Page 1

OWNERS

MANUAL

MODEL NO.

900.233550

CAUTION:

Read Rules for

Safe Operation

and instructions

Carefully

8"1/4in. OO___POUNDMITER SAW

Introduction

Operation

Maintenance

Repair Parts

sold by SEARS, ROEBUCK AND CO,, Chicago, IL 60684 USA°

Form No, 875437

Printed in W Germany

Product Made in W Germany

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN PORTABLE ELECTRIC SAWS 1

if this CRAFTSMAN Saw fails togive complete satisfaction within one year from date of purchase, return it to the nearest t

Sears store throughout the U.S Sears wilt repair it, free, If this CRAFTSMAN Saw is used for commercial or rental pur-

poses warranty applies only for 90 days from date of purchase 1

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY

FROM STATE TO STATE. ........... !

SEARS,

ROEBUCK AND CO,, DEPT, 698/731 A, SEARS TOWER, CHICAGO, IL 60684 t

INTIODUOTION

"(our new 1114in. Compound liter Saw is a rugged, dependable tool that will miter wood and other materials with

accuracy and repeatability Easy to operate, its the ideal saw for the serious Do-it-Yourselfer

Please take the time to read this Owner's Manual thoroughly Pay particular attention to the safety rules provided Only

with a thorough understanding of your Miter Saw will you be able to utilize its full potential

SAFETY RULES:

1, KEEP GUARDS IN PLACE and in working order,,

2. REtVlOVE ADJUSTING KEYS AND WRENCHES, Form a habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

3, KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents,.

4. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet locations, or' expose them to

rain. Keep work area well tighted_

5, KEEP CHILDREN AWAY. All visitors should be kept a safe distance away from work area.

6 MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys,

7 DON'T FORCE TOOL. It will do the job b_tter and be safer at the rate for which it was designed,

8, USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not designed.

9. WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get caught in

moving parts. Nonslip footwear is recommended Wear protective hair covering to contain long hair.

10. ALWAYS USE SAFETY GLASSES° Also use face or dust mask if cutting operation is dusty, Everyday eyeglasses

only have impact resistant lenses, they are NOT safety glasses

I1, SECURE WORK, Use clamps or vise to hold work when practical It's safer than using your hand and it frees both

hands to operate tool.

12. DON'T OVERREACH. Keep proper footing and balance at all times,

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance, Follow instructions

for lubricating and changing accessories,

14 DISCONNECT TOOLS before servicing; when changing accessories such as blades, bits, cutters, etc

15 REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in OFF position before plugging in,

16, USE RECOMMENDED ACCESSORIES. Consul the Owner's Manual fo[ recommended accessories,. The use of

improper accessories may cause risk of injuryto persons,,

17 NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally

contacted

18, CHECK DAfVtAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully

checked to determine that itwill operate properly and perform its intended function_check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect itsoperation. A

guard or other part that is damaged should be properly repaired or replaced.

19, NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool until itcomes to a complete

stop

20, DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN GASEOUS OR EXPLOSIVE

ATMOSPHERES, Motors in these tools may spark and ignite fumes

21. For your own safety, read instruction manual before operating miter saw,.

22 KEEP HANDS OUT OF PATH OF SAW BLADE.

23 DO NOT ATTEMPT ANY FREE HAND CUTTING with this saw

24. NEVER REACH around or behind saw btade.

25, SHUT OFF POWER AND WAIT FOR SAW BLADE TO STOP before servicing or adjusting the saw

.R

t_

ADDITIONAL SAFETY RULES FOR THE POWER MITER SAW'

1, DO--Protect line with at least a 15 ampere time

delay fuse,

2. DO--Make certain the blade rotates in the correct

direction,,

DO--Be sure all clamp handles are tight before

starting any operation.

Page 2

Page 3

ADDmTIONAL SAFETY RULES (Cont'd)

4. DO--Be sure blade and arbor collars are clean and

recessed side of collars are against blade. Tighten

arbor nut securely

5, DO--Keep saw blade sharp and properly set.

