Page 1

Operator's Manual

ICRAFTSMnN°I

LAW TRACTOR

22 HR* 48" Mower

Electric Start

Automatic Transmission

Model No.

917.20391

. EspaSol, p. 35

_] his product has a low emission engine which operates

differently from previously built engines. Before you start the

engine, read and understand this manual.

iMPORTANT:

Read and follow all Safety

Rules and instructions before

operating this equipment.

For answers to your questions

about this product, call:

1-888-331-4569

Craftsman Customer Help Line

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

* The power rating as declared by the engine manufacturer is the

average gross power output at the specified RPM of a typical

production engine for the engine model measured using SAE

Standards for engine gross power. Please refer to the engine

manufacturer for details.

* La potencia nominal declarada per el fabricante del motor es la

salida media de potencia bruta a las RPM especificadas de un

motor de serie tipico para el modelo de motor, medida segt_n

las normas SAE sobre potencia bruta de moton Para m_ts

informaci6n, consulte al fabricante del motor.

586123696 Rev. 2

Page 2

Warranty ................................................ 2

Safety Rules .......................................... 3

Product Specifications ........................... 6

Assembty/Pre-Operation ....................... 7

Operation ............................................... 9

Maintenance Schedule ........................ 16

Maintenance ........................................ 16

Service and Adjustments ..................... 21

Storage ................................................ 29

Troubleshooting ................................... 30

Espahol ................................................ 35

Sears Service ........................ Back Cover

CRAFTSMAN FULL WARRANTY

FOR TWO YEARS from the date of purchase, all non-expendable parts of this riding equipment are

warranted against any defects in material or workmanship. A defective non-expendable part will receive

free in-home repair or replacement if repair is unavailable.

BATTERY LIMITED WARRANTY

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of this riding equipment is

warranted against any defects in material or workmanship. A new battery will be supplied free of charge.

You are responsible for the labor cost of battery installation.

ADDITIONAL LIMITED WARRANTmES

In the following additional warranties, you are responsible for the labor cost of part installation after

the second year from the date of purchase.

FOR FIVE YEARS from the date of purchase, the frame of this riding equipment is warranted against any

defects in material or workmanship. A new frame will be supplied free of charge.

FOR TEN YEARS from the date of purchase, the front axle of this riding equipment is warranted against any

defects in material or workmanship. A new front axle will be supplied free of charge.

FOR AS LONG AS IT IS USED by the original owner after the tenth year from the date of purchase, the

cast iron front axle (if equipped) of this riding equipment is warranted against any defects in material or

workmanship. With proof of purchase, a new cast iron front axle will be supplied free of charge.

WARRANTY SERVICE

For warranty coverage details to obtain free repair or replacement, call 1-888-331-4569 or visit the web

page: www.craftsman.com/warranty

In all cases above, if part repair or replacement is impossible, the riding equipment will be replaced free of

charge with the same or an equivalent model.

All of the above warranty coverage is void if this riding equipment is ever used while providing commercial

services or if rented to another person.

This warranty covers ONLY defects in material and workmanship. Warranty coverage does NOT

include:

• Expendable parts (except battery) that can wear out from normal use within the warranty period, including

but not limited to blades, spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or

glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or

maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by towing

objects beyond the capability of the riding equipment, impacting objects that bend the frame, axle

assembly or crankshaft, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical

damage caused by improper storage, failure to use the proper grade and amount of engine oil, failure

to keep the deck clear of flammable debris, or failure to maintain the riding equipment according to the

instructions contained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized

(stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

Page 3

_I_,DANGER: This cutting machine is capable of amputating hands and feet and

throwing objects. Failure to observe the following safety instructions could result

in serious injury or death.

_WARNING: In order to prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_,WARNING: Do not coast down a hill in

neutral, you may lose control of the tractor.

_,WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Too heavy of a load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

_WARNING: Engine exhaust, some of

its constituents, and certain vehicle compo-

nents contain or emit chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

_,WAR NING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling,

I. GENERAL OPERATION

• Read, understand, and follow all instruc-

tions on the machine and in the manual

before starting.

• Do not put hands or feet near rotating

parts or under the machine. Keep clear

of the discharge opening at all times.

• Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

• Be sure the area is clear of bystanders

before operating. Stop machine ifanyone

enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely

necessary. Always took down and behind

before and while backing.

Never direct discharged material toward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

surfaces.

Do not operate machine without the en-

tire grass catcher, discharge chute, or

other safety devices in place and working.

• Slow down before turning.

Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

Disengage blades when not mowing.

Shut off engine and wait for all parts to

come to a complete stop before cleaning

the machine, removingthe grass catcher,

or unclogging the discharge chute.

• Operate machine ontyin daytightorgood

artificial light.

Do not operate the machine while under

the influence of alcohol or drugs.

• Watch for traffic when operating near or

crossing roadways.

• Use extra care when loading or unloading

the machine into a trailer or truck.

Always wear eye protection when operat-

ing machine.

Use ear protectors to avoid damage to

hearing.

Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

Followthe manufacturer's recommenda-

tion for wheel weights or counterweights.

Keep machine free of grass, leaves or

other debris build-up which can touch hot

exhaust / engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc-

cur. Clean any oil or fuel spillage before

operating or storing the machine. Allow

machine to cool before storage.

Page 4

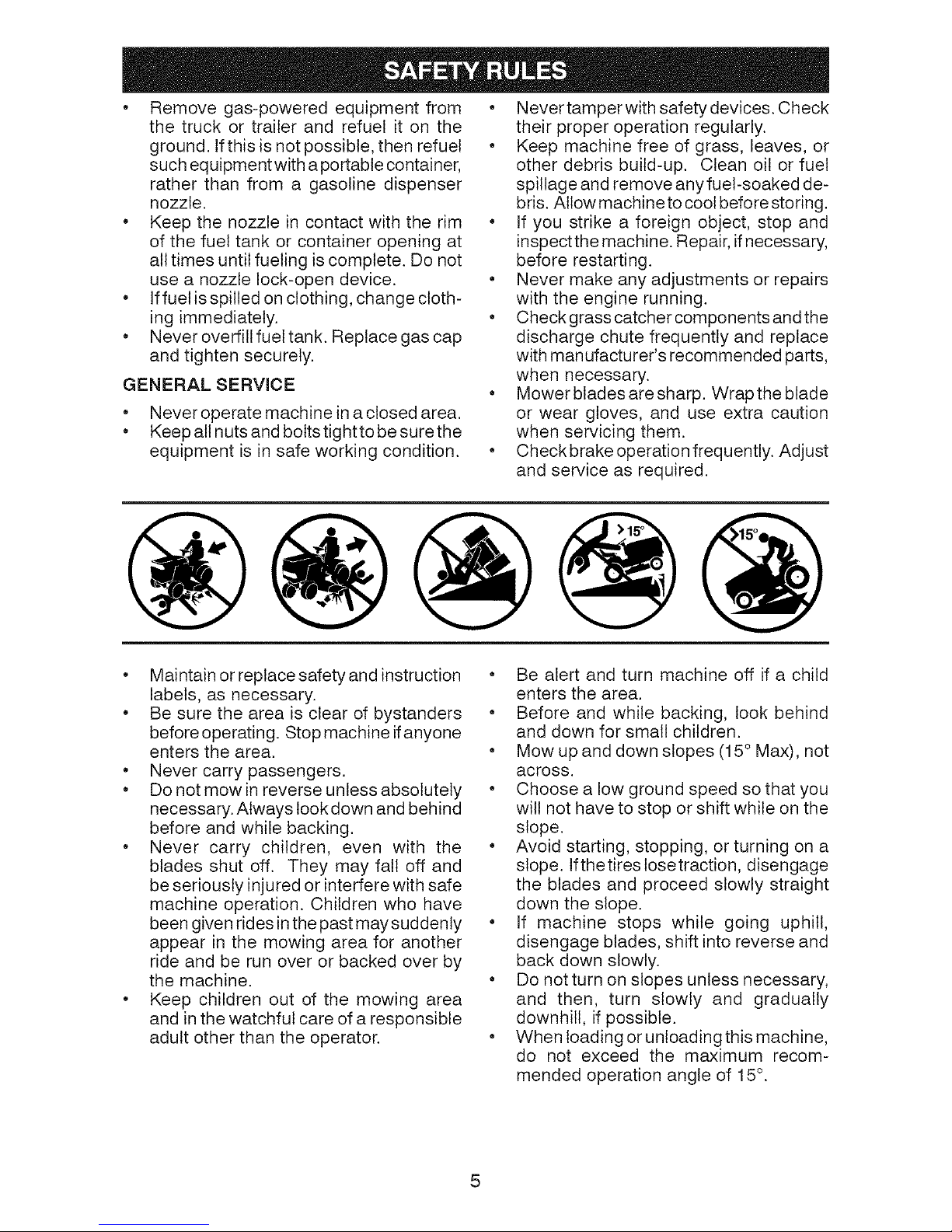

II.SLOPEOPERATION

Slopesareamajorfactorrelatedtolossof

controlandtip-overaccidents,whichcan

resultinsevereinjuryordeath.Operation

onallslopesrequiresextra caution. If you

cannot back upthe slope or ifyou feet uneasy

on it, do not mow it.

* Mow up and down slopes, not across.

* Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

* Choose a low ground speed so that you

will not have to stop or shift while on the

slope.

* Do not mow on wet grass. Tires may lose

traction.

Always keep the machine in gear when

going down slopes. Do not shiftto neutral

and coast downhill.

* Avoid starting, stopping, or turning on a

slope. Ifthetirestosetraction, disengage

the blades and proceed slowly straight

down the slope.

* Keep all movement on the slopes stow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

* Use extra care while operating machine

with grass catchers or other attachments;

they can affect the stability of the ma-

chine. Do no use on steep slopes.

* Do not try to stabilize the machine by

putting your foot on the ground.

* Do not mow near drop-offs, ditches,

or embankments. The machine could

suddenly roll over if a wheel is over the

edge or if the edge caves in.

Ill. CHILDREN

_/IWARNING: CHILDREN CANBE INJURED

BYTHIS EQUIPMENTThe American Acade-

my of Pediatrics recommends that children

be a minimum of 12 year of age before op-

erating a pedestrian controlled lawn mower

and a minimum of 16 years of age before

operating a riding lawn mower.

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

* Keep children out of the mowing area

and in the watchful care of a responsible

adult other than the operator.

* Be alert and turn machine off if a child

enters the area.

* Before and while backing, look behind

and down for small children.

* Never carry children, even with the btades

shutoff. They may fall offand be seriously

injured or interfere with safe machine

operation. Children who have been given

rides in the past may suddenly appear in

the mowing area for another ride and be

run over or backed over bythe machine.

* Never allow children to operate the ma-

chine.

* Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child.

IV. TOWING

* Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

* Fotlowthemanufacturer'srecommenda-

tion for weight timits for towed equipment

and towing on slopes.

. Never allow children or others in or on

towed equipment.

* On stopes, theweightofthetowed equip-

ment may cause loss of traction and toss

of control.

* Travel slowly and allow extra distance to

stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

. Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

. Use only approved gasoline container.

. Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

. Never fuel the machine indoors.

. Neverstorethemachineorfuelcontainer

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

Never fill containers inside a vehicle or

on a truck or trailer bed with plastic liner.

Always place containers on the ground

away from your vehicle when filling.

4

Page 5

• Removegas-poweredequipmentfrom

thetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuel

suchequipmentwithaportablecontainer,

ratherthanfromagasolinedispenser

nozzle.

Keepthenozzleincontactwiththerim

ofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donot

useanozzlelock-opendevice.

Iffuelisspilledonclothing,changecloth-

ingimmediately.

Neveroverfillfueltank.Replacegascap

andtightensecurely.

GENERALSERVICE

• Neveroperatemachineinaclosedarea.

Keepallnutsandboltstighttobesurethe

equipmentisinsafeworkingcondition.

Nevertamperwithsafetydevices.Check

theirproperoperationregularly.

Keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanoilorfuel

spillageandremoveanyfuel-soakedde-

bris.Allowmachinetocootbeforestoring.

Ifyoustrikeaforeignobject,stopand

inspectthemachine.Repair,ifnecessary,

beforerestarting.

Nevermakeanyadjustmentsorrepairs

withtheenginerunning.

Checkgrasscatchercomponentsandthe

dischargechutefrequentlyandreplace

withmanufacturer'srecommendedparts,

whennecessary.

Mowerbladesaresharp.Wraptheblade

orweargloves,anduseextracaution

whenservicingthem.

• Checkbrakeoperationfrequentty.Adjust

andserviceasrequired.

Maintainorreplacesafetyandinstruction

labels,asnecessary.

Besuretheareaisclearofbystanders

beforeoperating.Stopmachineifanyone

entersthearea.

• Nevercarrypassengers.

Donotmowinreverseunlessabsolutely

necessary.Alwaystookdownandbehind

beforeandwhilebacking.

Nevercarrychildren,evenwiththe

bladesshutoff.Theymayfalloffand

beseriouslyinjuredorinterferewithsafe

machineoperation.Childrenwhohave

beengivenridesinthepastmaysuddenly

appearinthemowingareaforanother

rideandberunoverorbackedoverby

themachine.

Keepchildrenoutofthemowingarea

andinthewatchfulcareofaresponsible

adultotherthantheoperator.

• Bealertandturnmachineoffifachild

entersthearea.

• Beforeandwhilebacking,tookbehind

anddownforsmallchildren.

Mowupanddownslopes(15°Max),not

across.

Choosealowgroundspeedsothatyou

willnothavetostoporshiftwhileonthe

slope.

Avoidstarting,stopping,orturningona

slope.Ifthetirestosetraction,disengage

thebladesandproceedslowlystraight

downtheslope.

• If machinestopswhilegoinguphill,

disengageblades,shiftintoreverseand

backdownslowly.

Donotturnonslopesunlessnecessary,

andthen,turnslowlyandgradually

downhill,ifpossible.

• WhenIoadingorunloadingthismachine,

donotexceedthemaximumrecom-

mendedoperationangleof15°.

