects or other reproductive harm.

_JlLWAR NING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth detects

or other reproductive harm. Wash hands

after handling.

I. CHILDREN

_WARNING! CHILDREN CAN BE IN-

JURED BYTHIS EQUIPMENT. TheAmeri-

can Academy of Pediatrics recommends

that children be a minimum of 12 year of

age before operating a pedestrian controlled

lawn mower and a minimum of 16 years of

age before operating a riding lawn mower.

_WARNING! CHILDREN CAN BE

SERIOUSLY INJURED OR KILLED BY

THIS EQUIPMENT. Carefully read and

follow all of the safety instructions below.

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

• Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carry children, even with the

blades shut off. They may fall off and

be seriously inju red or interfere with safe

machine operation. Children who have

been given rides in the past mays uddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

Never allow children to operate the ma-

chine.

• Use extreme caution when approaching

blind corners, shrubs, trees, or other

objects that may block your view of a

child.

II. GENERAL OPERATION

Read, understand, and follow all instruc-

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine. Keep clear

of the discharge opening at all times.

• Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

• Ensure the area is clear of bystanders

before operating. Stop machine ifanyone

enters the area.

• Never carry passengers,

Do not mow in reverse unless absolutely

necessary, Always look down and behind

before and while backing.

• Never direct discharged materialtoward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces,

• Do not operate machinewithout the enUre

grass catcher, discharge chute, or other

safety devices in place and working.

Page 4

• Slowdownbeforeturning.

• Neverleavearunningmachineunat-

tended.Alwaysturnoffblades,set

parkingbrake,stopengine,andremove

keysbeforedismounting.

Disengagebladeswhennetmowing.

Shutoffengineandwaitforallpartsto

cometoacompletestopbeforecleaning

themachine,removingthegrusscatcher,

oruncloggingthedischargechute.

Operate machine only in daylight or good

artificial light.

Do not operate the machine while under

the influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Use extreme caution when loading or

unloading the machine into a trailer or

truck.

Always wear eye protection when operat-

ing machine.

Use ear protectors to avoid damage to

hearing.

• Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

Follow the manufacturer's recommenda-

tion forwheelweights orcounterweights.

• Keep machine free of grass, [eaves or

other debris build-up which can touch hot

exhaust/engine parts and burn. Do not

allow the mower deck to plow leaves or

other debris which can cause build-up

to occur. Clean any oil or fuel spillage

before operating or storing the machine.

Allow machine to cool before storage.

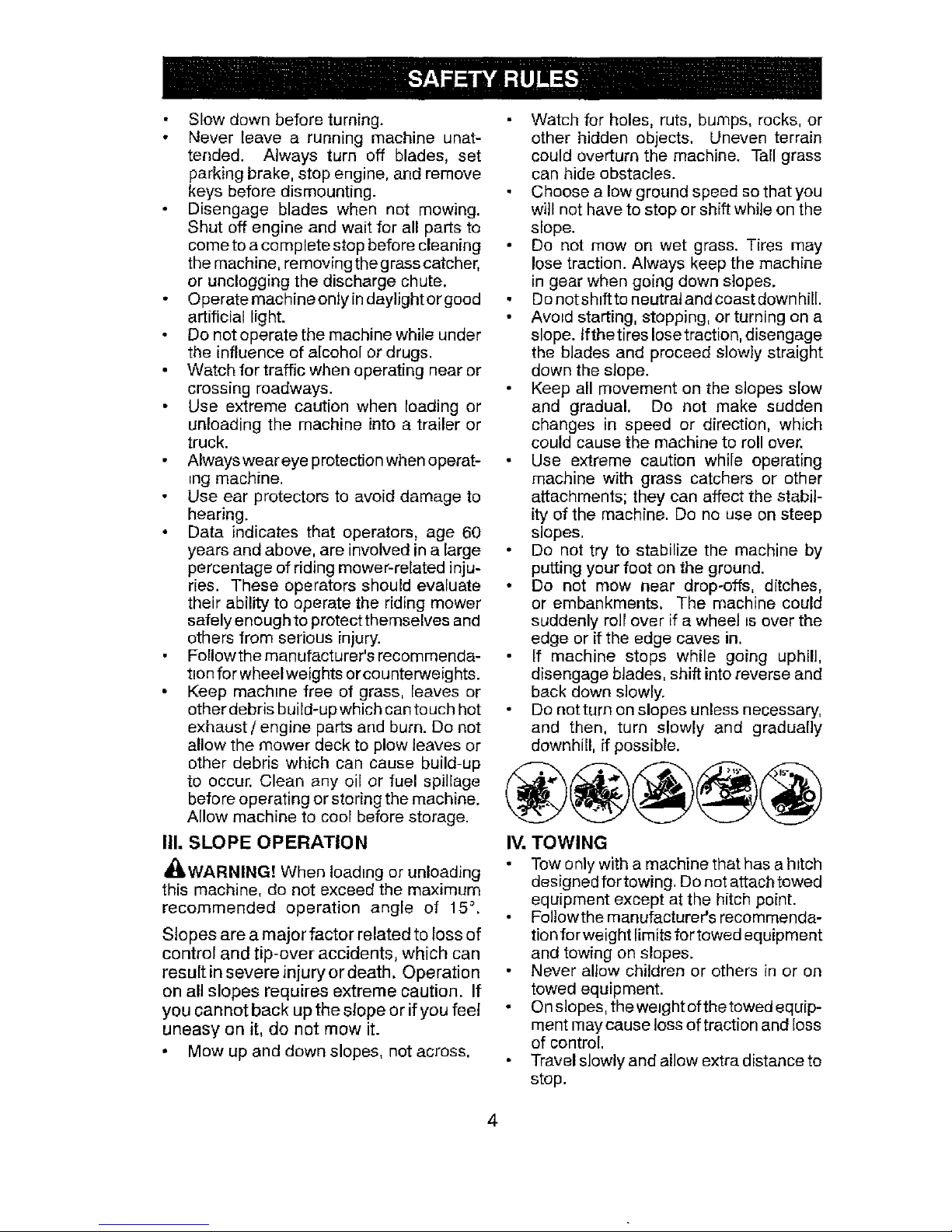

Iil. SLOPE OPERATION

_,WARNING! When loading or unloading

this machine, do not exceed the maximum

recommended operation angle of 15 °.

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death, Operation

on all slopes requires extreme caution. If

you cannot back up the stope or if you feet

uneasy on it, do not mow it.

* Mow up and down slopes, not across.

Watch for holes, ruts, bumps, rocks, or

other hidden objects, Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

Do not mow on wet grass. Tires may

lose traction. Always keep the machine

in gear when going down slopes.

• Do not shftte neutral and coast downhill.

• Avoid starting, stopping, or turning on a

slope, tfthetires Iosetraction, disengage

the blades and proceed slowly straight

down the slope.

Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

Use extreme caution while operating

machine with grass catchers or other

attachments; they can affect the stabil-

it,i of the machine. Do no use on steep

slopes.

Do not try to stabilize the machine by

putting your foot on the ground.

* Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

If machine stops while going uphill,

disengage blades, shift into reverse and

back down slowly.

Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

IV. TOWING

Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

Follow the manufacturer's recommenda-

tion for weight limits for towed equipment

and towing on slopes.

Never allow children or others in or on

towed equipment.

On slopes, the weight of the towed equip-

ment may cause loss of traction and loss

of control.

Travel slowly and allow extra distance to

stop.

Page 5

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

• Use only approved gasoline container.

Never remove gas cap or add fuel with

the engine running.

Allow engine to coot before refueling.

Never fuel the machine indoors.

• Neverstore the machine orfuel container

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

• Never fill containers inside a vehicle or

on a truck or traiter bed with plastic liner.

Always place containers on the ground

away from your vehicle when filling.

• Remove gas-powered equipment from

the truck or trailer and refuel it on the

ground. Ifthis is not possible, then refuel

such equipment with a portable contai her,

rather than from a gasoline dispenser

nozzle.

Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until fueling is complete. Do not

use a nozzle lock-open device.

Iffuel isspilled on clothing, change cloth-

ing immediately.

Never overfill fuel tank. Replace gas cap

and tighten securely.

GENERAL SERVICE

• Neveroperate machine in actosed area.

• Keep all nuts and bolts tightto ensure the

equipment is in safe working condition.

• Nevertamperwithsafetydevices. Never

interfere with the intended function of a

safety device or reduce the protection

provided by a safety device. Check there

proper operation regularly. NEVER oper-

ate a machine with a safety device that

does not function properly.

Keep machine free of grass, leaves, or

other debris build-up. Clean oil or fuel

spilFage and remove any fuel-soaked

debris. Allow machine to cool before

storing.

• If you strike a foreign object, stop and

inspectthe machine. Repair, ffnecessary,

before restarting.

Never make any adjustments or repairs

with the engine running.

• Check grass catcher components and the

discharge chute frequently and replace

with manufacturer's recommended parts,

when necessary.

Mower blades are sharp. Wrap the blade

or wear gloves, and use extreme caution

when servicing them.

• Check brakeoperation frequently. Adjust

and service as required.

• Maintain or replace safety and instruction

labels, as necessary.

Use ear protectors to avoid damage to hearing.

Always wear eye protection when operating machine.

Page 6

PRODUCT SPECIFICATIONS

Gasoline Capactty 3.0 Gallons!11,35 L

and type. RegularUn[eaded*

OiI Type: SAE 30 (above 32°F/0°C

(APt.SG-SL) SAE 5W30 (below 32_F/0°C

OilCapacity: W/FIEter' 64 Oz./1,89 L

W/out Filter 60 Oz./1,77 L

Spark Plug Champion RC12YC

(Gap..030"/0.76 ram)

Charging System. 16Amps @ 3600 RPM

Battery: Amp/Hr' 28

Min. CCA: 230

Case stze: UI R

Blade Bolt Torque. 45-55 Ft. Lbs./62-75 Nm

_bGasohne containing up to 10% ethanol (El0) ts

acceptabte for use in this machine. The use of

any gasoline exceedtng 10% ethanol (El0) will

vo=d the product warranty.

CONGRATULATIONS on your purchase of

a new tractor. It has been designed, engi-

neered and man ufactu red to give you the best

possible dependability and performance.

Should you experience any problem you can-

not easily remedy, please co ntact a Sears or

other qualifted service center. We have com-

petent, well-trained representatives and the

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regularschedu[e in maintaining,

caring for and using your tractor.

• Follow instructions under"Maintenance"

and "Storage" sections of this manual.

• Wear proper Personal Protective Equip-

ment ('PPE) while operating this machine,

including (at a minimum) sturdy footwear,

eye protection, and hearing protection.

Do not mow in shorts and/or open toed

footwear.

• Always letsomeone knowyou are outside

mowing.

_kWARNING: This tractor is eq uipped with

an internal combustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass-

covered land unless the engine's exhaust

system is equipped with a spark arrester

meeting applicable local or state laws (if

any). If a spark arrester is used, it should

be maintained in effective working order by

the operator.

Inthe state of California the above isrequired

by law (Section 4442 of the California Public

Resources Code). Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

availablethrough your nearest Sears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman® product is

designed and manufactured for years of

dependable operation. But like all products,

it may require repair from timeto time. That's

when having a Repair Protection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here's what's included in the Agreement:

, Expertservicebyour 12,000 professional

repair specialists.

° Un[imitedservJceand no charge for parts

and labor on all covered repairs.

Product replacement if your covered

product can't be fixed.

• Discount of 25% from regular price of

service and servtce-related parts not

covered by the agreement; also, 25% off

regular price of prevenWe maintenance

check.

• Fast help by phone - phone support

from a Sears representative on products

requiring tn-home repair, plus convenient

repair scheduling.

Once you purchase theAgreement, asimple

phone call is all that ittakes for you to sched-

ule service. You can call anytime day or nig ht,

or schedule a service appointment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories. That's

the kind of profess ionalism you can count on

to help prolong the life of your new purchase

for years to come. Purchase your Repair

Protection Agreement today[

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, Jnthe

U.S.A. call 1-800-4-MY-HOME®.

