Craftsman 58099015, 020680-00 Owner’s Manual

Not for

Reproduction

Electric Pressure Washer

OPERATOR’S MANUAL

This pressure washer is rated in accordance to the Pressure Washer

Manufacturers Association (PWMA) standard PW101-2010 (Testing and

BRIGGS & STRATTON CORPORATION

Rating Performance of Pressure Washers).

MILWAUKEE, WISCONSIN, U.S.A.

Manual No. 80022991 Revision B

Not for

Reproduction

Thank you for purchasing this quality-built Briggs & Stratton® electric pressure washer. We are pleased that you’ve

placed your confidence in the Briggs & Stratton brand. When operated and maintained according to the instructions in this

manual, your Briggs & Stratton electric pressure washer will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with electric pressure

washers and how to avoid them. Because Briggs & Stratton does not necessarily know all the applications this electric

pressure washer could be used for, it is important that you read and understand these instructions thoroughly before

attempting to start or operate this equipment. Save these original instructions for future reference.

This electric pressure washer requires final assembly before use. Refer to the Assembly section of this manual for

instructions on final assembly procedures. Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your electric pressure washer. Consult

your Yellow Pages. There are over 30,000 Briggs & Stratton authorized service dealers worldwide who provide quality

service. You can also contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the Internet at

BRIGGSandSTRATTON.COM.

Electric Pressure Washer

Model Number _____________________________

Revision __________________________________

Serial Number ______________________________

Date Purchased ___________________________

Register Your Product

To ensure prompt and complete warranty coverage, register your product online at www.onlineproductregistration.com.

Table of Contents

Operator Safety.............................. 3

Assembly................................... 6

Features and Controls ........................ 9

Operation.................................. 10

Maintenance ...............................13

Storage ...................................14

Troubleshooting ............................15

Warranty ..................................16

Specifications ..............................18

Copyright © 2017. Briggs & Stratton Corporation

Milwaukee, WI, USA. All rights reserved.

BRIGGS & STRATTON is a registered

trademark of Briggs & Stratton Corporation.

2 BRIGGSandSTRATTON.COM

Not for

Reproduction

Operator Safety

SAVE THESE INSTRUCTIONS

Equipment Description

WARNING Failure to read and follow the operator’s

manual and all operating instructions before

using could result in death or serious injury.

• Read this manual carefully and become familiar with

your electric pressure washer. Know its applications, its

limitations, and any hazards involved.

This electric pressure washer operates at a maximum of

1,800 PSI with yellow spray tip and a flow rate of up to 1.2

GPM (gallons per minute) with turbo spray tip.

Every effort has been made to ensure that the information

in this manual is accurate and current. However, we

reserve the right to change, alter, or otherwise improve the

product and this document at any time without prior notice.

This ISM device complies with Canadian ICES-001.

Ground Fault Circuit Interrupter Protection

This pressure washer is provided with a ground-fault

circuit-interrupter (GFCI) built into the plug of the power

supply cord. This device provides additional protection

from the risk of electric shock. Should replacement of

the plug or cord become necessary, use only identical

replacement parts that include GFCI protection.

Automatic Shut-Off

The electric pressure washer is equipped with a sensor

that will detect that water flow has stopped when releasing

or locking the spray gun trigger. The sensor will cause the

motor to shut off for as long as the spray gun trigger is

released or locked.

If the motor continues to run when the spray gun trigger is

released or locked, DO NOT USE THE MACHINE. Call the

electric pressure washer helpline at (800) 743-4115 for

assistance.

NOTICE The electric pressure washer is equipped with a

main power ON/OFF switch. The switch should always be

moved to the OFF position (0) when the electric pressure

washer is not being used to prevent possible damage.

Motor Overload

The electric motor in this electric pressure washer is

equipped with an overload protection device (thermostat).

This device will automatically shut off the motor if the motor

overheats or draws excessive current.

If the overload protection device is tripped, disconnect the

power supply by turning the master ON/OFF switch to the

OFF (0) position. Let unit cool for 30 minutes. Then turn

the master ON/OFF switch to the ON (I) position to resume

operation.

Important Safety Information

Please read and understand this entire manual before

attempting to assemble, operate or service the product.

Follow the maintenance instructions specified in this manual.

If you have any questions regarding the product, please call

customer service at (800) 743-4115, 8 a.m. - 5 p.m., CST,

Monday - Friday.

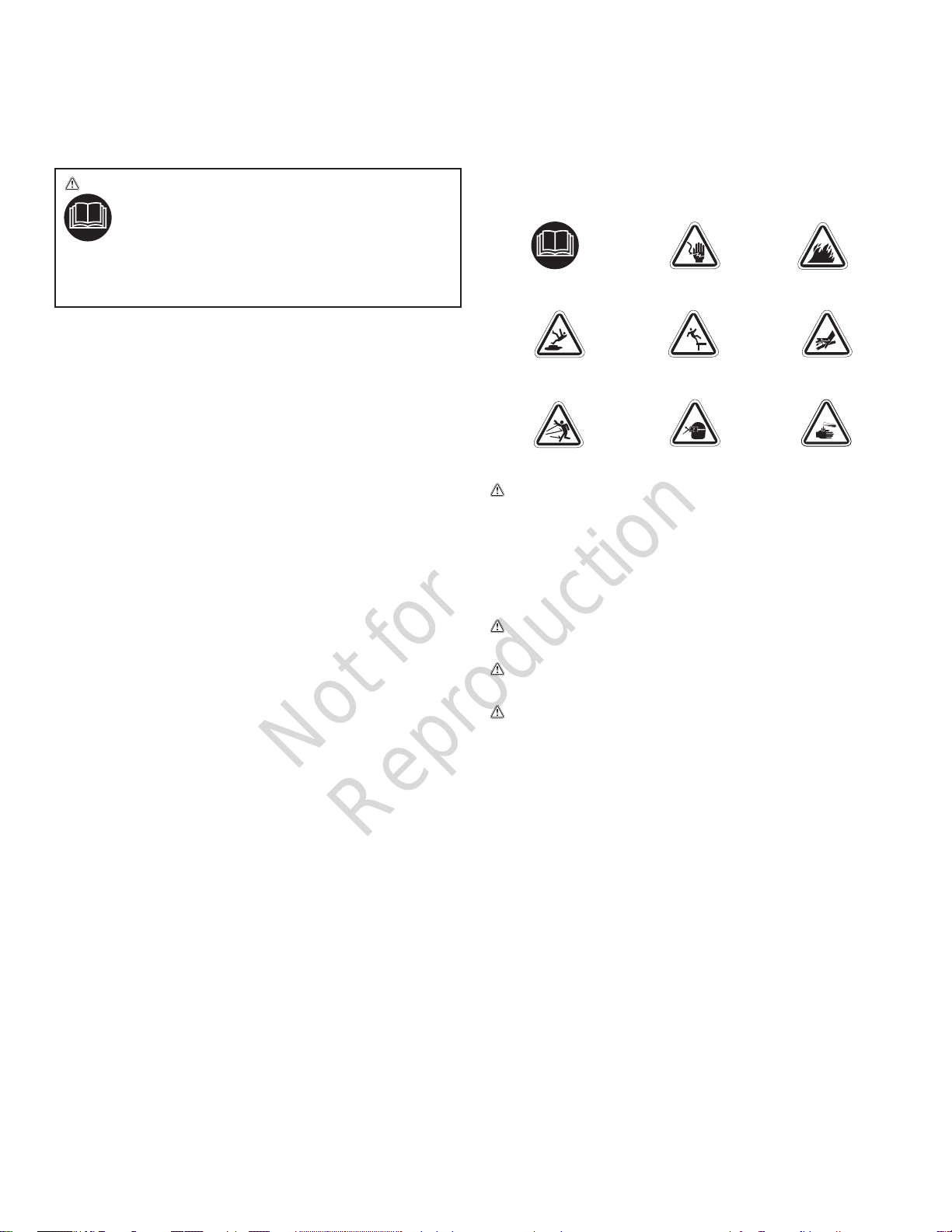

Safety Symbols and Meanings

Read Manual

Slippery Surface Fall

Projectile

The safety alert symbol indicates a potential personal

injury hazard. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to designate a

degree or level of hazard seriousness. A safety symbol

may be used to represent the type of hazard. The signal

word NOTICE indicates information considered important,

but not hazard-related.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE indicates information considered important, but

not hazard-related.

