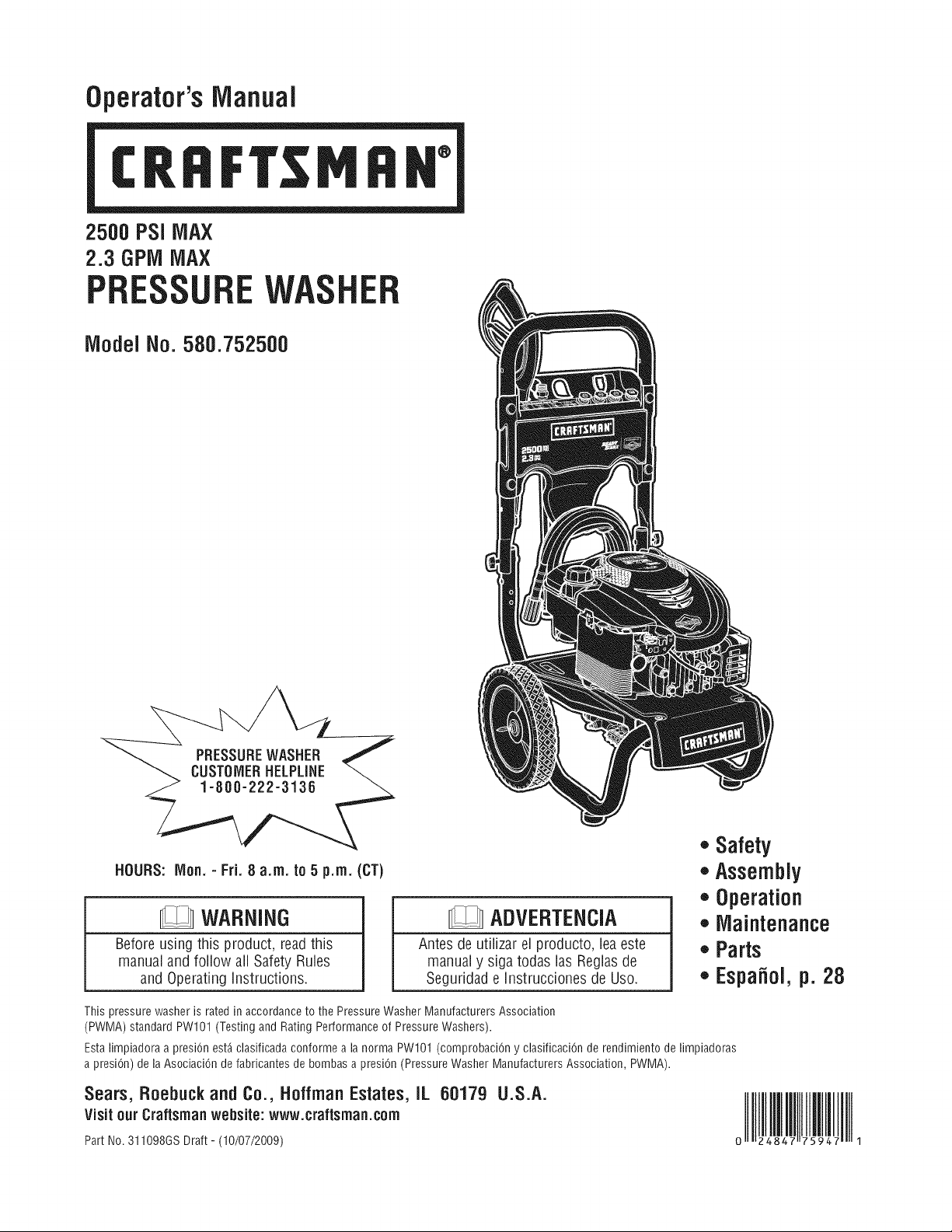

Craftsman 580752500 Owner’s Manual

Operator'sIVianual

2500 PSi iViAX

2.3 GPiViMAX

iViodelNo. 580.752500

®

,, Safety

HOURS: IVlon.- Fri. Ba.m. to 5 p.m. (CT)

,, Assembly

,, Operation

WARNING

Beforeusing this product, readthis

manualand follow all Safety Rules

and Operatinginstructions.

This pressure washer is rated in accordance to the Pressure Washer Manufacturers Association

(PWMA) standard PWl01 (Testing and Rating Performance of Pressure Washers).

Esta limpiadora a presiOnest_ clasificada conforme a la norrna PWl01 (comprobaciOn y clasificaciOn de rendimiento de limpiadoras

a presiOn) de la AsociaciOn defabricantes de bombas a presiOn (Pressure Washer Manufacturers Association, PWMA).

Sears, Roebuckand Co., HoffrnanEstates,IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

Part No. 311098GS Draft - (10/07/2009)

Antes de utilizar el producto, leaeste

manualy siga todas las Reglasde

Seguridad e Instrucciones de Uso.

ADVERTENCIA

,,iVlaintenance

,, Parts

,, Espafiol,p. 28

WARRANTY .......................................... 2

REPAIRPROTECTIONAGREEMENT........................ 2

SAFETYRULES...................................... 3-5

FEATURESAND CONTROLS.............................. 6

ASSEMBLY......................................... 7-9

OPERATION....................................... 10-13

SPECIFICATIONS..................................... 14

MAINTENANCE.................................... 15-18

STORAGE........................................... 19

TROUBLESHOOTING.................................. 20

REPLACEMENTPARTS.............................. 21-25

EMISSIONCONTROLWARRANTY..................... 26-27

ESPANOL......................................... 28-51

HOWTO ORDERPARTS........................ BACKPAGE

CRAFTSMANLIMITEDWARRANTY

If this Craftsmanproduct fails due to a defect in material or workmanship within two years from the date of purchase, return it

to anySearsstore, Sears Parts & RepairService Center,or other Craftsmanoutlet inthe United Statesfor free repair (or

replacementif repair proves impossible).

This warranty appliesfor only 90 days from the dateof purchase if this product is ever usedfor commercial or rental

purposes.

Thiswarranty coversOHLYdefects in material andworkmanship.Searswill HOTpayfor:

* Expendableitems that can wear out from normal usewithin the warranty period, such as spray guns, hoses, nozzle

extensions, nozzles,filters and spark plugs.

, Repairsnecessarybecauseof accident, or failure to operateor maintainthe product according to all supplied instructions.

, Preventivemaintenance,or repairs necessarydue to improper fuel mixture, contaminated or stalefuel.

This warranty givesyou specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Congratulations on making a smart purchase.

Your new Craftsman® product is designed and manufactured

for years of dependableoperation. But like all products, it

may require repair from time to time. That's when havinga

Repair ProtectionAgreement can saveyou money and

aggravation.

Here'swhat the RepairProtection Agreement*includes:

* Expert service by our 10,000 professional repair

specialists

, Unlimited service and no chargefor parts and labor on

all covered repairs

, Product replacementup to $1500 if your covered

product can't be fixed

, Discountof 10% from regular priceof serviceand related

installed parts not covered by the agreement;also, 10%

off regular price of preventivemaintenancecheck

* Fasthelp by phone-we call it Rapid Resolution- phone

support from aSears representative.Think of us as a

"talking owner's manual".

Onceyou purchasethe Repair Protection Agreement, a

simple phone carlis all it takes for you to schedule service.

You can call anytimeday or night, or schedule a service

appointment online.

The Repair ProtectionAgreementis a risk-free purchase, if

you cancelfor any reasonduring the product warranty

period,we will provide a full refund. Or, a prorated refund

anytime after the product warranty period expires. Purchase

your RepairProtectionAgreement today!

Some limitations and exclusions apply. Forprices and

additional informationin the U.S.A. caii 1-800-827-6655.

* Coverage in Canada varies on some items. Forfuji

details, caii Sears Canada at 1-800-361-6665.

SearsInstallation Service

ForSears professional installation of home appliances,

garagedoor openers, water heaters,and other major home

items, in the U.S.A.or Canadacall 1-800-4-MY-HOME®.

© 2010

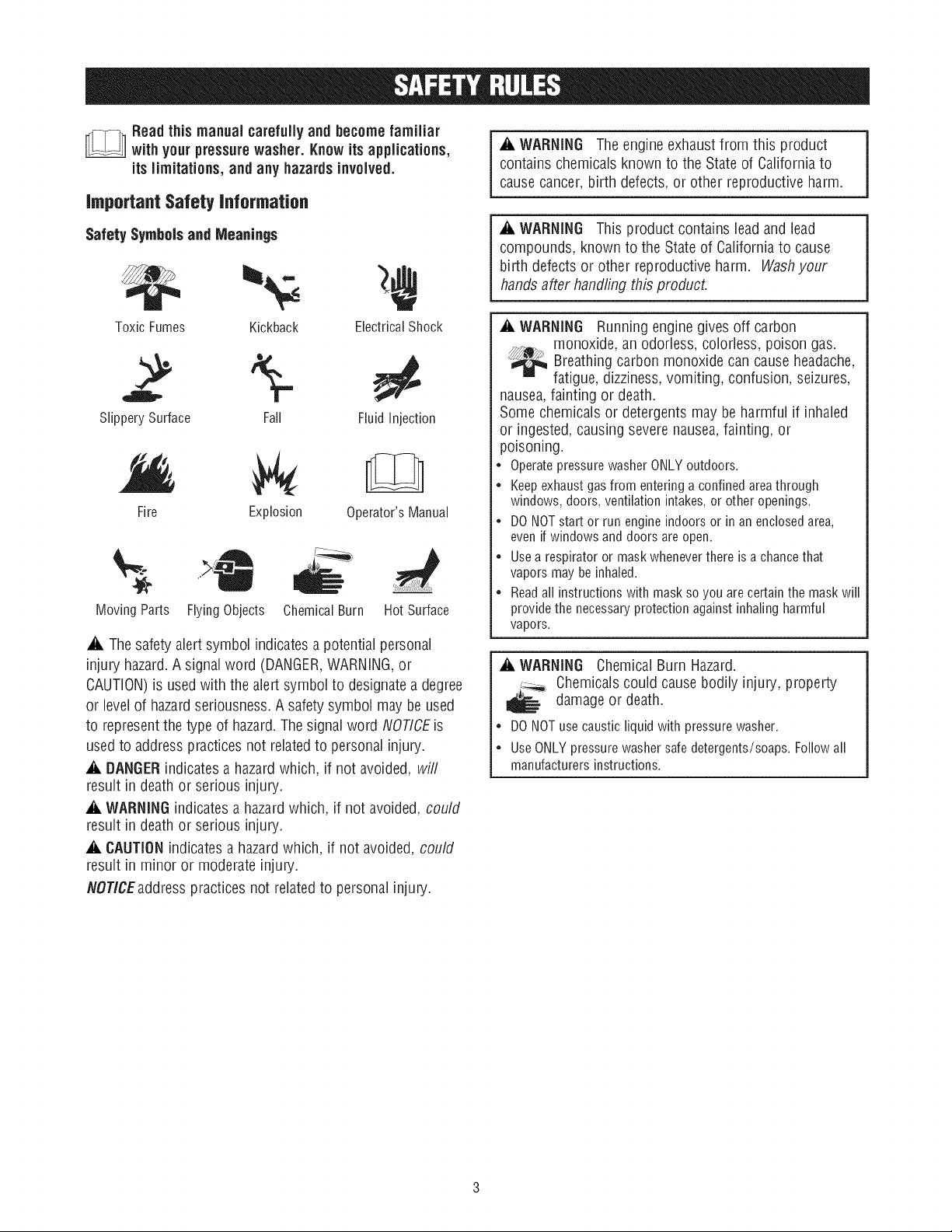

Readthis manual carefully and becomefamiliar

with yourpressurewasher. Knowits applications,

itslimitations, and any hazardsinvolved.

important Safety I.formation

Safety Symbolsand Meanings

_i, WARNING Theengine exhaustfrom this product

contains chemicals known to the Stateof California to

cause cancer,birth defects, or other reproductive harm.

_i, WARNING This product contains lead and lead

compounds, known to the State of Californiato cause

birth defects or other reproductive harm. Washyour

handsafter handling this product.

ToxicFumes Kickback

ElectricalShock

M

SlipperySurface Fall

Fire

Explosion Operator'sManual

ilb

MovingParts

,A The safety alert symbol indicatesa potential personal

injury hazard.A signalword (DANGER,WARNING,or

CAUTION)is usedwith thealert symbol to designatea degree

or level of hazardseriousness. A safety symbol may be used

to representthe type of hazard.The signal word NOTICEis

usedto addresspractices not relatedto personalinjury.

_i, DANGERindicatesa hazardwhich, if not avoided, will

result in deathor serious injury.

_i, WARNINGindicates a hazardwhich, if not avoided, could

result in deathor serious injury.

_i, CAUTIONindicates a hazardwhich, if not avoided, could

result in minor or moderate injury.

NOTICEaddresspractices not related to personal injury.

Flying Objects Hot Surface

ChemicalBurn

FluidInjection

_i, WARNING Runningengine gives off carbon

monoxide, an odorless, colorless, poison gas.

_ Breathingcarbon monoxide headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

Some chemicals or detergentsmay be harmful if inhaled

or ingested, causing severenausea,fainting, or

poisoning.

• OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringa confinedareathrough

windows,doors,ventilationintakes,or otheropenings.

• DONOTstartorrun engineindoorsorin anenclosedarea,

evenifwindowsanddoorsareopen.

• Usearespiratoror maskwheneverthereisa chancethat

vaporsmaybeinhaled.

• Readall instructionswith masksoyouarecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

_i, WARNING ChemicalBurn Hazard.

.... Chemicalscould cause bodily injury, property

_: damage or death.

• DONOTusecausticliquidwith pressurewasher.

• UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

can cause

A. WARNING Starter cord kickback(rapid retraction) can

result in bodily injury. Kickbackwill pull hand and

,_arm toward enginefaster than you can let go.

Broken bones,fractures, bruises, or sprains

could result.

• NEVERpullstarter cord without first relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance isfelt

andthen pull rapidly to avoid kickback.

• After each starting attempt, where enginefails to run, always

point spray gun in safe direction, press red button and squeeze

spray guntrigger to releasehigh pressure.

• Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

A. WARNING Riskof electrocution.

"_.dh Contactwith power source can causeelectric

shock or burn.

• NEVERspraynearpowersource.

A. WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

• DONOTallow CHILDRENto operate pressure washer.

• NEVERrepairhigh pressure hose. Replaceit.

• NEVERrepairleaking connections with sealant of any kind.

Replaceo-ring or seal.

• NEVERconnect high pressure hoseto nozzleextension.

• Keephigh pressure hose connectedto pump and spraygun

while system is pressurized.

• ALWAYS point spray gun in safedirection, pressred button

andsqueezespray gun trigger to releasehigh pressure, every

time you stop engine.

• NEVERaim spray gun at people,animals, or plants.

• DO NOTsecure spraygun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

• NEVERuseaspray gun which does not have a trigger lock or

trigger guard in placeand in working order.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

A. WARNING Fuel and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns

or death.

WHENADDING OR DRAININGFUEL

* Turn pressurewasher OFFand let it cool at least2 minutes

before removing fuel cap. Loosen capslowly to relievepressure

in tank.

. Fill or drain fuel tank outdoors.

. DONOToverfill tank. Allow spacefor fuel expansion.

. Iffuel spills, wait until it evaporates beforestarting engine.

. Keepfuel away from sparks, open flames, pilot lights, heat,and

other ignition sources.

. DONOTlight a cigaretteor smoke.

WHENSTARTINGEQUIPMENT

* Ensurespark plug, muffler,fuel cap,and air cleanerarein place.

* DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPMENT

* DONOTtip engine or equipmentat angle which causes fuel to

spill.

* DONOTsprayflammable liquids.

WHENTRANSPORTING,MOVINGOR REPAIRINGEQUIPMENT

. Transport/move/repair with fuel tank EMPTYor with fuel shutoff

valveOFF.

. DONOTtip engine or equipment at angle which causes fuel to

spill.

. Disconnectspark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUELIN TANK

* Store awayfrom furnaces, stoves, water heaters,clothes

dryers, or other appliancesthat have pilot light or other ignition

source becausethey can ignitefuel vapors.

A. WARNING Contact with muffler area can result in

serious burns.

,_ _ Exhaust heat/gases can ignite

fuel tank causing a fire.

• DO NOTtouch hot parts and AVOIDhot exhaust gases.

• Allow equipment to cool beforetouching.

• Keepat least5 feet (152 cm) of clearanceon all sides of

pressure washer including overhead.

• It is aviolation of California Public Resource Code,Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust

system is equipped with a spark arrester, as defined in Section

4442, maintained in effective working order. Other states or

federaljurisdictions may have similar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain aspark arrester designed for the exhaust system

installed on this engine.

• Replacement parts must bethe sameand installed in the same

position as the original parts.

combustibles, structures or damage

_i, WARNING Use of pressure washer can create

_' Kickback from spray gun can cause you

• Operatepressurewasher from a stable surface.