Page 6

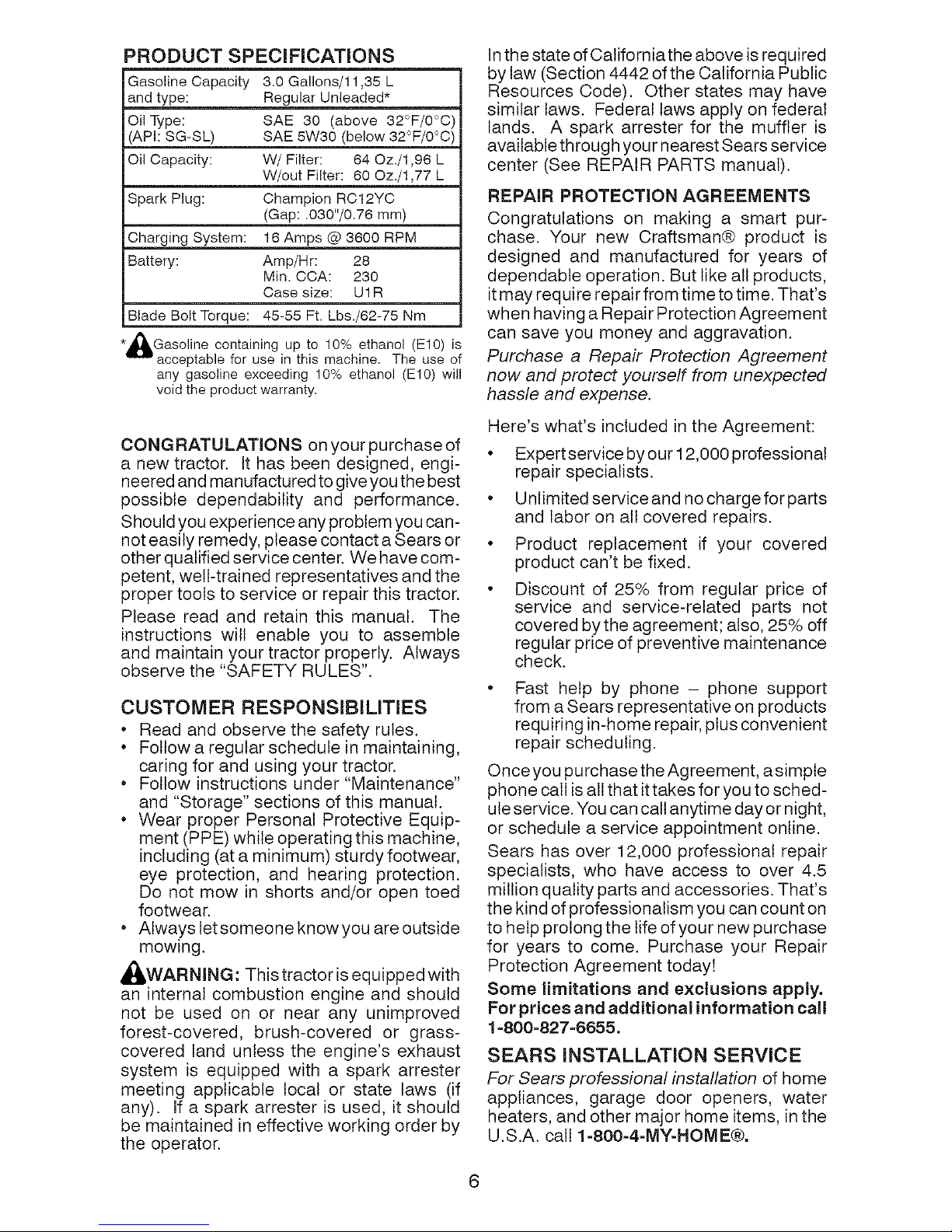

PRODUCTSPECIFiCATiONS

Gasoline Capacity 3.0 Gallons/11,35 L

and type: Regular Unleaded*

Oil Type: SAE 30 (above 32°F/0°C)

5W30 (below 32°F/_0)

Oil Capacity: W/Filter: 64 Oz./1,96 L

W/out Filter: 60 Oz./1,77 L

Spark Plug: Champion RC12YC

(Gap: .030"/0.76 mm)

Charging System: 16 Amps @ 3600 RPM

Battery: Amp/Hr: 28

Min. CCA: 230

Case size: U1R

Blade Bolt Torque: 45-55 Ft. Lbs./62-75 Nm

*_Gasoline containing up to 10% ethanol (El0)is

acceptable for use in this machine. The use of

any gasoline exceeding 10% ethanol (El0) will

void the product warranty.

CONGRATULATIONS on your purchase of

a new tractor. It has been designed, engi-

neered and manufactured to giveyou the best

possible dependability and performance.

Should you experience any problem you can-

not easily remedy, please contact a Sears or

other qualified service center. We have com-

petent, well-trained representatives and the

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly. Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

Read and observe the safety rules.

* Follow a regular schedule in maintaining,

caring for and using your tractor.

* Follow instructions under"Maintenance"

and "Storage" sections of this manual.

* Wear proper Personal Protective Equip-

ment (PPE) while operating this machine,

including (at a minimum) sturdy footwear,

eye protection, and hearing protection.

Do not mow in shorts and/or open toed

footwear.

Always let someone know you are outside

mowing.

_IbWARNING" This tractor is equipped with

an internal combustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass-

covered land unless the engine's exhaust

system is equipped with a spark arrester

meeting applicable local or state laws (if

any). If a spark arrester is used, it should

be maintained in effective working order by

the operator.

Inthe state ofCalifornia the above is required

by law (Section 4442 of the California Public

Resources Code). Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

available through your nearest Sears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur-

chase. Your new Craftsman@ product is

designed and manufactured for years of

dependable operation. But like all products,

it may require repair from time to time. That's

when having a Repair Protection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here's what's included in the Agreement:

Expert service by our 12,000 professional

repair specialists.

Unlimited service and no charge for parts

and labor on all covered repairs.

Product replacement if your covered

product can't be fixed.

Discount of 25% from regular price of

service and service-related parts not

covered bythe agreement; also, 25% off

regular price of preventive maintenance

check.

Fast help by phone - phone support

from a Sears representative on products

requiring in-home repair, plus convenient

repair scheduling.

Once you purchase the Agreement, asimpte

phone call is all that ittakes for you to sched-

ule service. You can call anytime day or night,

or schedule a service appointment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories. That's

the kind of professionalism you can count on

to help prolong the life of your new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call

1-800=827-6655,

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, inthe

U.S.A. call 1-800-4-MY-HOME@.

6

Page 7

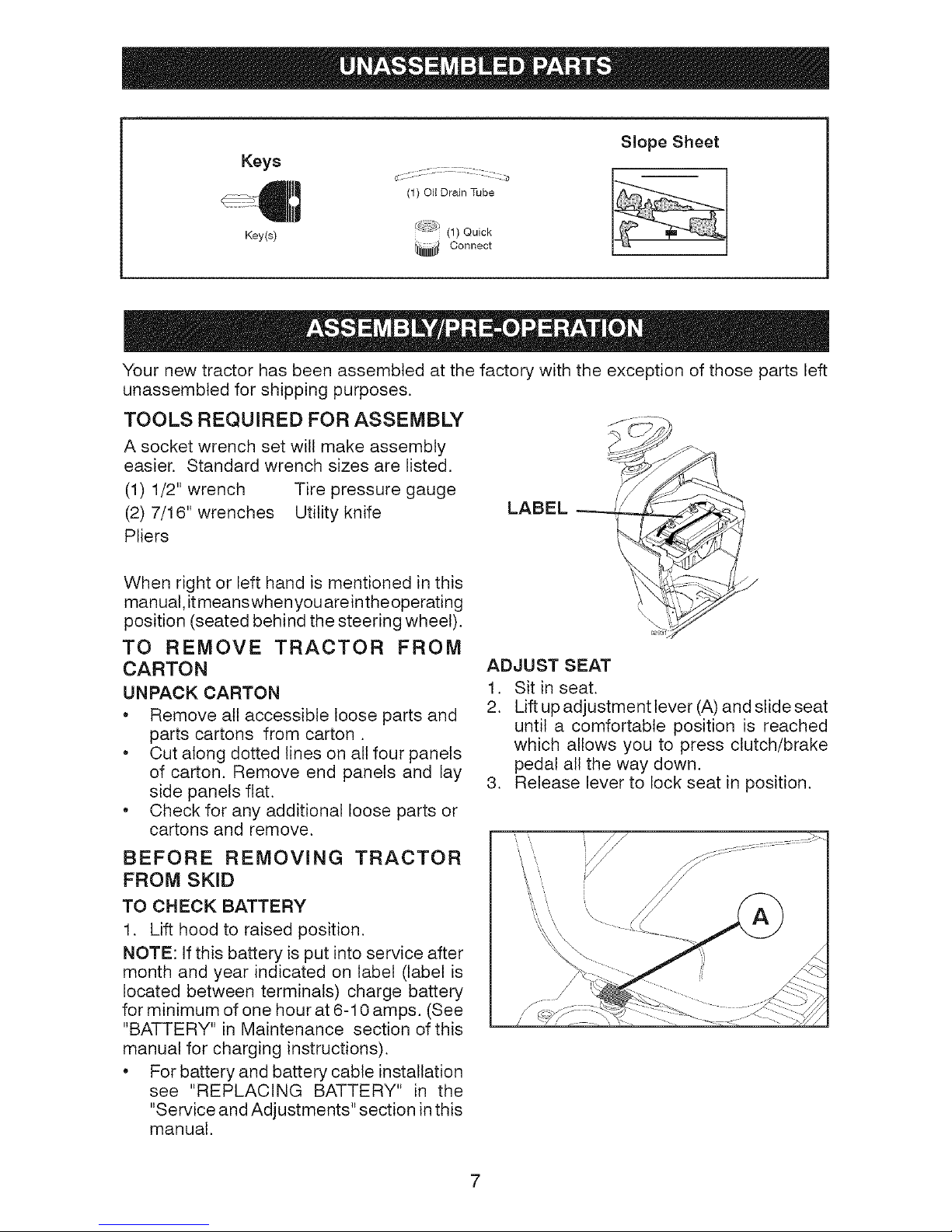

Keys

d::: ............ -::::::: o

II (!) Oit Drain Tube

...............9,,I

_-_) (1) Quick

Key(s)

Connect

Slope Sheet

Your new tractor has been assembled at the factory with the exception of those parts left

unassembted for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY J

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) 1/2" wrench Tire pressure gauge

(2) 7/16" wrenches Utility knife LABEL

Pliers

When right or left hand is mentioned in this

manual, itmeans when you areinthe operating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

Remove all accessible loose parts and

parts cartons from carton.

* Cut along dotted lines on all four panels

of carton. Remove end panels and lay

side panels flat.

* Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

TO CHECK BATTERY

1. Lift hood to raised position.

NOTE: If this battery is put into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of one hour at 6-10 amps. (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

For battery and battery cable installation

see "REPLACING BATTERY" in the

"Service and Adjustments" section in this

manual.

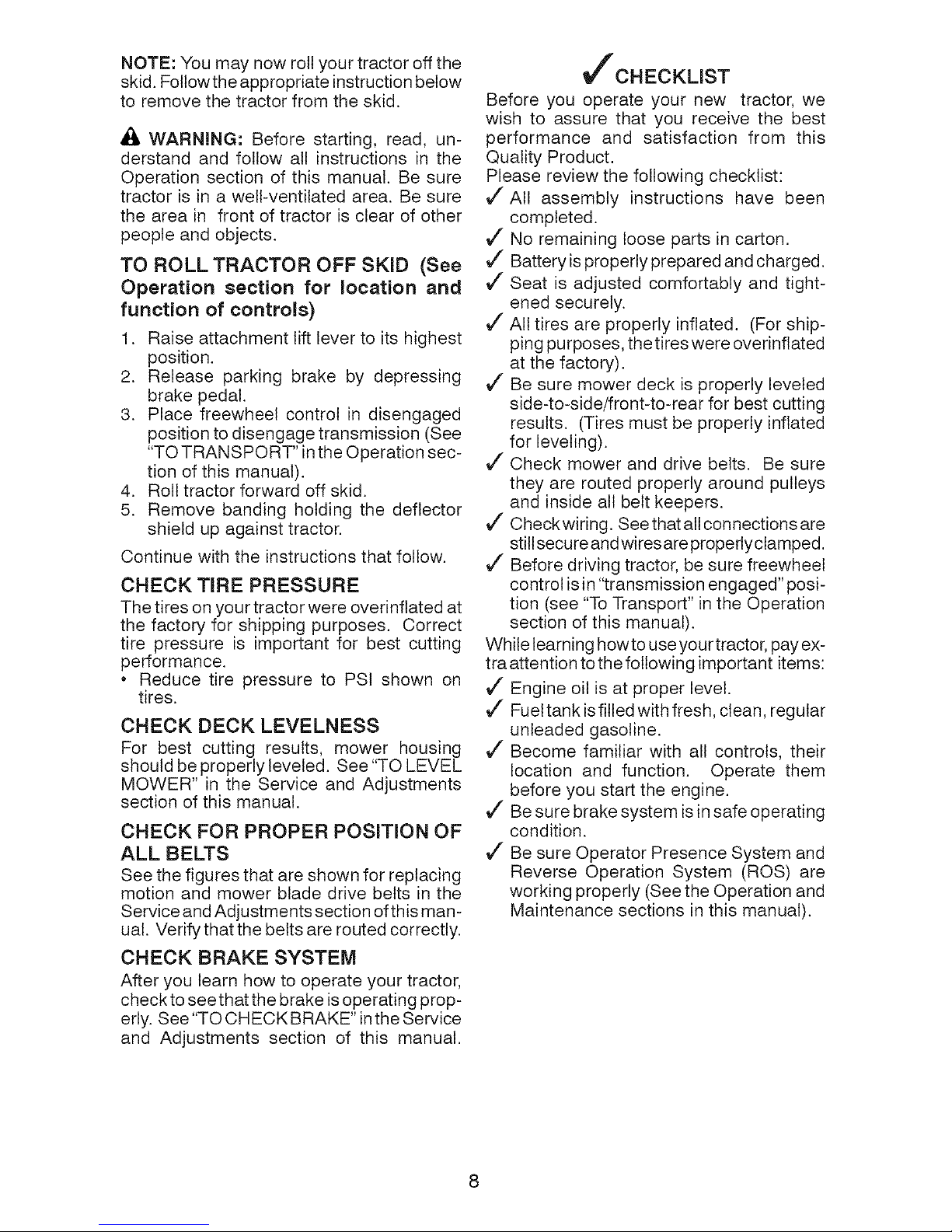

ADJUST SEAT

1. Sit in seat.

2. Lift up adjustment lever (A) and slide seat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down.

3. Release lever to lock seat in position.

Page 8

NOTE:Youmaynowrollyourtractoroffthe

skid.Followtheappropriateinstructionbelow

toremovethetractorfromtheskid.