Electrical Shock

Flying Objects

Fire

Fluid Injection

Chemical Burn

3

Not for

Reproduction

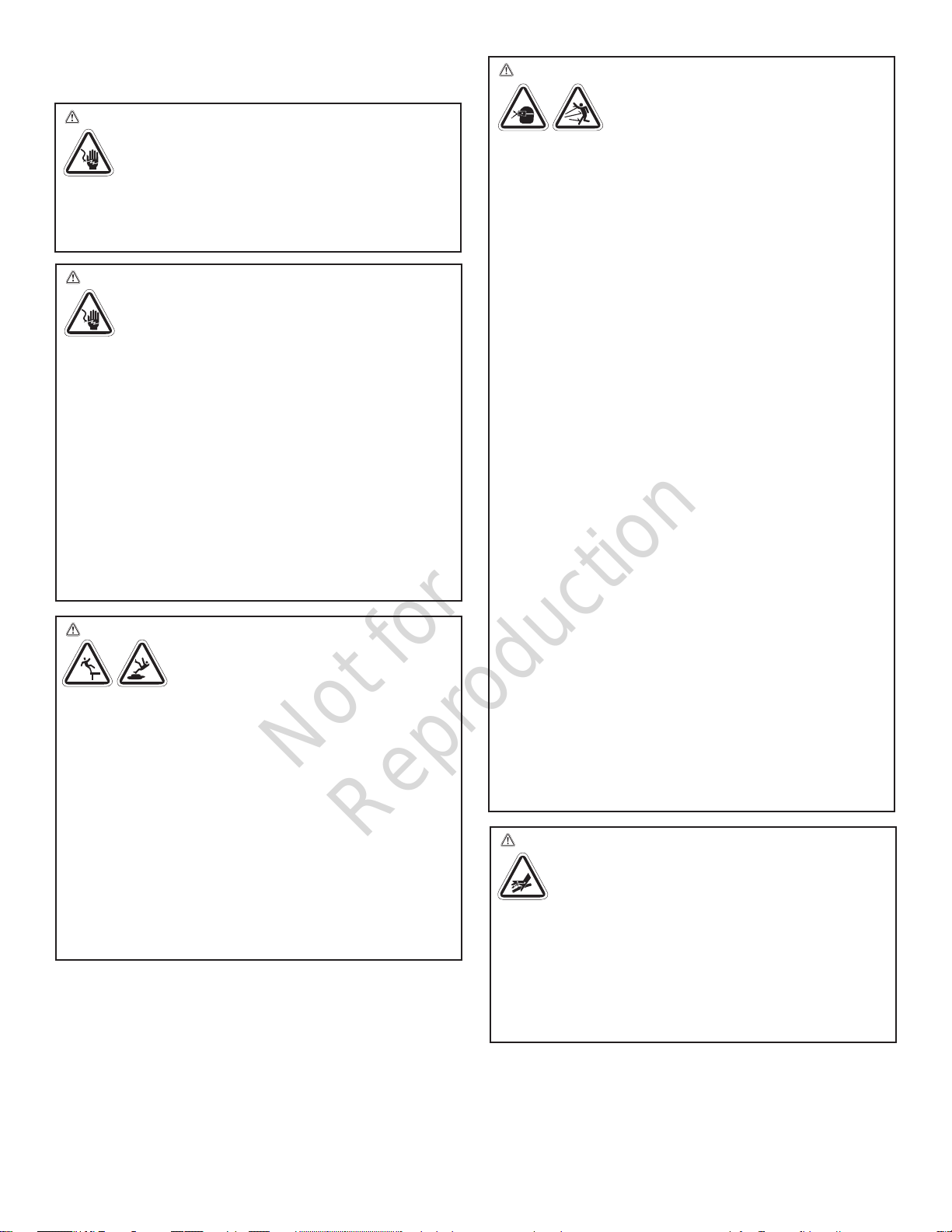

For Servicing of a Double-Insulated Appliance, See

Assembly Section.

WARNING Risk of electrocution. Use of an

extension cord could cause electric shock or

burn resulting in death or serious injury.

• DO NOT use an extension cord with this electric

pressure washer. Your home’s electrical circuit

receptacle or extension cord may not provide lifesaving

ground-fault circuit-interruption protection.

WARNING Risk of electrocution. Contacting both

power conductors, at the same time could

cause electric shock or burn resulting in death

or serious injury.

• Inspect cord before each use, DO NOT use if cord is

damaged.

• The product is equipped with a ground fault circuit

interrupter (GFCI) built into the power cord plug. If

replacement of the plug or cord is required, use only

identical replacement parts.

• Keep all connections dry and off the ground.

• DO NOT touch plug with wet hands.

• DO NOT run cord through doorways, windows, holes in

ceilings, walls, or floors.

• DO NOT walk on cord.

• DO NOT drive over, drag or place objects over cord.

• DO NOT spray near power source.

WARNING Use of electric pressure washer could

create puddles and slippery surfaces.

Risk of kickback. Spray gun could

kickback causing you to fall resulting in

death or serious injury.

• Operate the electric pressure washer from a

stable surface.

• Do not overreach or stand on unstable support. Keep

good footing and balance at all times.

• The cleaning area should have adequate slopes

and drainage to reduce the possibility of a fall due to

slippery surfaces.

• Be extremely careful if you must use the electric

pressure washer from a ladder, scaffolding, or any

other similar location.

• Firmly grasp spray gun with both hands when using

power spray modes to avoid injury when spray gun

kicks back.

WARNING Risk of eye or bodily injury. Spray could

splash back, propel objects or cause

internal harm resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment. NEVER substitute safety

glasses or dry-condition goggles for indirect vented

safety goggles.

• Know how to stop the pressure washer and bleed

pressure quickly. Be thoroughly familiar with the

controls.

• DO NOT allow CHILDREN to operate the electric

pressure washer.

• Keep operating area clear of all persons.

• Inspect high pressure hose before each use. NEVER

repair high pressure hose; replace it.

• DO NOT repair leaking connections with sealant of any

kind; replace o-rings and gaskets.

• Keep hose connected to electric pressure washer and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction while system

is pressurized and squeeze spray gun trigger to release

high pressure, every time you turn off the pressure

washer.

• DO NOT aim spray gun at people or animals.

• DO NOT

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while the electric

pressure washer is in ON (I) position.

• DO NOT use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun and accessories are

correctly attached.

• Stay alert – watch what you are doing.

• DO NOT operate the product when fatigued or under

the influence of alcohol or drugs.

• Close supervision is necessary when this product is

used near children.

WARNING The high pressure stream of water that

Spray gun traps high water pressure, even when motor

is stopped and water is disconnected, which could result

in serious injury.

• NEVER aim spray gun at people, animals, or plants.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you turn off pressure washer.

drink from hose connected accessories.

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

4 BRIGGSandSTRATTON.COM

Not for

Reproduction

WARNING Risk of fire. Spraying flammable liquids

could result in death or serious injury.

• DO NOT spray flammable liquids.

WARNING Risk of fire. Overheated cord could result

in death or serious injury.

• Uncoil cord completely prior to use.

• DO NOT cover cord with any material.

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting

in death or serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

chemicals.

• DO NOT substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

• DO NOT use caustic liquid with electric pressure

washer.

• Use ONLY pressure washer safe detergents/soaps.

Follow all manufacturers instructions.

WARNING This product contains lead and lead

compounds, known to the State of California to cause

birth defects or other reproductive harm. Wash your

hands after handling this product.

NOTICE High pressure spray could damage fragile

items including glass.

• DO NOT point spray gun at glass when using turbo

spray tip.

• NEVER aim spray gun at plants.

NOTICE You must protect your unit from freezing

temperatures.

• Failure to do so will permanently damage your pump

and render your unit inoperable.

• Freeze damage is not covered under warranty.

NOTICE Improper treatment of electric pressure washer

could damage it and shorten its life.

• If you have questions about intended use, ask dealer or

contact authorized service center.

• DO NOT operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by-pass any safety device on the electric

pressure washer.

• DO NOT modify the electric pressure washer in any

way.

• Before starting the electric pressure washer in cold

weather, check all parts of the equipment to be sure ice

has not formed there.

• DO NOT move the electric pressure washer by pulling

on hoses. Move unit using the transport handle

supplied.

• Use ONLY branded accessories intended for use with

this product.

5

Not for

Reproduction

Assembly

Read entire Operator’s Manual before you

attempt to assemble or operate your new

electric pressure washer.

Your electric pressure washer requires some assembly

but is quickly ready for use. If you have any problems with

the assembly of your electric pressure washer, please call

the electric pressure washer helpline at (800) 743-4115. If

calling for assistance, please have the model, revision, and

serial number from the identification label available.

Tools Needed

• Philips screwdriver #2

Unpack Electric Pressure Washer

1. Remove everything from carton.

2. Ensure you have all included items prior to assembly.

Items Included in the Carton

• Main unit

• Handle

• Spray gun

• Wheels (2)

• High pressure hose

• Spray wand

• Quick Connect (QC) spray tips (3)

• Spray gun holder

• Parts bag (which includes the following):

• Axle studs (2)

• Retaining pins (2)

• Washers (2)

• Spacers (2)

• Screw

• Operator’s Manual

Check all contents. If any parts are missing or damaged,

DO NOT use, call the electric pressure washer helpline at

(800) 743-4115.

