Page 1

Owner's Manual

Pneumatic 3/8" Drive

RATCHET C

Model No.

875.199320

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

Safety

Warranty

Features & Operation

Maintenance

EspaSol

Distributed by Sears, Roebuck and Co., Hoffrnan Estates, IL 60179

www=Sears.corn

Page 2

Read Operating Instructions

Please become familiar with all the instructions and

warnings before operating any pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should meet or exceed

the standards set forth in ANSI Z87.1, Occupational and

Educational Eye and Face Protection. Look for marking

Z87.1 on your eye protection to ensure that it is an

approved style.

Hearing Protection is Recommended

Hearing protection should be used when the noise level

exposure equals or exceeds an 8 hour time-weighted

average sound level of 85dBA. Process noise, reflective

surfaces, other tools being operated nearby, all add to the

noise level in a given work area. Ifyou are unable to

determine your noise level exposure, we recommend the

use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use. Prolonged

exposure to vibration or very repetitive hand and arm

movements can cause injury. Discontinue the use of any

tool if you experience tingling, numbness, discomfort or

pain in your hands or arms. You should consult your

physician before resuming use of tool.

90 PSI Maximum

This tool is designed to operate at an air pressure of 90

pounds per square inch gauge pressure (90 PSI)

maximum, at the tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher air pressure

places the internal components under loads and

stresses they were not designed for, causing premature

tool failure.

NOTE: THEAIR SUPPLY SHOULD BE CLEAN, DRYAND

PREFERABLY LUBRICATED. FOR BEST RESULTS

DRAIN THE MOISTURE FROM YOUR COMPRESSOR

DAILY.

Use Only Power Sockets & Accessories

Sockets and accessories used shall be of the power

socket type. Always check sockets, retainers and

drives regularly for wear or damage and replace when

necessary.

[, WARNINGJ

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemi-

cals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals

are:

• Lead from lead based paint

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as dust masks that

are specifically designed to filter out microscopic par-

ticles.

FULL ONE YEAR WARRANTY ON

CRAFTSMAN AIR-DRIVE TOOLS

If this Craftsman tool fails to give complete satisfaction

within one year from the date of purchase, RETURN IT

TO THE NEAREST SEARS STORE IN THE UNITED

STATES, and Sears will repair or replace it free of charge.

If this Craftsman tool is used for commercial or rental

purposes, this warranty applies for only 90 days from the

date of purchase. This warranty gives you specific legal

rights, and you may also have other rights which vary

from state to state.

Distributed by Sears, Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179.

The Craftsman Model 875.199320 3/8" Drive Ratchet

Wrench is designed for applications such as automotive

repair, general assembly, transmission teardown and

maintenance. Features include a lever throttle for speed

control and low profile head for work in close quarters.

Features

• Lever throttle for ease of operation.

• 1-1/8" Ratchet head height (without socket) for use in

close-quarter applications.

• Front exhaust directs air away from operator.

Specifications

Drive size............................................................................... 3/8"

Free speed (No Load) .............................................. 180 RPM

Ultimate torque ......................................................... 45 ft. Ibs.

Weight ............................................................................. 2 YzIbs.

Overall length......................................................................... 10"

Average air consumption .......................................... 5.5 SCFM

Recommended hose size ........................................... 3/8" I.D.

Air inlet.......................................................................... 1/4" NPT

Maximum Air Pressure .................................................. 90 PSI

Pre-Operation

Before the tool is connected to the air supply, clear the air

hose of accumulated dust and moisture by running air

freely through the air hose for 5-10 seconds. Before

removing a tool for service or changing sockets, make

sure the air line is shut-off at the compressor. This will

prevent the tool from operating if the throttle is accidently

engaged.