WARNING:Beforestarting,read,un-

derstandandfollowallinstructionsinthe

Operation section of this manual. Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

TO ROLL TRACTOR OFF SKID (See

Operation section for location and

function of controls)

1. Raise attachment lift lever to its highest

position.

2. Release parking brake by depressing

brake pedal.

3. Place freewheel control in disengaged

position to disengage transmission (See

"TO TRANSPORT" in the Operation sec-

tion of this manual).

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Continue with the instructions that follow.

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at

the factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

Reduce tire pressure to PSI shown on

tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See "TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for replacing

motion and mower blade drive belts in the

Service and Adjustments section ofthis man-

ual. Verifythat the belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

checkto seethat the brake is operating prop-

erly. See "TO CHECK BRAKE" inthe Service

and Adjustments section of this manual.

_fCHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product.

Please review the following checklist:

J" All assembly instructions have been

completed.

J" No remaining loose parts in carton.

J" Battery isproperly prepared and charged.

J" Seat is adjusted comfortably and tight-

ened securely.

All tires are properly inflated. (For ship-

ping purposes, thetires were overinftated

at the factory).

J" Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling).

J" Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

Check wiring. See that all connections are

stillsecure and wires are properly clamped.

Before driving tractor, be sure freewheel

control is in "transmission engaged" posi-

tion (see "To Transport" in the Operation

section of this manual).

While learning howto use your tractor, pay ex-

tra attention to the following important items:

Engine oil is at proper level.

Fueltank isfilled with fresh, clean, regular

unleaded gasoline.

Become familiar with all controls, their

location and function. Operate them

before you start the engine.

Be sure brake system isin safe operating

condition.

Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (See the Operation and

Maintenance sections in this manual).

8

Page 9

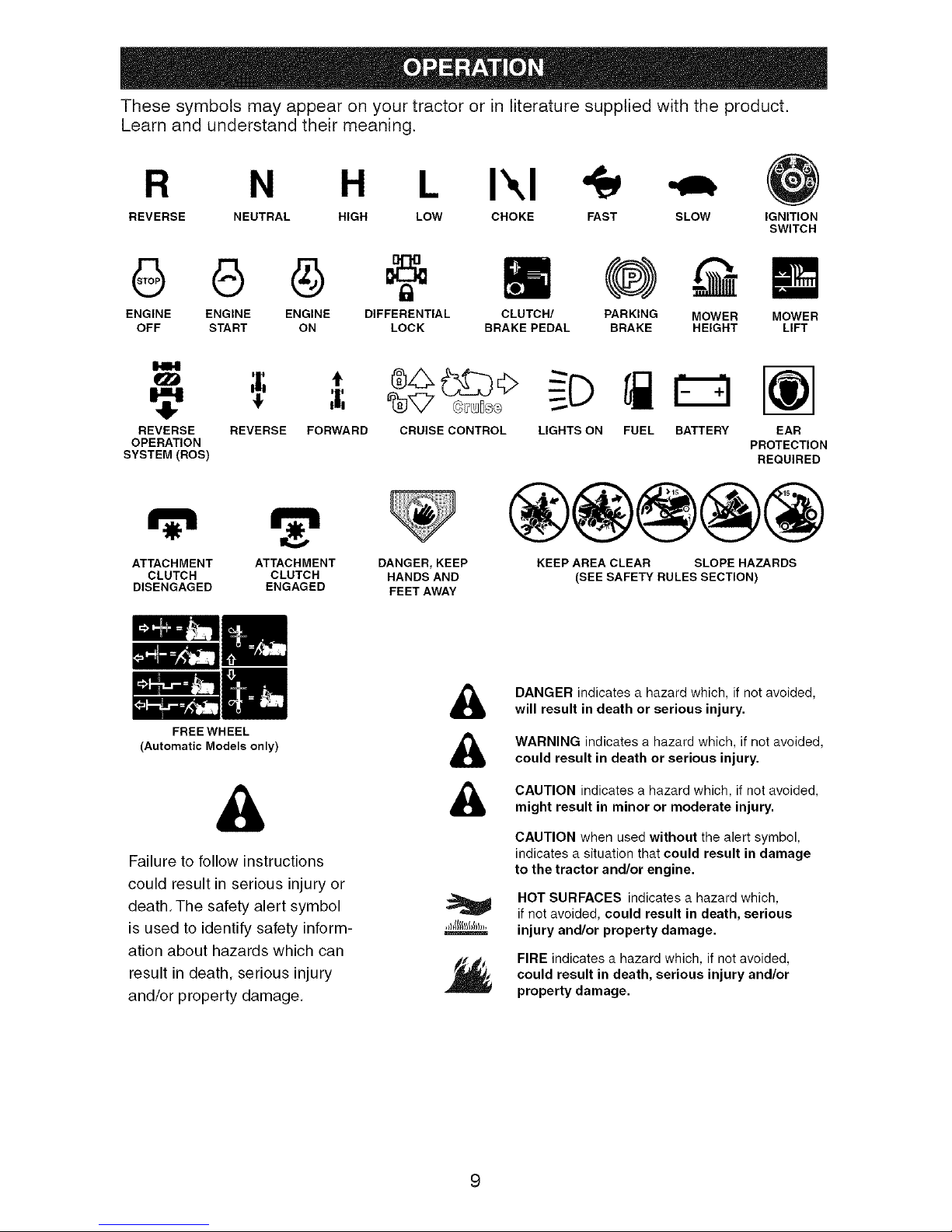

These symbols may appear on your tractor or in literature supplied with the product.

Learn and understand their meaning.

R N H L I',,I

REVERSE NEUTRAL HIGH LOW CHOKE FAST SLOW IGNITION

SWITCH

6 6 @

ENGINE ENGINE ENGINE DIFFERENTIAL

OFF START ON LOCK

CLUTCH/ MOWER

BRAKE PEDAL LIFT

PARKING MOWER

BRAKE HEIGHT

1414

REVERSE

OPERATION

SYSTEM(ROS)

REVERSE FORWARD

m

CRUISE CONTROL LIGHTS ON FUEL BATTERY EAR

PROTECTION

REQUIRED

ATTACHMENT ATTACHMENT DANGER, KEEP

CLUTCH CLUTCH HANDS AND

DISENGAGED ENGAGED FEET AWAY

FREE WHEEL

(Automatic Models only)

®@@@@

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

&

Failure to follow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury

and/or property damage.

&

&

&

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION when used without the alert symbol,

indicates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious

injury and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage.

Page 10

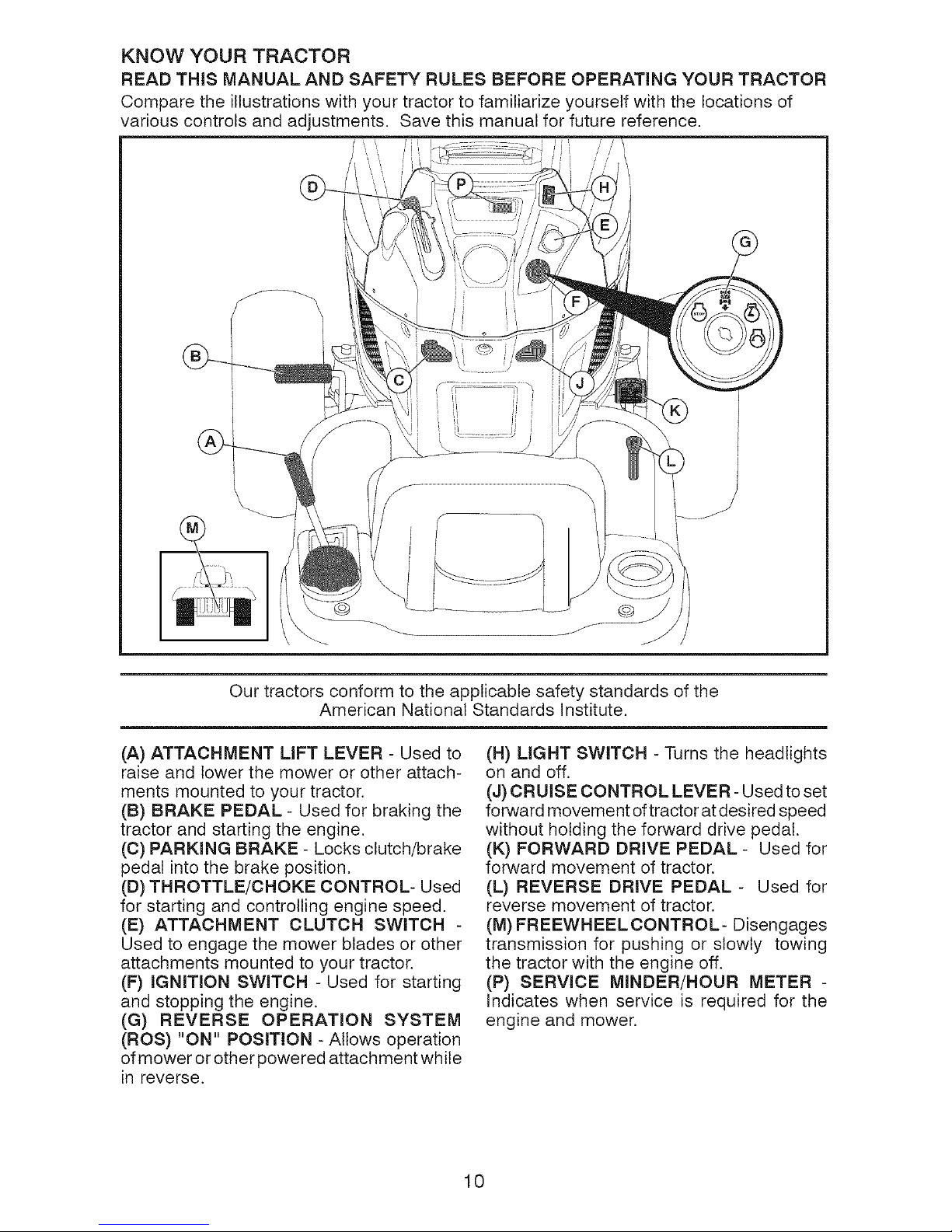

KNOW YOUR TRACTOR

READ THiS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of

various controls and adjustments. Save this manual for future reference.

T

\

Our tractors conform to the applicable safety standards of the

American National Standards institute.

(A) ATTACHMENT LiFT LEVER - Used to

raise and lower the mower or other attach-

ments mounted to your tractor.

(B) BRAKE PEDAL - Used for braking the

tractor and starting the engine.

(C) PARKING BRAKE - Locks clutch/brake

pedal into the brake position.

(D) THROTTLE/CHOKE CONTROL- Used

for starting and controlling engine speed.

(E) ATTACHMENT CLUTCH SWITCH -

Used to engage the mower blades or other

attachments mounted to your tractor.

(F) iGNiTiON SWITCH - Used for starting

and stopping the engine.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSiTiON - Allows operation

ofmower or other powered attachment while

in reverse.

(H) LIGHT SWITCH - Turns the headlights

on and off.

(J) CRUISE CONTROL LEVER- Used toset

forward movement oftractor atdesired speed

without holding the forward drive pedal.

(K) FORWARD DRIVE PEDAL - Used for

forward movement of tractor.

(L) REVERSE DRIVE PEDAL - Used for

reverse movement of tractor.

(M) FREEWHEELCONTROL- Disengages

transmission for pushing or slowly towing

the tractor with the engine off.

(P) SERVICE MINDER/HOUR METER -

indicates when service is required for the

engine and mower.

10

Page 11

1

The operation of any tractor can result in foreign objects thrown into_

the eyes, which can result in severe eye damage. Always wear safety_

glasses or eye shields while operating your tractor or performing any_

adjustments or repairs. We recommend standard safety glasses or a_

wide vision safety mask worn over spectacles, J

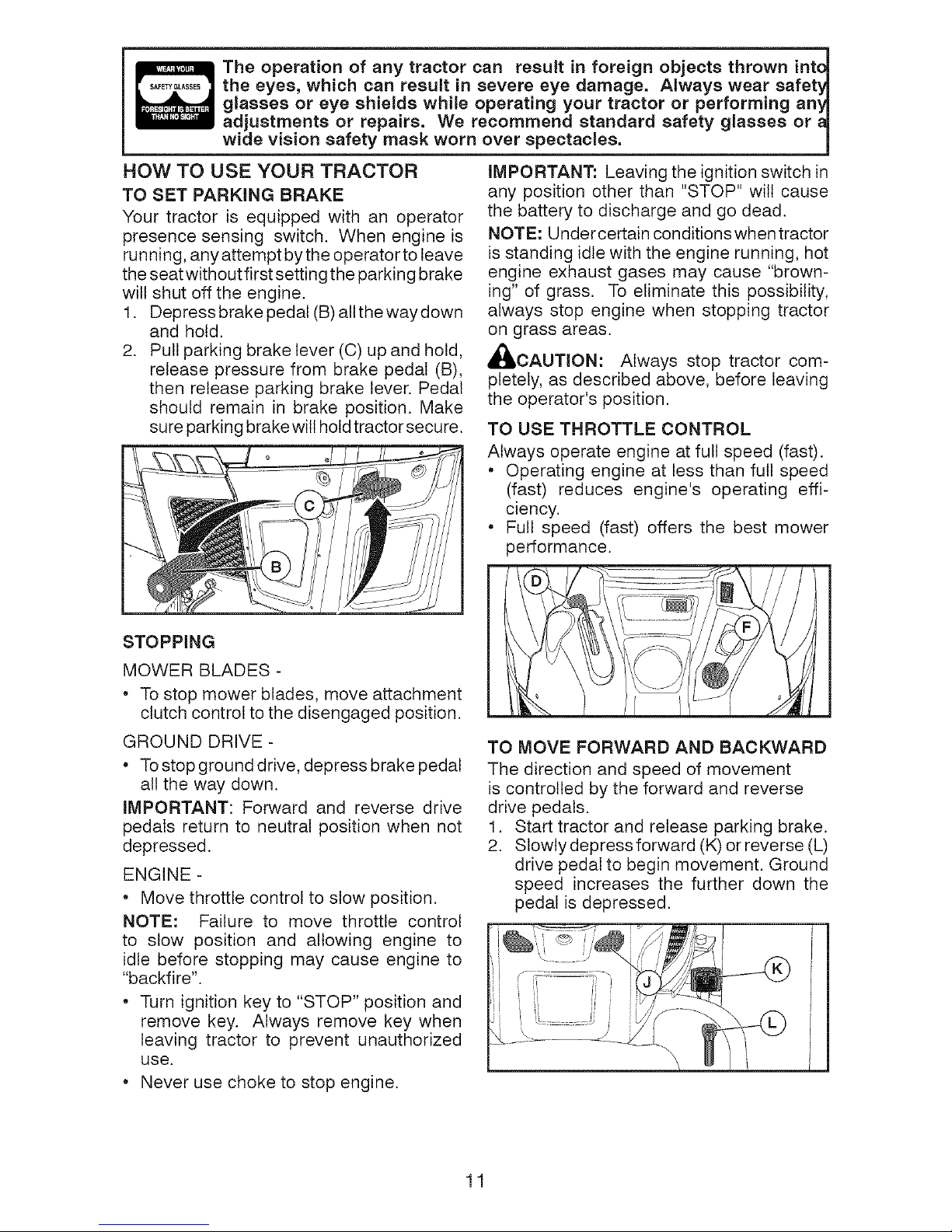

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

running, any attempt bythe operator to leave

the seat without first setting the parking brake

will shut off the engine.