• Thecleaning areashould have adequateslopes and drainageto

reducethe possibility of a fall dueto slippery surfaces.

• Beextremely careful if you must usethe pressurewasherfrom

a ladder,scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

A, WARNING Unintentional sparking can result in fire or

WHENADJUSTINGOR MAKING REPAIRSTOYOURPRESSURE

WASHER

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Use approved spark plug tester.

• DONOTcheckfor spark with spark plug removed.

puddles and slippery surfaces.

to fall.

_¢ electric shock.

A, WARNING Starter and other rotating partscan

entanglehands, hair, clothing, or accessories.

. NEVERoperatepressurewasherwithoutprotectivehousingor

covers.

. DONOTwearlooseclothing,jewelryor anythingthat maybe

caughtin thestarteror otherrotatingparts.

* Tieuplonghairandremovejewelry.

A, WARNING Riskof eyeinjury.

Spray cansplash back or propel objects.

• Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSI Z87.1 when using or in vicinity of

this equipment.

• NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

NOTICE High pressure spray may damage fragile items

including glass.

• DONOTpointspraygunat glasswhenusingred(0°)spraytip.

= NEVERaimspraygunatplants.

NOTICE Improper treatment of pressure washer can

damage it and shorten its life.

• If you have questions about intended use,ask dealer or contact

Sears.

• NEVERoperate units with broken or missing parts,or without

protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• DONOTtamper with governed speed.

• DONOToperate pressure washer above rated pressure.

• DONOTmodify pressure washer in any way.

• Before starting pressure washer in cold weather, check all parts

of the equipment to besure ice has not formed there.

• NEVERmove machine by pulling on hoses. Use handle provided

on unit.

• Checkfuel system for leaks or signs of deterioration, such as

chafed or spongy hose,loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure washer.

• This equipment is designedto be used with Searsauthorized parts

ONLY.If equipment is used with parts that DONOTcomply with

minimum specifications, user assumesall risksand liabilities.

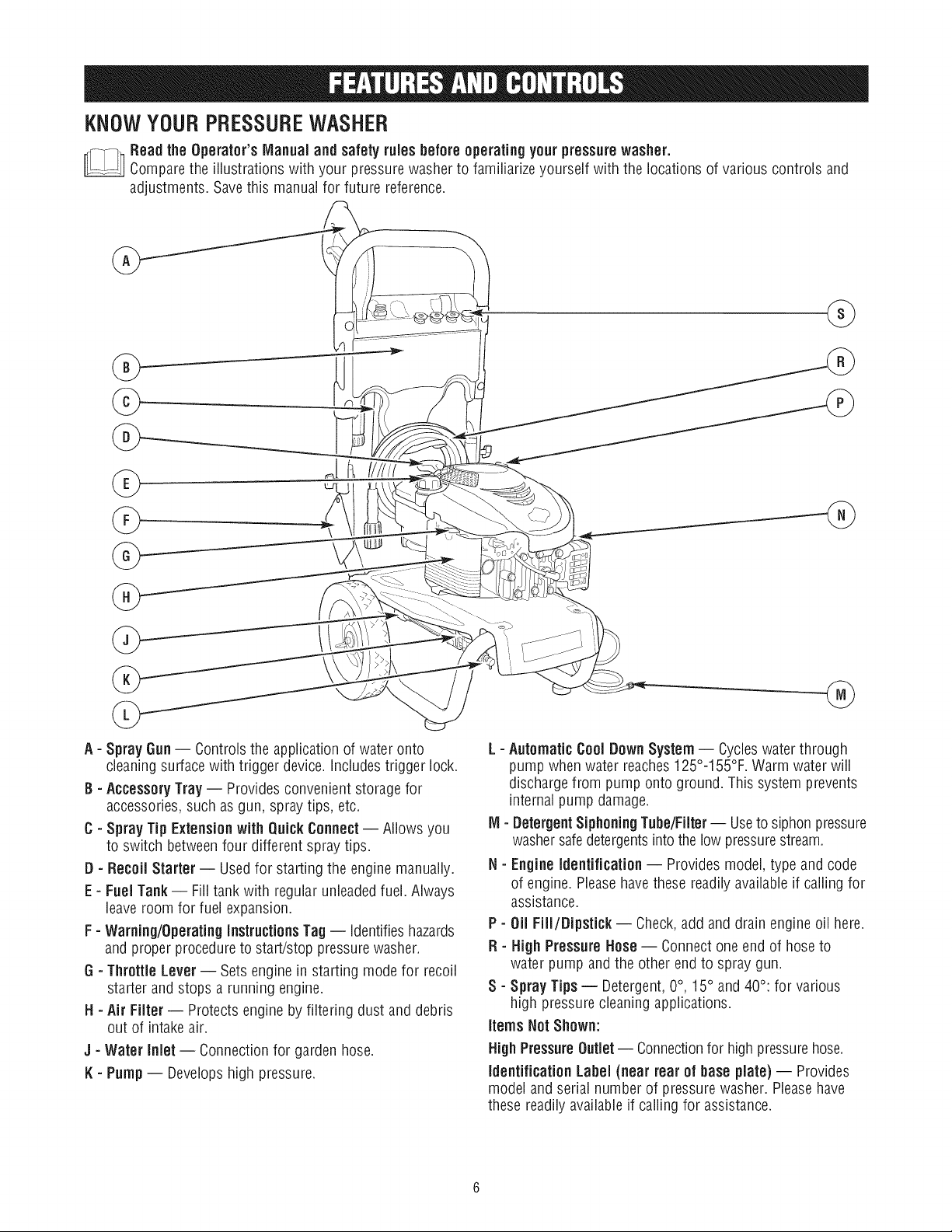

KNOWYOURPRESSUREWASHER

Readthe Operator's Manual and safetyrules before operating your pressure washer.

Comparethe illustrations with your pressurewasherto familiarize yourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

A - Spray Gun-- Controlsthe application of water onto

cleaningsurface with trigger device, includes trigger lock.

B- Accessory Tray -- Provides convenientstorage for

accessories, such as gun, spray tips, etc.

C- Spray Tip Extension with QuickConnect -- Allows you

to switch betweenfour different spray tips.

D - Recoil Starter -- Usedfor starting the engine manually.

E - FuelTank -- Fill tank with regular unleadedfuel. Always

leaveroom for fuel expansion.

F- Warning/OperatingInstructions Tag -- identifies hazards

and proper procedureto start/stop pressurewasher.

G - Throttle Lever-- Sets engine in starting mode for recoil

starter and stops a running engine.

H - Air Filter-- Protects engine by filtering dust and debris

out of intake air.

J - Water Inlet -- Connectionfor garden hose.

I( - Pump-- Developshigh pressure.

L=AutomaticCool DownSystem-- Cycleswater through

pump when water reaches125°-155°F.Warm water wiii

dischargefrom pump onto ground. This system prevents

internal pump damage.

IVl- DetergentSiphoning Tube/Filter-- Useto siphon pressure

washersafedetergentsinto thelow pressurestream.

N- EngineIdentification -- Provides model, type and code

of engine. Pleasehavethese readilyavailable if calling for

assistance.

P - Oil Fill/Dipstick -- Check,add and drain engine oil here.

R- HighPressure Hose-- Connectone end of hoseto

water pump and the other end to spray gun.

S - Spray Tips-- Detergent,0°, 15° and 40°: for various

high pressure cleaningapplications.

items Not Shown:

HighPressure Outlet-- Connectionfor high pressurehose.

Identification Label (near rear of base plate) -- Provides

model and serial number of pressurewasher. Pleasehave

these readily availableif calling for assistance.

Your pressure washer requires some assembly and is ready

for useonly after it has been properly servicedwith the

recommendedoil andfuel.

If you haveany problemswith theassemblyof your

pressurewasher, pleasecall the pressurewasher helpline

at 1=800-222-3136.

UNPACKTHEPRESSUREWASHER

1. Removeeverything from carton except pressurewasher.

2. Opencarton completely by cutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

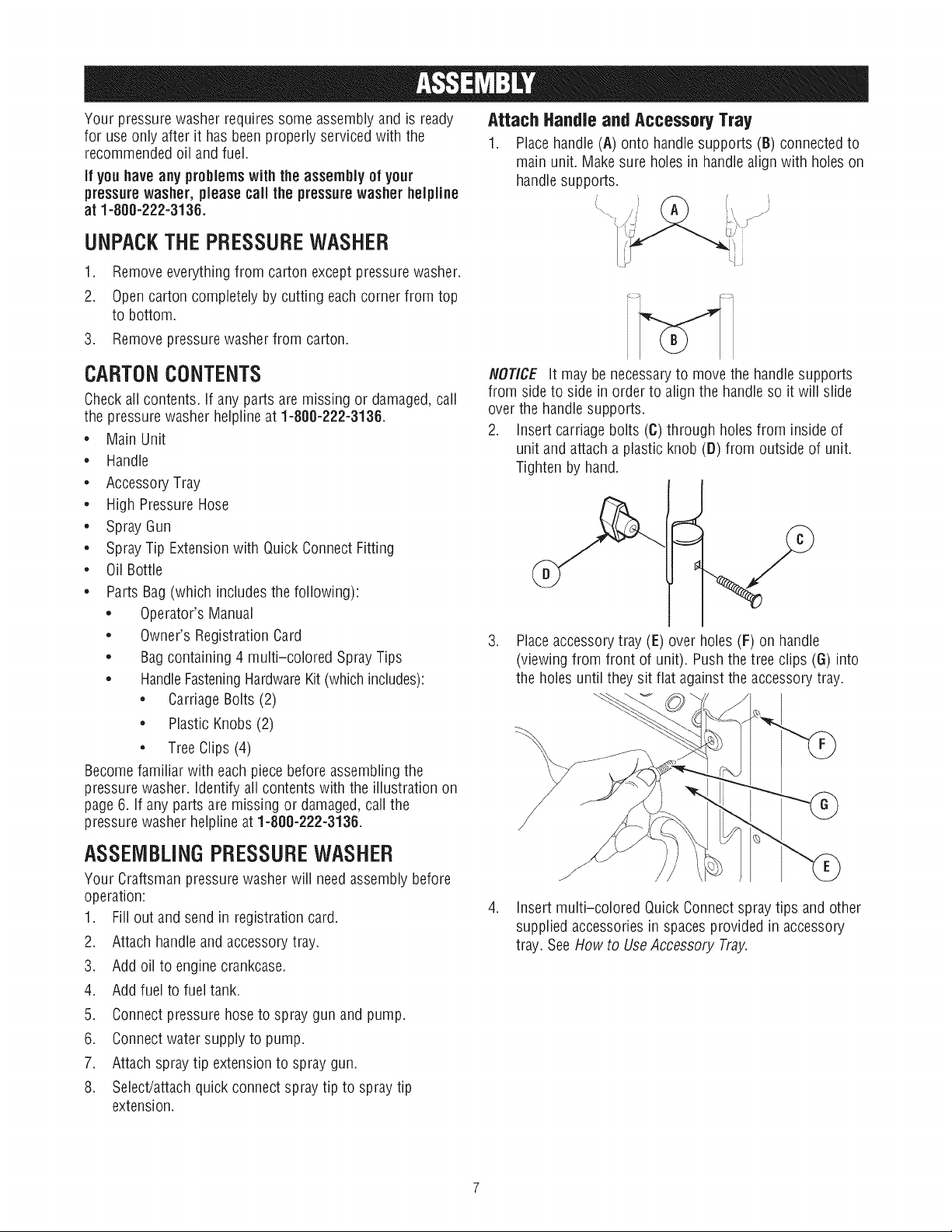

Attach Handle and Accessory Tray

1. Placehandle(A) onto handle supports (B) connectedto

main unit. Make sure holes in handlealign with holes on

handlesupports.

i

-\ J

CARTONCONTENTS

Checkall contents. If anyparts are missing or damaged,call

the pressure washer helplineat 1-800-222-3136.

* Main Unit

* Handle

* AccessoryTray

* High PressureHose

* Spray Gun

* SprayTip Extensionwith Quick ConnectFitting

* Oil Bottle

* Parts Bag(which includes the following):

* Operator's Manual

* Owner's Registration Card

* Bag containing 4 multi-colored Spray Tips

* HandleFasteningHardwareKit (whichincludes):

* Carriage Bolts (2)

* Plastic Knobs (2)

* Tree Clips (4)

Becomefamiliar with eachpiece beforeassemblingthe

pressure washer, identify all contents with the illustration on

page 6. if any parts are missing or damaged, call the

pressure washer helpline at 1-800-222-3136.

NOTICE It may be necessaryto move the handlesupports

from side to side in order to align the handleso it will slide

overthe handlesupports.

2. insert carriage bolts (C) through holesfrom inside of

unit and attach a plastic knob (D) from outside of unit.

Tighten by hand.

3. Placeaccessory tray (E) over holes (F) on handle

(viewing from front of unit). Push the tree clips (G)into

the holes until they sit fiat against the accessory tray.

Y

ASSEMBLINGPRESSUREWASHER

Your Craftsman pressure washer will needassemblybefore

operation:

1. Fill out and sendin registration card.

2. Attach handle and accessory tray.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connectpressure hose to spray gun and pump.

6. Connectwater supply to pump.

7. Attach spray tip extensionto spray gun.

8. Select/attach quick connect spray tip to spray tip

extension.

4. insert multi-colored Quick Connect spray tips andother

supplied accessoriesin spacesprovided in accessory

tray. SeeHow to UseAccessory Tray.

AddEn!tine(Ill

1. Placepressure washer on a flat, levelsurface.

2. Cleanarea around oil fill andremove yellow oil fill

cap/dipstick.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE Improper treatment of pressure washer can

damage it and shorten its life.

• DO NOTattempt to crank or start the engine beforeit has been

properly servicedwith the recommended oil. This may result in an

enginefailure.

.

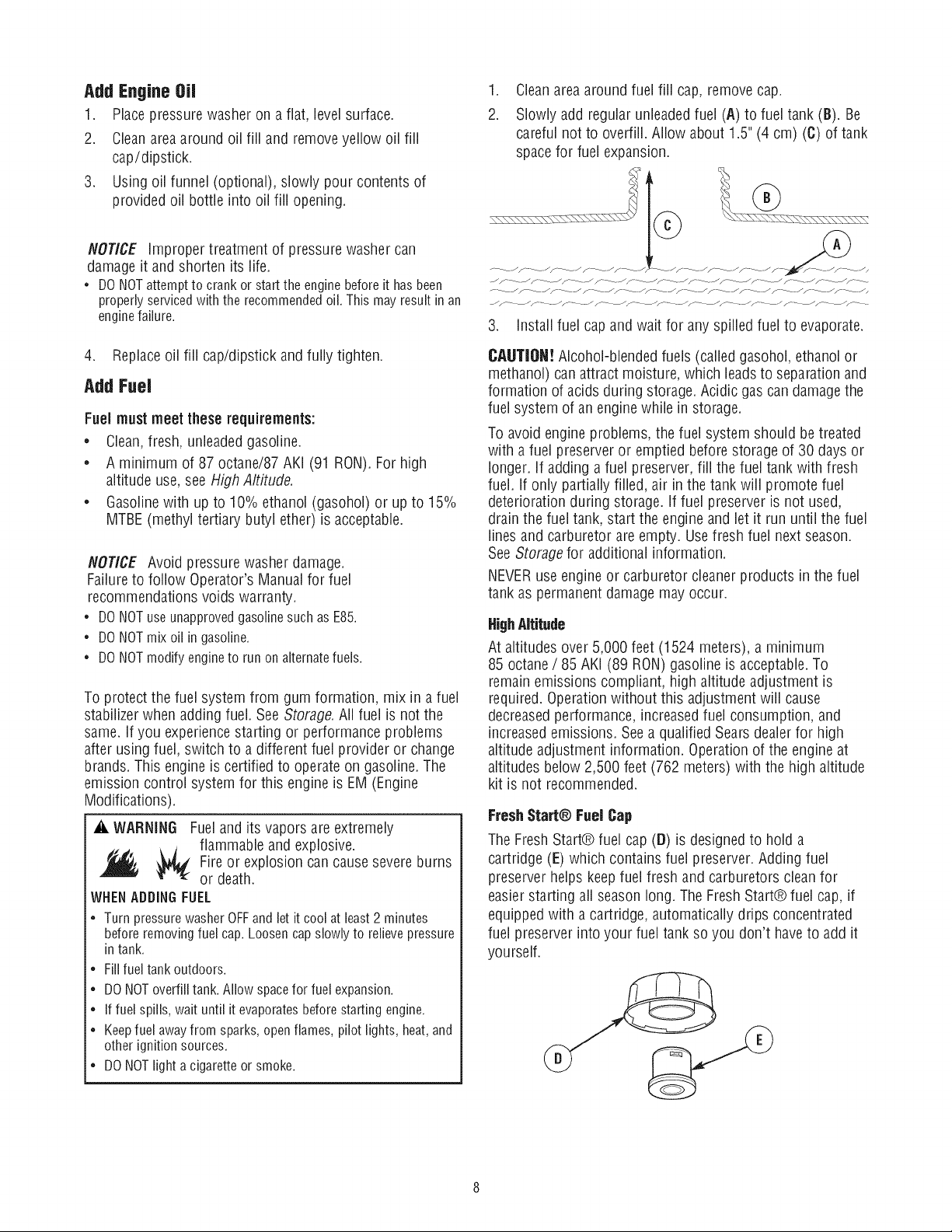

Cleanareaaround fuel fill cap, removecap.