Page 7

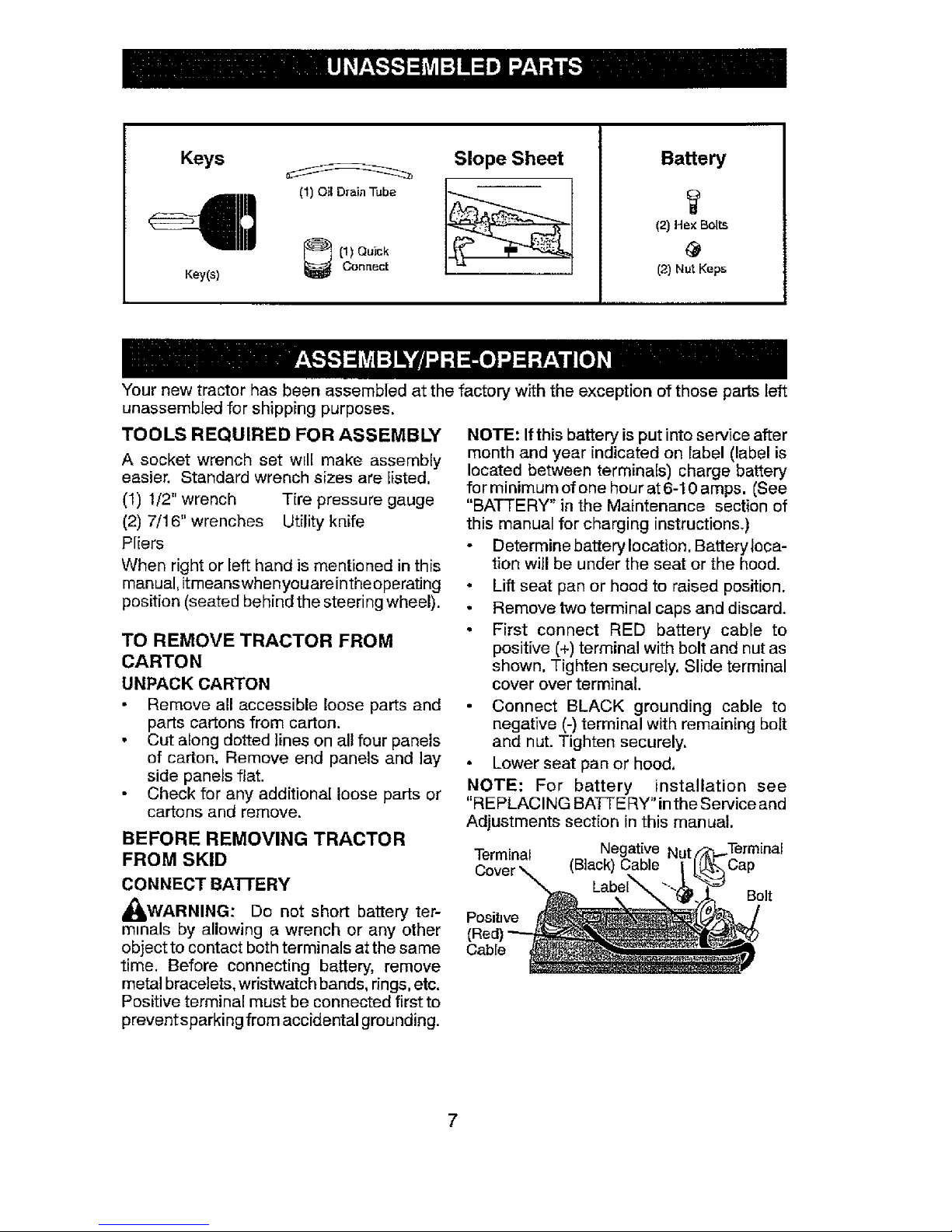

Keys _ Slope Sheet

[1) Quick

Key(s) Connect

Battery

(2) Hex Bolts

@

(2) Nut Keps

Your new tractor has been assembled at the factory with the exception of those parts left

unassembled for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are f[sted,

(1) !/2" wrench Tire pressure gauge

(2) 7/16" wrenches Utility knife

Pliers

When right or left hand is mentioned in this

manual, itmeanswhenyou areinthe operating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

Remove all accessible loose parts and

parts cartons from carton.

• Cut along dotted lines on all four panels

of carton. Remove end panels and lay

side panels flat.

Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

CONNECT BA]-rERY

_WARNING: Do not short battery ter-

m=nals by allowing a wrench or any other

object to contact bothterminalsat thesame

time. Before connecting battery, remove

metalbracelets,wristwatch bands,rings,etc.

Positive terminal must be connected first to

prevent sparking from accidental grounding.

NOTE: If this battery isput into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of one hour at 6-10 amps. (See

"BATTERY" in the Maintenance section of

this manual for charging instructions.)

Determine battery location. Battery loca-

tion will be under the seat or the hood.

• Lift seat pan or hood to raised position.

Remove two terminal caps and discard.

• First connect RED battery cable to

positive (+) terminal with bolt and nut as

shown. Tighten securely. Slide terminal

cover over terminal.

Connect BLACK grounding cable to

negative (-) terminal with remaining bolt

and nut. Tighten securely.

• Lower seat pan or hood.

NOTE: For battery installation see

"RE PLACING BATf'E RY" in the Service and

Adjustments section in this manual.

Terminal Negative N

Cover _ (Black) Cable Cap

Bolt

Positwe

Cable

7

Page 8

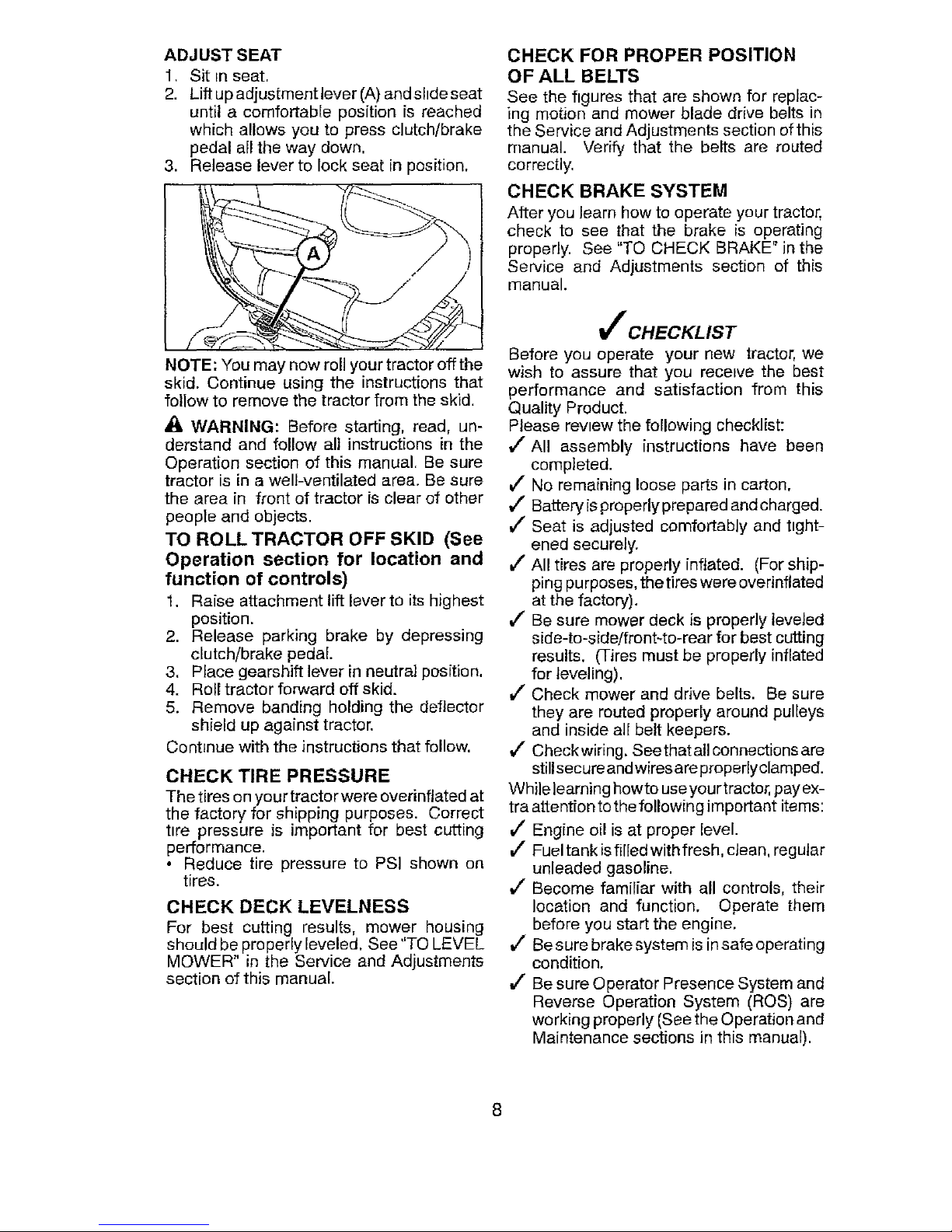

ADJUST SEAT

1. Sit In seat.

2. Lift up adjustment lever (A) and shde seat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

3. Release lever to lock seat in position.

NOTE: You may now roll your tractor off the

skid. Continue using the instructions that

follow to remove the tractor from the skid.

_1_WARNING: Before starting, read, un-

derstand and follow all instructions in the

Operation section of this manual. Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

TO ROLL TRACTOR OFF SKID (See

Operation section for location and

function of controls)

1. Raise attachment lift lever to its highest

position.

2. Release parking brake by depressing

clutch/brake pedal.

3, Place gearshift lever in neutral position.

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Continue with the instructions that follow.

CHECK TIRE PRESSURE

The tires on your tractor were overinftated at

the factory for shipping purposes. Correct

ttre pressure is important for best cutting

performance.

• Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled, See "TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION

OF ALL BELTS

See the figures that are shown for replac-

ing motion and mower blade drive belts in

the Service and Adjustme nts section of this

manual. Verify that the belts are routed

correctly,

CHECK BRAKE SYSTEM

After you Jearn how to operate your tractor,

check to see that the brake is operating

properly. See "TO CHECK BRAKE" in the

Service and Adjustments section of this

manual.

_CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product.

Please revtew the following checklist:

,/All assembly instructions have been

completed.

J No remaining loose parts in carton,

J" Battery isproperly prepared and charged.

,/Seat is adjusted comfortably and ttght-

ened securely.

All tires are properly inflated. (For ship-

ping purposes, the tires were overinflated

at the factory).

,/" Be sure mower deck is properly leveled

side-to-side!fronbto-rear for best cutting

results. (Tires must be properly inflated

for leveling),

,/Check mower and drive belts, Be sure

they are routed properly around pulleys

and inside all belt keepers.

J Checkwiring. Seethatall connections are

stillsecureand wiresare properlyclamped.

While learning howte use yourtractor, pay ex-

tra attention to the following important items;

J' Engine oil is at proper level.

_/Fuel tank isfilledwithfresh, dean, regular

unleaded gasoline.

,/ Become familiar with all controls, their

location and function. Operate them

before you start the engine.

J" Be sure brake system is in safe operating

condition.

,/Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (See the Operation and

Maintenance sections in this manual).

8

Page 9

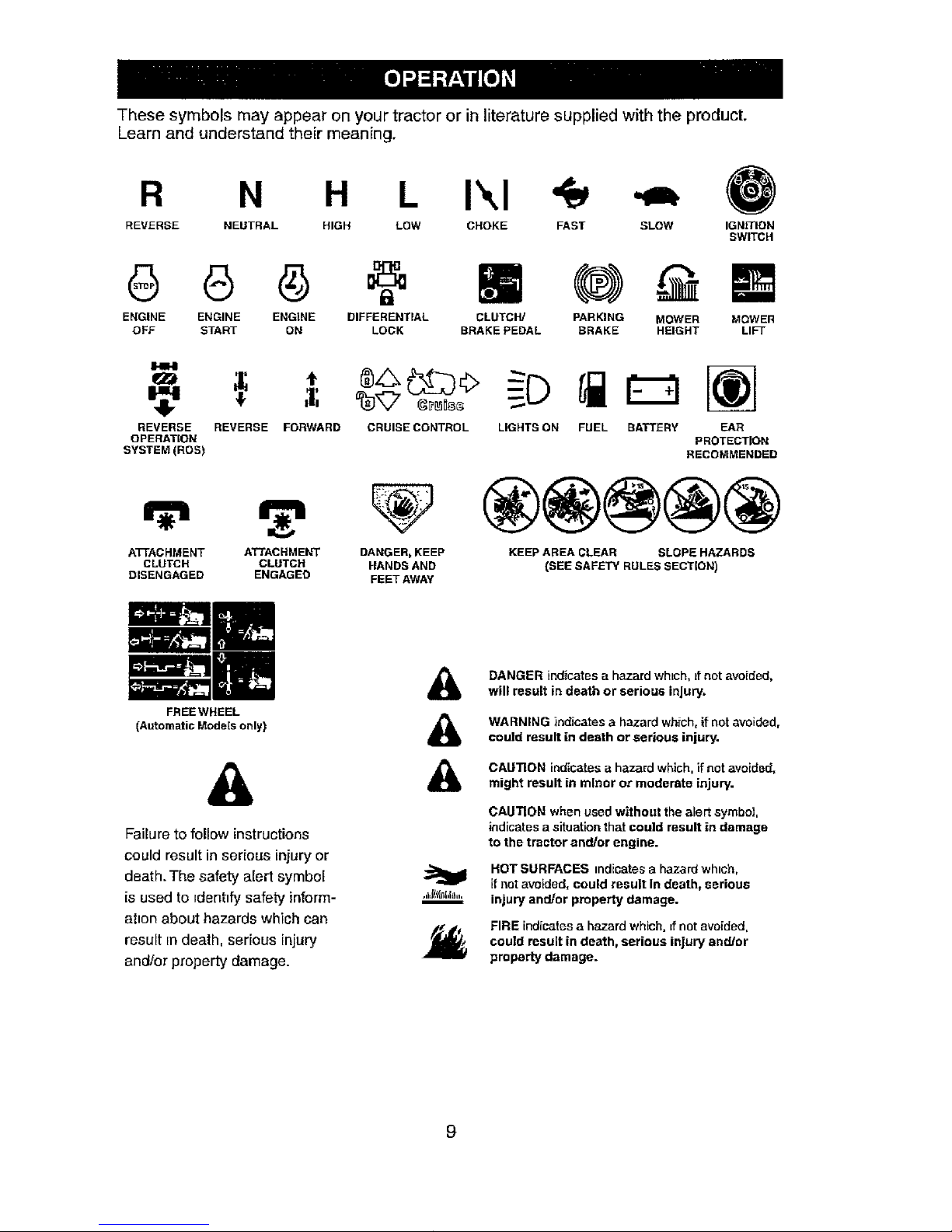

Thesesymbolsmayappearonyourtractororinliteraturesuppliedwiththeproduct.