1. Depress brake pedal (B)all the way down

and hold.

2. Pull parking brake lever (C) up and hold,

release pressure from brake pedal (B),

then release parking brake lever. Pedal

should remain in brake position. Make

sure parking brake will holdtractor secure.

STOPPING

MOWER BLADES -

• To stop mower blades, move attachment

clutch control to the disengaged position.

IMPORTANT: Leaving the ignition switch in

any position other than "STOP" will cause

the battery to discharge and go dead.

NOTE: Undercertain conditionswhentractor

is standing idle with the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass. To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

,_CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

TO USE THROTTLE CONTROL

Always operate engine at full speed (fast).

Operating engine at less than full speed

(fast) reduces engine's operating effi-

ciency.

Full speed (fast) offers the best mower

performance.

GROUND DRIVE -

Tostop ground drive, depress brake pedal

all the way down.

IMPORTANT: Forward and reverse drive

pedals return to neutral position when not

depressed.

ENGINE -

Move throttle control to slow position.

NOTE: Failure to move throttle control

to stow position and allowing engine to

idle before stopping may cause engine to

"backfire".

Turn ignition key to "STOP" position and

remove key. Always remove key when

leaving tractor to prevent unauthorized

use.

Never use choke to stop engine.

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement

is controlled by the forward and reverse

drive pedals.

1. Start tractor and release parking brake.

2. Slowly depress forward (K) or reverse (L)

drive pedal to begin movement. Ground

speed increases the further down the

pedal is depressed.

11

Page 12

TO USE CRUISE CONTROL

The cruise control feature can be used for

forward travel only.

SYSTEM CHARACTERISTICS

The cruise control should only be used

while mowing or transporting on relatively

smooth, straight surfaces. Other conditions

such as trimming at slow speeds may cause

the cruise control to disengage. Do not use

the cruise control on slopes, rough terrian

or while trimmimg or turning.

With forward drive pedal (K) depressed to

desired speed, pull cruise control lever (J)

up and hold while lifting your foot off the

pedal, then release the lever.

Todisengage the cruise control, depress the

brake pedal or tap on forward drive pedal.

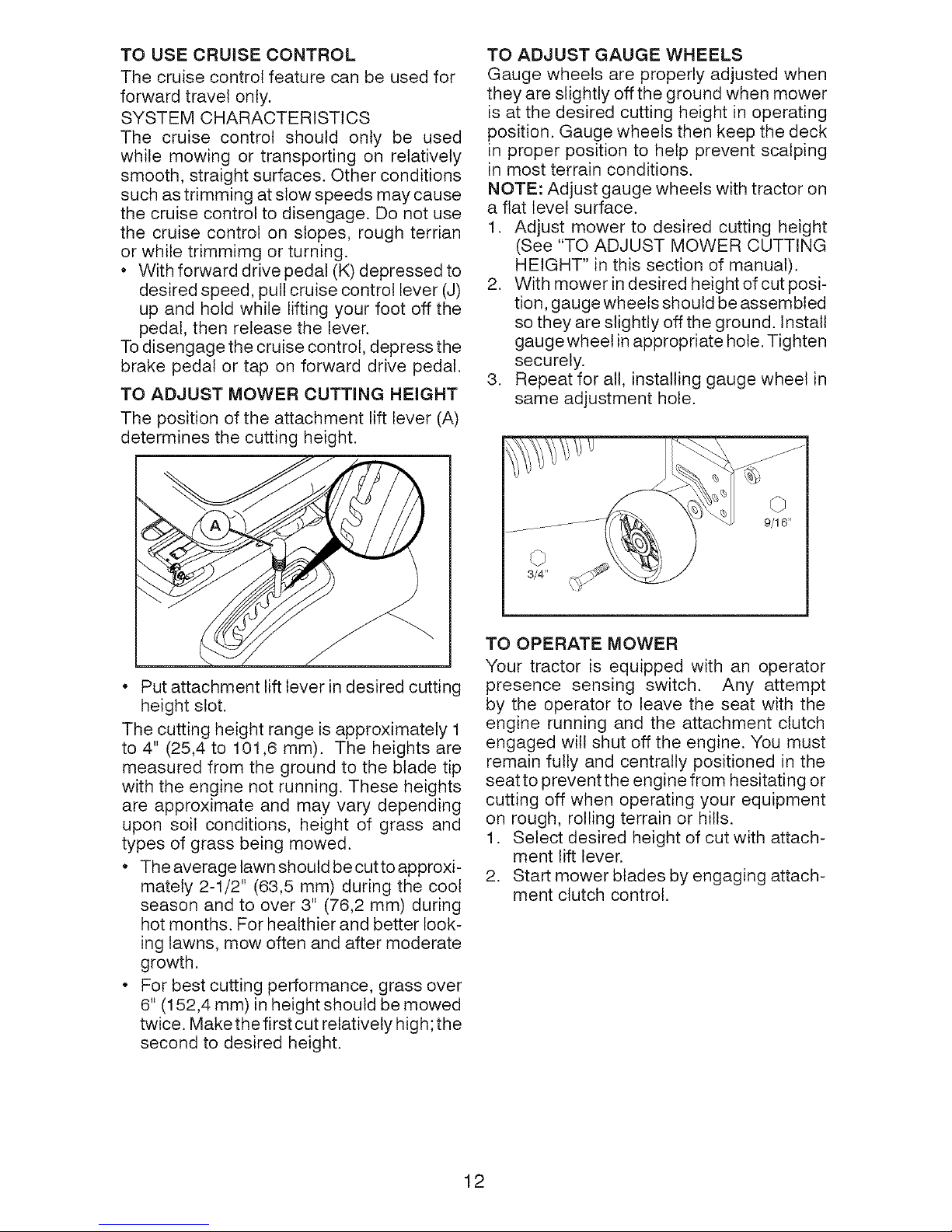

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever (A)

determines the cutting height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted when

they are slightly off the ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper position to help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a flat level surface.

1. Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

2. With mower in desired height of cut posi-

tion, gauge wheels should be assembled

so they are slightly off the ground. Install

gauge wheel inappropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

Put attachment lift lever in desired cutting

height slot.

The cutting height range is approximately 1

to 4" (25,4 to 101,6 mm). The heights are

measured from the ground to the blade tip

with the engine not running. These heights

are approximate and may vary depending

upon soil conditions, height of grass and

types of grass being mowed.

The average lawn should be cutto approxi-

mately 2-1/2" (63,5 mm) during the cool

season and to over 3" (76,2 mm) during

hot months. For healthier and better look-

ing lawns, mow often and after moderate

growth.

For best cutting performance, grass over

6" (152,4 mm) inheight should be mowed

twice. Make the first cut relatively high; the

second to desired height.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Any attempt

by the operator to leave the seat with the

engine running and the attachment clutch

engaged wilt shut off the engine. You must

remain fully and centrally positioned in the

seat to prevent the engine from hesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills.

1. Select desired height of cut with attach-

ment lift lever.

2. Start mower blades by engaging attach-

ment clutch control.

12

Page 13

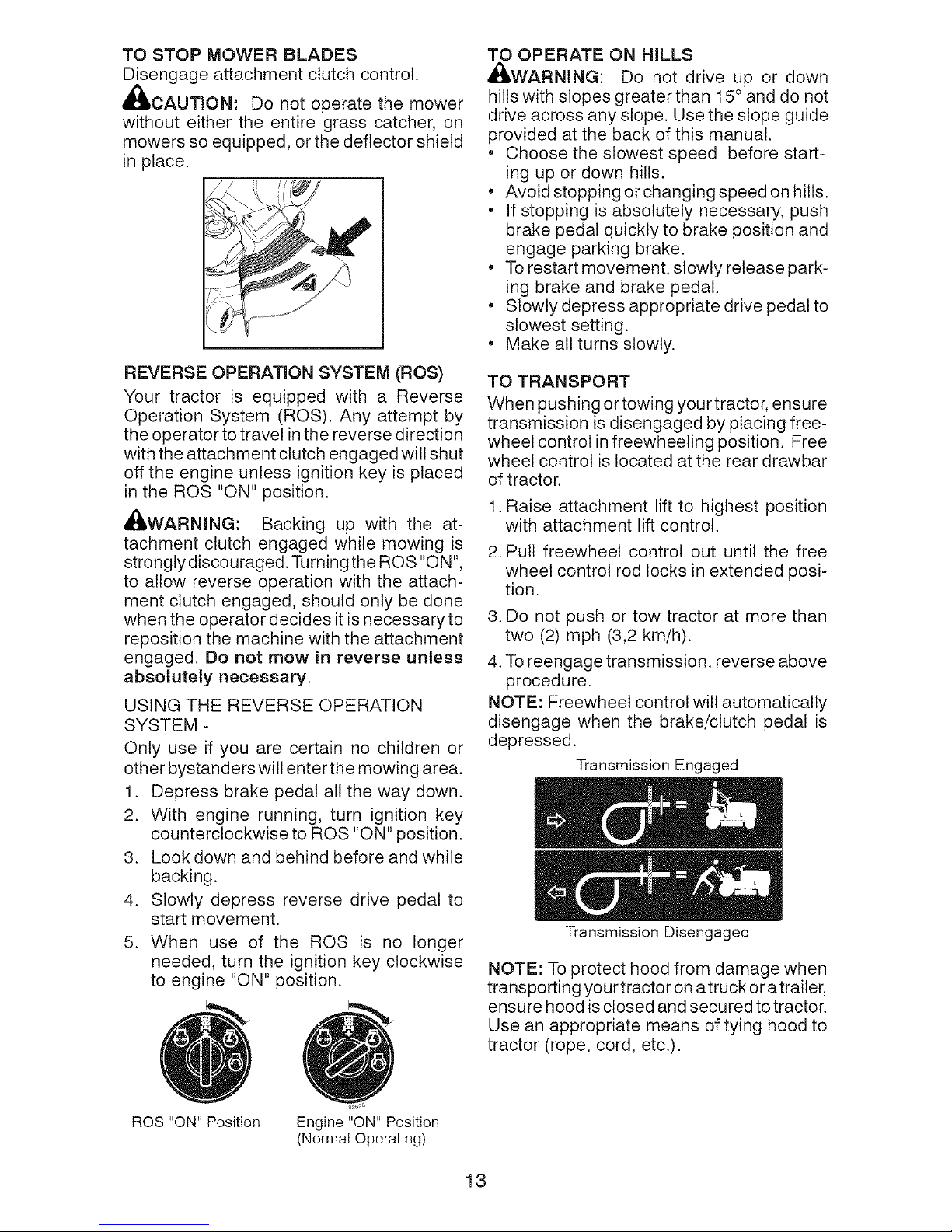

TO STOP MOWER BLADES

Disengage attachment clutch control.

_IOAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, or the deflector shield

in place.

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direction

with the attachment clutch engaged will shut

off the engine unless ignition key is placed

in the ROS "ON" position.

AI_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discouraged. Turning the ROS "ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides it is necessary to

reposition the machine with the attachment

engaged. Do not mow in reverse unless

absolutely necessary.

USING THE REVERSE OPERATION

SYSTEM -

Only use if you are certain no children or

other bystanders will enter the mowing area.

1. Depress brake pedal all the way down.

2. With engine running, turn ignition key

counterclockwise to ROS "ON" position.

3. Look down and behind before and while

backing.

4. Slowly depress reverse drive pedal to

start movement.

5. When use of the ROS is no longer

needed, turn the ignition key clockwise

to engine "ON" position.

TO OPERATE ON HILLS

_IWARNING: Do not drive up or down

hills with slopes greater than 15° and do not

drive across any slope. Use the slope guide

provided at the back of this manual.

* Choose the slowest speed before start-

ing up or down hills.

* Avoid stopping or changing speed on hills.

* If stopping is absolutely necessary, push

brake pedal quickly to brake position and

engage parking brake.

* To restart movement, slowly release park-

ing brake and brake pedal.

* Slowly depress appropriate drive pedal to

slowest setting.

* Make all turns slowly.

