Page 1

2723303

Owner's Manual

1

E185030

Serial No.

NOTE: Model and serial numbers may be found on the name plate

located on the tool.

You should record both numbers and retain them in a safe place.

CAUTION: Before using this Nailer, read this manual and follow all

its Safety Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Page 2

TABLE OF CONTENTS

SECTION PAGE

Warranty.................................................................................................2

Product Specifications........................................................................ 2

Safety Instructions................................................................................3

Accessories and Attachments

Know Your Brad Nailer

.........................................................................

.............................................................

Operation ............................................................................................. 7

Maintenance ..........................................................................................8

Troubleshooting Guide.........................................................................9

Parts .....................................................................................................10

WARRANTY

FULL ONE YEAR WARRANTY ON CRAFTSMAN PROFESSIONAL

ELECTRIC NAILER

If this Craftsman Nailer fails due to a defect in material or workmanship within

one year from the date of purchase, Sears will REPAIR it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY RETURNING THE

TOOL TO THE NEAREST SEARS STORE OR CRAFTSMAN OUTLET IN

THE UNITED STATES .

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

6

7

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

PRODUCT SPECIFICATIONS

Power Source

Nailing Speed

Nail Size - Diameter

- Head size

- Length

Magazine Capacity

Dimensions

Weight

AWARNING

To avoid electrical hazards, fire hazards, or damage to the tool, use proper

circuit protection.

Your nailer is wired at the factory for 120V operation. Connect to a 120V, 15 amp

branch circuit and use a 15 amp time delay fuse or circuit breaker. To avoid shock

or fire, replace power cord immediately if it is worn, cut or damaged in any way.

120V, 60Hz, 9 Amps., AC only

1 Nall per Second

.039 ' .049 inch

.070 ' .087 inch ■'

3/8 - 1 -3/16 inch

100 Nails

8-1/2 inches long x 2-1/2 inches wide x 10 i.^.ches high

4.7 pounds

Page 2

Page 3

SAFETY

GENERAL SAFETY

6. DONT FORCE THE TOOL It will do

INSTRUCTIONS

A WARNING

Do not attempt to operate this tool until

you have read and thoroughly

understand all instructions, safety

rules, etc., contained in this manual.

Failure to comply can result in accidents

involving fire, electric shock, or serious

personal injury. Save this owner’s

manual and review it frequently for

continuing safe operation and instructing

possible third-paiiy users.

7. USETHERIGHTTOOL. Donotuse

8. ALWAYSWEAR SAFETY GOGGLES

READ ALL INSTRUCTIONS

9. DON’T ABUSE TOOL POWER

1. KEEP WORK AREA CLEAN.

Cluttered work areas and benches

invite injuries.

2. GUARD AGAINST ELECTRICAL

SHOCK. Be sure your body does

not come in contact with grounded

surfaces such as pipes, radiators,

ranges, refrigerators, etc.

3. AVOID DANGEROUS WORK AREA

ENVIRONMENT. Do not use power

tools in damp or wet locations. Keep

work area well lit. Do not expose

power tools to rain. Do not use

power tools in the presence of

flammable liquids or gases.

4. KEEP CHILDREN AWAY. All visitors

should wear safety goggles or safety

glasses with side shields and be

kept a safe distance from work area.

Do not let visitors come in contact

with tool or extension cords.

5. STORE IDLE TOOLS. When not in

use, store tools in a high, dry

location that can be locked,

KEEP THEM OUT OF THE REACH

OF CHILDREN.

the job better and safer if used at

the rate for which it was designed.

a too! for a purpose it was not

intended. For example, do not force

a small tool or attachment to do the

job of a heavy-duty tool.

or safety glasses with side shields

when using power tools. Also use

a face mask or dust mask if the job

is dusty.

CORD. Never carry the tool by the

cord or yank the cord to disconnect

it from the wall. Keep the cord away

from heat, oil, and sharp edges.

