Page 1

Operator's Manual

JCRAFTSMAN°I

BRUSHCU'I-rER A'I-rACHMENT

Model No.

358,792443

NOT DESIGNED FOR USE

WITH ELECTRIC POWERHEADS

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Espar_ol, p. 17

DANGER:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product: Call 7

am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 (Hours listed are Central Time)

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

530164972 9/12/06

Page 2

Warranty Statement 2 Service & Adjustments 14

Identification of Symbols 2 Storage 15

Safety Rules 2

Assembly 5

Parts List 16

Operation 10 Spanish 17

Maintenance 14 Parts and Ordering Back Cover

ONE YEAR FULL WARRANTY ON CRAFTSMAN ® BRUSHCUTTER ATTACHMENT

When used and maintained according to the operator's manual, ifthis product fails

due to a defect in material or workmanship within one year from the date of pur-

chase, return it to any Sears store, Sears Service Center, or other Craftsman outlet in

the United States for free repair (or replacement if repair proves impossible).

This warranty excludes expendable parts that can wear out from normal use in

less than one year.

This warranty applies for only 30 days from purchase date if this product is used

for commercial or rental purposes.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

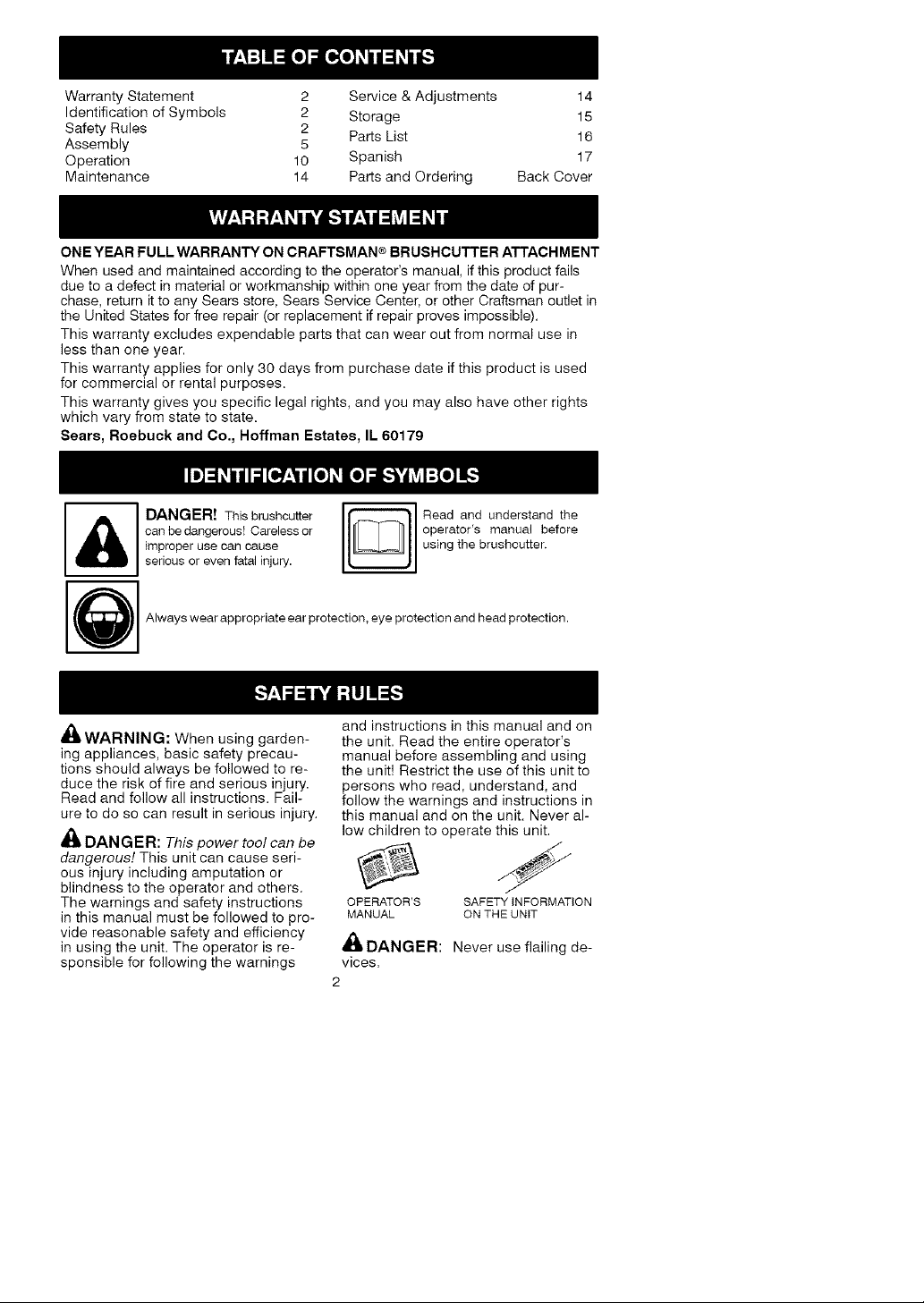

DANGER! This brushcutter

can be dangerous! Carelessor

improperuse can cause

seriousor evenfatal injury.

Always wear appropriate ear protection, eye protection and head protection.

_WARNING: When using garden-

ing appliances, basic safety precau-

tions should always be followed to re-

duce the risk of fire and serious injury.

Read and follow all instructions. Fail-

ure to do so can result in serious injury.

DANGER: This power tool can be

dangerous! This unit can cause seri-

ous injury including amputation or

blindness to the operator and others.

The warnings and safety instructions

in this manual must be followed to pro-

vide reasonable safety and efficiency

in using the unit. The operator is re-

sponsible for following the warnings

Read and understand the

operator's manual before

using the brushcutter.

and instructions in this manual and on

the unit. Read the entire operator's

manual before assembling and using

the unit! Restrict the use of this unit to

persons who read, understand, and

follow the warnings and instructions in

this manual and on the unit. Never al-

low children to operate this unit.

OPERATOR'S SAFETY iNFORMATION

MANUAL QN THE UNIT

A

DANGER: Never use flailing de-

vices.

Page 3

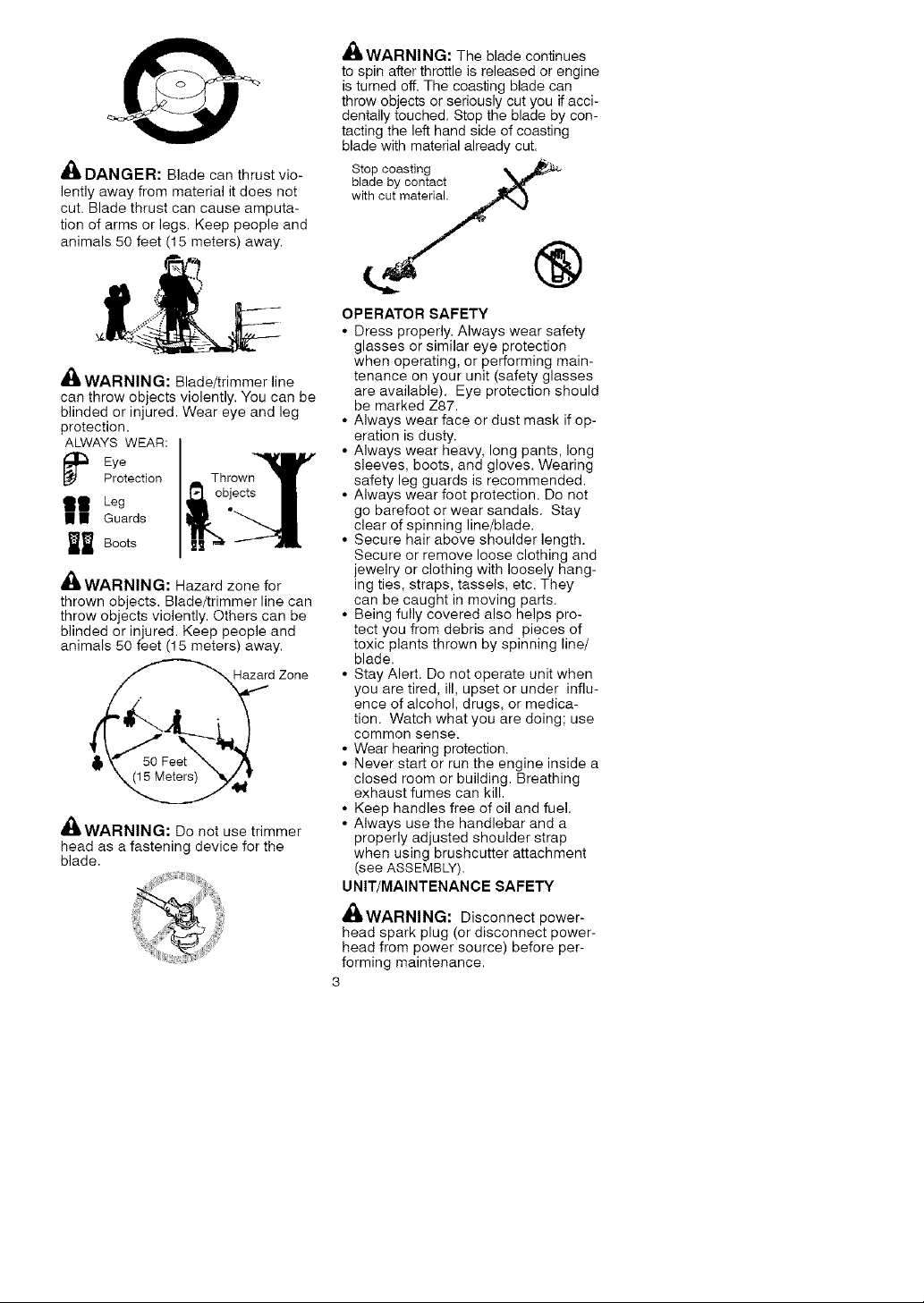

_. DANGER: Blade can thrust vio-

lently away from material it does not

cut. Blade thrust can cause amputa-

tion of arms or legs. Keep people and

animals 50 feet (15 meters) away.

,1_ WARNING: Blade/trimmer line

can throw objects violently. You can be

blinded or injured. Wear eye and leg

protection.

ALWAYS WEAR:

Eye

Protection

II Leg

I I Guards

_ Boots

_WARNING: Hazard zone for

thrown objects. Blade/trimmer line can

throw objects violently. Others can be

blinded or injured. Keep people and

animals 50 feet (15 meters) away.

Hazard Zone

I,t

_.WARNING: Do not use trimmer

head as a fastening device for the

blade.

_, WARNING: The blade continues

to spin after throttle is released or engine

is turned off. The coasting blade can

throw objects or seriously cut you if acci-

dentally touched. Stop the blade by con-

tacting the left hand side of coasting

blade with material already cut.

bS,t°dPeC_yst'onngaot ._

with cut materi_

®

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection

when operating, or performing main-

tenance on your unit (safety glasses

are available). Eye protection should

be marked Z87.

• Always wear face or dust mask if op-

eration is dusty.

• Always wear heavy, long pants, long

sleeves, boots, and gloves. Wearing

safety leg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals. Stay

clear of spinning line/blade.

• Secure hair above shoulder length.

Secure or remove loose clothing and

jewelry or clothing with loosely hang-

ing ties, straps, tassels, etc. They

can be caught in moving parts.

• Being fully covered also helps pro-

tect you from debris and pieces of

toxic plants thrown by spinning line/

blade.

• Stay Alert. Do not operate unit when

you are tired, ill, upset or under influ-

ence of alcohol, drugs, or medica-

tion. Watch what you are doing; use

common sense.

• Wear hearing protection.

• Never start or run the engine inside a

closed room or building. Breathing

exhaust fumes can kill.

• Keep handles free of oil and fuel.

• Always use the handlebar and a

properly adjusted shoulder strap

when using brushcutter attachment

(see ASSEMBLY).

UNIT/MAINTENANCE SAFETY

A_WARNING: Disconnect power-

head spark plug (or disconnect power-

head from power source) before per-

forming maintenance.

3

Page 4

• Lookforandreplacedamagedor

loosepartsbeforeeachuse.Look

forandrepairfuelleaksbeforeuse.

Keepunitingoodworkingcondition.

• Throwawaybladesthatarebent,

warped,cracked,broken,ordam-

agedinanyotherway.Replacetrim-

merheadpartsthatarecracked,

chipped,broken,ordamagedinany

otherwaybeforeusingtheunit.

• Maintaintheunitaccordingtorecom-

mendedprocedures.Keeptheblade

sharp.Neveruseflailingdevices,

wire,rope,string,etc.

