Craftsman 875191183 Owner’s Manual

Owner's Manual

Pneumatic 1/2 " Drive

IMPACT WRENCH

Model No.

875.191183

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

• Safety

• Warranty

• Features&Operation

• Maintenance

• Espa_ol

Distributed by Sears, Roebuck and Co., Hoffman

www.Sears.com

Estates, IL 60179

INSTRUCTIONS PERTAiNiNG TO A RiSK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS

WARNING- Some dust created by using power tools contains chemicals known to the

State of California to cause cancer and birth defects or other reproductive harm

WARNING-When using the product, basic precautions should always be

followed, including the following:

General: To reduce the risks of electric shock, fire, and injury to persons,

read all the instructions before using the tool.

Work area

t. Keep the work area clean and well lighted. Cluttered benches and dark areas

increase the risks of electric shock, fire and injury to persons.

2. Do not operate the tool in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. The tool is able to create sparks resulting in

the ignition of the dust or fumes.

3. Keep bystanders, children, and visitors away while operating the product.

Distractions are able to result in the loss of control of the tool.

Personal safety

1. Stay alert. Watch what you are doing and use common sense when operating

the product. Do not use the product while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention while operating the tool increases

the risk of injury to persons.

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or 10ng

hair increases the risk of injury to persons as a result of being caught in moving parts.

3. Remove adjusting keys and wrenches before turning the tool on. A wrench or a

key that is left attached to a rotating part of the tool increase the risk of personal injury.

4. Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool in unexpected situations.

5. Use safety equipment. A dust mask, non-skid safety shoes and a hard hat must be used for

the applicable conditions.

6. Always wear eye protection.

7. Always wear hearing protection when using the tool. Prolonged exposure to high

intensity noise is able to cause hearing loss.

8. Disconnect the product from the air source before making any adjustments.

9. Avoid unintentional starting. Be sure the switch is off before connecting to

the air supply. Do not carry the tool with your finger on the switch or connect the tool to the

air supply with the switch on.

,_ CAUTION J

1. Inspect hose connection before each use

2. Do not exceed 90psi when using pneumatic tools.

3. Do not kink, twist, knot or abrade hose;

Applicable Range:

is applicable for pneumatic tool and accessories.

Specifications:

Air tools Maximum Working Pressure .......... 90psi

Operation

Tool use and care

1. Use clamps or another practical way to secure and support the workpiece

to a stable platform, Holding the work by hand or against the body is unstable and to lead

to loss of control.

2. Do not force the tool. Use the correct tool for the application. The correct t0ol

will do the job better and safer at the rate for which the tool is designed.

3. Do not use the tool if the switch does not turn the tool on or off. Any tool that

cannot be controlled with the switch is dangerous and must be repaired.

4. Disconnect the tool from the air source before making any adjustments,

changing accessories, or storing the tool, Such preventive safety measures reduce

the risk of starting the tool unintentionally.

5. Store the tool when it is idle out of children and other untrained persons. A

tool is dangerous in the hands of untrained users.

6, Maintain the tool with care, Keep a cutting tool sharp and clean. A property maintained

too, with sharp cutting edges reduced the risk of binding and is easier to control.

7. Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that affects the tool's operation. If damaged, have the tool

serviced before using. Many accidents are caused by poorly maintained tools. There is a risk

of bursting if the tool is damaged.

8. Use only accessories that are identified by the manufacturer for the specific

tool model. Use of an accessory not intended for use with the specific tool model, increases

the risk of injury to persons.

Service

1, Too| service must be performed only by qualified repair personnel,

2. When servicing a tool, use only identical replacement parts. Use only

authorized parts.

3. Use on|y the lubricants supplied with the tool of specified by the

manufacturer.

Air source

1. Never connect to an air source that is capable of exceeding 115psi.Over

pressurizing the tool is able to result in busting, abnormal operation, and breakage of the

tool or serious injury to persons. Use only clean, dry, regulated compressed air at the rated

pressure or within the rated pressure range as marked on the tool. Always verify prior to using

the tool that the air source has been adjusted to the rated air pressure or within the rated

air-pressure range.

2. Never use oxygen, carbon dioxide, combustible gases or any bottled gas as an air source for

the tool. Such gases are capable of explosion and serious injury to persons.

USER-MAINTENANCE INSTRUCTIONS

SAVE THESE iNSTRUCTiONS

ENG-4

Read Operating instructions

Please become familiar with all the instructions and

warnings before operating any pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should meet or exceed

the standards set forth in ANSi Z87.1, Occupational and

Educational Eye and Face Protection. Look for marking

Z87.1 on your eye protection to ensure that it is an

approved style.

