Craftsman 875199900 Owner’s Manual

_S Owner's Manual

CRRFTSMRNo

Pneumatic

Cut-Off Tool

Model No.

875.199900

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

4, Safety

4, Warranty

_, Features & Operation

4, Maintenance

4, Espa5ol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Read Operating Instructions

Please become familiar with all the instructions and

warnings before operating any pneumatic tool,

Always Wear Approved Eye Protection

Impact resistant eye protection should meet or

exceed the standards set forth in ANSI Z87.1,

Occupational and Educational Eye and Face

Protection. Look for marking Z87. ! on your eye

protection to ensure that it is an approved style.

Hearing Protection is Recommended

Hearing protection should be used when the noise

level exposure equals or exceeds an 8 hour time-

weighted average sound level of 85dBA. Process

noise, reflective surfaces, other tools being operated

nearby, all add to the noise level in a given work area.

If you are unable to determine your noise level expo-

sure, we recommend the use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic toolscan vibrate during use. Prolonged

exposure to vibration or very repetitive hand and arm

movements can cause injury. Discontinue the use of

any tool if you experience tingling, numbness, dis-

comfort or pain in your hands or arms. You should

consult your physician before resuming use of tool.

FULL TWO YEAR WARRANTY ON

CRAFTSMAN AIR-DRIVE TOOLS

If this Craftsman tool fails to give complete satisfaction

within two years from the date of purchase, RETURN

IT TO THE NEAREST SEARS SERVICE CENTER/

DEPARTMENT IN THE UNITED STATES,and Sears

will repair or replace it free of cl_arge. If this Craftsman

tool is used for commercial or rental purposes, this

warranty applies for only 90 days from the date of

purchase. This warranty gives you specific legal

rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179.

The Craftsman Model 875.199900 Pneumatic Cut-

Off Tool is designed to cut through muffler clamps

and hangers with ease, Slices sheet metal, radiator

hose clamps, rusted bumper bolts, even 3/4" thick

steel rods. Ideal for autobody work. Includes two 3"

discs,

90 PSIG Maximum

This tool is designed to operate at an air pressure of

90 pounds per square inch gauge pressure (90 PSlG)

maximum, at the toot. Use of higher air pressure can,

and may cause injury. Also, the use of higher air

pressure places the internal components under loads

and stresses they were not designed for, causing

premature tool failure.

NOTE: THE AIR SUPPLY SHOULD BE CLEAN AND

DRY, PREFERABLY LUBRICATED. FOR BEST

RESULTS DRAIN THE MOISTURE FROM YOUR

COMPRESSOR DALLY.

Do Not Operate Without Guard

Always use cut-off wheels with an RPM rating that

meets or exceeds the tool RPM rating. Always

examine cut-off wheels for chips, cracks or signs of

damage before mounting. Never use cut-off wheels

that have been dropped or exposed to: water, solvent

or extreme temperatures. It is a good practice to

operate the tool in a protected enclosure for one

minute after mounting a cut-off wheel.

Features

• High impact nylon handle with safety lock-off lever.

• Cuts shoe: metal, pipe and hose clamps, hangers

and rusted bolts.

• Clear Lexan guard for better visibility.

The Craftsman Pneumatic Cut-Off Tool is designed to

operate on 90 PSIG. Lower pressure (below 90 PSIG)

will reduce performance of the tool, while higher air

pressure (over 90 PSIG) raises the performance of the

tool beyond its rated capacity and could cause

serious damage to tool and user.

Before the tool is connected to the air supply, clear

the air hose of accumulated dust and moisture, and

add 1/4 oz. of air tool oi! into air tool inlet. Be sure to

lubricate tool daily for best performance.

Always use c!ean dry air, Excessive moisture and

dirt will greatly reduce the life of any air moron

We recommend the installation of an in-line

filter-regulatorqubricator as close to the tool as

possible.

(2)

A3/8"airhoseisrequireduptoalengthof8ft.

Ifmorelengtt_isrequired,a1/2"airhoseshouldbe

connectedtothe3/8"hosetoensurethetoolhasthe

necessaryairsupply.Besureallhosesandfittings

arethecorrectsizeandtightlysecured.

WARNING:DISCONNECTTOOL FROM AIR

SUPPLY BEFORE SERVICING OR CHANGING

DISCS.

PLEASE NOTE: USE ONLY CUT-OFF WHEELS

RATED AT OR ABOVE 20,000 RPM ONLY (SEARS

ACCESSORY 18834). THE CUT-OFF WHEEL MUST

HAVE A 3/8" CENTER HOLE. NEVER OPERATE

THIS TOOL IF GUARD IS BROKEN OR REMOVED.

Always disconnect tool from power supply before

changing accessories. Never hold work in hands, lap

or against other parts of the body. Secure all work with

clamps or a vise so that both hands are free to

operate tool. Keep proper footing and balance at all

times. Do not force tools, allow tool to work at

designed pace.

In the event that it becomes necessary to store the

tool for an extended period of time (overnight,

weekend, etc.), it should receive a generous amount

of lubrication at that time. The tool should be run for

approximately 30 seconds to ensure oil has been

evenly distributed throughout the tool. The tool should

be stored in a clean and dry environment.

