Page 1

Instruction Manual

CRRF °

4 INCH

ANGLE GRINDER

Model 900.116500

_4WARNING:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

www.sears.com/craftsman

Form No. 587857-00 MAR-04 Printed in China

• Safety

• Operation

• Maintenance

• Parts List

• Espa_ol

Page 2

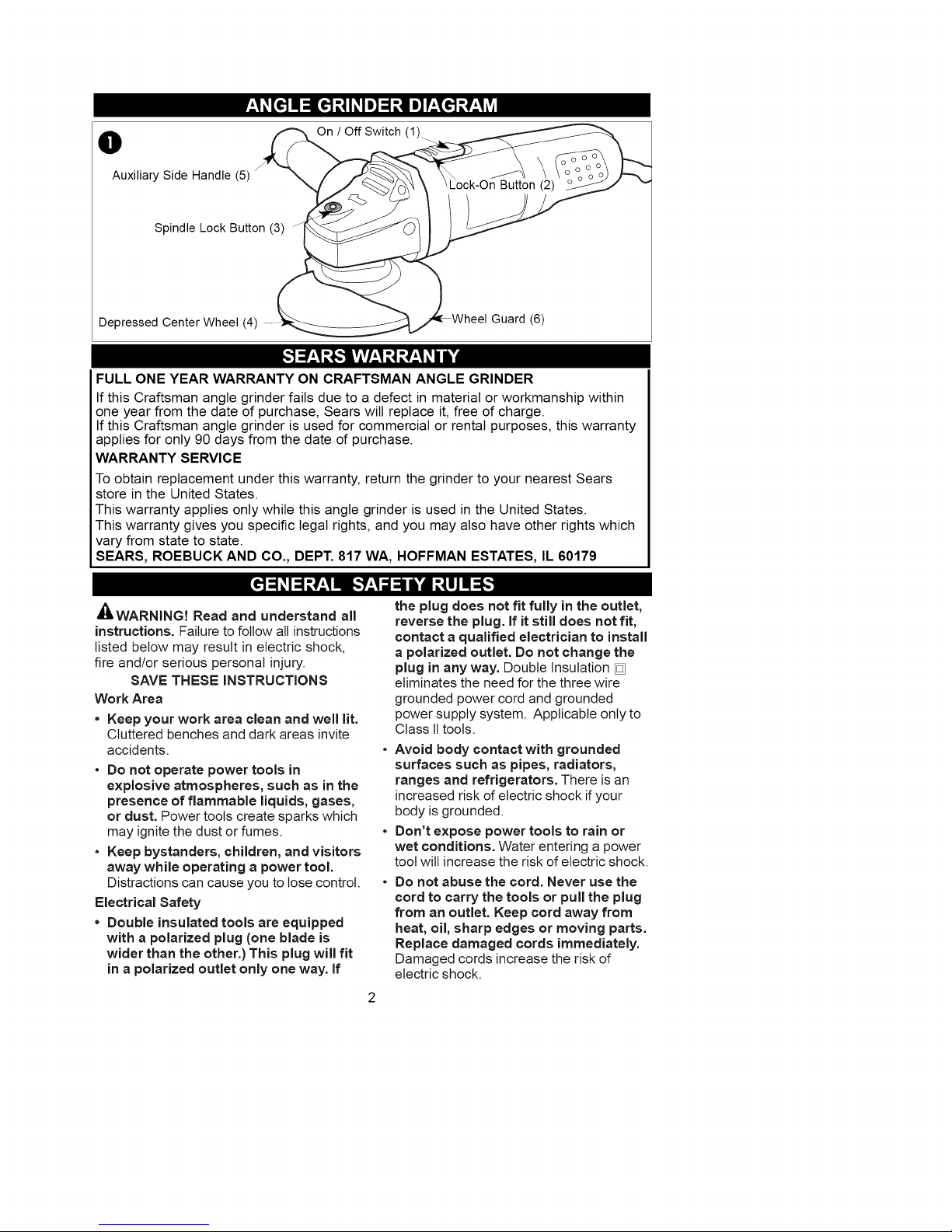

O On / Off Switch (1)

Auxiliary Side Handle (5)

Spindle Lock Button (3)

Depressed Center Wheel (4)

Guard (6)

[,._1 WI-'I ;_1;1-'I_/ Ik'd

FULL ONE YEAR WARRANTY ON CRAFTSMAN ANGLE GRINDER

If this Craftsman angle grinder fails due to a defect in material or workmanship within

one year from the date of purchase, Sears wilt replace it, free of charge.

If this Craftsman angle grinder is used for commercial or rental purposes, this warranty

applies for only 90 days from the date of purchase.

WARRANTY SERVICE

To obtain replacement under this warranty, return the grinder to your nearest Sears

store in the United States.

This warranty applies only while this angle grinder is used in the United States.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

SEARS, ROEBUCK AND CO., DEPT. 817 WA, HOFFMAN ESTATES, IL 60179

[_ =l_l=l;_Inu _'7.,I==Inuk'dI;_L_"]

A

AI_WARNING! Read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

• Do not operate power tools in

explosive atmospheres, such as in the

presence of flammable liquids, gases,

or dust. Power tools create sparks which

may ignite the dust or fumes.

• Keep bystanders, children, and visitors

away whine operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double insulated tools are equipped

with a polarized plug (one blade is

wider than the other.) This plug will fit

in a polarized outlet only one way. If

the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit,

contact a qualified electrician to install

a polarized outlet. Do not change the

plug in any way. Double Insulation []

eliminates the need for the three wire

grounded power cord and grounded

power supply system. Applicable only to

Class It tools.

Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your

body is grounded.

Don't expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of

electric shock.

Page 3

• When operating a power tool outside,

use an outdoor extension cord marked

"W-A" or "W." These cords are rated for

outdoor use and reduce the risk of electric

shock.

Personal Safety

• Stay alert, watch what you are doing

and use common sense when

operating a power tool. Do not use tool

while tired or under the influence of

drugs, alcohol, or medication. A

moment of inattention while operating

power tools may result in serious

personal injury,

• Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves

away from moving parts. Loose clothes,

jewelry, or tong hair can be caught in

moving parts.

• Avoid accidental starting. Be sure

switch is off before plugging in.

Carrying tools with your finger on the

switch or plugging in tools that have the

switch on invites accidents.

• Remove adjusting keys or wrenches

before turning the tool on. Awrench or

a key that is left attached to a rotating part

of the tool may result in personal injury.

• Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

• Use safety equipment. Always wear

eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing

protection must be used for appropriate

conditions.

Tool Use and Care

• Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by

hand or against your body is unstable and

may lead to loss of control.

• Do not force tool. Use the correct tool

for your application. The correct toot will

do the job better and safer at the rate for

which it is designed.

• Do not use tool if switch does not turn

it on or off. Any toot that cannot be

controlled with the switch is dangerous

and must be repaired.

• Disconnect the plug from the power

source before making any

adjustments, changing accessories, or

storing the tool. Such preventive safety

measures reduce the risk of starting the

tool accidentally.

• Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained

users.

• Maintain tools with care. Keep cutting

tools sharp and clean. Properly

maintained tools, with sharp cutting

edges are less likely to bind and are

easier to control.

• Check for misalignment or binding of

moving parts, breakage of parts, and

any other condition that may affect the

tools operation. If damaged, have the

tool serviced before using. Many

accidents are caused by poorly

maintained tools.

• Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become

hazardous when used on another tool.

Service

• Tool service must be performed only

by qualified repair personnel. Service

or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only

identical replacement parts. Follow

instructions in the Maintenance

section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create a

risk of electric shock or injury.