Become familiar with each component before assembling

the electric pressure washer. Identify contents with the

illustration shown in Features and Controls.

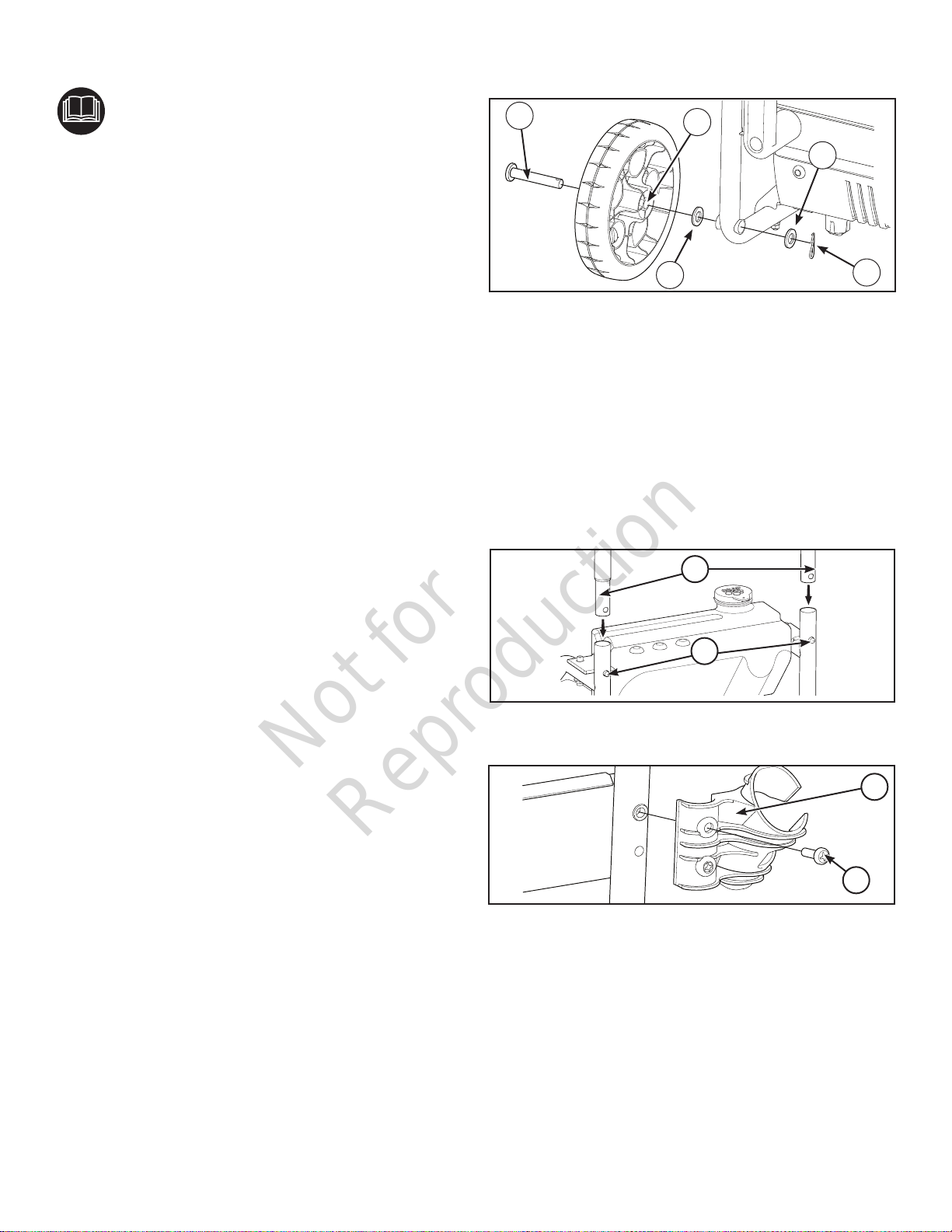

Attach Wheels

1. Slide axle stud (A) through wheel (B).

A

NOTICE Be sure to install wheel with raised hub inward.

2. Slide a spacer (C) over axle stud on back side of

wheel.

3. Tilt pressure washer forward and slide axle stud

through hole.

4. Slide a washer (D) over axle stud.

5. Insert retaining pin (E) through hole on axle stud.

6. Repeat steps 2 through 5 to secure second wheel.

B

D

C

E

Attach Handle and Spray Gun Holder

1. Push and hold lock-pin buttons (F) on each side of the

handle. Slide handle (G) down into the handle support

until lock-pins buttons snap into the holes.

G

F

2. Attach spray gun holder (H) to back of handle on right

side. Align holes and insert screw (J). Tighten with a

#2 philips screwdriver.

