Page 1

CRAFTSMAN.

OWNERS

MANUAL

MODEL NO.

757.243481

Caution:

Read Rules for

Safe Operation

and Instructions

Carefully

FOR USE WITH RIDERS

AND LAWN/GARDEN TRACTORS

LAWN AERATOR

(PLUG-TYPE)

Assembly

Installation

Operation

Repair Parts

L-1S90-SC-2 Sears, Roebuck and Co., Hoffman Estates, IL 60t79, U. S. A.

Page 2

LIMITED TWO YEAR WARRANTY ON AERATOR

For 2 years from the date of purchase, when this Aerator is maintained

and lubricated according to the operating and maintenance instructions in

the owner's manual, Sears will repair, free of charge, any defect in material

or workmanship.

This warranty does not cover:

---repairs necessary because of operator abuse or negligence including the

failure to maintain the equipment according to instructions contained in

the owner’s manual; and Aerator used for commercial or rental

purposes.

WARRANTY SERVICE IS AVAILABLE BY RETURNING TO THE NEAREST

SEARS SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. This

warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA, Hoffman Estates, IL 60179, U.S.A.

CONGRATULATIONS on your purchase of a Sears Craftsman Aerator, It has been designed,

engineered and manufactured to give you the best possible dependability and performance.

Should you experience any problem you can not easily remedy, please contact your nearest

Sears Service Center/Department. We have competent, well trained technicians and the proper

tools to service or repair your Aerator.

Please read and retain this manual. The instructions will enable you to assemble and maintain

your Aerator properly. Always observe the "SAFETY RULES".

• THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL ATTACHED TO THE FRONT

CORNER OF THE TRAY.

• YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A

SAFE PLACE FOR FUTURE REFERENCE.

MODEL

NUMBER

SERIAL

NUMBER

DATE OF

PURCHASE

757.243481

CUSTOMER RESPONSIBILITIES

• Read and observe the "SAFETY RULES".

* Follow a regular schedule in maintaining, caring

for and using your Coring Aerator.

WARRANTY..............................................2

SAFETY RULES

CARTON CONTENTS

ASSEMBLY...........................................5&6

.......................................

................................

TABLE OF CONTENTS

3

3&4

OPERATION............................................... 7

CUSTOMER RESPONSIBIUTY............................7

REPAIR PARTS

...........................................

8

Page 3

A

RULES FOR SAFE OPERATION

Know controls and how to stop quickly, READ THE

OWNER’S MANUAL

Do not allow children to operate the vehicle, do

not allow adults to operate without proper

instruction and without having read the owner's

manual.

’ Do not carry passengers. Keep children and pets

a safe distance away.

> Always wear substantial footwear. Do not wear

loose fitting clothing that can get caught in

moving parts.

* Keep your eyes and mind on your tractor/attach

ment and area being covered. Don’t let other

interests distract you.

► Stay alert for holes in the terrain and other

hidden hazards.

Keep the vehicle and attachment in good operating

condition and keep safety devices in place.

Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

The vehicle and attachment should be stopped and

inspected for damage after striking a foreign

object. The damage should be repaired before

restarting and operating the equipment.

' See tractor equipment owner’s manual for safe

operation of the equipment.

• Do not drive close to creeks, ditches and public

highways.

> Watch out for traffic when crossing or near

roadways.

* When using any attachment , don't allow anyone

near the vehicle while in operation.

A

To avoid damage to Spoons, always engage

transport wheels to raise the Spoons when crossing

concrete or asphalt walks, drives, or roads.

^Use the Aerator only on an established

lawn, never on newly laid sod.

• To avoid possible personal injury and/or equipment

never exceed the recommended operating speed

range of 3 to 5 MPH.

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS. IT MEANS - ATTENTION!

A

No A L-1S90-SC-2

Owner s Manual No. B Z-1530

1 Used Hardware Bag

Plugging (Spoon) Tines

1 Used

BECOME ALERT! YOUR SAFETY IS INVOLVED.

