Page 1

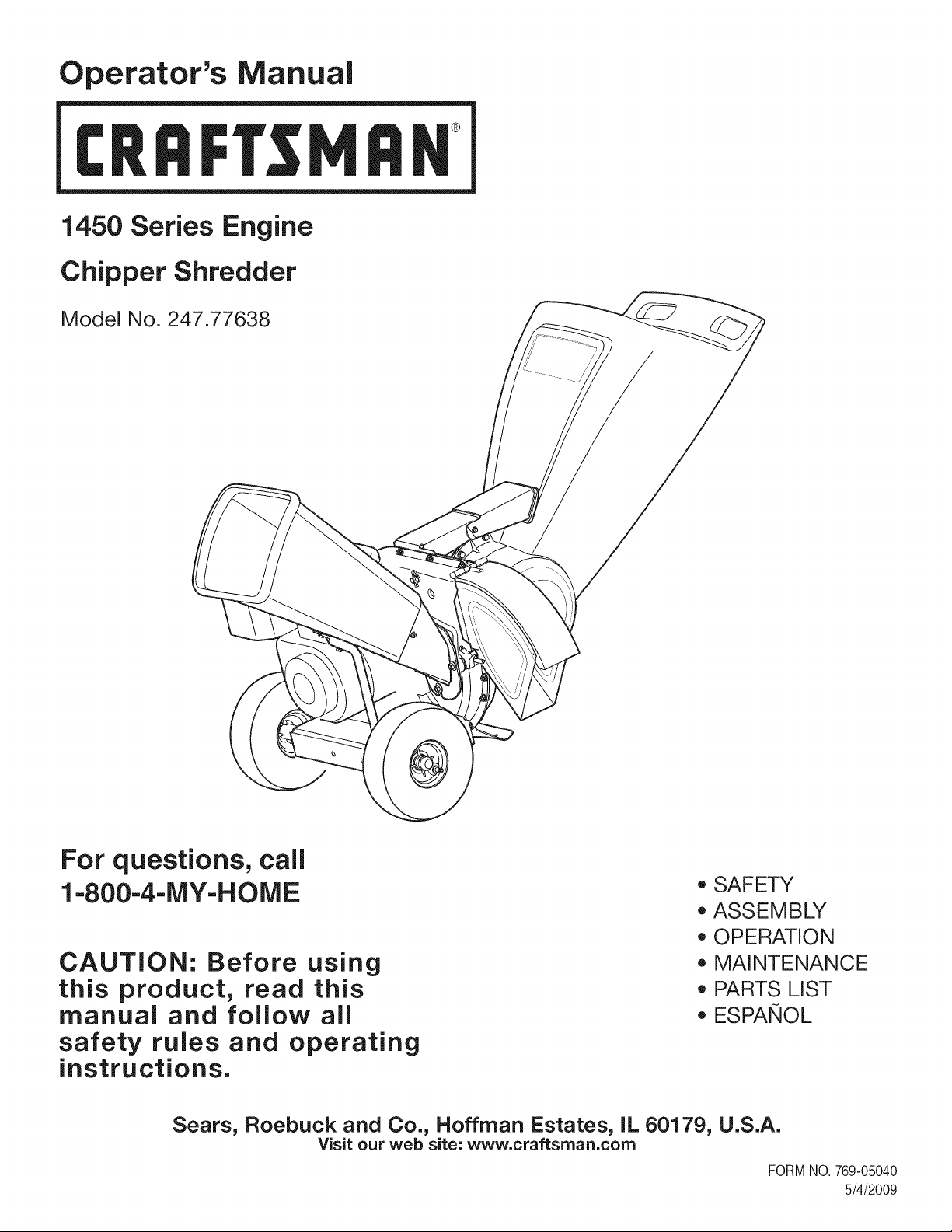

Operator's Manual

I:Rl FI'SlVl N

1450 Series Engine

Chipper Shredder

Model No. 247.77638

For questions, call

1-800-4-MY-HOME

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our web site: www.craftsman.com

,, SAFETY

* ASSEMBLY

* OPERATION

* MAINTENANCE

* PARTS LIST

. ES PAI'i,IOL

FORM1/O.769-05040

5/4/2009

Page 2

WarrantyStatement..................................Pac

SafeOperationPractices..........................Pac

SafetyLabels............................................Pac

Assembly..................................................Pac

Operation..................................................Pac

ServiceandMaintenance.........................Pac

Off-SeasonStorage..................................Pac

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthischippershredderfailsdueto a defectin materialorworkmanship

withintwoyearsfromthedate ofpurchase,returnittoany Searsstore,SearsParts&RepairServiceCenter,or otherCraftsmanoutletinthe

UnitedStatesforfreerepair(or replacementif repairprovesimpossible).

Thiswarrantyappliesfor only90daysfromthedateof purchaseif thischippershredderiseverusedfor commercialor rentalpurposes.

ThiswarrantycoversONLYdefectsin materialandworkmanship.SearswillNOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnotlimitedtoblades, sparkplug,aircleaner,flail screenand catcher

bag.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedby puncturesfromoutsideobjects,suchasnails,thorns,stumps,or glass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnot limitedtodamagecausedbyimpactingobjectsthat bendtheframeor

crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeand amountofengineoil,or failureto maintaintheequipmentaccordingtothe instructions

containedin theoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedor oxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,or productlabelreplacement.

e2

es3-6

e7

es8-11

es12-13

es14-17

TroubleShooting.......................................Page19

PartsList...................................................Page20-30

LabelMap.................................................Page31

RepairProtectionAgreement...................Page34

Espa_ol.....................................................Page35

ServiceNumbers......................................BackCover

e18

CRAFTSMAN FULLWARRANTY

Thiswarrantyappliesonlywhilethisproductiswithinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

Sears, Roebuckand Co.,Hoffman Estates,IL60179

EngineSeries: 1450

EngineOilType: SAE30

EngineOilCapacity: 28ounces

Fuel: UnleadedGasoline

SparkPlug: Champion®RC-12YC

SparkPlugGap: .030"

©SearsBrands,LLC 2

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthe personalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthismanual.Aswithanytypeof powerequipment,

carelessnessorerroronthepart oftheoperatorcan resultin

seriousinjury.Thismachineis capableofamputatingfingers,hands,

toesandfeetandthrowingdebris.Failureto observethefollowing

safetyinstructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

TRAINING

• Read,understand,andfollowall instructionson the machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplacefor futureand regularreference

andfororderingreplacementparts.

• ReadtheOperator'sManualand followallwarningsand safety

instructions.Failuretodosocanresultin seriousinjurytothe

operatorand/orbystanders.Forquestions,call 1-800-659-5917.

• Befamiliarwithallcontrolsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder16yearsofagetooperatethis

machine.Children16andovershouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultstooperatethismachinewithoutproper

instruction.

• Keepbystanders,pets,andchildrenatleast75feetfromthe

machinewhileitisin operation.Stopmachineifanyoneenters

thearea.

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotputhandsandfeetnearrotatingpartsor inthefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Neverattempttounclogeitherthefeedintakeordischarge

opening,removeor emptybag,or inspectand repairthemachine

whilethe engineisrunning.Shutthe engineoff andwaituntilall

movingpartshavecometo a completestop.Disconnectthe spark

plugwireandgroundit againsttheengine.

Your Responsibility=Restrict theuseofthis powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine.

SAVETHESEINSTRUCTIONS!

PREPARATION

• Thoroughlyinspecttheareawheretheequipmentistobeused.

Removeall rocks,bottles,cans,orotherforeignobjectswhich

couldbepickedupor thrownandcausepersonalinjuryor

damageto themachine.

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentor repair,to protectyour

eyes.Thrownobjectswhichricochetcancauseseriousinjuryto

theeyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesorjewelrycan becaughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.Wear

leatherworkgloveswhenfeedingmaterialinthe chipperchute.

• Beforestarting,checkallboltsandscrewsfor propertightnessto

besurethe machineisinsafeworkingcondition.Also,visually

inspectmachineforany damageatfrequentintervals.

• Maintainor replacesafetyandinstructionslabels,asnecessary.

3

Page 4

SafeHandling of Gasoline:

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyan approvedgasolinecontainer.

• Neverfillcontainersinsidea vehicleor ona truckor trailerbed

witha plasticliner.Alwaysplacecontainersonthe groundaway

fromyourvehiclebeforefilling.

• Whenpractical,removegas-poweredequipmentfromthetruck

ortrailerand refuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

• Keepthenozzleincontactwiththerimof thefueltankor

containeropeningatalltimesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

• Extinguishallcigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

• Neverremovegas caporaddfuelwhiletheengineishotor run-

ning.Allowenginetocool atleasttwo minutesbeforerefueling.

• Neveroverfillfueltank. Filltankto nomorethan1/2inchbelow

bottomoffillerneckto allowspacefor fuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitofftheengineandequipment.Move

unitto anotherarea.Wait5 minutesbeforestartingtheengine.

• Toreducefirehazards,keepmachinefreeof grass,leaves,or

otherdebrisbuild-up.Cleanupoil orfuelspillageand removeany

fuelsoakeddebris.

• Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlightas on awaterheater,spaceheater,

furnace,clothesdryer orothergasappliances.

OPERATION

• Donotputhandsandfeetnearrotatingpartsor in thefeeding

chambersanddischargeopening.Contactwiththe rotating

impellercanamputatefingers,hands,andfeet.

• Beforestartingthemachine,makesurethechipperchute,feed

intake,andcuttingchamberare emptyandfreeofall debris.

• Thoroughlyinspectall materialtobe shreddedandremoveany

metal,rocks,bottles,cans,or otherforeignobjectswhichcould

causepersonalinjuryor damagetothemachine.

• Ifitbecomesnecessaryto pushmaterialthroughtheshredder

hopper,usea smalldiameterstick.Donotuseyourhandsor feet.

• Iftheimpellerstrikesaforeignobjector ifyourmachineshould

startmakinganunusualnoiseorvibration,immediatelyshut

theengineoff. Allowthe impellertocometoa completestop.

Disconnectthesparkplugwire,grounditagainsttheengineand

performthefollowingsteps:

a. Inspectfordamage.

b. Repairorreplaceanydamagedparts.

c. Checkforanyloosepartsandtightento assurecontinued

safeoperation.

• Donotallowanaccumulationof processedmaterialto buildupin

thedischargearea.Thiscanpreventproperdischargeandresult

inkickbackof materialthroughthefeedopening.

• Donotattempttoshredorchipmateriallargerthanspecified

on themachineor inthismanual.Personalinjuryormachine

damagecouldresult.

• Neverattemptto unclogeitherthefeedintakeor discharge

openingwhilethe engineisrunning.Shuttheengineoff,waituntil

all movingpartshavestopped,disconnectthe sparkplugwireand

grounditagainsttheenginebeforeclearingdebris.

• Neveroperatewithoutthe shredderhopper,chipperchute,or

chutedeflectorproperlyattachedtothe machine.Neveremptyor

changedischargebagwhiletheengineis running.

• Keepallguards,deflectorsand safetydevicesin placeand

operatingproperly.

• Keepyourfaceandbodybackandtothesideof thechipper

chutewhilefeedingmaterialintothemachineto avoidaccidental

kickbackinjuries.

• Neveroperatethis machinewithoutgoodvisibilityorlight.

• Donotoperatethismachineona paved,gravelor non-level

surface.

• Donotoperatethismachinewhileundertheinfluenceof alcohol

or drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.

• Neverpick uporcarrymachinewhiletheengineisrunning.

• Ifsituationsoccurwhichare notcoveredinthis manual,usecare

andgoodjudgement.ContactCustomerSupportforassistance

andthenameofthe nearestservicedealer.

MAINTENANCE & STORAGE

• Nevertamperwith safetydevices.Checktheirproperoperation

regularly.

• Checkboltsandscrewsforpropertightnessatfrequentintervals

to keepthemachineinsafeworkingcondition.Also,visually

inspectmachinefor anydamageandrepair,ifneeded.

• Beforecleaning,repairing,or inspecting,stoptheengineand

makecertaintheimpellerandall movingpartshavestopped.

Disconnectthesparkplugwireandgrounditagainsttheengine

to preventunintendedstarting.

• Donotchangetheenginegovernorsettingsoroverspeedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

4

Page 5

• Maintainor replacesafetyandinstructionlabels,asnecessary.

Followthismanualforsafeloading,unloading,transporting,and

storageof thismachine.

Neverstorethemachineorfuel containerinsidewherethereis an

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryer,etc.

Allowmachinetocoolat least5 minutesbeforestoring.

• Alwaysrefertotheoperator'smanualforproperinstructionson

off-seasonstorage.

• Ifthefuel tankhasto bedrained,dothisoutdoors.

• Observeproperdisposallawsandregulationsforgas,oil,etc. to

protecttheenvironment.

• Accordingto theConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan Average UsefulLifeofseven(7)years,or 60hoursof

operation.At theendoftheAverage UsefulLife havethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failuretodo socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryordeath,donot modifyenginein anyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(CO),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineis equippedwithan internalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkarresterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthe mufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

Page 6

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowallinstructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

• ®

il

BYSTANDERS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop

machine if anyone enters the area.

WARNING-- THROWN DEBRIS

Never operate without the chute deflector properly attached to the machine.

EYEPROTECTION

Always wear safety glasses or safety goggles when operating this machine.

warningsandinstructionsinthis manualandonthemachine.

I_ ARNING: YourResponsibility--Restricttheuseof thispowermachinetopersonswhoread,understandandfollowthe

SAVETHESEINSTRUCTIONS!

