Page 1

Owner's Manual

Pneumatic 3/8" Drive

RATCHET WRENCH

Model No.

875.191170

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

• Safety

• Warranty

• Features & Operation

• Maintenance

• EspaSol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

w3_rw.sears.cGn_

Page 2

Read Operating instructions

Please become familiar with all the instructions and

warnings before operating any pneumatic tool.

Always Wear Approved Eye Protection

Impact resistant eye protection should meet or exceed

the standards set forth in ANSI Z87.1, Occupational and

Educational Eye and Face Protection. Look for marking

Z87.1 on your eye protection to ensure that it is an

approved style.

Hearing Protection is Recommended

Hearing protection should be used when the noise level

exposure equals or exceeds an 8 hour time-weighted

average sound level of 85dBA. Process noise, reflective

surfaces, other tools being operated nearby, all add to the

noise level in a given work area. If you are unable to

determine your noise level exposure, we recommend the

use of hearing protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use. Prolonged

exposure to vibration or very repetitive hand and arm

movements can cause injury. Discontinue the use of any

tool if you experience tingling, numbness, discomfort or

pain in your hands or arms. You should consult your

physician before resuming use of tool.

90 PSiG Maximum

This tool is designed to operate at an air pressure of 90

pounds per square inch gauge pressure (90 PSIG)

maximum, at the tool. Use of higher air pressure can, and

may cause injury. Also, the use of higher air pressure

places the internal components under loads and

stresses they were not designed for, causing premature

tool failure.

NOTE: THE AIR SUPPLY SHOULD BE CLEAN, DRY AND

PREFERABLY LUBRICATED. FOR BEST RESULTS

DRAIN THE MOISTURE FROM YOUR COMPRESSOR

DAIL_

Use Only Impact Sockets & Accessories

Sockets and accessories used shall be of the impact

socket type. Always check sockets, retainers and drives

regularly for wear or damage and replace when

necessary.

FULL TWO YEAR WARRANTY ON

CRAFTSMAN AIR-DRIVE TOOLS

If this Craftsman tool fails to give complete satisfaction

within two years from the date of purchase, RETURN IT

TO THE NEAREST SEARS STORE IN THE UNITED

STATES, and Sears will repair it free of charge. If this

Craftsman tool is used for commercial or rental

purposes, this warranty applies for only 90 days from the

date of purchase. This warranty gives you specific legal

rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co. Dept. 817WA, Hoffman

Estates, iL 60179.

The Companion Model 875.191170 3/8" Drive

Ratchet Wrench is designed for applications such as

automotive repair, general assembly, transmission

teardown and maintenance. Features include a lever

throttle for speed control and low profile head for work in

close quarters.

Features

Lever throttle for ease of operation.

1-1/8" Ratchet head height (without socket) for use in

close-quarter applications.

Front exhaust directs air away from operator.

Specifications

Maximum Torque ......................................... 45 ft.-Ibs.

Air inlet ........................................................ 1/4" NPT

Maximum operating pressure .......................... 90 PSI

Free speed .................................................. 160 RPM

Air consumption .............................................. 4 CFM

Drive size ............................................................. 3/8"

Overall length ........................................................ 10"

Weight ........................................................... 2½ Ibs.

Hose Size ............................................................ 3/8"

[ WARNINGI

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemi-

cals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals

are:

Lead from lead based paint

crystalline silica from bricks and cement

and other masonry products, and

arsenic and chromium from chemically-

treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as dust masks that

are specifically designed to filter out microscopic par-

ticles.

Pre-Operation

Before the tool is connected to the air supply, clear the air

hose of accumulated dust and moisture by running air

freely through the air hose for 5-19 seconds. Before

removing a tool for service or changing sockets, make

sure the air line is shut-off at the compressor. This will

prevent the tool from operating if the throttle is accidenfiy

engaged.