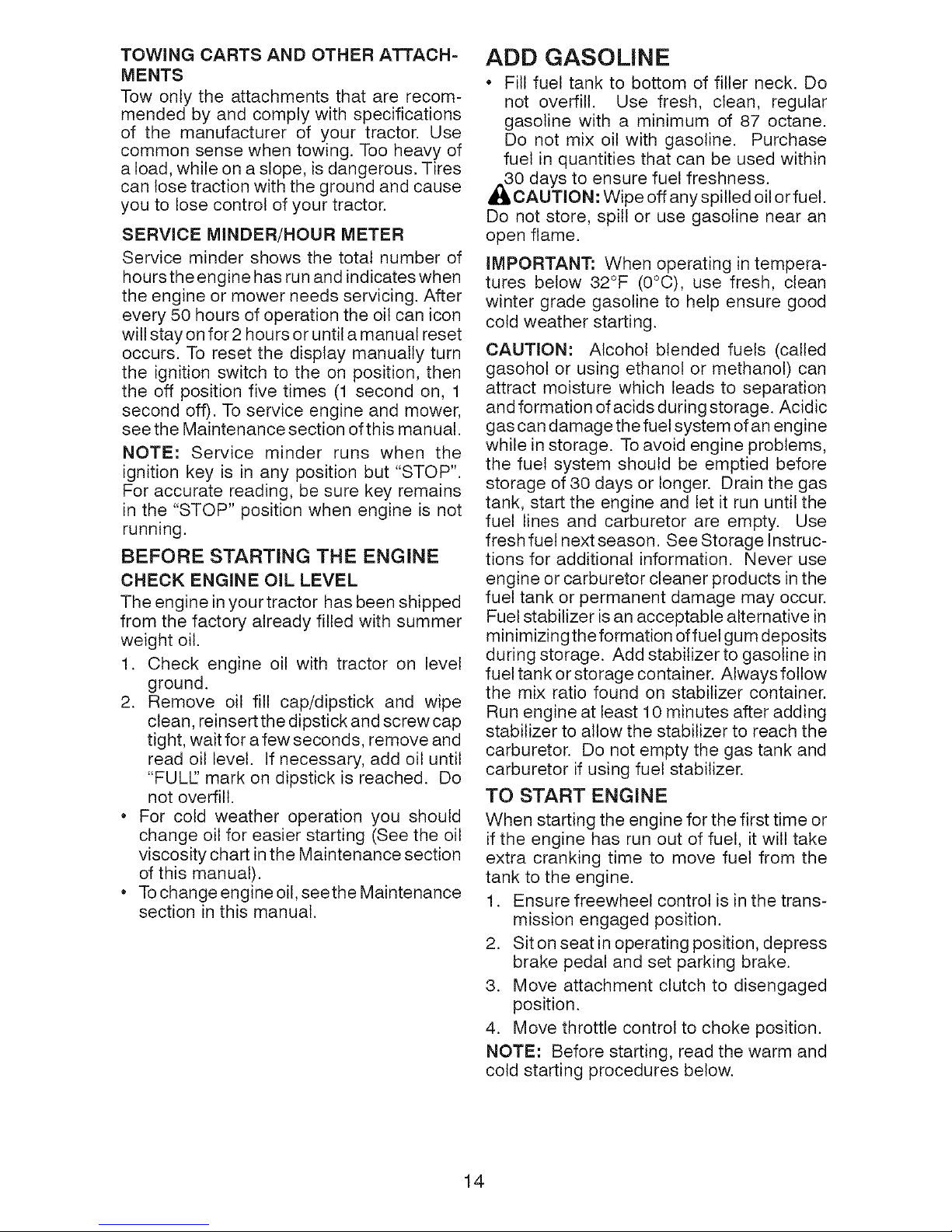

TO TRANSPORT

When pushing or towing your tractor, ensure

transmission is disengaged by placing free-

wheel control in freewheeling position. Free

wheel control is located at the rear drawbar

of tractor.

1. Raise attachment lift to highest position

with attachment lift control.

2. Pull freewheel control out until the free

wheel control rod locks in extended posi-

tion.

3. Do not push or tow tractor at more than

two (2) mph (3,2 km/h).

4. To reengage transmission, reverse above

procedure.

NOTE: Freewheel control will automatically

disengage when the brake/clutch pedal is

depressed.

Transmission Engaged

Transmission Disengaged

NOTE: To protect hood from damage when

transporting your tractor on atruck oratrailer,

ensure hood is closed and secured totractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

ROS "ON" Position

Engine "ON" Position

(Normal Operating)

13

Page 14

TOWING CARTS AND OTHER ATTACH-

MENTS

Tow only the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on a slope, is dangerous. Tires

can lose traction with the ground and cause

you to lose control of your tractor.

SERVICE MINDER/HOUR METER

Service minder shows the total number of

hours the engine has run and indicateswhen

the engine or mower needs servicing. After

every 50 hours of operation the oil can icon

will stay on for 2 hours or until a manual reset

occurs. To reset the display manually turn

the ignition switch to the on position, then

the off position five times (1 second on, 1

second off). To service engine and mower,

see the Maintenance section of this manual.

NOTE: Service minder runs when the

ignition key is in any position but "STOP".

For accurate reading, be sure key remains

in the "STOP" position when engine is not

running.

BEFORE STARTING THE ENGINE

CHECK ENGINE OiL LEVEL

The engine in your tractor has been shipped

from the factory already filled with summer

weight oil.

1. Check engine oil with tractor on level

ground.

2. Remove oil fill cap/dipstick and wipe

clean, reinsert the dipstick and screw cap

tight, wait for a few seconds, remove and

read oil level. If necessary, add oil until

"FULL' mark on dipstick is reached. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart inthe Maintenance section

of this manual).

• To change engine oil, seethe Maintenance

section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of fitter neck. Do

not overfill. Use fresh, clean, regular

gasoline with a minimum of 87 octane.

Do not mix oil with gasoline. Purchase

fuel in quantities that can be used within

0 days to ensure fuel freshness.

CAUTION: Wipe off any spilled oil or fuel.

Do not store, spill or use gasoline near an

open flame.

IMPORTANT: When operating in tempera-

tures below 32°F (0°C), use fresh, clean

winter grade gasoline to help ensure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

and formation of acids during storage. Acidic

gas can damage the fuel system of an engine

while in storage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty. Use

fresh fuel next season. See Storage tnstruc-

tions for additional information. Never use

engine or carburetor cleaner products inthe

fuel tank or permanent damage may occur.

Fuel stabilizer is an acceptable alternative in

minimizing theformation offuel gum deposits

during storage. Add stabilizer to gasoline in

fuel tank orstorage container. Always follow

the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor. Do not empty the gas tank and

carburetor if using fuel stabilizer.

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel, it will take

extra cranking time to move fuel from the

tank to the engine.

1. Ensure freewheel control is inthe trans-

mission engaged position.

2. Siton seatin operating position, depress

brake pedal and set parking brake.

3. Move attachment clutch to disengaged

position.

4. Move throttle control to choke position.

NOTE: Before starting, read the warm and

cold starting procedures below.

14

Page 15

5.

Insert key into ignition and turn key

clockwise to start position and release

key as soon as engine starts. Do not run

starter continuously for more than fifteen

seconds per minute. If the engine does

not start after several attempts, move

throttle control to fast position, wait a

few minutes and try again. If engine still

does not start, move the throttle control

back to the choke position and retry.

WARM WEATHER STARTING

(50°F (10°0) and above)

6. When engine starts, move the throttle

control to the fast position.

The attachments and ground drive

can now be used. Ifthe engine does

not accept the toad, restart the engine

and allow it to warm up for one minute

using the choke as described above.

COLD WEATHER STARTING

(50°F (10°C) and below)

6. When engine starts, leave throttle control

in choke position until engine warms up

and begins to run roughly. Once rough

running begins, immediately move the

throttle control tothe fast position. Engine

warm-up may take from several seconds

to several minutes (the colder the tem-

perature, the longer the warm-up).

AUTOMATIC TRANSMISSION WARM UP

Before driving the unit in cold weather, the

transmission should be warmed up as fol-

lows:

1. Ensure the tractor is on level ground.

2. Release the parking brake and tet the

brake slowly return to operating position.

3. Allow one minute for transmission to

warm up. This can be done during the

engine warm up period.

The attachments can also be used

during the engine warm-up period after

the transmission has been warmed up.

MOWING TIPS

• DO NOT use tire chains when the mower

housing is attached to tractor.

• Mower should be properly leveled for best

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

The left hand side of mower should be

used for trimming.

• Drive so that clippings are discharged onto

the area that has already been cut. Have

the cut area to the right ofthe tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

• When mowing large areas, start byturning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing.

Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough gear to give the

mower cutting performance as well as the

quality of cut desired.

• When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

15

Page 16

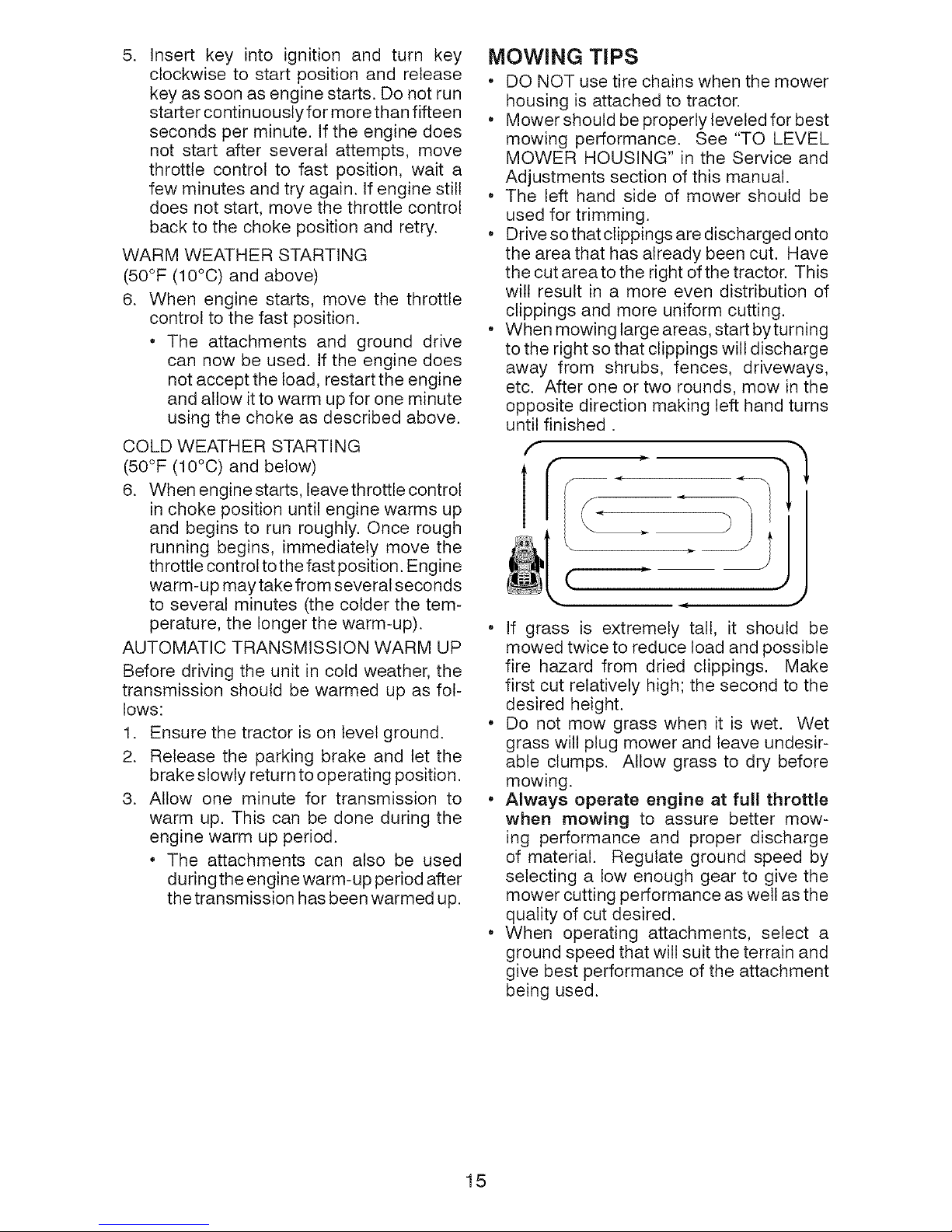

MAINTENANCE BEFORE EVERY EVERY EVERY EVERY EVERY BEFORE

SCHEDULE EABB 8 25 SO rob SEASONSTORAGE

USE HOURS HOURS HOURS HOURS

Check Brake Operation if

¢ ¢

Check Tire Pressure

Check Operator Presence & ROS Systems

¢

A Check for Loose Fasteners _ _

C Check/Replace Mower Blades q_#'3

[ Lubrication Chart _

0 Check Battery Level _4

R Clean Battery and Terminals _

Clean Debris Off Steering Plate _._

Check Mower Levelness

Check V-Belts

Check Engine Oil Level _

Change Engine Oil (models with oil filter) _1,2

Change Engine Oil (models without oil filter) _1,2

NE Clean Air Filter _#'2

G Clean Air Screen ,_2

] Inspect Muffler/Spark Arrester

N Replace Oil Filter (If equipped) _2

E Clean Engine Cooling Fins 1##'2

Replace Spark Plug _

Replace Air Filter Paper Cartridge _#2

__ Re lace Fuel Filter ____ ___

1 Change mole often when operstEng under 8 heaw load or in high _mbJent temlaeratures

2 Sew_ mo,e often when operating _n d_,ty or dusty conditions

s Replace b_ades mole often wher_ mowing in 9andy soiE 6 See C_eaning in Mainter_ance Section

4 ao_ ,equated _f equipped w_, maintenance free batter_

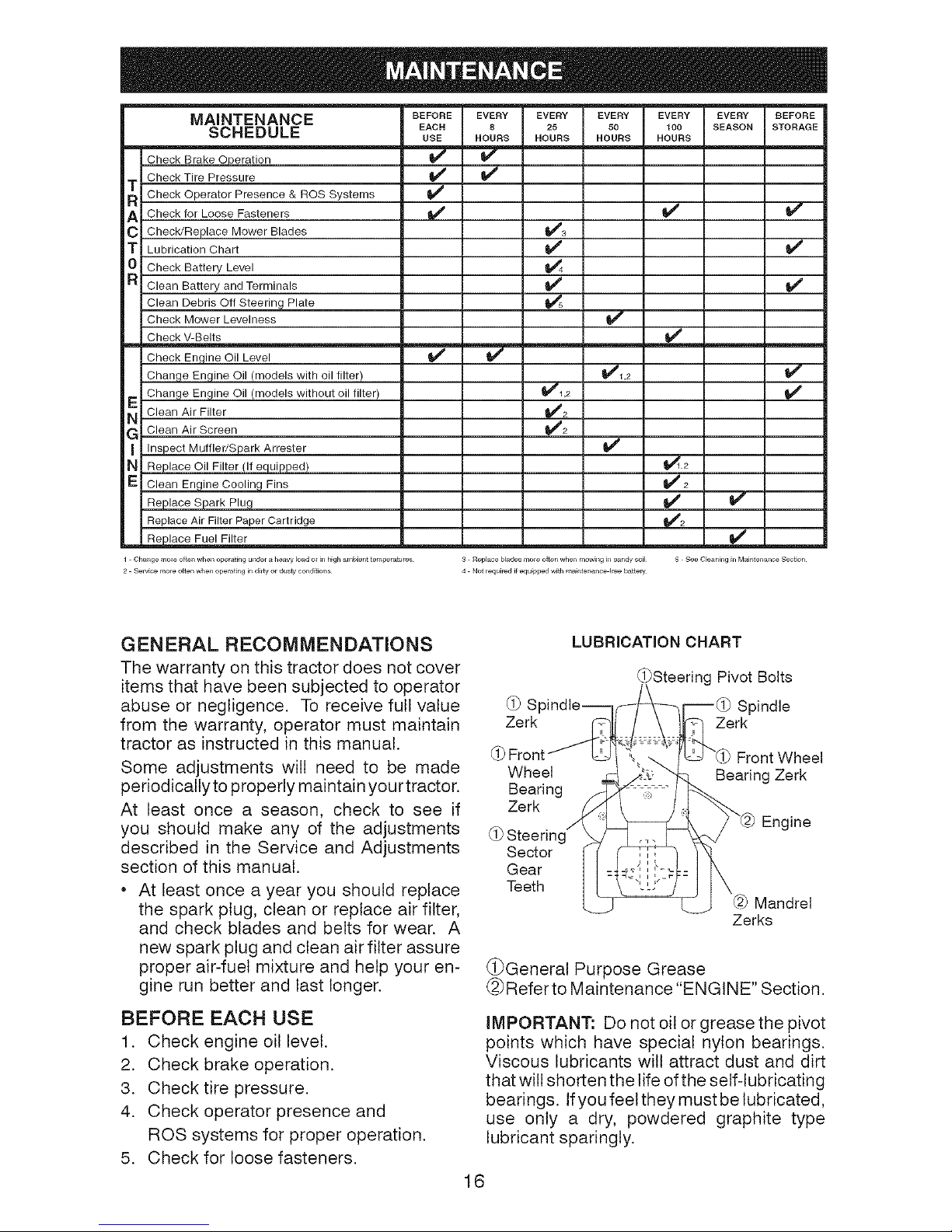

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

items that have been subjected to operator

abuse or negligence. To receive full value _ S

from the warranty, operator must maintain Zerk

tractor as instructed in this manual.