6

J

Page 7

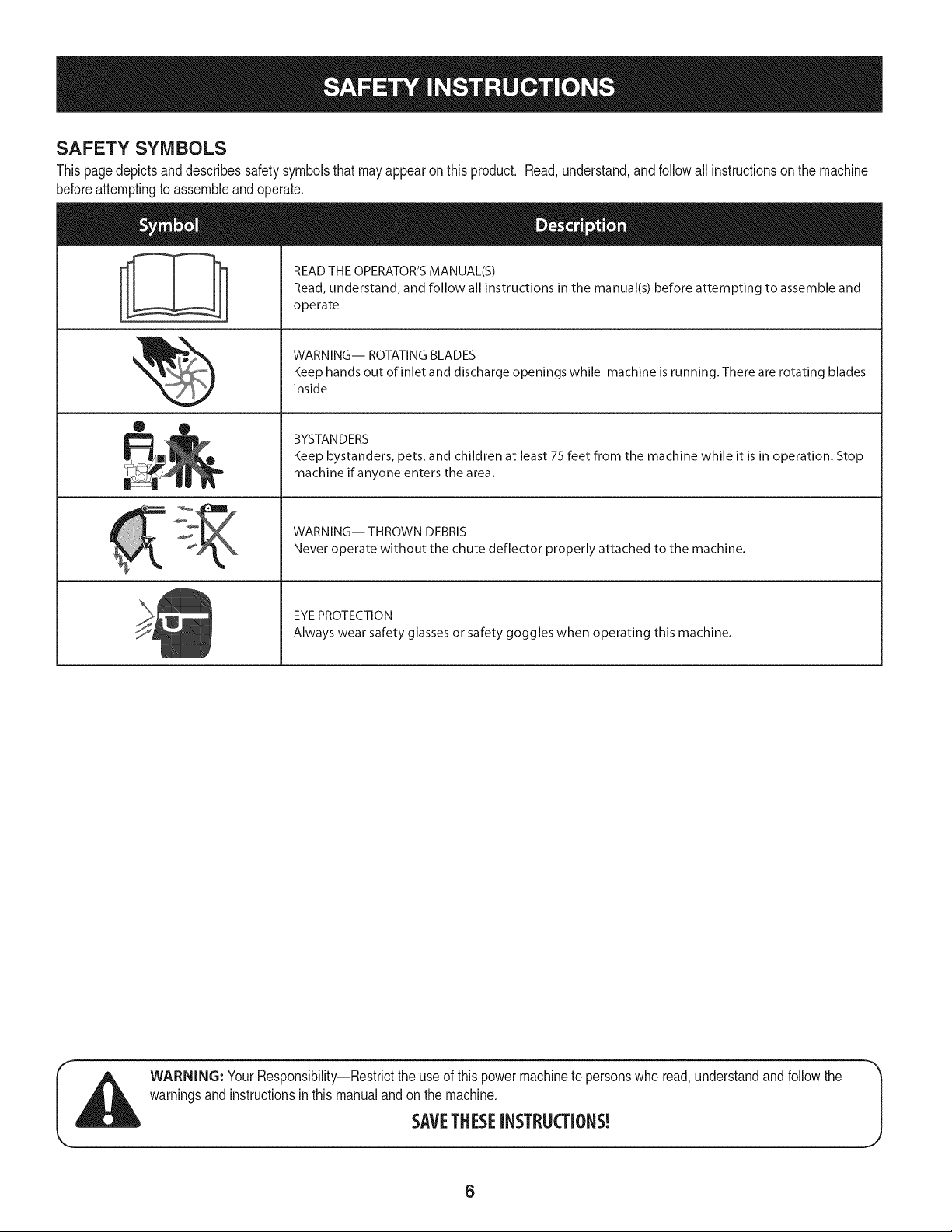

TO AVOID SERIOUS iNJURY:

• Do not operate on uneven ground where unit is

unstable, Do not operate on pavement, gravel or

other hard surfaces since objects can ricochet

and cause injury,

• To avoid a fire hazard, keep leaves, grass, and other

combustible materials away from hot engine and

muffler,

• Keep children and others away from area of

operation,

• Wear approved safety glasses, gloves and ear

protection.

TO AVOID SERIOUS iNJURY:

Read the owner's manual(s) before starting and

using unit.

Keep all shields and guards in place and securely

attached.

Keep hands, feet, face, clothing and long hair out of

Shredder Hopper, Chipper Chute and Discharge

Chute while the engine is running. Rotating cutting

blades inside these openings will cause serious

personal injury if contacted. Material being

)rocessed

may bounce back from inlet openings or be thrown

from the discharge chute. Long hair or loose clothing

may be pulled sucked into the inlet openings.

• Do not place branches over 1/2 inch diameter into

the large Shredder Hopper. Branches over 1/2 inch in

diameter should be placed in the Small Chipper

Chute.

• If the chipped shredder jams or becomes clogged,

immediately shut off the engine and wait for all

moving parts to come to a complete stop before

clearing.

• Do not install remove, adjust, or service the

discharge screen or any other part while the engine

is running, Blade contact can occur.

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

iS RUNNING.

4

7

Page 8

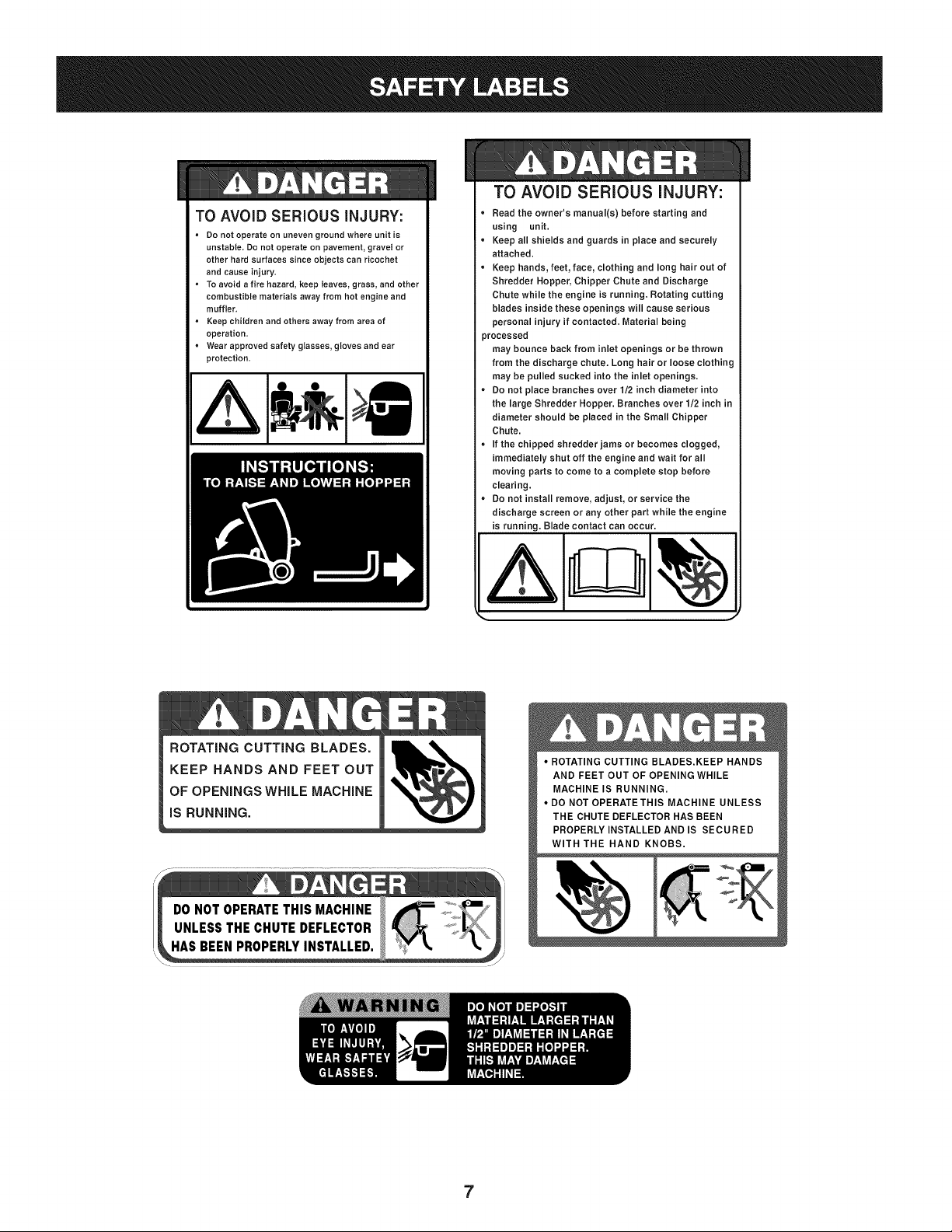

IMPORTANT:Thisunitisshippedwithoutgasolineoroil intheengine.

Becertaintoserviceenginewithgasolineandoilas instructedinthe

Operationsectionof this manualbeforeoperatingyourmachine.

NOTE:Referenceto rightand lefthandsideof theChipperShredder

isobservedfromthe operatingposition.

OPENING CARTON

1. Cuteachcornerof thecartonverticallyfromtopto bottom.

2. Removeall looseparts.

3. Removeloosepackingmaterial.

REMOVING UNiT FROM CARTON

1. Liftunit fromthereartodetachit fromunderlyingcartonmaterial

androllunitout ofcarton.

2. Checkcartonthoroughlyforanyotherlooseparts.

LOOSE PARTS IN CARTON

• HopperAssembly

• Bag

• ChuteDeflector

• ChipperChute

• Tamper

• SafetyGlasses

• EngineOil

• Owner'sManual

f

J

Figure1

f

ATTACHING THE HOPPER ASSEMBLY

1. A. Removesixhexnutsandwashersfromtheweldstudson the

impellerhousing.Donotremovesupportplate.SeeFigure1.

B. Placehopperassemblyintopositioninfrontof impeller

housing,aligningholesinhopperassemblycollarwithweld

studs.

C. Slidehopperassemblyontoweldstudsand replacewashers

andhexnuts.Donottightencompletely.

2. A. Lifthopperassemblyupto impellerbracketassembly.See

Figure2.

B.Slidethe releaserodout slightlytohookthehopperbracket

ontothe rod.SeeFigure2.

C.Tightenthesixhex nutsthatsecurehopperassemblyto

impellerhousingandalsotightenthe hexnutsthat secure

hopperbracketto hopperassembly.

Figure2

8

Page 9

ATTACHING THE CHUTE DEFLECTOR

A.Removethewingknobsfromeachside ofthe lowerimpeller

housing.SeeFigure3.

B.Removethehexlocknut,spacers,andhexboltfromthetopof

theimpellerhousing.

.

A.Alignthe chutedeflectorinpositiononthe dischargeopening

andinserthexbolt withspacerthroughhingeonchute

deflector(spacersfit insideof hinges).SeeFigure4.

B.Placesecondspaceroverhex boltinsideotherhingeand

securewithhexlocknut.

C. Securebothsidesofchutedeflectorto impellerhousingusing

wingknobspreviouslyremoved.

ATTACHING THE CHIPPER CHUTE

A.Removethethreecuppedwashersandhex nutsfromweld

studsaroundthe openingonthesideofthe impellerhousing.

SeeFigure5.

B.Removethehexbolts,flatwashers,andlocknutsfromthe two

holeson theupperendofthesupportbrace.

i

Figure3

f

Figure4

Figure5

9

Page 10

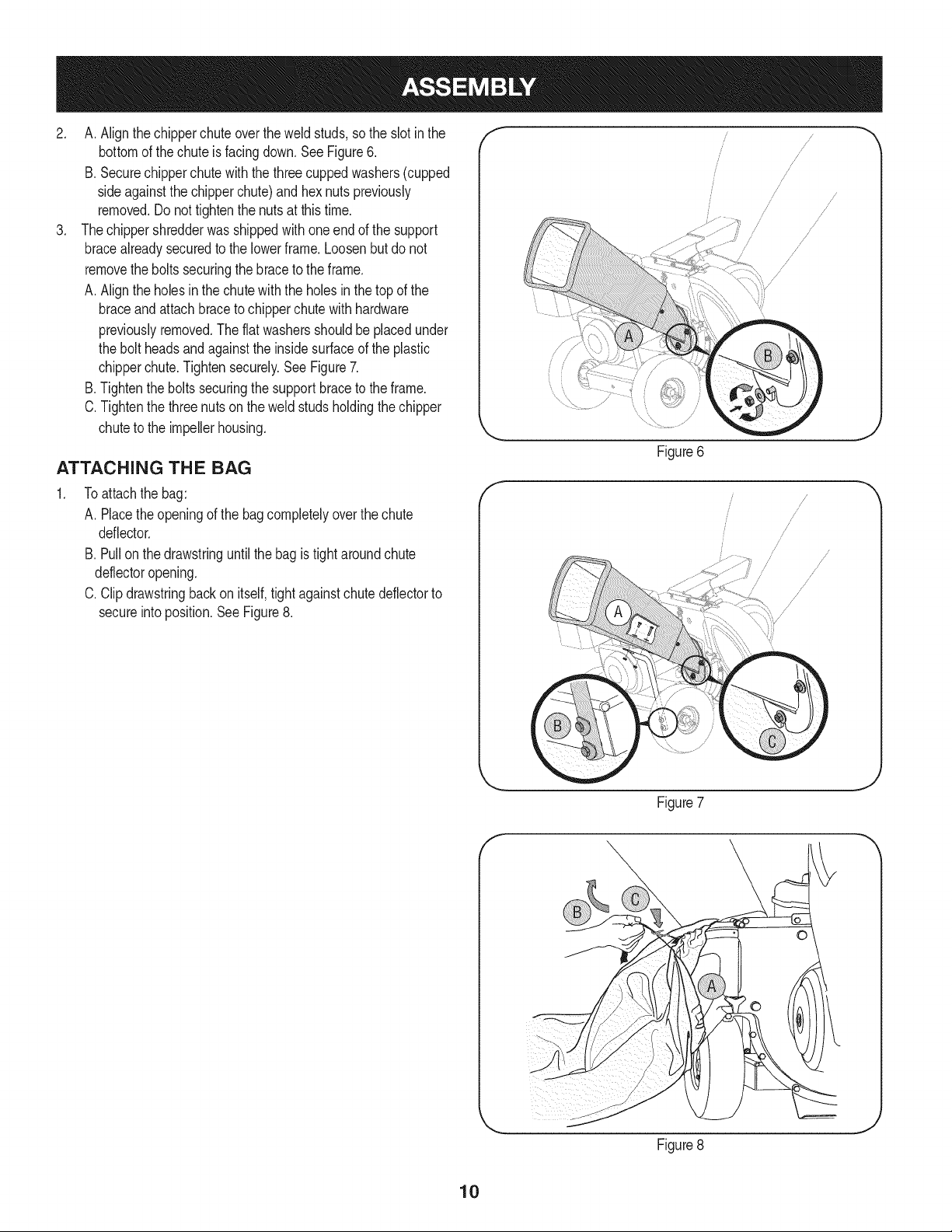

A,Alignthe chipperchuteovertheweld studs,sotheslotin the

bottomof thechuteis facingdown.SeeFigure6.

