Craftsman 900277230 Owner’s Manual

158818-03

INSTRUCTION

MANUAL

MODEL NO.

900.277230

©

CAUTION"

Read Rules for

Safe Operation

and Instructions

Carefully

CRRFi'$MnHo

4 1/2" ANGLE GRINDER

Introduction

Operation

Maintenance

Repair Parts

158818-03

Form No. 158818-03

sold by SEARS, ROEBUCKAND CO., Hoffman Estates, IL 60179 U.S.A.

(MAY95-CD-8)

PRINTED IN U.S.A.

0

If this Sears Angle Grinder fails to give complete satisfaction within one year from the date of purchase, return

it to any Sears store in the United States and Sears will repair it or replace it, free of charge.

If this Sears Angle Grinder is used for commercial or rental purposes, the warranty applies for only ninety (90)

days from the date of purchase.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

FULL ONE YEAR WARRANTY ON SEARS 4 1/2" ANGLE GRINDER

_====,

SEARS, ROEBUCK AND CO, D817WA, HOFFMAN ESTATES, IL 60179

)

INTRODUCTION

Designed with all of the rugged dependability for which Sears is

famous, your new grinder is sure to give you years of reliable service.

Features like Double Insulation, a built-in Spindle Lock, and an

included Depressed Center Wheel (so you're ready to work right

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions

should always be followed to reduce risk of fire, electric shock, and

personal injury, including the following:

READ ALL INSTRUCTIONS

DOUBLE INSULATION

Double insulated tools are constructed throughout with two separate

layers of electrical insulation or one double thickness of insulation

between you and the tool's electrical system. Tools built with this insu-

lation system are not intended to be grounded. As a result, your tool is

equipped with a two prong plug which permits you to use extension

cords without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety pre-

cautions when operating this tool. The insulation system is for added

protection against injury resulting from a possible electrical insulation

failure within the tobl.

CAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACE-

MENT PARTS. Repair or replace damaged cords.

POLARIZED PLUGS

Polarized plugs (one blade is wider than the other) are used on equip-

ment to reduce the risk of electric shock. When provided, this plug will

fit into a polarized outlet only one way. If the plug does not fit fully into

the outlet, reverse the plug. If it still does not fit, contact a qualified elec-

trician to install the proper outlet. Do not change the plug in any way.

SAFETY INSTRUCTIONS FOR ALL TOOLS

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite

injuries.

2. CONSIDER WORK AREA ENVIRONMENT. Don't expose power

tools to rain. Don't use power tools in damp or wet locations. Keep

work area well lit. Do not use tool in presence of flammable liquids

or gases.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact

with grounded surfaces. For example; pipes, radiators, ranges,

and refrigerator enclosures.

4. KEEP CHILDREN AWAY. Do not let visitors contact tool or exten-

sion cord. All visitors should be kept away from work area.

5. STORE IDLE TOOLS. When not in use, tools should be stored in

dry, and high or locked-up place -- out of reach of children.

6. DON'T FORCE TOOL. It will do the job better and safer at the rate

for which it was intended.

away) make your new grinder a real value for grinding and sanding

most metals and masonry. Please take the time to read this

informative instruction manual and pay particular attention to the

safety instructions we've included for your protection.

7. USE RIGHT TOOL. Don't force small tool or attachment to do the

job of a heavy-duty tool. Don't use tool for purpose not intended.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. They

can be caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors. Wear protec-

tive hair covering to contain long hair.

9. USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

10. DON'T ABUSE CORD. Never carry tool by cord or yank it to dis-

connect from receptacle. Keep cord from heat, oil, and sharp

edges.

11. SECURE WORK. Use clamps or a vise to hold work. It's safer

than using your hand and it frees both hands to operate tool.

12. DON'T OVERREACH. Keep proper footing and balance at all

times.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

better and safer performance. Follow instructions for lubricating

and changing accessories. Inspect tool cords periodically and if

damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep han-

dles dry, clean, and free from oil and grease.