Learnandunderstandtheirmeaning.

R N H L Ikl

REVERSE NEUTRAL HIGH LOW CHOKE FAST SLOW IGNITION

SWITCH

ENGINE ENGINE ENGINE DIFFERENTIAL

OFF START ON LOCK

m

CLUTCH] PARKING MOWER MOWER

BRAKE PEDAL BRAKE HEIGHT LIFT

REVERSE

OPERATION

SYSTEM (ROS)

REVERSE FORWARD CRUISE CONTROL LIGHTS ON FUEL BATTERY EAR

PROTECTION

RECOMMENDED

A'I-FACHMENT ATTACHMENT DANGER_ KEEP

CLUTCH CLUTCH HANDS AND

DISENGAGED ENGAGED FEET AWAY

®@@@@

KEEP AREA CLEAR SLOPE HAZARDS

{SEE SAFETY RULES SECTION)

FREEWHEEL

[Automatic Models only)

&

Failure to fellow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safety inform-

at_onabout hazards which can

result in death, serious injury

and/or property damage.

&

&

&

DANGER indicatesa hazard which, Jfnot avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor oz- moderate injury.

CAUTION when used without thealert symbol,

indicates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard wh=ch,

if net avoided, could result In death, serious

injury and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage.

Page 10

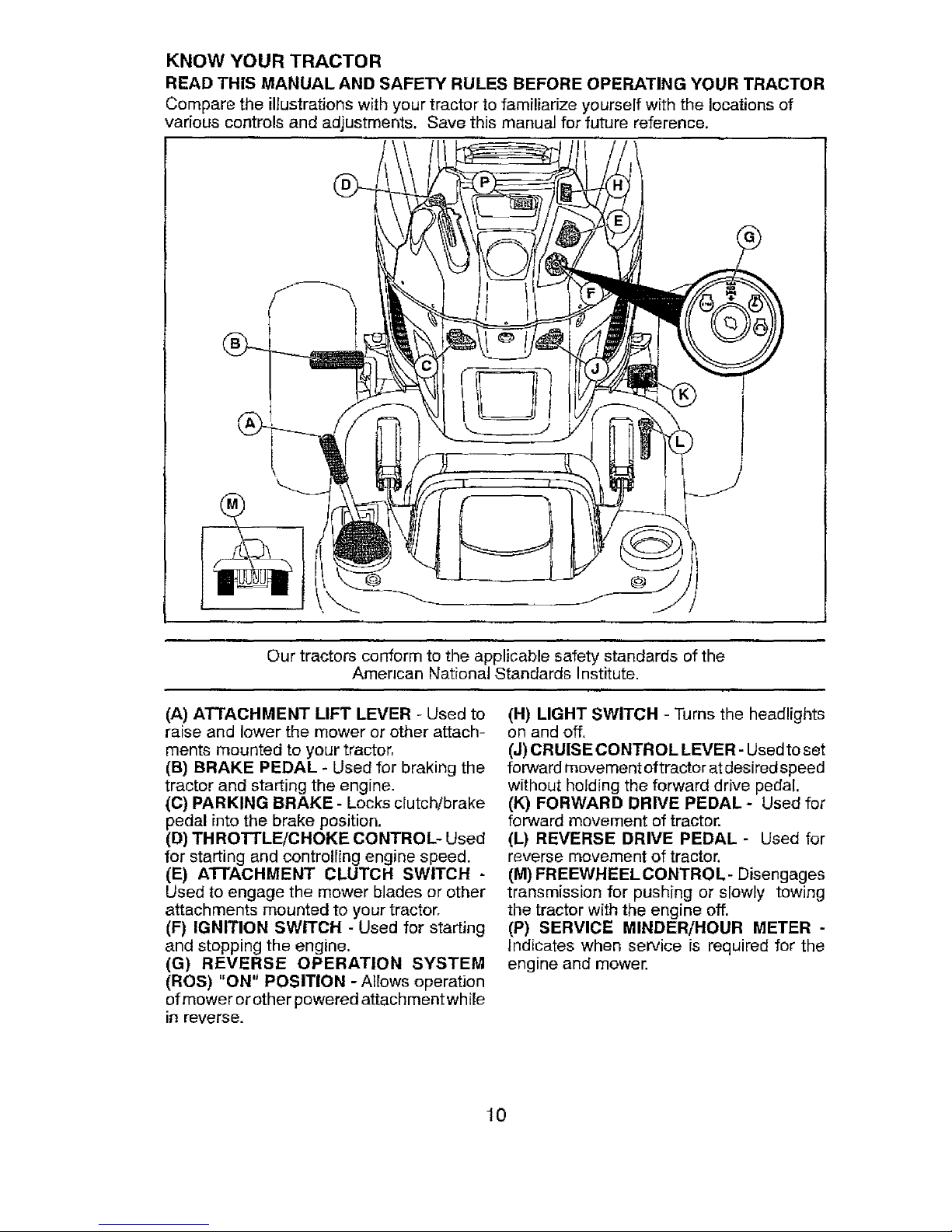

KNOW YOUR TRACTOR

READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the ilJustrationswith your tractor to familiarize yourself withthe locations of

various controls and adjustments. Save this manual for future reference.

@

Our tractorsconform to the applicable safety standards of the

Amencan National Standards Institute.

(A) ATTACHMENT LIFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor,

(B) BRAKE PEDAL - Used for braking the

tractor and starting the engine.

(C) PARKING BRAKE - Locks clutch/brake

pedal into the brake position.

(D) THROTTLE/CHOKE CONTROL- Used

for starting and controlling engine speed.

(E) ATTACHMENT CLUTCH SWITCH -

Used to engage the mower blades or other

attachments mounted to your tractor.

(F) IGNITION SWITCH - Used for starting

and stopping the engine,

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION - Allows operation

of mower or other powered attachmentwhile

in reverse.

(H) LIGHT SWITCH - Turns the headlights

on and off.

(J) CRUISE CONTROL LEVER- Used to set

forward movement of tractor atdesired speed

without holding the forward drive pedal.

(K) FORWARD DRIVE PEDAL - Used for

forward movement of tractor.

(L) REVERSE DRIVE PEDAL - Used for

reverse movement of tractor.

(M) FREEWHEEL CONTRO L- Disengages

transmission for pushing or slowly towing

the tractor with the engine off.

(P) SERVICE MINDER/HOUR METER -

indicates when service is required for the

engine and mower.

10

Page 11

The operation of any tractor can result in foreign objects thrown intol

the eyes, which can result in severe eye damage. Always wear safety_

glasses or eye shields while operating your tractor or performing any1

adjustments or repairs. We recommend standard safety glasses ora I

wide vision safety mask worn over spectacles. |

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

ru nning, any attempt bythe operator to leave

the seat without first setting the parking brake

will shut off the engine.

1, Depress brake pedal (B) allthe way down

and hold.

2. Pull parking brake lever (C) up and hold,

release pressure from brake pedal (B),

then release parking brake lever. Pedal

should remain in brake position. Make

sure parking brake will hold tractorsecure.

IMPORTANT: Leaving the ignition switch in

any position other than "STOP" will cause

the battery to discharge and go dead.

NOTE: Under certain conditions when tractor

is standing idle with the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass. To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

TO USE THRO'I'rLE CONTROL

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast) reduces engine's operating effi-

ciency.

• Pull speed (fast) offers the best mower

performance.

STOPPING

MOWER BLADES -

• To stop mower blades, move attachment

clutch control to the disengaged position.

GROUND DRIVE -

• To stop ground drive, depress brake pedal

all the way down.

IMPORTANT: Forward and reverse drive

pedals return to neutral position when not

depressed.

ENGINE -

• Move throttle control to slow position.

NOTE: Failure to move throttle control

to slow position and allowing engine to

idle before stopping may cause engine to

"backfire".

• Turn ignition key to "STOP" position and

remove key. Always remove key when

leaving tractor to prevent unauthorized

use.

• Never use choke to stop engine.

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement

is controlled by the forward and reverse

drive pedals.

1. Start tractor and release parking brake.

2. Slowlydepressforward (K) orreverse (L)

drive pedal to begin movement. Ground

speed increases the further down the

pedal is depressed.

II

11

Page 12

TO USE CRUISE CONTROL

The cruise control feature can be used for

forward travel only.

SYSTEM CHARACTERISTICS

The cruise control should only be used

whtle mowing or transporting on relatively

smooth, straight surfaces. Other conditions

such as trimming at slow speeds may cause

the cruise control to disengage. Do not use

the cruise control on slopes, rough ternan

or while trimmimg or turning.

• With forward drive pedal (K) depressed to

desired speed, pull cruise control lever (J)

up and hold while lifting your foot off the

pedal, then release the lever.

To disengage the cruise control, depress the

brake pedal or tap on forward drive pedal,

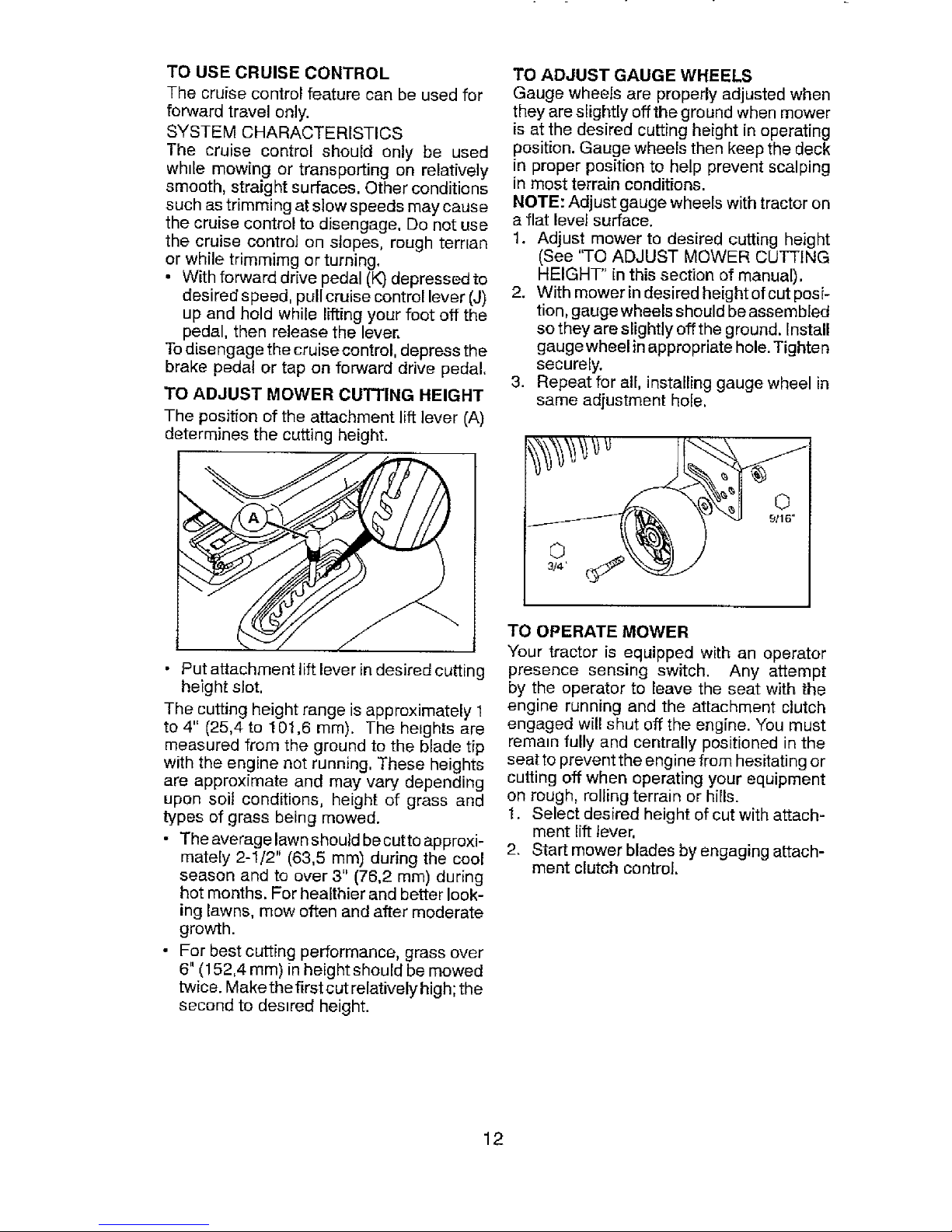

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever (A)

determines the cutting height.

