Page 1

Owner's Manual

Nlodei No. 875.198650

1/2-in. Composite impact Wrench

Unpacking

When unpacking this product, carefully inspect for any damage that may have occurred

during transit, Make sure any loose fittings, bolts, etc, are tightened before putting this

product into service,

WARNING: Please read and save these safety and operating instructions. Read carefully

before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

Sears, Roebuck and Co,, Hoffman Estates, IL 60179

www.CRAFTSMAN.com

102109

Page 2

Owner's Manual Model No. 875.198650 Owner's Manual Model No. 875.198650

90 PSI Maximum

This tool is designed to operate at an air

Features & Benefits

_, Specifications

Product Warranty

_, Compressor Requirements

Important Safety Instructions

Installation and Operation

Maintenance

_, Exploded View Drawing & Parts List

_, Troubleshooting

The Craftsman Model 875.198650 1/2-in.

composite impact wrench features a hard

hitting, twin hammer design that

produces 725 ft. Ibs. of maximum torque.

Exceptionally fast 1,100 impacts per

minute and 8,000 RPM free speed gets

the job done quickly. High impact

resistant composite housing and

magnesium hammer case weighs only

4.25 Ibs.

Drive size ........................................... 1/2"

Free speed (No Load) .......... 8,000 RPM

Maximum torque ..................... 725 ft. Ibs.

Weight .......................................... 4.251bs.

Overall length ............................. 5-7/8 in.

Average air consumption ........ 5.0 SCFM

Recommended hose size .......... 3/8"1.D.

Air inlet ....................................... 1/4" NPT

Maximum Air Pressure .................. 90 PSI

ONE YEAR FULL WARRANTY ON

CRAFTSMAN TOOL

If this Craftsman tool fails to give

complete satisfaction within one year

from the date of purchase, RETURN IT

TO ANY SEARS STORE OR PARTS &

REPAIR CENTER OR OTHER

CRAFTSMAN OUTLET IN THE UNITED

STATES FOR FREE REPAIR (or

replacement if repair proves impossible).

If this Craftsman tool is ever used for

commercial or rental purposes, this

warranty applies for only 90 days from the

date of purchase.

This warranty does not include

expendable parts, such as lamps,

batteries, bits or blades.

This warranty gives you specific legal

rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179

Light Use - 26 Gallon

Typical Use - 33 Gallon

Heavy Use - 60 Gallon Professional

Read Operating Instructions

Please become familiar with all the

instructions and warnings before

operating any pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should

meet or exceed the standards set forth in

ANSI Z87.1, Occupational and

Educational Eye and Face Protection.

Look for marking Z87.1 on your eye

protection to ensure that it is an approved

style.

Hearing Protection is Recommended

Hearing protection should be used when

the noise level exposure equals or

exceeds an 8 hour time-weighted average

sound level of 85dBA. Process noise,

reflective surfaces, other tools being

operated nearby, all add to the noise level

in a given work area. If you are unable to

determine your noise level exposure, we

recommend the use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use.

Prolonged exposure to vibration or very

repetitive hand and arm movements can

cause injury. Discontinue the use of any

tool if you experience tingling, numbness,

discomfort or pain in your hands or arms.

You should consult your physician before

resuming use of tool.

pressure of 90 pounds per square inch

gauge pressure (90 PSi) maximum, at the

tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher

air pressure places the internal

components under loads and stresses

they were not designed for, causing

premature tool failure.

California Prop 65

Some dust created by power sanding,

sawing, grinding, drilling and other

construction activities contains

chemicals known to cause cancer, birth

defects or other reproductive harm.

Some examples of these chemicals are:

Lead from lead based paint, crystalline

silica from bricks and cement and other

masonry products, arsenic and

chromium from chemically-treated

lumber,

Your risk from those exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemicals: work in a well

ventilated area, and work with approved

safety equipment, such as dust masks

that are specifically designed to filter

out microscopic particles.

ENG-2 ENG-3

Page 3

Owner's Manual Model No. 875.198650 Owner's Manual Model No. 875.198650

Disconnect the air tool from air supply

before changing tools or attachments,

servicing and during non-operation,

Do not wear loose fitting clothing,

scarves, or neck ties in work area, Loose

clothing may become caught in moving

parts and result in serious personal injury,

Do not wear jewelry when operating

any tool, Jewelry may become caught in

moving parts and result in serious

personal injury,

Do not depress trigger when connecting

the air supply hose,

Never trigger the tool when not applied

to a work object,

Attachments must be securely

attached, Loose attachments can cause

serious injury,

Protect air lines from damage or

puncture.

Never point an air tool at oneself or any

other person, Serious injury could occur,

Check air hoses for weak or worn

conditions before each use, Make sure all

connections are secure,

Release all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

Keep all nuts, bolts and screws tight

and ensure equipment is in safe working

condition,

Use attachments designed for use with

air powered tool. Always examine

accessories before mounting for chips,

cracks, or signs of damage.

Never use mounted points or other

accessories that have been dropped or

exposed to water, solvent or extreme

temperature changes, it is a good practice

to operate the tool in a protected

enclosure for one minute after mounting

any accessory.

Always use accessories with an RPM

rating that meets or exceeds the tool

RPM rating,

Never carry a tool by the hose or pull

the hose to move the tool or a

compressor, Keep hoses away from

heat, oil and sharp edges. Replace any

hose that is damaged, weak or worn,

Inhalation hazard: Abrasive tools, such

as grinders, sanders and cut-off tools

generate dust and abrasive materials

which can be harmful to human lungs

and respiratory system. Always wear

MSHA/NIOSH approved, properly fitting

face mask or respirator when using

such tools,

Some materials such as adhesives and

tar, contain chemicals whose vapors

could cause serious injury with

prolonged exposure. Always work in a

clean, dry, well ventilated area.