SPECIFIC SAFETY RULES

• Always use proper guard with

grinding wheel. A guard protects

operator from broken wheel fragments.

Always position the guard so that as

much of the exposed disc as possible

is pointing away from you.

• Accessories must be rated for at

least the speed recommended on the

tool warning label. Wheels and other

accessories running over rated speed

can fly apart and cause injury.

• Hold tool by insulated gripping

surfaces when performing an

operation where the cutting tool may

contact hidden wiring or its own

cord. Contact with a "live" wire wilt make

exposed metal parts of the tool "live"

and shock the operator.

Page 4

ADDITIONAL SAFETY RULES

• Always wear eye protection.

• Keep guards in place.

• Use only accessories having a

maximum operating speed at least as

high as the speed specified in the

warning on the tool's label.

• Before using, inspect recommended

accessory for cracks or flaws. If such

a crack or flaw is evident, discard the

accessory. The accessory should also

be inspected whenever you think the

tool may have been dropped.

• When starting the tool (with a new or

replacement wheel or brush installed)

hold the tool in a well protected area

and let it run for one minute. If the

wheel or brush has an undetected crack

or flaw, itshould burst or separate in

tess than one minute. Never start the

tool with a person in line with the

accessory. This includes the operator.

• In operation, avoid bouncing the

wheel or giving it rough treatment. If

this occurs, stop the tool and inspect

the wheel.

• Always use guards with grinding

wheels and wire brushes. Always

position the guard so that as much of

the exposed wheel or wire brush as

possible ispointing away from you.

• Clean your tool out periodically.

• Do not use Type 1 flat cut-off or diamond

wheels without proper guard.

• Always direct stream of sparks from

grinding away from flamable materials.

• _,WARNING: Some dust created by

power sanding, sawing, grinding, drilling,

and other construction activities contains

chemicals known to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and

cement and other masonry products, and

• arsenic and chromium from

chemically-treated lumber (CCA).

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to

these chemicals: work in a welt

ventilated area, and work with approved

safety equipment, such as those dust

masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust

from power sanding, sawing,

grinding, drilling, and other

construction activities. Wear

protective clothing and wash exposed

areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay

on the skin may promote absorption of

harmful chemicals.

• _I,WARNING: Use of this tool can

generate and/or disburse dust, which

may cause serious and permanent

respiratory or other injury. Always

use NIOSH/OSHA approved

respiratory protection appropriate for

the dust exposure. Direct particles

away from face and body.

• -_CAUTION: Wear appropriate

hearing protection during use. Under

some conditions and duration of use,

noise from this product may contribute to

hearing loss.

• The label on your tool may include the

following symbols.

V .............. volts

A .............. amperes

Hz ............ hertz

W ............ watts

min .......... minutes

'_ ............ alternating current

.... ........direct current

no ............ no toad speed

[] ............ Class II Construction

.../min ......revolutions or reciprocation

per minute

............ earthing terminal

............ safety alert symbol

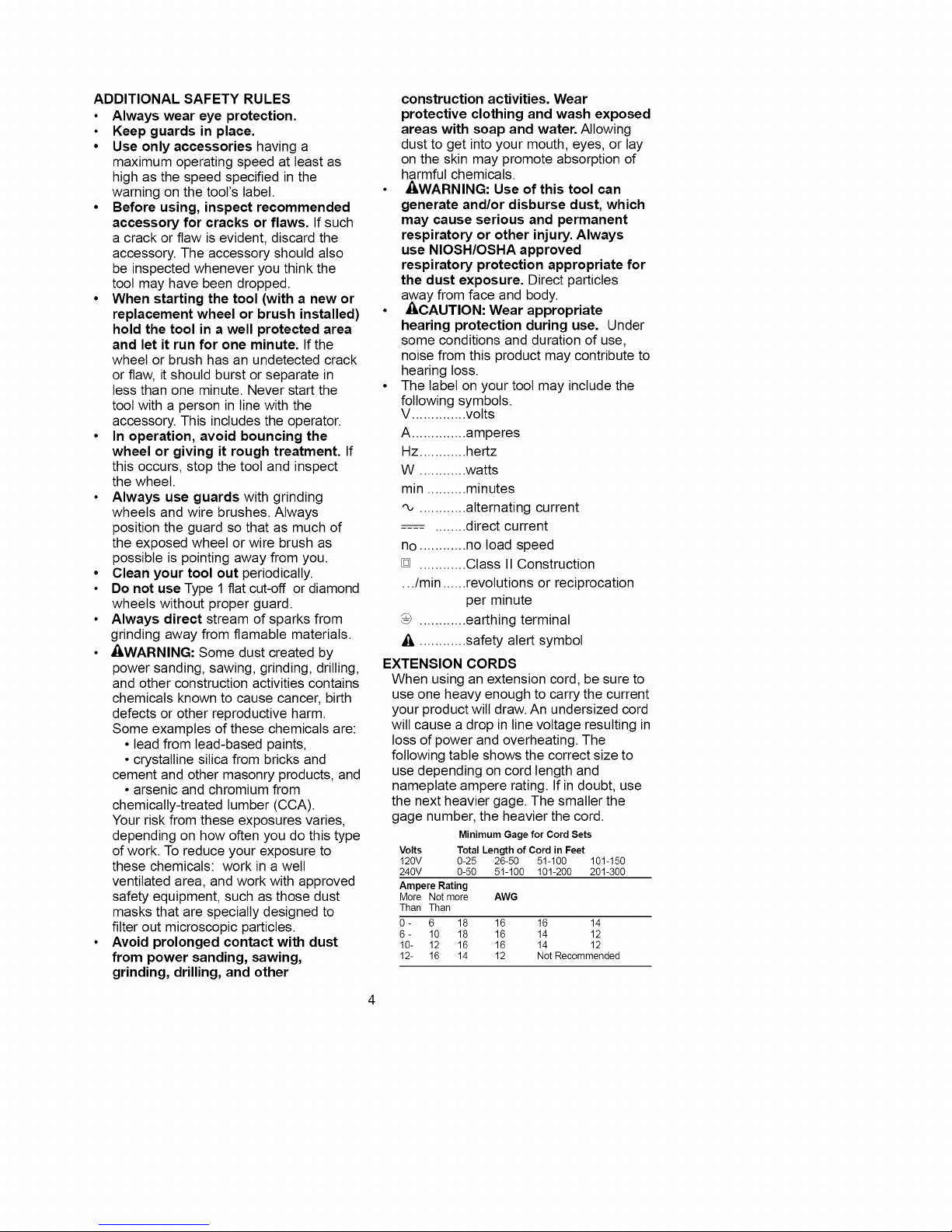

EXTENSION CORDS

When using an extension cord, be sure to

use one heavy enough to carry the current

your product wilt draw. An undersized cord

wilt cause a drop in line voltage resulting in

loss of power and overheating. The

following table shows the correct size to

use depending on cord length and

nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the

gage number, the heavier the cord.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

0- 6 18 16 16 14

6- 10 18 16 14 12

10- 12 16 16 14 12

12- 16 14 12 Not Recommended

Page 5

MOTOR

Be sure your power supply agrees with

nameplate marking. 120 Volts AC only

means your tool wilt operate on standard

60 Hz household power. Do not operate

AC tools on DC. A rating of 120 volts

AC/DC means that your tool wilt operate

on standard 60 Hz AC or DC power. This

information is printed on the nameplate.

Lower voltage will cause toss of power

and can result in over-heating. All

Craftsman tools are factory-tested; if this

toot does not operate, check the power

supply.

