Craftsman 875199850 Owner’s Manual

Owner's Manual

Pneumatic 3/4"Anvil Drive

IMPACT WRENCH

Model No.

875.199850

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

Safety

, Warranty

Features & Operation

Maintenance

, EspaSol

Distributed by Sears, Roebuck and Co., Hoffman Estates, IL 60179

www.Sears.com

Read Operating Instructions

Please become familiar with all the instructions and

warnings before operating any pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should meet or exceed

the standards set forth in ANSI Z87.1, Occupational and

Educational Eye and Face Protection. Look for marking

Z87.1 on your eye protection to ensure that it is an

approved style.

Hearing Protection is Recommended

Hearing protection should be used when the noise level

exposure equals or exceeds an 8 hour time-weighted

average sound level of 85dBA. Process noise, reflective

surfaces, other tools being operated nearby, all add to the

noise level in a given work area. If you are unable to

determine your noise level exposure, we recommend the

use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use. Prolonged

exposure to vibration or very repetitive hand and arm

movements can cause injury. Discontinue the use of any

tool if you experience tingling, numbness, discomfort or

pain in your hands or arms. You should consult your

physician before resuming use of tool.

90 PSI Maximum

This tool is designed to operate at an air pressure of 90

pounds per square inch gauge pressure (90 PSI)

maximum, at the tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher air pressure

places the internal components under loads and

stresses they were not designed for, causing premature

tool failure.

NOTE: THEAIR SUPPLY SHOULD BE CLEAN, DRYAND

PREFERABLY LUBRICATED. FOR BEST RESULTS

DRAIN THE MOISTURE FROM YOUR COMPRESSOR

DAILY.

Use Only Impact Sockets & Accessories

Only use sockets designated "FOR USE WITH IMPACT

WRENCHES." Hand tool sockets can break, creating a

hazard from flying pieces. Always check sockets,

retainers and drives regularly for wear or damage and

replace when necessary.

[, WARNINGJ

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemi-

cals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals

are:

• Lead from lead based paint

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as dust masks that

are specifically designed to filter out microscopic par-

ticles.

FULL ON E YEAR WARRANTY ON

CRAFTSMAN AIR-DRIVE TOOLS

If this Craftsman tool fails to give complete satisfaction

within one year from the date of purchase, RETURN IT

TO THE NEAREST SEARS STORE IN THE UNITED

STATES, and Sears will repair or replace it free of charge.

If this Craftsman tool is used for commercial or rental

purposes, this warranty applies for only 90 days from the

date of purchase. This warranty gives you specific legal

rights, and you may also have other rights which vary

from state to state.

Distributed by Sears, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179.

The Craftsman Model 875.199850 3/4" Square Drive

Impact Wrench is ideal for general assembly,

automotive, agricultural and industrial applications.

Features

• Built-in regulator for power output adjustment.

• Twin hammer clutch for increased power output.

• Ring-type socket retainer allows quick socket

changes.

Specifications

Drive size ............................................................................... 3/4"

Impacts per minute ..................................................... 990 IPM

Free speed (No Load)........................................... 4,500 RPM

Ultimate torque........................................................ 750 ft. Ibs.

Weight ............................................................................... 8.7 Ibs.

Overall length .................................................................. 9-1/2"

Average air consumption ............................................. 8 SCFM

Recommended hose size ........................................... 3/8" I.D.

Air inlet .......................................................................... 3/8" NPT

Maximum Air Pressure .................................................. 90 PSI

Pre-Operation

Before the tool is connected to the air supply, clear the air

hose of accumulated dust and moisture by running air

freely through the air hose for 5-10 seconds. Before

removing a tool for service or changing sockets, make

sure the air line is shut-off at the compressor. This will

prevent the tool from operating if the throttle is accidently

engaged.

