Page 1

Instruction Manual

IC,,,,,,,,RAF

4-1/2 inch

ANGLE GRINDER

Model 900.24543

WARNING:

A Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

• Safety

• Operation

• Maintenance

• Parts List

. Espa_ol

Sears Brands Management Corporation, Hoffman Estates, IL 60179

www.craftsman,com

Form No. 90565294 June 2010 Printed in China

Page 2

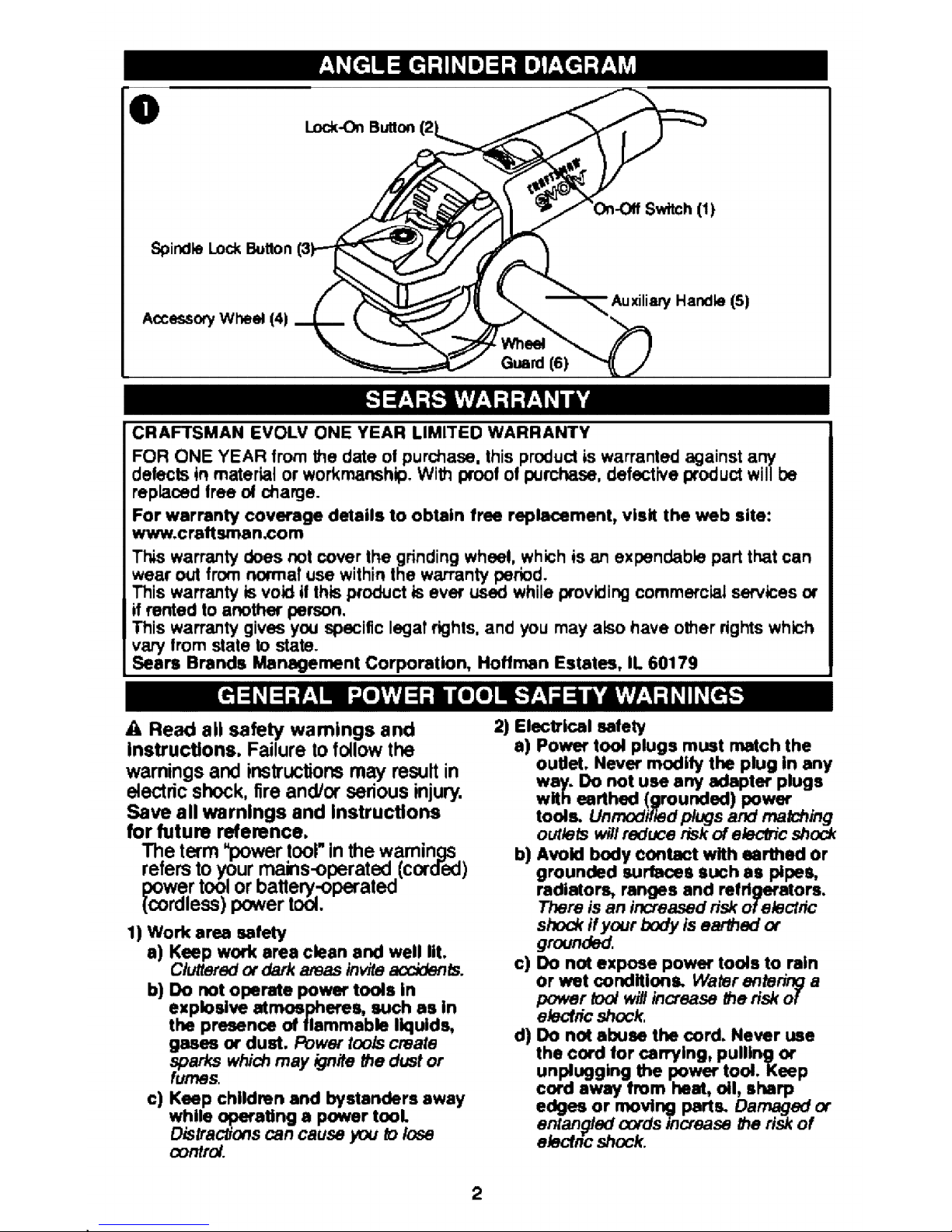

4)

Lock-OnSutton(2]

SpindleLock B_Jtton

Sw_ch(1)

Accesso_Whee_(41

.Whee!

Guard (6)

CRAFTSMAN EVOLV ONE YEAR LIMITED WARRANTY

Handle (5)

FOR ONE YEAR from the date of purchase, this product is warranted against a

any

de!ects in material or workmanship. With proof of purchase, defective product will be

replaced lree ol charge.

For warranty coverage details to obtain free replacement, visit the web site:

www.craftsman_com

Th_s warranty does not cover the grinding wheel, which is an expendable part that can

wear out from norrnaf use within the warranty period.

This warranty is void il this product is ever used while providing commercial services or

if rented to another person.

This warranty gives you specific legat rights, and you may also have o_er rights which

vary from state to state,

Sears Brands Management Corporation, Hoffmen Estates, IL 60179

& Read all safety wamlngs and

!nstruct!ons. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and Instructions

for future reference.

The term "power tooi"inthe warnings

refers to your mains-operated (corded)

power tool or battery-operated

(cordless) power tool.

!) Work area safety

a) Keep work area clean and wel! lit.

Cluttered ordark areas inviteaccidents.

b) Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust. Power tools create

sparks which may ignite the dust or

fumes

c) Keep children and bystanders away

while operating a power tooL

D_strac_onscan cause you _olose

control.

2) Electrical safety

a) Power too! plugs must match the

outlet, Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power

tools. Unmodified ptugs and matching

outlets wil! reduce risk of electric shock

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk o! electric

shock if your body is earned or

grounded.

c) Do not expose power tools to rain

or wet oondltion_ Water entering a

power _oolwill increase the risk of

electric shock.

d) Do not abuse the cord. Never use

the cord for can'ying, pulltngor

unplugging the power tool, Keep

cord away from heat, oil, sharp

edges or moving parts, Oamags:_ or

entangled cords increase the risk of

ekgcfric shock.

2

Page 3

suitable for outdoor use, Use ofa

oord suitable for ou_oor use

the risk of_ sho_.

f) If operating a power too! in a damp

locatlm is unavoidable, use a

lGround fault circuit Interrupter

FC!) protected supply, Use of a

GFCt reduces the risk of e_ _,

3) Personal ssfery

a) Stay alert, watch what you are

doing and use common sense

when operating a power tool, Do

not use a power tool while you are

tired or under the influence of

drugs, alcohol or medication. A

n'_ment of inattention while operating

power tools may result in serious

personal injury.

b) Use personal protective equipment,

Always wear eye protection.

Protective equipment such as dust

mask, non-skid safety _, hard

hat, or heanng protection used for

appropriate conditions will reduce

person# injuries.

c) Prevent unintentional starting.

Ensure the switch is in the off-

position before connecting to

power source and/or battery pack,

picking up or carrying the too!,

tools that have the swish on invites

accidents.

d) Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left

attached to a K_ating part of the power

too! may result in persona! inju_

e) Do not overreach, Keep proper

footing and balance at al! times.

This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery, Keep your

hair, clothing and gloves away from

moving parts. Loose c_!othes,

jewetle_ or longhair can be caughtin

movingparts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used,

Use of dust collection can reduce

dust-related hazards.

4) Power tool use and care

a) Do not force the power too!. Use

the correct power too! for your

application. The correct power _ol

will do the job better and safer at the

rate for which it was designed,

b) Do not use the power tool if the

switch does not turn it on and off.

Any power too! that cannot be

controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the

power source and/or the battery

pack from the power tool before

making any adjustments, changing

accessories, or stodng power

tools. Such preventive safety

measures reduce the risk of starting

#_e power tool accidentaf_

d) Store Idle power tools out of the

reach of children and do not allow

parsons unfamiliar with the power

too! or these instructions to

operate the power tooL Power _/s

are dangerous in the hands of

e) Maintain power tools. Check for

3

g)

other condition that may affect the

wer tool's operation. If damaged,

ve the power tool repaired before

Use. Many _ are caused by

poorly maintained power tools.

Keep tools sharp and clean.

Properly maintained tools with sharp

edges are tess likely to bind and are

easier _ oon_o!.

Use the power tool, accessories

and tool bits etc,, in accordance

with these instructions, taking into

account the working conditions

and the work to be performed. Usa

of the power tool for operations

different from _ose intended could

result in a hazardous situation.

S) Service

a) Have your power tool serviced by a

qualified repair person using only

Identica! replacement parts, This wN

ensure that the safety of _e power

_o! is maintained.

SAFETY INSTRUCTIONS FOR

ALL OPERATIONS

Safety Warnings Common for Grinding,

Sanding, Wire Brushing

a) This power tool is intended to

function as a grinder, wire brush,

sander. Read al! safety warnings,

instructions, illustrations and

specifications provided with this

power tool. Failure to fogow all

ran'struclior_ listed below may result in

etectdc shock, fire and/or serious

injury. Operations such as poliehing

Page 4

or cuttlng-off am not recommended

tObe performed with this power

tooL Opeh'ationsforwhichthe power

toot was not designed may create a

hazard and cause persona0 injury.

b) Do not use accessories which are

not specifically designed and

recommended by the tool

manufacturer. Just because the

accessory can be attached to your

power tool, it does not assure sale

operation.

c) The rated speed of the accessory

must be at least equal to the

m_ximum speed marked on the

wer too!. Accessories running

letthan their rated speed can

break and fly apart.

d) The outside diameter and the

thickness of your accessory must

be within the capacity rating of

your power tool. Incorrectly sized

accessories cannot be adequately

guarded or controlled.

e) The arbor size of wheels, flanges,

backing pads or any other

accessory must properly fit the

spindle of the power tool.

Accessories with arbor holes that do

not match the mounting hardware o!

the power toot will run out of balance.

vibrate excessively and may cause

loss of control.

f) Do not use a damaged accessory.