2.

Slowly add regular unleadedfuel (A) to fuel tank (B). Be

careful not to overfill. Allow about 1.5" (4 cm) (O)of tank

spacefor fuel expansion.

/f __/_ _/__/f_ _/f-_ Jf _/F ¸__ _/f __._/F_/F_/f_ _/f _

3. Install fuel cap and wait for any spilledfuel to evaporate.

4. Replaceoil fill cap/dipstick and fully tighten.

Add Fuel

Fuel mustmeet theserequirements:

* Clean,fresh, unleaded gasoline.

* A minimum of 87 octane/87 AKI (91 RON).Forhigh

altitude use, seeHigh Altitude.

* Gasolinewith upto 10% ethanol (gasohol) or up to 15%

MTBE (methyl tertiary butyl ether) is acceptable.

NOTICE Avoid pressure washer damage.

Failureto follow Operator's Manualfor fuel

recommendations voids warranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoil in gasoline.

• DONOTmodifyengineto runonalternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizerwhen adding fuel. SeeStorage.All fuel is not the

same. If you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline. The

emission control system for this engine is EM (Engine

Modifications).

A. WARNING Fueland its vapors are extremely

flammable and explosive.

Fireor explosion can causesevere burns

or death.

WHEN ADDINGFUEL

• Turn pressure washer OFFand let it cool at least2 minutes

before removing fuel cap. Loosen capslowly to relieve pressure

in tank.

• Fill fuel tank outdoors.

• DONOToverfill tank. Allow spacefor fuel expansion.

• If fuel spills, wait until it evaporatesbefore starting engine.

• Keepfuel away from sparks, open flames, pilot lights, heat,and

other ignition sources.

• DONOTlight a cigarette or smoke.

(IAIITIOII! Alcohol-blendedfuels (called gasohol, ethanol or

methanol) canattract moisture, which leadsto separation and

formation of acids during storage.Acidic gas candamagethe

fuel system of an enginewhile in storage.

To avoid engine problems, the fuel system should be treated

with a fuel preserveror emptied beforestorage of 30 days or

longer. If adding a fuel preserver,fill the fuel tank with fresh

fuel. If only partially filled, air in the tank will promote fuel

deterioration during storage. If fuel preserver is not used,

drain the fuel tank, start the engine and let it run until the fuel

lines and carburetor are empty. Usefresh fuel next season.

SeeStoragefor additional information.

NEVERuse engine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

HighAltitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane / 85 AKI (89 RON)gasoline is acceptable.To

remainemissions compliant, high altitude adjustment is

required. Operationwithout this adjustment win cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seea qualified Searsdealerfor high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

FreshStart@ Fuel Cap

The FreshStart® fuel cap (D) is designedto hold a

cartridge (E) which contains fuel preserver.Adding fuel

preserver helps keepfuel fresh and carburetors clean for

easierstarting all season long. TheFresh Start® fuel cap, if

equippedwith a cartridge, automatically drips concentrated

fuel preserver into your fuel tank so you don't haveto add it

yourself.

NOTICE FreshStart® fuel preserver cartridge isavailableas

an optional accessory, retail item7133386. It is not included

with the pressurewasher. Contact the original equipment

manufacturer, retailer,or dealerto obtain a cartridge

designedfor the FreshStart® fuel cap installed on this

engine.

Readand follow all instructions andwarnings given in the

FreshStart® fuel preservercartridge package.

Connect Hose and Water Supply to Pump

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

• Damagetoequipmentresultingfrom failuretofollowthis

instructionwill voidwarranty.

4. Runwater through garden hosefor 30 seconds to flush

itof debris. Turn off water.

NOTICE DONOTsiphon standing water for the water

supply. Use ONLYcold water (less than 100°F).

5. Connectgarden hose(not to exceed50 feet in length) to

water inlet.Tighten by hand.

NOTICE Removeand discard the shipping caps from the

pump's high pressure outlet and water inlet before attaching

hoses.

1. Uncoil high pressure hose and attachone end of hoseto

baseof spray gun. Tighten by hand.

_, WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

• NEVERconnect high pressure hoseto nozzleextension.

• Keephigh pressure hose connectedto pump and spraygun

while system is pressurized.

• Always becertain spray gun, nozzlesand accessoriesare

correctly attached.

2. Attach other end of high pressure hoseto high pressure

outlet on pump. Tighten by hand.

NOTICE Using a OneWay Valve (vacuumbreakeror check

valve) at pump inlet can cause pump or inlet connector

damage.

• ThereMUSTbeat leasttenfeetof unrestrictedgardenhose

betweenthepressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

• Damageto equipment resulting from failure to follow this

instruction will void warranty.

A. WARNING Riskof eyeinjury.

Spray cansplash back or propel objects.

• Always wear indirect vented (chemical splash) safety goggles

markedto comply with ANSI Z87.1 when using or in vicinity of

this equipment.

• NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

6. Turn ONthe water, press red button (B) on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

.

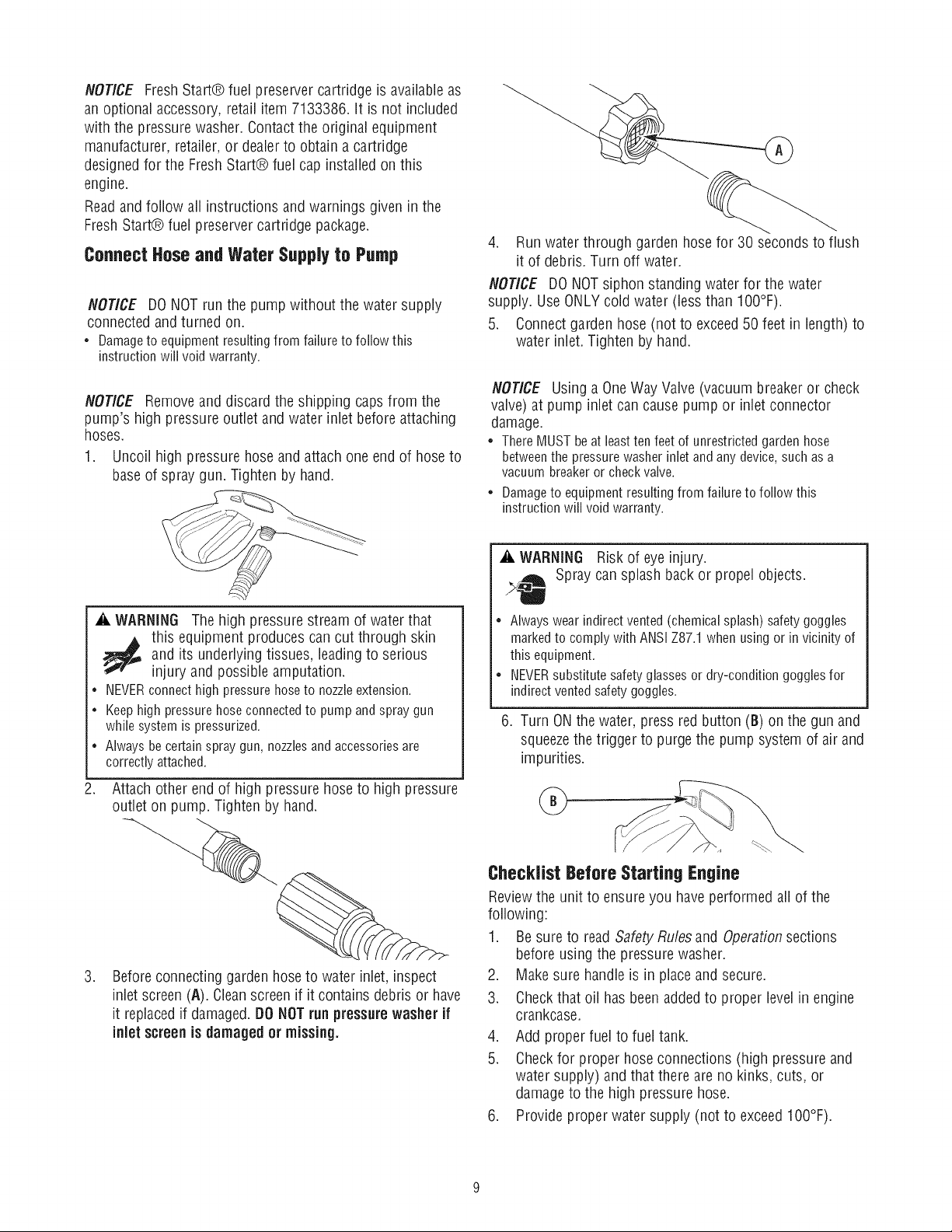

Beforeconnecting garden hose to water inlet, inspect

inlet screen (A). Cleanscreen if it contains debris or have

it replacedif damaged.DO NOTrunpressurewasher if

inlet screenisdamaged or missing.

Checklist Before Starting Engine

Reviewthe unit to ensureyou haveperformed all of the

following:

1. Besure to read SafetyRules and Operationsections

before using the pressure washer.

2. Makesure handleis in placeand secure.

3. Checkthat oil has beenadded to proper levelin engine

crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor proper hoseconnections (high pressureand

water supply) and that there are no kinks, cuts, or

damageto the high pressure hose.

6. Provide proper water supply (not to exceed100%).

HOWTO USEYOURPRESSUREWASHER

If you haveanyproblems operating your pressure washer,

pleasecall the pressure washer helpline at 1-800-222-3136.

PressureWasherLocation

PressureWasherCJearance

A. WARNING Exhaustheat/gases can ignite

combustibles, structures or damagefuel tank

causing a fire.

* Keepat least 5 ft. (152 cm) clearanceon all sides of pressure

washer including overhead.

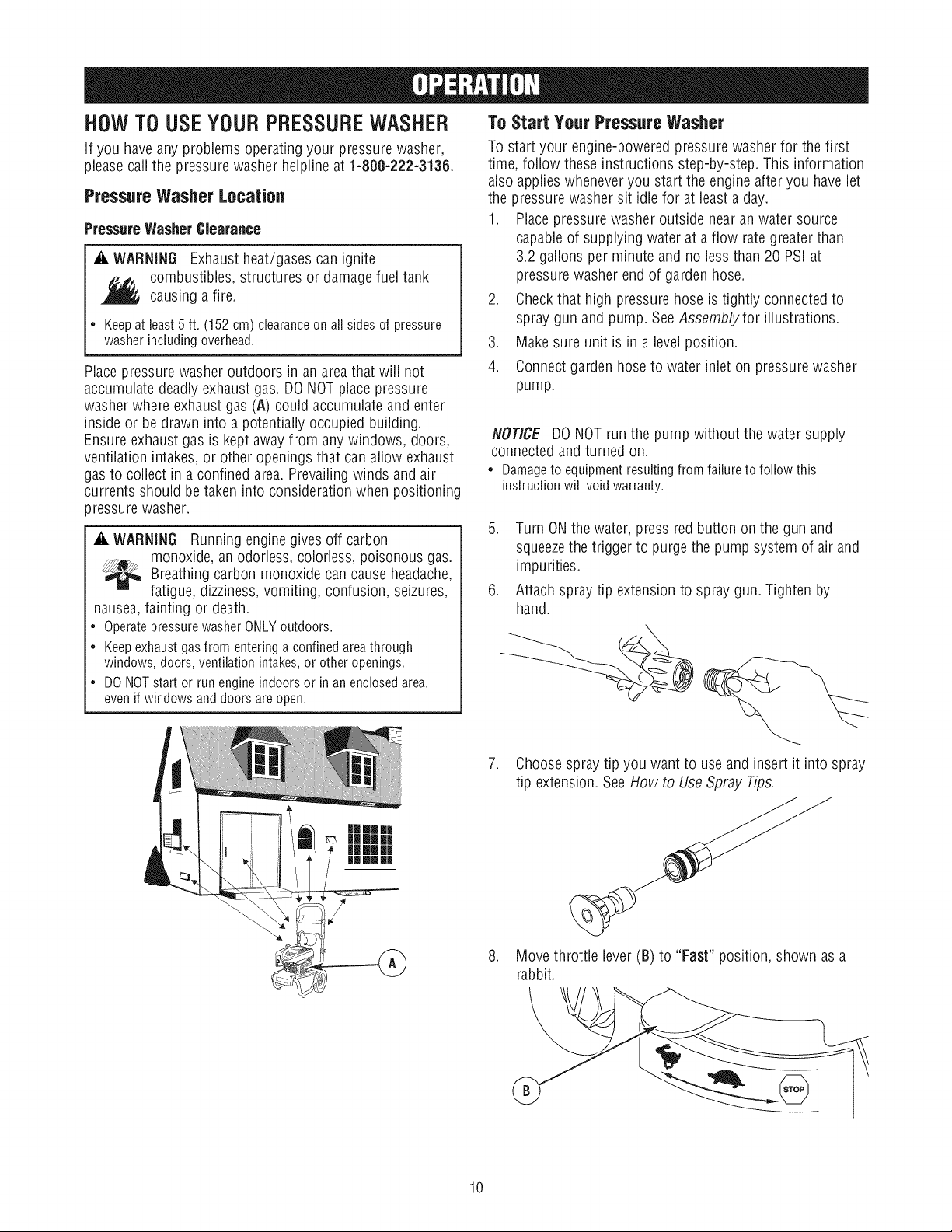

Placepressure washer outdoors in an area that will not

accumulate deadlyexhaustgas. DO NOTplacepressure

washer where exhaustgas (A) could accumulate and enter

inside or be drawn into a potentially occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventilation intakes, or other openings that can allow exhaust

gasto collect in aconfined area. Prevailing winds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

A. WARNING Running enginegives off carbon

monoxide,an odorless, colorless, poisonous gas.

_ Breathing cancause headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

• OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringa confinedareathrough

windows,doors,ventilationintakes,or otheropenings.

• DONOTstartorrunengineindoorsor in anenclosedarea,

evenifwindowsanddoorsareopen.

carbon monoxide

To StartYourPressureWasher

To start your engine-powered pressurewasher for the first

time, follow these instructions step-by-step. This information

alsoapplies wheneveryou start the engine after you havelet

the pressure washer sit idle for at leasta day.

1. Placepressurewasher outside nearan water source

capableof supplying water at a flow rate greaterthan

3.2 gallons per minute and no less than 20 PSi at

pressurewasher end of garden hose.

2. Checkthat high pressure hose is tightly connected to

spray gun and pump. SeeAssembly for illustrations.

3. Makesure unit is in a levelposition.

4. Connectgarden hoseto water inlet on pressurewasher

pump.

NOTICE DONOTrun the pump without the water supply

connectedand turned on.

• Damageto equipmentresultingfromfailuretofollowthis

instructionwill voidwarranty.

.

Turn ONthe water, press red button on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

.

Attach spray tip extension to spray gun. Tighten by

hand.

.

Choosespray tip you want to use and insert it into spray

tip extension. See How to Use Spray Tips.

.