• Useonlyspecifiedbladeortrimmer

head;makesureitisproperlyin-

stalledandsecurelyfastened.

• Neverstartenginewithclutchshroud

removed.Theclutchcanflyoffand

causeseriousinjury.

• Besurebladeortrimmerheadstops

turningwhenengineidles.

• Makecarburetoradjustmentswiththe

lowerendsupportedtopreventthe

bladeortrimmerlinefromcontacting

anyobject.Holdtheunitbyhand;do

notusetheshoulderstrapforsupport.

• Keepothersawaywhenmakingcar-

buretoradjustments.

• UseonlyrecommendedCraftsman

accessoriesandreplacementparts.

• Haveallmaintenanceandservice

notexplainedinthismanualper-

formedbyaSearsServiceCenter.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near

fuel or the unit or while using the unit.

• Avoid spilling fuel or oil. Wipe up all

fuel spills before starting engine.

• Move at least 10 feet (3 meters) away

from fueling site before starting engine.

• Stop engine and allow it to cool be-

fore removing fuel cap.

• Remove fuel cap slowly.

CUTTING SAFETY

WARNING: Inspect tile area to be

cut before each use. Remove objects

(rocks, broken glass, nails, wire, string,

etc.) which can be thrown or become

entangled in the blade or trimmer line.

• Keep others including children, ani-

mals, bystanders, and helpers at

least 50 feet (15 meters) away. Stop

the engine immediately if you are ap-

proached.

• Always keep engine on the right-

hand side of your body.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do

not overreach.

• Keep blade/trimmer head below

waist level.

• Do not raise powerhead engine above

your waist.

• Keep all parts of your body away

from spinning blade/line and muffler.

• Cut from your left to your right. CUt-

ting on right side of shield will throw

debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual.

TRANSPORTING AND STORAGE

• Stop the powerhead engine before

carrying unit.

• Keep muffler away from your body.

• Allow engine to cool and secure unit

before storing or transporting it in a

vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fuel in an area where

fuel vapors cannot reach sparks or

open flames from water heaters,

electric motors or switches, furnaces,

etc.

• Store unit so the blade or line limiter

blade on shield cannot accidentally

cause injury.

• Store unit indoors, out of reach of

children.

SPECIAL NOTICE: Exposure to vibra-

tions through prolonged use of gaso-

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or abnor-

mal swellings. Prolonged use in cold

weather has been linked to blood ves-

sel damage in otherwise healthy

people. If symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention. An anti-

vibration system does not guarantee

the avoidance of these problems.

Users who operate power tools on a

continual and regular basis must moni-

tor closely their physical condition and

the condition of this tool.

SAVE THESE INSTRUCTIONS

Page 5

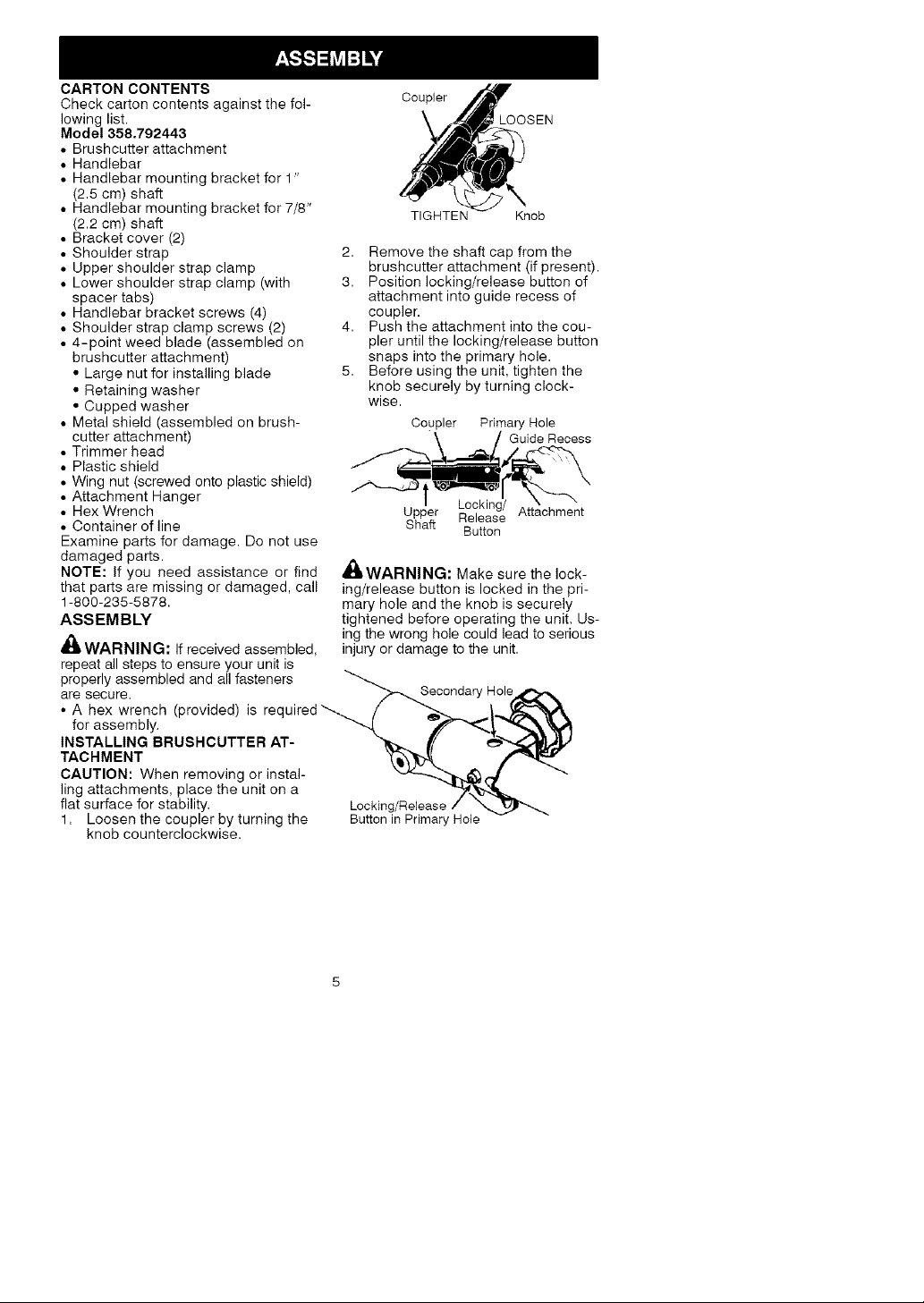

CARTONCONTENTS

Checkcartoncontentsagainstthefol- Coupler

lowinglist. LOOSEN

Model358.792443

• Brushcutterattachment

• Handlebar

• Handlebarmountingbracketfor1"

(2.5cm)shaft

• Handlebarmountingbracketfor7/8" TIGHTEi', Knob

(2.2cm)shaft

• Bracketcover(2)

• Shoulderstrap

• Uppershoulderstrapclamp

• Lowershoulderstrapclamp(with

spacertabs)

• Handlebarbracketscrews(4)

• Shoulderstrapclampscrews(2)

• 4-pointweedblade(assembledon

brushcutterattachment)

• Largenutforinstallingblade

• Retainingwasher

• Cuppedwasher

• Metalshield(assembledonbrush-

cutterattachment)

• Trimmerhead

2. Removetheshaftcapfromthe

brushcutterattachment(ifpresent).

3. Positionlocking/releasebuttonof

attachmentintoguiderecessof

coupler.

4. Pushtheattachmentintothecou-

pleruntilthelocking/releasebutton

snapsintotheprimaryhole.

5. Beforeusingtheunit,tightenthe

knobsecurelybyturningclock-

wise.

Coupler Primary Hole

Guide Recess

• Plasticshield

• Wingnut(screwedontoplasticshield)

• AttachmentHanger Locking/

• HexWrench UpperReleaseAttachment

• Containerofline Shaft

Examinepartsfordamage.Donotuse

Button

damagedparts.

NOTE:Ifyouneedassistanceorfind

thatpartsaremissingordamaged,call

1-800-235-5878.

ASSEMBLY

_i WARNING:Ifreceivedassembled,

,_ WARNING: Make sure the lock-

ing/release button is locked in the pri-

mary hole and the knob is securely

tightened before operating the unit. Us-

ing the wrong hole could lead to serious

injury or damage to the unit.

repeatallstepstoensureyourunitis

properlyassembledandallfasteners

aresecure.

• A hex wrench (provided) is required'_

for assembly.

INSTALLING BRUSHCUTTER AT-

TACHMENT

CAUTION: When removing or instal-

ling attachments, place the unit on a

flat surface for stability. Locking/Release

1. Loosen the coupler by turning the Button in Primary Hole

knob counterclockwise.

Page 6

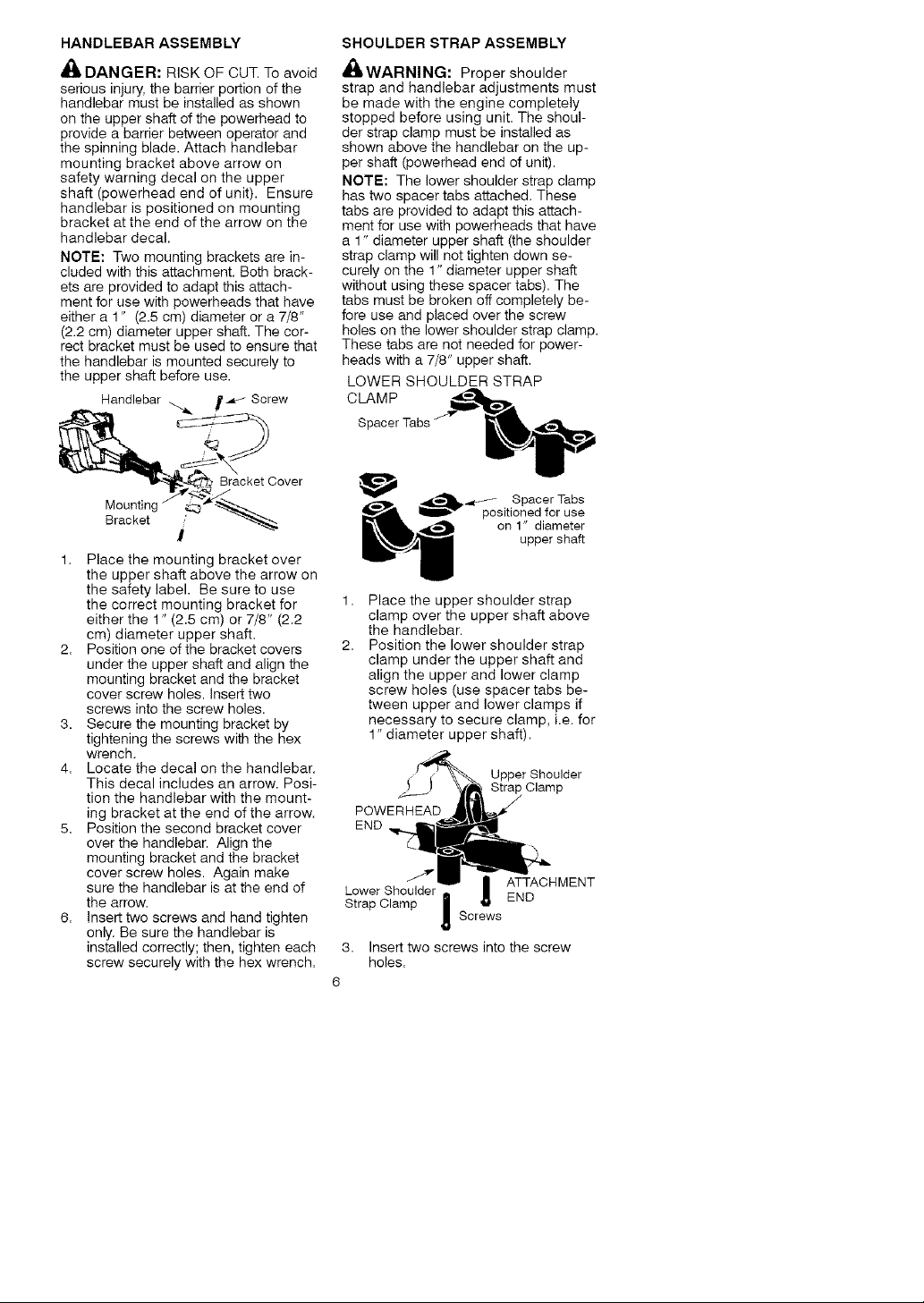

HANDLEBAR ASSEMBLY

,_ DANGER: RISK OF CUT. To avoid

serious injury, the barrier portion of the

handlebar must be installed as shown

on the upper shaft of the powerhead to

provide a barrier between operator and

the spinning blade. Attach handlebar

mounting bracket above arrow on

safety warning decal on the upper

shaft (powerhead end of unit). Ensure

handlebar is positioned on mounting

bracket at the end of the arrow on the

handlebar decal.