10. SECURE WORK. Whenever

possible, use clamps or a vise to

hold the work. It’s safer than using

your hands and it frees both hands

to use ii ic luoi.

11. DONT OVERREACH. Keep proper

footing and balance; make sure

your footing is stable.

12. KEEP TOOL WELL MAINTAINED.

Follow instructions for lubricating

and changing accessories. When

applicable, keep tool sharp and

clean. Inspect cord frequently and

have damaged parts repaired by a

Sears'service center. Keep tool

handle and housing clean, dry and

free of grease and oil. Never use

strong solvents or petroleum-based

products to clean tool.

SAVE THESE INSTRUCTIONS

Page 3

Page 4

13. DtSC0NNECTT00L when not in

use, before servicing and when

ioading or changing accessories.

17. REPLACEMENT PARTS, When

14. AVOID UNINTENTIONAL

STARTING. Never carry tool with

your finger on the switch.

18. WEAR HEARING PROTECTION

15.STAY ALERT. Watch what you are

doing and use common sense. Do

not operate tool when you are tired

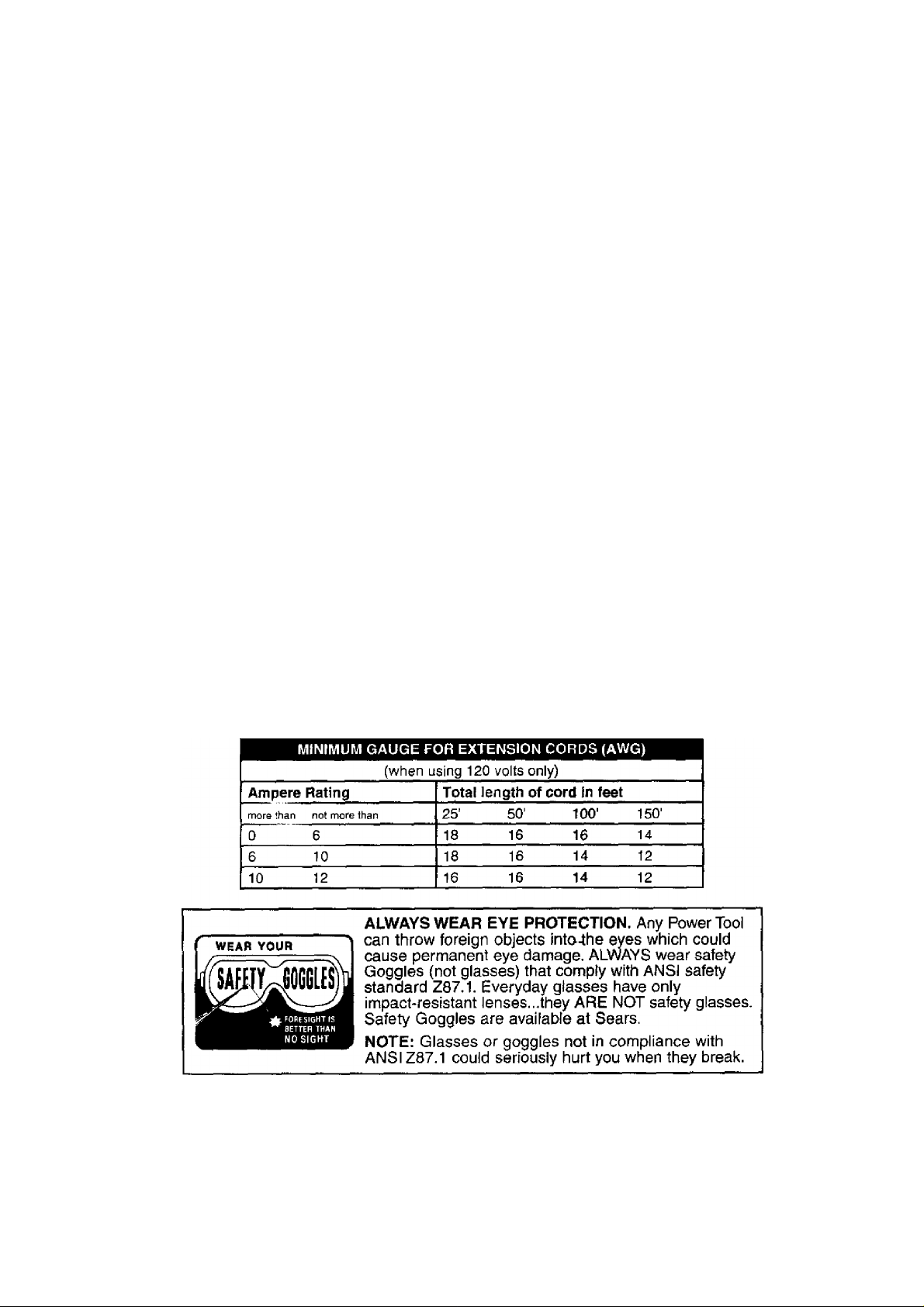

GUIDELINES FOR EXTENSION CORDS

or under the influence of drugs,

alcohol, or medication.

If you are using an extension cord

outdoors, be sure it is marked with the

16. CHECK Dmi'kiAGED PARTS, Before

using too!, check that ail parts will

operate correctly and will perform as

designed. Any damaged parts

should be repaired or replaced by

an authorized Sears service facility.

Also, check for misalignment,

binding, and broken parts. Check

that the switch works properly and

DO NOT USE TOOL IF THE

SWITCH DOES NOTTURNTHE

TOOL ON AND OFF.

suffix “W-A" (“W” in Canada) to indicate

that it is acceptable for outdoor use.

Be sure your extension cord is

properly wired, and in good electrical

condition. Always replace a damaged

extension cord or have it repaired by a

qualified person before using it.

Protect your extension cords from

sharp objects, excessive heat and

damp or wet areas.

servicing, use only identical

replacement parts ordered from a

Sears service facility.