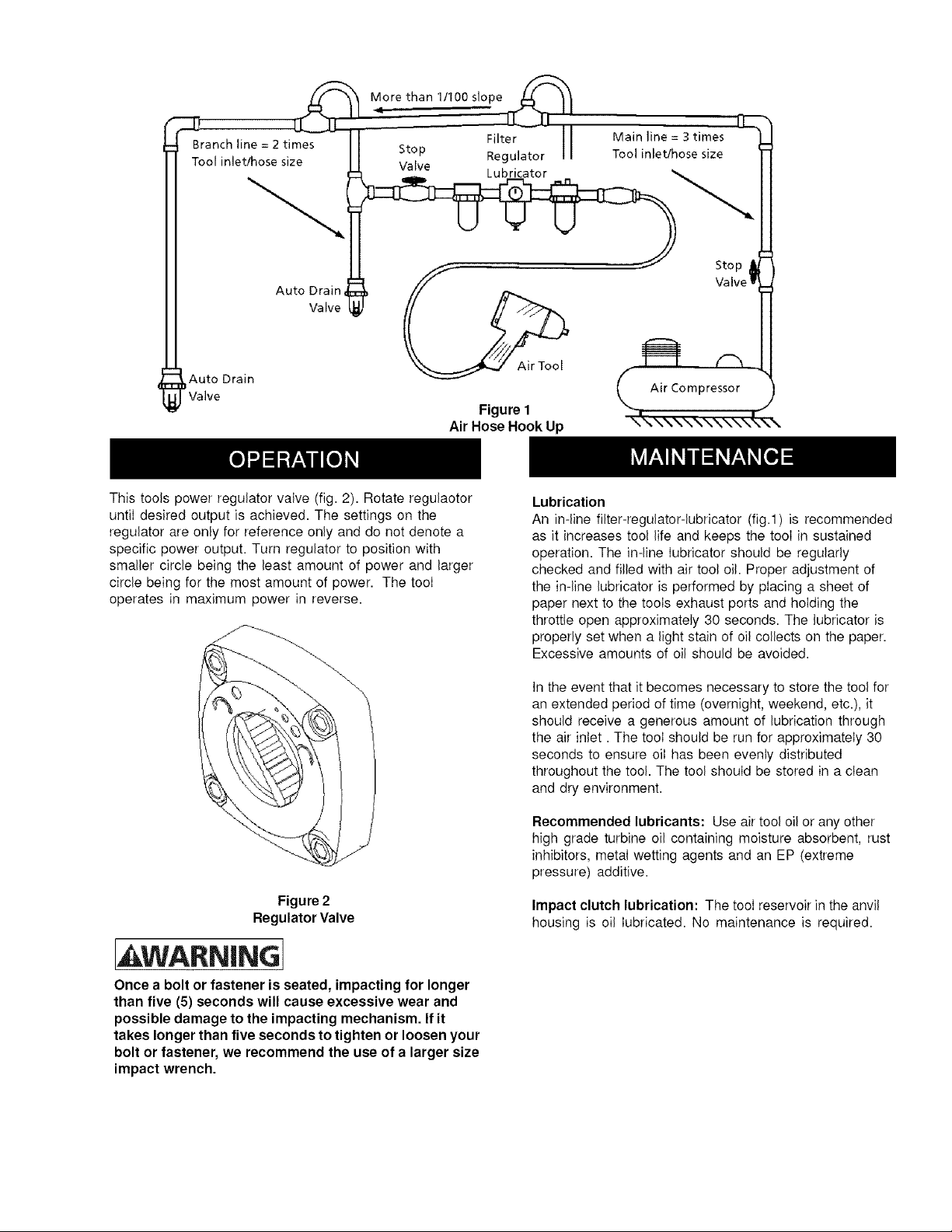

Installation (See figure 1)

This tool is designed to operate at 90 psi. Lower pres-

sure (below 90 psi) will reduce performance of the tool

while higher air pressure (over 90 psi) raises the perfor-

mance of the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air motor. We recommend

the installation of an in-line filter-regulator-lubricator as

close to the tool as possible.

A 3/8" air hose is required up to a length of 8 ft. If more

length is required a 1/2" air hose should be used at the

compressor. Attach a 3/8" whip hose for the remaining

4 - 8 ft. for flexibility. Be sure all hoses and fittings are the

correct size and tightly secured before using air tool.

