Craftsman 706385540, 706385550 Owner’s Manual

OPERATOR'S MANUAL

CRRFTSMFIH°

[

DANGER ,i_ is used to indicate a hazardous situation which,

if not avoided, will result in serious injury or death.

WARNING z_ indicates a hazardous situation which,

if not avoided, could result in serious injury or death.

CAUTION is used to indicate a hazardous situation which, if not

avoided, may result in minor injury, moderate injury, or property

damage.

CAUTION: Read and follow all Safety Rules and Operating

Instructions before first use of this product.

INDUSTRIAL CANOPY

DANGER _,

• DO NOT stand on this product. You may fall or cause product

to tip.

• DO NOT mount this product on a truck bed or any other moving

object.

WARNING ,/K

• Use appropriate safety equipment when using power and hand

tools.

• DO NOT alter this product in any manner. For example, do not

weld external Iockbars or attach electrical equipment.

• Use adequate manpower when assembling and moving this

unit.

• Keep the product on level surfaces. The product may become

unstable and tip if stored or moved on an uneven surface.

• BE CAREFUL when closing the cover. Remove hands before

the cover closes completely.

• DO NOT step on the shelves.

CAUTION

• Appropriately secure this product before moving it with a

forklift.

CALL 1-800-366-7278 FOR SERVICE PARTS. Refer to Service

Parts Drawing for full listing of Service Parts.

LOCATING MODEL # INFORMATION

Model numbers and other information required for service parts is

located on a label on the interior right side.

• Lubricate the slides with grease or equivalent,(twice yearly.)

• Lubricate lock with graphite, (yearly).

• Periodically surfaces should be cleaned with a mild detergent

and water.

• Auto wax will preserve the unit's luster finish. Apply the wax

as to a car. The wax will also help protect the unit against

scratches.

• Grease and oil can be removed with most standard

cleaning fluids. For safety, use a nonflammable cleaning fluid.

Distributed by Sears Brands Management Corporation, Hoffman Estates, IL 60179 F1968