Before each use inspect the

accessory such as abrasive wheel

for chips and cracks, backing pad

for cracks, tear or excess wear,

wire brush for loose or cracked

wires. If power too! or accessory

is dropped, inspect for damage or

instal! an undamaged accessory.

After inspecting and installing an

accessory, position yourself and

bystanders away from the plane of

the rotating accessory and run the

power too! at maximum no-load

speed for one minute. Damaged

accessories will normally break apart

dudng this test time.

g) Wear personal protective

equipment. Depending on

application, use face shield, safety

goggles or safety glasses. As

appropriate, wear dust mask,

hearing protectors, gloves and

work shop apron capable of

stopping small abrasive or

workplace fragments. The eye

protection must be capable o!

stoppingflying debris generated by

vanous operations. The dust mask or

respirator must be capable o!

4

filtrating particles generated by your

operation. Prolonged exposure to

high intensity noise may cause

hearing loss.

h) Keep bystanders a safe distance

away from work area, Anyone

entering the work area must wear

_rarSOnal protective equipment,

grnents of workplace or of a

broken accessory may fly away and

cause injury beyond immediate area

of operation.

i) Ho!d power tool by insulated

gripping surfaces only, when

performing an operation where the

accessory may contact hidden

wiring or Its own cord, Accessory

contacting a "live" wire may make

exposed metal pads o! the power

toot "live" and shock the operator.

j) Position the cord clear of the

spinning accessory. If you ;ose

control, the cord may be cut or

snagged and your hand or arm may

be pulled into the spinning accessory.

k) Never lay the power tool down

until the accessory has come to a

complete stop. The spinning

accesson/may grab the sudace and

pull the power tool out o4your control.

I) Do not nJn the power tool while

carrying it at your side, ,Accidental

contactwil_the spinningaccessory

could snag your oiolhing, pullingthe

accesso_ intoyour boo_,

m)Regularly clean the power too!'s

alr vents. The motor's lan will draw

the dust inside the housing and

excessive accumulation olpowdered

metal may cause electrical hazards.

n) Do not operate the power tool near

flammable materials. Sparks could

ignite these materials.

o) Do not use accessories that

require liquid coolants. Using water

or other liquid coolants may result in

electrocution or shock,

p) Do not use Type 11 (flaring cup)

wheels on this tooL Usr_ _te

accessories can result in injury.

q) Always use side handle. Tighten

the handle securely= The

side

handle should always be used to

maintain control of 1he too_at all times.

R) Use clamps or another practical

way to secure and support the

work piece to a stable platform.

Holding the work by hand or against

OaUrbody leaves it unstable and may

d to loss of control.

Page 5

Further safety instructions for all

operations

Kickback and Related Warnings

Kickback is a sudden reaction to a

_inched or snagged rotating wheel,

acking pad, brush or any other

accessory. Pinching or snagging

causes rapid s_lling of the rotating

accessory which in turn causes the

uncontrolled power tool to be forced

in the direction opposite of the

acce_'s rotation at the pointol the

binding,

For example, i!an abrasive wheel is

snagged or pin_ by the wod<piece.

the edge of the wheel that is entering

into the pinch point can dig into the

surface of the material causing the

wheel to climb out or kick out. The

wheeAmay either jump toward or

away from the operator, depending

on direction of the wheel's movement

at the point of pinchmgoAbrasive

wheels may also break under these

conditions.

Kickback is the resu|t of tool misuse

andtor incorrect operating procedures

or conditions and can be avoided by

taking proper precautions as given

below:

a) Malntain a firm grip on the power

too! and position your body and

arm to allow you to resist kickback

forces. Always use auxiliary

handle, If provided, for maximum

control Over kickback or torque

reaction during start up. The

operator can control torque reaction

or kickback forces, ifproper

precautions are taken.

b) Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

c) Do not position your body in the

area where power tool will move if

kickback occurs. Kickback will

propel the toot in direction opposite to

the whee!'s movement at the point of

snagging.

d) Use special care when working

corners, sharp edges etc. Avoid

bouncing and snagging the

accessory. Corners, sharp edges or

bouncing have a tendency to snag

the rolatl"ngaccessory and cause/oss

ot control or kickback.

e) Do not attach a saw chain

woodcarving blade or toothed saw

blade. Such blades oreate frequent

kickback and loss of control,

Safety Warnings Specific for Grinding

Operations

a) Use only wheel types that are

recommended for your power too!

and the specific guard designed

for the selected wheel. Wheels for

which the power too_ was not

designed cannot be adequately

guarded and are unsate.

b) The guard must be securely

attached to the power tool and

positioned for maximum safety, so

the least amount of wheel is

exposed towards the operator. The

guard helps to protect operator from

broken wheel fragments and

a_cidentat contact wilfl wheel.

c) Wheels must be used only for

recommended applications. For

example: do not grind with the side

of wheel Abrasive wheels are

inter_ed for peripheral grinding, side

forces applied to these wheels may

cause them to shatter.

d) Always use undamaged wheel

flanges that are of correct size and

shape for your selected wheel.

Proper wheel flanges support the

wheel thus reducing the possibility ot

wheel breakage. Flanges for cut-off

wheels may be different from grinding

wheel flanges,

e) Do not use worn down wheels from

larger power tools. Wheel intended

for larger power tool is not suitable for

the higher speed of a smaller tool and

may burst.

Safety Warnings Specific for Sanding

Operatlons

a) DO not use excessively oversized

sanding disc paper. Follow

manufacturers recommendations,

when selecting sanding paper.

Larger sanding paper extending

beyond the sanding pad presents a

laceration hazard and may cause

snagging,tearingol the disc or kickback.

Safety Warnings Specific for Wire

Brushing Operations

a) Be aware thal wire bristles are

thrown by the brush even during

ordinary operation. Do not

overstress the wires by applying

excessive load to the brush. The

wire bristles can easily penetrate light

dolhing andlor skin.

b) !f the use Of a guard Is recommended

for wire brushlng, do not allow any

Interference of the wlre wheel or

brush with the guard. Wire wheel or

txush may expand in diameter due to

work and centrifugal forces.

5

Page 6

ADDITIONAL SAFETY

INFORMATION

• Do not use Type t fiat abrasive

diamond wheels without proper guard.

(Guard not included with unit.)

& WARNfNG: ALWAYS usesafety glasses.

Everyday eyeglassas are NOT safety

glasses. A/so use face or dust mask if

F REo O, ALWA

SAFETY EQUIPMENT."

• ANS! Z87.1 eye protection (CANtCSA

Z94.3},

• ANSI $12.6 ($3.19) hearing protection,

• NIOS!-!_SHAJMSHA respiratory

protection.

WARNING: Some dust created by

power sanding, sawing, grinding,

drilling, and other construction

activities co.ins chemicals known to

the State of California to cause cancer,

birth defects or other reproductive

harm. Some examples of these

chemicals are:

• lead from/eaoLbased paints,

• crystalline silica from bricks and cement

and other masonry product;s, and

• arsenic and chromium from

chemical/y-treated lumber.

Your risk from these exposures varies,

depending on how o#en you do this type

of work. To reduce your e;q_osure to these

chemicals: work in a we# venti/a_ad area,

and work with _ safety

such as #'_osedust masks that am specially

d_ to filter out rni_ parScles.

. Avoid prolonged contact with dust

from power sanding, sawing,

grinding, drilling, and other

construction activities, Wear

protective clothing and wash exposed

areas with soap and water. Allowing

dust to get into you[ mouth, eyes, or lay

on the skin may promote absorption of

-&WARNING: Use of this tool can

generate and/or disperse dust, which

may cause serious and permanent

respiratory or other injury. Always use

NIOSH/OSHA approved respiratory

protection appropriate for the dust

exposure. L_'racfparticles away from face

antibody

A WARNING: Always wear proper

personal hearing protection that

conforms to ANSI $12.6 (S3.19) during

use. Under some conditions and duration

of use, noise from this product may

contribute tohearing loss.

_1,WARNING: Always use eye

protection. A# users and bystanders

must wear eye pro_ecfion that conforms

to ANSI Z87. !.

-& WARNING; When not in use, place

grinder on a stable surface where it

will not move inadvertently, roll or

cause a tripping or falling hazard.

A CAUTION: To reduce the risk of

personal injury, use extra care when

working into a comer or edge because a

sudden, sharp movement of the _ may

be experlertced when the wheel or other

accessory contacts a secondary surface

orasurfaceedge.

, The label on your tool may include the

following symbols.