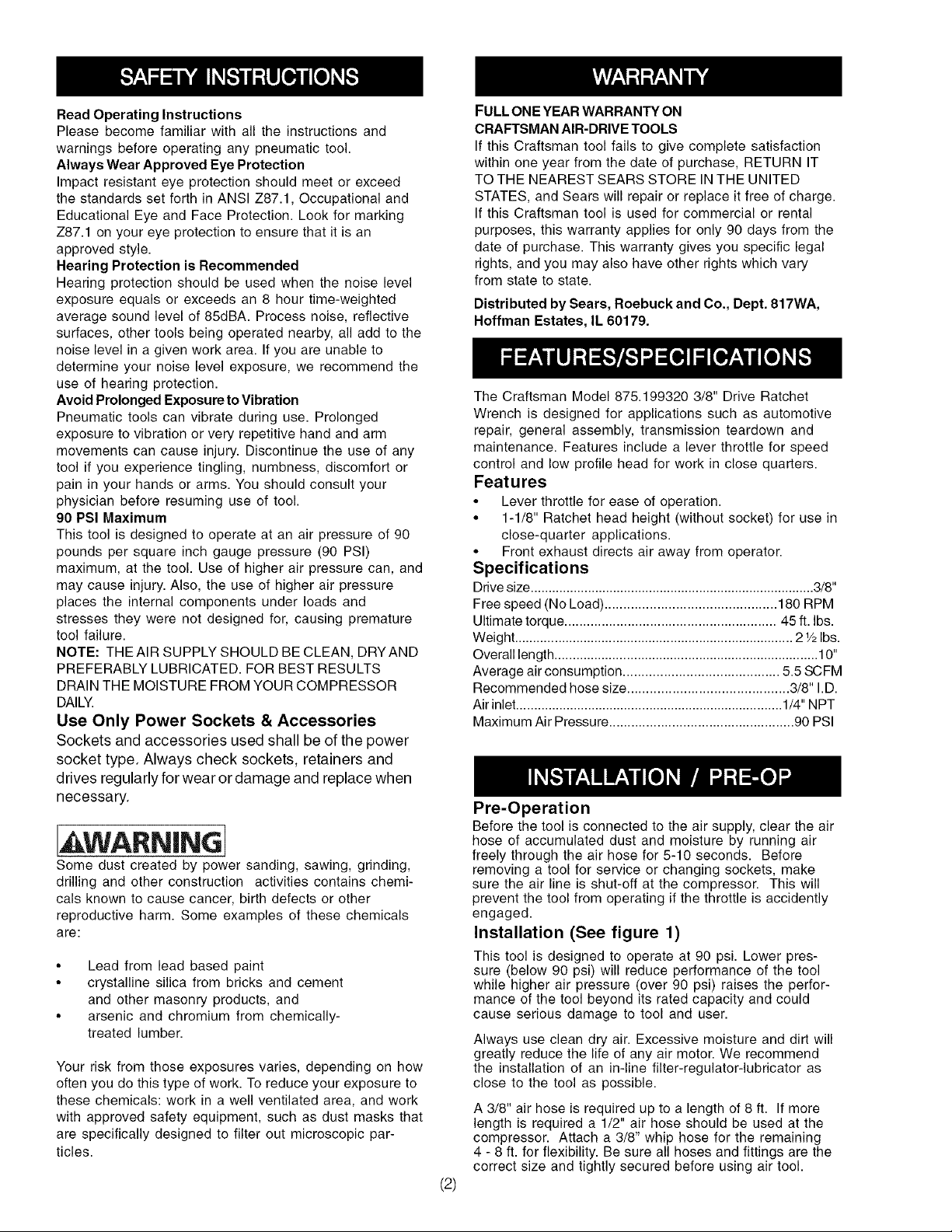

Installation (See figure 1)

This tool is designed to operate at 90 psi. Lower pres-

sure (below 90 psi) will reduce performance of the tool

while higher air pressure (over 90 psi) raises the perfor-

mance of the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air motor. We recommend

the installation of an in-line filter-regulator-lubricator as

close to the tool as possible.

A 3/8" air hose is required up to a length of 8 ft. If more

length is required a 1/2" air hose should be used at the

compressor. Attach a 3/8" whip hose for the remaining

4 - 8 ft. for flexibility. Be sure all hoses and fittings are the

correct size and tightly secured before using air tool.

(2)

Page 3

,_ Morethan1/100slope

., 3t

Branch ne = 2 t mes Sto Filter ivlam me = imes

]--I" Tool inlet/hose size Iii valPe Regulator Tool inlet/hose size

II II _ stop

H Auto Drain _ _ Valve

I_U 'A:lve _ Air Cornpressor

'_' " Figure I _ -_

Air Hose Hook Up q\\\\X\\\\\\_\\

WARNING: DISCONNECT TOOL FROM AiR SUPPLY

BEFORE SERVICING OR CHANGING SOCKETS. This

ratchet is equipped with a lever throttle which ailows the

operator to vary the speed. Direction control is located on

the back of the ratchet head. Initial tightening and loosen-

ing of fasteners should be done manually with ratchet

used as a hand tool. Fasteners may then be run on and

off with relative ease.

Keep socket firmly against work surface when running the

ratchet to avoid dislodging the socket from the anvil.

Excessive torque leverage above tooI specifications will

result in premature gear wear.

Lubrication

An in-line filter-regulator-lubricator (fig 1) is recommended

as it increases tool life and keeps the tool in sustained

operation. The in-line lubricator should be regularly

checked and filled with air tool oil. Proper adjustment of

the in-line lubricator is performed by placing a sheet of

paper next to the tools exhaust ports and holding the

throttle open approximately 30 seconds. The lubricator is

properly set when a light stain of oil collects on the paper.

Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

should receive a generous amount of lubrication through

the air inlet. The tool should be run for approximately 30

seconds to ensure oil has been evenly distributed through

out the tool. The tooI should be stored in a clean and dry

enviroment

Recommended lubricants: Use air tool oil or any other

high grade turbine oil containing moisture absorbent, rust

inhibitors, metal wetting agents and an EP (extreme

pressure) additive.

Page 4

Sears CRAFTSMAN Model 875.199320

Pneumatic 38" Drive Ratchet Wrench

Exploded View and Parts List

Ref. Part No. Description

1 9106459 Housing

2 9106460 Air Inlet Bushing

3 9106461 Throttle Lever

4 9106462 Dowel Pin

5 9106463 O-Ring

6 9106464 Valve Stem

7 9106465 Valve Spring

8 9106466 O-Ring

9 9106467 Valve Plug

10 9106468 Muffler Cover

11 9106469 Ball Bearing

12 9106470 Rear End Plate

13 9106471 Rotor Blade

14 9106472 Rotor

15 9106473 Set Pin

16 9106474 Cylinder

17 9106475 Washer

18 9106476 Front End Plate

19 9106477 Bearing

20 9106478 Washer

21 9106479 Gear Ring

22 9106480 Idler Gear

O'ty

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

3

Ref. Part No. Description

23 9106481 Gear Pin

24 9106482 Gear Cage

25 9106483 Clamp Nut

26 9106484 Bushing

27 9106485 Needle Bearing

28 9106486 Crank Shaft

29 9106487 Ratchet Housing

30 9106488 Drive Bushing

31 9106489 Ratchet Yoke

32 9106490 Locking Pin

33 9106491 Spring

34 9106492 Reverse Switch

35 9106493 Washer

36 9106494 Ratchet Pawl

37 9106495 Anvil Cage

38 9106496 Spring

39 9106497 Steel Ball

40 9106498 Set Pin

41 9106499 Thrust Washer

42 9106500 Retainer Ring

43 9106501 Handle Grip

44 9106502 Ratchet Cover

(4)

Q'ty

3

1

1

1

1

1

1

1

1

2

2

1

1

2

1

2

2

2

1

1

1

1

Page 5

Troubles ooting

Tool runs slowly or will not operate 1. rit or gum in tool

2. No oil in tooI

3. Low air pressure

4. Air hose leaks

5. Pressure drops

• Worn rotor blade in motor

7. Worn ball bearing in motor

Moisture blowing out of tool exahust 1. Water in tank 1. Drain tank. (See air compressor manual)• Oil tool

1. Flush the tool with air tool oil or gum

solvent•

2. Lubricate the tool according to the lubrication

instructions in this manuai

3. a. Adjust the regulator on the tool to the maxi

mum setting

b. Adjust the compressor regulator to tool

maximum of 90 psi.

4. Tighten and seal hose fittings if leaks are found

use teflon tape.

5. a. Be sure the hose is the proper size. Long

hoses or tools using large volumes of air may

require a hose with an I.D. of 1/2" or larger

depending on the total length of the hose

b. Do not use a multiple number of hoses

connected together with quick connect fittings•

This causes additional pressure drops and

reduces the tool power• Directly connect the

hoses together

•Replace rotor blade

7. Remove and inspect bearing for rust, dirt and

grit. Replace or clean and grease bearing with

bearing grease

and run until no water is evident• Oil tool again and

run 1 2 seconds

Impacts slowly or will not impact 1. Lack of lubrication 1. Lubricate the air motor and the impact mechanism•

(See Lubrication section of this manual)

2. Tool regulator set in wrong

position

3. In line regulator or

compressor regulator

set too low

Impacts rapidly but

will not remove bolts

Does not impact 1. Broken impact mechanism 1. Replace broken impact mechanism components

1. Worn impact mechanism 1. Replace worn impact mechanism components

2. Adjust the regulator on the tool to the maximum

setting

3. Adjust regulators in the air system

(5)

Page 6

For the repair or replacement

parts you need delivered directly to your home

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

Para ordenar piezas con entrega

a domicilio - 1-800-659-7084

For the location of a

Sears Parts and Repair Center

in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For more information on

purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

Call 9 am - 5 pm, Monday-Saturday

1-800-827-6655

The model number of your air tool is located

on the serial plate attached to the tool.

When requesting service or ordering parts,

always give the following information:

SE/ARS

• Product Type

• Model Number

• Pneumatic Tool

• Part Description

Distributed by Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Loading...

Loading...