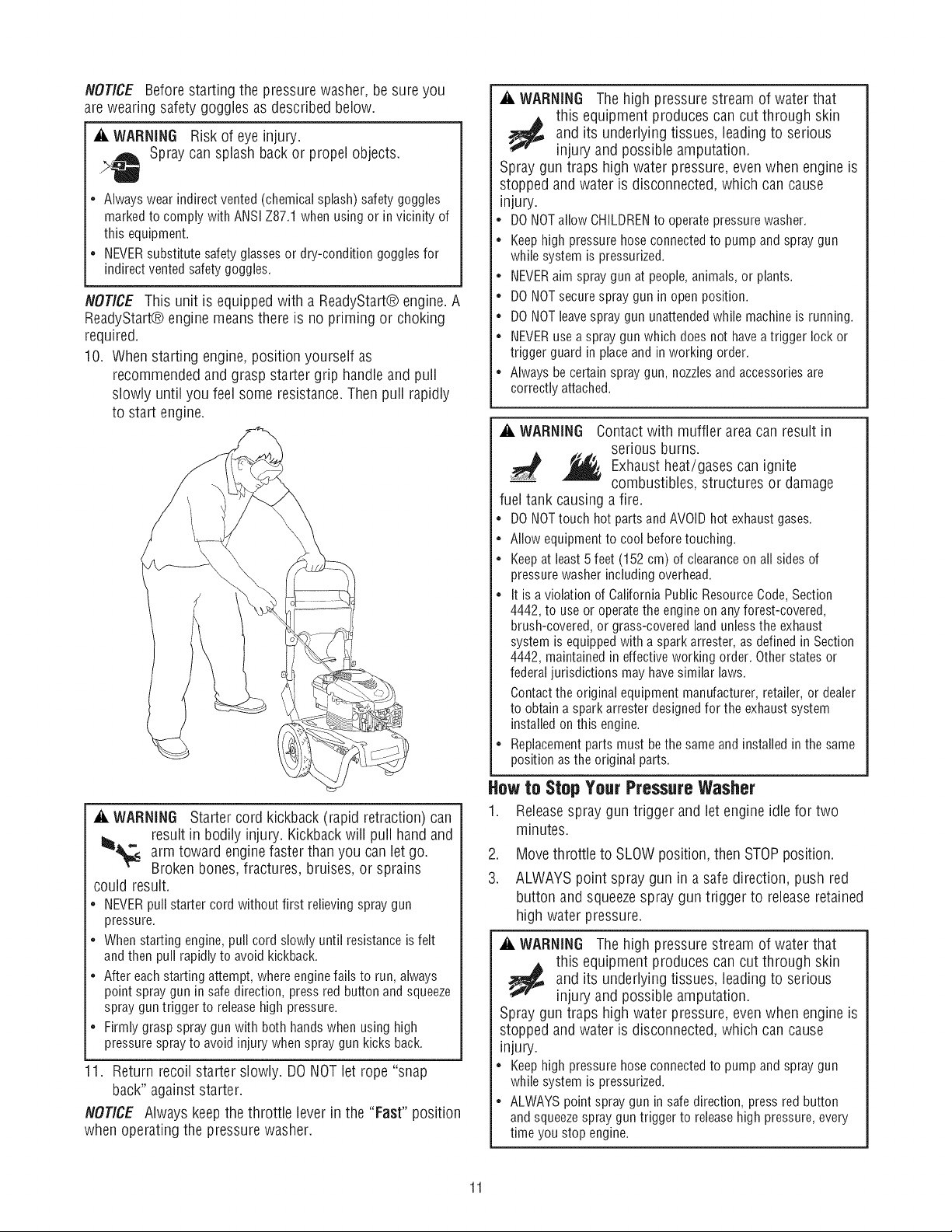

Move throttle lever (8) to "Fast" position, shown as a

rabbit.

10

NOTICE Beforestarting the pressure washer, be sureyou

are wearing safety goggles asdescribed below.

_i, WARNING Riskof eye injury.

Spraycan splash backor propelobjects.

• Always wear indirect vented (chemical splash) safetygoggles

markedto comply with ANSI Z87.1 when using or in vicinity of

this equipment.

• NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

NOTICE This unit is equipped with a ReadyStart® engine.A

ReadyStart® engine means there is no priming or choking

required.

10. When starting engine, position yourself as

recommendedand grasp starter grip handle and pull

slowly until you feel some resistance. Then pull rapidly

to start engine.

_i, WARNING The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leading to serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

• DONOTallow CHILDRENto operatepressure washer.

• Keephigh pressure hose connectedto pump and spraygun

while system is pressurized.

• NEVERaim spray gun at people,animals, or plants.

• DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

• NEVERuse a spray gun which does not have atrigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, nozzlesand accessoriesare

correctly attached.

_i, WARNING Contact with muffler area can result in

serious burns.

_ heat/gases can ignite

fuel tank causing a fire.

• DO NOTtouch hot parts and AVOIDhot exhaust gases.

• Allow equipment to cool beforetouching.

• Keepat least5 feet (152 cm) of clearanceon all sides of

pressure washer including overhead.

• It isa violation of California PuNic ResourceCode, Section

4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unlessthe exhaust

system is equippedwith a spark arrester,as defined in Section

4442, maintained in effective working order. Otherstates or

federaljurisdictions may havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a spark arrester designed for the exhaustsystem

installed onthis engine.

• Replacementparts must be the same and installed in the same

position asthe original parts.

Exhaust

combustibles, structures or damage

_i, WARNING Starter cord kickback (rapid retraction) can

result in bodily injury. Kickback will pull hand and

I1_ arm toward engine faster than you can let go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVERpullstarter cord without first relieving spray gun

pressure.

• When starting engine, pull cord slowly until resistance isfelt

andthen pull rapidly to avoid kickback.

• After each starting attempt, where enginefails to run, always

point spray gun in safe direction, press red button and squeeze

spray guntrigger to releasehigh pressure.

• Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

1. Return recoil starter slowly. DONOT let rope "snap

back" against starter.

NOTICE Always keepthe throttle leverin the "Fast" position

when operating the pressure washer.

Howto Stop Your Pressure Washer

1. Release spray gun trigger and let engine idle for two

minutes.

.

Movethrottle to SLOWposition, then STOPposition.

3.

ALWAYSpoint spray gun in a safe direction, push red

button and squeezespray gun trigger to release retained

high water pressure.

_i, WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure,even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

11

NOTICE Spraygun traps high water pressure,evenwhen

engine is stopped and water is disconnected.

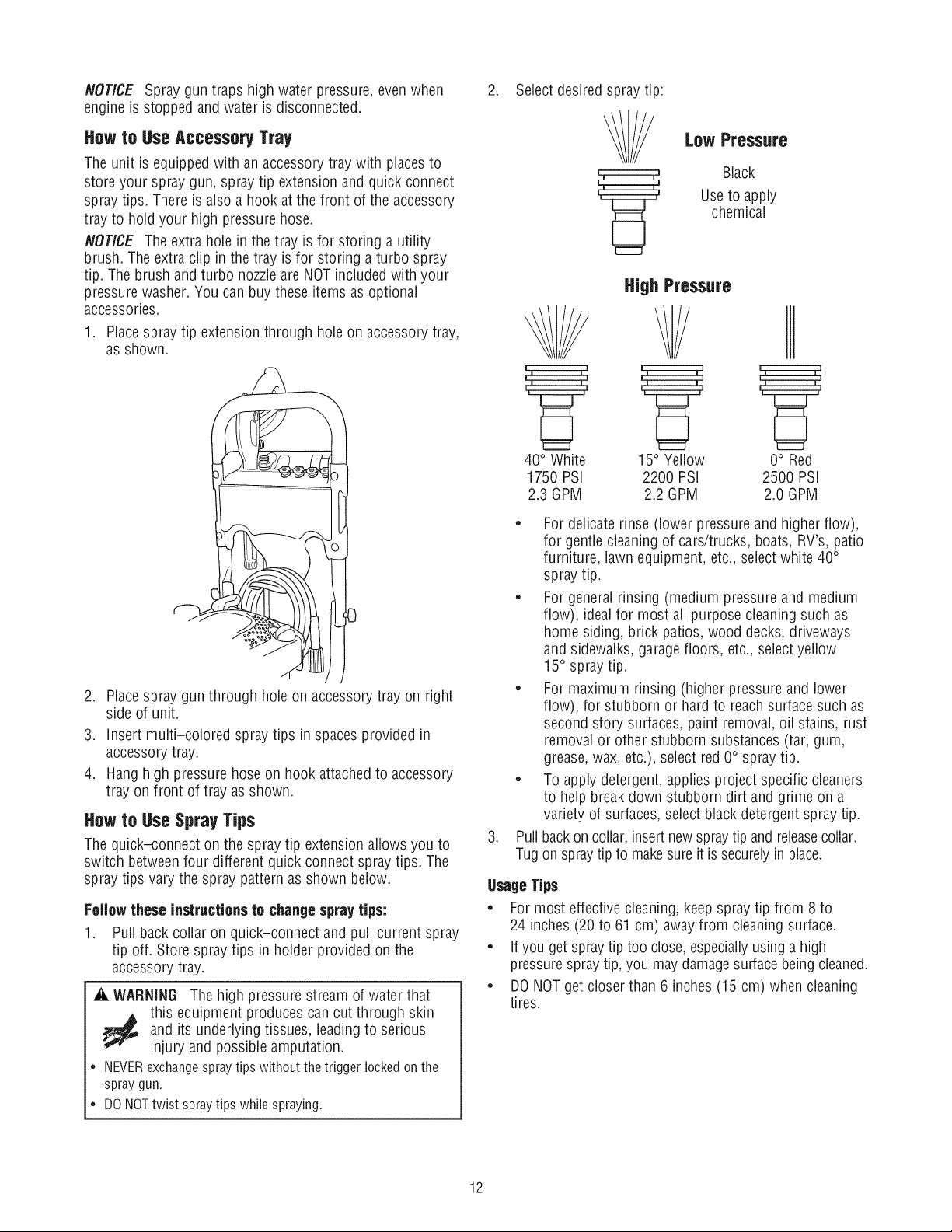

2. Select desired spray tip:

How to Use Accessory Tray

The unit is equipped with an accessorytray with places to

store your spray gun, spray tip extension and quick connect

spray tips. Thereis also a hook at the front of the accessory

tray to hold your high pressure hose.

NOTICE Theextra hole in the tray is for storing a utility

brush. The extra clip in the tray is for storing a turbo spray

tip. The brush and turbo nozzleare NOTincluded with your

pressure washer. You can buy these items as optional

accessories.

1. Placespraytip extensionthrough holeon accessory tray,

as shown.

2. Placespraygun through hole on accessorytray on right

side of unit.

3. insert multi-colored spray tips in spaces provided in

accessorytray.

4. Hanghigh pressure hoseon hook attached to accessory

tray on front of tray asshown.

How to Use Spray Tips

The quick-connect on the spray tip extension allows you to

switch betweenfour different quick connect spray tips. The

spray tips vary the spray pattern as shown below.

Foflowtheseinstructions to changespraytips:

1. Pull back collar on quick-connect andpull current spray

tip off. Storespray tips in holder provided on the

accessorytray.

_i, WARNING The high pressure stream of water that

Low Pressure

Black

Use to apply

chemical

High Pressure

m i

40° White

1750 PSi

2.3 GPM

* Fordelicate rinse (lower pressure and higher flow),

for gentle cleaning of cars/trucks, boats, RV's, patio

furniture, lawn equipment, etc., select white 40°

spray tip.

Forgeneral rinsing (medium pressure and medium

flow), idealfor most all purpose cleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garagefloors, etc.,selectyellow

15° spray tip.

Formaximum rinsing (higher pressure and lower

flow), for stubborn or hard to reach surface such as

second story surfaces, paint removal, oil stains, rust

removal or other stubborn substances (tar, gum,

grease, wax, etc.), select red 0° spray tip.

To apply detergent, appliesproject specific cleaners

to help breakdown stubborn dirt and grime on a

variety of surfaces, select black detergent spray tip.

.

Pullbackon collar, insert newspraytip andreleasecollar.

Tugon spraytip to makesure it is securelyin place.

UsageTips

* Formost effective cleaning, keep spray tip from 8 to

24 inches (20 to 61 cm) away from cleaning surface.

* If you getspray tip too close, especiallyusinga high

pressurespray tip, you maydamagesurface beingcleaned.

* DONOTget closer than 6 inches (15 cm) when cleaning

tires.

15° Yellow 0° Red

2200 PSi 2500 PSi

2.2 GPM 2.0 GPM

and its underlying tissues, leadingto serious

this equipment produces cancut through skin

injury and possible amputation.

• NEVERexchangespraytipswithoutthetriggerlockedonthe

spraygun.

• DONOTtwist spraytips whilespraying.

12

CleaningandApplyingDetergent

A WARNING Chemical Burn Hazard.

--- Chemicalscould cause bodily injury, property

_ damage or death.

• DONOTusecausticliquidwithpressurewasher.

• UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

Toapply detergent, follow thesesteps:

1. Reviewuse of spray tips.

2. Preparedetergent solution as required by job.

3. Placesmall filter end of detergent siphoning tube into

detergent container.

NOTICE Contact with the hot muffler can damage detergent

siphoning tube.

• When inserting the siphon into a detergent solution bottle, route

the tube so as to keepit from inadvertently contacting the hot

muffler.

NOTICE Make surethe filter is fully submergedin detergent

while applying detergent.

4. Make sure black spray tip is installed.

NOTICE Detergentcannot be applied with the high pressure

spray tips (White, Yellow or Red).

5. Make sure garden hose is connectedto water inlet.

Checkthat high pressure hoseis connected to spray gun

and pump. Turn on water.

NOTICE You must attach all hoses before you start the

engine.

• Starting the engine without all the hoses connected and without

the water turned ONwill damagethe pump.

• Damageto equipment resulting from failure to follow this

instruction will void warranty.

.

Start enginefollowing instructions How to Start Your

Pressure Washer.

7.

Apply detergent to a dry surface, starting at lower

portion of areato be washedand work upward, using

long, even,overlapping strokes.

8. Allow detergent to "soakin" for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surfacefrom drying. DO NOTallow detergentto dry on

(prevents streaking).

iMPORTANT:You must flush the detergent siphoning system

after each use by placing the filter into a bucket of clean

water, then run the pressure washer in low pressure for 1-2

minutes.

Pressure Washer Rinsin9

ForRinsing:

1. Removeblack spray tip from nozzleextension.

2. Select and install desired high pressure spray tip

following instructions Howto UseSpray Tips.

.

Keepthe spray gun a safe distancefrom the areayou

plan to spray.

A WARNING Kickback from spray gun can cause you to

fall.

• Operatepressure washer from a stable surface.

• Beextremely careful if you must use the pressure washer from

a ladder,scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury whenspray gun kicks back.

4. Apply a high pressure spray to a small areaand then

check surfacefor damage. If no damageis found, you

can assume it is okay to continue rinsing.

5. Start at top of areato be rinsed, working down with

same overlapping strokes asyou usedfor cleaning.

Cleaning Detergent Siphoning Tube

If you usedthe detergent siphoning tube, you must flush it

with cleanwater before stopping the engine.

1. Placedetergent siphoning tube/filter in a bucketfull of

cleanwater.

2. Removehigh pressure spray tip from spray tip

extension.

3. Select and install black detergent spray tip following

instructions How to UseSpray Tips.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint spray gun in a safe direction push red

button and squeezespray gun trigger to release retained

high water pressure.

NOTICE Spray gun traps highwater pressure, evenwhen

engine is stopped and water is disconnected.

A WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure,even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

Automatic Cool Down System {Thermal Relief}

If you runthe engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reachtemperatures above

125°F.The system engagesto cool the pump by discharging

the warm water onto the ground.

13

ENGINETECHNICALiNFORMATiON

This is a single cylinder, L-head,air cooled engine, it is a low

emissions engine.

In the State of California, Model 120000 engines are certified

by the California Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respectto the performance or

operational life of this engine. Theengine is warranted solely

according to the product and emissions warranties stated

elsewherein this manual.

PowerRatings

Thegross power rating for individual gas engine models is

labeled in accordancewith SAE(Society of Automotive

Engineers)code J1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been

obtained and corrected in accordancewith SAEJ1995

(Revision 2002-05). Torque values are derived at 3060 RPM;

horsepower values are derived at 3600 RPM.Actual gross

engine power will be lower and is affected by, among other

things, ambient operating conditions and engine-to-engine

variability. Given both the wide arrayof products on which

enginesare placed andthe variety of environmental issues

applicableto operatingthe equipment,the gas engine wiii not

developthe ratedgross power when used in a given pieceof

power equipment (actual "on-site"or net power). This

difference is due to a variety of factors including, but not

limited to, accessories (air cleaner, exhaust, charging,

cooling, carburetor, fuel pump, etc.), application limitations,

ambient operating conditions (temperature, humidity,

altitude), and engine-to-engine variability. Dueto

manufacturing and capacity limitations, Briggs & Stratton

may substitute an engine of higher ratedpower for this

Seriesengine.

This pressurewasher is rated in accordanceto the Pressure

Washer ManufacturersAssociation (PWMA) standard PW101

(Testing and Rating Performanceof PressureWashers).

PRODUCTSPECIFICATIONS

PressureWasherSpecifications

Max Outlet Pressure ....................... 2,500 PSi

Max Flow Rate............................. 2.3 GPM

DetergentMix ........................ Use asdirected

Water Supply Temperature .......... Not to exceed100%

Engine Specifications

Bore ................................. 2.69 in. (68mm)

Stroke ............................... 2.04 in.(52mm)

Displacement ........................ 11.57in.(190cc)

SparkPlug

Type:............... Briggs & Stratton 802592 or 5095

SetGapTo: ...................... 0.030inch (0.76mm)

ArmatureAir Gap:........... 0.006-0.010in.(0.15-0.25mm)

Valveclearancewithvalvesprings installedand piston 1/4 in.

(6 mm) pasttop deadcenter(checkwhenengineiscold).

