Craftsman 580752330 Owner’s Manual

Owner's Manual

6.75 HORSEPOWER

2550 PS(

2.0 GPM

Model No. 580.752330

®

CAUTION

Before using this product, read this

manuN and follow all Safety Rules and

Operating instructions.

Sears, Roebuck and Co., Hoffman Estates, _L 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

Part No. 195794GS Draft 4 (09, 19,21_05)

Antes de utilizar el producto, lea este

manuN y siga todas las Reglas de

Seguridad e Instrucciones de Uso.

PRECAUCION

o Safety

o AssemNy

o Operation

o Naintenance

o Parts

o EspahoN

WARRANTY .................................... 2

SAFETY RULES ............................... 2-4

FEATURES AND CONTROLS ...................... 5

ASSEMBLY ................................... 6-8

OPERATION ................................. 9-13

SPECIFICATIONS ............................... 14

MAINTENANCE .............................. 15-19

STORAGE .................................. 20-21

TROUBLESHOOTING ............................ 22

REPLACEMENT PARTS ....................... 24-28

NOTES ................................... 23 & 29

EMISSION CONTROL WARRANTY .............. 30-31

ESPAIqOL ................................... 32-55

HOW TO ORDER PARTS ................ BACK PAGE

L_M_TED WARRANTY ON CRAFTSMAN PRESSURE WASHER

For one year from the date of purchase, ,,whenthis Craftsman pressure ,,washeris maintained and operated

according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and

workmanship.

if this washer is used for commercial purposes, this warranty applies for only 90 days from the date of

purchase. If this pressure washer is used for rental purposes, this warranty applies for only 30 days after date

of purchase.

This warranty does not cover:

• Expendable items such as spark plugs or air filters, which become worn during normal use.

• Repairs necessary because of operator abuse or negligence, including damage resulting from no water

being supplied to pump or failure to maintain the equipment according to the instructions contained in the

owner's manual.

Warranty service is available by returning the high pressure washer to the nearest Sears service center or

dealer in the United States.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

This is the safety alert symbol, it is used to alert you to potential personam injury hazards.

Obey aH safety messages that follow this symbol to avoid possible injury or death.

=r-T-]_ Read this manuam carefully and become

familiarwithyourpressurewasher.Knowits

applications, its limitations, and any hazards

involved.

The safety alert symbol (,&) is used with a signal

word (DANGER, CAUTION, WARNING), a pictorial

and/or a safety message to alert you to hazards.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury. WARNING indicates a

hazard which, if not avoided, could result in death or

serious injury. CAUTION indicates a hazard which, if

not avoided, might result in minor or moderate injury.

CAUTION, when used without the alert symbol,

indicates a situation that could result in equipment

damage. Follow safety messages to avoid or reduce

the risk of injury or death.

Hazard Symbols and Meanings

Toxic Fumes

Slippery Surface

Fire

Hazardous Chemical

Fal!

Explosion

Electrical Shock

Fluid Injection

Hot Surface

© Sears Brands, LLC

Moving Parts

Flying Objects

Kickback

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

Operate pressure washer ONLY outdoors.

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate pressure washer inside any building or

enclosure, even if doors or windows are open.

Use a respirator or mask whenever there is a chance

that vapors may be inhaled.

Read all instructions packed with mask so you are certain

mask will provide necessary protection against inhaling

harmful vapors.

WARNING

,&

Fresh Start TM fuel cap is designed to hold a cartridge

which contains fuel stabilizer.

If SWALLOWED, call physician immediately. DO NOT

induce vomiting. If inhaled, remove to fresh air. In case

of eye or skin contact, flush with water for 15 minutes.

Store unopened cartridges in a coo!, dry, well ventilated

area. Keep open cartridge in fue! cap, and fue! cap

closed on fuel tank when not in use.

In the case of an emergency, contact a physician

immediately and cal! 1o800o424o9300 for material safety

information.

_Fuel stabilizer contains: 2,6-di-tret-butylpheno{ (128-39-2) and aliphatic

petroleum distillate (64742-47-8)

WARNING

Keep spray nozzle between 8 to 24 inches away from

cleaning surface.

Operate this unit on a stable surface.

Cleaning area should have adequate slopes and

drainage to reduce possibility of falls due to slippery

surfaces.

Be extremely careful if you must use pressure washer

from a ladder, scaffolding or any other relatively unstable

location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

WARNING

When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze

trigger on spray gun.

WHEN ADDING OR DRAINING FUEL

Turn pressure washer OFF and let it cool at least 2

minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

Fill or drain fuel tank outdoors.

DO NOT overfill tank. Allow space for fuel expansion.

Keep fue! away from sparks, open flames, pilot lights,

heat, and other ignition sources.

DO NOT light a cigarette or smoke.

VHEN STARTING EQUIPMENT

Ensure spark plug, muffler, fue! cap and air cleaner are

in place.

DO NOT crank engine with spark plug removed.

If fuel spills, wait until it evaporates before starting

engine.

VHEN OPERATING EQUIPMENT

* Do not tip engine or equipment at angle which causes

fuel to spill.

, DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRBNG EQUIPMENT

Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

* Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL IN

TANK

Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fue! vapors.

WARNING

NEVER aim spray gun at people, animals or plants.

DO NOT allow CHILDREN to operate pressure washer.

NEVER repair high pressure hose. Replace it.

NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal.

Keep high pressure hose connected to pump and spray

gun while system is pressurized.

Squeeze trigger on spray gun to relieve trapped

pressure, every time you stop engine. Engage trigger

lock on spray gun.

WARNING

DO NOT touch hot surfaces.

Allow equipment to cool before touching.

The pressure washer must be at least 5 feet from

structures having combustible walls and/or other

combustible materials.

Keep at least 3 feet of clearance on all sides of pressure

washer for adequate cooling, maintenance and servicing.

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark arrester,

it must be maintained in effective working order.

WARNING

WARNING

Keep water spray away from electric wiring or fatal

electric shock may result.

WARNING

* Always wear eye protection when using equipment or when

in vicinity of equipment in use.

CAUTION

* DO NOT tamper with governed speed.

, DO NOT operate pressure washer above rated pressure.

CAUTION

m

* DO NOT secure spray gun in open position.

* DO NOT leave spray gun unattended while machine is

running.

* NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

Always be certain spray gun, nozzles and accessories

are correctly attached.

CAUTION

* DO NOT point spray gun at glass when using MAX (pin

point) nozzle.

NEVER aim spray gun at plants.

CAUTION

• DO NOT wear loose clothing, jewelry or anything that

may be caught in starter or other rotating parts.

• Tie up long hair and remove jewelry.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

PRESSURE WASHER

Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTBNG FOR ENGINE SPARK

Use approved spark plug tester.

DO NOT check for spark with spark plug removed.

* If you have questions about intended use, ask dealer or

contact Sears.

, NEVER operate units with broken or missing parts, or

without protective housing or covers.

DO NOT by-pass any safety device on this machine.

Before starting pressure washer in cold weather, check

all parts of the equipment to be sure ice has not formed

there.

NEVER move machine by pulling on high pressure hose.

Use handle provided on unit.

, Check fuel system for leaks or signs of deterioration,

such as chafed or spongy hose, loose or missing

clamps, or damaged tank or cap. Correct all defects

before operating pressure washer.

This equipment is designed to be used with Sears

authorized parts ONLY. If equipment is used with parts

that DO NOT comply with minimum specifications, user

assumes al! risks and liabilities.

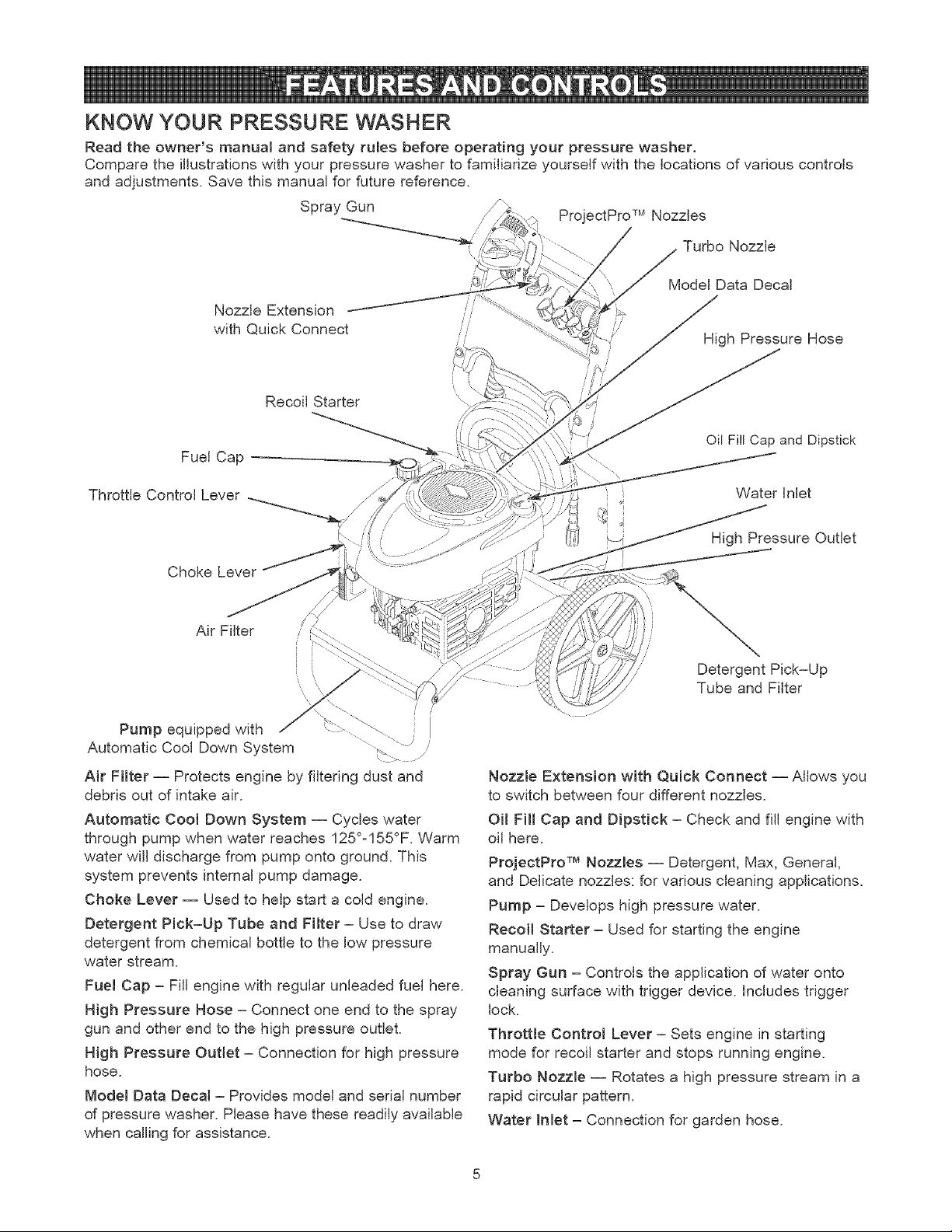

KNOW YOUR PRESSURE WASHER

Read the owner's manual and safety rules before operating your pressure washer.

Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls

and adjustments. Save this manual for future reference.

Spray Gun

Nozzle Extension

with Quick Connect _,

RecoiJ Starter

Fuel Cap

Choke Lever

ProjectPro TM Nozzles

Turbo Nozzle

Model Data Decal

///

High Pressure Hose

Oil Fill Cap and Dipstick

Water inlet

High Pressure Outlet

Air Filter

/ /

Pump equipped with _ I

Automatic Cool Down System _... /

Air FHter -- Protects engine by filtering dust and

debris out of intake air.

Automatic Cool Down System -- Cycles water

through pump when water reaches 125°-155°F. Warm

water will discharge from pump onto ground. This

system prevents internal pump damage.

Choke Lever -- Used to help start a cold engine.

Detergent Pick-Up Tube and Filter = Use to draw

detergent from chemical bottle to the low pressure

water stream.

FuemCap - Fill engine with regular unleaded fuel here.

High Pressure Hose - Connect one end to the spray

gun and other end to the high pressure outlet.

High Pressure Outlet - Connection for high pressure

hose.

Model Data Decal - Provides model and serial number

of pressure washer. Please have these readily available

when calling for assistance.

Detergent Pick-Up

Tube and Filter

Nozzle Extension with Quick Connect -- Allows you

to switch between four different nozzles.

OH Fill Cap and Dipstick = Check and fill engine with

oil here.

ProjectPro TM Nozzles -- Detergent, Max, General,

and Delicate nozzles: for various cleaning applications.

Pump = Develops high pressure water.

Recoil Starter = Used for starting the engine

manually.

Spray Gun = Controls the application of water onto

cleaning surface with trigger device. Includes trigger

lock.

Throttle Control Lever = Sets engine in starting

mode for recoil starter and stops running engine.

Turbo Nozzle -- Rotates a high pressure stream in a

rapid circular pattern.

Water Inlet = Connection for garden hose.

Yourpressurewasherrequiressomeassemblyandis

readyforuseonlyafterithasbeenproperlyserviced

withtherecommendedoilandfuel.

Ifyouhaveanyproblemswiththeassemblyof

yourpressurewasher,pleasecallthe pressure

washerhelpIineat 1-800-222-3136.

REMOVE PRESSURE WASHER

FROM CARTON

• Slice two corners of carton from top to bottom so

the panel can be folded down flat.

• Remove fillers, accesories and parts bag shipped

with your pressure washer.

• Roll pressure washer out open end of carton.

• Check carton for additional loose parts.

CARTON CONTENTS

Check all contents. If any parts are missing or damaged,

call the pressure washer helpline at 1-800-222-3136.

• The main unit

Handle

Accessory tray

Spray gun

High pressure hose

Nozzle extension with quick connect fitting

Turbo nozzle

Engine oil

Parts bag (which includes items listed beJow)

• Owner's manual

• Registration card

• Bag containing 4 multi-colored ProjectPro TM

nozzles

• Fresh StartTM fuel cartridge

• Handle fastening hardware kit (which includes):

• Carriage bolt (2)

• Plastic knobs (2)

• Tree clips (4)

Become familiar with each piece before assembling

the pressure washer. Check all contents against the

illustration on page 5. If any parts are missing or

damaged, call the pressure washer helpline at

1-800-222-3136.

ASSEMBLING YOUR PRESSURE

WASHER

Your Craftsman high pressure washer was mostly

assembled at the factory. However, you will need to

perform these tasks before you can operate your

pressure washer:

1. Fill out and send in registration card.

2. Attach handle.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connect pressure hose to spray gun and pump.

6. Connect water supply to pump.

7. Attach nozzle extension to spray gun.

8. Select/attach quick connect nozzle to nozzle

extension.

Attach Handme

1. Place handle onto handle supports connected to

main unit. Make sure holes in handle align with

holes on handle supports.

\

Handle /

Align Holes _-_p_/>

, !

Handlei

// Supports/

NOTE: It may be necessary to move the handle

supports from side to side in order to align the handle

so it will slide over the handle supports.

2. Insert carriage bolts through holes from outside of

unit and attach a plastic knob from inside of unit.

Tighten by hand.

3. Place accessory tray over holes on handle

(viewing from front of unit). Push tree clips into

holes until they sit flat against accessory tray.

ii i

i i

/

Jm J

ii

4. Insert multi-colored ProjectPro TM nozzles and

other supplied accessories in spaces provided in

accessory tray. See "How to Use Accessory Tray".

Add Engine Oi_

CAUTRON! Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

1. Place pressure washer on a level surface.

2. Clean area around oil fill and remove oil dipstick.

3. Using oil funnel (optional), slowly pour entire

contents of provided oil bottle (18 oz.) into oil fill

opening.

4. Replaceoildipstickandfullytighten.

NOTE:Seethesection"Oil"onpage17toreviewoil

recommendations.

Add Fuel

NOTE: This gasoline engine is certified to operate on

gasoline. Exhaust Emission Control System: EM

(Engine Modifications).

WARNING

Fresh Start TM Fuel Cap

Adding fuel preserver helps keep fuel fresh and

carburetors clean for easier starting, all season long.

This new fuel cap automatically drips concentrated

fuel preserver into your fuel tank.

DANGER

WHEN ADDING FUEL

Turn pressure washer OFF and let it cool at least 2

minutes before removing fuel cap. Loosen cap slowly to

relieve pressure in tank.

Fill or drain fue! tank outdoors.

DO NOT overfill tank. Allow space for fuel expansion.

Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

DO NOT light a cigarette or smoke.

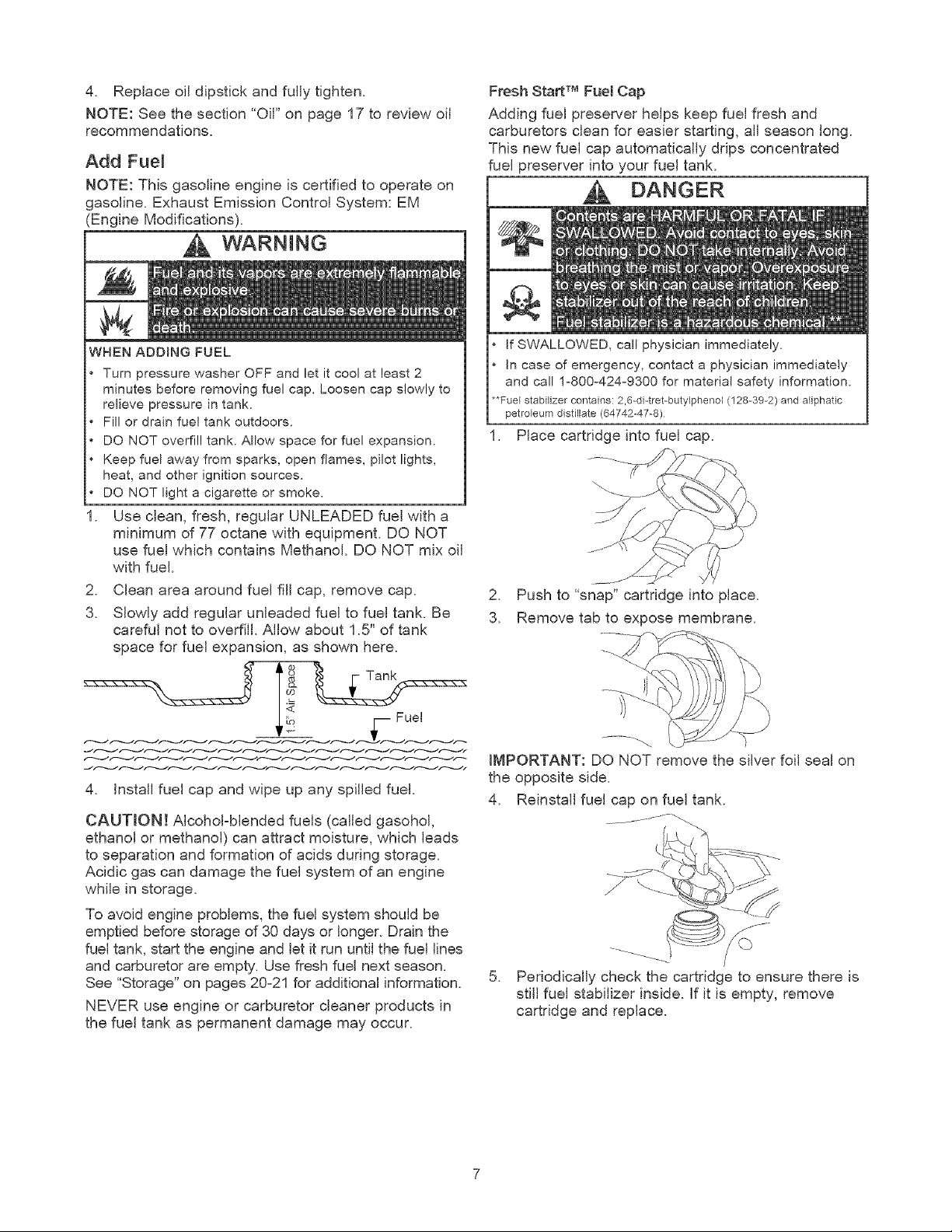

1. Use clean, fresh, regular UNLEADED fuel with a

minimum of 77 octane with equipment. DO NOT

use fuel which contains Methanol. DO NOT mix oil

with fuel.