6. DO--Keep motor air slots clean and free of chips,

7. DO--Use both upper and lower blade guards at all

times°

8, DO--Operate only on designated voltage and

frequency

9 DO--Tighten all clamps before operating

10o DO--Use blades of recommended size only

11 DO--Hold motor shaft/saw blade only as instructed

in this manual.

12, DO--Operate in dry environment only

,13, DO--Allow motor to reach full speed before cutting

14. DO--Keep visitors clear.

!5. DO--Keep hands clear of blade area when saw is

plugged in.

16. DO--Use blades recommended for operation at

greater than 3600 RPM only

NOTE: This saw should not be used to cut ferrous metals

or masonry°

NOTE: This saw should never be used to recut small

pieces.

ELECTRRCAL CONNECTION

Be sure your power supply agrees with the nameplate

marking. 120 Volts, 60 Hz or '_,C only" means your tool

must be operated only with alternating current and NEVER

with direct current. A voltage decrease of more than 10%

will cause loss of power and overheating All Sears tools

are factory tested; if this tool does not operate, check the

power supply

DOUBLE=INSULATION

improved insulation system isfor added protection against

injury resulting from a possible electrical insulation failure

within the tool.

This tool is intended for residential use only.

CAUTION: When servicing Double-Insulated Tools,

USE ONLY IDENTICAL REPLACEMENT PARTS. Replace

or repair damaged cords.

NOTE: The lower the wire size number, the heavier the

wire, and the farther it will carry current without a

significant voltage drop.

EXTENSION CORDS

When using the tool at a considerable distance from the

power source, an extension cord of adequate size must

be used for safety, and to prevent loss of power and

overheating Use the table below to determine minimum

wire size required.

Before using cords, inspect them for loose or exposed

wires and damaged insulation.. Make any needed repairs

or replacement before using your power tool.