d_

Some adjustments will need to be made Wheel

periodically to properly maintain your tractor. Bearing

At least once a season, check to see if Zerk

you should make any of the adjustments _Steerin(

described in the Service and Adjustments Sector

section of this manual. Gear

• At least once a year you should replace Teeth

the spark plug, clean or replace air filter,

and check blades and belts for wear. A

new spark plug and clean air filter assure

proper air-fuel mixture and help your en-

gine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3. Check tire pressure.

4. Check operator presence and

ROS systems for proper operation.

5. Check for loose fasteners.

LUBRICATION CHART

_Steering Pivot Bolts

Spindle

Zerk

Front Wheel

Bearing Zerk

Engine

Mandrel

Zerks

(_Generat Purpose Grease

@Refer to Maintenance "ENGINE" Section.

IMPORTANT: Do not oil or grease the pivot

points which have special nylon bearings.

Viscous lubricants will attract dust and dirt

that will shorten the life ofthe self-lubricating

bearings. If you feet they must be lubricated,

use only a dry, powdered graphite type

lubricant sparingly.

16

Page 17

TRACTOR

Always observe safety rules when perform-

ing any maintenance.

BRAKE OPERATION

If tractor requires more than 5 feet (1,5 m)

to stop at highest speed in highest gear on

a level, dry concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

• Maintain proper air pressure in all tires

(See the side of tires for proper PSI.)

Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation systems are working properly. If

your tractor does not function as described,

repair the problem immediately.

• The engine should not start unless the

brake pedal is fully depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE SYSTEM

• When the engine isrunning, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engine.

• The attachment clutch should never oper-

ate unless the operator is in the seat.

CHECK REVERSE OPERATION (ROS)

SYSTEM

• When the engine isrunning with the ignition

switch inthe engine "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

shut off the engine.

• When the engine isrunning with the ignition

switch in the ROS "ON" position and the

attachment clutch engaged, any attempt

by the operator to drive in reverse should

NOT shut off the engine.

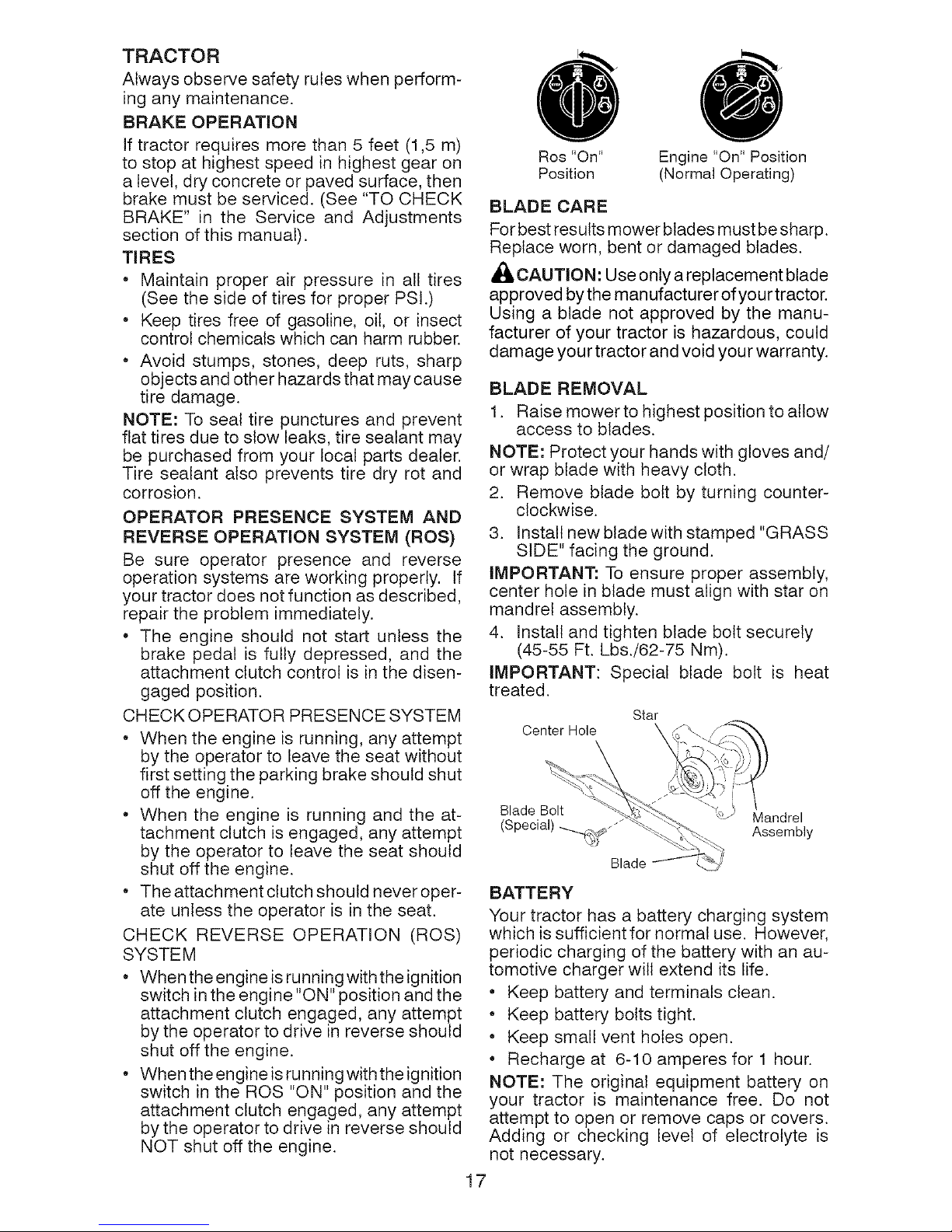

Ros "On" Engine "On" Position

Position (Normal Operating)

BLADE CARE

For best results mower blades must be sharp.

Replace worn, bent or damaged blades.

_, CAUTION: Use only areplacement blade

approved bythe manufacturer of your tractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage your tractor and void your warranty.

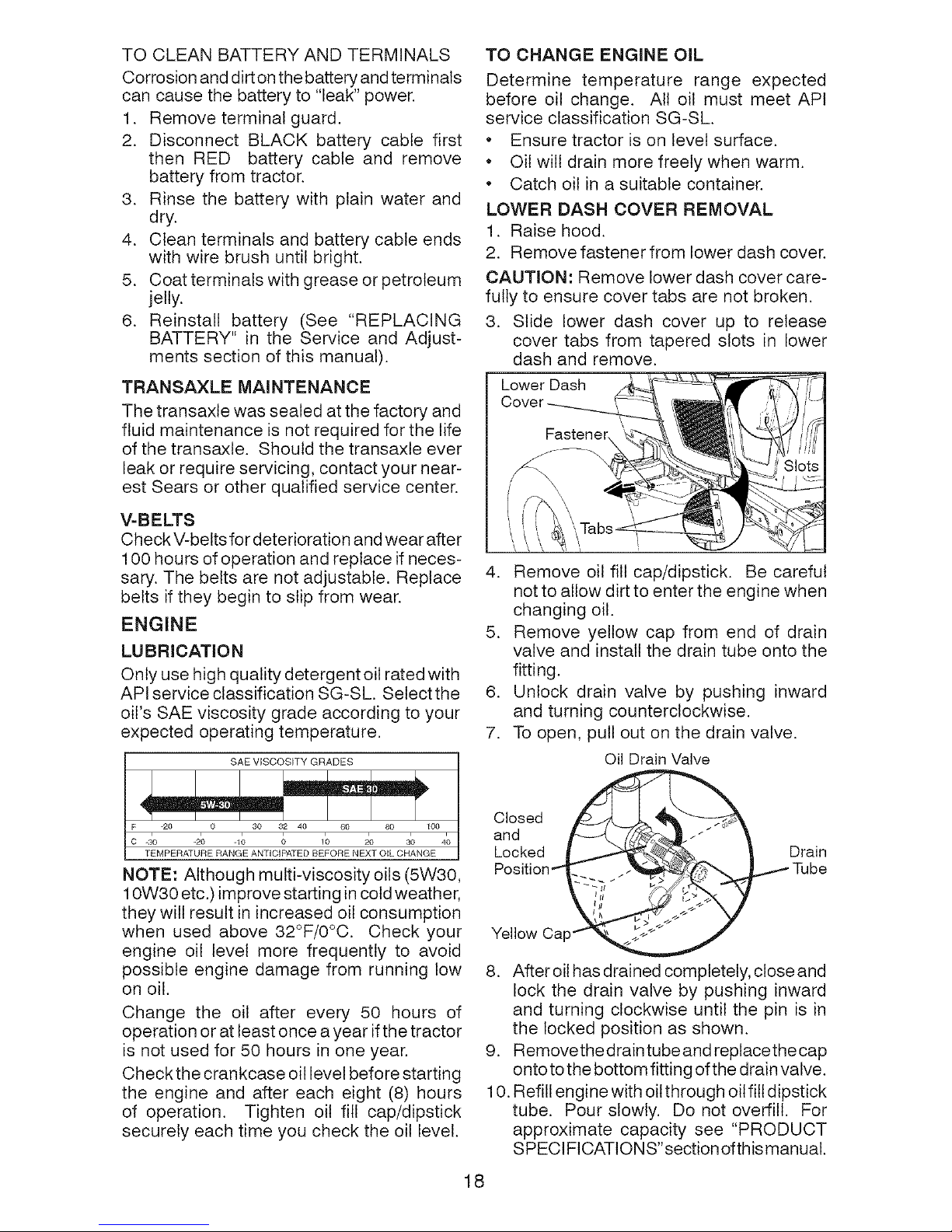

BLADE REMOVAL

1. Raise mower to highest position to allow

access to blades.

NOTE: Protect your hands with gloves and/

or wrap blade with heavy cloth.

2. Remove blade bolt by turning counter-

clockwise.

3. install new blade with stamped "GRASS

SIDE" facing the ground.

iMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. install and tighten blade bolt securely

(45-55 Ft. Lbs./62-75 Nm).

iMPORTANT: Special blade bolt is heat

treated.

Star

Center Hole \

Blade Bolt

Mandrel

(Special) ......_ - Assembly

Blade _S _

BATTERY

Your tractor has a battery charging system

which is sufficient for normal use. However,

periodic charging of the battery with an au-

tomotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

17

Page 18

TOCLEANBATTERYANDTERMINALS

Corrosionanddirtonthebatteryandterminals

cancausethebatteryto"leak"power.

1. Removeterminalguard.

2. DisconnectBLACKbatterycablefirst

thenREDbatterycableandremove

batteryfromtractor.

3. Rinsethebatterywithplainwaterand

dry.

4. Cleanterminalsandbatterycableends

withwirebrushuntilbright.

5. Coatterminalswithgreaseorpetroleum

jelly.

6. Reinstallbattery(See"REPLACING

BATTERY"intheServiceandAdjust-

mentssectionofthismanual).

TRANSAXLE MAINTENANCE

The transaxle was sealed at the factory and

fluid maintenance is not required for the life

of the transaxle. Should the transaxle ever

leak or require servicing, contact your near-

est Sears or other qualified service center.

V=BELTS

Check V-belts for deterioration and wear after

100 hours of operation and replace if neces-

sary. The belts are not adjustable. Replace

belts if they begin to slip from wear.

