Craftsman 900277303 Owner’s Manual

Operator's Manual

CRAFrSMAN

PLATE JOINER

Model No.

900.277303

CAUTION: Read and follow all

Safety Rules and Operating

Instructions before First Use

of this Product

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Form No 631088-00 AUG05

• Safety

• Operation

• Maintenance

• Parts List

• Espahol pg. 14

ONEYEAR FULL WARRANTY ON CRAFTSMAN PROFESSIONAL TOOL

If this Craftsman Professional tool fails to give complete satisfaction within one

year from the date of purchase, RETURN IT TO ANY SEARS STORE OR PARTS

& REPAIR CENTER OR OTHER CRAFTSMAN OUTLET IN THE UNITED STATES

FOR FREE REPAIR.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

IMPORTANT SAFETY

INSTRUCTIONS

AWARNING: When using electric tools,

basic safety precautions should always be

followed to reduce risk of fire, electric

shock, and personal injury, including the

following:

READ ALL

INSTRUCTIONS

DOUBLE INSULATION

Double insulated tools are constructed

throughout with two separate layers of

electrical insulation or one double thickness

of insulation between you and the tool's

electrical system. Tools built with this

insulation system are not intended to be

grounded. As a result, your tool is equipped

with a two prong plug which permits you to

use extension cords without concern for

maintaining a ground connection.

NOTE: Double insulation does not take

the place of normal safety precautions

when operating this tool. The insulation

system is for added protection against

injury resulting from a possible electrical

insulation failure within the tool.

ACAUTION: WHEN SERVICING USE

ONLY IDENTICAL REPLACEMENT

PARTS. Repair or replace damaged cords.

POLARIZED PLUGS

Polarized plugs (one blade is wider than

the other) are used on equipment to

reduce the risk of electric shock. When

provided, this plug will fit into a polarized

outlet only one way. If the plug does not fit

fully into the outlet, reverse the plug. If it

still does not fit, contact a qualified

electrician to install the proper outlet. Do

not change the plug in any way.

• KEEP WORK AREA CLEAN. Cluttered

areas and benches invite injuries.

• CONSIDER WORKAREA ENVIRON-

MENT. Don't expose power tools to rain.

Don't use power tools in damp or wet

locations. Keep work area well lit. Do not

use tool in presence of flammable liquids

or gases.

• GUARD AGAINST ELECTRIC SHOCK.

Prevent body contact with grounded

surfaces. For example; pipes, radiators,

ranges, and refrigerator enclosures.

• KEEP CHILDREN AWAY. Do not let

visitors contact tool or extension cord. All

visitors should be kept away from work

area.

• STORE IDLE TOOLS. When not in use,

tools should be stored in dry, and high or

locked-up place - out of reach of

children.

• DON'T FORCE TOOL. It will do the job

better and safer at the rate for which it

was intended.

• USE RIGHT TOOL. Don't force small

tool or attachment to do the job of a

heavy-duty tool. Don't use tool for

purpose not intended.

• DRESS PROPERLY. Do not wear loose

clothing or jewelry. They can be caught

in moving parts. Rubber gloves and non-

skid footwear are recommended when

working outdoors. Wear protective hair

covering to contain long hair. Air vents

often cover moving parts and should

also be avoided.

• USE SAFETY GLASSES. Also use face

or dust mask if operation is dusty.

• DON'T ABUSE CORD. Never carry tool

by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil, and

sharp edges.

• SECUREWORK.Useclampsora

visetoholdworkIt'ssaferthanusing

yourhandanditfreesbothhandsto

operatetool

• DON'TOVERREACH.Keepproper

footingandbalanceatalltimes

• MAINTAINTOOLSWITHCARE.Keep

toolssharpandcleanforbetterand

saferperformanceFollowinstructions

forlubricatingandchangingaccessories

Inspecttoolcordsperiodicallyandif

damaged,haverepairedbyauthorized

servicefacilityInspectextensioncords

periodicallyandreplaceifdamaged

Keephandlesdry,clean,andfreefrom

oilandgrease

• DISCONNECTORLOCKOFFTOOLS

whennotinuse,beforeservicing,and

whenchangingaccessories,suchas

blades,bits,cutters

• REMOVEADJUSTINGKEYSAND

WRENCHES.Formhabitofchecking

toseethatkeysandadjusting

wrenchesareremovedfromtool

beforeturningiton

• AVOIDUNINTENTIONALSTARTING.

Don'tcarrytoolwithfingeronswitchBe

sureswitchisoffwhenpluggingin

• EXTENSIONCORDS.Makesureyour

extensioncordisingoodcondition

Whenusinganextensioncord,besure

touseoneheavyenoughtocarrythe

currentyourproductwilldrawAnunder-

sizedcordwillcauseadropinlinevol-

tageresultinginlossofpowerand

overheatingThefollowingtableshows

thecorrectsizetousedependingon

cordlengthandnameplateampere

ratingIfindoubt,usethenextheavier

gageThesmallerthegagenumber,the

heavierthecord

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0- 6 18 16 16 14

6- 10 18 16 14 12

10 -12 16 16 14 12

12 -16 14 12 Not Recommended

• OUTDOOR USE EXTENSION CORDS.