• Put attachment lift lever in desired cutting

height slot,

The cutting height range is approximately 1

to 4" (25,4 to 101,6 ram). The heights are

measured from the ground to the blade tip

with the engine not running, These heights

are approximate and may vary depending

upon soil conditions, height of grass and

types of grass being mowed.

• The average lawn should be cutto approxi-

mately 2-1/2" (63,5 mm) during the cool

season and to over 3" (76,2 mm) during

hot months. For healthier and better look-

ing lawns, mow often and after moderate

growth.

• For best cutting performance, grass over

6" (152,4 mm) in height should be mowed

twice. Make the first cut relatively high; the

second to destred height.

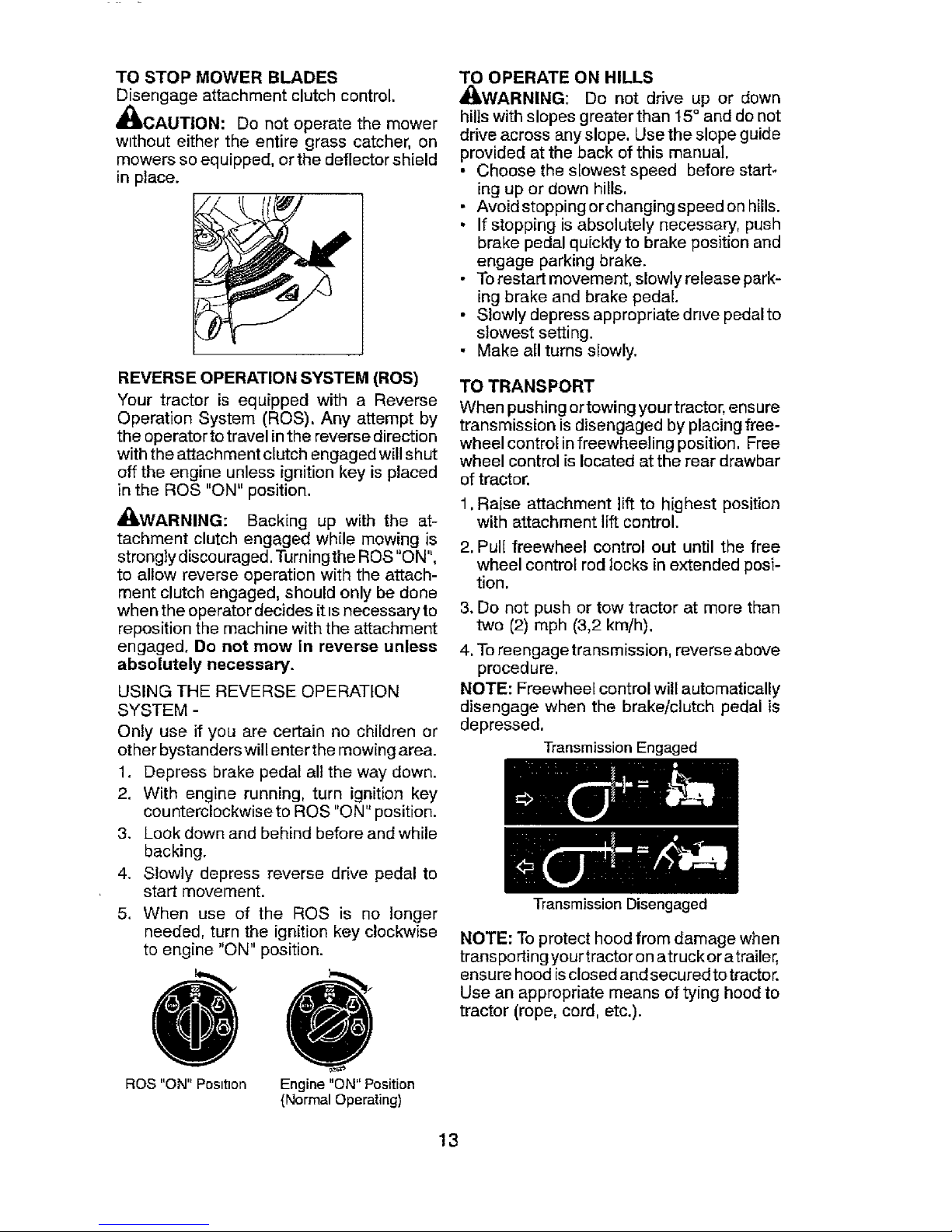

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly off the ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a flat level surface.

1. Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

2. With mower in desired heightofcut posi-

tion, gauge wheels should be assembled

so they are slightly off the ground. Install

gaugewheel in appropriate hole. Tighten

securely.

3. Repeat for air, installing gauge wheel in

same adjustment hole.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Any attempt

by the operator to feave the seat with the

engine running and the attachment clutch

engaged will shut off the engine. You must

remain fully and centrally positioned in the

seat to prevent the engine from hesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills.

t. Select desired height of cut with attach-

ment lift lever.

2. Start mower blades by engaging attach-

ment clutch control.

12

Page 13

TO STOP MOWER BLADES

Disengage attachment clutch control.

_CAUTION: Do not operate the mower

w_thout either the entire grass catcher, on

mowers so equipped, or the deflector shield

in place.

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direction

with the attachment clutch engaged will shut

off the engine unless ignition key is placed

in the ROS "ON" position.

_(_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discouraged. Turningthe ROS "ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides it is necessary to

reposition the machine with the attachment

engaged, Do not mow in reverse unless

absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM -

Only use if you are certain no children or

other bystanders will enter the mowing area.

1. Depress brake pedal all the way down.

2. With engine running, turn ignition key

counterclockwise to ROS "ON" position.

3. Look down and behind before and while

backing.

4. Slowly depress reverse drive pedal to

start movement.

5. When use of the ROS is no longer

needed, turn the ignition key clockwise

to engine "ON" position.

ROS "ON" Position

Engine "ON" Position

{Normal Operating)

TO OPERATE ON HILLS

_WARNING: Do not drive up or down

hills with slopes greater than 15 ° and do not

drive across any slope. Use the slope guide

provided at the back of this manual.

• Choose the s[owest speed before start-

ing up or down hills.

• Avoid stopping orchanging speed on hills.

• If stopping is absolutely necessary, push

brake pedal quickly to brake position and

engage parking brake.

• To restart movement, slowly release park-

ing brake and brake pedal.

• Slowly depress appropriate drive pedalto

slowest setting.

• Make all turns s[owly.

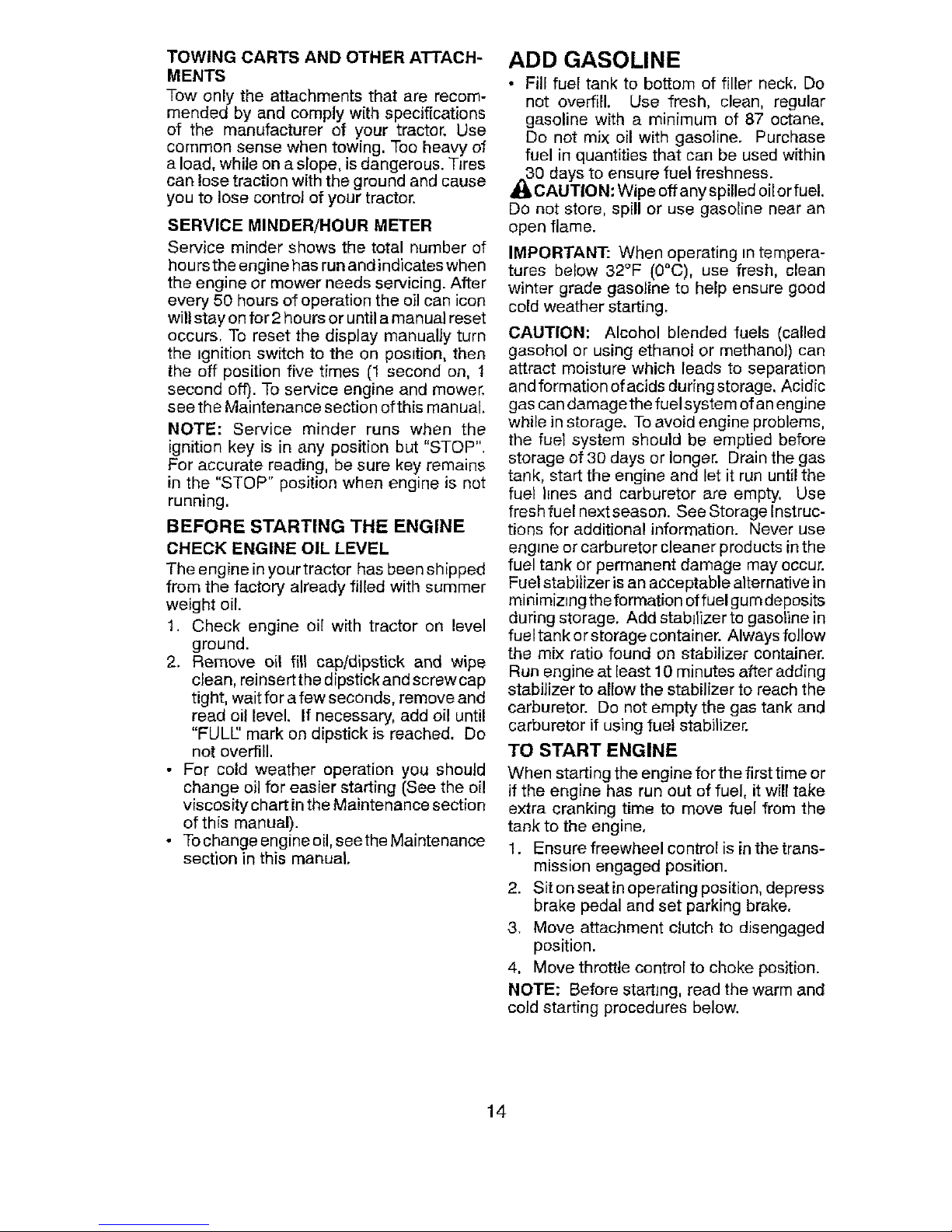

TO TRANSPORT

When pushing or towing your tractor, ensure

transmission is disengaged by placing free-

wheel control infreewheeling position. Free

wheel control is located at the rear drawbar

of tractor.

1. Raise attachment lift to highest position

with attachment lift control.

2, Pul[ freewheel control out until the free

wheel control rod locks in extended posi-

tion,

3, Do not push or tow tractor at more than

two (2) mph (3,2 kin/h).

4. To ree ngage transmission, reverse above

procedure.

NOTE: Freewheel control will automatically

disengage when the brake/clutch pedal is

depressed.

Transmission Engaged

Transmission Disengaged

NOTE: Toprotect hood from damage when

transporting yourtractor on atruckor atrailer,

ensure hood isclosed and secured totractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

13

Page 14

TOWING CARTS AND OTHER A'I-I'ACH-

MENTS

Tow only the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on a slope, is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

SERVICE MINDER/HOUR METER

Service minder shows the total number of

hours the engine has run and indicates when

the engine or mower needs servicing. After

every 50 hours of operation the oil can icon

will stay on for 2 hours or until a manual reset

occurs. To reset the display manually turn

the _gnition switch to the on pos=tion, then

the off position five times (1 second on, 1

second off). To service engine and mower.

see the Maintenance section of this manual.

NOTE: Service minder runs when the

ignition key is in any position but "STOP".

For accurate reading, be sure key remains

in the "STOP" position when engine is not

running.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine inyour tractor has been shipped

from the factory already filled with summer

weight oil.

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean, reinsertthe dipstick and screw cap

tight, wait fer a few seconds, remove and

read oil level. If necessary, add oil until

"FULL' mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the oi!

viscosity chart in the Maintenance section

of this manual).

• Tochange engineoil,seethe Maintenance

section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

gasoline with a minimum of 87 octane.

Do not mix oil with gasoline. Purchase

fuel in quantities that can be used within

0 days to ensure fuel freshness.

CAUTIO N: Wipe off any spilled oilor fuel.

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tempera-

tures below 32°F (0°C), use fresh, clean

winter grade gasoline to help ensure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

and formation of acids during storage. Acidic

gas can damage the fuel system of an engine

while in storage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel hnes and carburetor are empty, Use

fresh fuel next season. See Storage Instruc-

tions for additional information. Never use

engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

Fuel stabilizer is an acceptable alternative in

minimiz=ng the formation offuel gum deposits

during storage. Add stabilizer to gasoline in

fuel tank or storage container. Always follow

the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor. Do not empty the gas tank and

carburetor if using fuel stabilizer.

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel, it will take

extra cranking time to move fuel from the

tank to the engine.

1. Ensure freewheel control is in the trans-

mission engaged position.

2. Sit on seat in operating position, depress

brake pedal and set parking brake.

3. Move attachment clutch to disengaged

position.

4. Move throttle control to choke position.

NOTE: Before starting, read the warm and

cold starting procedures below.