AUXILIARY HANDLE (FIG. 1)

An auxiliary handle is furnished with your

grinder and can be screwed into either

side of the grinder housing. This handle

SHOULD BE USED ATALL TIMES to

maintain complete control of the tool.

TIGHTEN SECURELY.

STARTING AND STOPPING THE TOOL

Tostart the tool, slide the ON/OFF switch

forward. For continuous operation, slide

the switch fully forward and press front

end down. To stop the tool, release the

ON/OFF switch. To stop the tool while

running in continuous mode, press the

rearward part of the switch.

NOTE: Do not switch the tool on or off

while under toad conditions. Allow the

grinder to run up to full speed before

touching the surface to be ground. Lift the

toot from the surface before turning the

tool off. _,CAUTION: Allow the tool to

stop before setting down.

OVERLOAD

Overloading wilt cause damage to the

motor of your angle grinder. This can

happen if your angle grinder is subjected

to heavy use for prolonged periods of

time. Do not in any circumstances,

attempt to exert too much pressure on

your angle grinder to speed up your work.

The abrasive accessories operate more

efficiently when light pressure is exerted,

thus avoiding a drop in the speed of your

angle grinder.

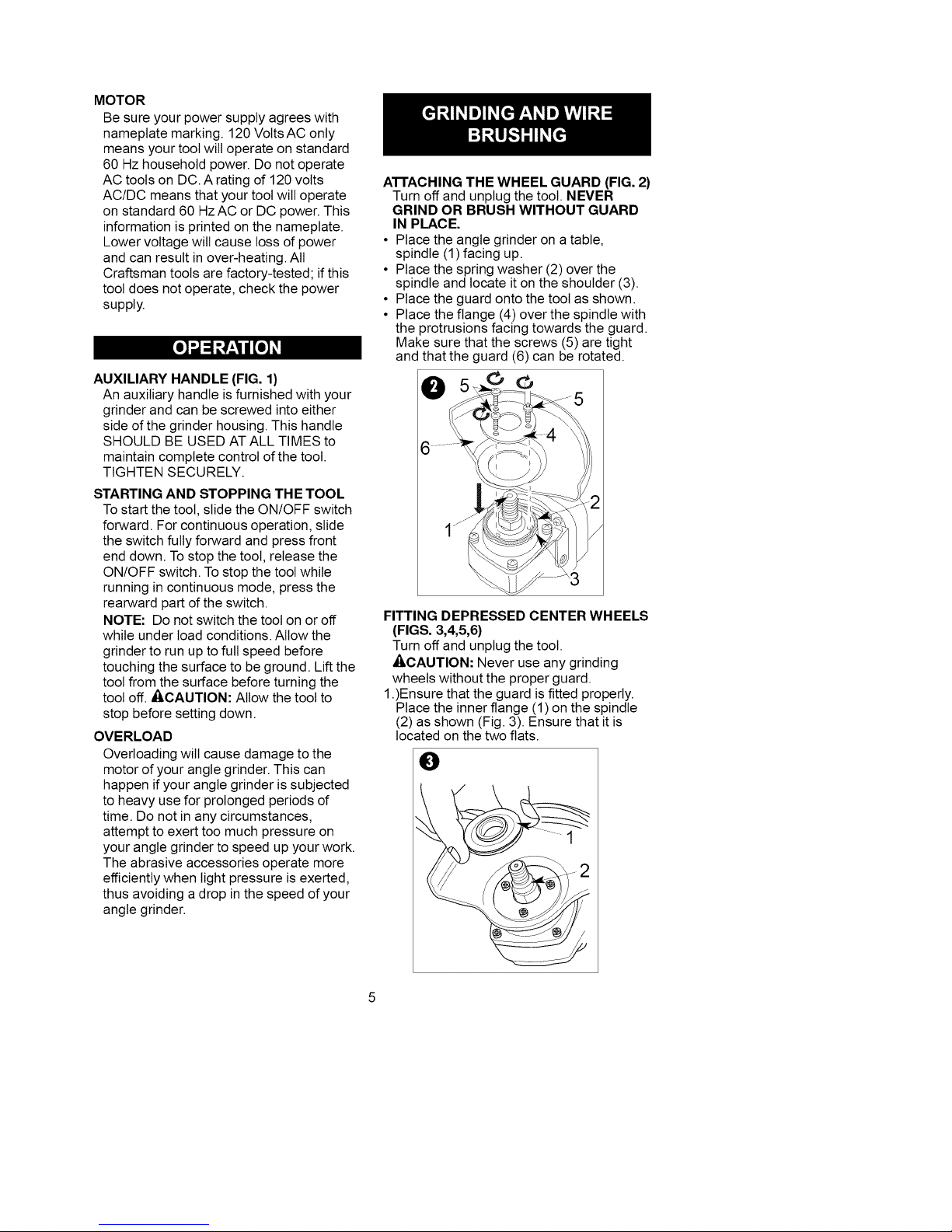

An'ACHING THE WHEEL GUARD (FIG. 2)

Turn off and unplug the tool. NEVER

GRIND OR BRUSH WITHOUT GUARD

IN PLACE.

• Place the angle grinder on a table,

spindle (1) facing up.

• Place the spring washer (2) over the

spindle and locate it on the shoulder (3).

• Place the guard onto the tool as shown.

• Place the flange (4) over the spindle with

the protrusions facing towards the guard.

Make sure that the screws (5) are tight

and that the guard (6) can be rotated.

