Craftsman 875199330 Owner’s Manual

3/8-in. Ratchet Wrench

Owner's Manual

Model No. 875.199330

Unpacking

When unpacking this product, carefully

inspect for any damage that may have

occurred during transit. Make sure any

loose fittings, bolts, etc. are tightened

before putting this product into service.

WARNING: Please read and save these safety and operating instructions. Read carefully

before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 o807

www.CRAFTSMAN.com

Owner's Manual Model No. 875.199330 Owner's Manual Mode! No. 875.199330

90 PSI Maximum

This tool is designed to operate at an air

_, Features & Benefits

_, Specifications

_, Product Warranty

_, Compressor Requirements

Important Safety Instructions

_, Installation and Operation

_, Maintenance

_, Exploded View Drawing & Parts List

_, Troubleshooting

The Craftsman Model 875.199330 3/8"

Drive Ratchet Wrench is designed for

applications such as automotive repair,

general assembly, transmission teardown

and maintenance. Features include a lever

throttle for speed control and low profile

ratchet head height (without socket) for

use in close-quarter applications. 360°

swivel exhaust directs air away from

operator.

Drive size ........................................... 3/8"

Free speed (No Load) .............. 160 RPM

Max Torque ................................ 50 ft. Ibs.

Weight ........................................... 2.3 Ibs.

Overall length ..................................... 10"

Average air consumption ........ 4.0 SCFM

Recommended hose size .......... 3/8" I.D.

Air inlet ....................................... 1/4" NPT

Maximum Air Pressure .................. 90 PSI

ONE YEAR FULL WARRANTY ON

CRAFTSMAN TOOL

If this Craftsman tool fails to give complete

satisfaction within one year from the date

of purchase, RETURN IT TO ANY SEARS

STORE OR OTHER CRAFTSMAN

OUTLET IN THE UNITED STATES FOR

FREE REPLACEMENT.

If this Craftsman tool is ever used for

commercial or rental purposes, this

warranty applies for only 90 days from the

date of purchase.

This warranty does not include

expendable parts, such as lamps,

batteries, bits or blades.

This warranty gives you specific legal

rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179

Light Use - 17 Gallon

Typical Use - 26 Gallon

Heavy Use - 33 Gallon Professional

Read Operating Instructions

Please become familiar with all the

instructions and warnings before

operating any pneumatic tool,

Always Wear Approved Eye Protection

Impact resistant eye protection should

meet or exceed the standards set forth in

ANSI Z87.1, Occupational and

Educational Eye and Face Protection.

Look for marking Z87.1 on your eye

protection to ensure that it is an approved

style.

Hearing Protection is Recommended

Hearing protection should be used when

the noise level exposure equals or

exceeds an 8 hour time-weighted average

sound level of 85dBA. Process noise,

reflective surfaces, other tools being

operated nearby, all add to the noise level

in a given work area. If you are unable to

determine your noise level exposure, we

recommend the use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use.

Prolonged exposure to vibration or very

repetitive hand and arm movements can

cause injury. Discontinue the use of any

tool if you experience tingling, numbness,

discomfort or pain in your hands or arms.

You should consult your physician before

resuming use of tool.

pressure of 90 pounds per square inch

gauge pressure (90 PSI) maximum, at the

tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher

air pressure places the internal

components under loads and stresses

they were not designed for, causing

premature tool failure.

California Prop 65

Some dust created by power sanding,

sawing, grinding, drilling and other

construction activities contains

chemicals known to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

Lead from lead based paint, crystalline

silica from bricks and cement and other

masonry products, arsenic and

chromium from chemically-treated

lumber.

Your risk from those exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemicals: work in a well

ventilated area, and work with approved

safety equipment, such as dust masks

that are specifically designed to filter

out microscopic particles.

ENG-2 ENG-3

Owner's Manual Model No. 875.199330 Owner's Manual Mode! No. 875.199330

Disconnect the air tool from air supply

before changing tools or attachments,

servicing and during non-operation.

Do not wear loose fitting clothing,

scarves, or neck ties in work area. Loose

clothing may become caught in moving

parts and result in serious personal injury.

Do not wear jewelry when operating

any tool. Jewelry may become caught in

moving parts and result in serious

personal injury.

Do not depress trigger when connecting

the air supply hose.

Never trigger the tool when not applied

to a work object.

Attachments must be securely

attached. Loose attachments can cause

serious injury.

Protect air lines from damage or

puncture.

Never point an air tool at oneself or any

other person. Serious injury could occur.

Check air hoses for weak or worn

conditions before each use. Make sure all

connections are secure.