V .............. votts

A.............. amperes

W ............ watts

min .......... minutes

"_ ............ alternating current

----- ........ direct current

no ............ no load speed

m ............ Class II Construction

...!rain ...... revolutions or reciprocation

per minute

............earthingterminal

_i,............safety alert symbOl

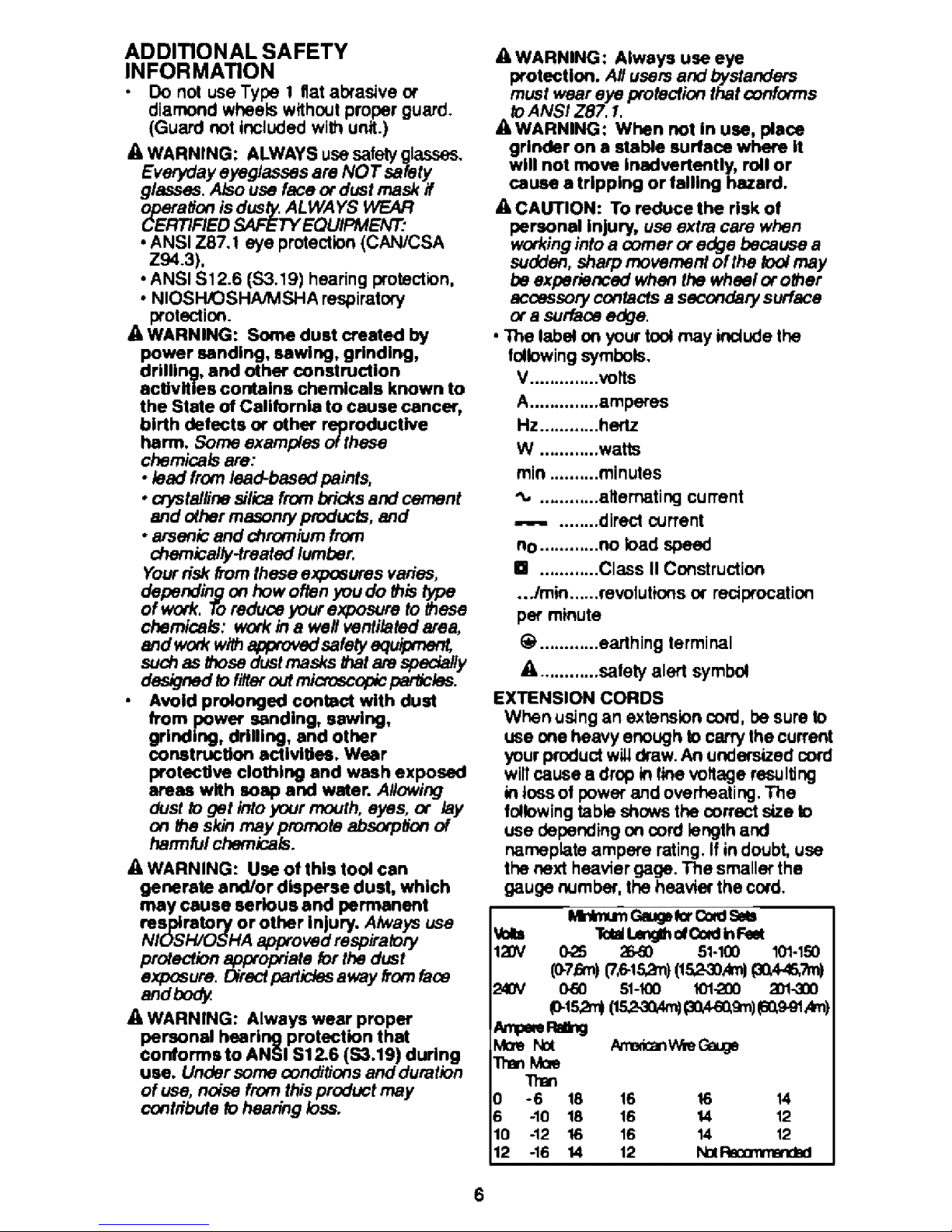

EXTENSION CORDS

Wher_ using an extensiort co_l, be sure to

use one heavy enough tocarry the current

your product wiJ,J,draw. An undersized cord

wilt cause a drop in _ine voltage resulting

in Jossof power and overheating. The

following table shows the correct size to

use depending on cord length and

nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the

gauge number, the heavier the cord.

120V

240V

_ Lexj_¢Co_bF_

0-25 _ 51-100 i01-150

pTa_) F_is3_ (l_Am) m4_Tm)

060 51-100 !01-;300 3)1-3:10

_s2nl (__)mA_grn)_Am

_Ralng

FRxeNot

TrlanM_le

Than

0 -6 18

6 -10 18

10 -12 16

12 -16 14

e canw,eGauge

16 16 14

16 14 12

16 14 12

12 N01Re0olvllendsd

6

Page 7

MOTOR

Be sure your power supply agrees with

nameplate marking. 120 Volts AC only

means your too( will operate on stamdard

60 Hz household power, Do nol operate

AC tools on DC.A rating of !20 volts

AC/DC means lhatyour tool will operate

on standard 60 Hz AC or DC power. This

information is printed on thenameplate.

Lower voltage will cause _ossof power and

can resultinover-he_ng. AI Cra_ Evdv

tools are !actory-tested; i! this too&does not

operate, chock the power supply.

AUXIliARY HANDLE (FIG. 1)

An auxiliary handle (5) is furnished with

your grinder and can be screwed into

TIMES to maintain complete control of the

toot, TIGHTEN SECURELY,

STARTING AND STOPPING THE TOOL

To start the too&,slide the ON/OFF switch

forward (1). For contir.JouS operation.

slide the switch(2) fully !orward and press

front end down. Tostopthe tool. release the

ON/OFF switch. To stop the tool while

punningin continuous mode, press the

rearward part ol the switch.

NOTE: Do nol switch the tool on or off

while under load conditions, Allow the

grinder to runup to fu&¢speed before

touching the surface to be ground. Liftthe

tool !tom,he sudace before turrfingthe

tool off. _CALmON: Allow the tool to

stop be!ore setting down,

OVERLOAD

Overloading wigcause damage to the

motor olyour angle gdnder. This can

happen if your angle grinder is subjected

to heavy use !orprolonged periods of time,

Do not in any circumstances, attempt to

exert too much pressure on your angle

grinder to speed up your woek.

The abrasive discs operate more efficiently

when lightpressureisexerted,thus avoiding

a drop in the speed of your angle grinder.

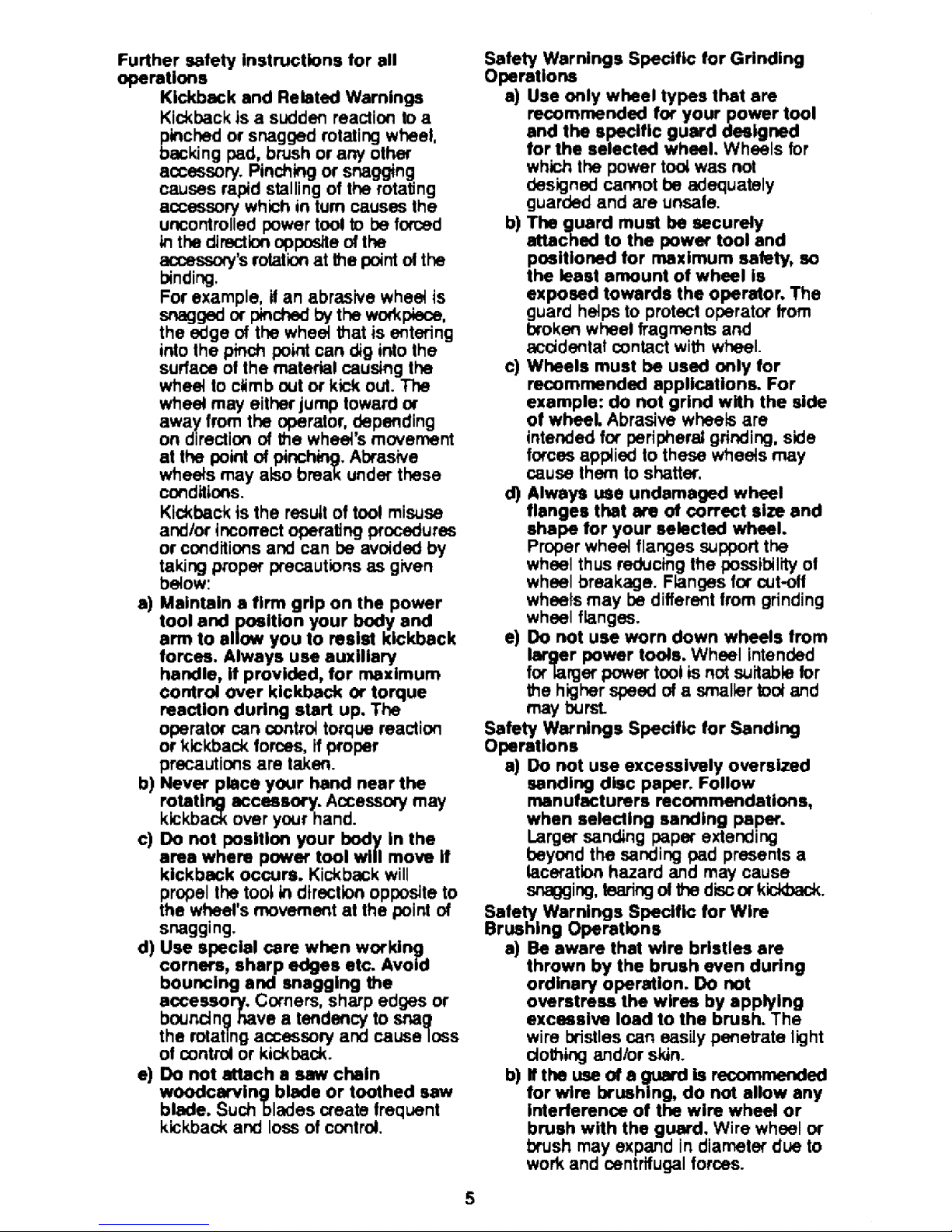

ATTACHING THE WHEEL GUARD (FIG. 2)

