Page 1

Owner's Manual

CRRFTSMAN

6.5 Horse Power _]

3" diameter chipping capacity

CHIPPER-SHREDDER

Model No. B

247.775870

[]

m

CAUTION: Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Printed in U,S.A.

i

Page 2

Content Page Content Page

Warranty Information 2 Service & Adjustment 14

Safe Operation Practices 3 Off-Season Storage 16

Assembly 5 Trouble-Shooting 17

Operation 8 Repair Parts 18

Maintenance 11

One-Year Warranty on Craftsman Chipper-Shredder

For one year from the date of purchase, when this Craftsman chipper-shredder is maintained, lubricated, and

tuned up according tothe operating and maintenance instructions inthe operator's manual, Sears will repair, free

of charge, any defect in material or workmanship.

This warranty excludes the blades, chipper blades, flails, air cleaners, spark plugs, catcher bags and tires which

are expendable parts and become worn during normal use.

If this chipper-shredder is used for commercial or rental purposes, this warranty applies for only 30 days from the

date of purchase.

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER IN THE

UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE INTHE UNITED

STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., D/817WA, Hoffman Estates, II 60179

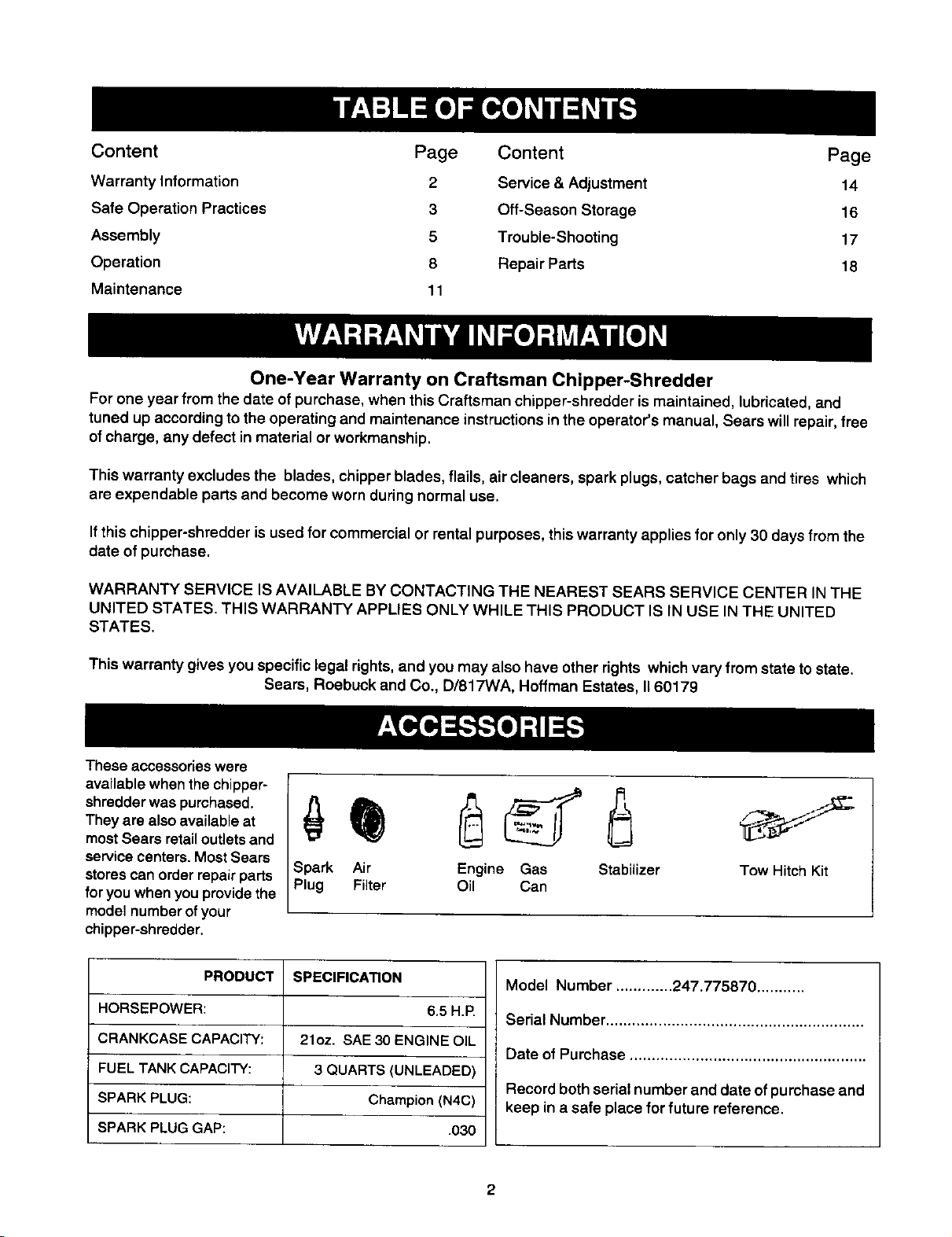

These accessorieswere

available when the chipper-

shredderwas purchased.

They are also available at

mostSears retailoutletsand

service centers. Most Sears

storescan order repair parts

foryou when you provide the

Spark Air Engine Gas Stabilizer Tow Hitch Kit

Plug Filter Oil Can

model numberof your

chipper-shredder.

PRODUCT

HORSEPOWER:

CRANKCASE CAPACITY:

SPECIFICATION

6.5 H.P.

21oz. SAE 30 ENGINE OIL

Model Number ............. 247.775870 ...........

Serial Number ...........................................................

Date of Purchase ......................................................

FUEL TANK CAPACITY:

SPARK PLUG:

SPARK PLUG GAP:

3 QUARTS (UNLEADED)

Champion (N4C)

.030

Record both serial number and date of purchase and

keep in a safe place for future reference.

2

Page 3

This symbol points out important safety instructions which, if not followed, could endanger the per-

sonal safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate your chipper shredder. Failure to comply with these instructions may result in per-

sonal injury. When you see this symbol--heed its warning.

I Your chipper-shredder was built to be operated according to the rules for safe operation in

,_ DANGER" this manual. As with any type of power equipment, carelessness or error on the part of the oper-

_" " ator can result in serious injury. If you violate any of these rules, you may cause serious

injury to yourself or others.

,_ WARNING: The Engine Exhaustfrom this product containschemicals known to

the State of California to cause cancer, birth defects or other reproductive harm.

GENERAL OPERATION

Read this owner's guide carefully in its entirety before

attempting to assemble this machine. Read,

understand, and follow all instructions on the machine

and in the manual(s) before operation. Be completely

familiar with the controls and the proper use of the

machine before operating it. Keep this manual in a

safe place forfuture and regular reference and for

ordering replacement parts.

Your chipper-shredder is a powerful tool, not a

plaything. Therefore, exercise extreme caution at all

times. Your unit has been designed to perform two

jobs; to chip and shred vegetation found in a normal

yard. Do not use itfor any other purpose.

Never allow children under age 16 to operate the unit.

Children 16 years and older should only operate the

unit under close parental supervision. Only

responsible individuals who are familiar with these

rules of safe operation should be allowed to use your

unit.

Keep ths area ofoperation clear of all persons,

particulady small children and pets. Stop the engine

when they are inthe vicinity of the unit. Keep work

area clean and clear of branches or obstacles which

could cause you to stumble or fall.

When feeding material into this equipment, be

extremely careful that pieces of metal, rocks, bottles,

cans or other foreign objects are not included.

Personal injury ordamage to the machine could result.

Always wear safety glasses or safety goggles, during

operation and while performing an adjustment or

repair, to protect eyes from foreign objects that may be

thrown from the machine.

Wear sturdy, rough-soled work shoes and close fitting

slacks and shirt. Shirt and slacks that cover the arms

and legs and steel-toed shoes are recommended. Do

not wear loose fitting clothes orjewelry and secure hair

so it is above shoulder length. They can be caught in

moving parts. Never operate a unitin bare feet,

sandals or sneakers. Wear gloves when feeding

material in the chipper chute or shredder hopper.

Never place your hands, feet, or any part of your body

intothe shredder hopper, chipper chute, discharge

opening, or near any moving part while the engine is

running. Keep clear of the discharge opening at all

times. If it becomes necessary to push material into

the chipper chute or shredder hopper, use a small

diameter stick, NOT YOUR HANDS,

Ifit is necessary for any reason to unclog the feed

intake or discharge openings or to inspect or repair any

part of the machine where a moving part can come in

contact with your body or clothing, stop the machine,

allow it to cool, disconnect the spark plug wire from the

spark plug and move it away from the spark plug

before attempting to unclog, inspect or repair.

Do not operate unit while under the influence of alcohol

or drugs.