When tool is used outdoors, use only

extension cords intended for use

outdoors and so marked

• STAY ALERT. Watch what you are

doing Use common sense Do not

operate tool when you are tired

• CHECK DAMAGED PARTS. Before

further use of the tool, a guard or other

part that is damaged should be carefully

checked to determine that it will operate

properly and perform its intended

function Check for alignment of moving

parts, binding of moving parts, breakage

of parts, mounting, and any other

conditions that may affect its operation

A guard or other part that is damaged

should be properly repaired or replaced

by an authorized service center unless

otherwise indicated elsewhere in this

instruction manual Have defective

switches replaced by authorized service

center Do not use tool if switch does not

turn it on and off

ADDITIONAL SAFETY INSTRUCTIONS

_,CAUTION: Wear appropriate personal

hearing protection during use Under some

conditions and duration of use, noise from

this product may contribute to hearing loss

_WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects or other

reproductive harm Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber (CCA)

Your risk from these exposures varies,

depending on how often you do this type of

work To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles

• Avoid prolonged contact with dust

from power sanding, sawing,

grinding, drilling, and other

construction activities. Wear

protective clothing and wash

exposed areas with soap and water.

Allowing dust to get into your mouth,

eyes, or lay on the skin may promote

absorption of harmful chemicals.

_WARNING: Use of this tool can generate

and/or disburse dust, which may cause

serious and permanent respiratory or other

injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the

dust exposure. Direct particles away from

face and body.

SAVE THESE

INSTRUCTIONS

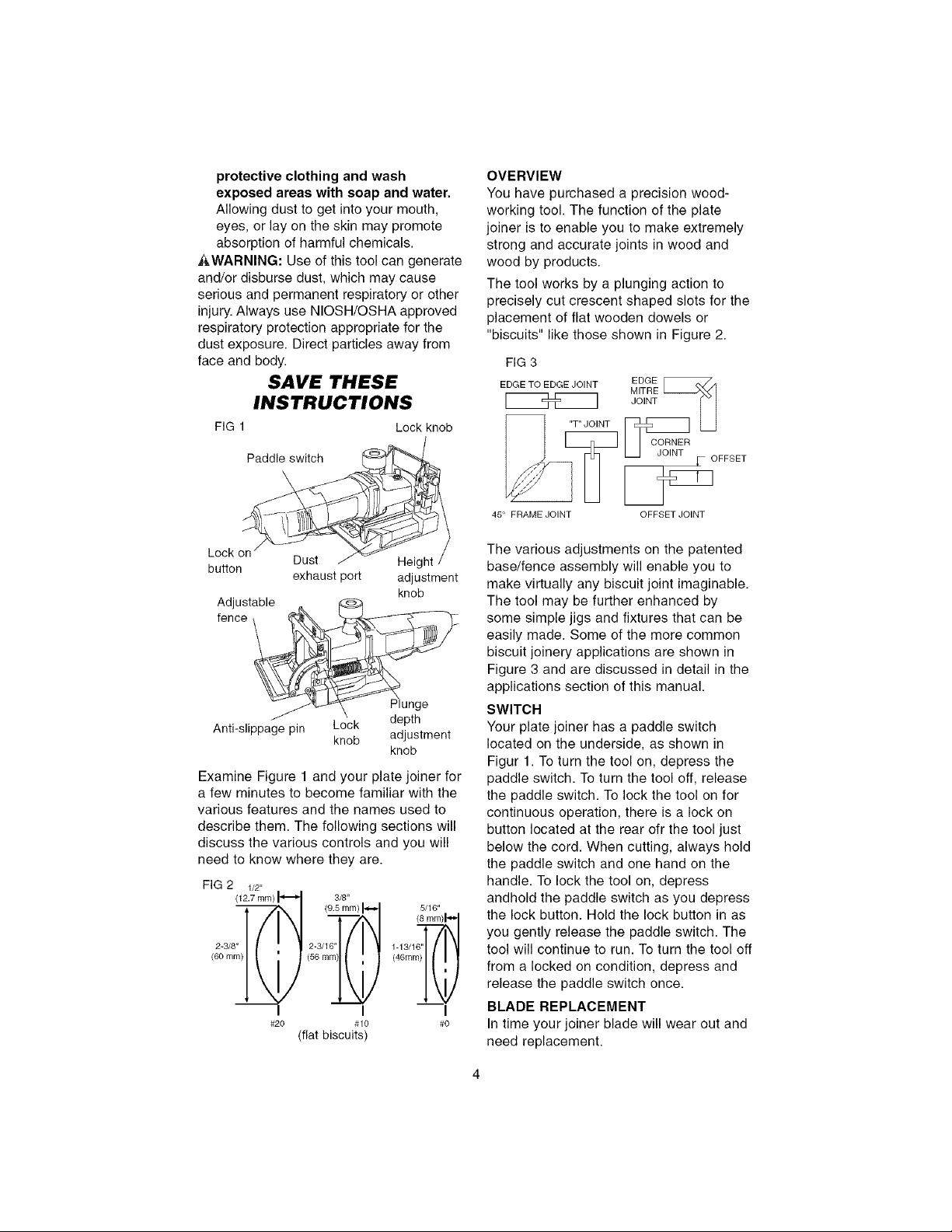

FIG 1 Lock knob

Paddle switch

\

OVERVIEW

You have purchased a precision wood-

working tool. The function of the plate

joiner is to enable you to make extremely

strong and accurate joints in wood and

wood by products.

