Craftsman 875501152 Owner’s Manual

Owner's

Manual

MODEL NO.

875.501152

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

IB-501152

Sold by SEARS, ROEBUCK AND CO., Hoffman Estates, IL 60179 U.S.A.

J

3 TON CAPACITY

SERVICE JACK

• Operation

° Maintenance

• Repair Parts

° Warranty

OPERATION

, This Jack Is a Lifting Device Only •

Designed only for lifting part of the total

vehicle (ie. one wheel). Do not move or dolly

thevehicle while it ison the jack.

• Position the Jack •

Position this jack to only lift on the areas of

the vehicle specified by the vehicle

manufacturer.

• Use Support Stands •

After lifting the vehicle always support the

load with appropriately rated vehiclesupport

stands before working on the vehicle.

• Do Not Overload Jack •

Do not overload this jack beyond its rated

capacity. Overloading can cause damage

toor failure of the jack.

• Use on Hard Level Surfaces •

This jack is designed only for use on hard

level surfaces capable of sustaining the

load. Use on other than hard level surfaces

can result in jack instability and possible

loss of load.

• Center Load on Jack Saddle •

Center load on jack saddle before lifting

vehicle. Off-center loads and loads lifted

when the jack is not level can cause loss of

load or damage to the jack.

Read Operating Instructions •

Study, understand and follow all

ins_'uctions in this manual before operating

the jack. Failure to heed these warnings

may result in loss of load, damage to the

jack and/or jack failure resulting in _ersonal

injury or property damage.

During shipment and handling, air may get

trapped in the hydraulic system, which can

interfere with the jack's lifting performance.

Follow these steps to release air from the

hydraulic system:

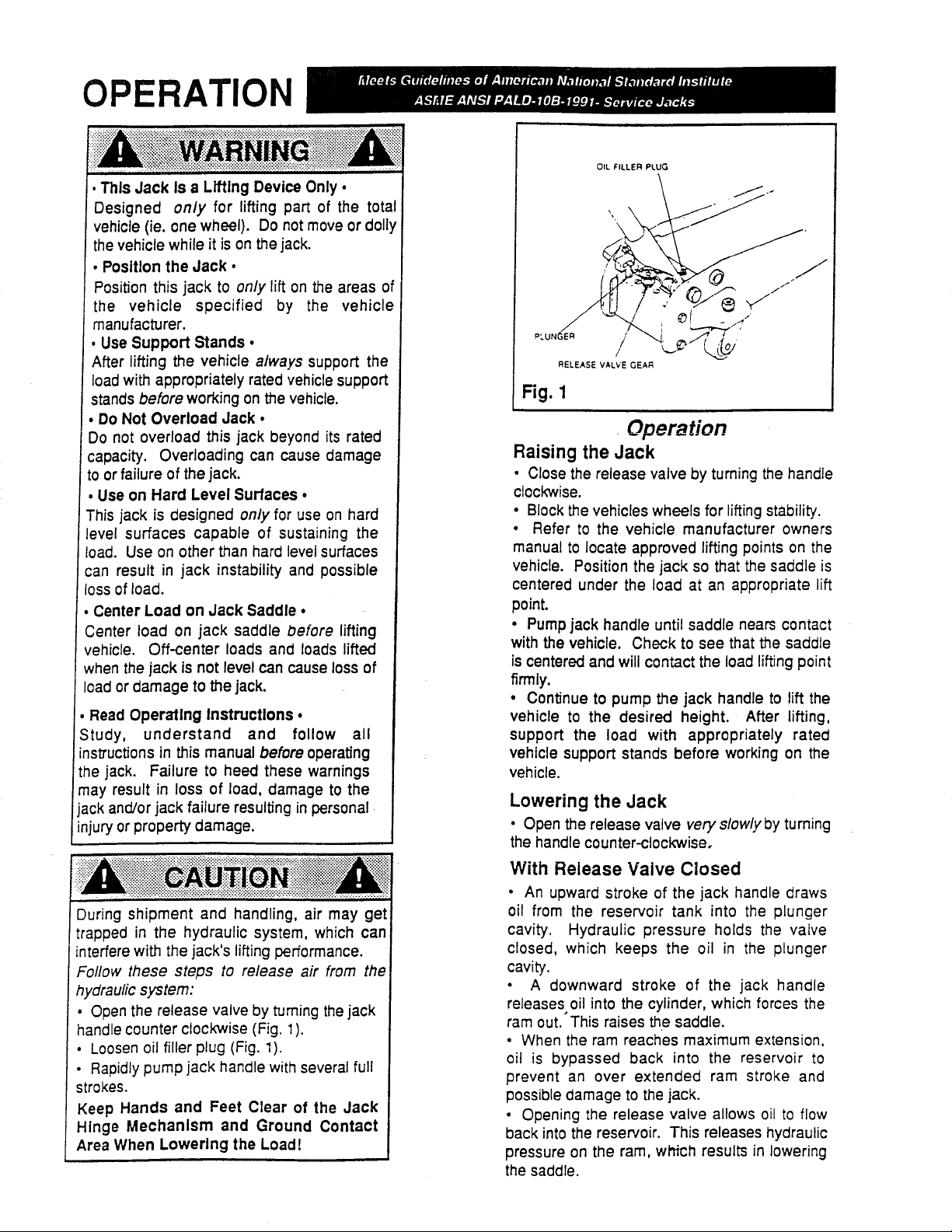

• Open the release valve by turning the jack

handle counter clockwise (Fig. 1).

• Loosen oil filler plug (Fig. 1).

• Rapidly pump jack handle with several full

strokes.

Keep Hands and Feet Clear of the Jack

Hinge Mechanism and Ground Contact

Area When Lowering the Load!

OIL FILLER PLUG

.J

RELEASE VALVE GEAR

Fig. 1

Operation

Raising the Jack

. Close the release valve by turning the handle

clockwise.

• Block the vehicles wheels for lifting stability.

• Refer to the vehicle manufacturer owners

manual to locate approved lifting points on the

vehicle. Position the jack so that the saddle is

centered under the load at an appropriate lift

point.

• Pump jack handle until saddle nears contact

with the vehicle. Check to see that the saddle

is centered and will contact the load lifting point

firmly.

• Continue to pump the jack handle to lift the

vehicle to the desired height. After lifting,

support the load with appropriately rated

vehicle support stands before working on the

vehicle.

Lowering the Jack

• Open the release valve very slowlyby turning

the handle counter-clockwise.

With Release Valve Closed

• An upward stroke of the jack handle draws

oil from the reservoir tank into the plunger

cavity. Hydraulic pressure holds the valve

closed, which keeps the oil in the plunger

cavity.

• A downward stroke of the jack handle

releases oil into the cylinder, which forces the

ram out.'This raises the saddle.

• When the ram reaches maximum extension,

oil is bypassed back into the reservoir to

prevent an over extended ram stroke and

possible damage to the jack.

• Opening the release valve allows oil to flow

back into the reservoir. This releases hydraulic

pressure on the ram, which results in lowering

the saddle.

Loading...

Loading...