The machine should only be operated on a level

surface. Never operate your uniton a slippery, wet,

muddy or icy surface. Keep your work area clean and

clear of branches or obstacles which could cause you

to stumble and fall Do not overreach. Maintaining

proper footing and balance is essential to preventing

accidents.

Do not allow an accumulation of processed material to

build-up in the discharge area as this will prevent

proper discharge and can result in kick-back from the

chipper chute.

Keep your face and body back from chipper chute to

avoid accidental bounce back of any material.

Do not transport machine while engine is running.

Ifthe cutting mechanism strikes a foreign object or if

your machine should start making an unusual noise or

vibration, immediately stopthe engine and allow the

machine to come to a complete stop. Disconnect the

spark plug wire and move it away from the spark plug.

Take the following steps.

a. inspect fordamage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure

continued safe operation.

Never attempt to attach or remove catcher bag when

engine is running. Shut the engine off and wait for the

impeller to come to a complete stop. The impeller

continues to rotate for a few seconds after the engine is

shut off. Never place any part of the body in the

impeller area until you are sure the impeller has

stopped rotating.

Muffler and engine become hot and can cause a burn.

Do not touch.

3

Page 4

Do not ailow leaves or other debris to build-upon

engine's muffler. The debris could ignite and cause a

fire.

Do not attempt to shred or chip material larger than

specified in this manual. Personal injury or damage

to the machine could result.

Do not operate engine if air cleaner or cover over

carburetor air-intake is removed, except for

adjustment, Removal of such parts could create a fire

hazard.

Only use accessories approved for this machine by

the manufacturer. Read, understand, and follow all

instructions provided with the approved accessory.

If situations occur which are not covered by this

manual, use care and good judgment. Contact your

dealer for assistance.

Keep discharge discharge chute, chipper chute door,

and ell other guards end safety devices in place and

operating properly.

Only operate unit in good daylight. Do not operate

unit at night or in dark areas where your vision may be

impaired.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of small children. Children are often attracted to

the chipper-shredder and the chipping and shredding

activity. Never assume that children will remain where you

last saw them.

Keep children out of the work area and under the

watchful eye of a responsible adult other than the

operator.

Be alert and turn the unit off if a childenters the area.

• Never allow children under the age of 16 to operate

the chipper-shredder.

SERVICE

Use extreme care in handling gasoline end other

fuels. They are extremely flammable and the vapors

are explosive.

a. Store fuel and oil in approved containers, away

from heat and open flame, and out of the reach

of children. Check and add fuel before starting

the engine. Never remove gas cap or add fuel

while the engine isrunning. Allow engine to

cool at least two minutes before refueling.

b. Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as it

may cause a fire or explosion.

c. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

d. Never refuel unit indoors because flammable

vapors will accumulate in the area.

e. Never store the machine or fuel container inside

where there is an open flame or spark such as a

gas hot water heater, space heater, clothes

dryer or furnace.

Never run your machine in an enclosed area as the

exhaust from the engine contains carbon monoxide,

which is an odorless, tasteless and deadly poisonous

gas.

To reduce fire hazard, keep engine and muffler free of

leaves, grass, and other debris build-up. Clean up

fuel and oil spillage. Allow unit to cool at least 5

minutes before storing.

Before cleaning, repairing, or inspecting, make certain

the impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep wire away

from spark plug to prevent accidental starting. Do not

use flammable solutions to clean air filter.

Check the blade and engine mounting screws at

frequent intervals for proper tightness. Also visually

inspect blades for wear and/or damage (e.g., bent,

cracked). Replace with blades which meet original

equipment specifications.

Keep all nuts, bolts, and screws tight to be sure the

equipment isin safe working condition.

Never tamper with safety devices. Check their proper

operation regularly.

After stdking e foreign object, immediately stop the

engine, disconnect the spark plug wire from the spark

plug, end thoroughly inspect the unit for any damage.

Repair damage before starting and operating unit.

Do not alter or tamper with the engine's governor

setting. The governor controls the maximum safe

operating speed of the engine. Over-speeding the

engine is dangerous and will cause damage to the

engine and to other moving parts of the machine.

YOUR RESPONSIBILITY

Restrict the use of this power machine to

persons who read, understand and follow the

warnings and instructions inthis manual and on

the machine.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered orgrass-covered land unless the engine's exhaust system is equipped with a spark arrester

meeting applicable local or state laws (if any). If a spark arrester isused, it should be maintained in effective working

order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other

states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center (See the REPAIR PARTS section of this manual.)

4

Page 5

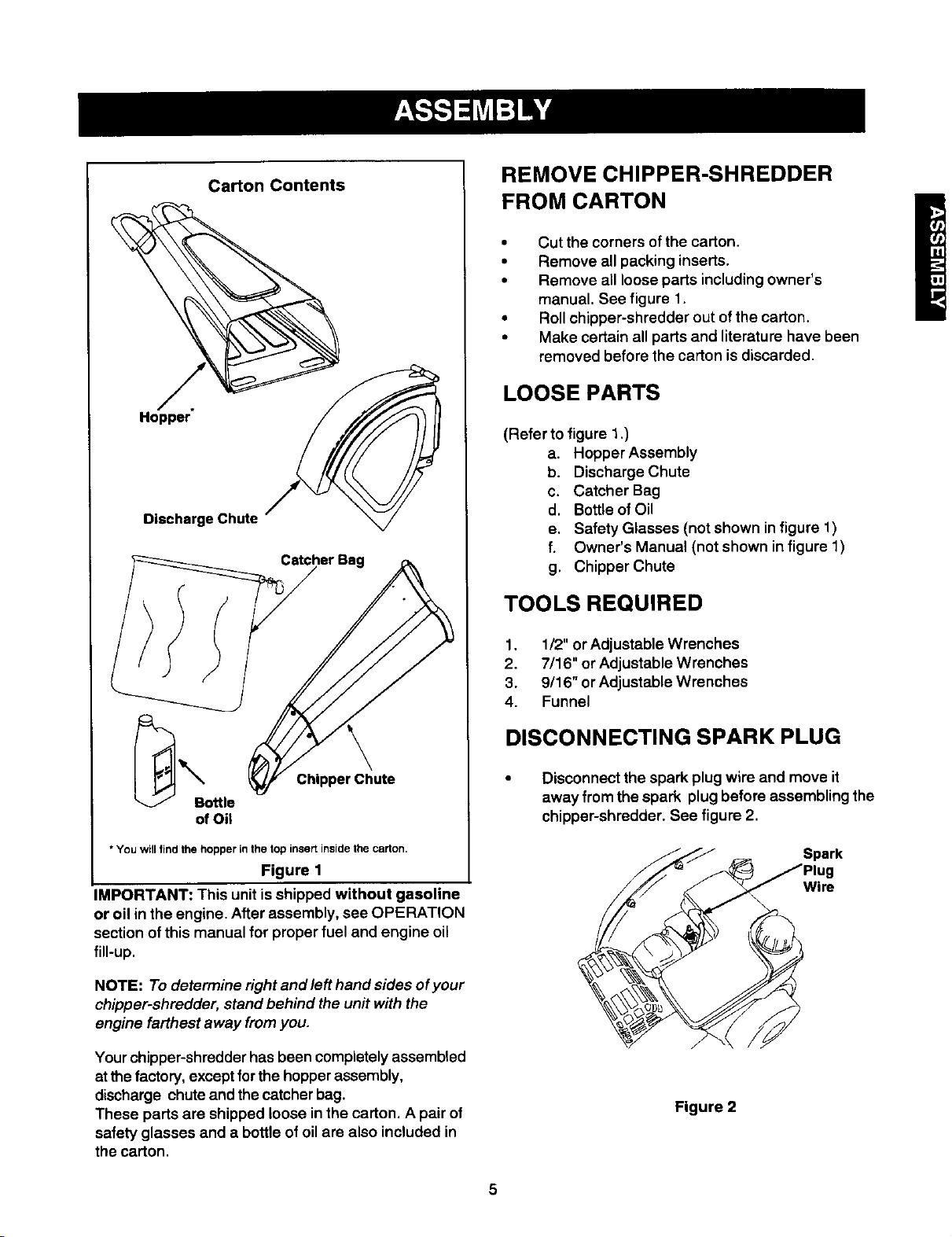

Carton Contents

Hopper

Discharge Chute

Catcher Bag

REMOVE CHIPPER-SHREDDER

FROM CARTON

• Cut the corners of the carton.

• Remove all packing inserts.

• Remove allloose parts including owner's

manual. See figure 1.

• Roll chipper-shredder out of the carton.

• Make certain all parts and literature have been

removed before the carton is discarded.

