Craftsman 580752352 Owner’s Manual

Operator'sManual

6.0 GROSSHORSEPOWER

2500 PSi

2.0 GPM

CLEAN GSYSTEM

Model No. 580.752352

®

CUSTOMERHELPLINE

PRESSUREWASHER

HOURS: Mon. - Fri. 8 a.m. to 5 p.m. (CT)

WARmG

Before usingthis product, readthis

manualand follow all SafetyRules

and Operating Instructions.

Sears, Roebuckand Co., RoffmanEstates,IL 60179 U.S.A.

Visit ourCraftsman website: www.craftsman.com

Part No. 199576GS Draft - (10/02/2006)

1_-illADVERTEHCIA

Antes de utilizar el producto, leaeste

manualy siga todas las Regiasde

Seguridade Instrucciones de Uso.

,, Safety

,,Assembly

,, Operation

. Maintenance

,, Parts

,, Espafiol,p. 34

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-15

SPECIFICATIONS..................................... 16

MAINTENANCE.................................... 17-21

STORAGE........................................... 22

TROUBLESHOOTING.................................. 23

REPLACEMENTPARTS.............................. 24-30

NOTES ............................................. 31

EMISSIONCONTROLWARRANTY..................... 32-33

ESPANOL......................................... 34-59

HOWTO ORDERPARTS........................ BACKPAGE

One-Year Full Warranty on Craftsman Pressure Washer

Whenassembled, operatedand maintainedaccordingto all supplied instructions, if this Craftsman PressureWasher fails due

to a defectin material or workmanship within oneyear from the dateof purchase, return it to anySearsstore or Parts &

RepairCenter or other Craftsmanoutlet in the UnitedStates for free repair (or replacementif repair provesimpossible).

This warranty excludes sparkplugs andair filters, which are expendablepartsthat can wear out from normal usein less than

one year.

All warranty coverageapplies for only 90 days from dateof purchaseif this pressure washer is ever usedfor commercial or

rentalpurposes.

This warranty gives you specific legal rights, andyou mayalso have other rights which vary from stateto state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

,_ Thisisthe safetyalert symbol.It isusedto alert youtopotential personalinjuryhazards.Obeyall safetymessages

thatfollow thissymbol te avoid possibleinjuryor death.

_Read this manualcarefully and becomefamiliar

with yourpressurewasher. Knowits applications,

its limitations, and any hazardsinvolved.

Thesafety alert symbol (_.) is used with asignal word

(DANGER,CAUTION,WARNING),apictorial and/or a safety

messageto alert you to hazards.BANGERindicates a hazard

which, if not avoided, willresult in deathor serious injury.

WARNINGindicates ahazard which, if not avoided, could

result in deathor serious injury. CAUTIONindicatesa hazard

which, if not avoided, might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage. Follow safety messagesto avoid or

reducethe risk of injury or death.

Hazard Symbolsand Meanings

ToxicFumes Hazardous Chemical ElectricalShock

2 5-

SlipperySurface Fall FluidInjection

Fire

MovingParts FlyingObjects

Explosion Operator'sManual

Kickback HotSurface

© Sears Brands, LLC

A WARNING

Theengineexhaustfrom thisproductcontains

chemicalsknowntothe Stateof California to cause

cancer,birth defects,orotherreproductiveharm.

DANGER

Contents are harmful or fatal if swallowed. Avoid

_ ontact to eyes, skin or clothing. DO NOT take

o FreshStartTMfuel cap is designedto hold acartridge which

o If SWALLOWED,callphysician immediately. DONOTinduce

o Store unopened cartridges in acool, dry, well ventilated area.

o In the caseof an emergency, contact a physician immediately

**Fuel stabilizer contains: 2,6-di-tret-butylphenol (128-39-2) and aliphatic petroleum

_ atigue, dizziness, vomiting, confusion, seizures,nausea, fainting or death.

o Operatepressurewasher ONLYoutdoors.

o Keepexhaustgas from entering a confined areathrough

o DONOTstart or run engine indoors or in an enclosedarea,

o Usea respirator or maskwheneverthere is a chance that

o Readall instructions with mask so you arecertain the mask

internally. Avoid breathing the mist or vapor.

Overexposure to eyes or skin can cause irritation.

Keep stabilizer out of the reach of children.

Fuel stabilizer is a hazardous chemical.**

contains fuel stabilizer.

vomiting. If inhaled, remove to fresh air. In case of eye or skin

contact, flush with water for 15 minutes.

Keepopen cartridge in fuel cap, and fuel cap closed on fuel

tank when not in use.

andcall 1-800-424-9300 for material safety information.

distillate (64742-47-8).

WABHIHG

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting, or poisoning.

windows, doors, ventilation intakes, or other openings.

evenif windows and doors are open.

vapors may be inhaled.

will provide the necessary protection against inhaling harmful

vapors.

_Fuel and its are extremely flammable and

WHEN ADDING OR DRAINING FUEL

o Turn pressurewasher OFFand let it cool at least 2 minutes

o Fillor drain fuel tank outdoors.

o DONOToverfill tank. Allow space for fuel expansion.

o If fuel spills, wait until it evaporatesbefore starting engine.

o Keepfuel away from sparks, open flames, pilot lights, heat,

o DONOTlight a cigarette or smoke.

WHENSTARTINGEQUIPMENT

o Ensurespark plug, muffler, fuel cap, andair cleaner are in

o DONOTcrankengine with spark plug removed.

WHENOPERATINGEQUIPMENT

o DONOTtip engine or equipmentat angle which causes fuel to

o DONOTspray flammable liquids.

WHENTRANSPORTINGOR REPAIRINGEQUIPMENT

o Transport/repair with fuel tank EMPTYor with fuel shutoff

o Disconnect spark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUELIN TANK

o Storeaway from furnaces, stoves, water heaters,clothes

explosive.

death.

Fire or explosion can cause severe burns or

before removing fuel cap. Loosen cap slowly to relieve

pressure intank.

andother ignition sources.

place.

spill.

valve OFF.

dryers, or other appliances that havepilot light or other

ignition source becausethey can ignite fuel vapors.

vapors

WARHIHG

_¢ Risk of electrocution.

o NEVERspray nearpower source.

Contact with power source can cause electric

shock or burn.

Startercord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handandarm

_,1_ toward engine faster than you can let go.

Brokenbones, fractures, bruises, or sprains

could result.

o NEVERpull starter cord without first relieving spray gun

pressure.

o When starting engine, pull cord slowly until resistance is felt

andthen pull rapidly to avoid kickback.

o After each starting attempt, where engine fails to run, always

point spray gun insafe direction and squeezespray gun trigger

to releasehigh pressure. Engagespray gun trigger lock.

o Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

WARHIHG

._ Use of pressure washer can create puddles and

slippery surfaces.

_1_ Kickback from spray gun can cause you to fall.

o Operatepressurewasher from a stable surface.

o Thecleaning area should haveadequateslopes and drainageto

reducethe possibility of afall due to slippery surfaces.

o Beextremely careful if you must usethe pressurewasher from

a ladder, scaffolding, or any other similar location.

o Firmly grasp spray gun with both hands when using high

pressure sprayto avoid injury when spray gun kicks back.

WARHIHG

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

o DONOTallow CHILDRENto operate pressure washer.

o NEVERrepair high pressure hose. Replaceit.

o NEVERrepair leaking connections with sealantof any kind.

Replaceo-ring or seal.

o NEVERconnect high pressure hoseto nozzleextension.

o Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

o ALWAYSpoint spray gun in safe direction and squeezespray

gun trigger, to releasehigh pressure, everytime you stop

engine. Engagetrigger lockwhen not in use.

o NEVERaim spray gun at people, animals, or plants.

o DONOTsecurespray gun in open position.

o DONOTleavespray gun unattendedwhile machine is running.

o NEVERusea spray gun which does not have a trigger lock or

trigger guard in place and inworking order.

o Alwaysbe certain spray gun, nozzlesand accessoriesare

correctly attached.

_ Unintentional sparking can result in fire or

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

_, ontact with muffler area can result in serious

_ Exhaust heat/gases can ignite combustibles,

o DONOTtouch hot parts and AVOIDhot exhaust gases.

o Allow equipment to cool before touching.

o Keepat least 5 feet (152cm) of clearance on all sides of

o Codeof FederalRegulation (CFR)Title 36 Parks,Forests, and

burns.

structures or damage fuel tank causing a fire.

pressure washer including overhead.

Public Property require equipment powered by an internal

combustion engineto have a spark arrester, maintained in

effective working order, complying to USDAForestservice

standard 5100-10 or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may havesimilar laws.

_¢ electric shock.

WHENADJUSTINGOR MAKINGREPAIRSTOYOURPRESSURE

WASHER

o Disconnect the spark plug wire from the spark plug andplace

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

o Useapproved spark plug tester.

o DONOTcheck for sparkwith spark plug removed.

ihands, hair, clothing, or accessories.

Starter andother rotating parts canentangle

. NEVERoperatepressurewasherwithoutprotectivehousingor

covers.

° DONOTwearlooseclothing,jewelryor anythingthatmaybe

caughtinthestarteror otherrotatingparts.

° Tieuplonghairandremovejewelry.

A wnems

. lways wear safety goggles when using this equipment or in

vicinity of where equipment is in use.

° Before starting the pressure washer, be sure you are wearing

adequatesafety goggles.

NOTICE

High pressure spray may damage fragile items including

glass.

DO NOTpoint spray gun at glass when using MAX (pin point)

nozzle.

NEVERaim spray gun at plants.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

If you have questions about intended use, ask dealeror contact

Sears.

NEVERoperate units with broken or missing parts, or without

protective housing or covers.

DO NOTby-pass any safety device on this machine.

DO NOTtamper with governed speed.

DO NOToperate pressure washer above rated pressure.

DO NOTmodify pressure washer in anyway.

Beforestarting pressure washer in cold weather, check all

parts ofthe equipment to be sure ice hasnot formed there.

NEVERmove machineby pulling on hoses. Usehandle

provided on unit.

Checkfuel systemfor leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washer.

This equipment is designed to be used with Searsauthorized

parts ONLY.If equipment is usedwith parts that DONOT

comply with minimum specifications, userassumes all risks

and liabilities.