H

J

6 BRIGGSandSTRATTON.COM

Not for

Reproduction

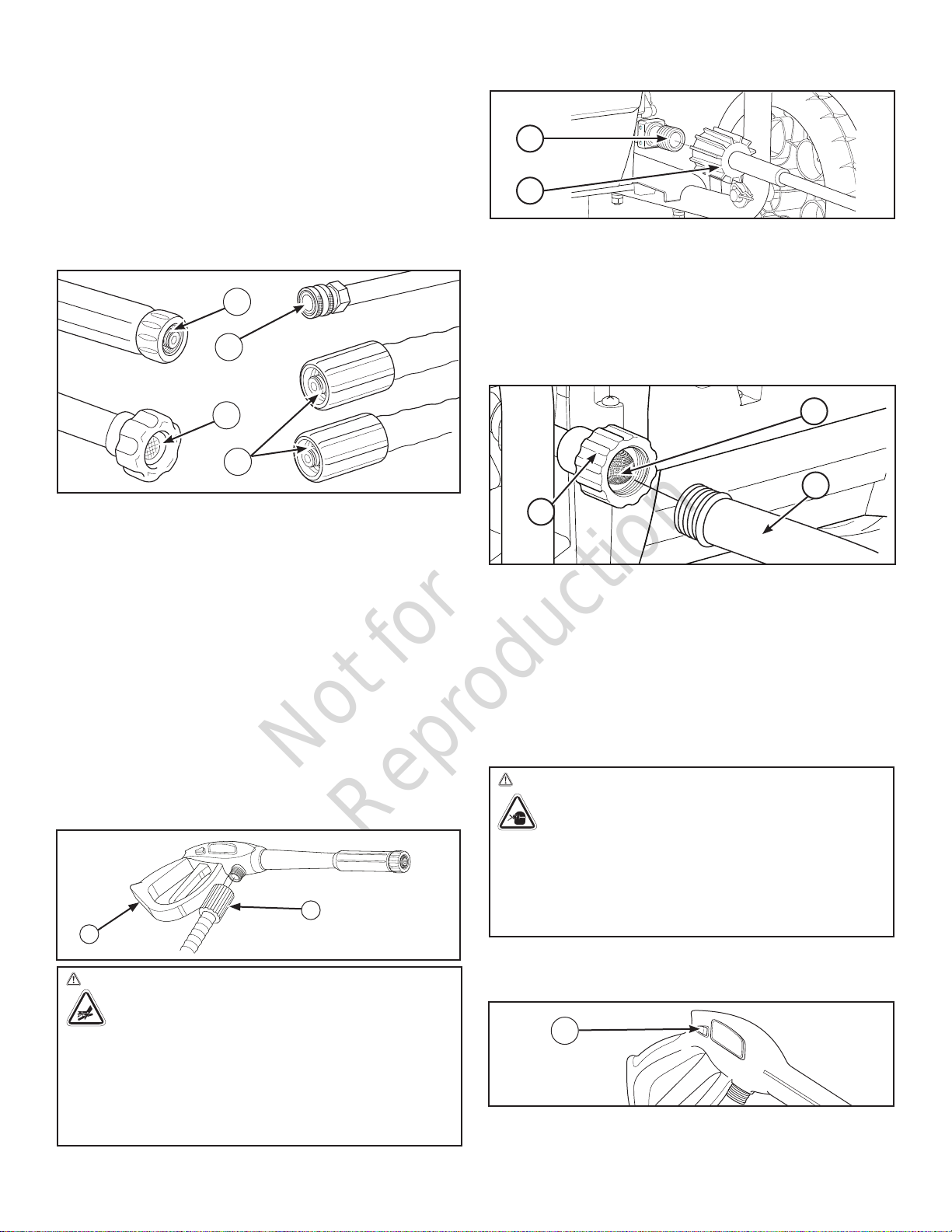

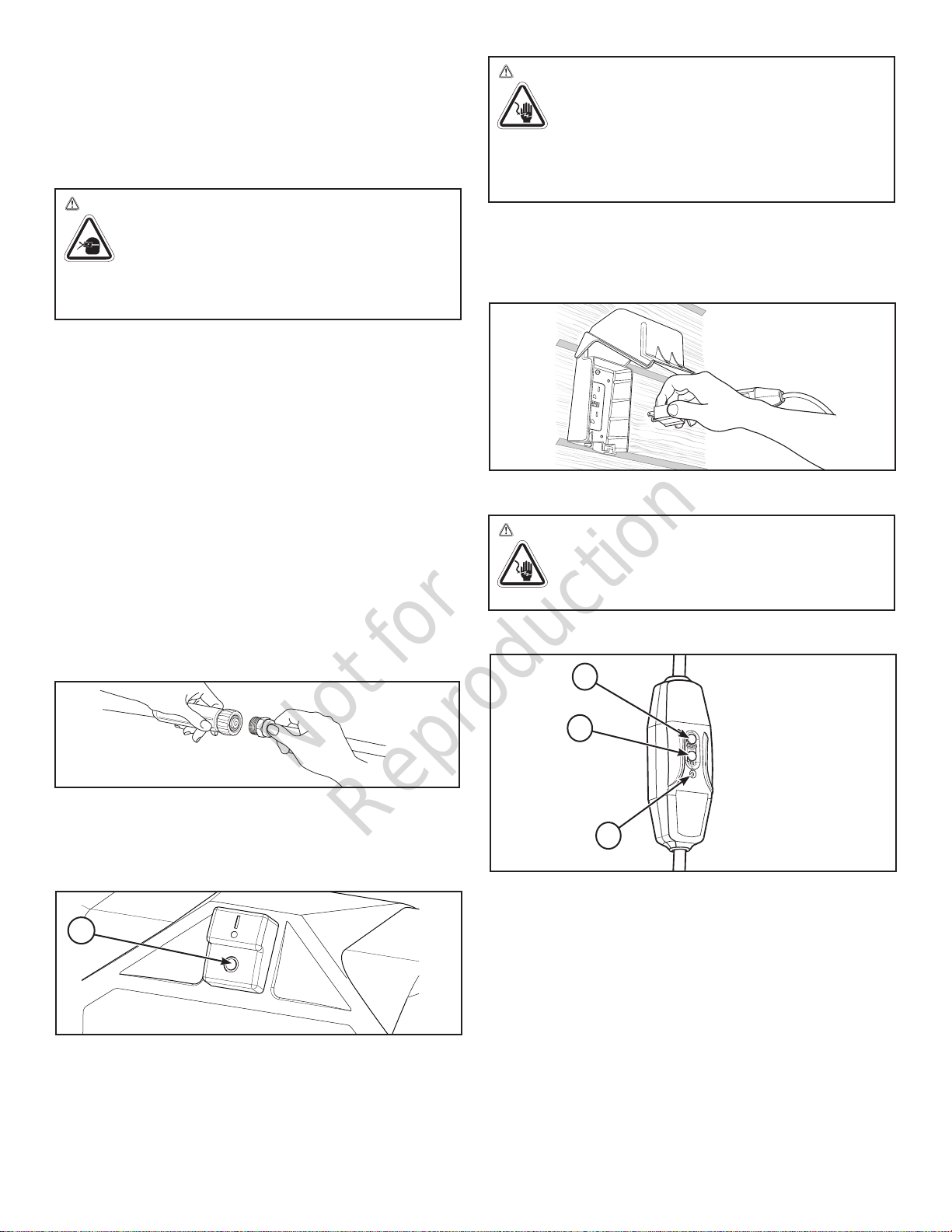

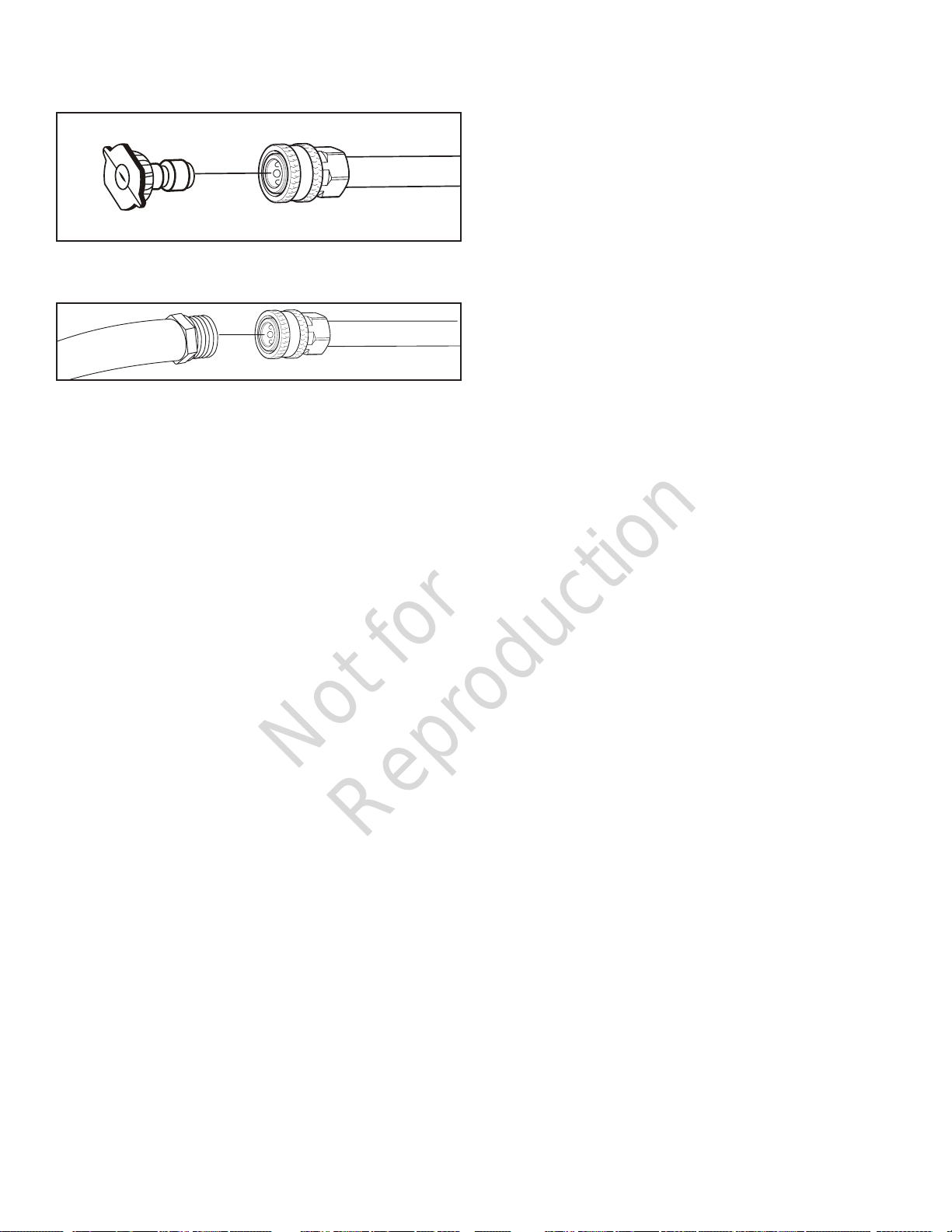

Lubricate O-Rings

Lubrication of o-rings is extremely important for installation

and operation. The use of a lubricant (petroleum or

synthetic grease) during assembly helps seat o-rings

properly and provides an improved seal. It also helps

protect the o-ring from damage by abrasion, pinching or

cutting and extends the life of the o-ring.

NOTICE ALWAYS apply a small amount of lubricant on

o-rings prior to assembling the garden hose to the pump

(A), high pressure hose (B), spray gun (C), and spray

wand (D).

C

D

2. Attach red end of high pressure hose (G) to high

pressure outlet (H) on pump. Tighten by hand.

H

G

3. Run water through your garden hose for 30 seconds

to clean out any debris.

NOTICE DO NOT siphon standing water for the water

supply. Use ONLY cold water (less than 100°F (38°C)).

4. Before connecting garden hose (J) to water inlet (K),

inspect inlet screen (L). Clean screen if it contains

debris or have it replaced if damaged. DO NOT run

pressure washer if inlet screen is damaged.

A

B

Lubricate all connections shown below, following

these instructions:

1. Inspect and clean connecting surfaces prior to

lubrication and assembly.

2. Use lubricants sparingly during assembly; a light film

is all that is required.

3. Use a small brush or cotton swab to apply grease

directly to o-rings where they are not accessible (QC

fitting, M22 fitting).

Connect Hose and Water Supply to Pump

NOTICE DO NOT run the pump without the water supply

connected and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

1. Uncoil high pressure hose (E) and attach black end of

hose to base of spray gun (F). Tighten by hand.

E

F

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

• NEVER connect high pressure hose to spray wand.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

L

J

K

NOTICE Using a One Way Valve (vacuum breaker or

check valve) at pump inlet could cause pump or inlet

connector damage.