2. Clean area around fuel fill cap, remove cap.

3. Slowly add regular unleaded fuel to fuel tank. Be

careful not to overfill. Allow about 1.5" of tank

space for fuel expansion, as shown here.

4. Install fuel cap and wipe up any spilled fuel.

CAUTION! Alcohol-blended fuels (called gasohol,

ethanol or methanol) can attract moisture, which leads

to separation and formation of acids during storage.

Acidic gas can damage the fuel system of an engine

while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. Drain the

fuel tank, start the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel next season.

See "Storage" on pages 20-21 for additional information.

NEVER use engine or carburetor cleaner products in

the fuel tank as permanent damage may occur.

* If SWALLOWED, call physician immediately.

* In case of emergency, contact a physician immediately

and call 1-800-424-9300 for material safety information.

_*Fuel stabilizer contains: 2,6-di-tret-butylphenol (128-39-2) and aliphatic

petroleum distillate (64742-47-8)

Place cartridge into fuel cap.

2. Push to "snap" cartridge into place.

3. Remove tab to expose membrane.

IMPORTANT: DO NOT remove the silver foil seal on

the opposite side.

4. Reinstall fuel cap on fuel tank.

5. Periodically check the cartridge to ensure there is

still fuel stabilizer inside. If it is empty, remove

cartridge and replace.

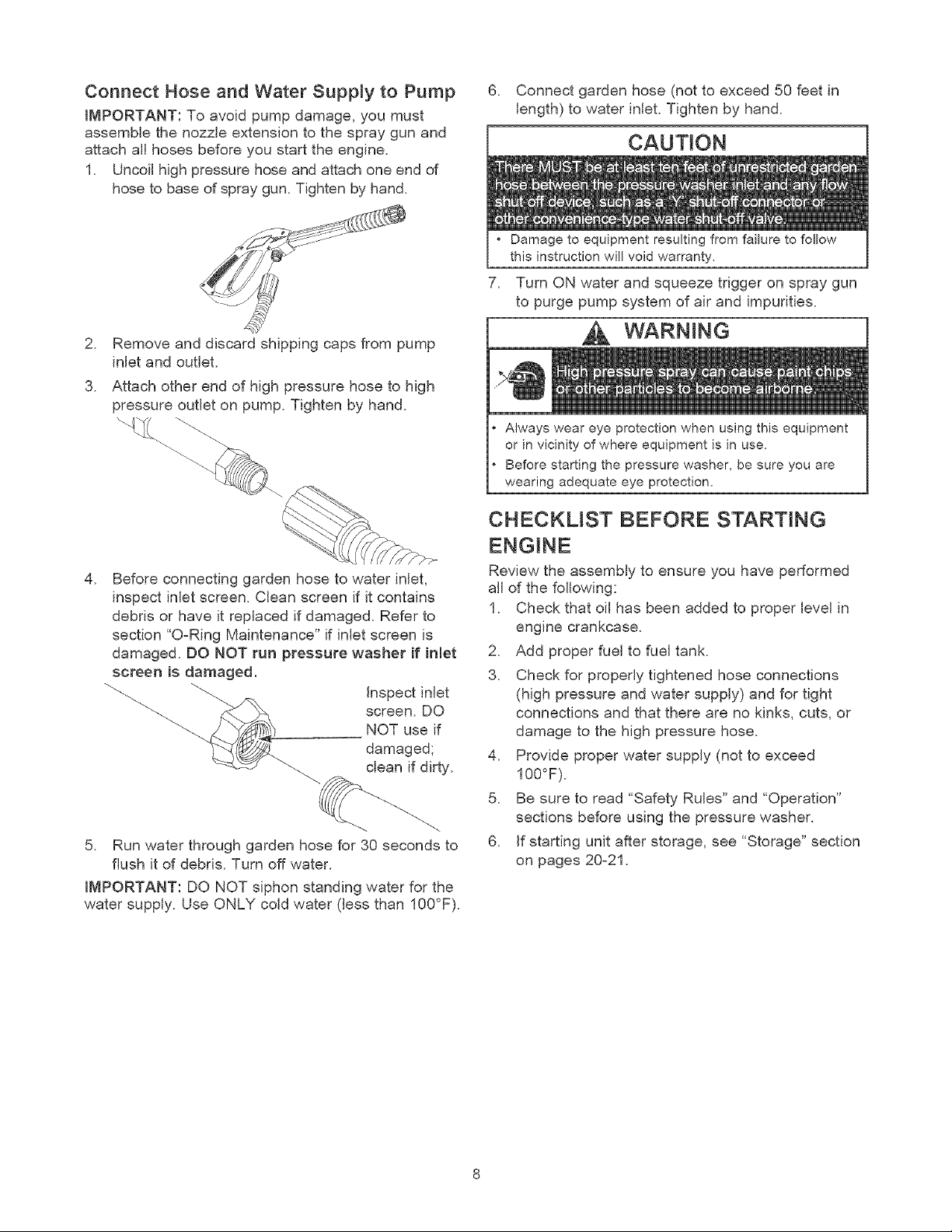

Connect Hose and Water Supply to Pump

IMPORTANT: To avoid pump damage, you must

assemble the nozzle extension to the spray gun and

attach all hoses before you start the engine.

1. Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

6. Connect garden hose (not to exceed 50 feet in

length) to water inlet. Tighten by hand.

CAUTION

* Damage to equipment resulting from failure to follow

this instruction will void warranty,

7. Turn ON water and squeeze trigger on spray gun

to purge pump system of air and impurities.

2. Remove and discard shipping caps from pump

inlet and outlet.

3. Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

.

Before connecting garden hose to water inlet,

inspect inlet screen. Clean screen if it contains

debris or have it replaced if damaged. Refer to

section "O-Ring Maintenance" if inlet screen is

damaged. DO NOT run pressure washer if inlet

screen Bsdamaged.

inspect inlet

screen. DO

NOT use if

damaged;

clean if dirty.

5. Run water through garden hose for 30 seconds to

flush it of debris. Turn off water.

IMPORTANT: DO NOT siphon standing water for the

water supply. Use ONLY cold water (less than 100°F).

WARNING

Always wear eye protection when using this equipment

or in vicinity of where equipment is in use.

Before starting the pressure washer, be sure you are

wearing adequate eye protection,

CHECKLIST BEFORE STARTING

Review the assembly to ensure you have performed

all of the following:

1. Check that oil has been added to proper level in

engine crankcase.

2. Add proper fuel to fuel tank.

3. Check for properly tightened hose connections

(high pressure and water supply) and for tight

connections and that there are no kinks, cuts, or

damage to the high pressure hose.

4. Provide proper water supply (not to exceed

100°F).

5. Be sure to read "Safety Rules" and "Operation"

sections before using the pressure washer.

6. if starting unit after storage, see "Storage" section

on pages 20-21.

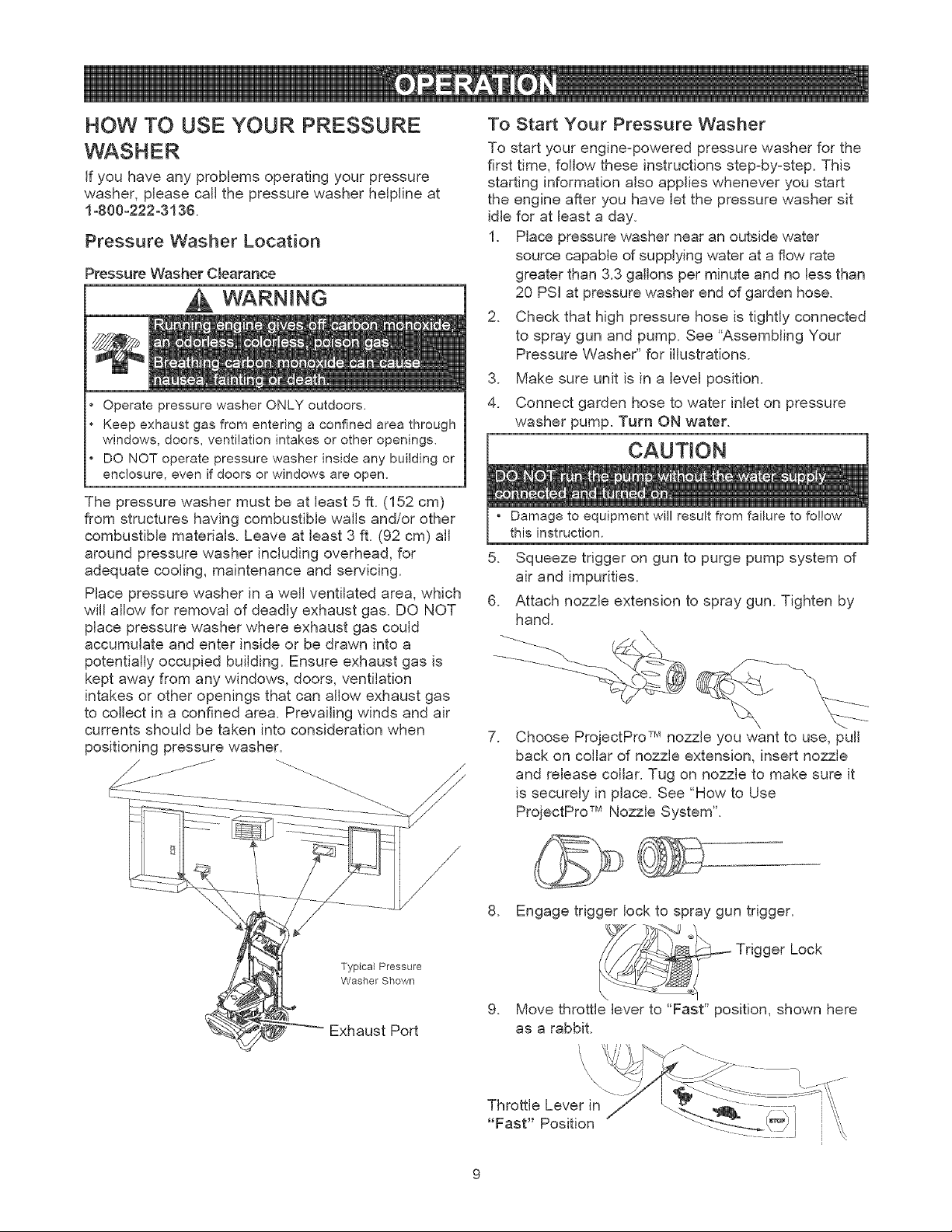

HOW TO USE YOUR PRESSURE

WASHER

if you have any problems operating your pressure

washer, please call the pressure washer helpline at

1-800-222-3136.