NOTE: Two mounting brackets are in-

cluded with this attachment. Both brack-

ets are provided to adapt this attach-

ment for use with powerheads that have

either a 1" (2.5 cm) diameter or a 7/8"

(2.2 cm) diameter upper shaft. The cor-

rect bracket must be used to ensure that

the handlebar is mounted securely to

the upper shaft before use.

Handlebar ._ J_ _ Screw

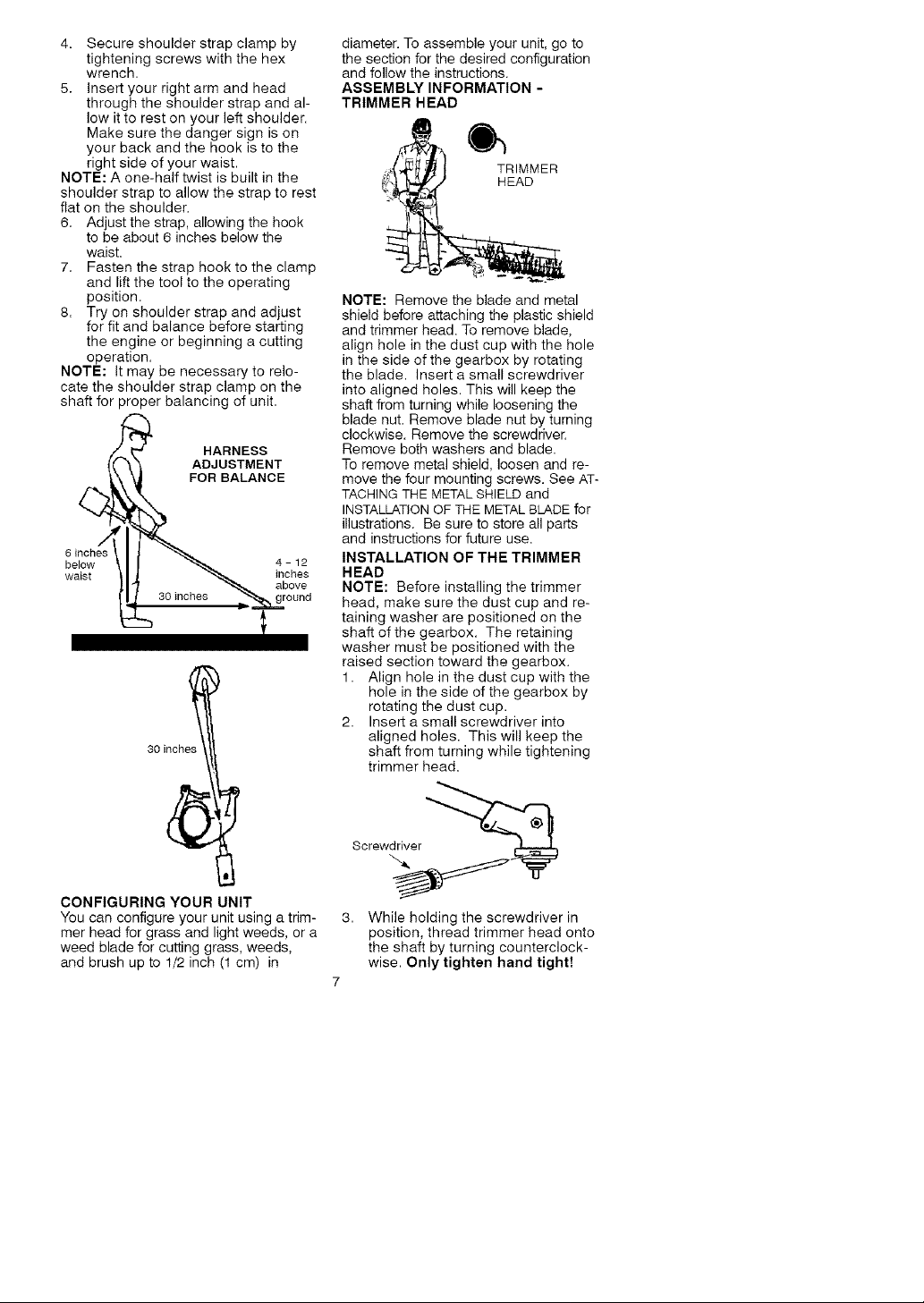

SHOULDER STRAP ASSEMBLY

_bWARNING: Proper shoulder

strap and handlebar adjustments must

be made with the engine completely

stopped before using unit. The shoul-

der strap clamp must be installed as

shown above the handlebar on the up-

per shaft (powerhead end of unit).

NOTE: The lower shoulder strap clamp

has two spacer tabs attached. These

tabs are provided to adapt this attach-

ment for use with powerheads that have

a 1" diameter upper shaft (the shoulder

strap clamp will not tighten down se-

curely on the 1" diameter upper shaft

without using these spacer tabs). The

tabs must be broken off completely be-

fore use and placed over the screw

holes on the lower shoulder strap clamp.

These tabs are not needed for power-

heads with a 7/8" upper shaft.

LOWER SHOULDER STRAP

CLAMP

_et Cover

Bracket .'

I

1. Place the mounting bracket over

the upper shaft above the arrow on

the safety label. Be sure to use

the correct mounting bracket for

either the 1" (2.5 cm) or 7/8" (2.2

cm) diameter upper shaft.

2. Position one of the bracket covers

under the upper shaft and align the

mounting bracket and the bracket

cover screw holes. Insert two

screws into the screw holes.

3. Secure the mounting bracket by

tightening the screws with the hex

wrench.

4. Locate the decal on the handlebar.

This decal includes an arrow. Posi-

tion the handlebar with the mount-

ing bracket at the end of the arrow.

5. Position the second bracket cover

over the handlebar. Align the

mounting bracket and the bracket

cover screw holes. Again make

sure the handlebar is at the end of

the arrow.

6. Insert two screws and hand tighten

only. Be sure the handlebar is

installed correctly; then, tighten each

screw securely with the hex wrench.

.,_L_L_ / Spacer Tabs

1,

Place the upper shoulder strap

clamp over the upper shaft above

the handlebar.

2.

Position the lower shoulder strap

clamp under the upper shaft and

align the upper and lower clamp

screw holes (use spacer tabs be-

tween upper and lower clamps if

necessary to secure clamp, i.e. for

1" diameter upper shaft).

POWERHEAD

END

Lower Shoulder | ATTACHMENT

Strap Clamp n _' END

3. Insert two screws into the screw

holes.

6

positioned for use

Screws

!

on 1" diameter

upper shaft

Strap Clamp

Page 7

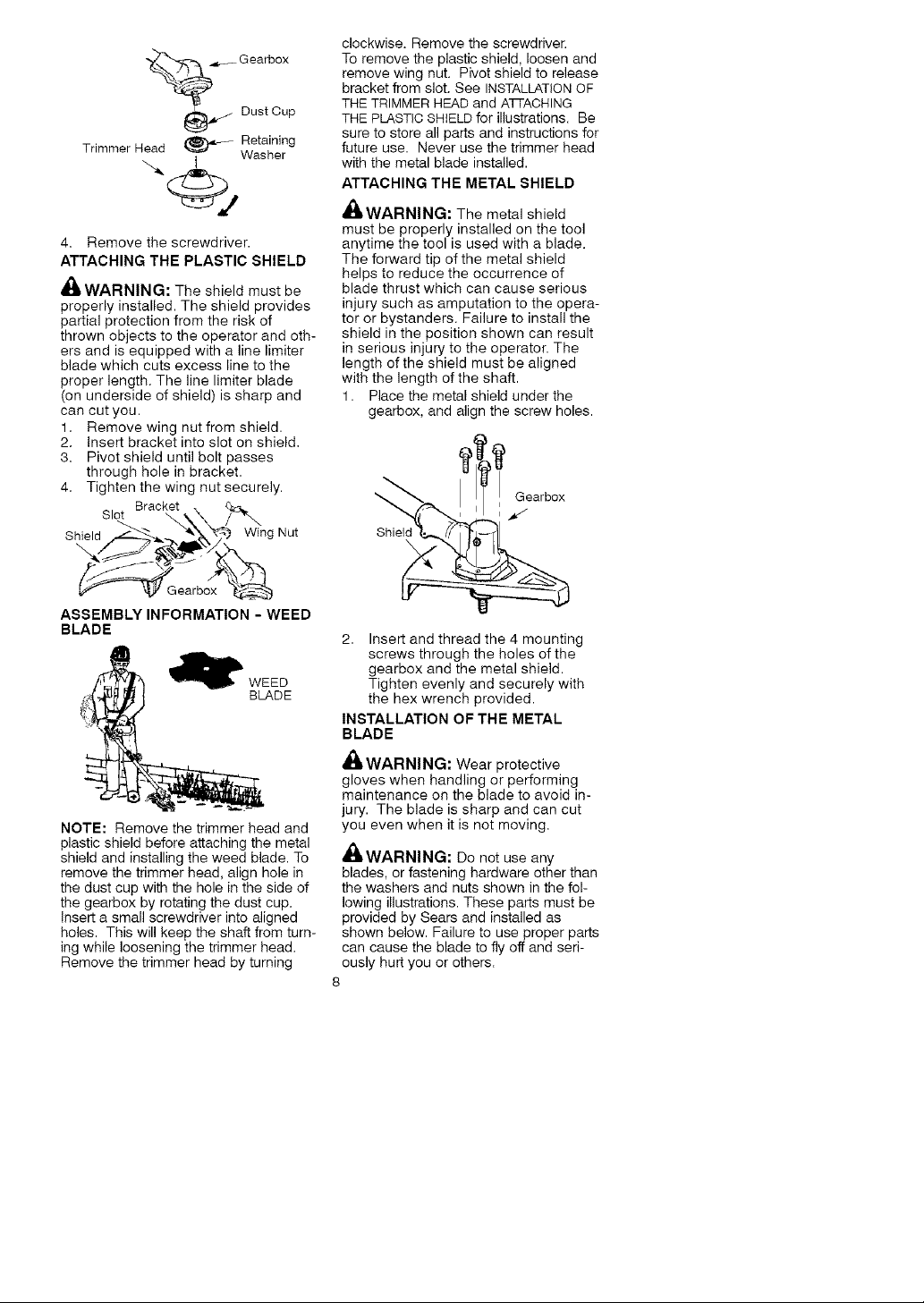

4. Secureshoulderstrapclampby

tighteningscrewswiththehex

wrench.

5. Insertyourrightarmandhead

throughtheshoulderstrapandal-

lowittorestonyourleftshoulder.

Makesurethedangersignison

yourbackandthehookistothe

rightsideofyourwaist.

NOTE:Aone-halftwistisbuiltinthe

shoulderstraptoallowthestraptorest

flatontheshoulder.

6. Adjustthestrap,allowingthehook

tobeabout6inchesbelowthe

waist.

7. Fastenthestraphooktotheclamp

andliftthetooltotheoperating

position.

8. Tryonshoulderstrapandadjust

forfitandbalancebeforestarting

theengineorbeginningacutting

operation.

NOTE:Itmaybenecessarytorelo-

catetheshoulderstrapclamponthe

shaftforproperbalancingofunit.

HARNESS

ADJUSTMENT

FOR BALANCE

6 inches

below 4 - 12

waist inches

30 i

above

ground

diameter. To assemble your unit, go to

the section for the desired configuration

and follow the instructions.