Tools which contain moving elements,

or drive other moving tools, such as

grinding wheels, sockets, sanding

discs, etc., can become entangled in

hair, clothing, jewelry and other loose

objects, resulting in severe injury.

Never wear loose fitting apparel which

contains loose straps or ties, that could

become tangled in moving parts of the

tool Remove any jewelry, watches, etc,,

which might become caught by the

tool. Keep hands away from moving

parts, Tie up or cover long hair.

Improperly maintained tools and

accessories can cause serious injury.

Maintain the tool with care. A properly

maintained tool, with sharp cutting

edges, reduces the risk of binding and

is easier to control,

There is a risk of bursting if the tool is

damaged. Check for misallgnment or

binding of moving parts, breakage of

parts and any other condition that

affects the tool's operation, if damaged,

have the tool serviced before using,

Tools which cut, shear, drill, staple,

punch, chisel, etc. are capable of

causing serious injury. Keep the

working part of the tool away from

hands and body.

After an air tool has been lubricated, oil

will discharge through the exhaust port

during the first few seconds of

operation. Thus, the exhaust port must

be covered with a towel before applying

air pressure,

Use Only Impact Sockets & Accessories

Only use sockets designated "FOR USE

WITH IMPACT WRENCHES. "'Hand tool

sockets can break, creating a hazard

from flying pieces. Always check

sockets, retainers and drives regularly

for wear or damage and replace when

necessary.

ENG-4 ENG-5

Page 4

Owner's Manual Model No. 875.198650 Owner's Manual Model No. 875.198650

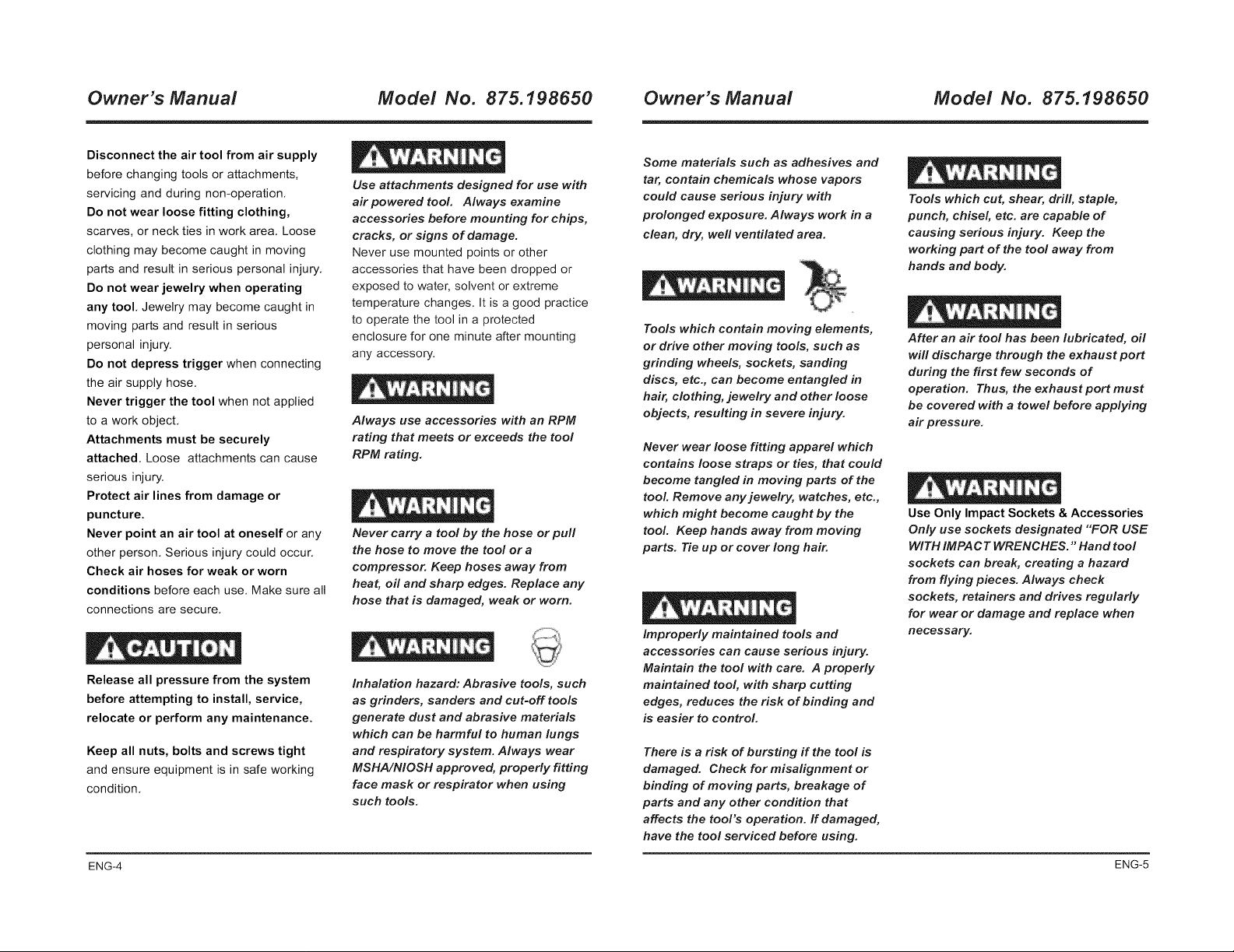

Air Tool Hook Up

Never carry a tool by the hose or pull the

hose to move the tool or a compressor.

Before the tool is connected to the air

supply, clear the air hose of accumulated

dust and moisture by running air freely

through the air hose for 5-10 seconds,

Air Hoses for your Air Tools

Figure 1 Illustrates a recommended air

hose hook up,

A 3/8 inch ID air hose is required up to a

length of 25 feet, A 3/8 inch ID hose

longer than 25 feet will cause a pressure

drop and may impede performance, If

more length is required, a ½ inch ID air

hose is recommended, Be sure all hoses

and fittings are the correct size and

correctly secured before using the tool,

ENG-6 ENG-7

Keep hoses away from heat, oil and sharp

edges, Replace any hose that is damaged,

weak or worn.