ENGINE

LUBRiCATiON

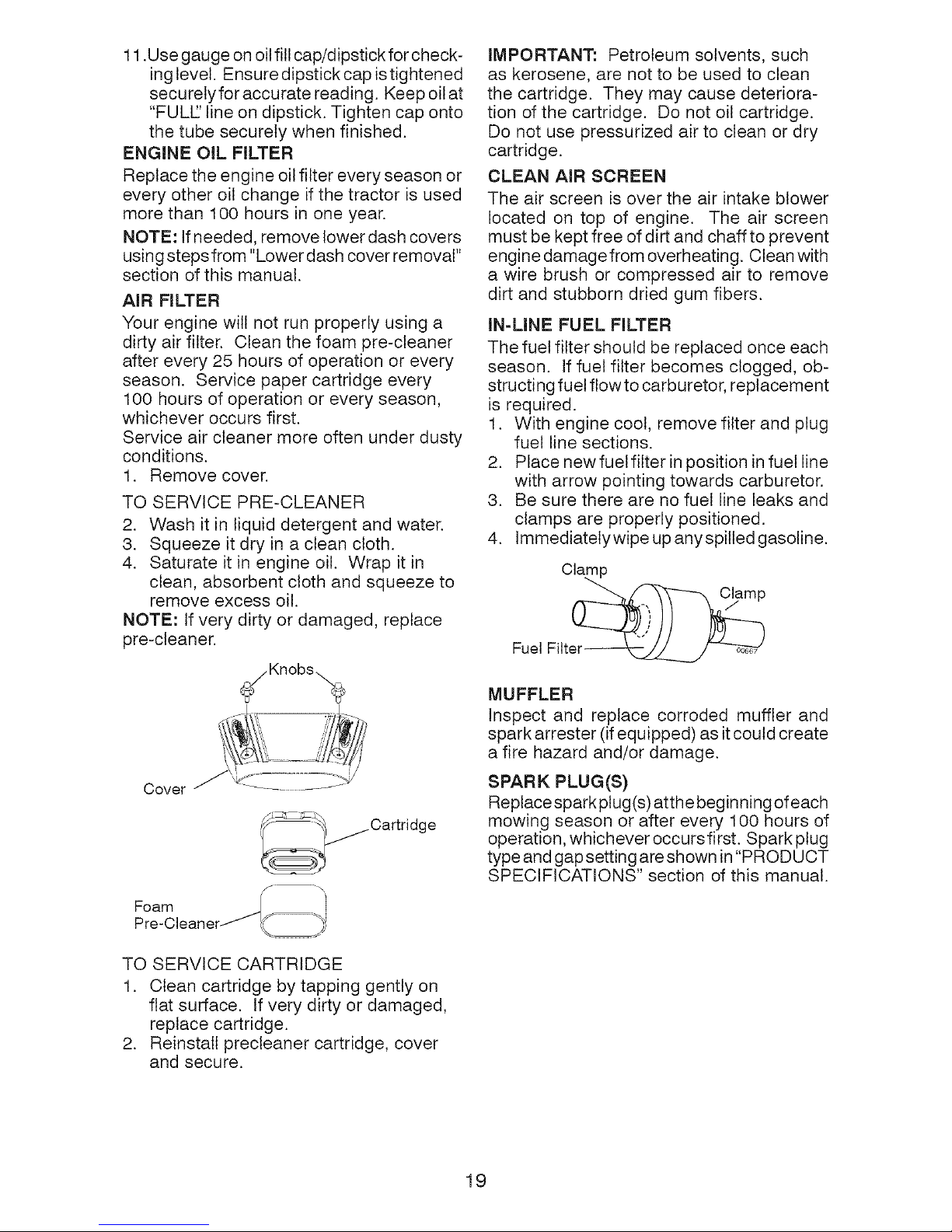

Only use high quality detergent oil rated with

API service classification SG-SL. Selectthe

oil's SAE viscosity grade according to your

expected operating temperature.

SAE VISCOSITY GRADES

c -30 _20 qo 0 10 20 3o 40

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oils (5W30,

10W30 etc.) improve starting in cold weather,

they will result in increased oil consumption

when used above 32°F/0°C. Check your

engine oil level more frequently to avoid

possible engine damage from running low

on oil.

Change the oil after every 50 hours of

operation or at least once ayear if the tractor

is not used for 50 hours in one year.

Checkthe crankcase oil level before starting

the engine and after each eight (8) hours

of operation. Tighten oil fill cap/dipstick

securely each time you check the oil level.

TO CHANGE ENGINE OiL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

Ensure tractor is on level surface.

Oil will drain more freely when warm.

Catch oil in a suitable container.

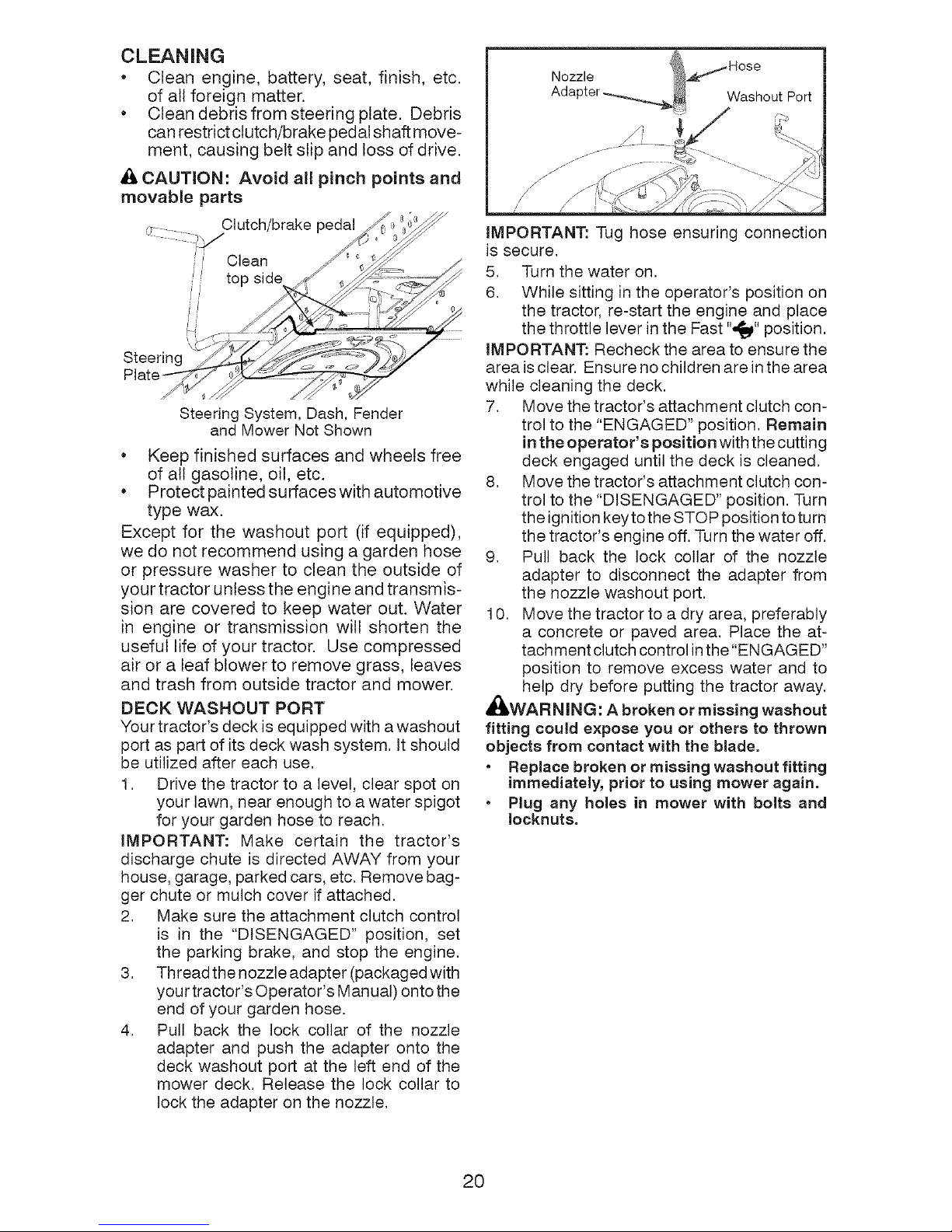

LOWER DASH COVER REMOVAL

1. Raise hood.

2. Remove fastener from lower dash cover.

CAUTION: Remove lower dash cover care-

fully to ensure cover tabs are not broken.

3. Slide lower dash cover up to release

cover tabs from tapered slots in lower

dash and remove.

Lower Dash

4. Remove oil fill cap/dipstick. Be careful

notto allow dirt to enter the engine when

changing oil.

5. Remove yellow cap from end of drain

valve and install the drain tube onto the

fitting.

6. Unlock drain valve by pushing inward

and turning counterclockwise.

7. To open, putt out on the drain valve.

Oil DrainValve

Closed

tondcked __ _ Drain

Position__ Tube

Yellow Cap_

8. After oilhas drained completely, close and

lock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked position as shown.

9. Removethe drain tube and replacethe cap

onto tothe bottom fitting of the drain valve.

10. Refill engine with oilthrough oil fill dipstick

tube. Pour slowly. Do not overfill. For

approximate capacity see "PRODUCT

SPECIFICATIONS"section ofthis manual.

18

Page 19

11.Use gauge on oilfill cap/dipstick for check-

ing level. Ensure dipstick cap istightened

securely for accurate reading. Keep oil at

"FULL' line on dipstick. Tighten cap onto

the tube securely when finished.

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the tractor is used

more than 100 hours in one year.

NOTE: Ifneeded, remove lower dash covers

using steps from "Lower dash cover removal"

section of this manual.

AIR FILTER

Your engine will not run properly using a

dirty air filter. Clean the foam pre-cleaner

after every 25 hours of operation or every

season. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

1. Remove cover.

TO SERVICE PRE-CLEANER

2. Wash it in liquid detergent and water.

3. Squeeze it dry in a clean cloth.

4. Saturate it in engine oil. Wrap it in

clean, absorbent cloth and squeeze to

remove excess oil.

NOTE: If very dirty or damaged, replace

pre-cleaner.

d Kn°bs"-,_b

Cover j _7_- 2 ---_IW

l_Cartridg e

f----\

Foam r i

Pre-Cleaner_l<

TO SERVICE CARTRIDGE

1. Clean cartridge by tapping gently on

flat surface. If very dirty or damaged,

replace cartridge.

2. Reinstall precleaner cartridge, cover

and secure.

IMPORTANT: Petroleum solvents, such

as kerosene, are not to be used to clean

the cartridge. They may cause deteriora-

tion of the cartridge. Do not oil cartridge.

Do not use pressurized air to clean or dry

cartridge.

CLEAN AIR SCREEN

The air screen is over the air intake blower

located on top of engine. The air screen

must be kept free of dirt and chaff to prevent

engine damage from overheating. Clean with

a wire brush or compressed air to remove

dirt and stubborn dried gum fibers.

IN=LINE FUEL FILTER

The fuel filter should be replaced once each

season. If fuel filter becomes clogged, ob-

structing fuel flow to carburetor, replacement

is required.

1. With engine cool, remove filter and plug

fuel line sections.

2. Place new fuetfilter in position in fuel line

with arrow pointing towards carburetor.

3. Be sure there are no fuel line leaks and

clamps are properly positioned.

4. Immediatetywipe up anyspilled gasoline.

Clamp

Clamp

FuelFilte_

MUFFLER

inspect and replace corroded muffler and

spark arrester (if equipped) as it could create

a fire hazard and/or damage.

SPARK PLUG(S)

Replace spark plug(s) atthe beginning ofeach

mowing season or after every 100 hours of

operation, whichever occurs first. Spark plug

type and gapsetting are shown in"PROD UCT

SPECIFICATIONS" section of this manual.

19

Page 20

CLEANING

• Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Clean debris from steering plate. Debris

can restrict clutch/brake pedal shaft move-

ment, causing belt slip and loss of drive.

CAUTION: Avoid all pinch points and

movable parts

Steering System, Dash, Fender

and Mower Not Shown

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

• Protectpaintedsurfaceswithautomotive

type wax.

Except for the washout port (if equipped),

we do not recommend using a garden hose

or pressure washer to clean the outside of

your tractor unless the engine and transmis-

sion are covered to keep water out. Water

in engine or transmission will shorten the

useful life of your tractor. Use compressed

air or a leaf blower to remove grass, leaves

and trash from outside tractor and mower.

DECK WASHOUT PORT

Your tractor's deck is equipped with a washout

port as part of its deck wash system. It should

be utilized after each use.

1. Drive the tractor to a level, clear spot on

your lawn, near enough to a water spigot

for your garden hose to reach.

iMPORTANT: Make certain the tractor's

discharge chute is directed AWAY from your

house, garage, parked cars, etc. Remove bag-

ger chute or mulch cover if attached.

2. Make sure the attachment clutch control

is in the "DISENGAGED" position, set

the parking brake, and stop the engine.

3. Thread the nozzle adapter (packaged with

your tractor's Operator's Manual) onto the

end of your garden hose.

4. Pull back the lock collar of the nozzle

adapter and push the adapter onto the

deck washout port at the left end of the

mower deck. Release the lock collar to

lock the adapter on the nozzle.

Nozzle _._ 1_H°se

Adapter._._ @ Washout Port

iMPORTANT: Tug hose ensuring connection

is secure.

5. Turn the water on.

6. While sitting in the operator's position on

the tractor, re-start the engine and place

the throttle lever in the Fast ",_" position.

iMPORTANT: Recheck the area to ensure the

area is clear. Ensure no children are inthe area

while cleaning the deck.

7. Move the tractor's attachment clutch con-

trol to the "ENGAGED" position. Remain

in the operator's position with the cutting

deck engaged until the deck is cleaned.

8. Move the tractor's attachment clutch con-

trol to the "DISENGAGED" position. Turn

the ignition keyto the STOP position to turn

the tractor's engine off. Turn the water off.

9. Pull back the lock collar of the nozzle

adapter to disconnect the adapter from

the nozzle washout port.

10. Move the tractor to a dry area, preferably

a concrete or paved area. Place the at-

tachment clutch control in the "ENGAGED"

position to remove excess water and to

help dry before putting the tractor away.

Aid.WARNING: A broken or missing washout

fitting could expose you or others to thrown

objects from contact with the blade.

Replace broken or missing washout fitting

immediately, prior to using mower again.