B.Securechipperchutewith thethreecuppedwashers(cupped

sideagainstthe chipperchute)andhexnutspreviously

removed.Donottightenthenutsatthistime.

.

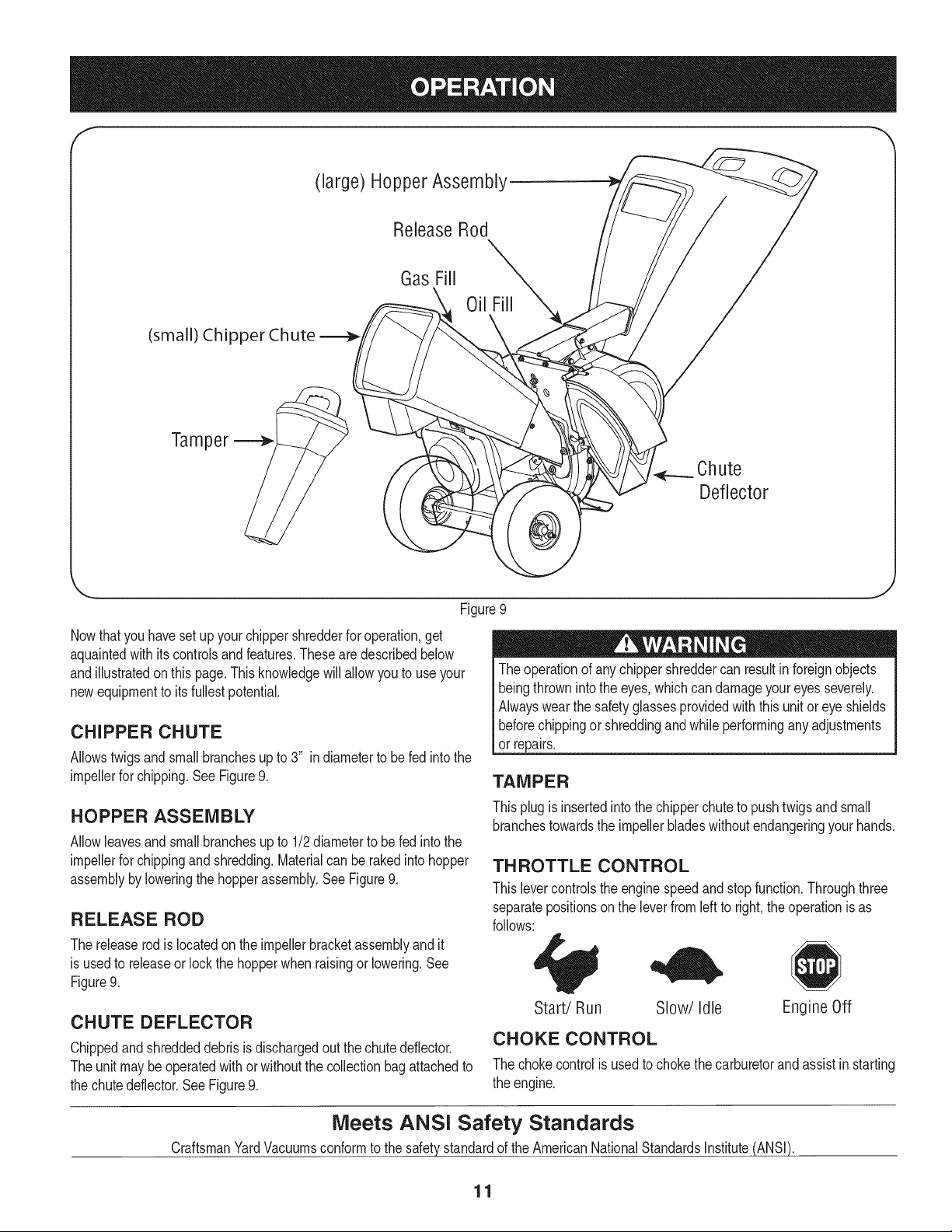

Thechippershredderwasshippedwithoneendofthesupport

bracealreadysecuredto thelowerframe.Loosenbutdo not

removetheboltssecuringthe braceto theframe.

A.Alignthe holesinthe chutewiththeholesinthe topof the

braceandattachbraceto chipperchutewithhardware

previouslyremoved,Theflatwashersshouldbeplacedunder

thebolt headsandagainstthe insidesurfaceoftheplastic

chipperchute.Tightensecurely.SeeFigure7.

B.Tightenthe boltssecuringthesupportbracetothe frame.

C.Tightenthethreenutsontheweld studsholdingthechipper

chuteto theimpellerhousing.

ATTACHING THE BAG

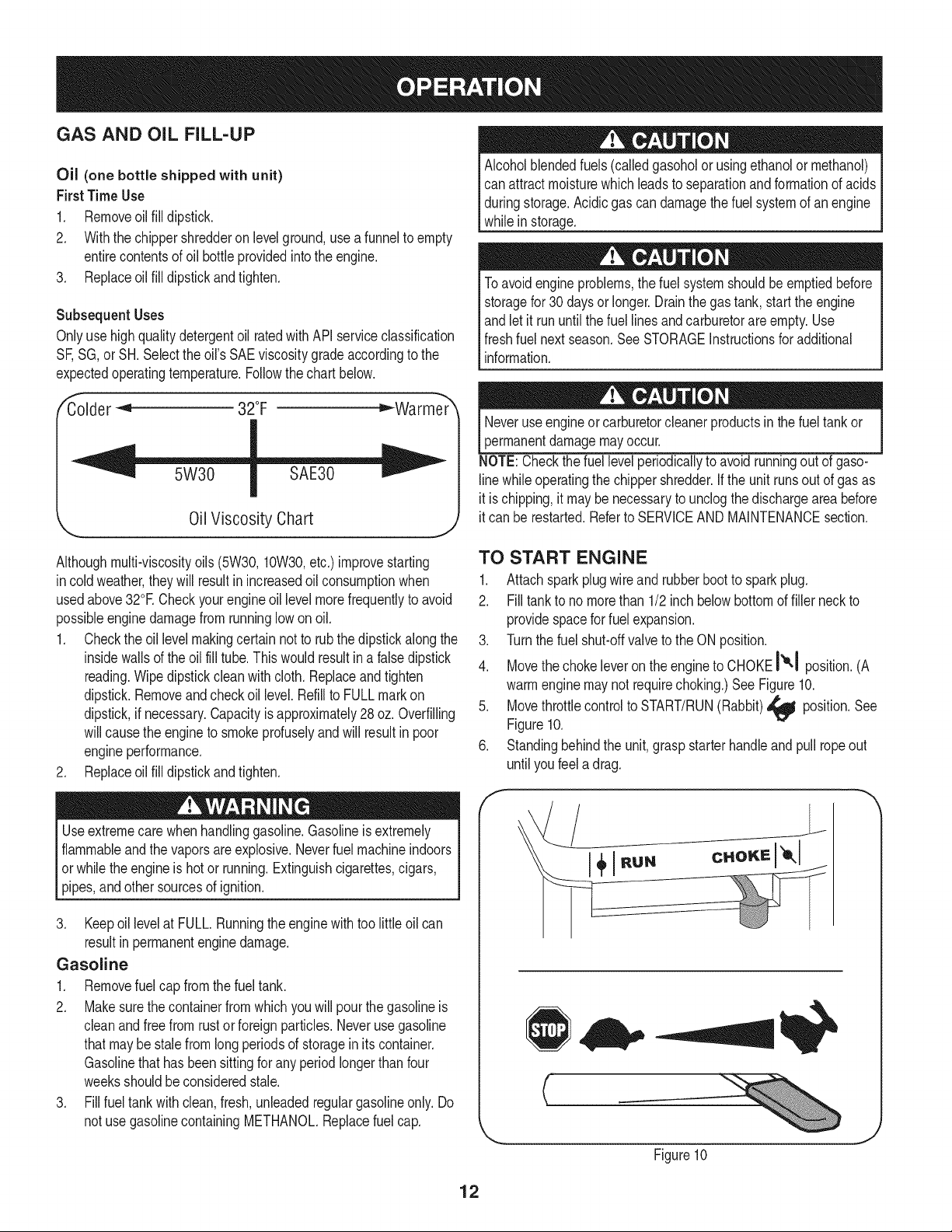

1. Toattachthe bag:

A. Placetheopeningof thebagcompletelyoverthechute

deflector,

B. Pullonthedrawstringuntilthebagistightaroundchute

deflectoropening.

C. Clipdrawstringbackon itself,tightagainstchutedeflectorto

secureintoposition.SeeFigure8.

/

/

/

/

/ ,,

/'

/

,/

/

',\ ,//

\,\ ,/

/

/ /

/ / ,,/

i /

/

J

Figure6

f

i /

/

/

/

/

/

/

/

/

/ /

/ /

10

Figure7

f

Figure8

Page 11

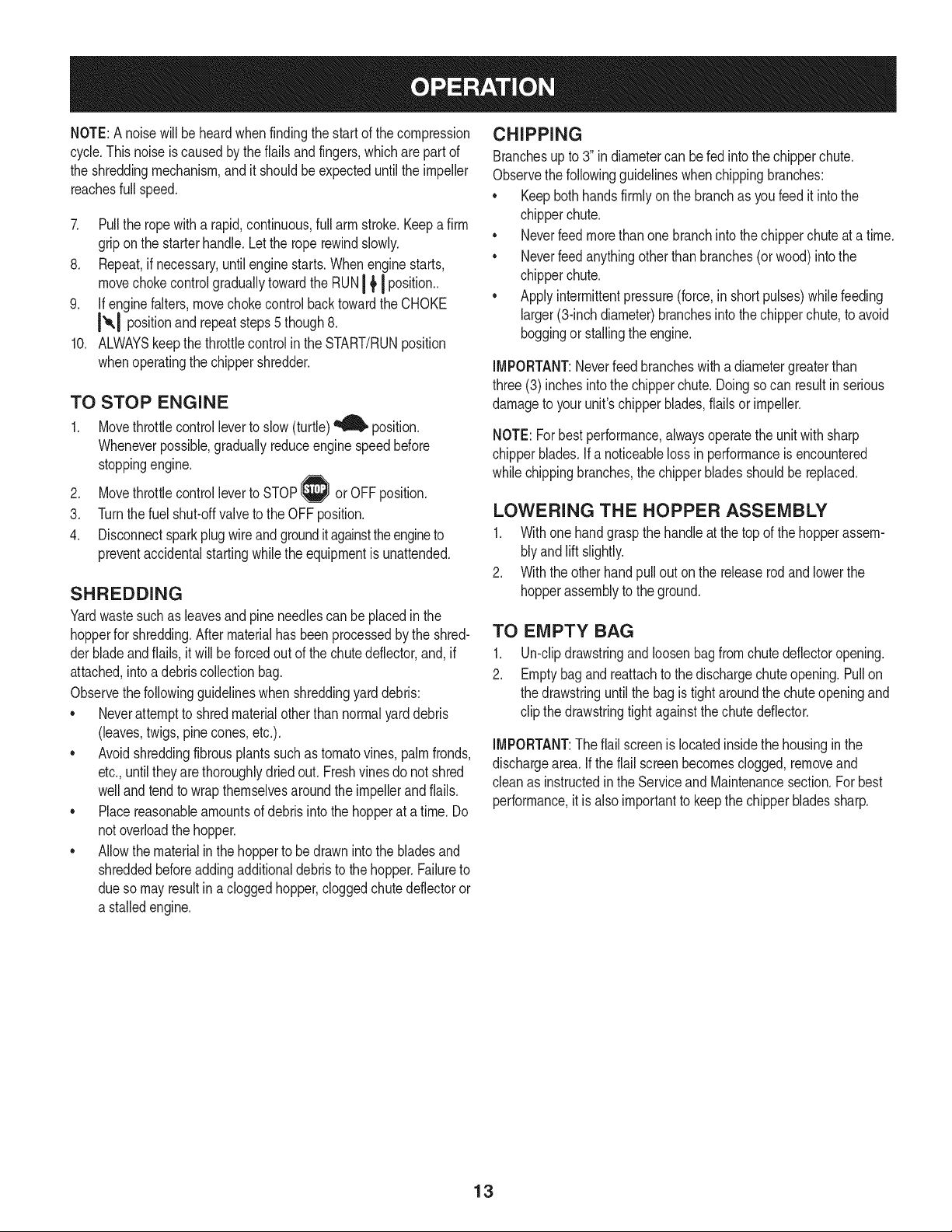

(large) HopperAssembly

ReleaseRod

GasFill

(small) Chipper Chute

Tamper===--_

Figure9

Nowthatyouhavesetupyourchippershredderforoperation,get

aquaintedwith itscontrolsandfeatures.Theseare describedbelow

andillustratedon thispage.Thisknowledgewillallowyou touseyour

newequipmenttoits fullestpotential.

CHIPPER CHUTE

Allowstwigsandsmallbranchesupto 3" indiametertobefedintothe

impellerforchipping.SeeFigure9.

HOPPER ASSEMBLY

Allowleavesandsmallbranchesupto 1/2diameterto befedintothe

impellerforchippingandshredding.Materialcanberakedintohopper

assemblybyloweringthehopperassembly.SeeFigure9.

RELEASE ROD

Thereleaserodislocatedon the impellerbracketassemblyandit

isusedto releaseorlockthehopperwhen raisingorlowering.See

Figure9.

CHUTE DEFLECTOR

Chippedandshreddeddebrisis dischargedoutthechutedeflector.

Theunit maybeoperatedwithorwithoutthecollectionbagattachedto

thechutedeflector.SeeFigure9.

Chute

Deflector

@

Theoperationof anychippershreddercan resultinforeignobjects

beingthrownintothe eyes,whichcan damageyoureyesseverely.

Alwayswearthesafetyglassesprovidedwiththisunitor eyeshields

beforechippingor shreddingandwhileperformingany adjustments

or repairs.