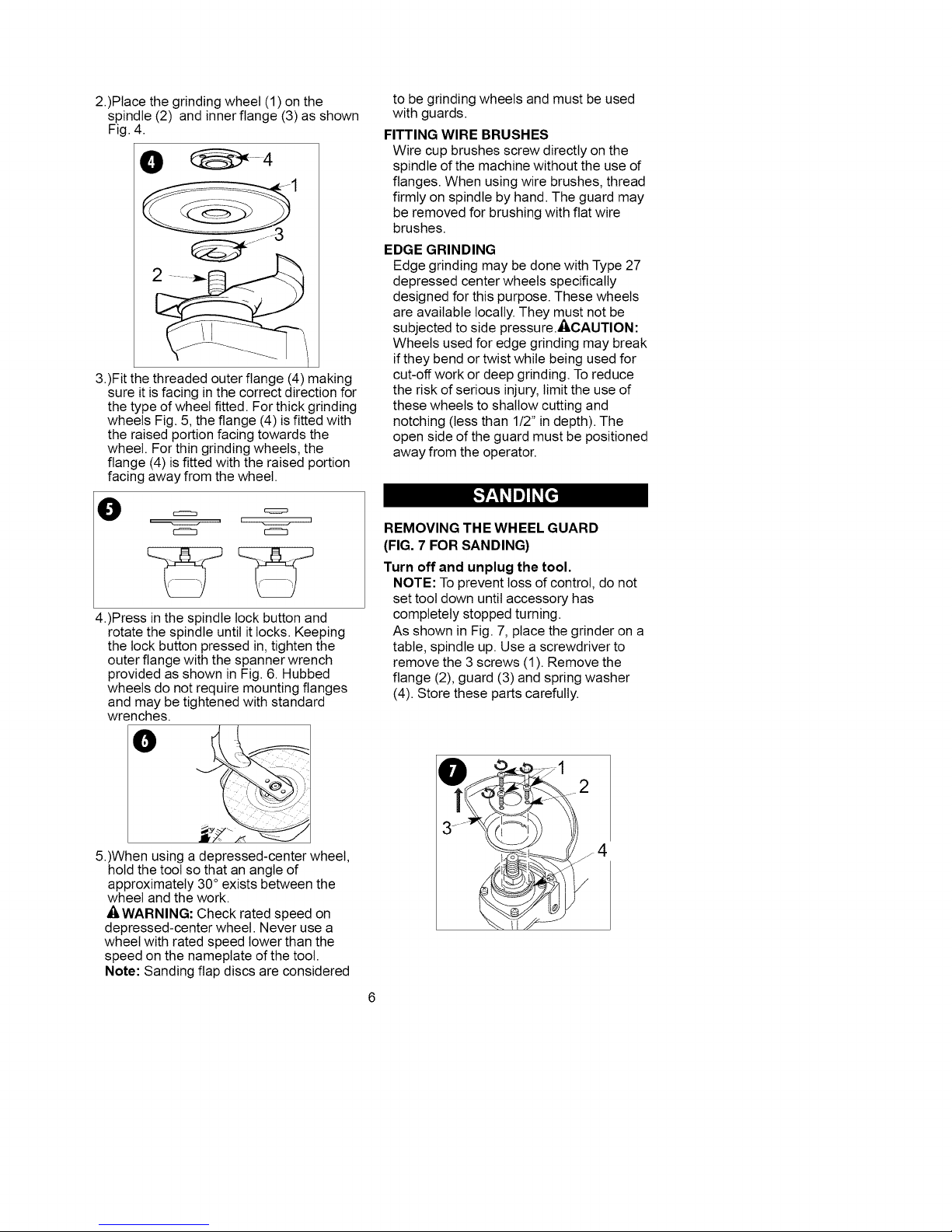

FITTING DEPRESSED CENTER WHEELS

(FIGS. 3,4,5,6)

Turn off and unplug the tool.

-ZkCAUTION: Never use any grinding

wheels without the proper guard.

1.)Ensure that the guard is fitted properly.

Place the inner flange (1) on the spindle

(2) as shown (Fig. 3). Ensure that it is

located on the two flats.

o

Page 6

2.)Place the grinding wheel (1) on the

spindle (2) and innerflange (3) as shown

Fig. 4.

3.)Fit the threaded outer flange (4) making

sure it is facing in the correct direction for

the type of wheel fitted. For thick grinding

wheels Fig. 5, the flange (4) is fitted with

the raised portion facing towards the

wheel. For thin grinding wheels, the

flange (4) is fitted with the raised portion

facing away from the wheel.

0

4.)Press in the spindle lock button and

rotate the spindle until it locks. Keeping

the lock button pressed in, tighten the

outer flange with the spanner wrench

provided as shown in Fig. 6. Hubbed

wheels do not require mounting flanges

and may be tightened with standard

wrenches.

to be grinding wheels and must be used

with guards.

FITTING WIRE BRUSHES

Wire cup brushes screw directly on the

spindle of the machine without the use of

flanges. When using wire brushes, thread

firmly on spindle by hand. The guard may

be removed for brushing with flat wire

brushes.

EDGE GRINDING

Edge grinding may be done with Type 27

depressed center wheels specifically

designed for this purpose. These wheels

are available locally. They must not be

subjected to side pressure._,CAUTION:

Wheels used for edge grinding may break

if they bend or twist while being used for

cut-off work or deep grinding. To reduce

the risk of serious injury, limit the use of

these wheels to shallow cutting and

notching (tess than 1/2" indepth). The

open side of the guard must be positioned

away from the operator.

REMOVING THE WHEEL GUARD

(FIG. 7 FOR SANDING)

Turn off and unplug the tool.

NOTE: To prevent toss of control, do not

set tool down until accessory has

completely stopped turning.

As shown in Fig. 7, place the grinder on a

table, spindle up. Use a screwdriver to

remove the 3 screws (1). Remove the

flange (2), guard (3) and spring washer

(4). Store these parts carefully.

5.)When using a depressed-center wheel,

hold the tool so that an angle of

approximately 30°exists between the

wheel and the work.

AWARNING: Check rated speed on

depressed-center wheel. Never use a

wheel with rated speed lower than the

speed on the nameplate of the tool.

Note: Sanding flap discs are considered

4

Page 7

PRECAUTIONS TO TAKE WHEN

SANDING PAINT

1. Sanding of lead based paint is NOT

RECOMMENDED due to the difficulty

of controlling the contaminated dust.

The greatest danger of lead poisoning

is to children and pregnant women.

2. Since it is difficult to identify whether

or not a paint contains lead without a

chemical analysis, we recommend the

following precautions when sanding

any paint:

PERSONAL SAFETY

1. No children or pregnant women should

enter the work area where the paint

sanding is being done until all cleanup

is completed.

2. A dustmask or respirator should be

worn by all persons entering the work

area. The filter should be replaced

daily or whenever the wearer has

difficulty breathing.

NOTE: Only those dustmasks suitable

for working with lead paint dust and

fumes should be used. Ordinary

painting masks do not offer this

protection. See your local hardware

dealer for the NIOSH approved

proper mask.

ENVIRONMENTAL SAFETY

1. Paint should be removed in such a

manner as to minimize the amount of

dust generated.

2. Areas where paint removal is occurring

should be sealed with plastic sheeting

of 4 mils thickness.

3. Sanding should be done in a manner

to reduce tracking of paint dust outside

the work area.

FITTING ABRASIVE DISCS

Turn off and unplug the tool.

Use an abrasive disc with a backing

pad for sanding with your angle

grinder.

1. Remove the guard.

2. Place the flange, (backing pad and

abrasive disc sold separately) and

outer flange on the spindle as shown in

Figure 8. Figure 8A shows how to

attach an abrasive disc with a rubber

backing pad.

O

3.

Tighten the abrasive disc as shown in

Figure 9 by depressing the spindle lock

button and turning the abrasive disc by

hand.