LOOSE PARTS

(Refer to figure 1.)

a. Hopper Assembly

b. Discharge Chute

c. Catcher Bag

d. Bottleof Oil

e. Safety Glasses (not shown infigure 1)

f. Owner's Manual (not shown infigure 1)

g. Chipper Chute

TOOLS REQUIRED

__Bottle

of Oii

• You will find the hopper in the top insert inside the carton.

IMPORTANT: This unitis shipped without gasoline

or oil in the engine. After assembly, see OPERATION

section of this manual for proper fuel and engine oil

fill-up.

NOTE: To determine right and left hand sides ofyour

chipper-shredder, stand behind the unit with the

engine farthest away from you.

Your chipper-shredder has been completely assembled

at thefactory, exceptfor the hopperassembly,

discharge chute and the catcher bag.

These parts are shipped loose in the carton. A pair of

safety glasses and a bottle of oilare also included in

the carton.

Chipper Chute

Figure 1

1. 1/2" or Adjustable Wrenches

2. 7/16" or Adjustable Wrenches

3. 9/16" or Adjustable Wrenches

4. Funnel

DISCONNECTING SPARK PLUG

Disconnect the spark plug wire and move it

away from the spark plug before assembling the

chipper-shredder. See figure 2.

Spark

Wire

Figure 2

5

Page 6

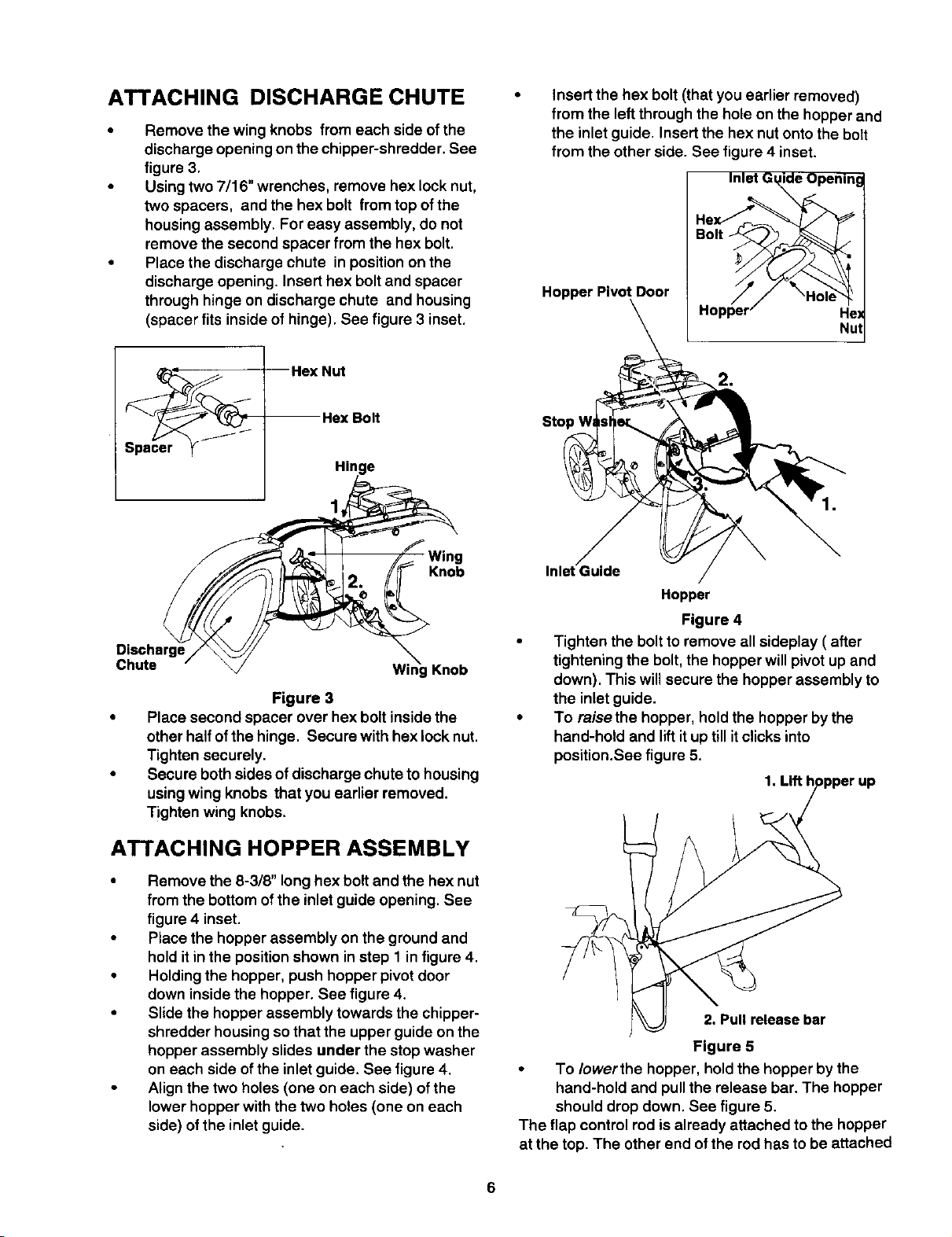

ATTACHING DISCHARGE CHUTE

• Remove the wing knobs from each side of the

discharge opening on the chipper-shredder. See

figure 3.

• Using two 7/16" wrenches, remove hex lock nut,

two spacers, and the hex bolt from top of the

housing assembly. For easy assembly, do not

remove the second spacer from the hex bolt.

• Place the discharge chute in position on the

discharge opening. Insert hex boltand spacer

through hinge on discharge chute and housing

(spacer fits inside of hinge). See figure 3 inset.

Hex Nut

Insert the hex bolt (that you earlier removed)

from the left through the hole on the hopper and

the inlet guide. Insert the hex nut onto the bolt

from the other side. See figure 4 inset.

Inlet G_

Hopper Pivot Door

Nu1

-- Hex Bolt

Hinge

Wing

Knob

Discharge

Chute

tg Knob

Figure 3

Place second spacer over hex bolt inside the

other half of the hinge. Secure with hex lock nut.

Tighten securely.

Secure both sides of discharge chute to housing

using wing knobs that you earlier removed.

Tighten wing knobs.

ATTACHING HOPPER ASSEMBLY

Sto:

Inlet Guide

Hopper

Figure 4

Tighten the boltto remove all sideplay ( after

tightening the bolt, the hopper willpivot up and

down). This will secure the hopper assembly to

the inlet guide.

To raise the hopper, hold the hopper by the

hand-hold and lift itup till itclicks into

position.See figure 5.

1. Lift

• Remove the 8-3/8" long hex boltand the hex nut

from the bottom of the inlet guide opening. See

figure 4 inset.

• Place the hopper assembly on the ground and

hold it in the position shown in step 1 in figure 4.

• Holding the hopper, push hopper pivot door

down inside the hopper. See figure 4.

• Slide the hopper assembly towards the chipper-

shredder housing so that the upper guide on the

hopper assembly slides under the stop washer

on each side ofthe inlet guide. See figure 4.

• Align the two holes (one on each side) of the

lower hopper with the two holes (one on each

side) of the inlet guide.

2. Pull release bar

Figure 5

• To Iowerthe hopper, hold the hopper by the

hand-hold and pull the release bar. The hopper

should drop down. See figure 5.