• There MUST be at least 10 ft. (3 m) of unrestricted

garden hose between the pressure washer inlet and any

device, such as a vacuum breaker or check valve.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

5. Connect the garden hose (J) (not to exceed 50 ft. (15

m) in length) to the water inlet (K). Tighten by hand.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when

using or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

6. Turn ON the water, press red button (M) on the gun

and squeeze the trigger to purge the pump system of

air and impurities.

M

7

Not for

Reproduction

Checklist Before Starting Pump Motor

Review the unit’s assembly to ensure you have performed

all of the following.

1. Be sure to read Operator Safety and Operation before

using the electric pressure washer.

2. Check for properly tightened hose connections.

3. Check to make sure there are no kinks, cuts, or

damage to hoses.

4. Provide a proper water supply at an adequate flow.

5. Plug electrical power cord into a dedicated electrical

circuit rated for 120 Volts AC at 15 Amps that is

properly installed in accordance with all local codes and

ordinances. Check that circuit is not used to supply any

other electrical needs.

Servicing Of A Double-Insulated Appliance

In a double-insulated product, two systems of insulation

are provided instead of grounding. No grounding means

is provided on a double-insulated product, nor should a

means for grounding be added to the product. Servicing

a double-insulated product requires extreme care and

knowledge of the system, and should be done only by

qualified service personnel. Replacement parts for a

double-insulated product must be identical to the parts

they replace. A double-insulated product is marked

with the words “DOUBLE INSULATION” or “DOUBLE

INSULATED.”

The symbol means DOUBLE-INSULATED

APPLIANCE.

8 BRIGGSandSTRATTON.COM

Not for

Reproduction

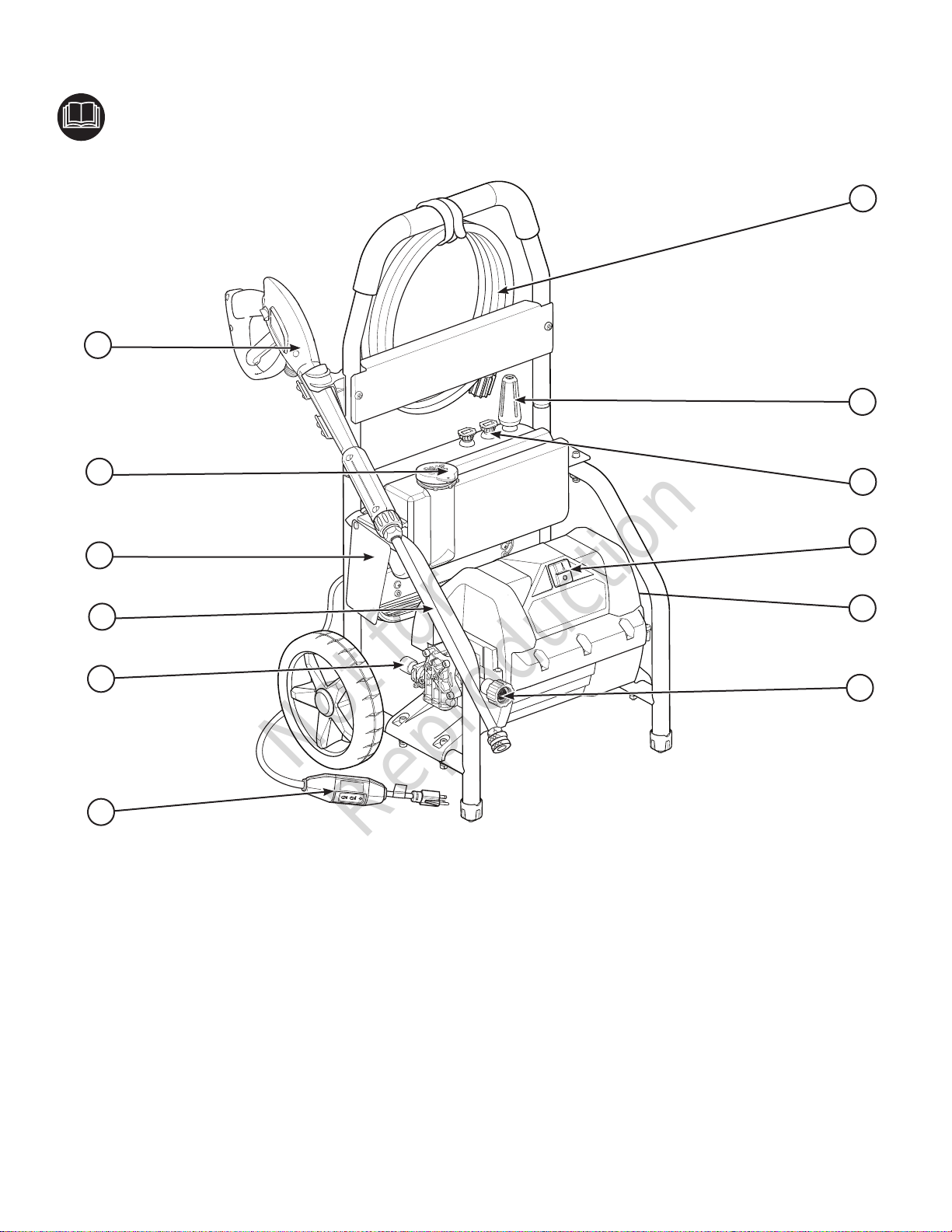

Features and Controls

Read the Operator’s Manual and safety rules before operating your electric pressure washer.

Compare the illustrations with your electric pressure washer to familiarize yourself with the locations of various

controls and adjustments. Save this original manual for future reference.

A

M

L

B

C

D

E

F

A - Spray Gun — Controls the application of water onto

cleaning surface with trigger device. Includes trigger lock.

B - Detergent Tank — Use to hold up to 40 oz. (1.2 l) of

pressure washer safe detergent.

C -Warning Label — Identifies hazards to be avoided

when using your pressure washer.

D - Spray Wand — Allows you to switch between different

spray tips.

E - High Pressure Outlet — Connection for high pressure

hose.

F - Electric Cord with GFCI — The electric pressure

washer and operator is protected by a ground fault

circuit interrupter (GFCI).

G - Water Supply Inlet — Connect to water supply using a

50 ft. (15.24 m) maximum garden hose.

K

J

H

G

H - Identification Label — Provides model and serial

number of pressure washer. Please have these readily

available if calling for assistance.

J - Master ON/OFF Toggle Switch — Push top of switch

in (I) to turn pressure washer ON. Push bottom of switch

in (0) to turn pressure washer OFF.

K - Spray Tips — Black spray tip for general soap

applications. Yellow spray tip is for various high

pressure applications.

L - Turbo Spray Tip — Whirls a powerful pin-point jet of

water for intense cleaning.

M - High Pressure Hose — Connect red end to high

pressure water outlet and black end to spray gun.

9

Not for

Reproduction

Operation

How to Start Your Electric Pressure Washer

Follow the instructions below in the order presented. If

you have any problems operating your electric pressure

washer, please call the electric pressure washer helpline at

(800)-743-4115.

WARNING Risk of eye injury. Spray could splash

back or propel objects resulting in serious

injury. Always wear indirect vented (chemical

splash) safety goggles marked to comply with

ANSI Z87.1 when using or in vicinity of this equipment.

NEVER substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than

3.0 gallons (11.4 l) per minute and no less than 20 PSI

(1.3 BAR) at pressure washer end of garden hose. DO

NOT siphon supply water.

2. Check that high pressure hose is tightly connected to

spray gun and pump. See Assembly section.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump.

NOTICE DO NOT run the pump without the water supply

connected and turned on.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.

5. Turn ON water, point gun in a safe direction, press red

button and squeeze trigger to purge pump system of air

and impurities.

6. Attach spray wand to spray gun. Tighten by hand.

WARNING Risk of electrocution. Use of an

extension cord could cause electric shock or

burn resulting in death or serious injury.

• DO NOT use an extension cord with this electric

pressure washer. Your home’s electrical circuit

receptacle or extension cord may not provide lifesaving

ground-fault circuit-interruption protection.

9. Plug electrical power cord into a dedicated electrical

circuit rated for 120 Volts AC at 15 Amps that is

properly installed in accordance with all local codes and

ordinances. Circuit is not to supply any other electrical

needs. The indicator light on the GFCI should be ON.

NOTICE The indicator light must be ON for the electric

pressure washer to operate.

WARNING Risk of electrocution. Non-operating

ground fault circuit interrupter (GFCI) could

result in death or bodily injury. If indicator light

does not stay ON after test and reset, do not

use GFCI.