0

Page 8

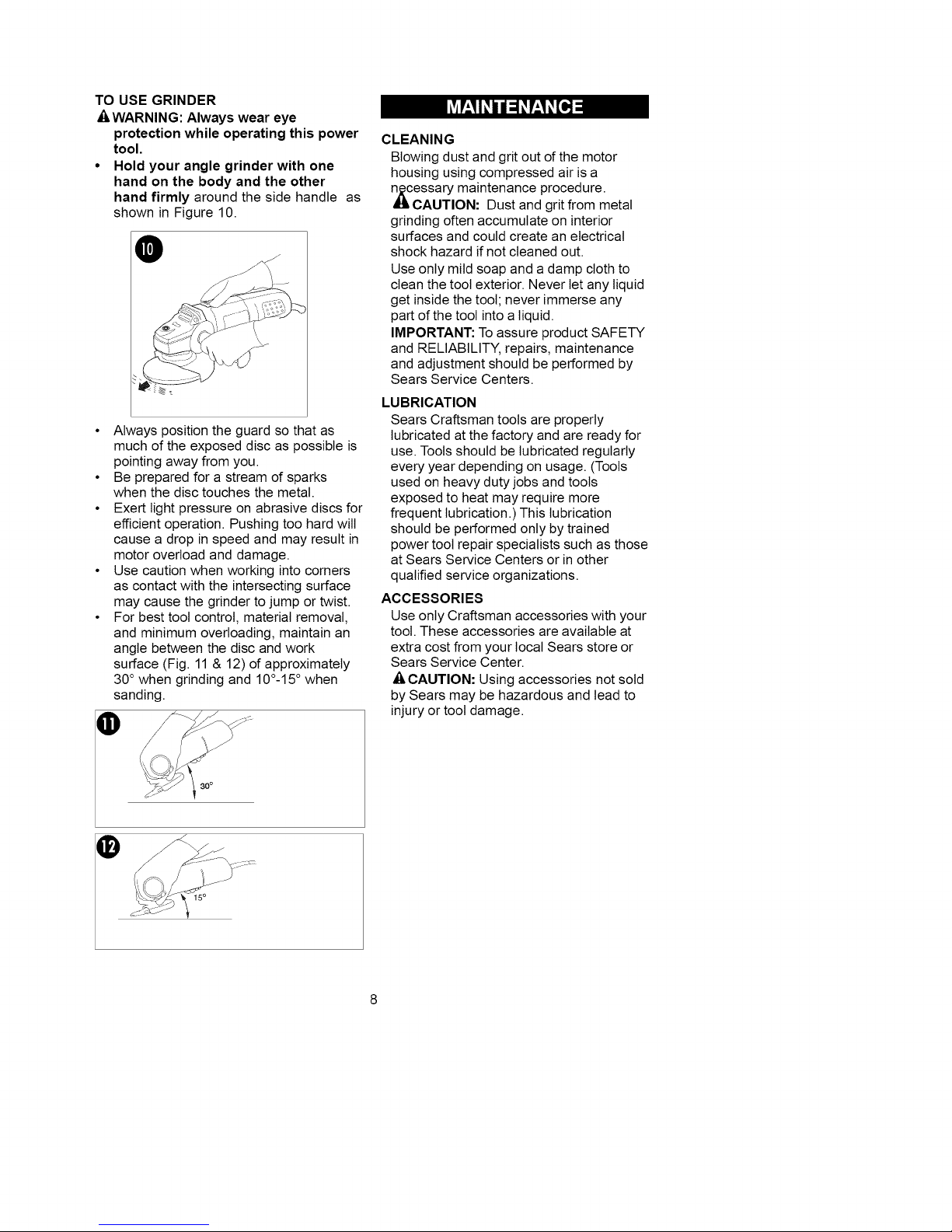

TO USE GRINDER

-&WARNING: Always wear eye

protection while operating this power

tool.

• Hold your angle grinder with one

hand on the body and the other

hand firmly around the side handle as

shown in Figure 10.

• Always position the guard so that as

much of the exposed disc as possible is

pointing away from you.

• Be prepared for a stream of sparks

when the disc touches the metal.

• Exert light pressure on abrasive discs for

efficient operation. Pushing too hard wilt

cause a drop in speed and may result in

motor overload and damage.

• Use caution when working into corners

as contact with the intersecting surface

may cause the grinder to jump or twist.

• For best toot control, material removal,

and minimum overloading, maintain an

angle between the disc and work

surface (Fig. 11 & 12) of approximately

30° when grinding and 10°-15 ° when

sanding.

O

CLEANING

Blowing dust and grit out of the motor

housing using compressed air is a

CceSSarymaintenance procedure.

AUTION: Dust and grit from metal

grinding often accumulate on interior

surfaces and could create an electrical

shock hazard if not cleaned out.

Use only mild soap and a damp cloth to

clean the tool exterior. Never let any liquid

get inside the tool; never immerse any

part of the toot intoa liquid.

IMPORTANT: To assure product SAFETY

and RELIABILITY, repairs, maintenance

and adjustment should be performed by

Sears Service Centers.

LUBRICATION

Sears Craftsman tools are properly

lubricated at the factory and are ready for

use. Tools should be lubricated regularly

every year depending on usage. (Tools

used on heavy duty jobs and tools

exposed to heat may require more

frequent lubrication.) This lubrication

should be performed only by trained

power tool repair specialists such as those

at Sears Service Centers or inother

qualified service organizations.

ACCESSORIES

Use only Craftsman accessories with your

tool. These accessories are available at

extra cost from your local Sears store or

Sears Service Center.

-& CAUTION: Using accessories not sold

by Sears may be hazardous and lead to

injury or tool damage.

30 °

O

Page 9

Page 10

Manual de instrucciones

@

Esmeriladora angular

de 102 mm (4 pulg.)

No. modelo 900.116500

AADVERTENCIA:

Antes de usar este producto,

lea este manual y siga sus

Reglas de seguridad e

Instrucciones de

funcionamiento

Sears, Roebuck y Co., Hoffman Estates, IL 60179 EE.UU.

www.sears.com/craftsman

• Seguridad

• Operacibn

• Mantenimiento

• Lista de piezas

• Espa_ol

10

Page 11

Im]F-'(e']Z..f-'1_v_!'-'11m]=lI-'_ _..."]_N=lz..llal'_,ImIo]z..f_,V_,1_[e'IIJI_,I;..!

[e']':1_-'I _ItIIF-'_[,._"]

GARANTJA COMPLETA POR UN ANO PARA LA ESMERILADORA ANGULAR

CRAFTSMAN

Siesta esmeriladora angular Craftsman falla debido a defectos en materiales o mano de

obra dentro del afio siguiente a la fecha de compra, Sears to reemplazar& sin costo alguno.

Siesta esmeriladora angular se utitiza con fines comerciales o de renta, esta garantia

aptica L_nicamente durante 90 dias a partir de la fecha de compra.

SERVICIO DE GARANTIA

Para obtener un reemplazo bajo esta garantia, devuelva la esmeriladora angular a su

tienda Sears mas cercana en los Estados Unidos.

Esta garantia aplica s61o mientras la esmeriladora angular sea utilizada en los Estados

Unidos.

Esta garantia te da derechos legales especificos ademas de los cuales puede tenet

otros, los cuales varian entre estados.

SEARS, ROEBUCK Y CO., DEPT. 817WA, HOFFMAN ESTATES, IL 60179

Ir,,l=[_"] le]=l[.,."]_e"lllJr,,lleT_,le][e']=l_l=lz/_,lll=[.,."]

A ADVERTENCIA: Lea todas las

instrucciones hasta comprenderlas. No

ajustarse alas instrucciones siguientes

puede set causa de choque electrico,

incendio o lesiones graves.

CONSERVE ESTAS INSTRUCCIONES

Area de trabajo

• Mantenga el area de trabajo limpia y

bien iluminada. Las bancadas

desordenadas y las zonas oscuras

propician los accidentes.

• No opere herramientas electricas en

atmosferas explosivas, como en

presencia de liquidos, gases o polvos

inflamables. Las herramientas

electricas producen chispas que pueden

originar ta ignici6n del polvo o los

vapores.

• Mientras opere una herramienta

electrica, mantenga lejos a los

observadores, niSos y visitantes. Las

distracciones pueden ocasionar que

pierda el control.

Seguridad Electrica

• Las herramientas con doble

aislamiento estan equipadas con una

clavija polarizada (una pata es mas

ancha que la otra). Esta clavija se

acoplara a un enchufe polarizado de

una sola manera. Si la clavija no se

acopla al contacto, inviertala. Si at)n

asi no se ajusta, comuniquese con un

electricista cualificado para que

instale un enchufe polarizado

apropiado. Nunca cambie la ctavija. Et

doble aislamiento [] elimina la

necesidad de cables con tres hitos y

sistemas de suministro electrico con

11

Page 12

conexi6natierra.S6toesapticablealas

herramientasdeClaseII.

• Evite el contacto del cuerpo con

superficies conectadas a tierra, tales

como tuberias, radiadores, registros y

refrigeradores. El riesgo de choque

electrico aumenta si su cuerpo hace

tierra.

• No exponga las herramientas

electricas a la Iluvia o a condiciones

de mucha humedad. Si entra agua en

una herramienta electrica, aumenta el

riesgo de choque electrico.

• No maltrate el cable. Nunca tome el

cable para transportar la herramienta

ni para desconectarla del enchufe.

Mantenga el cable alejado de las

fuentes de calor, el aceite, las orillas

afiladas o las piezas en movimiento.