CHART FOR M_NtMUM WIRE SIZE (AWG) OF EXTENSION CORDS

TOTAL EXTENSION CORD LENGTH--FEET

25 50 75 100

t 20 Vol| Tools t 6 14 12 10

NOTE: The lower the wire size number, the heavier the

wire, and the farther it will carry current without a

significant voltage drop,,

OPERATUON

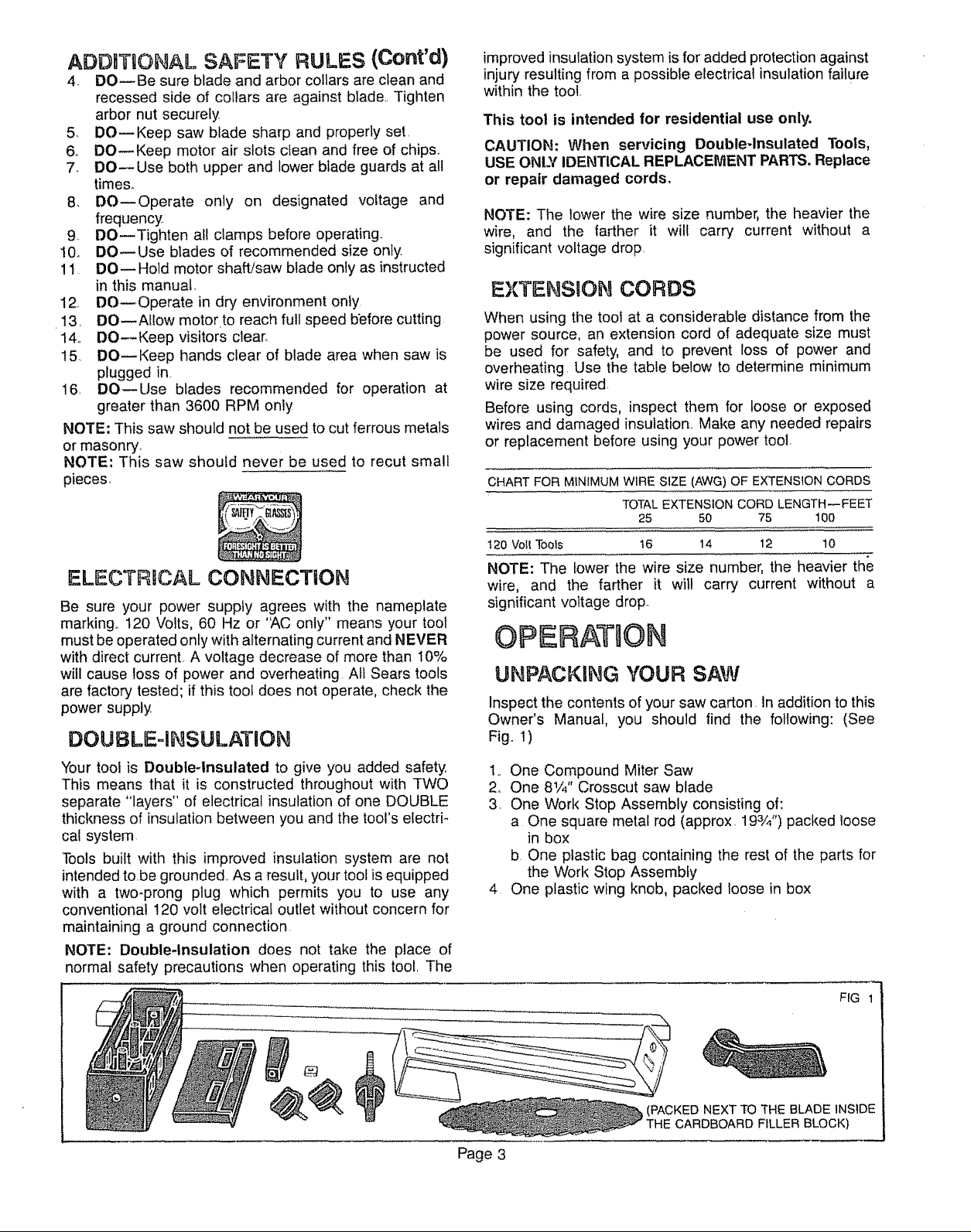

UNPACKING YOUR SAW

Inspect the contents of your saw carton. In addition to this

Owner's Manual, you should find the following: (See

Fig, 1)

Your tool is Double4nsulated to give you added safety.

This means that it is constructed throughout with TWO

separate "layers" of electrical insulation of one DOUBLE

thickness of insulation between you and the tool's electri-

cal system

Tools built with this improved insulation system are not

intendedtobe grounded.. As a result, your tootis equipped

with a two-prong plug which permits you to use any

conventional 120 volt electrical outlet without concern for

maintaining a ground connection.

NOTE: Double-Insulation does not take the place of

normal safety precautions when operating this tool. The

1,, One Compound Miter Saw

2, One 8V4" Crosscut saw blade

3, One Work Stop Assembly consisting of:

a One square metal rod (approx, 193/4") packed loose

in box

b One plastic bag containing the rest of the parts for

the Work Stop Assembfy

4 One plastic wing knob, packed loose in box

FIG 1

, (PACKED NEXT TO THE BLADE INSIDE

THE CARDBOARD FILLER BLOCK)

