Craftsman 580752290 Owner’s Manual

Operator'siVlanual

3100 PSi MAX

2.8 GPMMAX

Model No. 580.752290

®

CUSTOMERHELPLINE

PRESSUREWASHER ,_

HOURS: Non. - Fri. 8 a.m. to 5 p.m. (CT)

WAemG

Before usingthis product, readthis

manualand follow all Safety Rules

and Operating Instructions.

Sears, Roebuckand Co., RoffmanEstates,IL 60179 U.S.A.

Visit our Craftsman website:www.craftsman.cnm

Part No. 206170GS Draft A (01/18/2008)

1_-illADVERTEHCIA

Antes de utilizar el producto, lea este

manualy siga todas las Regiasde

Seguridade Instrucciones de Uso.

,, Safety

,,Assembly

,, Operation

=Maintenance

,, Parts

• Espafiol,p. 32

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-16

SPECIFICATIONS..................................... 17

MAINTENANCE.................................... 18-22

STORAGE........................................... 23

TROUBLESHOOTING.................................. 24

REPLACEMENTPARTS.............................. 25-29

EMISSIONCONTROLWARRANTY..................... 30-31

ESPANOL......................................... 32-55

HOWTO ORDERPARTS........................ BACKPAGE

ONE-YEARFULLWARRAHTYONCRAFTSMAHPRESSUREWASHER

If this pressurewasher fails dueto a defect in material or workmanship within one year from the dateof purchase,return it to

any Searsstore, other Craftsman outlet, or SearsParts & RepairCenterin the UnitedStates or Canadafor free repair (or

replacementif repairproves impossible).

All warranty coverageapplies for only 90 days from dateof purchaseif this pressure washeris ever usedfor commercial or

rentalpurposes.

This warranty gives you specific legal rights, and you mayalso haveother rights which vary from stateto state.

Sears, Roebuck and Co., Hoffman Estates, IL 60178

Sears Canada Inc., Toronto, Ontario, Canada M5B 288

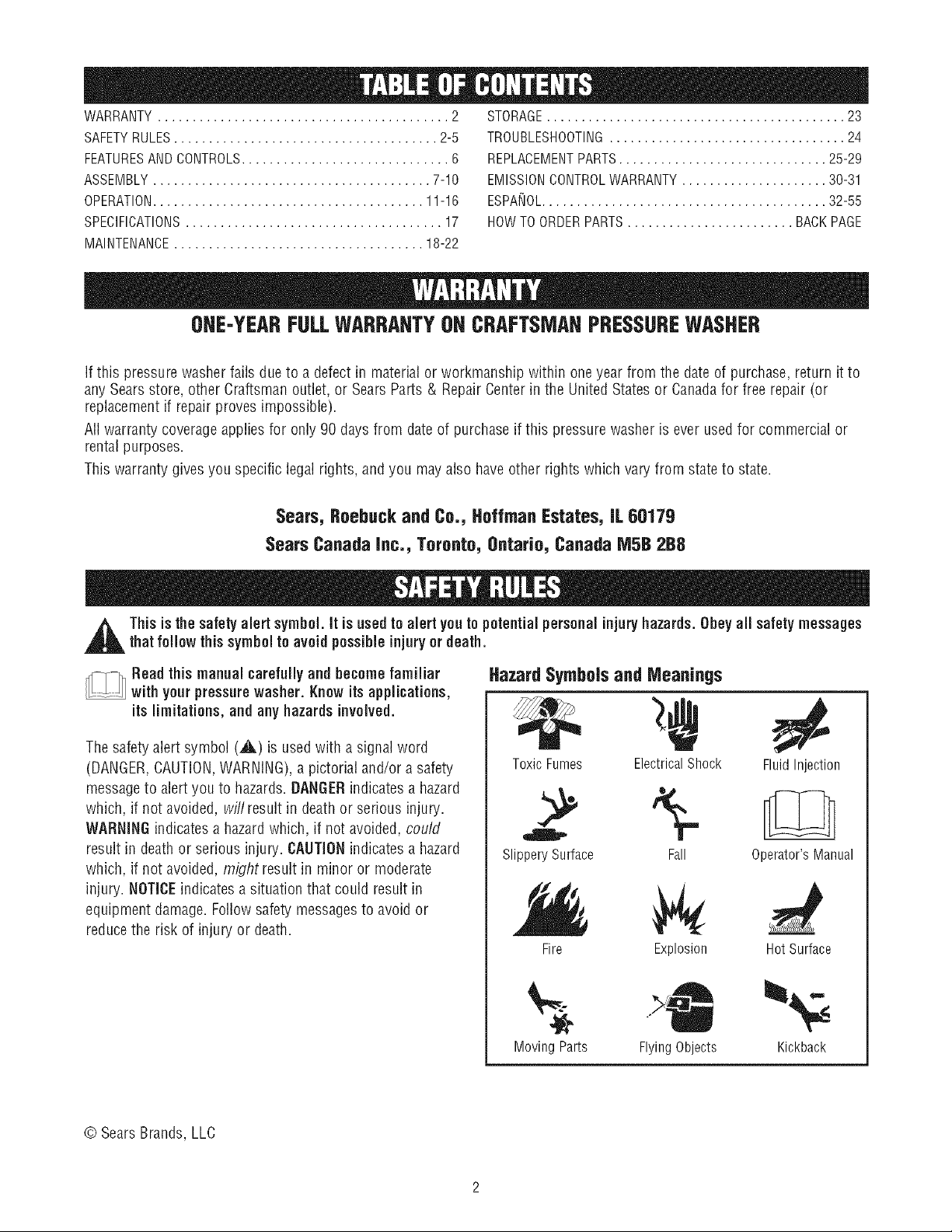

,_ Thisisthe safetyalert symbol.It isusedto alert youtopotentialpersonalinjuryhazards. Obeyall safetymessages

thatfollow thissymbolto avoid possibleinjuryor death.