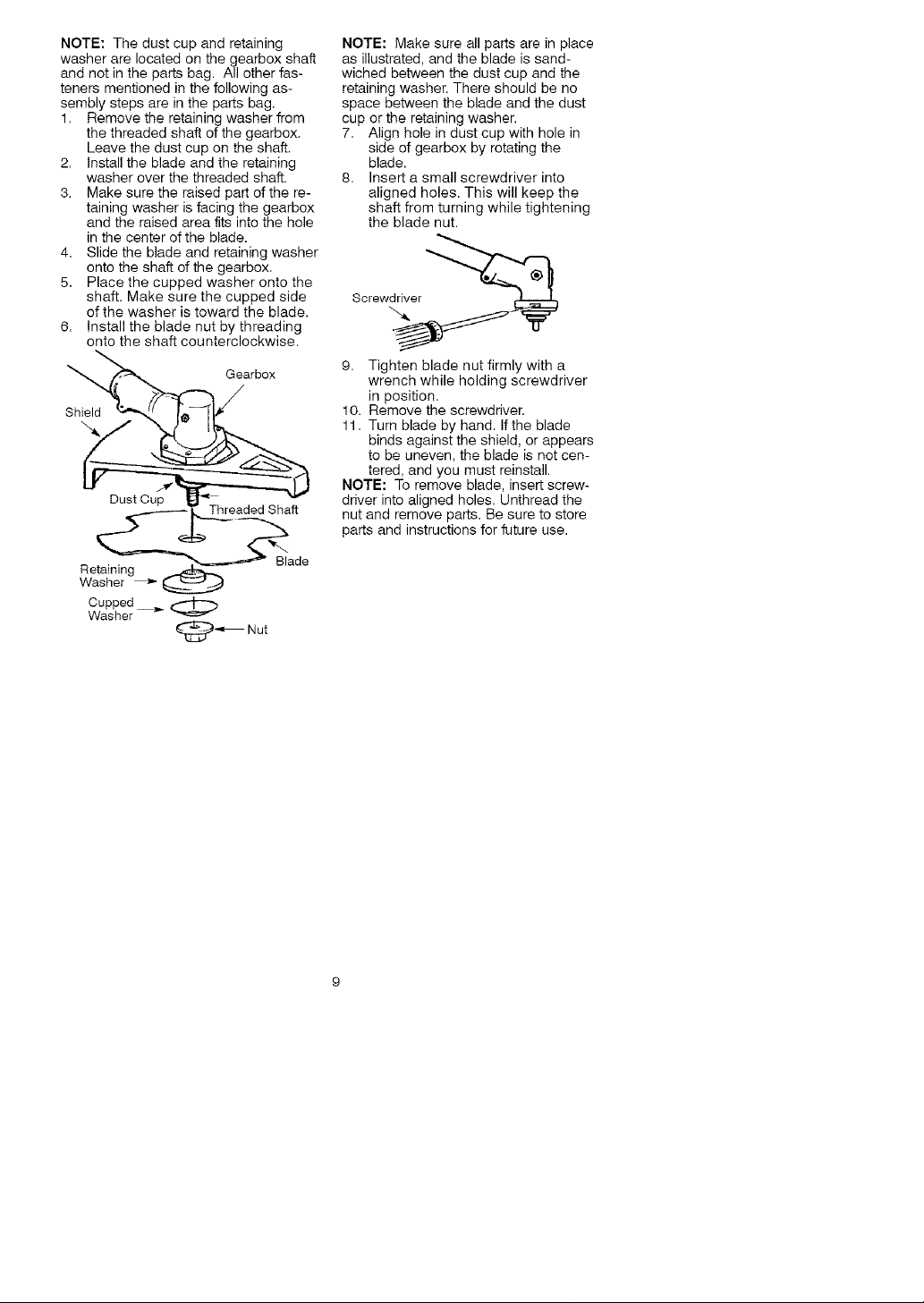

ASSEMBLY INFORMATION -

TRIMMER HEAD

._ TRIMMER

NOTE: Remove the blade and metal

shield before attaching the plastic shield

and trimmer head. To remove blade,

align hole in the dust cup with the hole

in the side of the gearbox by rotating

the blade. Insert a small screwdriver

into aligned holes. This will keep the

shaft from turning while loosening the

blade nut. Remove blade nut by turning

clockwise. Remove the screwdriver.

Remove both washers and blade.

To remove metal shield, loosen and re-

move the four mounting screws. See AT-

TACHING THE METAL SHIELDand

INSTALLATIONOF THE METAL BLADE for

illustrations. Be sure to store all parts

and instructions for future use.

INSTALLATION OF THE TRIMMER

HEAD

NOTE: Before installing the trimmer

head, make sure the dust cup and re-

taining washer are positioned on the

shaft of the gearbox. The retaining

washer must be positioned with the

raised section toward the gearbox.

1. Align hole in the dust cup with the

hole in the side of the gearbox by

rotating the dust cup.

2. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

trimmer head=

CONFIGURING YOUR UNIT

You can configure your unit using a trim-

mer head for grass and light weeds, or a

weed blade for cutting grass, weeds,

and brush up to 1/2 inch (1 cm) in

Screw._er _

3,

While holding the screwdriver in

position, thread trimmer head onto

the shaft by turning counterclock-

wise. Only tighten hand tight!

Page 8

.,___Gearbox

_ Dust Cup

Trimmer Head _ Retainh_g

Washer

4. Remove the screwdriver.

ATTACHING THE PLASTIC SHIELD

_ WARNING: The shield must be

properly installed. The shield provides

partial protection from the risk of

thrown objects to the operator and oth-

ers and is equipped with a line limiter

blade which cuts excess line to the

proper length. The line limiter blade

(on underside of shield) is sharp and

can cut you.

1. Remove wing nut from shield.

2. Insert bracket into slot on shield.

3. Pivot shield until bolt passes

through hole in bracket.

4. Tighten the wing nut securely.

Slot Bracket _:_

Shield Wing Nut

\

clockwise. Remove the screwdriver.

To remove the plastic shield, loosen and

remove wing nut. Pivot shield to release

bracket from slot. See INSTALLATIONOF

THE TRIMMER HEAD and Alq-ACHING

THE PLASTIC SHIELD for illustrations. Be

sure to store all parts and instructions for

future use. Never use the trimmer head

with the metal blade installed.

ATTACHING THE METAL SHIELD

,4(_,WARNING: The metal shield

must be properly installed on the tool

anytime the tool is used with a blade.

The forward tip of the metal shield

helps to reduce the occurrence of

blade thrust which can cause serious

injury such as amputation to the opera-

tor or bystanders. Failure to install the

shield in the position shown can result

in serious injury to the operator. The

length of the shield must be aligned

with the length of the shaft.

1. Place the metal shield under the

gearbox, and align the screw holes.

_ Gearbox

Shiek

\

Gearbox

ASSEMBLY INFORMATION - WEED

BLADE

_' WEED

BLADE

NOTE: Remove the trimmer head and

plastic shield before attaching the metal

shield and installing the weed blade. To

remove the trimmer head, align hole in

the dust cup with the hole in the side of

the gearbox by rotating the dust cup.

Insert a small screwdriver into aligned

holes. This will keep the shaft from turn-

ing while loosening the trimmer head.

Remove the trimmer head by turning

2. Insert and thread the 4 mounting

screws through the holes of the

gearbox and the metal shield.

Tighten evenly and securely with

the hex wrench provided.

INSTALLATION OF THE METAL

BLADE

WARNING: Wear protective

gloves when handling or performing

maintenance on the blade to avoid in-

jury. The blade is sharp and can cut

you even when it is not moving.

_WARNING: Do not use any

blades, or fastening hardware other than

the washers and nuts shown in the fol-

lowing illustrations. These parts must be

provided by Sears and installed as

shown below. Failure to use proper parts

can cause the blade to fly off and seri-

ously hurt you or others.

8

Page 9

NOTE:Thedustcupandretaining

washerarelocatedonthegearboxshaft

andnotinthepartsbag.Allotherfas-

tenersmentionedinthefollowingas-

semblystepsareinthepartsbag.

1. Removetheretainingwasherfrom

thethreadedshaftofthegearbox.

Leavethedustcupontheshaft.

2. Installthebladeandtheretaining

washeroverthethreadedshaft.

3. Makesuretheraisedpartofthere-

tainingwasherisfacingthegearbox

andtheraisedareafitsintothehole

inthecenteroftheblade.

4. Slidethebladeandretainingwasher

ontotheshaftofthegearbox.

5. Placethecuppedwasherontothe

shaft.Makesurethecuppedside

ofthewasheristowardtheblade.

6. Installthebladenutbythreading

ontotheshaftcounterclockwise.

Gearbox

Shield

Dust Cup

Retaining pE_lt_,_..

Washer _

Cupped

Washer

_ Nut

de

NOTE: Make sure all parts are in place

as illustrated, and the blade is sand-

wiched between the dust cup and the

retaining washer. There should be no

space between the blade and the dust

cup or the retaining washer.

7. Align hole in dust cup with hole in

side of gearbox by rotating the

blade.

8. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

the blade nut.

Screwdriver _

9. Tighten blade nut firmly with a

wrench while holding screwdriver

in position.

10. Remove the screwdriver.

11. Turn blade by hand. If the blade

binds against the shield, or appears

to be uneven, the blade is not cen-

tered, and you must reinstall.

NOTE: To remove blade, insert screw-

driver into aligned holes. Unthread the

nut and remove parts. Be sure to store

parts and instructions for future use.

Page 10

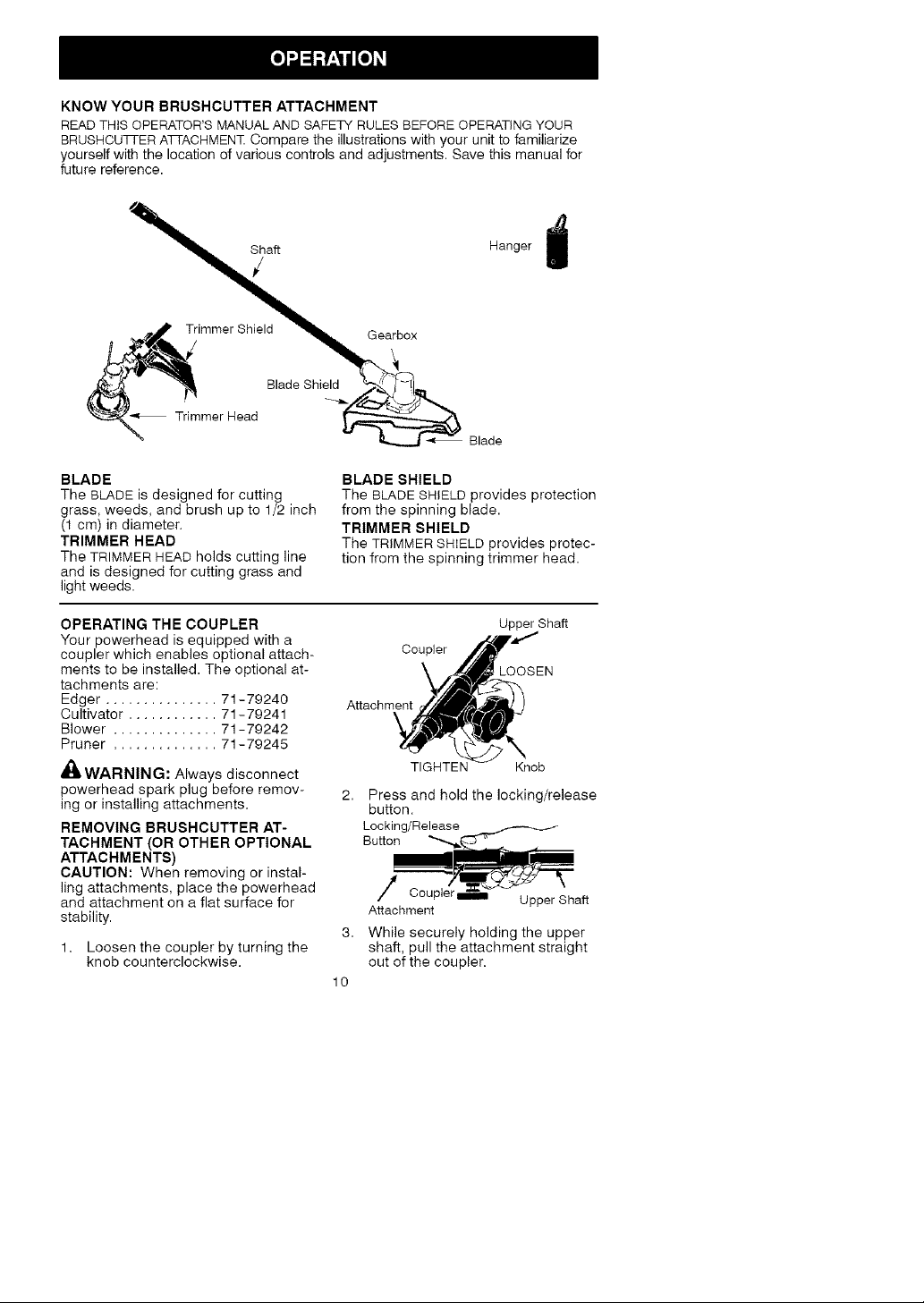

KNOWYOURBRUSHCUTTER ATTACHMENT

READ THiS OPERATOR'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

BRUSHCUTI-ERATTAOHMENT Compare the illustrations with your unit to familiarize

yourself with the location of various controls and adjustments. Save this manual for

future reference.

Hanger j

immerShield _

B,adeBhied

Heo B'adeBh% B,ade

BLADE

The BLADE is designed for cutting

grass, weeds, and brush up to 1/2 inch

(1 cm) in diameter.