The flap control rod is already attached to the hopper

at the top. The other end of the rodhas to be attached

6

Page 7

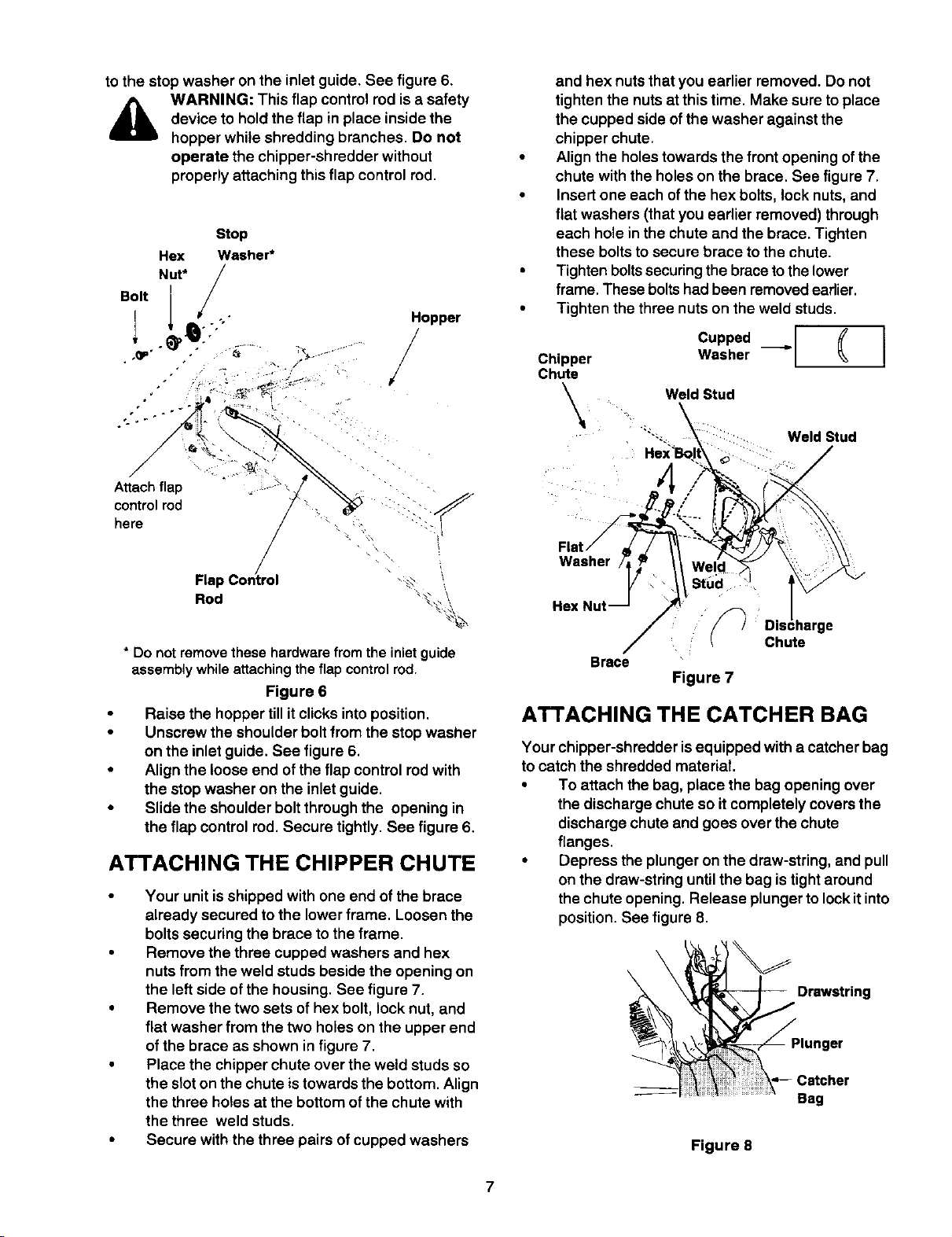

to the stop washer on the inlet guide. See figure 6.

,_ WARNING: This flap control rod is a safety

device to hold the flap in place inside the

hopper while shredding branches. Do not

operate the chipper-shredder without

properly attaching this flap control rod.

Hopper

and hex nuts that you earlier removed• Do not

tighten the nuts at this time. Make sure to place

the cupped side of the washer against the

chipper chute.

• Align the holes towards the front opening of the

chute with the holes on the brace. See figure 7.

• Insert one each ofthe hex bolts, lock nuts, and

flat washers (that you earlier removed) through

each hole inthe chute and the brace. Tighten

these bolts to secure brace to the chute.

• Tighten bolts securingthe brace to the lower

frame. These boltshad been removedearlier.

• Tighten the three nuts on the weld studs.

Attach flap

control rod f

here

Flap Control

Rod

* Do notremovethese hardwarefromthe inletguide

assembly while attachingtheflap controlrod.

Figure 6

• Raise the hopper tillit clicks into position.

• Unscrew the shoulder bolt from the stop washer

on the inletguide. See figure 6.

• Align the loose end of the flap control rodwith

the stop washer on the inlet guide.

• Slide the shoulder bolt through the opening in

the flap control rod. Secure tightly. See figure 6.

ATTACHING THE CHIPPER CHUTE

• Your unit is shipped with one end of the brace

already secured tothe lowerframe. Loosen the

bolts securing the brace to the frame.

• Remove the three cupped washers and hex

nuts from the weld studs beside the opening on

the left side of the housing. See figure 7.

• Remove the two sets of hex bolt, lock nut, and

flat washer from the two holes on the upper end

of the brace as shown in figure 7.

• Place the chipper chute over the weld studs so

the sloton the chute is towards the bottom. Align

the three holes at the bottom of the chute with

the three weld studs.

• Secure with the three pairs of cupped washers

Chipper

Chute

Washer

Brace

Cw::::-

Weld Stud

Weld Stud

Chute

Figure 7

ATTACHING THE CATCHER BAG

Your chipper-shredder is equipped with a catcher bag

to catch the shredded material.

• To attach the bag, place the bag opening over

the discharge chute so it completely covers the

discharge chute and goes over the chute

flanges.

• Depress the plunger on the draw-string, and pull

on the drew-string until the bag is tight around

the chute opening. Release plungerto lockitinto

position. See figure 8.

Drawstring

Bag

Figure 8

Page 8

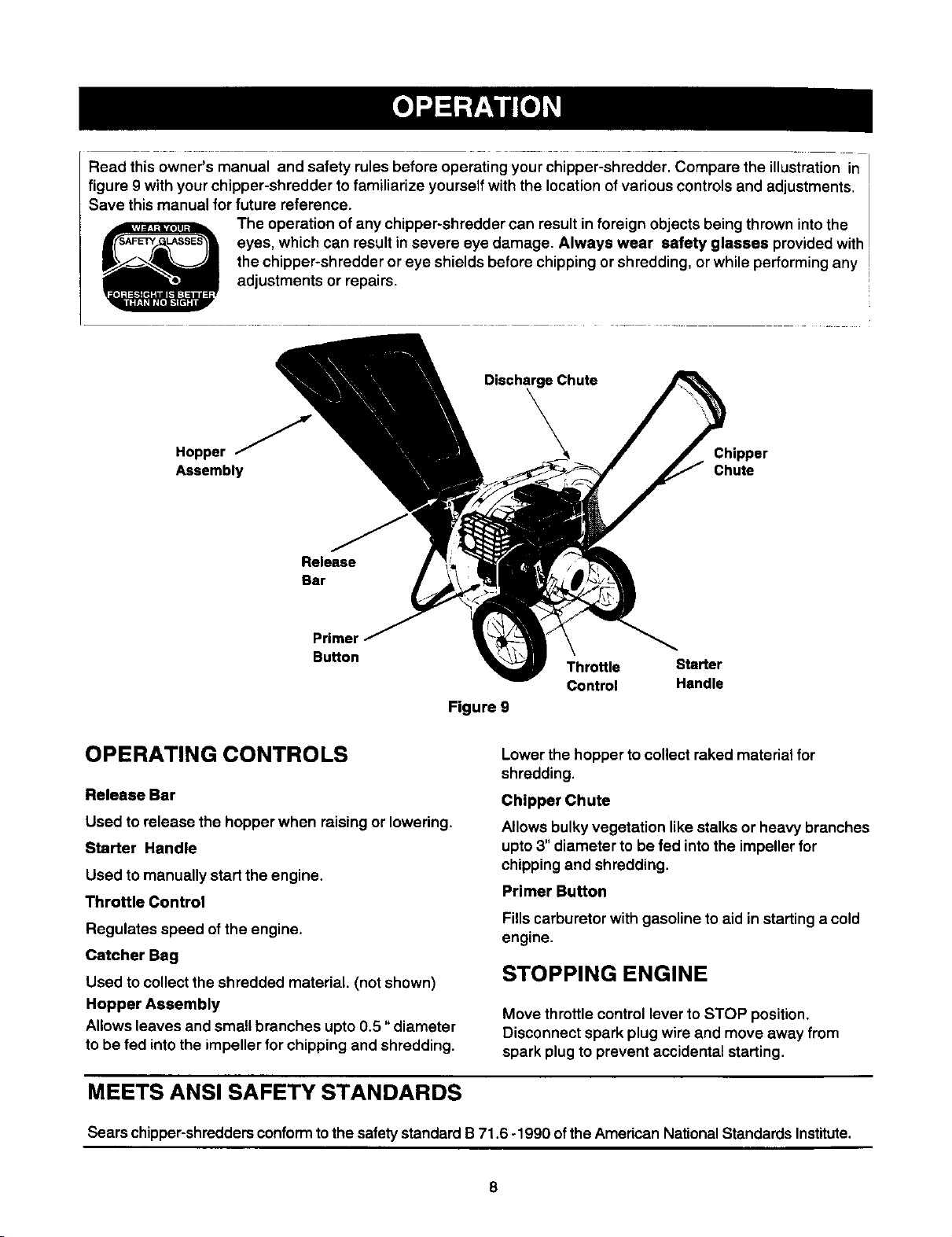

Read this owner's manual and safety rules before operating your chipper-shredder. Compare the illustration in I

I

figure9withy_urchipper_shreddert_fami_iarizey_urselfwiththe__cati_n_fVari_usc_ntr__sandadjustments_ _1

Save this manual for future reference. I

The operation of any chipper-shredder can result in foreign objects being thrown intothe

eyes, which can result in severe eye damage. Always wear safety glasses provided w th

the chipper-shredder oreye shields before chipping or shredding, or while performing any

adjustments or repairs.