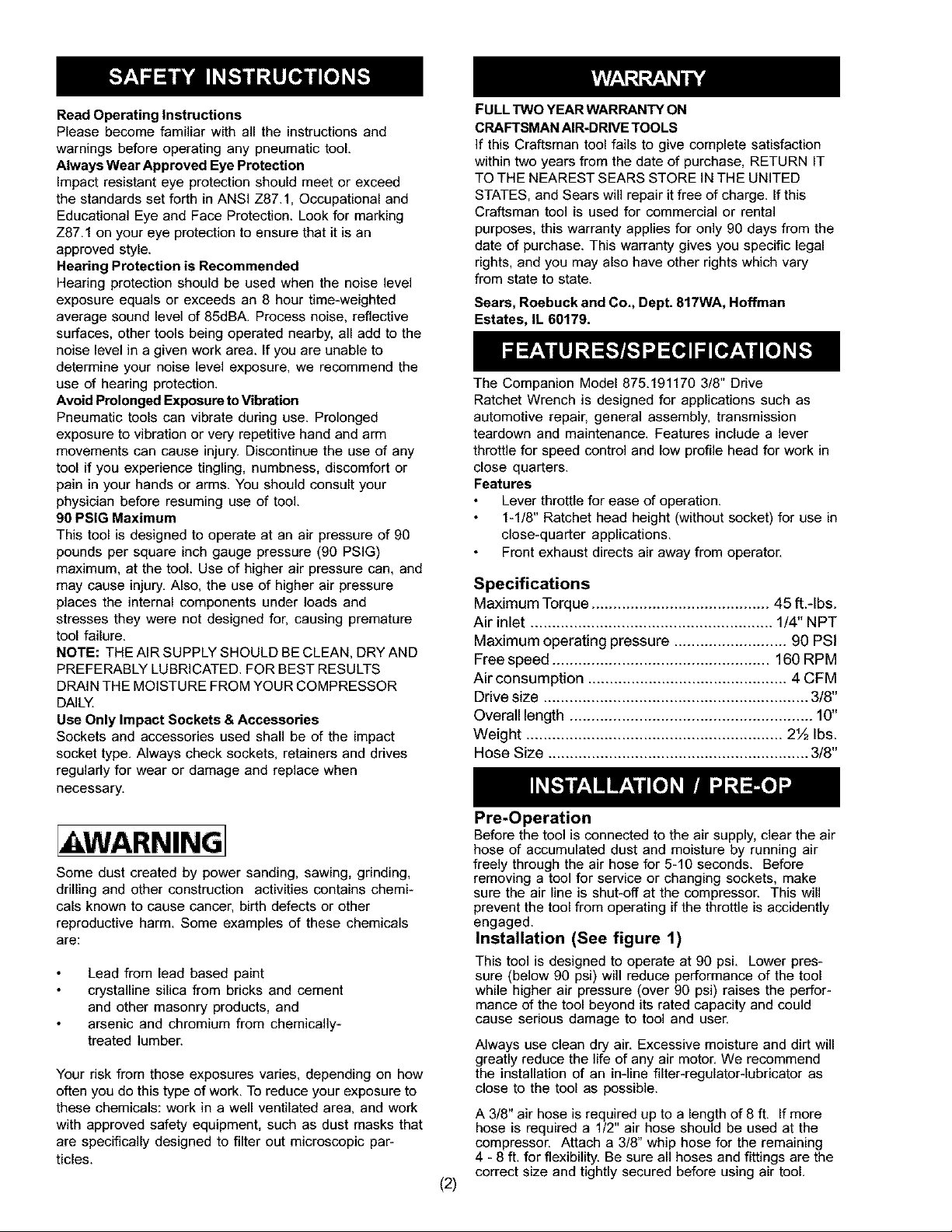

Installation (See figure 1)

This tool is designed to operate at 99 psi. Lower pres-

sure (below 90 psi) will reduce performance of the tool

while higher air pressure (over 90 psi) raises the perfor-

mance of the tool beyond its rated capacity and could

cause serious damage to tool and user.

Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air motor. We recommend

the installation of an in-line filter-regulator-lubricator as

close to the tool as possible.

A 3/8" air hose is required up to a length of 8 ft. If more

hose is required a 1/2" air hose should be used at the

compressor. Attach a 3/8" whip hose for the remaining

4 - 8 ft. for flexibility. Be sure all hoses and fittings are the

correct size and tightly secured before using air tool.

(2)

Page 3

More than 1/100 slope

JI

Stop

Valve Lubricator

olinlet_ose_

AutoDrain

Iianch line=2times

VaIve

toDrain

lye

This ratchet is equipped with a lever throttle which

allows the operator to vary the speed.

Initial tightening and loosening of fasteners should be

done manually with the ratchet being used as a hand

tool. Fasteners maythen be run on and off with

relative ease.

