Craftsman 580752380 Owner’s Manual

Operator'sManual

3800 PSi

4.0 GPM

Model No. 580.752300

®

CUSTOMERHELPLINE

PRESSUREWASHER

HOURS: Non. - Fri. 8 a.m. to 5p.m. (CT)

WARm.G

Before usingthis product, readthis

manualandfollow all SafetyRules

and Operating Instructions.

Sears, Roebuckand Co., RoffmanEstates,IL 60179 U.S.A.

Visit our Craftsman website:www.craftsmamcom

Part No. 205732GS Draft A (01/10/2008)

Antes de utilizar el producto, lea este

manualy siga todas las Reglasde

Seguridade Instrucciones de Uso.

ADVERTENCJA

• Safety

,, Assembly

,, Operation

,, Maintenance

,, Parts

,, Espafiol, p. 34

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-4

FEATURESANDCONTROLS.............................. 5

ASSEMBLY......................................... 6-8

OPERATION........................................ 9-13

SPECIFICATIONS..................................... 14

MAINTENANCE.................................... 14-20

STORAGE........................................ 21-22

TROUBLESHOOTING.................................. 23

REPLACEMENTPARTS.............................. 24-31

EMISSIONCONTROLWARRANTY..................... 32-33

ESPANOL......................................... 34-59

HOWTO ORDERPARTS........................ BACKPAGE

TWO-YEARFULLWARRANTYOHCRAFTSMANPRESSUREWASHER

If this pressure washerfails dueto a defectin material or workmanship within two years from the dateof purchase, return it

to any Searsstore, other Craftsman outlet, or SearsParts & RepairCenterin the United States or Canadafor free repair (or

replacementif repair proves impossible).

All warranty coverageappliesfor only 90 days from date of purchase if this pressure washer is ever used for commercial or

rental purposes.

This warranty gives you specific legal rights, and you may also haveother rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Sears Canada Inc., Toronto, Ontario, Canada M5B 288

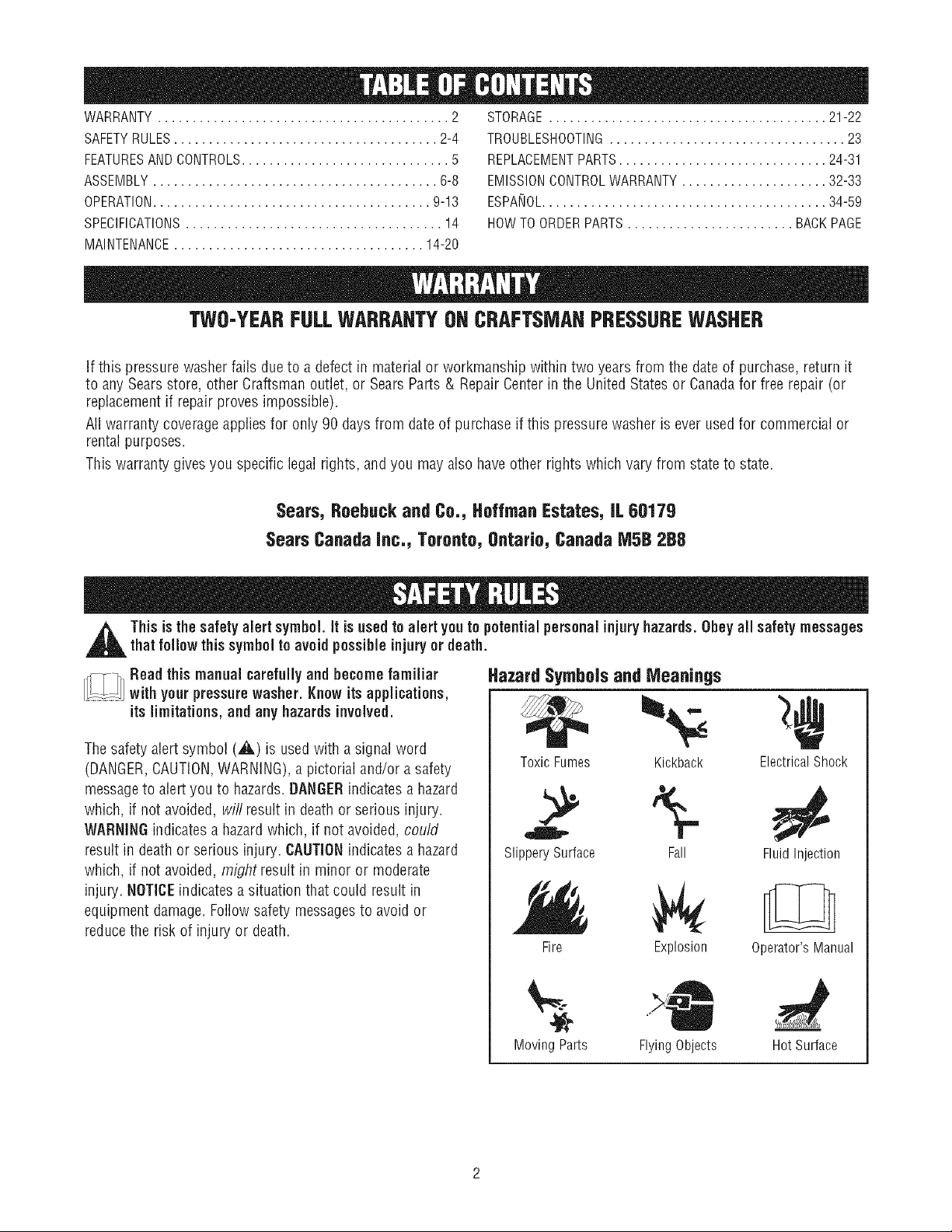

Thisis the safety alert symbol.It isusedtoalert youto potentialpersonal injuryhazards.Obey all safetymessages

thatfollow thissymbol to avoid possibleinjury or death.

II_] Read this manual carefully and becomefamiliar

...................with your pressurewasher. Knowitsapplications,

its limitations, and any hazardsinvolved.

Thesafety alert symbol (_t:i.)is used with asignal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert you to hazards. DANGERindicatesa hazard

which, if not avoided, will result in death or serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in deathor serious injury. CAUTIONindicatesa hazard

which, if not avoided, might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage.Follow safety messagesto avoid or

reducethe risk of injury or death.

Hazard Symbols and Meanings

ToxicFumes Kickback

2 5-

SlipperySurface Fall

Fire

MovingParts FlyingObjects

Explosion Operator'sManual

ElectricalShock

FluidInjection

HotSurface

WARHJNG

Theengineexhaustfromthisproductcontains

chemicalsknowntotheState of California tocause

cancer,birthdefects,or otherreproductiveharm.

WARHJHG

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathingcarbon monoxide can cause headache,

_ atigue, dizziness,vomiting, confusion, seizures,

* OperatepressurewasherONLYoutdoors.

Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,or otheropenings.

DONOTstartor runengineindoorsor in anenclosedarea,

evenif windowsanddoorsareopen.

Usea respiratoror maskwheneverthereisa chancethat

vaporsmaybeinhaled.

Readallinstructionswithmasksoyouarecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

nausea,fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severenausea,

fainting, or poisoning.

WARHIHG

_¢ isk of electrocution.

* NEVERspraynearpowersource.

Contactwith power source can causeelectric

shock or burn.

WARHIHG

s_ Contact with muffler area can result in serious

_ Exhaustheat/gases can ignite combustibles,

* Keepat least 5feet (152 cm) of clearanceon all sides of

* Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

burns.

structures or damagefuel tank causing a fire.

DO NOTtouch hot parts and AVOID hot exhaust gases.

Allow equipment to cool before touching.

pressure washer including overhead.

Public Property require equipment powered by an internal

combustion engine to have aspark arrester, maintained in

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may havesimilar laws.

WARHIHG

Fueland its vapors are extremely flammable and

explosive.

death.

Fireor explosion cancause severe burns or

WHENADDINGOR DRAININGFUEL

* TurnpressurewasherOFFandletit coolat least2 minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

Fillor drainfueltankoutdoors.

DONOToverfilltank.Allowspaceforfuelexpansion.

Iffuelspills,waituntil it evaporatesbeforestartingengine.

Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

DONOTlighta cigaretteorsmoke.

WHENSTARTIN6EQUIPMENT

* Ensuresparkplug,muffler,fuelcap,andair cleanerarein

place.

. DONOTcrankenginewith sparkplugremoved.

WHENOPERATIN6EQUIPMENT

* DONOTtip engineor equipmentat anglewhichcausesfuel to

spill.

. DONOTsprayflammableliquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

* Transport/repairwithfueltank EMPTYor withfuelshutoffvalve

OFF.

. Disconnectsparkplugwire.

WHENSTORINGFUELOREQUIPMENTWITH FUELIN TANK

* Storeawayfromfurnaces,stoves,waterheaters,clothes

dryers,orotherappliancesthathavepilotlightor otherignition

sourcebecausetheycanignitefuelvapors.

WARHJHG

Starter cord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

_,_< toward enginefaster thanyou canlet go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

Whenstartingengine,pullcord slowlyuntilresistanceis felt

andthenpullrapidlyto avoidkickback.

• Aftereachstartingattempt,whereenginefailsto run,always

pointspraygunin safedirection,pressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

• Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

WARHIHG

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

• DONOTallow CHILDRENto operate pressure washer.

• NEVERrepair high pressure hose. Replaceit.

• NEVERrepairleaking connections with sealantof any kind.

Replaceo-ring or seal.

• NEVERconnect high pressure hoseto nozzleextension.

Keephigh pressure hoseconnectedto pump and spray gun

while system is pressurized.

• ALWAYS point spray gun in safe direction, press red button

and squeezespray gun trigger to releasehigh pressure, every

time you stop engine.

• NEVERaim spray gun at people, animals, or plants.

DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machine is running.

NEVERusea spray gun which does not havea trigger lock or

trigger guard in place and in working order.

Always becertain spray gun, spray tips and accessories are

correctly attached.

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

WARHIHG

WARHIHG

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

* NEVERoperate pressure washerwithout protective housing or

covers.

. DONOTwear loose clothing, jewelry or anything that may be

caught in the starter or other rotating parts.

Tie up long hair and remove jewelry.

WARNING

Risk of eye injury.

_Spray can splash back or propel objects.

Alwayswear safety goggleswhen using this equipment or in

vicinity of where equipment is in use.

Before starting the pressure washer, be sure you are wearing

adequatesafety goggles.

NEVERsubstitute safety glasses for safety goggles.

NOTICE

High pressure spray may damage fragile items including

lass.

DO NOTpoint spray gun at glass when using red (0°) spray tip.

NEVERaim spray gun at plants.

NOTICE

Use of pressure washer can create puddles and

slippery surfaces.

Kickback from spray gun can cause you to fall.

• Operatepressure washer from astable surface.

The cleaning area should haveadequateslopes and drainageto

reducethe possibility of afall due to slippery surfaces.

• Be extremelycareful if you must usethe pressure washer from

a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARHIHG

Unintentional sparking can result in fire or

_¢ electric shock.

WHENADJUSTING OR MAKING REPAIRSTO YOUR

PRESSUREWASHER

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Use approved spark plug tester.

• DONOTcheck for sparkwith spark plug removed.

Improper treatment of pressure washer can damage it and

shorten its life.

Ifyou havequestions about intended use, ask dealer or contact

Sears.

NEVERoperate units with broken or missing parts, or without

protective housing or covers.

DONOT by-pass any safetydevice on this machine.

DONOTtamper with governed speed.

DONOToperate pressure washer above rated pressure.

DONOT modify pressure washer in any way.