Hearing Protection is Recommended

Hearing protection should be used when the noise level

exposure equals or exceeds an 8 hour time-weighted

average sound level of 85dBA. Process noise, reflective

surfaces, other tools being operated nearby, all add to the

noise level in a given work area. if you are unable to

determine your noise level exposure, we recommend the

use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use. Prolonged

exposure to vibration or very repetitive hand and arm

movements can cause injury. Discontinue the use of any

tool if you experience tingling, numbness, discomfort or

pain in your hands or arms. You should consult your

physician before resuming use of tool.

90 PSi Maximum

This tool is designed to operate at an air pressure of 90

pounds per square inch gauge pressure (90 PSi)

maximum, at the tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher air pressure

places the internal components under loads and

stresses they were not designed for, causing premature

tool failure.

NOTE: THEAIR SUPPLY SHOULD BE CLEAN, DRYAND

PREFERABLY LUBRICATED. FOR BEST RESULTS

DRAIN THE MOISTURE FROM YOUR COMPRESSOR

DAILY.

Use Only impact Sockets & Accessories

Only use sockets designated "FOR USE WiTH iMPACT

WRENCHES." Hand tool sockets can break, creating a

hazard from flying pieces. Always check sockets,

retainers and drives regularly for wear or damage and

replace when necessary.

I

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemi-

cals known to the Stateof California cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

- Lead from lead based paint

• crystalline silica from bricks and cement

and other masonry products, and

, arsenic and chromium from chemically-

treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as dust masks that

are specifically designed to filter out microscopic par-

ticles.

FULL ONE YEAR WARRANTY ON

CRAFTSMAN AIR=DRIVETOOLS

If this Craftsman tool fails to give complete satisfaction

within one year from the date of purchase, RETURN iT

TO THE NEAREST SEARS STORE IN THE UNITED

STATES, and Sears will repair or replace it free of charge.

If this Craftsman tool is used for commercial or rental

purposes, this warranty applies for only 90 days from the

date of purchase. This warranty gives you specific legal

rights, and you may also have other rights which vary

from state to state.

Distributed by Sears, Roebuck and Co.

Hoffman Estates, IL 60179.

The Craftsman Model 875.191183 1/2" Square Drive

impact Wrench is ideal for genera assembly,

automotive, agricultural and industrial applications.

Features

, Built-in regulator for power output adjustment.

• Pin type clutch for increased power output.

• Ring-type socket retainer allows quick socket

changes.

Specifications

Drive size...............................................................................1/2"

impacts per minute .................................................... 550 IPM

Free speed (No Load) ........................................... 7,500 RPM

Ultimate torque ....................................................... 300 ft. Ibs.

Weight ............................................................................. 41/2Ibs.

Overall length....................................................................... 71/2"

Average air consumption ........................................ 4.4 SCFM

Recommended hose size........................................... 3/8" I.D.

Air inlet..........................................................................1/4" NPT

Maximum Air Pressure .................................................. 90 PSi

Pre=Operation

Before the tool is connected to the air supply, clear the air

hose of accumulated dust and moisture by running air

freely through the air hose for 5-10 seconds. Before

removing a tool for service or changing sockets, make

sure the air line is shut-off at the compressor. This will

prevent the tool from operating if the throttle is accidently

engaged.