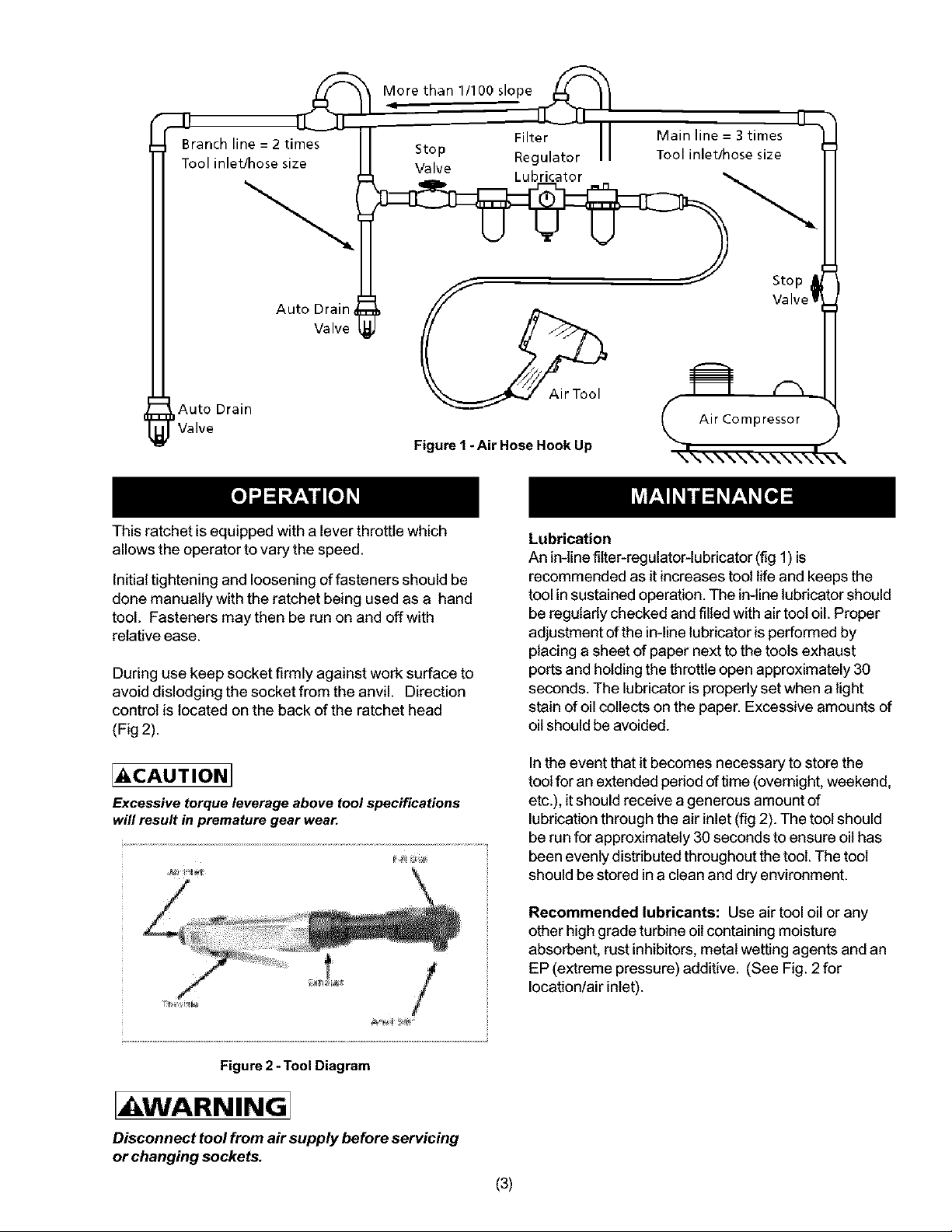

During use keep socket firmly against work surface to

avoid dislodging the socket from the anvil. Direction

control is located on the back of the ratchet head

(Fig 2).

Figure 1 *Air Hose Hook Up

Filter

Air Tool

Lubrication

An in-line fitter-regulator-lubricator (fig 1) is

recommended as it increases tool life and keeps the

tool in sustained operation. The in-line lubricator should

be regularly checked and filled with air toot oil. Proper

adjustment of the in-line lubricator is performed by

placing a sheet of paper next to the tools exhaust

ports and holding the throttle open approximately 30

seconds. The lubricator is properly set when a light

stain of oil collects on the paper. Excessive amounts of

oil should be avoided.

Main line = 3 times

Tool inlet/hose size

Stop

Valve!

