Page 1

Owner's Manual

PNEUMATIC

AIR HAMMER

Model No.

875.191190

WARNING:

Before operating too!, read this

manual and follow all

Safety Recommendations and

Operating instructions.

♦ Safety

♦ Warranty

♦ Features & Operation

♦ Maintenance

♦ Español

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

www.sears.com

Page 2

SAFETY INSTRUCTIONS

WARRANTY

Read Operating Instructions

Please become familiar with all the instructions and

warnings before operating any pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should meet or exceed

the standards set forth in ANSI Z87.1, Occupational and

Educational Eye and Face Protection. Look for marking

Z87.1 on your eye protection to ensure that it is an

approved style.

Hearing Protection is Recommended

Hearing protection should be used when the noise level

exposure equals or exceeds an 8 hour time-weighted

average sound level of 85dBA. Process noise> reflective

surfaces, other tools being operated nearby, all add to the

noise level in a given work area. If you are unable to

determine your noise level exposure, we recommend the

use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use. Prolonged

exposure to vibration or very repetitive hand and arm

movements, can cause injury. Discontinue the use of any

tool if you experience tingling, numbness, discomfort or

pain in your hands or arms. You should consult your

physician before resuming use of tool.

90 PSI Maximum

This tool is designed to operate at an air pressure of 90

pounds per square inch gauge pressure {90 PSI)

maximum, at the tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher air pressure

places the internal components under loads and

stresses they were not designed for, causing premature

tool failure.

NOTE: THE AIR SUPPLY SHOULD BE CLEAN AND DRY,

PREFERABLY LUBRICATED. FOR BEST RESULTS

DRAIN THE MOISTURE FROM YOUR COMPRESSOR

DAILY.

Use May Produce Flying Objects

Care should be taken when using any percussion tool.

Keep the point of the chisel in contact with the work

surface. Inspect all accessories carefully for damage

before use. Chisels and chisel retainers should be kept

in good condition and replaced as needed. Discard any

accessory that has been damaged to prevent anyone

from using it.

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains chemi

cals known to cause cancer, birth defects or reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paint

• Cystalline silica from bricks, cement and other

masonry products

• Arsenic and chromium from chemically treated

lumber

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals, work in a well-ventilated area and work

with approved safety equipment such as dust masks that

are specially designed to filter out microscopic particles.

FULL TWO YEAR WARRANTY ON

CRAFTSMAN AIR-DRtVE TOOLS

If this Craftsman tool fails to give complete satisfaction

within two years from the date of purchase, RETURN IT

TO THE NEAREST SEARS STORE IN THE UNITED

STATES, and Sears will repair it free of charge. If this

Craftsman tool is used for commercial or rental

purposes, this warranty applies for only 90 days from the

date of purchase. This warranty gives you specific legal

rights, and you may also have other rights which vary

from state to state.

Seai^, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179.

FEATURES/SPECIFICATIONS

The Craftsman Model 875.191190 Air Hammer is

designed for chipping, trimming, riveting, cutting, piercing

and peening.

Features

• Uses standard .401 inch shank chisels.

• Alloy steel barrel and heat-treated piston for long life.

• Produces 4,000 powerful blows per minute with

a 1 -5/8" stroke.

Specifications

Blows per minute............................................ ....4,000

Stroke length

Bore diameter......

Overall Length

Weight

Recommended hose size

............................................................

.............................................. 3/4"

........................................................

....................................................... 2.3 ibs.

................................

3/8” I.D.

IW

6.1"

Air Inlet.............................................................1/4" NPT

Average Air Consumption...............................

...4 CFM

Maximum Operating Pressure.............................90 psi

INSTALLATION / PRE-OP

Pre-Operation

Before the tool is connected to the air supply, clear the air

hose of accumulated dust and moisture by running air

freely through the air hose for 5-10 seconds. Before

removing a tool for service or changing chisels, make

sure the air line is shut-off at the compressor. This will

prevent the tool from operating if the throttle is accidently

engaged.