Gamble inmediatamente los cables

da_ados. Los cables da_ados

aumentan el peligro de choque electrico.

• Cuando opere una herramienta

electrica a la intemperie, utilice una

extension marcada "W-A.)" o "W".

Estas extensiones estan ctasiflcadas

para uso a la intemperie y para reducir

el riesgo de choque electrico.

Seguridad personal

• AI utilizar una herramienta electrica,

este atento, concentrese en Io que

hace y aplique el sentido comun. No

utilice la herramienta si se encuentra

fatigado o bajo la influencia de

drogas, alcohol o farmacos. Mientras

se utitizan herramientas electricas, basta

un instante de distracci6n para sufrir

lesiones graves.

• Lleve ropa adecuada. No utilice ropa

suelta ni joyas. Recojase el cabello

largo. Mantenga el cabello, la ropa y

los guantes apartados de las piezas

en movimiento. Las pares m6viles

pueden atrapar tas prendas de vestir

sueltas, tas joyas y el cabello.

• Evite puestas en marcha

accidentales. AsegL_rese de que el

interruptor este apagado antes de

enchufar la maquina. Transportar las

herramientas con el dedo sobre el

interruptor o enchufartas con el

interruptor encendido favorece los

accidentes.

• Antes de poner en marcha la

herramienta, retire las Ilaves de

ajuste. Una ltave que se deje en una

pieza giratoria de la herramienta puede

provocar tesiones.

No ponga en peligro su estabilidad.

Mantengase siempre bien apoyado y

equilibrado. Un buen apoyo y equitibrio

permiten controtar mejor la herramienta

si se produce algt_n imprevisto.

Utilice el equipo de seguridad. Lleve

siempre lentes protectores. Cuando

sea adecuado, tambien se debe usar

mascaritta antipotvo, zapatos de suela

antideslizante, casco o protectores

auditivos.

Uso y cuidados de la herramienta

• Utilice abrazaderas u otro elemento

adecuado para sujetar y apoyar la

pieza de trabajo en una plataforma

estable. Sujetar ta pieza con la mano o

contra el cuerpo es inestable y facilita

la perdida de control.

• No fuerce la herramienta. Emplee la

herramienta correcta para cada

aplicacion. La herramienta correcta

hace el trabajo mejor y mas seguro

dentro del rango para el que ha sido

diseSada.

• No utilice la herramienta si el

interruptor no la enciende y apaga.

Cualquier herramienta que no pueda

controlarse con el interruptor es

peligrosa y se debe reparar.

• Desconecte la clavija del enchufe

antes de proceder a cualquier ajuste,

cambiar un accesorio o guardar la

herramienta. Estas medidas de

seguridad preventiva reducen el riesgo

de poner en marcha la herramienta

accidentalmente.

• Cuando no las utilice, guarde las

herramientas fuera del alcance de

los niSos o de cualquier persona no

capacitada. Las herramientas son

peligrosas en manos de usuarios no

capacitados.

• Guide las herramientas. Conserve

las herramientas de corte afiladas y

limpias. Unas herramientas

adecuadamente cuidadas y con los

bordes de corte afilados se atascan

menos y son mas faciles de controlar.

• Compruebe si las piezas moviles se

desalinean o atascan, si hay alguna

pieza rota o cualquier otra

circunstancia que pueda afectar la

operacion de la herramienta. Si la

herramienta esta daSada, hagala

reparar antes de usarla. Muchos

accidentes los provocan unas

12

Page 13

herramientasmalcuidadas.

Utilice unicamente los accesorios

recomendados por el fabricante para

su modelo. Un mismo accesorio

puede ser adecuado para una

herramienta, pero peligroso si se usa

en otra.

Servicio

• El servicio a la herramienta solo

deber ser realizado por personal de

reparacion calificado. Si el servicio o

mantenimiento es realizado por

personal no calificado, podria resultar

en riesgo de tesi6n.

• Cuando se repare una herramienta,

solo se deben usar repuestos

originales. Siga las instrucciones en

la seccion de mantenimiento de este

manual. El uso de repuestos no

autorizados o el incumplimiento de tas

instrucciones de mantenimiento pueden

crear un riesgo de descarga electrica o

lesi6n.

NORMAS ESPECiFICAS DE SEGURIDAD

• Use siempre el protector debido con

el disco de esmerilado. Un protector

protege al operador de los fragmentos

que se desprendan del disco. Coloque

siempre el protector de modo que ta

mayor parte posible del disco expuesto

quede apuntando en direcci6n opuesta

a usted.

• Los accesorios deben estar

clasificados por Io menos para la

velocidad recomendada en la etiqueta

de advertencia de la herramienta. Si

funcionan a velocidades superiores a la

prevista, los discos y otros accesorios

pueden salir despedidos y provocar

lesiones.

• Sujete la herramienta por las

superficies aislantes si Ileva a cabo

una operacion en que la herramienta

pueda tocar un conductor oculto o su

propio cable. El contacto con un

conductor activo provocara que las

piezas metaticas de la herramienta

conduzcan electricidad y que el

operador reciba una descarga electrica.

REGLAS DE SEGURIDAD ADICIONALES

• Utilice siempre proteccion ocular.

• Mantenga los protectores en su

sitio.

• Use solo aquellos accesorios que

tengan una velocidad maxima de

operaci6n al menos tan alta como ta

velocidad especificada en la advertencia

de ta etiqueta de ta herramienta.

• Antes de utilizarlo, revise el

accesorio recomendado para

confirmar que no tenga trizaduras o

fallas. Si tuviera alguna trizadura o

falta, descarte el accesorio. Et accesorio

deberia tambien ser revisado siempre

que se piense que ta herramienta

pudiera haberse caido.

• Cuando arranque la herramienta

(con un disco o escobilla nuevo o de

reemplazo instalado), sostenga la

herramienta en un area bien protegida

y dejela andar por un minuto. Si el

disco o ta escobitta tiene una trizadura

o falta no detectada, deberia romperse

o separarse en menos de un minuto.

Nunca arranque la herramienta si hay

alguna persona parada en linea con el

accesorio. Esto inctuye al operador.

• Durante la operacion, evite hacer

rebotar el disco o tratarlo

bruscamente. Si esto ocurre, detenga

la herramienta y revise el disco.

• Utilice siempre los protectores con

los discos de esmeritado y las escobiltas

de metal. Coloque siempre el protector

de modo que la mayor parte posible del

disco expuesto quede apuntando en

direcci6n opuesta a usted.

• Limpie su herramienta peri6dicamente.

• No use discos abrasivos Tipo 1 o de

diamante sin la guarda apropiada.

• Siempre dirija ta corriente de chispas

originada al esmeritar tejos de

materiales inflamables.

• _ADVERTENCIA: Parte del polvo

generado al lijar, serrar, esmeritar y

taladrar, asi como al realizar otras

actividades del sector de ta

construcci6n, contienen productos

quimicos que pueden producir cancer,

defectos congenitos u otras afecciones

reproductivas. Ejemplos de esas

substancias quimicas son:

• ptomo procedente de pinturas a base

de plomo,

• 6xido de siticio cristalino procedente

de tadriltos, cemento y otros

productos de mamposteria, y

• arsenico y cromo procedentes de

madera tratada quimicamente (CCA).

El peligro derivado de estas exposiciones

que usted enfrente varia en funci6n de ta

frecuencia con que se realice este tipo de

13

Page 14

trabajo.Parareducirtaexposici6naesas

sustanciasquimicas:trabajeenunazona

bienventitadayttevandoequiposde

seguridadaprobados,comomascarittas

antipolvoespecialmentediseSadaspara

filtrarparticulasmicrosc6picas.