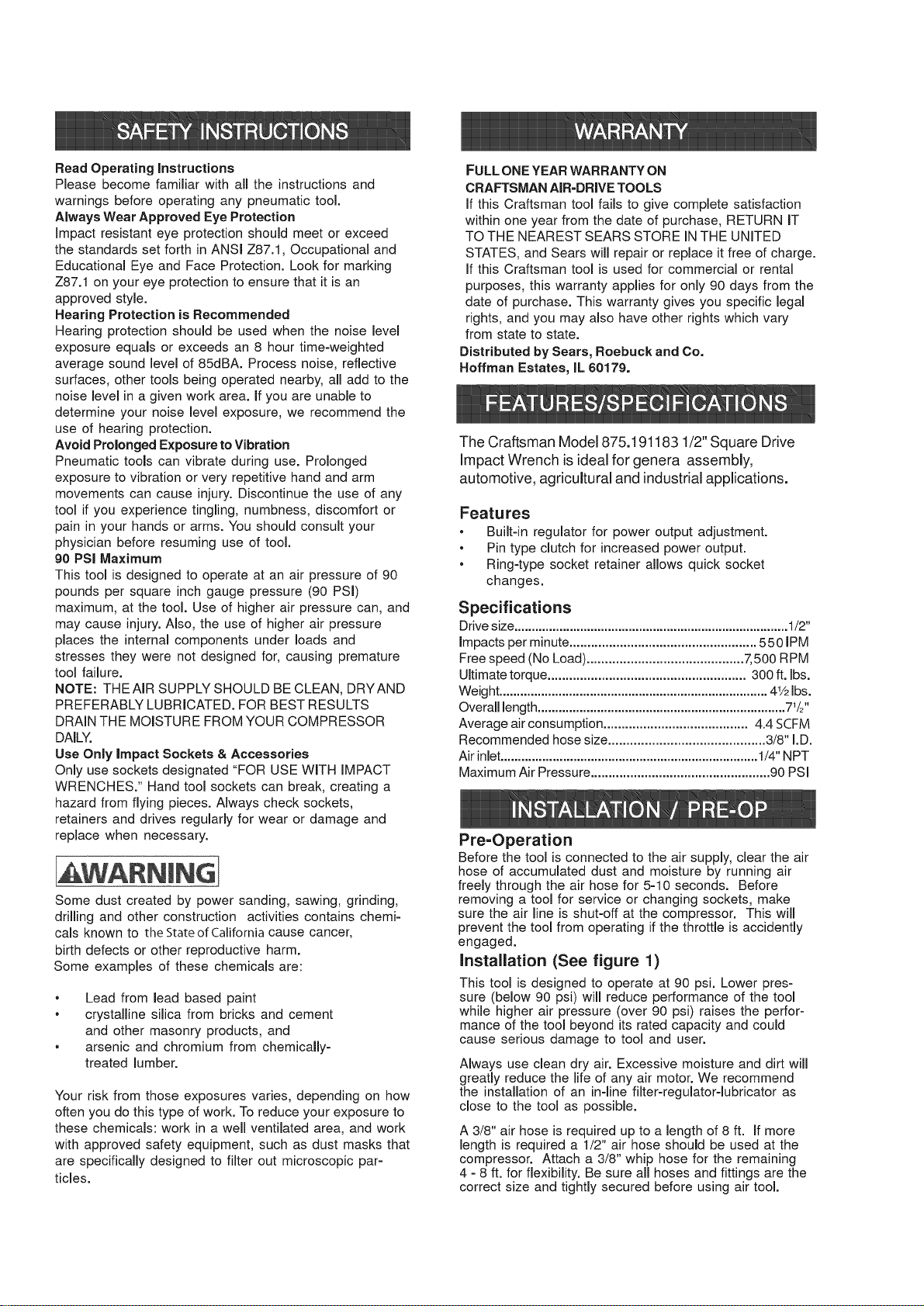

Installation (See figure 1)

This tool is designed to operate at 90 psi. Lower pres-

sure (below 90 psi) will reduce performance of the tool

while higher air pressure (over 90 psi) raises the perfor-

mance of the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air motor. We recommend

the installation of an in-line filter-regulator-lubricator as

close to the tool as possible.

A 3/8" air hose is required up to a length of 8 ft. if more

length is required a 1/2" air hose should be used at the

compressor. Attach a 3/8" whip hose for the remaining

4 - 8 ft. for flexibility. Be sure all hoses and fittings are the

correct size and tightly secured before using air tool.