Place the flange (1t) over the spindle

with the protrusions facing towards the

Uakard,

e sure that the screws are tight and

that the guard can be rotated,

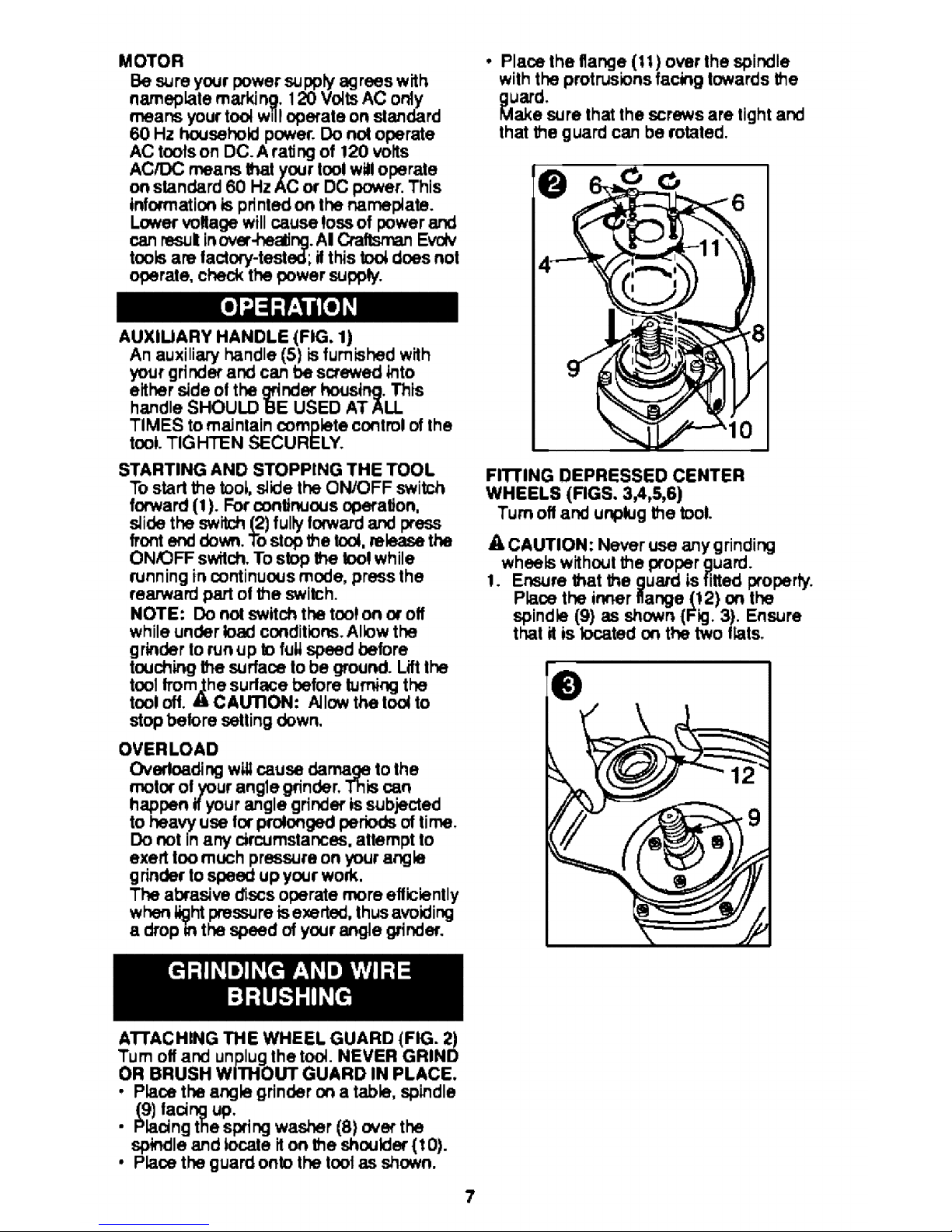

FITTING DEPRESSED CENTER

WHEELS (RGS. 3,4,5,6)

Turn off and unplug the tool.

A CAUTION: Never use any grinding

wheels without the proper guard.

!. Ensure that 1heguard is tilted property.

Place the irmer flange (12) ort the

spindle (9) as shown (Fig. 3). Ensure

that il is located on the two !lats,

@

Turn off and unplug the tool. NEVER GRIND

OR BRUSH WITHOUT GUARD IN PLACE.

, Place the angle grinder on a table, spindle

(9) lacing up.

• Placing the s_ng washer (8) over the

sp_dle and tocate iton the shoulder (i 0).

, Place the guard onto the toot as shown,

7

Page 8

2,

.

,

Place the grinding wheel (4) on the

spindle_9) and inner flange (!2) as

shown rig. 4.

Fit the threaded outer flange (! 4)

making sure it is lacing in the correct

direction for De type of wheel fitted. For

thick grinding wheels Fig. 5, the flange

(14) is fitted with the raised portion

lacing towards the wheel For thin

grinding wheels, the flange (!4) is fitted

with the inner portion lacing away from

the wheel.

Press in the spindle fock button and

rolate 1he spindle until it locks. Keeping

the k)ck button pressed _, tkjhten the

outer flange with the sparmer wrench

pin,vialedas shown in Fig. 6. Hubbed

wheels do not require mounting flanges

and may be t_ghtenedw_lhstud

wrenches.

When using a depressed-center wheel,

hold the tool so that art angle of

approximately 30° exists between the

wheel and the work.

AWARNING: Check rated speed on

depressed-center wheel Never use a

wheel with rated speed lower than the

speed on the nameplate of the tool.

No_: Sanding flap discsare considered to

be grindingwheels and must be used with

guards.

FITTING WIRE BRUSHES

Wire cup brushes screw din_ollyon the

spindle of the machine without the use of

flanges. When usingwire brushes, thread

firmly on spindle byhand. The guard may

be removed forbrushing with fiat wire

b_'ushes.

EDGE GRINDING

Edge grinding may be done with Type 27

depressed center wheels specifically

designed for this purpose. These wheels

are available loca!ly. They must not be

subject to s_depressure, d]_CAUT!ON:

Wheels used for edge grinding may break

i!they bend or twist while being used tot

cut-off wod_ or deep gnnding. Toreduce

the risk of serious injury, limitthe use o!

these wheels to shallow cuttingand

notching (less than 1/2 _ch in depth). The

open side of the guard must be positioned

away from the operator.

REMOVING THE WHEF-J. GUARD (FIG. 7

FOR SANDING AND USING FLAT WIRE

BRUSHES.)

TURN OFF AND UNPLUG THE TOOL

NOTE: To prevent toss ot conlrot, do not

set tool down until accessorf has

completely stopped turning.

As shown in Fig. 7, place the grinder on a

table, spindle up. Use a screwdriver to

remove the 3 screws (6). Remove the

flange (7), guard (4) and spring washer

(8). Store these parts carelully.

8

Page 9

PRECAUTIONSTOTAKEWHEN

SANDINGPAINT

t. Sandingof lead based paint is NOT

RECOMMENDED due to the difficulty

o! controlling the contaminated dust.

The greatest danger of lead poisoning

is to children and pregnant woman,

2. Since it is dif!icutt to identify whether or

not a paint contains lead without a

chemicaJ analysis, we recommend the

following precautions when sanding

any paint:

PERSONAL SAFETY

1. No children or pregnant women should

enter _e work area where the paint

sanding is being done until all cleanup

is completed.

A duslmask or respirator should be

worn byatl persons entering the work

areal The filter shou|d be rel:>Taced

daily or whenever the wearer has

difficulty breathing.

NOTE: ONLY THOSE DUSTMASKS

SUITABLE FOR WORKING WITH LEAD

PAINT DUST AND FUMES SHOULD BE

USED. ORDINARY PAINTING MASKS

DO NOT OFFER THIS PROTECTION.

SEE YOUR LOCAL HARDWARE

DEALER FOR THE NIOSH APPROVED

PROPER MASK,

ENVIRONMENTAL SAFETY

1. Paint should be removed in such a

manner as to minimize Ihe amount ol

dust generated,

2. Areas where paint remova! is occurring

shou_ be sealed with plastic sheeting

of 4 mls thickness.

3, Sanding shoutd be done in a manner

to reduce tracking o! paint dust outside

the work area.

RI-rlNG ABRASIVE DISCS

TURN OFF AND UNPLUG THE TOOL

Use an abrasive disc wilh a backing pad

for sanding with your angle grinder.

1. Remove the guard.

2. Place lhe flange, (backing pad and

abrasive disc sold separately) and

outer flange on the spindle as shown in

Figure 8. Figure 8A shows how to

attach an abrasive disc with a ruiner

backing pad.

.

"r'Kjhtenthe abrasive disc as shown in

Figure 9 by depress_g the spindle !ock

button and fuming the abrasive disc by

hand.

GENERAL INFORMATION

HELPFUL HINTS

* Hold your angle grinder with one hand on

the body and the other hand firmly

around the side handle as shown in

Figure 10.

@

• Always positio_ the guard so that as

much ol the exposed disc as possible is

pointing away from you.

• Be prepared for a stream o! sparks when

the disc touches lhe metal, Direct away

from people and fiammable materials.

9

Page 10

Maintainananglebetweenthediscand

worksudace(Fig.!! ) Olapproximately

30' when grinding and t0°-15 °when

sanding ( Fig. t2) for best toolcontrol,

material removal, and minimal loading,

A, WARNING: Always wear eye

protection while operating thls power

tool including face end body

protecUon when brushing.

exposed to heat may require more

frequent Iubrication.)This lubrication

shou|d be attempted only by trained power

tool repair specialists such as those at

Sears Service Centers or in other qualilied

service organizatior_s.

REPLACEMENT GRINDING WHEEL

Replace the gdnding wheel with a

Craftsman 4-1/2 inch Type 27, available

at Sears stores and other Craltsrnar_

outlets.

30

®

15

CLEANING

B|owing dust and grit out of the motor

housing using compressed air is a

necessary maintenance procedure.

A CALrlrlON: Dust and grit f_om metal

grinding o!ten accumulate on interior

sudaces and could create an electrical

shock hazard i! not cleaned out,

Use only mild soap and a damp cloth to

clean the tool. Never let any liquidgel

inside the tool;never immerse any part of

the Iool intoa liquid.

IMPORTANT: To assure product SAFETY

and RELIABILITY, repairs, maintenance

and adjustment shouid be performed by

Sears Service Centers.