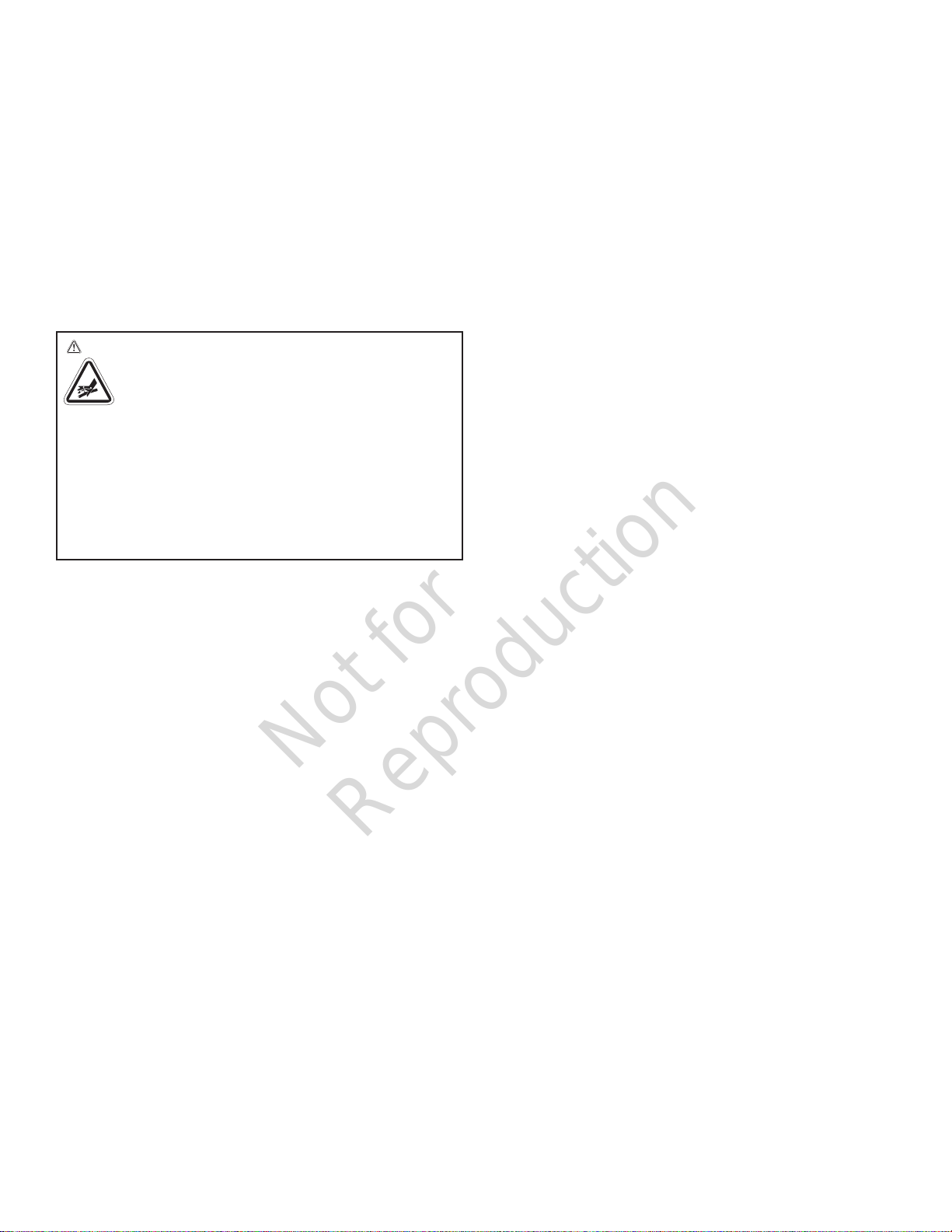

10. Press TEST button (B). The indicator light (C) should

be OFF.

D

7. Choose spray tip you want to use, pull back on collar

of spray wand, insert spray tip and release collar. Tug

on spray tip to make sure it is securely in place. See

How to Use Spray Tips.

8. Push master ON/OFF switch (A) to OFF (0) position.

A

B

C

11. Press RESET button (D). The indicator light (C)

should be ON.

NOTICE DO NOT use the electric pressure washer if

above test fails.

12. Press the master ON/OFF switch (A) to the pressure

washer ON (I) position.

13. Point gun in a safe direction, press trigger lock button

and squeeze trigger.

The electric pressure washer motor will start and stop as

spray gun trigger is depressed and released.

The electric pressure washer is now ready for use.

Instructions for use of the supplied accessories are given

later in this section.

10 BRIGGSandSTRATTON.COM

Not for

Reproduction

How to Stop Your Electric Pressure Washer

How to Use Spray Tips

The electric pressure washer motor runs only when the

trigger is engaged. To stop the electric pressure washer

and turn off the motor:

1. Release spray gun trigger.

2. Press the master ON/OFF switch to the OFF (0)

position.

NOTICE Releasing the trigger will shut off the motor but

does not shut off electrical power to the unit.

3. Turn off water supply.

4. ALWAYS point spray gun in a safe direction, press

trigger lock button and squeeze trigger to relieve built

up pressure in the unit.

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when motor

is stopped and water is disconnected, which could result

in serious injury.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you turn off pressure washer.

There are three spray tips supplied with the pressure

washer. The turbo spray tip whirls a powerful pin-point

jet of water for intense cleaning. The black spray tip is for

general soap applications and the yellow spray tip is for

various high pressure applications.

Usage Tips

• For most effective cleaning, keep spray tip from 8 to

24 inches away from cleaning surface.

• If you get spray tip too close, especially using a high

pressure spray tip, you may damage surface being

cleaned.

• DO NOT get closer than 6 inches when cleaning tires.

5. Disconnect GFCI plug from outlet.

11

Not for

Reproduction

Applying Detergent

WARNING Chemical Burn Hazard.

Chemicals could cause burns resulting

in death or serious injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

chemicals.

• DO NOT substitute safety glasses or dry-condition

goggles for indirect vented safety goggles.

• DO NOT use caustic liquid with electric pressure

washer.

• Use ONLY pressure washer safe detergents/soaps.

Follow all manufacturers instructions.

To apply detergent, follow these steps:

1. Review use of spray tips in How to Use Spray Tips.

2. Prepare your detergent solution as required by job to

be performed.

3. Remove cap from detergent tank and fill with

detergent solution. Replace cap.

Electric Pressure Washer Rinsing

1. Remove black detergent spray tip from wand.

2. Install yellow spray tip.

3. Keep spray gun a safe distance from area you plan to

spray.

WARNING Risk of kickback.

Spray gun could kickback causing you to fall

resulting in death or serious injury.

• Operate the electric pressure washer from a

stable surface.

• Be extremely careful if you must use the electric

pressure washer from a ladder, scaffolding, or any

other similar location.

• Firmly grasp spray gun with both hands when using

power spray modes to avoid injury when spray gun

kicks back.

4. Apply a high pressure spray to a small area and then

check surface for damage. If no damage is found, you

can assume it is okay to continue rinsing.

5. Start at top of area to be rinsed, working down with

same overlapping strokes as you used for cleaning.

4. Install black detergent spray tip.

NOTICE Detergent cannot be applied with turbo or yellow

spray tip.

5. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun and high pressure outlet. Turn on water.

NOTICE You must attach all hoses before you start the

pressure washer.

6. Start the pressure washer as instructed in How to

Start Your Electric Pressure Washer.

7. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward using

long, even, overlapping strokes.

8. Allow detergent to “soak in” for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. To prevent streaking, do not allow

detergent to dry on surface.

Other Cleaning Tips

• NEVER leave the electric pressure washer unattended

while it is plugged into an electrical outlet and while

water is supplied to the equipment.

• If you have the spray tip too far away from the surface

being washed, the cleaning may not be as effective.

How to Store Accessories

The unit is equipped with areas to store your high pressure

hose, spray gun, spray wand, and power cord. Coil power

cord on brackets. Store high pressure hose by wrapping

the velcro hook-and-loop strap around hose and handle.

Store spray gun and spray wand in the spray gun holder.

Store spray tips in holes on top of detergent tank. Identify all

accessories with the illustrations in Features and Controls.

12 BRIGGSandSTRATTON.COM

Not for

Reproduction

Maintenance

General Recommendations

Regular maintenance will improve the performance and

extend the life of the electric pressure washer.

The electric pressure washer’s warranty does not cover

items that have been subjected to operator abuse or

negligence. To receive full value from the warranty, the

operator must maintain the electric pressure washer as

instructed in this manual, including proper storage.

NOTICE Should you have questions about replacing

components on your electric pressure washer, please call

(800) 743-4115 for assistance.

