Page 1

_ Owner's Manual

Model No. 875.199810

3/8-in. Impact Wrench

Unpacking

When unpacking this product, Carefully

inspect for any damage that may have

occurred during _ransit. Make sure any

ioose _ttings,bolts,etc. are tightened

before pt_ting this product into sewice.

WARNING: Please read and save these safety and ope[aUng instructions. Read carefully

before attempting to assemble, Install, operate or maintain _e ploduct described.

Prefect yourse/f and others by observing all safety information. Failure to comply with

instJructions could result In personal injury arid/or property danlege! Retain Instrucfions

for future reference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 0807

www.CRAF_SMAN.com

Page 2

Owner's Manual Model No. 875.199810 Owner's Manual Model No. 875.199810

90 PSi M_mum

This tool is designed to operate at an air

• Features & Benefits

SpeCifications

,_ Product W'arranty

Oomp_so{ Requirements

• important Safety Instructions

• Installation and Operation

Maintenance

+ Exploded View Drawing & Parts List

• Troubleshooting

The Craftsman Model 875.199810 3/8"

Square Drive Impact Wrench is ideal for

general assembly, automotive, ag_culfur_d

and lndustda_applications. Features ,_

Built-in regulator for power Q_utput

ad}ustmen_;pJr_type clutc_hfor increased

power output; ring_/pe socket retainer

aflow_ quick socket changes,

Drive s_ze ........................................... 318"

Impacts per minute .................. 1,100 IPM

Free speed (No Load) ........... 9,000 RPM

Ultimate torque ........................ 145 it. Ibs,

Weight ........................................... 2.8 Ibs.

Ovefali' h_ngth.................................... 6.5 _

Average air consumption ........ 3,5 SCFM

Recommended hose size .......... 3/8" f.D.

Air inlet ....................................... I!4" NPT

Maximum Air Pressure .................. fl0 PSI

ONE YEAR FULL WARRANTY ON

CRAFTSMAN TOOL

}f this Cfa_:sman tool fails to give complete

satisfaction _in one year from the dale

of purchase, RETURN IT TO ANY SEARS

STORE OR OTHER cRAFTSMAN

OUTLET IN THE UNITED STATES FOR

FREE REPLACEMEN£

ffthis Craftsman tool is ever used for

commerciaf or renal purples, this

warranty applies for orgy 90 days from the

date of purchase. This warranty does not

include expendable parts, such as lamps,

batteries, _ or blades. This warranty

gives you specific legal _Jhts. and you

may also have other rights which vary

from state to state.

,,_ws, Roebuck and Co.,

Hotfn_n Estates, _. S017e

Light Use- 12 Gatlo_

Typical Use. 17 Ga|lon

Heavy Use - 33 Gallon Profee_|onal

Read Operating In_0'l_ctions

Please becon_ familiar with all the

insP=_Jo,",s a_'_ _,-a_Ings b_fore

operating any pneumatic toot,

AlwaysWearApproved EyeProt_,tion

Impactresistanteyeprotectionshould

meetor exceedthe standarcissetforth in

ANS!ZBT.1,Occupationaland

EducationalEye andFace Protection.

LookformaWjngZ87,1 onyoureye

protectionto ensure_at ft is an approved

style.

Hearieg Protection is Recommended

Heanng protection shouk_ be used when

the noise level exposure equals or

exceeds an 8 hour time-weighted average

sound level of 85dBA. Process noise,

reflective surfaces, other tools being

operated nearby, all add tothe noise [eve|

Jna given wo_ area_ if you a_e unable to

determine your noise _evet exposure, we

recom,-_d the use of hearing pretect'_n.

Avoid Prolonged Exposure to Vibration

Pneum__ticto_s can vibrate dudng _se.

Prolonged e_posure to uCbralionor very

repetitive hand and arm movements can

cause injuq/. Discontinue the use of any

tool if you experience tingling, numbness,

discomfort or pain in your hands or arms,

You should consult your physician before

resuming use of tool.

pressure of 90 pounds per square inch

gauge pressure (90 PSI) maximum, at the

toG. U_e of higher air pre_sure can, and

may cause injuPj. Also, tt_ use _f higher

air pressure places the internal

components under loads and stresses

they were net designed for, causing

premature tool failure.

