Page 1

iii,_llllll,_i,_l,,ii_llllll,i_,11, :

Save This Manual

For Future Reference

owners

manual

MODEL NO=

720.25251

CAUTION:

READ ALL

INSTRUCTIONS

CAREFULLY

OUTE

° assembly

° operating

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

Printed in U.S.A.

Page 2

generaU safety instructions for router crafter

WRARNING:FAILURE TO HEED ALL SAFETY AND OPERATING INSTRUCTIONS AND WARNINGS REGARDING USE OF THIS

ODUCT CAN RESULT IN SERIOUS BODILY INJURY_

1. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANS Z87.t) at all times Also, use face or dust mask if cutting operation is

dusty, and ear protectors (plugs or muffs) during extended periods of operation

2. DON'T FORCE TOOL

The Router' Crafter was designed for smooth operation, therefore, parts should never be forced to operate.

3. KEEP HAND CLEAR OF BITS AND WORKING AREA°

4. KEEP ROUTER CRAFTER AND ROUTER CLEAN.

After every use clean saw dust off the Router Crafter and Router

NOTE: Motors used on wood-working tools are particularly susceptible to the acumu]ation of sawdust and wood chips

and should be blown out or "vacuumed" frequently to prevent interference with normal motor ventilation

general safety instructions for power tools

1. KNOW YOUR POWER TOOL

Read the owner's manual carefully Learn its applica-

tion and limitations as well as the specific potential

hazards peculiar' to this tool

2o GROUND ALL TOOLS (UNLESS

DOUBLE INSULATED)

If tool is equipped with an approved 3-conductor cord

and a 3-prong grounding type plug, it should be plugged

into a three hole electrical receptacle. If adapter' is used

to accommodate a two-prong receptacle, the adapter

wire must be attached to known ground, (usually the

screw securing receptacle cover plate) Never remove

third prong Never connect green ground wire to a

terminal

3. KEEP GUARDS IN PLACE

in working order, and in proper adjustment arid

afignment..

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjust-

ing wrenches are removed from tool before turning

it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents, Floor

must not be slippery due to wax or sawdust..

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain, Keep work area well lighted

Provide adequate surrounding work space.

7o KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area

8. MAKE WORKSHOP KID-PROOF

--with padlocks, master switches, or by removing

starter keys

9, DON'T FORCE TOOL

It will do the job better and safer at the rate for which

it was designed

10. USE RIGHT TOOL

Don't force tool or attachment to do a job it was not

designed for

11. WEAR RIGHT APPAREL

Do not w_ar loose clothing, gloves, neckties or

jewelry (rings, wrist watches) to get caught in mov-

ing parts Nonslip footwear is recommended Wear

protective hair covering to contain long hair Roll

long sJeeves above the elbow

12. USE SAFETY GOGGLES (Head Protection)

Wear Safety goggles (must comply with ANS Z87,1)

at all times. Also, use face or dust mask if cutting

operation is dusty, and ear protectors (plugs or

muffs) during extended periods of operation

13, SECURE WORK

Use clamps or a vise to hold work when practical

It's safer than using your hand, frees both hands to

operate too!

14, DON'T OVERREACH

Keep proper' footing and bala0ce at all times

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories

16. DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plug-

ging in

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended ac_

cessories Follow the instructions that accompany

the accessories. The use of improper accessories

may cause hazards

19.

NEVER STAND ON TOOL

Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

Do not store materials above or near the tool such

that it is necessary to stand on the tool to reach

them

20.

CHECK DAMAGED PARTS

Before further use of the toot, a guard or other part

that is damaged should be carefully checked to en-

sure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced

21.

DIRECTION OF FEED

Feed work into a blade or cutter against the direc-

tion of rotation of the blade or cutter only

22.

NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power off Don't leave tool until it comes to a

complete stop.

Page 3

preliminary instructions and pack ng tist

CONTENTS

General Safety Instructions for Router Crafter ...... 2

Genera_ Safety Instructions for Power Toots ........ 2

Preliminary Instructions and Packing List ,. 3

Assembly of Name Plate ............. 3

Assembly of Template Follower , 3

Introduction .................... 4

Construction ............. 4

Before Setting Up a Work Piece ............... 5

Mounting the Router on the Router Carriage ...... 5

Wood Preparation ............................ 6

Mounting the Wood Piece in the Router Crafter ..... 6

READING TIME FOR THIS MANUAL IS APPROXIMATELY 30 MINUTES, AND 30 MINUTES SPENT READING THIS

MANUAL MAY SAVE YOU HOURS OF FRUSTRATION.

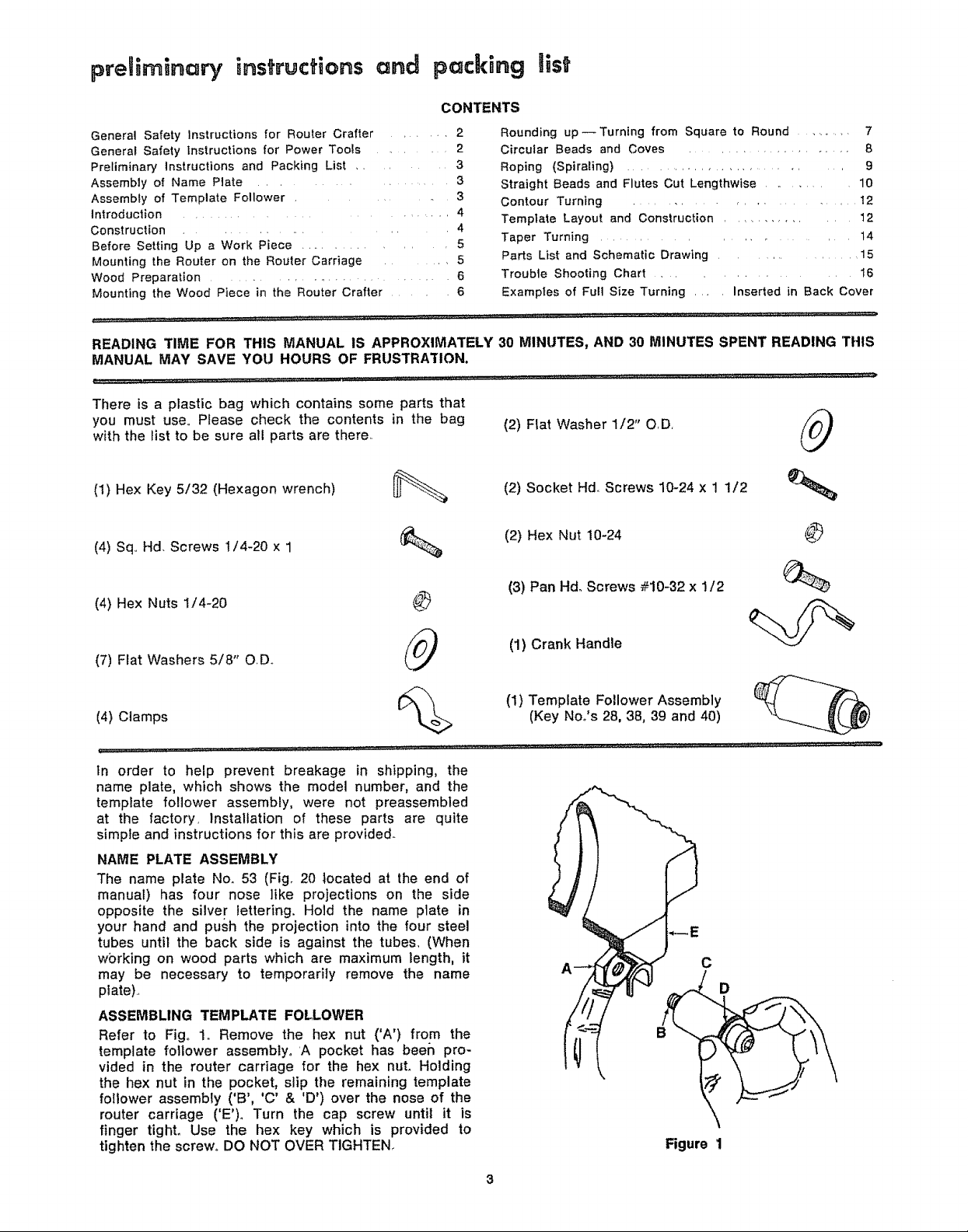

There is a plastic bag which contains some parts that

you must use,. Please check the contents in the bag

with the list to be sure all parts are there,.

