Craftsman 875190280 Owner’s Manual

,_ Owner's Manual

CRRFTSMRN"

Pneumatic

4" CHIPPING HAMMER

Model No.

875.190280

WARNING:

Before operating tool, read this

manual and follow all

Safety Recommendations and

Operating Instructions.

Safety

Warranty

Features & OperaUon

Maintenance

Espanol

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Read Operating instructions

Please become familiar with all the instructions

and warnings before operating any pneumatic

tool.

Always Wear Approved Eye Protection

Impact resistanteye protection should meet or

exceed the standards set forth in ANSI Z87.1, Occu-

pational and Educational Eyeand FaceProtection.

Look for marking Z87.1 on your eye protection to

ensure that it isan approved style.

FULL TWO YEAR WARRANTY ON

CRAFTSMAN AIR-DRIVE TOOLS

ifthisCraftsmantoolfailstogivecompletesatisfaction

withintwoyearsfromthedateofpurchase,RETURN

IT TO THE NEAREST SEARS SERVICE CENTER/

DEPARTMENTINTHE UNITEDSTATES,andSears

willrepairorreplaceitfreeofcharge.If thisCraftsman

toolis usedforcommercialor rental purposes,this

warTantyappliesfor only90 daysfrom thedateof

purchase.Thiswarrantygivesyouspecificlegal

rights,andyoumayalsohave otherrightswhichvary

from statetostate.

Hearing Protection is Recommended

Hearing protection should be usedwhen the noise

level exposure equals or exceeds an 8 hour time-

weighted average sound level of 85dBA. Process

noise, reflective surfaces,other tools being operated

nearby, all add to the noise level in a given work area.

If you are unable to determine your noise level

exposure, we recommend the useof hearing

protection.

Avoid Prolonged Exposure to Vibration

Pneumatic tools can vibrate during use. Prolonged

exposureto vibration orvery repetitive hand and arm

movements, can cause injury. Discontinue the use ot

any tool if you experience tingling, numbness, dis-

comfort or pain in your hands or arms. You should

consultyour physicianbefore resuming useof tool.

90 PSIG Maximum

Thistool isdesigned to operate at an air pressure of

90 pounds per square inch gauge pressure (90 PSIG)

maximum, at the tool. Use of higher air pressure can,

and may cause injury. Also, the use of higher air

pressureplacesthe internal components under loads

and stressesthey were not designed for, causing

premature toolfailure.

NOTE: THE AIR SUPPLY SHOULD BE CLEAN AND

DRY, PREFERABLY LUBRICATED. FOR BEST

RESULTS DRAIN THE MOISTURE FROM YOUR

COMPRESSOR DAILY,

Sears, Roebuck and Co., Dept. 817WA, Hoffman

Estates, IL 60179.

The Craftsman Model 875.190280 4" Chipping

Hammer features a 4 bolt back head design to

eliminate handle loosening and breakage. The

variable speed trigger provides easy start-up and

better control while the heat treated barrel and

retainer provide maximum durability and long

service life.

Features

• Four bolt backhead design

• Adjustableexhaustdeflector

• 3/8"-24 inlet bushing

The Craftsman Model 875,190280 chipping

hammer isdesignedto operate on 90 PSIG.Lower

pressure(below 90 PSIG)will reduceperformance

of the tool, while higher air pressure(over 90 PSIG)

raisesthe performance of the tool beyond its rated

capacityand could causeseriousdamage to tool

and user.

Always useclean dry air. Excessivemoisture and dirt

will greatly reduce the life of any air motor. We

recommend the installation of an in-line

filter-regulator-lubricator as closeto the tool as

possible.

A 1/2" air hose isrequired ensure the tool has the

necessary air supply. Be sure all hoses and fittings

are the correct size and tightly secured.

(2)

1_003

WARNING:

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

reproductive harm. Some examples of these chemicals

are:

Lead from lead-based paints

Crystalline silica from bricks, cement arid other

masonry products

Arsenic and chromium from chemically treated

lumber

Your risk from these exposures vades, depending on

how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated

area and work with approved safety equipment such as

those dust masks that are specially designed to filter out

microscopic particles.

WARNING: Disconnecttoolfromair supplybefore

servicingor changing chisels.

To Install Chisel:

Designedfor use with oval .680 round shank collar

chisels.

Remove retainer spring (red. # 2t) from retainer (ref. #

20). Slide retainer (ref. # 20) off the cylinder (ref. # 16).

Insertchisel throughretainer (ref. # 20) oval hole.Turn a

1/4 of a turn until chiselseats and piece chisel and

retainer (ref.# 20) on cylinder(ref. # 16), Insert retainer

springintoslot on retainer spring (ref. # 21)slide around

groovooncylinderrof,# 16.

Before the toolis aonnected to the air supply,clearthe air

hose of accumulateddust and moisture and add several

dropsof air toolell.

ToRemove Chisel:

1. Remove retainer swing (red.# 21).

2. Remove retainer (ref. # 20) with chisel.

Lubrication

An automatic in-linefllter-regu|ator-lubdcatoris recom-

mended as it in.eases tool life and keeps the tool in

sustained operation,The in-line lubricator should be

chedr.edregularlyand filled withair tool oil.Proper

adjuaimenlof the in-linelubricatoris performed by

placinga sheet of paper next to the exhaust portsand

holdingthe throttleopen approximately30 seconds.The

lubricatoris properlyset when a lightstainof oll collects

on the paper. Excessive amountsof oil shouldbe

avoided.