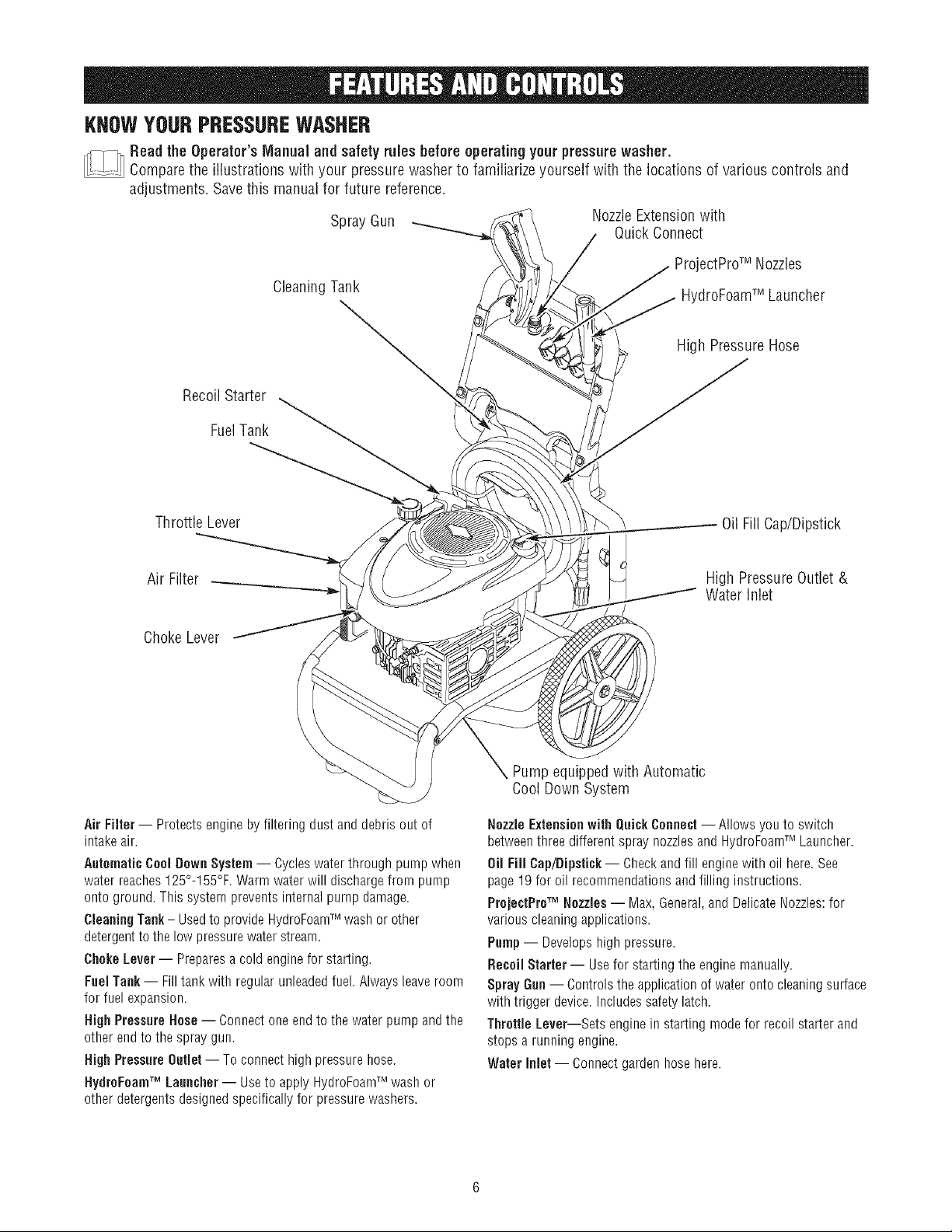

KNOWYOURPRESSUREWASHER

_Read the Operator'sManual andsafety rules before operatingyourpressurewasher.

Comparethe illustrations with your pressurewasher to familiarize yourself with the locations of various controls and

adjustments. Savethis manual for future reference.

Spray Gun

CleaningTank

RecoilStarter

FuelTank

NozzleExtensionwith

Quick Connect

ProjectProTM Nozzles

HydroFoamTM Launcher

High PressureHose

Throttle Lever

Air Filter

Choke Lever

Air Filter-- Protects engine byfiltering dust and debris out of

intakeair.

Automatic Cool Down System -- Cycleswater through pump when

water reaches 125°-155°F. Warm water will discharge from pump

onto ground. This system prevents internal pump damage.

Cleaning Tank- Usedto provideHydroFoamTM wash or other

detergentto the low pressurewater stream.

Choke Lever -- Preparesa cold engine for starting.

FuelTank -- Fill tank with regular unleadedfuel. Always leave room

for fuel expansion.

High Pressure Hose-- Connectone end to the water pump andthe

other endto the spray gun.

High Pressure Outlet -- To connect high pressure hose.

NydroFoamTM Launcher -- Use to apply HydroFoamTM wash or

other detergents designed specifically for pressure washers.

Oil FillCap/Dipstick

High PressureOutlet &

Water Inlet

Pumpequipped with Automatic

Cool Down System

NozzleExtensionwithQuickConnect-- Allowsyouto switch

betweenthreedifferentspraynozzlesandHydroFoamTM Launcher.

Oil FillCap/Dipstick-- Checkandfill enginewithoil here.See

page19for oil recommendationsandfilling instructions.

ProjectProTM Nozzles-- Max,General,andDelicateNozzles:for

variouscleaningapplications.

Pump-- Developshighpressure.

RecoilStarter-- Useforstartingtheenginemanually.

SprayGun-- Controlstheapplicationofwaterontocleaningsurface

withtriggerdevice.Includessafetylatch.

ThrottleLever--Setsengineinstartingmodefor recoilstarterand

stopsa runningengine.

WaterInlet-- Connectgardenhosehere.

Yourcleaningsystemrequiressomeassemblyandisready

foruseonlyafterithasbeenproperlyservicedwiththe

recommendedoilandfuel.

If you have any problemswith the assemblyof your

pressurewasher, please call the pressurewasher heipline

at 1-800-222-3135.

UNPACKTHE PRESSUREWASHER

1. Removeeverything from carton exceptpressure washer.

2. Opencarton completely by cutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

CARTONCONTENTS

Checkall contents. If any parts are missing or damaged,call

the pressure washer helpline at 1-800-222-3136.

• Main Unit

• Handlewith CleaningTankAssembly

• AccessoryTray

• High PressureHose

• Spray Gun

• NozzleExtensionwith Ouick ConnectFitting

• HydroFoamTM Wash

• Oil Bottle

• Parts Bag (which includes the following):

• Operator's Manual

• Owner's Registration Card

• SafetyGoggles

• Bagcontaining 3 multi-colored ProjectProTM Nozzles

• HydroFoamTM Launcher

• HydroFoamTM Launcher & Wash Instruction Sheet

• FreshStart FuelCartridge

• HandleFasteningHardwareKit (whichincludes):

• CarriageBolts (2)

• Plastic Knobs (2)

• TreeClips (4)

Becomefamiliar with eachpiecebefore assemblingthe

pressure washer. Identify all contents with the illustration on

page 6. If any parts are missing or damaged,callthe

pressure washer helpline at 1-800-222-3136.

ASSEMBLINGCLEANIHGSYSTEM

Your Craftsmancleaning system wiil needassembly before

operation:

1. Fillout and send in registration card.

2. Attach handleand accessorytray.

3. Connectdetergentsiphon hose to pump.

4. Add oil to engine crankcase.

5. Add fuelto fuel tank.

6. Connectpressure hoseto spray gun and pump.

7. Connectwater supply to pump.

8. Attach nozzleextension to spray gun.

9. Select/attachquickconnect ProjectProTM nozzleto nozzle

extension.

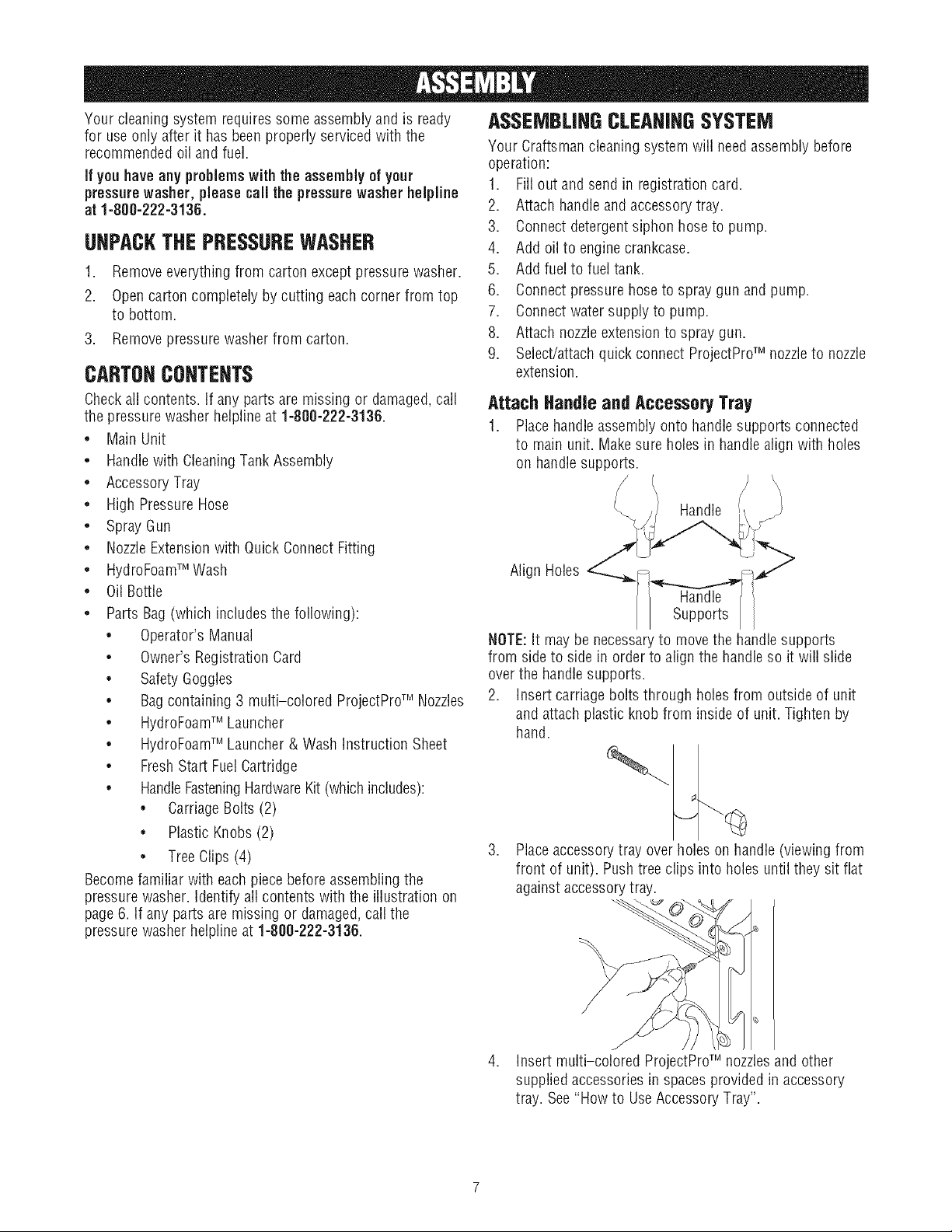

Attach Handle and Accessory Tray

1. Placehandle assembly onto handlesupports connected

to main unit. Makesure holes in handle align with holes

on handlesupports.