(1) Hex Key 5/32 (Hexagon wrench) (2) Socket Hd. Screws 10-24 x 1 1/2 _I_

Rounding up--Turning from Square to Round ........ 7

Circular Beads and Coves .................. 8

Roping (Spiraling) .......................... 9

Straight Beads and Flutes Cut Lengthwise ........ 10

Contour Turning ................ 12

Template Layout and Construction ............. 12

Taper Turning ................. 14

Parts List and Schematic Drawing ............. 15

Trouble Shooting Chart ......... 16

Examples of Full Size Turning .., Inserted in Back Cover

(2) Flat Washer 1/2" OD,

(4) Sq,. Hd. Screws !/4_20 x 1

(4) Hex Nuts 1/4-20

(7) Flat Washers 5/8" O,D.

(_ (1) Crank Handle

(4) Clamps

tn order to help prevent breakage in shipping, the

name plate, which shows the model number, and the

template follower assembly, were not preassembled

at the factory. Installation of these parts are quite

simple and instructions for this are provided.

NAME PLATE ASSEMBLY

The name plate No. 53 (Fig, 20 located at the end of

manual) has four nose like projections on the side

opposite the silver lettering. Hold the name plate in

your hand and pu½h the projection into the four steel

tubes until the back side is against the tubes, (When

wbrking on wood parts which are maximum length, it

may be necessary to temporarily remove the name

plate)..

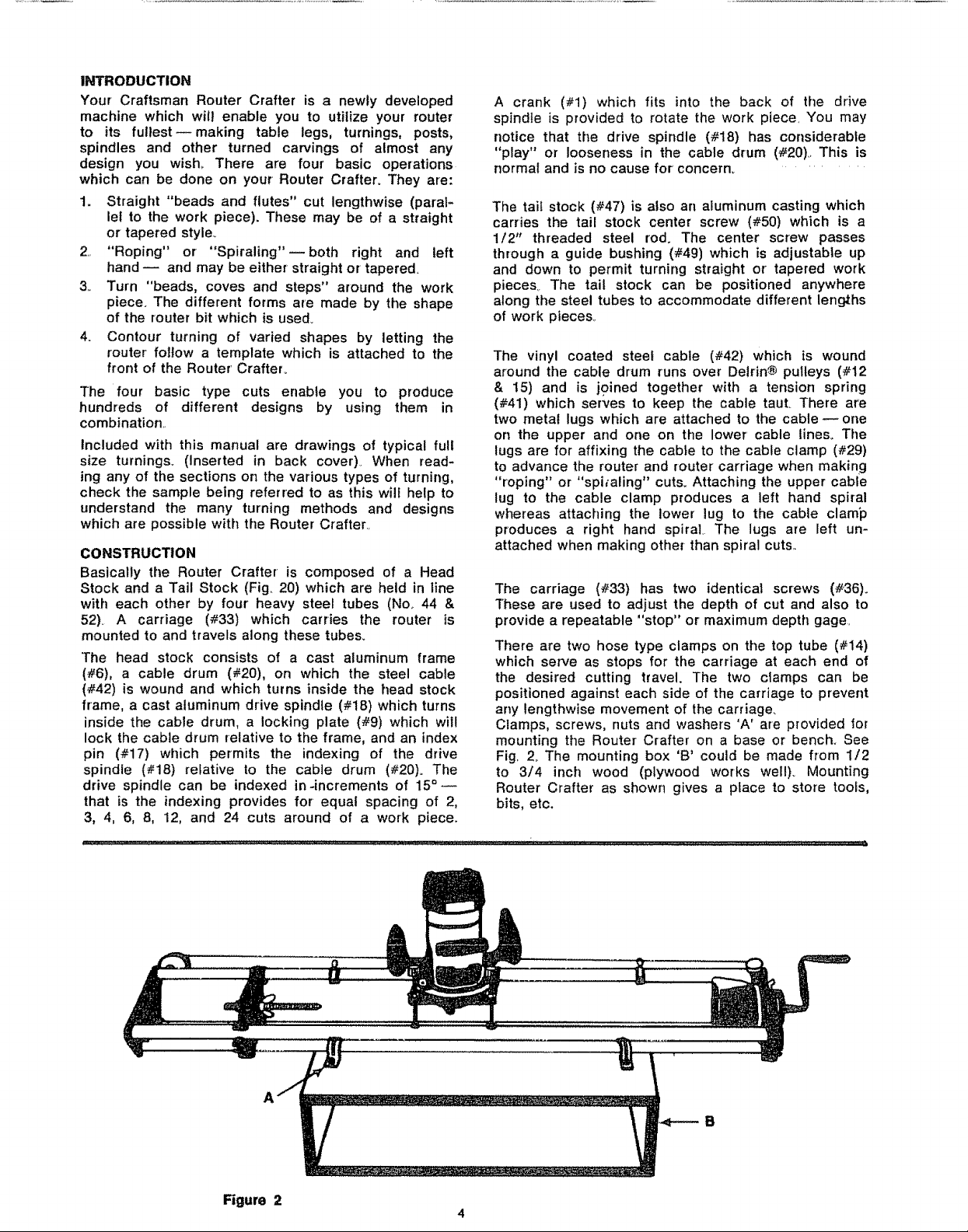

ASSEMBLING TEMPLATE FOLLOWER

Refer to Fig,. 1. Remove the hex nut ('A') from the

template follower assembly° A pocket has been pro-

vided in the router carriage for the hex nut. Holding

the hex nut in the pocket, slip the remaining template

follower assembly ('B', 'C' & 'D') over the nose of the

router carriage ('E'). Turn the cap screw until it is

finger tighL Use the hex key which is provided to

tighten the screw. DO NOT OVER TIGHTEN

(2) Hex Nut 10-24 _

(3) Pan HaloScrews #10-32 x 1/2

(1) Template Follower Assembly(Key NOo'S28, 38, 39 and 40)

C

D

Figure 1

Page 4

INTRODUCTION

Your Craftsman Router Crafter is a newly developed

machine which wilt enable you to utilize your router

to its fullest--making table legs, turnings, posts,

spindles and other turned carvings of almost any

design you wish. There are four basic operations

which carl be done on your Router Crafter. They are:

1. Straight "beads and flutes" cut lengthwise (paral-

lef to the work piece). These may be of a straight

or tapered style.

2. "Roping" or "Spiraling" _ both right and left

hand -- and may be either straight or tapered.

3. Turn "beads, coves and steps" around the work

piece. The different forms are made by the shape

of the router bit which is used°

4. Contour turning of varied shapes by letting the

router follow a template which is attached to the

front of the Router' Crafter..

The four basic type cuts enable you to produce

hundreds of different designs by using them in

combination.

Included with this manual are drawings of typical full

size turnings. (Inserted in back cover) When read-

ing any of the sections on the various types of turning,

check the sample being referred to as this wilt help to

understand the many turning methods and designs

which are possible with the Router Crafter..

CONSTRUCTION

Baslca_ty the Router Crafter is composed of a Head

Stock and a Tail Stock (Fig. 20) which are held in line

with each other by four heavy steel tubes (Nor 44 &

52). A carriage (#33) which carries the router is

mounted to and travels along these tubes_

The head stock consists of a cast aluminum frame

(#6), a cable drum (#20), on which the steel cable

(#42) is wound and which turns inside the head stock

frame, a cast aluminum drive spindle (#18) which turns

inside the cable drum, a locking plate (#9) which will

lock the cable drum relative to the frame, and an index

pin (#!7) which permits the indexing of the drive

spindle (#18) relative to the cable drum (#20)° The

drive spindle can be indexed in-increments of 15°-

that is the indexing provides for equal spacing of 2,

3, 4, 6, 8, 12, and 24 cuts around of a work piece.

A crank (#1) which fits into the back of the drive

spindle is provided to rotate the work piece, You may

notice that the drive spindle (#18) has considerable

"play" or looseness in the cable drum (#20),_ This is

normal and is no cause for concern_

The tail stock (#47) is also an aluminum casting which

carries the tail stock center screw (#50) which is a

1/2" threaded steel rod° The center screw passes

through a guide bushing (#49) which is adjustable up

and down to permit turning straight or tapered work

pieces,. The tail stock can be positioned anywhere

along the steel tubes to accommodate different lengths

of work pieces,.