Intake.................... 0.005-0.007in.(0.13-0.18mm)

Exhaust .................. 0.007-0.009in.(0.18-0.23mm)

FuelCapacity............................... 1.6Quarts

0il Capacity........................ 18 Ounces(0.5liter)

NOTICE Forpractical operation, the engine load should not

exceed85% of rated power. Enginepower will decrease

3-1/2% for each1,000 feet (300 meters) above sealeveland

1% for each 10° F(5.6° C) above77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

14

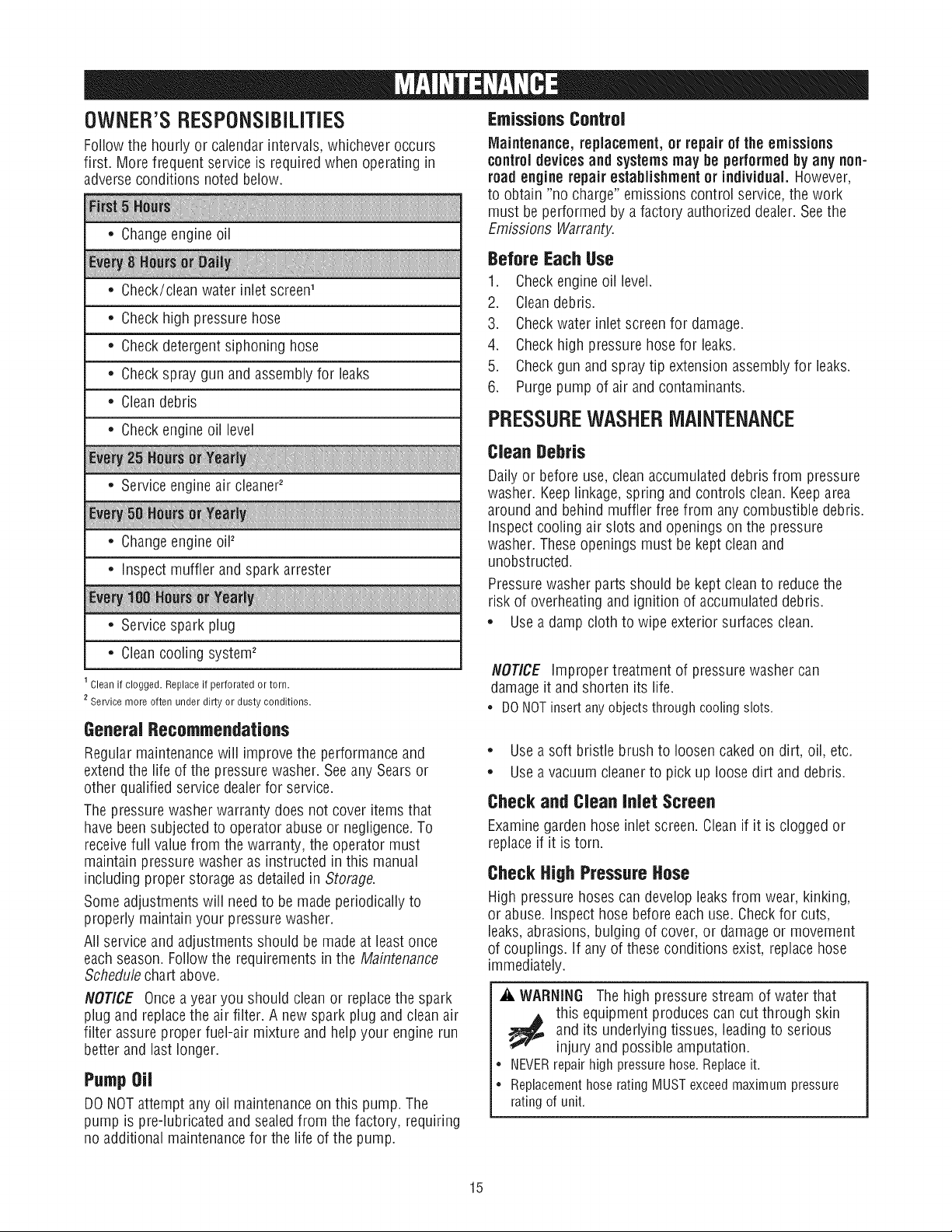

OWNER'SRESPONSiBiLiTiES

Follow the hourly or calendar intervals, whichever occurs

first. More frequent service is required when operating in

adverseconditions noted below.

* Changeengine oil

* Check/clean water inlet screen'

* Check high pressure hose

* Checkdetergent siphoning hose

* Checkspray gun and assembly for leaks

* Cleandebris

* Checkengine oil level

* Serviceengine air cleaner2

* Changeengine oil2

* inspect muffler and spark arrester

* Servicespark plug

Emissions Control

Maintenance, replacement, or repair of the emissions

controldevices and systemsmay be performedbyany non-

roadengine repair establishment or individual. However,

to obtain "no charge" emissions control service, the work

must be performed by a factory authorizeddealer. Seethe

Emissions Warranty.

Before Each Use

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screenfor damage.

4. Checkhigh pressure hose for leaks.

5. Checkgun and spray tip extension assemblyfor leaks.

6. Purge pump of air and contaminants.

PRESSUREWASHERMAINTENANCE

CleanDebris

Daily or before use, clean accumulateddebris from pressure

washer. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

inspect cooling air slots and openings on the pressure

washer. Theseopenings must be kept clean and

unobstructed.

Pressurewasher parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

* Usea damp cloth to wipe exterior surfaces clean.

* Cleancooling system2

' Clean if clogged. Replace if perforated or torn.

2Service more often under dirty or dusty conditions.

GeneralRecommendations

Regularmaintenance will improve the performance and

extendthe life of the pressurewasher. Seeany Sears or

other qualified service dealerfor service.

Thepressure washer warranty does not cover items that

havebeensubjected to operator abuseor negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressurewasher as instructed in this manual

including proper storage as detailed in Storage.

Someadjustments will needto be made periodically to

properly maintain your pressurewasher.

All service and adjustments should be madeat least once

eachseason. Follow the requirementsin the Maintenance

Schedulechart above.

NOTICE Oncea yearyou should cleanor replace the spark

plug and replacethe air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and helpyour engine run

better and last longer.

Pump Oil

DONOTattempt any oil maintenanceon this pump. The

pump is pre-iubricated and sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

NOTICE improper treatment of pressurewasher can

damageit and shorten its life.

• DONOTinsertanyobjectsthroughcoolingslots.

* Usea soft bristle brush to loosencaked on dirt, oil, etc.

* Usea vacuum cleanerto pick up loosedirt and debris.

Checkand Cleaninlet Screen

Examinegarden hose inlet screen. Cleanif it is clogged or

replaceif it is torn.

Check High Pressure Hose

High pressure hoses can develop leaksfrom wear,kinking,

or abuse, inspect hose before eachuse. Check for cuts,

leaks,abrasions, bulging of cover, or damage or movement

of couplings. If anyof these conditions exist, replacehose

immediately.

_lLWARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

• NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

15

Check Spray Gunand Spray Tip Extension

Examinehoseconnectionto spraygun and makesure it is

secure.Testtrigger bypressingit and makingsureit springs

backintoplacewhenyou releaseit. Donotdepressredbutton

andtesttrigger.Youshould not beableto presstrigger. Replace

spraygun immediatelyif it fails anyof thesetests.

Spray Tip Maintenance

A pulsing sensationfelt while squeezingthe spray gun trigger

may be causedby excessivepump pressure. Theprincipal

causeof excessivepump pressure is a spray tip clogged or

restricted with foreign materials, such asdirt, etc. To correct

the problem, immediately cleanthe spray tip following these

instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction, press red

button and and squeezespray gun trigger to release

retainedhigh water pressure.

_i, WARNING The high pressure stream of water that

and its underlying tissues, leadingto serious

this equipment produces cancut through skin

injury and possible amputation.

Spraygun traps high water pressure,even when engine is

stopped and water is disconnected, which can cause

injury.

* Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

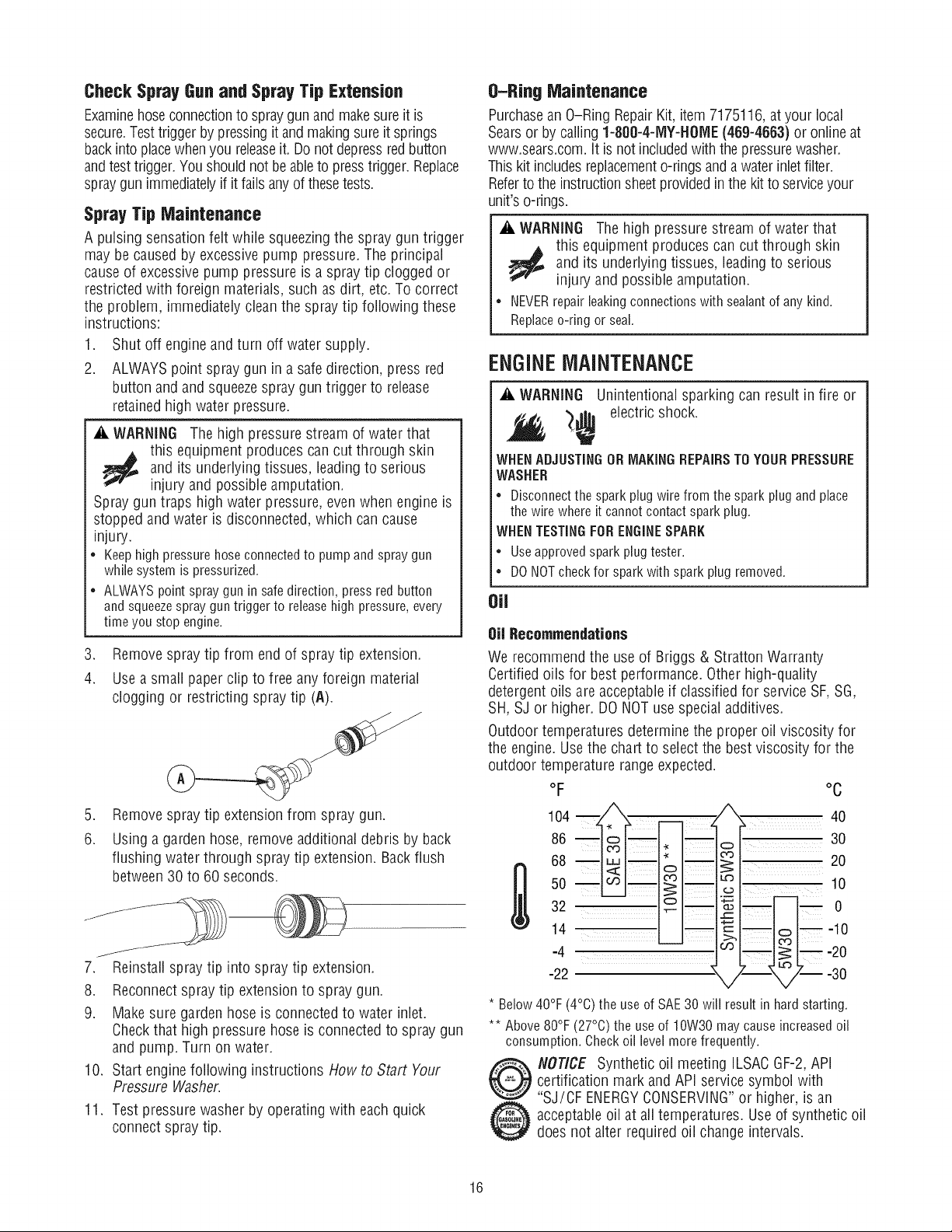

3. Removespray tip from endof spray tip extension.

4. Use a small paper clip to free any foreign material

clogging or restricting spray tip (A).

5. Removespray tip extension from spray gun.

6. Usinga garden hose, remove additionaldebris by back

flushingwater through spray tip extension. Backflush

between 30 to 60 seconds.

7. Reinstall spray tip into spray tip extension.

8. Reconnectspray tip extensionto spray gun.

9. Make sure garden hose is connectedto water inlet.

Checkthat high pressure hoseis connected to spray gun

and pump. Turn on water.

10. Start enginefollowing instructions How to Start Your

Pressure Washer.

11. Test pressurewasher by operating with each quick

connect spray tip.

O-Bino Maintenance

Purchasean O-Ring RepairKit,item 7175116,atyour local

Searsor by calling1-888-4-1VlY-NOME(469-4663)or onlineat

www.sears.com,it is not includedwiththe pressurewasher.

This kit includesreplacemento-rings anda waterinlet filter.

Refertothe instructionsheetprovidedin thekit to serviceyour

unit'so-rings.

_i, WARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

* NEVERrepairleakingconnectionswithsealantof anykind.

Replaceo-ringor seal.

ENGINEMAINTENANCE

_i, WARNING Unintentional sparking can result in fire or

_ electric shock.

WHENADJUSTINGOR MAKING REPAIRSTOYOUR PRESSURE

WASHER

* Disconnectthe spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

* Useapproved spark plug tester.

. DONOTcheckfor spark with spark plug removed.

Oil

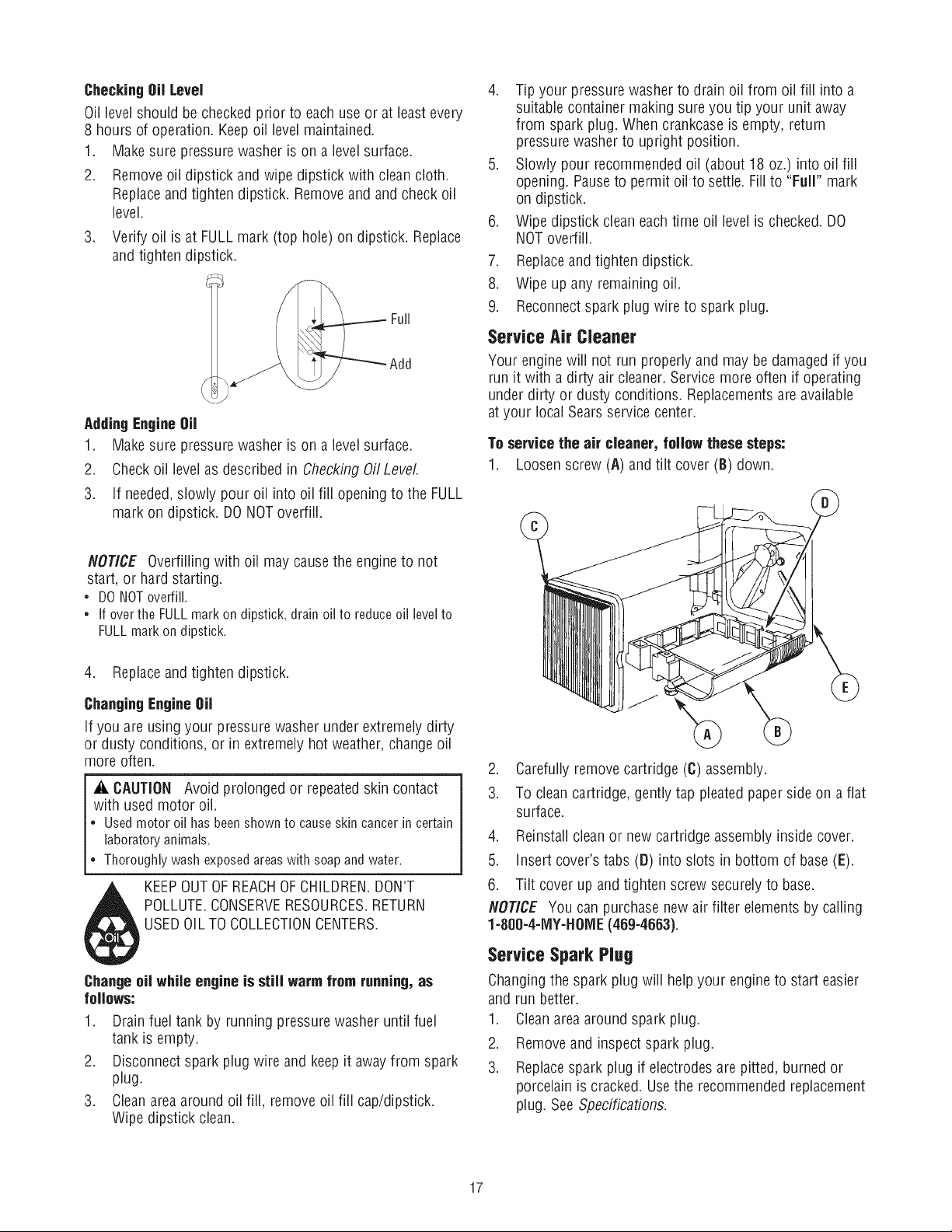

8il Recommendations

We recommendthe use of Briggs & Stratton Warranty

Certifiedoils for best performance. Other high-quality

detergent oils are acceptable if classified for serviceSF,SG,

SH,SJ or higher. DO NOTusespecial additives.

Outdoortemperatures determine the proper oil viscosity for

the engine.Usethe chart to select the best viscosity for the

outdoor temperature range expected.

oF

\ 40

;_30

104___506886 _o__

32 .o

14

-4

-22

* Below40°F(4°C)theuseof SAE30will resultin hardstarting.

** Above80°F(27°C)the useof 10W30maycauseincreasedoil

consumption.Checkoil levelmorefrequently.

O OTICE Syntheticoil meetingILSACGF-2,API

certification mark and API service symbol with

"SJ/CF ENERGYCONSERVING"or higher, is an

acceptableoil at all temperatures. Useof synthetic oil

does not alter required oil changeintervals.