Handle

Supports /

NOTE:It may be necessaryto move the handle supports

from sideto side in order to align the handleso it will slide

overthe handlesupports.

2. Insert carriage bolts through holesfrom outside of unit

and attachplastic knob from inside of unit. Tighten by

hand.

%.

3. Placeaccessorytray over holes on handle (viewing from

front of unit). Push treeclips into holes until they sit flat

against accessory tray.

4. Insert multi-colored ProjectProTM nozzlesand other

supplied accessories inspaces provided in accessory

tray. See"How to UseAccessory Tray".

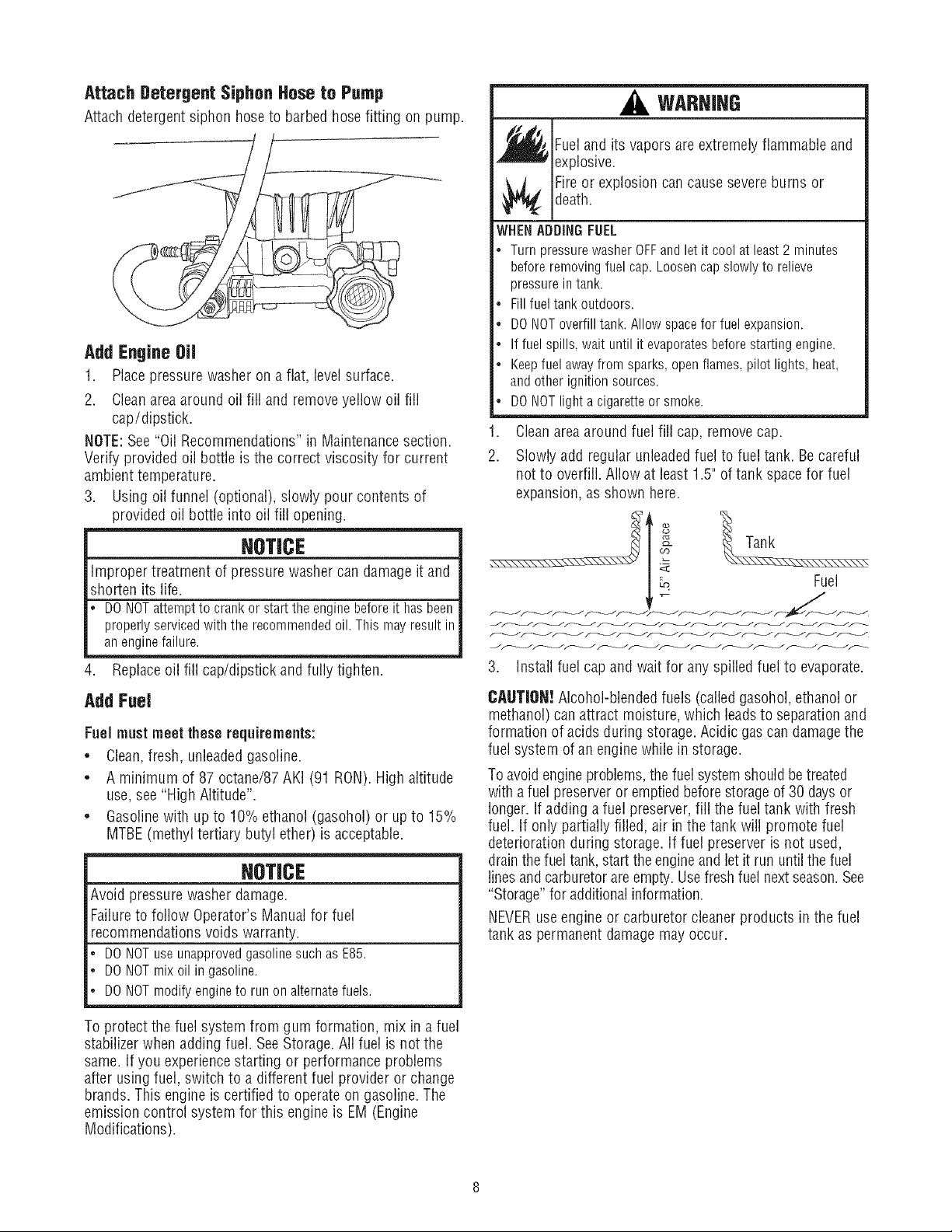

Attach Detergent Siphon Hose to Pump

Attach detergent siphon hoseto barbed hose fitting on pump.

Add Engine Oil

1. Race pressurewasher on a flat, ]eve]surface.

2. Cleanarea around oil fill andremove yellow oil fill

cap/dipstick.

NOTE:See"Oil Recommendations" in Maintenancesection.

Verify provided oil bottle is the correct viscosity for current

ambient temperature.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

DONOTattemptto crankor starttheenginebeforeit hasbeen

properlyservicedwiththerecommendedoil. Thismayresultin

anenginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

_ uel and itsvapors are extremely flammable and

WHENADDINGFUEL

° TurnpressurewasherOFFandletit coolatleast2 minutes

° Fillfueltankoutdoors.

° DONOToverfilltank.Allowspacefor fuelexpansion.

° If fuelspills,waituntilit evaporatesbeforestartingengine.

° Keepfuelawayfromsparks,openflames,pilot lights,heat,

° DONOTlightacigaretteor smoke.

1. Cleanareaaround fuel fill cap, removecap.

2. Slowly add regularunleadedfuel to fuel tank. Becareful

3. Install fuel cap and wait for any spilled fuel to evaporate.

explosive.

death.

Fireor explosion can causesevere burns or

beforeremovingfuelcap.Loosencapslowlyto relieve

pressureintank.

andotherignitionsources.

not to overfill. Allow at least 1.5" of tank spacefor fuel

expansion,as shown here.

Add Fuel

Fuel must meetthese requirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87 AKI (91 RON).Highaltitude

use,see"High Altitude".

• Gasolinewith up to 10% ethanol (gasohoI) or up to 15%

MTBE(methyl tertiary butyl ether) is acceptable.

NOTICE

Avoid pressure washer damage.

Failureto follow Operator's Manualfor fuel

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchasE85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizerwhen adding fuel. SeeStorage. All fuel is not the

same. If you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline. The

emission control system for this engine is EM(Engine

Modifications).

CAUTION! Alcohol-blendedfuels (calledgasohol, ethanol or

methanol) can attract moisture, which leadsto separationand

formation of acids during storage. Acidic gas candamagethe

fuel system ofan engine while in storage.

To avoid engineproblems,thefuel systemshould betreated

with afuel preserveror emptiedbeforestorageof 30 days or

longer.If adding a fuel preserver,fill the fuel tank with fresh

fuel. if only partially filled, air in the tank will promote fuel

deterioration during storage, if fuel preserver is not used,

drainthefuel tank,start the engineandletit run untilthe fuel

linesandcarburetorareempty. Usefreshfuel nextseason.See

"Storage"for additionalinformation.

NEVERuseengine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

FreshStartFuelCap

Adding fuel preserver helps keepfuel fresh and carburetors

cleanfor easier starting, all seasonlong. Thisnew fuel cap

automatically drips concentratedfuel preserver into your fuel

tank_

Connect Hose and Water Supply to Pump

DANGER

Contentsareharmful or fatal if swallowed. Avoid

_ ontact to eyes,skin or clothing. DONOTtake

o If SWALLOWED,callphysicianimmediately.