e Drai

--_ More 1/100slope

than

Air Hose Hook Up

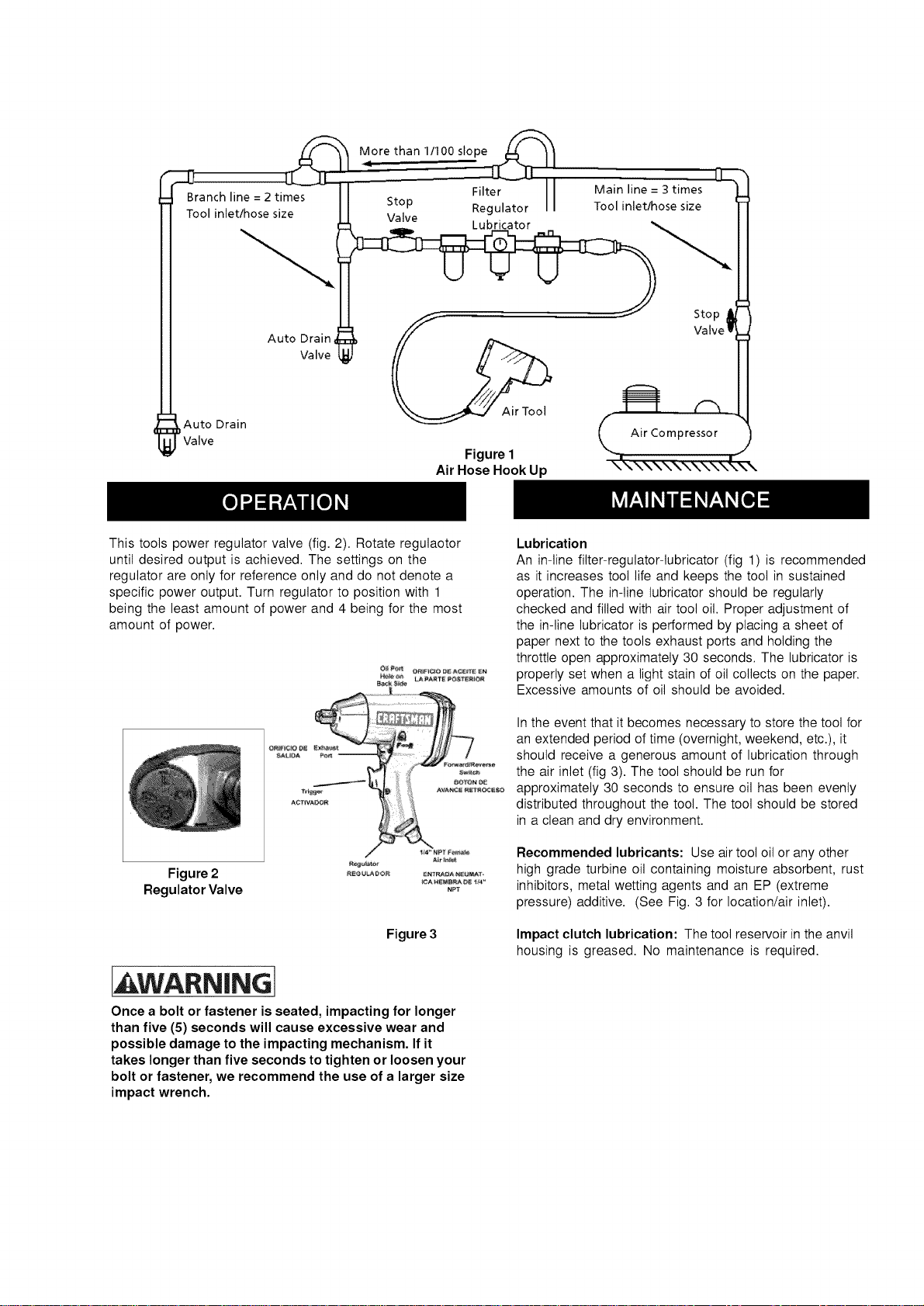

This tools power regulator valve (fig. 2). Rotate regulaotor

until desired output is achieved. The settings on the

regulator are only for reference only and do not denote a

specific power output. Turn regulator to position with 1

being the least amount of power and 4 being for the most

amount of power.

.......... } ...................

ACT_W_O_

Figure 2

Regulator Valve

_rp_r

Figure 3

[AWARNING

Once a bolt or fastener is seated, impacting for longer

than five (5) seconds will cause excessive wear and

possible damage to the impacting mechanism. If it

takes longer than five seconds to tighten or loosen your

bolt or fastener, we recommend the use of a larger size

impact wrench.

Lubrication

An in-line filter-regulator-lubricator (fig 1) is recommended

as it increases tool life and keeps the tool in sustained

operation. The in-line lubricator should be regularly

checked and filled with air tool oil. Proper adjustment of

the in-line lubricator is performed by placing a sheet of

paper next to the tools exhaust ports and holding the

throttle open approximately 30 seconds. The lubricator is

properly set when a light stain of oil collects on the paper.

Excessive amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

should receive a generous amount of lubrication through

the air inlet (fig 3). The tool should be run for

approximately 30 seconds to ensure oil has been evenly

distributed throughout the tool. The tool should be stored

in a clean and dry environment.

Recommended lubricants: Use air tool oil or any other

high grade turbine oil containing moisture absorbent, rust

inhibitors, metal wetting agents and an EP (extreme

pressure) additive. (See Fig. 3 for location/air inlet).

Impact clutch lubrication: The tool reservoir in the anvil

housing is greased. No maintenance is required.

Loading...

Loading...