The vinyl coated steel cable (#42) which is wound

around the cable drum runs over Deirin® pulleys (#12

& 15) and is joined together with a tension spring

(#41) which serves to keep the cable taut. There are

two metal lugs which are attached to the cable- one

on the upper and one on the lower cable lines° The

lugs are for affixing the cable to the cable clamp (#29)

to advance the router and router carriage when making

"roping" or "spi;aling" cuts. Attaching the upper cable

lug to the cable clamp produces a left hand spiral

whereas attaching the lower lug to the cable clam'p

produces a right hand spiral. The lugs are left un-

attached when making other than spiral cuts..

The carriage (#33) has two identical screws (#36).

These are used to adjust the depth of cut and also to

provide a repeatable "stop" or maximum depth gage_.

There are two hose type clamps on the top tube (#14)

which serve as stops for the carriage at each end of

the desired cutting travel. The two clamps can be

positioned against each side of the carriage to prevent

any lengthwise movement of the carriage.

Clamps, screws, nuts and washers 'A' are provided _or

mounting the Router Crafter on a base or bench. See

Fig, 2, The mounting box 'B' could be made from 1/2

to 3/4 inch wood (plywood works weII)_ Mounting

Router Crafter as shown gives a place to store toofs,

bits, etc.

Figure 2

B

4

Page 5

C B

D

ARROW

C

Figure 3

BEFOR'E SE'i_TINGUP A WORK PIECE in the Router .....

Crafter, do the following:

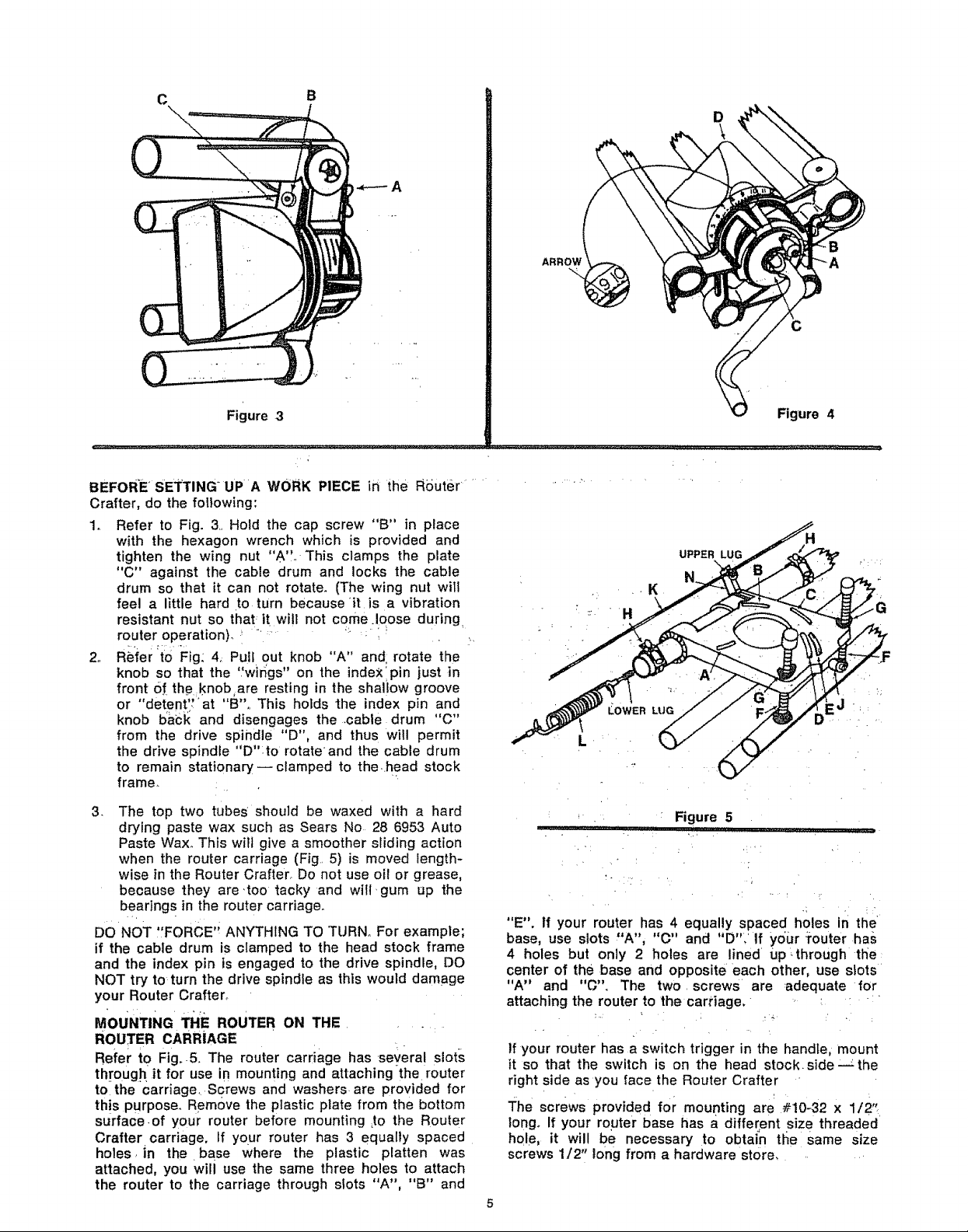

1o Refer to Fig. 3. Hold the cap screw "B" in place

with the hexagon wrench which is provided and

tighten the wing nut "A".. This clamps the plate

"C" against the cable drum and locks the cable

drum so that it can not rotate. (The wing nut wilt

feel a little hard to turn becauseitis a vibration

resistant nut so that _it will not come.loose during.

router operation)..' ......... " ._"

2,, R_fer'to Fig: 4,: Pull= out knob "A" and rotate the

knob so that the '_wings" on the indeX'pin just in

front 5_ the knob are resting in the shallow groove

or "detent_'at "B',. This holds the index pin and

knob back and disengages the .cable drum "C"

from the drive spindle "D", and thus will permit

the drive spindle "D":to rotateand the cable drum

to remain stationary _ clamped to the..head stock

frame.

=

3. The top two tubes should be waxed with a hard

drying paste wax such as Sears No 28 6953 Auto

Paste Wax. This wilt give a smoother sliding action

when the router carriage (Fig., 5) is moved length-

wise in the Router Crafter. Do not use oil or grease,

because they are,too tacky and will _gum up the

bearings in the router carriage.

DONOT !!FORCE" ANYTHING TO TURN° For example;

if the cable drum is clamped to the head stock frame

and the index pin is engaged to the drive spindle, DO

NOT try to turn the drive spindle as this would damage

your Router Crafter°

MOUNTING TH:E ROUTER ON THE .....

ROUTER CARRIAGE

J r _ =

r r

Refer to Fig.5. The router carriage has several slots

through it for use in mounting and attachingthe, router

to the carriage. Screws and washers are provided for

this purpose. Remove the plastic plate from the bottom

surface.of your router before mounting _to the Router

Crafter.carriage. If your router has 3 equally spaced

holes, in the base where the plastic platten was

attached, you will use the same three holes to attach

the router to the carriage through slots "A', "B" and

Figure 4

.................................................. :: :::::::::::::::::::::::::::: "' L

UPPER LUG

L •

Figure 5

.=

! .... i

' "M'II' '

r,,_,, •

"E". If your router has 4 equally spaced holes in the

base, use slots ,A", "O" and "D",' If your Touter has

4 holes but only 2 holes are lined Up.through ttle

center of the base and opposite each other, use slots

"A" and "C"_ The two .screws are adequate for

attaching the router to the carriage. _ _ : •

If your router has a switch trigger in the hand_e, mount

it so that the switch is on the head stock.side _ the

right side as you face the Router Crafter

The screws provided foi mout_ting are #10-32 x 1/2"..

longo If your router base has a different .size threaded

hole, it will be necessary to obtain the same size

screws 1/2" long from a hardware st0re ....