C,zdifomia Prop 65

Some du_t crea_ed by power sanding,

sawing, grinding, drilling and o_er

construction activities contains

chemicals known to cause cancer, birth

defects or other reproduc_ve harm.

Some examples of these chemicals are:

Lead from lead based paim, crystalline

silica from bricks and cement and other

masonry products, arsenic an_l

ch_mium from chemically-treated

lumber.

Your risk from those exposures varies,

depending on how often you do this

type of worP.. To t_duce your exposure

to these chemicals: work in a welt

veedilated area, at_i work wfth approved

safety equipment, such as dust masks

that are SpeciftcJ41y designed to filter

out microscopic p_rticles.

ENG~2 _NG-3

Page 3

Owner's Manual Model No. 875.199810 Owner's Manual Model No. 875.199810

Discoi_nect the air tool from air supply

before.changir_ tools or atta_menls_ .....

servicing and during non-operation.

DO not wear loose fitting clothing,

scarves, orneck ties in work area. Loose

clothing may become Caught in moving

paris and result in serious personal injury.

Do not wear jewelry when operating

any tool. Jewelry may become caught in

moving partsand result in serious

personal injury

Do not deprasS trigger when connectin9

the air supply hose.

Never trigger the tool when not applied

to a work object.

Attachments must be securely

attached. Loose attachments can cause

sedous injury.

Protect air lines from damage or

pullcture.

Never point an air tool at oneself or any

other parson. Serious injury could occur.

Check air hoses for weak or worn

conditions before each use. Make sum all

connections ate secure.

Release all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

Keep allnuts, bolts and screws tight

and ensure equipment is in safe working

condition.

ENG-4 ENG-5

air powered tool Always examine

accessories before mounting for chips,

cracks, or signs of damage.

Never use mounted points or other

accessories that have been dropped or

exposed to water, solvent or extreme

temperature changes. It is a good practice

to operate the tool in a protected

enclosure for one minute after mounting

any accessory.

Always use accessories with an RPM

rating that meets or exceeds the tool

RPM taUng.

Never cany a tool by the hose or putl

the hose to move the tool or a

compressor. Keep hoses away from

heat, oil and sharp edges, Replace any

hose that is damaged, weak or worn.

Inhalation hazard: Abrasive tools, sj.__h

as g#nders, sanders and cut-off tools

generate dust end abrasive materials

which can be harmful to human lungs

and respiratory system. Always wear

MSHA/NIOSH approved, properly rdting

face mask or respirator when using

such tools.

SOme materials such as adhesives and

could cause serious injury with

prolonged exposure. Always work in a

clean, day, well ventilated area.

Tools which contain moving elements,

or drive other moving tools, such as

gnnding wheels, sockets, sanc_ng

discs, etc_, can become entangled in

hair, clothing, jewelry and other loose

objects, resulting in severe injury.

Never wear loose t_ffing apparel which

contains loose straps or ties, that could

become tangled m moving parts of the

tool. Remove any Jewelry_ watches, etc.,

which might become caught by the

tool Keep hands away from moving

parts. Tie up or cover long hair.

Improperly maintained tools and

accessories can cause serious injur F

Maintain the tool with care. A properly

ma{ntaiBed tool, with sharp cutting

edges, reduces the risk of binding and

is easier to control.

There is a risk of bursting if the tool is

damaged. Check for misalignment or

binding of moving parts, breakage of

parts and any other condition that

affects the fool's operation, ff damaged,

have the tool serviced before using.

Too_ whP..h cut, sheer, ddll, staple,

punch, r__hiseJ,etc. =re capable of

causing serious injury. Keep the

working part of the tool away from

hands and body,

After an air tool has been lubricated, oil

will discharge through the exhaust port

during the first few seconds of

operation. Thus, the exhaust port must

be covered with a towel before applying

air pressure.

Only use sockets designated "FOR USE

WITH IMPA C T WRENCHES. "Hand tool

sockets can break, creating a hazard

from flying pieces. Always check

sockef_ retainers and drives regularly

for wear or damage and replace when

necessary.