Small (home) shop hard piping:

A piping diagram for a typical home shop

is shown, Some helpful tips are:

Always use hoses and pipes rated for

higher pressure than your system will

encounter.

Never use PVC pipes for

compressed air piping systems as

explosion and serious injury may

result,

The connection from the compressor

to the initial take-off hard pipe must

be a flexible hose in order to isolate

movement of the compressor,

Route the initial take-off line (pipe)

as straight up the shop wall and as

high as possible, This will help

minimize water leaving the

compressor and traveling through

system

Slope the main lines down at least

3/4 inch per 10 feet of pipe away

from air compressor; this will draw

the condensate with the flow of air

and away from the compressor,

Place the first drop as far from the

compressor as the size of your shop

will allow (50 feet is optimal, although

unrealistic for a small shop), The

further the drop, the more that

condensation can occur, and the

drier the air will be when it reaches

the water separator,

In order to reduce the amount of

water and contaminants that get into

the water separator, install the take-

off line on the top of the main air

supply line for each air drop,

A drain line should be placed at the

end of the main line for condensate

drainage.

Drain valves should be placed at the

end of branch lines and the drain

line, and drained daily,

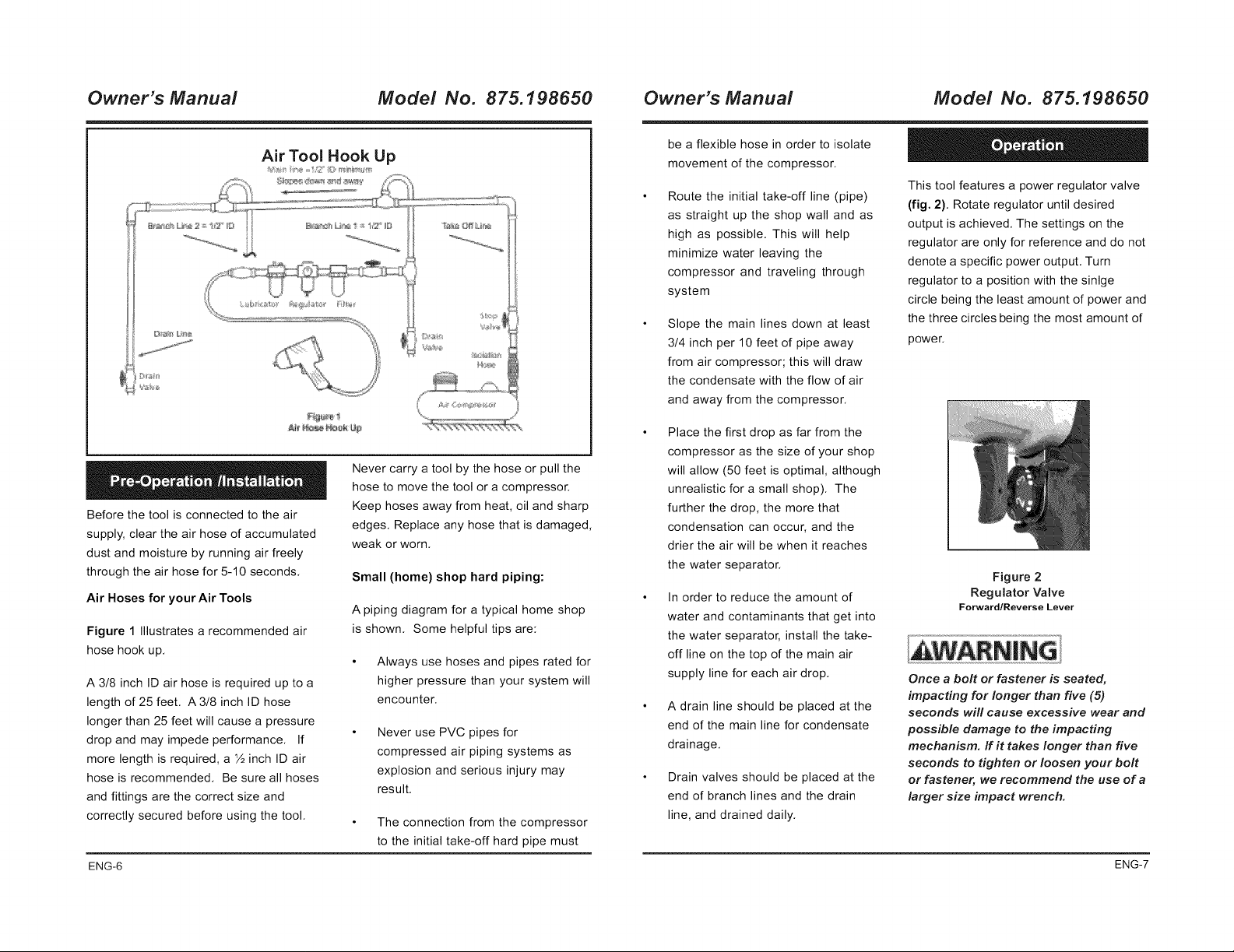

This tool features a power regulator valve

(fig. 2), Rotate regulator until desired

output is achieved, The settings on the

regulator are only for reference and do not

denote a specific power output, Turn

regulator to a position with the sinlge

circle being the least amount of power and

the three circles being the most amount of

power,

Figure 2

Regulator Valve

Forward/Reverse Lever

Once a bolt or fastener is seated,

impacting for longer than five (5)

seconds will cause excessive wear and

possible damage to the impacting

mechanism, ff it takes longer than five

seconds to tighten or loosen your bolt

or fastener, we recommend the use of a

larger size impact wrench,

Page 5

Owner's Manual Model No. 875.198650 Owner's Manual Model No. 875.198650

Lubrication

An in-line filter-regulator-lubricator (fig 1)

is recommended as it increases tool life

and keeps the tool in sustained operation.