Discharge Chute

Hopper f Chipper

Assembly Chute

Release

Bar

Primer

Button

OPERATING CONTROLS

Release Bar

Used to release the hopper when raising or lowering.

Starter Handle

Used to manually start the engine.

Throttle Control

Regulates speed of the engine.

Catcher Bag

Used to collect the shredded material. (not shown)

Hopper Assembly

Allows leaves and small branches upto 0.5 "diameter

to be fed into the impeller for chipping and shredding.

MEETS ANSI SAFETY STANDARDS

Throttle Starter

Control Handle

Figure 9

Lower the hopper to collect raked materiat for

shredding.

Chipper Chute

Allows bulky vegetation like stalks or heavy branches

upto3" diameter to be fed intothe impeller for

chipping and shredding.

Primer Button

Fills carburetor with gasoline to aid in starting a cold

engine.

STOPPING ENGINE

Move throttle control lever to STOP position.

Disconnect spark plug wire and move away from

spark plug to prevent accidental starting.

Sears chipper-shreddersconformtothe safetystandard B 71.6 -1990 ofthe American National Standards Institute.

8

Page 9

WARNING: Before using your chipper-

&

shredder, refer to the safety rules on

pages 3 and 4 of this manual again.

Always be careful.

GAS AND OIL FILL-UP

Tiltchipper-shreddertowardthe left (from behind

the hopper). See figure 11.Check oillevel. Put the

unitbackon the groundcarefully.

,_ WARNING: Do not tilt unit holdingthe

hand-hold.

Oil (Packed with unit)

• Only use high qualitydetergent oil rated with

API service classification SF, SG or SH. Select

the oil's viscosity grade according to your

expected operating temperature. Follow the

chart below.

Co der _ 32°F _ Warmer

_.==_.o L

5W30 I SAE 30

NOTE: Although multi-viscosity oils (5W30, 10W30,

etc.) improve starting in cold weather, these

multiviseosity oils will result in increased oil

consumption when used above 32°[::. Check the oil

level more frequently to avoid possible engine

damage from running low on oil.

Fillengine with oil as follows.

• Remove dipstick. See figure 10.

1. Remove dipstick

end fill oll

2. Remove cap

and fill gas

F

Figure 10

With chipper-shredder on level ground, use a

funnel to fillengine with oil to FULL mark on

dipstick. Capacity is approximately 20 ounces.

Be careful not to overfill.

Add oil if necessary. Replace dipstick and

tighten.

Hold unit this

to tilt

Figure 11

NOTE: Do not overfill. Oil bottle packed with unit

contains 20 oz. of oil.

Gasoline

Warning: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol)

can attract moisture which leads to separation and

formation of acids during storage. Acidic gas can

damage the fuel system of an engine while instorage.

To avoid engine problems, the fuel system should be

emptied before storage for 30 days or longer. Drain

the gas tank, start the engine and let itrun until the

fuel lines and carburetor are empty. Use fresh fuel

next season. See STORAGE instructions for

additional information. Never use engine or

carburetor cleaner products inthe fuel tank or

permanent damage may occur.

Fill gas tank withgas as follows.

• Remove fuel cap. See figure 10.

• Make sure the container (from which you will

pour the gasoline) is clean and free from rust or

foreign particles. Never use gasoline that may

be stale from long periods of storage inthe

container.

• Fill fuel tank with fresh, lead-free gasoline. DO

NOT use Ethyl or high octane gasoline.Replace

fuel cap.

Page 10

WARNING:Do not fill closer than 1/2 inch

oftop of fuel tank to prevent spills and to

allow for fuel expansion. If gasoline is

accidently spilled, move chipper-shredder

away from area of spill. Avoid creating any

source of ignition untilgasoline vapors have

disappeared.

Check the fuel level periodically to avoid

running out of gasoline while operating the

chipper-shredder.

If the unit runs out of gas as it is shredding or

chipping, it may be necessary to unclog the unit

before it can be restarted. Refer to Removing

the Flail Screen in SERVICE AND

ADJUSTMENT section.

STARTING ENGINE

WARNING: Be sure no one other than

the operator is standing near the chipper-

shredder while starting or operating. Do not

operate this chipper-shradder unless the

discharge chute has been properly installed

and is secured with the hand knobs.

NOTE: To prevent the unit from sliding, place your

foot firmly against the tire.

Attach spark plug wire and rubber boot to spark

plug. See figure 12.

1. Attach spark plug wire

2. Place Throttle

in Fast Position

• Pull rope with a rapid full arm stroke. Let rope

return to starter slowly. See figure 12.

• When engine starts, move throttle control to

IDLE position for a few minutes warm-up.

NOTE: A noise will be heard when finding the start of

the compression cycle. This noise is caused by the

flails and fingers which are part of the shredding

mechanism falling intoplace, and should be

expected. In addition, the flailsand fingers will be

noisy after the engine is started, until the impeller

reaches furlspeed.

STOPPING ENGINE

• Move throttlecontrol lever to STOP position

(DOWN).

• Disconnect spark plugwire and move away from

spark plug to prevent accidental starting.

USING YOUR CHIPPER-SHREDDER

WARNING: Do not attempt to shred or

chipany material other than vegetation

found in a normal yard (i.e., branches,

leaves, twigs, etc.).

The chipper-shredder is designed for two different

methods of operation.

a. Leaves and small branches up to 1/2"

diameter (maximum) can be fed intothe

hopper assembly when it is inthe raised or

lowered position. See figure 13.

b. Bulky material, such as stalks or heavy

branches, up to3" in diameter can be fed

intothe chipper chute. See figure 13.

3. Prime 3 times

Figure 12

• Place the throttle control lever in FAST position

(UP).

• Push primer 2 or 3 times, waiting a couple of

seconds between each push. In cold weather

(50°F or below) prime 5 times.

• Grasp starter handle and pull rope out slowly

until engine reaches start of compression cycle

(rope will pull slightly harder at this point). Let

the rope rewind slowly.

4. Pull rope

WARNING: Do not put material larger

than is specified into the hopper or the

chipper chute. Personal injuryand/or

damage to the machine could result.

If it becomes necessary to push material intothe

chipper-shredder, use a small diameter stick-- not

your hands, The stick should be small enough that it

will be ground up ifit gets intothe impeller assembly.

WARNING: Never remove discharge

chute till the unithas completely stopped.

Never turn off the engine until all

chipping is completed,

For best performance, it is important to keep the

shredding blade and the chipper blades sharp.

If the composition of the material being discharged

changes (becomes stringy, etc.) or if the rate at which

the material is discharged slows down considerably, it

is likely that the shredding blade and/or chipper

10

Page 11

blades are dull and need to be sharpened or

replaced. To sharpen or replace the blades, refer to

Service and Adjustments section.

IMPORTANT: There isa flail screen located inside

the housing in the discharge area. If the flail screen

becomes clogged, remove and clean as instructed in

the Service and Adjustments section on page 14.

WARNING: The chipper-shredder discharges materials with considerable velocity. Keep away from

the area around the discharge chute. Always stop the engine and disconnect spark plug wire when

removing or attaching the bag, changing containers, or removing the shredded material. Wear safety

glasses and gloves whenever using your chipper-shredder.

Shred material upto 112 inch in diameter

\

TO LOWER THE HOPPER

ASSEMBLY

• To lower the hopper assembly, use one hand to

grasp the hand-hold at the top ofthe hopper

assembly and lift slightly. Refer to figure 5.

• Pull up on the release bar, and lower the hopper

assembly tothe ground. Release the bar. Refer

to figure 5.

GENERAL RECOMMENDATIONS

• Always observe safety rules when performing

any maintenance.

• The warranty on this chipper shredder does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, operator must maintain the

chipper-shredder as instructed in this manual.

• Some adjustments will be needed periodically for

proper maintenance ofyour chipper shredder.

These adjustments are covered inthe following

section of this manual.

• All adjustments mentioned here should be

checked at least once each season.

• Follow the maintenance schedule given below.

Figure 13

Periodically check all fasteners and make sure

these are tight.

CLEANING

• Clean the chipper-shredder by running water

from a hose through the hopper assembly and

chipper chute with the engine running. Allow the

chipper-shredder to dry thoroughly.

• Wash the bag periodically with water. Allow to

dry thoroughly in the shade. Do not use heat.

WARNING: Always stop the engine and

disconnect the spark plug wire before

performingany maintenance oradjustments.

Never remove discharge chute tillthe engine

hascompletely stopped.