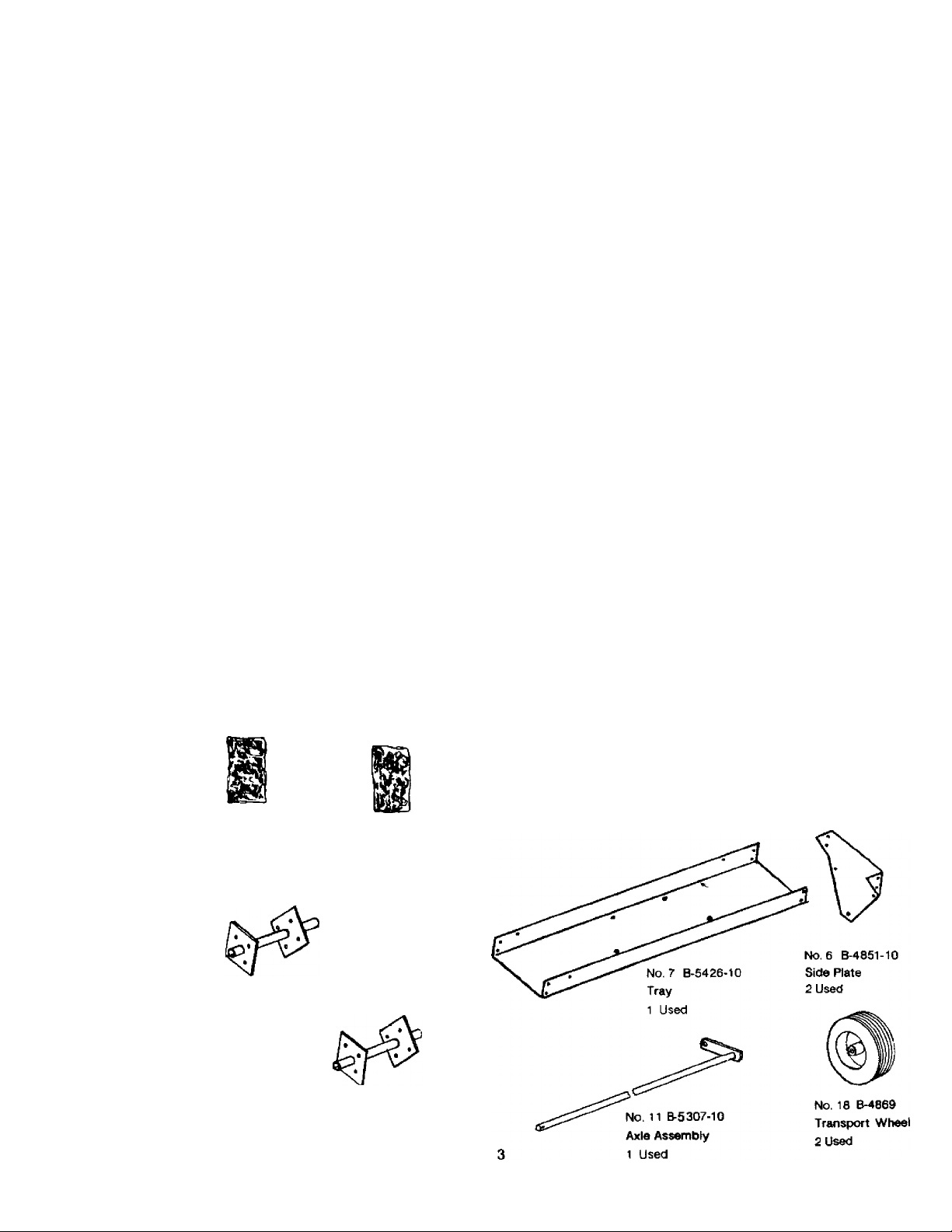

CONTENTS OF SHIPPING CARTON

No C 2-1531

Hardware Bag

1 Used

CAUTION

• Only tow your Aerator behind vehicles for

which it was designed, lawn/garden tractors.

• Do not stand/ride on Aerator, bodily injury

could result.

• Never exceed the Weight Tray capacity of 150 pounds

• Do not attempt to disconnect Aerator from

tractor with weight in Hopper.

• When backing, carefully back straight to avoid Jack

knifing, which could result in damage to equipment.

30Z

No. 9 B-54 27-10

Frame Angle

2 Used

€3t:3í/

No. 12 B-4859-10

Lift Handle Assembly

1 Used

No. 13 B-5309-10

Outer Tube Assembly

2 Used

No.D Z-1531-A

Hardware Bag

Nylon Bearings

1 Used

No. 14 B-5311-10

Center Tube Assembly

1 Used

Page 4

Z-1531 HARDWARE BAG

No. 5 B-4786

H u Look Nut, 5/18*

17 Us«d

No. 15 B-4867

Handle Grip

1/4" X 1-1/2"

1 Used

No . 26 40M1600P

Lock Washer, 1/2“

2 Used

No. 9 R-618

Heavy Washer- 5/16'

Used

N0.28 45M1717P

Flat washer, 172"

4 Used

No. 29 B-676P

Rat Washer, 3/4*

3 Used

No. 17 B-4868

Hex Head BoH

5/16" X 2-1/2"

2 Used

No. 20 D-146P

Hairpin Cotter, 1/8"

1 Used

No. 22 2M1012P

Hex Head Bolt

5/16" X 3/4"

13 Used

No. 23 2M1660P

Hex Head Bolt

1/2" X 3-3/4"

2 Used

Page 5

ASSEMBLY

It is recommended that you carefully read this Owner’s

Manual BEFORE starting assembly of this unit.