°_20

_m m 0

--_C °

°C

10

-20

-30

16

CheckingOil Level

Oil level should be checked prior to eachuseor at least every

8 hours of operation. Keepoil level maintained.

1. Make sure pressure washer is on a levelsurface.

2. Removeoil dipstick and wipe dipstick with clean cloth.

Replaceand tighten dipstick. Remove and and check oil

level.

3. Verify oil is at FULL mark (top hole) on dipstick. Replace

and tighten dipstick.

Full

Adding EngineOil

1. Make sure pressure washer is on a levelsurface.

2. Checkoil level as described in CheckingOilLevel

3. If needed,slowly pour oil into oil fill opening to the FULL

mark on dipstick. DONOToverfill.

4. Tip your pressure washer to drain oil from oil fill into a

suitable container making sure you tip your unit away

from spark plug. When crankcaseis empty, return

pressurewasher to upright position.

5. Slowly pour recommendedoil (about 18 oz.) into oil fiii

opening. Pauseto permit oil to settle. Fill to "Full" mark

on dipstick.

6. Wipe dipstick cleaneachtime oil level is checked. DO

NOToverfill.

7. Replaceand tighten dipstick.

8. Wipe up any remaining oil.

9. Reconnectspark plug wire to spark plug.

Service Air Cleaner

Your engine will not run properly and may be damagedif you

run it with a dirty air cleaner. Service more often if operating

under dirty or dusty conditions. Replacementsare available

atyour local Searsservicecenter.

To service the air cleaner, follow these steps:

1. Loosenscrew (A) and tilt cover (B) down.

NOTICE Overfilling with oil may cause the engine to not

start, or hard starting.

• DO NOT overfill.

• If overthe FULL mark on dipstick, drain oil to reduce oil level to

FULLmark on dipstick.

4. Replaceand tighten dipstick.

ChangingEngineOil

if you are usingyour pressurewasher under extremely dirty

or dusty conditions, or in extremely hot weather, change oil

more often.

A CAUTION Avoid prolonged or repeatedskin contact

with usedmotor oil.

• Usedmotoroil hasbeenshownto causeskincancerincertain

laboratoryanimals.

• Thoroughlywashexposedareaswith soapandwater.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTO COLLECTIONCENTERS.

Changeoil while engineis still warmfrom running,as

follows:

1. Drain fuel tank by running pressure washer until fuel

tank is empty.

2. Disconnect spark plug wire and keepit away from spark

plug.

3. Cleanarea around oil fill, removeoil fill cap/dipstick.

Wipe dipstick clean.

2. Carefullyremove cartridge (C) assembly.

3. To clean cartridge, gently tap pleatedpaperside on a fiat

surface.

4. Reinstallclean or new cartridge assembly inside cover.

5. insert cover's tabs (B) into slots in bottom of base (E).

6. Tilt cover up and tighten screw securely to base.

NOTICE You can purchasenew air filter elements by calling

1-800-4-1VlY-NOIVlE(469-4663).

Service Spark Plug

Changingthe spark plug will help your engine to start easier

and run better.

1. Cleanareaaround spark plug.

2. Removeand inspect spark plug.

3. Replacespark plug if electrodes are pitted, burned or

porcelain is cracked. Usethe recommendedreplacement

plug. See Specifications.

17

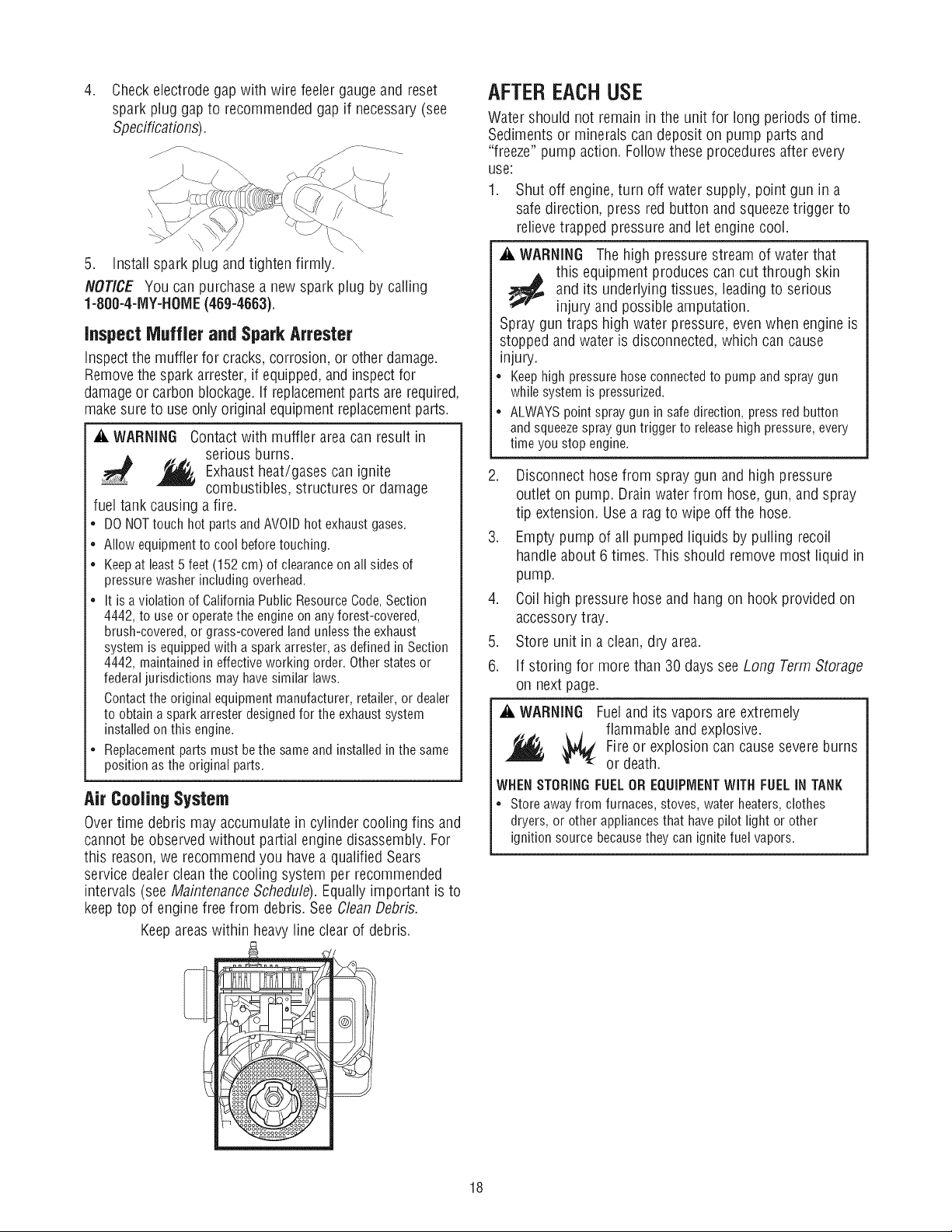

.

Checkelectrode gap with wire feeler gaugeand reset

spark plug gap to recommended gap if necessary(see

Specifications).

5. install spark plug and tighten firmly.

NOT/CE You can purchase a new spark plug by calling

1-800-4-iVlY-NOiVlE(469-4663).

inspect Muffler and Spark Arrester

inspectthe mufflerfor cracks,corrosion, or otherdamage.

Removethe spark arrester,if equipped,and inspectfor

damageor carbonblockage,if replacementpartsare required,

makesureto useonly original equipmentreplacementparts.

A, WARNING Contact with muffler area can result in

serious burns.

_ Exhaust heat/gases can ignite

combustibles, structures or damage

fuel tank causing a fire.

• DO NOTtouch hot parts and AVOID hot exhaust gases.

• Allow equipment to cool before touching.

• Keepat least 5 feet (152 cm) of clearanceon all sidesof

pressure washer including overhead.

• It isa violation of California Public Resource Code,Section

4442, to use or operatethe engine on any forest-covered,

brush-covered,or grass-covered land unless the exhaust

system is equippedwith a spark arrester,as defined in Section

4442, maintained in effectiveworking order. Otherstates or

federal jurisdictions may havesimilar laws.

Contactthe original equipment manufacturer, retailer, or dealer

to obtain a sparkarrester designedfor the exhaustsystem

installedon this engine.

• Replacementparts must be the sameand installed in the same

position as the original parts.

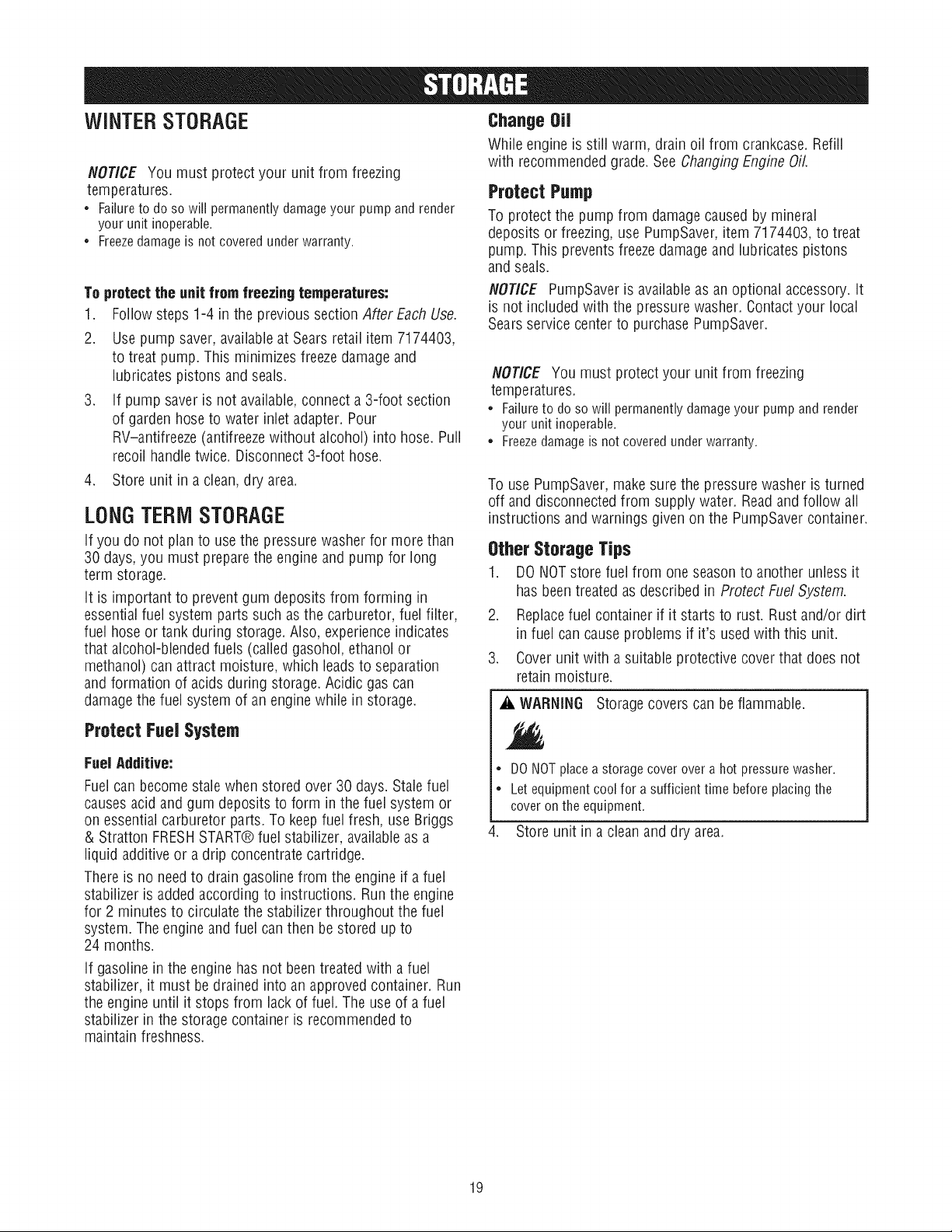

Air Cooling System

Overtime debris may accumulate in cylinder cooling fins and

cannot be observedwithout partial engine disassembly. For

this reason,we recommendyou have a qualifiedSears

servicedealer cleanthe cooling system per recommended

intervals (see MaintenanceSchedule). Equallyimportant is to

keeptop of engine free from debris. See CleanDebris.

Keepareaswithin heavyline clear of debris.

AFTEREACHUSE

Water should not remain in the unit for long periods of time.

Sedimentsor minerals candeposit on pump parts and

"freeze" pump action. Follow these procedures after every

use:

1. Shut off engine,turn off water supply, point gun in a

safedirection, press red button and squeezetrigger to

relievetrapped pressure and let engine cool.

_ILWARNING The high pressure stream of water that

and its underlying tissues, leading to serious

this equipment produces can cut through skin

injury and possible amputation.

Spray gun traps high water pressure,even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

.

Disconnecthose from spray gun and high pressure

outlet on pump. Drainwater from hose,gun, and spray

tip extension. Usea ragto wipe off the hose.

.

Empty pump of aii pumped liquids by puffing recoil

handleabout 6 times. This should remove most liquid in

pump.

.

Coilhigh pressurehose and hang on hook provided on

accessorytray.

5.

Store unit in a clean, dry area.

6.

If storing for more than 30 days see Long Term Storage

on next page.

_ILWARNING Fueland its vapors are extremely

flammable and explosive.

Fireor explosion can causesevere burns

or death.

WHENSTORINGFUELOREQUIPMENTWITHFUELINTANK

* Storeawayfromfurnaces,stoves,waterheaters,clothes

dryers,orotherappliancesthathavepilotlightorother

ignitionsourcebecausetheycanignitefuelvapors.

18

WINTERSTORAGE ChangeOil

While engine is still warm, drain oil from crankcase.Refill

NOTICE You must protect your unit from freezing

temperatures.

= Failure to do so will permanently damageyour pump and render

your unit inoperable.

= Freezedamage is not covered underwarranty.

To protectthe unit from freezingtemperatures:

1. Follow steps 1-4 in the previous section AfterEach Use.

2. Use pump saver, availableat Sears retailitem 7174403,

to treat pump. This minimizes freezedamageand

lubricates pistons and seals.

3. If pump saver is not available,connect a 3-foot section

of garden hose to water inlet adapter. Pour

RV-antifreeze (antifreezewithout alcohol) into hose. Pull

recoil handletwice. Disconnect 3-foot hose.

4. Store unit in a clean,dry area.

LONGTERIViSTORAGE

If you do not plan to usethe pressure washer for morethan

30 days, you must preparethe engine and pump for long

term storage.

It is important to prevent gum deposits from forming in

essentialfuel system parts such as the carburetor, fuel filter,

fuel hoseor tank during storage. Also, experienceindicates

that alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leadsto separation

and formation of acids during storage. Acidic gas can

damagethe fuel system of an enginewhile in storage.

with recommendedgrade. See ChangingEngineOil.

Protect Pump

To protect the pump from damagecaused by mineral

deposits or freezing, use PumpSaver, item 7174403, to treat

pump. This preventsfreeze damageand lubricates pistons

and seals.

NOTICE PumpSaveris availableas an optional accessory, it

is not included with the pressure washer. Contactyour local

Searsservice center to purchase PumpSaver.

NOTICE You must protect your unit from freezing

temperatures.

= Failureto do so will permanently damage your pump and render

your unit inoperable.

= Freezedamageis not covered under warranty.

To usePumpSaver,make surethe pressurewasher is turned

off and disconnected from supply water. Readand follow all

instructions and warnings given on the PumpSavercontainer.

Other Storage Tips

1. DONOTstore fuel from oneseasonto another unless it

hasbeen treated asdescribed in Protect FuelSystem.

.

Replacefuel container if it starts to rust. Rust and/or dirt

in fuel cancause problems if it's used with this unit.

3.

Coverunit with a suitable protective cover that does not

retain moisture.

_i, WARNING

Storagecovers can be flammable.

Protect Fuel System

FueJAdditive:

Fuelcan becomestale when stored over 30 days.Stale fuel

causesacid and gum deposits to form in the fuel system or

on essential carburetor parts. To keepfuel fresh, use Briggs

& Stratton FRESHSTART®fuel stabilizer, availableasa

liquid additive or a drip concentrate cartridge.

Thereis no needto drain gasolinefrom the engine if a fuel

stabilizer is added according to instructions. Run the engine

for 2 minutes to circulate the stabilizerthroughout the fuel

system. The engine andfuel canthen be stored up to

24 months.

If gasoline in the engine hasnot beentreated with afuel

stabilizer, it must be drained into an approvedcontainer. Run

the engine until it stops from lackof fuel. The useof a fuel

stabilizer in the storage container is recommendedto

maintain freshness.

• DO NOT placea storage cover over ahot pressure washer.

• Let equipment cool for a sufficient time before placing the

cover on the equipment.