_Read this manualcarefully and becomefamiliar

with your pressurewasher. Knowits applications,

its limitations, and any hazardsinvolved.

Thesafety alert symbol (_&.) is used with a signal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert you to hazards.BANGERindicates a hazard

which, if not avoided, willresult in deathor serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in death or serious injury. CAUTIONindicatesa hazard

which, if not avoided,might result in minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage. Follow safetymessagesto avoid or

reducethe risk of injury or death.

Hazard Symbolsand Meaninos

ToxicFumes ElectricalShock

2 5-

SlipperySurface Fall

Fire

MovingParts FlyingObjects

Explosion

FluidInjection

Operator'sManual

HotSurface

Kickback

© SearsBrands, LLC

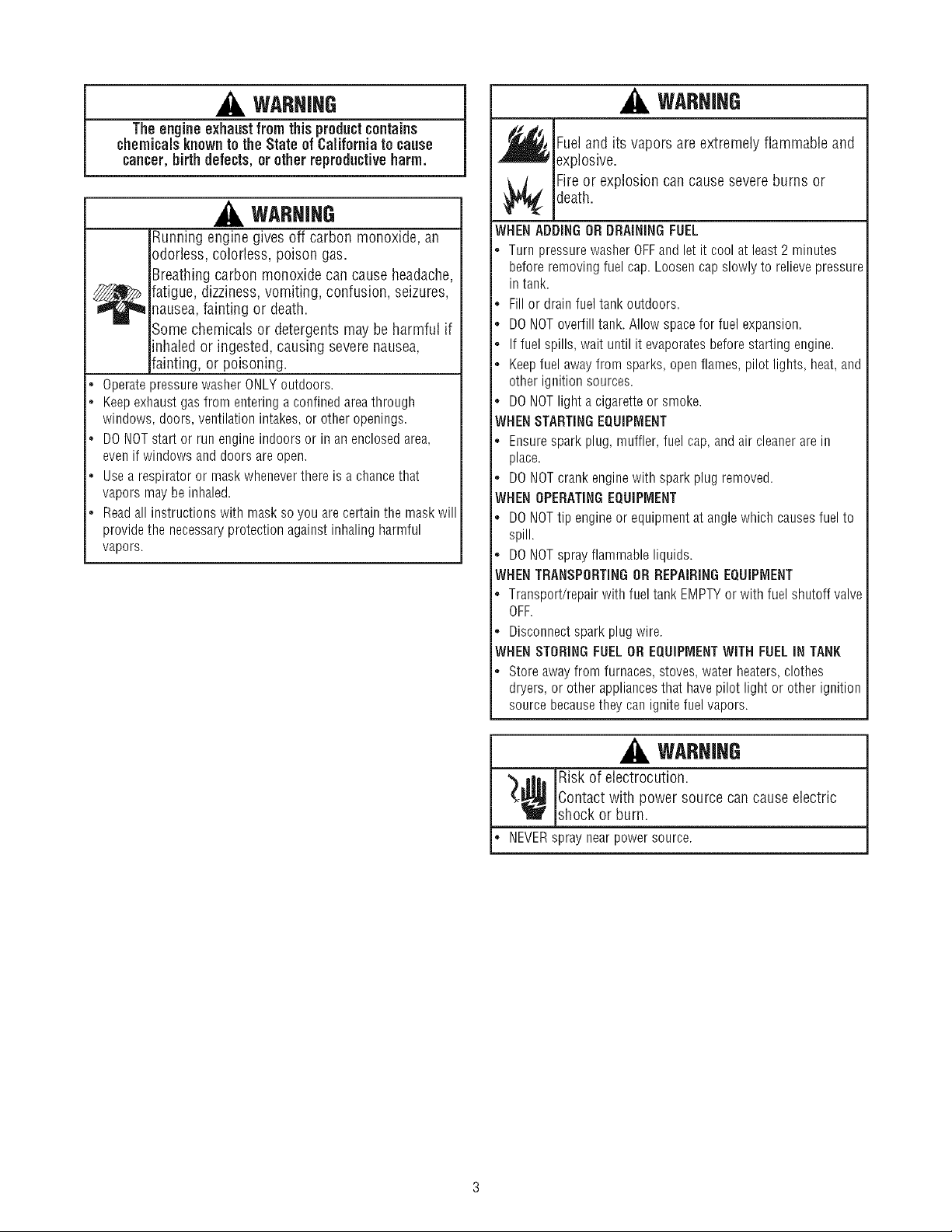

WARHING

Theengineexhaustfromthisproductcontains

chemicalsknownto the State of California tocause

cancer,birthdefects,or otherreproductiveharm.

WARHIHG

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathingcarbon monoxide can causeheadache,

_ atigue, dizziness, vomiting, confusion, seizures,

* OperatepressurewasherONLYoutdoors.

Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,or otheropenings.

DONOTstartor runengineindoorsor in anenclosedarea,

evenif windowsanddoorsareopen.

Usea respiratoror maskwheneverthereis a chancethat

vaporsmaybeinhaled.

* Readall instructionswith masksoyouarecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

nausea,fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severenausea,

fainting, or poisoning.

WARHIHG

_Fuel and its are extremelyflammable and

WHENADDINGORDRAININGFUEL

* TurnpressurewasherOFFandletit coolatleast2 minutes

WHENSTARTINGEQUIPMENT

* Ensuresparkplug,muffler,fuelcap,andair cleanerarein

* DONOTcrankenginewith sparkplugremoved.