TAMPER

Thisplugisinsertedinto thechipperchuteto pushtwigsandsmall

branchestowardstheimpellerbladeswithoutendangeringyour hands.

TH ROTTLE CONTROL

Thislevercontrolstheenginespeedandstopfunction.Throughthree

separatepositionsontheleverfromleftto right,theoperationisas

follows:

Start/Run Slow/Idle Engine Off

CHOKE CONTROL

Thechokecontrolis usedto chokethecarburetorand assistinstarting

theengine.

Meets ANSI Safety Standards

CraftsmanYardVacuumsconformtothesafetystandardof theAmericanNationalStandardsInstitute(ANSI).

11

Page 12

GAS AND OIL FILL-UP

Oil (one bottle shipped with unit)

FirstTimeUse

1. Removeoil filldipstick.

2. Withthe chippershredderonlevelground,usea funnelto empty

entirecontentsofoil bottleprovidedintotheengine.

3. Replaceoilfill dipstickandtighten.

Subsequent Uses

Onlyuse highqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,or SH.Selecttheoil'sSAEviscositygradeaccordingtothe

expectedoperatingtemperature.Followthechartbelow.

_older _ 32°F _Warmer'_

OilViscosity Chart

Althoughmulti-viscosityoils(5W30,10W30,etc.)improvestarting

incoldweather,theywill resultinincreasedoil consumptionwhen

usedabove32°E Checkyourengineoillevel morefrequentlytoavoid

possibleenginedamagefromrunninglowon oil.

1. Checktheoil levelmakingcertainnotto rubthe dipstickalongthe

insidewallsof theoilfilltube.Thiswouldresultina falsedipstick

reading.Wipedipstickcleanwithcloth. Replaceandtighten

dipstick.Removeandcheckoil level.Refillto FULLmarkon

dipstick,if necessary.Capacityisapproximately28oz. Overfilling

willcausethe enginetosmokeprofuselyandwill resultinpoor

engineperformance.

2. Replaceoilfill dipstickandtighten.

J

Alcoholblendedfuels(calledgasoholorusingethanolormethanol)

canattractmoisturewhichleadsto separationand formationofacids

duringstorage.Acidicgascandamagethefuel systemofanengine

whilein storage.

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor30daysorlonger.Drainthegastank,starttheengine

andletit rununtilthefuellinesandcarburetorare empty.Use

freshfuelnextseason.See STORAGEInstructionsforadditional

information.

Neveruseengineorcarburetorcleanerproductsinthefuel tankor

permanentdamagemayoccur.

NOTE:Checkthefuel levelperiodicallytoavoidrunningoutofgaso-

linewhileoperatingthe chippershredder.Ifthe unitrunsoutof gasas

itis chipping,itmaybenecessarytounclogthedischargeareabefore

itcan be restarted.RefertoSERVICEANDMAINTENANCEsection.

TO START ENGINE

1. Attach sparkplugwireandrubberboottosparkplug.

2. Filltankto nomorethan1/2inchbelowbottomoffillerneckto

providespaceforfuelexpansion.

3. Turnthefuel shut-offvalvetothe ONposition.

4. Movethechokeleverontheengineto CHOKEI'i,I position.(A

warmenginemaynotrequirechoking.)See Figure10.

5. Movethrottlecontrolto START/RUN(Rabbit),_ position.See

Figure10.

6. Standingbehindtheunit,graspstarterhandleand pullropeout

untilyoufeela drag.

f

l Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthe vaporsareexplosive.Neverfuelmachineindoors

or whiletheengineis hotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesofignition.

3. Keepoil levelat FULL.Runningtheenginewithtoo littleoil can

resultinpermanentenginedamage.

Gasoline

1. Removefuelcap fromthefuel tank.

2. Makesurethecontainerfromwhichyouwillpourthegasolineis

cleanandfreefromrustor foreignparticles.Neverusegasoline

thatmaybestalefromlongperiodsofstoragein itscontainer.

Gasolinethathasbeensittingfor anyperiodlongerthanfour

weeksshouldbeconsideredstale.

3. Fillfueltankwithclean,fresh,unleadedregulargasolineonly.Do

notusegasolinecontainingMETHANOL.Replacefuelcap.

J

Figure10

12

Page 13

NOTE:A noisewillbeheardwhenfindingthestartofthe compression

cycle.Thisnoiseis causedbythe flailsandfingers,whicharepartof

theshreddingmechanism,andit shouldbe expecteduntiltheimpeller

reachesfull speed.

7. Pullthe ropewitha rapid,continuous,fullarmstroke.Keepa firm

griponthestarterhandle.Lettheroperewindslowly.

8. Repeat,if necessary,untilenginestarts.Whenenginestarts,

movechokecontrolgraduallytowardtheRUNI JtIposition..

9. If enginefalters,movechokecontrolbacktowardtheCHOKE

I'o,I positionandrepeatsteps5 though8.

10. ALWAYSkeepthe throttlecontrolinthe START/RUNposition

whenoperatingthe chippershredder.

TO STOP ENGINE

1. Movethrottlecontrolleverto slow(turtle)'_ position.

Wheneverpossible,graduallyreduceenginespeedbefore

stoppingengine.

2. Movethrottlecontrolleverto STOPI or OFFposition.

3. Turnthefuel shut-offvalvetotheOFFposition.

4. Disconnectsparkplugwireandgrounditagainsttheengineto

preventaccidentalstartingwhiletheequipmentisunattended.

SHREDDING

Yardwastesuchas leavesandpineneedlescanbe placedinthe

hopperforshredding.Aftermaterialhasbeenprocessedbythe shred-

derbladeandflails,it willbeforcedout ofthechutedeflector,and,if

attached,into adebriscollectionbag.

Observethefollowingguidelineswhenshreddingyarddebris:

• Neverattempttoshredmaterialotherthannormalyarddebris

(leaves,twigs,pinecones,etc.).

• Avoidshreddingfibrousplantssuchas tomatovines,palmfronds,

etc.,untiltheyare thoroughlydriedout.Freshvinesdo notshred

wellandtend towrapthemselvesaroundtheimpellerandflails.

• Placereasonableamountsofdebrisintothe hopperata time.Do

notoverloadthe hopper.

• Allowthematerialinthehopperto bedrawnintothebladesand

shreddedbeforeaddingadditionaldebristo thehopper.Failureto

duesomayresultin acloggedhopper,cloggedchutedeflectoror

a stalledengine.

CHIPPING

Branchesupto3" in diametercanbefedintothechipperchute.

Observethefollowingguidelineswhenchippingbranches:

• Keepbothhandsfirmlyonthebranchas youfeed itintothe

chipperchute.

• Neverfeed morethanonebranchintothechipperchuteata time.

• Neverfeed anythingotherthan branches(orwood)intothe

chipperchute.

• Applyintermittentpressure(force,inshortpulses)whilefeeding

larger(3-inchdiameter)branchesintothechipperchute,toavoid

boggingor stallingtheengine.

IMPORTANT:Neverfeed brancheswitha diametergreaterthan

three(3)inchesintothechipperchute.Doingsocan resultin serious

damageto yourunit'schipperblades,flailsor impeller.

NOTE:Forbestperformance,alwaysoperatetheunitwith sharp

chipperblades.If a noticeablelossinperformanceisencountered

whilechippingbranches,thechipperbladesshouldbe replaced.

LOWERING THE HOPPER ASSEMBLY

1. Withonehandgraspthehandleat thetopofthe hopperassem-

blyandlift slightly.

2. Withthe otherhandpulloutonthereleaserodandlowerthe

hopperassemblytotheground.

TO EMPTY BAG

1. Un-clipdrawstringandloosenbagfromchutedeflectoropening.

2. Emptybagandreattachtothe dischargechuteopening.Pullon

thedrawstringuntilthe bagistightaroundthe chuteopeningand

clipthe drawstringtightagainstthechutedeflector.

IMPORTANT:Theflailscreenislocatedinsidethehousingin the

dischargearea.Iftheflailscreenbecomesclogged,removeand

cleanas instructedintheServiceand Maintenancesection.Forbest

performance,itisalso importanttokeepthechipperbladessharp.

13

Page 14

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

EachUse

1st5 - 8 hours

25 hours

Annuallyor50hours

Annuallyor100hours

BeforeStorage 1. Fuelsystem

Underheavyloador inhightemperatures

.

Engineoillevel

2.

Looseormissinghardware

3.

Unitandengine.

1.

Engineoil

1.

Engineoill-

2.

Aircleaner

3.

Controllinkagesand pivots

1.

Engineoil

2.

Muffler

1.

Sparkplug

1. Check

2. Tightenor replace

3. Clean

1. Change

1. Change

2. Replace

3. Lubewithlightoil

1. Change

2. Inspect

1. Clean,checkand resetgap,or

1. Runengineuntilit stopsfromlackof

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumnto keeptrackof

completedmaintenancetasks.Tolocatethe nearest SearsService

Centeror toscheduleservice,simplycontactSearsat

1-800-4-MY-HOME®.

replacesparkplug.

fueloradda gasolineadditivetothe

gasin thetank.

Alwaysstopengineanddisconnectsparkplugwire beforeperforming

Ianymaintenanceoradjustments.Alwayswearsafetyglassesduring

[operationor whileperforminganyadjustmentsor repairs.

GENERAL RECOMMENDATIONS

• Alwaysobserveallsafetyrulesfoundonproductlabelsandin

thisoperator'smanualwhenperforminganymaintenance.Safety

rulescan befoundonthe productlabelsandin thisOperator's

Manualbeginningon page3.

• Thewarrantyonthischippershredderdoesnotcoveritemsthat

havebeensubjectedto operatorabuseor negligence.Toreceive

fullvalue fromwarranty,operatormustmaintaintheequipmentas

instructedhere.

• Someadjustmentswillhaveto be madeperiodicallyto maintain

yourunit properly.

• Periodicallycheckallfastenersand makesurethesearetight.

ENGINE MAINTENANCE

Checking the Spark Plug

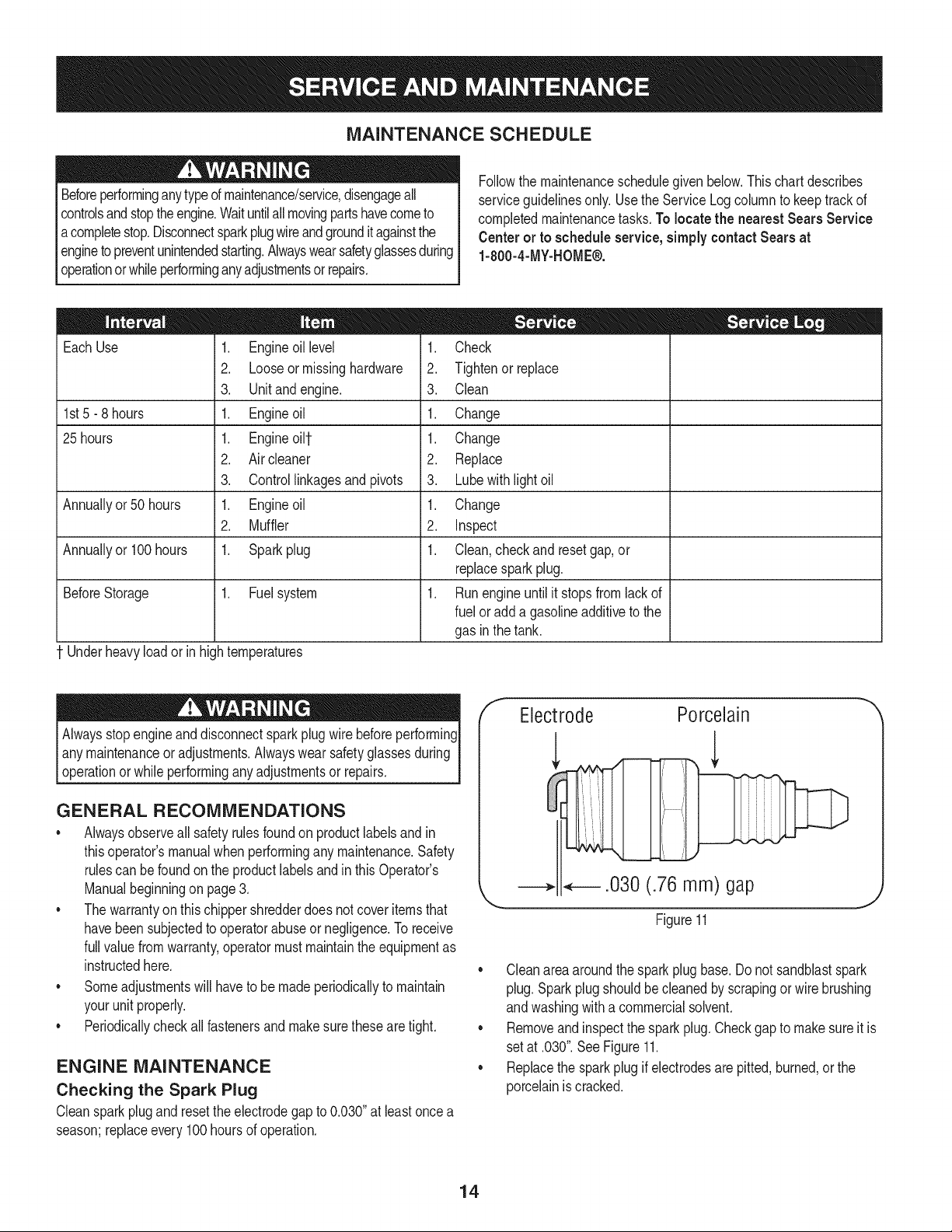

Cleansparkplugandresettheelectrodegapto0.030"atleastoncea

season;replaceevery100hoursof operation.

f

Electrode

Porcelain

,L

.030 (.76 mm) gap

Figure 11

• Cleanareaaroundthesparkplugbase.Donot sandblastspark

plug.Sparkplugshouldbecleanedbyscrapingorwirebrushing

andwashingwitha commercialsolvent.

• Removeandinspectthe sparkplug.Checkgaptomakesureitis

setat .030".SeeFigure11.

• Replacethe sparkplugif electrodesare pitted,burned,orthe

porcelainiscracked.