The in-line lubricator should be regularly

checked and filled with air tool oil. Proper

adjustment of the in-line lubricator is

performed by placing a sheet of paper

next to the tools exhaust ports and holding

the throttle open approximately 30

seconds. The lubricator is properly set

when a light stain of oil collects on the

paper,

Excessive amounts of oil should be

avoided. In the event that it becomes

necessary to store the tool for an

extended period of time (overnight,

weekend, etc.), it should receive a

generous amount of lubrication through

the air inlet (Figure 3). The tool should be

run for approximately 30 seconds to

ensure oil has been evenly distributed

throughout the tool. The tool should be

stored in a clean and dry environment.

Recommended Lubricants

Use air tool oil or any other high grade

turbine oil containing moisture absorbent,

rust inhibitors, metal wetting agents and

an EP (extreme pressure) additive. See

Figure 3 for location/air inlet.

IMPACT MECHANISM LUBRICATION

The impact mechanism transfers power

from the tool to a nut or bolt.

The impact mechanism is grease

lubricated and does not require

Lubricate

impact mecha-

nism here.

re-greasing under normal usage.

Lubricate air motor here

Figure 3

ENG-8 ENG-9

Parts List

Ref# Part No, Description Q'ty Ref# Part No.

1 9638001M AIR INLET 1 24 9611224

2 90R2002 O-RING I 25 9611225

3 9287608 O-RING I 26 9611226

4 9287609 DEFLECTOR I 27 90R7718

5 9287610 SPRING I 28 9328830-4

6 9328804V VALVE STEM I 29 9611229

7 9328835 THROTTLE VALVE SEAT I 30 9611230

8 9328835S SPACER I 31 90RI 315

9 9287614 RETAINER RING I 32 9611232

10 9611210 MOTOR HOUSING 1 33 9287617

11 9SP0326 SPRING PIN 1 34 9611234

12 9611212 SCREW 1 35 9611235

13 9611213 BOLT 4 36 9611236

14 9611214 SCREW 3 37 9611237

1S 9SP2520 SPRING PIN 1 38 9611238

16 9BA001Z BALL BEARING 1 39 9611239

17 9611217 END PLATE 1 40 9611240

18 9611218 ROTOR 1

19 9611219 BLADE 6

20 9611220 CYLINDER I 43 90R8501

21 9611221-B GASKET I

22 9B6002 BALL BEARING I

23 9611223 HAMMER PIN 2

2')......

/ /

41 9589039

42 9611242

44 90R1301

45 9SBOO03-1

46 9638047

Description

HAMMER FRAME

HAMMER

ANVIL

O-RING

SOCKET RETAINER

BUSHING

HAMMER CASE

O-RING

VALVE STEM

O-RING

VALVE BUSHING

VALVE BODY

RETAINER

REVERSE VALVE

REVERSE VALVE LEVER

SPRING

POWER MANAGEMENTKNOB

SPRING PIN

TRIGGER

O-RING

O-RING

STEEL BALL

GREASE FITTING

Q 'ty

2

Page 6

Owner's Manual Model No. 875.198650 Owner's Manual Model No. 875.198650

Tool runs

slow or will

not operate.

1. Grit or gum in tool

2. No oil in tool

3. Low air pressure

4. Air hose leaks

5. Pressure drops

1. Flush the tool with air tool oil, gum

solvent, or an equal mixture of SAE 10

motor oil and kerosene. Lubricate the tool

after cleaning

2. Lubricate the tool according to the

lubrication instructions in this manual

3a. Adjust the regulator on the tool to the

maximum setting (If applicable).

3b. Adjust the compressor regulator to tool

maximum while the tool is running free.

4. Tighten and seal hose fittings if leaks are

found. Use pipe thread tape where possible.

5a. Be sure the hose is the proper size.

Long hoses or tools using

large volumes of air may require a hose with

an I.D. of 1/2" or larger depending on the

total length of the hose.

5b. Do not use multiple number of hoses

connected together with quick connect

fittings. This causes additional pressure

drops and reduces the tool power. Directly

connect the hoses together.

Impacts slowly

or will not impact

Impacts rapidly but 1. Worn impact 1. Replace worn impact mechanism

will not remove bolts mechanism components

Does not impact 1. Broken impact 1. Replace broken impact mechanism

1. Lack of lubrication

2. Tool regulator set in

wrong

position

3. In-line regulator or 3. Adjust regulators in the air system

compressor regulator

set too low

mechanism components

1. Lubricate the air motor and the

impact mechanism. (See Lubrication

section of this manual)

2. Adjust the regulator on the tool to

the maximum setting

Notes:

Moisture

blowing out

of tool

1. Water in tank

2. Water in the air lines/

hoses

ENG-10 ENG-11

1. Drain tank. (See air compressor manual).

Oil tool and run until no water is evident. Oil

tool again and run 1-2 seconds.

2a. Install a water separator/filter.

NOTE: Separators only work properly when

the air passing through the separator is

cool. Locate the separator/filter as far as

possible from the compressor.

2b. Install an air dryer.

2c. Anytime water enters the tool, the tool

should be oiled immediately.

Page 7

IPROFESSIONAL I

Llave de impacto compuesta de 112 pulg

Desempaquetar

Despues de desempaquetar el

examinelo cuidadosamente par_

dafios que pudieron haber ocurr

durante el transporte. Cerci6res

apretar cualquier accesorio, per

antes de poner este producto er

ADVERTENCIA: Lea y guarde estas instrucciones de seguridad y operaci6n. Lea

detafladamente antes de tratar de ensamblar, instalar, operar o mantener el producto

Prot6jase usted y protega a los demos respetando toda la informaci6n de seguridad.

incumplimiento con estas instrucciones podria resultar en una lesi6n personal, un

propiedad o ambos. Conserve las instrucciones como referencia futura.