4. Store unit in a clean and dry area.

19

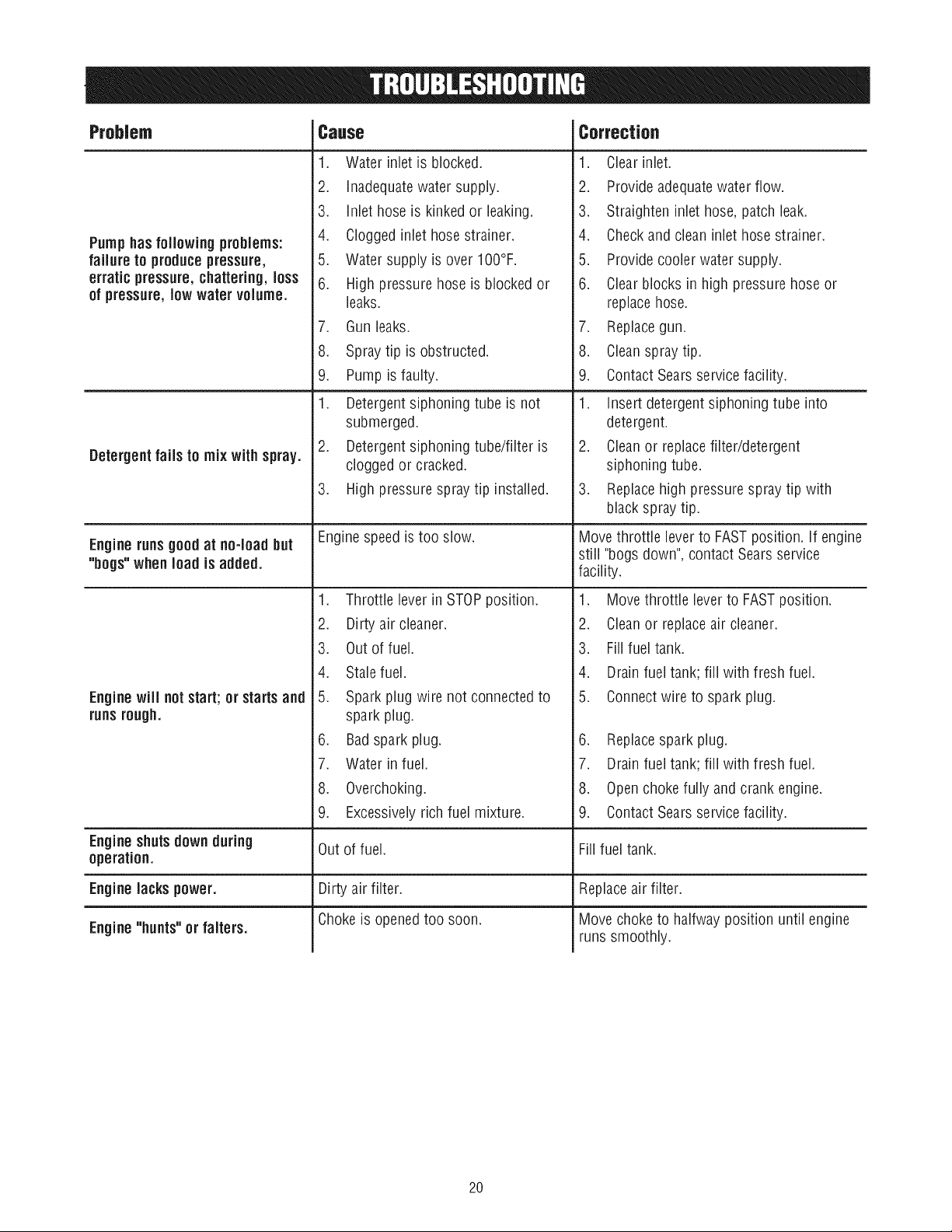

Problem Cause

Correction

Pump hasfollowing problems:

failure to producepressure,

erraticpressure, chattering,Joss

of pressure,low water volume.

Detergentfails to mix with spray.

Enginerunsgoodat no-load but

"bogs" whenload is added.

Enginewill not start;or startsand

runsrough.

1. Water inlet is blocked.

2. inadequatewater supply.

3. inlet hose is kinkedor leaking.

4. Clogged inlet hosestrainer.

5. Water supply is over IO0°F.

6. High pressure hoseis blocked or

leaks.

7. Gun leaks.

8. Spraytip is obstructed.

9. Pump is faulty.

1. Detergentsiphoning tube is not

submerged.

2. Detergentsiphoning tube/filter is

clogged or cracked.

3. High pressure spray tip installed.

Engine speedis too slow.

1. Throttle leverin STOPposition.

2. Dirty air cleaner.

3. Out of fuel.

4. Stalefuel.

5. Spark plug wire not connected to

spark plug.

6. Badspark plug.

7. Water in fuel.

8. Overchoking.

9. Excessivelyrich fuel mixture.

1. Clearinlet.

2. Provide adequatewater flow.

3. Straighten inlet hose, patch leak.

4. Checkand cleaninlet hose strainer.

5. Provide cooler water supply.

i

i

i6. Clearblocks in high pressure hose or

replacehose.

7. Replacegun.

8. Cleanspray tip.

9. Contact Searsservicefacility.

1. insert detergent siphoning tube into

detergent.

2. Cleanor replacefilter/detergent

siphoning tube.

3. Replacehigh pressure spray tip with

black spray tip.

Move throttle lever to FASTposition, if engine

still "bogsdown", contact Sears service

facility.

1. Move throttle lever to FASTposition.

2. Cleanor replaceair cleaner.

3. Fillfuel tank.

i

i

i4. Drain fuel tank; fill with fresh fuel.

5. Connectwire to spark plug.

6. Replacesparkplug.

7. Drain fuel tank; fill with fresh fuel.

8. Openchoke fully and crank engine.

9. Contact Searsservicefacility.

Engine shutsdown during Out of fuel. Fillfuel tank.

operation.

Engine Jackspower. Dirty air filter.

Engine"hunts" or faJters.

Choke is openedtoo soon.

Replaceair filter.

Move choke to halfway position until engine

runs smoothly.

2O

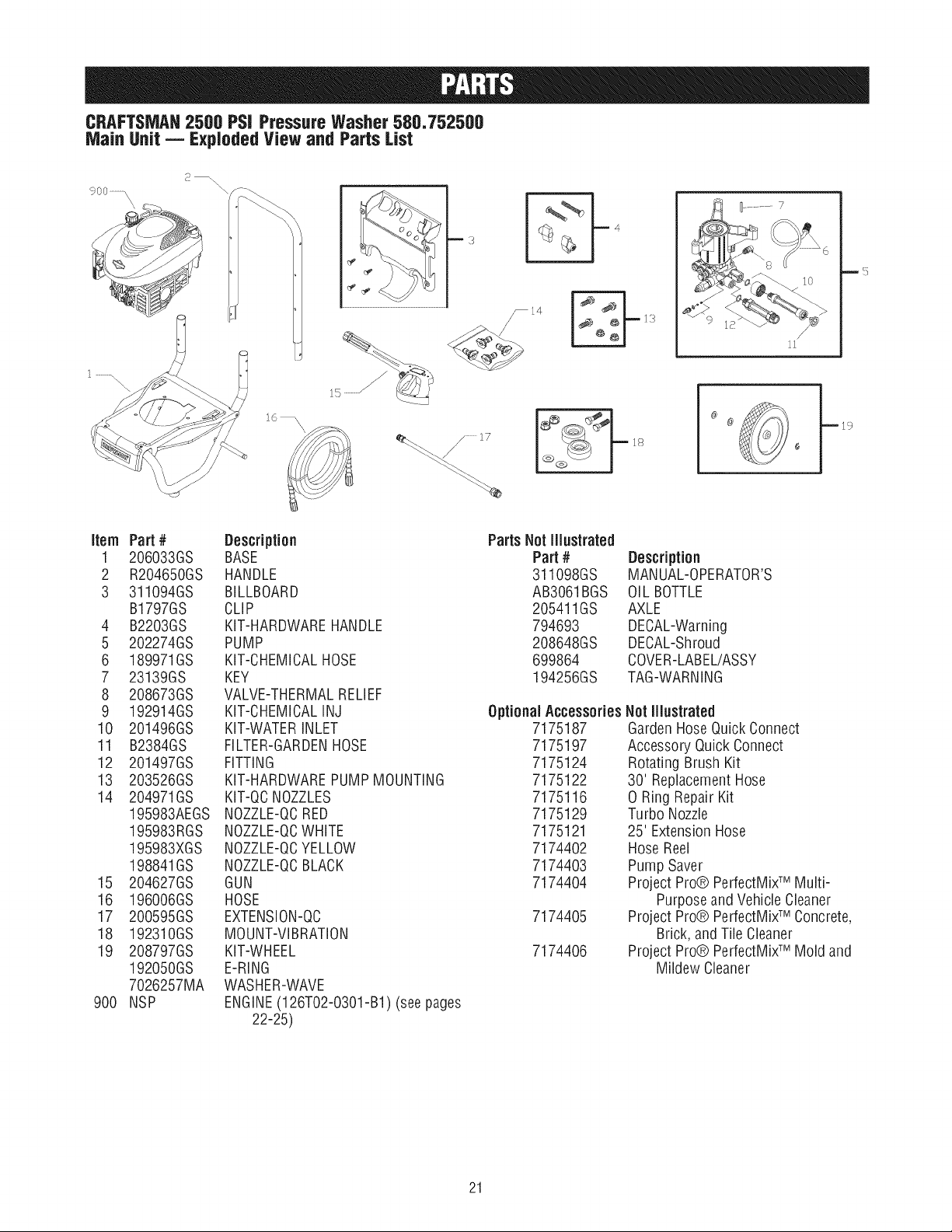

CRAFTSMAN2500 PSi Pressure Washer 580.752500

Main Unit m Exploded View and Parts List

900

\

item

Part #

1

206033GS

2

R204650GS

3

311094GS

B1797GS

4

B2203GS

5

202274GS

6

189971GS

7

23139GS

8

208673GS

9

192914GS

10

201496GS

11

B2384GS

12

201497GS

13

203526GS

14

204971GS

195983AEGS

195983RGS

195983XGS

198841GS

15

204627GS

16

196006GS

17

200595GS

18

192310GS

19

208797GS

192050GS

7026257MA

900

NSP

Description

BASE

HANDLE

BILLBOARD

CLIP

KIT-HARDWAREHANDLE

PUMP

KIT-CHEMICALHOSE

KEY

VALVE-THERMALRELIEF

KIT-CHEMICALINJ

KIT-WATERINLET

FILTER-GARDENHOSE

FITTING

KIT-HARDWAREPUMPMOUNTING

KiT-QCNOZZLES

NOZZLE-QCRED

NOZZLE-QCWHITE

NOZZLE-QCYELLOW

NOZZLE-QCBLACK

GUN

HOSE

EXTENSION-QC

MOUNT-VIBRATION

KIT-WHEEL

E-RING

WASHER-WAVE

ENGINE(126TO2-O301-B1)(see pages

22-25)

PartsNot Illustrated

Part#

311098GS

AB3061BGS

205411GS

794693

208648GS

699864

194256GS

Optional Accessories

7175187

7175197

7175124

7175122

7175116

7175129

7175121

7174402

7174403

7174404

7174405

7174406

@

18

Description

MANUAL-OPERATOR'S

OILBOTTLE

AXLE

DECAL-Warning

DECAL-Shroud

COVER-LABEL/ASSY

TAG-WARNING

Not Illustrated

GardenHoseQuick Connect

Accessory Quick Connect

Rotating Brush Kit

30' ReplacementHose

0 RingRepair Kit

Turbo Nozzle

25' Extension Hose

HoseReel

PumpSaver

Project Pro@ PerfectMixTM Multi-

Purposeand VehicleCleaner

Project Pro@ PerfectMixTM Concrete,

Brick, andTile Cleaner

Project Pro@ PerfectMixTM Mold and

Mildew Cleaner

19

21

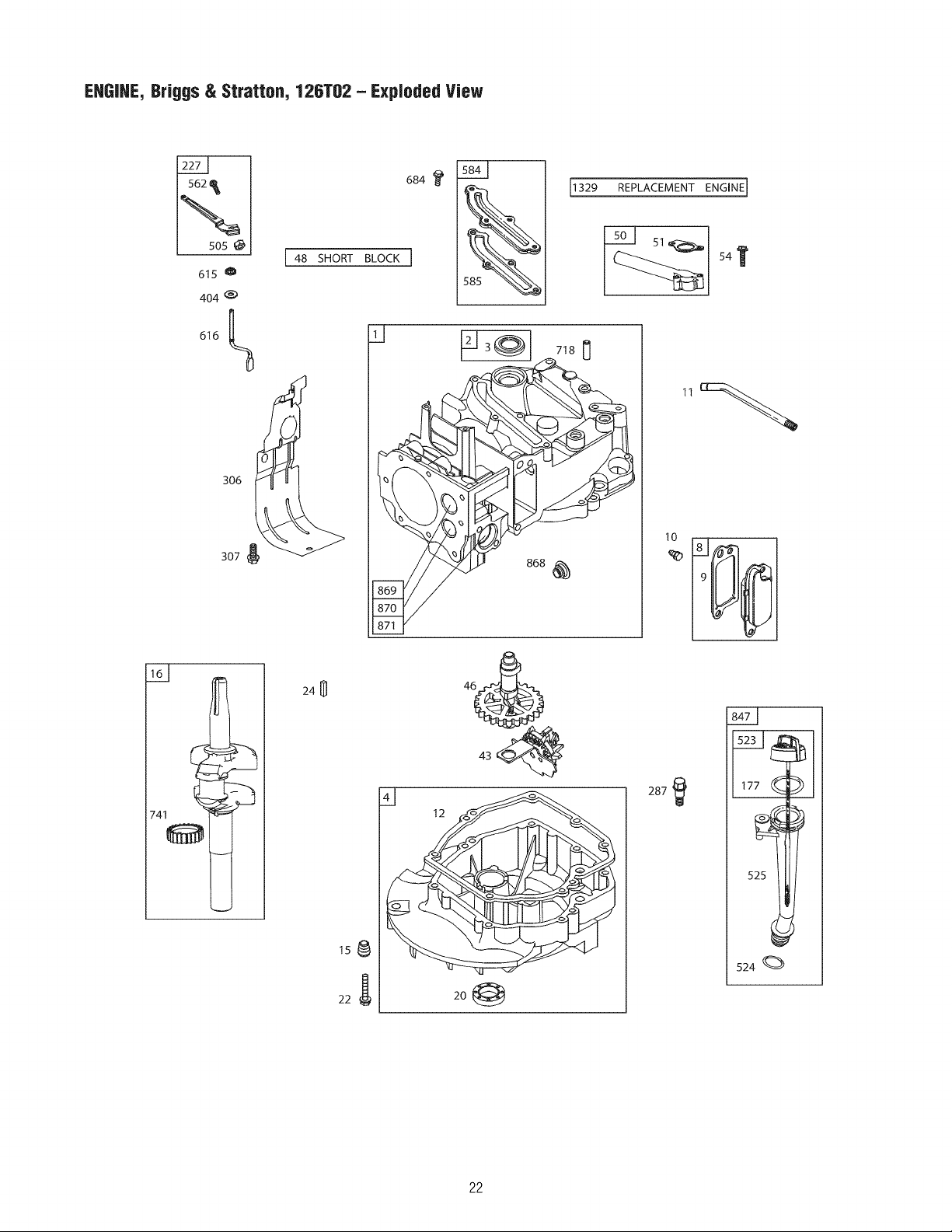

ENGINE,Briggs & Stratton, 126T02 - ExpJodedView

[sos

615 0

404 _

616 __

306

48 SHORT BLOCK ]

d

684 ?