LUBRICATION

Craftsman Evofv tools are propedy

tutxicated at the factory and are ready for

use, Tools shou|d be lutx_cated regularly

every year depending on usage. (Tools

used on heavy duty jobs and tools

10

Page 11

CRAFTSMAN Angle Grinder- MODEL NUMBER 900.24543

I The ModelNumberwil be foundon the NameplAte.AIwsysmention

1

theModel Numberwhenco_cting Seersabout yourtoot_ I

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

REPLACEMENT PARTS UST

39--

35

_J

ITEM PART

NO. NO. DESCRIPTION QTY

i6 569176-00 Side Han_tle

35 569197-00 SpannerWnBnch

35 5140005-33 OuterFlange

37 5140005-34 InnerFlange

38 569202-00 Screw

39 569203-00 Flange

40 5140092-62 Guard

47 5140016-99 Sl>dngWasher

I

I

I

1

3

1

1

I

PARTS NOT ILLUSTRATED:

90565294 InstructionManuad

Model No. Volts Amps RPM

900.245430 120 5.5 i0,000

11

Page 12

Manual de instrucciones

IRA MAN°I

ivTM

Esmeriladora angular de

114 mm (4-_/_pulg

No. modeio 900.24543

A ADVERTENCIA:

Antes de usar este producto, lea

este manual y siga sus Reglas de

seguridad e Instrucciones de

funcionamiento.

• Seguridad

• Operacion

• Mantenimiento

• Lista de piezas

• Espa_ol

Sears Brands Management CorporaUon,Hoffman Estates, IL 60179

www.craftsman,com

13

Page 13

Disco a_

Mango a_l_ (5)

disco(61

UN A_ DE GARAN'rlA LIM_ADA PAPA LOS PRODUCTOS CRAFTSMAN EVOLV

Este producto est_ garantizado contra todo defecto de materia; o rnano de obra

DURANTE UN AI_O a partir de la techa de cornpr& ,.Rereemplazar/z el producto

delecluoso sin cargo al presentar el comprobante de corlnpra.

Para €onocer detalles sobre la cobertura de la garantia para obtener un reemplazo

gratuitO, v!slte el sltIO Web: www.cmftsman.com

Esta garantia no cubre el disco de esmerilado, que es una I_eza consumible que puede

desgastarse debido a| uso normal dentro del periodo de garantia.

Esta garantia queda nula si el producto se utiliza aJguna vez para proporcionar servicios

comerciakss o si se alquila aotra persona.

Esta garantia ksconcede d_echos legakss especificos yes posible que adem_ usted

tenga otros derechos que varien de un estado a otto.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

A ADVERTENCIA: Lea todes las

advertenclas de seguridad •

Instrucc!ones El incump4imiento de [as

adverlencias e instrucciones puede

provocar descargas electricas, incendios

o lesiones graves.

Conserve todas las advertenclas •

Instrucc!ones para futuras

consultas.

El termino"herramientaelectric.a"

inc!uidoen las advertenciashace

relerenciaa las herramientas

eh;_ctricasoperadascon corriente

((>oncableeli_ctrico)o a las

herramientaselectncasoperadas

con baterias (ina!&mbricas),

1) Segurided en el &tea de trabajo

a) Mantenga el &rea de trabalo llmpia

y bien |!uminada,/.as areas

abarroladas y oscuras propician

accidentes.

b) No opere herramientas electricas

en atmbsferas explosivas, como

amblentes donde se encuentran

liqu!dos, gases o potvo !nflamables.

Las herramientas el#ctricas originan

chispas que pueden encender el

po/vo o/o6 vapores,

c) Mantenga a los nir3os y espectadores

alejados de la herramienla el=Jcltrica

en tunclonam!ento. Las

distracciones pueden provocar la

p6rdida de control.

2) Segurldad eld.t,ctrica

a) Los enchufes de la herramlenta

el_ctrica deben adaptarse el

tomacorrlente. Nunca mod#lque e!

enchufe de ninguna manera.No

utilice ning_n erichufe adapt,tKIor

con herramlentu el(_ctrlcas con

COnex!bn a Uerra. Los enchufes no

modilicados y que se adaptan a los

tomacorrientes reducidm el #esgo de

descarga el_ctriceL

14

Page 14

b) Evite e! contacto corpora! con

superficies pueslas a tlerra, como

por ejemplo tuberias, radladores,

tangos y refrigeradores. Ex_ste

mayor desgo de descarga ek_ctrica si

su cuerpo est_l puesto a tierra.

c) NO exponga les _!enlas

el_ldcas a la lluvla o a corKliciones

de humeded. Si ingresa agua a una

herramienta el_fnca, aumenta_ el

riesgo de descarga e!_-'b'P_.a.

d) NO maltrate al cable. Nunca utilice

e! cable para transportar, tlrar o

desenchufar le herramlente _ica.

Mantenga el cable lejos del calor,

acelte, bordes afllados o plezas

m6vileS. Los cables dafiados o

enredados aumenlan el [iesgo de

descarga eldctrica.

e) AI operar una herramlenta el_ctrica

en el exterior, utilice un cable

prolongador adecuado pera tal uso.

Utilice un cable adecuado para uso

en exterioresa finde reducire!riesgo

de descargaetkctrica.

f) Si el uso de una herramlenta

ei_.r;ctrica en un lugar h_medo es

Imposlble de evitar, uUl!ce un

sumlnlstro protegido con un

interruptor de clrcuito pot falla a

Uerra (GFCl). El uso de un GFCt

reduceelr esgodedescargas

3) Seguridad personal

a) Permanezca alerta, controle loque

est6 hacleftdo y utilios el sentido

com_n cuando emplee una

herram!enta el6ctrlca. No ut#ice una

herramienta e/dctrica si estd cansado

o bajo el efecto de drogas, alcohol o

medicamenOos. Un momento de

descuido mientras se opera una

herrarnientae/_rica puedeprovocar

lesiones personales graves.

b) Utilice equipos de protecclbn

personal. Slempre utillce protecclbn

para los ojos. En/as condiciones

adecuadas, e! uso de equipos de

proteccibn, como mascaras para polvo,

celzado de seguridad antidesfizante,

cascos o proteock_n auditiva, reducir_

las lesiones persona!es.

c) Evite el encendido por accidente.

Aseg_rese de que el Interruptor

ester en la pos|cldn de apagado

antes de conectar!o a la fuente de

energia o paquele de baterias, o

antes de !evantar o transportar la

herramlenta. Transpotlar herramientas

et#cfficas con el dedo apoyado en el

interruptor o enchufar herramientas

ekJctricas con el inten'uptor en la

posic_'6n de encendido puede propiciar

d) Retire las clavljas de ajuste o Ileves

de tuercas antes de encender la

herramlenta el_ctrica Una l/ave de

tuercas o una c!avija de ajuste que se

deje conectada a una pieza giratoda

de la herramienta e#Jclrica pueden

provocar lesiortes personales.

e) NO se estire. Conserve e! equilibrio

adecuado y mant&ngase parado

correctamente en todo momento.

Esto permite un me|or contro! de !a

herramienta e!_ica en situaciones

f) Use la veslimenta adecuada. No

use ropas holgadas nl joyas.

Mantenga el cabello, la ropa y los

guantes alejados de las plezas en

mov!miento. Las ropas hotgadas, /as

joyas o e! cabel!o largo pueden

quedar atrapados en /as piezas en

movimiento.

g) SI se suminlstran dispositivos para

le conexlbn de accesorlos con

fines de recolecclbn y extracci6n

de polvo, aseg_rese de que estdn

conectados y que se utilicen

correctemente. El uso de dispositivos

de reco_i_ de poh,o puede reduo'r

!ospe#grosrelacionadoscone!pdvo.

4) Uso y mantenlmlento de la

herramienta el_ctrica

a) No fuerce la herramlenta el_ctrica.

Utilice la herramienta el_ctrlca

correct==pare el trabajoque resllzam.

La herramienta eldctrica correcta harzt

e! trabajo me|or y rr_s seguro a la

vetocidad para ta que rue diserlada.

b) NO utilice la herramlenta eldctrica

sl no puede encenderla o apagarla

con el interruptor. Toda herramienta

e!#ctrica que no puede set conb'olada

mediante e/interruptor es pet_grosa y

debe set reparada.

c) Desconecte e! enchufe de la fuente

de energia y/o e! paquete de

baterias de la herramlenta ektctrlca

antes de realizar ajustes, cambJar

accesor!os o almacenar

herramlentas el_ctricas. Es_as

medJdas de seguridad preventivas

reducen e! riesgo de encender /a

herramienta e!#ctrica en forma

accidental.

o71Guarde las herramlentas el_ctrlcas

que no est_n en uso fuera del

alcance de los nlr3os y no permite

que otras personas no

familiarlzadas con ella o con estas

instrucciones operen la

herramlenta. Las herramientas

ei4)ctricas son pe!igrosas en /as

manos de usuarios no entrenados.

15

Page 15

e) Manlenimiento de las herramienlas

q

g)

trabadas, piezas rotes y toda otra

situacibn que pueda afectar el

funcionamienlo de las herram|entas

el_ctricas. Si encuentra dar3os,

haga reparar le hen'amienta e_ctrlca

antes de utillzarla. Se/xoducen

muchos accidentes a cause de/as

herramierrlas e!6ctricas que camcen

de un mantenimiento adecuado.

Mantenga las herram|erdas de

corte afllades y l!mp|as, Las

hErram_entas de _ con rnank_i_

adecuado, con los bordes de corfe

a#lados son rnenos propensas a

_'abarse y son mas _ciles de confrolar.

Ut|lice la herram|enta el_,ctrica, los

accesorios y las brocas de la

herramlenta, etc. de acuerdo con

estas |nstrucciones y tenlendo en

cuenta las condiciones de

trabajo y e! trabajo que debe

reallzarse. El uso de ia hen'amienta

e/dctrica pare operaciones diferentes

de .z_u_flas pare/as que rue diserlada

podnaonginarunasituaa'_pelJgrosa.

5) Mantenimlento

a) Haga que una persona de

reparac!ones califlcada realice el

mantenimlento de su herramlenta

el6ctrica y utilice plezas de repuesto

id_,nticas so!emerita. Esto garantizara

ia segurktadde iaherm'nienta

INSTRUCCIONES DE

SEGURIDAD PARA TODAS LAS

OPERACIONES

Advertencias de seguridad comunes

pare todas !as operaciones de

esmer!lado, !!jado, cepi!lado con cepil!o

de alambre y pulido, y pare operaclones

de corte y desbaste abrasivo

a) Esta herramlenta el_,ctrlca est_

dlser'iada pare utlllzarse como

esmerlladora, lljadora, cepillo de

alambre, pulidora o desbastadorao

Lea todas las advertenclas de

seguridad, instrucciones,

ilustraclones y especlflcaclones

b)

las instp_ciones enumeradas a

contirtuacibn puede provocar una

descarga e_clrica, un incendio o

lesiones graves.