o Inthecaseof anemergency,contactaphysicianimmediately

**Fuel stabilizer contains: 2,6-di-tret-butylphenol (128-39-2) and alipbatie petroleum

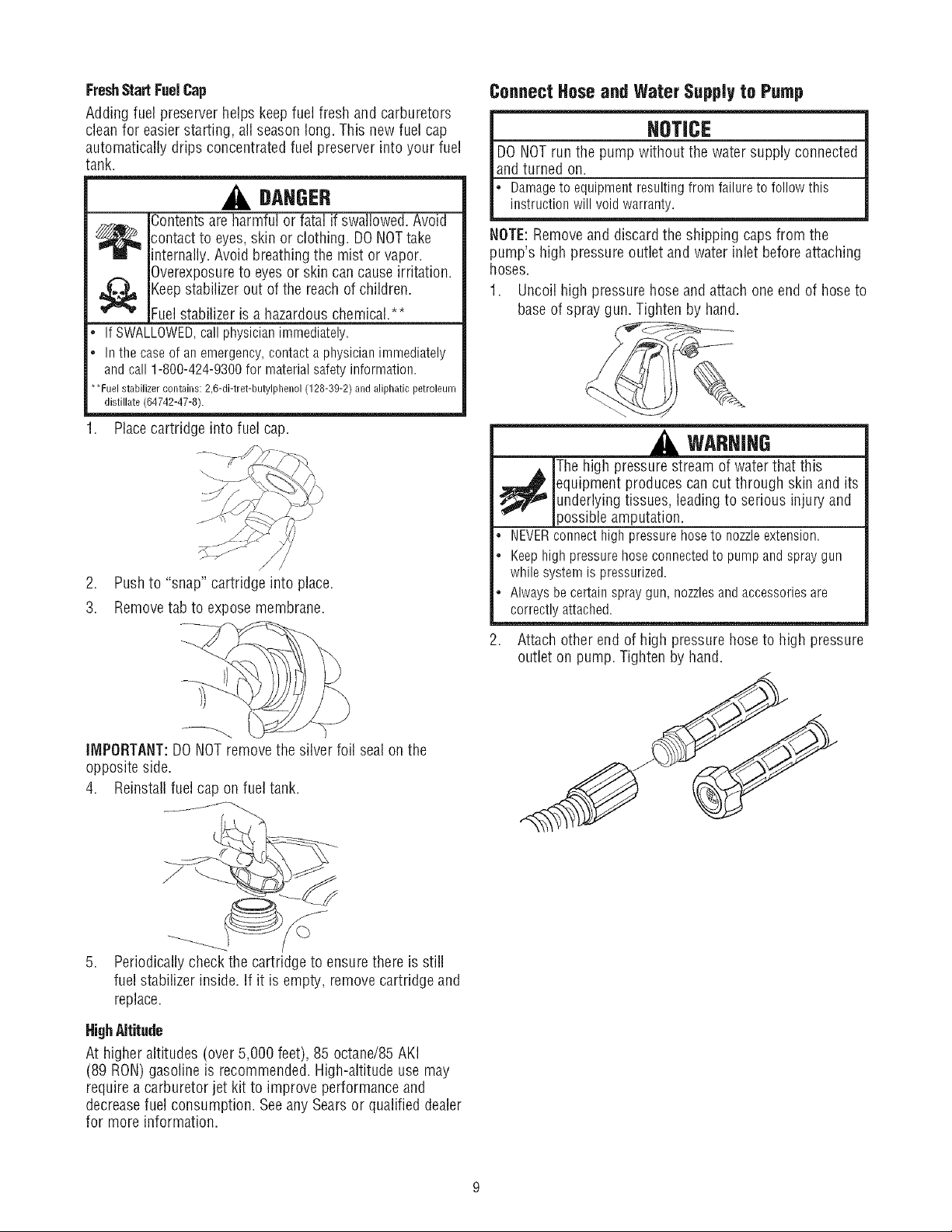

1. Placecartridge into fuel cap.

2. Pushto "snap" cartridge into place.

3. Removetab to expose membrane.

internally.Avoid breathing the mist or vapor.

Overexposureto eyesor skin can causeirritation.

Keepstabilizerout of the reachof children.

Fuelstabilizer is a hazardouschemical.**

andcall1-800-424-9300for materialsafetyinformation.

distillate (64742-47-8).

J

instructionwill voidwarranty.

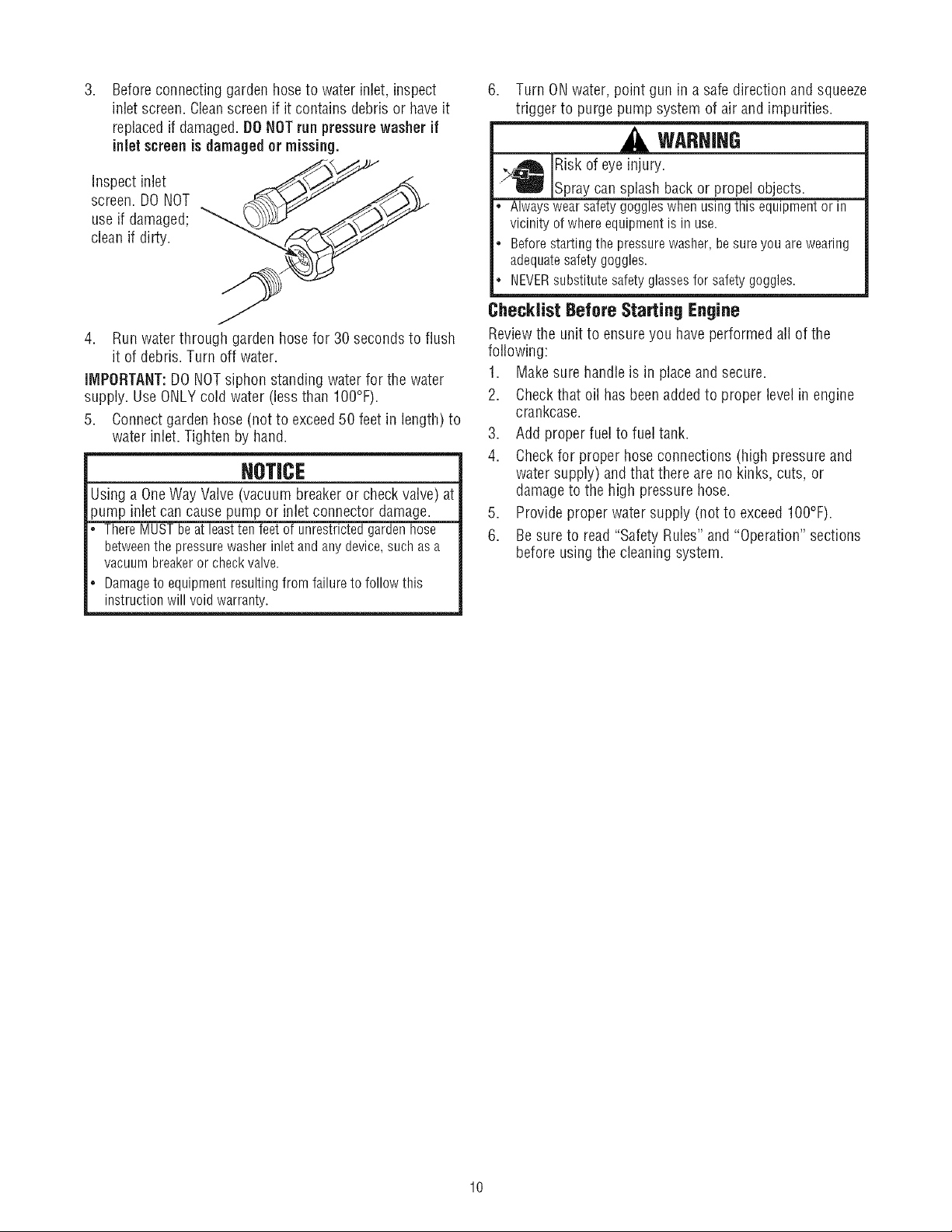

NOTE:Removeand discardthe shipping caps from the

pump's high pressure outlet andwater inlet beforeattaching

hoses.

1. Uncoil high pressurehose andattach one end of hoseto

baseof spray gun. Tighten by hand.

Thehigh pressurestream of waterthat this

_ quipment produces cancut through skin and its

underlyingtissues, leadingto serious injury and

)ossible amputation.

o NEVERconnecthighpressurehoseto nozzleextension.

o Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

o Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

2. Attach other end of high pressure hoseto high pressure

outlet on pump. Tighten by hand.

IMPORTANT:DO NOTremovethe silver foil sealon the

opposite side.

4. Reinstallfuel cap on fuel tank.

5. Periodicallycheckthe cartridge to ensurethere is still

fuel stabilizer inside. If it is empty, remove cartridge and

replace.

HighAJtitude

At higher altitudes (over 5,000 feet), 85 octane/85 AKi

(89 RON)gasoline is recommended. High-altitude use may

require a carburetorjet kitto improve performanceand

decreasefuel consumption. Seeany Sears or qualified dealer

for more information.

,

Beforeconnectinggarden hoseto water inlet, inspect

inlet screen•Cleanscreen if it contains debris or haveit

replacedif damaged•DONOTrun pressure washer if

inlet screenis damagedor missing.

Inspect inlet

screen•DO NOT

useif damaged;

clean if dirty.

4. Run water through garden hose for 30 secondsto flush

it of debris• Turn off water•

IMPORTANT:DO NOTsiphon standing water for the water

supply• UseONLYcold water (lessthan IO0°F).

5. Connectgarden hose (not to exceed50 feet in length) to

water inlet•Tighten by hand•

NOTICE

Using a OneWay Valve(vacuum breakeror checkvalve) at

pump inlet cancause pump or inlet connector damage•

ThereMUSTbeatleasttenfeetof unrestrictedgardenhose

betweenthepressurewasherinletandanydevice,suchasa

vacuumbreakerorcheckvalve•

Damageto equipmentresultingfromfailureto followthis

instructionwill voidwarranty•

6. Turn ONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities•

WARNING

Riskof eye injury•

• _ ISpray can splash back or propel objects•

o lwayswearsafetygoggleswhen usingthis equipmentor in

vicinityof whereequipmentisin use.

. Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles•

ChecklistBefore Starti.g Engine

Reviewthe unit to ensureyou have performed all of the

following:

1. Makesure handle is in placeand secure•

2. Checkthat oil has beenaddedto proper level in engine

crankcase•

3. Add proper fuelto fuel tank•

4. Checkfor proper hoseconnections (high pressureand

water supply) andthat there areno kinks, cuts, or

damageto the high pressure hose•

5. Provideproper water supply (not to exceedIO0°F).

6. Besure to read "Safety Rules" and "Operation" sections

before usingthe cleaning system•

10

HOWTOUSEYOURCLEANIHGSYSTEM

If you haveany problems operating your pressure washer,

pleasecallthe pressure washer helpline at 1-800-222-3136.