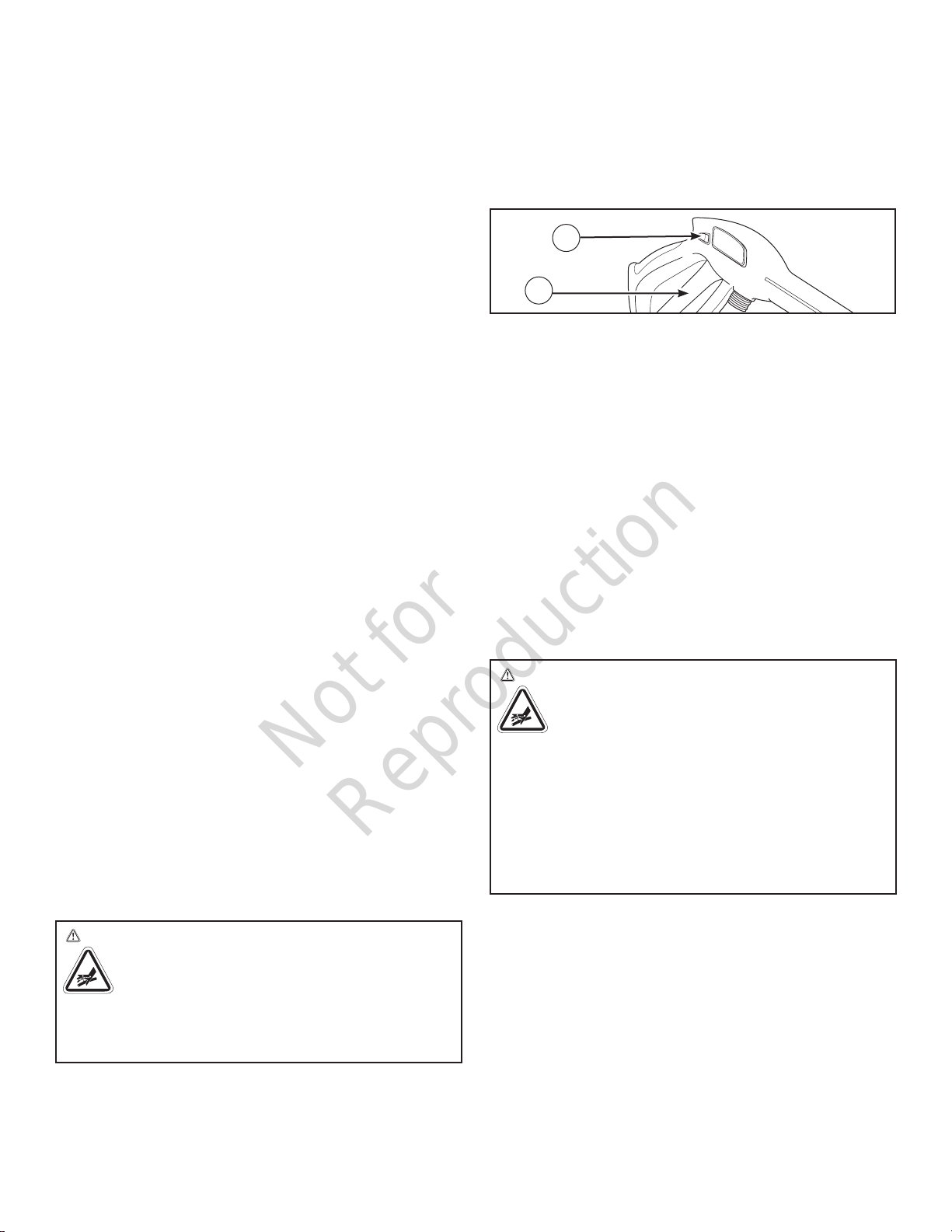

Check Spray Gun

Examine the hose connection to the spray gun and

make sure it is secure. Test the trigger (A) by pressing

the triggger lock button (B) and making sure the trigger

“springs back” into place when you release it. You should

not be able to press the trigger without pressing the trigger

lock button. Replace spray gun immediately if it fails any of

these tests.

B

A

Before Each Use

1. Clean debris.

2. Check water inlet screen for debris or damage.

3. Check high pressure hose for leaks.

4. Check spray gun operation.

Electric Pressure Washer Maintenance

Clean Debris

Daily or before use, clean accumulated debris from electric

pressure washer. Inspect cooling air slots and openings on

the front, rear and bottom of the electric pressure washer.

These openings must be kept clean and unobstructed.

The electric pressure washer parts should be kept clean to

reduce the risk of overheating and ignition of accumulated

debris.

• Use a damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of the electric pressure

washer can damage it and/or shorten its life.

• DO NOT insert any objects through cooling slots.

Check and Clean Water Inlet Screen

Examine the screen on the unit’s water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from wear,

kinking, or abuse. Inspect the hose each time before

using it. Check for cuts, leaks, abrasions or bulging of

cover, damage or movement of couplings. If any of these

conditions exist, replace the hose immediately.

Spray Tip Maintenance

Excessive pump pressure can cause a pulsing sensation

felt while squeezing the spray gun trigger. The principal

cause of excessive pump pressure is a spray tip clogged or

restricted with foreign materials such as dirt, etc. A clogged

spray tip could lead to pump cycling ON/OFF or not turning

on even when there is some flow.

To correct the problem, immediately clean the nozzle by

following these instructions:

1. Press the master ON/OFF switch to the OFF (0)

position. Remove power cord plug from electrical outlet.

2. Disconnect water supply at the electric pressure

washer.

3. ALWAYS point spray gun in a safe direction, press

trigger lock button and squeeze spray gun trigger to

release retained high water pressure.

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when motor

is stopped and water is disconnected, which could result

in serious injury.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you turn off pressure washer.

WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST equal or exceed

maximum pressure rating of unit.

13

Not for

Reproduction

4. Remove spray tip from end of spray wand.

5. Use a small paper clip to free any foreign material

clogging or restricting any of the spray tips.

6. Using a garden hose, remove additional debris by

back flushing water through spray wand. Back flush

between 30 to 60 seconds.

7. Reinstall spray tip into spray wand.

8. Reconnect spray wand to spray gun.

9. Make sure garden hose is connected to water inlet.

Check that high pressure hose is connected to spray

gun. Turn on water.

10. Plug power cord into electrical outlet and press the

master ON/OFF switch to the pressure washer ON (I)

position.

11. Test the electric pressure washer by operating with

each spray tip.

Pump and Motor Maintenance

The electric pressure washer does not require any

maintenance to the pump or motor. Both assemblies

are pre-lubricated and sealed, requiring no additional

lubrication ever.

After Each Use

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and “freeze”

pump action. Follow these procedures after every use:

1. Press the master ON/OFF switch to the OFF (0) position.

2. Turn off water supply, point gun in a safe direction,

press red button and squeeze trigger to relieve trapped

pressure, and let engine cool.

3. Disconnect hose from spray gun and high pressure

outlet on pump. Drain water from hose, spray gun,

and spray wand. Use a rag to wipe off the hose.

4. Drain water from pump by tipping unit forward (water

inlet facing down) for two minutes. Tip backward (high

pressure outlet facing down) for an additional two minutes.

5. Store high pressure hose by wrapping the velcro hookand-loop strap around hose and handle.

6. Coil power cord on brackets.

7. Store spray gun and spray wand in the spray gun holder.

Store spray tips in holes on top of detergent tank.

8. Store unit in a clean, dry area.

9. If storing for more than 30 days see Winter or Long

Term Storage.

Winter or Long Term Storage

Follow steps 1-7 in After Each Use.

NOTICE Water left in pump could freeze and permanently

damage pump. Freeze damage is not covered under

warranty.