Use attachments designed for use with

air powered tool. Always examine

accessories before mounting for chips,

cracks, or signs of damage.

Never use mounted points or other

accessories that have been dropped or

exposed to water, solvent or extreme

temperature changes. It is a good practice

to operate the tool in a protected

enclosure for one minute after mounting

any accessory.

Always use accessories with an RPM

rating that meets or exceeds the tool

RPM rating.

Never carry a tool by the hose or pull

the hose to move the tool or a

compressor. Keep hoses away from

heat, oil and sharp edges. Replace any

hose that is damaged, weak or worn.

Some materials such as adhesives and

tar, contain chemicals whose vapors

could cause serious injury with

prolonged exposure. Always work in a

clean, dry, well ventilated area.

Tools which contain moving elements,

or drive other moving tools, such as

grinding wheels, sockets, sanding

discs, etc., can become entangled in

hair, clothing, jewelry and other loose

objects, resulting in severe injury.

Never wear loose fitting apparel which

contains loose straps or ties, that could

become tangled in moving parts of the

tool. Remove any jewelry, watches, etc.,

which might become caught by the

tool. Keep hands away from moving

parts. Tie up or cover long hair.

Tools which cut, shear, drill, staple,

punch, chisel, etc. are capable of

causing serious injury. Keep the

working part of the tool away from

hands and body.

After an air tool has been lubricated, oil

will discharge through the exhaust port

during the first few seconds of

operation. Thus, the exhaust port must

be covered with a towel before applying

air pressure.

Always make sure that tool accessories

meet or exceed the tools reccomended

output.

improperly maintained tools and

accessories can cause serious injury.

Release all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

Keep all nuts, bolts and screws tight

and ensure equipment is in safe working

condition.

ENG-4 ENG-5

Inhalation hazard: Abrasive tools, such

as grinders, sanders and cut-off tools

generate dust and abrasive materials

which can be harmful to human lungs

and respiratory system. Always wear

MSHA/NIOSH approved, properly fitting

face mask or respirator when using

such tools.

Maintain the tool with care. A properly

maintained tool, with sharp cutting

edges, reduces the risk of binding and

is easier to control.

There is a risk of bursting if the tool is

damaged. Check for misallgnment or

binding of moving parts, breakage of

parts and any other condition that

affects the tool's operation. If damaged,

have the tool serviced before using.

Disconnect tool from air supply before

servicing or changing sockets.

When tightening, do not torque down

the nuts or bolts with the ratchet as

typically done with a hand wrench. This

can damage the tool by breaking parts

in the ratchet mechanism.