Pressure Washer Location

PressureWasherClearance

_ Exhaustheat/gases can ignitecombustibles,

o Keepat least 5 ft. (152 cm) clearance on all sides of pressure

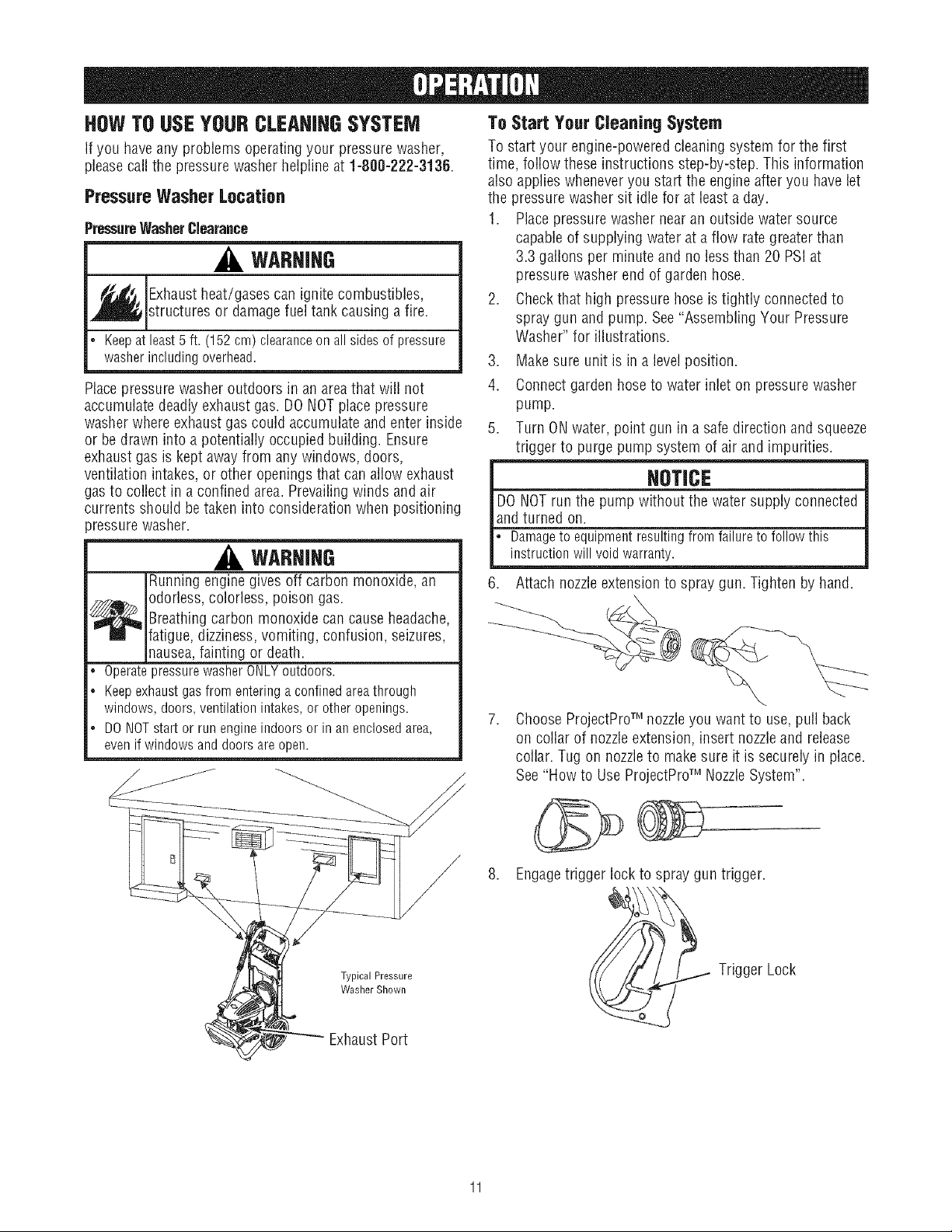

Placepressure washer outdoors in an areathat will not

accumulate deadly exhaustgas. DONOTplacepressure

washer where exhaustgas could accumulate and enter inside

or bedrawn into a potentially occupied building. Ensure

exhaustgas is kept awayfrom any windows, doors,

ventilation intakes, or other openings that can allow exhaust

gasto collect in a confined area. Prevailingwinds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

structures or damage fuel tankcausing a fire.

washerincludingoverhead.

WARNING

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

To Start Your Cleaning System

To start your engine-poweredcleaning system for the first

time, follow these instructions step-by-step. This information

also applies wheneveryou start the engineafter you have let

the pressure washer sit idle for at leasta day.

1. Placepressure washer nearan outsidewater source

capableof supplying waterat aflow rate greater than

3.3 gallons per minute andno less than 20 PSI at

pressurewasher end of gardenhose.

2. Checkthat high pressure hose is tightly connected to

spray gun andpump. See"Assembling Your Pressure

Washer" for illustrations.

3. Makesure unit is in a levelposition.

4. Connectgarden hoseto water inlet on pressure washer

pump.

5. Turn ONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities.

I DO NOTrun the pump without the water supply connected

land turned on.

I ° Damageto equipmentresultingfromfailuretofollowthis

instructionwill voidwarranty.

6. Attach nozzleextension to spray gun. Tighten by hand.

_ reathingcarbon monoxide can causeheadache,

o OperatepressurewasherONLYoutdoors.

o Keepexhaustgasfromenteringaconfinedareathrough

o DONOTstartor runengineindoorsorinan enclosedarea,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

windows,doors,ventilationintakes,orotheropenings.

evenif windowsanddoorsareopen.

ChooseProjectProTM nozzleyou want to use,pull back

on collar of nozzleextension,insert nozzleand release

collar. Tug on nozzleto makesure it is securely in place.

See"How to Use ProjectProTM NozzleSystem".

8. Engagetrigger lock to spray guntrigger.

Trigger Lock

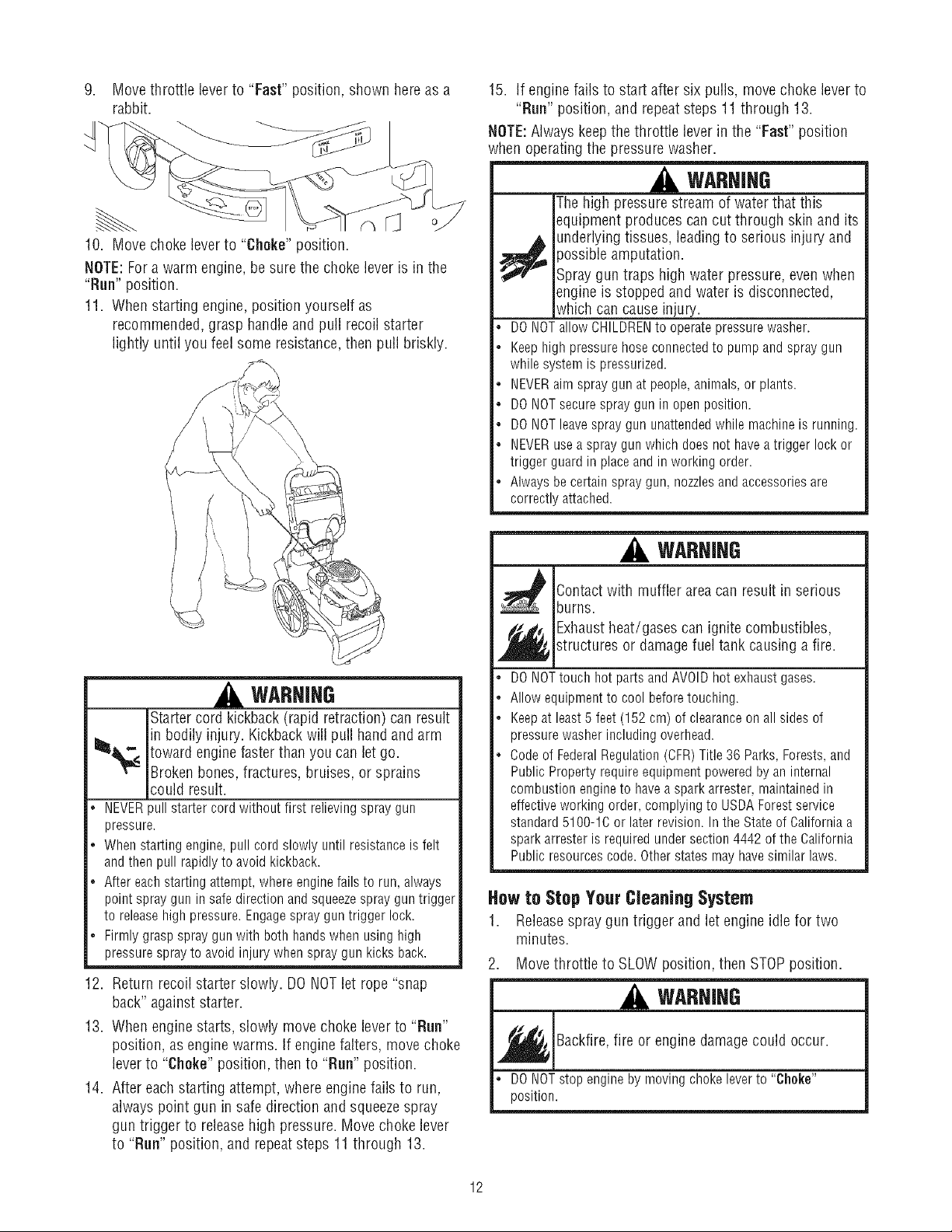

9. Move throttle lever to "Fast" position, shown hereas a

rabbit.

10. Move choke lever to "Choke" position.

NOTE:For a warm engine, besure the choke lever is in the

"Run" position.

11. When starting engine, position yourself as

recommended, grasp handle and pull recoil starter

lightly until you feel some resistance,then pull briskly.

15. If enginefails to start after six pulls, movechoke leverto

"Run" position, and repeatsteps 11through 13.

NOTE:Always keepthe throttle lever inthe "Fast" position

when operatingthe pressure washer.

WARNING

Thehigh pressurestream of waterthat this

equipment producescan cut through skin and its

_ nderlying tissues, leadingto serious injury and

o DONOTallowCHILDRENto operatepressurewasher.

o Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

o NEVERaim spraygunatpeople,animals,or plants.

o DONOTsecurespraygunin openposition.

o DONOTleavespraygununattendedwhilemachineis running.

o NEVERuseaspraygunwhichdoesnot haveatriggerlockor

triggerguardin placeandinworkingorder.

o Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

Startercord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handandarm

_,_ toward enginefaster than youcan let go.

Brokenbones, fractures, bruises, or sprains

could result.

o NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

o Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpullrapidlyto avoidkickback.

o Aftereachstartingattempt,whereenginefailsto run,always

pointsprayguninsafedirectionandsqueezesprayguntrigger

to releasehighpressure.Engagesprayguntriggerlock.

o Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

12. Return recoil starter slowly. DO NOTlet rope "snap

back" againststarter.

13. When engine starts, slowly move choke lever to "Run"

position, asengine warms. If engine falters, move choke

leverto "Choke" position, then to "Run" position.

14. After each starting attempt, where engine fails to run,

alwayspoint gun in safe direction and squeezespray

gun trigger to releasehigh pressure. Movechoke lever

to "Run" position, and repeatsteps 11through 13.

_s Contact with muffler result in serious

_ Exhaustheat/gases can ignite combustibles,

o DONOTtouchhotpartsandAVOIDhotexhaustgases.

o Allowequipmentto coolbeforetouching.

o Keepatleast5 feet(152cm) of clearanceon allsidesof

. CodeofFederalRegulation(CFR)Title36Parks,Forests,and

burns.

structures or damagefuel tankcausing a fire.

pressurewasherincludingoverhead.

PublicPropertyrequireequipmentpoweredbyaninternal

combustionengineto haveasparkarrester,maintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-10or later revision.In the StateofCaliforniaa

sparkarresteris requiredundersection4442oftheCalifornia

Publicresourcescode.Otherstatesmayhavesimilarlaws.

area can

Howto Stop Your Cleaning System

1. Releasespray gun trigger and let engine idle for two

minutes.

2. Movethrottle to SLOWposition, then STOPposition.

WARNING

_ Backfire,fire or engine damagecould occur.

o DONOTstopenginebymovingchokeleverto"Cheke"

position.

12

3. ALWAYSpointsprayguninasafedirectionandsqueeze

sprayguntriggertoreleaseretainedhighwater

pressure.