The tool works by a plunging action to

precisely cut crescent shaped slots for the

placement of flat wooden dowels or

"biscuits" like those shown in Figure 2.

FIG3

EDGE TO EDGE JOINT EDGE [_A

__ _ OFFSET

45' FRAME JOINT OFFSET JOINT

Lock on

button

Adjustable

fence _

Anti-slippage pin Lock

Dust Height

exhaust port adjustment

knob

knob

Plunge

depth

adjustment

knob

Examine Figure 1 and your plate joiner for

a few minutes to become familiar with the

various features and the names used to

describe them. The following sections will

discuss the various controls and you will

need to know where they are.

FIG2 1/2.

3/8"

(9.5 mm)_ 5/16'

2-3/8" 2-3/16" 1-13/16"

(60 mm) (56 m_)_ (48mm6)"1 _

I I I

#20 #10 #0

(flat biscuits)

The various adjustments on the patented

base/fence assembly will enable you to

make virtually any biscuit joint imaginable.

The tool may be further enhanced by

some simple jigs and fixtures that can be

easily made. Some of the more common

biscuit joinery applications are shown in

Figure 3 and are discussed in detail in the

applications section of this manual.

SWITCH

Your plate joiner has a paddle switch

located on the underside, as shown in

Figur 1. To turn the tool on, depress the

paddle switch. To turn the tool off, release

the paddle switch. To lock the tool on for

continuous operation, there is a lock on

button located at the rear ofr the tool just

below the cord. When cutting, always hold

the paddle switch and one hand on the

handle. To lock the tool on, depress

andhold the paddle switch as you depress

the lock button. Hold the lock button in as

you gently release the paddle switch. The

tool will continue to run. To turn the tool off

from a locked on condition, depress and

release the paddle switch once.

BLADE REPLACEMENT

In time your joiner blade will wear out and

need replacement.