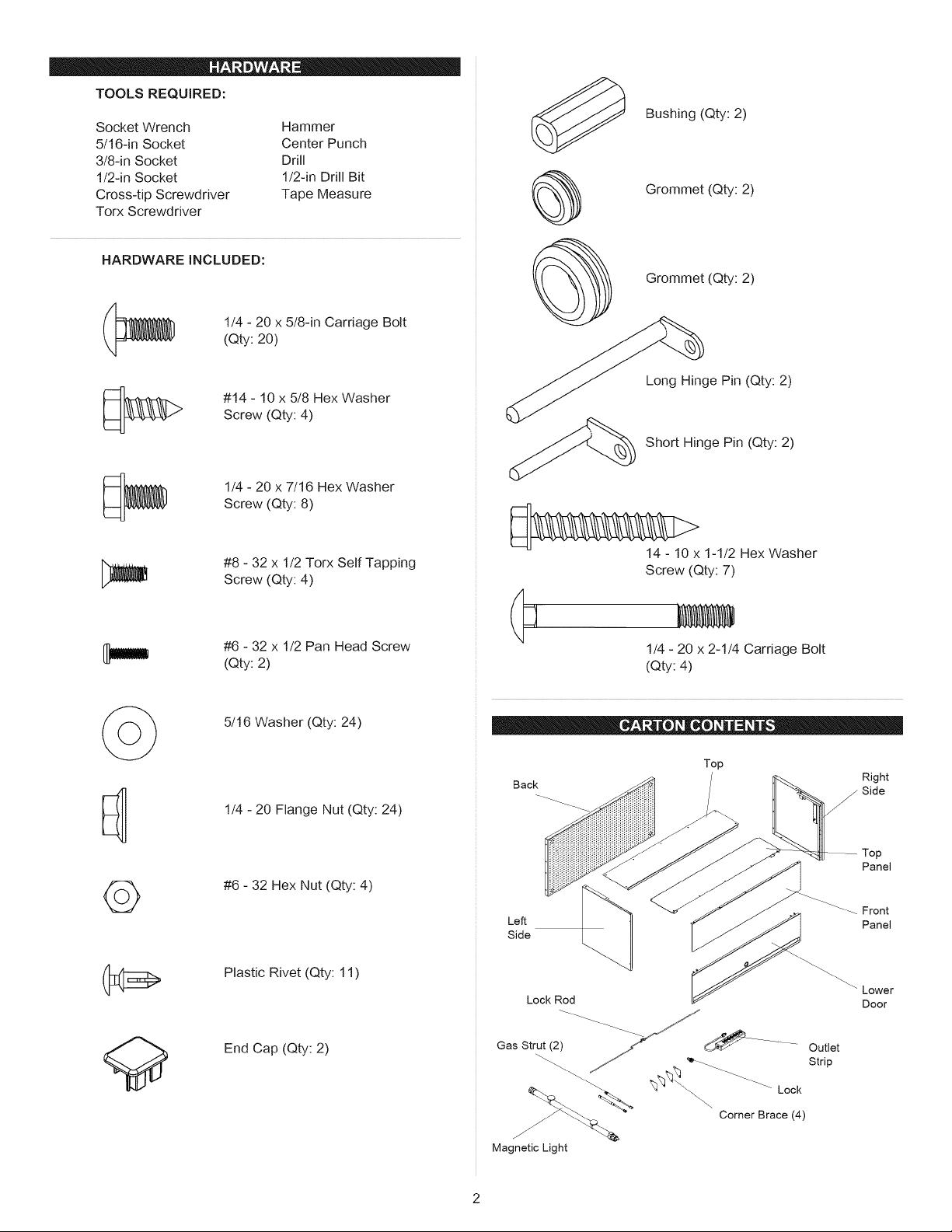

TOOLS REQUIRED:

Socket Wrench Hammer

5/16-in Socket Center Punch

3/8-in Socket Drill

1/2-in Socket 1/2-in Drill Bit

Cross-tip Screwdriver Tape Measure

Torx Screwdriver

HARDWARE INCLUDED:

1/4 - 20 x 5/8-in Carriage Bolt

(Qty: 20)

#14 - 10 x 5/8 Hex Washer

Screw (Qty: 4)

1/4 - 20 x 7/16 Hex Washer

Screw (Qty: 8)

Bushing (Qty: 2)

Grommet (Qty: 2)

Grommet (Qty: 2)

Long Hinge Pin (Qty: 2)

Short Hinge Pin (Qty: 2)

©

#8 - 32 x 1/2 Torx Self Tapping

Screw (Qty: 4)

#6 - 32 x 1/2 Pan Head Screw

(Qty: 2)

5/16 Washer (Qty: 24)

1/4 - 20 Flange Nut (Qty: 24)

#6 - 32 Hex Nut (Qty: 4)

Plastic Rivet (Qty: 11)

14 - 10 x 1-1/2 Hex Washer

Screw (Qty: 7)

1/4 - 20 x 2-1/4 Carriage Bolt

(Qty: 4)

Top

Back

Left

Side

Lock Rod Door

Right

Side

Top

Panel

_Front

Panel

\ Lower

End Cap (Qty: 2)

Gas Strut (2)_ _ .......... ----- Outlet

_t_'_ __" Lock Strip

Corner Brace (4)