14

Page 15

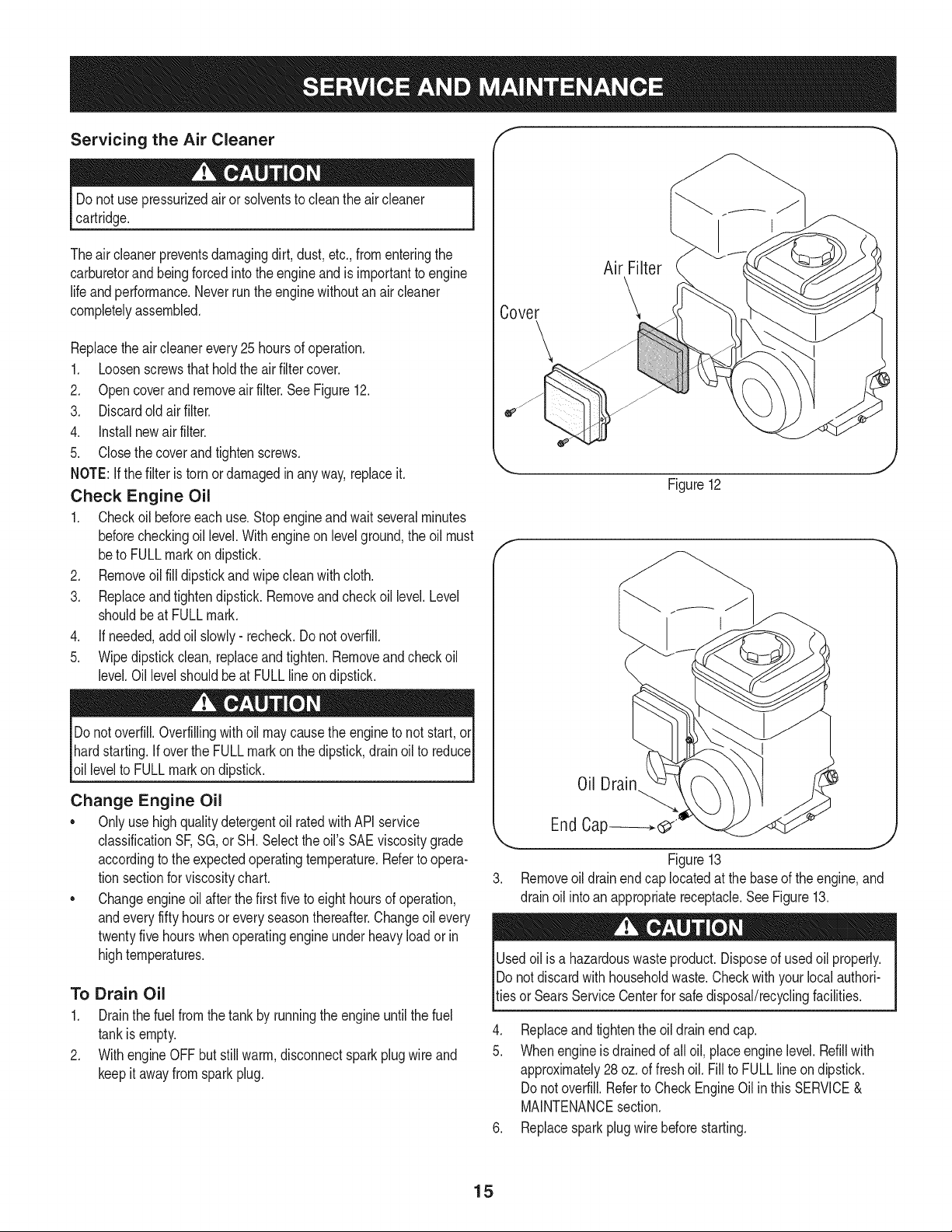

Servicing the Air Cleaner f

Donotusepressurizedairor solventstocleantheaircleaner

cartridge.

Theair cleanerpreventsdamagingdirt,dust,etc.,fromenteringthe

carburetorand beingforcedintotheengineandis importanttoengine

lifeandperformance.Neverruntheenginewithoutan aircleaner

completelyassembled.

Replacetheaircleanerevery25 hoursof operation.

1. Loosenscrewsthatholdtheairfiltercover.

2. Opencoverandremoveairfilter.See Figure12.

3. Discardold airfilter.

4. Installnewairfilter.

5. Closethe coverandtightenscrews.

NOTE:Ifthe filteristorn ordamagedinanyway,replaceit.

Check Engine Oil

1. Checkoilbeforeeachuse.Stopengineandwaitseveralminutes

beforecheckingoil level.Withengineon levelground,theoil must

beto FULLmarkondipstick.

2. Removeoilfilldipstickandwipecleanwithcloth.

3. Replaceandtightendipstick.Removeandcheckoil level.Level

shouldbeat FULLmark.

4. If needed,addoil slowly- recheck.Donotoverfill.

5. Wipedipstickclean,replaceandtighten.Removeandcheckoil

level.Oil levelshouldbe atFULLlineondipstick.

3over

_ J

Figure12

Donotoverfill.Overfillingwithoil maycausetheenginetonotstart,or

hardstarting.If overthe FULLmarkon thedipstick,drainoilto reduce

oil leveltoFULLmarkondipstick.

Change Engine Oil

* OnlyusehighqualitydetergentoilratedwithAPIservice

classificationSF,SG, orSH.Selecttheoil'sSAEviscositygrade

accordingtotheexpectedoperatingtemperature.Refertoopera-

tionsectionforviscositychart.

, Changeengineoil afterthefirst fivetoeighthoursofoperation,

andeveryfifty hoursoreveryseasonthereafter.Changeoilevery

twentyfivehourswhenoperatingengineunderheavyloadorin

hightemperatures.

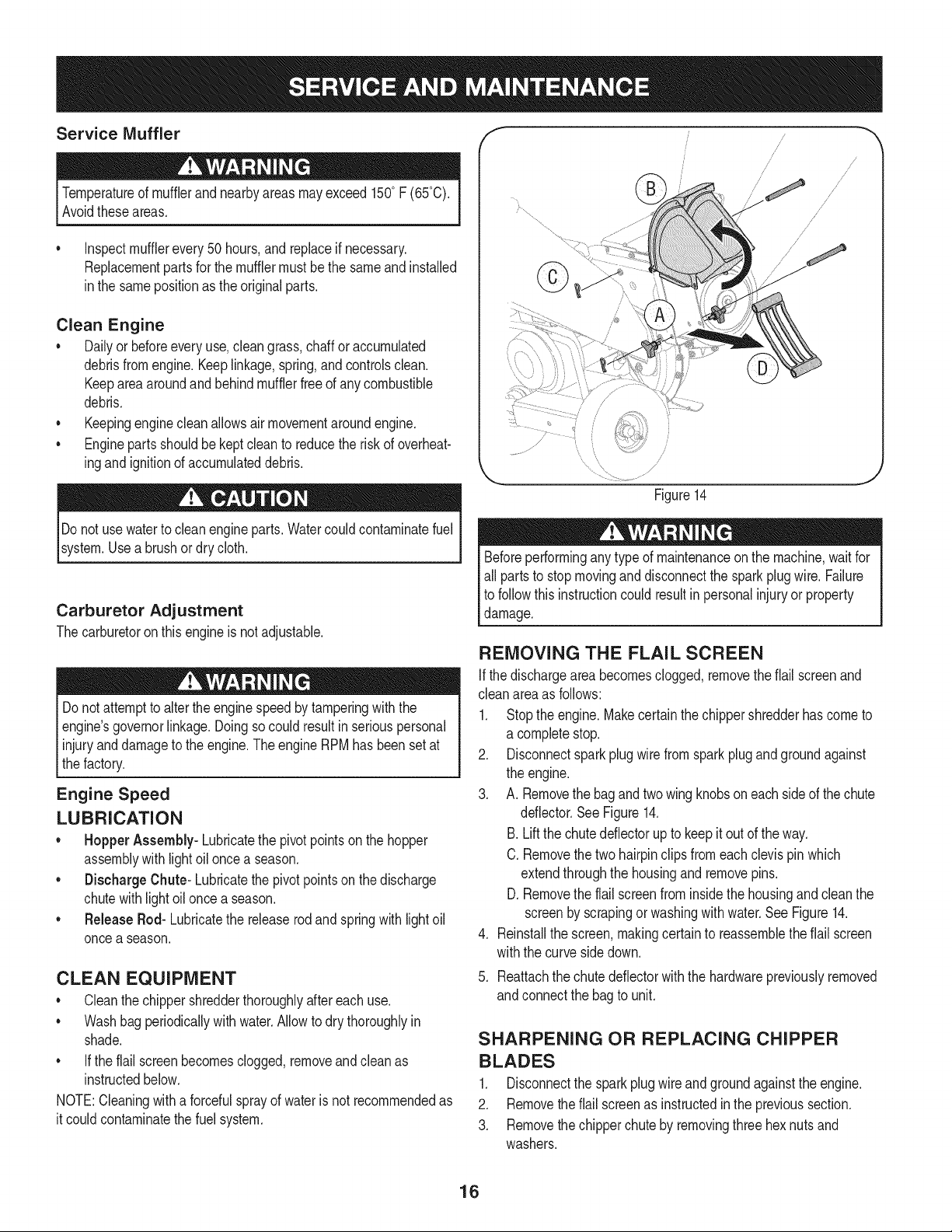

To Drain Oil

1. Drainthefuelfromthetankby runningtheengineuntil thefuel

tankisempty.

2. WithengineOFFbutstillwarm,disconnectsparkplugwire and

keepitawayfromsparkplug.

End Cap----_d_ _

J

Figure13

3. Removeoil drainendcap locatedatthebaseoftheengine,and

drainoil intoanappropriatereceptacle.SeeFigure13.

Usedoil isahazardouswasteproduct.Disposeofusedoil properly.

IDo notdiscardwithhouseholdwaste.Checkwithyour localauthori-

_tiesorSearsServiceCenterforsafedisposal/recyclingfacilities.

.

Replaceandtightentheoildrainendcap.

5.

Whenengineis drainedofall oil,placeenginelevel.Refillwith

approximately28oz.offreshoil.Fill toFULLlineondipstick.

Donot overfill.Referto CheckEngineOil inthis SERVICE&

MAINTENANCEsection.

6. Replacesparkplugwirebeforestarting.

15

Page 16

Service IVluffler f

Temperatureof mufflerandnearbyareasmayexceed150°F(65°C).

Avoidtheseareas.

• Inspectmufflerevery50 hours,andreplaceif necessary.

Replacementpartsforthemufflermustbethe sameandinstalled

inthe samepositionastheoriginalparts.

Clean Engine

Dailyor beforeeveryuse,cleangrass,chaffor accumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustible

debris.

• Keepingenginecleanallowsairmovementaroundengine.

• Enginepartsshouldbe keptcleanto reducetheriskof overheat-

ingandignitionofaccumulateddebris.

Donot usewatertocleanengineparts.Watercouldcontaminatefuel

system.Usea brushordrycloth.

Carburetor Adjustment

Thecarburetoronthis engineis notadjustable.

Donot,attempttoaltertheenginespeedbytamperingwiththe

engines governorlinkage.Doingsocouldresultin seriouspersonal

Iinjuryanddamagetotheengine.TheengineRPMhasbeensetat

thefactory.

Engine Speed

LUBRICATION

• HopperAssembly-Lubricatethe pivotpointson thehopper

assemblywithlightoilonceaseason.

• DischargeChute- Lubricatethepivotpointsonthedischarge

chutewithlightoilonce a season.

• ReleaseRod-Lubricatethereleaserodand springwith lightoil

oncea season.

CLEAN EQUIPMENT

• Cleanthechippershredderthoroughlyaftereachuse.

• Washbagperiodicallywithwater.Allowto drythoroughlyin

shade.

• Iftheflailscreenbecomesclogged,removeandcleanas

instructedbelow.

NOTE:Cleaningwitha forcefulsprayof waterisnotrecommendedas

itcouldcontaminatethefuelsystem.

//

/

i

/

/

Figure14

Beforeperforminganytypeof maintenanceonthe machine,waitfor

all partsto stopmovinganddisconnectthesparkplugwire.Failure

tofollowthis instructioncouldresultin personalinjuryor property

damage.

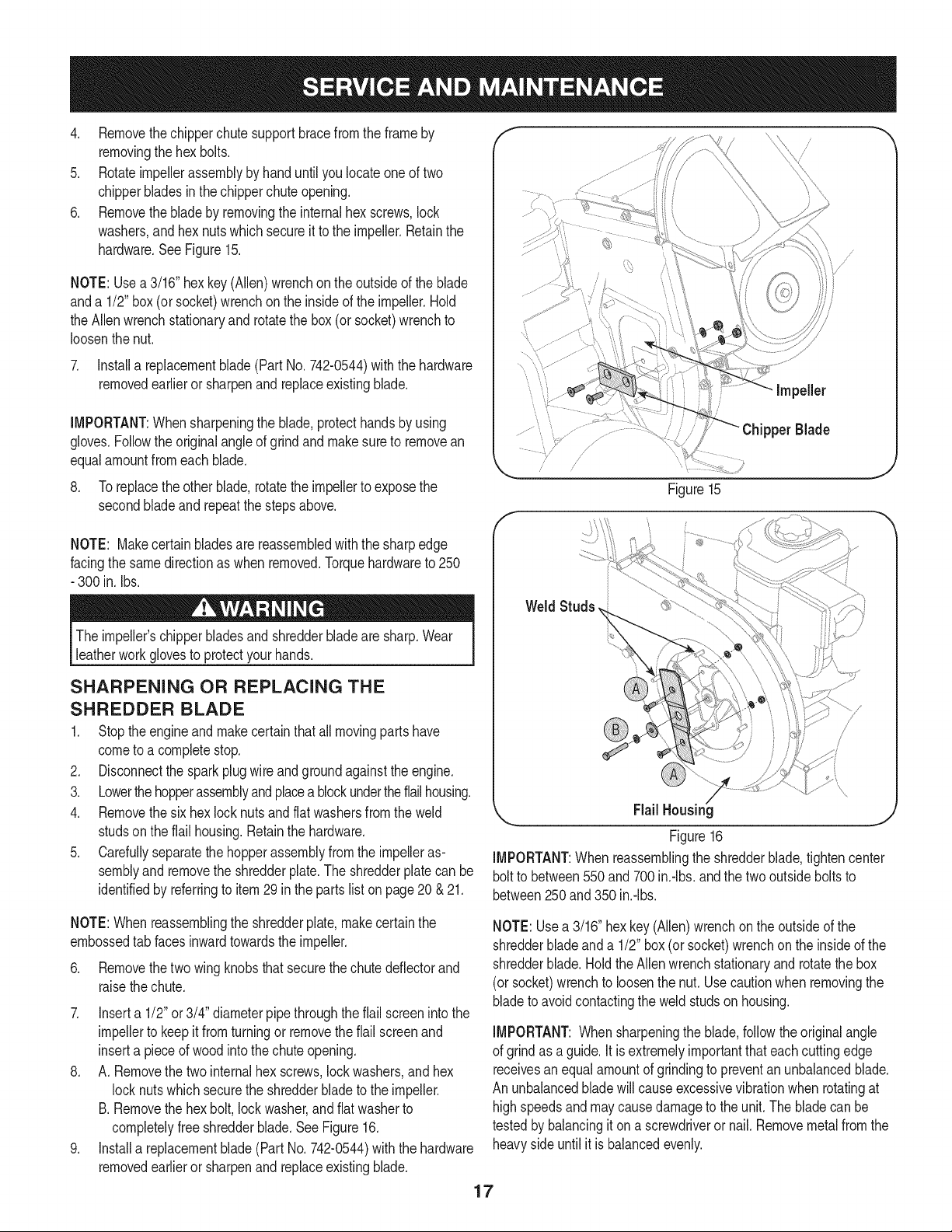

REMOVING THE FLAIL SCREEN

Ifthedischargeareabecomesclogged,removethe flailscreenand

cleanareaas follows:

1. Stoptheengine.Makecertainthechippershredderhascometo

a completestop.