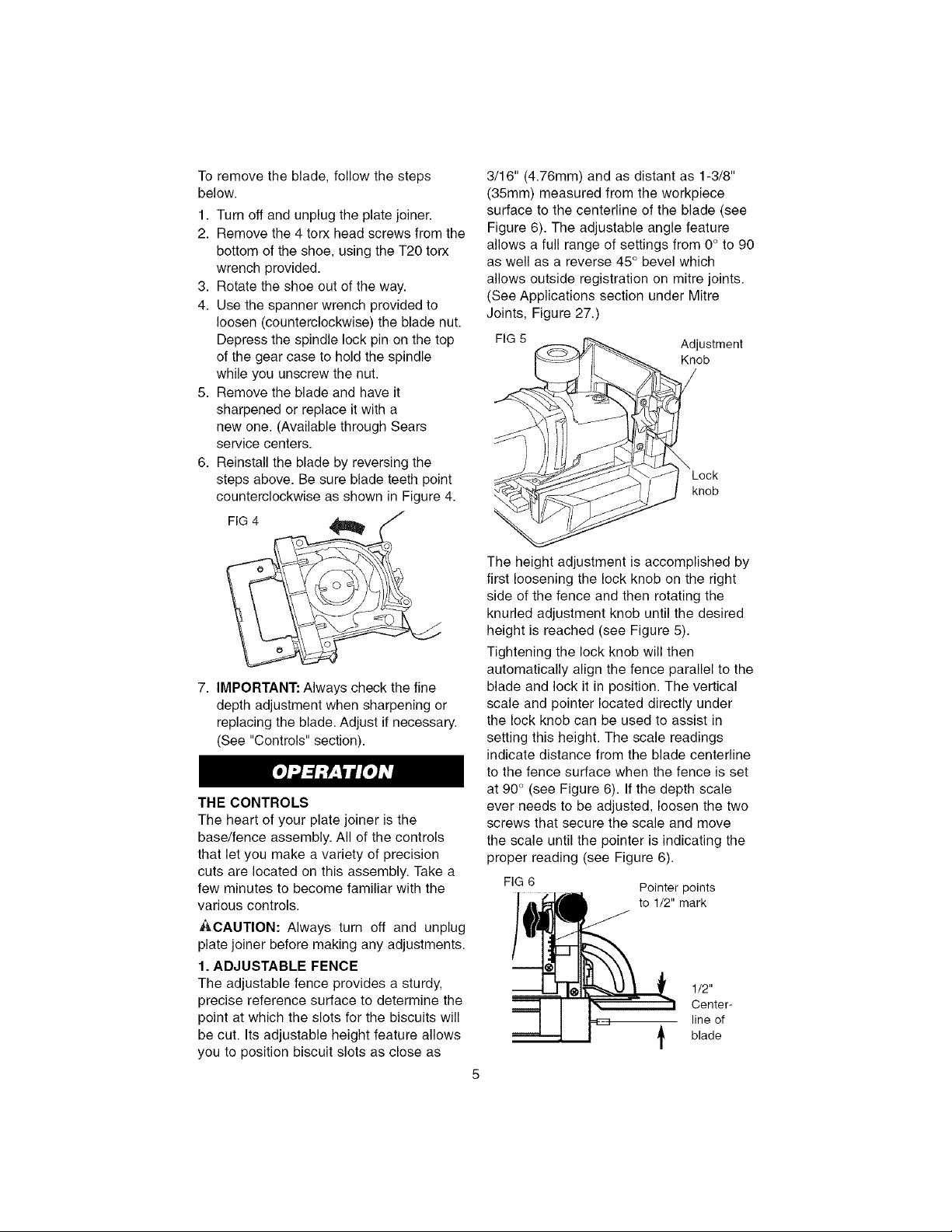

Toremovetheblade,followthesteps

below.

1.Turnoffandunplugtheplatejoiner.

2.Removethe4torxheadscrewsfromthe

bottomoftheshoe,usingtheT20torx

wrenchprovided.

3.Rotatetheshoeoutoftheway.

4.Usethespannerwrenchprovidedto

loosen(counterclockwise)thebladenut.

Depressthespindlelockpinonthetop

ofthegearcasetoholdthespindle

whileyouunscrewthenut.

5.Removethebladeandhaveit

sharpenedorreplaceitwitha

newone.(AvailablethroughSears

servicecenters.

6.Reinstallthebladebyreversingthe

stepsabove.Besurebladeteethpoint

counterclockwiseasshowninFigure4.

F,G4

7. IMPORTANT: Always check the fine

depth adjustment when sharpening or

replacing the blade. Adjust if necessary.

(See "Controls" section).

THE CONTROLS

The heart of your plate joiner is the

base/fence assembly. All of the controls

that let you make a variety of precision

cuts are located on this assembly. Take a

few minutes to become familiar with the

various controls.

ACAUTION: Always turn off and unplug

plate joiner before making any adjustments.

1. ADJUSTABLE FENCE

The adjustable fence provides a sturdy,

precise reference surface to determine the

point at which the slots for the biscuits will

be cut. Its adjustable height feature allows

you to position biscuit slots as close as

3/16" (4.76mm) and as distant as 1-3/8"

(35ram) measured from the workpiece

surface to the centerline of the blade (see

Figure 6). The adjustable angle feature

allows a full range of settings from 0° to 90

as well as a reverse 45° bevel which

allows outside registration on mitre joints.

(See Applications section under Mitre

Joints, Figure 27.)

FIG 5

The height adjustment is accomplished by

first loosening the lock knob on the right

side of the fence and then rotating the

knurled adjustment knob until the desired

height is reached (see Figure 5).

Tightening the lock knob will then

automatically align the fence parallel to the

blade and lock it in position. The vertical

scale and pointer located directly under

the lock knob can be used to assist in

setting this height. The scale readings

indicate distance from the blade centerline

to the fence surface when the fence is set

at 90° (see Figure 6). Ifthe depth scale

ever needs to be adjusted, loosen the two

screws that secure the scale and move

the scale until the pointer is indicating the

proper reading (see Figure 6).

FIG6 Pointerpoints

Adjustment

Knob

knob

to 1/2" mark

1/2"