14. DISCONNECT OR LOCK OFF TOOLS when not in use, before

servicing, and when changing accessories, such as blades, bits,

cutters.

16. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of

checking to see that keys and adjusting wrenches are removed

from tool before turning it on.

17. AVOID UNINTENTIONAL STARTING. Don't carry tool with finger

on switch. Be sure switch is off when plugging in.

18. EXTENSION CORDS. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one

heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. The following table shows the correct size

to use depending on cord length and nameplate ampere rating. If

in doubt, use the next heavier gage. The smaller the gage number,

the heavier the cord.

Minimum Gage for Cord Sets

Volts

120V 0-25

240V 0-50

Ampere Rating

More Not more AWG

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

Total Length of Cord in Feet

26-50 51-100 101-150

51-100 101-200 201-300

....

19. OUTDOOR USE EXTENSION CORDS. When tool is used out-

doors, use only extension cords intended for use outdoors and so

marked.

20. STAY ALERT. Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

21. CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction

manual. Have defective switches replaced by authorized service

center. Do not use tool if switch does not turn it on and off.

ADDITIONAL SAFETY INSTRUCTIONS FOR GRINDERS

1.

ALWAYS WEAR EYE PROTECTION.

KEEP GUARDS IN PLACE.

2.

3.

Use only grinding wheels having a maximum operating speed at

least highas "No Load RPM" marked on the tool'snameplate.

4. Before using, inspect recommended accessoryfor cracks or

flaws. If such a crack or flaw is evident, discardthe accessory.

The accessory should also be inspected whenever you think the

tool may have been dropped.

5. When starting the tool (with a new or replacement wheel installed)

hold the tool in a well protected area and let it run for one minute.

If the wheel has an undetected crack or flaw, it should burst in less

than one minute. Never start the tool with a person in line with the

wheel. This includes the operator.

6. In operation, avoid bouncing the wheel or giving it rough treat-

ment. If this occurs, stop the tool and inspect the wheel.

7. ALWAYS USE GUARDS with depressed center wheels or flaring

cup grinding wheels.

8. Clean your tool out periodically.

9. CAUTION: Some wood contains preservatives such as copper

chromium arsenate (CCA) which can be toxic. When sanding

these materials extra care should be taken to avoid inhalation and

minimize skin contact.