Pressure Washer Location

Pressure Washer Clearance

WARNtNG

Operate pressure washer ONLY outdoors.

Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

DO NOT operate pressure washer inside any building or

enc!osure, even if doors or windows are open.

To Start Your Pressure Washer

To start your engine-powered pressure washer for the

first time, follow these instructions step-by-step. This

starting information also applies whenever you start

the engine after you have let the pressure washer sit

idle for at least a day.

1. Place pressure washer near an outside water

source capable of supplying water at a flow rate

greater than 3.3 gallons per minute and no less than

20 PSI at pressure washer end of garden hose.

2. Check that high pressure hose is tightly connected

to spray gun and pump. See "Assembling Your

Pressure Washer" for illustrations.

3. Make sure unit is in a level position.

4. Connect garden hose to water inlet on pressure

washer pump. Turn ON water.

CAUTION

The pressure washer must be at least 5 ft. (152 cm)

from structures having combustible walls and/or other

combustible materials. Leave at least 3 ft. (92 cm) all

around pressure washer including overhead, for

adequate cooling, maintenance and servicing.

Place pressure washer in a well ventilated area, which

will allow for removal of deadly exhaust gas. DO NOT

place pressure washer where exhaust gas could

accumulate and enter inside or be drawn into a

potentially occupied building. Ensure exhaust gas is

kept away from any windows, doors, ventilation

intakes or other openings that can allow exhaust gas

to collect in a confined area. Prevailing winds and air

currents should be taken into consideration when

positioning pressure washer.

Typical Pressure

Washer Shown

* Damage to equipment will result from failure to follow

this instruction.

.

Squeeze trigger on gun to purge pump system of

air and impurities.

6.

Attach nozzle extension to spray gun. Tighten by

hand.

7.

Choose ProjectPro TM nozzle you want to use, pull

back on collar of nozzle extension, insert nozzle

and release collar. Tug on nozzle to make sure it

is securely in place. See "How to Use

ProjectPro TM Nozzle System".

8. Engage trigger lock to spray gun trigger.

Trigger Lock

Exhaust Port

g.

Move throttle lever to "Fast" position, shown here

as a rabbit.

\

\

Throttle Lever in

"Fast" Position

10.Movechokeleverto"Choke"position.

NOTE:Forawarmengine,besurethechokeleveris

inthe"Run"position.

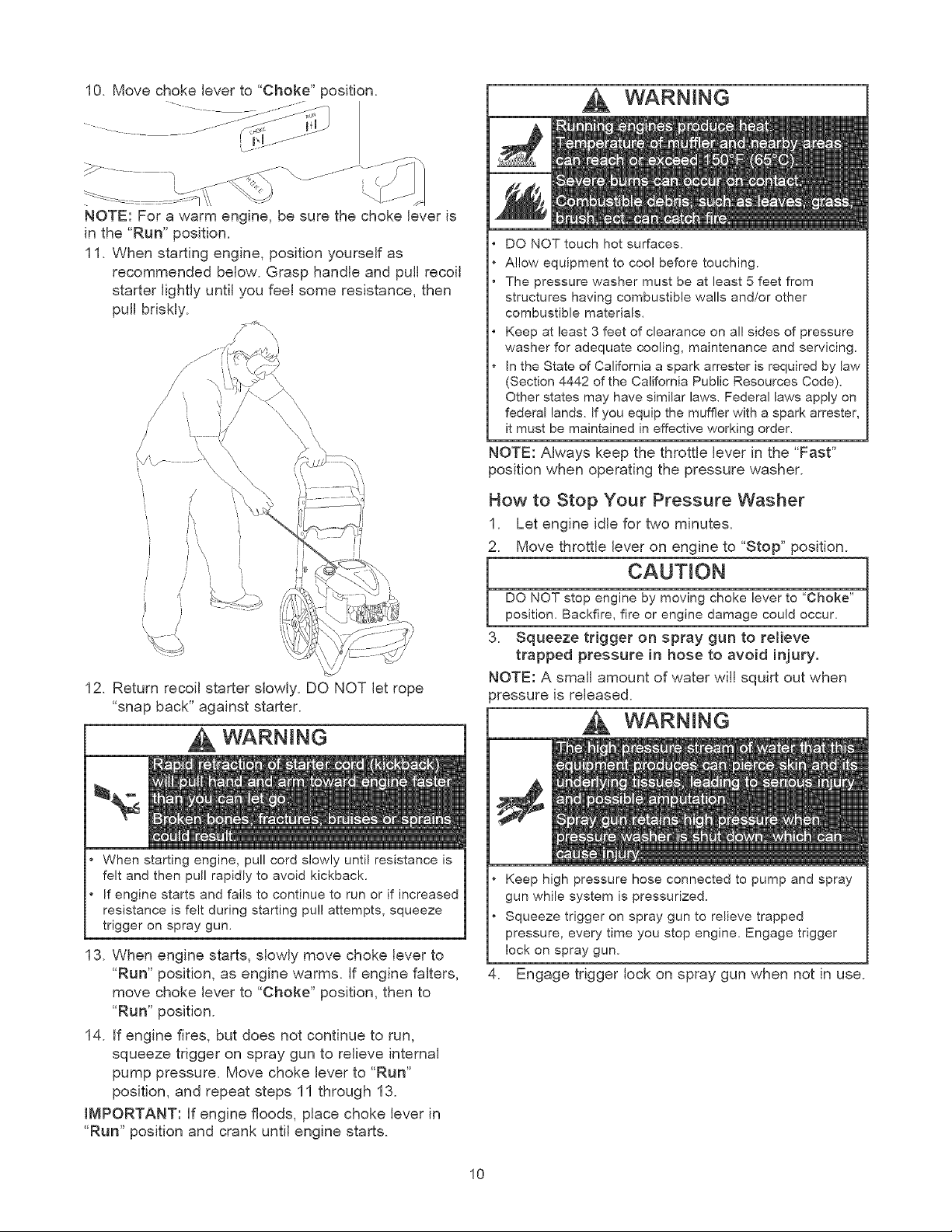

11.Whenstartingengine,positionyourselfas

recommendedbelow.Grasphandleandpullrecoil

starterlightlyuntilyoufeelsomeresistance,then

punbriskly.

/

/ '

s.....

io \<

i Jw i

I J I

, \

12. Return recoil starter slowly. DO NOT let rope

"snap back" against starter.

WARNING

7

WARNING

DO NOT touch hot surfaces.

Allow equipment to coo! before touching.

The pressure washer must be at least 5 feet from

structures having combustible walls and/or other

combustible materials.

Keep at least 3 feet of clearance on al! sides of pressure

washer for adequate cooling, maintenance and servicing.

In the State of California a spark arrester is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on

federal lands. If you equip the muffler with a spark attester,

it must be maintained in effective working order.

NOTE: Always keep the throttle lever in the "Fast"

position when operating the pressure washer.

How to Stop Your Pressure Washer

1. Let engine idle for two minutes.

2. Move throttle lever on engine to "Stop" position.

CAUTION

l DO NOT stop engine by moving choke lever to "Choke"

position. Backfire, fire or engine damage could occur.

3. Squeeze trigger on spray gun to relieve

trapped pressure in hose to avoid injury.

NOTE: A small amount of water will squirt out when

_ressure is released.

WARNING

When starting engine, pull cord slowly until resistance is

felt and then pull rapidly to avoid kickback.

If engine starts and fails to continue to run or if increased

resistance is felt during starting pull attempts, squeeze

trigger on spray gun.

3. When engine starts, slowly move choke lever to

"Run" position, as engine warms. If engine falters,

move choke lever to "Choke" position, then to

"Run" position.

14. If engine fires, but does not continue to run,

squeeze trigger on spray gun to relieve internal

pump pressure. Move choke lever to "Run"

position, and repeat steps 11 through 13.

IMPORTANT: If engine floods, place choke lever in

"Run" position and crank until engine starts.

Keep high pressure hose connected to pump and spray

gun while system is pressurized.

Squeeze trigger on spray gun to relieve trapped

pressure, every time you stop engine. Engage trigger

lock on spray gun.

.

Engage trigger lock on spray gun when not in use.