WHENOPERATINGEQUIPMENT

* DONOTtip engineorequipmentat anglewhichcausesfuelto

* DONOTsprayflammableliquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

* Transport/repairwithfueltank EMPTYorwithfuel shutoffvalve

* Disconnectsparkplugwire.

WHENSTORINGFUELOREQUIPMENTWITHFUELINTANK

* Storeawayfromfurnaces,stoves,waterheaters,clothes

explosive.

death.

Fireor explosion cancause severe burns or

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

Fillor drainfueltankoutdoors.

DONOToverfilltank.Allowspaceforfuelexpansion.

Iffuelspills,waituntil it evaporatesbeforestartingengine.

Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

DONOTlighta cigaretteorsmoke.

place.

spill.

OFF.

dryers,orotherappliancesthathavepilotlightor otherignition

sourcebecausetheycanignitefuelvapors.

vapors

WARHIHG

'__¢ Risk of electrocution.

NEVERspraynearpowersource.

Contactwith power source can causeelectric

shock or burn.

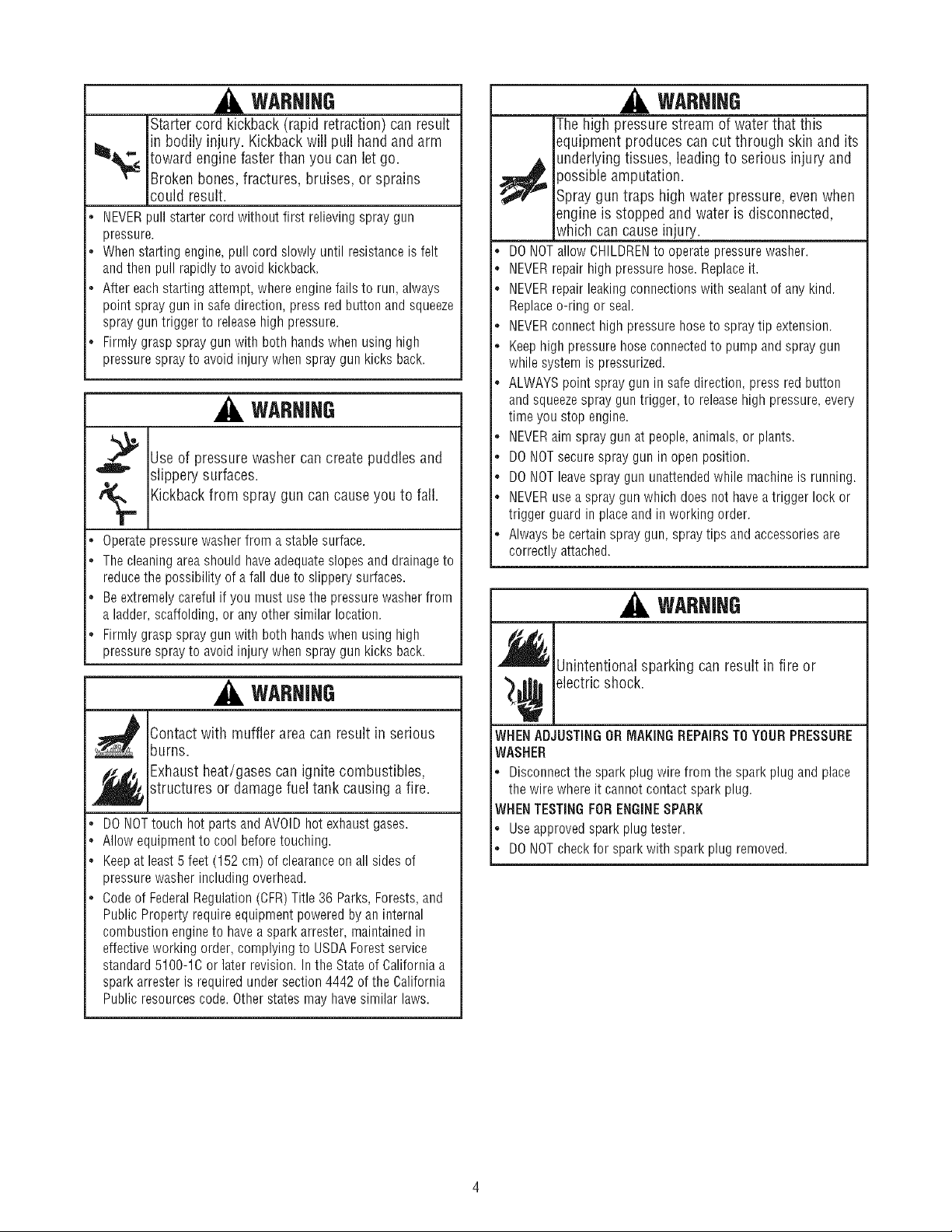

WARHIHG

Startercord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

_,_< toward enginefaster than youcan let go.

Brokenbones, fractures, bruises, or sprains

could result.

* NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

* Whenstartingengine,pullcordslowlyuntilresistanceisfelt

andthenpull rapidlyto avoidkickback.

Aftereachstartingattempt,whereenginefailsto run,always

pointspraygunin safedirection,pressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

WARHIHG

Useof pressurewasher cancreate puddles and

slippery surfaces.

Kickbackfrom spray gun cancause you to fall.

%

* Operatepressure washer from astable surface.

The cleaningarea should haveadequate slopes and drainageto

reducethe possibility of afall due to slippery surfaces.

Be extremelycareful if you must usethe pressure washer from

a ladder, scaffolding, or any other similar location.

Firmly grasp spray gun with both hands when using high

pressure spray to avoidinjury when spray gun kicks back.