line of

Center-

_. blade

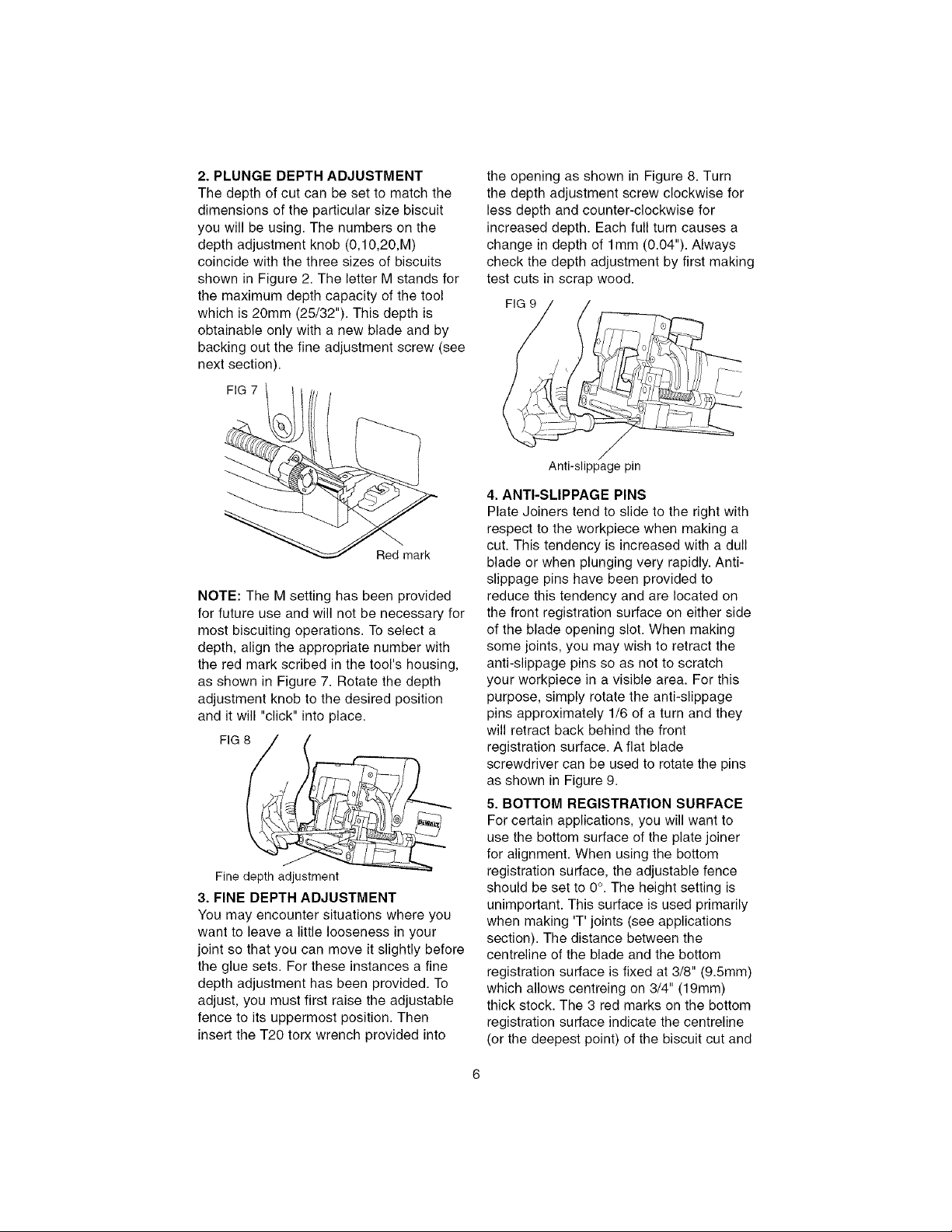

2. PLUNGE DEPTH ADJUSTMENT

The depth of cut can be set to match the

dimensions of the particular size biscuit

you will be using. The numbers on the

depth adjustment knob (0,10,20,M)

coincide with the three sizes of biscuits

shown in Figure 2. The letter M stands for

the maximum depth capacity of the tool

which is 20ram (25/32"). This depth is

obtainable only with a new blade and by

backing out the fine adjustment screw (see

next section).

F' 7\/

Red mark

NOTE: The M setting has been provided

for future use and will not be necessary for

most biscuiting operations. To select a

depth, align the appropriate number with

the red mark scribed in the tool's housing,

as shown in Figure 7. Rotate the depth

adjustment knob to the desired position

and it will "click" into place.

FIG

Fine depth adjustment

3. FINE DEPTH ADJUSTMENT

You may encounter situations where you

want to leave a little looseness in your

joint so that you can move it slightly before

the glue sets. For these instances a fine

depth adjustment has been provided. To

adjust, you must first raise the adjustable

fence to its uppermost position. Then

insert the T20 torx wrench provided into

the opening as shown in Figure 8. Turn

the depth adjustment screw clockwise for

less depth and counter-clockwise for

increased depth. Each full turn causes a

change in depth of lmm (0.04"). Always

check the depth adjustment by first making

test cuts in scrap wood.

FIG9

/

Antkslippage pin

4. ANTI-SLIPPAGE PINS

Plate Joiners tend to slide to the right with

respect to the workpiece when making a

cut. This tendency is increased with a dull

blade or when plunging very rapidly. Anti-

slippage pins have been provided to

reduce this tendency and are located on

the front registration surface on either side

of the blade opening slot. When making

some joints, you may wish to retract the

anti-slippage pins so as not to scratch

your workpiece in a visible area. For this

purpose, simply rotate the anti-slippage

pins approximately 1/6 of a turn and they

will retract back behind the front

registration surface. A flat blade

screwdriver can be used to rotate the pins

as shown in Figure 9.

5. BOTTOM REGISTRATION SURFACE

For certain applications, you will want to

use the bottom surface of the plate joiner

for alignment. When using the bottom

registration surface, the adjustable fence

should be set to 0°. The height setting is

unimportant. This surface is used primarily

when making 'T' joints (see applications

section). The distance between the

centreline of the blade and the bottom

registration surface is fixed at 3/8" (9.5ram)

which allows centreing on 3/4" (19mm)

thick stock. The 3 red marks on the bottom

registration surface indicate the centreline

(or the deepest point) of the biscuit cut and

theapproximatewidthofa#20biscuitso

thatyou'llknowwheretheedgeofthe

bladeisandcanpreventbreakthrough.To

avoidbreakingthroughtheworkpiece,

aligntheshoesothatneitheroutsidemark

extendsbeyondtheendoftheworkpiece.