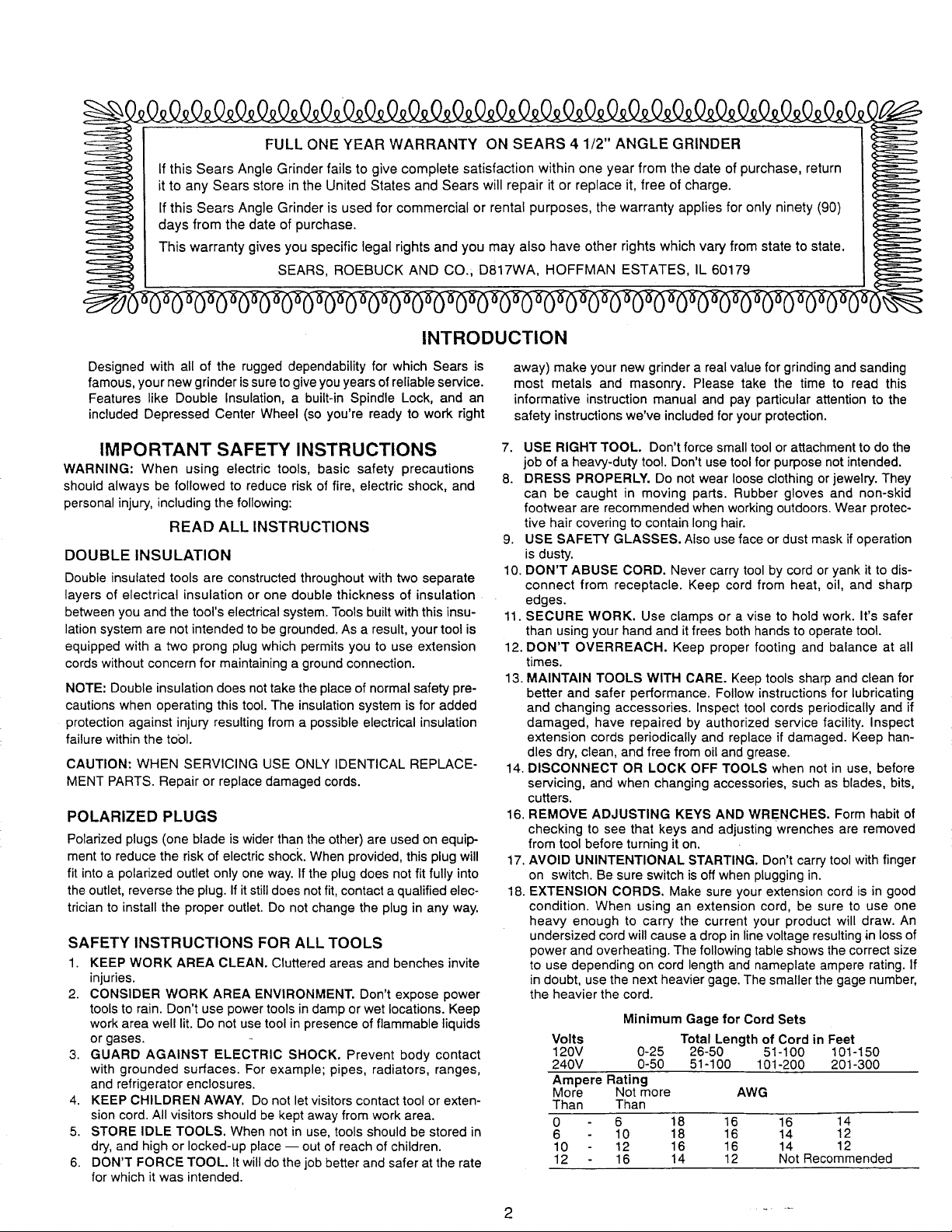

AUXILIARY HANDLE (FIG. 2)

An auxiliary handle is furnished with your grinder and can be screwed

into either side or the top of the front housing, as shown in Figure 3.

This handle SHOULD BE USED AT ALL TIMES to maintain complete

control of the tool.