Fold out the carton for use as a pad during assembly

and arrange each kind of hardware Into a group to ease

assembly.

All reference to Right Hand and Left Hand are made

while standing behind unit facing forward.

TOOLS REQUIRED FOR ASSEMBLY

1 - Pair Pliers

2 - 1 /2" Wrenches

2 - 3/4" Wrenches

OR

2 - 10" Adjustable wrenches

FRAME ASSEMBLY

Refer to Fig. 1

• Sit the Tray (7) on the pad with flanges facing up.

• Attach the Side Plates (6) to Tray as shown using

eight 5/16"x3/4" Hex Bolts (22- from ÍNSIDE of

Tray), Flat Washers (27- next to Bolt heads) and

Lock Nuts (5). Tighten all Bolts while maintaining

41" to 41-1/4" inside the Side Plates (6).

Refer to Figs. 1 &2

• Assemble the Transport Lock Pin (31) into the

front hole at Left Hand Side Plate (6) from the

outside. Secure with 5/16" Lock Nut (5) holding

Pin with Pliers as you tighten. This Pin is used to

lock the Wheels in Transport.

Refer to Fig.2

• Attach the two Frame Angles (8) to underside of

Tray (7) using four 5/16” x 3/4" Hex Bolts (22),

Heavy Flat Washers (9) next to Frame Angle holes, and

Nylon Insert Nuts (5). Do not tighten at this time.

• Align the front holes of Angles and fasten at two

smaller holes using two 5/16"x2-l/2" full threaded

Hex Bolts (17). Bolts extend inside legs of Angles

and secure with 5/16" Hex (regular) Nuts (24). See

Inset "A". Tighten these and Tray Bolts (22)

securely. '

Fig. 1

• Assemble the Drawbar Clevis (2) to Full Threaded

Bolts extending from Frame Angies, securing with

two 5/16" Lock Nuts (5).

PLUGGING SPOON PRE-ASSEMBLY

Refer to Fig. 3.

(Center Tube[l4]shown)

• Assemble Plugging Spoons (10) to each welded

plate (SIDES OPPOSITE WELDS) of the three Tube

Assemblies (13 & 14) using 5/16”x3/4" Hex Bolts

(22) and Lock Nuts (32). Rounded part of Spoon fits

against tube to lock in place. Tighten all 24

securely.

•

• Insert a 3/4" Nylon Bearing (16) into each end of

Tube Assemblies.

Page 6

PLUGGING UNIT ASSEMBLY

Refer to Fig. 4

• Identify the two Outer Tube Assemblies (13- has

one plate welded close to end of tube) and the

Center Tube Assembly (14- has both plates welded

close to end of tube).

• Insert the Axle Assembly (11) partially through

hole in Side Plate (6) at RIGHT SIDE.

• Install as follows:

• 3/4“ Flat Washer (29).

•Outer Tube Assembly (13)- with short Hub

end next to Right Side Plate.

• 3/4" Fiat Washer (29).

• Center Tube Assembly (14).

• 3/4" Flat Washer (29).

•Outer Tube Assembly (13) with short Hub

end next to Left Side Plate.

• 3/4" Flat Washer (29).

IMPORTANT: Make sure Nylon Bearings are inside

Tube Assemblies. See Fig.3.

• Align Axle Assembly shaft end with hole in Left

Side Plate and push through as far as possible.

Slide on a 3/4" Flat Wash'^r (29).

• Install Lift Handle Assembly (12) over Axle

Assembly Shaft- Welded Tube on Lift Handle

FACING OUT.

• Position strap on Axle Assembly (at opposite

side) in line with short end extending from Lift

Handle (with Wheel mounting holes) and align

holes in Handle Tube and Axle Shaft. Insert a

5/16"x 1-1/2" Hex Bolt (21) and secure with a 5/16"

Lock Nut (1).

• Slip Handle Grip (15) over end of Lift Handle.

NOTE: Soapy water will ease this assembly,

TRANSPORT WHEELS

Refer to Fig.5

• Pre-assemble the two Transport Wheels (18)

using l/2"x3-3/4" Hex Bolts (23) and Fiat Washers

(28) next to Bolt Head through Wheel Hubs

(opposite extended Hub side).

• Install a Flat Washer (28) next to Hub and 1 /2"

Hex Nut (25) threaded on as far as possible with

Boit still free to turn.

• Install both Wheels through holes in Side Straps

(11 & 12) securing with Lock Washers (26) and Hex

Nuts (25). Tighten securely, but with Wheels free to

•

turn.

• Check all fasteners for tightness. Your Aerator is

now ready for use.

Page 7

OPERATION

A

• To avoid personal injury and/or

equipment damage, never exceed the

recommended operating speed range of

3 to 5 MPH.