Ifeithersidedoes,thereisagoodchance

thatthebladewillbreakthroughthe

surfaceandruinyourwork.

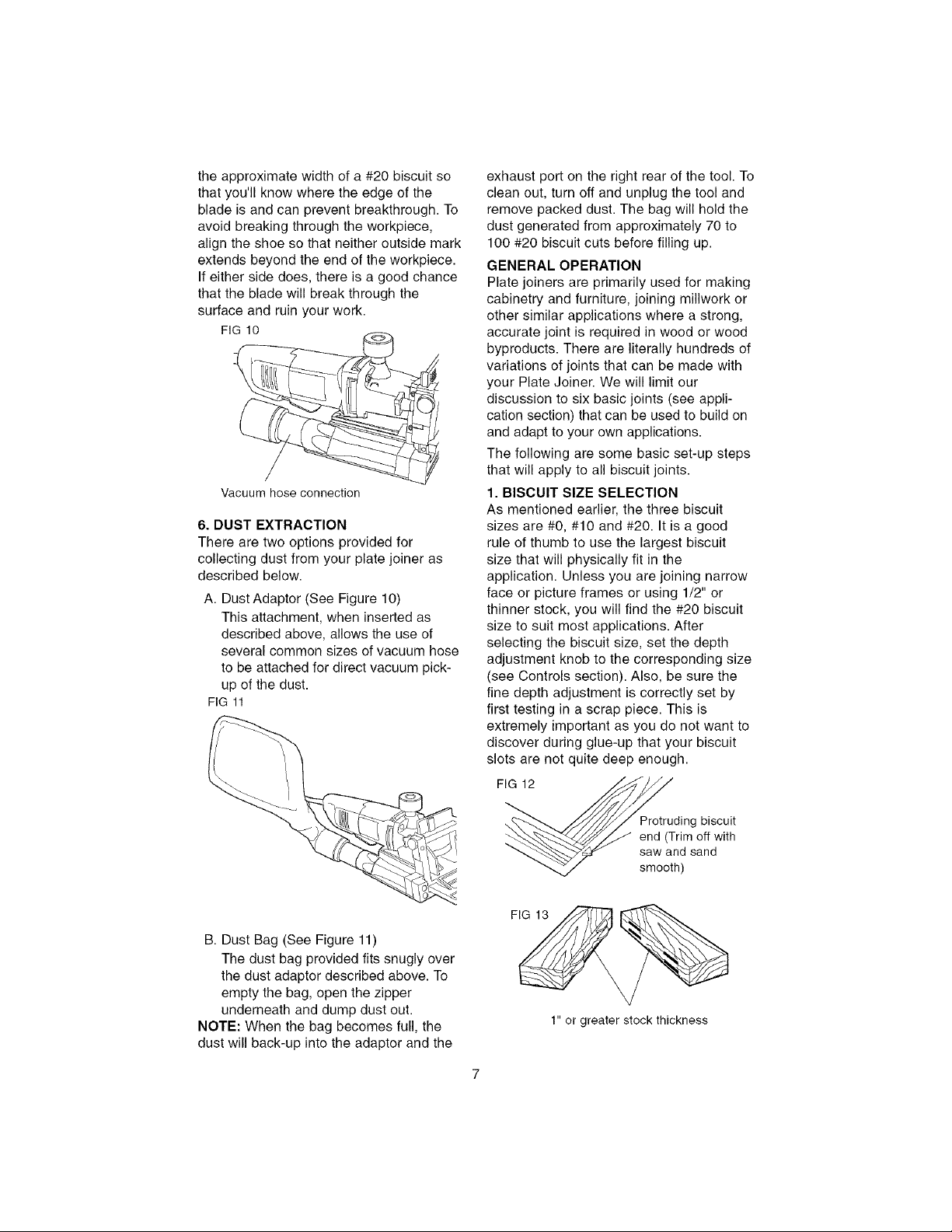

FIG10

Vacuum hose connection

6. DUST EXTRACTION

There are two options provided for

collecting dust from your plate joiner as

described below.

A. Dust Adaptor (See Figure 10)

This attachment, when inserted as

described above, allows the use of

several common sizes of vacuum hose

to be attached for direct vacuum pick-

up of the dust.

FIG 11

exhaust port on the right rear of the tool. To

clean out, turn off and unplug the tool and

remove packed dust. The bag will hold the

dust generated from approximately 70 to

100 #20 biscuit cuts before filling up.

GENERAL OPERATION

Plate joiners are primarily used for making

cabinetry and furniture, joining millwork or

other similar applications where a strong,

accurate joint is required in wood or wood

byproducts. There are literally hundreds of

variations of joints that can be made with

your Plate Joiner. We will limit our

discussion to six basic joints (see appli-

cation section) that can be used to build on

and adapt to your own applications.

The following are some basic set-up steps

that will apply to all biscuit joints.