Page 8

Manual dei Hropietarlo Modeio No. 75. 19 6bU Manual dei Hropietarlo Modeio No. 75. 1

90 PSIG M,&XIMO

Esta herramienta est_fidise5ada I

operar a una presi6n neumatica r

indicador de 90 libras por pulgads

(90 PSI), en la herramienta. El us

presi6n de aire mayor puede y po

causar lesiones. Tambi6n, el uso

presi6n neumatica mayor sometc

componentes internos a cargas y

para las cuales no fueron dise5ac

causando una falla prematura de

herramienta.

Proyecto de ley 65 de Californi_

Algunos polvos creados por el

aserrado, desgastado, taladraa

actividades de construcci6n co

substancias quimicas conocid_

causantes de cancer, defectos _

nacimiento u otras lesiones en

sistema de reproducci6n. Algu_

ejemplos de esas sustancias qd

SOn:

Plomo de pinturas que contien

silice cristalino de ladrillos, cer

otros productos de albabileria

y cromo de madera quimicamE

tratada

Su riesgo de esas exposicione,.

dependiendo de cuan a menud

electra este tipo de trabajo. Pa

su exposici6n a estos material_

en un area bien ventilada y con

equipos de protecci6n aprobac

mascaras de polvo que esten

especificamente disebadas pat

particulas microsc6picas.

Caracteristicas y operaci6n

Especificaciones

Garantia del producto

Requisitos del compresor

Instrucciones de seguridad importantes

Instalaci6n y operaci6n

Mantenimiento

Piano de vista despiezada y lista de

piezas

Localizaci6n y soluci6n de fallas

Craftsman Modelo 875,198650 1/2-in.

Ilave inglesa compuesta de impacto

representa un golpear duro, dise_o

gemelo de martillo que produce 725 Ibs.

de Pies de momento de torsi6n maximo.

Excepcionalmente rapidamente 1.100

impactos por minuto y 8.000 RPM libertan

velocidad consigue el trabajo hecho

rapidamente. El impacto alto envoltura

que resistente de compuesto y caso de

martillo de magnesio pesan s61o4,25 Ibs.

]-ama_o del accionador ............................... 1/2"

delocidad libre (sin carga) ................ 8,000 RPM

Partorsor final ........................ 725 pies por libra

Peso .................................................... 4.25 libras

Longitud total ........................................... 5-7/8"

Consumo promedio de aire ............... 5.0 SCFM

1-ama_o recomendado

3ara la manguera .............. Dia. int. de 3/8 pulg

_,dmisi6n de aire .......................... 1/4 pulg NPT

Presi6n de aire maxima .......................... 90 PSI

GARANTiA COMPLETA POR UN ANO DE

HERRAMIENTA CRAFTSMAN

Si esta herramienta Craftsman falla en

proporcionarle una satisfacci6n completa

dentro de un a_o a partir de su fecha de

compra, DEVUELVALAA CUALQUIER

TIENDA O CENTRO DE PIEZAS Y

REPARACION DE SEARS U OTROS

ESTABLECIMIENTOS DE SEARS EN LOS

ESTADOS UNIDOS, PARA UNA

REPARACION GRATIS (o reemplazo si la

reparaci6n es imposible).

Siesta herramienta Craftsman alguna vez se

usa para fines comerciales o de alquiler, esta

garantia se aplica solamente por 90 dias a

partir de la fecha de compra. Esta garantia

no incluye las piezas consumibles, como

I_mparas, baterias, brocas u hojas.

Esta garantia leproporciona derechos legales

especificos, y usted puede tener tambi6n

otros derechos que varian de estado a

estado.

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179, EE.UU.

Poco uso -26 galones

Uso regular - 33 galones

Uso pesado - 60 galones profesional

Lea las instrucciones de operaci6n

Familiaricese con todas las instrucciones y

advertencias antes de usar cualquiera

herramienta neumatica.

Use siempre proteccion adecuada para

los ojos

La protecci6n ocular resistente al impacto

debera satisfacer o superar las normas

especificadas en ANSI Z87.1, bajo el titulo

Protecci6n ocular y facial ocupacional y

educativa. Busque la marca Z87.1 en su

protector de los ojos para asegurar que es

un estilo aprobado.

Se recomienda proteccion de los oidos

La protecci6n de los oidos debe usarse

cuando la exposici6n de nivel de sonido

iguala o excede un nivel promedio

ponderado por tiempo, de 8 horas, de

85dBA. El ruido del proceso, superficies

reflectoras, otras herramientas operadas

en la cercania, todos agregan al nivel de

ruido en un area determinada de trabajo. Si

no es posible determinar la exposici6n al

nivel de ruido, se recomienda usar

protecci6n auditiva.

Evite la exposicion prolongada a la

vibracion.

Las herramientas neumaticas pueden

vibrar durante su uso. La exposici6n

prolongada a las vibraciones o los

movimientos muy repetidos de manos y

brazos pueden causar lesiones. Interrumpa

el uso de cualquier herramienta si

experimenta cosquilleo, adormecimiento,

malestar o dolor en las manos o brazos.

Debera consultar con su m6dico antes de

seguir usando la herramienta.

Page 9

Manual del Propietario Modelo No. 875.198650Manual del Propietario Modelo No. 875.198650

Desconecte Ja herramienta del

suministro de aJre antes de cambiar

herramientas o accesorios, darle servicio o

durante el tiempo que no est6 funcionando.

No use ropa suelta, bufandas o corbatas

en el_rea de trabajo. La ropa suelta podria

quedar atrapada en las piezas en

movimiento y resultar en una lesi6n

personal grave.