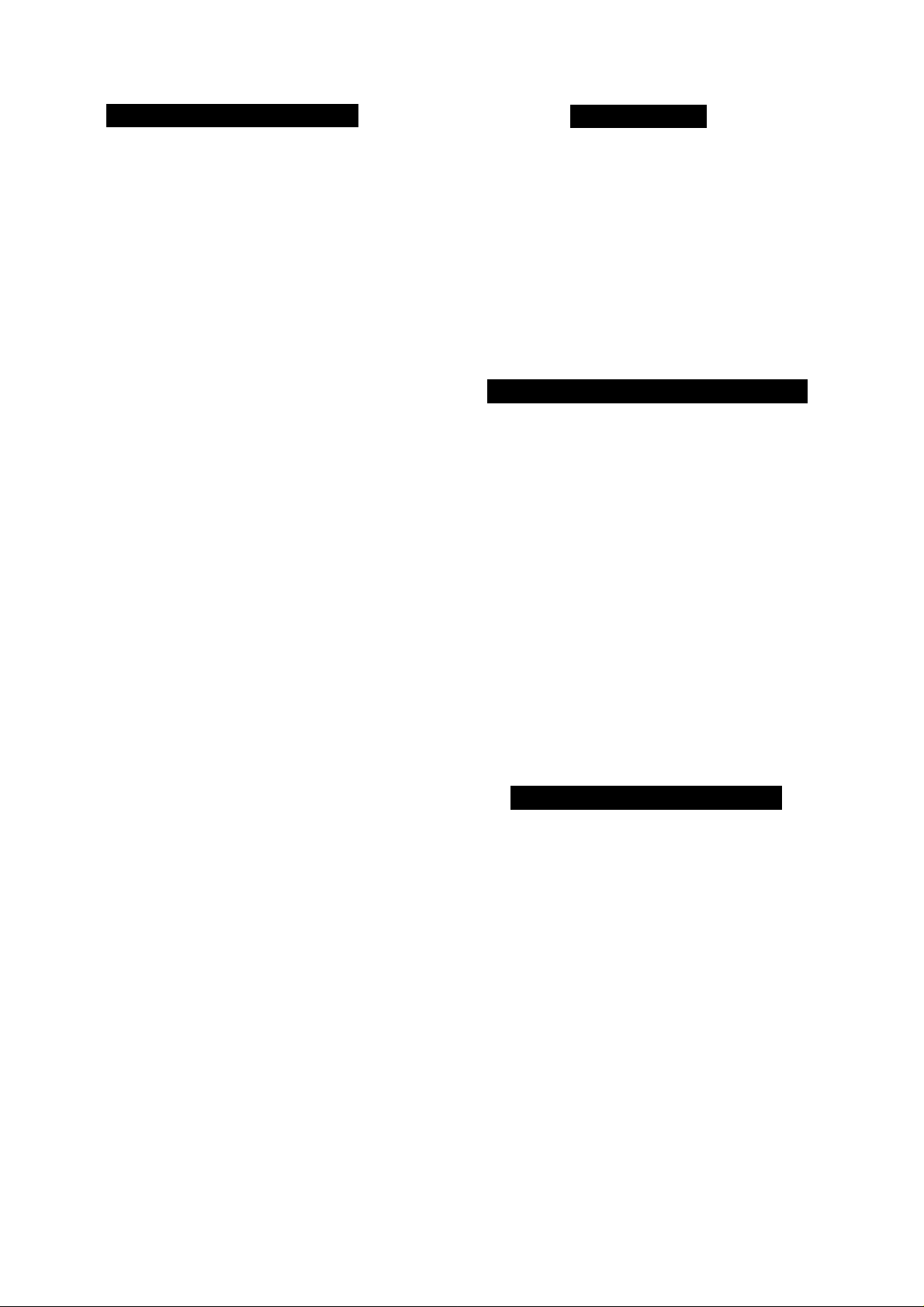

Installation (See figure 1)

This tool Is designed to operate at 90 psi. Lower pres

sure (below 90 psi) will reduce performance of the tool

while higher air pressure (over 90 psi) raises the perfor

mance of the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air motor. We recommend

the installation of an in-line filter-regulator-lubricator as

dose to the tool as possible. {Fig 1)

A 3/8" air hose is required up to a length of 8 ft. If more

length is required a 1/2" air hose should be used at the

compressor. Attach a 3/8" whip hose for the remaining 4 8 ft. for flexibility. Be sure all hoses and fittings are the

correct size and tightly secured before using air tool.