2. Disconnectsparkplugwirefromsparkplugandgroundagainst

theengine.

3. A. Removethebagandtwowingknobsoneachsideofthechute

deflector.SeeFigure14.

B.Liftthe chutedeflectorupto keepitoutofthe way.

C.Removethetwo hairpinclipsfromeachclevispinwhich

extendthroughthehousingandremovepins.

D.Removetheflailscreenfrominsidethehousingandcleanthe

screenbyscrapingorwashingwithwater.SeeFigure14.

4. Reinstallthescreen,makingcertainto reassembletheflailscreen

withthecurvesidedown.

5. Reattachthechutedeflectorwiththehardwarepreviouslyremoved

andconnectthe bagto unit.

SHARPENING OR REPLACING CHIPPER

BLADES

1. Disconnectthesparkplugwireandgroundagainsttheengine.

2. Removetheflailscreenas instructedinthe previoussection.

3. Removethechipperchuteby removingthreehexnutsand

washers.

16

Page 17

4, Removethechipperchutesupportbracefromthe frameby

removingthehexbolts.

5. Rotateimpellerassemblybyhanduntilyoulocateoneoftwo

chipperbladesin thechipperchuteopening.

6, Removethebladeby removingtheinternalhexscrews,lock

washers,andhexnutswhichsecureittothe impeller.Retainthe

hardware,SeeFigure15,

NOTE:Usea3/16"hexkey(Allen)wrenchon theoutsideofthe blade

anda 1/2"box(or socket)wrenchontheinsideofthe impeller.Hold

theAllenwrenchstationaryandrotatethe box(or socket)wrenchto

loosenthenut.

7. Installa replacementblade(Part No.742-0544)withthe hardware

removedearlierorsharpenandreplaceexistingblade.

Impeller

IMPORTANT:Whensharpeningthe blade,protecthandsby using

gloves.Followtheoriginalangleofgrindandmakesuretoremovean

equalamountfromeachblade.

8. To replacetheotherblade,rotatetheimpellertoexposethe

secondbladeand repeatthestepsabove.

NOTE: Makecertainbladesare reassembledwiththesharpedge

facingthesamedirectionas whenremoved.Torquehardwareto250

- 300in.Ibs.

Theimpeller'schipperbladesandshredderbladearesharp.Wear

leatherworkglovesto protectyourhands.

SHARPENING OR REPLACING THE

SHREDDER BLADE

1. Stoptheengineandmakecertainthatallmovingpartshave

cometoa completestop.

2. Disconnectthesparkplugwire andgroundagainsttheengine.

3. Lowerthehopperassemblyandplacea blockundertheflailhousing.

4. Removethesix hexlocknutsandflatwashersfromtheweld

studsonthe flailhousing.Retainthehardware.

5. Carefullyseparatethehopperassemblyfromthe impelleras-

semblyandremovetheshredderplate.Theshredderplatecan be

identifiedby referringtoitem29in the partsliston page20 &21.

Blade

J

Figure15

Weld Studs,

/

Flail Housing

Figure16

IMPORTANT:Whenreassemblingtheshredderblade,tightencenter

boltto between550and700in.-Ibs,andthetwooutsideboltsto

between250and350in.-Ibs.

NOTE:Whenreassemblingtheshredderplate,makecertainthe

embossedtabfacesinwardtowardstheimpeller.

6. Removethetwo wingknobsthatsecurethe chutedeflectorand

raisethe chute.

7. Inserta 1/2"or3/4" diameterpipethroughtheflailscreenintothe

impellertokeepit fromturningorremovetheflailscreenand

inserta pieceof woodintothe chuteopening.

8. A. Removethetwointernalhexscrews,lockwashers,andhex

locknutswhichsecurethe shredderbladetotheimpeller.

B.Removethehexbolt,lockwasher,andflat washerto

completelyfreeshredderblade.SeeFigure16.

9. Installa replacementblade(Part No.742-0544)withthehardware

removedearlierorsharpenandreplaceexistingblade.

NOTE:Usea 3/16"hexkey(Allen)wrenchonthe outsideofthe

shredderbladeanda 1/2"box(or socket)wrenchon theinsideof the

shredderblade.HoldtheAllenwrenchstationaryandrotatethebox

(orsocket)wrenchtoloosenthenut. Usecautionwhen removingthe

bladetoavoidcontactingthe weldstudson housing.

IMPORTANT:Whensharpeningtheblade,followtheoriginalangle

ofgrindas a guide.Itisextremelyimportantthateachcuttingedge

receivesan equalamountofgrindingtopreventanunbalancedblade.

An unbalancedbladewillcauseexcessivevibrationwhenrotatingat

highspeedsandmaycausedamagetotheunit.Thebladecanbe

testedby balancingiton ascrewdriverornail.Removemetalfromthe

heavysideuntil itisbalancedevenly.

17

Page 18

Neverstorechippershredderwithfuel in tankindoorsor in poorly

ventilatedareaswherefuelfumesmayreachan openflame,spark,

or pilotlightasona furnace,waterheater,clothesdryer,orgas

appliance.

PREPARING THE ENGINE

Forenginesstoredover30 days:

1. To preventgumfromforminginfuel systemoroncarburetor

parts,runengineuntilit stopsfromlackof fuelor addagasoline

additivetothe gasinthe tank.Ifyouusea gasadditive,runthe

engineforseveralminutestocirculatetheadditivethroughthe

carburetor--afterwhichtheengineandfuel canbestoredup to

six months.

2. Whileengineis stillwarm,changetheoil. SeeChangeEngineOil

in SERVICEANDMAINTENANCEsection.

3. Removesparkplugand pourapproximately1oz. (30ml)ofclean

engineoil intothe cylinder.Pulltherecoilstarterseveraltimesto

distributetheoil,andreinstallthe sparkplug.

4. Cleanengineofsurfacedebris.

PREPARING THE CHIPPER SHREDDER

* Whenstoringthechippershredderinan unventilatedor metal

storageshed,careshouldbetakento rustproofthenon-painted

surfaces.Usinga lightoil orsilicone,coattheequipment,

especiallyanysprings,bearings,andcables.

, Removealldirt fromexteriorof engineandequipment.

, Followlubricationrecommendations.

o Storeequipmentina clean,dry area.Donotstorenextto

corrosivematerials,suchasfertilizer.Donotstoreinan area

whereequipmentispresentthatmayusea pilot lightorhasa

componentthatcancreatea spark.

18

Page 19

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

Enginefailstostart

Enginerunserratically

Engineoverheats

Enginehesitatesat highRPMs 1. Sparkpluggapsettooclose

Engineidlespoorly 1. Fouledsparkplug

Excessivevibration 1. Loosepartsor damagedimpeller

Unitdoesnotdischarge 1. Chuteddlectorclogged

Rateofdischargeslows

considerablyorcompositionof

dischargedmaterialchanges

1. Throttlelevernot incorrectstartingposition

2. Chokenot intheCHOKEposition

3. Sparkplugwiredisconnected

4. Faultysparkplug

5. Fueltankemptyorstalefuel

6. Cannotpullrecoilcord

7. Engineflooded

1. UnitrunningonCHOKE

2. Sparkplugwireloose

3. Stalefuel

4. Waterordirt in fuel system

5. Dirtyair cleaner

6. LowengineRPM

7. Carburetoroutofadjustment

1. Engineoillevellow

2. Airflowrestricted

2. Dirtyair cleaner

2. Foreignobjectlodgedin impeller

3. Lowengine RPM

1. LowengineRPM

2. Chipperbladedull

1. Movethrottleleverto START/RUNposition.

2. MoveCHOKEto theCHOKEposition.

3. Connectwireto sparkplug.

4. Clean,adjustgap,or replace.

5. Filltankwithclean,freshgasoline.

6. Obstructionlodgedinimpeller.Disconnectspark

plugwireandremovelodgedobject.

7. Waita fewminutesto restart.

1. Movechokelevertothe RUNposition.

2. Connectandtightensparkplugwire.

3. Filltankwithfreshgasoline.

4. Refillwithfreshfuel.

5. Cleanor replaceair cleanerfilter.

6. Alwaysrunengineatfull throttle.

7. ContactyourSearsParts& RepairCenter.

1. Fillenginewithproperamountand typeofoil.

2. Cleandebrisfromaroundthe engine'scoolingfins

andblowerhousing.

1. Removesparkplugandadjustgap.

1. Replacesparkplugandadjustgap.

2. Replaceaircleanercartridge.

1. Stopengineimmediatelyanddisconnectsparkplug

wire.ContactyourSearsParts& RepairCenter.

1. Stopengineimmediatelyanddisconnectspark

plugwire.Cleanflail screenandinsideof discharge

opening.

2. Stopengineanddisconnectsparkplugwire.

Removelodgedobject.

3. Alwaysrunengineatfull throttle.

1. Alwaysrunengineatfull throttle.

2. Replaceorsharpenchipperbladeor contactyour

SearsParts& RepairCenter.

Page 20

Craftsman Chipper Shredder -- Model No. 247.77638

/ ;/

/ /

; /

/

_ ....

/

2O

Page 21

Craftsman Chipper Shredder B IViodel No. 247.77638

936-0217 LockWasher,3/8

2. 914-0149B CotterPin 23.

3. 720-0170 Wing Knob5/16-18 24.

4. 681-0094-0721 ChuteDeflectorAssembly 25.

5. 911-0835 ClevisPin 26.

6. 781-0457-0637 ShredderScreen 27.

7. 926-0211 U-Nut5/16-18 28.

8. 950-0793 Spacer 29.

9. 912-3027 HexLockNut,1/4-20 30.

10. 712-3004A HexLockNut5/16-18 31.

11. 936-0119 LockWasher5/16 32.

12. 681-0117-0721 InnerImpellerHousingAssembly 33.

13. 710-3025 HexCapScrew5/16-18x.625 34.

14. 710-0157 HexCapScrew5/16-24x.75 35.

15. 942-0544 ChipperBlade 36.

16. 710-1054 HexCapScrew5/16-24x1.0 37.

17. 681-04095 ImpellerAssembly 38.

18. 912-0411 HexLockNut5/16-24 39.

19. 712-0266A Nut,JamLock,3/8-16 40.

20. 719-04308 FlailBlade 41.

21. 738-04286 ShoulderPin, .5x 2.625

710-3008

736-0247

942-0571

710-1254

681-0004A-0721

710-0825

781-0515-0637

781-0574-0637

681-0104-0721

932-0306A

936-0117

914-0104

936-0264

710-0376

748-0453

731-1707A

912-0429

731-1710A

681-0123-0721

711-1128

HexCapScrew5/16-18x .75

FiatWasher3/8 x 1.25

ShredderBlade

HexCapScrew3/8-24x 2.25

OuterImpellerHousingAssembly

HexCapScrew1/4-20x3.75

FrontSupportBracket

ShredderPlate

RearHopperBracketAssembly

CompressionSpring1.75

FlatWasher

CotterPin

FlatWasher.330IDx .630OD

HexCapScrew5/16-18x 1.0

Spacer,.375IDx2.50LG

HopperAssembly

HexLockNut5/16-18

HopperCollar

FrontHopperBracketAssembly

LockRod

21

Page 22

Craftsman Chipper Shredder B IViodel No. 247.77638

22

Page 23

Craftsman Chipper Shredder B IViodel No. 247.77638

728-0175 PopRivet

2 753-05094 ChipperShredderChute 16

3 735-0249A ChuteFlap 17

4 781-0633 ChuteFlapStrip 18

5 681-0068A-0637 ChipperChuteAssembly 19

6 710-0751 HexCapScrew1/4-20x.620 20

7 712-04064 HexLockNut 1/4-20 21

8 710-0106 HexCapScrew1/4-20x 1.25 22

9 736-0173 FlatWasher.28IDx .74OD 23

10 736-0242 BellWasher.340IDx .872OD 24

11 912-3010 HexNut5/16-18 25

12 749-1004-0721 SupportBrace 26

13 712-3004A HexLockNut5/16-18 27

14 710-3180 HexCapScrew5/16-18x 1.75

936-0170 BellWasher5/16x 1.0

950-0786 Spacer

738-0813 AxleAssembly

737-0298 Pipe,Oil Drain

634-04009 WheelComplete,10.0x4.0 Gray

726-0214 PushCap

681-0183B-0721 Frame

936-0451 Washer,.320IDx.93 OD

710-0502A Screw,3/8-16x 1.250

723-0400 SafetyGlasses(NotShown)

964-04024 ChipperBagAss'y(NotShown)

737-0132 Oil DrainEndCap

731-1617 Tamper

23

Page 24

Craftsman Engine Model 204312=0529 For Chipper Shredder Model No. 247.77638

110_8OPERATORSMA,0A']I 48S,OmB.OOKI I1329_EP.AOEMENTENG,NEII 13_9_E_A'_A"0A']

529 _,

396

615 _)

616

5o5 _

397

24_j

746

742 _

12

'Y 718 __b

J

...."_ 718A

1427 _

1194

22

32

30

358 ENGINE GASKET SET

2O

12

163

12

868

24

51A

1022

Page 25

Craftsman Engine IViodel 204312-0529 For Chipper Shredder IViodel No. 247.77638

632

_o9_

1095 VALVE GASKET SET

51A

_22

1O22

188 (_

25

Page 26

Craftsman Engine IViodel 204312-0529 For Chipper Shredder IViodel No. 247.77638

121 CARBURETOR OVERHAUL KiT

633 3 C:-._

130

95@

127°

117@

118 _@

51A(

127 0

163

633 (o_

51A(

369 i_

137

1127 _

105 0

\

53

_%_.. 967

I _ 445

161I'i_'_s

957 _,."'t_,_- _"s

613

i_72A]

24O

190 _?'