No utilice accesor|os que no est6n

dise_ados y recomendados

especiflcamente pot e! tabricante

de la herramlenta. El hecho que el

accesotio pueda conectarse a La

16

herramienta eJ6ctricano garantiza un

funcionamiento seguro.

c) La velocidad nominal del

accesorlo debe ser equivalente a

la velocidad mdxima Indicada en

la herramlenta ek_ctrica, como

pueden romperse y desprenderse.

d) E! d!_metro extemo y e! grosor del

accesorio deben ester dentro del

rango de capacidad de la

herramlenta e!6ctrlca. Los

accesonos de tamafio incorrecto no

ni controlarse

e) El tamar_o del eje de los discos,

las bridas, las almohadillas de

respaldo y cualqu|er otro

accesorlo debe adaptarse

correctamente al eje de la

herramtenta eliictrica. Los

accesorios con onficios que no

coincidan con el sisterna de m_taje

de la herramienta el6ctrica se

desequilibrarSn, vibrar_m

excesivamente y podr_tn producir la

p6rdida de control de ia herramienta.

f) No utilice un accesor!o dai_ado.

Inspeccione el accesorto antes de

cada uso; por ejemplo, el disco

abrasivo pare verificar que no

tenga astillas ni grietas; la

almohadilla de respaldo pare ver

s! hay grietas, desprendimierdos o

desgaste excesivo y e! ceplllo de

alambre pare vet sl tlene alambres

sue#os o quebrados. Si la herm_ienta

eli_ctr!ca o e! accesorlo sufre una

caide, Inspecctone pare ver si hay

daP,os o instale un accesorto en

buen eslado. Despu6sde

inspecdonar e instalar un

accesorio, ubiquese y ublque a los

espectadores lejos del piano del

accesor!o girator!o yhaga

funcionar la herramienta a

veloctdad mltxlma sin carga durante

un minuto. Los accesorios da_ados

genem_nente se rornpe_n durante

esta prueba.

g) Ut|lice equipos de proteccibn

persona!. Seg_n la aplicacibrk

protectores auditivos, guantes y

de!antal de taller pare protegerse

de los pequet_os fragmentos

abraslvos y de los fragmentos de

la pieza de trabajo. La proteccibn

pare los ojos debe ser capaz de

Page 16

delenerlosresiduosvolStikssque se

ne_anen l'asdifemntesoperaciones.

rr_scarapara polvoo respirad_

debe setcapaz de filtrarlasparticulas

_aeneradasporelfuncionamientode

herramienla.La exposicibn

l:Xolongada8.1ruidointensopuede

provocarp_rdidade laaudicibn.

h) Manlenga a los espectadores a una

dlstancla segura del 1_Beade

trabajo. Toda persona que Ingrese

al _rea de trabajo debe utlllzar

lrabajo o de un accesono roto

pueden volary p¢ovocar lesiones rn_s

all_ del Nea de operaciones cercana.

i) Cuando reallce una operac!6n en

que e! accesor|o de corte pueda

tocar cables el_ctricos ocuItos o

su proplo cable, sostenga la

herramlenta solamente por las

superficies de agarre alsladas. El

contacto con un cable con "corriente

ei_cVica"har_ que tas parles rnel_licas

expuestas de la herramienta tambi_n

lengan =co_ksnte el_ctrica" y e!

operador sulfa una descarga.

j) Coloque el cable lejos del accesorio

glratorlo. Si pksrdeel control de la

herramienla, el cable puede codarse

o enredarse y jalarks la mano o e|

brazo hacia e_accesorio giratorio.

k) Nunca apoye la herramienta hasta

que el accesorlo se haya detenldo

completamente. E_accesorio

giralorio puede enganchar la

superficksy producir la p_rdida de

control de la herramienta.

!) No haga funclonar la herram!enta

elJJctrica mlentras le carga a su

lack). E_ contacto accidental con el

accesodo g,iratodo !_Jede hacer que

Sste se ksenganche en ta Topa y

lance el accesono hacia su cuerpo.

m)Limple frecuenternente los orlfic!os

de ventllaci6n de la herramlenta

el_._ctrlic&El ventilador del motor

atraer8 el po14odentro de la cubksrta,y

la acumulacibn excesiva de po4vo

pu e pindar gos

n) NO use la herramienta el_ctrica

cerca de mater|ales Inflarnables.

Las chispas pueden encender estos

matedales.

o) No utlllce accesorios que

requleran refr|gerantes liquidos. El

uso de agua u otros refr_gerantes

liquidos puede producir una

eksctrocucibn o descarga ek_ctrica.

p) No utlllca dlscos "npo 11 (copas

17

c6nicas) an esta herramlenta, Et uso

de accosorios inco_ectos puede

produck kssiones.

o.) Slempre utlllce el mango lateral.

Ajuste el mango con flrmeza. Se

debe utilizar sksmpre el mango lateral

aamantener el control de la

mienta en Iodo momenlo.

R) Utilice abrazaderas u otro me_todo

pr_k:tlco para asegurar y soslener la

pleza de trabajo en una plataforma

estable. Sostener la pieza de trabajo

con la mano o contra su cuerpo

'ovoca inestabilidad y puede Ilevar a

p6rdida del control,

Causas del retroceso y su prevencibn

por parte del operador

ELretroceso es una reaccibn repentina al

petlizco o atascamiento de un disco

giratorio, una almohadilla de respaldo, un

cepilio o oJalquLerolro accesono. El

pellizco o e! atascamiento hacen clue el

accesodo giralorio se trabe r_pidamente,

lo que a su vez I:xrovocaque la

herramie_ta e_ctrica fuera de controt

vaya en sentido opuesto al giro del

accesorio en e_punto del atascamiento.

Pot ejempio, si la pieza de trabajo

atasca o pellizca el disco abrasivo, el

bon:le del disco que ingresa en ePpunto

de plksgue puede clavarse en {a

supedicie de_material y provocar que el

disco salte o se desengonche. Ei disco

puede sallar hacia et operador o en

sentido contrar|o, seg0n la direocibn det

movimiento de_disco en el I:xJntode

pellizco. Los discos abrasivos tambiq_n

se pueden €omper en eslas cond_c_ones,

Et mtmceso es el resu_tado de un real

uso de fa herrarnksnta o de condiciones

o pmcedimientos operativos inconrectos

y se puede evitar tomando las

precauciones apropiadas que se

_ndican a continuacibn:

a) Sostenga la herramlenta el_,ctrica

con firmeza y ubique el cuerpo y el

brazo para poder reslstir las fuerzas

de retroceso. Siempre util|ce el

mango lateral, en caso de lenerlo,

para Iograr el m_ximo control sobm

el retroceso o la reacck_n de torsi6n

durante e! encendido, ELoperador

puede controtar la reaccibn de torsibn

o las fuerzas de retroceso si toma las

precauciones adecuadas.

b) Nunca coloque la mano cerca del

accesorlo glratorlo, ya que _ste puede

hacer un retroceso so_e la mano.

c) No ubk:lue el cuerpo en el &rea

hacia donde la herramienta

el_ctrlca se desplazar_ si se

produce un retroceso. E_ reVoceso

tmpulsar_ la herramienta en ta

Page 17

direccibn opuesta el movimiento de!

disco en e! punto de alascamiento.

d) Tenga especial cuidedo el trebajar

en esquirms, bordes f!!osos, etc.

f_osos y e_rebote tienden a

enganchar el aocesono giratorio y

ptodudr la p_:lida de control o el

retroceso de la unidad.

e) No conecte una hoja pare

carpinteria pera sierra de cadena ni

una hoja de sierra dentada. Estas

hojas puede producir el retroceso y

la I_rdida de control Irecuentes.

Advertencias de seguridad especificas

para operac!ones de esrnerilado

a) Utilice s61o los tipos de disco

recomendadco pare su herremienta

ek_ctrica y el protector espec#!co

pare el disco selecclonado, Los

discos para los que la herramienta

el_ctrica no esl_ dise_ada no pueden

protegerse adecuadamenle y son

a) Utllice Ontcemente tipos de disco

recomendlados pare su herremlenta

el_;ctrtca y el protector espec#Ico

di_ para el disco sele(x_,

Los discos no diser_adospara la

herramienta e_ctdca no l_Jeden

protegerse adecuadamente y son

mseguros.

b) El protector debe sujetarse

firmemente a ie herramienta

el_-,ctrlca y estar en una postctbn

que brlnde rn&xima seguridad, de

manere que una minima parle del

disco quede expuesta hacla el

operador. RE]protector ayuda a

resguardar al operador de los

fragrnentos de discos rotos y del

contacto aocidenta_con e| disco.

c) Los discos deben ut!!Izarse

_nlcamente para las apllcaclones

recomendadas. Por ejemplo: no

esmerile con el costado del disco.

Los discos abras;vos est_m disei_ados

para esmerilado perif_rico yes

posibie que Jasfuerzas lat_aJes

apticadas a estos discos _ovoquen

que se rompan.

d) Siempre utllice brides de disco que

no estJJnder3adas y clue tengen le

forma y el temar_o aproplados para

el disco seleccionado, Las bridas de

disco adecuadas bdndan soporte al

disco y as! reducen ta posibilidad de

que el disco se rompa. I.as bridas

para Ios discos de corte pueden ser

distintas de las bddas de discos de

esmerilado.

e) No utilice discos desgastados de

herramlentas el<_,clrlcas m_rm

grandes. Los discos dise_ados para

herramientas el_ctricas rr_s grandes

no son adecuados para ta mayor

velocidad de una herramienta ross

pequef'm y podrian estallar.