IMPORTANT:Sprayguntrapshighwaterpressure,even

whenengineisstoppedandwaterisdisconnected.

Thehighpressurestreamofwaterthatthis

equipmentproducescancutthroughskinandits

Howto UseProjectProTM HozzleSystem

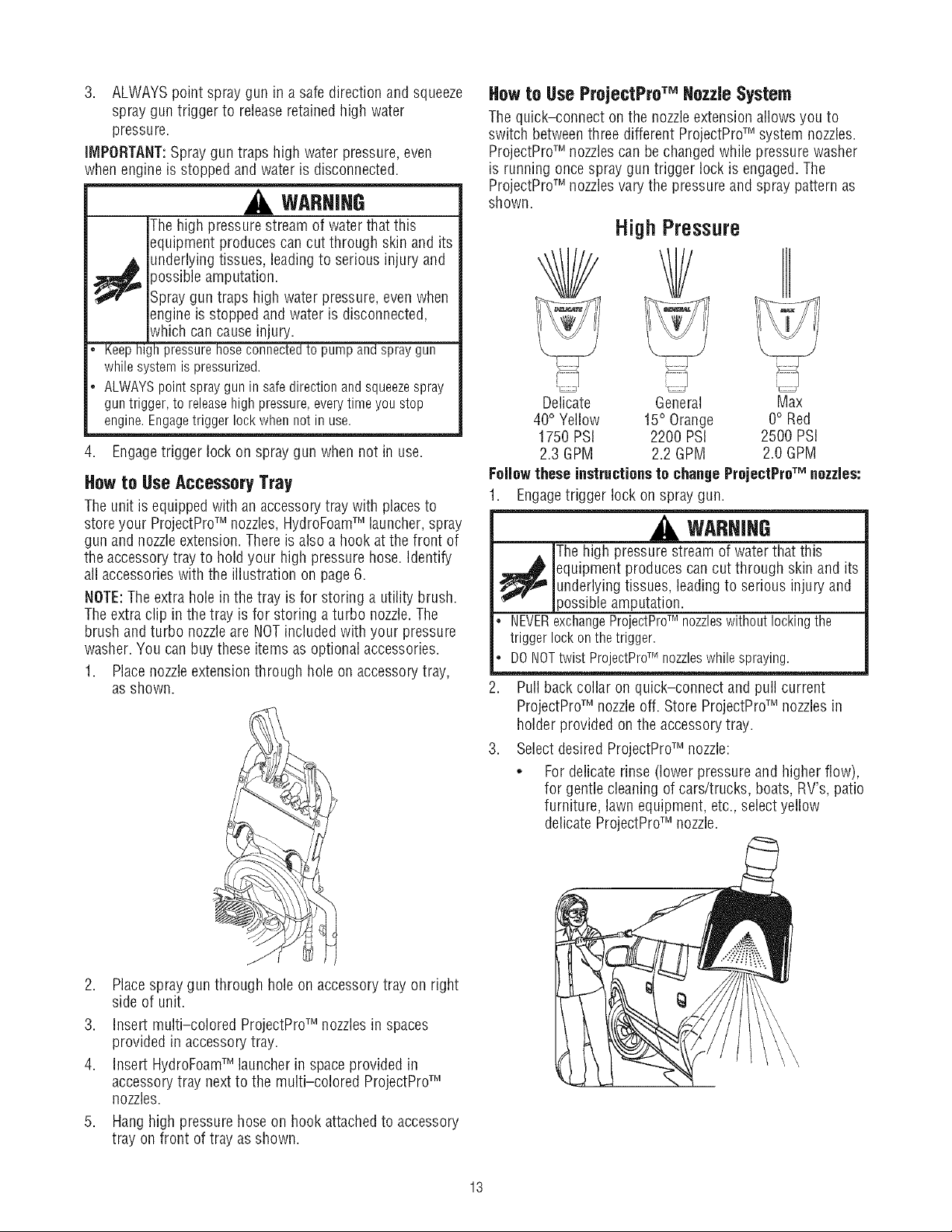

Thequick-connect onthe nozzleextensionallows you to

switch betweenthree different ProjectProTM system nozzles.

ProjectProTM nozzlescan be changed while pressure washer

is running oncespray gun trigger lock is engaged.The

ProjectProTM nozzlesvarythe pressure and spray pattern as

shown.

HighPressure

_ nderlyingtissues,leadingtoseriousinjuryand

)ossibleamputation.

Sprayguntrapshighwaterpressure,evenwhen

engineisstoppedandwaterisdisconnected,

whichcancauseinjury.

oKeephighpressurehoseconnectedtopumpandspraygun

whilesystemispressurized.

oALWAYSpointsprayguninsafedirectionandsqueezespray

guntrigger,toreleasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennotinuse.

4. Engagetriggerlockonspraygunwhennotinuse.

How to Use Accessory Tray

Theunit is equipped with an accessory tray with placesto

store your ProjectProTM nozzles,HydroFoamTM launcher,spray

gun and nozzleextension. Thereis also a hook at the front of

the accessorytray to hold your high pressure hose. Identify

all accessorieswith the illustration on page6.

NOTE:The extra hole in the tray is for storing a utility brush.

Theextra clip in thetray is for storing a turbo nozzle.The

brush and turbo nozzleareNOTincludedwith your pressure

washer.You canbuy these items as optional accessories.

1. Placenozzleextensionthrough hole on accessorytray,

asshown.

Delicate General Max

40° Yellow 15° Orange 0° Red

1750 PSI 2200 PSI 2500 PSI

2.3 GPM 2.2 GPIV1 2.0 GPM

Followthese instructionsto changePrejectPre TM nozzles:

1. Engagetrigger lock on spray gun.

WARHJHG

Thehigh pressurestream of waterthat this

,_ equipment produces cancut through skin and itsunderlyingtissues, leadingto serious injury and

_ossibleamputation.

o NEVERexchangeProjectProTM nozzleswithoutlockingthe

triggerlockonthetrigger.

o DONOTtwist ProjectProTM nozzleswhilespraying.

2. Pull backcollar on quick-connect and pull current

ProjectProTM nozzleoff. Store ProjectProTM nozzlesin

holder provided on the accessory tray.

,

Select desired ProjectProTM nozzle:

* For delicate rinse (lower pressure and higher flow),

for gentlecleaning of cars/trucks, boats, RV's,patio

furniture, lawn equipment, etc., selectyellow

delicate ProjectProTM nozzle.

,

Placespray gun through hole on accessorytray on right

side of unit.

3.

Insert multi-colored ProjectProTM nozzlesin spaces

provided in accessorytray.

4.

Insert HydroFoamTM launcherin spaceprovided in

accessorytray next to the multi-colored ProjectProTM

nozzles.

,

Hanghigh pressure hose on hook attachedto accessory

tray onfront of tray as shown.

13

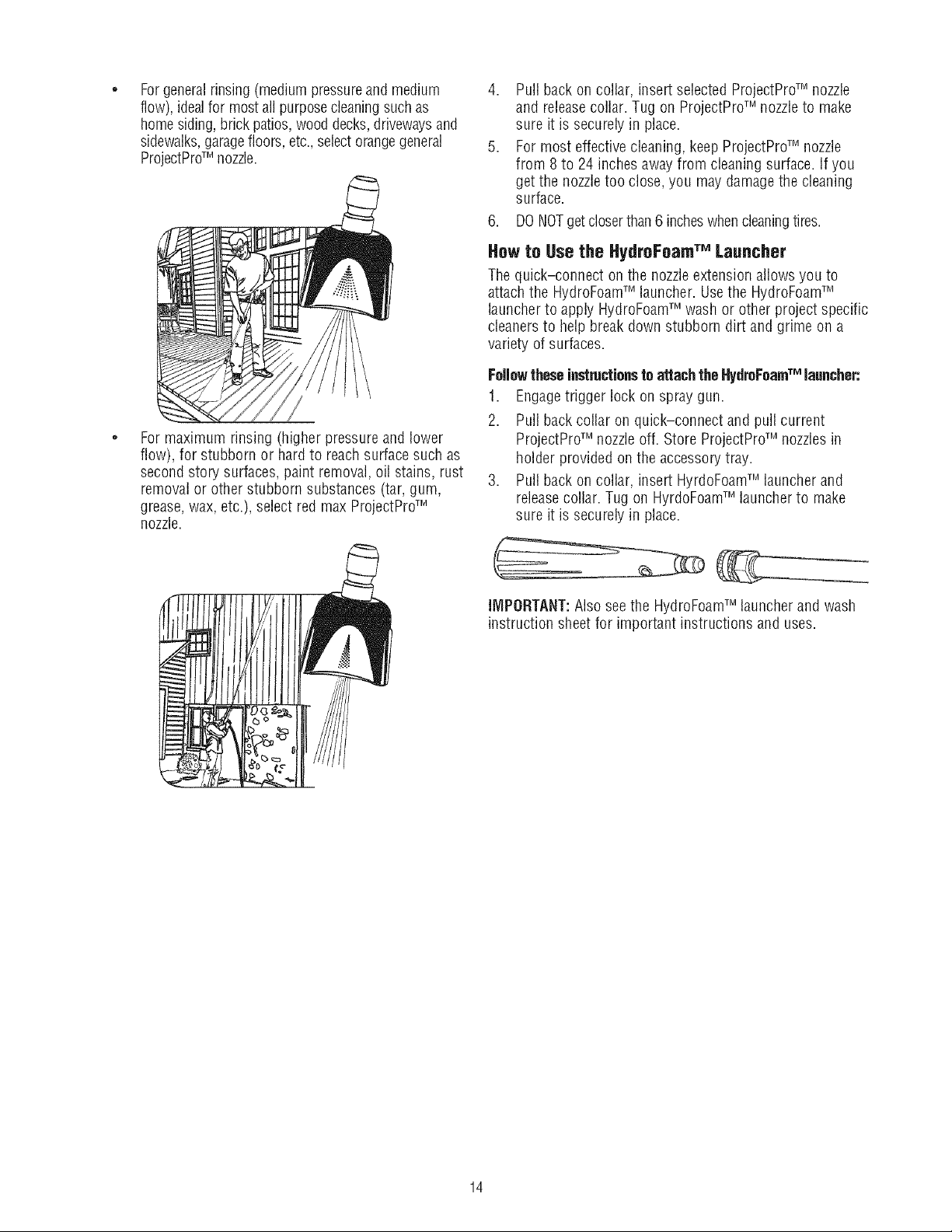

Forgeneralrinsing (medium pressureand medium

flow), idealfor mostall purposecleaningsuch as

homesiding,brick patios,wooddecks,drivewaysand

sidewalks,garagefloors, etc.,selectorangegeneral

ProjectProTM nozzle.