Page 6

CENTER

HOLE

Figure 6

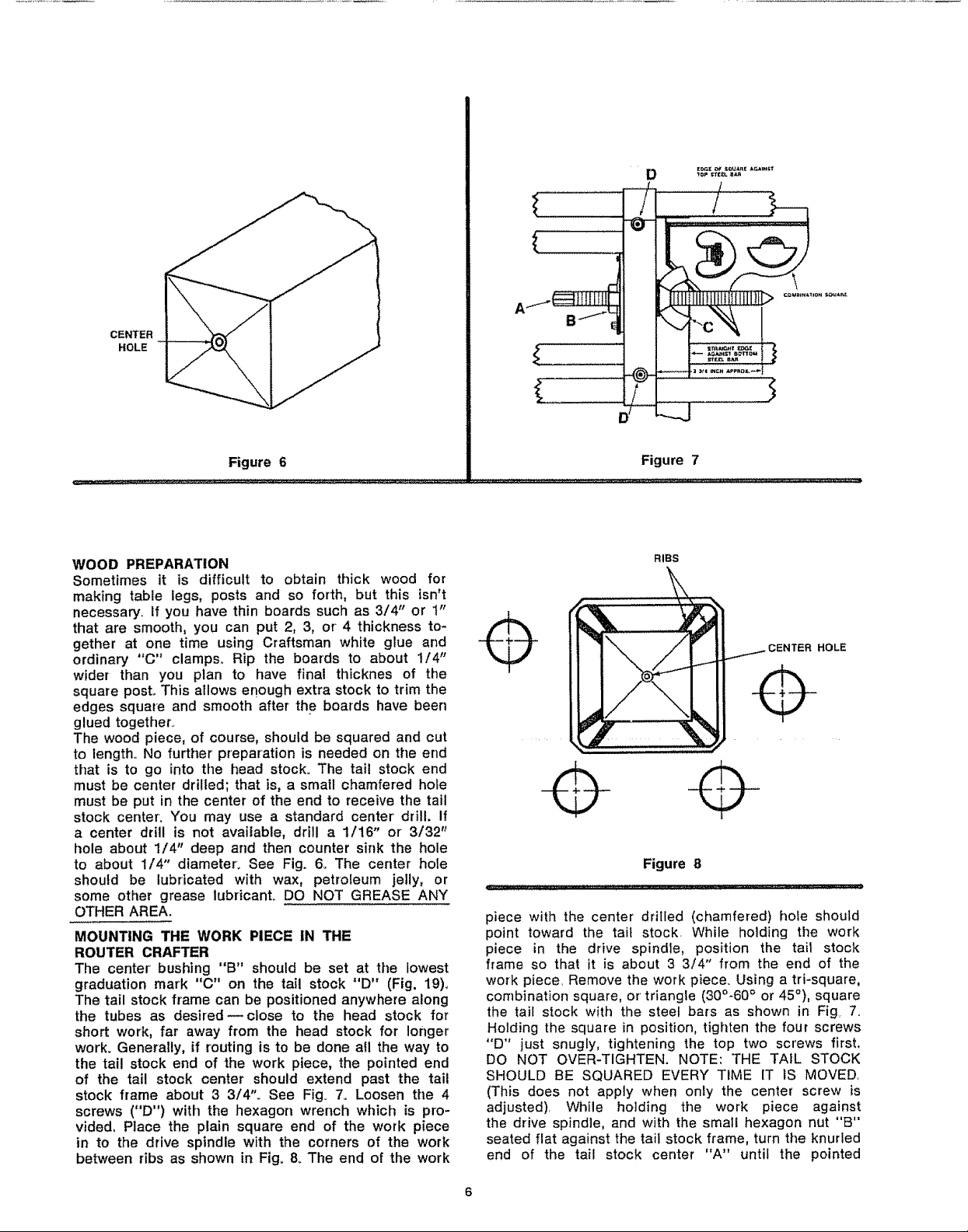

WOOD PREPARATION

Sometimes it is difficult to obtain thick wood for

making table legs, posts and so forth, but this isn't

necessary. If you have thin boards such as 3/4" or 1rt

that are smooth, you can put 2, 3, or4 thickness to-

gether at one time using Craftsman white glue and

ordinary "C" clamps_ Rip the boards to about 1/4"

wider than you plan to have final thicknes of the

square post..This allows er!oughextra stock to trim the

edges square and smooth after the boards have been

glued together_

The wood piece, of course, should be squared and cut

to length° No further preparation is needed on the end

that is to go into the head stock° The tail stock end

must be center drilled; that is, a small chamfered hole

must be put in the center of the end to receive the tail

stock center. You may use a standard center' drill. If

a center drill is not available, drill a 1/16" or 3/32"

hole about 1/4" deep and then counter sink the hole

to about 1/4" diameter_ See Fig. 6. The center hole

should be lubricated with wax, petroleum jelly, or

some other grease lubricant° DO NOT GREASE ANY

OTHER AREA.

MOUNTING THE WORK PIECE IN THE

ROUTER CRAFTER

The center' bushing "B" should be set at the lowest

graduation mark "C" on the tail stock "D" (Fig. 19).

The tail stock frame can be positioned anywhere along

the tubes as desired _ close to the head stock for

short work, far away from the head stock for longer

work. Generally, if routing is to be done all the way to

the tail stock end of the work piece, the pointed end

of the tail stock center should extend past the tail

stock frame about 3 3/4"_ See Fig° 7. Loosen the 4

screws ("D") with the hexagon wrench which is pro-

vided. Place the plain square end of the work piece

in to the drive spindle with the corners of the work

between ribs as shown in Fig, 8_The end of the work

Figure 7

RIBS

;ENTER HOLE

G

Figure 8

piece with the center drilled (chamfered) hole should

point toward the tail stock. While holding the work

piece in the drive spindle, position the tail stock

frame so that it is about 3 3/4" from the end of the

work piece. Remove the work piece_ Using a tri-square,

combination square, or triangle (30°-60 _ or 45°), square

the tail stock with the steel bars as shown in Fig 7.

Holding the square in position, tighten the four screws

"D" just snugly, tightening the top two screws first,

DO NOT OVER-TIGHTEN. NOTE: THE TAiL STOCK

SHOULD BE SQUARED EVERY TIME iT IS MOVED

(This does not apply when only the center screw is

adjusted). While holding the work piece against

the drive spindle, and with the small hexagon nut "B"

seated flat against the tail stock frame, turn the knurled

end of the tail stock center "A" until the pointed

Page 7

Figure 9

Figure 10

center enters the chamfered hole in the end of the

work piece and you can just barely feel the center

touching the bottom of the hole in the work piece°

The small nut "B" should still be against the tail stock

framer (If it is not, you have turned the tail stock

center in too far). With the nut "B" against the tail

stock frame and the tail stock center just touching the

end of the work piece, tighten the large wing nut

("C") firmly with your fingers. Do not over tighten as

it is not necessary and could possibly bend or damage

the tail stock assembly This procedure has locked the

tail stock center in position with the work piece held

firmly between the head stock drive spindle and the

tail stock center

You should now be able to rotate the work piece freely

by hand. If, when you rotate the work piece by hand,

it feels tight rather than free 1o turn, loosen the nut

"C" slightly and back the tail stock center screw "A"

out about 1/8th of a turn and retighten the wing nut

"C" snugly. Fig. 7 If, however, after you snugged up

the wing nut "C", the work piece feels loose and

sloppy on the tail stock center, the nut "C" should be

loosened and the tail stock screw "A" should be

turned about 1/8th of a turn toward the work piece

and nut "C" retightenedo

The correct conditions are:

1 Nut "B" is resting fiat against the tail stock frame.

2. The work piece seems to be supported firmly

between the tail stock center and the head stock.

3o The work piece is free to rotate easily by hand°

"ROUNDING UP" _ TURNING FROM

SQUARE TO ROUND

BE SURE THE ROUTER POWER CORD IS DISCON-

NECTED FROM THE ELECTRICAL OUTLET°

To do the rounding of the portion desired, the use of

a Craftsman Rabbetting and Surfacing Bit number

9 26310, which is used with _g2589 Arbor and Pilot

Set, must be used. The arbor and bit only are used°

DO NOT USE A PILOT IN THE CUTTER BIT. Adjust-

able "stops .... H" (Fig. 5), are provided to limit the

permissible travel of the router carriage both toward

the head stock and toward the tail stock The stop

nearest the head stock shouid be positioned and

tightened to prevent the router bit from being moved

beyond the desired end of the round portion of the

work piece° The stop nearest the tait stock should be

positioned out of the way--as far to the left as it

can be set--if the work piece is to be round all the

way to the left end of the work piece. (if it is desired

that only a middle portion of the work piece be round

and a portion left square on both ends, then the left

stop should be positioned accordingly to limit the

movement of the router bit to the left)

Before starting the actual cutting, the cabfe (K) should

be disconnected from the cable clamp (N) and the

cable drum should be turned so that the spring (L)

in the cable is positioned as near the tail stock as it

will go. Fig. 5 (This is only to get the spring out of

the way because the cable is not used in the "round-

ing-up" operation) The cabte drum shouid then be

clamped to the head stock frame by tightening the

w_ng nut "A" in Fig 3 Putl the index pin knob "A"

(Fig 4) out and rotate the knob 1/4 turn so it will

remain in the out position when you let go. Now

position the bottom of the router bit as shown in Fig

9 Set the feed clown screws "F" (Fig 9) so that they

just barely touch the front bar and lock the screws in

position by tightening the wing nuts "G" (Fig 9) firmly

With the router carriage off to the left, near the tail

stock (or lifted up out of contact with the work piece),

rotate the drive spindle 1/8 of a turn as in Fig 10 (this

is 3 numbers on the graduated drive spindle) and then

pull back slightly on the index pin knob "A" (Fig. 4),

rotate the knob 1/4 turn and push knob back in_ This

is to engage the index pin in a locating hole in the

Page 8

drivespindleandprevent,rotationof_.thedrivespindie.