1. BISCUIT SIZE SELECTION

As mentioned earlier, the three biscuit

sizes are #0, #10 and #20. It is a good

rule of thumb to use the largest biscuit

size that will physically fit in the

application. Unless you are joining narrow

face or picture frames or using 1/2" or

thinner stock, you will find the #20 biscuit

size to suit most applications. After

selecting the biscuit size, set the depth

adjustment knob to the corresponding size

(see Controls section). Also, be sure the

fine depth adjustment is correctly set by

first testing in a scrap piece. This is

extremely important as you do not want to

discover during glue-up that your biscuit

slots are not quite deep enough.

FIG 12

B. Dust Bag (See Figure 11)

The dust bag provided fits snugly over

the dust adaptor described above. To

empty the bag, open the zipper

underneath and dump dust out.

NOTE: When the bag becomes full, the

dust will back-up into the adaptor and the

3rotruding biscuit

end (Trim off with

saw and sand

smooth)

1" or greater stock thickness

2.BISCUITLOCATIONANDLAYOUT

Generally,biscuitsmaybespacedand

locatedatyourdiscretion.Foredgejoints,a

goodruleofthumbistospacebiscuits

every6-10inchesoncentre.Itisfurther

recommendedthatbiscuitsbeplacedso

thatthecentrelineoftheendbiscuitsis

2-3inchesfromtheendoftheworkpiece.

Whenjoiningfaceframesorpictureframes

wheretheworkpieceisnarrow,youmay

havetochoosethesmallerbiscuitsizesto

keepfrom"breakingout"ontheendofthe

joint.Breakingoutshouldbeavoidedif

possible,butifnotyoucanassemblethe

jointandtrimofftheexposedbiscuittipafter

thegluesets(seeFigure12).Whenworking

withmaterialupto1"thick,weadvisetouse

asinglebiscuitlocatedintheapproximate

centreofthematerialthickness.Ifthicker

stockistobejoined,youmaychooseto

use2biscuitsacrossthethicknessfor

greaterstrength(seeFigure13).Biscuit

locationsshouldbemarkedbyfirst

positioningthematingpiecesexactlyas

theyaretobeassembled.

FIG14

Next,makeamarkat90°tothejoint

interfaceacrossbothpiecesatthedesired

biscuitlocations(seeFigure14).See

Applicationsectionformorespecific

informationonjointlayout.Themarksyou

makewillthenbealignedwithoneofthe

centreregistrationmarksonthetool,

again,dependinguponyourspecific

application.

FIG 15

3. MAKING THE CUT

Prior to making any cut, be sure that all

fence adjustments are set and lock knobs

are tight. Also, be sure you have selected

the proper depth setting. Clamp your

workpiece firmly and align the plate joiner's

centre registration mark with your layout

mark. Turn on the tool and let the blade

come up to full speed (approximately 1

second). Grasping the paddle switch and

handle and positioning the fence firmly and

squarely against the workpiece, plunge the

blade until it bottoms against the stop.

Continuing to hold the tool squarely and

firmly, allow the return spring to retract the

blade from the work and then release the

switch to shut the tool off. It will take some

practice to obtain a "feel" for the tool to

produce accurate joints, so practicing in

scrap wood first is advisable.

4. JOINT ASSEMBLY

After your joints are cut, you may wish to

trial fit everything together before gluing.

When you are satisfied with your joints,

evenly spread any good quality wood-

working glue in each slot as well as on

the mating flat surfaces of your joint. Place

biscuits in the slots, assemble the joint

and clamp until dry. For a biscuit joint to

be most effective, it is important that the

biscuits themselves be in contact with the

glue. This is because the biscuits absorb

the moisture in the glue and expand to

form a tight joint.

APPLICATIONS

1. EDGE TO EDGE JOINTS

This is the simplest to make and most

common joint for the plate joiner. Follow

the steps below to produce this joint.

A. Prepare the workpieces and lay them

on a work surface exactly as they are to

be assembled.

B. Spacing biscuits 2-3" in from the ends

and 6-10" apart, lay out the biscuit

centres.

C. Set up the plate joiner by first selecting

the proper depth setting. Set the fence

to 90°. Set the height adjustment to

position the biscuit in the approximate

centre of the stock thickness.