In the event that it becomes necessaryto store the toolfor

an extended periodof time (overnight,weekend, etc.), it

shouldreceive a generous amountof lubricationat that

time.The toolshould be run for approximately30 sec-

onds to ensure oil has been evenly distributedthroughout

the tool. The tool should be stored in a dean and dry

environment.

Recommended lubricants: Use airtool oilor any other

high grade turbine oil containingmoisture absorbent, rust

inhibltom,metal wetting agents and an EP (extreme

pressure) additive.

Specifications

Chiselsize................................................... 680" Oval Collar

Blowsperminuta ...................................................1.700BPM

Len_ ................................................................................16½

Weighl..............................................................................20 Ib8,

Airinlet...........................................;..............................3/8"NPT

new,ram,ended_ si_e...........................................I/2" I.D.

Averageair consumption...............................................5 CFM

Maximumoperatingpressure......................................90 PSI

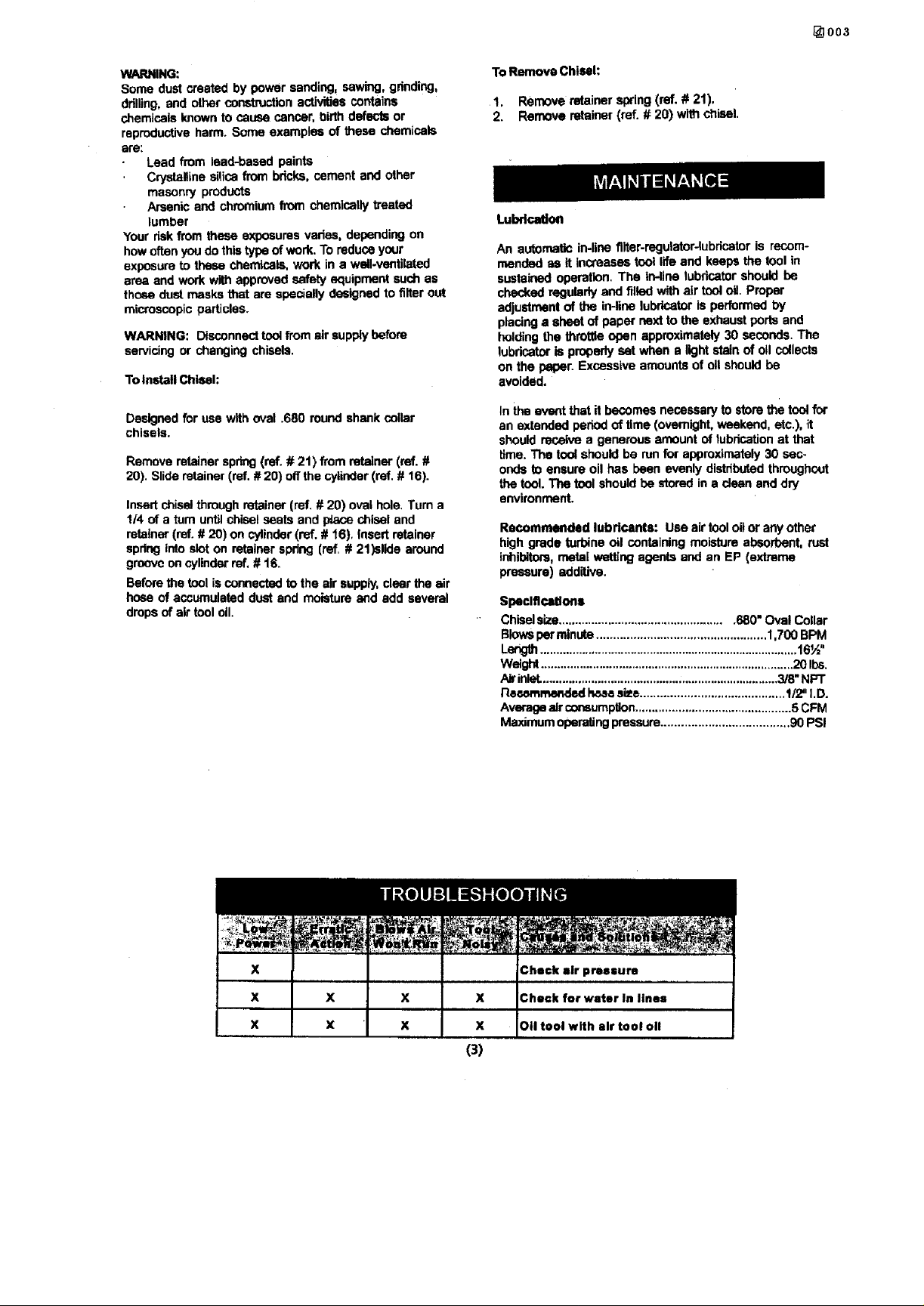

4 a

X Check air prtesure

X X X Check for wirer In lines

X X X X 011tool with air tool oll

(3)

Loading...

Loading...