J

Magnetic Light

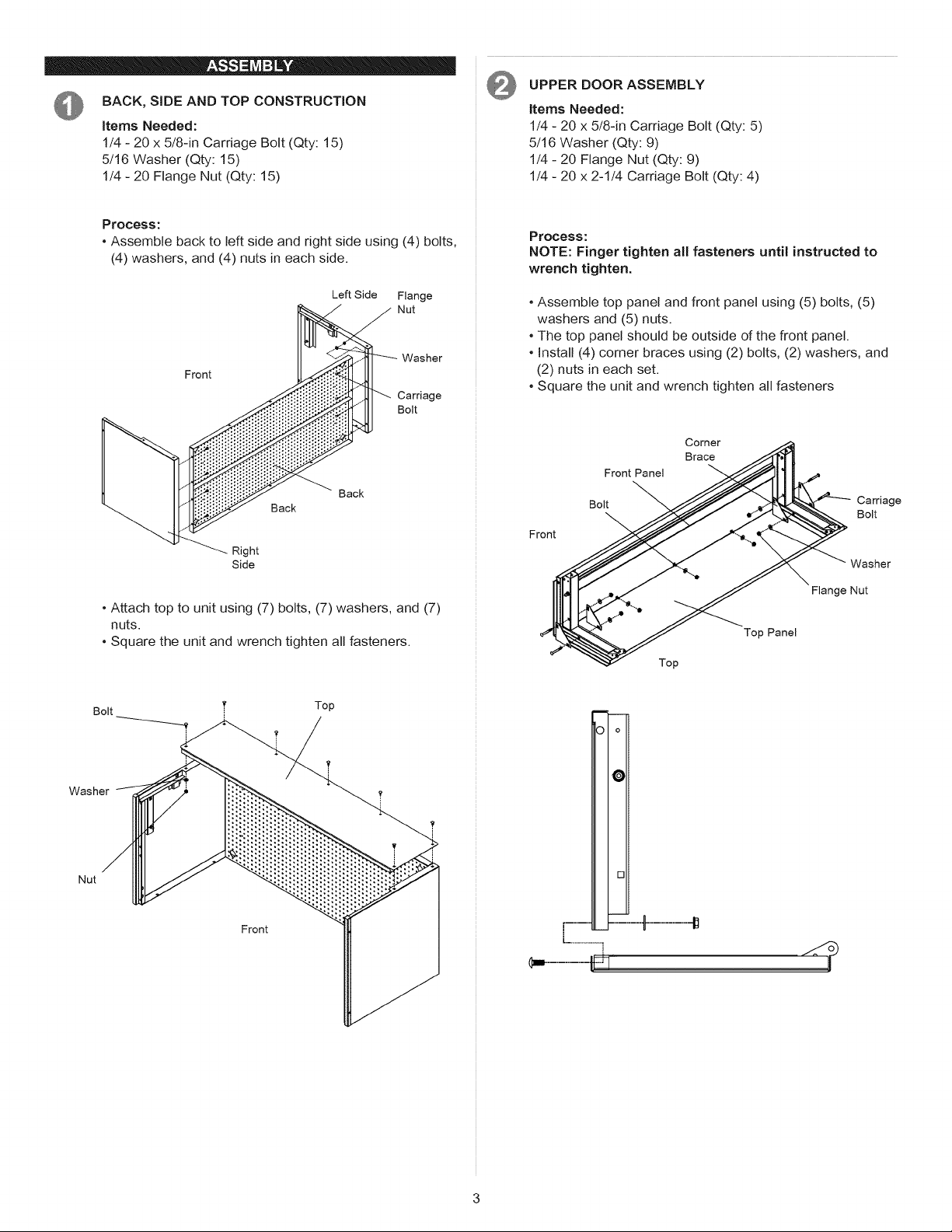

BACK, SIDE AND TOP CONSTRUCTION

Items Needed:

1/4 - 20 x 5/8-in Carriage Bolt (Qty: 15)

5/16 Washer (Qty: 15)

1/4 - 20 Flange Nut (Qty: 15)

UPPER DOOR ASSEMBLY

Items Needed:

1/4 - 20 x 5/8-in Carriage Bolt (Qty: 5)

5/16 Washer (Qty: 9)

1/4 - 20 Flange Nut (Qty: 9)

1/4 - 20 x 2-1/4 Carriage Bolt (Qty: 4)

Process:

• Assemble back to left side and right side using (4) bolts,

(4) washers, and (4) nuts in each side.

Left Side Flange

Nut

Washer

Front

Carriage

Bolt

Back

Back

Right

Side

• Attach top to unit using (7) bolts, (7) washers, and (7)

nuts.

• Square the unit and wrench tighten all fasteners.

Process:

NOTE: Finger tighten all fasteners until instructed to

wrench tighten.

• Assemble top panel and front panel using (5) bolts, (5)

washers and (5) nuts.

• The top panel should be outside of the front panel.

• Install (4) corner braces using (2) bolts, (2) washers, and

(2) nuts in each set.

• Square the unit and wrench tighten all fasteners

Corner

Brace

Front Panel

Bolt _,

Front

Top Panel

Top

Carriage

Bolt

Washer

Flange Nut

Washer

Nut

Bolt

Front

Top

.......