Owner's Manual Model No. 875.199330 Owner's Manual Mode! No. 875.199330

be a flexible hose in order to isolate

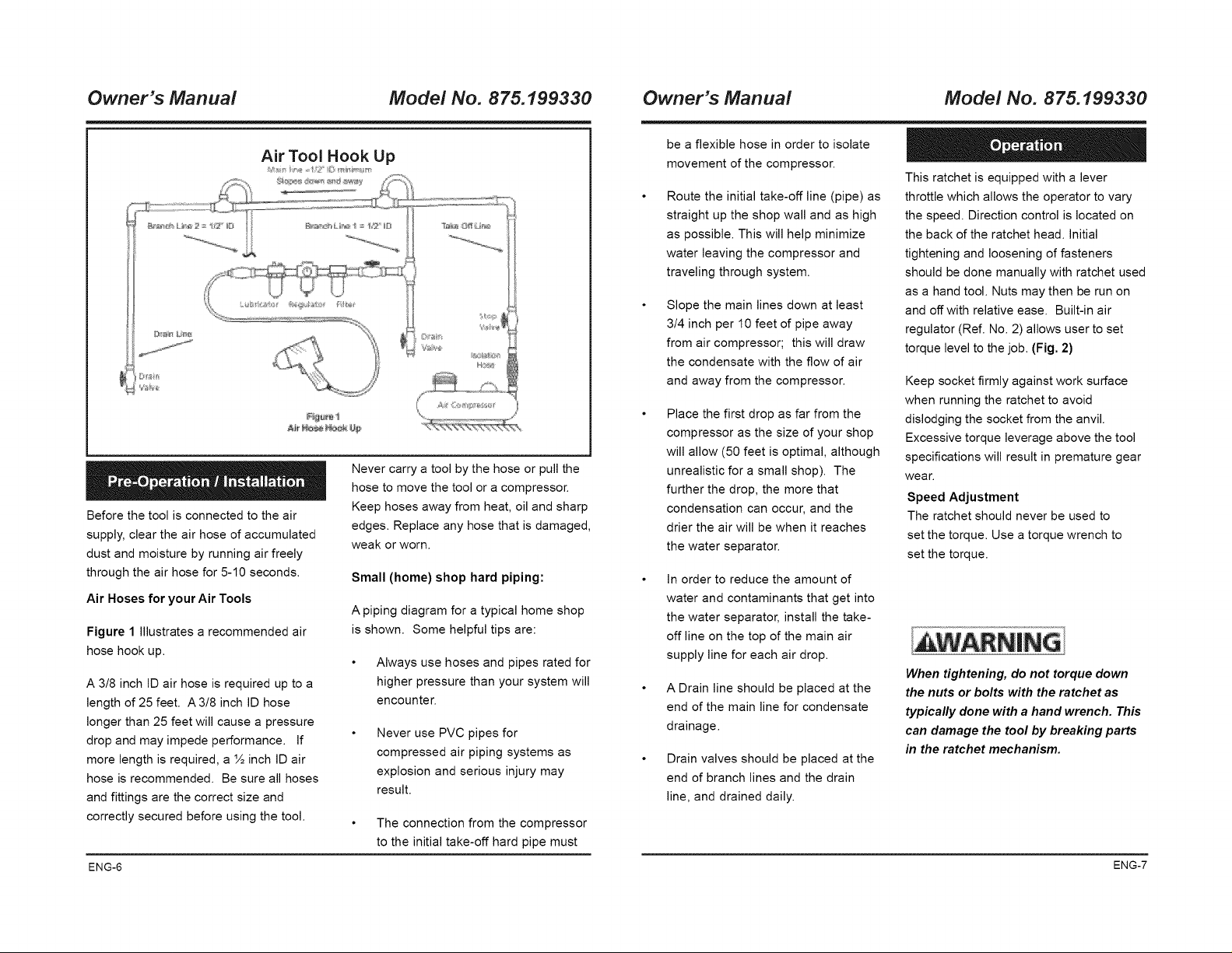

Air Tool Hook Up

Never carry a tool by the hose or pull the

hose to move the tool or a compressor.

Before the tool is connected to the air

supply, clear the air hose of accumulated

dust and moisture by running air freely

through the air hose for 5-10 seconds.

Air Hoses for your Air Tools

Figure 1 Illustrates a recommended air

hose hook up.

A 3/8 inch ID air hose is required up to a

length of 25 feet. A 3/8 inch ID hose

longer than 25 feet will cause a pressure

drop and may impede performance. If

more length is required, a ½ inch ID air

hose is recommended. Be sure all hoses

and fittings are the correct size and

correctly secured before using the tool.

ENG-6 ENG-7

Keep hoses away from heat, oil and sharp

edges. Replace any hose that is damaged,

weak or worn.

Small (home) shop hard piping:

A piping diagram for a typical home shop

is shown. Some helpful tips are:

Always use hoses and pipes rated for

higher pressure than your system will

encounter.

Never use PVC pipes for

compressed air piping systems as

explosion and serious injury may

result.

The connection from the compressor

to the initial take-off hard pipe must

movement of the compressor.

Route the initial take-off line (pipe) as

straight up the shop wall and as high

as possible. This will help minimize

water leaving the compressor and

traveling through system.

Slope the main lines down at least

3/4 inch per 10 feet of pipe away

from air compressor; this will draw

the condensate with the flow of air

and away from the compressor.

Place the first drop as far from the

compressor as the size of your shop

will allow (50 feet is optimal, although

unrealistic for a small shop). The

further the drop, the more that

condensation can occur, and the

drier the air will be when it reaches

the water separator.

In order to reduce the amount of

water and contaminants that get into

the water separator, install the take-

off line on the top of the main air

supply line for each air drop.

A Drain line should be placed at the

end of the main line for condensate

drainage.

Drain valves should be placed at the

end of branch lines and the drain

line, and drained daily.

This ratchet is equipped with a lever

throttle which allows the operator to vary

the speed. Direction control is located on

the back of the ratchet head. Initial

tightening and loosening of fasteners

should be done manually with ratchet used

as a hand tool. Nuts may then be run on

and off with relative ease. Built-in air

regulator (Ref. No. 2) allows user to set

torque level to the job. (Fig. 2)

Keep socket firmly against work surface

when running the ratchet to avoid

dislodging the socket from the anvil.

Excessive torque leverage above the tool

specifications will result in premature gear

wear.

Speed Adjustment

The ratchet should never be used to

set the torque. Use a torque wrench to

set the torque.

When tightening, do not torque down

the nuts or bolts with the ratchet as

typically done with a hand wrench. This

can damage the tool by breaking parts

in the ratchet mechanism.

Loading...

Loading...