WARHIHG

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

• DONOTallow CHILDRENto operate pressure washer.

, NEVERrepair high pressure hose. Replaceit.

• NEVERrepair leaking connections with sealantof any kind.

Replaceo-ring or seal.

, NEVERconnect high pressure hoseto spray tip extension.

• Keephigh pressure hose connectedto pump and spray gun

while system is pressurized.

• ALWAYSpoint spray gun in safe direction, press red button

and squeezespray gun trigger, to release high pressure, every

time you stop engine.

• NEVERaim spray gun at people, animals, or plants.

, DONOTsecure spray gun inopen position.

• DO NOTleavespray gun unattendedwhile machineis running.

, NEVERusea spray gun which does not have atrigger lock or

trigger guard in place and in working order.

• Always be certain spray gun, spray tips and accessories are

correctly attached.

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

WARHIHG

_ Unintentional sparking can result in fire or

WARHIHG

_ ontact with muffler area can result in serious

_ Exhaustheat/gases can ignite combustibles,

, DONOTtouchhotpartsandAVOIDhot exhaustgases.

, Allowequipmentto cool beforetouching.

* Keepatleast5feet (152cm) ofclearanceonall sidesof

, Codeof FederalRegulation(CFR)Title36 Parks,Forests,and

burns.

structures or damagefuel tank causing a fire.

pressurewasherincludingoverhead.

PublicPropertyrequireequipmentpoweredbyaninternal

combustionengineto haveasparkarrester,maintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-1Corlaterrevision.IntheStateof Californiaa

sparkarresteris requiredundersection4442of the California

Publicresourcescode.Otherstatesmayhavesimilarlaws.

_¢ electric shock.

WHENADJUSTINGORMAKING REPAIRSTOYOUR PRESSURE

WASHER

Disconnectthe sparkplug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

* Useapproved sparkplug tester.

DONOTcheck for spark with spark plug removed.

WARHJHG

_ IStarter and other rotating parts can entangle

* NEVERoperate pressure washer without protective housing or

. DO NOTwear loose clothing, jewelry or anything that may be

. Tie up long hair and remove jewelry.

hands, hair, clothing, or accessories.

covers.

caught in the starter or other rotating parts.

WARNING

Risk of eye injury.

Spray can splash back or propel objects.

Alwayswear safety goggles when using this equipment or in

vicinity of where equipment is in use.

Beforestarting the pressure washer, be sureyou are wearing

adequatesafety goggles.

NEVERsubstitute safety glasses for safety goggles.

NOTICE

High pressure spray may damage fragile items including

lass.

DONOTpoint spraygunatglasswhenusingred (0°) spraytip.

NEVERaim spray gun at plants.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

Ifyou have questions about intended use, ask dealer or contact

Sears.

NEVERoperate units with broken or missing parts, or without

protective housing or covers.

DONOT by-pass any safety device on this machine.

DONOTtamper with governed speed.

DONOToperate pressure washer above rated pressure.

DONOT modify pressure washer inany way.

Before starting pressure washer in cold weather, check all parts

of the equipment to besure ice has not formed there.

NEVERmove machine by pulling on hoses. Use handle

provided on unit.

Checkfuel system for leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washer.

This equipment is designedto be usedwith Searsauthorized

parts ONLY.If equipment is used with parts that DO NOT

comply with minimum specifications, userassumes all risks

and liabilities.