Before starting pressure washer in cold weather, check all parts

of the equipment to besure ice has not formed there.

NEVERmove machine by pulling on hoses. Use handle

provided on unit.

Checkfuel system for leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washer.

This equipment is designedto be used with Searsauthorized

parts ONLY.If equipment is usedwith parts that DO NOT

comply with minimum specifications, user assumes all risks

and liabilities.

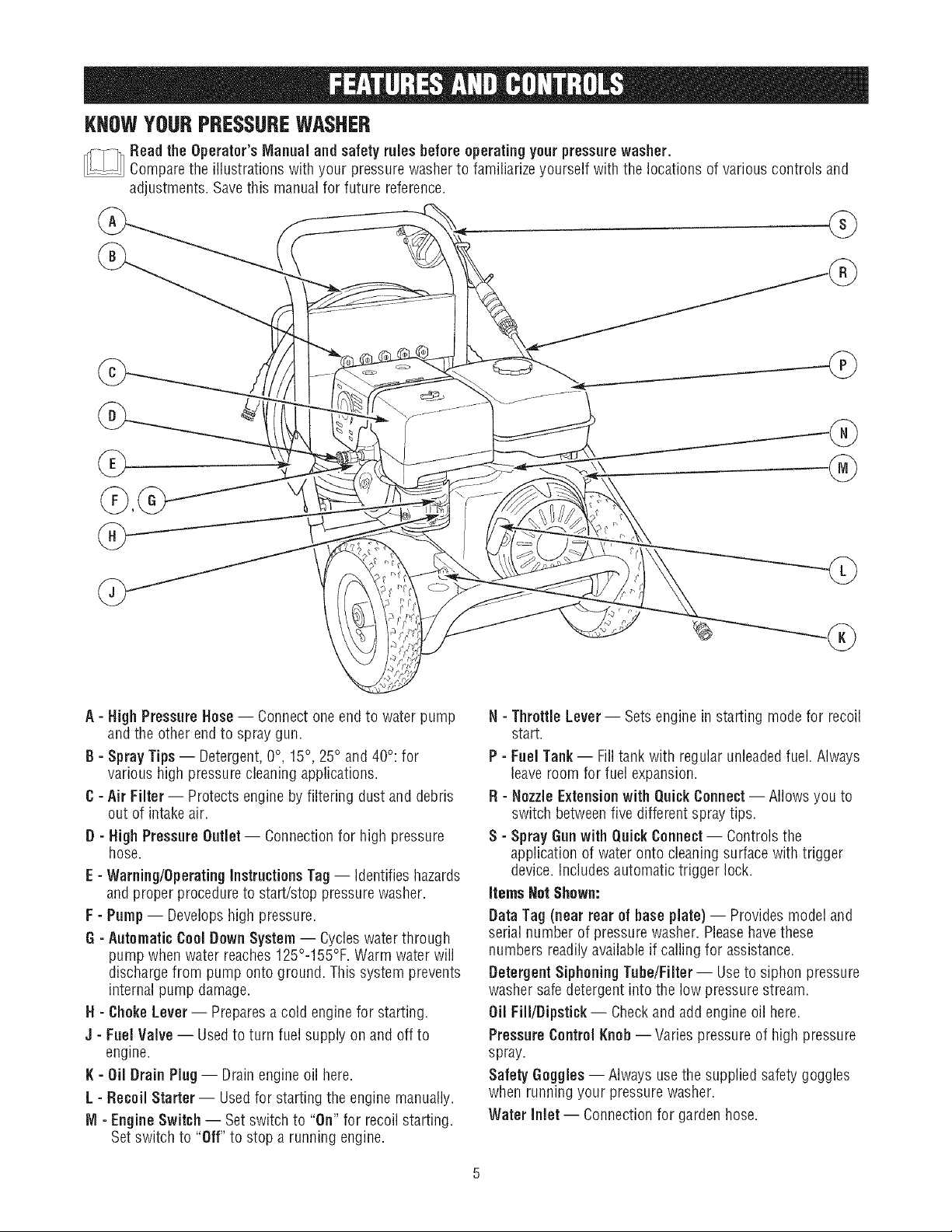

KNOWYOURPRESSUREWASHER

_Head the Operator'sIVianualandsafety rulesbeforeoperating your pressurewasher.

Comparethe illustrations with your pressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

A- High PressureHose-- Connectone end to water pump

and the other end to spray gun.

B - Spray Tips -- Detergent,0°, 15°, 25° and 40°: for

various high pressure cleaningapplications.

C- Air Filter -- Protects engine by filtering dust and debris

out of intake air.

O - HighPressureOutlet -- Connectionfor high pressure

hose.

E - Warning/Operating Instructions Tag-- Identifies hazards

and proper procedureto start/stop pressurewasher.

F - Pump-- Developshigh pressure.

G - AutomaticCool DownSystem-- Cycleswater through

pump when water reaches125°-155°F. Warm water will

dischargefrom pump onto ground. This system prevents

internal pump damage.

H - ChokeLever-- Preparesa cold engine for starting.

J - Fuel Valve -- Usedto turn fuel supply on and off to

engine.

K - Oil Drain Plug-- Drainengine oil here.

L - Recoil Starter -- Usedfor starting the engine manually.

M - Engine Switch -- Setswitch to "On" for recoil starting.

Setswitch to "Off" to stop a running engine.

H - ThrottleLever-- Setsengine in starting mode for recoil

start.

P - Fuel Tank-- Fill tank with regular unleadedfuel. Always

leaveroom for fuel expansion.

H - NozzleExtensionwith QuickConnect-- Allows you to

switch betweenfive different spray tips.

S - Spray Gunwith QuickConnect -- Controls the

application of water onto cleaning surfacewith trigger

device. Includesautomatic trigger lock.

items Not Shown:

Data Tag (near rear of base plate) -- Provides modeland

serial number of pressure washer. Pleasehavethese

numbers readily available if calling for assistance.

DetergentSiphoning Tube/Filter-- Useto siphon pressure

washer safe detergent into the low pressure stream.

Oil Fill/Dipstick -- Checkand add engine oil here.

Pressure Control Knob -- Varies pressure of high pressure

spray.

SafetyGoggles-- Always use the supplied safety goggles

when running your pressure washer.

Water Inlet -- Connectionfor garden hose.

Yourpressurewasherrequiressomeassemblyandisready

foruseonlyafterithasbeenproperlyservicedwiththe

recommendedoilandfuel.

If you have any problemswith the assembly of your

pressurewasher, please call the pressurewasher helpline

at 1-800-222-3136.

IMPORTANT:Any attempt to runthe engine before it has

been servicedwith the recommended oil will result in an

engine failure.

Unpack the Pressure Washer

1. Removeeverything from carton except pressure washer.

2. Opencarton completely bycutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

Carton Contents

Checkall contents.If anyparts are missingor damaged,call

thepressurewasherhelplineat 1-888-222-3136.

• The main unit

• Handle

• Spraygun

• Highpressure hose

• Nozzleextension with quick connect fitting

• Engineoil

• Parts bag (which includes items listed below)

• Owner's manual

• Registrationcard

• Bagcontaining 5 multi-colored quick connect spray

tips

• HandleFasteningHardwareKit (whichincludes):

• CarriageBolt (2)

• Plastic Knobs (2)

Becomefamiliar with eachpiecebefore assemblingthe

pressure washer. Checkall contents against the illustration

on page5. if any parts are missing or damaged,call the

pressure washer helpline at 1-888-222-3136.

AssembJingYour Pressure Pasher

Your Craftsman pressure washer will need assembly before

operation:

1. Fill out and send in registration card.

2. Attach handle.

3. Add oil to engine crankcase.

4. Addfuel to fuel tank.

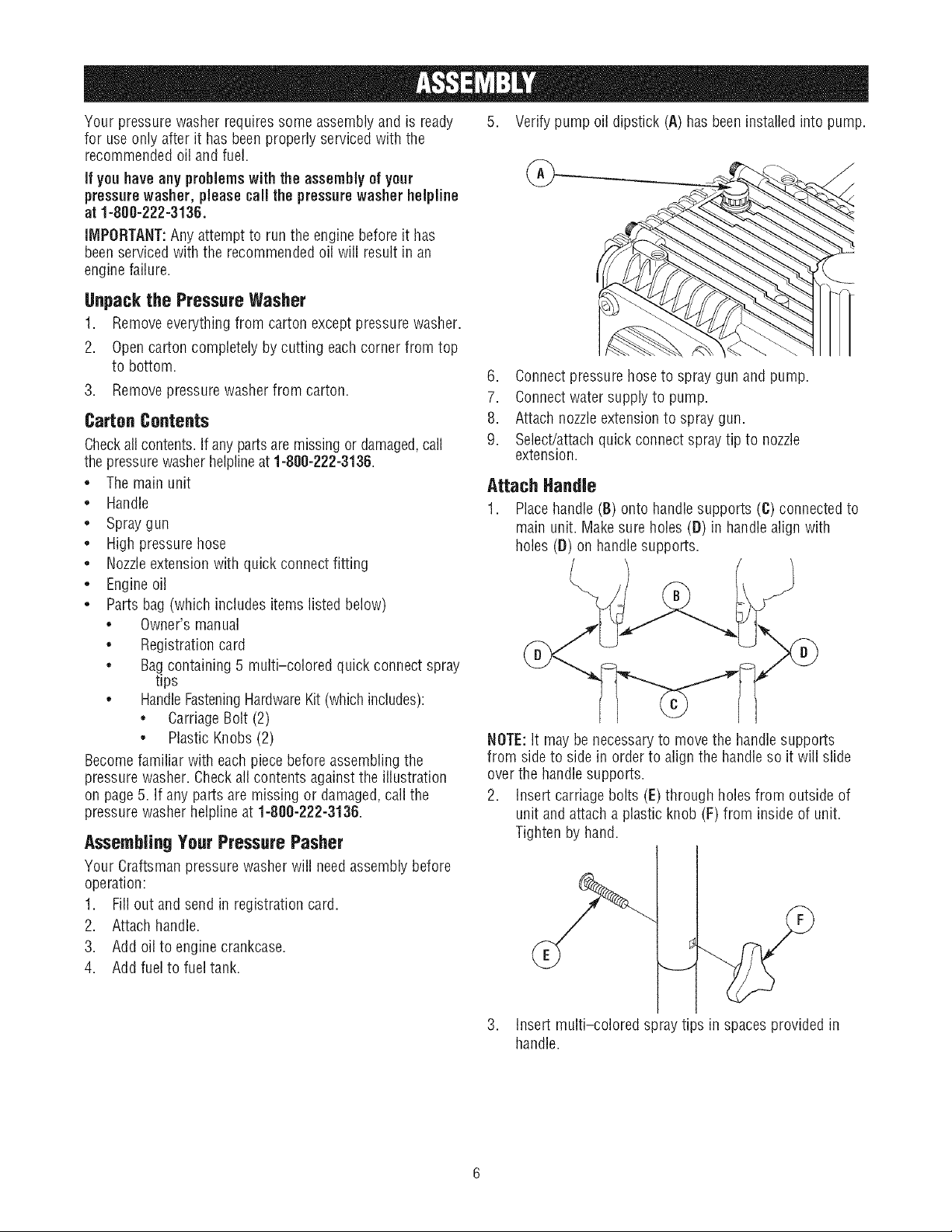

5. Verifypump oil dipstick (A) has beeninstalled into pump.

6. Connectpressure hoseto spray gun and pump.

7. Connectwater supply to pump.

8. Attach nozzleextensionto spray gun.

9. Select/attachquick connect spray tip to nozzle

extension.