TRIMMER HEAD

The TRIMMER HEAD holds cutting line

and is designed for cutting grass and

light weeds.

OPERATING THE COUPLER

Your powerhead is equipped with a

coupler which enables optional attach-

ments to be installed. The optional at-

tachments are:

Edger ............... 71-79240

Cultivator ............ 71-79241

Blower .............. 71-79242

Pruner .............. 71-79245

_. WARNING: Always disconnect

powerhead spark plug before remov-

ing or installing attachments.

REMOVING BRUSHCUTTER AT-

TACHMENT (OR OTHER OPTIONAL

ATTACHMENTS)

CAUTION: When removing or instal-

ling attachments, place the powerhead

and attachment on a flat surface for

stability.

1= Loosen the coupler by turning the

knob counterclockwise.

BLADE SHIELD

The BLADE SHIELD provides protection

from the spinning blade.

TRIMMER SHIELD

The TRIMMER SHIELD provides protec-

tion from the spinning trimmer head.

Upper Shaft

Coupler

LOOSEN

Attachment

TIGHTEiX Knob

Press and hold the locking/release

button.

Locking/Release

Button ""-,.,_ _---._

Attachment

3,

While securely holding the upper

shaft, pull the attachment straight

out of the coupler.

10

Page 11

INSTALLINGOPTIONAL ATTACH-

MENT

1. Remove the shaft cap from the at-

tachment (if present) and discard.

2. Position locking/release button of

attachment into guide recess of

upper shaft coupler.

3. Push the attachment into the cou-

pler until the locking/release button

snaps into the primary hole.

4. Before using the unit, tighten the

knob securely by turning clockwise.

Coupler Primary Hole

Upper Locking/ Attachment

Shaft Release

,_ WARNING: Make sure the lock-

ing/release button is locked in the pri-

mary hole and the knob is securely

tightened before operating the unit. Us-

ing the wrong hole could lead to serious

injury or damage to the unit.

Secondary Hoie

Locking/Release

Button in Primary HoIe

INSTALLING ATTACHMENT

HANGER

An attachment hanger is provided for

storage when attachment is not in use.

To install hanger on attachment:

1. Remove the shaft cap from the at-

tachment (if present) and discard.

2. Press and hold the locking/release

button.

3. Push hanger onto the attachment

until the locking/release button

snaps into the hole.

OPERATING POSITION

ALWAYS WEAR:

Heavy,

Long Pants

Button

Guide Recess

Eye Protection

Cut from

your left to

your right,

NOTE: This brushcutter attachment is

not designed for use with electric pow-

erheads.

When operating unit with brushcutter

attachment, clip shoulder strap onto

upper shoulder strap clamp, stand as

shown and check for the following:

• Wear eye protection and heavy

clothing.

• Keep arms extended with right hand

holding the trigger handle of power-

head.

• Keep left arm extended with left hand

holding the handlebar.

• Keep unit below waist level.

• Shoulder strap pad should be cen-

tered on your left shoulder and dan-

ger sign centered on your back.

• Maintain full weight of tool on left

shoulder.

• Without bending over, keep the blade

near and parallel to the ground and

not crowded into material being cut.

OPERATING INSTRUCTIONS FOR

USE OF BRUSHCUTTER ATTACH-

MENT WITH TRIMMER HEAD

WARNING: Always wear eye

protection. Never lean over tile trimmer

head. Rocks or debris can ricochet or

be thrown into eyes and face and

cause blindness or other serious injury.

Before trimming, bring engine to a

speed sufficient to cut material to be

trimmed.

Do not run the engine at a higher speed

than necessary. The cutting line will cut

efficiently when the engine is run at less

than full throttle. At lower speeds, there

is less engine noise and vibration. Al-

ways release the throttle trigger and

allow the engine to return to idle speed

when not cutting.

CUTTING METHODS

,_WARNING: Use minimum speed

and do not crowd the line when cutting

around hard objects (rock, gravel,

fence posts, etc.), which can damage

the trimmer head, become entangled

in the line, or be thrown causing a seri-

ous hazard.

• The tip of the line does the cutting.

You will achieve the best perform-

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

11

Page 12

Tip of line does the

Right

Line crowded into

wor__

Wrong

• The line will easily remove grass and

weeds from around walls, fences,

trees and flower beds, but it also can

cut the tender bark of trees or shrubs

and scar fences.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

• During light duty cutting.

• Near objects around which the line

can wrap such as small posts,

trees or fence wire.

• For mowing or sweeping, use full

throttle for a good clean job.

TRIMMING - Hold the bottom of the

trimmer head about 3 inches (8 cm)

above the ground and at an angle. Allow

only the tip of the line to make contact.

Do not force trimmer line into work

area,

Trimming

3 inches

(8 cm) abow

ground

SCALPING - The scalping technique

removes unwanted vegetation down to

the ground. Hold the bottom of the

trimmer head about 3 inches (8 cm)

above the ground and at an angle. Al-

low the tip of the line to strike the

ground around trees, posts, monu-

ments, etc. This technique increases

line wear.

Scalping

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action of the

rotating line can be used to blow away

loose debris from an area. Keep the line

parallel to and above the area surface

and swing the tool from side to side.

Sweeping

OPERATING INSTRUCTIONS FOR

USE OF BRUSHCUTTER ATTACH-

MENT WITH WEED BLADE

• Blade Thrust is a reaction that only

occurs when using a bladed unit. This

reaction can cause serious injury such

as amputation. Carefully study this

section. It is important that you under-

stand what causes blade thrust, how

you can reduce the chance of its oc-

curring, and how you can remain in

control of unit if blade thrust occurs.

• WHAT CAUSES BLADE THRUST -

Blade Thrust can occur when spin-

ning blade contacts an object that it

does not cut. This contact causes

blade to stop for an instant and then

suddenly move or "thrust" away from

object that was hit. The "thrusting" re-

action can be violent enough to cause

operator to be propelled in any direc-

tion and lose control of unit. The un-

controlled unit can cause serious injury

if blade contacts operator or others.

• WHEN BLADE THRUST OCCURS

- Blade Thrust can occur without

warning if the blade snags, stalls, or

binds. This is more likely to occur in

12

Page 13

areaswhereitisdifficulttoseethe

materialbeingcut.Byusingtheunit

properly,theoccurrenceofblade

thrustwillbereducedandtheopera-

torwillbelesslikelytolosecontrol.

• Cutonlygrass,weeds,andwoody

brushupto1/2inch(1cm)indiameter

withweedblade.Donotletbladecon-

tactmaterialitcannotcutsuchas

stumps,rocks,fences,metal,etc.,or

clustersofhard,woodybrushwitha

diametergreaterthan1/2inch(1cm).

• Useasharpblade.Adullbladeis

morelikelytosnagandthrust.

• Cutonlyatfullthrottle.Thebladewill

havemaximumcuttingpowerandis

lesslikelytobindorstall.

• "Feed"thebladedeliberatelyandnot

toorapidly.Thebladecanthrust

awayifitisfedtoorapidly.

• Cutonlyfromyourlefttoyourright.

Cuttingonrightsideoftheshieldwill

throwdebrisawayfromtheoperator.

• Usetheshoulderstrapandkeepa

firmgripontheunitwithbothhands.

Aproperlyadjustedshoulderstrap

willsupporttheweightoftheunit,

freeingyourarmsandhandstocon-

trolandguidethecuttingmotion.

• Keepfeetcomfortablyspreadapart

andbracedforapossiblesudden,

rapidthrustofunit.Donotoverreach.

Keepfirmfootingandbalance.

• Keepbladebelowwaistlevel.Itwill

beeasiertomaintaincontrolofunit.

• Donotraisetheengineaboveyour

waistasthebladecancomedanger-

ouslyclosetoyourbody.

• Donotswingtheunitwithsuchforce

thatyouareindangeroflosingyour

balance.

Bringthepowerheadenginetocutting

speedbeforeenteringthematerialto

becut.

Ifthebladedoesnotturnwhenyou

squeezethethrottletriggerofthepow-

erhead,makesuretheattachmentis

fullyinsertedintothecoupler.

Alwaysreleasethethrottletriggerand

allowpowerheadenginetoreturnto

idlespeedwhennotcutting.Theblade

shouldnotturnwhiletheengineisrun-

ningatidle.Ifthebladeturnsatidle,

donotuseyourunit.RefertotheCAR-

BURETORADJUSTMENTsectionofthe

powerheadmanualorcontactyour

SearsServiceCenter.

• Maintaingoodfirmfootingwhileus-

ingtheunit.Dothisbyplantingfeet

firmlyinacomfortableapartposition.

•Cutwhileswingingtheupperpartof

yourbodyfromlefttoright.

•Asyoumoveforwardtothenext

areatocut,besuretomaintainyour

balance,andfooting.

RECOMMENDEDCUTTINGPOSITION

O'ClOC_

Cutusingthe2 _.41"_._,_...,_... 2

o'ctock to 4 o'clock

position of the _ __ %"€'4o'clock

blade

V't'f'I/.'

"IV

_i, WARNING: The operator or oth-

ers must not try to clear away cut ma-

terial with the engine running or the

blade turning to avoid serious injury.

Stop engine and blade before remov-

ing materials wrapped around blade or

shaft.

13

Page 14

MAINTENANCE SCHEDULE

_IWARNING: Always stop unit and disconnect spark plug wire before

performing maintenance.

CARE AND MAINTENANCE TASK

Check for loose fasteners and parts

Check for damaged or worn parts

Inspect and clean unit and decals

Check or replace blade

GENERAL RECOMMEN DATIONS

The warranty on this attachment does

not cover items that have been sub-

jected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the brushcutter attachment as instruct-

ed in this manual.

CHECK FOR DAMAGED OR

WORN PARTS

Contact Sears Service Center for re-

placement of damaged or worn parts.

• Blade Shield - Discontinue use of

brushcutter attachment if shield is

damaged.

• CHECK FOR LOOSE

FASTENERS AND PARTS

• Blade nut

• Fasteners

INSPECT AND CLEAN UNIT

AND DECALS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit and decals using a damp

WHEN TO PERFORM

Before each use

Before each use

After each use

Every 5 hours of operation

• Wipe off unit with a clean dry cloth.

BLADE MAINTENANCE

_ WARNING: The blade will contin-

ue to spin after the engine stops or af-

ter the throttle trigger has been re-

leased. To avoid serious injury, make

sure the blade has stopped coasting

and disconnect the spark plug before

performing work on the blade.

,_ WARNING: Always replace a

blade that is bent, warped, cracked,

broken, or damaged in any other way.

Never attempt to straighten and reuse

a damaged blade. Use only specified

replacement blade. Wear protective

gloves when handling or performing

maintenance on the blade to help

avoid injury.

• Check blade for flatness periodically.

Lay the blade on a flat surface to in-

spect for flatness. Throw away a

blade that is not flat.

cloth with a mild detergent.

LINE REPLACEMENT

• Always use Craftsman replacement

line.

Choose the line size best suited for the

job at hand. Red line is designed for

cutting grass and small weeds. The

black colored line is designed for cut-

ting larger weeds and light brush.

NOTE: Before inserting new line into

the holes in the cutting head, identify

the proper holes. Follow directions as

shown on the line glide plate.

1. Remove the old line and line glide

plate from the cutting head.

2. Clean entire surface of cutting

head.

3. Reinstall line glide plate (see il-

lustration). Align arrow with:

(_ when using medium (red) or

large (black)line

when using lines with diameter

(_) smaller than medium (red) line

(optional)

Line glide Arrow

Trimmer head

14

Page 15

NOTE:Lineglideplatemustberein-

stalledincuttingheadbeforeinserting

newline.

4. Insertbothendsofyourline

throughtheproperholesinthe

sideofthecuttinghead.

!

Positioning

Tunnel

6. Correctly installed line will be the

same length on both ends.

REPLACING THE CUTTING HEAD

1. Align hole in tile dust cup with tile

hole in the side of the gearbox by

rotating the dust cup.

2. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while removing

and installing trimmer head.

Ssrew ,er

5, Pull the line and make sure the

line is against the hub and ex-

tended full through the positioning

tunnels.

Positioning

Tunnel \

A

411 WARNING: Perform the following

steps after each use:

• Allow attachment and gearbox to

cool before storing or transporting.

• Store attachment with blade shield in

place. Position attachment so that

any sharp object cannot accidentally

cause injury.

• Store the attachment in a dry, well

ventilated area out of the reach of

children.

SEASONAL STORAGE

Prepare attachment for storage at end

of season or if it will not be used for 30

days or more.

