Craftsman 580768332 Owner’s Manual

Owner's Manual

CRRFTSMRN°

6.0 HORSEPOWER

2,400 PSI

2.2 GPM

HIGH PRESSUR

Model No. 580.768332

WASHER

HOURS: Mon.- Fri. 8 a.m. to 5 p.m. (CT)

CAUTION" Before using this product,

read this manual and follow all Safety

Rules and Operating Instructions.

SEARS, ROEBUCK and CO., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

Part No. 186546 Draft 3 (5/31/2000)

• Safety

• Assembly

• Operation

• Maintenance

• Parts

• Espahol

WARRANTY ................................... 2

SAFETY RULES .............................. 2-3

ASSEMBLY .................................. 4-5

OPERATION ................................. 6-9

MAINTENANCE ............................. 9-12

SPECIFICATIONS ............................. 10

STORAGE ................................... 13

TROUBLESHOOTING .......................... 14

REPLACEMENT PARTS ...................... 16-23

EMISSION CONTROL WARRANTY ................ 24

ESPANOL ................................. 25-39

HOW TO ORDER PARTS ............... BACK PAGE

LIMITED WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman pressure washer is maintained and operated

according to the instructionsin the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

If this washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase. If this high pressure washer is used for rental purposes, this warranty applies for only 30 days after

date of purchase.

This warranty does not cover:

• Expendable items such as spark plugs or air filters, which become worn during normal use.

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instructions contained in the

owner's manual.

Warranty service is available by returning the high pressure washer to the nearest Sears service center or

dealer in the United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects, or

other reproductive harm.

,_ CAUTION! When setting up, transporting,

adjusting or making repairs to your high

pressure washer, always disconnect the spark

plug wire from the spark plug and place the wire

where it cannot contact spark plug.

,_ DANGER! Engine exhaust gases contain

DEADLY carbon monoxide gas. This dangerous

gas, if breathed in sufficient concentrations, can

cause unconsciousness or even death. Operate

this equipment only in the open air where

adequate ventilation is available.

,_ DANGER! Gasoline is highly FLAMMABLE

and its vapors are EXPLOSIVE. Do Not permit

smoking, open flames, sparks or heat in the

vicinity while handling gasoline. Avoid spilling

gasoline on a hot engine. Allow unit to cool

before refueling. Comply with all laws regulating

storage and handling of gasoline.

Read this manual carefully and become familiar

with your pressure washer. Know its applications,

its limitations, and any hazards involved.

• Locate this pressure washer in areas away from

combustible materials, combustible fumes or dust.

• The high pressure equipment is designed to be

used with Sears authorized parts ONLY. If you use

this equipment with parts that do not comply with

minimum specifications, the user assumes all risks

and liabilities.

• Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting or poisoning. The harmful elements may

cause property damage or severe injury.

• DoNotallowCHILDRENtooperatethepressure

washeratanytime.

• Operateengineonlyatgovernedspeed.Running

theengineatexcessivespeedsincreasesthe

hazardofpersonalinjury.DoNottamperwithparts

whichmayincreaseordecreasethegoverned

speed.

• DoNotwearlooseclothing,jewelryoranything

thatmaybecaughtinthestarterorotherrotating

parts.

• Beforestartingthepressurewasherincold

weather,checkallpartsoftheequipmentandbe

sureicehasnotformedthere.

• Neverusea spraygunwhichdoesnothavea

triggerlockortriggerguardin placeandinworking

order.

• Keepthehoseconnectedtomachineorthespray

gunwhilethesystemispressurized.Disconnecting

thehosewhiletheunitispressurizedisdangerous.

• Unitswithbrokenormissingparts,orwithout

protectivehousingorcovers,shouldNEVERbe

operated.

• Checkthefuelsystemforleaksorsignsof

deterioration,suchaschafedorspongyhose,

looseormissingclamps,ordamagedtankorcap.

Correctalldefectsbeforeoperatingthepressure

washer.

• DoNotsprayflammableliquids.

• Usearespiratorormaskwheneverthereisa

chancethatvaporsmaybeinhaled.Readall

instructionswithmasksoyouarecertainthemask

willprovidethenecessaryprotectionagainst

inhalingharmfulvapors.

• Neveraimthespraygunatpeople,animalsor

plants.Thehighpressurestreamofwaterthatthis

equipmentproducescanpierceskinandits

underlyingtissues,leadingto seriousinjuryand

possibleamputation.

• Neverallowanypartofthebodytocomein

contactwiththefluidstream.DoNotcomein

contactwithafluidstreamcreatedbyaleakinthe

highpressurehose.

• Alwaysweareyeprotectionwhenyouusethis

equipmentorwhenyouareinthevicinitywhere

theequipmentisinuse.

• Highpressurespraycancausepaintchipsorother

particlestobecomeairborne.

• DoNotoperatethepressurewasherabovethe

ratedpressure.

• Nevermovethemachinebypullingonthehigh

pressurehose.Usethehandleprovidedonthe

unit.

• Alwaysbecertainthespraygun,nozzlesand

accessoriesarecorrectlyattached.

• DoNotsecurethesprayguninthe(open)

position.

• Highpressurespraymaydamagefragileitems

includingglass.DoNotpointspraygunatglass

wheninthejetspraymode.

• Holdthespraygunfirmlyinyourhandbeforeyou

starttheunit.Failuretodosocouldresultinan

injuryfromawhippingspraygun.DoNotleavethe

spraygununattendedwhilethemachineis

running.

• Thecleaningareashouldhaveadequateslopes

anddrainagetoreducethepossibilityofafalldue

toslipperysurfaces.

• Keepwatersprayawayfromelectricwiringorfatal

electricshockmayresult.

• DoNotby-passanysafetydeviceonthis

machine.

• Themufflerandengineheatupduringoperation

andremainhotimmediatelyaftershuttingitdown.

Avoidcontactwithahotmufflerorengineasyou

couldbeseverelyburned.

• Operateandstorethisunitonastablesurface.

• Highpressurehosecandevelopleaksfromwear,

kinking,abuse,etc.Watersprayingfromaleakis

capableofinjectingmaterialintoskin.Inspecthose

eachtimebeforeusingit.Checkallhosesforcuts,

leaks,abrasionsorbulgingofcover,ordamageor

movementofcouplings.Ifanyoftheseconditions

exist,replacehoseimmediately.Neverrepairhigh

pressurehose.Replaceitwithanotherhosethat

exceedsmaximumpressureratingofyourunit.

• Themufflerandaircleanermustbeinstalledandin

goodconditionbeforeoperatingthepressure

washer.Thesecomponentsactassparkarresters

iftheenginebackfires.

IntheStateofCaliforniaa sparkarresterisrequired

bylaw(Section4442oftheCaliforniaPublic

ResourcesCode).Otherstatesmayhavesimilarlaws.

Federallawsapplyonfederallands.

NOTE:Ifyouequipthemufflerwithasparkarrester,it

mustbemaintainedineffectiveworkingorder.You

canordera sparkarresterthroughyourauthorized

Searsservicecenter.

,_ THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL

PERSONAL INJURY HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS

SYMBOL TO AVOID POSSIBLE INJURY OR DEATH.

Your pressure washer requires some assembly and is

ready for use only after it has been properly serviced

with the recommended oil and fuel.

If you have any problems with the assembly of

your pressure washer, please call the pressure

washer helpline at 1-800-222-3136.

IMPORTANT: Any attempt to run the engine before it

has been serviced with the recommended oil will result

in an engine failure.

REMOVE PRESSURE WASHER

FROM CARTON

• Remove parts box shipped with your pressure

washer.

• Slice two corners opposite guide handle end of

carton from top to bottom so the panel can be

folded down flat.

• Roll the pressure washer out the open end of the

carton.

• Raise guide handle, secure in place.

Become familiar with each piece before assembling

the pressure washer. Check all contents against the

illustration on page 6. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

ASSEMBLING YOUR PRESSURE

WASHER

Your Craftsman high pressure washer was mostly

assembled at the factory. However, you will need to

perform these tasks before you can operate your

pressure washer:

• Add oil to engine crankcase.

