Craftsman 88136505 Owner’s Manual

Sears ]

owners

manual

MODEL NO.

881.36505

CRAFTSMAN

MITER BOX

Operating Instructions

Repair Parts

Sears, Roebuck and Co., Chicago, Ill. 60684 U.S.A.

and Simpsons Sears Lirr_ited, Toronto, Ontario

12470-0

YOUR NEW CRAFTSMAN MITER BOX

HAS BEEN FACTORY TESTED AND ADJUSTED

FOR YOUR IMMEDIATE USE

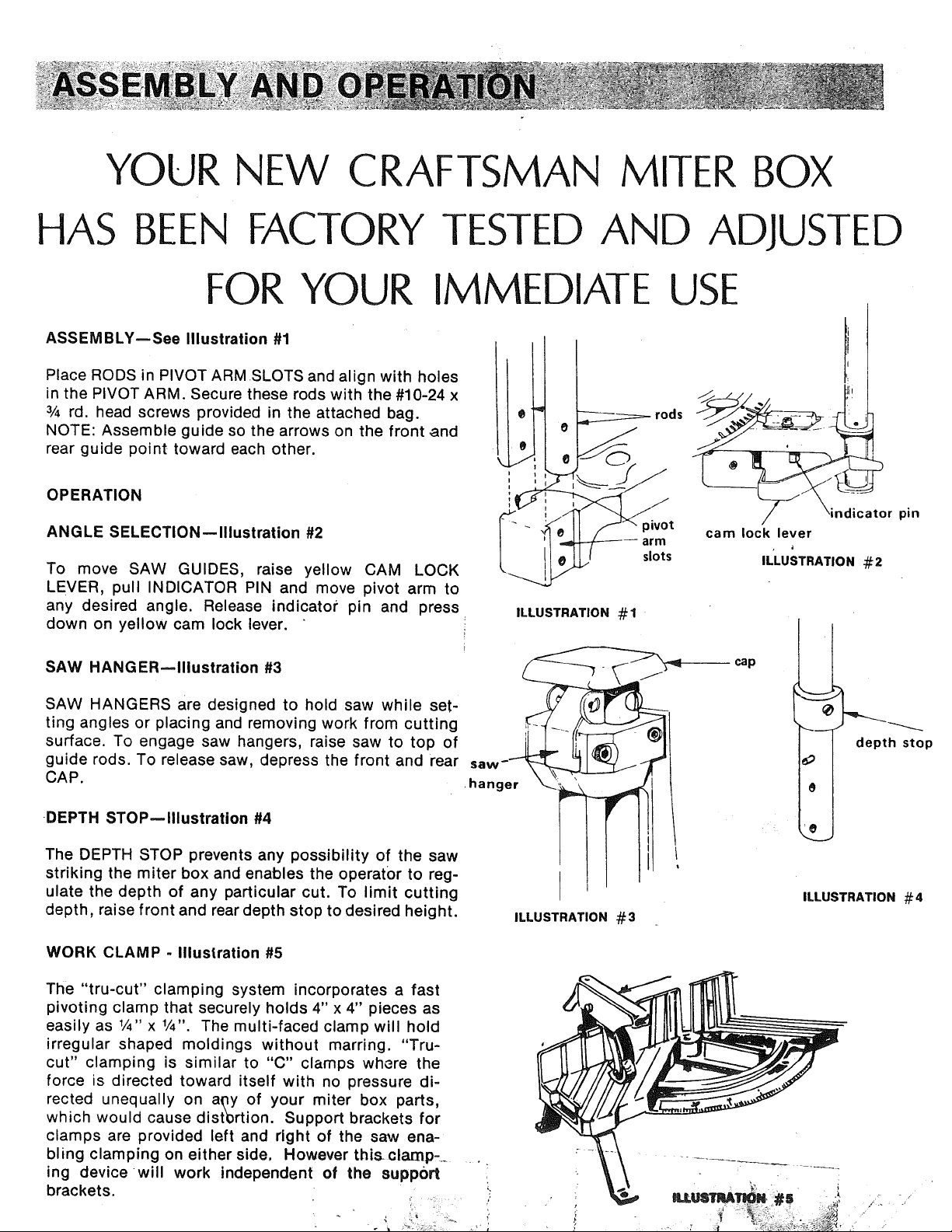

ASSEMBLY--See Illustration #1

Place RODS in PIVOT ARMSLOTS and align with holes

in the PIVOT ARM. Secure these rods with the #10-24 x

3/4rd. head screws provided in the attached bag.

NOTE: Assemble guide so the arrows on the front and

rear guide point toward each other.

OPERATION

ANGLE SELECTION--Illustration #2

._ rods

ndicator pin

cam lock lever

To move SAW GUIDES, raise yellow CAM LOCK

LEVER, pull INDICATOR PIN and move pivot arm to

any desired angle. Release indicator pin and press

down on yellow cam lock lever.

SAW HANGER--Illustration #3 j --

SAW HANGERS are designed to hold saw while set-

ting angles or placing and removing work from cutting

surface. To engage saw hangers, raise saw to top of

guide rods. To release saw, depress the front and rear saw- _T_j _-

CAP.. hanger "..__

DEPTH STOPmlllustration #4

The DEPTH STOP prevents any possibility of the saw

striking the miter box and enables the operator to reg-

ulate the depth of any particular cut. To limit cutting

depth, raise front and rear depth stop to desired height. ILLUSTRATION#3

WORK CLAMP - Illustration #5

The "tru-cut" clamping system incorporates a fast

pivoting clamp that securely holds 4" x 4" pieces as

easily as 1/4" x 1/4". The multi-faced clamp will hold

irregular shaped moldings without marring. "Tru-

cut" clamping is similar to "C" clamps where the

force is directed toward itself with no pressure di-

rected unequally on a_y of your miter box parts,

which would cause distertion. Support brackets for

clamps are provided left and right of the saw ena-

bling clamping on either side, However thisclamp=

ing device will work independent of the support

brackets.

t

'i!_i

ILLUSTRATION #1

'rl

IL'LUSTRATION #2

cap

depth stop

ILLUSTRATION #4

Loading...

Loading...