26

Page 27

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

356

37

78 _ 306

363

1005

1070

334

332

774

635

356A ........... C_

12

1211

592 @) 55

65

27

Page 28

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

D = O

1

2

3

5

7

11

12

794849

698340

391086s.

794870

694872.+

696796

694953.

CylinderAssembly

Kit-Bushing/Seal(MagnetoSide)

Seal-Oil(MagnetoSide)

Head-Cylinder

Gasket-CylinderHead

Tube-Breather

Gasket-Crankcase

13 794829 Screw(CylinderHead)

15 697757 Plug-OilDrain

16 794874 Crankshaft

18 791965 Cover-Crankcase

19 698340 Kit-Bushing/Seal(PTOSide)

20 391086s• Seal-Oil(PTOSide)

21 281658s Cap-OilFill

22 794825 Screw(CrankcaseCover/Sump)

23 794814 Flywheel

24 222698s Key-Flywheel

25 792117 PistonAssembly(Standard)

792144 PistonAssembly(.020"Oversize)

26 793561 RingSet (Standard)

792073 RingSet(.020"Oversize)

27 690975 Lock-PistonPin

28 696581 Pin-Piston

29 691691 Rod-Connecting

30 694692 Dipper-ConnectingRod

32 690976 Screw(ConnectingRod)

33 499596 Valve-Exhaust

34 792200 Valve-Intake

35 694865 Spring-Valve(Intake)

36 694865 Spring-Valve(Exhaust)

37 790730 Guard-Flywheel

42 499586 Keeper-Valve

45 690977 Tappet-Valve

46 790958 Camshaft

48 N/A Short Block

D = O I

51

51A

53

55

58

59

6948740.+

6948750.+

794830

695288

693389

805957

Gasket-Intake

Gasket-Intake

Stud(Carburetor)

Housing-RewindStarter

Rope-Starter

Insert-Grip

60 490652 Grip-StarterRope

65 699228 Screw(RewindStarter)

78 795026 Screw(FlywheelGuard)

81 794817 Lock-MufflerScrew

95 690718 Screw(ThrottleValve)

97 696387 Shaft-Throttle

98 6954080 KiNdleSpeed

104 6949180 Pin-FloatHinge

105 6961360 Valve-FloatNeedle

108 696143 Valve-Choke

109 790149 Shaft-Choke

117 696134 Jet-Main(Std.)(InclO-RingSeal)

118 696135 Jet-Main(HighAIt.)(InclO-RingSeal)

121 696146 Kit-CarburetorOverhaul

122 694876 Spacer-Carburetor

125 699966 Carburetor

127 6907270 Plug-Welch

130 696139 Valve-Throttle

133 694914 Float-Carburetor

135 696142 Tube-FuelTransfer

137 6954260 Gasket-FloatBowl

141 696145 Kit-ChokeShaft

146 690979 Key-Timing

161 794768 Base-AirCleaner

163 6922770. Gasket-AirCleaner

187 791766 Line-Fuel(CutTo RequiredLength)

188 699479 Screw(ControlBracket)

190 699220 Screw(FuelTank)

192 690083 Adjuster-RockerArm

28

Page 29

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

D = I! II

209

211

219

220

694867

695307

693578

691724

Spring-Governor(Red)

Spring-GovernedIdle

Gear-Governor

Washer(GovernorGear)

222 794799 Bracket-Control

227 694864 Lever-GovernorControl

240 298090s Filter-Fuel

265 691024 Clamp-Casing

267 699492 Screw(CasingClamp)

271 695381 Lever-Control

278 792008 Washer(GovernorControlLever)

281 697268 Panel-Control

300 794806 Muffler

304 791478 Housing-Blower

305 699480 Screw(BlowerHousing)

306 697240 Shield-Cylinder

307 794822 Screw(CylinderShield)

332 794824 Nut(Flywheel)

333 492341 Armature-Magneto

334 699477 Screw(MagnetoArmature)

337 491055s Plug-Spark

356 692603 Wire-Stop

356A 692390 Wire-Stop

356B 695815 Wire-Stop

356C 695295 Wire-Stop

358 695438 GasketSet-Engine

363 19203 Puller-Flywheel

369 695422 Spring-FloatBowl

383 19374s Wrench-SparkPlug

410 695382 Link-Control

415 691363 Plug(Cylinder)

425 794835 Screw(AirCleanerCover)

445 491588s Filter-AirCleanerCartridge

446 794941 Spring-Retainer

455 794867 Cup-Flywheel

D = I! It

456

459

493

5O4

5O5

529

692299

281505s

691177

695383

691251

791822

Plate-PawlFriction

PawI-Ratchet

Bracket-Mounting

WasherSet-Friction

Nut(GovernorControlLever)

Grommet(Cylinder)

552 694674 Bushing-GovernorCrank

562 793216 Bolt(GovernorControlLever)

592 690800 Nut(RewindStarter)

597 691696 Screw(PawlFrictionPlate)

601 791850 Hose-Clamp

608 695287 Starter-Rewind

613 794846 Screw(Muffler)

613A 794848 Screw(Muffler)

615 694676 Retainer-GovernorShaft

616 694675 Crank-Governor

621 692310 Switch-Stop

632 695917 Spring/Link-MechanicalGovernor

633O 690998 Seal-Choke/ThrottleShaft

635 691909 Boot-SparkPlug

663 699492 Screw(ControlPanel)

663A 795026 Screw(ControlPanel)

668 694257 Spacer(ControlBracket)

689 691855 Spring-Friction

718 690959 Pin-Locating(Cylinder)

718A 695178 Pin-Locating(CylinderHead)

741 691288 Gear-Timing

742 692564 Retainer-ERing

746 694679 Gear-Idler

773 694258 Retainer

774 695447 Screw(StopWire)

798 697890 Screw(RockerArm)

832 795035 Guard-Muffler

836 794845 Screw(MufflerGuard)

836A 710023 Screw(MufflerGuard)

29

Page 30

Craftsman Engine IViodel 204312=0529 For Chipper Shredder IViodel No. 247.77638

I = O O

851

868

883

914

951

957

967

968

692424

690968.+

794818.

794827

699961

792647

491435s

794785

Terminal-SparkPlug

Seal-Valve

Gasket-Exhaust

Screw(RockerCover)

Lever-Choke

Cap-FuelTank

Filter-PreCleaner

Cover-AirCleaner

972 694260 Tank-Fuel

975 696138 Bowl-Float

998 696683 Pipe-Oil

1005 794815 Fan-Flywheel

1022 690971.+ Gasket-RockerCover

1023 697691 Cover-Rocker

1026 695177 Rod-Push

1029 690972 Arm-Rocker

1036 Label-Emissions

1058 MS3797 Operator'sManual

1070 794821 Screw(FlywheelFan)

1095 695440 GasketSet-Valve

1100 791959 Pivot-RockerArm

1127 695407 Screw(FloatBowl)

1138 694255 Nut(ControlBracket)

• 1194 691876 Seal-ORing(Plug)

1210 498144 Pulley/SpringAssembly(Pulley)

1211 498144 Pulley/SpringAssembly(Spring)

1329 2043120536e9 ReplacementEngine

1330 272147 RepairManual

1427 695757 Cap-Pipe

• IncludedinEngineGasketSet,KeyNumber358

0 IncludedinCarburetorOverhaulKit,KeyNumber121

+ IncludedinValveGasketSet,KeyNumber1095

3O

Page 31

Craftsman Chipper Shredder Model No. 247.77638

777333113 777333200 777332036

®ROTATING CUTTING BLADES. KEEP HANDS AND

FEET OUT OF OPENING WHILE MACHINE mS

RUNNING.

=DO NOT OPERATE THiS MACHINE UNLESS THE

CHUTE DEFLECTOR HAS BEEN PROPERLY

iNSTALLED ANDJS SECURED WiTH THE HAND

KNOBS.

777S30185

777S30181

ROTATING CUTTING BLADES.

KEEP HANDS AND FEET OUT

OF OPENINGS WHILE MACHINE

iS RUNNING.

777S32282

DONOTOPERATETHISMACHINE

UNLESSTHECHUTEDEFLECTOR

Operatien Of This Equipment May Create

Sparks That Can Start Fires Around Dry

Vegetation. A Spark Arrestor May Be

Required. The Operator Should Contact

Local Fire Agencies For Laws Or ReguJa=

ionsTo Fire Prevention Requirements.

777X43688

.................DOHOT................

USEE85 ORFUEL...............

CUHTAiNiNGMORE

THAH10% ETHAHOL

TO AVOID SERIOUS iNJURY:

• Read the operator's msnaaJ(s) before starting and

using unit.

• Keep aiJ shieJds and guards in place and secureJy

attached.

• Keep hands, feet, face, cJothing and Jong hair out of

Shredder Hopper, Chipper Chute and Discharge

Chute wbge the engine is running. Rotating cutting

bJades inside these openings wiJJcause serious

persanaJ injury if contacted. Material being processed

may bounce back from inJet openings or be thrown

from the discharge chute. Long hair or Jooseclothing

may be puJJedor sucked into the inlet openings.

• Do not place branches over 1/2 inch diameter into

the large Shredder Hopper. Branches over 1/2 inch in

diameter shouJd be pJaeed in the SmaJJChipper

Chute.

• if the chipped shredder jams or becomes clogged,

immediately shut off the engine and wait for aJJ

moving parts to come to a compJete stop before

cJearing.

• Do not instaJJ,remove, adjust, or service the

discharge screen or any other part whiJe the engine

is running. Blade contact can occur.

$32O36 AC

777S32037

TO AVOID SERIOUS INJURY:

* DO not operate on uneven ground where unit is

unstable. Do net operate on pavement, gravel or

other hard surfaces since objects can ricochet

and cause injury.

To avoid a fire hazard, keep Jeaves, grass, and other

combustible materials away from hot engine and

muffler.

o Keep children and others away from area of

operation.

, Wear approved safety glasses, gloves and ear

protection.

777D12676

31

Page 32

(Thispageapplicableinthe U.S.A.and Canadaonly.)

Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARD)

and the United States Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLWARRANTYCOVERAGEISAPPLICABLETOCERTI-

FIEDENGINESPURCHASEDINCALIFORNIAIN1995ANDTHEREAF-

TER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODEL

California and United States Emission

TheCaliforniaAirResourcesBoard(CARD),U.S.EPAand Searsare pleased

toexplainthe EmissionControlSystemWarrantyonyour modelyear2000and

latersmalloff-roadengine(SORE).InCalifornia,newsmall off-roadengines

mustbe designed,builtand equippedto meettheState'sstringentanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark-ignition

enginescertifiedformodelyear1997and latermustmeetsimilarstandardsset

forthbythe U.S.EPA.Searsmustwarranttheemissioncontrolsystemonyour

YEAR1997ANDLATERENGINESWHICHAREPURCHASEDANDUSED

ELSEWHEREINTHEUNITEDSTATES(ANDAFTERJANUARY1,2001 IN

CANADA).

Control Defects Warranty Statement

enginefortheperiodsoftime listedbelow,providedtherehasbeennoabuse,

neglector impropermaintenanceofyour smalloff-roadengine.Youremis-

sioncontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,mufflerandcatalyticconverter.Also includedmaybeconnectorsand

otheremissionrelatedassemblies.Wherea warrantableconditionexists,Sears

will repairyoursmalloff-roadengineatnocostto youincludingdiagnosis,parts

andlabor.

Sears Emission Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativetoemissioncontrolpartsdefects

fora periodofone year,subjecttoprovisionssetforthbelow.Ifanycovered

Owner's Warranty

Asthe smalloff-roadengineowner,youareresponsiblefor theperformanceof

therequiredmaintenancelistedinyourOperatingand MaintenanceInstruc-

tions.Searsrecommendsthatyouretainallyourreceiptscoveringmaintenance

onyoursmalloff-roadengine,butSearscannotdenywarrantysolelyforthe

lackofreceiptsorforyourfailuretoensuretheperformanceof allscheduled

maintenance.As the smalloff-roadengineowner,youshouldhoweverbe

awarethat Searsmaydenyyouwarrantycoverageifyoursmalloff-roadengine

ora part hasfaileddueto abuse,neglect,impropermaintenanceor unap-

parton yourengineis defective,the part willbe repairedorreplacedbySears.

Responsibilities

provedmodifications.Youareresponsiblefor presentingyour smalloff-road

engineto anAuthorizedSearsServiceDealeras soonas a problemexists.The

undisputedwarrantyrepairsshouldbecompletedina reasonableamountof

time,notto exceed30days.Ifyouhaveanyquestionsregardingyourwarranty

rightsandresponsibilities,youshouldcontacta SearsServiceRepresentative

at 1-800-469-4663.Theemissionwarrantyisa defectswarranty.Defectsare

judgedonnormalengineperformance.Thewarrantyis notrelatedtoan in-use

emissiontest.

Sears Emission Control Defects Warranty Provisions

ThefollowingarespecificprovisionsrelativetoyourEmissionControlDefectsWarrantyCoverage.ItisinadditiontotheSearsenginewarrantyfornon-regulated

enginesfoundintheOperatingandMaintenanceInstructions.