during extended periods of

operation.

SAVE THESE INSTRUCTIONS

Page 4

Page 5

SPECtFIC SAFETY INSTRUCTIONS FOR THIS NAILER

A WARNING

DO NOT AIM NAILER OR SHOOT

NAILS AT A PERSON OR ANIMAL.

Released nails can cause severe injuries.

10.OUR1NG OPERATION, the nailer

may feel warm to the touch. This is

normal. However, if the nailer starts

to feel hot, discontinue use until the

unit cools down.

GROUNDING INSTRUCTIONS

1. USE ONLY THE NAILS INDICATED

in this manual. Use of accessories

that are not designed for this tool

could result in personal injury and/or

damage to the tool.

2. DO NOT TOUCH metal parts of tool

during operation. Hold only plastic

handle or housing.

3. KEEP tacking speed at one nail

per second.

4. NAILER should be used only for

the purposes outlined in this manual.

It is designed for use on wood.

Do not use on hard surfaces like

rock, concrete, etc. personal injury

or damage to the tool could result.

5. When nailing thin wood, special

caution must be taken for

possible penetration of naiis

through the wood.

6. When using this tool in high '

locations, ALWAYS make sure there

is no one below that could be

injured. ALWAYS be sure you have

a firm footing when using this tool.

IN THE EVENT OF A MALFUNCTION

OR BREAKDOWN, grounding provides

a path of least resistance for electric

current to reduce the risk of electric

shock. This tool is equipped with an

electric cord having an equipment

grounding conductor and a grounding

plug. The plug must be plugged into a

matching outlet that is properly installed

and grounded in accordance with all

local codes and ordinances.

DO NOT MODIFY THE 3-PRONG

PLUG. If it will not fit the outlet, have the

proper outlet installed by a qualified

electrician. Improper connection of the

equipment-grounding conductor can

create a risk of shock. The conductor

with insulation having an outer surface

that is green (sometimes, but not always

with yellow stripes) is the equipment

grounding conductor.

