Craftsman 900271221 Owner’s Manual

OWNERS

MANUAL

MODEL NO.

900.271221

CAUTION

Read Rules for

Safe Operation

and Instructions

Carefully

CRAFTSH N

DUAL SPEED

RECIPROCAT NG

DOUBLE iNSULATED

Introduction

Operation

Maintenance

Repair Parts

®

sold by SEARS, ROEBUCK AND CO, Chicago, IL 60684 U S A

Form No 446901-07 (JUL91-CD-1) PRINTED IN U SA

FULL ONE YEAR WARRANTY ON CRAFTSMAN INDUSTRIAL PORTABLE RECIPROCATING SAW

If this CRAFTSMAN Industrial Reciprocating Saw fails due to a defect in material or workmanship within one year from the date of

purchase, Sears wilt repair it free of charge,

WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE TOOL TO THE NEAREST SEARS STORE OR SERVICE

CENTER THROUGHOUT THE UNITED STATES

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE

SEARS ROEBUCK AND CO, DEPT 698/731 A, SEARS TOWER CHICAGO, IL 60684

INTRODUCTION

DOUBLE INSULATION

Double insulation is a concept in safety, in electric power

tools, which eliminates the need for the usual three wire

. grounded power cord and grounded supply system

- Wherever there is electric current in the tool there are two

complete sets of insulation to protect the user All expos-

ed metal parts are isolated from the internal metal motor

components with protecting insulation

IMPORTANT

Servicing of a tool with double insulation requires extreme

care and knowledge of the system and should be perform-

ed only by a qualified service technician For service we

suggest you return the tool to your nearest Sears Store for

repair Always use original factory replacement parts

when servicing

iMPORTANT SAFETY INSTRUCTIONS (FOR ALL TOOLS)

WARNING: When using Electric Tools, basic safety precautions should always be followed to

reduce the risk of fire, electric shock, and personal irrjury, including the following:

READ ALL INSTRUCTIONS

1 KEEP WORK AREA CLEAN. Cluttered areas and benches

invite injuries

2 CONSIDER WORK AREA ENVIRONMENT. Don't expose

power tools to rain Dont use power tools in damp or wet

locations Keep work area well lit

3 GUARD AGAINST ELECTRIC SHOCK,, Prevent body contact

with grounded surfaces For example: pipes, radiators,

ranges, refrigerator enclosures

4 KEEP CHILDREN AWAY. All visitors should be kept away from

work area Do not let visitors contact tool or extension cord

5 STORE IDLE TOOLS. When not in use, tools should be stored

in dry, and high or locked-up place--out of reach of children

6 DON'T FORCE TOOL. It wil! do the job better and _afer at the

rate for which it was intended

7 USE RIGHT TOOL. Don't force small tool or attachment to do

the job of a heavy-duty tool Don't use tool for purpose not

intended, for example, don't use circular saw for cutting tree

limbs or logs

8 DRESS PROPERLY,, Do not wear loose clothing or jewelry

They can be caught in moving parts Rubber gloves and non-

skid footwear are recommended when working outdoors

Wear protective hair covering to contain long hair

9 USE SAFETY GLASSES. Also use face or dustmask if cutting

operation is dusty

10 DON'T ABUSE CORD. Never carry tool by cord or yank it to

disconnect from receptacle Keep cord from heat, oil, and

sharp edges

11 SECURE WORK. Useclampsoravisetoholdwork Itssafer

than using your hand and it frees both hands to operate tool

12 DON'T OVERREACH. Keep proper footing and balance at all

times

13 MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

ADDITIONAL SAW SAFETY RULES

1 KEEP HANDS AWAY from cutting area Never reach underneath the material for any reason

2 KEEP BLADE SHARP. Dull blades may cause the saw to swerve or stall under pressure

for better and safe performance Follow irrstructions for lubri-

caring and changing accessories Inspect tool cords periodi-

cally and if damaged have repaired by authorized service facil-

ity Inspect extension cords periodically and replace if

damaged Keep handles dry, clean and free from oil and

grease

14

DISCONNECT TOOLS, When not in use, before servicing, and

when changing accessories, such as blades, bits, cutters

15

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit

of checking to see that keys and adjusting wrenches are

removed from tool before turning it on

16

AVOID UNINTENTIONAL STARTING. Don't carry plugged-in

tool with finger on switch Be sure switch is off when plugging

in

17 OUTDOOR USE EKTENSION CORDS. When tool is used

outdoors, use only extension cords intended for use outdoors

and so marked

18 STAYALERT. Watchwhatyouaredoing Use common sense

Do not operate tool when you are tired

19 CHECK DAMAGED PARTS. Before further use of the tool, a

guard or other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and any

other conditions that may affect its operation A guard or other

part that is damaged should be properly repaired or replaced

by an authorized service center unless otherwise indicated

elsewhere in this instruction manual Have defective switches

replaced by authorized service center Do not use tool if switch

does not turn it on and off

20 DO NOT OPERATE portable electric tools near flammable

liquids or in gaseous or explosive atmospheres Motors in

these tools normally spark, and the sparks might ignite fumes

SAVE THESE INSTRUCTIONS

2

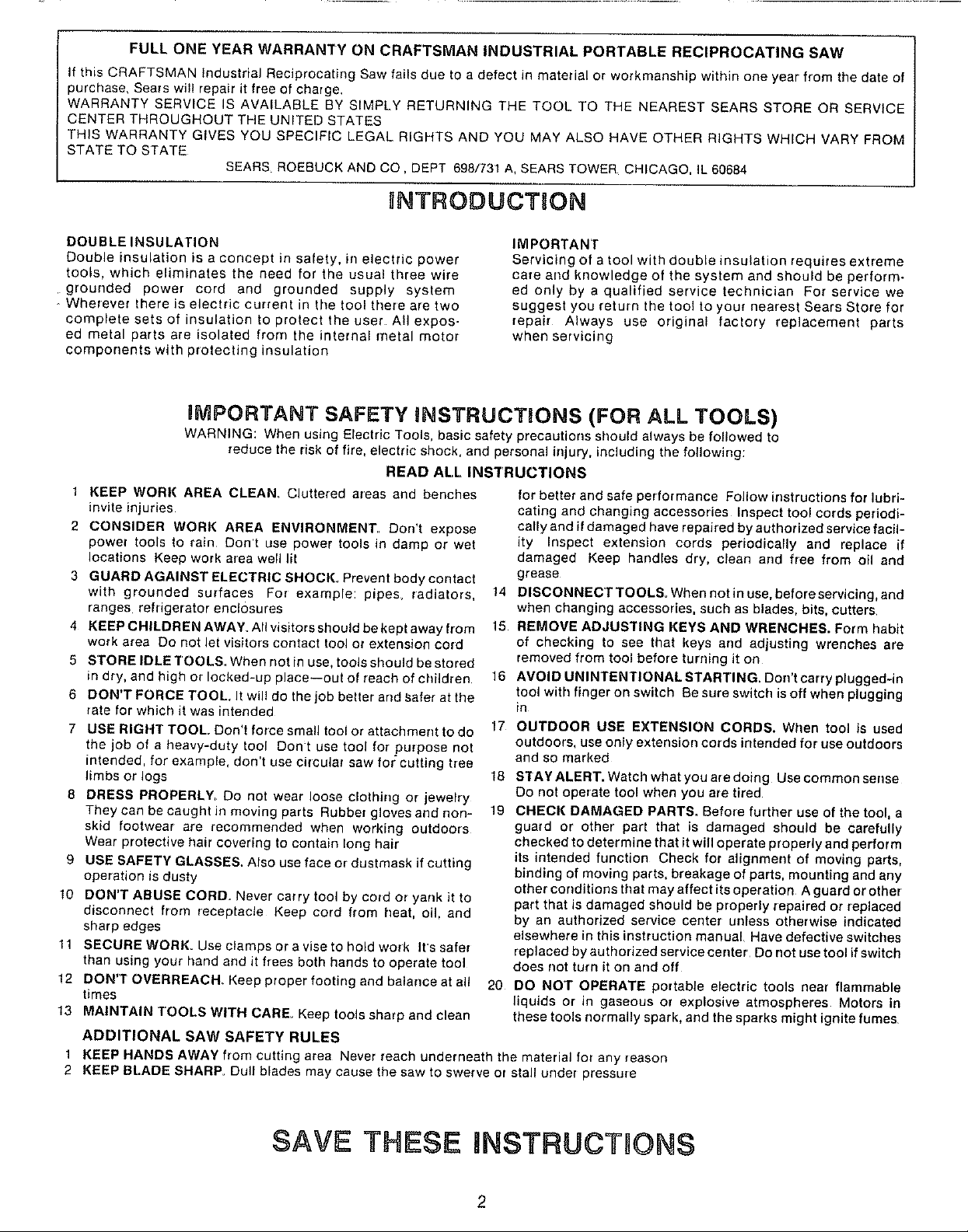

SWITCH

Depress the Trigger Switch to turn tool ON" Releasing the

trigger turns tool "OFF" To lock the trigger switch in the "ON

position for continuous operation, depress the trigger, push in

locking button on left side of handle and then release the

trigger To release locking mechanism, depress trigger fully.