Attach HandJe

1. Placehandle (B) onto handle supports (C) connected to

main unit. Makesure holes (D) in handlealign with

holes (D) on handle supports.

NOTE:it may be necessaryto movethe handlesupports

from sideto side in order to align the handle so it will slide

over the handle supports.

2. Insert carriage bolts (E)through holes from outside of

unit and attach a plastic knob (F) from inside of unit.

Tighten by hand.

3. Insert multi-colored spray tips in spacesprovided in

handle.

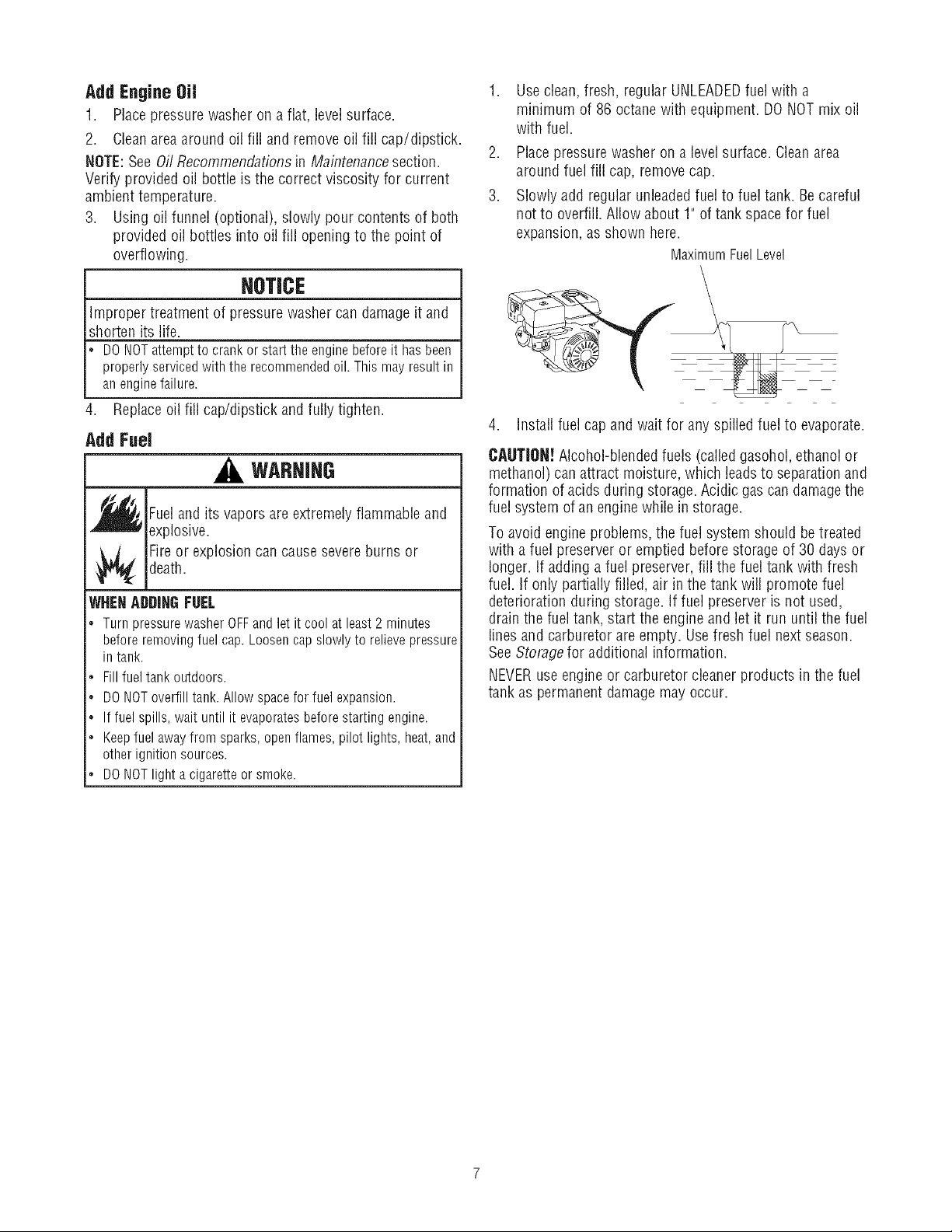

Add Engine Oil

1. Placepressurewasher on a fiat, ]eve]surface.

2. Cleanareaaround oil fill and remove oil fill cap/dipstick.

NOTE:SeeOffRecommendations in Maintenancesection.

Verify provided oil bottle is the correct viscosity for current

ambienttemperature.

3. Usingoil funnel (optional), slowly pour contents of both

provided oil bottles into oil fill openingto the point of

overflowing.

NOTICE

Improper treatment of pressurewasher can damageit and

shorten its life.

DONOTattempttocrankor starttheenginebeforeit hasbeen

properlyservicedwith therecommendedoil. Thismayresultin

anenginefailure.

4. Replaceoilfill cap/dipstick and fully tighten.

Add Fuel

WARHIHG

are extremeJy

_Fue] and its flammable and

WHENADDINGFUEL

* TurnpressurewasherOFFandletit coolat least2 rninutes

. Fillfueltankoutdoors.

* DONOToverfilltank.Allowspacefor fuelexpansion.

* If fuelspills,waituntilit evaporatesbeforestartingengine.

explosive.

death.

Fireor explosion can causesevere burns or

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

DONOTlighta cigaretteor smoke.

vapors

1. Useclean,fresh, regular UNLEADEDfuel with a

minimum of 86 octanewith equipment. DONOTmix oil

with fuel.

2. Placepressure washer on a level surface. Cleanarea

around fuel fill cap, remove cap.

3. Slowlyadd regular unleadedfuel to fuel tank. Becareful

not to overfill. Allow about 1" oftank space for fuel

expansion,as shown here.

MaximumFuelLevel

4. Install fuel cap and wait for any spilled fuel to evaporate.

CAUTION!Alcohol-blendedfuels (called gasohol, ethanol or

methanol) canattract moisture, which leads to separation and

formation of acids during storage.Acidic gas can damagethe

fuel system of an enginewhile in storage.

Toavoid engine problems, the fuel system should be treated

with a fuel preserver or emptied before storage of 30 days or

longer. If adding a fuel preserver,fill the fuel tank with fresh

fuel. if only partially filled, air in the tank will promote fuel

deterioration during storage. If fuel preserver is not used,

drain the fuel tank, start the engine and let it run until the fuel

lines and carburetor are empty. Usefresh fuel next season.

SeeStoragefor additional information.

NEVERuseengine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

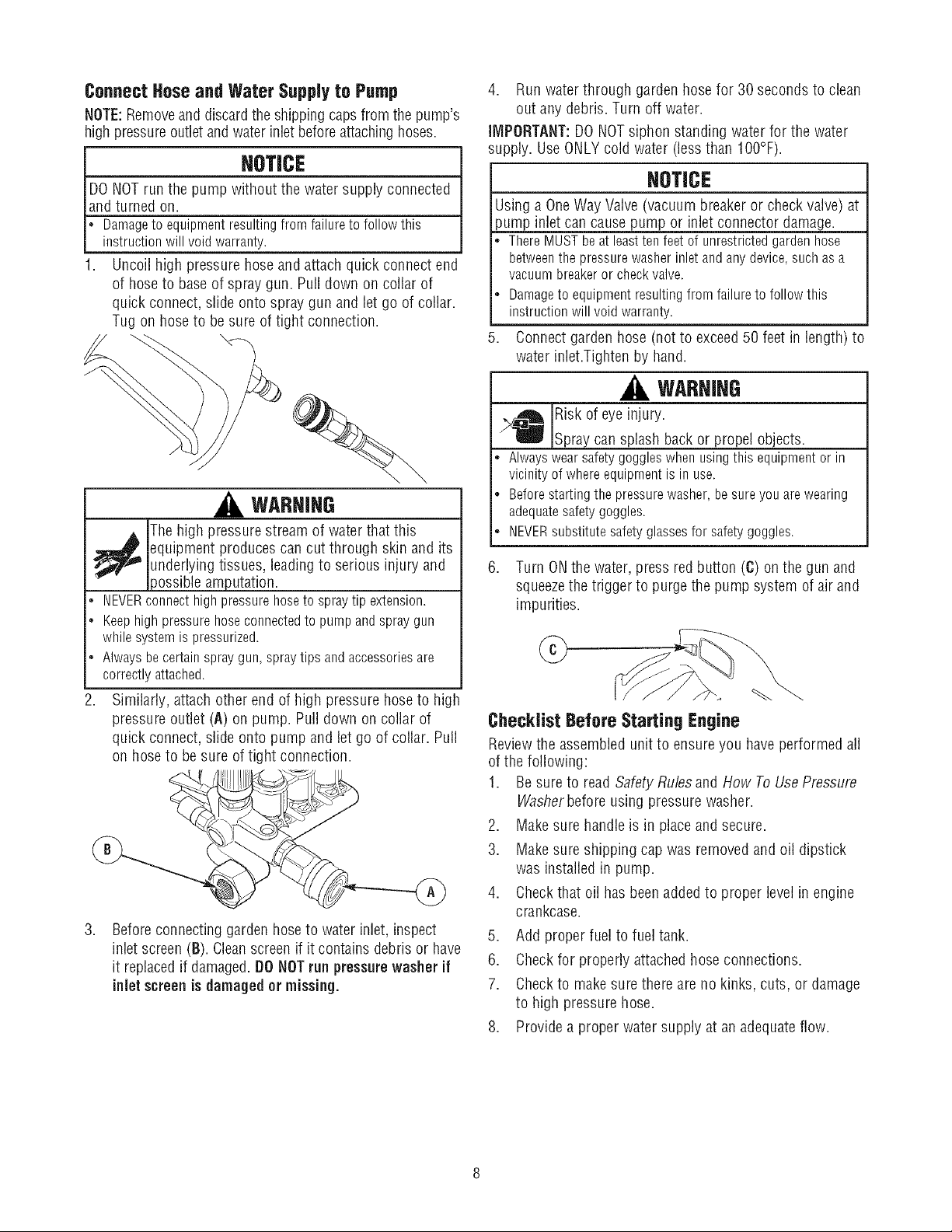

Connect Hose and Water Supply to Pump

NOTE:Removeand discardthe shippingcaps from the pump's

high pressureoutlet andwater inletbeforeattachinghoses.

NOTICE

DONOTrun the pump without the water supply connected

and turned on.

Damageto equipmentresultingfrom failuretofollowthis

instructionwill void warranty.

Uncoil high pressure hoseand attach quick connect end

of hoseto baseof spray gun. Pull down on collar of

quick connect, slide onto spray gun and let go of collar.

Tug on hoseto be sure of tight connection.

WARHIHG

The high pressure stream of water that this

4. Runwater through garden hosefor 30 secondsto clean

out any debris. Turn off water.

IMPORTANT:DO NOTsiphon standing water for the water

supply. Use ONLYcold water (less than I O0°F).

NOTICE

Using a OneWay Valve(vacuum breakeror checkvalve) at

pump inlet can cause pump or inlet connector damage.

ThereMUSTbeat leasttenfeetof unrestrictedgardenhose

betweenthepressurewasherinletandanydevice,suchasa

vacuumbreakeror checkvalve.

Damageto equipmentresultingfrom failureto followthis

instructionwillvoidwarranty.

5. Connectgarden hose (notto exceed50 feet in length) to

water inlet.Tighten by hand.

WARHIHG

Riskof eyeinjury.

_Spray can splash back or propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentisin use.

Beforestartingthe pressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

_ quipment produces can cut through skin and its

* NEVERconnecthighpressurehoseto spraytip extension.

* Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* Alwaysbecertainspraygun,spraytipsandaccessoriesare

correctlyattached.

2. Similarly, attachother end of high pressure hose to high

,

underlyingtissues, leadingto serious injury and

)ossible amputation.

pressure outlet (A) on pump. Pull down on collar of

quick connect, slide onto pump and let go of collar. Pull

on hose to be sure of tight connection.

Beforeconnecting garden hoseto water inlet, inspect

inlet screen (B). Cleanscreen if it contains debris or have

it replacedif damaged.DO NOTrun pressurewasherif

inlet screenis damagedor missing.

6. Turn ONthe water,press red button (C) on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

C>

Checklist Before Starting Engine

Reviewthe assembledunit to ensure you haveperformed all

of the following:

1. Besure to read SafetyRules and How ToUsePressure

Washerbefore using pressurewasher.

2. Makesure handle is in place and secure.

3. Makesure shipping cap was removed and oil dipstick

was installed in pump.

4. Checkthat oil has beenadded to proper levelin engine

crankcase.

5. Add proper fuelto fuel tank.

6. Checkfor properly attached hoseconnections.

7. Checkto makesure there are no kinks, cuts, or damage

to high pressure hose.

8. Providea proper water supply at an adequateflow.

HOWTOUSEYOURPRESSUREWASHER

If you haveany problems operating your pressure washer,

pleasecall the pressure washer helpline at 1-800-222-3136.

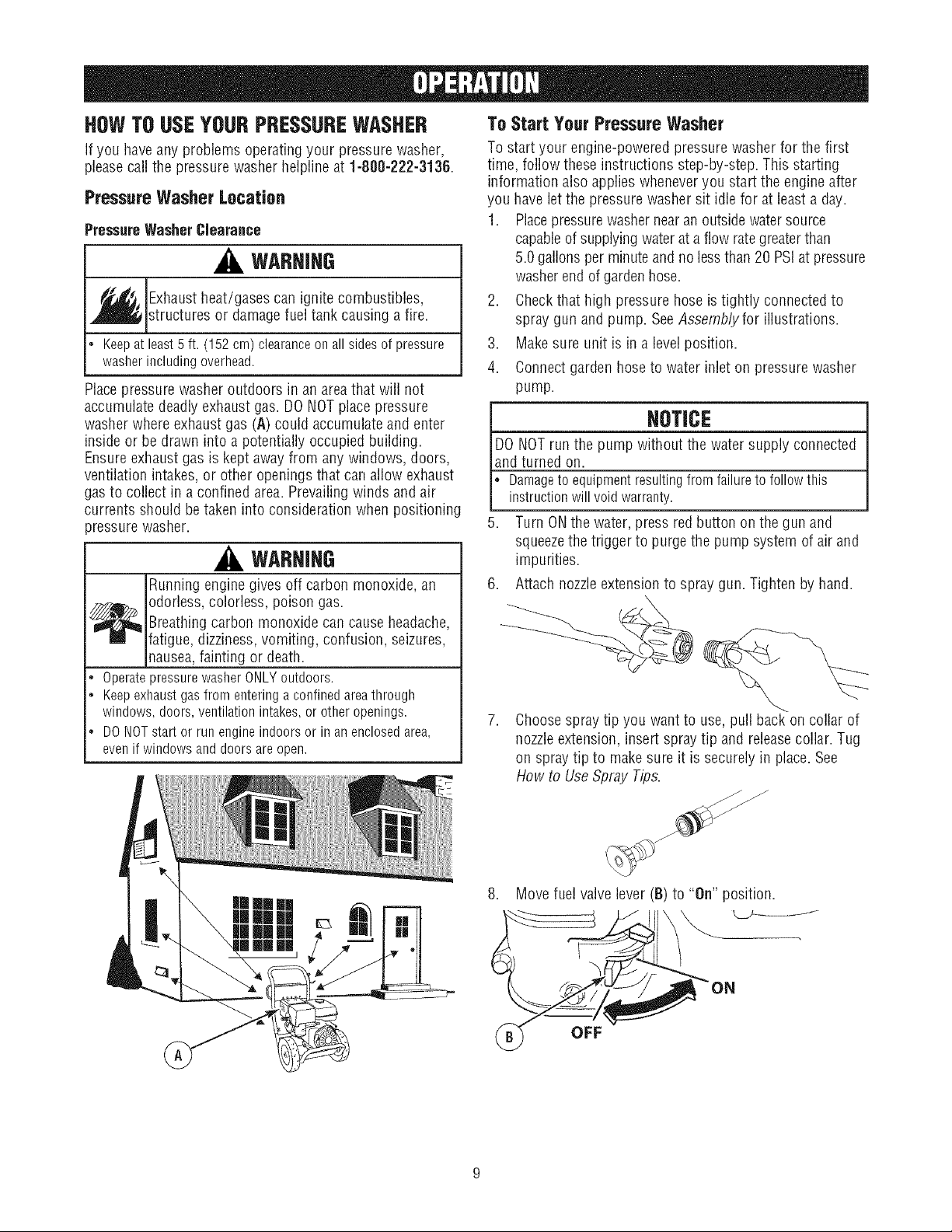

Pressure Washer Location

PressureWasherClearance

WARNING

_ Exhaustheat/gases can ignitecombustibles,

• Keepatleast5ft. (152cm)clearanceonall sidesofpressure

Placepressure washer outdoors in an areathat will not

accumulate deadlyexhaustgas. DONOTplacepressure

washer where exhaust gas (A) could accumulateand enter

inside or be drawn into a potentially occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventilation intakes, or other openingsthat can allow exhaust

gasto collect in a confined area. Prevailingwinds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

structures or damagefuel tank causing a fire.

washerincludingoverhead.

WARHIHG

Runningengine gives off carbon monoxide, an

To Start Your Pressure Washer

To start your engine-powered pressure washer for the first

time, follow these instructions step-by-step. This starting

information also applies wheneveryou start the engine after

you have letthe pressure washer sit idle for at least a day.

1. Placepressurewashernearan outsidewater source

capableof supplyingwater ata flow rate greaterthan

5.0gallons per minuteand no lessthan 20 PSIat pressure

washerend of gardenhose.

2. Checkthat high pressure hose istightly connectedto

spray gun and pump. SeeAssemblyfor illustrations.

3. Makesure unit is in a level position.

4. Connectgarden hoseto water inlet on pressure washer

pump.

[ NOTICE

IDO NOT the without the connected

and turned on.

L amageto equipmentresultingfromfailureto followthis

5. Turn ONthe water, press red button on the gun and

6. Attach nozzleextensionto spray gun. Tighten by hand.

run

instructionwillvoidwarranty.

squeezethe trigger to purge the pump system of air and

impurities.

pump

water

supply

_ dorless, colorless, poison gas.

. OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringaconfinedareathrough

• DONOTstartor runengineindoorsorin anenclosedarea,

Breathingcarbon monoxide can causeheadache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

windows,doors,ventilationintakes,or otheropenings.

evenif windowsanddoorsareopen.

||

mJ

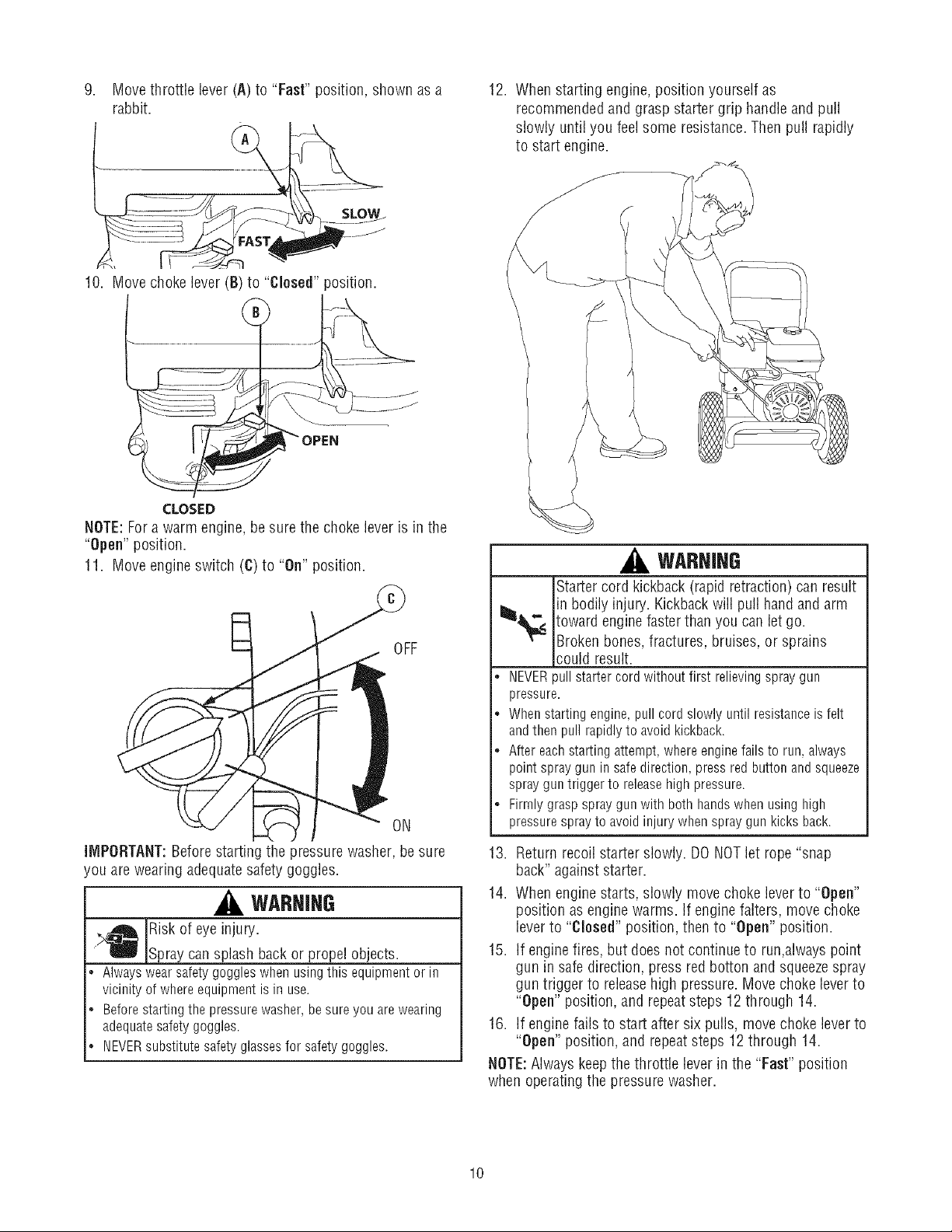

Choosespray tip you want to use, pull back on collar of

nozzleextension, insert spray tip and releasecollar. Tug

on spray tip to makesure it is securely in place. See

How to Use Spray Tips.

8. Movefuel valve lever (B) to "On" position.

OFF

9. Movethrottlelever(A)to"Fast"position,shownasa

rabbit.

10. Move choke lever (B) to "Closed" position.

CLOSED

NOTE:For a warm engine, be sure the choke lever is in the

"Open" position.