(2)

Page 3

OPERATION

MAINTENANCE

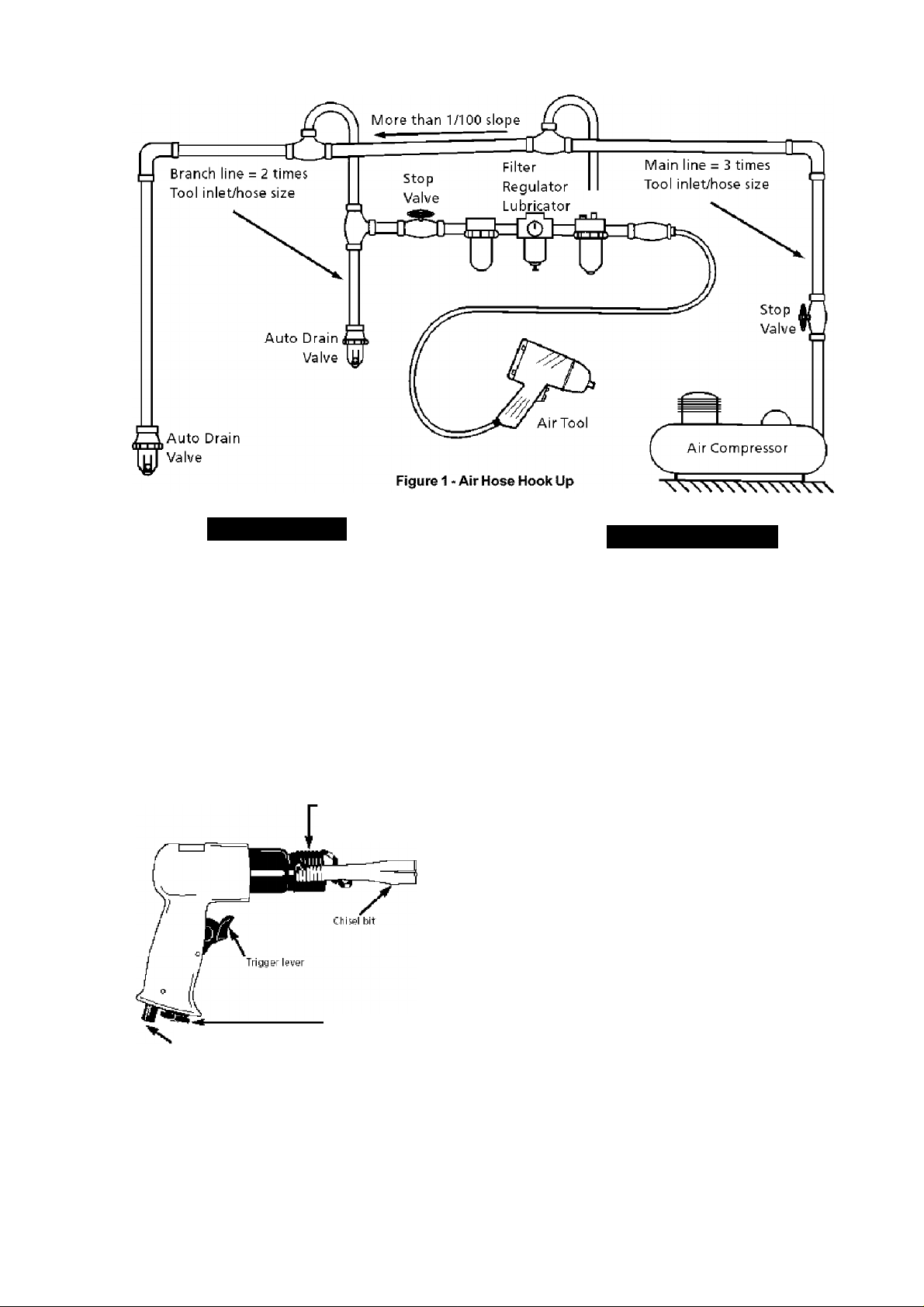

USING QUICK CHANGE RETAINER

1. Disconnect air supply and remove all accessories.

2. Thread quick change chisel retainer onto end of

barrel.