I ICAUTiONI

Excessive torque leverageabove tool specifications

will result inpremature gear wear.

1t_7I;<Ii!7

Figure2 - ToolDiagram

IAiWARNING]

Disconnect tool from air supply before servicing

or changing sockets.

In the event that it becomes necessary to store the

tool for an extended period of time (overnight, weekend,

etc.), it should receive a generous amount of

lubrication through the air inlet (fig 2). The tool should

be run for approximately 30 seconds to ensure oil has

been evenly distributed throughout the tool. The tool

should be stored in a clean and dry environment.

Recommended lubricants: Use air tool oil orany

other high grade turbine oil containing moisture

absorbent, rust inhibitors, metal wetting agents and an

EP (extreme pressure) additive. (See Fig. 2for

location/air inlet).

(3)

Page 4

Sears Craftsman Model 875.191170

Pneumatic 3/8" Drive Ratchet Wrench

Exploded View and Parts List

9 8 7 6 5

33 35 36 37

32

Ref. Part No. Description Qty. Ref. Part No. Description Qty.

1 910341B Air Inlet 1

2 910302 Housing 1

3 910303 Roll Pin 1

4 910304 Throttle Lever 1

5 9110305 Valve Pin 1

6 9110306 Valve Pin 1

7 9110307 Spring 1

8 9103120 O Ring 1

9 9110309 Valve Plug 1

10 965815 Ball Bearing 1

11 9110311 Rear End Plate 1

12 9110312 Rotor 1

13 962817 Vanes 1

14 9110314 Cylinder 1

15 9110315 Front end Plate 1

16 962821 Bearing 1

17 9110317 Washer 1

18 962823 Thread Ring Gear 1

19 962824 Idler Gear 1

20 965825 Idler Gear Pin 1

21 9110321 Idler Gear Plate 1

22 9110322 Spacer 1

23 910323 Clamp Nut 1

24 910324 Ratchet Housing 1

25 962829 Spacer 1

26 910326 Crank Shaft 1

27 910327 Drive Bushing 1

28 910328 Yoke 1

29 910329 Lock Pin 1

30 910330 Spring 1

31 910331 Reverse Button 1

32 910332 Wave Washer 2

33 910333 Ratchet Pawl 1

34 910334 Ratchet Anvil 1

35 962840 Pin 1

36 910338 Thrust Washer 1

37 962844 Retaining Ring 1

(4)

Page 5

Troubleshooting

Tool runs slowly or will not operate

Moisture blowing out of tool exahust 1, Water in tank 1. Drain tank, (See air compressor manual). Oil tool

1. Grit or gum in tool 1, Flush the tool with air tool oil or gum

2. No oil in tool

3. Low air pressure

4. Air hose leaks

5. Pressure drops

6. Worn rotor blade in motor

7. Worn ball bearing

in motor 7. Remove and inspect bearing for rust, dirt and

solvent.

2. Lubricate the tool according to the lubrication

instructions in this manual

3. Adjust the compressor regulator to tool maxi-

mum of 90 psi.

4. Tighten and seal hose fittings if leaks are found.

Use teflon tape.

5.a. Be sure the hose is the proper size. Long

hoses or tools using large volumes of air may

require a hose with an I.D. of 1/2" or larger

depending on the total length of the hose

b. Do not use a multiple number of hoses

connected together with quick connect fittings.

This causes additional pressure drops and

reduces the tool power. Directly connect the

hoses together

6. Replace rotor blade

grit. Replace or clean and grease bearing with

bearing grease

and run until no water is evident. Oil tool again and

run 1-2 seconds

(5)

Page 6

Lea las instrucciones de operacibn

Por favor famiiiaricese con todas ias instrucciones y

advertencias antes de operar cualquier herramienta

neum_tica.

Siempre use proteccibn aprobada para la vista

La protecci6n a la vista resistente al impacto debe

satisfacer o exceder las normas establecidas en ANSi

Z87.1, Protecci6n Educativa y Ocupacional de los Ojos y

el Rostro. Busque la marca Z87.1 en su protecci6n de la

vista para asegurarse que es un estilo aprobado.

Se recomienda proteccibn del Dido

La protecci6n del Dido debe usarse cuando la exposici6n

al nivel del ruido iguaia o excede un nivel promedio de

sonido ponderado de tiempo en 8 horas, de 85dBA.