11. Move engine switch (6) to "On" position.

OFF

ON

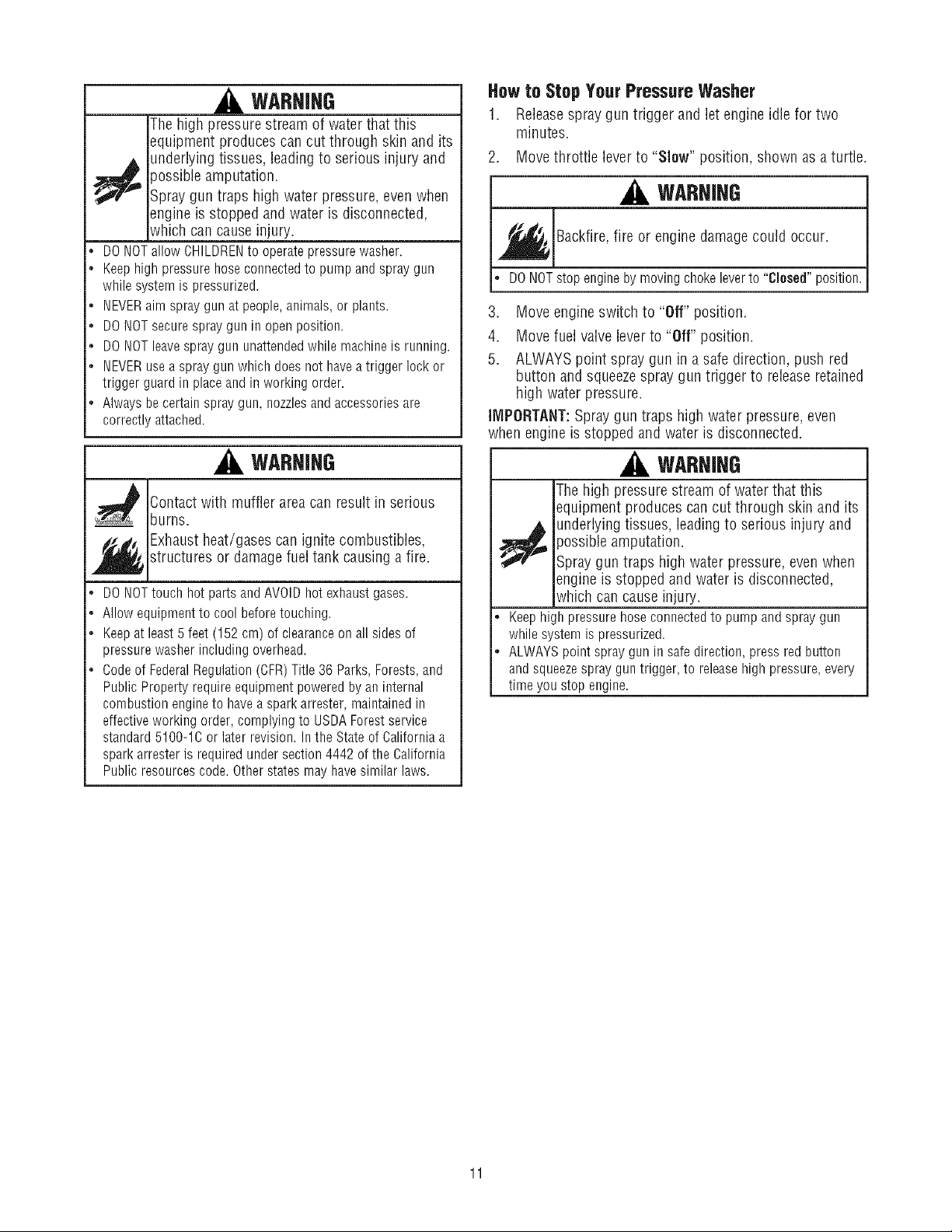

12. When starting engine, position yourself as

recommendedand grasp starter grip handleand pull

slowly until you feel some resistance.Then pull rapidly

to start engine.

WARHIHG

Starter cord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

_,_.< toward enginefaster than you canlet go.

Brokenbones, fractures, bruises, or sprains

could result.

* NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

* Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpullrapidlyto avoidkickback.

* Aftereachstartingattempt,whereenginefailsto run,always

pointspraygunin safedirection,pressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

* Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

IMPORTANT:Before starting the pressure washer, be sure

/ou are wearing adequatesafety goggles.

WARHIHG

,_ Riskof eyeinjury.

_Spray cansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthisequipmentor in

vicinityof whereequipmentisin use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

13. Return recoil starter slowly. DO NOTlet rope "snap

back"against starter.

14. When engine starts, slowly movechoke leverto "Open"

position as engine warms. If engine falters, movechoke

leverto "Closed" position, then to "Open" position.

15. If enginefires, but doesnot continue to run,always point

gun in safe direction, press red botton and squeezespray

gun trigger to releasehigh pressure. Move choke lever to

"Open" position, and repeatsteps 12through 14.

16. If enginefails to start after six pulls, movechoke leverto

"Open" position, and repeatsteps 12through 14.

NOTE:Always keepthe throttle lever in the "Fast" position

when operatingthe pressure washer.

10

WARHJHG

The high pressure stream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

• DONOTallowCHILDRENto operatepressurewasher.

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• NEVERaim spraygunat people,animals,or plants.

. DONOTsecurespraygunin openposition.

• DONOTleavespraygununattendedwhilemachineis running.

. NEVERuseaspraygunwhichdoesnot havea triggerlockor

triggerguardin placeandinworkingorder.

. Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

Howto Stop Your Pressure Washer

1. Releasespraygun trigger and let engine idle for two

minutes.

2. Movethrottle lever to "Slow" position, shown as a turtle.

WARNING

_ Backfire,fire or engine damagecould occur.

• DONOTstopenginebymovingchokeleverto "Clesed"position.

3. Moveengine switch to "Off" position.

4. Movefuel valve lever to "Off" position.

5. ALWAYSpoint spray gun in a safe direction, push red

button and squeezespray gun trigger to release retained

high water pressure.

IMPORTANT:Spraygun traps high water pressure, even

when engine is stopped and water is disconnected.

WARHIHG

s_ Oontactwith muffler area can result in serious

f,_ Exhaustheat/gases can ignite combustibles,

. DONOTtouchhotpartsandAVOIDhotexhaustgases.

• Allowequipmentto coolbeforetouching.

• Keepatleast5feet (152cm) ofclearanceonall sidesof

• Codeof FederalRegulation(CFR)Title36Parks,Forests,and

burns.

structures or damagefuel tank causing a fire.

pressurewasherincludingoverhead.

PublicPropertyrequireequipmentpoweredby aninternal

combustionengineto haveasparkarrester,maintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-1Corlaterrevision.IntheStateof Californiaa

sparkarresteris requiredundersection4442of theCalifornia

Publicresourcescode.Otherstatesmayhavesimilarlaws.

WARHIHG

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

. ALWAYSpointspraygunin safedirection,pressred button

andsqueezesprayguntrigger,to releasehighpressure,every

timeyoustop engine.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

11

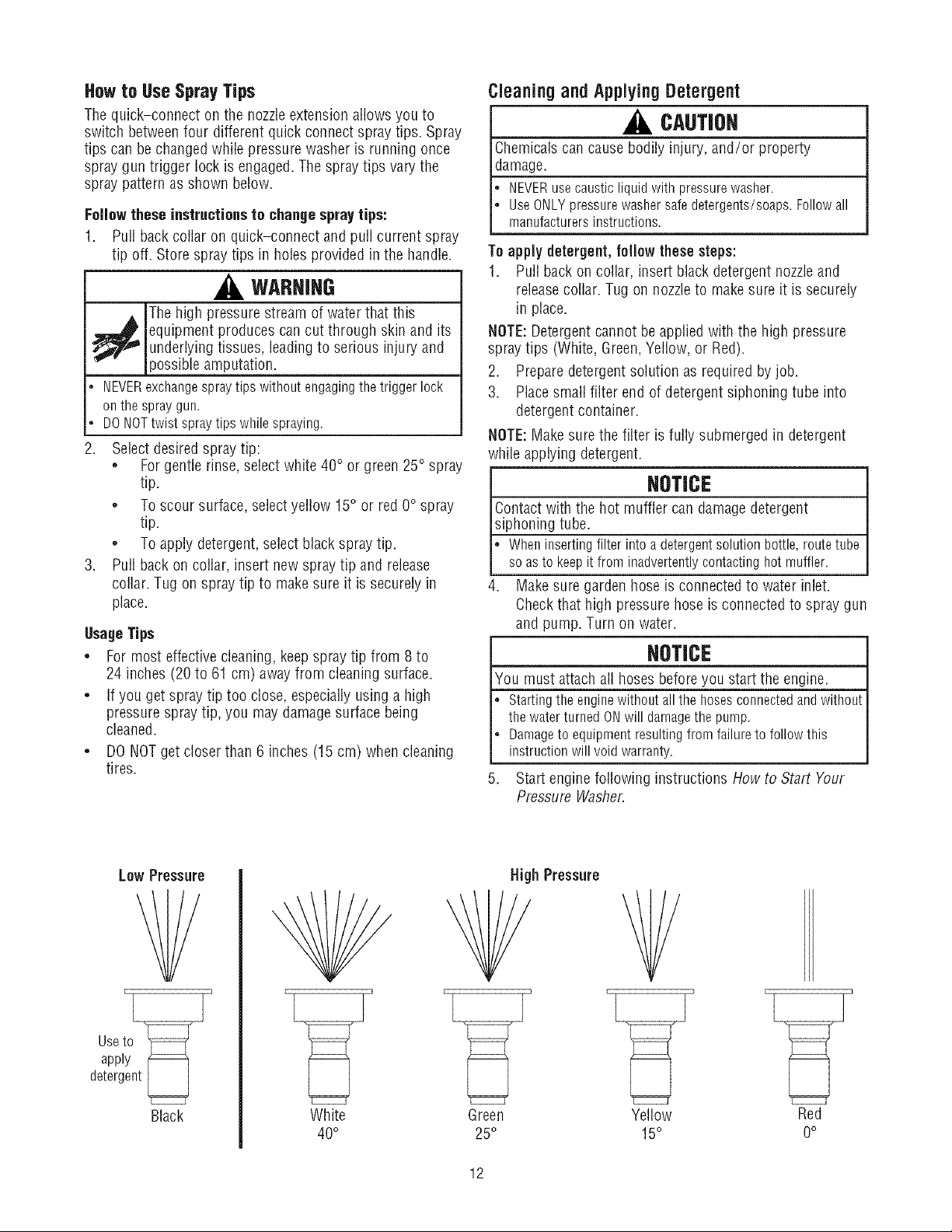

How to Use Spray Tips

Thequick-connect on the nozzleextensionallows you to

switch between four different quick connect spray tips. Spray

tips can be changedwhile pressure washer is running once

spray gun trigger lock is engaged. The spray tips vary the

spray pattern asshown below.

Followthese instructionsto changespraytips:

1. Pull back collar on quick-connect andpull current spray

tip off. Storespray tips in holes provided in the handle.

WARHIHG

The high pressure stream of water that this

_ quipment produces can cut through skin and its

. NEVERexchangespraytips withoutengagingthetriggerlock

* DONOTtwist spraytipswhilespraying.

2. Selectdesiredspray tip:

3. Pull back on collar, insert new spray tip and release

UsageTips

* Formost effective cleaning, keepspray tip from 8 to

. If you get spray tip too close, especiallyusing a high

. DO NOTget closer than 6 inches (15 cm) when cleaning

underlyingtissues, leadingto serious injury and

possible amputation.

onthespraygun.

. Forgentle rinse,select white 40° or green 25° spray

tip.

. To scour surface, selectyellow 15° or red 0° spray

tip.

. To apply detergent,selectblack spray tip.

collar. Tug on spray tip to make sure it is securely in

place.

24 inches (20 to 61 cm) awayfrom cleaning surface.

pressure spray tip, you may damagesurface being

cleaned.

tires.

Cleaning and AppJyingDetergent

CAUTION

Chemicalscan cause bodily injury, and/or property

damage.

NEVERusecausticliquidwithpressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

To apply detergent,fellow thesesteps:

1. Pullback on collar, insert black detergent nozzleand

releasecollar. Tug on nozzleto make sure it is securely

in place.

NOTE:Detergentcannot be applied with the high pressure

spray tips (White, Green,Yellow, or Red).

2. Preparedetergentsolution as required byjob.

3. Placesmall filter end of detergent siphoning tube into

detergentcontainer.

NOTE:Makesure the filter is fully submerged in detergent

while applying detergent.

[ NOTICE

Contact with the hot muffler can damagedetergent

|s phon no tube.

Wheninsertingfilter intoadetergentsolutionbottle,routetube

soasto keepit from inadvertentlycontactinghot muffler.

4. Makesure garden hose is connected to water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

NOTICE

You must attachall hosesbefore you start the engine.

Startingtheenginewithoutallthehosesconnectedandwithout

thewaterturnedONwill damagethe pump.

Damageto equipmentresultingfrom failureto followthis

instructionwillvoidwarranty.

5. Startengine following instructions How to Start Your

Pressure Washer.

Low Pressure

\

Useto

apply

detergent

Black

HighPressure

L 1 L

White Green Yellow Red

4O° 25° 15° 0o

12

r

'L

6. Applydetergenttoadrysurface,startingatlower

portionofareatobewashedandworkupward,using

long,even,overlappingstrokes.

7. Allowdetergentto"soakin"for3-5minutesbefore

washingandrinsing.Reapplyasneededtoprevent

surfacefromdrying.DONOTallowdetergenttodryon

(preventsstreaking).

IMPORTANT:Youmustflushthedetergentsiphoningsystem

aftereachusebyplacingthefilterintoabucketofclean

water,thenrunthepressurewasherwithblackdetergent

nozzlefor1-2minutes.

Pressure Washer Binsing

1. Removeblack detergent nozzlefrom nozzleextension.

2. Selectand install desiredhigh pressurespray tip

following instructions How to UseSpray Tips.

3. Keepspraygun a safe distance from areayou plan to

spray.

WARHIHG

Cleaning Detergent Siphoning Tube

If you usedthe detergentsiphoning tube,you must flush it

with cleanwater before stopping the engine.

1. Removehigh pressurespray tip from nozzleextension.

2. Selectandinstallblack detergent nozzle.

3. Placedetergent siphoning tube/filter ina bucket full of

clean water.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to release retained

high water pressure.

IMPORTANT:Spraygun traps high water pressure, even

when engine is stopped and water is disconnected.

WARHIHG

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

Kickbackfrom spray gun can cause you to fall.

, Operatepressurewasherfromastablesurface.

• Beextremelycarefulif youmustusethepressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

, Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

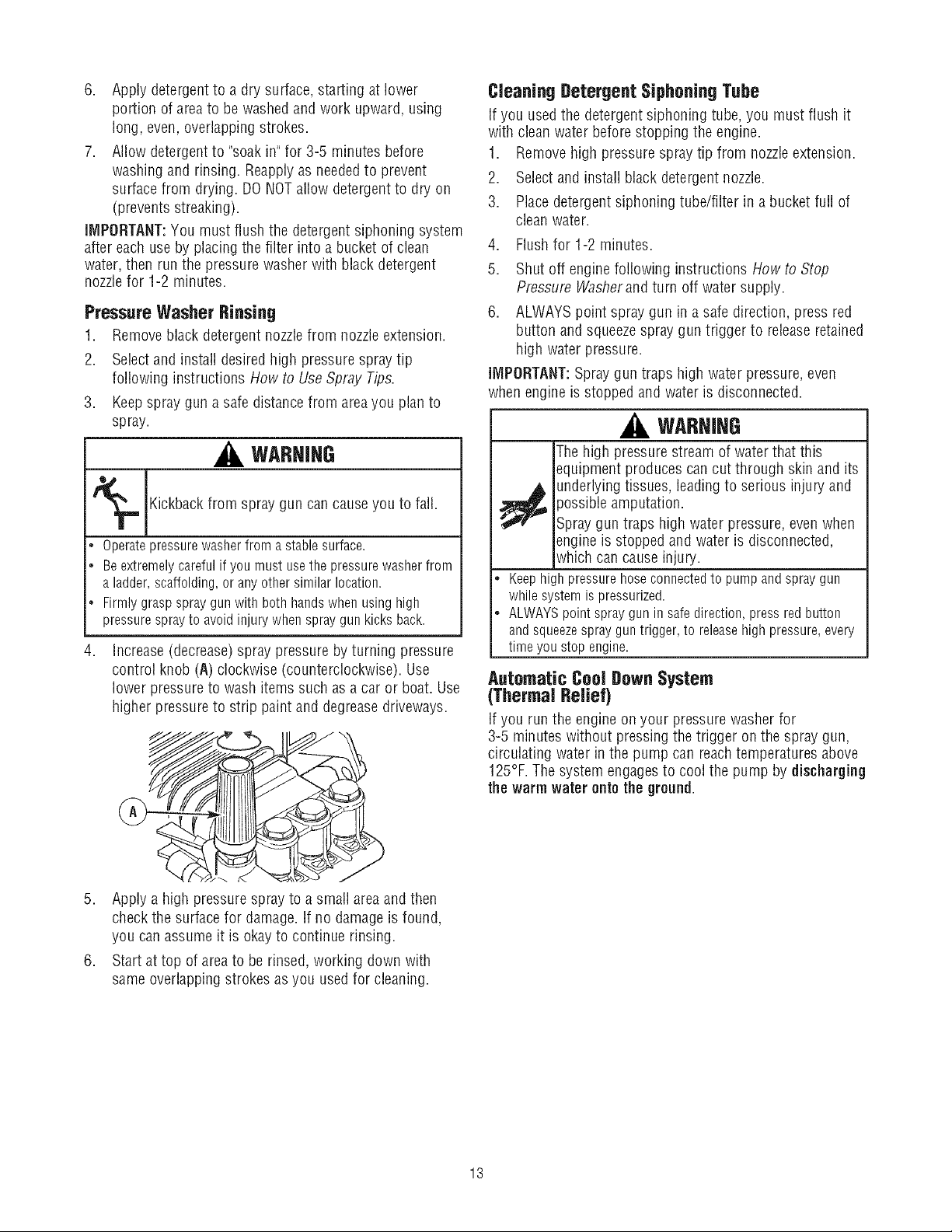

4. Increase(decrease)spray pressure by turning pressure

control knob (A) clockwise (counterclockwise). Use

lower pressureto wash items such as a car or boat. Use

higher pressureto strip paint and degreasedriveways.

5. Apply a high pressure spray to a small areaand then

checkthe surface for damage. If no damage is found,

you canassume it is okay to continue rinsing.

6. Startat top of area to be rinsed, working down with

same overlappingstrokes asyou used for cleaning.

,_ underlyingtissues, leadingto serious injury and

, Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntrigger,to releasehighpressure,every

timeyoustop engine.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

Automatic Cool Down System

(ThermalRefief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures above

125°F.The system engagesto cool the pump by discharging

the warmwater onto the ground.

13

PRODUCTSPECIFICATIONS

Pressure Washer Specifications

Pressure ..................... 3,800 PSi

Flow Rate..................... 4.0 GPM

DetergentMix ................. Useas directed

Water Supply Temperature ....... Notto exceed IO0°F

PumpOil Capacity.............. 12 fl. oz. (0.35 I)

Engine Specifications

RatedHorsepower............... 13 at3600 rpm

Bore .......................... 3.5in.(88 ram)

Stroke ......................... 2.5in. (64 ram)

Displacement................... 23.7 in. (389 cc)

SparkPlug

Resistor .................... NGKBPR6ES

SetGapTo: ................... 0.028-0.031in (0.70-0.80

ram)

IntakeValveClearance............ 0.15 _+0.02 mm (cold)

ExhaustValveClearance........... 0.20 _+0.02 mm (cold)

FuelCapacity ................... 1.72 Gallons

OilType ....................... SAE10W-30

This pressurewasher is rated in accordanceto the Pressure

Washer Manufacture Association (PWMA) standard PW101

(Testingand Rating Performanceof PressureWashers).

OWNER'SRESPONSIBILITIES

Followthe hourly or calendar intervals, whichever occurs

first. Morefrequent service is requiredwhen operatingin

adverse conditions noted below.

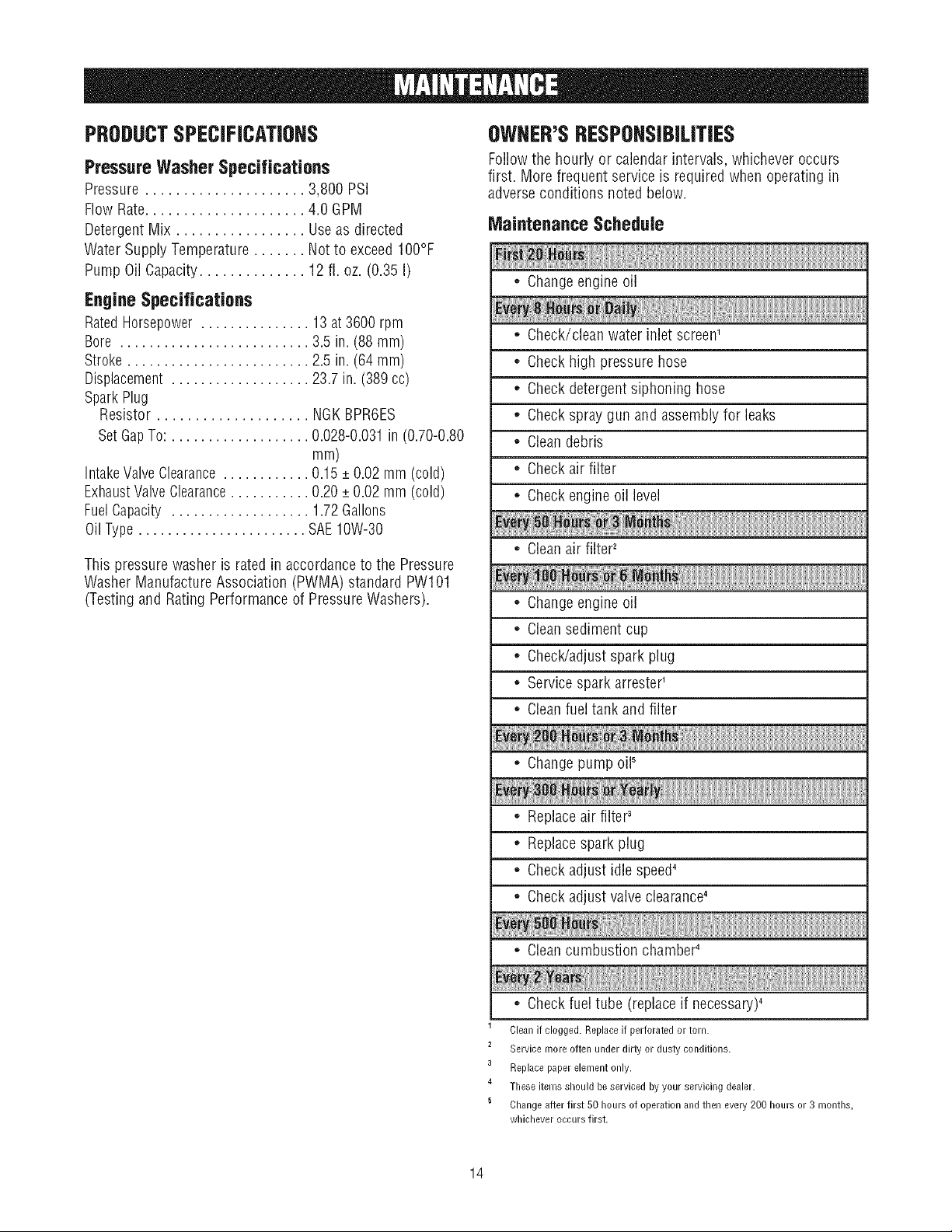

Maintenance Schedule

[i[ i[ i[i[ i[[[ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [ [

• Changeengine oil

• Check/clean water inlet screen1

Checkhigh pressure hose

• Checkdetergentsiphoning hose

• Checkspray gun and assembly for leaks

• Cleandebris

• Checkair filter

• Checkengine oil level

[ [[[ iii [[[[[[[[

• Cleanair filter'

} }: }: } [ t : ii }f}}: }: }: }: }} } } } } } } } } } } } } } } } } } } } } } }_

• Changeengine oil

• Cleansediment cup

• Check/adjustspark plug

• Servicespark arrester1

• Cleanfuel tank and filter

-- =

• Change pump oil_

):):) ))))):):)):):) ))))))))))))))))))))))))

• Replaceair filters

• Replacespark plug

• Checkadjust idle speed'

• Checkadjust valve clearance_

[_J JJt[

• Cleancumbustion chamber'

tLtLtLt i_ }[iJ[ 1iLL: J[ [ [[i[[ [ [[[ ij[ [ [j[ [ [iij[ [ Li}iL LJL LLLLL L L L L L L L L L L L

• Checkfuel tube (replaceif necessary)'

Clean if clogged. Replace if perforated or torn.