then release it

MOTOR

Be sure your power supply agrees with the nameplate marking

VOLTS 50/60 Hz or AC ONLY means your tool must be oper-

ated only with Alternating Current and never with Direct Cur-

rent VOLTS DC-60 Hz or AC/DC means your tool may be

operated with either Alternating or Direct Current Voltage

decrease of more than 10% will cause loss of power or over-

heating All tools are factory-tested; if this tool does not oper-

ate, check the power supply

OPERATUON

LOCKING

BUTTON

TRIGGER

SWITCH

The Dual Speed Reciprocating Saw offers a choice of speeds

for greatly improved cutting rates in various materials Note

that the High-Speed setting is more efficient in softer materials

such as wood, while the Low-Speed is best for cutting metals

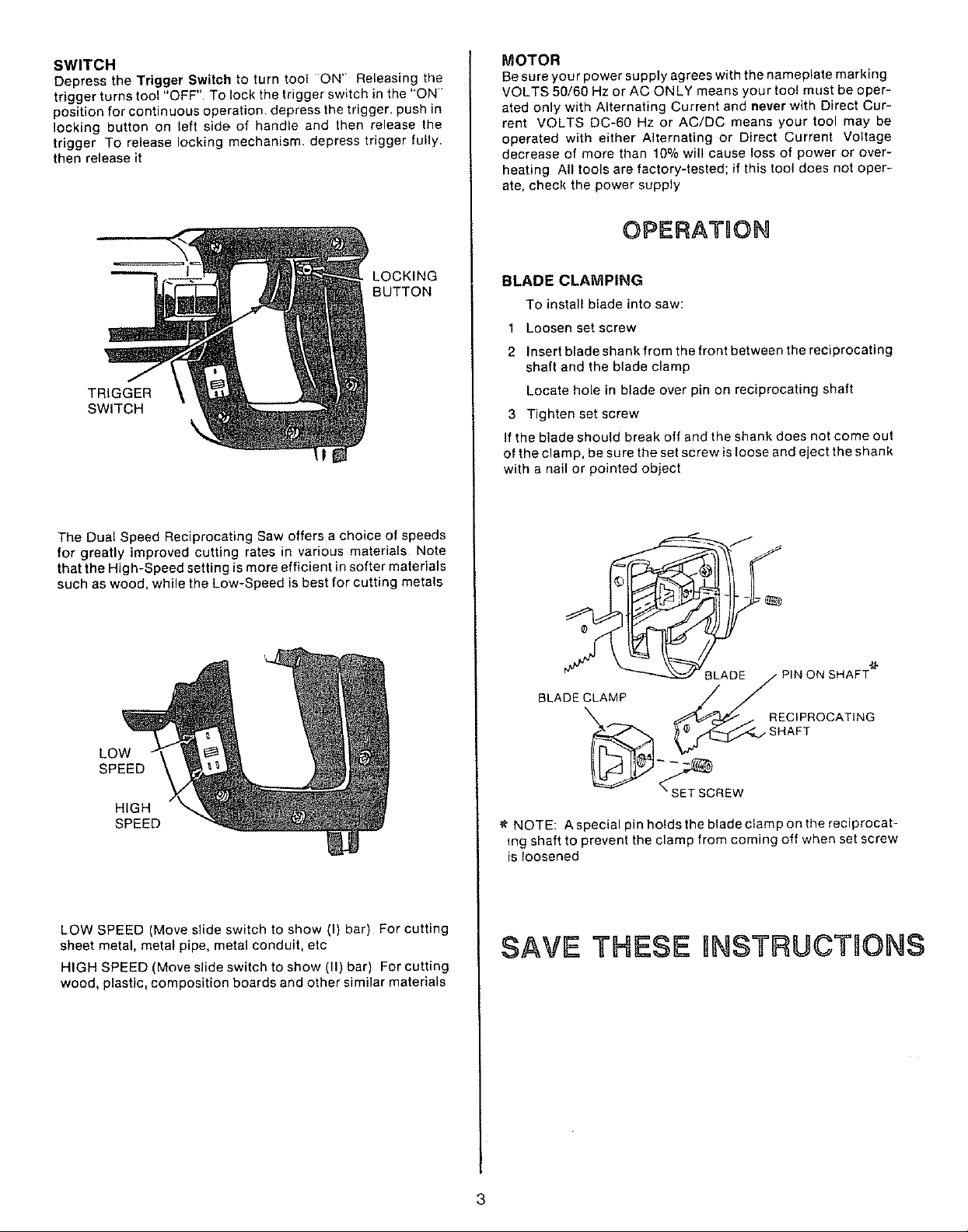

BLADE CLAMPING

To install blade into saw:

1 Loosen set screw

2 Insert blade shank from the front between the reciprocating

shaft and the blade clamp

Locate hole in blade over pin on reciprocating shaft

3 Tighten set screw

If the blade should break off and the shank does not come out

of the clamp, be sure the set screw is loose and eject the shank

with a nail or pointed object

LOW

SPEED

HIGH

SPEED

LOW SPEED (Move slide switch to show (I) bar) For cutting

sheet metal, metal pipe, metal conduit, etc

HIGH SPEED (Move slide switch to show (ll) bar) For cutting

wood, plastic, composition boards and other similar materials

__ SHAFT

_: NOTE: A special pin holds the blade clamp on the reciprocat-

ing shaft to prevent the clamp from coming off when set screw

is loosened

SAVE THESE UNSTRUCTaONS

3

Loading...

Loading...