Advertencias de seguddad especificas

para operaciones de lijado

e) No utillce pepel pare disco de

!ijado de tamer3o exce$ivamente

grende. Sige las recomendaclones

de! febrlcante al seiecclonar el

papel de Ilia. Los papeles de lija rr_s

grandes que sobresalen de ta

alrnohadilla de lijado representan un

peligm de laceracibn y pueden

provocar el retroceso o que el disco

se enganche o se rompa.

Advertencles especiflcas de seguridad

pare operaclones de cepillado met_llco

a) Tenga en cuenta que se

desprenden cerdes de eiembre del

cepillo Incluso durante el

funclonamiento normal. No

sobrecargue los elambres al

eplicar une carge excestve el

cepillo. Las cerdas de alambre

pueden penetrar f,_cilrnenleen la

ropa delgada ylo la piel,

b) S! me recomlende e! uso de un

protector pars el cepiliedo

met&lico, no permita ntngune

Interferencla entre el protector y el

disco o e! cepll!o de alembre, El

disco o el ospillo de alambre pueden

expandk su di_rnetro debido a la

pieza de Irabajo y las fuerzas

centrifugas.

Seguridad adicional

Informacibn

• No ulilice discos pianos abrasivos o de

diarnanle tipo I sin la proleccibn

adecuada. (La unidad no incluye el

protector),

_I_ADVERTENCIA: SIEMPRE uUlice

anteojos de seguridad. Los anteojos de

uso dia6o NO son anteojos de segu6dad.

Uti!ice tarnbkJnuna m_scara facial o

antipol_ si la operacibn produce poMl/o.

SIEMPRE UTILtCE EQUtPOS DE

SEGURIDAD CERTIFICAOOS:

* Proteoci6n para Io6 ojos ANSfZS7.1

(CAN/CSA ,_94. 3),

* Proteccidn para !os oidos ANS! $!2.6

(s3. 9),

. ProtecckJn para !as Was respiratorias

N!OSWOSHA/MSHA.

18

Page 18

A ADVERTENCIA: Parte dell polvo que

se produce al ,jar, aserrar, esmerilar,

takzdrar y al realizar otras actlvldsdes

de construccibn contlene productos

uimicos reconocidos por el Estado de

alifomia como causanles de cttncer,

defectosdenadmbr_ uom:mproblm'u_

reproductivos. Algunos ejemplos de

estos productos quimlcos son:

•elp, mode p ras basedep mo,

• el ars_nico y el ctomo de ia rnad_a con

tratamiento quire|co.

E! riesgo derivado de estas exposiciones

varia seg_sn!a frecuencia con !a que se

realice este #po de trabajo. Para redudr ia

equipos de segutidad aptobados, corno

/as rmJscaras antipolvo especialmente

disefladas para filtrar parliculas

rnictosc6p,cas.

- Evlte el contacto prolongado con el

polvo orlginado a! !|jar, aserrar,

esmerilar, taladrar y a! realizar otras

actividades de construccibn. Ulllice

indumentarla protectora y lave las

_reas expuestas con agua y jabbn. $i

permite que el polvo entre en su boca y

ojos, o que pennanezca sobre su pie/,

podria provocar !a absorck_n de

AP Oductos quimicos nocivos.

ADVERTENClA: E! uso de esta

herram|enta puede generar polvo y/o

dispersarlo, Io que puede causar

lesiones resplratorlas graves y

permanentes u otras. Para ia exposici6n

at potvo, siem/xe utitice pro_ecci(_n

respiratoria aprobada por N/OSH/OSHA.

Oirija /as particu/as /ejos de la cara y e/

_uerpo.

ADVERTENCIA: Durante el uso,

siempre utilice proteccibn Individual

para los oidos adecuada que cumpla

con la norrna ANSI $12.6 ($3.19). Bajo

ciertas circunstancias y seg(m el periodo

de uso, e! ruido producido pot este

producto puede contribuir a/a p#rdida de

audi_i6n.

A ADVERTENCIA: Siempre uUlice

protecc!_)n para !os ojos. Todos/os

usuarios y/as personas a su a/rededor

deben utilizar profeccidr_para los ojos clue

cumpla con/as norrnas ANS! Z87.1,

ADVERTENCIA: Cuando no la utilice,

coloque la esmer|ladora sobre una

superflcie estable donde no pueda

moverse de rnanera accidental, rodar

ni provocar rlesgos de tropezones o

caides,

A PRECAUCI(_N: Para reduc!r e! r|esgo

de leslones personales, tenga mucho

cuidado ai trabajar en una esquina o

horde, ya que puede producirse un

rnovimiento repentino y violento de la

hen'amienta st el ck'scou otto accesorio

entra en contacto con una supefficie

secundaria o con e/borde de una

La etiqueta de la herramienta puede

incluir los siguientes simbolos:

v,.................. vo/t_s

,4................ amperk)s

/,_ ................ herfzios

W ................ ratios

min .............. m#xttos

"_ .............. corriente attema

.-.=.= ............ corriente direcla

no ................ velooklad sJncarga

0 ................ construcck_n de Clase II

..Jmin .......... revoluciones o

reciproca_ones por minuto

_) ................ terminal con conexidn a

tiena

l[_ .............. slmbok9 de aterfa segurktad

CABLES DE EXTENSION

Cuando use un cable de extension,

aseg0rese de usar uno de un calibre

suficie_ntecomo para cargar con Ia

corriente que requedr_, su producto. Un

cable de menor calibre causar_ una

caida en et voitaje de la linea Io que

resultar_ en p_dida de potencia y

sobrecalentamlento. El siguierde cuadro

muestra el tarnafio correcto a utilizar,

dependiendo de| targo dei cabJey el

amperaje nominal Si tiene dudas sobre

cual,calibre usar, use un calibre mayor.

Mientras menor el nurnem del calibre,

mayor ta capaddad del cable.

Calibre ndnimo parn iu!Igos de r..ablel

Voltiol Largo total del cable tn metrOI

130V 0.7,e 7,s.tS2 t5,2-30,4 30A-4s,7

340v 0-1_ _.30__ 30,4:_ e03:_,4 _

M_s No _ American Wire Gag,=

de de

0 -6 18 i6 16 t4

6 -t0 18 t6 14 12

10 -12 16 16 14 12

12 -16 14 12 No Recomendado

MOTOR

Aseg_rese de que la luente de energia

corlcuerde con Io marcado en la placa de

identificacibn. CA de 120 voltios solamenle

signitica que su herramlenta funcionar8

19

Page 19

con la energia dom_stica est_mdar de 60

Hz, No haga !undonar herramientas de CA

con CC, Una dasificacibn de CA/CC de

! 20 voll_ossignifica que su herramienta

!uncionar_ con energia est_nclar de CA o

CC de 60 Hz. Esta informadbn est_

im._esa en la placa de identilicacibn. Un

vormje menor producir_,p_dida de

potencia y puade provocar

sobrecatentamiento. Todas las

herramientas Craftsman Evolv se prueban

en la !_d:mca;siesta herramienta no

funciona, revise ta fuante de energia.

MANGO AUXILIAR (FIG. 1)

La esmefiladoraesl_provis_de un mayo

la esmedladora. Este mango DEBE

UT!L!ZARSE EN TODO MOMENTO para

mantene_ el conlrol absolulo de la

herramienta, Aj0steio !irmemente.

ENCENDIDO Y APAGADO DE LA

HERRAMIENTA

Para encendef la herramienta, deslice el

interruplor de encendido/apagado

(ON/OFF) hack] adelante (1). Para un

!uncionamiento continuo, deslice el

interruptor (2) tolalmente hada adelante y

opdma hacia abajo el extremo delantero.

Para apagar la herramienta, suelte el

interruplor de encemdido/apagado

(ON/OFF), Para apagar la herramienla

mientras fundona en modo continuo,

optima la parte posterior del interruptor.

NOTA: No endenda ni apague Is

herramienta mientras est_ sometida a

carga, Permita qua la esmefiladora alcance

la veiocidad m_xima antes de ponerla en

contacto con ta supedicie a esmerilar.

Levanle la herramienta de la superficie

antes de apagada.

_, PRECAUC!_)N: Permita que la

herramienta se detenga antes de

depositarla sobreuna superfide.

SOBRECARGA

La sobrecarga provocar8 d_os en el motor

de su esmeriladora angular. Esto puede

suceder si su esrneriladora angutar est_

sujeta a uso intensivo durante periodos

protongados, No intente en ninguna

circunstancia aplicar demasiada presi6_

sobre la esmefiladora angular para agi!izar

su trabajo,

Los discos abrasivos fundo_ar_n con m&s

e!icacla sise aplica poca wesibn y esto

evitar_ una disminucibn de la veloddad de

su esrnedladora angular.

ESMERILADO Y CEPILLADO METALICO

(FIG. 2)

APAGUE Y DESENCHUFE LA

HERRAMIENTA. NUNCA ESMERILE NI

CEPILLE SIN EL PROTECTOR EN SU

LUGAR.

• Co_oqua laesmeriladora angular sobre

urta mesa con el eje {9) mirando hacia

arriba.

• Coloqua la arandela de resorte (8) sobre

el eje y ubiquala sobre el reborde (10).

• Cotoque el Woteclor sobre la herramienta

tat como se muestra.

• Cotoqua la txtla (11} sobre el eje con las

_otu berandas mirando hacla el protector.

Aseg0rese de que !os Iomitlos est6n

aiustados y de que el protector se puada

g=rar.

INSTALACI_)N DE DISCOS CON

CENTRO HUNDIDO (FIGS. 3, 4, 5, 6)

Apague y desenchufe la herramienta.