Page 4

Owner's Manual Model No. 875.199810 Owner's Manual Model No. 875.199810

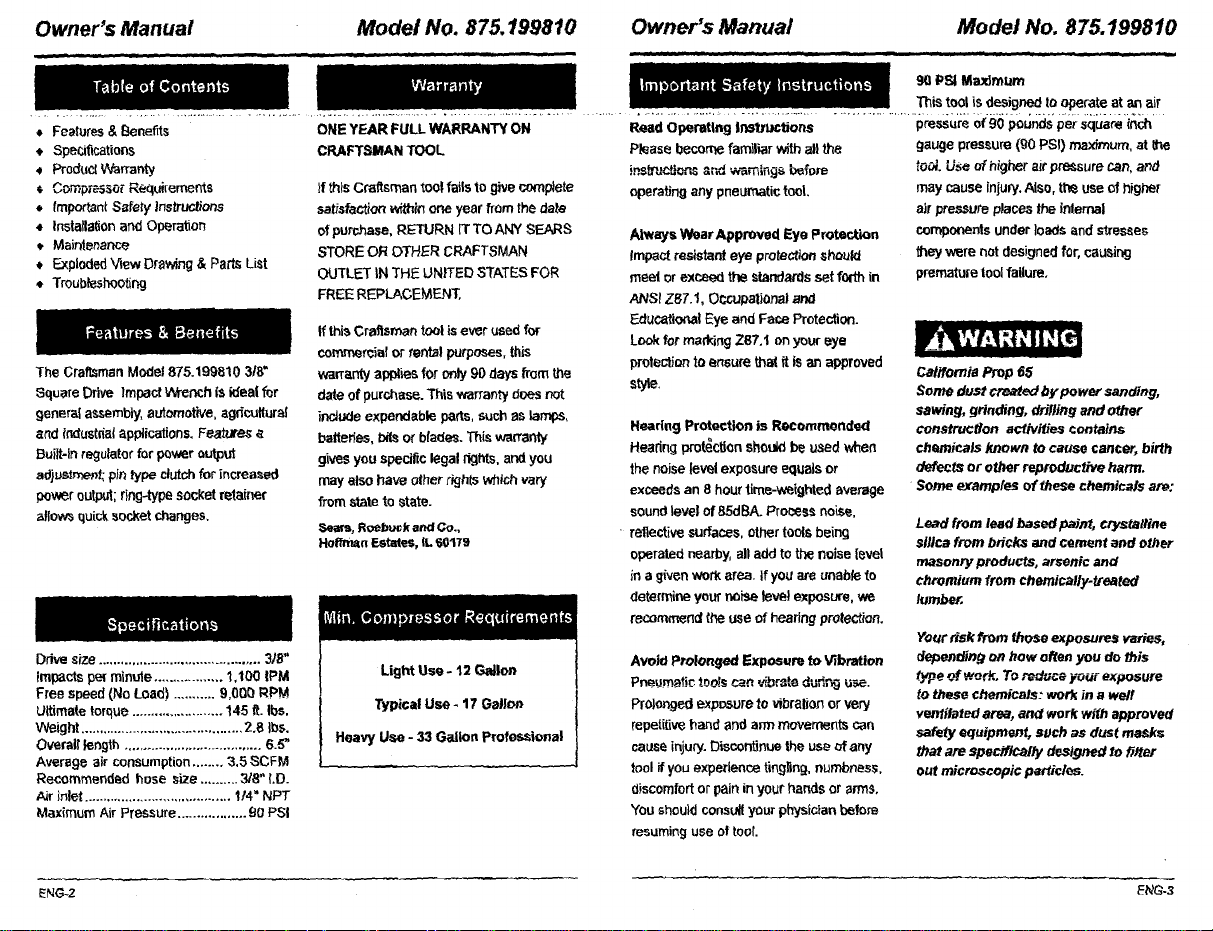

Air Tool Hook Up

Never carry a tool by the hose or pu[Ithe

hose to move the tool or a compressor.

Before the tool is connected to the air

supply, dear the air hose of accumulated

dust and moisture by runn{ng air freely

through the air hose for 5-10 seconds.