1329

718

10

8o8

241_

287

12

524 (_

22

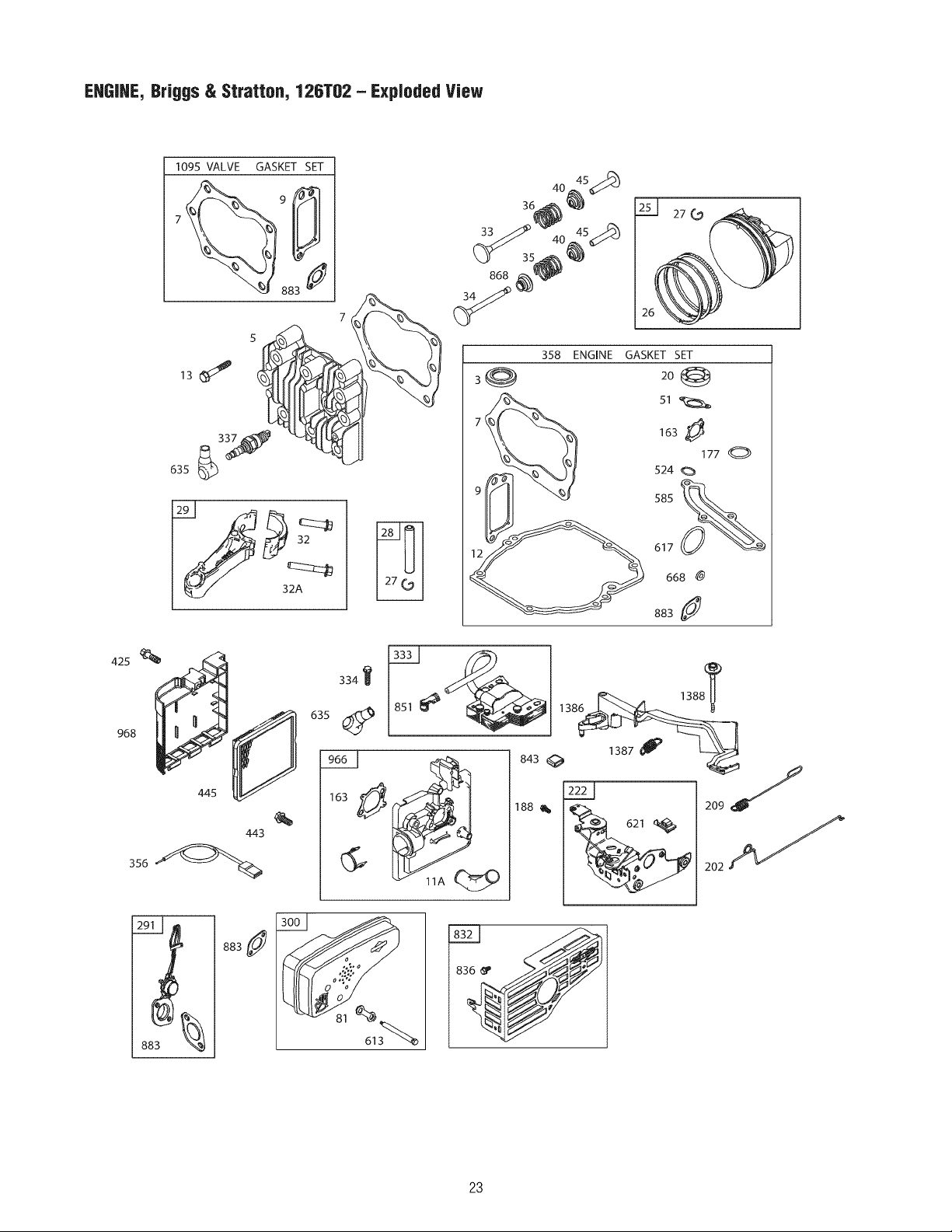

ENGINE,Briggs & Stratton, 126T02 - ExpJodedView

1095 VALVE GASKET SET

883 _

34_

364o_

2sl 27(__

3583_ENGINE GASKET SET

2o_

51 _

163 _

177 0

524

585

617

425 _

356 _

443

32A

668 @

883 J

163

23

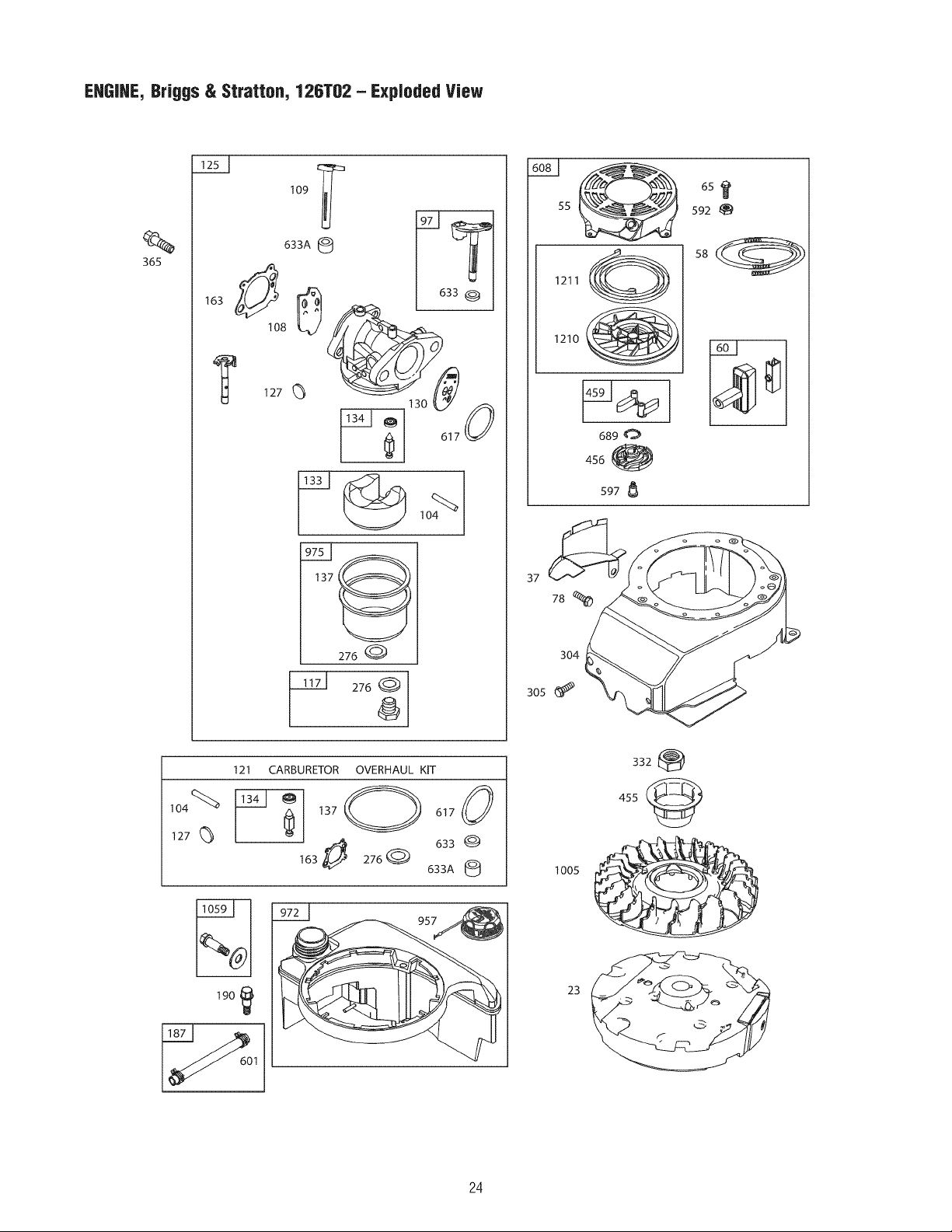

ENGINE,Briggs & Stratton, 126T02 - ExpJodedView

365

109

137

37

55

Q

1211

1210

456

78

65

$92

689 0

597

276

276

121 CARBURETOR OVERHAUL KIT

1341 @

137

163# 276_ )

190

617

633 (_

633A (_

304

305

332

455

23

24

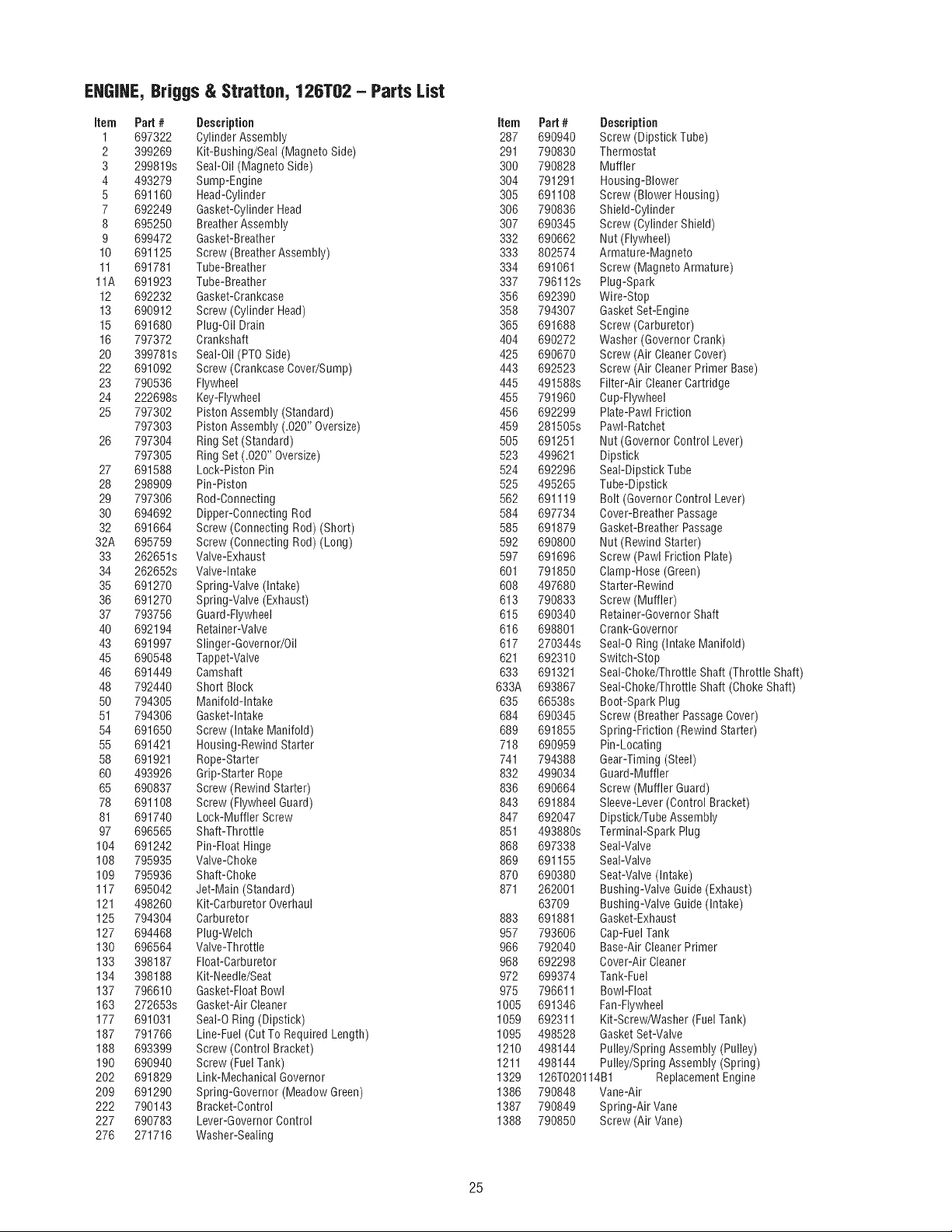

ENGIHE,Briggs & Stratton, t26T82 - Parts List

Item Part # Description

1 697322 Cylinder Assembly

2 399269 Kit-Bushing/Seal (Magneto Side)

3 299819s Seal-Oil (Magneto Side)

4 493279 Sump-Engine

5 691160 Head-Cylinder

7 692249 Gasket-Cylinder Head

8 695250 BreatherAssembly

9 699472 Gasket-Breather

10 691125 Screw (Breather Assembly)

11 691781 Tube-Breather

11A 691923 Tube-Breather

12 692232 Gasket-Crankcase

13 690912 Screw (Cylinder Head)

15 691680 Plug-Oil Drain

16 797372 Crankshaft

20 399781s Seal-Oil(PTOSide)

22 691092 Screw (Crankcase Cover/Sump)

23 790536 Flywheel

24 222698s Key-Flywheel

25 797302 Piston Assembly (Standard)

797303 Piston Assembly (.020" Oversize)

26 797304 Ring Set (Standard)

797305 Ring Set (.020" Oversize)

27 691588 Lock-Piston Pin

28 298909 Pin-Piston

29 797306 Rod-Connecting

30 694692 Dipper-Connecting Rod

32 691664 Screw (Connecting Rod) (Short)

32A 695759 Screw (Connecting Rod) (Long)

33 262651s Valve-Exhaust

34 262652s Valve-intake

35 691270 Spring-Valve (intake)

36 691270 Spring-Valve (Exhaust)

37 793756 Guard-Flywheel

40 692194 Retainer-Valve

43 691997 Slinger-Governor/Oil

45 690548 Tappet-Valve

46 691449 Camshaft

48 792440 Short Block

50 794305 Manifold-intake

51 794306 Gasket-intake

54 691650 Screw (intake Manifold)

55 691421 Housing-Rewind Starter

58 691921 Rope-Starter

60 493926 Grip-Starter Rope

65 690837 Screw (Rewind Starter)

78 691108 Screw (FlywheelGuard)

81 691740 Lock-Muffler Screw

97 696565 Shaft-Throttle

104 691242 Pin-Float Hinge

108 795935 Valve-Choke

109 795936 Shaft-Choke

117 695042 Jet-Main (Standard)

121 498260 Kit-Carburetor Overhaul

125 794304 Carburetor

127 694468 Plug-Welch

130 696564 Valve-Throttle

133 398187 Float-Carburetor

134 398188 Kit-Needle/Seat

137 796610 Gasket-FloatBowl

163 272653s Gasket-Air Cleaner

177 691031 SeaFORing (Dipstick)

187 791766 Line-Fuel(Cut To Required Length)

188 693399 Screw (Control Bracket)

190 690940 Screw (FuelTank)

202 691829 Link-Mechanical Governor

209 691290 Spring-Governor (Meadow Green)

222 790143 Bracket-Control

227 690783 Lever-Governor Control

276 271716 Washer-Sealing

Item Part#

287 690940

291 790830

300 790828

304 791291

305 691108

306 790836

307 690345

332 690662

333 802574

334 691061

337 796112s

356 692390

358 794307

365 691688

404 690272

425 690670

443 692523

445 491588s

455 791960

456 692299

459 281505s

505 691251

523 499621

524 692296

525 495265

562 691119

584 697734

585 691879

592 690800

597 691696

601 791850

608 497680

613 790833

615 690340

616 698801

617 270344s

621 692310

633 691321

633A 693867

635 66538s

684 690345

689 691855

718 690959

741 794388

832 499034

836 690664

843 691884

847 692047

851 493880s

868 697338

869 691155

870 690380

871 262OO1

63709

883 691881

957 793606

966 792040

968 692298

972 699374

975 796611

1005 691346

1059 692311

1095 498528

1210 498144

1211 498144

1329 126T0201

1386 790848

1387 790849

1388 790850

Description

Screw (Dipstick Tube)

Thermostat

Muffler

Housing-Blower

Screw (Blower Housing)

Shield-Cylinder

Screw (Cylinder Shield)

Nut (Flywheel)

Armature-Magneto

Screw (Magneto Armature)

Plug-Spark

Wire-Stop

GasketSet-Engine

Screw (Carburetor)

Washer (Governor Crank)

Screw (Air Cleaner Cover)

Screw (Air Cleaner Primer Base)

Filter-Air Cleaner Cartridge

Cup-Flywheel

Plate-Pawl Friction

PawI-Ratchet

Nut (Governor Control Lever)

Dipstick

Seal-Dipstick Tube

Tube-Dipstick

Bolt (Governor Control Lever)

Cover-Breather Passage

Gasket-Breather Passage

Nut (Rewind Starter)

Screw (Pawl Friction Plate)

Clamp-Hose (Green)

Starter-Rewind

Screw (Muffler)

Retainer-Governor Shaft

Crank-Governor

Seal-O Ring (intake Manifold)

Switch-Stop

Seal-Choke/Throttle Shaft (Throttle Shaft)

Seal-Choke/Throttle Shaft (Choke Shaft)

Boot-Spark Plug

Screw (Breather PassageCover)

Spring-Friction (Rewind Starter)

Pin-Locating

Gear-Timing (Steel)

Guard-Muffler

Screw (Muffler Guard)

Sleeve-Lever (Control Bracket)

Dipstick/Tube Assembly

Terminal-Spark Plug

Seal-Valve

Seal-Valve

Seat-Valve(Intake)

Bushing-Valve Guide (Exhaust)

Bushing-Valve Guide (Intake)

Gasket-Exhaust

Cap-FuelTank

Base-AirCleaner Primer

Cover-Air Cleaner

Tank-Fuel

Bowl-Float

Fan-Flywheel

Kit-Screw/Washer (Fuel Tank)

GasketSet-Valve

Pulley/Spring Assembly (Pulley)

Pulley/Spring Assembly (Spring)

14BI Replacement Engine

Vane-Air

Spring-Air Vane

Screw (Air Vane)

25

California, U.S. EPA,and Sears Emissions

ControlWarrantyStatement

YourWarranty RightsAnd Obligations

TheCalifornia Air Resources Board,U.S. EPA,and Sears,

Roebuckand Co.,U.S.A.(Sears) are pleasedto explain the

emissions control system warranty on your Model Year2008

and later engine/equipment. In California,new small off-road

engines must be designed, built, and equippedto meet the

State'sstringent anti-smog standards. Searsmust warrant

the emissions control system on your engine/equipmentfor

the periods of time listed below provided there has been no

abuse, neglect,or impropermaintenance of your small off-

road engine.

Your emissions control system may includepartssuch as

the carburetor or fuel injection system, fuel tank, ignition

system, and catalytic converter. Also includedmay be hoses,

belts, connectors, sensors, and other emissions-related

assemblies.Where a warrantable condition exists, Searswill

repair your engine/equipmentat no cost to you including

diagnosis, parts, and labor.

Manufacturer'sWarrantyCoverage:

Small off-road engines arewarranted for two years. If any