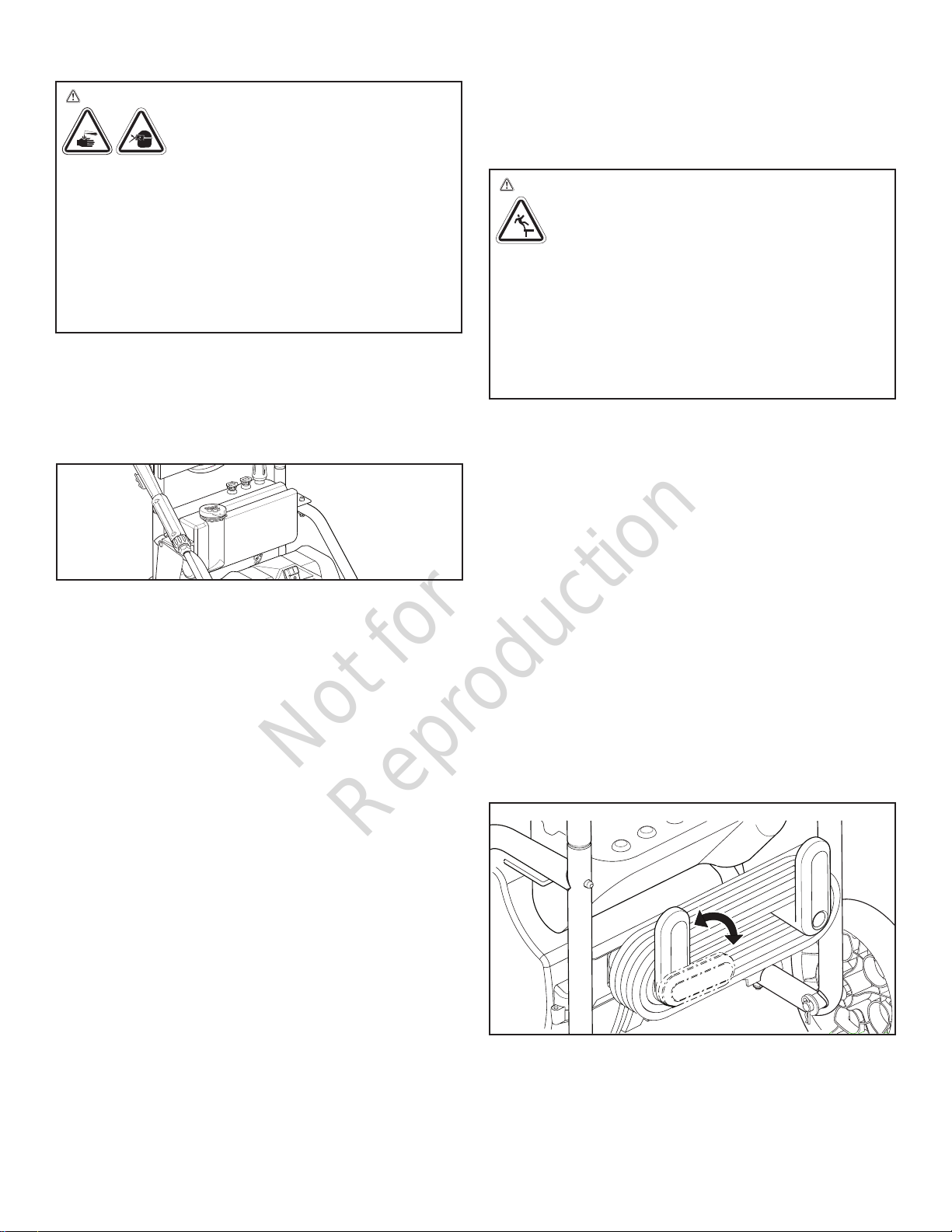

Protecting the Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver, Model 6039, to treat

pump. This prevents freeze damage and lubricates plunger

and seals.

NOTICE PumpSaver is available as an optional

accessory. It is not included with the electric pressure

washer. Contact the nearest authorized service center to

purchase Pump Saver.

NOTICE You must protect your unit from freezing

temperatures.

• Failure to do so will permanently damage your pump

and render your unit inoperable.

• Freeze damage is not covered under warranty.

To use PumpSaver, make sure the electric pressure

washer is turned off and inlet and outlet hoses are

disconnected. Read and follow all instructions and

warnings given on the PumpSaver container.

Final Storage Procedures

1. Store high pressure by wrapping the velcro hook-andloop strap around hose and handle

2. Coil power cord on brackets.

3. Store spray gun and spray wand in the spray gun

holder. Store spray tips in holes on top of detergent

tank.

4. Store unit in a clean, dry area that is protected from

freezing temperatures.

5. Cover unit with a suitable protective cover that does

not retain moisture.

14 BRIGGSandSTRATTON.COM

Not for

Reproduction

Troubleshooting

Problem Cause Correction

Pump has following

problems: failure to produce

pressure, erratic pressure,

chattering, loss of pressure,

low water volume.

1. Water inlet is blocked.

2. Inadequate water supply.

3. Garden hose is kinked or leaking.

4. Clogged water inlet screen.

5. Water supply is over 100°F (38°C).

6. High pressure hose is blocked or

leaks.

7. Spray tip is obstructed.

1. Clear inlet.

2. Provide adequate water flow.

3. Straighten garden hose or replace if leaking.

4. Check and clean water inlet screen.

5. Provide cooler water supply.

6. Clear blocks in high pressure hose or

replace hose.

7. Clean spray tip.

Unit fails to start when spray

gun trigger is squeezed.

Detergent fails to mix with

spray.

Hose connections leaking.

1. Water supply is not turned on.

2. Unit is not turned on.

3. Garden hose is too long.

4. Fuse blown or circuit breaker tripped.

1. High pressure spray tip is installed.

2. Inlet water supply pressure too high.

1. Garden hose loose to water inlet.

2. Loose high pressure hose

connections.

3. Damaged o-ring.

1. Turn on water supply.

2. Press the master ON/OFF switch to the

ON (I) position. Reset GFCI.

3. Use only 50 ft. (15.24 m) maximum

garden hose.

4. a.) Check fuse box for blown fuse and

replace as necessary or reset circuit

breaker. Do not use a fuse or circuit

breaker with a higher rating than that

specified for your particular branch

circuit.

b.) Disconnect other electrical

appliances and turn off lights in the

circuit or operate the pressure washer

on its own dedicated circuit.

c.) Run pressure washer with any spray

tip for 5 minutes. Motor break in may be

necessary.

1. Install black detergent spray tip.

2. Slowly close water supply valve until

chemical just starts to draw (soap

suds will appear when chemical starts

to draw).

1. Hand tighten garden hose to water

inlet.

2. Remove hose completely and reinstall

hand tight.

3. Replace o-ring.

For all other issues, see a Briggs & Stratton authorized dealer.

15

Not for

Reproduction

BRIGGS & STRATTON WARRANTY POLICY

Briggs & Stratton warrants that, during the warranty period specified below, it will repair or replace, free of charge, any part that is defective in material or workmanship

or both. Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser. This warranty is effective for and

is subject to the time periods and conditions stated below. For warranty service, contact Briggs & Stratton Customer Service by phone at (800) 743-4115, or on the

internet at BRIGGSANDSTRATTON.COM.

There is no other express warranty. Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to the

warranty period listed below, or to the extent permitted by law. Liability for incidental or consequential damages are excluded to the extent exclusion

is permitted by law. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state or country to country.**

** In Australia - Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be

of acceptable quality and the failure does not amount to a major failure. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at

BRIGGSandSTRATTON.COM, or by calling 1300 274 447, or by emailing or writing to salesenquires@briggsandstratton.com.au, Briggs & Stratton Australia Pty Ltd, 1

Moorebank Avenue, NSW, Australia, 2170.

The warranty period begins on the date of purchase by the first retail or commercial consumer. “Consumer use” means personal residential household use by a retail

consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once a product has experienced commercial

use, it shall thereafter be considered as a commercial use product for purposes of this warranty.

Save your proof of purchase receipt. If you do not provide proof of the initial purchase date at the time warranty service is requested, the manufacturing date of the

product will be used to determine the warranty period. Product registration is not required to obtain warranty service on Briggs & Stratton products.

LIMITED WARRANTY

WARRANTY PERIOD

Consumer Use Commercial Use

12 months None

ABOUT YOUR WARRANTY

Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. This warranty covers only defects in materials or

workmanship. It does not cover damage caused by improper use or abuse, improper maintenance or repair, normal wear and tear, or stale or unapproved fuel.

Improper Use and Abuse - The proper, intended use of this product is described in the Operator’s Manual. Using the product in a way not described in the Operator’s

Manual or using the product after it has been damaged will not be covered under this warranty. Warranty coverage will also not be provided if the serial number on the

product has been removed or the product has been altered or modified in any way, or if the product has evidence of abuse such as impact damage or water/chemical

corrosion damage.

Improper Maintenance or Repair - This product must be maintained according to the procedures and schedules provided in the Operator’s Manual, and serviced or

repaired using genuine Briggs & Stratton parts or equivalent. Damage caused by lack of maintenance or use of non-original parts is not covered by warranty.

Normal Wear and Tear - Like most mechanical devices, your unit is subject to wear even when properly maintained. This warranty does not cover repairs when normal

use has exhausted the life of a part or the equipment. Maintenance and wear items such as filters, belts, cutting blades, and brake pads (except engine brake pads) are

not covered by warranty due to wear characteristics alone, unless the cause is due to defects in material or workmanship.

Stale or Unapproved Fuel - In order to function correctly, this product requires fresh fuel that conforms to the criteria specified in the Operator’s Manual. Engine or

equipment damage caused by stale fuel or the use of unapproved fuels (such as E15 or E85 ethanol blends) is not covered by warranty.

Other Exclusions - This warranty excludes damage due to accident, abuse, modifications, alterations, improper servicing, freezing or chemical deterioration.

Attachments or accessories that were not originally packaged with the product are also excluded. There is no warranty coverage on equipment used for primary power in

place of utility power or on equipment used in life support applications. This warranty does not include used, reconditioned, second-hand, or demonstration equipment or

engines. This warranty also excludes failures due to acts of God and other force majeure events beyond the manufacturer’s control.

80018419_EN Rev A

16 BRIGGSandSTRATTON.COM

Not for

Reproduction

17

Loading...

Loading...