No use joyas mientras usa la

herramienta. Las joyas podrian quedar

atrapadas en las piezas en movimiento y

resultar en una lesi6n personal grave.

No presione el disparador cuando est6

conectando la manguera de suministro de

aire.

No apriete eJ disparador de la

herramienta cuando nose aptique a un

objeto de trabajo.

Los accesorios deben acopJarse de

forma segura. Los accesorios sueltos

pueden causar una lesi6n grave.

Protega Jas JJneasde aJre contra Jos

da_os y puncJones.

Nunca apunte una herramienta

neum_tica a sus propJa persona nia

ninguna otra persona. Podria ocurrir una

lesi6n grave.

Revise Jasmangueras de aJre en busca

de condicJones d_bJles o de desgaste

antes de cada uso. AsegOrese de que todas

las conexiones est@ bien afianzadas.

Libere toda Japresi6n del sistema antes

de tratar de instalar, dar servicio,

reubicar o realJzar cualquier

mantenJmiento.

Mantenga todas las tuercas, pemos y

tomillos apretados, y asegure que el

equipo est6 en condiciones de trabajo

seguras.

SPA-4 SPA-5

Use accesorios disehados para utilizar

con la herramienta el_ctrica neumatica.

Siempre examine los accesorios antes

del montaje en busca de astiflas, grietas

o indicios de alg_n daho.

Nunca use puntos montados u otros

accesorios que se ban caido o se ban

expuesto al agua, disolventes o cambios

extremos de temperatura. Es bueno usar la

herramienta en unalojamiento protegido por

un minuto despu6s de montarle cualquier

accesorio.

Siempre use accesorios clasificados

para revoluciones por minutos (RPM)

que cumplan o excedan con la

dasificaci6n de RPM de la herramienta.

Nunca Ileve una herramienta por la

manguera ni nunca tire de la manguera

para mover una herramienta o un

compresor. Mantenga /as mangueras

alejadas del calor, aceite y bordes

afilados. Reemplace cualquier manguera

que est_ dahada, d_bil o desgastada.

Peligro de inhalaci6n: Las herramientas

abrasivas, como mofinillos, lijadoras y

herramientas de corte, generan polvo y

materiales abrasivos que pueden ser

dabinos para los pulmones y el sistema

respiratorio de las personas. Siempre

use una mascara facial o respirador con

buen ajuste, que este aprobado por

MSHA/NIOSH, cuando utifice tales

herramien tas.

AIgunos materiales, como adhesivos y

alquitr&n, continen compuestos

quimicos cuyos vapores podrian causar

una grave lesi6n con la exposici6n

prolongada. Trabaje siempre en un area

limpia, seca y bien ventilada.

Las herramientas que contienen piezas

m6viles, o que impulsan a otras

herramientas m6viles, como ruedas

amoladoras, cubos, discos lijadores,

etc., pueden enredarse en el pelo, ropa,

joya y otros objetos sueltos, resultando

en una grave lesi6n.

Nunca use ropa suelta que contengan

correas o corbatas, que podrian quedar

atrapados en las piezas m6viles de la

herramienta. Quitese cualquierjoya,

reloj, etc. que podria ser atrapado por la

herramienta. Mangenga las manos

alejadas de las piezas m6viles. Rec6jase

o c_brase el pelo.

Las herramientas y accesorios mal

mantenidos pueden causar una lesi6n

grave. D_le mantenimiento a la

herramienta con cuidado. Estas

herramientas de corte con el

mantenimiento adecuado, con bordes

de corte afilados, reducen el riesgo de

atasco y son mas faciles de controlar.

Si la herramienta esta dabada existe el

peligro de que explote repentinamente.

Revise los desajustes o atascos de las

piezas m6viles, roturas de las piezas y

cualquier otra condici6na que afecte el

funcionamiento de la herramienta. Si la

misma esta dabada, haga que se le d_

mantenimiento antes de usarla.

Las herramientas que cortan, cizallan,

barrenan, apilan, punzonan, cincelan,

etc. pueden causar una lesi6n grave.

Mantenga la pieza de trabajo de la

herramienta alejada de las manos y el

cuerpo.

Despubs de lubricar la herramienta

neumatica, el aceite sera descargado

por el puerto de escape durante los

primeros segundos de operaci6n. Por

Io tanto, el puerto de escape debe estar

tapado con una toalla antes de apficar

presi6n de aire.

Use solamente los casquillos y accesorios

clasificados para impactos

Use solamente aquellos casquillos que

estbn marcados como "PARA USAR

CON LLAVES DE IMPACTO". Los

casqufllos para herramientas de mano

pueden romperse y crear el riesgo de

despedir proyectiles. Siempre verifique

el estado de los casquillos, retenedores

y elementos de accionamiento para

detectar desgastes o averias.

Reemplacelos cuando sea necesario.

Page 10

Manual del Propietario Modelo No. 875.198650Manual del Propietario Modelo No. 875.198650

Conexidn de la manguera de aire

Linea principal = Dia, int, min, 1/2 pulg

Inclinado hacia abajo y alejandose

Linea bifurcaci6n 1 =

Lubricador Regulador Filtro

Linea de drenaje

Valvula de

drenaje

Figura 1

Cone×i6n de la

rnanguera de aire

Antes de conectar la herramienta al

suministro de aire, limpie la manguera de

aire para quitarle el potvo y lahumedad

acumulados. H_gato pasando aire

libremente por la manguera por un tiempo

de 5 a 10 segundos.

Mangueras de aire para sus

herramientas neum_ticas

La Figura 1 ilustra la conexi6n

recomendada de una manguera de aire.