3. While pushing end of spring to side of the tool, insert

a standard .401" taper shank chisel into barrel and

allow spring tension to rest against chisel. Make sure

chisel collar is between barrel and retaining part of

spring.

4. Remove chisel by pushing spring to side of tool and

pull chisel out of barrel.

5. Always hold chisel to work surface before operating

tool.

’ Regulator

'Spring Retainer

Air inlet

Figure 2 - Tool Diagram

Place chisel against work surface and pull trigger in

short bursts until chisel sets in work. Use both hands to

hold hammer for better control.

Lubrication

An in-iinefiiter-reguiator-lubricator{fig 1) is

recommended as it increases too! life and keeps the

tool in sustained operation. The in-iine lubricator should

be regulariy checked and filled with air tool oil. Proper

adjustment of the indine lubricator is performed by

placing a sheet of paper next to the tools exhaust

ports and holding the throttle open approximately 30

seconds. The lubricator is properly set when a light

stain of oil collects on the paper. Excessive amounts of

oil should be avoided.

In the event that it becomes necessary to store the

tool for an extended period of time (overnight, weekend,

etc.), it should receive a generous amount of

lubrication through the air inlet (fig 2). The tool should

be run for approximately 30 seconds to ensure oil has

been evenly distributed throughout the tool. The tool

should be stored in a dean and dry environment.

Recommended lubricants: Use air tool oil or any

other high grade turbine oil containing moisture

absorbent, rust inhibitors, metal wetting agents and an

EP (extreme pressure) additive. (See Fig. 2 for

iocation/air inlet).

ACAUTION

Never operate hammer without a chisel installed and

placed against the work surface. Doing so may result in

personal Injury or damage to the tool.

Sears offers a variety of chisels for this hammer.

(3)

Page 4

Sears CRAFTSMAN Model 875.191190 Pneumatic Air Hammer

Exploded View and Parts List

Ref. Description

1 Handle

2 Spring Pin (2) 9AH-15002

3

4

5 Air Regulator

6 Trigger

7 Coil Spring 9AH-15007

8

9

Steel Washer

Coil Spring

Valve Stem

Valve

Part No.

9AH-15001

9AH-15003

9AH-15004

9AH-15005

9AH-15006

9AH-15008

9AH-15009

Ref.

10

11

12

13

14 Lower Valve 9AH-15014

15

16

17 Spring Retainer 9AH-15017

Description

Spring

Air Inlet

Upper Valve

Valve Disc

Piston

Cylinder 9AH-15016

Part No.

9AH-15010

9AH-15011

9AH-15012

9AH-15013

9AH-15015

(4)

Page 5

Troubleshooting

Symptom Possible Cause Corrective Action I

Tool runs slowly or will not operate

Moisture blowing out of tool exahust

1. Grit or gum in tool

2. No oi! in tool

3. Low air pressure

4. Air hose leaks

5. Pressure drops

1. Water in tank

1, Flush the tool with air tool oil or gum

solvent.

2, Lubricate the tool according to the lubrication

instructions in this manual

3- a. Adjust the regulator on the tool to the maxL

mum setting

b. Adjust the compressor regulator to too!

maximum of 90 psi.

4, Tighten and seal hose fittings if leaks are found.

Use teflon tape.

5- a. Be sure the hose is the proper size. Long

hoses or tools using large volumes of air may

require a hose with an I.D, of 1/2” or larger

depending on the total length of the hose,

b. Do not use a multiple number of hoses

connected together with quick connect fittings.

This causes additional pressure drops and

reduces the tool power. Directly connect the

hoses together

1. Drain tank. (See air compressor manual). Oil tool

and run until no water is evident. Oil tool again and

run 1-2 seconds

(5)

Page 6

INSTRUCCIONES DE OPERACION

Lea las instrticciones de operación

Por favor familiarícese con todas las instrucciones y

advertencias antes de operar cualquier herramienta

neumática.