11

Page 12

ENGINE MAINTENANCE

Air Cleaner

Engine Oil

• Only use high quality detergent oil rated with

API service classification SF, SG or SH. Select

the oil's viscosity grade according to your

expected operating temperature. Refer to page

9 of this manual for viscosity chart.

• The four-cycle engine of your chipper-shredder

will normally consume some oil. Therefore,

check engine oil level regularly approximately

every five hours of operation and before each

usage.

• Stop engine and wait several minutes before

checking oil level. With engine on level ground,

the oil must be to FULL mark on dipstick.

• Change engine oil after the first five hours of

operation, and every twenty-five hours

thereafter.

To Drain Oil

Drain oilwhile engine is warm. Follow the instructions

given below.

• Remove oil drain plug. Catch oil in a suitable

container.

• When engine is drained of all oil, replace drain

plug securely.

• Refill with fresh oil. Refer to GAS AND OIL FILL-

UP section. Replace dipstick.

The air cleaner prevents damaging dirt, dust, etc.,

from entering the carburetor and being forced into the

engine and is important to engine life and

performance. The air cleaner consists of a pre-

cleaner or foam filter, and a paper filter. Never run

the engine without air cleaner completely assembled.

-- Wing Nut

_Cover

Base

/

Paper Filter

/ Pre-Cleaner

Figure 14

CUSTOMER RESPONSIBILITIES

MAINTENANCE _# @'_ _ ,@ ,,_ _ SERVICE

I--

Oil pivot points

0

Clean shredder _

Check engine oil _

Change engine oil _

LU

z

Service air cleaner

z

LU

Clean engine _

Reset spark plug _

Clean muffler

12

Page 13

To Service Air Cleaner:

1. Service pre-cleaner after every 25 hours of use,

or at least once a season.

2. Service filter every 100 hours of use, or at least

once a season.

3. Service pre-cleaner and filter more often under

dusty conditions.

Remove wing nut and cover. For location, see

figure 14 inset.

Slide pre-cleaner off filter. Clean the inside of

base and cover thoroughly. See figure 14.

• Clean pre-cleaner as follows:

c. Wash inwater and detergent solution, and

squeeze (donottwist)untilalldirtisremoved.

d. Rinse thoroughly in clear water.

e. Wrap in a clean clothand squeeze (do not

twist) untilcompletely dry, or allow to air dry.

f. Saturate with engine oil and squeeze (don't

twist) to distributeoiland remove excess oil.

NOTE: If the pre-cleaner is torn or damaged in any

way, replace it,

• If necessary, replace paper filter ---do not

attempt to clean. Install new filter on base.

• Slide pre-cleaner over filter.

• Install cover and wing nut.

• Tighten wing nut securely.

Clean Engine

• Clean engine periodically. Remove dirtand

debris with a cloth or brush.

• Frequently remove grass clippings, dirt and

debris from coolingfins, air intake screen and

levers and linkage. This will help ensure

adequate cooling and correct engine speed.

See figure 15.

_1_ WARNING: Temperature ofmuffler andnearby areas may exceed 150° F(65°C).

Avoid these areas.

Spark Plug

Clean the spark plug and reset the gap to .030"

at least once a season or every 50 hours of

operation. See figure 16. Spark plug

replacement is recommended at the start of

each season. Refer to engine parts list for

correct spark plug type.

.030" Feeler

_ Guage

g

Figure 16

NOTE: Do not sandblast spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

Muffler

Inspect periodically, and replace if necessary. If

your engine is equipped with a spark arrester

screen assembly, remove every 50 hours for

cleaning and inspection. Replace if damaged.

WARNING: Do not operate the chipper-

shredder without a muffler, or tamper with

the exhaust system. Damaged mufflers or

spark arresters could create a fire hazard.

LUBRICATION

Clean cooling

Figure 15

Yearly or every 25 hours, whichever occurs first,

remove the blower housing and clean the areas

shown in figure 15 to avoid overspeeding,

overheating and engine damage. Clean more

often if necessary.

NOTE: Cleaning with a forceful spray of water is not

recommended as water could contaminate the fuel

system.

Lubricate the pivot points on the release bar, hopper

assembly, and discharge chute once a season using

a light oil. Refer to the lubrication chart in figure 17.

Figure 17

13

Page 14

CLEANING THE FLAIL SCREEN

Ifthe discharge area becomes clogged, remove the

flail screen and clean area as follows.

• Stop engine, make certain the chipper-shredder

has come to a complete stop and disconnect

spark plug wire from the spark plug.

• Remove the two hand knobs on each side of the

discharge chute. Liftthe discharge chute up,

and keep it out ofthe way.

• Remove two hairpin clips from the clevis pins

which extend through the housing. Remove the

clevis pins. See figure 18.

Discharge Chute

Chipper Chute_'

Hairpin

Clips,

Clevis

Pins

Remove the flail screen as instructed in previous

section.

Using a 1/2" wrench, remove the chipper chute

by removing three hex nuts and washers. See

figure 18. (Only two hex nut positions shown in

figure.)

NOTE: When reassembling, the cupped washer goes

on theslot toward the bottom of thechipper chute with

the cupped side against the chute.

Rotate the impeller assembly by hand until you

locate one of the two chipper blades in the

chipper chute opening. Remove the blade, using

a 3/16" allen wrench on the outside of the blade

and 1/2" wrench on the impeller assembly

(inside the housing). See figure 19.

Blade

Slot

Discharge Chute

Screen

Hexl=ut,

Washer

Knobs

Figure 18

• Pul!the flailscreen from insidethe housing. See

figure 18. Clean the screen by scraping or washing

withwater.

• Reinstall the screen. Put the discharge chute

back to itsoriginal position and tighten the hand

knobs.

NOTE: Be certain toreassemble the flail screen with

the curved side down.

SHARPENING OR REPLACING THE

BLADES

Chipper Blades

• Disconnect spark plug wire and move it away

from spark plug.

Figure 19

Remove the other blade inthe same manner.

Replace or sharpen blades.

If sharpening, make certain to remove an equal

amount from each blade.

Reassemble inreverse order. Make certain

blades are reassembled with the sharp edge

facing the direction shown infigure 19 (sharp

edge is assembled toward the slotted opening at

the bottom).

Torque bolts and nutsto 250-350 inch-pounds.

14

Page 15

ShreddingBlade

Theshreddingblade may be removed for sharpening

or replacement as follows.

• Disconnect spark plug wire and move it away

from spark plug.

• Lower the hopper assembly. Block up the

housing. See figure 20.

Weld Bolt

Allen Screws

Pipe

angle of grind as a guide. It is extremely

important that each cutting edge receives an

equal amount of grinding to prevent an

unbalanced blade.

An unbalanced blade willcause excessive

vibrationwhen rotatingat highspeeds and may

cause damage totheunit.The blade can be tested

for balance by balancing it on a roundshaft

screwdriver ornail. Remove metal from the heavy

side untilitisbalanced evenly. See figure 21.

When reassembling the blade, tighten center

boltto between 550 and 650 inch-pounds and

the two outer bolts tobetween 250 and 350 inch-

pounds, or lacking torque wrench, tighten

securely.

I. Insert screw driver through hole

d./

2. Blade should be parallel to ground

Scre_

Driver'_ Blade

Blade

Figure 20

• Remove the six hex lock nuts and lockwashers

from the housing weld bolts using a 1/2" wrench.

Separate the chipper-shredder intotwo halves.

• Remove the back-up plate.

NOTE: When reassembling, make certain the

embossed tab faces inward towards the impeller, and

opening on the back-up plate is toward the bottom of

the unit.

• Remove the two hand knobs and cupped

washers which secure the discharge chute.

Raise the discharge chute.

• Insert a 1/2" or 3/4" diameter pipe through the

flail screen intothe impeller to keep it from

turning, or remove the flail screen and insert a

piece ofwood (2 x 4) intothe chute opening.

• Remove the two outside screws on the blade,

using a 3/16" allen wrench and a 1/2" wrench.

• Remove the blade by removing the center bolt,

lock washer and flat washer.

_hL WARNING: Use caution when removing

• When sharpening the blade, follow the original

the blade toavoid contacting the weld bolts

on the housing.

_1 o' ol--

Ground

Figure 21

ADJUSTING CARBURETOR

WARNING: Ifany adjustmentsare made to

the engine while the engine isrunning(e.g.

carburetor),keep clear of all moving parts.

Be carefulofheated surfaces and muffler.

The carburetor has been pre-set at the factory and

should not require adjustment. However, if your

engine does not operate properly due to suspected

carburetor problems, take your chipper-shredder to

your nearest SEARS service center.

ENGINE SPEED

The engine speed on yourchipper-shredder has been

set at the factory. Do not attempt to increase engine

speed or it may result in personal injury. If you believe

the engine is running too fast or too slow, take your

chipper-shredder to the nearest SEARS service

center for repair and adjustment.