(2)

._ Morsetha_n1/100slo. pe

ranch ne = 2 t Sto_ Filter Main line = 3 times

"If ........ I I v Reoulator Tool inlet/hose size

I I iool mien/nosesize I I Valve

I I Auto Drain _ AirTool I I

_)A:lve ( Air Compressor

"_ Figure I _-r •"

Air Hose Hook Up \\\\\\\\\\\\_x\\

This tools power regulator valve (fig. 2). Rotate regulaotor

until desired output is achieved. The settings on the

regulator are only for reference only and do not denote a

specific power output. Turn regulator to position with

smaller circle being the least amount of power and larger

circle being for the most amount of power. The tool

operates in maximum power in reverse.

Figure 2

Regulator Valve

Lubrication

An in-line filter-regulator-lubricator (fig.l) is recommended

as it increases tool life and keeps the tooI in sustained

operation. The in-line lubricator should be regularly

checked and filled with air tool oil. Proper adjustment of

the in-line lubricator is performed by placing a sheet of

paper next to the tools exhaust ports and holding the

throttle open approximately 30 seconds. The lubricator is

properly set when a light stain of oil collects on the paper.

Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

should receive a generous amount of lubrication through

the air inlet. The tool should be run for approximately 30

seconds to ensure oil has been evenly distributed

throughout the tool. The tool should be stored in a clean

and dry environment.

Recommended lubricants: Use air tool oil or any other

high grade turbine oil containing moisture absorbent, rust

inhibitors, metal wetting agents and an EP (extreme

pressure) additive.

Impact clutch lubrication: The tooI reservoir in the anvil

housing is oil lubricated. No maintenance is required.

WARNING

Once a bolt or fastener is seated, impacting for longer

than five (5) seconds will cause excessive wear and

possible damage to the impacting mechanism. If it

takes longer than five seconds to tighten or loosen your

bolt or fastener, we recommend the use of a larger size

impact wrench.