Siempre use protección aprobada para la vista

La protección a la vista resistente al impacto debe

satisfacer o exceder las normas establecidas en ANSI

Z87.1, Protección Educativa y Ocupacional de los Ojos y

el Rostro. Busque la marca Z87.1 en su protección de la

vista para asegurarse que es un estilo aprobado.

Se recomienda protección del oído

La protección del oído debe usarse cuando la exposición

al nivel del ruido iguala o excede un nivel promedio de

sonido ponderado de tiempo en 8 horas, de 85dBA.

Ruido del proceso, superficies reflectoras, otras

herramientas que se operan en la cercanía, todos

agregan al nivel del ruido en una área de trabajo dada. Si

usted no puede determinar su exposición al nivel de

ruido, recomendamos el use de protección de oído.

Evite exposición prolongada a la vibración

Las herramientas neumáticas pueden vibrar durante el

uso. Una exposición prolongada a la vibración o

movimientos muy repetitivos de la mano y el brazo

pueden causar lesiones. Discontinúe el uso de

cualquiera herramienta si usted experimenta cosquilleo,

entumecimiento, incomodidad o dolor en sus manos o

brazos. Usted debe consultar con su médico antes de

reanudar el uso de herramienta.

90 PSI máximas

Esta herramienta está diseñada para operar a una

presión atmosférica máxima de 90 libras por puigada

cuadrada de medidor de presión (90 PSI), en la

herramienta. El uso de presiones atmosféricas más

altas puede causar lesiones. También, el uso de

presiones atmosféricas más altas coloca a los

componentes interiores bajo cargas y tensiones para las

que no fueron diseñados, causando una falla prematura

de la herramienta.

GARANTIA

DOS AÑOS COMPLETOS DE GARjlU^TIA DE LAS

HERRAMIENTAS DE OPERACION NEUMATICA CRM=TSM>^

Si esta herramienta Craftsman no le proporciona una satisfacción

completa dentro de los dos años de la fecha de compra,

DEVUÉLVALA A LA TIENDA MAS CERCW^A DE SEARS EN LOS

ESTADOS UNIDOS, y Sears la reparación libre de cargo. Si esta

herramienta Craftsman se usa para lines comerciales o de alquiler,

esta garantía sólo se aplica durante 90 días desde la fecha de

compra. Esta garantía le proporciona derechos legales

específicos, y usted también puede tener otros derechos que

varían de estado a estado.

Sears, Roebuck y Cía., Dept. 817WA, Hoffman

Estates, IL 60179.

CARACTERISTiCAS/ESPECIFICACIONE

El martillo de aire modelo 875.191190 Craftsman está

diseñado para cincelar, recortar, remachar, perforar y

martillar.

Características

• Usa cinceles de vástago estándar de .401 de pulgada.

• Tambor de aleación de acero y pistón térmicamente

tratado para una larga duración,

• Produce 4000 golpes potentes por minuto con una

carrera de 1-5/8”.

Especificaciones

Golpes por minuto

Largo de la carrera

Diámetro del hueco

Largo total..............................................6.1"

Peso

......................................................

Tamaño recomendado de

la manguera

Entrada de aire.................................................1/4” NPT

Consumo neumático promedio.................4 PCM

Presión máxima operativa

.................................

................................

...............................

...........................................

.......................

4000

1-5/8”

3/4”

2.3 Ibs.

3/8” D.l.

90 psi

g

NOTA: EL SUMINISTRO NEUMATICO DEBE ESTAR

LIMPIO, SECO Y PREFERENTEMENTE LUBRIFICADO.

PARA OBTENER LOS MEJORES RESULTADOS, DRENE

DIARIAMENTE LA HUMEDAD DE SU COMPRESOR.

ADVERTBÍCIA

Algo del polvo creado por lijado, aserrado, desgastado

mecánico, y otras actividades de construcción, contienen

químicos conocidos como causantes de cáncer,

defectos congénitos o otras lesiones al sistema

reproductivo. Algunos ejemplos de estos químicos son;

• El plomo en la pintura basada en plomo.