Plug any holes in mower with bolts and

Ioeknuts,

20

Page 21

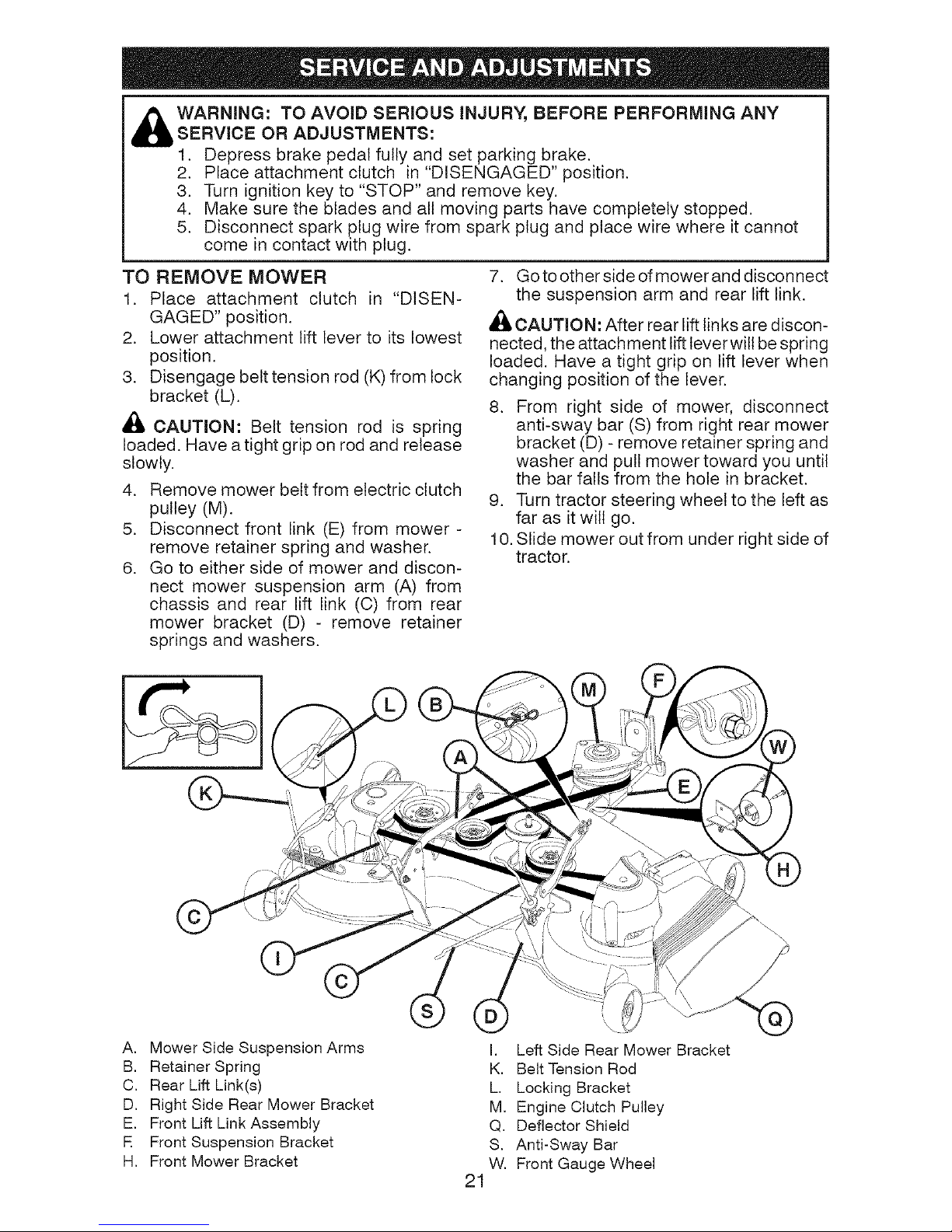

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

1. Depress brake pedal fully and set parking brake.

2. Place attachment clutch in "DISENGAGED" position.

3. Turn ignition key to "STOP" and remove key.

4. Make sure the blades and all moving parts have completely stopped.

5. Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug.

TO REMOVE MOWER

1. Place attachment clutch in "DISEN-

GAGED" position.

2. Lower attachment lift lever to its lowest

position.

3. Disengage betttension rod (K) from lock

bracket (L).

CAUTION: Belt tension rod is spring

loaded. Have a tight grip on rod and release

slowly.

4. Remove mower belt from electric clutch

pulley (M).

5. Disconnect front link (E) from mower -

remove retainer spring and washer.

6. Go to either side of mower and discon-

nect mower suspension arm (A) from

chassis and rear lift link (C) from rear

mower bracket (D) - remove retainer

springs and washers.

7. Gotootherside ofmowerand disconnect

the suspension arm and rear lift link.

CAUTION: After rear lift links are discon-

nected, the attachment lift lever will be spring

loaded. Have a tight grip on lift lever when

changing position of the lever.

8. From right side of mower, disconnect

anti-sway bar (S) from right rear mower

bracket (D) - remove retainer spring and

washer and pull mower toward you until

the bar falls from the hole in bracket.

9. Turn tractor steering wheel to the left as

far as it will go.

10. Slide mower out from under right side of

tractor.

A. Mower Side Suspension Arms

B. Retainer Spring

C. Rear Lift Link(s)

D. Right Side Rear Mower Bracket

E. Front Lift Link Assembly

R Front Suspension Bracket

H. Front Mower Bracket

I. Left Side Rear Mower Bracket

K. BeltTensionRod

L. Locking Bracket

M. Engine Clutch Pulley

Q. Deflector Shield

S. Anti-Sway Bar

W. FrontGauge Wheel

21

Page 22

TO INSTALL MOWER

1.

®

®

SET PARKING BRAKE LEVER AND

LOWER ATTACHMENT LIFT LEVER

Depress clutch/brake pedal alt the way

down and hold.

Pull parking brake lever up and hold,

release pressure from clutch/brake

pedal, then release parking brake lever.

Pedal should remain in brake position.

Ensure parking brake will hold tractor

secure.

Brake Lever

_CAUTION" Lift lever is spring loaded.

Have a tight grip on lift lever, lower it slowly

and engage in lowest position. Lift lever is

located on left side of fender.

Lift

Lever

3. TURN STEERING WHEEL LEFT AND

POSITION MOWER

Turn steering wheel to the left as far as it

will go and position mower on right side of

tractor with deflector shield (Q)tothe right.

Front

______Engine ?

_.j_ _ Transaxle

Q. Deflector Shield

4. SLIDE MOWER UNDER TRACTOR

* Bring beltforward and check belt for pro-

per routing in all mower pulley grooves.

NOTE: Be sure mower side suspension

arms (A) are pointing forward before sliding

mower under tractor.

. Slide mower under tractor until it is

centered under tractor.

2. ASSEMBLE FRONT GAUGE WHEEL

(W) TO FRONT OF MOWER

A. Mower Side Suspension Arms

Q. Deflector Shield

H. Front Mower Bracket

W. Front Gauge Wheel

X. Shoulder Bolt

Y. 1-1/40.D. Washer

Z. 3/8-16 Locknut

22

Page 23

5. INSTALL ANTI-SWAY BAR (S)

(IF EQUIPPED)

ANTI-SWAY BAR (S)

,_ Towards Towards

Transaxle Mower Deck

90° End integrated Washer End

From right side of mower, first insert

90° end of anti-sway bar (S) into hole in

transaxle bracket (T), located near left

rear tire in front of transaxle.

NOTE: Flashlight may be helpful.

Transaxle Bracket (T)

Located Between Rear Tires

NOTE: Depending on model, bracket (T)may

bedifferent than shown but hotefor anti-sway

bar will be in same position/location.

Pivot the integrated washer end of anti-

sway bar (S)towards mower deck bracket

on right side of mower. Insert integrated

washer end of bar into hole in rear mower

bracket (D). Move mower as needed to

insert integrated washer end of bar into

rear mower bracket (D).

Secure with small washer and small

retainer spring as shown.

D. Right Side Rear Mower Bracket

S. Anti-Sway Bar

T. Transaxle Bracket

6. ATTACH MOWER SIDE SUSPENSION

ARMS (A) TO CHASSIS

Position front hote inside suspension arm

(A) over pin on outside of tractor chassis

and secure with large washer and large

retainer spring (B).

Repeat on opposite side of tractor.

A. Mower Side Suspension Arms

B. Retainer Spring

D. Right Side Rear Mower Bracket

7. ATTACH REAR LIFT LINKS (C)

Insert rod end of rear lift link (C) into hole

(U) in tractor lift shaft suspension arm

and pivot link down to mower.

Lift rear corner ofmower and position slot

in link assembly over pin on rear mower

bracket (D) and secure with large washer

and large retainer spring.

Repeat on opposite side of tractor.

23

Page 24

C. Rear Lift Link(s)

D. Right Side Rear Mower Bracket

'U. Hole

8 ATTACH FRONT LINK (E)

Turn steering wheel to position wheels

straight forward.

From front of tractor, insert rod end of

front link (E) through front hole in tractor

front suspension bracket (F).

Move to left side of mower and and insert

large retainer spring (G) through hole in

front link (E) behind front suspension

bracket (F).

Insert other end of link (E) into hole in

front mower bracket (H) and secure with

washer and small retainer spring (J).

NOTE: Requires deck lifting.

Front Link ..........'

Location .............................

9 INSTALL BELT ON ENGINE CLUTCH

PULLEY (M)

Disengage belt tension rod (K) from

locking bracket (L).

Install belt onto engine clutch pulley (M).

M.Engine

Clutch Pulley

IMPORTANT: Check belt for proper routing

in all mower pulley grooves and under

mandrel covers.

* Engage belt tension rod (K) on locking

bracket (L).

_CAUTION: Belt tension rod is spring

loaded. Have atight grip on rod and engage

slowly.

* Raise attachment lift lever to highest

position.

* If necessary, adjust gauge wheels

before operating mower as shown in the

Operation section of this manual.

MOWER DRIVE BELT iNSTALLATiON

Follow procedure described in "TO

REPLACE MOWER BLADE DRIVE BELT"

in this section of this manual.

]. Front Lift Link Assembly

F. Front Suspension Bracket

G. Large Retainer Spring

H. Front Mower Bracket

J. Small Retainer Spring

M. Engine Clutch Pulley

24

Page 25

TO LEVEL MOWER

Ensure tires are properly inflated to the PSi

shown on tires. If tires are over or under

inflated, it may affect the appearance of your

lawn and lead you to think the mower is not

adjusted properly.

VISUAL SIDE-TO-SIDE ADJUSTMENT

1. With all tires properly inflated and if your

lawn appears unevenly cut, determine

which side of mower is cutting lower.

NOTE: As desired, you can raise the low

side of mower or lower the high side.

2. Go to side of mower you wish to adjust.

3. With a 3/4" or adjustable wrench, turn

lift link adjustment nut (A) to the left to

lower the mower, or, to the right to raise

the mower.

5. Recheck measurements; adjust if neces-

sary until both sides are equal.

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-

to-side.

To obtain the best cutting results, the mower

blades should be adjusted so the front tip

is 1/8 to 1/2" (3,1 to 12,7 mm) (lower than

the rear tip when the mower is in its highest

position.

,_CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

• Raise mower to highest position.

• Position any blade so the tip is pointing

straight forward. Measure distance "B" to

the ground at front and rear tip of blade.

Turnnut Turnnut

rightto left to

raise .... lower

mower mower

NOTE: Each full turn of adjustment nut will

change mower height about 3/16" (4,7 mm).

4. Test your adjustment by mowing some

uncut grass and visually checking the

appearance. Readjust, ifnecessary, until

you are satisfied with the results.

PRECISION SIDE-TO-SIDE ADJUSTMENT

1. With alttires properlyinflated, parktractor

on level ground or driveway.

,_CAUTION: Blades are sharp. Protect

your hands with gloves and/or wrap blade

with heavy cloth.

2. Raise mower to its highest position.

3. At both sides of mower, position blade

at side and measure distance "A" from

bottom edge of blade to ground. The dis-

tance should be the same on both sides.

4. If adjustment is necessary, see steps in

Visual Adjustment instructions above.

..............................................IA

• If front tip of blade is not 1/8 to 1/2" (3,1

to 12,7 mm) lower than the rear tip, go to

the front of tractor.

• With an 11/16" or adjustable wrench,

loosen jam nut "A" several turns to clear

adjustment nut "B".

• With a 3/4" or adjustable wrench, turn

front link adjustment nut "B" clockwise (y-_)

(tighten) to raise the front of mower, or,

counterclockwise (_-,) (loosen) to lower

the front mower.

Tighten adjust Loosen adjust

nut "B" to nut "B" to

raise mower ..../ z lower mower

Loosen jam nut "A" first

NOTE: Each full turn of adjustment nut will

change mower height about 1/8" (3,1 mm).

• Recheck measurements, adjust if neces-

sary until front tip of blade is 1/8 to 1/2"

(3,1 to 12,7 mm) lower than the rear tip.

• Hold adjustment nut in position with

wrench and tighten jam nut securely

against adjustment nut.

25

Page 26

TO REPLACE MOWER BLADE DRIVE

BELT

MOWER DRIVE BELT REMOVAL

1. Park tractor on a level surface. Engage

parking brake.

2. Lower attachment lift lever to its lowest

position.

3. Disengage belt tension rod (K) from lock

bracket (L).

CAUTION: Belt tension rod is spring

loaded. Have a firm grip on rod and release

slowly.

4. Remove screws (P) from R.H. and L.H.

mandrel covers and remove covers (Q).

5. Remove any dirt or grass clippings which

may have accumulated around mandrels

and entire upper deck surface.

6. Remove belt from electric clutch pulley

(M), both mandrel pulleys (R) and all idler

pulleys (V).

MOWER DRIVE BELT INSTALLATION

1. Install belt around both mandrel pulleys

(R)and around idler pulleys (V)as shown.

2. Install belt onto electric clutch pulley (M).

IMPORTANT: Check belt for proper routing

in all mower pulley grooves.

3. Reassemble R.H. and LH. mandrel cov-

ers (Q). Securely tighten all screws.

4. Engage belt tension rod (K) on locking

bracket (L).

CAUTION: Belt tension rod is spring

loaded. Have atight grip on rod and engage

slowly.

5. Raise attachment lift lever to highest

position.

BELT REMOVAL -

1. Remove mower (See "TO REMOVE

MOWER" in this section of manual).

NOTE: Observe entire motion drive belt

and position of all belt guides and keepers.

2. Remove bettfrom stationary idler (A)and

clutching idler (B).

3. Remove belt from centerspan idler (C).

6. Pull belt slack toward rear of tractor.

Carefully remove belt upwards from

transmission input pulley and over cool-

ing fan blades (D).

4. Remove belt downward from engine

pulley (E).

5. Slide belt toward rear of tractor, off the

steering plate (F) and remove from tractor.

BELT INSTALLATION -

1. Install new belt from tractor rear to front,

over the steering plate (F) and above

clutch brake pedal shaft (G).

2. Pull belt toward front of tractor and roll

belt onto engine pulley (E).

3. Pull belt toward rear of tractor. Carefully

work belt down around transmission

cooling fan and onto the input pulley (D).

Be sure belt is inside the belt keeper.

4. Install belt on centerspan idler (C).

5. Install belt through stationary idler (A)

and clutching idler (B).

6. Make sure belt is in all pulley grooves

and inside all belt guides and keepers.

7. Install mower (See "TO INSTALL MOW-

ER" in this section of manual).

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parking brake. For assistance, there is a

belt installation guide decal on bottom side

of left footrest.

26

Page 27

TO CHECK BRAKE

Iftractor requires more than five (5) feet (1,5

m) to stop at highest speed in highest gear

on a level, dry concrete or paved surface,

then brake must be serviced.

You may also check brake by:

1. Park tractor on a level, dry concrete or

paved surface, depress brake pedal all

the way down and engage parking brake.