14

Page 15

5. Insert key into ignition and turn key

clockwise to start position and release

key as soon as engine starts. Do not run

starter contin uously for more than fifteen

seconds per minute. If the engine does

not start after several attempts, move

throttle control to fast position, wait a

few minutes and try again. If engine still

does not start, move the throttle control

back to the choke position and retry.

WARM WEATHER STARTING

(50°F (10°C) and above)

6. When engine starts, move the throttle

control to the fast position.

• The attachments and ground drive

can now be used. If the engine does

not accept the load, restart the engine

and allow it to warm up for one minute

using the choke as described above.

COLD WEATHER STARTING

(50°F (10°C) and below)

6. When engine starts, leaveth rott[e control

in choke position until engine warms up

and begins to run roughly. Once rough

running begins, immediately move the

throttle control to the fast position. Engine

warm-up maytake from several seconds

to several minutes (the colder the tem-

perature, the longer the warm-up).

AUTOMATIC TRANSMISSION WARM UP

Before driving the unit in cold weather, the

transmission should be warmed up as fol-

lows:

1. Ensure the tractor is on level ground.

2. Release the parking brake and let the

brake slowly return to operating position.

3. Allow one minute for transmission to

warm up. This can be done during the

engine warm up period.

• The attachments can also be used

du ringthe engine warm-up period after

the transmission has been warmed up.

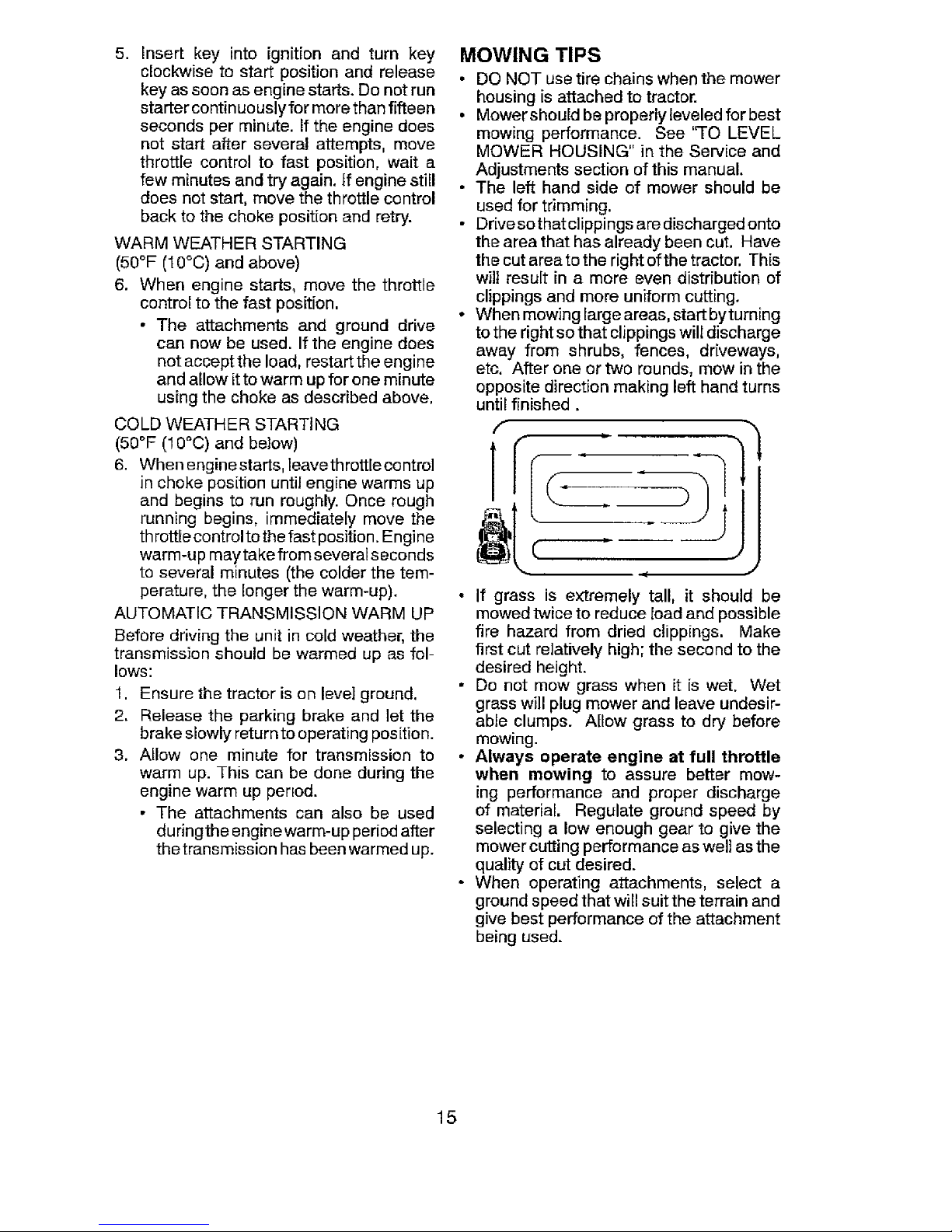

MOWING TIPS

• DO NOT use tire chains when the mower

housing is attached to tractor.

• Mower should be properly leveled for best

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

• The left hand side of mower should be

used for trimming.

• Driveso that clippings are discharged onto

the area that has already been cut. Have

the cut areato the right of the tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

• When mowing large areas, start byturning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

r L

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing.

• Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough gear to give the

mower cutting performance as well as the

quality of cut desired.

• When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

15

Page 16

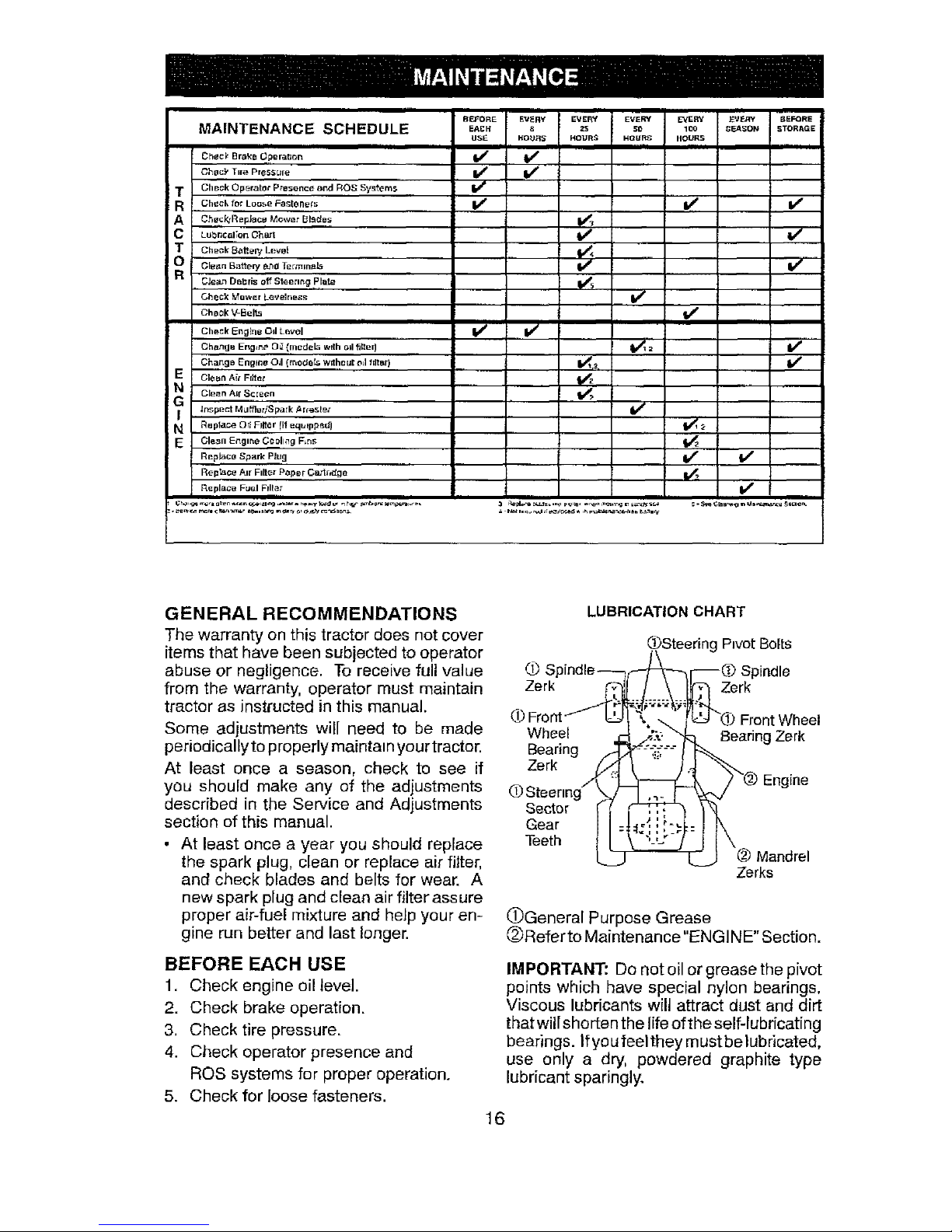

BFJ:ORE EVERy EVEn EVeR_ L_t=ERY EU_Ry BEFORE

MAINTENANCE SCHEDULE _=. _ =_ so ,_o _o. STORagE

USE HOURS HOURS HOUR_ HOURS

iii ii i

Check BrakB Opera,on V" V'

Choc_ T=re Press_[e V _ V r

T ChEck Operator Presence al_l ROS Systems V p

R ..,Cheo_to, L.... Fe_t ..... If I_, IV#'

A ChucktRepJac_ Mower B_des

C Lu_nc=l;onchat _

T Ch_ck Batte_ Level

O Cle_n Battery _p Termmal_ _ I_" "

R G_ Debris off Steering Flute

Gheck Mower Levelness V"

Check V- Be IL_

Check En_tlae Od Level ii _ V _

Chugs Eng_np O_ (modek w=th o=ltilted _ =

Ch_r_ge Eng{ne O_1(mode_ wdhout o_1flitst) II_t _. if

E cleanAi_F=_et

Cle_n Air Scleen

Inspect MLlffledSpa[k _rfeste; V _

_4eptece Or_ Fil_er I='feq.,ppe;_ fm¢_1

E Cle_n Engine Goolmg F_ns

Replace Spark Plug _ l

Rep_ce Air Filter Paper Catr=_ge

Replace Fuel Filter V'

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

items that have been subjected to operator

abuse or negligence. To receive full value

from the warranty, operator must maintain

tractor as instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your tractor.

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

• At least once a year you should repIace

the spark plug, clean or replace air filter,

and check blades and belts for wear. A

new spark plug and c[ean air filter assure

proper air-fuel mixture and heJp your en-

gine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3. Check tire pressure.

4. Check operator presence and

ROS systems for proper operation.