The knobShouldgo [n Unti[i_"itii!!t_ches or .almost

touches the _,able drum. Make:i_i:eii"_he index pin is

in eli the way. Yo'U _i_ow may {feel,i:.a;;iittle play or" wiggle

in the_work, piece',but it sho_jd:'h_{ be free to rotate.

J ggle.t_6..iwo_;k"piece back and:÷ifofth sffghtly by hand

to be sure th6_w0rk j3iece wilt not rotate before doing

any cutting I'f your work piece is 2 1/2!' square or

larger, do not try to cut aft the corner off, the work

piece_ Instead, loosen the wingnut on the_ right hand

feed screw and screw the pad down about 1/8" to

3/16" and :..re-tighten the Iock'nuL DO NOT CHANGE

the left _an:d feed screw. This has served'td..raise the

router bit so that it will m_.ke a lighter cuL

Now plug' the power cord !nto the electrical outlet

and holding both handles of the router, with the right

hand feed screw resting on the front bar, make the

first cut from left to right (from the tail stock end

toward the head'stock ) until the router carriage con-

tacts the stop nearest the head stock end which was

preset earlier. Turn the router off, raise it slightly off

the bar and return it to the left end of the work piece.

Now you are ready to index to the next cutting position.

Pull out the index knob and turn the drive, spindle 6

numbers (90°) and. push the pin bac k !n to keep the

work piece from being°free to rotate_ Lightly twist the

work piece back and forth to be sure it wOfl't' rotate,

and make the second cut just as the first cut was

made,

Repeat the same procedu.re for the. remaining ` two

corners.

After all four corners have beencut off, reset the right

feed down screw to/the same position as the left feed

down screw:Rotate the work piece 3 numbers (1/8

turn). Now make a cutjust as you did before, from

left to. right: After this first cut, pull out the index

pin again and rotate the_drive spindte-one number

counter clockwise ,and push the indeX, pin back in as

before. For example; if an arrow on the cable drum-is:

pointing to number 5 on .the _drive spindle, advan'ce

number 6 to the arrow_if the arrow is pointing to

number 15, ad'Jadce number 16 to.the ai'rSw.,.

After advancing, or rotating, the work piece one

number, and you have checked .to be sure the index

pin is "in" and the work piece is not free to rotate,

make another cut,from left to right as before. Repeat

this procedure until you have cut all the way around the

work piece -.checking each time to .be sure the index

pin is in the proper position.and the work piece; is not

free to rotate. : -

After going all the Way around the vvoH;{ piece, the

work piece will shOW a series of 24 small "flats _'

around the piece. To'remove these l_roceed as followso

Pull the index:pin out, rotate it 1/4 turn and release it.

This disengages the index pin-_r0rn-the drive Spindle

and the drive spindle is free to rotate_ With the router

carriage to the left of the work piece, loosen the Wing

nuts on the feed down: scre_vs.and raise the screws ,

just slightly/:_about a half turn each and lock them

in position by retightening the wing nuts/_ ....-_": '_

With. the hand Crank in ttle drive sp_indt_' and. tt_e

router on, (otate the work"_iece. With. tf_e c[aqk in a

counter' clockwisedirection' as y0u look atthe head

stock end of the Router Crafter. (The top surface of

the work piece, is turn!ng t(_wards you.) While rotating

the work piece with the 'fight hand rather: rapidly,

gradually pull the rot_ter towards the head stock until

the €'arriage contacts the stop which wasset earlier.

Thiscompletesthe rounding of the Work piece.

iyou wish, wrap one turn of adhesivetape around tl_e

square end of the hand crank and .lightly wedge the

hand ciank into the drive Spindle...This will keep tl_e

hand crank tight in the drive spindle,

UNPLUG THE POWER CORD. TO THE ROUTER

BEFORE CHANGING CUTTER BITS OR MAKING

ADJUSTMENTS ._

CIRCULAR :BEADS AND COVES : ...........

Circular beads and coves, as we refer" to thehi herel

are those which are formed 13ythe shape of the cuttei

bits used and/or a combination of different bits. In

cutting these,' _the rotfter does not move along the

steel bars of'the Router Crafter The {wo Stops are

positioned against the rOOter carriage =--one a_t'each

side _ to prevent such movement. The cable:drum is

c[amped just as it is during the "rounding-up, opera=

tion..r,The index pin is out, thus disengaging the drive

spindle from the cable drum and the drive .spindle is

free to rotate.

Refer to Fig 11. With the desired bit _'A" in the r:outer,

adjust the feed down screws "B!' until the bit makes

contact with the work piece. Continue to raise, the

feedS'screws until the distance between steel bar "C"

and the feed down screw is aplbroximately two times

that of the desired cut depth "X". '

Connect the powei" c01"d to the _elec:tric&l :outiet. With

the router running, turn the' :work piece with :the crank

and gradually lower the router inte._he work piece

until the feed down screws contact the front steel bar:

Lift."the ' rou'ter ;out .of the .'Cut before turning the

router off..

DIscONNECi_THEPOWER _oRD }='ROM THE ELEC-

T.R!CAL OUTLET BEFORE. CHANGING CUTTER B!TS

OR MAKING ADJUSTMENTS.

Page 9

ROUTER

BIT NO.

*These bits

Could be

used for

this cut

*26316

26315

26314

26312

Figure 12

You can make circular cuts in this r=tanner with any of

the cutter bits which will "plunge" or "end" cut.

If you wish, you can position the router carriage to the

right or left to make another cut to blend in with the

previous cut.,

ALWAYS BE SURE THE STOPS HAvE BEEN POSI-

TIONED AGAINST EACH SIDE OF THE ROUTER

CARRIAGE AND TIGHTENED BEFORE ATTEMPTING

TO MAKE CIRCULAR CUTS. FAILURE TO DO SO

COULD CAUSE YOU TO RUIN THE WORK PIECE° See

Fig 12 for typical beads, coves, and flats made on

the Router Crafter_

Fig. 21 through 31 show futl size drawings of various

style parts with coves, beads, etc, (These are on a

separate sheet and inside back cover)_

Sand the work piece with coarse sandpaper then

progressively with finer grit paper. You may turn the

work piece with the crank for initial sanding This

applies to all the various types of turning covered in

this manual.

ROPING (SPIRALING)

Among the many types of cutting which can be done

on .your Router Crafter is "roping" or "spiraling",

which is. rather unique.. Roping is the cutting of

spiraled beads around the work piece, so that the

piece looks somewhat like a rope° Spiraling is a

general term and refers to any form or shape of spirals

around the work piece. You can cut right hand and

_eft hand spirals _both on the same work piece if

you wish to produce a "pineapple" or diamond effect.

The drive spindle has 24 positions marked on it and

by means of the index pin, can be set to 24 equally

spaced positions; therefore, you can make your choice

of 2, 3, 4, 6, 8, 12, or 24 equalfy spaced spirals

The portion of a piece which is to be roped or spiraled

should, of course, be rounded up prior to the spiraling,

and, in order to achieve best resu/ts, the work piece

should not be removed from the Router Crafter after

rounding up until the roping or spiraling has been

done.

For roping spirals either a craftsman No. 9_26324

(3/16" quarter round) or a 9. 26323 (9/32" point cutting

Ogee) bit should be used. Put the cutter bit in the

router and set the feed down screws so that the bit

will cut about 1/8" deep in the portion bf the work

piece which is to be cuL When the cutter bit _s _n

Cutting position, the axis of the bit should point

directly to the center of the work piece (Fig,, 11)o NOw

set the carriage stops which are on the rear bar in a

position which will only permit the carriage to move

as far to the right and to the left as you want it to,.

This serves to prevent accidental over travel and the

cutter hitting some other part of the work piece. It is

preferred that the carriage movement to the left

(toward the tail stock) be far enough to get the cutter

past the left stop° This is preferred because the actual

cutting of all spirals and ropes is done with the router

moving from the tail stock end toward the head stock

end _eft to right)_ NEVER SPIRAL CUT FROM R_GHT

TO LEFT--_ doing so would produce an inconsistent

cut.