FIG. 2

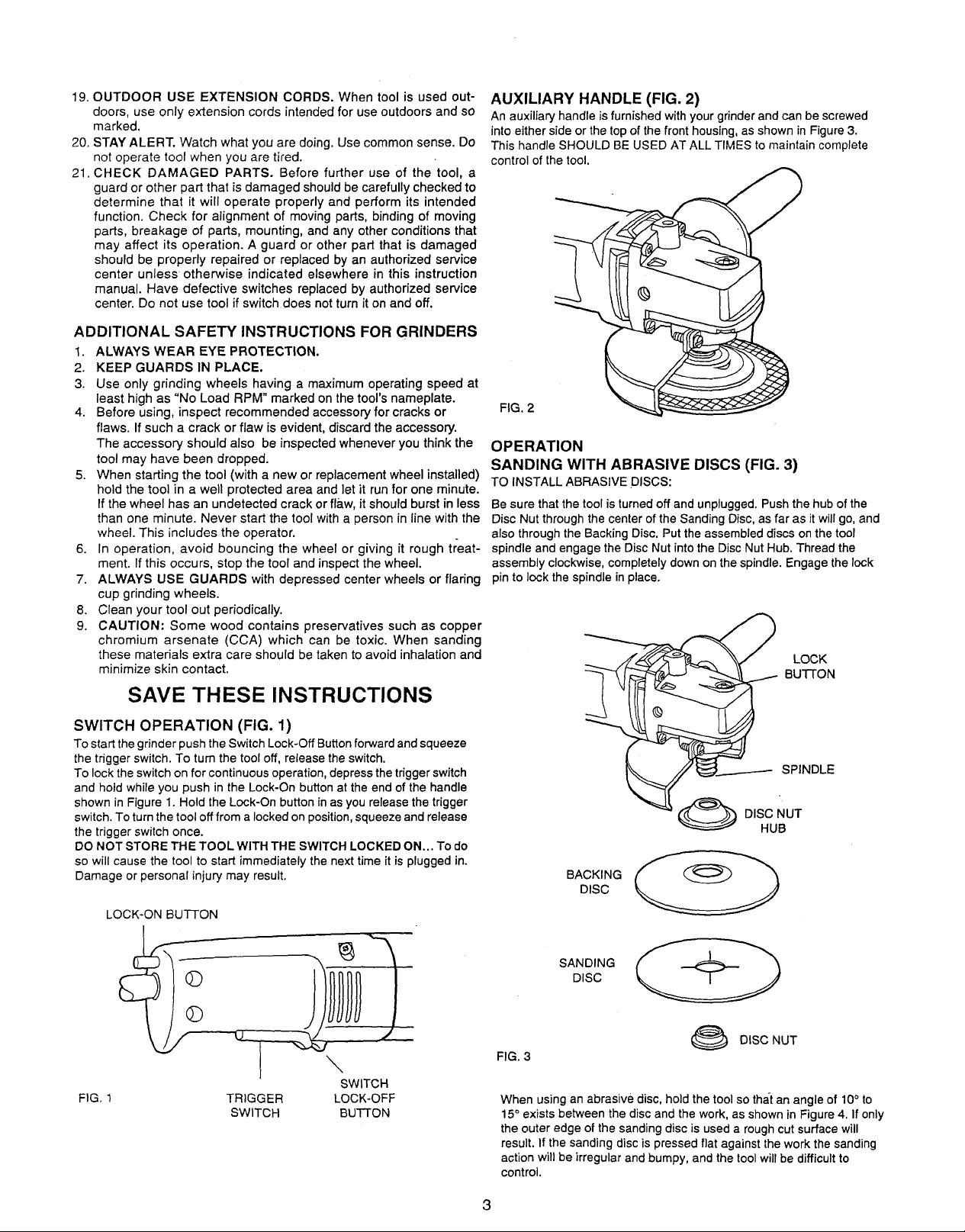

OPERATION

SANDING WITH ABRASIVE DISCS (FIG. 3)

TO INSTALL ABRASIVE DISCS:

Be sure that the tool is turned off and unplugged. Push the hub of the

Disc Nut through the center of the Sanding Disc, as far as it will go, and

also through the Backing Disc. Put the assembled discs on the tool

spindle and engage the Disc Nut into the Disc Nut Hub. Thread the

assembly clockwise, completely down on the spindle. Engage the lock

pin to lock the spindle in place.

SAVE THESE INSTRUCTIONS

SWITCH OPERATION (FIG. 1)

To start the grinder push the Switch Lock-Off Button forward and squeeze

the trigger switch. To turn the tool off, release the switch.

To lock the switch on for continuous operation, depress the trigger switch

and hold while you push in the Lock-On button at the end of the handle

shown in Figure 1. Hold the Lock-On button in as you release the trigger

switch. To turn the tool off from a locked on position, squeeze and release

the trigger switch once.

DO NOT STORE THE TOOL WITH THE SWITCH LOCKED ON... To do

so will cause the tool to start immediately the next time it is plugged in.

Damage or personal injury may result.

LOCK-ON BUTTON

©

©

\

FIG. 1

TRIGGER LOCK-OFF

SWITCH BU]-I'ON

SWITCH

BACKING

DISC

SANDING

DISC

(_ DISC NUT

FIG. 3

When using an abrasive disc, hold the tool so that an angle of 10° to

15° exists between the disc and the work, as shown in Figure 4. If only

the outer edge of the sanding disc is used a rough cut surface will

result. If the sanding disc is pressed flat against the work the sanding

action will be irregular and bumpy, and the tool will be difficult to

control.

3

Loading...

Loading...