• Add fuel to fuel tank.

• Connect pressure hose to spray gun and pump.

• Connect water supply to the pump.

Add Engine Oil

IMPORTANT: Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SG, or SH rated SAE 30 weight.

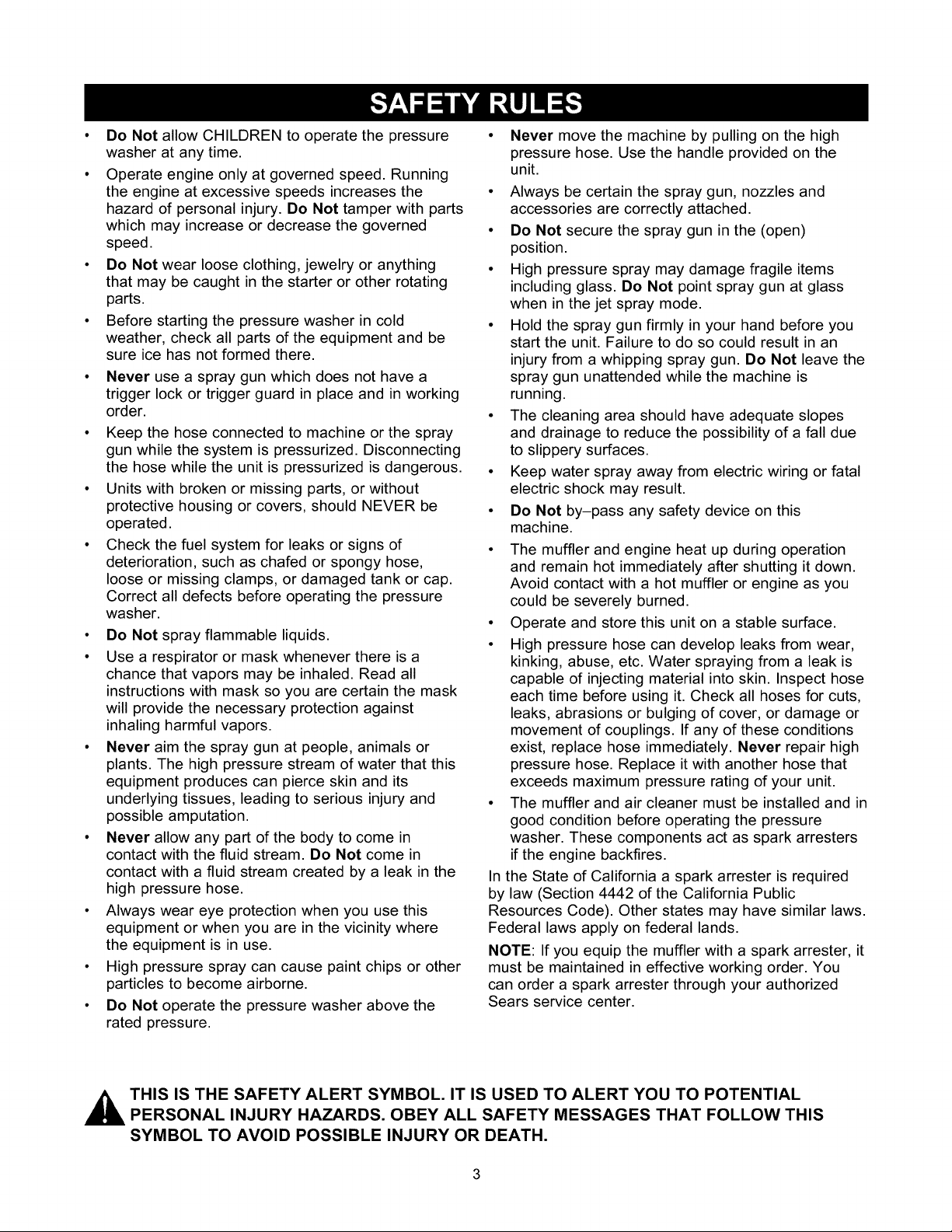

Other viscosity oils shown in the chart may be used

when the average temperature in your area is within

the recommended range.

/

Lift the handle to upright

position and slide the

locking caps into place

• Check carton for additional loose parts.

CARTON CONTENTS

Check all contents. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

• The main unit

• Parts box (which includes items listed below)

Spray gun

High pressure hose

Nozzle extension with quick connect

Quick connect nozzles

Engine oil

Owner's manual

Nozzle cleaning kit

O-Ring kit

oF

oc

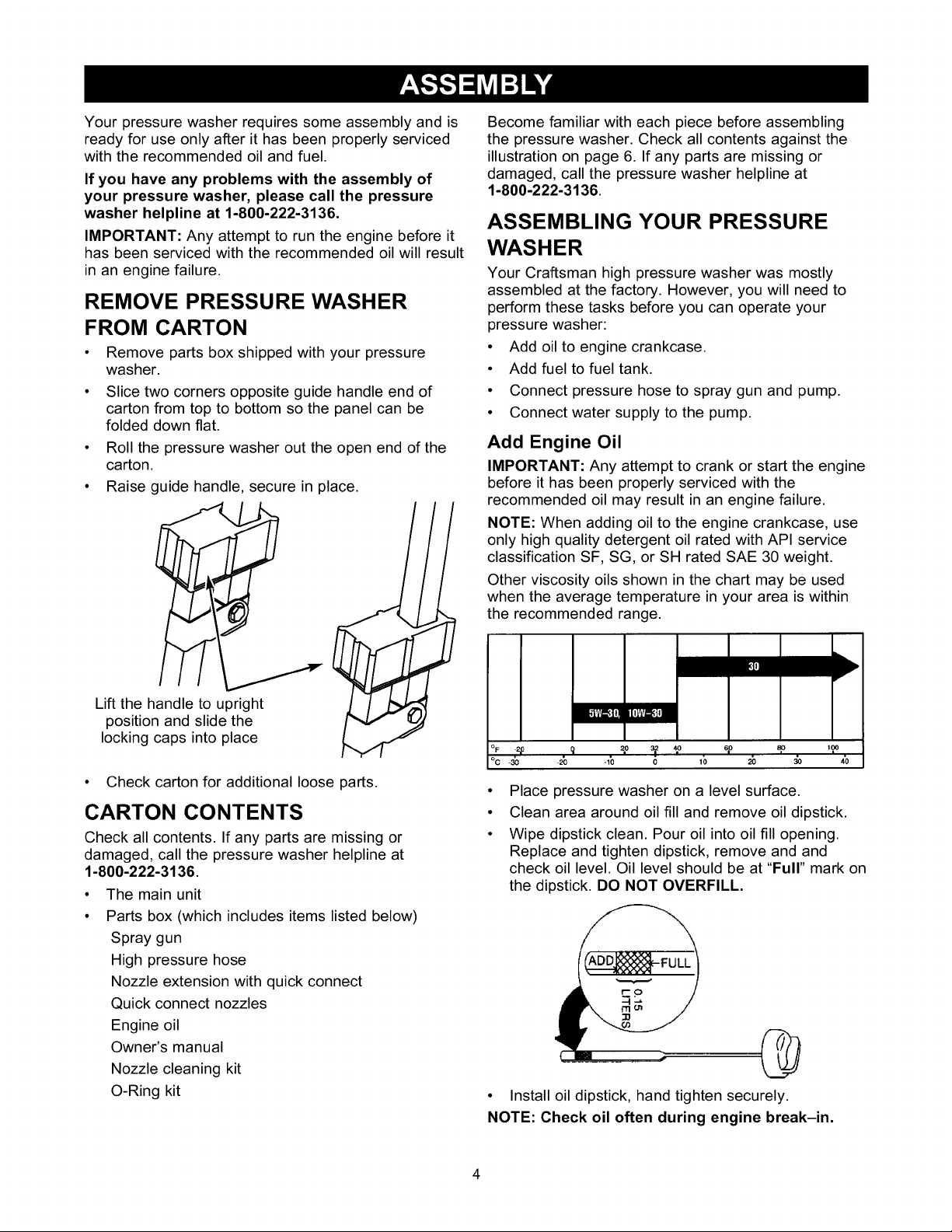

Place pressure washer on a level surface.