5. Check for loose fasteners.

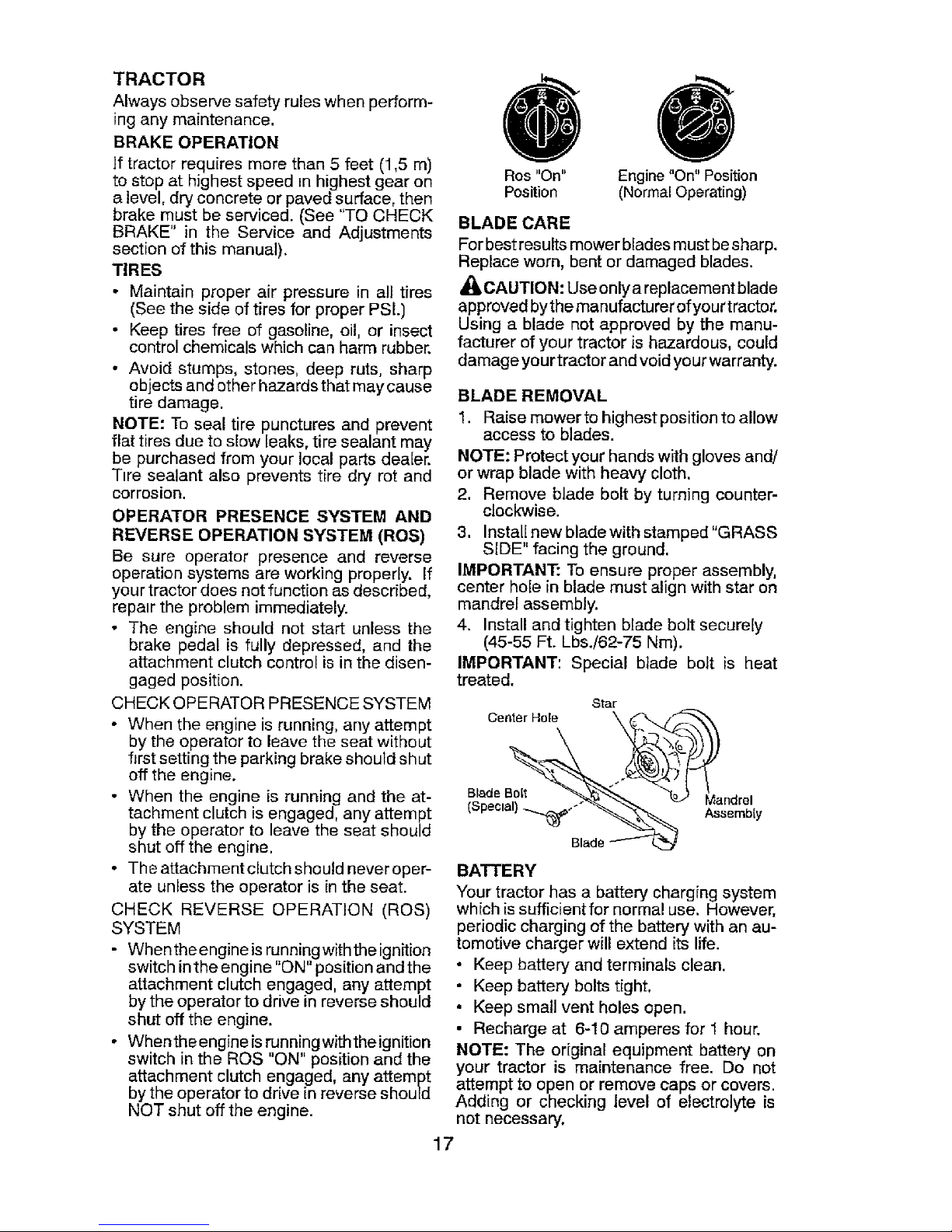

LUBRICATION CHART

_)Steering Pivot Bolts

Spindle----m_-i_ r-_ @ Spindle

Zerk ___#. =_'_L Zerk

Front _ WI*'_"" Z _''I;_j_" 1(1(_Front Wheel

Wheel ._ .7_:'"_ Bearing Zerk

Bearing ,.-_-'_" I

Zerk - /./['l - _._

._ '::_ _ _, 2"_ Engine

Gear I I :t_:!ir-__k: l IX

Teeth I I \ '-'_" / II \

k.J" " 1._ _- Mandrel

Zerks

(_)General Purpose Grease

@)RefertoMaintenance "ENGINE" Section.

IMPORTANT: Do not oil or grease the pivot

points which have special nylon bearings,

Viscous lubricants will attract dust and dirt

that will shorten the life ofthe self-lubricating

bearings. If you feelthey must belubricated,

use only a dry, powdered graphite type

lubricant sparingly.

16

Page 17

TRACTOR

Always observe safety rules when perform-

ing any maintenance.

BRAKE OPERATION

If tractor requires more than 5 feet (1,5 m)

to stop at highest speed In highest gear on

a level, dry concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

• Maintain proper air pressure in all tires

(See the side of tires for proper PSl.)

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dearer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation systems are working properly. If

your tractor does not function as described,

repair the problem immediately.

• The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE SYSTEM

• When the engine is running, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engine.

• The attachmentclutch should neveroper-

ate unless the operator is in the seat.

CHECK REVERSE OPERATION (ROS)

SYSTEM

• When the engineis running with the ignition

switch inthe engine "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

shut off the engine.

• When the engine is running with the ignition

switch in the ROS "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

NOT shut off the engine.

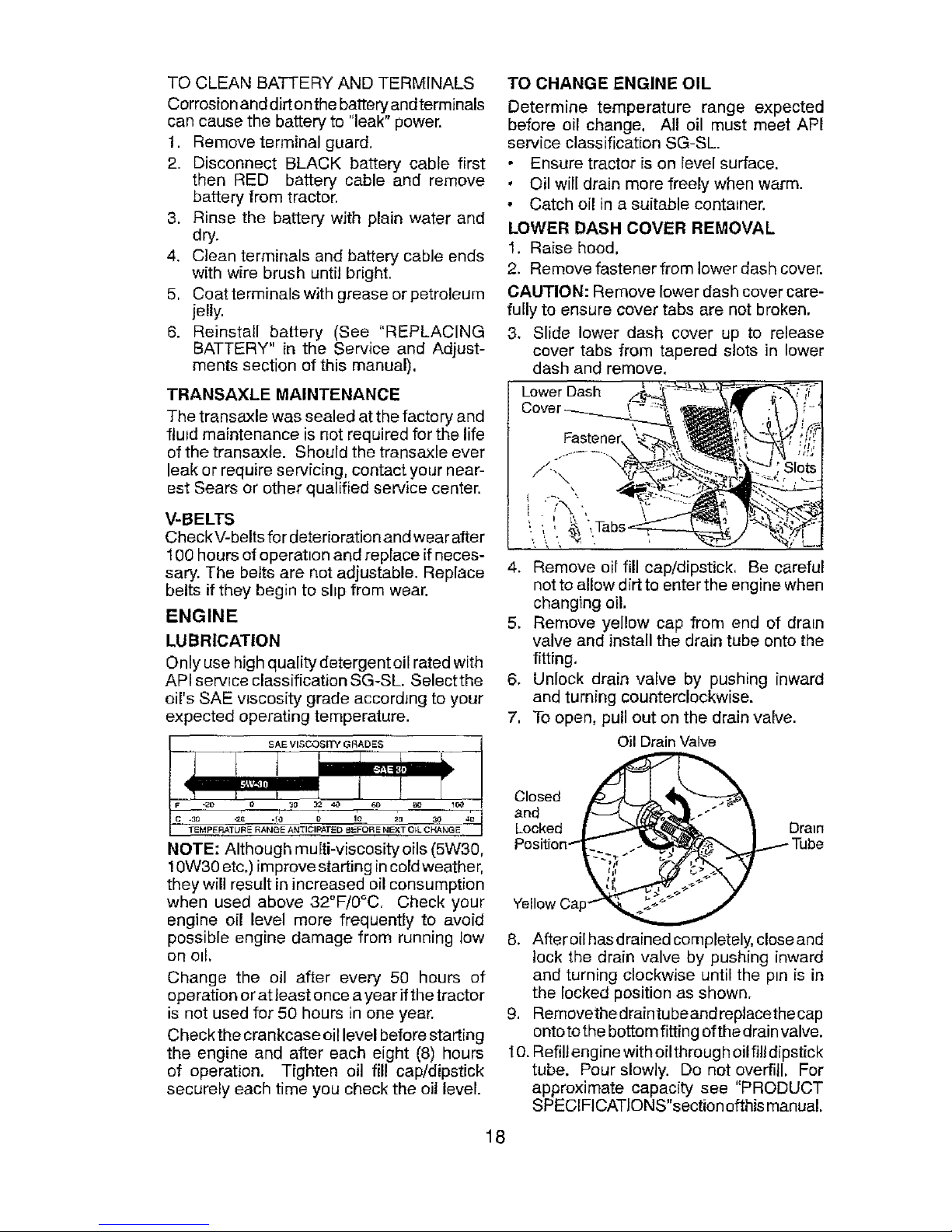

Ros "On" Engine "On" Position

Position (Normal Operating)

BLADE CARE

Forbestresults mower blades must besharp.

Replace worn, bent or damaged blades.

_I_CAUTION: Use only a replacement blade

approved bythe manufacturer ofyourtractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage yourtractor and void yourwarranty.

BLADE REMOVAL

1. Raise mower tohighestposition to allow

access to blades.

NOTE: Protectyourhands withglovesand!

or wrap blade with heavy cloth,

2, Remove blade bolt by turningcounter-

cJockwise.

3. Install new bladewith stamped"GRASS

SIDE" facing the ground.

IMPORTANT: Toensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. Install and tighten blade bolt secure[y

(45-55 Ft. Lbs./62-75 Nm).

IMPORTANT: Special blade bolt is heat

treated.

Star

Center Hole

Blade Bolt Mandrel

(Special) _. Assembfy

Blade

BATTERY

Your tractor has a battery charging system

which is sufficient for normal use. However,

periodic charging of the battery with an au-

tomotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight,

• Keep small vent holes open.

• Recharge at 6-10 amperes for I hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

17

Page 18

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals

can cause the battery to "leak" power.

1. Remove terminal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

3. Rinse the battery with plain water and

dry.

4. Clean terminals and battery cable ends

with wire brush until bright.

5, Coatterminals with grease orpetroleum

jelly,

6. Reinstall battery (See "REPLACING

BATTERY" in the Service and Adjust-

ments section of this manual).

TRANSAXLE MAINTENANCE

The transaxle was sealed at the factory and

fluid maintenance is not required for the life

of the transaxte. Should the transaxle ever

leak or require servicing, contact your near-

est Sears or other qualified service center.

V-BELTS

CheckV-belts for deterioration and wear after

100 hours of operation and replace if neces-

sary. The belts are not adjustable. Replace

belts if they begin to shp from wear.

ENGINE

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

Ensure tractor is on revel surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

LOWER DASH COVER REMOVAL

1. Raise hood,

2. Remove fastener from lower dash cover.

CAUTION: Remove lower dash cover care-

fully to ensure cover tabs are not broken.

3. Slide lower dash cover up to release

cover tabs from tapered slots in lower

5,

LUBRICATION

Only use high quality detergent oil rated with

API service classification SG-SL. Selectthe 6.

oil's SAE wscosity grade accordJng to your

expected operating temperature. 7,

1

_rE M PE RAT_'E RANGE AN'I'IC_A'FE D 8 _"FOR E N_ 13_L C}_NG E

1

NOTE: Although multi-viscosityoils (5W30,

! 0W30 etc.) improve starting incord weather,

they will result in increased oil consumption

when used above 32°F/0°C. Check your

engine oil level more frequently to avoid

possible engine damage from running low

or] o11,

Change the oil after every 50 hours of

operation or at least once a year if the tractor

is not used for 50 hours in one year.

Check the crankcase oil level before starting

the engine and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick

securely each time you check the oil level.

Remove oil fill cap/dipstick, Be careful

not to allow dirt to enter the engine when

changing oil.

Remove yellow cap from end of drain

valve and install the drain tube onto the

fitting.

Unlock drain valve by pushing inward

and turning counterclockwise.

To open, pull out on the drain valve.

Oil Drain Valve

O'n° e0

Locked __ _Tube

Position_

!

Yellow Cap_

8. Afleroilhasdrainedcompletely, closeand

lock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked position as shown.

9, Removethe draintu be and replace the cap

onto to the bottom fitting of the drain valve.

t O.Refill engine with oil through oil fill dipstick

tube. Pour slowly. Do not overfill. For

approximate capacity see "PRODUCT

SPECIFICATIONS"section ofthis manual.

18

Page 19

11,Usegaugeonoilfillcap/dipstickforcheck-

inglevel,Ensuredipstickcapistightened

securelyforaccuratereading.Keepoilat

"FULE'lineondipstick.Tightencaponto

thetubesecurelywhenfinished.

ENGINEOILFILTER

Replacetheengineoilfiltereveryseasonor

everyotheroilchangeifthetractorisused

morethan100hoursinoneyear.

NOTE:Ifneeded,removelowerdashcovers

usingstepsfrom"Lowerdashcoverremoval"

sectionofthismanual.