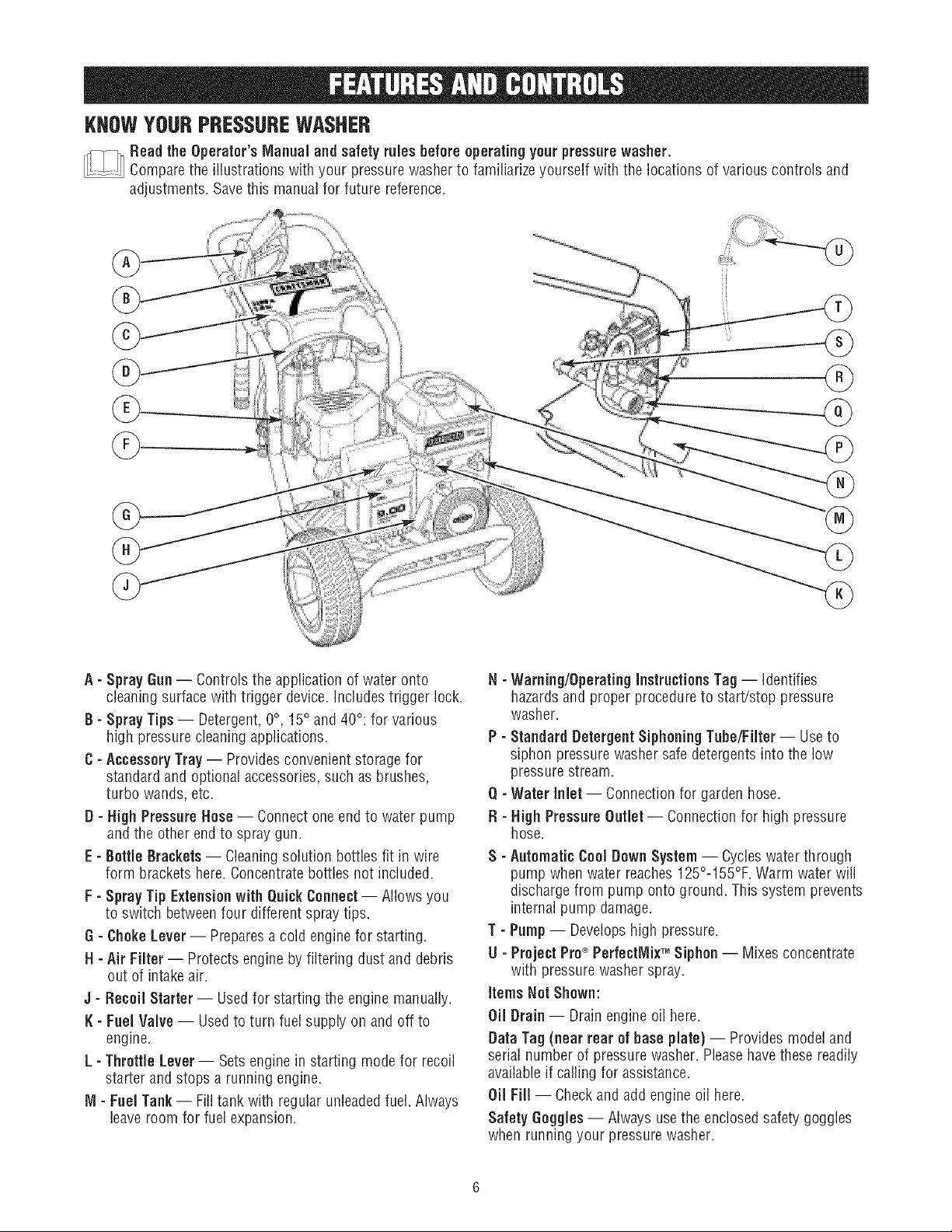

KNOWYOURPRESSUREWASHER

_Head the Operator'sManual andsafety rulesbefore operatingyourpressurewasher.

Comparethe illustrations with your _ressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

A - Spray Gun-- Controls the application of water onto

cleaning surfacewith trigger device.Includes trigger lock.

B - Spray Tips -- Detergent,0°, 15° and 40°: for various

high pressure cleaning applications.

C- Accessory Tray -- Providesconvenient storage for

standard and optional accessories,such as brushes,

turbo wands, etc.

D - High Pressure Hose-- Connect oneend to water pump

and the other end to spray gun.

E - Bottle Brackets -- Cleaningsolution bottles fit in wire

form brackets here.Concentratebottles not included.

F - Spray Tip Extensionwith QuickConnect -- Allows you

to switch betweenfour different spraytips.

G - Choke Lever-- Preparesa cold engine for starting.

H - Air Filter -- Protectsengine by filtering dust and debris

out of intake air.

J - Recoil Starter -- Usedfor starting the engine manually.

K- Fuel Valve-- Usedto turn fuel supply on and off to

engine.

L - Throttle Lever-- Setsengine in starting mode for recoil

starter and stops a running engine.

M - Fuel Tank -- Filltank with regular unleadedfuel. Always

leaveroom for fuel expansion.

N - Warning/OperatingInstructions Tag-- Identifies

hazards and proper procedureto start/stop pressure

washer.

P - Standard DetergentSiphoning Tube/Filter-- Useto

siphon pressure washersafe detergents into the low

pressure stream.

Q - Water Inlet -- Connectionfor garden hose.

R - HighPressure Outlet-- Connectionfor high pressure

hose.

S - Automatic Cool Down System -- Cycleswater through

pump when water reaches125°-155°F. Warm water will

discharge from pump onto ground. Thissystem prevents

internal pump damage.

T - Pump-- Developshigh pressure.

U - Project Pro®PerfectlVIWMSiphon -- Mixes concentrate

with pressurewasher spray.

Items Not Shown:

Oil Drain -- Drain engine oil here.

DataTag (near rear of base plate) -- Providesmodel and

serial number of pressure washer. Pleasehavethese readily

availableif calling for assistance.

Oil Fill -- Checkand add engine oil here.

Safety Goggles-- Always usethe enclosedsafety goggles

when running your pressure washer.

Your pressure washer requires someassembly and is ready

for useonly afterit has beenproperly serviced with the

recommendedoil and fuel.

If you haveany problemswith the assemblyof your

pressurewasher, please callthe pressurewasher heipline

at 1-800-222-3135.

UNPACKPBESSUREWASHER

1. Removeeverything from carton exceptpressure washer.

2. Opencarton completely bycutting each corner from top

to bottom.

3. Removepressure washerfrom carton.

CARTONCONTENTS

Checkall contents, if any parts are missing or damaged,call

the pressure washerhelpline at 1-800-222-3136.

* Main Unit

* Handle

* AccessoryTray

* High PressureHose

* Spray Gun

* Spraytip Extensionwith Quick Connect Fitting

* Bottle BracketWireform (2)

* PerfectMixTMSiphoningUnit/Hose

* StandardSiphoning Hose

* Oil Bottle

* Parts Bag (which includes the following):

* Operator's Manual

* Owner's Registration Card

* SafetyGoggles

* Bagcontaining 4 multi-colored Quick Connect

Spraytips

* HandleFasteningHardwareKit (whichincludes):

* CarriageBolts (4)

* Plastic Knobs (4)

, TreeClips (4)

Becomefamiliar with eachpiecebefore assemblingthe

pressure washer. Identify all contents with the illustration on

page 6. if any parts are missing or damaged,callthe

pressure washer helpline at 1-800-222-3136.

7. Attach spray tip extensionto spray gun.

8. Select/attachQuick Connectspray tip to spraytip

extension.