At this point, be sure that the cabie drum is not

clamped to the head stock frame., if it is, unctamp it by

loosening the wing nut "A" (Fig 3),

The cable clamp "N" (Fig,. 5) must now be attached to

a steel "fug" which is permanently attached to the

cable. There is one lug on the top cable and one lug

on the bottom cabfeo Attaching the cable clamp to the

lug on the top cable will produce a left hand spiral,,

Attaching the cable lamp to the lug on the bottom

cable will produce a right hand spiral There is a

recess or "pocket" in the cable clamp under the flat

washer in which the lug will fit,. Place the lug in the

recess of the cable clamp, and with the lug under the

flat washer, tighten the cap screw with the hexagon

wrench until the washer clamps the tug to hold the

lug in the recess, DO NOT OVER TIGHTEN _ JUST

TIGHT ENOUGH TO KEEP THE LUG FROM MOVING.

Page 10

Now,withtherouterliftedupslightlysothatthecutter

bitdoesnottouchtheworkpiece,rotatethecrankin

the directionthat pullsthe router'towardthe head

stockuntilthecarriagecontactsthestopnearestthe

headstockend.Checkto besurethatthecutteris

nowatthepointat whichyouwantthemovementof

thecuttertostop.Withtherouterstillliftedupslightly

off theworkpiece,reversethe crankdirectionand

returntheroutercarriagetothetailstockend.

Nowlet theroutercarriagefeedscrewpadsrest on

the front bar and turn the router on. Hold the router

handle with the left hand, and with the right hand,

turn the crank fairly slowly, but steadily, to pull the

router along the work piece toward the head stock. DO

NOT STOP TURNING THE CRANK WHILE THE

CUTTER BIT IS IN CONTACT WiTH THE WORK PIECE.

If for some reason you do not want to complete the

cut, lift the router up off the work piece and return the

router to the tail stock end.. Do not crank backward

with the cutter bit in contact with the work piece.. To

do so would cause an inconsistent spiral, thus ruining

the work piece°

After the first cut has been made, and the router has

been turned off and returned to the left end of the

work piece, notice what number the arrow on the

cable drum is pointing to (Fig 4)_ If you want eight

equal spaces around the work piece, pull the index

pin out and turn the drive spindle three numbers

(either direction) and push the index pin back in. This

has turned the work piece 1/8 of a turn and you are

now ready to make another spiral cut. if the original

depth of cut was not quite deep enough, you may

drop the cutter bit slightly by loosening the wing nuts

of the feed down screws, backing the feed screws off

slightly and retightening the wing nuts_

Make the second and remaining cuts in the same

manner as the first cut° The index positions are

numbered 1 through 24; therefore, for example, if you

want to make 8 equal spirals and the first cut was

made with the arrow pointing to number one, then the

other cuts should be made with the same arrow point-

ing to numbers, 4, 7, 10, 13, 16, 19 and 22° It is a good

practice to write down the number you start on and

nil the other numbers you must index the arrow to for

the correct number of equal spaces so that you don't

have to remember the original number you started

on--helps to prevent mistakes that could ruin the

work piece_

Figs. 21, 22, 25, 26, 30 and 31 are examples of ropes

and spirals..

DISCONNECT THE POWER CORD FROM THE ELEC-

TRICAL OUTLET BEFORE CHANGING CUTTER BITS

OR MAKING ADJUSTMENTS.

STRAIGHT BEADS AND FLUTES CUT LENGTHWISE

Cutting the straight, lengthwise, equally spaced beads

and flutes can be done very quickly. DISCONNECT

THE ROUTER POWER CORD FROM THE ELECTRICAL

OUTLET., Select the proper cutter bit for the shape of

cut you desire to make and install in the router coIlet.

The router is positioned on the router carriage so that

when the cutting depth is correct, the center Iine of

the cutter bit is pointed to the center of the work piece.

The depth of cut is set by positioning the down feed

screws "F" (Fig. 5). After positioning the down feed

screws, be sure to lock them in place by tightening the

wing nuts "G" (Fig,. 5). Of course, the router can be

adjusted up and down in its own base as is customary

with routers,

The carriage travel stops "H" (Fig. 5) should be set so

that the carriage, and thus the cutter bit, can only

move lengthwise in the area that is to be cut. This

serves to make consistent length of cuts and to

prevent accidentally moving the router carriage too far

and cutting into a portion of the work piece you don't

want cuL Turn the cable drum until the spring in the

cable is at the extreme left toward the tail stock as far

as it will go,.

The cable drum "C" (Fig_ 4) should now be c_amped

to the head stock frame. This is done by holding socket

head screw "B" with the hexagon wrench provided

and tightening the wing nut "A" (Fig_ 3),. The wing nut

will feel a little hard to turn because it is a vibration

resistant type wing nut.. Do not over tighten _ just

enough that you can't turn the cable drum by hand_

The index pin "A" (Fig. 4) should be "in" , that is, the

knob should be touching, or very near to touching, the

back side of the cable drum. This Eocks the cable

drum to the drive spindle so that the drive spindle

will not rotate.

The first cut should be made with both hands on the

router feeding from left to right at a reasonably steady

spee& Do not stop in the middle of a cuL tf for some

reason it is necessary to stop, raise the router up so

that the cutter bit is not in contact with the work piece

before stopping the feed of the carriage, When the

carriage has been moved all the way to the "stop" at

the head stock, or right end, lift the router up slightly

off the work piece, return the router to the left end

stop and turn off the router_

Now the work piece should be indexed to the position

to make the second cut. Be sure that the cutter bit is

not touching the work piece If, for example, you want

twelve equally spaced cuts, pull the index pin back

and rotate the drive spindle two number-s and push

the index pin back in_ It is important that you note

what number is next to an arrow head on the cable

drum. It is best to write down the number and then

write down all the numbers you must locate at the

arrow head to make the remaining cuts. If the first cut

was made at number 24 position, for example, to get

the twelve equal spaces, you would also cut at posi-

tions 2, 4, 6, 8, 10, 12, 14, 16, 18, 20 and 22.

ALWAYS REFER "TO THE SAME ARROW THAT WAS

REFERRED TO WHEN MAKING THE FIRST CUT.

(Fig. 4) ALWAYS BE SURE THE POWER CORD IS

DISCONNECTED BEFORE MAKING ADJUSTMENTS

AND CHANGING CUTTERS, ETC.

Fig. 23, 24 and 25 are examples of flutes cut length-

wise. Fig !3 shows shape of lengthwise beads of vari-

ous size work pieces with different numbers of equal

spaces.

10

Page 11

24 BEADS OR FLUTES

6 BEADS OR FLUTES

Typical cross sections of beads and

flutes cut lengthwise for various di-

ameters_ Beads above the center

line are as cut, Beads below the

center line are after sanding. Use

bit No, _926323or No, 9_26324.

Figure 13

tl

Page 12

CONTOUR TURNING ':

DISCONNECT THE POWER CORD BEFORE SETTING

UP. o:::'i : :. 1: ; ..... i-. .::

It is::neCe._sdry to make a tempi_te to make _,bi_toure_

turnings. There is a. !/2" diameter, cylinder on the front

of the router carriage "J" (Fig:" 5) which wiil rest on

the template and thus !aise and .lower the router as it

moves'along the rear steel bar. Craftsman No. 9 26326

Core Box Bit is used. when c6ntour turning (the

diamete_ 6f' the bit is the same as the diameter of the -

template fOllower "J" Fig. 5). One end.of tl_e template

is bolted to the head stock frame and the other end is

bolted to the tail stock frame as shown in Fig. 16.

(Instructions on making templates follow this section).

When contour turning is to be done, the cable drum

should be rotated so that the spring in the cable is

as far toward tSe left erid (tail stock)as it ,will go, and

then the 'cable:drum should, be clamped to the head

router toward the head stodk slowly. '

_"' While the:. feed screw pads are resting or] the front

• .... bar, you-_ilf be' cutting about i/8" deep; As you

..move. along; the. template will lift the-router up as :it

goes over:the higher portions of the template• When

you contact.: the stop a_tthe right, lfft the router up out

of contact with the work pie:ce turn:the router of.f and

return the carriage to the .left,end. "Again; w th the

fee'd down scre_vs_ let the router bit down about

another 1/8", tock the feed down screws by tighten-

ing the wing nuts and make another cut just as you

made the first cut Continue this process until the

template follower contacts the template for the full

length of the turned portion. Traverse the router very

slowly while making the last cut and then unpiug the

power cord.