Page 3

Page 4

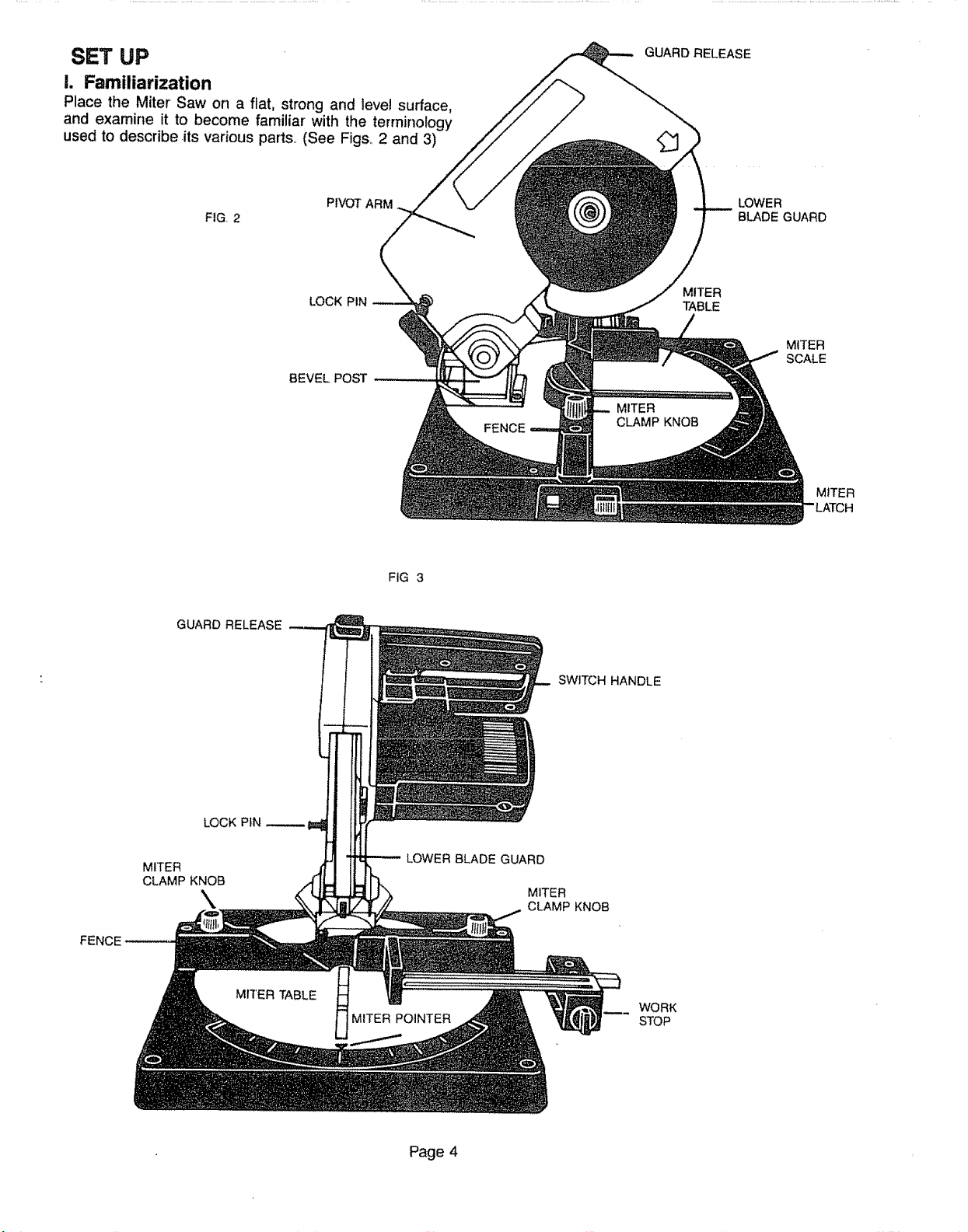

SET UP

I. Familiarization

Place the Miter Saw on a flat, strong and level surface

and examine it to become familiar with the terminology

used to describe its various parts, (See Figs,,2 and

GUARD RELEASE

FIG. 2

GUARD RELEASE

PIVOT ARM,

LOCK PIN

BEVEL POST

LOWER

BLADE GUARD

MITER

TABLE

MITER

SCALE

MITER

FIG 3

FE

LOCK PIN

MITER

CLAMP KNOB

X

MITER TABLE

LOWER BLADE GUARD

MITER POINTER

SWITCH HANDLE

MITER

CLAMP KNOB

WORK

STOP

Page 4

Page 5

II. Unlocking the Pivot Arm

Your saw was shipped from the factory with the pivot arm

in the locked down position. This position is used to

facilitate packaging and for storage,

Torelease the pivot arm, remove the cardboard filler bEock

and grasp'the switch handle with one hand and the end of

the lock pin with the other, as shown in Fig 5, (the

cardboard filler block you removed contains the wing

knob°) Push down on the switch handle lightly and pull out

on lock pin, When the pin is out as far as it wifl go, raise

the pivot arm to its full height., (The saw wilt look like the

picture on the front cover of this manual )

BENCH MOUNTING

BENCH MOUNTING (Cont'd)

An alternate mounting method that will enhance the saw's

portability is to mount the saw on a piece of W' or thicker

plywood, The saw can then be taken to remote locations

and the plywood clamped in place with a couple of large

"C" clamps.