Ruido del proceso, superficies reflectoras, otras

herramientas que se operan en ia cercania, todos

agregan al nivel del ruido en una _rea de trabajo dad& Si

usted no puede determinar su exposici6n al nivel de

ruido, recomendamos el use de protecci6n de Dido.

Evite exposicibn prolongada a la vibrscibn

Las herramientas neum_ticas pueden vibrar durante el

uso. Una exposici6n prolongada a la vibraci6n o

movimientos muy repetitivos de ia mano y el brazo

pueden causar lesiones. DiscontinQe el uso de

cuaiquiera herramienta si usted experimenta cosquilleo,

entumecimiento, incomodidad o dolor en sus manos o

brazos. Usted debe consultar con su medico antes de

reanudar el uso de herramienta.

90 PSI milximas

Esta herramienta est_ disefiada para operar a una

presi6n atmosf6rica m_xima de 90 libras por pulgada

cuadrada de medidor de presi6n (90 PSI), en la

herramienta. El uso de presiones atmosf6ricas m_s

altas puede causar iesiones. Tambi6n, el uso de

presiones atmosf6ricas m_s aitas coloca a los

componentes interiores bajo cargas y tensiones para las

que no fueron disefiados, causando una falla prematura

de la herramienta.

HERRAMIENTAS DE OPERACION NEUMATICA CRAFTSMAN

Siesta herramienta Craftsman no ie proporciona una satisfacci6n

compieta dentro de los dos afios de la fecha de compra,

DEVUELVALAA LATiENDA MAS CERCANADESEARS EN LOS

ESTADOS UNIDOS, y Sears la reparaci6n librede cargo. Siesta

herramienta Craftsman se usa para fines comerciales ode alquiler,

esta garantfa s61ose aplica durante 90dias desde la fecha de

compra. Esta garantia leproporciona derechos iegales

especificos, y usted tambi6n puede tener otros derechos que

varian de estado aestado.

Sears, Roebuck y Cia., Dept. 817WA, Hoffman

Estates, IL 60179.

La Ilave a cremallera de impulso Companion Modelo 875.191170

de 3/8" est_ dlsefiada para aplicaciones tales como reparaciones

automotrices, ensamble general, desarmado y mantenimiento de

transmisiones. Las caracteristicas incluyen una acelerador

a palanca para el control de velocidad y un cabezal de bajo

perfil para trabajos en espacios estrechos.

Caracteristicas

• Acelerador a palanca para facilidad de operaci6n.

• Altura del cabezal a cremallera de 1-1/8" (sin cubo) para usar

en aplicaciones en espacios estrechos.

• Escape delantero dirige el escape de aire alejado del

operador.

Espeeificaciones

Par torsor m_ximo .................................. 45 pies. libras

Entrada neum_tica ................................. 1/4" NPT

Presi6n max. de operaci6n .................... 90 PSi

Velocidad libre ........................................ 160RPM

Consumo neum_tico ............................... 4PCM

Tamafio del impulsor .............................. 3/8"

Largo total ............................................... 10"

Peso ......................................................... 2 1/2 Ibs.

Tamafio de la manguera ......................... 3/8"

NOTA: EL SUMiNISTRO NEUMATiCO DEBE ESTAR

LIMPIO, SECO Y PREFERENTEMENTE LUBRIFICADO.

PARA OBTENER LOS MEJORES RESULTADOS, DRENE

DiARiAMENTE LA HUMEDAD DE SU COMPRESOR.

Use sblo cubes y accesorios contra impacto

S6io use cubos designados PARA USO CON LLAVES DE

iMPACTO .Los cubos de la herramienta manual pueden

romperse, creando un riesgo por ]as piezas expeiidas.

inspeccione siempre regularmente los cubos,

retenedores e impulsores por desgaste o dafios y

reempiace cuando sea necesario.

ADVERTENCIA

Aigo del polvo creado por iijado, aserrado, desgastado

mec_nico, y otras actividades de construcci6n, contienen

quimicos conocidos coreD causantes de c_ncer,

defectos cong6nitos o otras iesiones al sistema

reproductivo. Aigunos ejemplos de estos quimicos son:

• El plomo en la pintura basada en plomo.

• La silice cristalina de los iadrillos y cemento

y otros productos de albafiileria, y el ars6nico y

cromo de ia madera quimicamente tratada.

Su riesgo de esas exposiciones varia, dependiendo de

cu_n a menudo usted hace este tipo de trabajo. Para

reducir su exposici6n a estos quimicos: trabaje en una

_rea bien ventilada, y con un equipo de seguridad

aprobado, como m_scaras protectoras contra el polvo

que se disefian especificamente para filtrar particulas

microsc6picas.