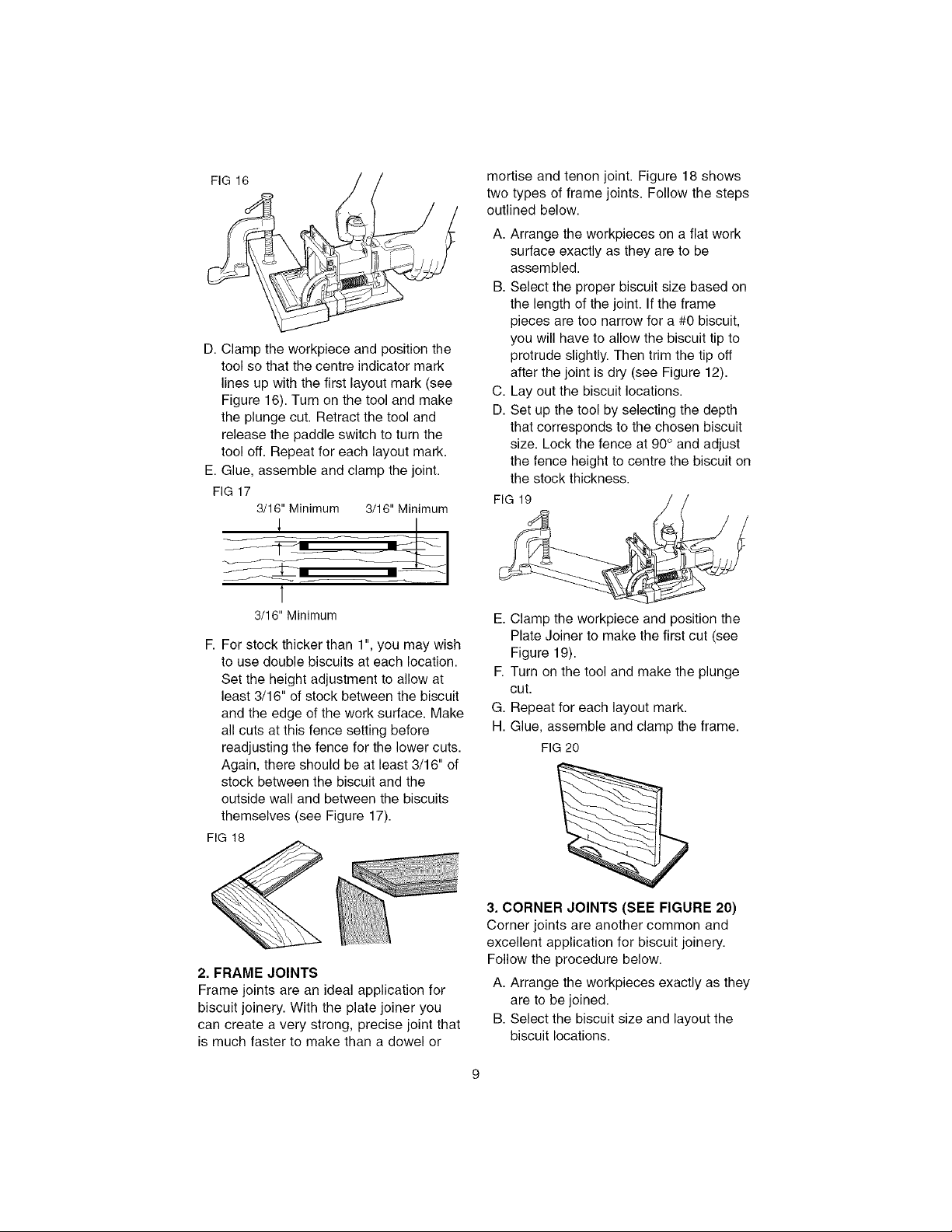

FIG16

D.Clamptheworkpieceandpositionthe

toolsothatthecentreindicatormark

linesupwiththefirstlayoutmark(see

Figure16).Turnonthetoolandmake

theplungecut.Retractthetooland

releasethepaddleswitchtoturnthe

tooloff.Repeatforeachlayoutmark.

E.Glue,assembleandclampthejoint.

FIG17

3/16"Minimum3/16"Minimum

1

3/16" Minimum

F. For stock thicker than 1", you may wish

to use double biscuits at each location.

Set the height adjustment to allow at

least 3/16" of stock between the biscuit

and the edge of the work surface. Make

all cuts at this fence setting before

readjusting the fence for the lower cuts.

Again, there should be at least 3/16" of

stock between the biscuit and the

outside wall and between the biscuits

themselves (see Figure 17).

FIG 18

mortise and tenon joint. Figure 18 shows

two types of frame joints. Follow the steps

outlined below.

A. Arrange the workpieces on a flat work

surface exactly as they are to be

assembled.

B. Select the proper biscuit size based on

the length of the joint. If the frame

pieces are too narrow for a #0 biscuit,

you will have to allow the biscuit tip to

protrude slightly. Then trim the tip off

after the joint is dry (see Figure 12).

C. Lay out the biscuit locations.

D. Set up the tool by selecting the depth

that corresponds to the chosen biscuit

size. Lock the fence at 90° and adjust

the fence height to centre the biscuit on

the stock thickness.

FIG 19

E. Clamp the workpiece and position the

Plate Joiner to make the first cut (see

Figure 19).

F. Turn on the tool and make the plunge

cut.

G. Repeat for each layout mark.

H. Glue, assemble and clamp the frame.

FIG20

2. FRAME JOINTS

Frame joints are an ideal application for

biscuit joinery. With the plate joiner you

can create a very strong, precise joint that

is much faster to make than a dowel or

3. CORNER JOINTS (SEE FIGURE 20)

Corner joints are another common and

excellent application for biscuit joinery.

Follow the procedure below.

A. Arrange the workpieces exactly as they

are to be joined.

B. Select the biscuit size and layout the

biscuit locations.

Loading...

Loading...