Clean area around oil fill and remove oil dipstick.

Wipe dipstick clean. Pour oil into oil fill opening.

Replace and tighten dipstick, remove and and

check oil level. Oil level should be at "Full" mark on

the dipstick. DO NOT OVERFILL.

• Install oil dipstick, hand tighten securely.

NOTE: Check oil often during engine break-in.

Add Gasoline

_ DANGER! Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot. Do

Not smoke when filling fuel tank.

_ ARNING! Never fill fuel tank completely full.

Provide space for fuel expansion. Wipe away

any fuel spillage from engine and equipment

before starting.

• Use fresh, clean unleaded automotive gasoline and

store in approved, clean, covered containers. Use

clean fill funnels. Never use "stale" gasoline left

over from last season or gasoline stored for long

periods.

• Clean area around fuel fill cap, remove cap.

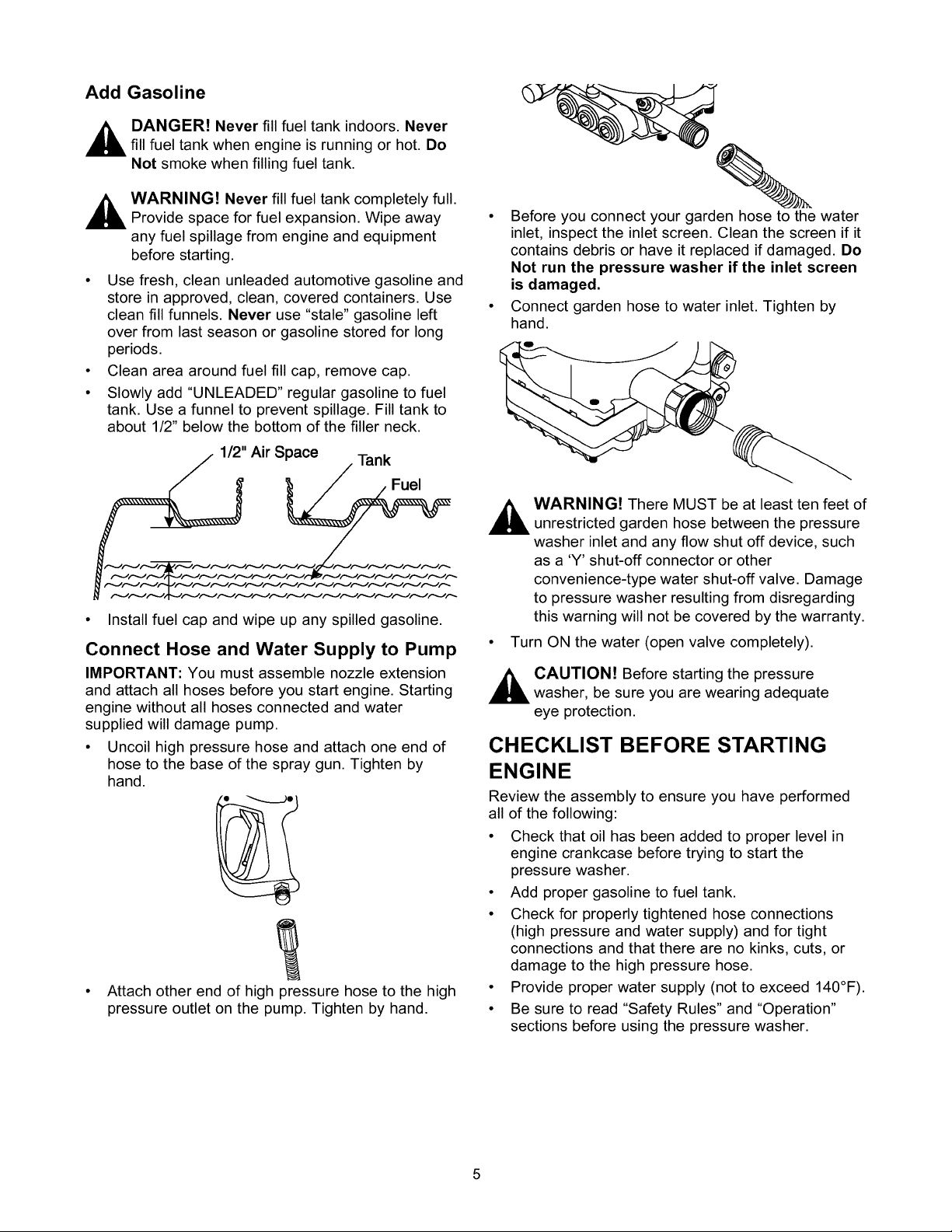

• Slowly add "UNLEADED" regular gasoline to fuel

tank. Use a funnel to prevent spillage. Fill tank to

about 1/2" below the bottom of the filler neck.

1/2" Air Space Tank

Fuel

• Install fuel cap and wipe up any spilled gasoline.

Connect Hose and Water Supply to Pump

IMPORTANT: You must assemble nozzle extension

and attach all hoses before you start engine. Starting

engine without all hoses connected and water

supplied will damage pump.

• Uncoil high pressure hose and attach one end of

hose to the base of the spray gun. Tighten by

hand.

Attach other end of high pressure hose to the high

pressure outlet on the pump. Tighten by hand.

• Before you connect your garden hose to the water

inlet, inspect the inlet screen. Clean the screen if it

contains debris or have it replaced if damaged. Do

Not run the pressure washer if the inlet screen

is damaged.

• Connect garden hose to water inlet. Tighten by

hand.

_ ARNING! There MUST be at least ten feet of

unrestricted garden hose between the pressure

washer inlet and any flow shut off device, such

as a 'Y' shut-off connector or other

convenience-type water shut-off valve. Damage

to pressure washer resulting from disregarding

this warning will not be covered by the warranty.

• Turn ON the water (open valve completely).

_ AUTION! Before starting the pressure

washer, be sure you are wearing adequate

eye protection.

CHECKLIST BEFORE STARTING

ENGINE

Review the assembly to ensure you have performed

all of the following:

• Check that oil has been added to proper level in

engine crankcase before trying to start the

pressure washer.

• Add proper gasoline to fuel tank.

• Check for properly tightened hose connections

(high pressure and water supply) and for tight

connections and that there are no kinks, cuts, or

damage to the high pressure hose.

• Provide proper water supply (not to exceed 140°F).

• Be sure to read "Safety Rules" and "Operation"

sections before using the pressure washer.