10

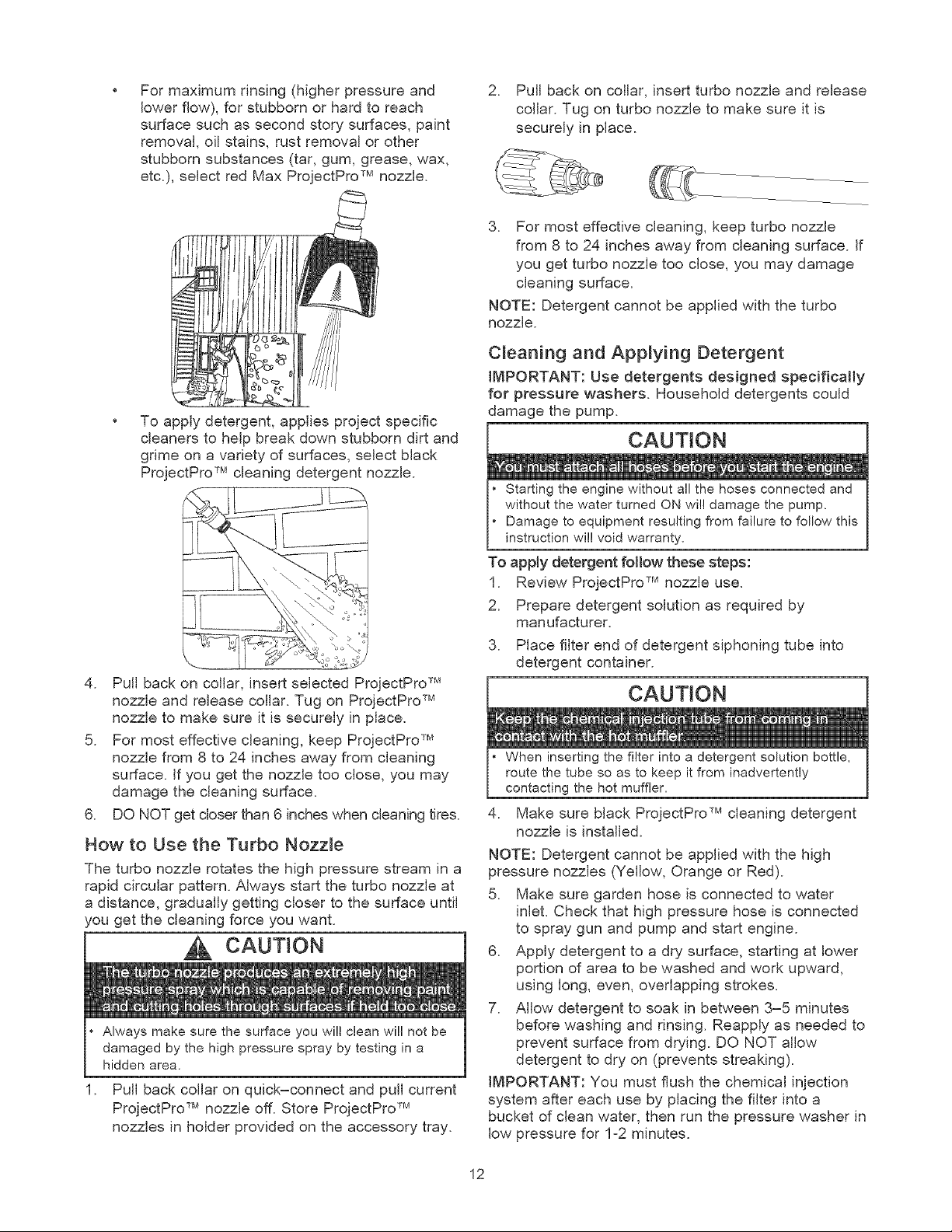

How to Use Accessory Tray

The unit is equipped with an accessory tray with

places to store your ProjectPro TM nozzles, turbo

nozzle, spray gun and nozzle extension. There is also

a hook at the front of the accessory tray to hold your

high pressure hose.

NOTE: The extra hole in the tray is for storing a utility

brush. The brush is NOT included with your pressure

washer. You can buy this item as an optional accessory.

1. Place nozzle extension through hole on accessory

tray, as shown.

Typical Pressure

Washer Shown

2. Place spray gun through hole on accessory tray

on right side of unit.

3. Push turbo nozzle up and into clip on accessory

tray until it snaps in.

4. Insert multi-colored ProjectPro TM nozzles in

spaces provided in accessory tray.

5. Hang high pressure hose on hook attached to

accessory tray on front of tray as shown.

Follow these instructions to change ProjectPro TM

nozzles:

1. Engage trigger lock on spray gun.

CAUTION

NEVER exchange ProjectPro TM nozzles without locking

the trigger lock on the trigger.

DO NOT twist ProjectPro TM nozzles while spraying.

.

Pull back collar on quick-connect and pull current

ProjectPro TM nozzle off. Store ProjectPro TM

nozzles in holder provided on the accessory tray.

.

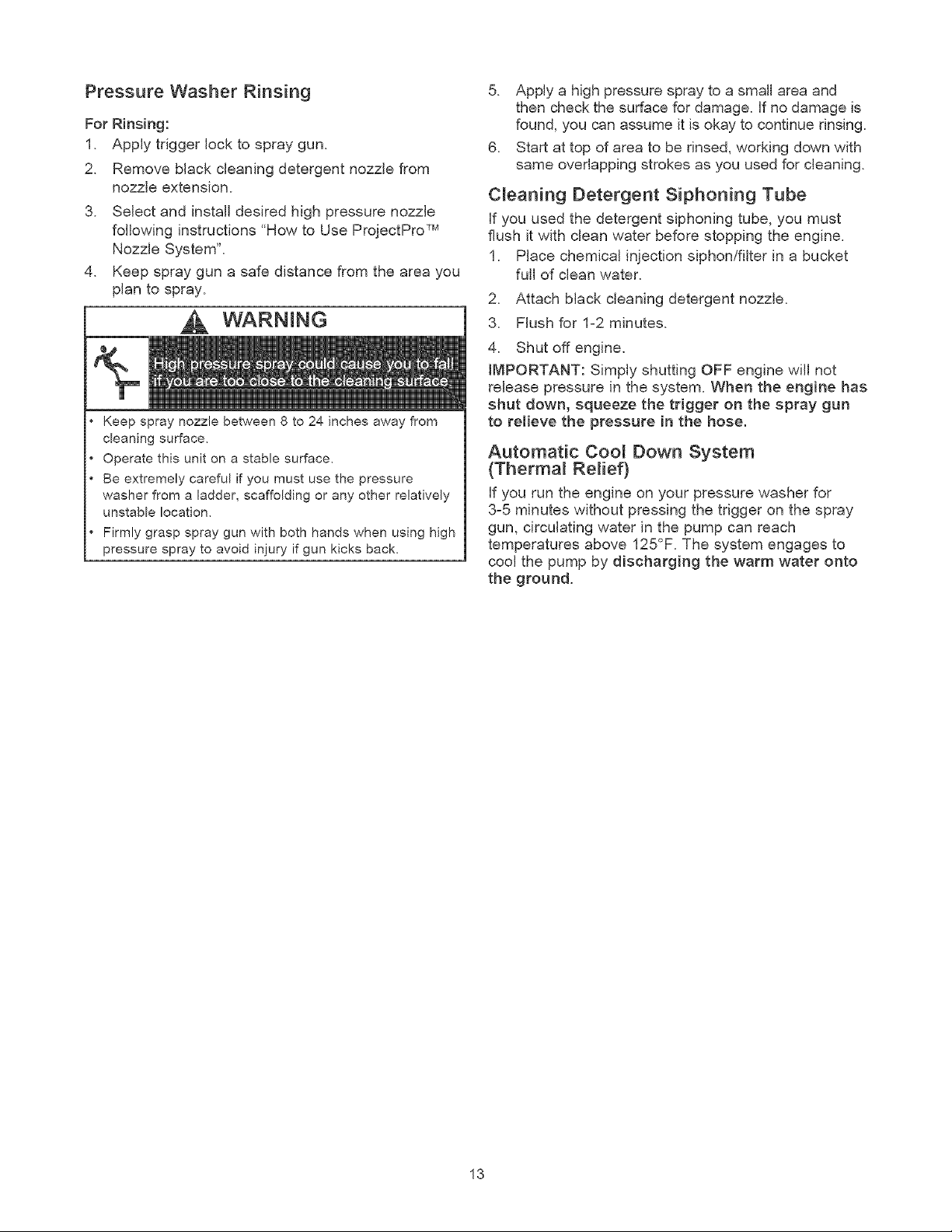

Select desired ProjectPro TM nozzle:

• For delicate rinse (lower pressure and higher

flow), for gentle cleaning of cars/trucks, boats,

RV's, patio furniture, lawn equipment, etc.,

select yellow Delicate ProjectPro TM nozzle.

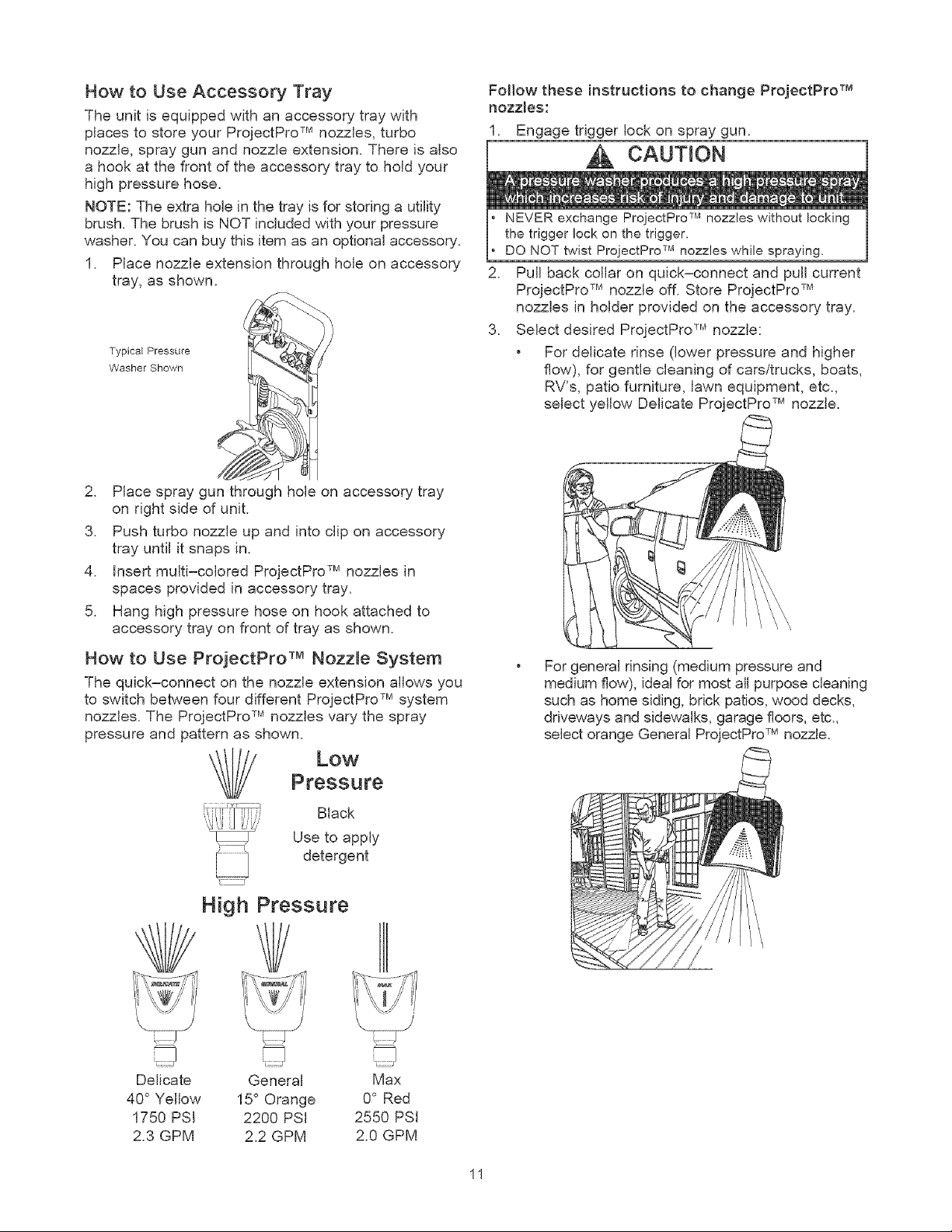

How to Use ProjectPro TM Nozzle System

The quick-connect on the nozzle extension allows you

to switch between four different ProjectPro TM system

nozzles. The ProjectPro TM nozzles vary the spray

pressure and pattern as shown.