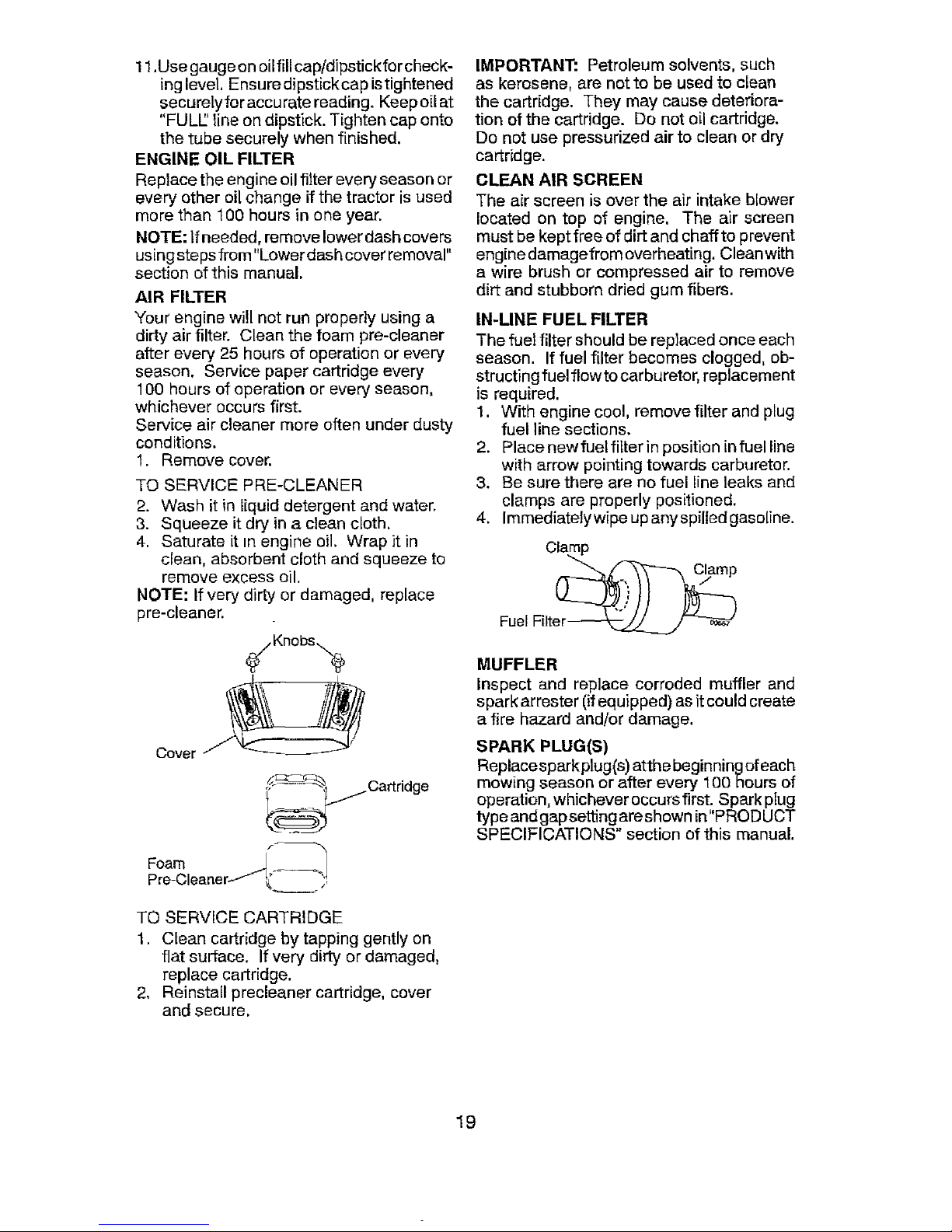

AIR FILTER

Your engine will not run properly using a

dirty air filter. Clean the foam pre-cleaner

after every 25 hours of operation or every

season. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

1. Remove cover.

TO SERVICE PRE-CLEANER

2. Wash it in liquid detergent and water.

3. Squeeze it dry in a clean cloth,

4, Saturate it in engine oi1. Wrap it in

clean, absorbent cloth and squeeze to

remove excess oil,

NOTE: If very dirty or damaged, replace

pro-cleaner.

1 Cartridge

f _

Pre-Cleanert f !_- _'r

TO SERVICE CARTRIDGE

1. Clean cartridge by tapping gently on

flat surface. If very dirty or damaged,

replace cartridge.

2, Reinstall precleaner cartridge, cover

and secure.

IMPORTANT: Petroleum solvents, such

as kerosene, are notto be used to clean

the cartridge. They may cause deteriora-

tion of the cartridge. Do not oil cartridge.

Do not use pressurized air to clean or dry

cartridge.

CLEAN AIR SCREEN

The air screen is over the air intake blower

located on top of engine, The air screen

must bekept free of dirt and chaff to prevent

enqine damagefrom overheating. Cleanwith

a wire brush or compressed air to remove

dirt and stubborn dried gum fibers.

IN-LINE FUEL FILTER

The fuel filter should be replaced once each

season. If fuel filter becomes clogged, ob-

structing fuel flow to carburetor, replacement

is required.

1. With engine cool, remove filter and plug

fuel line sections.

2. Place newfuetfilter in position infuel line

with arrow pointing towards carburetor.

3. Be sure there are no fuel line leaks and

clamps are properly positioned.

4. Immediatelywipe up anyspilledgaso[ine.

Clamp

""-..,_x----_ Clamp

Fuel Filte_

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as it could create

a fire hazard and/or damage.

SPARK PLUG(S)

Replacesparkplug(s) atthe beginningofeach

mowing season or after every 100 hours of

operation, whichever occurs first. Spark plug

type and gap setting are shown in"PROD UCT

SPECIFICATIONS" section of this manual,

19

Page 20

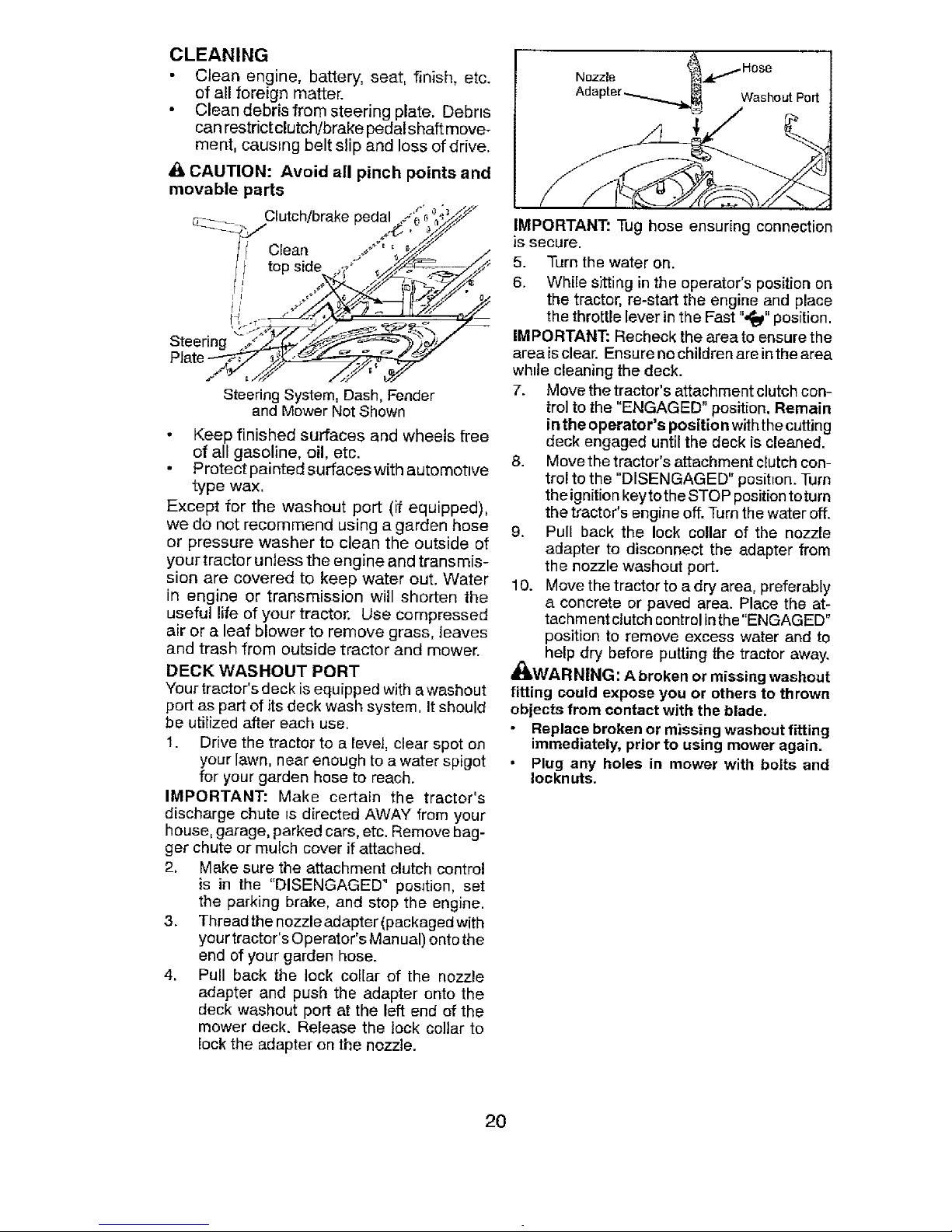

CLEANING

Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Clean debris from steering plate. Debris

can restrict clutch!brake pedal shaft move-

ment, causing belt slip and loss of drive.

CAUTION: Avoid all pinch points and

movable parts

"7--_ Clutch/brake ./" '_.'_×_.r

, pedal .,_.e__'_._Y

It Clean ./' '_4_ t

Steeri.n-

Plate__

Steering System, Dash, Fender

and Mower Not Shown

Keep finished surfaces and wheels free

of all gasoline, oil, etc.

Protect painted surfaces with automotive

type wax.

Except for the washout port (if equipped),

we do not recommend using a garden hose

or pressure washer to clean the outside of

your tractor unless the engine and transmis-

sion are covered to keep water out. Water

in engine or transmission will shorten the

useful life of your tractor. Use compressed

air or a leaf blower to remove grass, leaves

and trash from outside tractor and mower.

DECK WASHOUT PORT

Your tractor's deck is equipped with a washout

port as part of its deck wash system. It should

be utilized after each use.

1. Drive the tractor to a level, clear spot on

your lawn, near enough to a water spigot

for your garden hose to reach.

IMPORTANT: Make certain the tractor's

discharge chute is directed AWAY from your

house, garage, parked cars, etc. Remove bag-

ger chute or mulch cover if attached.

2. Make sure the attachment clutch control

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Thread the nozzle adapter (packaged with

your tractor's Operator's Man ual) onto the

end of your garden hose.

4. Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the left end of the

mower deck. Release the lock collar to

lock the adapter on the nozzle.

IMPORTANT: Tug hose ensuring connection

]s secure.

5. Turn the water on.

6. While sitting in the operator's position on

the tractor, re-start the engine and place

the throttle lever in the Fast ",_" position.

IMPORTANT: Recheck the area to ensure the

area isclear. Ensure no children are in the area

while cleaning the deck.

7. Move the tractor's attachment clutch con-

trol to the "ENGAGED" position. Remain

in the operator's positio n with the cutting

deck engaged until the deck is cleaned.

8. Move the tractor's attachment clutch con-

trol to the "DISENGAGED" position. Turn

the ignition keyto the STOP position toturn

the tractor's engine off. Turn the water off.

9. Pull back the lock collar of the nozzle

adapter to disconnect the adapter from

the nozzle washout port.

10. Move the tractor to a dry area, preferably

a concrete or paved area. Place the at-

tachment clutch control in the "ENGAGED"

position to remove excess water and to

help dry before putting the tractor away.

_WARNING: A broken or missing washout

fitting could expose you or others to thrown

objects from contact with the blade.

Replace broken or missing washout fitting

immediately, prior to using mower again.

Plug any holes in mower with bolts and

Iocknuts.

2O

Page 21

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

t. Depress brake pedal fully and set parking brake.

2. Place attachment clutch in"DISENGAGED" position.

3. Turn ignition key to "STOP" and remove key.

4. Make sure the blades and all moving parts have completely stopped.

5. Disconnect spark plugwire from spark plug and place wire where it cannot

come in contact with plug.

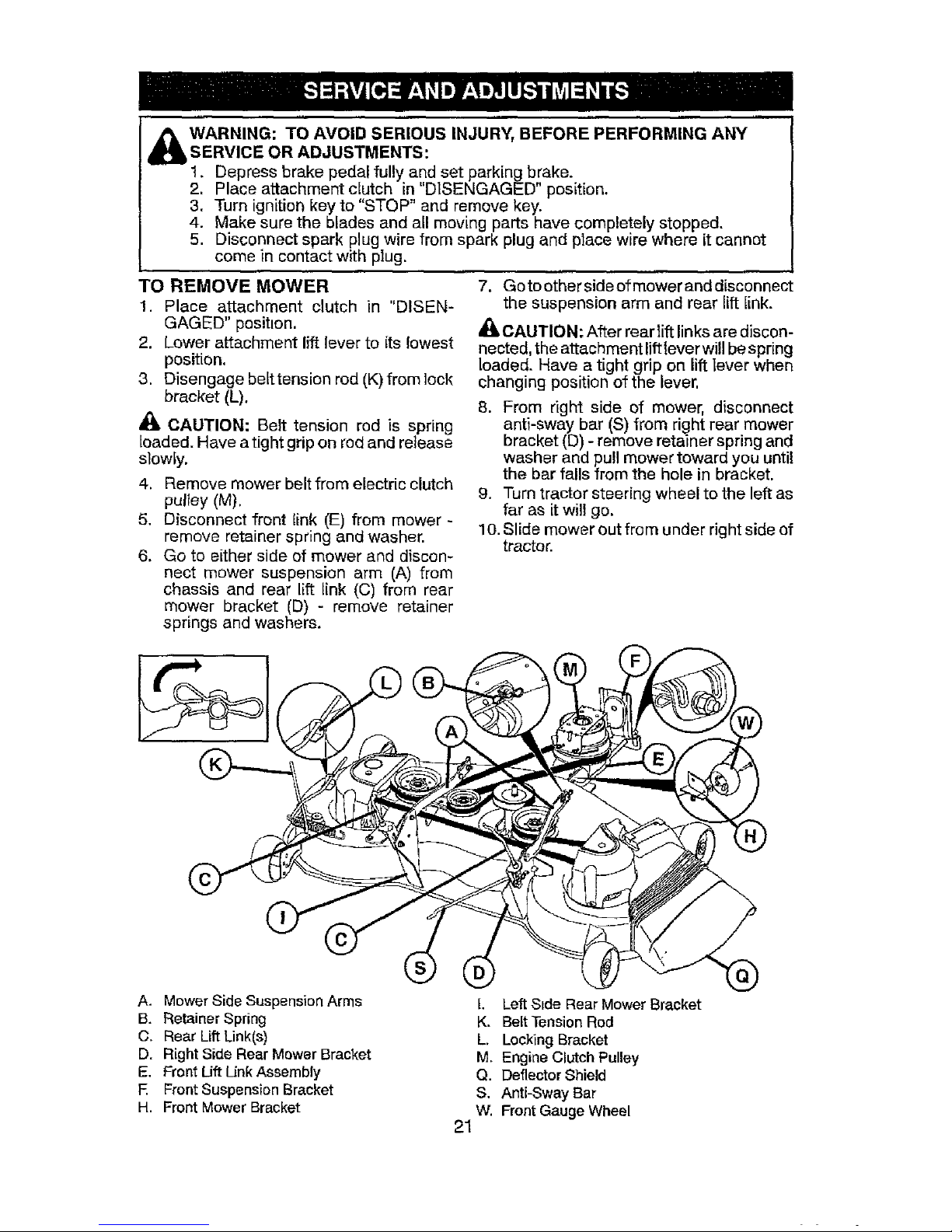

TO REMOVE MOWER

1. Place attachment clutch in "DISEN-

GAGED" position.