REPAIR OR REPLACE DAMAGED OR

WORN CORD IMMEDIATELY, if repair

or replacement of the electric cord or

plug is ever necessary. DO NOT connect

the equipment-grounding conductor to

a live terminal.

7. ALWAYS hold tool firmly.

8. NEVER connect tool to a DC

power source.

9. REGULAR CLEANING, inspection

and maintenance is necessary.

SAVE THESE INSTRUCTIONS

Page 5 .

Page 6

3-Prong Plug

Grounding Prong

Properfy Grounded

3-Prong Outlet

Figure B

Grounding Lug

Adapter

Make Sure This

is Connected to a

Known Ground

2-Prong

Receptacle

FIGURE (A) Shows a 3-wire electrical

plug and outlet that has a grounding

conductor. If a properly grounded outlet

is not available, an adapter (FIGURE B)

can be used to temporarily connect

this plug to a 2-contact ungrounded

outlet. The adapter (FIGURE B) has a

rigid lug extending from it that MUST

be connected to a permanent earth

ground, such as a properly grounded

outlet box. The Canadian Electrical

Code prohibits the use of adapters.

USE ONLY 3-WIRE EXTENSION

CORDS THAT HAVE 3-PRONG

GROUNDING PLUGS AND 3-POLE

RECEPTACLES THAT ACCEPT THE

TOOL’S PLUG.

ACCESSORIES AND ATTACHMENTS

AVAILABLE ACCESSORIES

Visit your Sears Hardware Department

or see the Craftsman Power and

Handtool Catalog for the following

brad nails;

Sears Stock No.

Inch .

27218 3/8

27216

27215

27214

These brad nails can be used for;

Cabinet making

Interior decorations

Wood furniture building/repair

Display assembly

Picture frames

Door & window trim

3/4 20

1 25

1-3/16 30

mm.

10

A WARNING

If you have any doubts as to whether

the tool is properly grounded or if the

grounding instructions are unclear,

check with a qualified electrician or

service technician.When using a

grounded tool around other ungrounded

devices, be sure that the ungrounded

devices are in good condition. An

ungrounded device can function, yet

have internal electrical problems that

could cause a hazard when brought in

contact with a grounded tool.

THE ADAPTER SHOULD ONLY BE USED

until a properly grounded outlet can

be installed by a qualified electrician.

NOTE: Use only brad nails

recommended for this nailer. Using

other sizes may be dangerous.

Sears may recommend other

accessories not listed in this manual.

Do not use accessories unless you

have completely read the instruction

manual for that accessory.

AWARNING

Do not attempt to modify this tool or

create accessories not recommended

for use with this tool. Any such

alteration or modification is misuse

and could result in a hazardous

condition leading to possible serious

personal injury.

Page 6

Page 7

KNOW YOUR BRAD NAILER

OPERATION

HOWTO LOAD YOUR BRAD NAILER (FIGURE 1)

Unplug nailer from power source.

1.

Use only brad nails recommended;

2.

see brad nail chart.

Push up the latch (1) toward the

3.

magazine and slide out the

magazine (2).

Position the nailer exposing the

4.

magazine chamber (3).

5. Load nails into the magazine, nail

points facing down toward the bottom

of the nailer.

6. When loading different lengths,

do not load nail heads into the

upper part of the slot.

Load so that the nail points are at

the bottom of the magazine (4).

7. Close magazine (2), making sure that

the nails stay seated in the track.

8. Make sure that the latch (1 ) is

securely locked.

Page 7

Page 8

TO NAIL (FIGURE 2)

AWARNING

Always wear safety goggles or safety

glasses with side shields when

operating your nailer. Failure to do so

could result in objects being thrown

into your eyes, resulting in possible

serious injury.