2

Service more often under dirty or dusty conditions.

3

Replacepaper element only.

4

These items should be serviced by your servicing dealer.

5

Changeafter first 50 hours of operation and then every 200 hours or 3 mooths,

whichever occurs first.

14

General Recommendations

Regularmaintenancewill improve the performance and

extendthe life of the pressure washer. Seeany Searsor

other qualified service dealerfor service.

Thepressure washer warranty doesnot cover items that

havebeen subjectedto operator abuse or negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressure washer as instructed in this manual

including proper storage as detailedin Storage.

Someadjustments will needto be madeperiodically to

properly maintain your pressure washer.

All service and adjustments should be madeat least once

eachseason. Follow the requirements in the Maintenance

Schedulechart.

NOTE:Oncea year you should clean or replacethe spark

plug and replacethe air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

Emissions Control

Maintenance, replacement,or repair of the emissions

controldevicesand systemsmay be performedby any non-

roadengine repair establishmentor individual.However,

to obtain "no charge" emissions control service,the work

must be performed by a factory authorized dealer. Seethe

Emissions Warranty.

Before Each Use

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hose for leaks.

5. Checkgun and nozzleextension assembly for leaks.

6. Purgepump of air and contaminants.

PRESSUREWASHERMAINTENANCE

Clean Debris

Dailyor before use, clean accumulated debris from pressure

washer. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

Inspectcooling air slots and openings on the pressure

washer.These openings must be kept cleanand

unobstructed.

Pressurewasher parts should be kept clean to reducethe

risk of overheatingand ignition of accumulated debris.

• Usea damp cloth to wipe exterior surfaces clean.

NOTICE

Jlmproper treatment of pressurewasher can damage it and

_horten its life. __ ....

[. DONOTinsertanyobjectsthroughcoolingslots.

• Usea soft bristle brush to loosen cakedon dirt, oil, etc.

• Usea vacuum cleaner to pick up loose dirt and debris.

Check and Clean Inlet Screen

Examinegarden hose inlet screen. Cleanif it is clogged or

replaceif it is torn.

Check High Pressure Hose

High pressure hoses can developleaksfrom wear, kinking,

or abuse, inspecthose before each use.Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings. If any of these conditions exist, replacehose

immediately.

WARHJHG

he high pressurestream of water th_

quipment produces cancut through skin and its

nderlying tissues, leadingto serious injury and

ossible amputation.

NEVERrepairhighpressurehose.Replaceit.

ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

Check Gunand Nozzle Extension

Examinehoseconnection to spray gun and makesure it is

secure. Testtrigger by pressing it and making sure it springs

back into placewhen you releaseit. Donot depress red

button and test trigger. You should not be ableto press

trigger. Replacespray gun immediately if it fails any ofthese

tests.

Nozzle Maintenance

A pulsing sensation felt while squeezingthe spray gun trigger

may be caused by excessivepump pressure. The principal

cause of excessive pump pressure is a spray tip clogged or

restricted with foreign materials,such as dirt, etc. To correct

the problem, immediately cleanthe spray tip following these

instructions:

1. Shut off engine andturn off water supply.

2. ALWAYSpoint spray gun in a safe direction, press red

button and and squeezespray gun trigger to release

retainedhigh water pressure.

WARHJHG

Thehigh pressure stream of water that this

equipment produces can cut through skin and its

:_ underlying tissues, leading to serious injury and

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntrigger,to releasehighpressure,every

timeyoustop engine.

)ossibie amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which can cause injury.

15

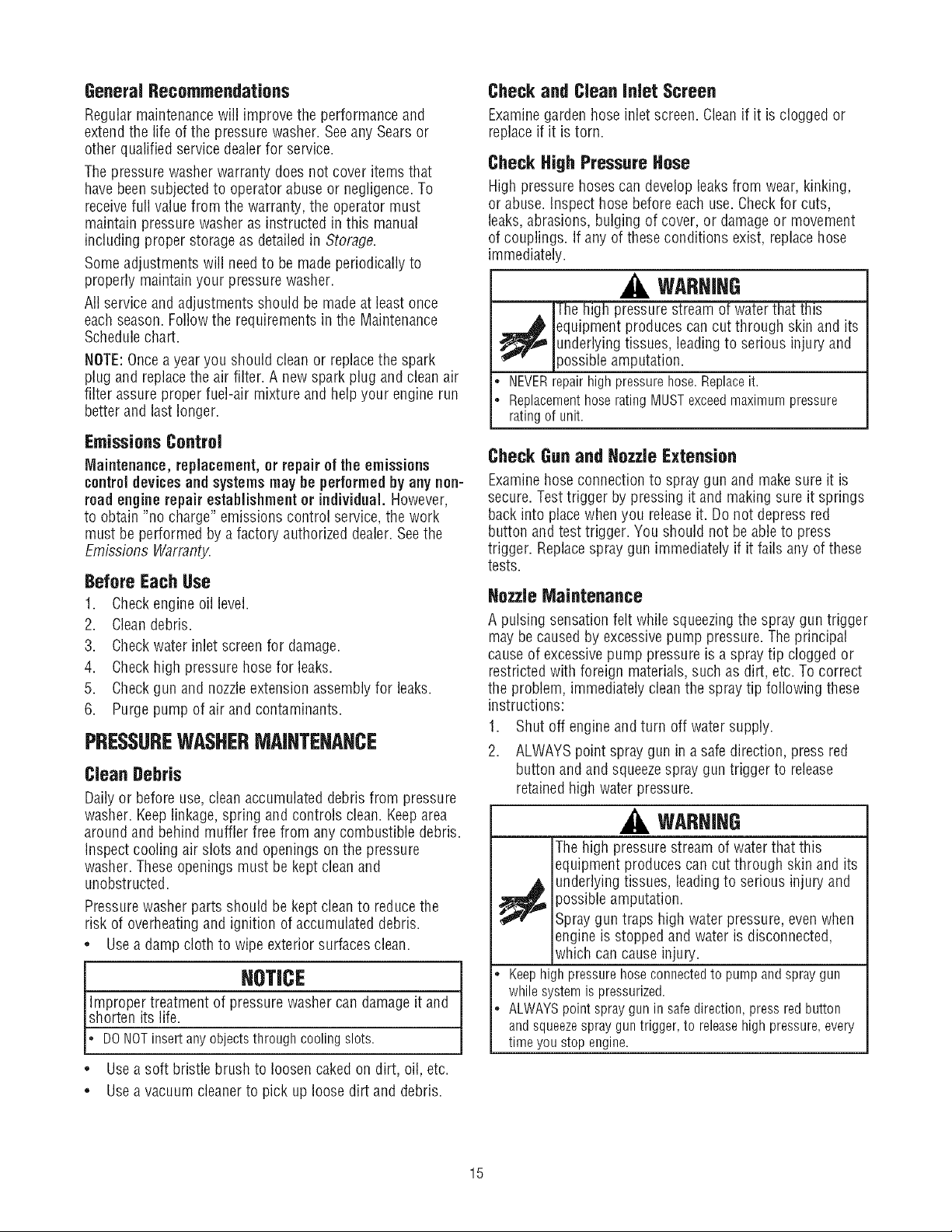

3. Removespraytipfromendofnozzleextension.

4. Useasmallpapercliptofreeanyforeignmaterial

cloggingorrestrictingspraytip(A).

5. Removenozzleextension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush

between 30 to 60 seconds.

7. Reinstallspray tip into nozzleextension.

8. Reconnectnozzleextensionto spray gun.

9. Makesure garden hose is connected to water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

10. Start engine following instructions How to Start Your

Pressure Washer.

11. Test pressure washer by operating with each quick

connect spray tip.

O-Ring Maintenance

Purchasean O-Ring RepairKitat your localSearsor by calling

1-800-4-1VlY-HOIVlE(469-4663) or onlineat www.sears.com.It

is notincludedwith thepressurewasher.Thiskit includes

replacemento-rings,rubberwasherandwater inletfilter. Referto

the instructionsheetprovidedinthekit to serviceyour unit's

o-rings.

WARHIHG

Thehigh pressurestream of water that this

_ quipment produces can cut through skin and its

• NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

Pump Maintenance

ChangingPumpOil

Changeoil after first 50 hours of operation andthen every

200 hours or 3 months, whichever occurs first.

NOTE:When changing pump oil, use only high quality

nondetergent30 weight oil. Use no special additives.

Changepumpoil as follows:

1. Cleanareaaround brass oil drain plug at bottom of

2. Removeoil drain plug. Drain oil completely into an

3. Whenoil has completely drained,install oil drain plug

4. Cleanareaaround pump oil dipstick. Removedipstick

5. Install pump oil dipstick.

6. Wipe up any spilled oil.

underlyingtissues, leadingto serious injury and

_ossibleamputation.

pump.

approvedcontainer.

and tighten firmly.

and fill pump with recommendedoil to "Full" mark on

dipstick (typically 0.35L or 12 oz.).

16

ENGINEMAINTENANCE

WARHIHG

_ Unintentionalsparking can result in fire or

ChangingEngineOil

Changeengine oil after the first 20 hours and every

100 hours or 6 months, whichever comes first, thereafter, if

you are using your pressurewasher under extremely dirty or

dusty conditions, or in extremely hot weather, changeoil

more often.

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTOYOUR

PRESSUREWASHEB

• Disconnectthesparkplugwire fromthe sparkplugandplace

thewire whereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

• Useapprovedsparkplugtester.

• DONOTcheckfor sparkwith sparkplugremoved.

0il

Oil Recommendations

NOTE:When adding oil to the engine crankcase,use only

high quality 4-stroke automotive detergent oil rated with API

serviceclassification SJ or SL rated SAE 10W-30weight. DO

NOTuse specialadditives.