MITER TABLE AND MITER SCALE

The miter table and miter scale permit you to set accurate

miters up to 45° left or right

Setting the Miter Table

Follow the steps below to set any miter angle,

t, Turn OFF and UNPLUG the saw.

2,,Loosen the two miter clamp knobs shown in Fig. 6,

(About V,_turn counterclockwise,,)

3 Push in the miter latch, shown in Fig, 7 and, using

the switch handle as a grip, rotate the saw around until

the miter pointer (Fig, 7) aligns with the desired

setting on the miter scale, also shown in Fig° 7,

FiG 6

MITER

CLAMP

KNOBS

Before using your miter saw, itmust be firmly mounted to

your workbench or other rigid frame, Four holes are

provided in the base of the saw for this purpose.

To mount the saw, position it as desired (don't forget about

the availability of an electrical outlet), and mark the

positions of the four holes in the saw Remove the saw and

drill four pilot holes in the places you marked, Reposition

the saw over the holes and secure it to the workbench

using 1/4"x 13/4" wood screws, as shown in Fig. 5, (Do

not overtighten,)

,/

SCREW

FIG 7

MITER

POINTER

Page 5

Page 6

MITER TABLE & MITER SCALE (Cont'd)

4_The miter scale is graduated in increments of one

degree (1°) The example shown in Fig 8 is 35°.

FIG 8

5 When you have set thedesired angle, l_ck it in place by

tightening the two miter clamp knobs that you loosened

in Step 2 above

NOTE: The miter latch will automatically lock the miter

table at 0°, 221/2° left and right and 45° left and right. Even

in these locked miter positions, you should tighen the two

miter clamp knobs.

WORK STOP

Packed with your saw in a plastic bag is a convenient work

stop This device, used to limit the travel of the work piece,

for repetitive cuts, must first be assembled To assemble

the work stop, refer to the exploded diagram (See Fig.

10).

FIG 10

SETTING THE BEVEL POST

Follow the steps below to set any bevel angle

1. Turn OFF and UNPLUG the saw.

2 install the plastic wing knob (packaged inside the

cardboard filler block) on the splined shaft, as shown in

Fig 9. (Make sure it is straight up, as shown)

3 Turn the knob counterclockwise about !/4 turn to

unlock the bevel post

4. Swing the saw arm to the desired angle on the bevel

post..

5. Turn the wing knob clockwise to firmly tock the bevel

angle..

SET

ANGLE

HERE

UNLOCK LOCK

Once your work stop has been assembled, you can mount

itin the saw in one of several ways depending on how you

wish to use it

Insert the square nut from plastic bag into the slot in the

side of the bar clamp as shown. Insert the bar clamp as

shown in Fig. 10A (IT WILL FIT ON EITHER SIDE

OF SAW.)

FIG 10A

BAR CLAMP "-___

The first step in assembling the work stop to the saw is to

insert the t93/4" square metal rod into the square hole in

the saw base, as shown in Fig. 11_ The plastic knob is

used to clamp the square rod in place

FIG 11

Page 6

Page 7

WORK STOP (Cont'd)

Attach the assembled work stop by sliding it over the

protruding end of the rod, as shown in Fig. 12.

As you work with the saw, you'll discover that the work

stop can be used many ways. WHENEVER USING THE

WORK STOP, BE SURE THAT IT IS FIRMLY TIGHT-

ENED AND CLAMPED IN PLACE BEFORE TURNING

THE SAW ON.

FIG 12

GUARD RELEASE

In order to lower the pivot arm to make a cut, the guard

release shown in Fig.. 13, must be released.. To release

the guard, push the button in fully as you lower the pivot

arm. The lower blade guard will retract automatically as

tou lower the arm.

FIG 13

GUARD

RELEASE

CUTTING TiPS

(Wear Eye Protection)

'The smoothness of any cut depends on a number of

variables, Things likematerial being cut, blade type, bIade

,sharpnessand rate of cut all combine to affect the quality

of the cuL

When cutting framing lumber or other types of lumber

where cut smoothness is not a point of concern, high

cutting rate coupled with a sharp general purpose blade

will produce satisfactory results.