• La sílice cristalina de los ladrillos y cemento

y otros productos de albañilería, y el arsénico y

cromo de la madera químicamente tratada.

Su riesgo de esas exposiciones varía, dependiendo de

cuán a menudo usted hace este tipo de trabajo. Para

reducir su exposición a estos químicos: trabaje en una

área bien ventilada, y con un equipo de seguridad

aprobado, como máscaras protectoras contra el polvo

que se diseñan específicamente para filtrar partículas

microscópicas-

!NSTALAC!ON/PRE-OP

Pre-Operación

Antes que la herramienta se conecte al suministro neumático,

limpie la manguera neumática de polvo y humedad acumulados,

haciendo circular aire a través de la manguera neumática durante

5-10 segundos. Antes de extraer una herramienta para prestar

servicio o cambiar cubos, asegúrese que ta tubería neumática esté

cerrada en el compresor. Esto evitará que ía herramienta funcione

si el acelerador se activa accidentalmente.

Instalación {Vea la figura 1)

Esta herramienta está diseñada para operar a 90 psí, una presión

menor (menor de 90 psi) reduce el rendimiento de la herramienta,

mientras que una presión neumática mayor (mayor de 90 psi)

eleva el rendimiento de la herramienta más allá de su capacidad

nomina! y puede causar lesiones graves y daños extensos al

usuario y a la herramienta.

Use siempre aire limpio seco. Una humedad y suciedad excesivos

reducirá substanciaimente la duración de cualquier motor

neumático. Recomendamos la instalación de un flltro-reguladorlubricador en línea tan cerca como sea posible de la herramienta.

Se requiere una manguera neumática de 3/8" hasta un largo de 8

pies. Si se requiere una largo mayor debe usarse una manguera

neumática de 1/2" en el compresor. Fije una manguera de tipo

“látigo” de 3/8" para los 4-8 pies restante, por flexibilidad. Antes

de usar la herramienta neumática, asegúrese que todas las

mangueras y adaptadores sean del tamaño correcto y estén bien

asegurados

(6)

Page 7

OPERACION

MANTENIMIENTO

uso DE UN RETENEDOR DE CAMBIO RAPIDO

1. Desconecte el suministro neumático y extraiga todos ios

accesorios.

2. Enrosque ei retenedor del cincel de cambio rápido sobre el

extremo dei barril.

3. A! empujar el extremo del resorte al lado de !a herramienta,

inserte un cincel de vástago cónico de .401 de pulgada dentro

del tambor y permita que ei resorte tensionado se apoye sobre

ei cincel. Asegúrese que el collar del cincel esté entre el tambor

y la parte retenedora dei resorte.

4. Extraiga ei cincel empujando ei resorte al lado de la

herramienta y tire de! cincel fuera de! tambor.

5. Coloque siempre el cincel sobre la superficie de trabajo, antes

de operar la herramienta.

Hém«*íéí'*íi: ewiási«

X

Figura 2 - Diagrama de ta herramienta

Lubricación

Se recomienda usar un filtro-regulador-lubricador en linea (fig 1)

ya que incrementa la duración de la herramienta y mantiene la

misma en una operación sostenida. El lubricadoren línea debe

inspeccionarse regularmente y llenarse con aceite para

herramientas neumáticas. Un ajuste apropiado del lubricadoren

línea se efectúa colocando una hoja de papel cerca de ios

orificios de escape neumáticos de la herramienta y manteniendo

el acelerador abierto por 30 segundos aproximadamente. El

iubricador está apropiadamente regulado cuando una mancha

leve de aceite se deposita sobre el papel. Deben evitarse

cantidades excesivas de aceite.

En ei caso que se haga necesario almacenar la herramienta por

un período prolongado (durante ta noche, fin de semana, etc.), la

misma debe recibir una gran cantidad de lubricación a través de

ia entrada neumática (fig 3). La herramienta debe hacerse

funcionar por 30 segundos aproximadamente para asegurar que

el aceite se haya distribuido uniformemente a través de la

herramienta. La herramienta debe almacenarse en un ambiente

limpio y seco.