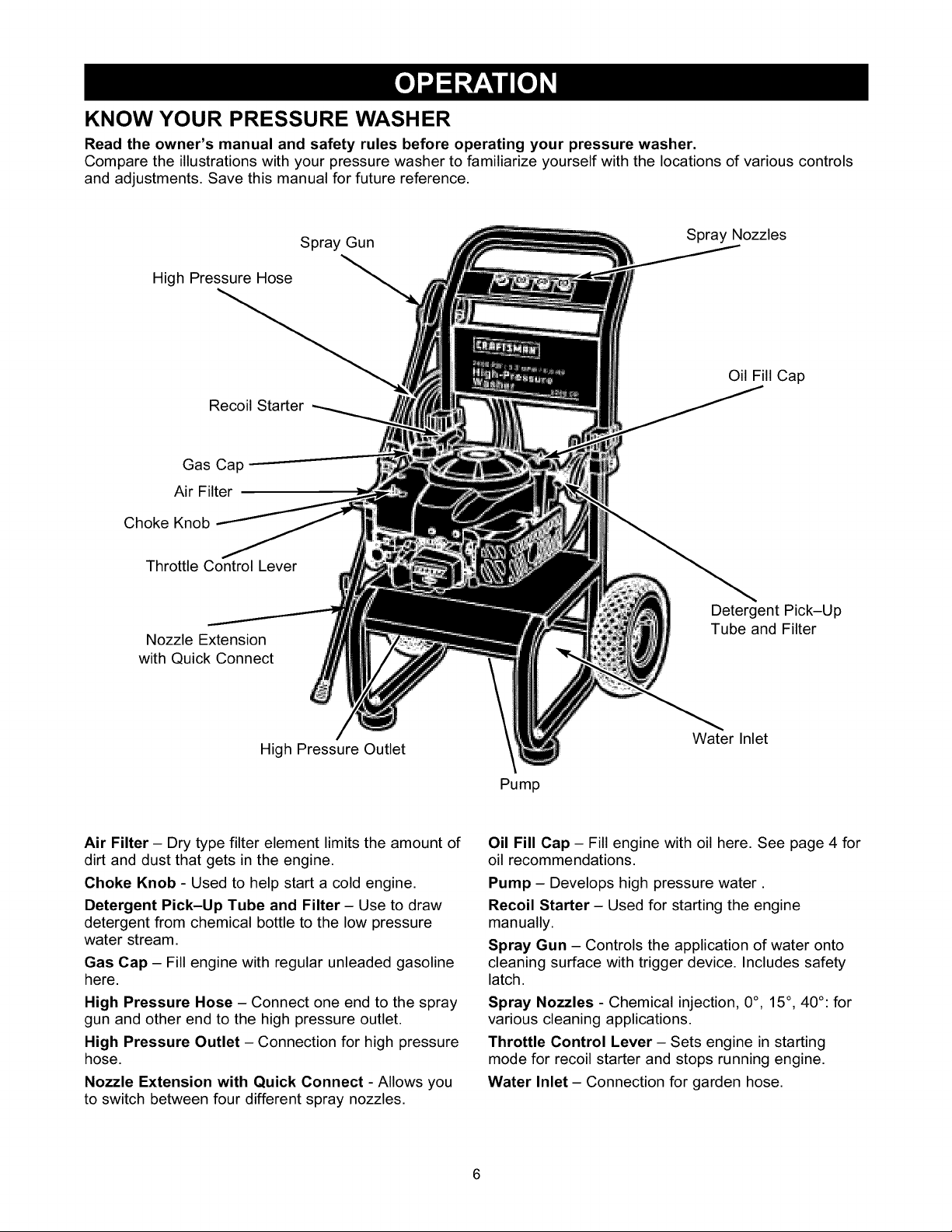

KNOW YOUR PRESSURE WASHER

Read the owner's manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

High Pressure Hose

Recoil Starter

Gas Cap

Air Filter

Choke Knob

Throttle Control Lever

Nozzle Extension

with Quick Connect

Spray Gun

Spray Nozzles

Oil Fill Cap

Detergent Pick-Up

Tube and Filter

High Pressure Outlet

Air Filter - Dry type filter element limits the amount of

dirt and dust that gets in the engine.

Choke Knob - Used to help start a cold engine.

Detergent Pick-Up Tube and Filter - Use to draw

detergent from chemical bottle to the low pressure

water stream.

Gas Cap - Fill engine with regular unleaded gasoline

here.

High Pressure Hose - Connect one end to the spray

gun and other end to the high pressure outlet.

High Pressure Outlet - Connection for high pressure

hose.

Nozzle Extension with Quick Connect - Allows you

to switch between four different spray nozzles.

Water Inlet

Pump

Oil Fill Cap - Fill engine with oil here. See page 4 for

oil recommendations.

Pump - Develops high pressure water.

Recoil Starter- Used for starting the engine

manually.

Spray Gun - Controls the application of water onto

cleaning surface with trigger device. Includes safety

latch.

Spray Nozzles - Chemical injection, 0°, 15°, 40°: for

various cleaning applications.

Throttle Control Lever - Sets engine in starting

mode for recoil starter and stops running engine.

Water Inlet - Connection for garden hose.

HOW TO USE YOUR PRESSURE

WASHER

If you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136.

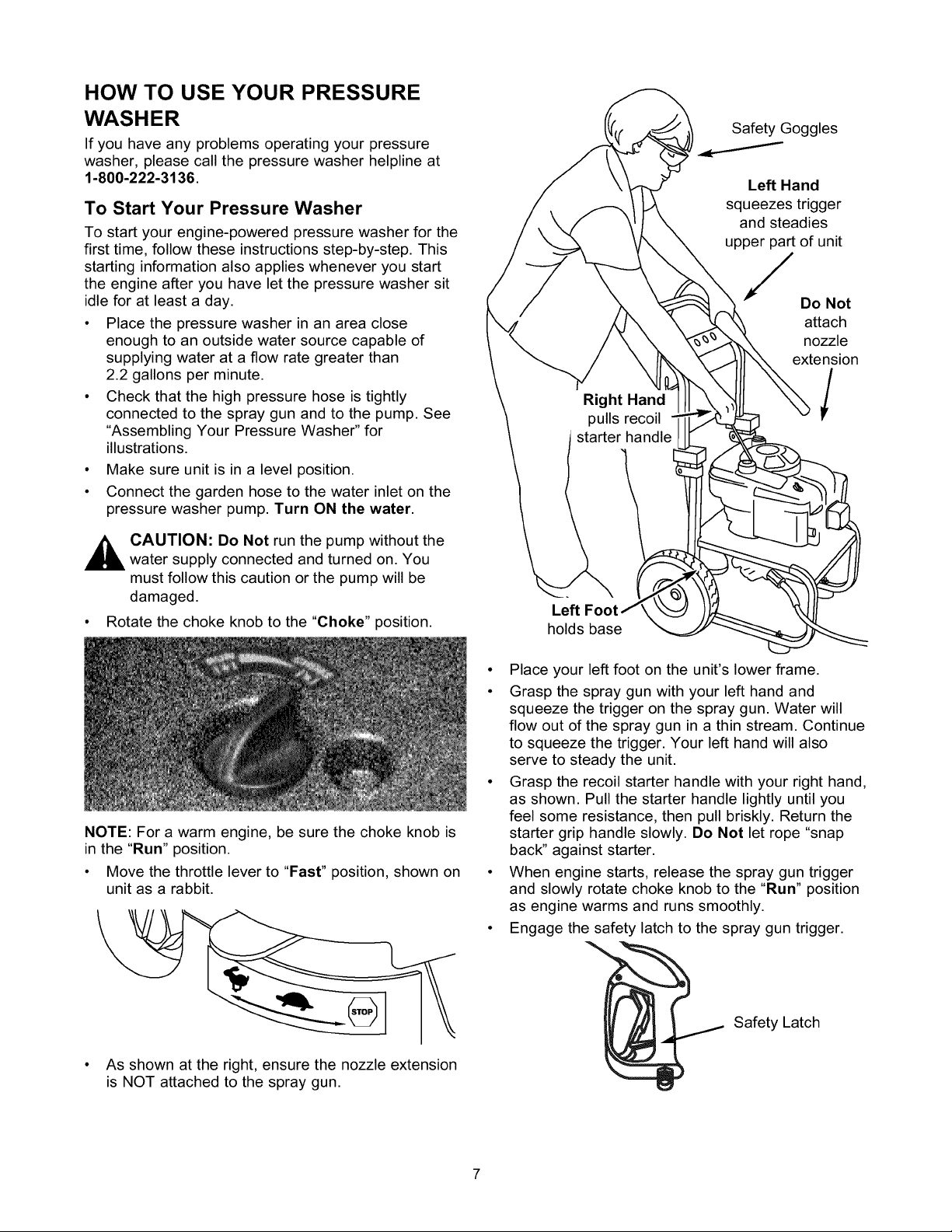

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

starting information also applies whenever you start

the engine after you have let the pressure washer sit

idle for at least a day.

• Place the pressure washer in an area close

enough to an outside water source capable of

supplying water at a flow rate greater than

2.2 gallons per minute.

• Check that the high pressure hose is tightly

connected to the spray gun and to the pump. See

"Assembling Your Pressure Washer" for

illustrations.

• Make sure unit is in a level position.

• Connect the garden hose to the water inlet on the

pressure washer pump. Turn ON the water.