• Evite el contacto prolongado con el

polvo procedente del lijado, serrado,

esmerilado y taladrado electricos,

asi como de otras actividades del

sector de la construccion. Lleve

ropa protectora y lave con agua y

jabon las zonas expuestas. Si

permite que el polvo se introduzca en

la boca u ojos o quede sobre la piel,

puede favorecer la absorci6n de

productos quimicos peligrosos.

• _ ABVERTENCIA: El uso de esta

herramienta puede generar o

dispersar polvo Io cual puede

causar lesiones respiratorias serias

y permanentes y otros tipos de

lesion. Siempre use proteccion

respiratoria aprobada por

NIOSH/OSHA para la exposicion al

polvo. Dirija las particulas en

direccion opuesta a su cara y

cuerpo.

• _, PRECAUCION: Utilice una

proteccion auditiva apropiada

durante el uso. En determinadas

condiciones y con utitizaciones

prolongadas, el ruido generado por

este producto puede favorecer la

perdida de audici6n.

• La etiqueta de ta herramienta puede

incluir los siguientes simbolos:

V...................voltios

A................amperios

Hz................hertzios

W ................vatios

min ..............minutos

'_ ..............corrientealtema

.... ............corrientedirecta

no ................velocidad sin carga

[] ................construcci6n de Clase II

G ................terminalcon conexi6na

tierra

..............sfmbolo dealerta

seguridad

.../min .......... revoluciones o

reciprocaciones por

minuto

CABLES DE EXTENSION

Cuando use un cable de extensi6n,

asegQrese de usar uno de un calibre

suficiente como para cargar con la

corriente que requerira su producto. Un

cable de menor calibre causara una

caida en el vottaje de ta linea lo que

resultara en perdida de potencia y

sobrecalentamiento.

El siguiente cuadro muestra el tamaSo

correcto a utilizar, dependiendo del largo

del cable y el amperaje nominal. Si tiene

dudas sobre cuat calibre usar, use un

calibre mayor. Mientras menor el nQmero

del calibre, mayor la capacidad del cable.

Calibre minimo para juegos de cables

Voltios Largo total del cable en metros

120V 0-7,6 7,6-15,2 15,2-30,4 30,4-45,7

240V 0-15,2 15,2-30.4 30,4-60.9 60.9-91,4

Amperaje Nominal

Mas No mas American Wire Gage

de de

0 - 6 18 16 16 14

6 -10 18 16 14 12

10 -12 16 16 14 12

12 -16 14 12 No Recomendado

MOTOR

AsegQrese de que su alimentaci6n

electrica sea la requerida en la placa

nominal. 120 voltios de corriente alterna

s61osigniflca que su herramienta operara

con la potencia domestica estandar de

60 Hz. No opere herramientas de

corriente alterna en corriente direct&

Una especificaci6n de 120 voltios AC/DC

significa que su herramienta operara en

60 Hz estandar de potencia en corriente

alterna o corriente direct& Esta

informaci6n esta impresa en la placa

nominal. Un voltaje menor causara

perdida de potencia y puede resultar en

sobrecalentamiento. Todas tas herramientas

Craftsman han sido probadas en la

fabrica; siesta herramienta no funciona,

revise la alimentaci6n electrica.

[o]_=l_0]_] _I

MANGO AUXILIAR (FIG. 1)

Su esmeritadora viene con un mango

auxitiar y puede ser atorniltada en

cualquiera de los dos tados de la caja

protectora de la esmeritadora. Este

mango DEBERiA SER UTILIZADO EN

TODO MOMENTO para mantener el

control total de la herramienta. AJUSTE

FIRMEMENTE.

14

Page 15

ARRANQUE Y DETENCION DE LA

HERRAMIENTA

Para arrancar ta herramienta, deslice el

conmutador de encendido y apagado

hacia adelante Para una operaci6n

continua, destice el conmutador

completamente hacia adelante y presione

el extremo delantero hacia abajo Para

detener ta herramienta, suelte el

conmutador de encendido y apagado

Para detener la herramienta durante su

operaci6n en modalidad continua,

presione ta parte posterior del conmutador

NOTA: No encienda o apague ta

herramienta cuando esta este bajo

condiciones de carga Permita a la

esmeriladora alcanzar su velocidad

completa antes de tocar ta superficie a ser

esmeritada Levante ta herramienta de la

superficie antes de apagarla.

PRECAUClON: Permita a la herramienta

detenerse antes de ponerla a un lado.

SOBRECARGA

La sobrecarga causara dafios al motor de

su esmeritadora angular. Esto puede

suceder si su esmeritadora angular es

sujeta a uso pesado durante periodos

largos de tiempo. Bajo ninguna circunstancia

intente ejercer demasiada presi6n sobre

su esmeritadora angular con el prop6sito

de acelerar su trabajo. Los accesorios

que son abrasivos operan con mayor

eficiencia cuando se ejerce una presi6n

ligera, asi evitando ta disminuci6n de ta

velocidad de su esmeriladora angular.

O

INSTALACION DE DISCOS DE CENTRO

HUNDIDO (FIG. 3, 4, 5, 6)

ague y desenchufe ta herramienta

PRECAUCION: Nunca use ningQn

disco de esmeritado sin el protector adecuado

1)AsegQrese que el protector este bien

puesto Coloque ta arandela interior (1)

en el eje (2) como se muestra (Fig 3)

AsegQrese que este ubicado sobre

ambas superficies planas

1

INSTALACION DEL PROTECTOR DEL

DISCO (FIG. 2)

Apague y desenchufe la herramienta

NUNCA ESIMIERILE O ESCOBILLE SI EL

PROTECTOR NO ESTA EN SU SITIO.

• Coloque ta esmeritadora angular sobre

una mesa con el eje (1) hacia arriba

• Coloque ta arandela del resorte (2) sobre

el eje y ubiquelo sobre el borde (3)

• Coloque el protector en la herramienta

como se muestra

• Coloque ta arandela (4) sobre el eje con

las protuberancias mirando hacia el

protector AsegQrese que los tornitlos (5)

esten ajustados y que el protector (6)

pueda ser rotado

2 )Coloque el disco de esmeritado (1 en

el eje (2) y ta arandela interior (3)

como se muestra (Fig 4)

0

15

Page 16

3.)Coloque ta arandela exterior roscada

(4) asegurandose que este mirando

en direcci6n correcta para el tipo de

disco instalado. Para discos de

esmeritado gruesos (Fig. 5), la arandela

(4) se instala con la parte elevada

mirando hacia el disco. Para discos de

esmeritado finos, la arandela (4) se

instala con la parte interior mirando en

direcci6n opuesta al disco.

4.)Presione el bot6n de bloqueo del eje y

gire el eje hasta que se bloquee. Con el

bot6n de bloqueo presionado, ajuste ta

arandela exterior con la ltave inglesa

como to muestra la Fig. 6. Los discos

con cubo no requieren arandelas de

montaje y pueden ser ajustados con

llaves estandar.

0

5.)Cuando use un disco con centro

hundido, sostenga la herramienta de

modo que exista un angulo de

aproximadamente 30° entre el disco y

el material de trabajo.

AADVERTENCIA: Revise ta velocidad

nominal del disco de centro hundido.

Nunca use un disco que tenga una

velocidad nominal menor que ta de la

placa nominal de ta herramienta.

Nota: Los discos de tijado con aletas

son considerados como discos de

esmeritado y deben ser usados con los

protectores.

INSTALACION DE ESCOBILLAS

METALICAS

Las escobitlas metalicas encopadas se

atornitlan directamente en el eje de la

maquina sin necesidad de utitizar

pestaSas. Cuando use escobiltas

metaticas, insertelas en el eje firmemente

con la mano. El protector se puede sacar

para escobillar con escobillas metalicas

ptanas.