If your brushcutter attachment is to be

stored for a period of time:

Line against

3. While holding the screwdriver in

position, remove trimmer head by

turning clockwise.

4. Thread replacement trimmer head

onto the shaft by turning counterclock-

wise. Only tighten hand tightt

5. Remove the screwdriver.

BLADE REPLACEMENT

Refer to the ASSEMBLY section for

blade replacement instructions and il-

lustrations=

• Clean the entire attachment.

• Inspect the blade shield area and

clean any dirt, grass, leaves, or de-

bris that has collected. Inspect the

blade and blade shield; replace a

blade that is bent, warped, cracked,

broken or damaged in any other way.

• Lightly oil external metal surfaces.

• Apply a coating of oil to the entire

surface of the blade; wrap it in heavy

paper or cloth.

• Check entire attachment for loose

screws or nuts= Replace any dam-

aged, worn or broken parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

15

Page 16

Declaraci6ndeGarantia 17 Mantenimiento 30

Identificaci6ndeSimbolos 17 ServicioyAjustes 31

ReglasdeSeguridad 17 Almacenaje 32

Montaje 20 ListadePiezas 16

Uso 26 RepuestoyEncargosContratapa

UNAI_IO COMPLETO DE GARANTiA PARA LA CORTADORA DE MALEZAS

ACCESORIO CRAFTSMAN ®

Si este producto falla por un defecto en el material o de mano de obra dentro del

a_o a partir de la fecha de compra y este se ha utilizado y mantenido de acuerdo

al manual del usuario, envielo a cualquier tienda Sears, Centro de Servicios

Sears u otra tienda Craftsman en los Estados Unidos para su reparaci6n gratuita

(o reemplazo si no es posible repararlo).

Esta garantia excluye las partes desechables que se pueden desgastarse al

usarlas normalmente en menos de un a_o.

Esta garantia es aplicable per s61o 30 dias desde la fecha de compra si este pro-

ducto se usa con fines comerciales o se usa para arriendo.

Esta garantia le otorga derechos legales especificos, y usted tambien puede

tener otros derechos que varian de estado a estado.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

PELIGRO: iEsta cortadora

demalezas puede serpeligrosa!

El uso descuidado o indebido de

esta herramienta puede causar

graves o at_nheridas fatales!

Use siempre la proteccion de oidos apropiada, Ia proteccion de

ojos y la protecci6n de la cabeza.

ADVERTENCIA: AI usar cualqui-

er herramienta de fuerza de jardineria,

deber&n observarse precauciones b&si-

cas de seguirdad en todo momento

para reducir el riesgo de incendio y

graves heridas. Lea y cumpla con todas

las instrucciones. Su incumplimiento

puede ocasionar lesiones graves.

PELIGRO: iEsta herramienta mo-

torizada puede ser peligrosa! Puede

ocasionar lesiones graves, incluso la

amputaci6n o la ceguera, tanto al opera-

dor como a otras personas. Las adver-

tencias e instrucciones de seguridad

contenidas en este manual deben cum-

plirse en redo momento para garantizar

Lea y comprenda eI

manual de1 usuado

antes de usar la corta-

dora de malezas.

un nivel de seguridad y efectividad ra-

zonable durante la utilizaci6n del apara-

to. El operador es responsable del

cumplimiento de las advertencias e

instrucciones indicadas en este manual

yen el aparato. Antes de ensamblar y

utilizar el aparato, lea integramente el

manual del usuario. Limite el uso de

este aparato a personas que previa-

mente hayan leido y comprendido, y

posteriormente cumplan, las adverten-

cias e instrucciones indicadas en este

manual yen el aparato. Nunca permita

que este aparato sea utilizado por niSos.

17

Page 17

MANUAL DEL INFORMACION DE

USUARIO SEGURIDAD DEL

APARATQ

Zona

peligro

PEMGRO: Nunca use dispositivos

desgranadores.

PELIGRO: La cuchilla puede rebo-

tar violentamente en materiales que no

puede cortar. Los rebotes de la cuchilla

pueden causar la amputaci6n de brazos

o piernas. Mantenga a personas y anima-

les lejos de la herramienta (15 metros).

ADVERTENClA: La cuchilla/

linea de corte puede despedir objetos

violentamente. Esto puede ocasionade

ceguera o lesiones. Prot6jase los ojos

y las piernas.

UTILICE SIEMPRE:

Protecci6n _

ocular

I1|

• • Perneras

Botas _

_,ADVERTENClA: Zona de peligro

de objetos despedidos. La cuchilla/linea

de corte puede despedir objetos violen-

tamente. Esto puede ocasionar ceguera

o lesiones a otros. Mantenga a perso-

nas y animales lejos de la herramienta

15 metros (50 pies).

Objetos

despedidos

o

1,1

_IkADVERTENClA: No utilice el ca-

bezal de corte come dispositivo de su-

jeci6n de la cuchilla.

,d_ ADVERTENClA: La cuchilla si-

gue girando incluso despu6s de soltar

el acelerador o de apagar el motor. In-

cluso cuando est& girando libremente,

la cuchilla puede despedir objetos o

causar cortes profundos si se toca ac-

cidentalmente. Detenga la cuchilla po-

niendo en contacto el lado izquierdo

de la misma con material ya cortado.

Para detener Ia cuchi- _ _

Ila cuando gire libre- "_t r

mente, p6ngata en ._'_

contacto con material J

previamente corta6_

®

SEGURIDAD DEL OPERADOR

• Vistase apropiadamente. Siempre

use anteojos de seguridad o similar

protecci6n para los ojos cuando use

o d6 mantenimiento a este aparato

(anteojos de seguridad est&n dispo-

nibles). La protecci6n para los ojos

debe ser marcada con Z87.

• Siempre utilize mascarilla para la

cara o mascarilla a prueba de polvo

si se va a trabajar en condiciones

donde hay polvo.

• Siempre utilize pantalones pesados

y largos, mangas largas, botas y

guantes. Se recomienda el uso de

pantorrilleras de seguridad.

• Siempre utilize protecci6n para los

pies. No trabaje descalzo ni en

sandalias. Evite la cuchilla/linea de

corte girante.

18

Page 18

• Mantengaelcabelloporencimade

loshombros,at&ndoloparatalefecto

siesnecesario.Nouseropasueltani

ropaconcorbatas,tiras,borlas,etc.

quecuelganlibremente.Puedenenre-

darseenlaspiezasenmovimiento.

• Siest&completamenttapado,estar&

m&sprotegidodelosescombrosy

pedazosdeplantast6xicosarroja-

dosparlacuchillagirante.

• Mant6ngasealerta.Nohagausadel

aparatoestandocansado,enfermo,

trastornadoobajolainfluenciadel

alcohol,dedrogasoderemedios.

VigilebienIoqueest&haciendo;use

delsentidocomQn.

• Useprotecci6ndeoidos.

• Nuncapongaelaparatoenmarcha

niIodejeenmarchadentrodeun

recintocerrado.Respirarlosvapores

delcombustibleIopuedematar.

• Mantengalasmanijaslibresde

aceiteydecombustible.

• Utilicesiempreelmangoyuna

correaparahombrecorrectamente

ajustadaalusarlacortadorade

malezasaccesorio(veaMONTAJE).

MANTENIMIENTO Y SEGURIDAD

DEL APARATO

_ADVERTENCIA: Desconecte la

buj[a (o desconecte aparato de la cor-

riente el6ctrica) antes de hacer cualqu-

ier mantenimiento.

• Antes de cada uso, busque las piezas

daSadas o sueltas y sustitOyalas. An-

tes de cada uso, busque posibles fu-

gas de combustible y, en su caso, re-

p&relas. Mantenga el aparato en buen

estado de funcionamiento.

• Deseche la cuchillas dobladas, den-

tadas, partidas, rotas o deterioradas

de algQn modo. Antes de utilizar la

unidad, sustituya las piezas del ca-

bezal de corte que esten partidas,

rotas o deterioradas de algOn modo.

• Realice el mantenimiento del aparato

siguiendo los procedimientos reco-

mendados. Mantenga la cuchilla afila-

da. Nunca utilice dispositivos desgra-

nadores, cable, cuerda, alambre, etc.

• Utilice exclusivamente la cuchilla o el

cabezal de corte especificado y ase-

g0rese de que est6 correctamente

instalado y firmemente sujeto.

• Nunca ponga en marcha el motor

con el cubierta del embrague des-

montado. El embrague podria des-

prenderse y causar graves lesiones.

• AsegQrese de que el cuchilla o el

cabezal de corte se detiene al pasar

el motor al ralent[.

• Realice los ajustes del carburador

con la parte inferior apoyada en alto

para impedir que la cuchilla entren

en contacto con alg0n objeto. Sujete

el aparato con las manos, sin utilizar

la correa al hombre.

• Cuando realice ajustes en el carbu-

rador, mantenga alejadas del lugar a

otras personas.

• Utilice exclusivamente los accesorios

y recambios recomendados por

Craftsman.

• Confie todas las tareas de manteni-

miento y reparaci6n no explicadas

en este manual a su Centre de

Servicio de Sears.

SEGURIDAD CON EL COMBUS-

TIBLE

• Mezcle y vierta el combustible en

exteriores.

• Mantenga el combustible alejado de

chispas y llamas.

• Utilice recipientes homologados para

el usa de combustibles.

• Impida que se fume cerca del com-

bustible o del aparato, tanto si este se

encuentra parado o se est& utilizando.

• Antes de poner en marcha el motor,

limpie todo posible resto de combus-

tible derramado.

• Antes de porter en marcha el motor,

al6jese coma minimo 3 metros del lu-

gar de repostaje.

• Antes de quitar el tap6n de combusti-

ble, detenga el motor y d6jelo enfriar.

• Remueva la tapa del tanque de com-

bustible lentamente.

SEGURIDAD AL CORTAR

_& ADVERTENCIA: Antes de cada

uso, inspeccione la zona de trabajo.

Retire todos los objetos (rocas, cris-

tales rotos, clavos, cables, hilos, etc.)

que puedan ser despedidos o quedar

enredados en la cuchilla.

• Mantenga alejados del lugar de tra-

bajo (15 metros) a otras personas,

ya sean niSos, acompaSantes o ayu-

dantes, y a animales. Detenga el

motor tan pronto como alguien se le

aproxime.

• Mantenga siempre el motor junto al

lado derecho de su cuerpo.

• Sujete firmemente la unidad con am-

bas manos.

• Pise con seguridad y mantenga el

equilibrio en todo memento. No esti-

re el cuerpo en exceso.

• Mantenga la cuchilla par debajo de

la cintura.

• No levante el cabeza de motor par en-

cima de su cintura.

19

Page 19

• Mantengatodaslaspartesdesu

cuerpoalejadasdelacuchillaydel

silenciador.

• Cortesiempredeizquierdaaderecha.

Sisecortaconlalineadelladodere-

chodelprotector,losescombrosvo-

lar&nensentidoopuestoalusuario.

• Useelaparato0nicamentedediao

enluzartificialfuerte.

• Utiliceelaparatosolamenteparalas

tareasexplicadasenestemanual.

TRANSPORTE Y ALMACENAMIENTO

• Antes de proceder a su transporte,

detenga el cabeza de motor.

• Mantenga el silenciador alejado del

cuerpo.

• Antes de almacenar o transportar el

aparato en un vehiculo, deje enfriar

el motor y sujete bien el aparato.

• Antes de guardar o transportar el

aparato, vacie el dep6sito de com-

bustible. Arranque el motor y d6jelo

en marcha hasta que se detenga

con el fin de agotar el combustible

que pueda quedar en el carburador.

• Guarde el aparato y el combustible

en un lugar donde los vapores ema-

nados del combustible no puedan

entrar en contacto con chispas ni lla-

mas procedentes de calentadores

de agua, motores o interruptores

el_ctricos, hornos, etc.

• Guarde el aparato de modo que la

cuchilla no puedan ocasionar lesio-

nes accidentalmente.

• Guarde el aparato dentro, fuera del

alcance de los hi,as.

NOTA ESPECIAL: El estar expuesto a

lae vibraciones a tray,s del uso prolon-

gado de herramientae de fuerza a gaso-

lina puede cuasar daSoe a los vasos

sanguineos o a los nervioe de los de-

doe, las manoe y las coyunturae en

aquellas personas que tienen propenei-

dad a los trastomos de la circulaci6n o a

lae hinchazones anormales. El uso pro-

Iongado en tiempo frio ha sido asociado

con daSos a los vaeos snaguineoe de

personas que por otra parte ee encuen-

tran en perfecto eetado de salud, Si

ocurren sintomas tales como el entume-

cimiento, el dolor, la falta de fuerza, los

cambioe en el color o la textura de la

piel o falta de sentido en los dedos, lae

manoe o las coyunturas, deje de usar

esta m&quina inmediatamente y procure

atenci6n medica. Los sistemae de anti-

vibraci6n no garantizan que ee eviten

tales problemes. Los usuarios que ha-

cen uso continuo y prolongando de las

herramientae de fuerza deben fiscalizar

atentamente su estado fisico y el estado

del aparato.