Formaximum rinsing (higher pressure and lower

flow), for stubborn or hard to reachsurface such as

second story surfaces,paint removal,oil stains, rust

removalor other stubborn substances (tar, gum,

grease,wax, etc.), select red max ProjectProTM

nozzle.

4. Pull back on collar, insert selectedProjectProTM nozzle

and releasecollar. Tug on ProjectProTM nozzleto make

sure it is securely in place.

5. Formost effectivecleaning, keep ProjectProTM nozzle

from 8 to 24 inches away from cleaning surface. Ifyou

get the nozzletoo close,you may damagethe cleaning

surface.

6. DONOTgetcloserthan 6 incheswhen cleaningtires.

How to Use the HydroFoamTM Launcher

The quick-connect on the nozzleextension allows you to

attach the HydroFoamTM launcher. Usethe HydroFoamTM

launcherto apply HydroFoamTM wash or other project specific

cleaners to help break down stubborn dirt and grime on a

variety of surfaces.

FelJowtheseinstructionstoattachtheHydruFoamTM launcher:

1. Engagetrigger lock on spray gun.

2. Pull back collar on quick-connect and pull current

ProjectProTM nozzle off. Store ProjectProTM nozzles in

holder provided on the accessory tray.

3. Pull back on collar, insert HyrdoFoamTM launcherand

releasecollar. Tug on HyrdoFoamTM launcherto make

sure it is securely in place.

IMPORTANT:Also seethe HydroFoamTM launcherand wash

instruction sheetfor important instructions and uses.

14

Cleaning and Applying Detergent

CAUTION

Chemicalscan cause bodily injury, and/or property

damage.

NEVERusecausticliquidwithpressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

ToapplydetergentfolJowthesesteps:

1. ReviewProjectProTM nozzleand HydroFoamTM launcher

use.

2. Prepare HydroFoamTM washaccording to instructions on

the bottle.

3. Pour detergentinto cleaningtank.

NOTE:The cleaning tank holds one gallon.

4. Make sure HyrdoFoamTM Launcher is installed.

NOTE:Detergentcannot be applied with the high pressure

nozzles(Yellow, Orange or Red).

5. Make sure garden hoseis connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

9. Allow HydroFoamTM wash to soak in between

3-5 minutes beforewashing and rinsing. Reapplyas

neededto prevent surface from drying. DO NOTallow

HydroFoamTM wash to dry on (preventsstreaking).

Forbest results, scrub the HydroFoamTM wash covered

surface to help remove stubborn dirt, grime and stains. For

vehicles, usea soft car washbrush or mitt. Fordecking,

siding and concrete, usea brush appropriatefor the type of

surface being cleaned.

Pressure Washer Rinsing

AfterHydreFoamTM washis applied,scourthesurfaceandrinse

it cleanasfollows:

1. Engagetrigger lockon spray gun.

2. Makesure detergent shut-off valve is in "Off" position.

3. RemoveHyrdoFoamTM Launcherfrom nozzleextension.

4. Selectand installdesired ProjectProTM nozzle,as

described in "How to UseProjectProTM NozzleSystem".

5. Keepspray gun a safe distance from spray surface.

WARNING

NOTICE

You must attachall hoses before __

Startingtheenginewithoutallthe hosesconnectedand

withoutthewaterturnedONwill damagethepump.

Damageto equipmentresultingfromfailureto followthis

instructionwill voidwarranty.

6. Engagetrigger lock on spray gun and start engine

following instructions "How to Start Your Pressure

Washer".

7. Rotatedetergent shut-off valve on cleaning tank to "On"

position.

"On" Position

8. Apply HydroFoamTM washto a dry surface, starting at

lower portion of areato be washedand work upward,

using long, even,overlapping strokes.

NOTE:To preventwater spotting on vehicles,work in a

shadedareaandallow surfacesto cool before beginning.

Kickbackfrom to fall.

o Operatepressurewasherfromastablesurface.

o Beextremelycarefulifyou mustusethe pressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

o Firmlygraspspraygunwith bothhandswhen usinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

6. Apply a high pressure spray to a small areaand then

check the surface for damage.If no damage,proceedto

step 7.

7. Start at top of areato be rinsed, working down with

same overlapping strokes usedfor cleaning.

spray gun cancauseyou

Automatic Cool Down System (Thermal Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures above

125°F.Thesystem engagesto cool the pump by discharging

the warm water ontothe ground.

15

EHGINETECHNICALINFORMATIOH PRODUCTSPECIFICATiOHS

This is a single cylinder, L-head,air cooled engine. It is a low

emissions engine.

Inthe Stateof California, ModelSeries 120000 engines are

certified by the CaliforniaAir ResourcesBoardto meet

emissions standardsfor 125 hours. Suchcertification does

not grant the purchaser,owner or operator of this engine any

additional warranties with respectto the performance or

operational life of this engine.The engineis warranted solely

according to the product and emmisions warranties stated

elsewhereinthis manual.

Power Ratings

* The gross power rating for individual gas engine modelsis

labeledin accordance with SAE(Societyof Automotive

Engineers)code J1940 (Small EnginePower &Torque

Rating Procedure),and rating performance hasbeen

obtained andcorrected in accordancewith SAEJ1995

(Revision2002-05). Actual gross engine power will be lower

and is affected by, among other things, ambient operating

conditions and engine-to-enginevariability. Givenboth the

wide array of products on which enginesareplaced and the

variety of environmental issues applicable to operating the

equipment,the gas engine will not develop the rated gross

power when used in a given piece of powerequipment

(actual"on-site"or net horsepower). This difference is due to

a variety of factors including, but not limited to, accessories

(air cleaner,exhaust,charging, cooling, carburetor, fuel

pump, etc.), applicationlimitations, ambient operating

conditions (temperature, humidity, altitude), andengine-to-

engine variability. Due to manufacturing and capacity

limitations, Briggs & Stratton may substitute an engine of

higher rated powerfor this Seriesengine.

Pressure Washer Specifications

Max Outlet Pressure ....................... 2,500 PSI

Max Flow Rate............................. 2.3 GPM

ChemicalMix......................... Useasdirected

Water SupplyTemperature .......... Not to exceed IO0°F

Shipping Weight ............................. 63 Ibs.

Engine Specifications

Gross*Horsepower..................... 6.0at 3600rpm

Bore ................................. 2.69 in. (68ram)

Stroke ............................... 2.04 in. (52mm)

Displacement ........................ 11.57in. (190 cc)

SparkPlug

Type: ............. Briggs & Stratton 802592 or 5095D

SetGapTo: ...................... O.030inch(0.76mm)

ArmatureAirGap: ........... 0.006-0.010in.(O.15-O.25mm)

Valveclearancewithvalvespringsinstalledandpiston1/4in.

(6 ram)pasttop deadcenter(checkwhenengineiscold).

Intake.................... 0.005-0.007in.(0.13-0.18mm)

Exhaust .................. 0.007-0.009in.(0.18-0.23mm)

FuelCapacity............................... 1.6Quarts

OilCapacity........................ 20 Ounces(0.6 liter)

NOTE:For practical operation, the horsepower loading should

not exceed85% of ratedhorsepower. Engine power will

decrease3-1/2% for each 1,000feet (300 meters) abovesea

leveland 1% for each 10° F (5.6° C) above 77° F (25° C). It

should operatesatisfactorily at an angle up to 15°.

16

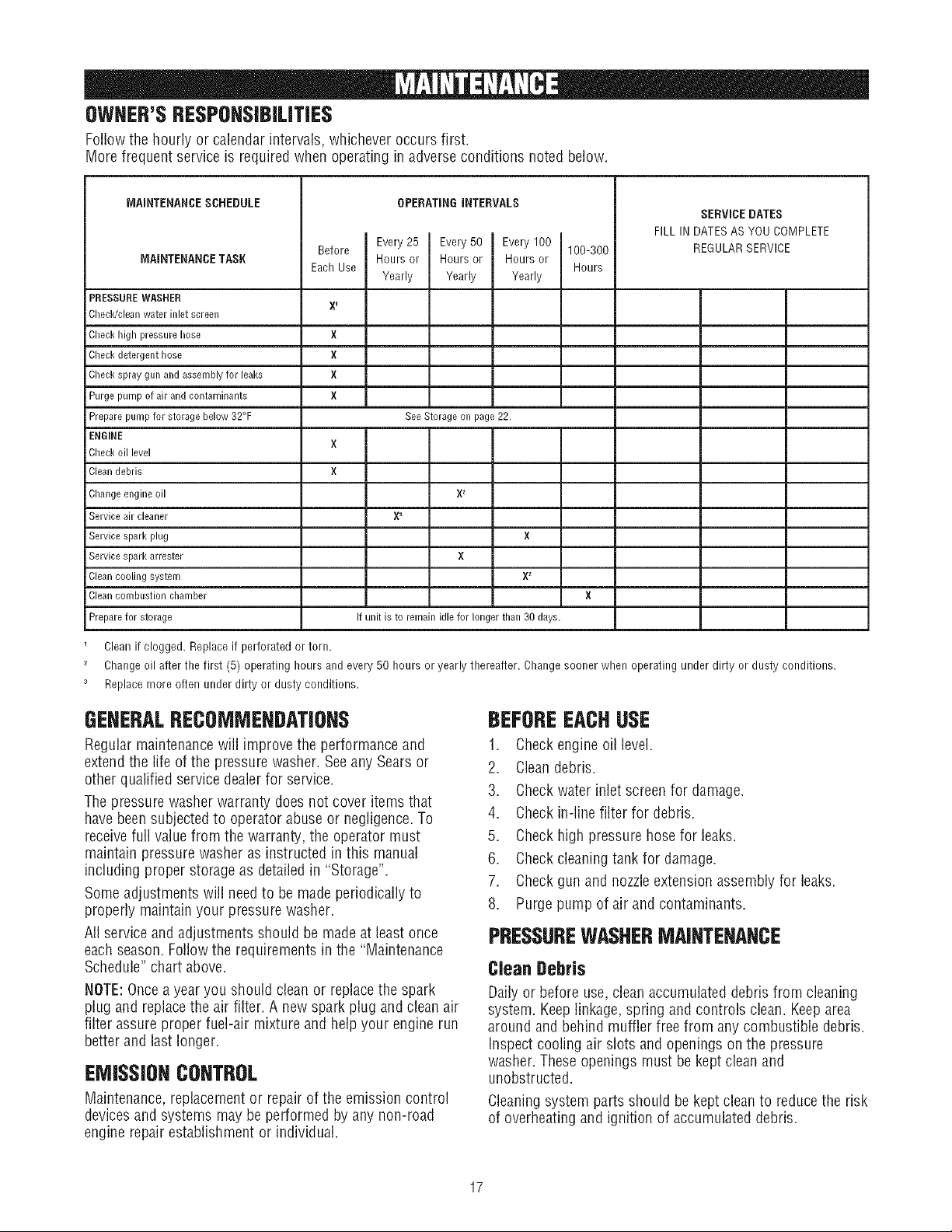

OWNER'SRESPONSIBILITIES

Followthe hourly or calendarintervals,whichever occurs first.