Air HoseS for yourAir Tools

Figure 1 Illustrates a recommended air

hose hook up.

A 3/8 inch ID air hose is required up to a

length of 25 feet. A 3/8 inch ID hose

longer than 25 feet will cause a pressure

drop and may impede performance. If

more length is required, a ½ inch ID air

hose is recommended. Be sure all hoses

and fittings are the correct size and

correctly secured before using the tool.

ENG-6 ENG-7

Keep hoses away from hea_, oil and sharp

edges. Replace any hose thai is damaged,

weak or worn.

Small (home) shop hard piping:

A piping diagram for a typical home shop

is shown. Some helpful tips are:

• Always use hosesandpipesratedfor

higherpressurethanyourSystemwill

encounter,

Never use PVC pipes for

compressed air piping systems as

explosion and serious injury may

result.

The connection from the compressor

to the initial take-off herd pipe must

be a flexible hose in order to isolate

movement of the compressor.

Route the initial take-off line (pipe) as

straight up the shop wall and as high

as possible, This will help minimize

water leaving the compressor and

traveling through system

Slope the main lines down at least

3/4 inch per 10 feet of pipe away

from air compressor; this will draw

the condensate with the flow of air

and away from the compressor.

Place the first drop as far from the

compressor as the size of your shop

wiltallow (50 feet is optimal, although

unrealistic for a small shop). The

further the drop, the more that

condensation can occur, and the

dher the air will be when it reaches

the water separator.

In older to reduce the amount of

water and contaminants that get into

the water separator, install the take-

offline on the top of the main air

supply line for each air drop,

A Drain line should be placed at the

end of the main line for condensate

drainage.

Drain valves should be placed at the

end of branch lines and the drain

line, and drained daily.