Low

Pressure

Black

Use to apply

_--....1 detergent

High Pressure

Delicate

40 ° Yellow

1750 PSI

2.3 GPM

General

15° Orange

2200 PSI

2.2 GPM

Max

0° Red

2550 PSI

2.0 GPM

For general rinsing (medium pressure and

medium flow), ideal for most all purpose cleaning

such as home siding, brick patios, wood decks,

driveways and sidewalks, garage floors, etc.,

select orange General ProjectPro TM nozzle.

11

Formaximumrinsing(higherpressureand

lowerflow),forstubbornorhardto reach

surfacesuchassecondstorysurfaces,paint

removal,oilstains,rustremovalorother

stubbornsubstances(tar,gum,grease,wax,

etc.),selectredMaxProjectProTM nozzle.

To apply detergent, applies project specific

cleaners to help break down stubborn dirt and

grime on a variety of surfaces, select black

ProjectPro TM cleaning detergent nozzle.

4. Pull back on collar, insert selected ProjectPro TM

nozzle and release collar. Tug on ProjectPro TM

nozzle to make sure it is securely in place.

5. For most effective cleaning, keep ProjectPro TM

nozzle from 8 to 24 inches away from cleaning

surface. If you get the nozzle too close, you may

damage the cleaning surface.

6. DO NOT get closer than 6 inches when cleaning tires.

How to Use the Turbo Nozzle

The turbo nozzle rotates the high pressure stream in a

rapid circular pattern. Always start the turbo nozzle at

a distance, gradually getting closer to the surface until

you get the cleaning force you want.

CAUTmO. ]

• Always make sure the surface you will clean will not be

damaged by the high pressure spray by testing in a

hidden area.

1. Pull back collar on quick-connect and pull current

ProjectPro TM nozzle off. Store ProjectPro TM

nozzles in holder provided on the accessory tray.

2. Pull back on collar, insert turbo nozzle and release

collar. Tug on turbo nozzle to make sure it is

securely in place.

3. For most effective cleaning, keep turbo nozzle

from 8 to 24 inches away from cleaning surface. If

you get turbo nozzle too close, you may damage

cleaning surface.

NOTE: Detergent cannot be applied with the turbo

nozzle.

Cleaning and Applying Detergent

IMPORTANT: Use detergents designed specifically

for pressure washers. Household detergents could

damage the pump.

CAUTION

Starting the engine without all the hoses connected and

without the water turned ON will damage the pumG

Damage to equipment resulting from failure to follow this

instruction will void warranty,

To apply detergent follow these steps:

1. Review ProjectPro TM nozzle use.

2. Prepare detergent solution as required by

manufacturer.

3. Place filter end of detergent siphoning tube into

detergent container.

CAUTION

When inserting the filter into a detergent solution bottle,

route the tube so as to keep it from inadvertently

contacting the hot muffler.

4. Make sure black ProjectPro TM cleaning detergent

nozzle is installed.

NOTE: Detergent cannot be applied with the high

pressure nozzles (Yellow, Orange or Red).

5. Make sure garden hose is connected to water

inlet. Check that high pressure hose is connected

to spray gun and pump and start engine.

6. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward,

using long, even, overlapping strokes.

7. Allow detergent to soak in between 3-5 minutes

before washing and rinsing. Reapply as needed to

prevent surface from drying. DO NOT allow

detergent to dry on (prevents streaking).

IMPORTANT: You must flush the chemical injection

system after each use by placing the filter into a

bucket of clean water, then run the pressure washer in

low pressure for 1-2 minutes.

12

Pressure Washer Rinsing

For Rinsing:

1. Apply trigger lock to spray gun.

2. Remove black cleaning detergent nozzle from

nozzle extension.

3. Select and install desired high pressure nozzle

following instructions "How to Use ProjectPro TM

Nozzle System".

4. Keep spray gun a safe distance from the area you

plan to spray.

WARNING

Keep spray nozzle between 8 to 24 inches away from

cleaning surface,

Operate this unit on a stable surface,

Be extremely careful if you must use the pressure

washer from a ladder, scaffolding or any other relatively

unstable location,

Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury if gun kicks back.

5. Apply a high pressure spray to a small area and

then check the surface for damage. If no damage is

found, you can assume it is okay to continue rinsing.

6. Start at top of area to be rinsed, working down with

same overlapping strokes as you used for cleaning.

C_eaning Detergent Siphoning Tube

if you used the detergent siphoning tube, you must

flush it with clean water before stopping the engine.

1. Place chemical injection siphon/filter in a bucket

full of clean water.

2. Attach black cleaning detergent nozzle.

3. Flush for 1-2 minutes.

4. Shut off engine.

IMPORTANT: Simply shutting OFF engine will not

release pressure in the system. When the engBne has

shut down, squeeze the trigger on the spray gun

to relieve the pressure in the hose.

Automatic Door Down System

(Therma_ Relief)

If you run the engine on your pressure washer for

3-5 minutes without pressing the trigger on the spray

gun, circulating water in the pump can reach

temperatures above 125°F. The system engages to

cool the pump by discharging the warm water onto

the ground.

13

ENGmNE TECHNICAL INFORMATION

This is a single cylinder, Uhead, air cooled engine, it

is a low emissions engine.

in the State of California, Model Series 120000

engines are certified by the California Air Resources

Board to meet emissions standards for 125 hours.

Such certification does not grant the purchaser, owner

or operator of this engine any additional warranties

with respect to the performance or operational life of

this engine. The engine is warranted solely according

to the product and emmisions warranties stated

elsewhere in this manual.

Power Ratings

The power ratings for an individual engine model are

initially developed by starting with SAE (Society of

Automotive Engineers) code J1940 (Small Engine

Power & Torque Rating Procedure) (Revision 2002-

05). Given both the wide array of products on which

our engines are placed, and the variety of

environmental issues applicable to operating the

equipement, it may be that the engine you have

purchased will not develop the rated horsepower when

used in a peice of power equipment (actual "on-site"

power). This difference is due to a variety of factors

including, but not limited to, the following: differences

in altitude, temperature, barometric pressure, humidity,

fuel, engine lubrication, maximum governed engine

speed, individual engine to engine variability, design of

the particular peice of power equipment, the manner in

which the engine is operated, engine run-in to reduce

friction and clean out of combustion chambers,

adjustments to the valves and carburetor, and other

factors. The power ratings may also be adjusted

based on comparisons to other similar engines

utilizedin similar applications, and will thereforenot

necessarily match the values derived using the

foregoing codes.

PRODUCT SPECIFICATIONS

Pressure Washer Specifications

Max Outlet Pressure .................. 2,550 PSI

Max Flow Rate ....................... 2.3 GPM

Detergent Mix ................... Use as directed

Water Supply Temperature .... Not to exceed 100°F

Shipping Weight ........................ 63 Ibs.

Engine Specifications

Rated Horsepower ............... 6.75 at 3600 rpm

Bore ............................ 2.69 in. (68mm)

Stroke .......................... 2.04 in. (52mm)

Displacement ................... 11.57 in. (190 cc)

Spark Plug

Type: ............ Champion RJ19LM or Equivalent

Set Gap To: ................. 0.030inch (0.76mm)

Armature Air Gap: ...... 0.006-0.0! 0 in.(0.15-0.25mm)

Valve clearance with valve springs installedand piston 1/4 in.

(6 mm) past top dead center (check when engine is cold).

Intake ............... 0.005-0.007 in.(0.13-0.18 ram)

Exhaust ............. 0.005-0.007 in.(0.13-0.!8 ram)

Fuel Capacity ......................... 1.6 Quarts

Oil Capacity .................. 20 Ounces (0.6 liter)

Oil Type:

Above 40° F .......................... SAE 30

Below 40° F .............. SAE 5W-30 or 10W-30

NOTE: For practical operation, the horsepower

loading should not exceed 85% of rated horsepower.

Engine power will decrease 3-1/2% for each

1,000 feet (300 meters) above sea level and 1% for

each 10° F (5.6° C) above 77° F (25 ° C). It should

operate satisfactorily at an angle up to 15°.

14

OWNER'S RESPONSiBtUTIES

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU

COMPLETE REGULAR SERVICE

MABNTENANCE TASK

PRESSURE WASHER

Check/clean water inlet screen

Check high pressure hose

Check detergent hose

Check spray gun and assembly for leaks

Purge pump of air and contaminants

Change pump oil

Prepare pump for storage below 32°F

ENGINE

Check oil level

Clean debris

Change engine oil

Service air cleaner

Service spark plug

Service spark arrester

Clean cooling system

Clean combustion chamber

Prepare for storage

Clean if clogged. Replace if perforated or torn.

Change oil after the first (5) operating hours and every 50 hours or yearty thereafter.

Change sooner when operating under dirty or dusty conditions.

Replace more often under dirty or dusty conditions.

Before

Each Use

x_

x

x

x

x

X

X

If unit is to remah_ idle for longer than 30 days.

GENERAL RECOMMENDATIONS

Regular maintenance will improve the performance

and extend the life of the pressure washer. See any

authorized Sears dealer for service.

The pressure washer warranty does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain pressure washer as

instructed in this manual including proper storage as

detailed in "Storage" on pages 20-21.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

"Maintenance Schedule" chart above.

NOTE: Once a year you should clean or replace the

spark plug and replace the air filter. A new spark plug

and clean air filter assure proper fuel-air mixture and

help your engine run better and last longer.

EMtSSION CONTROL

Maintenance, replacement or repair of the emission

control devices and systems may be performed by any

non-road engine repair establishment or individual.