More frequent service is required when operating inadverseconditions noted below.

MAINTENANCESCHEDULE

MAINTENANCETASK

PRESSURE WASHER

ChecWclean water inlet screen

Check high pressure hose

Check detergent hose

Check spray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Check oil level

Clean debris

Change engine oil

Service air cleaner

Service spark plug

Service spark arrester

Clean cooling system

Clean combustion chamber

Prepare for storage

Cleanif clogged. Replace if perforated or torn.

2 Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

3 Replace more often under dirty or dusty conditions.

Before

EachUse

X 1

X

X

X

X

X

X

OPERATINGiNTERVALS

Hours or Hours or Hours or

I Every 25 Every 50 Every 100

Yearly Yearly Yearly

See Storage on page 22.

X 2

X_

X

X

X_

If unit is to remain idle for longer than 30 days.

100-300

Hours

SERVICEDATES

FILL IN DATESAS YOU COMPLETE

REGULARSERVICE

GEHERALRECOMMEHDATIONS

Regularmaintenancewill improve the performance and

extendthe life of the pressure washer. Seeany Searsor

other qualified service dealerfor service.

Thepressure washer warranty doesnot cover items that

havebeen subjectedto operator abuseor negligence.To

receivefull valuefrom the warranty, the operator must

maintain pressure washer as instructed inthis manual

including proper storage as detailed in "Storage".

Someadjustments will needto be madeperiodically to

properly maintain your pressure washer.

All serviceand adjustments should be madeat least once

eachseason.Follow the requirements in the "Maintenance

Schedule" chart above.

NOTE:Onceayear you should clean or replacethe spark

plug andreplace the air filter. A new spark plug andclean air

filter assureproper fuel-air mixture and help your engine run

better and last longer.

EMISSIOHCOHTROL

Maintenance,replacementor repair of the emission control

devicesand systems may be performed by any non-road

engine repair establishment or individual.

BEFOREEACHUSE

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screenfor damage.

4. Checkin-line filter for debris.

5. Checkhigh pressure hose for leaks.

6. Checkcleaningtank for damage.

7. Checkgun and nozzleextension assembly for leaks.

8. Purge pump of air and contaminants.

PRESSUREWASHERMAIHTEHAHCE

Clean Debris

Daily or before use,clean accumulated debris from cleaning

system. Keeplinkage,spring and controls clean. Keeparea

around andbehind muffler free from any combustible debris.

Inspect cooling air slots and openings onthe pressure

washer. Theseopenings must be kept cleanand

unobstructed.

Cleaningsystem parts should be kept cleanto reduce the risk

of overheating and ignition of accumulated debris.

17

• Usea damp cloth to wipe exterior surfaces clean.

4. Assemble nozzleextensionto spray gun, as described

earlier in manual.

J NOTICE

Improper treatment of pressure washer can damage it and

|shorten its life.

_rough coolingslots.

• Usea soft bristle brush to loosen cakedon dirt, oil, etc.

Useavacuumcleanerto pickuploosedirt anddebris.

Check and Clean inlet Screen

Examinegardenhose inlet screen.Cleanif it is clogged or

replaceif it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear, kinking,

or abuse.Inspect hose beforeeach use. Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings. If any of theseconditions exist, replacehose

immediately.

WARNING

The high pressure stream of water that this

_ quipment produces cancut through skin and itsunderlyingtissues, leadingto serious injury and

)ossible amputation.

o NEVERrepairhighpressurehose.Replaceit.

o ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

CheckGunandNozzleExtension

Examinehose connectionto spray gun and makesure it is

secure.Testtrigger by pressing it and making sure it springs

back into placewhen you releaseit. Put safetylatch in UP

position andtest trigger. You should not beableto press

trigger. Replacespray gun immediately if it fails any of these

tests.

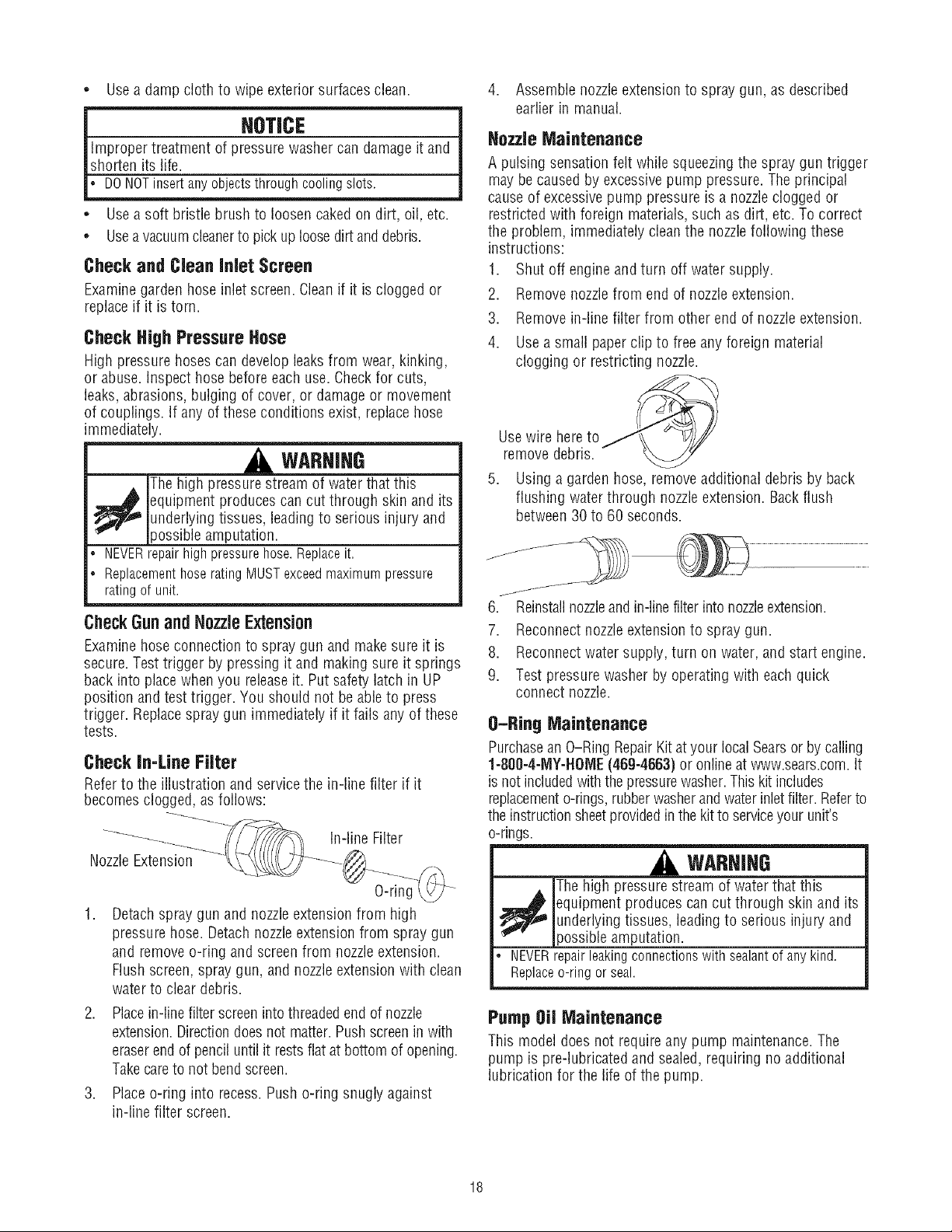

CheckIn=LineFilter

Referto the illustration and servicethe in-line filter if it

becomesclogged, asfollows:

In-line Filter

NozzleExtension

O-ring

1. Detachspray gun and nozzleextension from high

pressure hose. Detachnozzleextensionfrom spray gun

and removeo-ring and screen from nozzleextension.

Flush screen,spray gun, and nozzleextensionwith clean

water to clear debris.

2. Placein-line filter screeninto threadedendof nozzle

extension.Directiondoesnot matter.Pushscreenin with

eraserend of penciluntil it restsflat at bottom of opening.

Takecareto not bendscreen.

3. Placeo-ring into recess.Push o-ring snugly against

in-line filter screen.

Nozzle Maintenance

A pulsing sensation felt while squeezingthe spray gun trigger

may be caused by excessivepump pressure.The principal

cause of excessivepump pressure is a nozzleclogged or

restricted with foreign materials,such as dirt, etc. To correct

the problem, immediately cleanthe nozzlefollowing these

instructions:

,

Shut off engine andturn off water supply.

Removenozzlefrom end of nozzleextension.

2.

3.4.Removein-line filter from other endof nozzleextension.

Useasmall paperclip to free any foreign material

clogging or restricting nozzle.

oeW'v ehe °

5. Using a garden hose, removeadditional debris by back

flushing water through nozzleextension. Backflush

between30to 60 seconds.

J

6. Reinstallnozzleandin-linefilter into nozzleextension.

7. Reconnectnozzleextension to spray gun.

8. Reconnectwatersupply, turn on water, andstart engine.

9. Test pressure washer by operating with eachquick

connect nozzle.

O-Ring Maintenance

Purchasean O-Ring RepairKitatyour localSearsorby calling

1-888-4-MY-HOME(469-4663)or online atwww.sears.com.It

isnot includedwith the pressurewasher.Thiskit includes

replacemento-rings,rubberwasherandwaterinletfilter. Referto

the instructionsheetprovidedin the kit to serviceyour unit's

o-rings.

WARNING

Thehigh pressurestream of waterthat this

_ quipment produces cancut through skin and itsunderlyingtissues, leadingto serious injury and

)ossible amputation.

o NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ring orseal.

Pump Oil Maintenance

This model does not requireany pump maintenance.The

pump is pre-iubricated and sealed, requiring no additional

lubrication for the life of the pump.

18

Loading...

Loading...