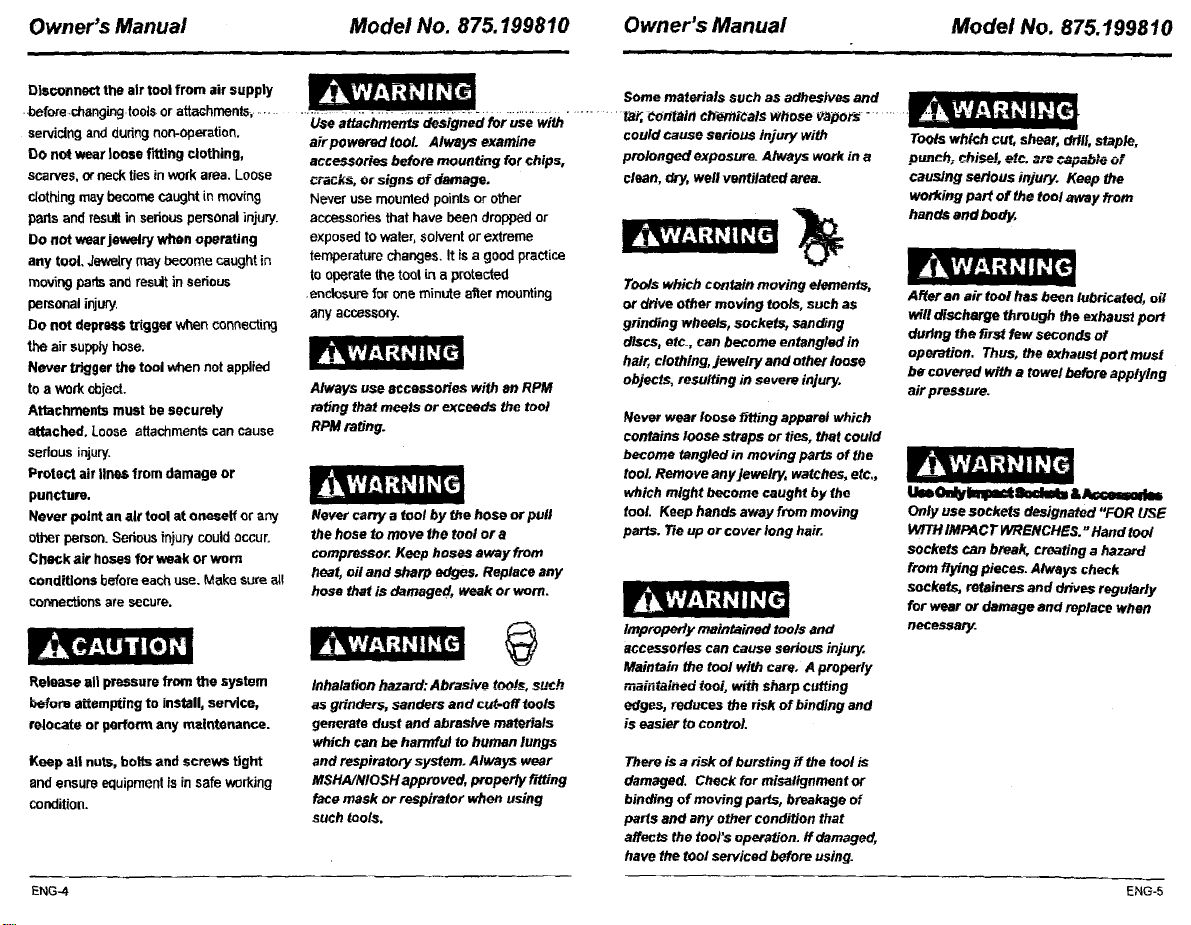

This toolsfeatures a power regulator ,a_zlve

(fig. 2). Rotate regulatoruntiJ desired output

is achieved. The settings on the regu!etor

are only for reference and do not denote a

specific power output.Turn regulator to

position with smaller circle being the least

amount of power end largef circle being/or

the most amount of power, The tool only

operates at maximum power in reverse.

Figure 2

Regulator Valve

•ARNINGI

Once ,_bolt Or Pastener is seated,

Impacting for longer than five (5)

seconds will cause excessive wear and

possible damage to the Impacfing

mechanism, flit takes longer than five

seconds to tighten or loosen your bolt

or fastener, we recommend the use of a

larger size impact wrench.

Page 5

Owner's Manual Model No. 875.199810 Owner's Manual Model No. 875.199810

1.Disconnect the impact wrench from

theairsupply.