GUARDE ESTAS INSTRUCClONES

CONTENIDO DE LA CAJA

Use la siguiente lista para verificar que

todas la piezas hayan sido incluido:

Model 358.792443

• Cortadora de malezas accesorio

• Mango

• Soporte del mango para eleje de 1 pul-

gada (2,5 cm)

• Soporte del mango para el eje de 2,2

cm (7/8 de pulgada)

• Tapa del soporte (2)

• Correa para al hombro

• Abrazadera superior del correa de

hombro

• Abrazadera inferior del correa de

hombro (con tabulaciones del espa-

ciador)

• Tornillos de soporte del mango (4)

• Tornillos de abrazadera del correa de

hombro (2)

• Cuchilla con 4 puntas para el corte de

malezas (ensamblado en el aparato)

• Tuerca larga para installar la cu-

chilla

• Arandela de r6ten

• Arandela abombada

• Protector met&lica (ensamblado en el

aparato)

• Cabezal de corte

• Protector pl&stica

• Tuerca mariposa (atornillada en la

protector)

• Suspensor del accesorio

• Llave hexagonal

• Recipiente de linea

Aseg0rese de que ninguna pieza est6

daSada. No utilice piezas daSadas.

NOTA: Si necesita ayuda o detecta que

alguna pieza falta o est& daSada, Ilame

al 1-800-235-5878.

MONTAJE

_IIADVERTENCIA: Si recibe el

aparato ya armado, repita todos los pa-

sos para asegurarse de que el aparato

est6 correctamente ensamblado y todas

las sujeciones firmes.

• Un Ilave hexagonale (incluidas) se

requiere para el montaje.

20

Page 20

INSTALAClONDELAACCESORIO

DELCORTADORADEMALEZAS

PRECAUClON: AI instalar lae acceso-

rio, ponga el aparato en una superficie

plana para estabilidad.

1. Afloje el acoplador dando vuelta a

la perilla a la izquierda.

Acoplador

_,FLOJE

Perilia

2. Retire la tapa de eje del accesorio

del cortadora de malezas (si pres-

ente).

3. oloque el bot6n de conexi6n/des-

conexi6n del accesorio en el aguj-

ero de la guia del acoplador.

4. Empuje el accesorio en el acopla-

dor hasta que el bot6n de conex-

i6n/desconexi6n se encaje en el

primer agujero.

5. Antes de usar el aparato, apriete

la perilla firmemente dando vuelta

a la derecha.

Acoplador Primer Agujero de

Agujero la Guia

INSTALLATION DEL MANGO

_& PELIGRO: RIESGO DE CORTA-

DURA. Para evitar graves heridas, la

parte del mango en forma de barrera

debe ser instalada en el eje superior

de la cabeza del motor/eje superior

con el fin de mantener la distancia

entre el operador y la cuchilla durante

el giro de _sta. Instale el soporte del

mango sobre la flecha de la etiqueta

de seguridad del eje superior (extremo

a la cabeza del motor de su aparato).

Asegure que el mango est& situado en

el soporte del mango en el extremo de

la flecha en la etiqueta de seguridad

adherida al mango.

AVlSO: Dos soportes del mango se

incluye con este accesorio. Estos so-

portes se proporcionan para adaptar

este accesorio para el uso con las ca-

bezas de motor/eje superior que tie-

nen 2,5 cm (1 pulgada) o 2,2 cm (7/8

de pulgada) de di&metro del eje supe-

rior. El soporte correcto se debe utili-

zar para asegurarse de que el mango

est& montado con seguridad al eje su-

perior antes del use.

Eje Boton de Accesorio

Superior Conexion/

ADVERTENCIA: Antes de oper-

ar este aparato, asegOrese de que el

bot6n de conexi6n/desconexi6n este

asegurado en el primer agujero y la

perilla est6 bien ajustada antes de op-

erar el aparato. Usar el agujero incor-

recto podria causar graves heridas o

daSos a el aparato.

Bot6n de

en el Primer Agujero

Desconexi6n

Agujero

Secundado

Tapa de1

Sopo_e

deIMango '

• Sopo_e

J

1. Coloque el soporte del mango en

la parte superior sobre la flecha en

la etiqueta de seguridad. Asegure

de que usted utilice el soporte de

mango correcto para el de 2,5 cm

(1 pulgada) o 2,2 cm (7/8 de pul-

gada) de di&metro del eje superior.

2. Coloque una de las tapas del so-

porte debajo del eje superior y ali-

nee los huecos del tornillo del so-

porte del mango y de la tapa del

soporte. Inserte dos tornillos en los

huecos del tornillo.

3. Asegure el soporte del mango

apretando los tornillos con la Ilave

hexagonal•

4. Localize la etiqueta adherida al

mango. Esta etiqueta contiene una

flecha. Coloque el mango en el

soporte del mango en el extremo

de esta flecha.

21

Page 21

5. Coloquelasegundatapadel

soportesobreelmango.Alineelos

huecosdeltornillodelasoporte

delmangoydelatapadelso-

porte.Aseg0resedequeelmango

quedesituadaenelextremodela

flecha.

6. Introduzcadostornillosyaprietea

mano.Aseg0resedequeelman-

goquedeinstaladocorrectamente,

despu6sacontinuaci6n,apriete

firmementecadaunodelostorni-

IlosconlaIlavehexagonal.

MONTAJE DE LA CORREA PARA EL

HOMBRO

_,ADVERTENCIA: Antes de hacer

algun ajuete de la correa o el mango, es

impreecindible que el motor este

completamente detenido. El abrazadera

del correa de hombro debe ser instalado

eobre el mango en el eje superior

(extreme con el cabeza del motor).

AVlSO: La abrazadera inferior del

correa para hombro tiene dos (2) tabu-

lacionee del eepaciador incluidas. Es-

tas tabulacionee se proporcionan para

adaptar eeta accesorio para el use con

lae cabezas de motor/eje superior que

tienen 1 pulgada del eje superior de

di&metro (la abrazadera del correa

para hombro no apretar& abajo con

seguridad en el eje superior de 1 pul-

gada de di&metro sin usar estae tabu-

lacionee del eepaciador). Estae tabu-

lacionee se deben remover antes del

use y ponerlos sobre los huecoe del

tornillo en la abrazadera inferior de la

correa para el hombro. Estas tabula-

clones no son necesarias para las oa-

bezas de motor/eje con un 7/8 de pul-

gada en el eje superior.

ABRAZADERA INFERIOR DEL

CORREA PARA HOMBRO

Tabulaciones

del Espaciador

_ _-_,_- Tabulaciones

_lk_ use en el 1putga-

_m--rm da de di¢tmetrodel

_v del Espaciador

colocadas para el

eje supenor

1,

Coloque la abrazadera superior de

la correa para hombro en la parte

superior sabre la mango.

2.

Coloque la abrazadera inferior de la

correa para hombro debajo del eje

superior y alinee los huecos del tor-

nillo de la abrazadera superior y la

abrazadera inferior (use las tabula-

clones del espaciador entre la abra-

zadera superior y abrazadera inferi-

or en case de necesidad para

asegurar la abrazadera, es decir

para ejes de 1 pulgada de di&metro

del eje superior).

Abrazadera Superior

EXTREMO CON

EL CABEZA DE

MOTOR

Abrazadera Tornilios

Inferior de la

Correa para Hombre

3. Inserte dos tornillos en los huecos

para tornillo.

4. Asegure la abrazadera de la cor-

rea para el hombre apretando los

tornillos con la Ilave hexagonal.

5. Introduzca el brazo derecho y la ca-

beza pot el arco de la correa y apo-

ye 6sta en el hombro izquierdo.

AsegQrese de que el signo de peli-

gro se encuentre en su espalda y

de que el enganche se encuentre

en el lado derecho de su cintura.

AVlSO: La correa puede girarse media

vuelta para garantizar que quede ape-

yada en toda su anchura sobre el

hombro.

6. Ajuste la correa para permitir que

el enganche quede a unos 15 cm

par debajo de la cintura.

7. Fije el enganche de la correa a la

abrazadera y levante la herramien-

ta hasta la posici6n de trabajo.

8. Antes de porter en marcha el motor

o iniciar cualquier tarea de corte,

p6ngase la correa en el hombro y

ajOstela a su medida de modo que

le permita mantener el equilibrio.

AVlSO: Puede ser necesario mover la

abrazadera de la correa para el hombro

en el eje para un equilibrio apropiado

del aparato.

de la Correa para

I EXTREMO CON

Hombro

ELACCESORIO

22

Page 22

AJUSTE DEL

CORREA AL HOMBRO

PARA ELBALANCE

15 cm 10 - 30 cm

(6 pulga- (4 - 12 pul-

das) de- gadas) del

bajo de la suelo

cintura

76 cm

(30 pul

CONFIGURACION DEL APARATO

El aparato puede configurarse con un

cabezal cortador para hierbas y plan-

tas de pequeSo tamaSo, o bien con

una cuchilla para hierbas, plantas y

brozas con tallos de hasta 1 cm (0,5

de pulgada) de di&metro. Para ensam-

blar el aparato, consulte la secci6n co-

rrespondiente a la configuraci6n des-

eada y siga las instrucciones que alli

se indican.

INFORMACION DE MONTAJE -

CABEZAL DE CORTE

CABEZAL

DE CORTE

taza para el polvo para hacer coincidir el

orificio con el otro orificio situado a un

lado del cajetin de engranajes.

Introduzca un destornillador pequeSo

por los orificios confrontados. Esto

impedir& que el eje gire mientras afloja

la tuerca de la cuchilla. Remueva la

tuerca de la cuchilla gir&ndola hacia la

derecha. Remueva el destornillador.

Remueva ambas arandelas y el cuchilla.

Para remover el protector met&lica,

afloje y remueva los 4 tornillos de

montaje. Vea las secciones MONTAJE

DE LA PROTECTOR MET/_,LICAy,

MONTAJE DE LA CUCHILLA METAUCA

para las ilustraciones. Guarde las piezas

y las instrucciones para el uso future.

PARA INSTALAR EL CABEZAL DE

CORTE

AVISO: Antes de instalar el cabezal

de corte, asegOrese de que la taza

para el polvo y la arandela de ret6n

esten colocada en el eje de la caja de

engranajes. La arandela ret6n debe

colocarse con la secci6n elevada

orientada hacia el caja de engranajes.

1. Haga girar el taza para el polvo

para hacer coincidir el orificio con

el otro orificio situado a un lade del

cajetin de engranajes.

2. Introduzca un destornillador peque-

5o per los orificios confrontados. Es-

to previene que el eje gire mientras

usted instale el cabezal de corte.

Destornillado_

3,

Sujete el destornillador en su posi-

ci6n y enrosque el cabezal de

corte en el eje dando vuelta a la

izquierda, iAjuste el eabezal

manualmente!

AVlSO: Remueva el cuchilla y el

protector met&lica antes de instalar el

protector pl&stica y cabezel de corte.

Para remover la cuchilla, haga girar el

Cabezal de

corte"...__

4,

Remueva el destornillador.

23

Engranajes

Taza para

Caja de

el Potvo

Arandeta

de reten

Page 23

PARA INSTALAR EL PROTECTOR

PLASTICA

,_ADVERTENCIA: El protector

deber& ser instalado correctamente.

El protector provee protecci6n parcial

contra el riesgo de los objetos arroja-

dos hacia el usuario y otras personas

y viene equipado con un cuchilla limi-

tadora de linea que corta el exceso de

linea. El cuchilla limitadora de linea

(en la parte inferior del protector) es

filoso y puede cortar.

1. Remueva la tuerca mariposa del

protector.

2. Inserte el soporte dentro de la ra-

nura del protector.

3. Gire el protector hasta que el tor-

nillo pase a trav6s del hueco en el

soporte.

4. Apriete firmemente la tuerca en

forma de alas.

Tuerca en

Abrazadera . _ forma de

Ranura "_.\_ ) a,as

_ _" e_..,__

Protector Engranajes

INFORMACION DE MONTAJE -

CUCHILLAS PARA

MALEZAS

CUCHILLAPARA

MALEZAS

Haga girar el protector para remueva

soporte de la ranura. Vea la secci6n

PARA INSTALAR EL CABEZAL DE CORTE

y PARA INSTALAR EL PROTECTOR

PLASTICA para las ilustraciones.