When smoother cuts are desired, a sharp blade designed

for smooth cuts and'a slow even cutting rate will produce

the desired quality of cuL

The blade shipped with your Miter Saw is a 100 tooth

crosscut type.. For varied cutting applications, refer to the

list of recommended accessories for your saw and select

the blade that best fits your needs

OPERATION

(Wear Eye Protection)

To cut a piece of wood, first determine that it's the right

size for the saw. Place the wood on the saw table and hold

itfirmly against the fence_ if the piece you're workingwith

is smaller than 6" long and would cause your hand to be

within 6" of the saw blade, TURN OFF and UNPLUG the

saw and clamp the wood to the fence before cutting it,

Do not attempt to hold small pieces_ NEVER ATTEMPT

ANY FREE HAND CUTTING WITH THIS SAW, (Free

hand cutting is cutting wood that is not held firmly

against the fence and the saw table,)

REPLACING SAW BLADES

Follow the steps below to replace a saw blade,

1._Turn OFF and UNPLUG the saw.

2. Allow the saw arm to raise to its full height.

3 Using the hex wrench located in the saw table, shown

in Figr 15, loosen hex screw '_A" in Fig 16 four full

turns counterclockwise.

4. Press the guard release button and manually raise the

lower blade guard°

SWITCH

To turn the too] ON, squeeze and hold the trigger switch,

as shown in Fig. 14.

To turn the saw OFF, release the trigger switch.

TRIGGER

SWITCH

, ,,,,,,,,,,,i...... ., --

FIG 14

FIG 15

FIG 16

I

W

Page 7

Page 8

REPLACING BLADES (Cont'd)

5., Using the same he× wrencfl, loosen the arbor screw in

the center' of the blade (Left hand thread; turn clock-

wise to loosens) NOTE: Place a screwdriver or a large

nail through the hole in the saw blade (see Fig. 17)

to hold it while you tighten or loosen the screw. BE

SURE TO REi_,']OVE_TWHEN YOU FINISH: .......

6. Remove the old blade and install the new one taking

care to orient the two blade washers carefully, as shown

in Fig. 18.

7. Manually lower the blade guard as far as it will go..

8. Tighten hex screw "A" clockwise until tight, (Do not"

overtighten..) Replace the hex wrench in the saw table

FIG 17

PICTURE FRAMES, SHADOW BOXES

& SiMiLAR FOUR SIDED PROJECTS

For a more thorough understanding, we suggest that you

perform these cuts using scrap wood..Your new saw is the

perfect tool for making closed objects where it's neces-

sary to join wood sides and construct corners,. Fig_19

shows two typical types of mitered corners

FIG t9

A B

FIG. 18

The example in Fig.. A is a joint made by using the bevel

adjustment to bevel the edges of the boards (at 45° each)

to form a 90° miter corner. For this operation, set the bevel

post adjustment of 45° and the miter table adjustment at

0°, Position the wood with the broad flat side against the

table and the narrow edge against the fence,

The example shown in Fig, B is a joint made by using the

miter table adjustrnent to miter the width of the board (at

45° each) to form a miter corner of 90°. For this operation,

set the bevel post adjustment at 0° and the miter table

adjustment at 45°. Position the wood with the broad flat

surface against the table and the narrow edge against the

fence.,

NOTE: The examples shown and discussed above are for

four sided figures only The chart in Fig 20 shows the

settings for the miter table or bevel post for several

different shapes. Observe that the angle of cut decreases

as the number of sides increases. These angtes are

derived from the formula: 180° + number of sides in

desired object = miter angle for each joint

FIG 20 _ EXAMPLES--

NO, ANGLE

SIDES MITER OR BEVEL

4 45°

5 36°

6 30"

7 25 7"

8 22 5"

9 20°

10 18°

Page 8

Page 9

Page 10

10

Page 11

CRAFTSMAN81/4"COMPOUNDMITER SAW- MODEL NUMBER 900.233550

The Model Number will be found on a plate attached tothe Field Case Always

mention the Model Number in all correspondence regarding your81/4" COM-

POUND MITER SAW or when ordering repair parts

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

PARTS LUST

(PARTS SHOWN FOR REFERENCE ONLY)