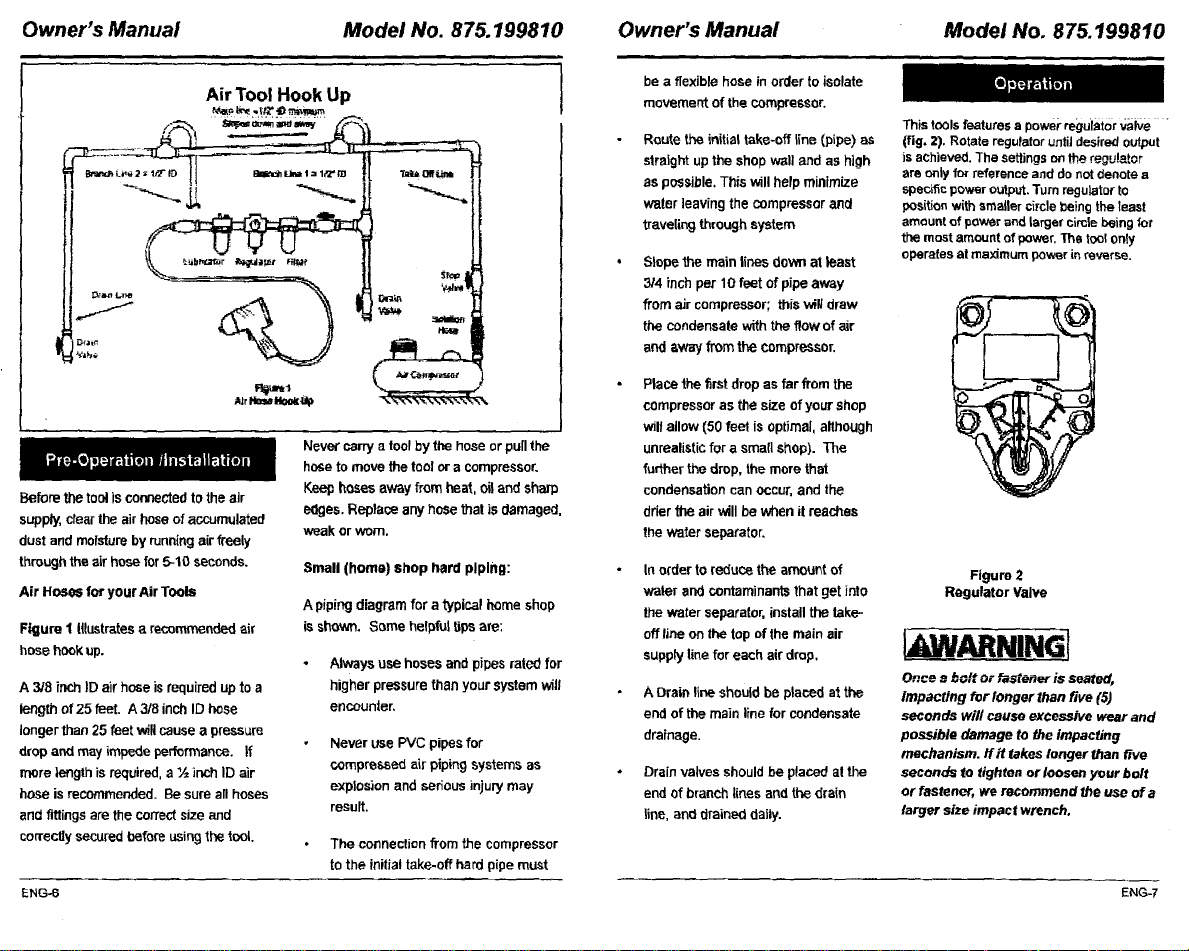

Lubdcatien

An in-line filter-regulator-lubricator (fig 1)

isrecommended as it increases tool life

ar_l keeps the tool insustained operation.

The in-line lubdcalor should be mgulady

checked and tiffedwith air loot oar.Proper

adjustment of the ir_line lubltcator is

performed by placing a sheet of paper

next to the tools exhaust ports and holding

the throttle open approxfmateiy 30

seconds. The lubricator is properly set

when a light stain of oil COfleCISon Ihe

paper.

Excessive amounts ofoil should be

avoided, fn the event that it becomes

necessary to store the tool for an

extended period of time (overnight,

weekend, etc.), it should receive a

generous amount of lubrication through

the air inlet (Figure 3). The tool should be

run for aptxoximatoly 30 seconds to

ensure oil has been everdy distributed

throughout thetool The tool should be

stored in a clean and dry environment.

Recommended Lubricants

Use air leo; oi!or any other high grade

turbine ogco_ltaining moisture absorbent,

rust inh_itors, metal _et_ng agents and

an EP (extreme pressure) addllive. See

Figure 3 for lecalion/air inleL

IMPACT MECHANISM LUBRICATION

The impact mechanism transfers power

from the toot to a nut or bolt. Oil in the

mechanism isforced out and must be

replaced. Lubricate the impact

mechanism one time a year, more

often If a tool is used more than ten

hours a week.

To lub_qcateand clean the impact

mechanism and the front bearing:

ENG-8 ENG-g

2. RRnlOvo the siol;ted screw or Allen

head screw from the oil port hole

(Ref, No. 51) (Refer to figure 3}.

3, Squeeze app_oxirrm.tely 1 oz. of 30 weight oil

through the oil port hole. Replace the screw.

4. Reconnectthe air supplyto theimpact

wrenchand runfor 201o 30 seconds.

Luixicate the entire impact mechanism

byrotatingthetool upsidedovm

endsidewayswh_ runningthetool

5. Remove the screw and held the oil

port hole over a suitable container to

allow excess oil to drain. S_n",etim'a,s

_ggefin9 the toof when dur_pang _e oils

helps to lone out the excess oil

6. If the oil is di_3', repeat the procedureabove

until the oil comes out de_'. Install the screw

and tighten. The residual oil remaining _ the

impact mechanism chamber is aftthat is

needed for proper lubrication.