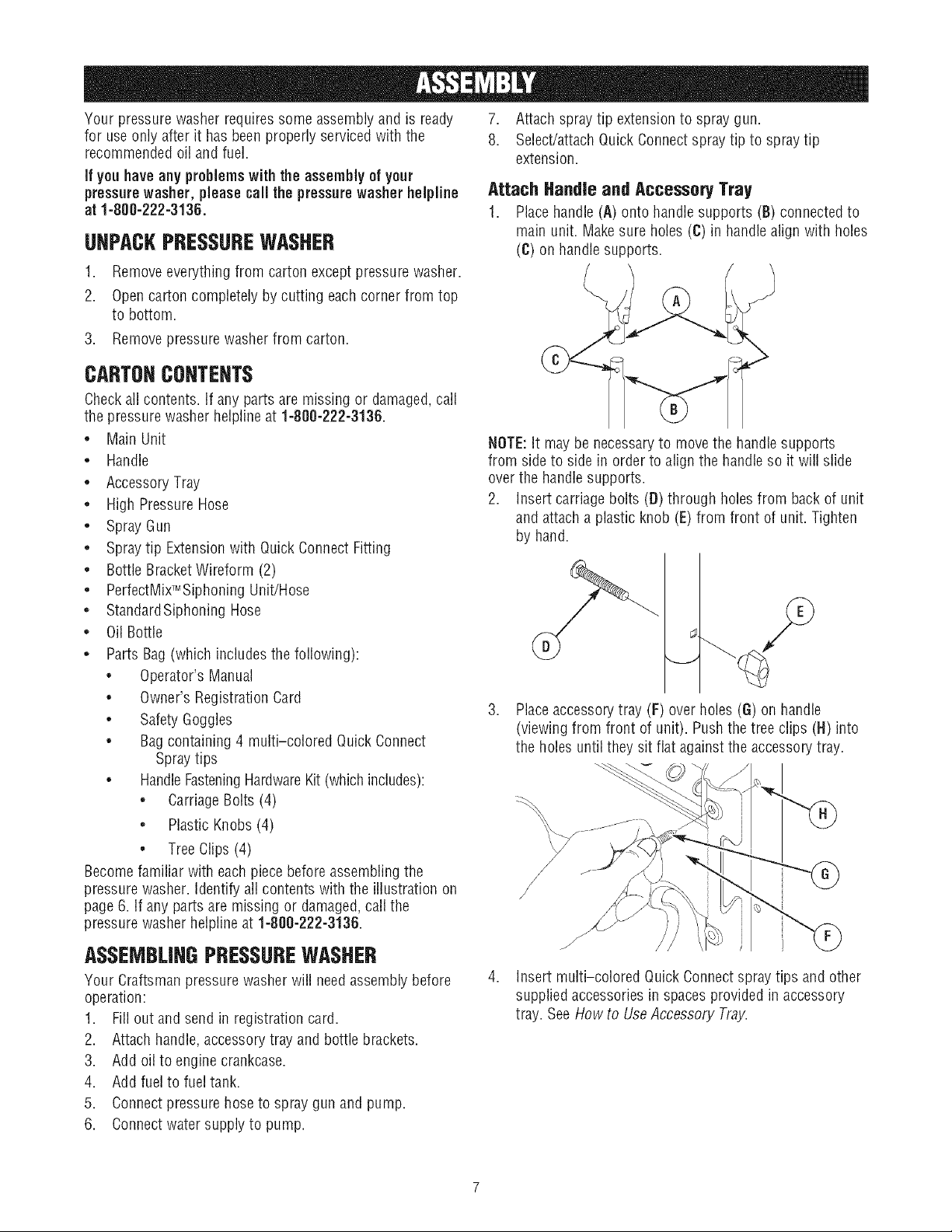

Attach Handle and Accessory Tray

1. Placehandle (A) onto handlesupports (B) connectedto

main unit. Make sure holes (C) in handlealign with holes

(C) on handlesupports.

NOTE:It may be necessaryto move the handle supports

from sideto side in order to align the handle so it will slide

overthe handlesupports.

2. Insert carriagebolts (D) through holes from back of unit

and attach a plastic knob (E)from front of unit. Tighten

by hand.

3. Placeaccessory tray (F) over holes (6) on handle

(viewing from front of unit). Push the tree clips (H) into

the holes until they sit flat againstthe accessorytray.

ASSEMBLINGPRESSUREWASHER

Your Craftsman pressurewasher will need assembly before

operation:

1. Fill out and send in registration card.

2. Attach handle,accessorytray and bottle brackets.

3. Add oil to engine crankcase.

4. Add fuel to fuel tank.

5. Connectpressure hoseto spray gun and pump.

6. Connectwater supply to pump.

Insert multi-colored Quick Connectspray tips andother

supplied accessories in spaces provided in accessory

tray. SeeHow to UseAccessory Tray.