Pre-Operacibn

Antes que la herramienta se conecte al suministro neum&tico,

limpie ia manguera neum&tica de polvo y humedad acumulados,

haciendo circular aire a trav6s de la manguera neum_tica durante

5-10 segundos. Antes de extract una herramienta para prestar

servicio o cambiar cubos, asegt_rese que la tuberia neum&tica est6

cerrada en el compresor. Esto evitar_ que la herramienta funcione

si el acelerador se activa accidentalmente.

Instalacibn (Yea la figura 1}

Esta herramienta est& disefiada para operar a 90 psi, una presi6n

menor (menor de 90 psi) reduce el rendimiento de la herramienta,

mientras que una presi6n neum_tica mayor (mayor de 90 psi)

eleva el rendimiento de la herramienta m_s all_ de su capacidad

nominal y puede causar lesiones graves y daf_os extensos al

usuario y a ia herramienta.

Use siempre aire limpiD seco. Una humedad y suciedad excesivos

reducir_ substancialmente la duraci6n de cualquier motor

neum_tico. Recomendamos la instalaci6n de un filtro-regulador-

lubricador en linea tan cerca como sea posible de la herramienta.

Se requiere una manguera neum_tica de 3/8" hasta un largo de 8

pies. Si se requiere una largo mayor debe usarse una manguera

neum_tica de 1/2" en el compresor. Fije una manguera de tipo

"l&tigo" de 3/8" para los 4-8 pies restante, por flexibilidad. Antes

de usar la herramienta neum&tica, asegQrese que todas las

mangueras y adaptadores scan del tamafio correcto y est6n bien

asegurados

(6)

Page 7

_] Tu rl rln I I v la ]-_

- Filtro be ap cpa =3 eces

tamaao de la__i_TUnbenc_derlla ahdearra12iVeenCe_ la V41vula Regulador entrada de la herramienta/

_., In_inaciOn m_sde 1/100

Ve% ro

V_lvula de

autodrenaje Compresor de aire

Figura 1 - Preparaci6n de Tuberia de Aire Recomendada

aire

.,%\\.,\\\\\\..t \\

Esta herramienta a cremallera est& equipada con un acelerador

a palanca que permite que el operador varie la velocidad.

El aflojamiento y ajuste inicial de los sujetadores debe

efectuarse manualmente usando la cremallera coma una

herramienta manual. A continuaci6n los sujetadores pueden

colocarse y extraerse con relativa facilidad.

Durante el usa mantenga el cuba firmemente contra la superficie

de trabajo para evitar que el cuba se separe del yunque. El

control de direcciOn esta ubicado en la parte posterior del

cabezal de cremallera (Fig,2),

Figura 2 - Diagrama de la herramienta

Lubricacide

Se recomienda usar un flltra-reg ulador-lubricador en linea (fig 1)

yaque incrementa la duraciOnde la herramienta y mantiene la

misma en una operaci6n sostenida, El lubricador enllnea debe

inspeccionarse regularmente y Ilenarse con aceite para

herramientas neum&ticas, Un ajuste apropiado del lubricador en

linea seefectQa co]ocando una haja de papel cerca de los

orificios de escape neum&ticos de laherramienta ymanteniendo

el acelerador abierto par 30 segundos aproximadamente, El

lubdcador est_aprapiadamente regulado cuando una mancha

leve de aceite se deposita sabre el papeL Deben evitarse

cantidades excesivas de aceite.

En el caso que se haga necesario almacenar la herramienta par

un periodo prolongado (durante la noche, fin desemana, etc,), ]a

misma debe recibir una gran cantidad de lubricaci6n a trav6s de

la entrada neum_tica (fig 3). La herramienta debe hacerse

funcionar par 30 segundos aproximadamente para asegurar que

el aceite se haya distribuido uniformementa a trav6s de ]a

herramienta, Laherramienta debe almacenarse en un ambiente

limpio y seco.