Se requiere una manguera neum_tica de un

di_metro interior de 3/8 pulg hasta un largo

de 25 pies. Una manguera con un di_metro

interior de 3/8 pulg m_s larga de 25 pies

causar_ una caida de presi6n, Io que podria

impedir el rendimiento. Si se requiere un

mayor Iongitud, se recomienda usar una

manguera de aire de un di_metro interior de

1/2 pulg. Aseg0rese de que todas las

Dia, int, 1/2 pulg

Linea de admisi6n

Valvula de

Valvula

de Manguera

drenaje de

Compresor de aire

cierre

aislamiento

correcto y que est6n bien conectados

antes de usar la herramienta neum_tica.

Nunca Ileve una herramienta por la

manguera ni nunca tire de la manguera

para mover una herramienta o un

compresor. Mantenga las mangueras

alejadas del cator, aceite y bordes afilados.

Reemptace cualquier manguera que est6

daSada, d6bil o desgastada.

Tuber{a para taller peque_o (para la

casa):

Se muestra undiagrama de tuberia para

un taller tipico de una casa. Algunos

consejos 0tiles son:

Siempre use mangueras y tuberias

que est6n clasificadas para una

presi6n mayor que la que su sistema

necesitar_.

Nunca use tuberias de PVC para

sistemas de tuberia de aire

comprimido porque pueden resultar en

una exptosici6n o una lesi6n grave.

• La conexi6n desde el compresor a

la tuberia rigida de admisi6n iniciat

debe ser a trav6s de una manguera

flexible para aislar el movimiento del

compresor.

Encamine la tuberia de admisi6n

inicial recta hacia hacia arriba por la

pared del taller y Io m_s alto posibte.

Esto ayudar_ a minimizar que el agua

que sale del compresor viaje por el

sistema.

Incline hacia abajo las lineas

principates por Io menos 3/4 de

pulg por cada 10 pies de tuberia

atej_ndose del compresor de aire.

Esto extraer_ la condensaci6n con

el flujo de aire que sale del

compresor.

Cotoque el primer bajante Io m_s lejos

posibte del compresor que el tamaSo

de su taller permita (50 pies es Io

6ptimo, aunque poco reatista para un

taller pequedo). Entre m_s atejado

est6 el bajante, mayor condensaci6n

puede ocurrir, y m_s seco ser_ el aire

cuando alcance el separador de agua.

Para reducir la cantidad de agua y

contaminantes que entran at

separador de agua, instale la tinea de

admisi6n arriba de la tinea principal de

suministro de aire para cada bajante

de aire.

Se debe colocar una linea de drenaje

al final de la linea principal para

evacuar la condensaci6n.

Las v_lvulas dedrenaje deben

colocarse at final de las lineas de

ramificaci6n y la linea de drenaje, y se

deben evacuar diariamente.

Este instrumento representa una v_lvula

de regulador de poder (Fig. 2). Gire

regulador hasta que salida deseada sea

Iograda. Los ajustes en el regulador son

s61o para referencia y no denotan una

salida especifica del poder. Gire regula-

dora una posici6n con el circulo de

sinlge que es Io menos cantidad del

poder y los tres circulos que son la m_is

cantidad del poder.

Figura 2

Palanca Valvuladel regulador y Rev_s.

I ,ADVERTENCIA 1

Una vez asentado un perno o sujetador,

la acci6n de impactar por mas de cinco

(5) segundos producir& desgaste en

exceso y posibles dabos a! mecanismo

de impactaci6n Si tarda m&s de cinco

segundos para ajustar o aflojar su perno

o sujetador, recomendamos el uso de

una flare de impacto de tamaho mayor.

mangueras y accesorios sean del tamaSo

SPA-6 SPA-7

Page 11

Manual del Propietario Modelo No. 875.198650 Manual del Propietario Modelo No. 875.198650

Piano de vista

Lubricaci6n

Se recomienda usar un filtro-regulador-

lubricador en linea (Fig.1) ya que incrementa la

duraci6n de la herramienta y mantiene la

herramienta en una operaci6n sostenida. Debera

comprobar el lubricador en linea con regularidad

y Ilenarlo con aceite para herramientas de aire

comprimido. El ajuste correcto del lubricador en

linea se realiza colocando una hoja de papel

pr6xima a los orificios de escape de la

herramienta y manteniendo abierto el acelerador

durante 30 segundos aproximadamente. Se

ajusta correctamente el lubricador cuando el

papel queda manchado con una ligera mancha

de aceite.

Deberan evitarse las cantidades excesivas de

aceite. En caso de ser necesario almacenar la

herramienta durante un largo tiempo (de la noche

a la manana, un fin de semana, etc.), debera

lubricarla abundantemente a trav6s de la entrada

de aire (Fig, 3). Debera operar la herramienta

durante 30 segundos aproximadamente para

asegurar la distribucion pareja del aceite en toda

la herramienta. Debera almacenarse la

herramienta en un medio limpio y seco.

Lubricantes recomendados

Use un aceite de herramienta neumatica u

cualquier otro aceite de grado elevado de turbina

que contenga absorbente de humedad,

inhibidores de 6xido, agentes humidificadores

del metal y un aditivo EP (presi6n extrema). Vea

la Fig. 3 para la ubicaci6n y entrada de aire.

LUBRICAClON DEL MECANISIVIO DE

IMPACTACK]N

El mecanismo de impactaci6n transfiere potencia

desde la herramienta a una tuerca o perno.

El mecanismo del impacto es grasa lubricada y

no requiere acerca de-engrasando bajo uso

normal.

Lubrique el

mecanismo

de impactaci6n

poraqui.