Right Hand

pulls recoil

starter handle

\

Safety Goggles

Left Hand

squeezes trigger

and steadies

upper part of unit

Do Not

attach

nozzle

extension

l

A AUTION: Do Not run the pump without the

water supply connected and turned on. You

must follow this caution or the pump will be

damaged.

• Rotate the choke knob to the "Choke" position.

NOTE: For a warm engine, be sure the choke knob is

in the "Run" position.

• Move the throttle lever to "Fast" position, shown on

unit as a rabbit.

Left

holds base

• Place your left foot on the unit's lower frame.

• Grasp the spray gun with your left hand and

squeeze the trigger on the spray gun. Water will

flow out of the spray gun in a thin stream. Continue

to squeeze the trigger. Your left hand will also

serve to steady the unit.

• Grasp the recoil starter handle with your right hand,

as shown. Pull the starter handle lightly until you

feel some resistance, then pull briskly. Return the

starter grip handle slowly. Do Not let rope "snap

back" against starter.

• When engine starts, release the spray gun trigger

and slowly rotate choke knob to the "Run" position

as engine warms and runs smoothly.

• Engage the safety latch to the spray gun trigger.

As shown at the right, ensure the nozzle extension

is NOT attached to the spray gun.

Safety Latch

• Attachthenozzleextensionandtightenbyhand.

• Choosethenozzleyouwanttouseandinsertit

intothenozzleextension.See"Howto Usethe

Nozzles"below.

How to Stop Your Pressure Washer

• Move throttle lever on engine to "Stop" position.

• Squeeze trigger on the spray gun to relieve

pressure in the hose.

NOTE: A small amount of water will squirt out when

you release the pressure.

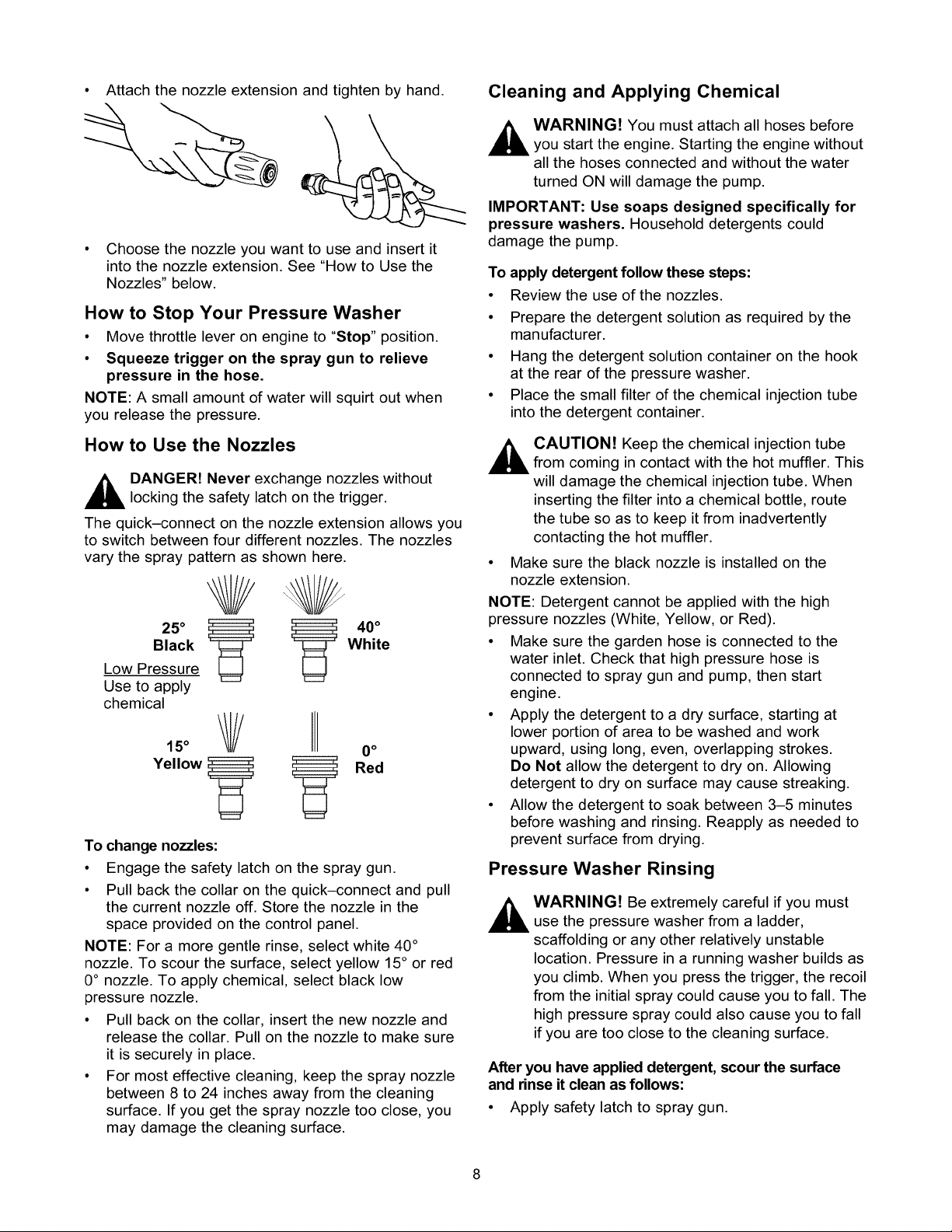

How to Use the Nozzles

,_ DANGER! Never exchange nozzles without

locking the safety latch on the trigger.

The quick-connect on the nozzle extension allows you

to switch between four different nozzles. The nozzles

vary the spray pattern as shown here.

Black

Low Pressure

Use to apply

chemical

To change nozzles:

• Engage the safety latch on the spray gun.

• Pull back the collar on the quick-connect and pull

the current nozzle off. Store the nozzle in the

space provided on the control panel.

NOTE: For a more gentle rinse, select white 40 °

nozzle. To scour the surface, select yellow 15° or red

0° nozzle. To apply chemical, select black low

pressure nozzle.

• Pull back on the collar, insert the new nozzle and

release the collar. Pull on the nozzle to make sure

it is securely in place.

• For most effective cleaning, keep the spray nozzle

between 8 to 24 inches away from the cleaning

surface. If you get the spray nozzle too close, you

may damage the cleaning surface.

25°

15°

Yellow

White

400

0o

Red

Cleaning and Applying Chemical

,_ WARNING! You must attach all hoses before

you start the engine. Starting the engine without

all the hoses connected and without the water

turned ON will damage the pump.

IMPORTANT: Use soaps designed specifically for

pressure washers. Household detergents could

damage the pump.

To apply detergent follow these steps:

• Review the use of the nozzles.

• Prepare the detergent solution as required by the

manufacturer.

• Hang the detergent solution container on the hook

at the rear of the pressure washer.

• Place the small filter of the chemical injection tube

into the detergent container.

_ AUTION! Keep the chemical injection tube

from coming in contact with the hot muffler. This

will damage the chemical injection tube. When

inserting the filter into a chemical bottle, route

the tube so as to keep it from inadvertently

contacting the hot muffler.

• Make sure the black nozzle is installed on the

nozzle extension.

NOTE: Detergent cannot be applied with the high

pressure nozzles (White, Yellow, or Red).

• Make sure the garden hose is connected to the

water inlet. Check that high pressure hose is

connected to spray gun and pump, then start

engine.

• Apply the detergent to a dry surface, starting at

lower portion of area to be washed and work

upward, using long, even, overlapping strokes.

Do Not allow the detergent to dry on. Allowing

detergent to dry on surface may cause streaking.

• Allow the detergent to soak between 3-5 minutes

before washing and rinsing. Reapply as needed to

prevent surface from drying.

Pressure Washer Rinsing

_ ARNING! Be extremely careful if you must

use the pressure washer from a ladder,

scaffolding or any other relatively unstable

location. Pressure in a running washer builds as

you climb. When you press the trigger, the recoil

from the initial spray could cause you to fall. The

high pressure spray could also cause you to fall

if you are too close to the cleaning surface.

After you have applied detergent, scour the surface

and rinse it cleanas follows:

• Apply safety latch to spray gun.