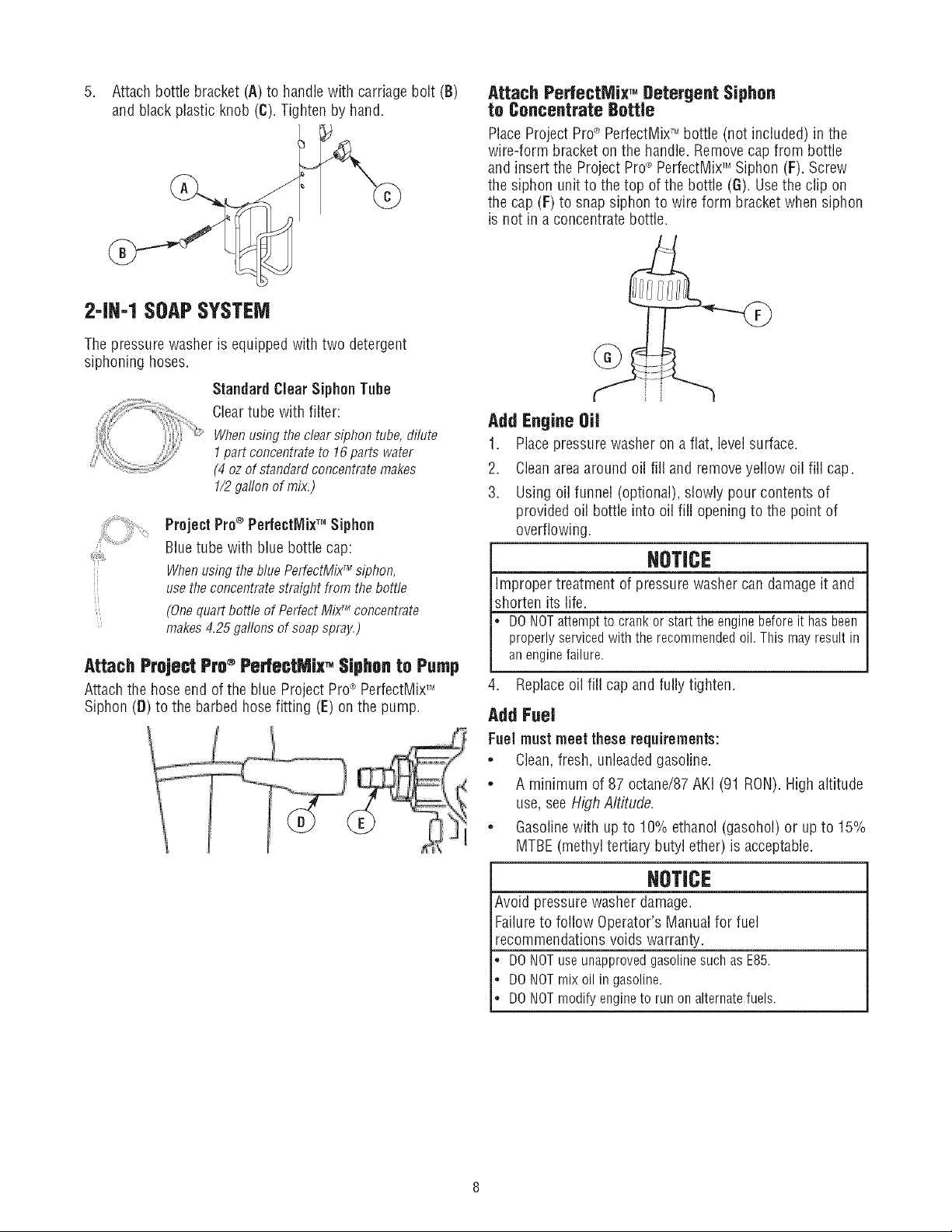

5. Attach bottle bracket (A) to handlewith carriagebolt (B)

and black plastic knob (C). Tighten by hand.

2-1N-1SOAPSYSTEM

Thepressure washeris equippedwith two detergent

siphoning hoses.

Standard Clear Siphon Tube

Cleartube with filter:

Whenusingtheclearsiphontube,dilute

1partconcentrateto 16partswater

(4 ozof standardconcentratemakes

1/2Cationofmix.)

Project Pro÷ PerfectMW" Siphon

Blue tube with blue bottle cap:

WhenusingthebluePerfectMi/'_siphon,

usetheconcentratestraightfrom thebottle

(Onequartbottleof PerfectMixTM concentrate

makes4.25gaflonsofsoapspray.)

AttachProjectPro®PerfectMixTM Siphonto Pump

Attachthe hose end of the blue Project Pro® PerfectMixTM

Siphon (D) to the barbed hosefitting (E) on the pump.

Attach PerfectMix,, Detergent Siphon

to Concentrate BottJe

PlaceProject Pro®PerfectMixTM bottle (not included) in the

wire-form bracket on the handle.Removecap from bottle

and insert the Project Pro®PerfectMixTM Siphon (F). Screw

the siphon unit to the top of the bottle (6). Usethe clip on

the cap (F) to snapsiphon to wire form bracketwhen siphon

is not in a concentratebottle.

AddEngineOil

1. Placepressure washer on a flat, level surface.

2. Cleanareaaround oil fill and removeyellow oil fill cap.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill openingto the point of

overflowing.

NOTICE

Improper treatment of pressure washer can damageit and

shorten its life.

DONOTattemptto crankor starttheenginebeforeit hasbeen

properlyservicedwiththerecommendedoil.Thismayresultin

anenginefailure.

4. Replaceoil fill cap and fully tighten.

AddFuel

Fuel must meet theserequirements:

* Clean,fresh, unleadedgasoline.

, A minimum of 87 octane/B7AKI (91 RON).High altitude

use, see High Altitude.

* Gasolinewith up to 10% ethanol (gasohol) or upto 15%

MTBE(methyl tertiary butyl ether) is acceptable.

NOTICE

Avoid pressure washerdamage.

Failureto follow Operator'sManual for fuel

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchasE85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

Toprotectthefuelsystemfromgumformation,mixinafuel

stabilizerwhenaddingfuel.SeeStorage.All fuel is not the

same. If you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engine is certified to operateon gasoline. The

emission control system for this engineis EM (Engine

Modifications).

WARRIRG

Fueland its vaporsare extremely flammable and

explosive.

Fireor explosion can causesevere burns or

death.

WHENADDING FUEL

• Turn pressure washer OFFand let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve pressure

in tank.

• Fillfuel tank outdoors.

, DONOToverfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting engine.

, Keep fuel away from sparks, openflames, pilot lights, heat, and

other ignition sources.

, DONOTlight a cigarette or smoke.