\

Lubrique el motor neum_tico por aqui

Figura 3

Lista de piezas

Ref# Part No. Description Q'ty Ref# Part No. Description Q'ty

1 9638001M CALAAEREA 1 24 9611224 MARCO de MARTILLO 1

2 90R2002 O-ANILLO 1 255 96112255 MARTILLO 2

3 9287608 O-ANILLO 1 26 9611226 YUNQUE 1

4 9287609 DEFLECTOR 1

55 9287610 PRIMAVERA 1

6 9328804V TALLO de VALVULA 1

7 93288355 ASIENTOde VALVULA d ADMISION 1 30 9611230 CASO de MARTILLO 1

8 932883555 ESPACIADOR 1

9 9287614 ANILLO de IGUALA 1 32 9611232 TALLO de VALVULA 1

10 9611210 ENVOLTURA MOTRIZ 1 33 9287617 O-ANILLO 1

11 95P0326 ALFILERde PRIMAVERA 1 34 9611234 BUJE de VALVULA 1

12 9611212 TORNILLO 1 355 96112355 CUERPO de VALVULA 1

13 9611213 CERROJO 4 36 9611236 IGUALA 1

14 9611214 TORNILLO 3 37 9611237 VALVULA INVERSA 1

1.5 9SP25520 ALFILERde PRIMAVERA 1 38 9611238 VALVULA INVERSAPALANCA 1

16 9B6001Z COJINETE 1 39 9611239 PRIMAVERA 3

17 9611217 FINAL CHAPA 1 40 9611240 PODER 1

18 9611218 ROTOR 1 41 955589039 ALFILER de la PRIMAVER 1

19 9611219 HOJA 6 42 9611242 DISPARADOR 1

20 9611220 CILINDR 1 43 90R85501 O-ANILLO 1

21 9611221-B 0 LaJUNTA DECULATA 1 44 90R1301 O-ANILLO 1

22 9B6002 COJINETE 1 455 9SBOOO3-1 PELOTA de ACERO 3

23 9611223 ALFILERde MARTILLO 2 46 9638047 ACCESORIO de GRASA 1

27 90R7718 O-ANILLO 1

28 9328830-4 IGUALA de ENCHUFE 1

29 9611229 BUJE 1

31 90R1315; O-ANILLO 1

SPA-8 SPA-9

Page 12

Manual del Propietario

Modelo No. 875.198650

Manual del Propietario

Modelo No. 875.198650

La herramienta 1. En la herramienta hay

funciona polvo, arena o resina.

lentamente o

no funciona.

2. En la herramienta no

hay aceite.

3. La presi6n del aire

est_ baja.

4. Fugas de la manguera

de aire

5. Caidas de presi6n.

1. Irrigue la herramienta con aceite para

herramientas neum_ticas, diluyente de resinas, o

una mezcla de igual proproci6n de aceite de motor

SAE 10 y queroseno. Lubrique la herramienta

despues de la limpieza.

2. Lubrique la herramienta de acuerdo a las

instrucciones de lubricaci6n indicadas en este

manual.

3a. Ajuste el regulador de la herramienta a su valor

m_ximo (si corresponde).

3b. Ajuste el regulador del compresor al m_ximo

de la herramienta mientras que la herramienta

funciona libre.

4. Apriete y selle los accesorios de la manguera si

ha encontrado escapes.

Utilice cinta de hilo de tubo donde posible.

5a. Asegt]rese de que la manguera que est_

usando tenga el tama_o correcto. Las mangueras

largas o las herramientas que usan grandes

volt]menes de aire podrian requerir una manguera

con un di_metro interno de 1/2 pulgada o m_s,

dependiendo de la Iongitud total de la manguera.

5b. No use varias mangueras conectadas una a la

otra a traves de accesorios de conexi6n rgpidos.

Esto causa caidas de presi6n adicionales

y reduce la potencia de la herramienta. Conecte

las mangueras una con la otra directamente.

Impactos lentos 1. Falta de lubricaci6n. 1. Lubrique el motor del aire y el mecanismo

o no hay de impactaci6n. (Consulte la secci6n

impacto en Io Lubricaci6n de este manual).

absoluto. 2. El regulador de la 2. Ajuste el regulador de la herramienta a su

herramienta esta puesto valor m_ximo.

en la posici6n incorrecta.

3. Regulador en linea o 3. Ajuste los reguladores del sistema de aire.

regulador del compresor

fijado muy bajo

Proyecta impactos 1. Mecanismo de

r_pidamente pero impactaci6n

no quita los pernos, desgastado.

No da impactos

1. Mecanismo de

impactaci6n roto.

1. Reemplace los componentes desgastados

del mecanismo de impactaci6n.

1. Reemplace los componentes rotos del

mecanismo de impactaci6n.

Notas:

Humedad

sale de la

herramienta

SPA-10 SPA-11

1. Agua en el tanque. 1. Drene el tanque. (Consulte el manual del

2. Agua en las lineas de aire

o mangueras.

compresor). Engrase la herramienta y h_gala

funcionar hasta que no vea agua. Engrase la

herramienta otra vez y dejela funcionar de 1a 2

segundos.

2a. Instale un separador/filtro de agua.

NOTA: Los separadores s61o funcionan bien

cuando el aire que pasa por los mismos est_ frio.

Ubique el separador/filtro Io m_s

separado posible del compresor.

2b. Instale un secador de aire.

2c. Cada vez que entra agua a la herramienta, la

herramienta debe engrasarse inmediatamente.

Page 13

Your Home

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME ® (1-800-469=4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

For expert home solutions advice: www.managemyhome.corn

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

Call anytime, day or night

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U.S.A.) 1-800-361-6665 (Canada)

Para pedir servicie de reparaci6n Au Canada pour service en fran_ais:

a domicilio, y para ordenar piezas: 1-800-LE-FOYER _c

1-888-SU -HOGAR ® (1-800-533-6937)

(1-888-784-6427) www.sears.ca

® Registered Trademark ] _M Trademark /s_ Service Mark of Sears Brands, LLC

® Marca Registrada / T_ Marca de F&brica / sr_ Marca de Se_,icio de Seam Brands, LLC

u¢ Marque de commerce / #D Marque d{_pos_e de Sears Brands, LLC @ Sears Brands, LLC

Loading...

Loading...