15

Page 16

WARNING: Never store machine with fuel

A

A yearly check-up by your local Sears service center

is a good way to make certain your chipper-shredder

will provide maximum performance for the next

season.

in the fuel tank inside of building where

fumes may reach an open flame or spark,

or where ignition sources are present such

as hot water and space heaters, furnaces,

clothes dryers, stoves, electric motors, etc.

CHIPPER-SHREDDER

Clean the chipper-shredder thoroughly.

Wipe unit with an oiled rag to prevent rust (use a

lightoil or silicone).

ENGINE

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as

carburetor, fuel filter, fuel hose, or tank during

storage. Also, experience indicates that alcohol

blended fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads to

separation and formation ofacids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

• Drain the fuel tank.

• Start the engine and let it rununtil the fuel lines

and carburetor are empty.

• Never use engine or carburetor cleaner products

inthe fuel tank or permanent damage may

Occur,

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable a/temative in

minimizing the formation of fuel gum deposits during

storage.

• Add stabilizer to gasoline in fuel tank orstorage

container.

• Always follow the mix ratio found on stabilizer

container.

• Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor.

• Do not drain the gas tank and carburetor if using

fuel stabilizer. Drain all the oil from the crankcase

(this should be done after the engine has been

operated and is stillwarm) and refill the

crankcase with fresh oil.

• If you have drained the fuel tank, protect the

inside of the engine as follows.

• Remove spark plug, pour approximately 1/2

ounce (approximately one tablespoon) of engine

oil into cylinder and crank slowly to distribute oil.

• Replace spark plug.

OTHER

Do not store gasoline from one season to

another.

Replace your gasoline can ifyour can starts to

rust. Rust and/or dirt in your gasoline will cause

problems. Store unit in a clean, dry area. Do not

store next to corrosive materials, such as

fertilizer.

NOTE: Ifstoring in an unventilated or metal storage

shed, be certain torustproof the equipment by coating

with a light oil or silicone.

16

Page 17

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Engine fails to start

Loss of power; operation erratic

Engine overheats

Too much vibration

1. Fuel tank empty, or stale fuel

2. Spark plug wire disconnected

3. Faulty spark plug

4. Throttle control not in correct

position

1. Spark plug wire loose

2. Unit running on Choke

3. Blocked fuel line or stale fuel

4. Water or dirt in fuel system

5. Carburetor out of adjustment

6. Dirty air cleaner

1. Carburetor not adjusted properly

2. Engine oil level low

1. Loose parts or damaged

impeller

1. Fill tank with clean, fresh fuel

2. Connect wire to spark plug.

3. Clean, adjust gap or replace.

4. Move throttle control to FAST

position

1. Connect and tighten spark plug

wire.

2. Move choke lever to OFF

position.

3. Clean fuel line; fill tank with

clean, fresh gasoline.

4. Disconnect fuel line at carburetor

to drain fuel tank. Refill with fresh

fuel.

5. Contact your SEARS service

center.

6. Service air cleaner.

1. Contact your SEARS service

center.

2. Fillcrankcase with proper oil.

1. Stop engine immediately and

disconnect spark plug wire.

Tighten all bolts and nuts. Make

all necessary repairs. If vibration

continues, have unit serviced by

a SEARS service center.

Unit does not discharge

Rate of discharge slows

considerably or composition of

discharged material changes

1. Discharge chute clogged

2. Foreign object lodged in

impeller

1. Shredding blade and/or chipping

blade dull

For repairs beyond the minor

adjustments listed above, please

contact your nearest SEARS

service center.

17

1. Stop engine immediately and

disconnect spark plug wire.

clean flail screen and inside of

blower housing.

2. Stop engine immediately and

disconnect spark plug wire.

Remove lodged object.

1. Sharpen or replace blade(s).

Page 18

SEARS CRAFTSMAN 6.5 H.P. CHIPPER-SHREDDER MODEL 247.775870

29

66

\

8

13

17

,/62

48

64

42

j 'i

53

42

58

18

Page 19

SEARS CRAFTSMAN 6.5 H.P. CHIPPER-SHREDDER MODEL 247.775870

11

Key

No

1

2

3

4

6

7

8

9

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Pe_ No

770-1231A

_11480

681-0111

681-0144

710-0542

710-0607

710-3256

712-0429

712-3027

714-0104

715-0129

726-0106

726-0135

728-0175

732-0546

732-0629

735-0127

735-0651

736-0119

738-0137A

738-0946

747-0531A

747-0747

747-1124

747-1125

781-0492A

781-0633

781-0698

781-0715

781-0752

781-0754-0483

781-0755-0483

720-0170

750-0793

714-0149B

681-0094-0483

781-0457

681-0030

Description

Owner's Manual

Stop Washer

Inlet Guide Assembly

Arm Bracket Assembly

Hex Flange Bolt: 5/16-18 x

8.375" (gr.5)

Hex Washer Head Self-Tap-

ping Screw: 5/16-18 x 0,5"

Button-Head Screw 1/4-20 x

0.5"

Lock Nut: 5/16-18

Hex Flange Lock Nut: 1/4-20

Internal Cotter Pin

Spiral Pin

Cap Nut

Speed Cap Nut

Pop Rivet

Torsion Spring

Hopper Door Spring

Rubber Washer

Hopper Flap

Lock Washer

Shdr. Scr: .340 x .285 x 1/4-20

Shdr. Scr: .56 x ,165 x 5/16-18

Ret. Rod: 5/16" dia.

Hopper Door Rod

Flap Retaining Rod

Flap Retaining Bail

Hopper Pivot Door

Chute Flap Strip

Hopper Lock Bracket

Shredder Plate

Flap Mounting Bracket

Upper Hopper

Lower Hopper

Hand Knob

Chute Hinge Spacer

Internal Cotter Pin

Discharge Chute Assembly

Shredder Screen

impeller Assembly

Key Pa_ No

No

38 710-0157

39 736-0119

40 710-1054

41 781-0490

42 719-0329

43 715-0166

44 712-0411

45 735-0249

46 736-0247

47 711-0833B

48 710-3008

49 710-0825

50 711-0835

51 736-0217

52 681-0004A

53 681-0117

54 726-0214

55 734-1600

56 750-0786

57 738-0814

58 712-3004A

59 736-0170

60 781-0510B

61 710-0805

62 761-0633

63 728-0175

64

65 781-0735

66 710-0751

67 736-0173

68 742-0571

69 712-3027

70 749-1004

71 710-0106

72 681-0068

73 712-3010

74 736-0242

75 731-1899

Description

Hex Bolt 5/16-24 X .75"

Lock Washer 5/16" Id

Flat Hd. Screw 5/16-24 X .75"

Chipper Blade

Flail Blade

Spring Roll Pin

Hex Top Lock Nut 5/16-24

(gr. 5)

Shredder Chute Flap

Flat Washer .406" ID X 1.25"

OD

Clevis Pin

Hex Bolt 5/16-18 X 1.5"

Hex Bolt 1/4-20 X 3.75"

Clevis Pin

Lock Washer

Flail Housing Assembly: Outer

Flail Housing Assembly: Inner

Push Cap 5/8" Dia,

Wheel Assembly Comp.

Spacer

Shredder Axle

Hex Lock Nut 5/16-18 (Gr.5)

Special Lock Washer

Shredder Frame

Hex Bolt 5/16-18 x 1.5"

Chute Flap Strip

Pop Rivet

Engine: Tecumseh 6.5 hp.

OHH65-71701

Pin Retaining Clip

Hex Bolt 1/4-20 x .625

Flat Washer .28 I.D. x .74 O.D.