1. Plug nailer into 120 Volt, 60Hz

power outlet,

2. Hold nailer firmly with the tacking

mouth (1) flat to the workpiece.

3. Use enough downward pressure to

depress the safety lock pin (2).

NOTE: The safety lock pin must be

depressed for this nailer to operate.

This nailer will not fire unless this

is done.

4. Squeeze the trigger (3) to drive the

brad nail.

5. If the workpiece is very hard, press

down on the housing cap (4) with

your free hand.

NOTE: AVOID BLANK SHOTS to

prevent wear and damage to

internal parts.

AWARNING

Do not allow familiarity of your nailer to

make you careless. Remember that a

careless fraction of a second is sufficient

to inflict severe injury.

Fig. 2

MAINTENANCE

AWARNING

The nailer must be disconnected from

the electrical power source during

maintenance.

STANDARD MAINTENANCE

1. Inspect all screws and tighten

if necessary.

2. Use a clean cloth to remove dirt

from the tool.

3. Do not use gasoline, brake fluid, oils,

or solvents to clean plastic parts.

These chemicals will damage,

weaken, or destroy plastics.

Page 8

4. Do not oil or grease any parts.

5. Keep the nail magazine chamber

dean.

6. Do not rotate or remove housing

cap.

AWARNING

Do not alter, redesign parts on this

nailer, or attach special fixturing. This

can be a source of personal injury.

Page 9

CLEARING A JAMMED NAIL (FIGURE 3)

1. Unplug the cord and remove all

brads from the magazine.

2. Remove the two screws and

washers (1) located on the tacking

mouth cover,

3. Remove the cover (2).

CAUTION: Be careful, the safety

lock pin and spring may shoot forward.

4. Remove safety lock pin (3) and

spring (4).

NOTE: Safety lock pin (3) has a

keyed slot on the pin which is seated

in the opening on the cover (2).

5. Remove the slot cover (5).

6. Remove the jammed nail.

7. Replace all parts in reverse order.

8. Tighten screws.

9. Make sure that the safety lock pin is

correctly sticking out of the tacking

mouth assembly.

Fig.3

PROBLEM

Nailer will not fire

Nail jammed

Power loss

TROUBLESHOOTING

PROBABLE CAUSE

1. Not plugged in

2. Circuit breaker tripped

3. Damaged cord

1. Dirty, rusty, or

deformed nails

2. incorrect nails

1. Damaged coil spring

Page 9

REMEDY

1. Plug in

2. Reset circuit breaker

or fuse

3. Have replaced by Sears

Service Center

1. Replace with new nails

2, Use recommended nail

style and size

I.Have repaired by Sears

Service Center

Page 10

ELECTRIC BRAD NAILER MODEL NUMBER 836.27233

Order by PART NUMBER, not by key number

Key Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Part Number

DCA0060030

DCA0050080

BMS0040010

[3CA0790070

BMDO010000

DHB0040010

BMS0040361

BMS0040210

DHA0190010

DAA0320060

2723301

2723302

2723303

2723304 ,

Description

Slot-cover (B)

Slot-cover (A)

Screw

Safety cover

Washer

Housing screw

Screw

Screw

Safety spring

Safety lock pin (Guide bar)

Screwdriver

Carry case

Owner’s manual

Hex Key

Page 10

Page 11

siavd

Page 12

13

ICMFnHHirj,

(U«mc Mullen

==_^,

11

^=Ь=щ^^

14

Page 13

For the repair or replacement parts you need

delivered directly to your home

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

For the location of a

Sears Parts and Repair Center in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

Cal! 9 am - 5 pm, Monday-Saturday

1-800-827-6655

The model number of your product is located

on the name plate on the front of the Electric Nailer.

When requesting service or ordering parts,

always give the following information:

• Product Type * Part Number

• Model Number • Part Description

REPAIR SERVICES

America's Repair Specialists

2723303 5/97

Loading...

Loading...