Index

No

10

!t

12

t3

2O

15

t6

17

I9

2t

22

23

24

25

26

27

28

30

31

32

33

_4

35

36

38

t

2

3

4

5

6

7

8

37

4O

42

43

44

46

47

48

49

50

51

Part

No

873t66-00

873 t 95-00

879741-00

874312-00

91 t784-00

870091-00

911794-00

911984-00

9t !891-00

9t 1946_00

870057-00

870049-00

911826_00

9I 1825-00

91t960-00

879747-00

879743-00

9t 1959-00

911879-00

870056-00

916105-00

911281-00

9It018-00

870968-00

873296*00

873275-00

911888-00

91t880-00

911972-00

911936-00

870007_00

870008-00

871676_00

918405-00

873277-02

879777-00

879778_00

87328t_02

872448-00

9!6243-00

911276-00

873826-00

872544_00

9H]558_00

index Part

Description Qty No No Description

Armature 1 52 872386-00 Brush Cap

Field 1 53 914632-00 Safety Ring

Guard I 54 911246,-00 Screw

Gear Case 1 55 910623_00 Washer

Lever 1 56 873298400 Inside Flange

Rivet 1 57 911795-00 Outside Flange

Locking Bar 1 59 874177-00 Screw

De-Locking Bar 1 60 911485-00 Screw

Ring 1 6t 873294_00 Cord & Plug

Spring 1 62 916968-00 Cord Protector

Adjustin 9 Screw ! 64 910556-00 Clamp

Spring 2 66 9115!5_00 Screw

Rod 2 67 874184-00 Switch Spacer Cap

Rod 1 68 873169-00 Switch

Locking Bolt 1 69 9t t026-00 Screw

Btock 1 71 911325-0b Screw

Bracket ! 72 911059-00 Screw

Lever 1 73 911300_00 Screw

Screw 1 74 911878-00 Screw

Insert 1 75 911521_00 Nut

Safety Washer 3 77 914080-00 Hex Wrench

Screw 4 81 873112-00 Rubber

Nut 4 82 918909-00 Fan

Turn Table t 87 871760_00 Miter Fence P_e¢_

Base PI'ate 1 88 870077-00 Adjuster Screw

Fence I 89 870076_00 Wedge

Adjuster 2 90 870080-00 Square Tube

Screw 2 9t 870081-00 Adjusting Bracket

Rubber Foot 4 92 918504-00 Wing Screw

Trigger t 94 870062-00 Block

Knob t 95 875436-00 Nameplate

Slide I 97 875439_00 Saw Blade

Spring 1 98 875438-00 Warning Label

Square Nut 2

Handle 1 PARTS NOT SHOWN:

Guard 1 875437_00 Owners Manual

Guard Cover 1

Housing 4

Bearing Holder 1

Bearing 1 VOLTS AMPS RPM

Screw 1 120 8 0 3600

Brush Holder 2 AC Only

Brush 2

Insert 2

Qty

2

1

3

2

!

1

4

!

I

1

6

1

t

4

9

2

2

2

5

1

1

1

!

t

1

1

1

1

t

1

1

1

Page 11

Page 12

®

OWNERS

MANUAL

SERVICE

MODEL NO.

900.233550

81/4 ino COMPOUND MUTER SAW

Now that you have purchased your Saw, should a

need ever exist for repair parts or service, simply

contact any Sears Service Center and most Sears,

Roebuck and Co. stores.

Be sure to provide all pertinent facts when you call or

visit.

The model number of your Saw will be found on the

plate attached to the field case.

HOW TO ORDER

_EPAIR PARTS

sold by SEARS, ROEBUCK AND CO, Chicago, IL 60684 USA°

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

e PART NUMBER

e MODEL NUMBER

900.233550

All parts listed may be ordered from any SEARS

SERVICE CENTER and most SEARS stores. If the

parts you need are not stocked locally, your order will

be electronically transmitted to a Sears Repair Parts

Distribution Center for Handling.

e PART DESCRIPTION

e NAME OF ITEM

Miter Saw

Loading...

Loading...