SERVICE DATES

Every 25 Every 50

Hours or Hours or

Yeady Yearly

x

See Storage on pages 20-21

X 2

X_

X

Every 100

Hours or

Yearly

100-300

Hours

X

X2

BEFORE EACH USE

1. Check engine oil level.

2. Clean debris.

3. Check water inlet screen for damage.

4. Check in-line filter for debris.

5. Check high pressure hose for leaks.

6. Check chemical filters for damage.

7. Check gun and nozzle extension assembly for

leaks.

8. Purge pump of air and contaminants.

PRESSURE WASHER MAINTENANCE

Cban Debris

Daily or before use, clean accumulated debris from

cleaning system. Keep linkage, spring and controls

clean. Keep area around and behind muffler free from

any combustible debris.

Cleaning system parts should be kept clean to reduce

the risk of overheating and ignition of accumulated

debris.

SERVICE DATES

15

CAUTION

• DO NOT insert any objects through cooling slots.

° Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil,

etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. inspect cooling air slots and openings on

the pressure washer. These openings must be kept

clean and unobstructed.

Check and Clean _n_et Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

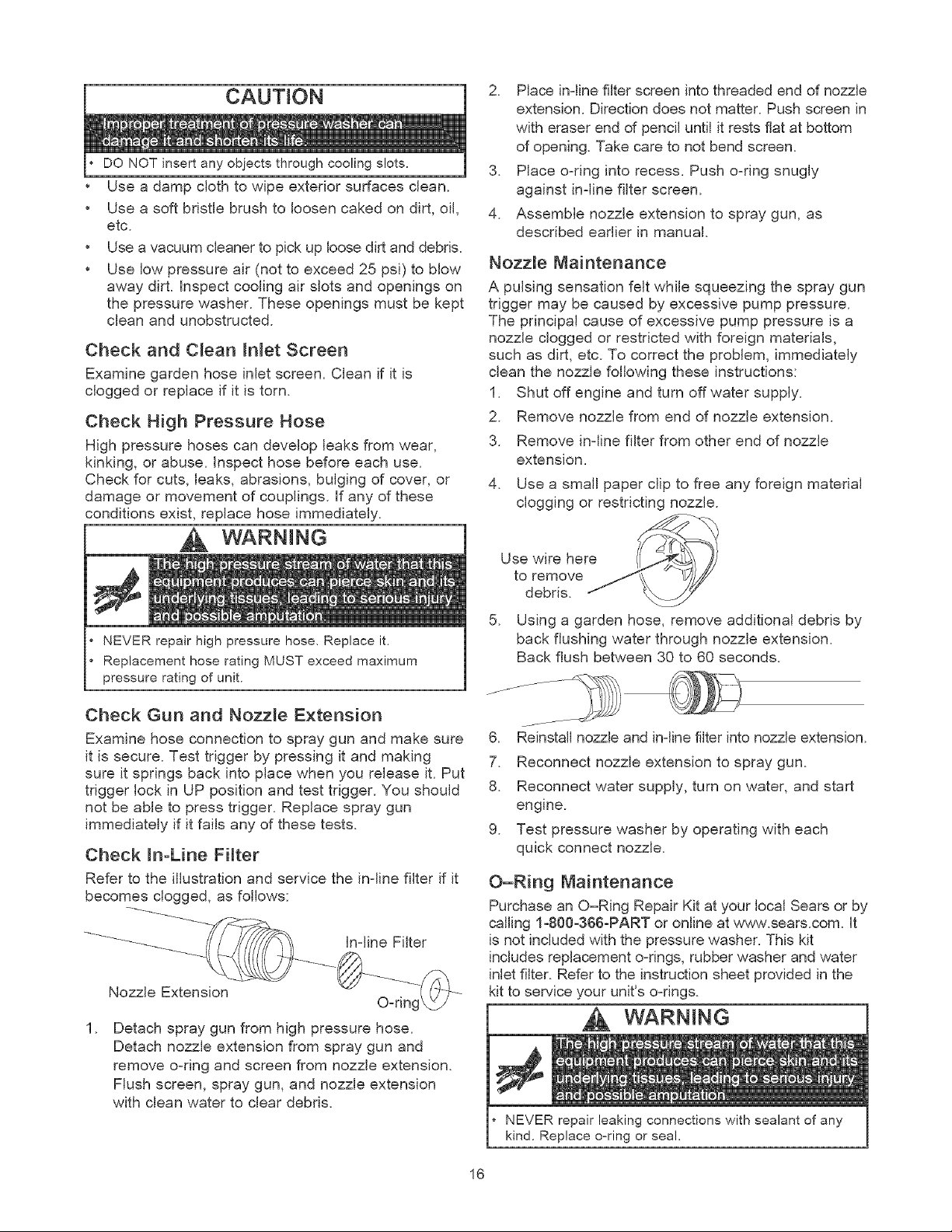

2. Place inqine filter screen into threaded end of nozzle

extension. Direction does not matter. Push screen in

with eraser end of pencil until it rests flat at bottom

of opening. Take care to not bend screen.

3. Place o-ring into recess. Push o-ring snugJy

against in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described eadier in manual.

NozzLe Maintenance

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure.

The principal cause of excessive pump pressure is a

nozzle clogged or restricted with foreign materials,

such as dirt, etc. To correct the problem, immediately

clean the nozzle following these instructions:

1. Shut off engine and turn off water supply.

Remove nozzle from end of nozzle extension..

3. Remove in-line filter from other end of nozzle

extension.

4. Use a small paper clip to free any foreign material

clogging or restricting nozzle.

l 1

• NEVER repair high pressure hose, Replace it,

• Replacement hose rating MUST exceed maximum

pressure rating of unit.

Check Gun and Nozzle Extension

Examine hose connection to spray gun and make sure

it is secure. Test trigger by pressing it and making

sure it springs back into place when you release it. Put

trigger lock in UP position and test trigger. You should

not be able to press trigger. Replace spray gun

immediately if it fails any of these tests.

Check _n-Line FHter

Refer to the illustration and service the inqine filter if it

becomes clogged, as follows:

NozzJe Extension

O-ring

Detach spray gun from high pressure hose.

Detach nozzle extension from spray gun and

remove o-dng and screen from nozzle extension.

Flush screen, spray gun, and nozzle extension

with clean water to clear debris.

Use wire here _'_4_ 1

to remove _\\ " _VJ_f

debris. J

5. Using a garden hose, remove additional debris by

back flushing water through nozzle extension.

Back flush between 30 to 60 seconds.

f-

6. Reinstall nozzle and in-line filter into nozzle extension.

7. Reconnect nozzle extension to spray gun.

8. Reconnect water supply, turn on water, and start

engine.

9. Test pressure washer by operating with each

quick connect nozzle.

O-Ring Maintenance

Purchase an O-Ring Repair Kit at your local Sears or by

calling 1-800-366-PART or online at ww_,_Lsears.com.It

is not included with the pressure washer. This kit

includes replacement o-dngs, rubber washer and water

inlet filter. Refer to the instruction sheet provided inthe

kit to service your unit's o-rings.

WARNING

NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal,

16

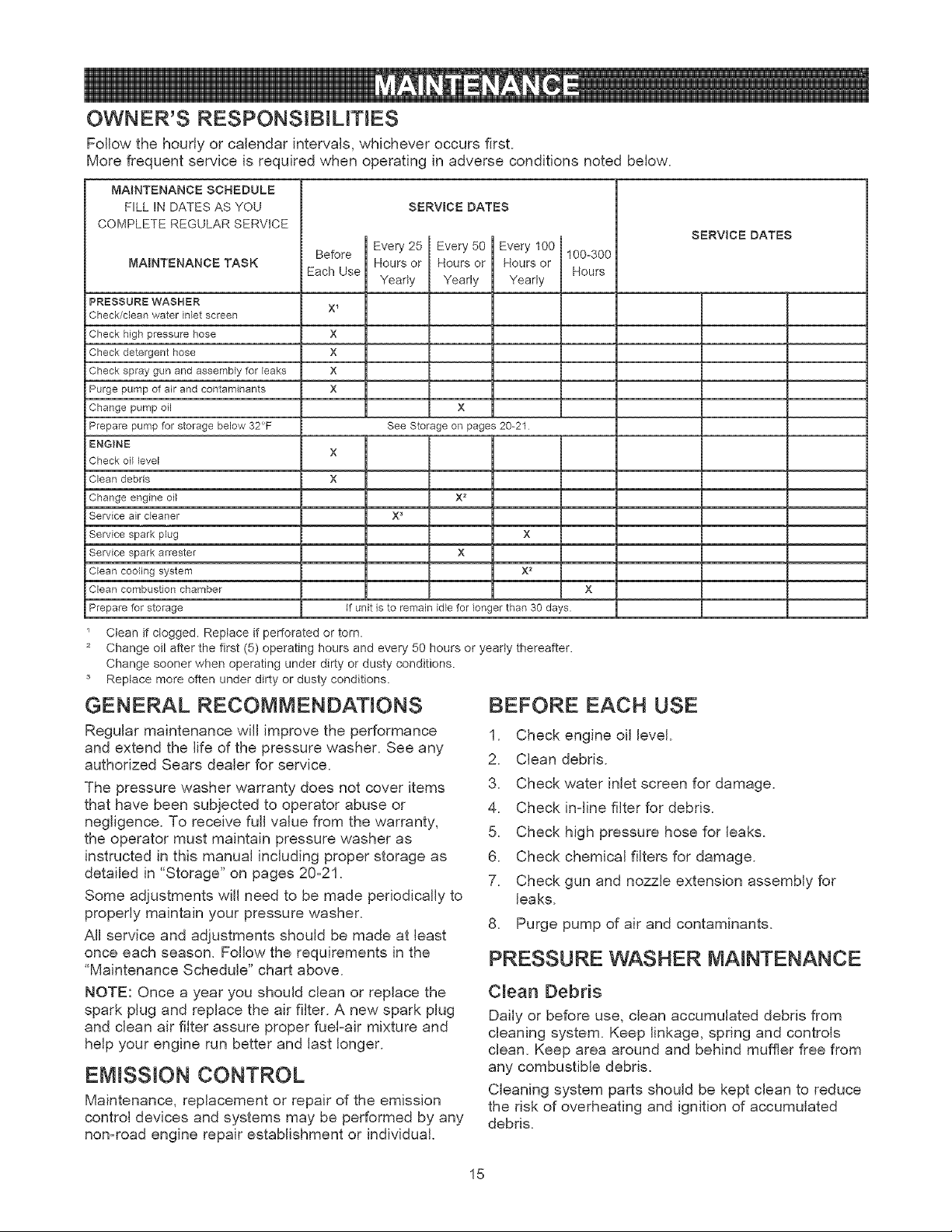

Pump Maintenance

OH

Changing Pump Oit

Change oil every 50 hours or once yearly, whichever

occurs first.