L................. ,

m

D

o

i

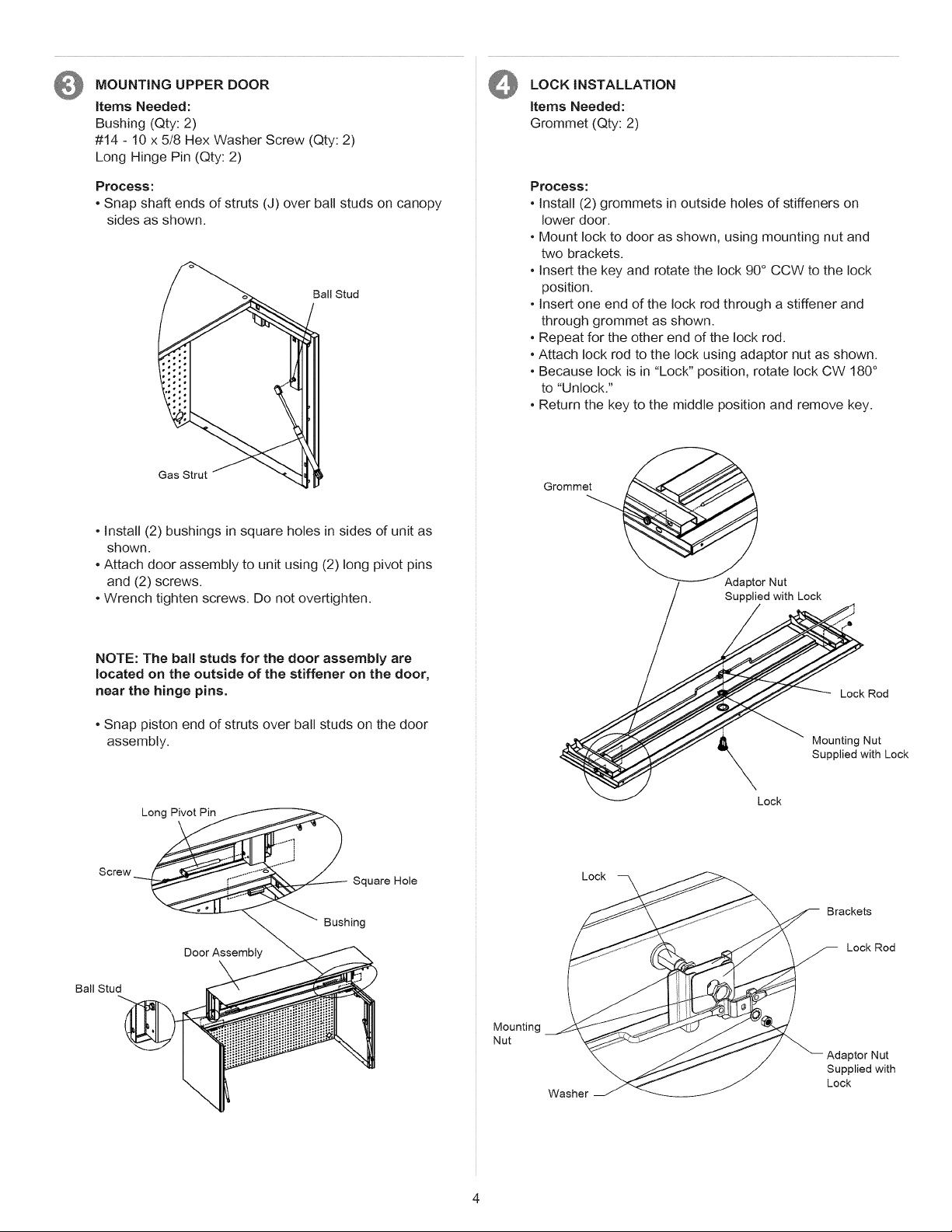

MOUNTING UPPER DOOR

items Needed:

Bushing (Qty: 2)

#14 - 10 x 5/8 Hex Washer Screw (Qty: 2)

Long Hinge Pin (Qty: 2)

LOCK iNSTALLATiON

items Needed:

Grommet (Qty: 2)

Process:

• Snap shaft ends of struts (J) over ball studs on canopy

sides as shown.

Bail Stud

Gas Strut

• Install (2) bushings in square holes in sides of unit as

shown.

• Attach door assembly to unit using (2) long pivot pins

and (2) screws.

• Wrench tighten screws. Do not overtighten.

Process:

• Install (2) grommets in outside holes of stiffeners on

lower door.

• Mount lock to door as shown, using mounting nut and

two brackets.

• insert the key and rotate the lock 90° CCW to the lock

position.

• insert one end of the lock rod through a stiffener and

through grommet as shown.

• Repeat for the other end of the lock rod.

• Attach lock rod to the lock using adaptor nut as shown.

• Because lock is in "Lock" position, rotate lock CW 180 °

to "Unlock."

• Return the key to the middle position and remove key.

Grommet

Adaptor Nut

Supplied with Lock

/i'_J

NOTE: The ball studs for the door assembly are

located on the outside of the stiffener on the door,

near the hinge pins.

• Snap piston end of struts over ball studs on the door

assembly.

Long Pivot Pin

Screw

Door Assembly

Ball Stud

Square Hole

Bushing

Mounting

Nut

Washer

_Rod

Supplied with Lock

_/_ % " Moun!in.g Nut

Lock

Lock

Brackets

Lock Rod

_ptor Nut

Supplied with

Lock

Loading...

Loading...