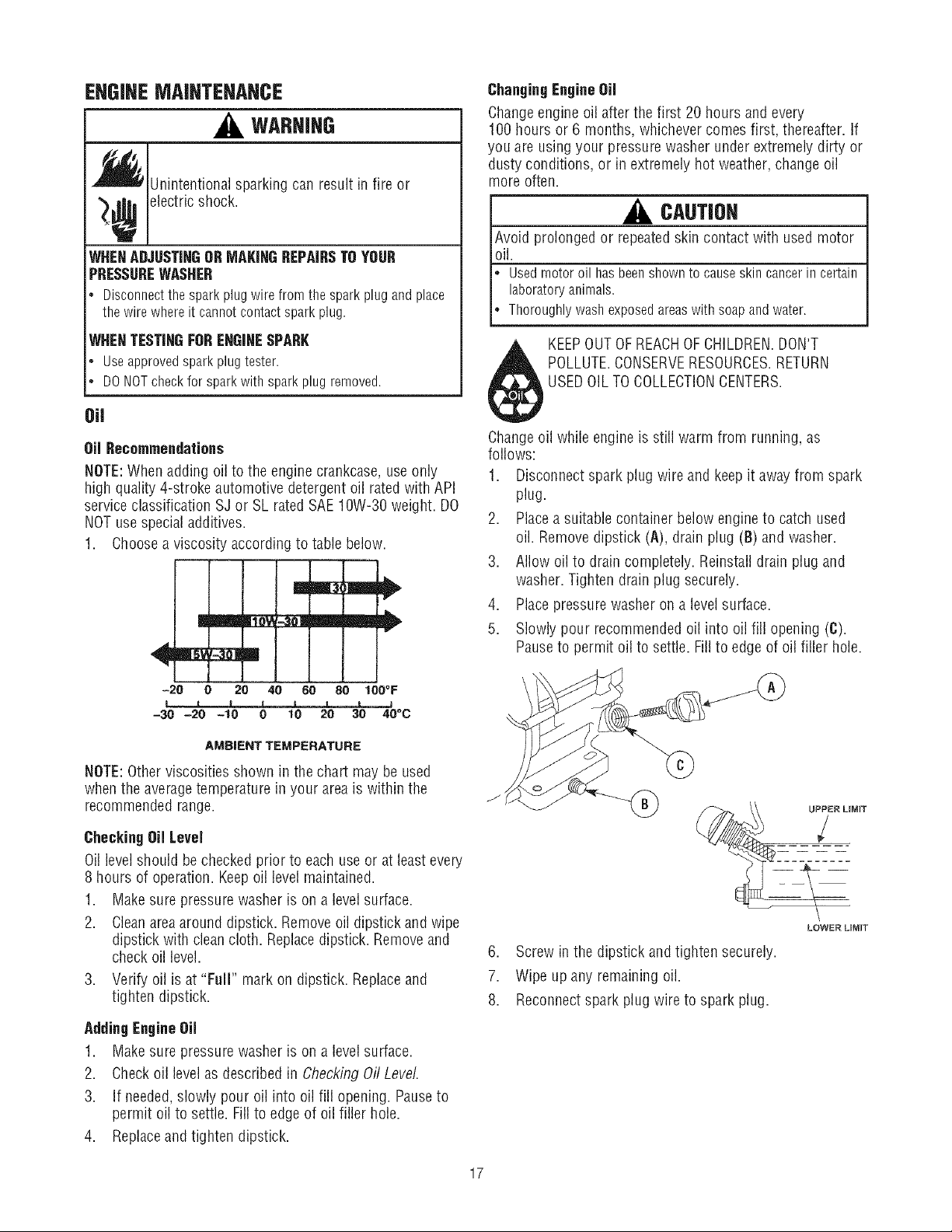

1. Choosea viscosity according to table below.

CAUTION

Avoid prolonged or repeatedskin contact with used motor

oil.

Usedmotoroil hasbeenshownto causeskincancerincertain

laboratoryanimals.

Thoroughlywashexposedareaswith soapandwater.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTO COLLECTIONCENTERS.

Changeoil while engine is still warm from running, as

follows:

1. Disconnectspark plug wire and keep it awayfrom spark

plug.

2. Placea suitable container below engine to catch used

oil. Removedipstick (A), drain plug (B) and washer.

3. Allow oil to drain completely. Reinstall drain plug and

washer. Tighten drain plug securely.

4. Placepressure washer on a level surface.

5. Slowlypour recommendedoil into oil fill opening (C).

Pauseto permit oil to settle. Fill to edge of oil filler hole.

-20 O 20 40 60 80 IOO°F

-30 -20 -t0 O 10 20 30 40°C

AMBIENTTEMPERATURE

NOTE:Other viscosities shown in the chart may be used

whenthe averagetemperature inyour areais within the

recommendedrange.

CheckingOil Level

Oil level should be checked prior to each use or at least every

8 hours of operation. Keepoil levelmaintained.

1. Make sure pressure washer is on a level surface.

2. Cleanareaaround dipstick. Removeoil dipstick and wipe

dipstick with clean cloth. Replacedipstick. Removeand

checkoil level.

3. Verify oil is at "Full" mark on dipstick. Replaceand

tighten dipstick.

AddingEngineOil

1. Make sure pressure washer is on a level surface.

2. Checkoil levelas described in Checking Oil Level

3. If needed,slowly pour oil into oil fill opening. Pauseto

permit oil to settle. Fillto edge of oil filler hole.

4. Replaceandtighten dipstick.

LOWER LIMIT

6. Screwin the dipstick and tighten securely.

7. Wipe up any remaining oil.

8. Reconnectsparkplug wire to spark plug.

17

Service Air Cleaner

Your engine will not run properly and may be damaged if you

run it with a dirty air cleaner.

Cleanthe air cleaner onceevery 50 hours of operation or

3 months, whichever comes first. Service more often if

operating under dirty or dusty conditions. Replacethe paper

filter element once every300 hours or once a year,

whichevercomes first. Replacementsareavailableat your

local Searsservicecenter.

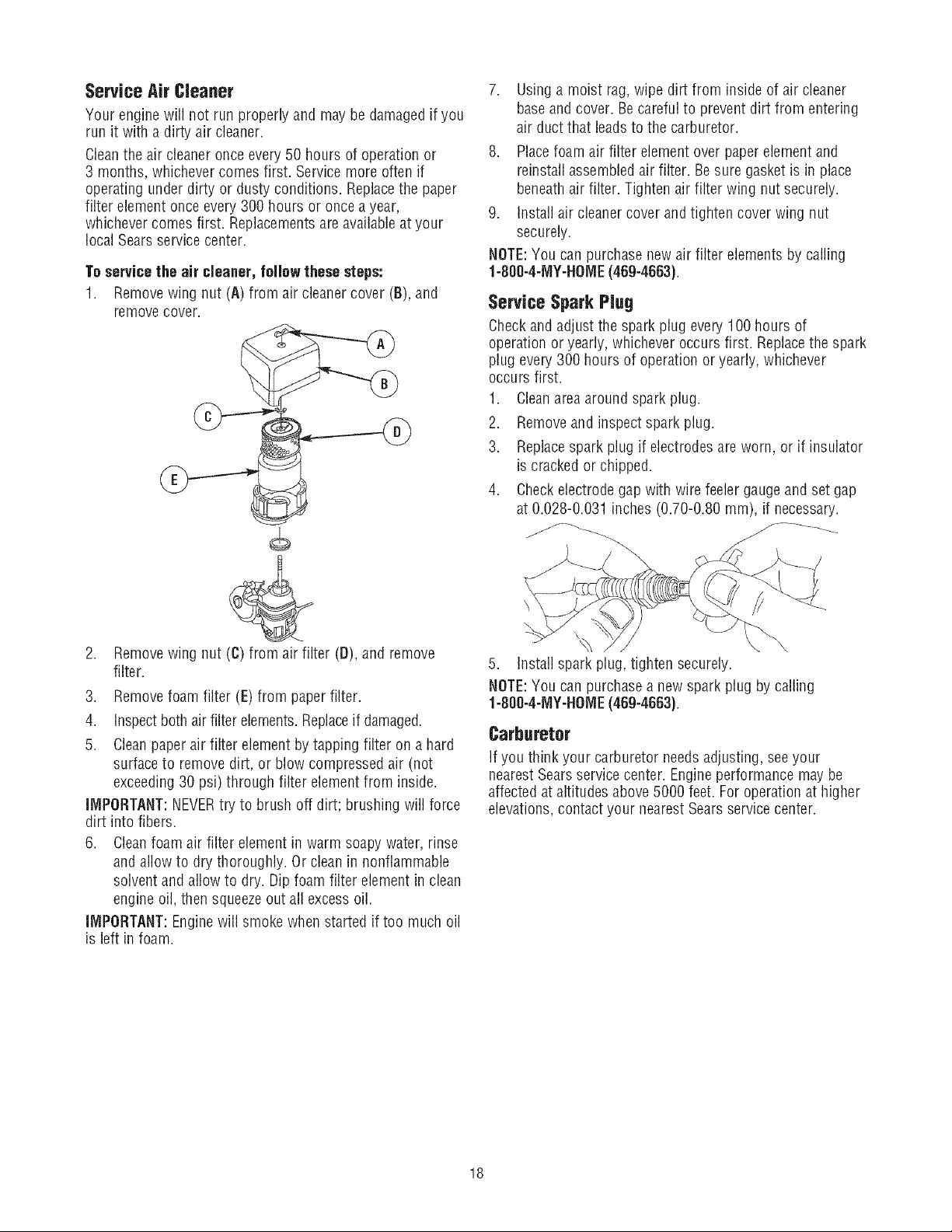

Toservice the air cleaner, follow these steps:

1. Removewing nut (A) from air cleaner cover (B), and

remove cover.

¢.

7. Usinga moist rag, wipe dirt from inside of air cleaner

baseand cover. Becareful to prevent dirt from entering

air duct that leadsto the carburetor.

8. Placefoam air filter element over paperelement and

reinstall assembledair filter. Besure gasket is in place

beneathair filter. Tighten air filter wing nut securely.

9. Install air cleaner cover andtighten cover wing nut

securely.

NOTE:You can purchase new air filter elements by calling

1-800-4-MY-HOME(46g-4663).

ServiceSparkPJug

Checkand adjust the spark plug every 100 hours of

operation or yearly, whichever occurs first. Replacethe spark

plug every300 hours of operation or yearly, whichever

occurs first.

1. Cleanarea around spark plug.

2. Removeand inspect spark plug.

3. Replacesparkplug if electrodes are worn, or if insulator

is cracked or chipped.

4. Checkelectrode gap with wire feeler gaugeand set gap

at 0.028-0.031 inches (0.70-0.80 ram), if necessary.

6

2. Removewing nut (C)fromair filter(O),and remove

filter.

3. Removefoam filter (E)from paper filter.

4. Inspectboth air filterelements. Replaceif damaged.

5. Cleanpaper air filterelement by tapping filter on a hard

surface to remove dirt, or blowcompressed air (not

exceeding30 psi) through filter elementfrom inside.

IMPORTANT:NEVERtry to brush off dirt; brushing will force

dirt into fibers.

6. Cleanfoam air filter element in warm soapy water, rinse

and allow to dry thoroughly. Or clean in nonflammable

solventand allow to dry. Dip foam filter elementin clean

engine oil, then squeezeout all excessoil.

IMPORTANT:Enginewill smokewhen started if too much oil

is left in foam.

_-_.. S Z --

5. install spark plug, tighten securely.

NOTE:You can purchasea newspark plug by calling

1-800-4-1VlY-HOIVlE(46g-4663).

Carburetor

if you think your carburetor needs adjusting, seeyour

nearest Searsservice center. Engineperformance may be

affected ataltitudes above 5000 feet. For operation at higher

elevations,contact your nearestSears service center.

18

Loading...

Loading...