Lubricantes recomendados: Use aceite de herramienta

neum&tica ocualquier otroaceite deturbina de grado elevado

quecontenga un absorbenta de humedad, inhibidores de 6xido,

agentas humectantes de metal y un aditivoEDP (presi6n

extrama), (Vea la Fig,3 parla ubicaci6n/entrada neum&tica),

PRECAUCION

El forzar el par torsor sabre las especificaciones de la

herramienta resulta en un desgaste prematuro del

engranaje

(7)

Page 8

Llave a cremallera de impulso Companion Modelo 875.191170

de 3/8" Craftsman Sears

Vista ampliada y lista de piezas

9 8 7 6 5

_ 33 35 36 37

28

Ref. No. depieza Descripcibn Cant. Ref. No. depieza Descripcibn Cant.

910341B Entrada de aire 1 20 965825 Clavija del engranaje

2

910362 Recinto 1 intermedio 1

3

910303 Clavija rodante 1 21 9110321 Placa del engranaje

4

910304 Palanca del acelerador 1 intermedio 1

5

9110306 Clavija de la v_lvula 1 22 9116322 Separador 1

6

9110306 Clavija de la vblvu]a 1 23 910323 Tuerca de la mordaza 1

9110307 Resorte 1 24 916324 Recinto de la cremallera 1

8

9103120 Anillo t6rico 1 25 962829 Separador 1

9

9110309 Tap6n de la v_lvula 1 26 910326 CigL_eSal 1

16

965815 Rodamiento 1 27 910327 Cojinete del impulsor 1

11

9110311 Placa del extremo 28 916328 Yugo 1

12 9110312 Rotor 1 30 916330 Resorte 1

13 962817 Aletas 1 31 910331 Bot6n de retroceso 1

14 9116314 Cilindro 1 32 910332 Arandela ondulada 2

15 9110315 Placa del extremo 33 910333 Ret6n de la cremailera 1

16 962821 Rodamiento 1 38 962840 Clavija 1

17 9110317 Arandela 1 36 910338 Arandela de empuje 1

18 962823 Engranaje anular 37 962844 Anillo retenedor 1

19 962824 Engranaje intermedio 1

posterior 1 29 910329 Clavija de seguridad 1

delantero 1 34 916334 Yunque de la cremallera 1

roscado 1

(8)

Page 9

Localizacibn de fallas

La herramienta funciona con lentitud o no funciona

1. Suciedad o goma en la herramienta

2. No hay aceite en la herramienta

3. PresiSn neum_tica baja

4. Pedida de la manguera neum_tica

5. Baja de presiSn

6. Hoja del rotor desgastada en el

motor

7. Rodamiento desgastado en el

motor

1. Limpie la herramienta con aceite de herramienta

neum_tica o solvente para goma.

2. Lubrique la herramienta de acuerdo con las

instrucciones de lubricaci6n en este manual

3. Ajuste el regulador del compresor a la m_xima de

la herramienta de 90 psi.

4. Ajuste y selle los adaptadores de la manguera si

se hallan p6rdidas. En ese caso use cinta de tefl6n.

5. a. Asegt]rese que la manguera tenga el tamaSo

apropiado. Mangueras largas o herramientas que

usan un gran volumen de aire pueden requerir una

manguera con un di_metro interno de 1/2" o mayor

dependiendo de la Iongitud total de la manguera.

b. No use una cantidad mt]ltiple de mangueras

conectadas juntas con adaptadores de conexiSn

r_pida. Esto causa caidas de presiSn adicionales y

reduce la potencia de la herramienta. Conecte

directamente las mangueras juntas

6. Reemplace la hoja del rotor

7. Extraiga e inspeccione el rodamiento por

desgaste, suciedad y hollin. Reemplace o limpie y

engrase el rodamiento con grasa para rodamientos

Escape hQmedo de la

herramienta

1. Agua en el tanque 1. Drene el tanque. (Vea el manual del compresor

neum_tico). Aceite la herramienta y haga funcionar

hasta que no sea evidente la presencia de agua.

Aceite nuevamente la herramienta y haga funcionar

por 1-2 segundos

(9)

Page 10

Your Home

For repair - in your home - of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner's manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-MY-HOME ® (1-800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location ofyour nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anytime, day or night (U.S.A. only)

www.sears.com

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655 (U,S,A.) 1-800-361-6665 (Canada)

For after sale

support and assistance

1-800-290-9054

® Registered Trademark / TMTrademark / SMService Mark of Sears, Roebuck and Co.

® Marca Registrada / TMMarca de F_brica / SMMarca de Servicio de Sears, Roebuck and Co.

MCMarque de commerce / MDMarque d6pos6e de Sears, Roebuck and Co. © Sears, Roebuck and Co.

Loading...

Loading...