Fig, 22, 23, 24, 25, 26, 27, 28, 29 an.d 30 show-examples

of contour turning.

stock frame by tighte0ii_g the': wing nut :"A" (Fig. 3).

DO NOT OVER TIGHTEN THE WING NUT --, tighten

just enough that you .can not rotate the cable drum by

hand. The index pin should be pulled back and.turned

1/4 turn so that the drive spindle is disconnected from ...

the cable dr_m and is fre_eto:,rbtate:. _: '

TEMPLATE LAYOUT,AND CONSTRUCTION

Refer to Fig_ i4L"]'he carriage "A" piv.ots about, steel

•bar "B'. With the center_,line of router bit !'C" in .Line

with center of.I he:work piece "D'[, t'he distance from

, -.,-:....................... ::,- ................. :'.-...................... :............ '. piyot point..t.iE" to the.centek of brat.......C.. is.appr_,_imately..

In this type turning,. the final depth of cu.t"is deter- ' one half the distance from point ":E" to template "F'I.

mined by the position of the end of the" router bit

relative to the template follower_ For the purpose of

explanation, assume' . there is a work piece:in the

Router' Crafter which you have a!ready rounded ,up_

Now, With the template follower "J" (Fig. 5) resting

on the highest.portion of.the' templar e (that is to say,.-

the router sh_ft is right over the portion';of..the work

piece which is to be the largest diameter after turning),

set the router so thatthe bottom end of the-'l_/2" core

box bit just touches the round surfade of the work

piece. Be sure the router' cotlet is adequately tighter_ed

to hold the bit. Now move the ro.uter to the left end so

that the bit is just off the work ldiece and agaih let the

template follower rest on the template, If the template

is on properly, the end of the router.bit should be

even with the desired finished_:dia'_et_fr"at the e6d of

With the fol!ower "G" onthe tempi&tO, any up or doWh

movement of the follo_er,_ as it moves .aiong..:_the

:template, will cai]se the router bit to mov.e up dr' down

approximately orle. tialf the a#lount that the follower

• moves t)p or down, For example, if a work piece is to

have a drop of 3/8 inch (3/4 inch diameter reduction),

the template would have a drop of 3/4 inch. That is,

a change in the height of the template produces

approximately the same change'i_i.:the diame_er;of"_the

work piece.

• See Fig, 15,, The first thing to do in making a template

for contour turning, is to draw the work iEiece "A"

_ (Fig 15), to,full size about center line "E". Having

completed the drawing,"aibide the. contoured section

J

irito 'equal parts; along the le'ngth,' bY drawing.' Vertical

the work piece (that is, the e_d:.of"the '=rbuter bit is ............._:.4inest'B" (1/8 inch or 1./4 inch spacing);-Measure'the

above the tail stock center by:a distance of one half , distance from the center tine to po.int "c",, Double this

the desired finish diameter at the end af the work i

piece)_ If the bit is higher than that, the left_nd of the

template must be lowered. If the.bit, is too _tow_ the

left end of the template must be raisedl . _,

Again, the actual cutting must be done from ieff to. •

right while turning the crank counter cl0_kwise as you

look at the head stock, or "crank" end of the Router, ........

Crafter° The top of the work piece should be coming

toward you as you ._face_the Route'r Grafter and •rotate

the oran'kwith your,, right,_hand: _ _-_', .. " .

N_'w,"set':the =feed ctown"s_rews _o?that the bit can take .'_'

ab;6ut:l_8_ depth o:fcut"aii_ ,!bc_ the,: screws in _

p'ositidr_'"b_':tigh{eni:hg'iJ:the •.wing'"nut& Do not" tr_;Zto "

take t'h'e fLilI dept)l of the"f0"r:m '_Su"are to cut 'at "_one .........:i._':

time if it is deeper than 1/8" Set the stops on the :_:

rear bar so that the carriage can only be moved over _

the portion of work piece to be turned

measurement and mark. point "D" "on. the vertical line.

VVhen all the'_bints have_b_en marked_draW_ a smooth

fine "F" through the points: This completes the

template 4ayout'..See examples 22, 23, 24, 25, 26, 27,

28;'29. and 30. The template layout is drawn above the

contoured section on all the examples with contoured

portions.

Long Contoured Turning, Sa,_La! pieceiof Vgb:dd:i,'_B".

(Fig./16 plywood .works well), about 1/2" or 3/4"

thick', 5 inches wide, and 10 inches longer than the

full i&ngth of the iwork piece° Glue or tape tt_e t_mp!ate

layout "C:" on the woocl" So that (1). the :teft end is

about 7_inches from the end, (2) the..highest point, on

the layout is e_en With t_ie_top' _edge of the wood, (;3)

tl_e c_nt_ Iii_e of the la_y_ut isparall'elt0 tf_e=tb'¢"_dg_: _

Saw along the layoU't line and _file: andl sand_-the

temp ate edge smooth_ .' ; _

The:template-is. now ready for mountin'g. With a

Now with the router on, turn the work p'iece, as

instructed abo_e aVmoderate speed and pull tl_e

rSunded work piece "D" in 'the Router Crafter, hod

the temp!ate against"the head and tail stock so that (1)

12

Page 13

G

D j7 B F

A C _

!

E t ',,_

B

Figure '14

D

G

the left end of the contoured section lines up with the

end of work piece, (2) the lowest point on the

contoured section is at least 3/8 inch above the front

steel bar "E". Spacing blocks or dowels "F" may be

used to keep the template straight while marking the

mounting hole and slot iocations. Drill a 1/4 inch

diameter hole in the head stock end of the template..

Drill a 1/4 inch diameter by 1 inch slot "G" in the tail

stock end of the template. The template may now be

mounted to the Router Crafter with number 10 screws,

nuts, and washers "A", which have been provided.

Keep the template for future turnings..

Short or Repetitive Turning. Saw a piece of wood

about 1/2" to 3/4" thick by 7 inches wide, "A" (Fig

17) The length should be 1 to 2 inches longer than the

contoured section of the work piece. Saw another

A

F F

Figure 15

1

\

A

Figure 16

1/2 inch piece of wood "B" about 3 1/2 inches wide_

The length should be the same as the first piece. Do

net fasten together. Glue a template layout to "A", and

saw the template as instructed in long contoured

turning,

With a rounded work piece "C" in the Router Grafter,

place pieces "A" and "B" in position. Saw the side

opposite the contoured edge of piece "A" until the

lowest point on the contoured edge is at least 3/8 inch

above steel bar "D",, Pieces "A" and "B" should be

either glued or screwed together as shown in Fig° 18.

The template is now ready to be positioned and

clamped to the Router Crafter Motmting Base "E"o

Piece "A" should be against steel bar "D"o Keep the

template for possible use on other parts in the future.

13

Page 14

.q

"_ *-- A

\1

,,_-A _A

B

D

1

E

Figure 17

TAPER TURNING

With a rounded work piece in the Router Crafter,

loosen wing nut "E" (Fig.. 19)_ With the hex key

provided, !oosen screw "A" and move the center

bushing "B" up about two marks "C" on the tail stock

"D"o Tighten screw "A". Adjust the center screw and

wing nut as instructed in the wood preparation section,

so that the work piece turns freely. With a No._g 26310

Rabbeting Bit, take approximately 1/8 inch cut as was

instructed in the latter part of Rounding Up., The

diameter of the work piece at the tail stock end will

be smaller than the diameter where the bit stopped

cutting We refer to th!s as taper turning.

On the tail stock, there are five graduation marks "C"

ranging from zero to one inch taper over the full length

of the work piece. Fig. 19. With the top edge of the

center bushing "B" positioned directly over the lowest

mark, the center screw "F" would be approximately

in line with the center of the head stock. Turning at

this setting would have zero taper (straight turnings).

Positioning the center bushing over the second mark

would raise the center screw approximately 1/8 inch

above the center of the head stock, thus producing a

taper of 1/4 inch over the length of the work piece.

Moving the center bushing up each additional mark

will increase the taper by 1/4 inch, up to one inch

taper over the full length of the work piece.