Lubricate impact

mechanism here

Lubricate air motor here

Figure 3

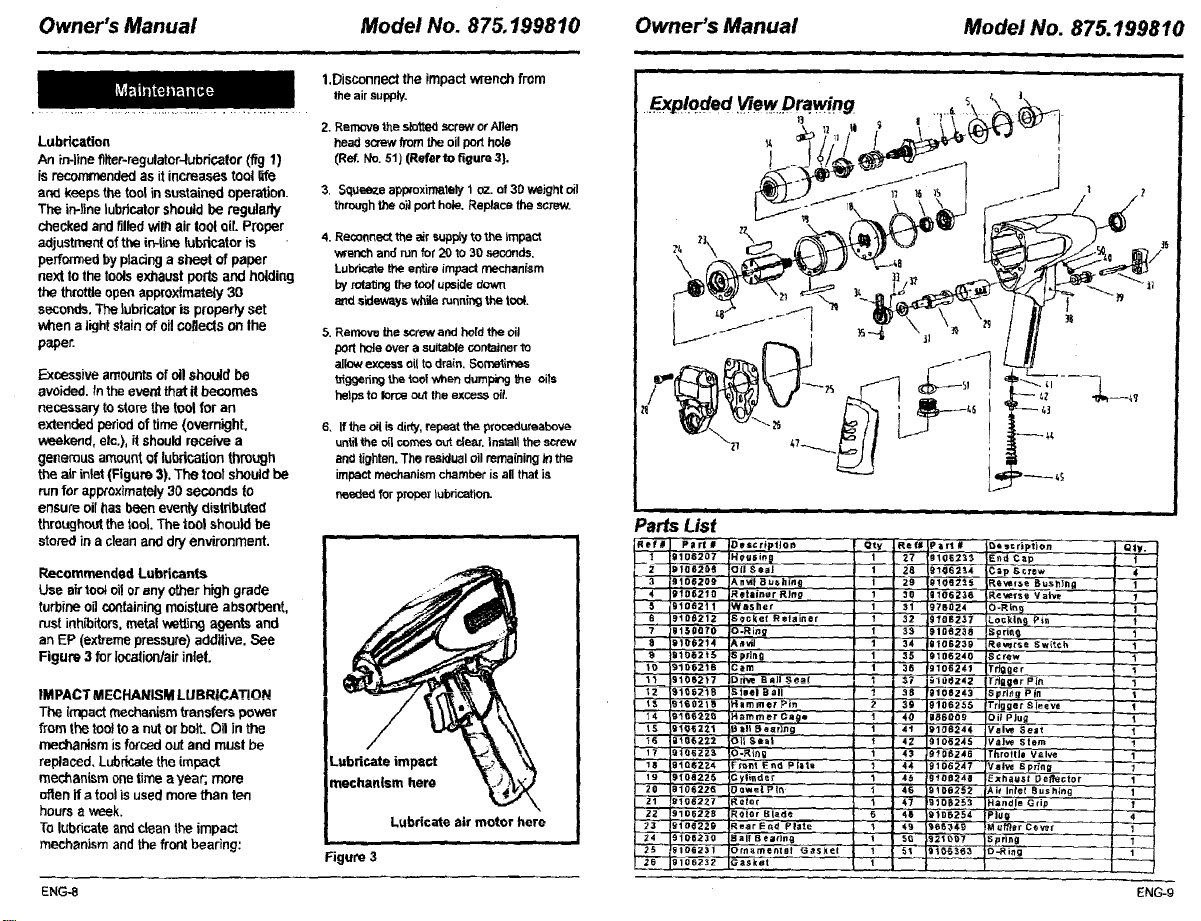

Parts List

Sef# Plrt#

3

4

B.