1. WarrantedParts

Coverageunderthiswarrantyextendsonly tothe parts listedbelow(the

emissioncontrolsystemsparts)to the extentthese partswere presenton

theenginepurchased.

a. FueIMeteringSystem

•Cold startenrichmentsystem

•Carburetorandinternalparts

• FuelPump

b. AirlnductionSystem

•Aircleaner

• Intakemanifold

c. IgnitionSystem

•Sparkplug(s)

• Magnetoignitionsystem

d. CatalystSystem

•Catalyticconverter

• Exhaustmanifold

•Air injectionsystemor pulsevalve

e. MiscellaneousItemsUsedin AboveSystems

•Vacuum,temperature,position,timesensitivevalves

andswitches

•Connectorsandassemblies

2. Lengthof Coverage

Searswarrantsto the initialownerandeachsubsequentpurchaserthat

theWarrantedPartsshallbefree fromdefectsin materialsandworkman-

shipwhich causedthefailureof the WarrantedPartsfora periodofone

yearfromthe datethe engineis deliveredtoa retailpurchaser.

Inthe USAandCanada,a 24hourhotline,1-800-469-4663,hasa menuofpre-recordedmessagesofferingyouenginemaintenanceinformation.

3. NoCharge

Repairorreplacementof anyWarrantedPartwill beperformedat no

chargeto the owner,includingdiagnosticlabor whichleadsto the

determinationthata WarrantedPartisdefective,ifthe diagnosticworkis

performedatanAuthorizedSearsServiceDealer.Foremissionswarranty

servicecontact yournearestAuthorizedSearsServiceDealeras listedin

the "YellowPages"under"Engines,Gasoline,""GasolineEngines,""Lawn

Mowers,"orsimilarcategory.

4. Claimsand CoverageExclusions

Warrantyclaimsshallbefiled in accordancewiththe provisionsofthe

SearsEngineWarrantyPolicy.Warrantycoverageshallbeexcludedfor

failuresof WarrantedPartswhichare notoriginalSearspartsor because

ofabuse,neglector impropermaintenanceassetforth inthe Sears

EngineWarrantyPolicy.Searsisnotliableto coverfailuresof Warranted

Partscausedby theuseof add-on,non-original,or modifiedparts.

5. Maintenance

AnyWarrantedPartwhichis notscheduledforreplacementasrequired

maintenanceor whichis scheduledonlyfor regularinspectionto the effect

of"repairor replaceasnecessary"shallbe warrantedastodefectsfor the

warrantyperiod.AnyWarrantedPartwhichis scheduledfor replacement

asrequiredmaintenanceshallbewarrantedas todefectsonlyforthe

periodoftime uptothe firstscheduledreplacementfor thatpart.Any

replacementpartthat isequivalentinperformanceanddurabilitymay

beusedinthe performanceofanymaintenanceorrepairs.The owneris

responsibleforthe performanceof all requiredmaintenance,asdefinedin

the SearsOperatingand MaintenanceInstructions.

6. ConsequentialCoverage

Coveragehereundershallextendto thefailureofanyenginecomponents

causedbythefailureofanyWarrantedPartstill underwarranty.

GDOC-100188Rev.A

32

Page 33

Look For Relevant Emissions Durability Period and

Air index information On Your Engine Emissions Label

Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must

display information regarding the Emissions Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A.

makes this information available to the consumer on our emission labels.

The Emissions Durability Period describes the number of hours of actual running time for which the engine is

certified to be emissions compliant, assuming proper maintenance in accordance with the Operating & Mainte-

nance Instructions. The following categories are used:

Moderate: Engine is certified to be emission compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to 25 hours per year. Therefore, the Emissions

Durability Period of an engine with an intermediate rating would equate to 10 to 12 years.

The Air Index is a calculated number describing the relative level of emissions for a specific engine family. The

lower the Air Index, the cleaner the engine. This information is displayed in graphical form on the emissions label.

After July 1,2000, Look For Emissions Compliance Period

On Engine Emissions Compliance Label

After July 1, 2000 certain Sears, Roebuck and Co., U.S.A. engines will be certified to meet the United States

Environmental Protection Agency (USEPA) Phase 2 emission standards. For Phase 2 certified engines, the Emis-

sions Compliance Period referred to on the Emissions Compliance label indicates the number of operating hours

for which the engine has been shown to meet Federal emission requirements.

For engines less than 225 cc displacement, Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B = 500 hours and A = 1000 hours.

This is a generic representation of the emission label typically found on a certified engine.

FAMILYYBSXS.3192VA 274812

33

GDOC-100182Rev.A

Page 34

Congratulationsonmakingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedforyearsofdependableopera-

tion.Butlikeallproducts,itmayrequirerepairfromtimetotime.That's

whenhavingaRepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhattheRepairProtectionAgreement*includes:

* Expertservicebyour10,000professionalrepairspecialists

* Unlimitedserviceandnochargeforpartsandlaboronall

coveredrepairs

* Productreplacementupto$1500ifyourcoveredproductcan'tbe

fixed

* Discountof 10%fromregularpriceof serviceandrelatedinstalled

partsnotcoveredby theagreement;also,10%off regularpriceof

preventivemaintenancecheck

* Fast help by phone- wecallitRapidResolution- phonesupport

froma Searsrepresentative.Thinkof usasa "talkingowner's

manual."

Onceyoupurchasethe Agreement,a simplephonecallisallthatit

takesfor youto scheduleservice.Youcancall anytimedayor night,or

schedulea serviceappointmentonline.

TheRepairProtectionAgreementisa risk-freepurchase.Ifyoucancel

forany reasonduringtheproductwarrantyperiod,wewill provideafull

refund.Or,aproratedrefundanytimeafterthe productwarrantyperiod

expires.PurchaseyourRepairProtectionAgreementtoday!

Somelimitations and exclusionsapply. Forprices andadditional

informationin the U.S.A.call 1-800-827-8855.

*CoverageinCanadavaries on some items.For full details call

SearsCanada at 1-800-381-8665.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andothermajorhomeitems,intheU.S.A.or

Canadacall 1-800-4-MY-HOME®.

34

Page 35

Declaraci6n de garant[a ....................... Pagina 35

Practicas operaci6n seguras ............... Paginas 36-39

Montaje ................................................ Paginas 40-43

Operaci6n ............................................ Paginas 44-45

Servicio y Mantenimiento .................... Paginas 46-49

Almacenamiento fuera de temporada ....Pagina 50

Soluci6n de problemas ...................... Pagina 51-52

Etiquetas de seguridad ....................... Pagina 7

Lista de piezas ..................................... Pagina 20

Acuerdo de Protecci6n Para

Reparaciones ....................................... Pagina 55

Labels .................................................. Pagina 31

NOmero de servicio ..................... Cubierta posterior

CRAFTSMANTOTAL GARANTIA

Cuandosonoperadosy mantenidosdeacuerdoconlasinstruccionessuministradasen sutotalidad,si estonoastilladoradefragmentaci6n

debidoa undefectodematerialo manodeobradentrodedosaSosa partirde lafechadecompra,el retornoa cualquiertiendaSears,Sears

partesdel CentrodeServicioy Reparaci6n,uotrosArtesanosalidaenlos EstadosUnidosparala reparaci6ngratuita(sila reparaci6no la

sustituci6nresulteimposible.

Estagarantiase aplicas61opara90 diasa partirdela fechadecomprasiestaastilladoradefragmentaci6ncadavezes utilizadoparaprop6si-

toscomercialesodealquiler.

Estagaranfias61ocubredefectosdematerialy manodeobra.Searsnopagar&por:

• Estagaranfias61ocubredefectosdematerialy manodeobra.SearsNO• Loselementosque sedesgastanduranteel usonormal,

incluyendoperonolimitadoalas hojas,labujia,elaire limpio,mayalpantallayreceptorbolsa.

• Normade serviciosde mantenimiento,cambiosdeaceite,o afinaci6n.

• Cambiodeneum&ticosdesustituci6noreparaci6nde pinchazoscausadosporobjetosdesdeelexterior,talescomoclavos,espinas,

tocones,o de vidrio.

• Cambiodeneum&ticoso ruedasde reemplazoo la reparaci6ncomoconsecuenciadedesgastenormal,accidente,o delamalaoper-

aci6no mantenimiento.

Lasreparacionesnecesariasdebidoa los abusosdeloperador,incluyendoperono limitadoa losda_oscausadosporobjetosque

impactandoblarelmarcoo cig(Je_al,o situaci6nde excesodevelocidaddelmotor.

Lasreparacionesnecesariasdebidoa la negligenciadel operador,incluyendoperonolimitadoa,productosel6ctricosy rnec_.nicosde

losda_oscausadosporalmacenamientoinadecuado,faltade utilizaci6ndelacategoriaapropiaday lacantidadde aceitede motor,o el

fracasoparamantenerelequipodeacuerdoconlas instruccionescontenidasen elmanualdeloperador.

• Motor(sistemadecombustible),la limpiezao reparacionescausadasporloscombustiblesdecididaasercontaminadoso oxidado(ran-

cio). Engeneral,elcombustibledebeserutilizadodentrodelos 30diassiguientesasufechadecompra.Normaldesgastey deteriorode

losacabadosexteriores,o laetiquetadelproductode reemplazo

Estagarantias61oseaplicamientrasqueesteproductoest,.dentrodelosEstadosUnidos.

Estagaranfiale otorgaderechoslegalesespecificos,y ustedtambi6npuedetenerotrosderechosquevariandeestadoa estado.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Serie: 1450

Tipodeaceitedelmotor: SAE30

Capacidadde aceitedel motor: 28onzas

Elcombustible: GasolinasinPIomo

Bujias: Champion®RC-12YC

Separaci6ndelasbujias: .030"

©SearsBrands,LLC 3,5

NSrnerode modelo ..........................................................

N_mero de serie..............................................................

Fechadecompra .............................................................

RegistrearribaelnOmerodel modelo,elnOmerode serieyla fecha

de compra

Page 36

Lapresenciade estesirnboloindicaquesetratadeinstrucciones

irnportantesdeseguridadque sedebenrespetarparaevitar

poneren peligrosuseguridadpersonaly/omaterialy la deotras

personas.Leay sigatodaslas instruccionesde estemanualantes

deponeren funcionarnientoestarn_.quina.Sino respetaestas

instruccionespodriaprovocarlesionespersonales.Cuandoveaeste

sirnbolo,ipresteatenci6nalaadvertencia!

Estarn_.quinarueconstruidaparaseroperadade acuerdocon

lasreglasdeseguridadcontenidaseneste manual.AIigualque

concualquiertipo de equipornotorizado,undescuidoo errorpor

partedel operadorpuedeproducirlesionesgraves.Estarn_.quina

escapazde arnputarrnanosypiesy dearrojarobjetoscon gran

fuerza.De norespetarlasinstruccionesdeseguridadsiguientesse

puedenproducirlesionesgraveso larnuerte.

PROPOSICION 65 DE CALIFORNIA

Elescapedel motorde esteproducto,algunosdesuscornponentes

y algunoscornponentesdelvehiculocontieneno liberansustancias

quirnicasqueelestadode Californiaconsideraque puedenproducir

c_.ncer,defectosde nacirnientouotrosproblernasreproductivos.

CAPACITACiON

• Lea,entienday curnplatodaslasinstruccionesincluidasen

la rnAquinayen los rnanualesantesde rnontarlayutilizarla.

Guardeestemanualenun lugarseguroparaconsultasfuturasy

regulares,asicornoparasolicitarrepuestos.

• LeaelManualdelOperadory sigatodaslasadvertenciase

instruccionesdeseguridad.El fracasodehacerasi puedecausar

la heridaseriaaloperadory/o personaspresentes.ParaIlarnada,

de preguntas,1-800-659-5917.

• Farniliaricesecontodosloscontrolesysuoperaci6nadecuada.

Sepac6rnodetenerla rn_.quinayc6rnodesengranarloscontroles

r_.pidarnente.

• Noperrnitanuncaquelosni_osrnenoresde 16a_os utilicen

estarn_.quina.Los ni_osde 16a_osy rn_.srnayoresdeben

leerycornprenderlas instruccionesde operaci6nylasreglas

de seguridadcontenidasen estemanual,y tarnbi_ndebenser

capacitadosy estarsupervisadosporunode lospadres.

• Nuncaperrnitaquelosadultosoperenestarn_.quinasinrecibir

antesla instrucci6napropiada.

• Mantengaa lostranseQntes,ayudantes,rnascotasy ni_osal

rnenosa75piesde la rn_.quinarnientrasest,.operando.Detenga

la rn_.quinasialguienentraenla zona.

• Nuncaenciendaun motorenespacioscerradosoenunazona

conpocaventilaci6n.Elescapedel motorcontienernon6xidode

carbono,un gasinodoroy letal.

• Nopongalasrnanosolos piescercadelaspiezasrotatoriaso

en lasc_.rnarasdealirnentaci6nnien laaberturadedescarga.El

contactocon el motorrotatoriopuedeproducirla arnputaci6nde

dedos,rnanosopies.

• Nuncatratededestaparlatornade alirnentaci6nola aberturade

descarga,nitratede sacaro vaciarla bolsadelaaspiradora,ni

de revisary repararlarn_.quinarnientrasel motorest,.enrnarcha.

Apagueel motory esperehastaquetodaslaspiezasrn6vilesse

hayandetenidoporcornpleto.Desconecteel cablede la bujiay

p6ngalodernaneraque hagarnasacontrael motor.

Su responsabilidad--Restrinja el usodeestarn_.quina

rnotorizadaalas personasque lean,cornprendany respetenlas

advertenciase instruccionesqueaparecenenestemanualyen la

rn_.quina.

iGUARDEESTASINSTRUCCIONES!

PREPARATIVOS

• Inspeccionerninuciosarnenteel _.readondeutilizar_,el equipo.

Retiretodaslaspiedras,botellas,latasuotrosobjetosextra_os

que puedanserlevantadoso arrojadoscausandolesiones

personaleso da_osa larn_.quina.

• Paraprotegerselosojosutilicesiernpreanteojoso antiparras

de seguridadrnientrasoperala rn_.quinao rnientraslaajusta