ESMERILADO DE BORDES

El esmeritado de bordes puede hacerse

con discos de centro hundido Tipo 27,

diseSados especificamente con este

prop6sito. Estos discos se encuentran

disponibles localmente. No deben ser

sujetos a presi6n lateral.

-& PRECAUCION: Los discos utitizados

para el esmerilado de bordes pueden

romperse si se doblan o tuercen

mientras son usados para trabajo de

corte o esmeritado profundo. Para

reducir el riesgo de tesiones graves,

restrinja el uso de estos discos a cortes

poco profundos y muescas (menores a

13 mm (1/2 pulg.) de profundidad). El

lado abierto del protector debe estar

puesto en direcci6n opuesta al operador.

REMOCION DEL PROTECTOR DEL

DISCO (FIG. 7 PARA LIJADO)

Apague y desenchufe la herramienta.

NOTA: Para evitar perder el control, no

deje la herramienta a un lado hasta que

el accesorio no haya dejado de girar

totalmente.

Como to muestra la Fig. 7, coloque ta

esmeriladora sobre una mesa, con el eje

hacia arriba. Use un atornittador para

quitar los 3 tornittos (1). Quite la pestaSa

(2), el protector (3) y ta arandela del

resorte (4). Atmacene estas piezas con

mucho cuidado.

16

Page 17

PRECAUCIONES A TOMAR CUANDO

LIJE PINTURA

1. El tijado de pinturas con base de

plomo NO SE RECOMIENDA debido a

la dificultad de control del polvo

contaminado. El envenenamiento por

plomo es mas peligroso para nifios y

mujeres embarazadas.

2. Ya que es dificit identificar si una

pintura contiene plomo o no, sin antes

hacer un anatisis quimico, te

recomendamos que se tomen las

siguientes precauciones cuando lije

cualquier pintura:

SEGURIDAD PERSONAL

1. Ningt_n nifio o mujer embarazada

deberia entrar al area de trabajo donde

se esta tijando ta pintura hasta que se

termine de limpiar el area.

2. Toda persona que entre al area de

trabajo debe usar una mascara

antipolvo o respirador. El fittro deberia

ser reemplazado a diario o cuando el

usuario tenga dificultades para respirar.

NOTA: Solo se deberian utilizar

aquellas mascaras antipolvo

adecuadas para el trabajo con

polvo y gases de pinturas de

plomo. Las mascaras regulares

para pintar no ofrecen esta

protection. Visite su distribuidor de

ferreteria local para obtener la

mascara NIOSH correcta.

SEGURIDAD MEDIOAMBIENTAL

1. La pintura debe ser quitada de tal

manera que se minimice la cantidad

de polvo generada.

2. Aquellas areas en las que se esta

quitando pintura deberian ser seltadas

con laminas de plastico de 4 mm de

grosor.

3. El lijado deberia hacerse de modo que

se reduzca la cantidad de polvo de

pintura que se lleve afuera.

INSTALACION DE DISCOS ABRASIVOS

Apague y desenchufe la herramienta.

Use un disco abrasivo con una

almohaditta de respaldo cuando lije

con su esmeriladora angular.

1. Quite el protector.

2. Cotoque ta pestafia (ta almohadilla de

respaldo y el disco abrasivo se

venden por separado) y ta pestafia

exterior en el eje, como 1o muestra la

Figura 8. La Figura 8A muestra c6mo

instalar un disco abrasivo con una

almohadilla de respaldo de goma.

0

3. Ajuste el disco abrasivo como to

muestra la Figura 9, presionando el

bot6n de bloqueo del eje y girando el

disco abrasivo a mano.

PARA USAR LA ESMERILADORA

-4,ADVERTENCIA: Utilice siempre

proteccion ocular cuando opere esta

maquina herramienta.

• Sostenga la esmeritadora angular con

una mano en el cuerpo y ta otra

firmemente agarrada del mango lateral,

como 1o muestra la Figura 10.

17

Page 18

• Coloquesiempreelprotectordemodo

quetamayorparteposibledeldisco

expuestoquedeapuntandoen

direcci6nopuestaausted.

• Estepreparadoparalaltuviade

chispasquesegeneraracuandoel

discotoqueelmetal.

• Ejerzaunapresi6nligerasobrelos

discosabrasivosparaunaoperaci6n

eficiente.Siempujademasiado,

disminuiralavelocidadlocualpodria

resultarensobrecargaydafiodelmotor.

• Usecautelacuandotrabajeen

esquinasyaqueelcontactoconla

superficieintersectadapodriahacer

quetaesmeritadorasalteosetuerza.

• Paracontrolarmejortaherramienta,

quitarmejorelmaterialyminimizarla

sobrecarga,mantengaunanguloentre

eldiscoylasuperficiedetrabajo(Fig.

11y12)deaproximadamente30°

cuandoesmeriley10°-15°cuandolije.

O

generalmente se acumulan en las

superficies interiores y pueden crear

peligro de choque electrico si no se

limpian.

Use s6to un jab6n suave y patio hL_medo

par timpiar el exterior de ta herramienta..

Jamas permita que te entre tiquido a la

herramienta; nunca sumerja ninguna

parte de ta herramienta.

IMPORTANTE: Las reparaciones, el

mantenimiento y los ajustes deberan ser

realizados por Centros de Servicio Sears

para garantizar ta SEGURIDAD y

FIABILIDAD del producto.

LUBRICACION

Las herramientas Sears Craftsman vienen

debidamente tubricadas de fabrica y estan

listas para usarse. Las herramientas

deben lubricarse en forma regular, todos

los afios, dependiendo del uso. (Aquellas

herramientas utitizadas para trabajos

pesados o expuestas a calor podrian

requerir una lubricaci6n mas frecuente.)

Esta lubricaci6n deberia s61oser intentada

por especialistas capacitados en la

reparaci6n de herramientas como los que

encontrara en los Centros de Servicio

Sears o en otras organizaciones de

servicio calificadas.

ACCESORIOS

Use s6to accesorios Craftsman con su

herramienta. Podra comprar estos

accesorios en su tienda Sears o Centro

de Servicio Sears local.

_, ATENCION: El uso de accesorios no

vendidos por Sears puede ser peligroso y

causar lesiones o dafios a la herramienta.

hif-'1_ii3_lhill3_il_i ,_

LIMPIEZA

Como procedimiento de mantenimiento

necesario, limpie el polvo y la arenitta

acumulada en la caja protectora del motor

con aire comprimido.

PRECAUCION: El polvo y ta arenitla

provenientes del esmerilado de metal

18

Page 19

Your Home

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owneris manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® Anytime, day or night

(1-800-469-4663) (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in products like vacuums, lawn equipment,

and electronics, call or go on-line for the nearest

Sears Parts and Repair Center.

1-800-488-1222 Anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protection agreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears:

1-800-361-6665 (Canada)

Para pedir servicio de reparaci6n

a domicilio, y para ordenar piezas:

1-888-SU-HOGAR su

(1-888-784-6427)

Au Canada pour service enfran£ais:

1-800-LE-FOYER Mc

(1-800-533-6937)

www.sears.ca

SEAR

© Sears, Roebuck and Co.

® Registered Trademark / TMTrademark / SMService Mark of Sears, Roebuck and Co.

® Marca Registrada / TMMarca de Fabrica / SM Marca de Servicio de Sears, Roebuck and Co.

MCMarque de commerce / MDMarque depos6e de Sears, Roebuck and Co.

19

Page 20

20

Loading...

Loading...