• Removetheblackchemicalnozzlefromthenozzle

extension.

• Selectandinstallthedesiredhighpressurenozzle

followingtheinstructions"HowtoUsetheNozzles".

• Keepthespraygunasafedistancefromthearea

youplantospray.

• Applyahighpressurespraytoansmallareaand

thencheckthesurfacefordamage.Ifnodamage

isfound,youcanassumeitisokaytocontinue

cleaning.

• Startatthetopoftheareatoberinsed,working

downwithsameoverlappingstrokesusedfor

cleaning.

Automatic Cool Down System

(Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach a

temperature between 140-145°F. When the water

reaches this temperature, the automatic cool down

system engages and cools the pump by discharging

the warm water onto the ground. This system prevents

internal damage to the pump. Once the pump has

cooled, it will stop discharging.

NOTE: This is not a leak. Do Not return the pressure

washer to the store.

• Theuseof a brushmaybehelpfulonsomehardto

cleansurfaces.

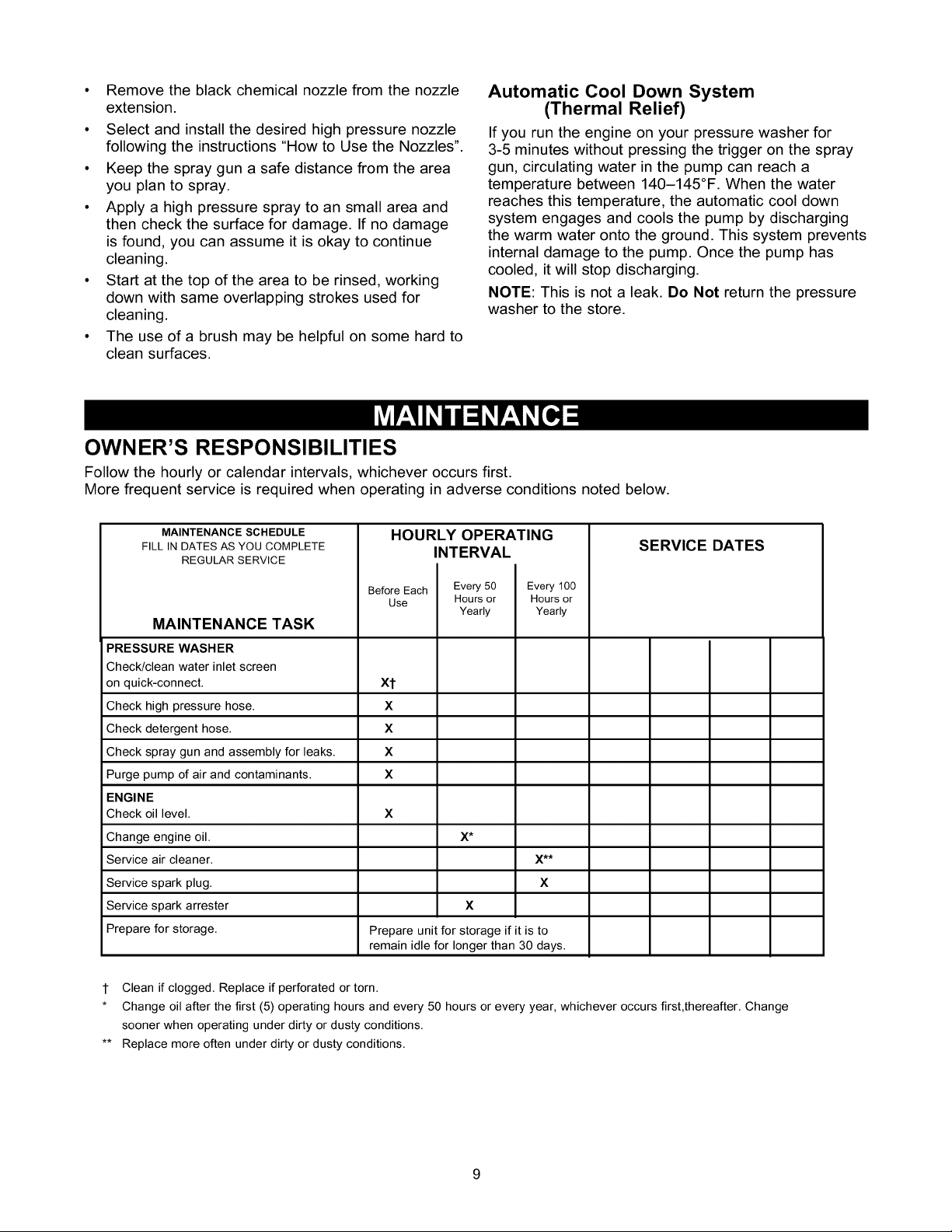

OWNER'S RESPONSIBILITIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE TASK

PRESSURE WASHER

Check/clean water inlet screen

on quick-connect.

Check high pressure hose.

Check detergent hose.

Check spray gun and assembly for leaks.

Purge pump of air and contaminants.

ENGINE

Check oil level.

Change engine oil.

Service air cleaner.

Service spark plug.

Service spark arrester

Prepare for storage.

HOURLY OPERATING

INTERVAL

Before Each

Use

Every 50

Hours or

Yearly

Every 100

Hours or

Yearly

xt

X

X

X

X

X

X*

X**

X

X

Prepare unit for storage if it is to

remain idle for longer than 30 days.

SERVICE DATES

1 Clean if clogged. Replace if perforated or torn.

* Change oil after the first (5) operating hours and every 50 hours or every year, whichever occurs first,thereafter. Change

sooner when operating under dirty or dusty conditions.

** Replace more often under dirty or dusty conditions.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Pressure ................... 2,400 PSI

Flow Rate .................. 2.2 GPM

Chemical Mix ............... Use as directed

Water Supply Temperature ..... Not to Exceed 140°F

Engine Specifications

Rated Horsepower ........... 6.0 HP

Spark Plug Type: ........... Champion RJ19LM

or Equivalent

Set Gap To: ............. 0.030 inches

(0.760ram)

Gasoline Capacity ............ 1.6 Quarts

Oil Above 40°F ............. SAE 30

0°F - 40°F ............... SAE 5W-30 orl0W-30

GENERAL RECOMMENDATIONS

The pressure washer's warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

"Maintenance Schedule" chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check water inlet screen for damage.

• Check high pressure hose for leaks.

• Check chemical filters for damage.

• Check spray gun and nozzle extension assembly

for leaks.

• Purge pump of air and contaminants.

PRESSURE WASHER

MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it istorn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

_ ANGER: Never repair a high pressure hose.

Replace with hose that exceeds the maximum

pressure rating of your pressure washer.

Check Gun and Nozzle Extension

Examine hose connection to spray gun and make sure

it is secure. Test trigger by pressing it and making

sure it springs back into place when you release it. Put

safety latch in UP position and test trigger. You should

not be able to press trigger. Replace spray gun

immediately if it fails any of these tests.