Guarde las piezas y las instrucciones

para el uso futuro. Nunca utilice el

cabezal de corte con la cuchilla

met&llica instalada.

MONTAJE DE LA PROTECTOR

METALICA

_ADVERTENCIA: Siempre que

esta herramienta vaya a utilizarse con

la cuchilla, la protector met&lica debe-

r& estar correctamente instalada. El

extremidad frontal de la protector

met&lica ayuda a reducir el n_mero de

rebotes de la cuchilla que pueden oca-

sionar lesiones graves, come la ampu-

taci6n, tanto al operador como alas

personas cercanas. La omisi6n de ins-

talar la protector en la posici6n mostra-

da puede acarrear graves lesiones al

operador. La protector debe estar ali-

neada Iongitudinalmente con la barra.

1. Coloque el protector met&lica bajo

la caja de engranajes, y alinee los

huecos del tornillos.

Caja de

engranajes

i

Protecto

\

AVISO: Remueva el cabezal de corte

y el protector pl#.stica antes de instalar

el protector met&lica y instalar la

cuchilla para malezas. Para remover el

cabezal de corte, haga girar el taza

para el polvo para hacer coincidir el

orificio con el otro orificio situado a un

lado del cajetin de engranajes.

Introduzca un destornillador pequeSo

por los orificios confrontados. Esto

impedir& que el eje gire mientras afloja

el cabezal de corte. Remueva el

cabezal de corte gir&ndola hacia la

derecha. Remueva el destornillador.

Para remover el protector pl&stica,

afloje y remueva la tuerca mariposa.

2. Inserte y enrosque los 4 tornillos

de la montaje a trav6s de los

huecos de la caja de engranajes y

del protector met&lica. Apriete

uniformemente y firmemente con

una de la Ilave hexagonale

includidas.

MONTAJE DE LA CUCHILLA

METALICA

_bADVERTENCIA: Use guantes

de protecci6n al tocar o al hacer man-

tenimiento a la cuchilla para evitar her-

idas. La cuchilla es muy filosa y corta

aOn no estando en movimiento.

_bADVERTENClA: No utilice nin-

guna cuchilla ni pieza de sujeci6n dis-

tinta de las arandelas y tuercas que

aparecen en las ilustraciones siguien-

tee. Estas piezas deben estar suminis-

24

Page 24

tradasporSearseinstalarsecomese

muestram_tsabajo.Lautilizaci6nde

piezasnoadecuadaspuedeocasionar

quelacuchillasalgadespedidaydahe

gravementealoperadoroaotros.

AVlSO:Eltazaparaelpolvoyla

arandelaret@nest@nIocalizadasenla

cajadeengranajesynoenlabolsade

piezas.Elrestodelafijadores

mencionadaenlospasosdeensamble

seencuentranenlabolsadepiezas.

1. Remuevalaarandelaret@ndeleje

roscadodelcajadeengranajes.

Dejeeltazaparaelpolvoenel

eje.

2. Instalelacuchillaylaarandelade

ret@nenelejeroscadoquesobre-

saledelcajadeengranajes.

3. Aseg0resedequeelladeelevado

delaarandeladeret@nest@orien-

tadohaciaelcajadeengranajesy

dequeelresaltequepaenelhue-

cocentraldelacuchilla(veala

ilustraci6n).

4. Deslicelacuchillaylaarandelade

ret@nperelejedelcajade

engranajes.

5. Ahoracoloquelaarandelaabom-

badaeneleje.Cerci6resedeque

elladem@.sanchodelaarandela

est@orientadohacialacuchilla.

6. Instalelatuercadelacuchilla

enrosc_.ndolaenelejedando

vueltaalaizquierda.

Cajade

__,_ _ranajes

AVlSO: Aseg0rese de que todas las

piezas est@n colocadas en su sitio y

de que la cuchilla est@aprisionada

entre el guardapolvos y la arandela de

ret@n. No debe quedar ninguna holgu-

ra entre la cuchilla y el guardapolvos

o la arandela de ret@n.

7. Gire la cuchilla para hacer coinci-

dir el orificio del taza para el polvo

con el orificio lateral del cajetin de

engranajes.

8. Introduzca un destornillador pe-

que_o por los orificios confronta-

dos. Esto previene que el eje gire

mientras usted apriete la tuerca de

la cuchilla.

9. Manteniendo el deetornillador en

su posicidn, apriete firmemente la

tuerca de la cuchilla con una Ilave.

10. Retire el destornillador.

11. Gire la cuchilla a mano. Si la

cuchilla se aproxima a la cubiecta

o parece girar irregularmente, sig-

nifica que no estfi centrada y serfi

neceeario reinstalarla.

AVIS0: Para desmontar la cuchilla,

introduzca el destornillador por los ori-

ficios confrontadoe. Desenrosque la

tuerca y desmonte lae piezae. AeegQ-

rese de guardar lae piezae y las ins-

trucciones par si las necesita en el

futuro.

Arandela

deret@n_

Arandela_

abombada_)_ Tuerca

25

Page 25

CONOZCASUCORTADORADEMALEZASACCESORIO

LEAESTEMANUALDELUSUARIOYLASREGLASDESEGURIDADANTESDECOM-

ENZARAUSARESTECORTADORADEMALEZASACCESORIO.Comparelasilustra-

clonesconsuaparatoparafamiliarizarseconlaubicaci6ndelosdiversoscon-

trolesyajustes.Guardeestemanualparausofuturo•

J

I__ Suspensor

Cajadees

C

Blade

CUCHILLA

La CUCHILLA ha sido dise_ada para

cortar hierba, plantas de pequeSo ta-

maSo y brozas con tallos de madera

de hasta 1 cm (0,5 de pulgada) de

di&metro.

CABEZAL DE CORTE

El CABEZAL DE CORTE sostiene la

linea de corte y ha sido diseSada para

cortar hierba y plantas de pequeSo

tamaSo.

PROTECTOR DE LA CUCHILLA

El PROTECTOR DE LACUCHILLA protege

al operador de la cuchilla girante.

PROTECTOR DE LA CABEZAL DE

CORTE

El PROTECTOR DE LACABEZAL DE

CORTE protege al operador de la cabe-

zal de corte girante.

OPERAClON DEL ACOPLADOR

Este modelo est& equipado con un

acoplador, el cual permite la instala-

ci6n de accesorios opcionales. Los

accesorios opcionales son:

Cortadora de Bordes .. 71-79240

Cultivador ........... 71-79241

Propulsor de Aire ..... 71-79242

Cortadora de Ramas .. 71-79245

,_ADVERTENClA: Siempre desco-

necte la bujia de la cabeza de motor

antes de retirar o instalar los accesorios.

COMO REMOVER EL ACCESORIO

DEL CORTADORA DE MALEZAS (U

OTROS ACCESORIOS OPCIONAL)

PRECAUCION: AI retirar o instalar las

accesorios, ponga el cabeza de motor

y el accesorio en una superficie plana

para estabilidad.

1. Afloje el acoplador dando vuelta a

la perilla a la izquierda.

Acoplador

AFLOJE

Accesorio

APRIETAi' Perilla

2. Oprima y sostenga el bot6n de

conexi6n/desconexi6n.

Botch de Conexi6n/

Desconexion

iAcoplad_ Eje Superior

Accesorio

3. Mientras sostiene el eje superior

con firmeza, retire el accesorio del

acoplador en forma recta•

26

Page 26

INSTALACIONDEL ACCESORIOS

OPCIONAL

1. Retire la tapa de eje del accesorio

(si presente) y deseche.

2. Coloque el bot6n de conexi6n/des-

conexi6n del accesorio en el aguj-

ero de la guia del acoplador del

eje supenor.

3. Empuje el accesorio en el acopla-

dor hasta que el bot6n de conex-

i6n/desconexi6n se encaje en el

primer agujero.

4. Antes de usar el aparato, apriete

la perilla firmemente dando vuelta

a la derecha.

Acoplador Primer Agujero de

Eje Boton de Accesorio

Superior Conexion/

ADVERTENClA: Antes de oper-

ar este aparato, asegOrese de que el

bot6n de conexi6n/desconexi6n est6

asegurado en el primer agujero y la

perilla est6 bien ajustada antes de op-

erar el aparato. Usar el agujero incor-

recto podria causar graves heridas o

daSos a el aparato.

Bot6n de

en el Primer Agujero

INSTACALION DEL SUSPENSOR

Una suspensor de la accesorio se pro-

porciona para el almacenaje cuando la

accesorio no se est& utilizando.

Para instalar la suspensi6n en la acce-

sorio:

1. Retire la tapa de eje del accesorio

(si presente) y deseche.

2. Presione y sostenga el bot6n de

conexi6n/desconexi6n.

3. Empuje la suspensor sobre la acce-

sorio hasta que el bot6n de conex-

i6n/desconexi6n se encaja en el

hueco.

Agujero la Guia

Desconexi6n

Agujero

Secundario

POSICION DE USO

SIEMPRE USE:

Protecci6n

para los

Pantalones

Pesados

y Largos

Botas

Ojos

AVISO: Esta cortadora de malezas

accesorio no se diset_a para el uso

con los cabezas del motor el6ctricos.

Cuando aparato de funcionamiento

con el cortadora de malezas acceso-

rio, enganche la correa para hombre

en el abrazadera de la correa para el

hombro, parese come se vea en la fi-

gura y verifique Io siguiente:

• Usando anteojos de seguridad y

ropa gruesa come protecci6n.

• Mantenga brazos extendido con la

mano derecha sostiene el mango del

gatillo acelerador del cabeza de motor.

• Mantenga el brazo izquierdo extendi-

do con la mano izquierda sostenga el

mango.

• Mantenga el aparato por debajo de

la cintura.

• Mantenga almohadilla de la correa al

hombro centrada en el hombre

izquierdo y seSal de peligro centrada

en su espalda.

• Mantenga todo el peso de la herra-

mienta en el hombro izquierdo.

• Sin tener que inclinarse, mantenga

la cuchilla debe permanecer paralelo

al suelo y entrar f&cilmente en con-

tacto con el material a cortar.

INSTRUCCIONES DE MANEJO CON

CABEZAL DE CORTE

_IL ADVERTENOIA: Use siempre

protecci6n para los ojos. Nunca se in-

cline por encima del cabezal. La linea

puede arrojar o hacer rebotar piedras

o desechos hacia los ojos y la cara,

pudiendo causar la p6rdida de la vista

u otras graves heridas.

Antes de penetrar en la hierba o mal-

ezas que va a cortar, acelere el motor

hasta la velocidad de corte.

No haga marchar el motor a revolu-

ciones m&s altas que las necesarias.

La linea de corte cortar& de una forma

m&s eficiente sin que el motor este

acelerado a fondo. A revoluciones

m&s bajas, habr& menos ruido y me-

nor vibraci6n del motor. Siempre que

27

Page 27

nosehallecortando,suelteelgatillo

aceleradorypermitaqueelmotor

vuelvaamarchalenta.

METODOS DE CORTE

ADVERTENCIA: Use la veloci-

dad minima y no acerque el aparato

demasiado al cortar cerca de objetos

s61idos (piedra, gravilla, postes, etc.):

estos pueden da_ar el cabezal, pue-

den enredarse en la linea o la linea los

puede arrojar violentamente al aire,

causando serio peligro.

• La punta de la linea es la que corta.

Se conseguir_t mejor rendimiento y el

minimo desgaste si no se mete la

linea dentro del material que se est,.

cortando. La ilustraci6n a continuaci6n

muestra la forma correcta e incorrecta

de cortar.

La punta de la linea

es la que corta,

La linea est#.metida

dentro de1material

de t_

Para Recortar

80ml

pulgadas)

del suelo

PARA ESCALPAR - La tecnica del as-

calpado retira la vegetaci6n no desea-

da abajo a la tierra. Sostenga el cabe-

zal unos 8 cm (3 pulgadas) del suelo y

en _.ngulo. Deje que la punta de la

linea golpee contra el suelo cerca de

los _trboles, los postes, los monumen-

tos, etc. Esta t6cnica incrementa el

desgaste de la linea.

Para Escalpar

Correcta Incorrecta

• La linea retira f&cilmente el c6sped y

las malas hierbas de alrededor de pa-

redes, cercados, _.rboles y macizos de

flores; pero tambi6n es capaz de cor-

tar la corteza tierna de _trboles y ar-

bustos y de marcar las cercas.

• Para recortar o escalpar, use el apa-

rato sin acelerar a fondo, para incre-

mentar la vida Otil de la linea y dismi-

nuir el desgaste del cabezal,

especialmente:

• AI hacer trabajos livianos.