2. Lower attachment lift lever to its lowest

position.

3. Disengage betttension rod (K) from lock

bracket (L).

CAUTION: Belt tension rod is spring

loaded. Have a tight grip on rod and release

slowly.

4. Remove mower belt from electric clutch

pulley (M),

5, Disconnect front link (E) from mower -

remove retainer spring and washer.

6. Go to either side of mower and discon-

nect mower suspension arm (A) from

chassis and rear lift link (C) from rear

mower bracket (D) - remove retainer

springs and washers.

7. Go to other side of mower and disconnect

the suspension arm and rear lift link.

_, CAUTION: After rear lift links are discon-

nected, the attachment lift lever will be spring

loaded. Have a tight grip on lift lever when

changing position of the lever.

8. From right side of mower, disconnect

anti-sway bar (S) from right rear mower

bracket (D) - remove retainer spring and

washer and pull mower toward you until

the bar falls from the hole in bracket.

9. Turn tractor steering wheel to the left as

far as it will go.

10. Slide mower out from under right side of

tractor.

A. Mower Side Suspension Arms

B. Retainer Spring

C. Rear Lift Link[s)

D. Right Side Rear Mower Bracket

E. Front Lift Unk Assembly

E Front Suspension Bracket

H. Front Mower Bracket

Left S_de Rear Mower Bracket

K. Belt Tension Rod

L. Locking Bracket

M. Engine Clutch Pulley

Q. Deflector Shield

S. Anti-Sway Bar

W. Front Gauge Wheel

21

Page 22

TO INSTALL MOWER

1. SET PARKING BRAKE LEVER AND

LOWER ATTACHMENT LIFT LEVER

• Depress clutch/brake pedal all the way

down and hold.

Pull parking brake lever up and hold,

release pressure from clutch/brake

pedal, then release parking brake lever.

Pedal should remain in brake posttion.

Ensure parking brake will hold tractor

secure.

Brake

A_,CAUTION: Ltft lever is spring loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position. Lift lever is

located on left side of fender.

Li_

Lever

2. ASSEMBLE FRONT GAUGE WHEEL

(W) TO FRONT OF MOWER

H. Front Mower Bracket

W Front Gauge Wheel

X Shoulder Bolt

Y. 1-1/40.D. Washer

Z. 3/8-16 Locknut

3, TURN STEERING WHEEL LEFT AND

POSITION MOWER

• Turn steering wheel to the left as far as it

will go and position mower on right side of

tractorwith deflector shield (Q) tothe right.

Front

_Engine ?

_ Transaxle

Q. Deflector Shield

4. SLIDE MOWER UNDER TRACTOR

Bring belt forward and check belt for pro-

per routing in alf mower pulley grooves.

NOTE: Be sure mower side suspension

arms (A) are pointing forward before sliding

mower under tractor.

Slide mower under tractor until it is

centered under tractor.

A. Mower Stde Sus _ension Arms

Q. Deflector Shield

i

22

Page 23

5. INSTALL ANTI-SWAY BAR (S) +

(IF EQUIPPED)

_AY BAR (S) 1

Towards Towards "_b,_l

nsaxle Mower Deck _'-I

%

90° End Integrated Washer End

From right side of mower, first insert

90° end of anti-sway bar (S) into hole in

transaxle bracket ('t"), located near left _ D__wer Bracket

rear tire in front of transaxle. [' S. Anti-Sway Bar I

T. Transaxie

NOTE: Flashlight may be helpful. I . Bracket , I

6. ATTACH MOWER SIDE SUSPENSION

Anti-Sway : '_ - "- .... ARMS (A) TO CHASSIS

" +_<'; ; "- • Positionfrontholeinsidesuspensionarm

Bar(S) _" - _ _ i - \ (A)overpinonoutsideoftractorchassis

...... '\_L_ 'i__"_-_"_,.. _ _', and secure with large washer and large

' -<-" _ retainer spring (B).

• Repeat on opposite side of tractor.

Transaxle Bracket _ _rtl

Located Between Rear Tires

J

A.

B.

D.

Mower Side Suspension Arms

Retainer Spdng

Right Side Rear Mower Bracket

NOTE: Depending on model, bracket (T) may

be different than shown but hole for anti-sway

bar will be in same position/location.

Ptvot the integrated washer end of anti-

sway bar (S) towards mower deck bracket

on right side of mower. Insert integrated

washer end of bar into hole in rear mower

bracket (D). Move mower as needed to

insert integrated washer end of bar into

rear mower bracket (D).

Secure with small washer and small

retainer spring as shown.

7. ATTACH REAR LIFT LINKS (C)

• Insert rod end of rear lift link (C) into hole

(U) in tractor lift shaft suspension arm

and pivot link down to mower.

• Lift rear corner ofmower and position slot

in link assembly over pin on rear mower

bracket (D) and secure with large washer

and large retainer spring.

• Repeat on opposite side of tractor.

23

Page 24

D. Mower Bracket

'U. Hole

8 ATTACH FRONT LINK (E)

• Turn steering wheel to position wheels

straight forward.

From front of tractor, insert red end of

front link (E) through front hole in tractor

front suspension bracket (F).

• Move to leftside of mower and and insert

large retainer spring (G) through hole in

front link (E) behtnd front suspension

bracket (F).

• Insert other end of link (E) into hole in

front mower bracket (H) and secure with

washer and small retainer spring (J).

NOTE: Requires deck itfting.

Front Link ; _ ": ' " -

Location ,," .__,___." ,_7_::....

9 INSTALL BELT ON ENGINE CLUTCH

PULLEY (M)

• Disengage belt tension rod (K) from

locking bracket (L).

Install belt onto engine clutch pulley (M).

M.Engine

Clutch Pulley

IMPORTANT: Check belt for proper routing

in all mower pulley grooves and under

mandrel covers.

• Engage bert tension rod (K) on locking

bracket (L).

_kGAUTION: Belt tension rod is spring

loaded. Have atight grip on rod and engage

slowly.

• Raise attachment lift lever to highest

position.

If necessary, adjust gauge wheels

before operating mower as shown inthe

Operation section of this manual.

MOWER DRIVE BELT INSTALLATION

Follow procedure described in "TO

REPLACE MOWER BLADE DRIVE BELT"

in this section of this manual.

\

E. Front Lift Link Assembly

E Front Suspension Bracket

G. Large Retainer Spring

H. Front Mower Bracket

J. Small Retainer Spring

M. Engine Clutch Pulley

/

24

Page 25

TO LEVEL MOWER

Ensure tires are properly inflated to the PSi

shown on tires. If tires are over or under

inflated, it may affect the appearance of your

lawn and lead you to think the mower is not

adjusted properly.

VISUAL SI DE-TOrSI DE ADJUSTMENT

1. With all tires properly inflated and if your

lawn appears unevenly cut, determine

which side of mower is cutting lower.

NOTE: As desired, you can raise the low

side of mower or lower the high side.

2. Go to side of mower you wish to adjust.

3. With a 3/4" or adjustable wrench, turn

lift link adjustment nut (A) to the [eft to

lower the mower, or, to the right to raise

the mower.

Turn nut Turn nut

right to [eft to

raise lower

mower mower

NOTE: Each full turn of adjustment nut will

change mower height about 3/16" (4,7 m m).

4. Test your adjustment by mowing some

uncut grass and visually checking the

appearance. Readjust, if necessary, until

you are satisfied with the results.

PRECISION SIDE-TO-SIDE ADJUSTMENT

1. With alltires properlyinflated, parktractor

on level ground or driveway.

AI_.CAUTION: Blades are sharp. Protect

your hands with gloves and!or wrap blade

with heavy cloth.

2. Raise mower to its highest position.

3. At both sides of mower, position blade

at side and measure distance "A" from

bottom edge of blade to ground. The dis-

tance should be the same on both sides.

4. If adjustment is necessary, see steps in

Visual Adjustment instructions above.

•

lA

25

5. Recheck measurements; adjust if neces-

sary until both sides are equal.

FRO NT-TO-BACK ADJU STMENT

IMPORTANT: Deck must be {eveI side-

to-side,

To obtain the best cutting results, the mower

blades should be adjusted so the front tip

[s 1/8to 1/2" (3,1 to 12,7 mm) (lower than

the rear tip when the mower is in its highest

position.

_CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing

straight forward. Measure distance "B" to

the ground at front and rear tip of blade.

• if front tip of blade is not 1/8 to 1/2" (3,1

to 12,7 mm) lower than the rear tip, go to

the front of tractor.

• With an 11/16" or adjustable wrench,

loosen jam nut "A" several turns to clear

adjustment nut "B".

• With a 3/4" or adjustable wrench, turn

front link adjustment nut"B" clockwise (_)

(tighten) to raise the front of mower, or,

counterclockwise (,_'_) (loosen) to lower

the front mower.

Tighten adjust Loosen adjust

nut "B" to nut "B" to

raise mower lower mower

Loosen jam nut "A" first

NOTE: Each full turnof adjustment nut will

change mower height about 1/8" (3,1 ram).

• Recheck measurements, adjust if neces-

sary until front tip of blade is 1/8 to 1f2"

(3,t to 12,7 mm) lower than the rear tip.

Hold adjustment nut in position with

wrench and tighten jam nut securely

against adjustment nut.

Page 26

TO REPLACE MOWER BLADE DRIVE

BELT

MOWER DRIVE BELT REMOVAL

1, Park tractor on a level surface, Engage

parking brake,

2. Lower attachment lift lever to its lowest

position,

3. Disengage belttension rod (K) from lock

bracket (L),

CAUTION: Belt tension rod is spring

loaded. Have a firm grip on rod and release

slowly.

4. Remove screws (P) from R.H. and L.H,

mandrel covers and remove covers (Q).

5. Remove anydirtorgrass clippingswhich

may have accumulated around mandrels

and entire upper deck surface.

6. Remove belt from electric clutch pulley

(M), both mandrel pulleys (R) and all tdler

pulleys (V).

MOWER DRIVE BELT INSTALLATION

I. Install be_t around both mandrel pulleys

(R) and around idler pulleys (V) as shown.

2, Install beltonto electric clutch pulley (M).

IMPORTANT: Check belt for proper routing

in all mower pulley grooves.

3, Reassemble R.H. and L,H, mandrel cov-

ers (Q), Securely ttghten all screws.

4, Engage be}t tension rod (K) on locking

bracket (L).

,i_ CAUTION: Belt tension rod is spring

loaded, Have a tight grip on rod and engage

slowly.

5. Raise attachment lift lever to highest

position.

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parking brake. For assistance, there is a

belt installation guide decal on bottom side

of left footrest.

BELT REMOVAL -

1. Remove mower (See "TO REMOVE

MOWER" in this section of manual).

NOTE: Observe entire motion drive belt

and position ot all belt guides and keepers.

2. Removebeltfromstattonaryidler(A) and

clutching idler (B).

3. Remove belt from centerspan idler (C).

6. Pull belt slack toward rear of tractor.

Carefully remove belt upwards from

transmission input pulley and over cool-

ing fan blades (13).

4. Remove belt downward from engtne

pulley (El.

5. Slide belt toward rear of tractor, off the

steering plate (F) and remove from tractor,

BELT INSTALLATION -

1. Instatl new belttrom tractor rear to front,

over the steering plate (F) and above

clutch brake pedal shaft (G).

2. Pull belt toward front of tractor and roll

belt onto engine pulley (El,

3. Pull belt toward rear of tractor. Carefully

work belt down around transmission

cooling fan and onto the input pulley (O).

Be sure belt is inside the belt keeper.

4. Install belt on centerspan idler (C).

5. Install belt through stationary idler (A)

and clutching idler (B),

6, Make sure belt is in all pulley grooves

and inside all belt guides and keepers.

7. Install mower {See "TO INSTALL MOW-

ER" in this section of manual).

26

Page 27

TO CHECK BRAKE

Iftractor requires more than five (5) feet (1,5

m) to stop at highest speed in highest gear

on a level, dry concrete or paved surface,

then brake must be serviced.

You may also check brake by:

t. Park tractor on a level, dry concrete or

paved surface, depress brake pedal all

the waydown and engage parking brake.