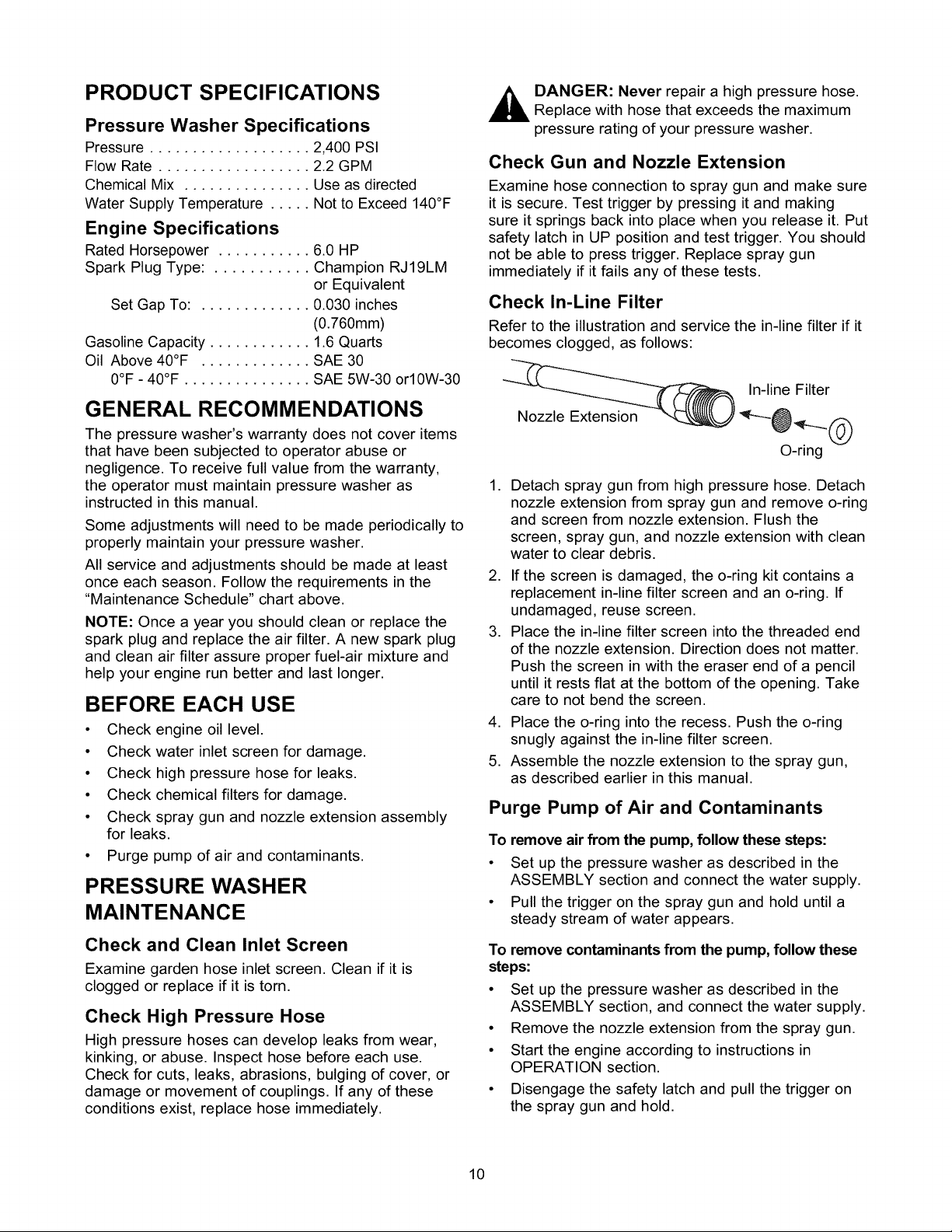

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes clogged, as follows:

In-line Filter

Nozzle Extension

O-ring

1. Detach spray gun from high pressure hose. Detach

nozzle extension from spray gun and remove o-ring

and screen from nozzle extension. Flush the

screen, spray gun, and nozzle extension with clean

water to clear debris.

2. If the screen is damaged, the o-ring kit contains a

replacement in-line filter screen and an o-ring. If

undamaged, reuse screen.

3. Place the in-line filter screen into the threaded end

of the nozzle extension. Direction does not matter.

Push the screen in with the eraser end of a pencil

until it rests flat at the bottom of the opening. Take

care to not bend the screen.

4. Place the o-ring into the recess. Push the o-ring

snugly against the in-line filter screen.

5. Assemble the nozzle extension to the spray gun,

as described earlier in this manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps:

• Set up the pressure washer as described in the

ASSEMBLY section and connect the water supply.

• Pull the trigger on the spray gun and hold until a

steady stream of water appears.

To remove contaminants from the pump, follow these

steps:

• Set up the pressure washer as described in the

ASSEMBLY section, and connect the water supply.

• Remove the nozzle extension from the spray gun.

• Start the engine according to instructions in

OPERATION section.

• Disengage the safety latch and pull the trigger on

the spray gun and hold.

10

• Whenthewatersupplyissteadyandconstant,

engagethesafetylatchandrefastenthenozzle

extension.

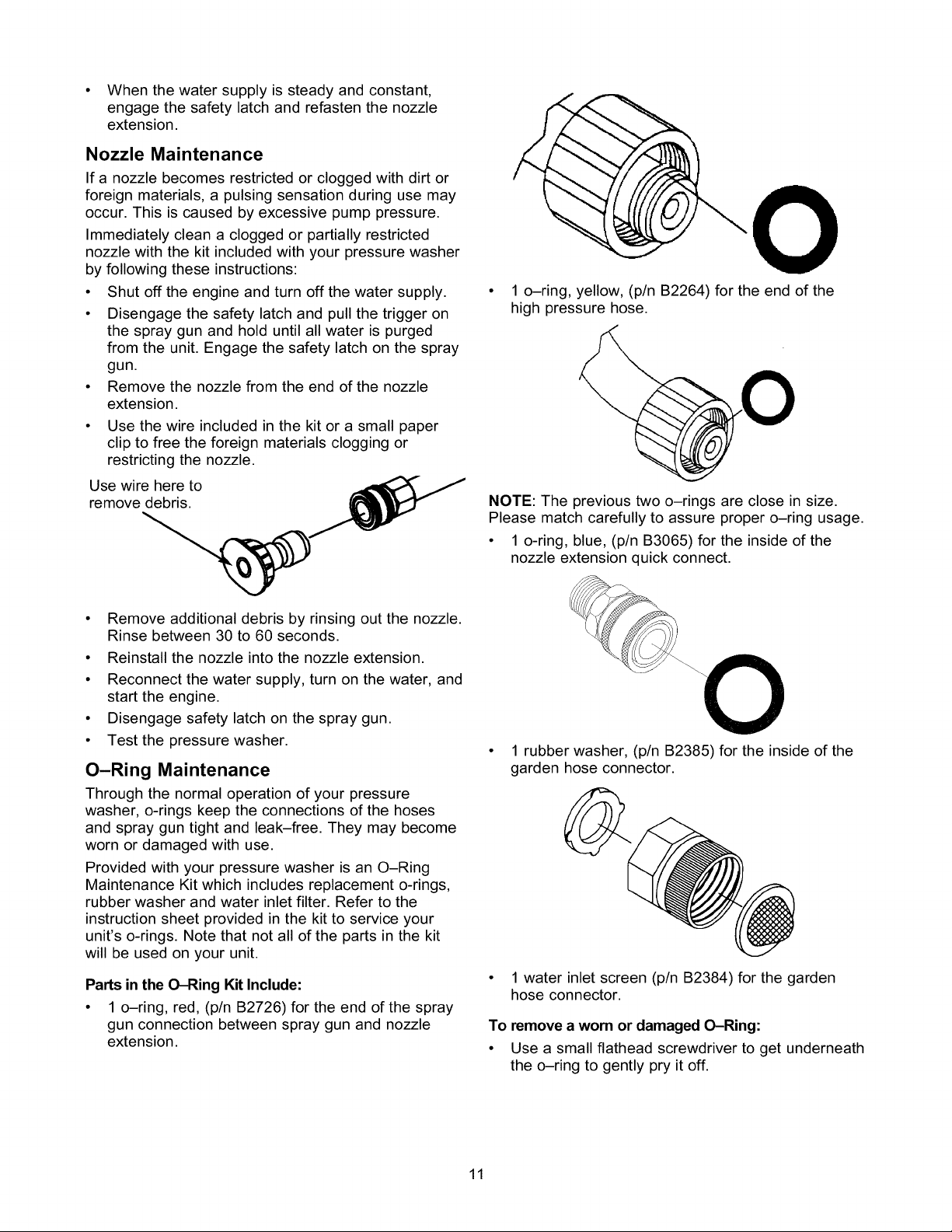

Nozzle Maintenance

If a nozzle becomes restricted or clogged with dirt or

foreign materials, a pulsing sensation during use may

occur. This is caused by excessive pump pressure.

Immediately clean a clogged or partially restricted

nozzle with the kit included with your pressure washer

by following these instructions:

• Shut off the engine and turn off the water supply.