NOTE: You must purchase an approved bottle of

pump oil by calling 1-800-366-PART or online at

www.sears, com.

Change pump oil as follows:

1. Drain engine oil and fuel from pressure washer.

2. Use a 8mm allen wrench to remove black pump

oil cap between high pressure outlet and garden

hose inlet.

Oil Cap

3. TiJtpressure washer to drain oil into an approved

container untiJ it drips slowly from pump.

4. Tilt pressure washer in opposite direction and

empty premeasured pump oiJbottle into same

opening (a small funnel may be helpful).

5. Install black pump oiJcap and tighten firmly.

6. Set pressure washer in upright position. Add fuel

and engine oil.

ENGINE MAINTENANCE

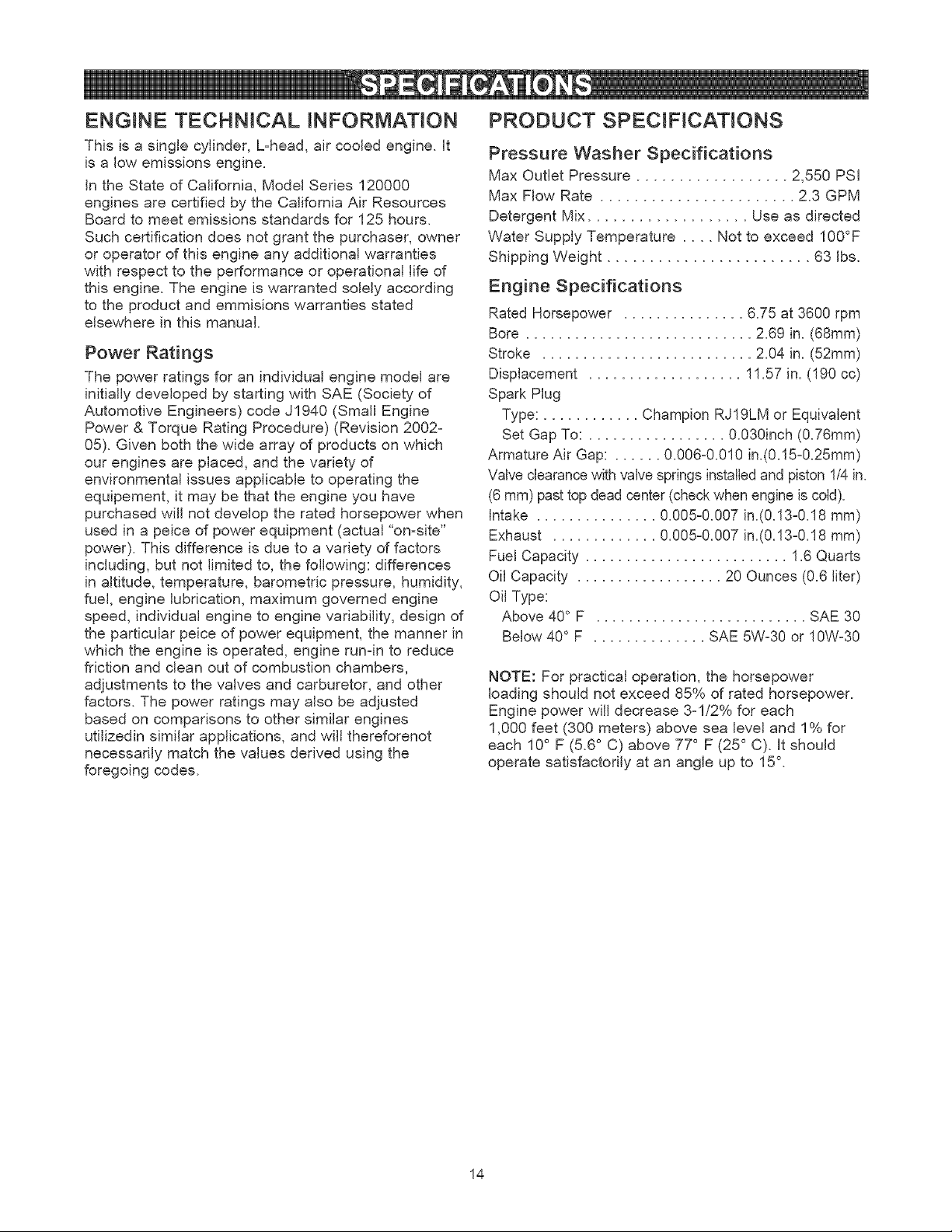

Oil Recommendations

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil rated with API service

classification SF, SG, SH, SJ or higher. DO NOT use

special additives.

1. Choose a viscosity according to the following table:

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Synthetic oil meeting ILSAC GF-2, API

certification mark and API service symbol with "SJ/CF

ENERGY CONSERVING" or higher, is an acceptable

oil at all temperatures. Use of synthetic oil does not

alter required oil change intervals.

* The use of multi-viscosity oils (5W-30, 10W-30, etc.)

in temperatures above 40°F (4°C) will result in higher

than normal oil consumption. When using a multi-

viscosity oil, check oil more frequently.

** If using SAE 30 oil in temperatures below 40°F

(4°C), it will result in hard starting and possible engine

bore damage due to inadequate lubrication.

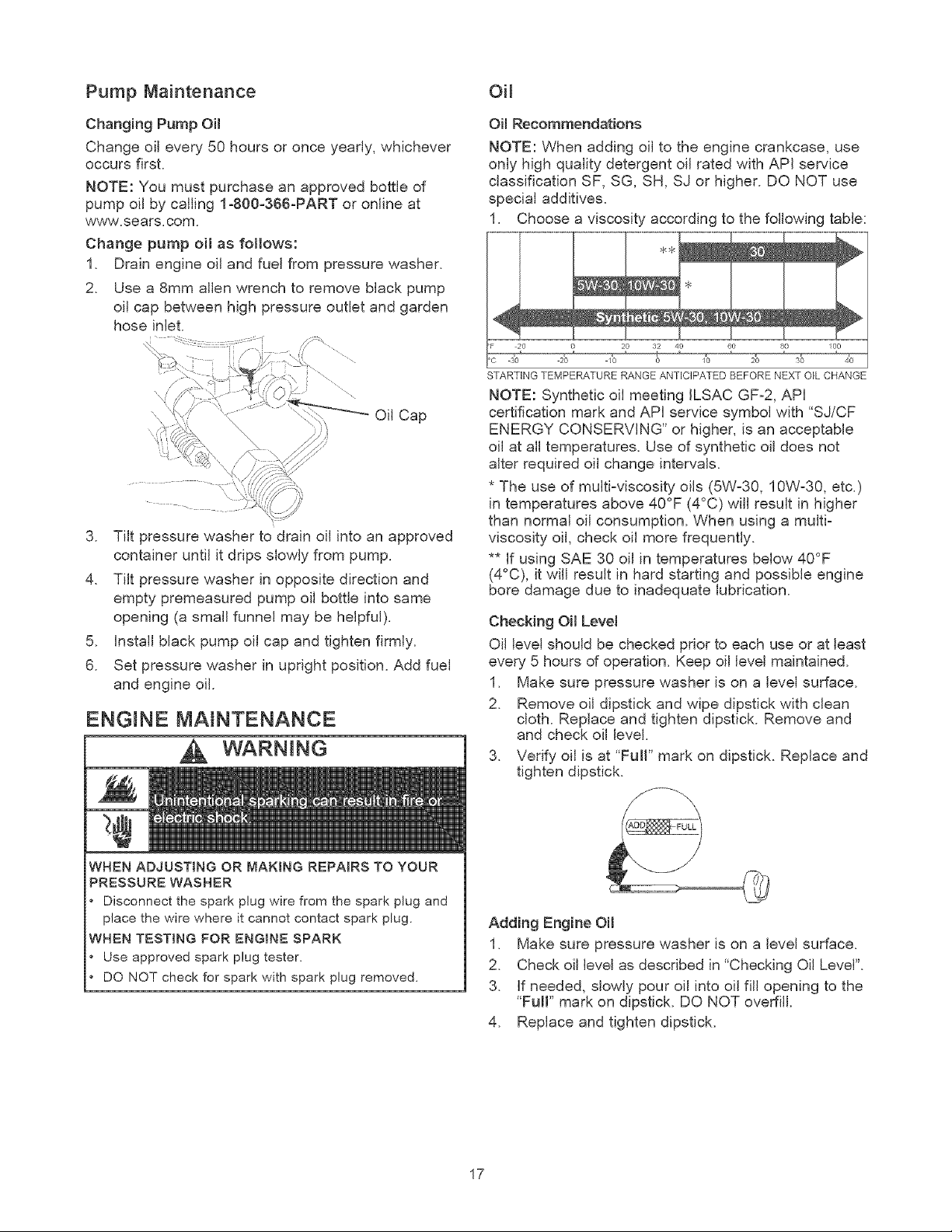

Checking Oil Level

Oil level should be checked prior to each use or at least

every 5 hours of operation. Keep oil level maintained.

1. Make sure pressure washer is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean

cloth. Replace and tighten dipstick. Remove and

and check oil level.

3. Verify oil is at "Fulr' mark on dipstick. Replace and

tighten dipstick.

WHEN ADJUSTING OR MAKING REPAIRS 3"O YOUR

PRESSURE WASHER

Disconnect the spark plug wire from the spark plug and

place the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

Use approved spark plug tester.

DO NOT check for spark with spark plug removed,

Adding Engine Oil

1. Make sure pressure washer is on a level surface.

2. Check oil level as described in "Checking Oil Level".

3. If needed, slowly pour oil into oil fill opening to the

"Full" mark on dipstick. DO NOT overfill.

4. Replace and tighten dipstick.

17

Loading...

Loading...