Lubricantes recomendados: Use aceite de herramienta

neumática o cualquier otro aceite de turbina de grado elevado

que contenga un absorbente de humedad, inhibidores de óxido,

agentes humectantes de metal y un aditivo EDP (presión

extrema). (Vea la Fig, 3 por la ubicación/entrada neumática).

PRECAUCION

Nunca opere el cincel sin un cincel instalado y coiocado contra la

superficie de trabajo. Ei hacerlo puede resultar en lesiones

personales o daños a la herramienta.Martillo neumático Modelo

875.191190 CRAFTSMAN Sears

Coloque el cincel sobre la superficie de trabajo y accione el

gatillo en disparos rápidos hasta que el cincel se asiente sobre

el trabajo. Use ambas manos para sujetar el martillo para un

mejor control.

Sears ofrece una variedad de cinceles para este martillo

(7)

Page 8

Martillo neumático Modelo 875.191190 CRAFTSMAN Sears Vista desplegada y lista de piezas

Ref.

1

2

3 Arandela de acero 9AH-15003

4

5

6 Activador 9AH-15006

7

8 Vastago de la válvula 9AH-15008

9 Válvula

Descripción No. de pieza

Mango 9AH-15001 10 Resorte 9AH-15010

Clavija riel resorte (2)

Muelle

Regulador neumático

Muelle

9AH-15002 11

9AH-15004

9AH-15005

9AH-15007

9AH-15009

Ref. Descripción

12 Válvula superior 9AH-15012

13 Disco de válvula 9AH-15013

14

15

16 Cilindro

17 Retenedor del resorte 9AH-15017

(8)

Entrada neumática

Válvula inferior

Pistón 9AH-15015

No. de pieza

9AH-15011

9AH-15014

9AH-15016

Page 9

Localización de falias

La herramienta funciona con lentitud o no funciona

1. Suciedad o goma en la herramienta

2. No hay aceite en la herramienta

3. Presión neumática baja

4. Pedida de la manguera neumática

5. Baja de presión

1. Limpie la herramienta con aceite de herramienta

neumática o solvente para goma.

2. Lubrique la herramienta de acuerdo con las

instrucciones de lubricación en este manual

3. a. Ajuste el regulador en la herramienta a la

graduación máxima

b. Ajuste el regulador del compresor a la máxima de

la herramienta de 90 psi.

4. Ajuste y selle los adaptadores de la manguera si

se hallan pérdidas. En ese caso use cinta de teflón.

5. a. Asegúrese que la manguera tenga el tamaño

apropiado. Mangueras largas o herramientas que

usan un gran volumen de aire pueden requerir una

manguera con un diámetro interno de 1/2” o mayor

dependiendo de la longitud total de la manguera,

b. No use una cantidad múltiple de mangueras

conectadas juntas con adaptadores de conexión

rápida. Esto causa caidas de presión adicionales y

reduce la potencia de la herramienta. Conecte

directamente las mangueras juntas

Escape húmedo de la

herramienta

1. Agua en el tanque

1. Drene el tanque. (Vea el manual del compresor

neumático). Aceite la herramienta y haga funcionar

hasta que no sea evidente la presencia de agua.

Aceite nuevamente la herramienta y haga funcionar

por 1-2 segundos

(9)

Page 10

Get it fixed, at your home or ours!

Your Home

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional instailation of home appliances

and items like garage door openers and water heaters.

1-800-MY-HOME® (1-800-469-4663)

Cali anytime, day or night (U.S.A. and Canada)

www.sears.comwww.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

.......

1-800-488-1222

Call anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protection agreement on a product serviced by Sears:

1-600-827-6655 {U.S.A.) 1-800-361-6665 (Canada)

For after sale

support and assistance

1-800-290-9054

®> Registered Trademark / ™ Trademark / Service Mark of Sears, Roebuck and Co.

®> Marca Registrada / ™ Marca de Fábrica / Marca de Servicio de Sears, Roebuck and Co.

Marque de commerce / Marque déposée de Sears, Roebuck and Co.

© Sears, Roebuck and Co.

Loading...

Loading...