• Disengage the safety latch and pull the trigger on

the spray gun and hold until all water is purged

from the unit. Engage the safety latch on the spray

gun.

• Remove the nozzle from the end of the nozzle

extension.

• Use the wire included in the kit or a small paper

clip to free the foreign materials clogging or

restricting the nozzle.

Use wire here to ,.JL__

remove debris. _ NOTE: The previous two o-rings are close in size.

__ Please match carefully to assure proper o-ring usage.

1 o-ring, yellow, (p/n B2264) for the end of the

high pressure hose.

1 o-ring, blue, (p/n B3065) for the inside of the

nozzle extension quick connect.

O

• Remove additional debris by rinsing out the nozzle.

Rinse between 30 to 60 seconds.

• Reinstall the nozzle into the nozzle extension.

• Reconnect the water supply, turn on the water, and

start the engine.

• Disengage safety latch on the spray gun.

• Test the pressure washer.

O-Ring Maintenance

Through the normal operation of your pressure

washer, o-rings keep the connections of the hoses

and spray gun tight and leak-free. They may become

worn or damaged with use.

Provided with your pressure washer is an O-Ring

Maintenance Kit which includes replacement o-rings,

rubber washer and water inlet filter. Refer to the

instruction sheet provided in the kit to service your

unit's o-rings. Note that not all of the parts in the kit

will be used on your unit.

Parts in the O-Ring Kit Include:

• 1 o-ring, red, (p/n B2726) for the end of the spray

gun connection between spray gun and nozzle

extension.

1 rubber washer, (p/n B2385) for the inside of the

garden hose connector.

• 1 water inlet screen (p/n B2384) for the garden

hose connector.

To remove a worn or damaged O-Ring:

• Use a small flathead screwdriver to get underneath

the o-ring to gently pry it off.

11

ENGINE MAINTENANCE

Checking Oil Level

Oil level should be checked prior to each use or at

least every 5 hours of operation. Keep oil level

maintained.

Changing Oil

Change engine oil after the first 5 hours and every

50 hours or annually thereafter. If you are using your

pressure washer under extremely dirty or dusty

conditions, or in extremely hot weather, change oil

every 25 hours.

Change oil while engine is still warm from running, as

follows:

• Remove drain plug from the bottom of engine.

• Drain oil into a suitable container. When crankcase

is empty, replace drain plug in engine.

• Slowly pour oil into oil fill opening. Replace and

tighten dipstick, remove and check oil level. Oil

level should be at "Full" mark on dipstick. Do Not

overfill above that mark.

• When engine crankcase is filled to proper level,

install and tighten oil cap/dipstick.

• Wipe up any remaining oil.

Service Air Cleaner

Your engine will not run properly and may be

damaged if you run it with a dirty air cleaner.

Service the air cleaner once every 100 hours of

operation or once each year, whichever comes first.

Service more often ifoperating under dirty or dusty

conditions. Replacements are available at your local

Sears service center.

To service the air cleaner, follow these steps:

• Remove screws and lift cover.

• Carefully remove pre-cleaner and cartridge

assembly.

• After servicing pre-cleaner and cartridge, assemble

pre-cleaner on cartridge.

• Install pre-cleaner/cartridge in base.

• Place cover on air cleaner and tighten screws

securely to base.

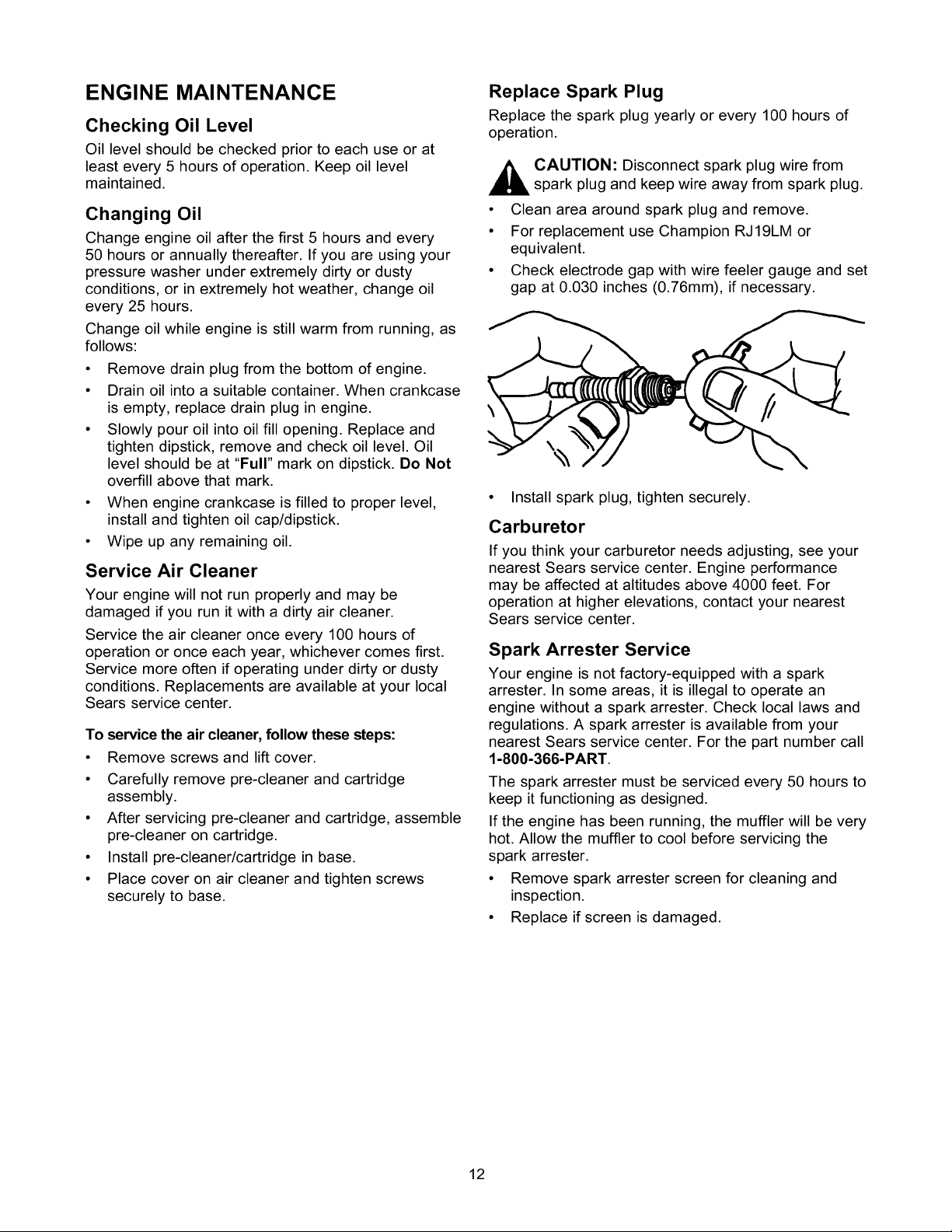

Replace Spark Plug

Replace the spark plug yearly or every 100 hours of

operation.

,_ CAUTION: Disconnect spark plug wire from

spark plug and keep wire away from spark plug.

• Clean area around spark plug and remove.

• For replacement use Champion RJ19LM or

equivalent.

• Check electrode gap with wire feeler gauge and set

gap at 0.030 inches (0.76mm), if necessary.

• Install spark plug, tighten securely.

Carburetor

If you think your carburetor needs adjusting, see your

nearest Sears service center. Engine performance

may be affected at altitudes above 4000 feet. For

operation at higher elevations, contact your nearest

Sears service center.

Spark Arrester Service

Your engine is not factory-equipped with a spark

arrester. In some areas, it is illegal to operate an

engine without a spark arrester. Check local laws and

regulations. A spark arrester is available from your

nearest Sears service center. For the part number call

1-800-366-PART.

The spark arrester must be serviced every 50 hours to

keep it functioning as designed.

If the engine has been running, the muffler will be very

hot. Allow the muffler to cool before servicing the

spark arrester.

• Remove spark arrester screen for cleaning and

inspection.

• Replace if screen is damaged.

12

Loading...

Loading...