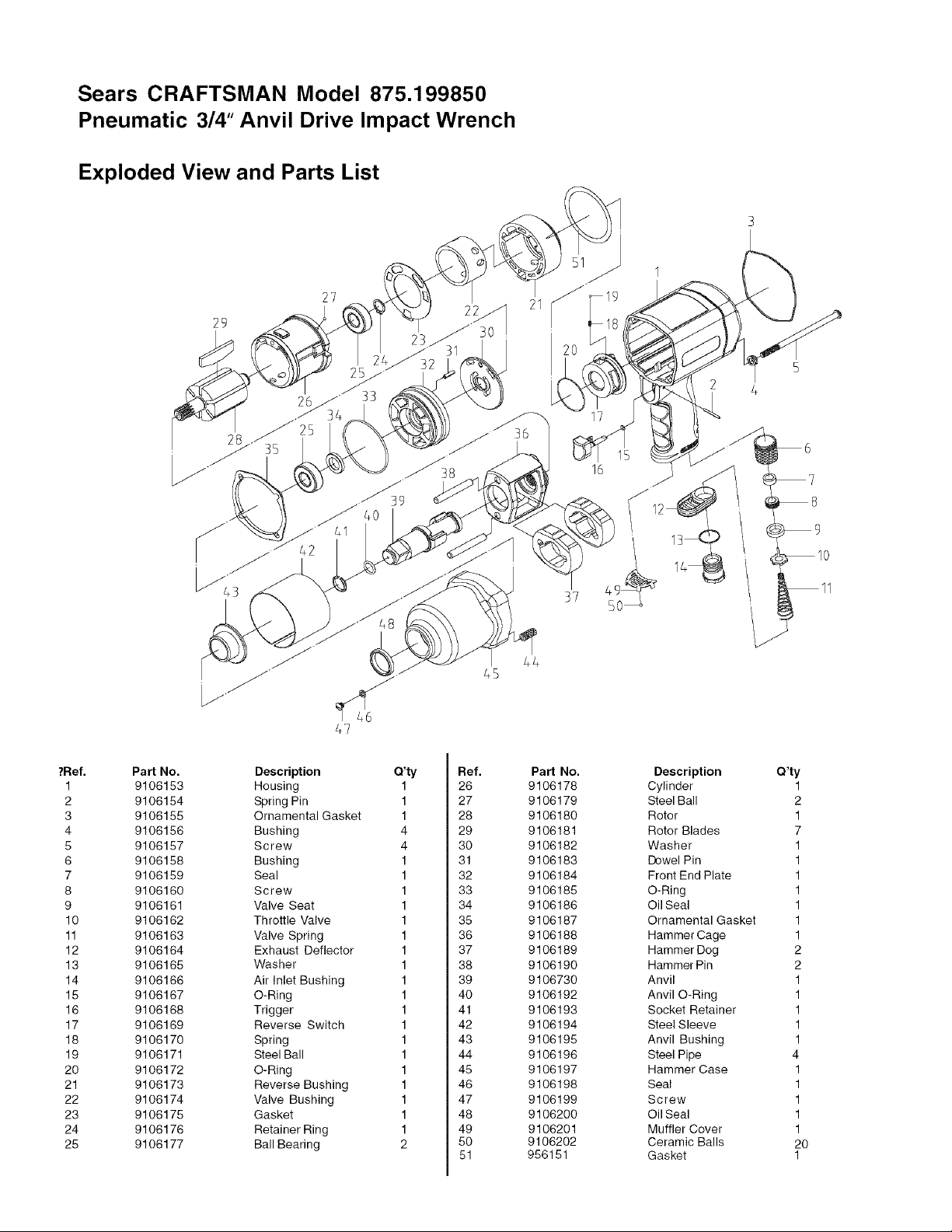

Sears CRAFTSMAN Model 875.199850

Pneumatic 3/4" Anvil Drive Impact Wrench

Exploded View and Parts List

29

26

21

5

4

?Ref.

1

2

3

4

5

8

7

8

9

10

11

12

13

14

15

18

17

18

19

2O

21

22

23

24

25

Pad No.

9106153

9106154

9106155

9106156

9106157

9106158

9106159

9106160

9106161

9106162

9106163

9106164

9106165

9106168

9106167

9106168

9106169

9106170

9106171

9106172

9106173

9106174

9106175

9106178

9106177

Description

Housing

Spring Pin

Ornamental Gasket

Bushing

Screw

Bushing

Seal

Screw

Valve Seat

Throttle Valve

Valve Spring

Exhaust Deflector

Washer

Air Inlet Bushing

O-Ring

Trigger

Reverse Switch

Spring

Steel Ball

O-Ring

Reverse Bushing

Valve Bushing

Gasket

Retainer Ring

Ball Bearing

Q'ty Ref.

1 26

1 27

1 28

4 29

4 30

1 31

1 32

1 33

1 34

1 35

1 36

1 37

1 38

1 39

1 40

1 41

1 42

1 43

1 44

1 45

1 46

1 47

1 48

1 49

2 50

51

45

44

Pad No.

9108178

9108179

9108180

9108181

9108182

9108183

9108184

9108185

9108188

9108187

9108188

9108189

9108190

9108730

9108192

9108193

9108194

9108195

9108198

9108197

9108198

9108199

9108200

9108201

9108202

956151

Description Q'ty

Cylinder 1

Steel Ball 2

Rotor 1

Rotor Blades 7

Washer 1

Dowel Pin 1

Front End Plate 1

O-Ring 1

Oil Seal 1

Ornamental Gasket 1

Hammer Cage 1

Hammer Dog 2

Hammer Pin 2

Anvil 1

Anvil O-Ring 1

Socket Retainer 1

Steel Sleeve 1

Anvil Bushing 1

Steel Pipe 4

Hammer Case 1

Seal 1

Screw 1

Oil Seal 1

Muffler Cover 1

Ceramic Balls 20

Gasket 1

Loading...

Loading...