,P,PRECAUCION: Nunca utilice discos de

esrnerilado sin el proteclor adecuado.

t. Aseg0rese de que el protectm est6

correctarnente instal,ado. Coloque Ia

brida interna (12) en et e_e (9) como set

muestra (Fig. 3). Aseg_rese de que

esl6ubicadosobm ambas superficies

plarlas.

2O

Page 20

O

12

_:_dsta cornose muestra en la Rg, 6,

iscoscon cubo no requieren txidas

de rno_taje y se pueden ajustar con

Ilaves est_ndar.

.

3_

4_

Coloque el disco de esrnerilado (4} en

el eje (9) y ta brida intema (t2) como

se muestra (Fig. 4).

0

14

Instale ta bdda extema roscada (!4)

asegur_ndose de que est_ odentado

hacia la direccibn cormcta para el t_po

de disco instalado. Para discos de

esmerilado gruesos (Fig. 5), la brida (t4)

se instaJacon la parte elevada orientada

hacia el disco. Para discos de

esrnedlado deigados, Labdda (14) se

instala con la parte intema odentada en

direccibn opuesta aJdisco.

E -- -J=

Optimae! bol_x_de b!oqueod_ e_ey

gireel eje hastaquese bloquee.Conel

botbnde t_oqueoo_mido, ajusteta

bridaextema conla Ilavede tuercas

5. AI utUiza.run disco con centro hundido,

sostenga ta herramienta de modo que

haya un _u'_guiode aproximadamente 30

grados entre el disco y la pieza de

trab .

_kADVERTENCIA: Veritique la velocidad

nominal del disco con centro hundido.

Nunca utilice un disco con una velocidad

nomina! menor que la indicada en ta

p4acade identificacibn de _aherramienta.

NOra: Los discos de lijado con aletas se

consideran discos de esmerilado y

deben utilizarse con I_otectores.

INSTALAC_N DIECF..RLLOS ME'rAucos

Los cepillos _t_lk_os con forma de copa

se e_oscan _rectamente en el eje de la

herramienta sin el uso de bfidas. AI utilizar

cepillos met_.licos,enrbsquelos

manualmente con lirmeza en el eje. Se

puede retirar e! protectorpara realizar un

cepillado con cepil_osmet.'_licospianos.

ESMERILADO DE BORDES

El esmerilado de hordes puede realizarse

utJlizandodiscos con centro hundido tipo

27 especificamente disei_ados para este

fin. Estos discos est_ dispordbles

IocaJrnente.No debe_ someterse a

presibn lateral

A PRECAUCI6N: Los discos que se

utilizan para esmerilade de hordes

pueden quebrarse si se doblan o luercen

mientras se utilizan para trabajo de corte

o esmerilado prolundo. Para reduck e_

riesgo de una lesi_ grave, limite el uso

de estos discos para cortes poco

_ofundos y muescas (menores de 12,7

mm (112 pulgada] de prolundidad). El lado

abierto del protector debe ubicarse lejos

del operador.

21

Page 21

RETIRO DEL PROTECTOR DEL DISCO

(FIG. 7 PARA UJADO Y USO DE

CEPILLOS METALICOS PLANOS.)

APAGUE Y DESENCHUFE LA

NOTA: Papa evitar la p_dida de| control,

no deposite _ahetramienta sobre una

supedicie hasta que el accesorio haya

dejado de girar pot completo,

Como se muestra en la Fig. 7, coloque la

esmedtadora sobre uaa mesa con el eje

hacia arriba. Utilice undestomillador para

relirar los 3 tomiilos (6). Retire la brida (7),

el protector (4) y la arandela de resorte (8).

Guarde eslas piezas con cuidado.

SEGURIDAD AMB|ENTAL

1.

polvo generada,

2. Las 8reas donde se realiza remocibn

de pintura deben estar selladas con

t_minas de pl_tico de 0,t0 mm

(4 mil_simas de pulgada) de espesor.

3. E! lijado se debe reaJizar de manera de

reducir los vestigios de polvo de

pintura tuera del _trea de Irabajo.

INSTALACI(_N DE DISCOS ABRASIVOS

APAGUE Y DESENCHUFE LA

HERRAMIENTA,

Utilice un disco abrasivo con una

almohadilla de respaldo para el Iijado con

su esmeriladora angular,

!. Retire el protector,

2. Cotoque la brida (ta almohadilla de

respaldo y el disco abrasivo se venden

por separado) y la brida externa en el

e como se muestra en la Figura 8. La

gura 8A muestra la fotma de instalar

el disco abrasivo con una almohadilla

de respaldo de goma,

PRECAUCIONES QUE SE DEBEN TOMAR

AL LIJAR PINTURA

1. NO SE RECOMIENDA el lijado de

pintura con base de piomo debido a la

dificultad para conlrotar el polvo

contaminado. El mayor pehg'ro de

envenenarniento pot p_ornoes para los

n_os y las mujeres embarazadas.

2. Daclo que es di!icil determinar si una

pintura convene plomo o no sin hacer

un an_lisis quimico, recomendamos

lornar las siguientes precauciones a]

lijar cualquier pintura:

SEGURIDAD PERSONAL

I. Ningun ni_,o ni mujer embarazada debe

itx:jresar al _.rea de trabajo donde se

est_ fijando la pifltura basra que se

haya terrninado toda _a |impieza.

2. Todas las personas que ingresen al

_rea de trabajo deben usar una

m&scara anlipolvo o una mascarilla de

respiracibn, El filtro debe reemplazarse

diariamenle o cada vez que el usuado

lenga dificultad para respirar.

NOTA: $61o se deben usar aquellas

mliscaras antipolvo adecuadlas para

.

Ajuste el disco abrasivo como se

muestra en la Figura 9, oprimiendo el

bot_xt de btoqueo del eje y girando el

disco abrasivo en forma manual.

para obtener la m&scara adlecuada

aprobada par NIOSH,

22

Page 22

INFORMACI6NGENERAL

CONSEJOSUTILES

• Soslengasuesrnedladora angular con

una mano sobre launidady laotra

marK) apoyada nrrr_mente alrededor

del mango lateral como se muestra en

la Figura 10

• Sk)mpre coloque el protector de modo

que J,amayor cantidad pos_blede fa

parle expuesta del disco apunte en

direccibr_opuesta a usted

• Est_ preparado para un !lujo de cNspas

cuando el disco loque el melal Dirijalo

k)jos de ras personas y los materiates

intlamab|es

• Manteno_ un _nguto enlre el disco y la

superfic_ede trabajo (Fig. !1) de

aproximadamente 30 grados al

esmerilary de t0 a 15 _rados al fijar

(Fig !2) para lograr mejo¢ control de la

herramie_ta, 6plima remocibn de

mateda| y carga minima

ADVERTENCIA: Siempre ulilice

protecci6n para los ojos cuando opere

esta herramienta el6ctrica, incluida

protecc!6n para la cara y e! cuerpo

cuando ceptlle.

@

30 °

LIMPIEZA

cornmmidoes un procedimientode

manlenimientonecesario

_t,PRECAUCI(_N: A rnenudo se acumulan

polvo y suck)dad de me_al sobre las

supedicies interiores y estos pueden

provocar riesgo de descarga ei_clrica si

no se eliminan

Pare limpiar la herramienla, sblo utilice

jabbn suave y un patio h_medo. Nunca

permita que penetre liquido dentro de la

he_ramk)nta; nunca surnerja r_nguna

p_eza en un liquido

IMPORTANTE: Paragaranlizar la

SEGURIDAD y CONFIABILIDAD del

producto, las reparaciones, e_

Manlenimiento de Sears

LUBRICACI(_N

Las herramientas Crallsman Evoiv se

lubdcan debidamente eft la f_brica y est_m

lislasparasu uso. Las he_ramientas

deben lubricameperibdicamenletodoslos

ai_osseg0n su uso. (Las herramientas

utilizadasen Irabajos pesados y aqu_dlas

expuestas at calor pueden necesitar una

lubdcacibn n_s fmcuerde). Esta

lubricacibn sblo debe ser realizada pot

personas capacitadas especialistas en ia

reparacibn de herramientas ei6ctricas,

corno aqu_llas de los Centros de

Mantenimienlo de Sears o de otras

mganizacionescaJ_ de manle_imiento

REEMPLACE EL DISCO DE

ESMERILADO

Con uno Crallsman de 114 mm

(4-1/2 putgadas) lipo 27, dispoeibk) en las

tiendas de Sears y an otms disldbuidores

de Craltsman

23

Page 23

=r

Get it fixed, at your home or ours

Your Home

For troubleshooting,product manuals and expertadvice:

managemylife

www,matzagemylile.com

For repair in your home ol all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it

For the replacement parts, accessories and

owner s manuals that you need to do-it-yoursell.

For Sears prolessional installation of home appliances

and items like garage door openers and water heaters.

! -800-4-MY-HOME

(1.8oo-4e_.4663)

www.sears.com

Call anytime, (Jayor night

(U.S.A.andCanada)

www+sesrS.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location ol the nearest

Sears Parts Repair Service Center

1-800-488-1222 (u.s.A.)

WWW.SeSr$,COlrll

1-800-469-4663 (Canada)

www.sears.ca

To purchasea protectionagreementon a productservicedbySears:

1-800-827-6655 (usA) 1.800-361-6665 (ca-a:la)

Parapedir servidode

a dorrtdlio, y para ordenar piezas:

1.888-$U4-1OGAR

www.se_.com

Au Canada pourservi_ en fran

1-800-LE-FOYER Mc

(l.eoo.,_3.s_P,

www.sears.ca

-Sea/rs

Regiete_edTrademark1_"Trademark of KCDIPoLLCin theLk_#edStales, or Seers BrandS,LLC in0(l'mrCO,unMeS

Mar,"AFlegietradaI TM l_trca de F_brta de KCOIP, LLC errEsladOeUnldos,o Seem B_ands,LLC in olxo=pelses

uc Me4_CLUede €ommeeceIV=>1,4mqued,_ de Seer'=Brsn,dn,LLC

Loading...

Loading...