7

S

_2

_4

15"

t6

t_

18

20 :8i0S2ZS 3e,el Pin

21 tt1062_7 _otor

22 9105229 _oiOr Blade

23 910d22g _ear E_d Plate

24 910B230 gall B ea.-ing

2'_; 9106231 !(_rn_me_t nl Gasket

26 9106232 Gasket

IDBscrIptlo;') I;tty Ref# Part #_

9108207

IH O'Je;in_l -- 1 27 g10S2_$

91052_9

(311 Seal 1 26 gI _162 "_.4

9!0620_

[A nv]l' _ us hins | 2T 910g2_

91D6210

_etainer RIng 1 30 ].106236

_1062tl

A/asher 1 31 976024

9t06212

G¢c_et Retainer 1 32 9?06237

91_0070

_-Ring 1 33 9106236

_106214

_t_J 1 34 9108239

91082i_

5 pFltl9 1 35 9106240

SIO_21S

3am 1 38 9106241

910S217

IDd_ e =tll-_@a! I 37 -_1Q_Z42'

_.teel B;all ? 38 91-08243

916S21_

4immer Pin -- _' 3_ 9106'255

91_$22_

H_mmer_a_. 1 40 gBgG'0g

9105221

Bill Bearing .. t 41 9106244

gt06_22

311 Sea| _ 42 9106245

9106223

_O.-R t0 g i 43 9_ 0S248

Fr_,_t Fnd Piat_ I 44 9106247'

9106,2Z4

9108226

._y|i_d s _" '1 45 gf0s241

I_ sc ription Qty.

End Cap i

_ap ectew 4

P.e_e_s _ VaF/e 1

3-Rin 9 ]

iLo_kln_ F'in I -

_¢rew

ri_oer

'Trigger,P n "_

_prl_g Pin _--

Trig ge t _ le eve f --

Oil P Jug 1

Val_ Seat -- 1

Val'_ Stem

Ti_rot tie Ve.lve

Valve Spring

46 9106262 Air Inlet Bushing - 1

1 _'7 9106253 H==ndle Grip

1 4_1 _6.6._149 M uft}er COV_'_ 1

t 50 S21_7 Sprtn 9 1

Exhaust DeRector 1

Page 6

Owner's Manual Model No. 875.199810 Owner's Manual

,=, ..m , ,

Model No. 875.199810

Toolruns

sloworv_ll

notoperate.

Mois_re

browing out

of toot

!. Grit or gum in tool

2. No oil in tool

3, Low air pressure

4. Air hose leaks

5. Pressure drops

1. V_ter in tank

1. Flush the tool with air tool oil, gum

solvent, or an equal mixture of SAE 10

motor oil and kerosene. Lubricate the tool

after cleaning.

2, Lubricate the tool according tO the

lubrication inslruclions in this manual.

3a. Adjust the regulator on the lool to the

maximum setting (If applicable).

3b. Adjust the compressor regulator to tool

maximum while the tool is running free

4. Tighten and seal hose fittings if leaks m'e

found.

5a. Be sure the hose is the proper size.

Long hoses or tools using

large volumes of air may require a hose with

an I.D. of 1/2" or larger depending on the

total lenglh of the hose.

5b. Do not use multiple number of hoses

connected together with quick connect

fittings. This causes additional pressure

drops and reduces the tool power. Directly

connect the hoses together.

1. Drain tank. (See air compressor manual).

Oil tool and run until no water Is evident. Oil

too} again and run 1-2 seconds.

Impactssrowiy

1. Lack of lubrication

orwiltnotimpact

2,Tool regulator set in

wrong position

3. In-line regulator or 3. Adjust regulators in the air system

compressor regulalor

set too low

lmpacls rapidly but 1. Worn impact

will not remove bolts mechanism

Does not impact 1. Broken impact

mechanism

Notes:

I. Lubricate the air motor and the

impact mechanism. (See Lubrication

sectionof this n-_uaT_

2.Adjust the regulator on the tool to

the maximum setting

1.Replace worn impact mechanism

components

1, Replace broken impact mechanism

components

2. Water in the air lines/

hoses

ENG-10 ENG-_I

2a. Install a water separator/fitter.

NOTE: Separators only work properly when

the air passing through the separator is

cool. Locate the separator/filter as far as

possible from the compressor.

2b. Install an air dryer,

2c, Anytime water enters the tool, the tool

should be oiled immediately.

Page 7

I_€ t_tmq _H_de ==_=orm_ / _ Iv_arqu_,nI_le)4 _e Beat_ _randJ, LUG

-==r _ isillli_,a

_P_ IBt=nvJ#, LLC

Loading...

Loading...