Shredder Blade

Flanged Lock Nut

Chipper Chute Support

Hex Screw 1/4-20 x .625 (gr. 21

Chipper Chute Assembly

Hex Nut 5/16-18 (gr. 5)

Bell Washer .345" I.D. x .88"

Chipper Chute

|

|

19

Page 20

SEARS CRAFTSMAN 6,5 H.P. ENGINE MODEL 143.986501 FOR

CHIPPER-SHREDDER MODEL 247.775870

161

310 --

308

305

307

I

\

279

161A

173

154

155

159

4O

130

135

900

41

}--43

130A

/

s

82

_207 252

182

185 /

184 _ •

6

240

245

126

16

120

125

38 2

245A

/

119

5

250A

/

20

251

Page 21

SEARS CRAFTSMAN 6.5 H.P. ENGINE MODEL 143.986501 FOR

CHIPPER-SHREDDER MODEL 247.775870

65 60

110

lOO

341

313

342

25A

\

292

26

£0

370A

261 261A I

260

21

390

287

/

O

/

327

Page 22

SEARS CRAFTSMAN 6.5 H.P. ENGINE MODEL 143.986501 FOR

CHIPPER-SHREDDER MODEL 247.775870

Key No. Part No. Description Key No. Part No. Description

1

2

4

5

14

15

16

19

2O

25

25A

26

30

35

37

38

40

41

42

43

45

46

48

49

5O

60

64

65

69

70

72

75

80

81

82

83

86

89

90

92

93

100

101

103

110

37120A

26727

31857

30969

651051

37108

37110

37111

32600

36621

36622

30200

36831

651053

29216

37109

40004

40005

36070

36071

40006

40007

20381

32875A

32610A

35616

36611

37040

36623A

651015

30200

36624

36625

27897

30574A

30590A

30591

36057

650488

610961

611205

650815

650816

34443B

610118

651007

36054

RPM High 3450 to 3750

RPM Low 2000 to 2300

Cylinder (Incl. 2, 20 & 72)

Dowel Pin

Oil Drain Extension

Extension Cap

Washer

Governor Rod

Governor Lever

Extension Spring

Oil Seal

Air Baffle (Left)

Air Baffle (Right)

Screw, 10-24 x 9/16"

Crankshaft

Screw, 10-32 x 63/64"

Lock Nut, 10-32

Retaining Ring

Piston, Pin, And Ring Set (Std.)

Piston, Pin, And Ring Set (.010" O.S.)

Piston & Pin Ass'¥ (Std.) (Incl. 43)

Piston & Pin Aes'y (.910" O.S.)(Inel. 43)

Ring Set (Std.)

Ring Set (.010" O.S.)

Piston Pin Retaining Ring

Connecting Rod Ass'y. (Incl. 46 & 49)

Connecting Rod Bolt

Valve Lifter

Oil Dipper

Camshaft

Blower Housing Extension

Screw, 1/4-20 x 1-1/8"

Screw, 10-24 x 9/16"

Cylinder Cover Gasket

Cylinder Cover (Incl. 75 thru 83)

Oil Drain Plug

Oil Seal

Governor Shaft

Washer

Governor Gear Ass'y. (Incl. 81)

Governor Spool

Screw, 1/4-20 x 1-1/4"

Flywheel Key

Flywheel

Belleville Washer

Flywheel Nut

Solid State Ignition

Spark Plug Cover

Screw, Torx "1"-15,10-24 x 15/16"

Ground Wire

119

12O

125

126

130

130A

135

150

151

153

154

155

157

158

159

160

161

161A

173

178

182

184

185

186

20O

206

2O7

2O9

215

223

224

238

239

240

245

245A

250

251

252

260

261

261A

262

275

277

278

279

280

285

287

290

292

3O0

301

36719

36721

36471

36472

29314C

29315C

650912

650999

34645

37039

31673

36649

650913

35624A

650914

36629

35626

36630A

651008

651012

36675A

650852

650451

26756

36631

36711

36736

610973

36632

650821

36638

650451

36581

28820

27272A

36633

36046

36634

37073

650886

650821

36864

651008

650821

651008

36722

650988

36674

650852

36893

35985B

30705

26460

36863

36246

Cylinder Head Gasket

Cylinder Head

Exhaust Valve (Std.) (Incl. 151)

Exhaust Valve (1/32" O.S.) (IncL 151)

Intake Valve (Std.) (Incl. 151)

Intake Valve (1/32" O.S.) (Incl. 151)

Screw, 5/16-18 x 1-1/2"

Screw, 5/16-18 x 2-41/64"

Spark Plug (N4C)

Valve Spring

Valve Spring Cap

Push Rod Guide

Rocker Arm Stud

Rocker Arm

Nut, 1/4-28

Push Rod

Rocker Arm Cover Gasket

Rocker Arm Cover

Screw, 1/4-20 x 31/64"

Stud

Breather Tube

Nut, 1/4-20

Screw, 1-4-20 x 1"

Carburetor to Intake Pipe Gasket

Intake Pipe

Governor Link

Control Bracket (Incl. 206 & 215)

Terminal

Throttle Link

Screw, 10-32 x 1/2"

Control Knob

Screw, 1/4-20 x 1"

Intake Pipe Gasket

Screw, 10-32 x 1/2"

Air Cleaner Gasket

Air Cleaner Body (Incl. 239)

Air Cleaner Filter

Air Cleaner Filter

Air Cleaner Cover

Wing Nut

Screw, 10-32 x 1/2"

Blower Housing

Screw, 1/4-20 x 31/64"

Screw, 10-32 x 1/2"

Screw, 1/4-20 x 31/64"

Muffler

Screw, 1/4-20 x 2-9/32"

Spacer

Nut & Lock Washer

Heat Shield

Starter Cup

Rivet (Can be purchased locally)

Fuel Line

Fuel Line Clamp

Fuel Tank (Incl. 292 & 301)

Fuel Cap

22

Page 23

SEARS CRAFTSMAN 6.5 H.P. ENGINE MODEL 143.986501 FOR

CHIPPER-SHREDDER MODEL 247.775870

Key Pad

No. No.

305 35554

307 35499

308 37079

310 36902

313 34080

325 29443

327 35392

341 36644

342 651010

Carburetor

Descri_ion Key Part

Oil FiJlTube 370A 36261

"O"-Ring 370B 35703

FillTube Clip 380 640025B

Dipstick 390 590736

Spacer 400 36720

Wire Clip 416 36085

Starter Plug 417 650760

Fuel Tank Bracket 900 --

Screw, 1/4-20 x 7/8" 900 --

"_ / 48...Q I

_20A 29/

28/__/27

_-- 37

_-- 37

No. No.

Key Part Description

No. No.

1 631615

2 631767

4 631184

5 631183

6 631036

7 650506

16 632164

17 651025

18

20

20A

25

27

28

29

30

31

35

36

37

40

44

47

48

640025B

630766

640018

640053

631867

631024

632019

631028

631021

631022

36045A

640019

632547

640015

27110

630748

631027

Description

Lubrication Decal

Speed Control Decal

Carburetor (Incl. !84)

Rewind Starter

Gasket Set

Spark Arrester Kit (Incl, 417)(Optional)

Screw, 8-32 x 3/8"

Replacement Engine -- none

Replacement S/B 754299A

Order Form 71-999

Carburetor (Incl. 184 of Engine

Parts List)

Throttle Shift & Lever Assembly

Throttle Return Spring

Dust Seal Washer

Dust Seal (Throttle)

Throttle Shutter

Shutter Screw

Fuel Fitting

Throttle Crack Screw/Idle Speed

Screw

Tension Spring

Idle Restrictor Screw

Idle Rsstrictor Screw Cap

Float Bowl

Float Shaft

Float

Float Bowl "O"-Ring

Inlet Needle, Seat & Clip (incL.31)

Spring Clip

Primer Bulb/Retainer Ring

Main Nozzle Tube

"O"-Ring, Main Nozzle Tube

High Speed Bowl Nut

Bowl Nut Washer

Welch Plug, Idle Mixture Well

Welch Plug, Atmospheric Vent

25/_

4O

23

Page 24

SEARS CRAFTSMAN 6.5 H.P. ENGINE MODEL 143,986501 FOR

CHIPPER-SHREDDER MODEL 247.775870

Recoil Starter

Key Part Description

No. No.

Key Part Descnption

No. No.

590736

1 590599A

2 590600

3 590696

4 590601

5 590697

6 590698

7 590699

8 590700

11 590705

O

12 590535

13 590701

Rewind Starter

Spring Pin (Incl, 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Pulley & Rewind Spring Ass'y

Starter Housing Ass'y

Starter Rope (98" x 9/64" Dia.)

Starter Handle

O

590748

1 590599A

2 590600

3 590679

4 590601

5 590678

6 590680

7 590412

8 590681

11 590747

12 590535

13 590701

Rewind Starter

Spring Pin (Incl. 4)

Washer

Retainer

Washer

Brake Spring

Starter Dog

Dog Spring

Pulley & Rewind Spring Ass'y

Starter Housing Ass'y

Starter Rope (98" x 9/64" Dia,)

Starter Handle

_'_5

24

Page 25

Fortherepairorreplacementpartsyouneed

delivereddirectlyto yourhome

Call7 am- 7 prn,7 daysaweek

1-800-366-PART

(1-800-366-7278)

Forin-homemajorbrandrepairservice

Call24 hoursa day,7 daysa week

1-8OO-4-REPAIR

(1-800-473-7247)

Forthelocationofa

SearsPartsandRepairCenterinyourarea s_u_s

Call24 hoursa day,7 daysa week _

1-800-488-1222

L"

For informationonpurchasinga Sears

Maintenance Agreementorto inquire

about an existingAgreement

call 9 am - 5 pm, Monday-Saturday

1-800-827-6655

mm

Helium

SEARS

America's Repair Spectagsts

Loading...

Loading...