Recommended lubricants: Use air tool oil or any

other high grade turbine oil containing moisture

absorbent, rust inhibitors, metal wetting agents and an

EP (extreme pressure) additive.

Specifications

Speed ..................................................... 20,000 RPM

Wheel size ................................... 2-7/8" x 1/16" x 3/8"

Arbor size ............................................................ 3/8"

Length .................................................................... 7"

Weight ........................................................ 1-3/4 Ibs.

Air inlet ....................................... i................. 1/4" NPT

Hose size ...................................................... 3/8" I.D,

Average air consumption ................................ 4 CFM

Maximum air pressure .................................... 90 PSI

Lubrication

An automatic in-line filter-regulator-lubricator is

recommended as it increases tool life and keeps the

tool in sustained operation. The in-line lubricator

should be regularly checked and filled with air tool oil.

Proper adjustment of the in-line lubricator is performed

by placing a sheet of paper next to the exhaust ports

and holding the throttle open approximately 30

seconds. The lubricator is properly set when a light

stain of oil collects on the paper. Excessive amounts

of oi! should be avoided.

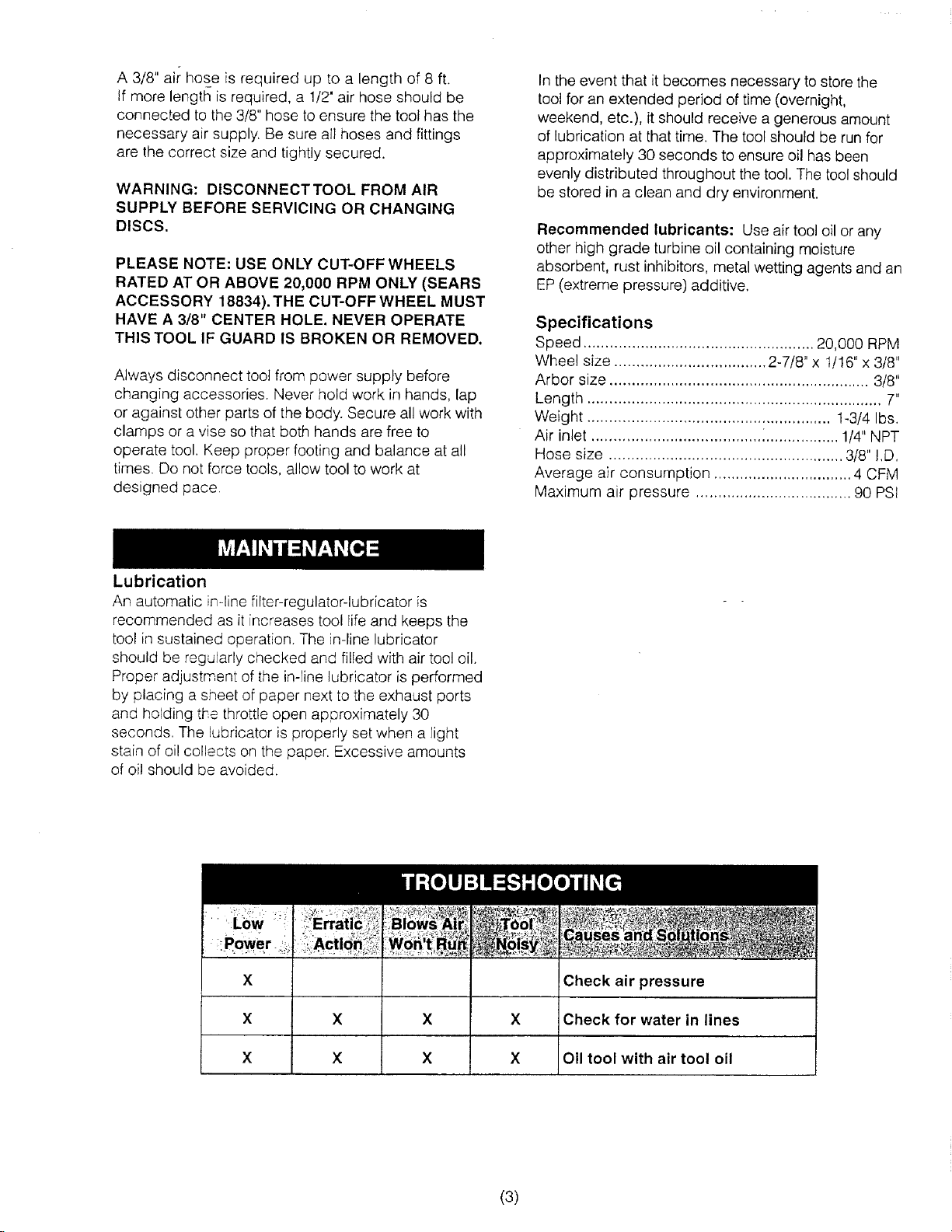

x

x x x

Check air pressure

X

Check for water in lines

x x x

(3)

X

Oil tool with air tool oil

Loading...

Loading...