The sections on Roping and Straight Beads and Flutes

Cut Lengthwise apply to tapered turnings° If a rope or

straight flute is to be put on a tapered section, the

center bushing must remain on the setting used for the

taper. If the work piece is to have circular beads or

coves, then these should be cut with the center

bushing set on tile lowest mark.,

Refer to Fig. 13 for possible cross section of different

diameters. For example, a 29 inch work piece is to

have a 12 inch tapered section with !2 lengthwise

flutes> The large diameter of the taper is to be 2

\.! B i

v/ i/ ssA

(a)

Figure 18

Figure 19

inches and the small diameter is to be 1 1/2 inch The

cross section would look like that shown in (c) Fig. 13o

The turning in Fig. 24 was turned as described above°

Turnings in Fig. 25 and 31 have tapered sections.

NOTE: When laying out a work piece on paper,

remember the graduation marks "C" Fig> 19 indicates

the amount of taper that would be produced if the

work piece was turned from the tail stock end to the

head stock end. On all work pieces, the difference

between the largest and smallest diameter, for any

tapered section, will be less than the graduation

mark setting.

(c)

14

Page 15

25

25

26

TO _E USED WH_:N ,k,'_OUIiTING

TEMPLATE TO TAIL STOCK ARO

HEAO .STOCK

24 54

TO B_ USeD WHE_ MOUNT|NG

ROUTEt_ TO ROUTER CARRIAGE

53

32

i

j j_

\

\

\

\

14_ 43

\

26

28

24

21

22

50

49

10

48

51

45

\

\

28

40

39

28 10

Figure 20

_5_

Page 16

19

24

21

23

PARTS LIST FOR CRAFTSMAN ROUTER CRAFTER

MODEL NO, 720_25251

Y,EY PART

htO, NUMBEn

1 29LDq42

2

3 1

29LD-138-2 ...... Lock ,Ring ......

4 1

29A-49t_2 Push Nut

5 1

29LD-137 Index Pin Knob

6 1

29LD-125 Head Stock

*7 4

29LD-159-1 Set Screw #10-32 x 1/4

8 1

29LD-154 Wing,Nut #10-24 (Nyl0,n !,nsert)

g 1

29LD-143 Cable Drum Ctamp

"10 7

29A-316-4 Screw #10-24 x 1 112 Socket Hd.---Cap

11 4

29A_250-4 Retaining Ring ...........

12 1

29LD-t30 One inc h pulley

13 29LD-t44 Double Pulley Shaft 1 41

C_'ank Handle I 29 29LD-133 Cable Clamp 1

DESCRIPTtON QUAt_ NO. NUMBER DESCelPTION QUAN,

aJu b!;stop , ...... .....2 42

15 2gLD_129 , Two ,!r_Ch Pulley ....... 2 43

16 29LD-t3g Spring .................1.... 44

17 29LD-146 Index Pin I "45

18 29LD-124 D_'ive Spindl e ....... 1 '46

19 29Ao324-7 Roll Pin 1/8 din. x 5/8 length 1 47 2gLD-t26

20 29LDq27 Cabie Drum 1 48 2gLD-152

"21 29A-306q0 Washer 1t4 inch 7 49 2gLD-153

' "22 29LD-140 Conduit Ciamp 3/4 inch ...... _ ............4.......... 50 29LD-136

"23 29A-305-I Screw Sq, Hd, 1/4-20 x.1.................... 4 *5t 2gA-242-6

"24 29A-242-4 Hex Nut 1/4-20 6 52 2_JLD-149

25 29LD-t34 Screw Knob 2 53 37LD-42

.......26 29LD-141 , Nyl.ine.r. Bea[!.Eg 2 "54 29A-264-5

• 27 29A-316-5 Screw S£cket Hd, Cap #!0[24 ,x 3/4 . 1 ........ 55 . 49LDq

"28 29A-305-11 Washer #10 1I

KEY PART

3t 2£LDqSO Retaining Ring 1

"32 29A-249-5 Hex Key (Wrench) 5/32 1

33 29LD-12B Router Carriage 1

"34 29LD-252-I0 Wing Nut 1/4-20 2

"35 29A-309-2 ,Screw, Sell Tapping #tO-24,Type F 2

36 29LD-147 Adjusting Screw 2

37 i 29LD_131 Rest Pad 2

38 29LD-t55 P/M Bushing 1

*39 29A-242-5 Hex Nul #10-24 B

40 2gA-3!6-3 Screw Socket Hd, Cap #10-24 x 1 2

29A-36 Spring Ext. 1

2gLD-132 Cabte Assembly !

29LD-146 Single Pulley Shaft t

29LD-145 Pulley Tube t

2gA-252-tl Wing Nut 1/2-t3 1

29A-306-12 Washer I/2 1

Tail Stock 1

Grooved Pin 3/16 din, x 5/8 Type D 1

Center Bushing 1

Center Screw 1

Hex Nut '_/2-13 1

Frame Tube 3

Name Plate t

S_rewPanH_ i0:32x i_,'_ 3

J Owners Manual ...... 1

"Standard items may be purchased locally

t _-_ This shael is intended for instruction Bed repair parts only and is nol a pecking slip

Page 17

TROUBLE SHOOTING CHART

TROUBLE SUGGESTED REMEDY

Burned places on turnings

Excessive Splintering la) Take smaller cuts

Work rotates freely (when not cutting) la) Have router checked

but is hard to rotate when cutting, lb) Sharpen or clean bit

Work piece will not stay snug in the

drive spindle

Rounding Up

(1) The cut section is not straight,

la) Moving router too slow la)

lb) Work rotating too slow tb)

1c) Bit remaining in place too long lc)

ld) Router is not running at full speed ld)

le) Pitch or gum on bit le)

tf) Bit is dull lf)

la) Cut is too deep

lb) Feeding bit too fast

la) Router is not running at full speed

lb) Bit is dull or gummed up

ta) Tail stock loose on steel tubes

lb) Work piece in drive spindle

incorrectly

t c) Center hole keeps enlarging

la) Center bushing is not in line with

the head stock

lb) Tail stock is not squared with steet

tubes

PROBABLE CAUSE

Move router faster

Crank work faster

Keep the router or work piece moving

when routering,

Have router checked

Clean bit with pitch and gum remover

Replace or' sharpen bit

lb) Feed slower

la)

Tighten tail stock, See Fig, 7.

lb)

Put work piece in drive spindle such

that the corners are between ribs_

See Fig, &

1c)

Readjust center screw and lubricate

center hole of work piece.

ta) Set center bushing on the lowest

setting, See Fig. 19

lb) Square up tail stock

Lengthwise Turning -- (Straight, taper, or

contoured)

(1) Finish cut is excessively rough, or

has spiral like cuts,

(2) Router bit surges into work piece,

(3) Length of cut was too long,

Beads & Flutes cut lengthwise

(1) Beads or flutes not spaced equally

around work piece,

Beads & Coves

(!) Router bit moves lengthwise into

circular beads or coves.

Spirals

(1) Spirals not equally spaced around

work piece,

Contoured Turning,

Finished turning does not look tike

layouL

ta) Router is traversed too fast,

lb) Work is in drive spindle incorrectly

lc) Router bit is loose in router.

ld) Work piece is loose on center screw.

2a) Work piece is being rotated

clockwise as the router is moving

from left to right

3a) Adjustable stops incorrectly

positioned

3b) Adjustable stops loose.

la} inaccurate indexing

tb) Cable drum was not clamped,,

Ic) Cable drum slipped.

la) Ciamps not tight against router

carriage_

1) Inaccurate indexing

la) Template was sawed incorrect

tb) Template was positioned

incorrectly

la) Feed router slower',.

lb) Reposition work piece. See Fig. &

Ic) Tighten router bit,

ld) Tighten center' screw,

2a) Change the direction of rotation,

of the crank,

3a) Reposition adiustable stops

3b) Reposition and tighten adjustable

stops,

la) Check indexing of work piece with

numbers written down,

lb) Clamp cable drum,

lc) Tighten clamp.

la) Tighten clamps with router in

position,

1) Check indexing of work piece with

number which was written down,

la) Remake or rework tempiate,

tb) Reposition template

Taper Turning

(1) Cannot get enough taper to

match layout.

la) Layout drawn incorrectly

lb) Taper setting is incorrect.

16

I a) Check to see if taper was drawn

for full length of work piece

lb) Reset taper setting. (The

maximum taper is one inch over

the full length of the work piece,)

Page 18

owners

manual

DEL NO.

720.25251

WHEN CORRESPONDING ALWAYS GIVE THE

FOLLOWING INFORMATION AS SHOWN IN THIS LIST.

1. The PART NUMBER

2. The PART DESCRIPTION

3. The MODEL NUMBER 720.25251

4. The NAME OF ITEM--ROUTER CRAFTER

11-91

Sold by SEARS, ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

/-

Loading...

Loading...