WHEN TO AERATE

Your Aerator should not be used when Lawn

Conditions are too Wet or too Dry. To determine

condition, dig a small amount of your soil (about

three inches deep):

• If soli appears powdery and brittle- it is

too dry. Wait until a later date, after a

rainfall. If soil is too dry, the Plugging

Spoons will not penetrate properly.

• If soil appears damp, roll a small amount

into a ball in the palm of your hand- if it

forms a ball, theff it is too wet. Ideally, the

soil should fall apart when rolled in the

palm of your hand. Wait till a later date for

soil to dry. If soil is too wet, the Plugging

Spoons will stop up and your Tractor could

lose tract ion, causing Lawn Damage

MOUNTING AND TRANSPORTING

• Attach Aerator to your Rider using Pin and

Hairpin Cotter supplied.

• To place in Transport Position;

Pull FORWARD on Lift Handle (12) and

move to Transport Lock Pin in Side Plate.

Pull OUT and move Handle to Lock-in

position. Aerator rests on Wheels.

• To place in Operating Position:

Pull OUT on Lift Handle (releasing from

Transport Position) and move back. Aerator

rests on Plugging Spoons.

WARNING

A

• Use the Plugging Aerator only on

established lawns, NEVER ON NEWLY

LAID SOD.

• Never exceed the Weight Tray capacity

of 150 pounds. If the Plugging Spoons

are going too deep, remove some of

the weight from the weight Tray.

• Always raise Plugging Spoons to

Transport position when crossing

asphalt or concrete.

• When backing - carefully back straight to

avoid jackknifing, which could result in

damage to equipment.

USE OF ADDITIONAL WEIGHT

The weight required to give a recommended

penetration of approximately three inches will vary

according to soil type and conditions. Concrete

Blocks, Patio Blocks, Sand Bags, or any other type

of weight can be added to Aerator Tray as

required. Weight can be secured by using tie

downs through holes in Tray Flanges. Tie downs

are not furnished with your unit. Usually three

Concrete Blocks will be sufficient, but more or less

may be required.

• Drive your Tractor to location to be Aerated.

• Lower Aerator to Operating Position.

• Drive the Tractor FORWARD approximately ten

feet and stop.

• Observe the operation- there should a Plug hole

approximately every 10 inches to 12 inches and

not more than 3 inches deep.

CAUTION

CUSTOMER RESPONSIBILITY

• Should rust appear on any other part of your

Aerator,, sand lightly to remove rust and coat lightly

with enamel.

• Apply a drop of lubricating oil to each Nylon Bearing

and the Aerator Axle before each use.

• To prevent rust on Plugging Spoons, apply a light

coat of oil on the working areas of Spoons after each

use.

• Add or remove weight to obtain this condition.

• Periodically check the Spoons - remove

any debris which might build up and restrict

their action.

• After each use, service unit as described - and

store in a dry area, shielding tines to avoid injury.

Page 8

LAWN AERATOR

Model Number 757.24348!!

PARTS US

7» Ref. Part Description Qty.

Ref.

No. No. 16 B-4866

1 B-5429 Model No. Decal 1

2 B-3034-10

3

4

5

6 B-4851-10 Side Plate 2

7 B-54 26-10 Tray 1 23 2M1660P

8 B-5427-10 Frame Angle 2

9 R-618

10 B-4855-10

11

12

13

14

15 B-4867

Part Description

Drawbar Clevis

B-3568-A

B-3686

B-4786

B-5307-10

B-4859-10 Lift Handle Assembly 1 28

B-6309-10

B-5311-10

L-15&0-SC-?

Caution Label

Logo Decal 1 20 D-146P

Lock Nut- 5/16"

5/16" Heavy Washer

Plugging Spoon

Axle Assembly 1 27

Outer Tube Assembly 2

Center Tube Assembly

Handle Grip

Qty. No.

17 21

24 26

17

1

1

4 25

1 30

1

18 B-4869

19 B-4870-01

22 2M1012P

24 30M1000P

29 B-676P

31

32.

No.

B-4868

2M1024P

30M1600P

40M1600P Lock Washer-1/2"

45M1111P Flat Washer- 5/16" 8

45M1717P

L-1590-SC-2

B-3307-S

Bimr

3/4" Nylon Bearing

Hex Bolt- 5/16x2-1/2"

TransfKjrt Wheel

Drawbar Pin

Hair Pin Cotter

Hex Bolt, 5/16"x1-1/2" 1

Hex Bolt- 5/16"x3/4"

Hex Bolt- 1/2*x3-3/4"

Hex Nut- 5/16"

Hex Nut- 1/2"

Flat Washer- 1/2"

Flat Washer- 3/4" 5

Instructions

Transport Lock Pin

f^exLock Nut 5/ lir

38

6

2

2

1

1

2

2

4

2

4

1

1

25

Loading...

Loading...