,

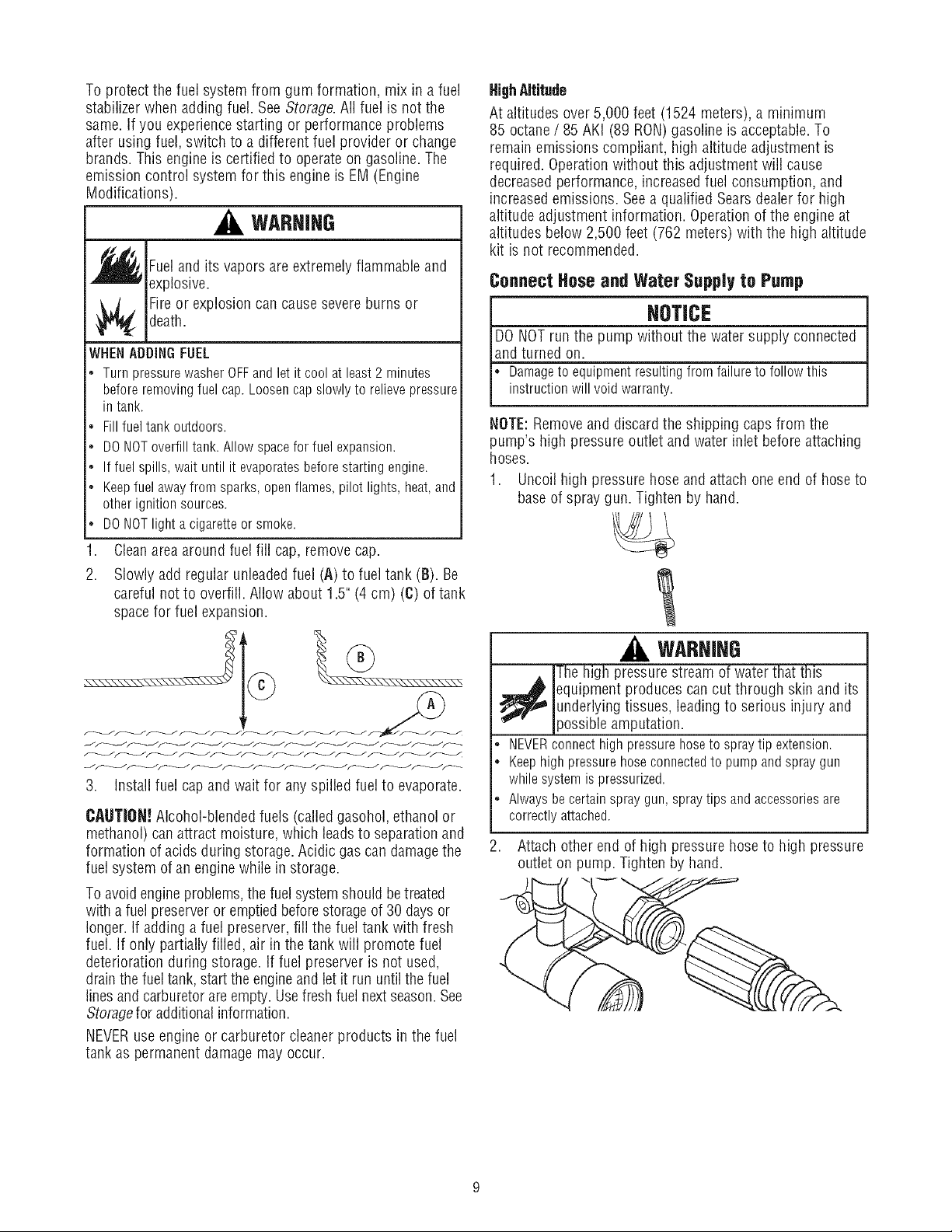

Cleanarea around fuel fill cap, removecap.

2.

Slowly add regular unleadedfuel (A) to fuel tank (B). Be

careful not to overfill. Allow about 1.5" (4 cm) (C) of tank

spacefor fuel expansion.

HighARRude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remainemissions compliant, high altitude adjustment is

required. Operationwithout this adjustmentwill cause

decreasedperformance, increased fuel consumption, and

increasedemissions. Seea qualified Searsdealerfor high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters)with the high altitude

kit is not recommended.

Connect Hose and Water Supply to Pump

[ ROTICE

DONOTrun the pump without the water supply connected

and turned on.

instructionwill void warranty.

L amageto equipmentresultingfromfailureto followthis

NOTE:Removeand discardthe shipping caps from the

pump's high pressure outlet and waterinlet beforeattaching

hoses.

1. Uncoil high pressure hose and attach oneend of hose to

baseof spray gun. Tighten by hand.

%

3. Installfuel cap and wait for any spilled fuel to evaporate.

CAUTION!Alcohol-blended fuels (calledgasohol, ethanol or

methanol) can attract moisture, which leadsto separation and

formation of acids during storage.Acidic gascan damagethe

fuel system of an enginewhile in storage.

Toavoidengineproblems,the fuel system should betreated

with afuel preserver or emptied beforestorageof 30 daysor

longer.If adding a fuel preserver,fill the fuel tank with fresh

fuel. If only partiallyfilled, air in the tank will promote fuel

deterioration during storage. If fuel preserver is not used,

drainthe fuel tank, start the engineandlet it run until the fuel

linesand carburetorareempty. Usefresh fuelnext season.See

Storagefor additional information.

NEVERuseengine or carburetor cleanerproducts inthe fuel

tank as permanent damage mayoccur.

WARRIRG

he high pressurestream of water that this

quipment produces cancut through skin and its

nderlying tissues, leadingto serious injury and

ossible amputation.

NEVERconnecthighpressurehoseto spraytip extension.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

Alwaysbecertainspraygun,spraytipsandaccessoriesare

correctlyattached.

2. Attach other end of high pressure hoseto high pressure

outlet on pump. Tighten by hand.

,

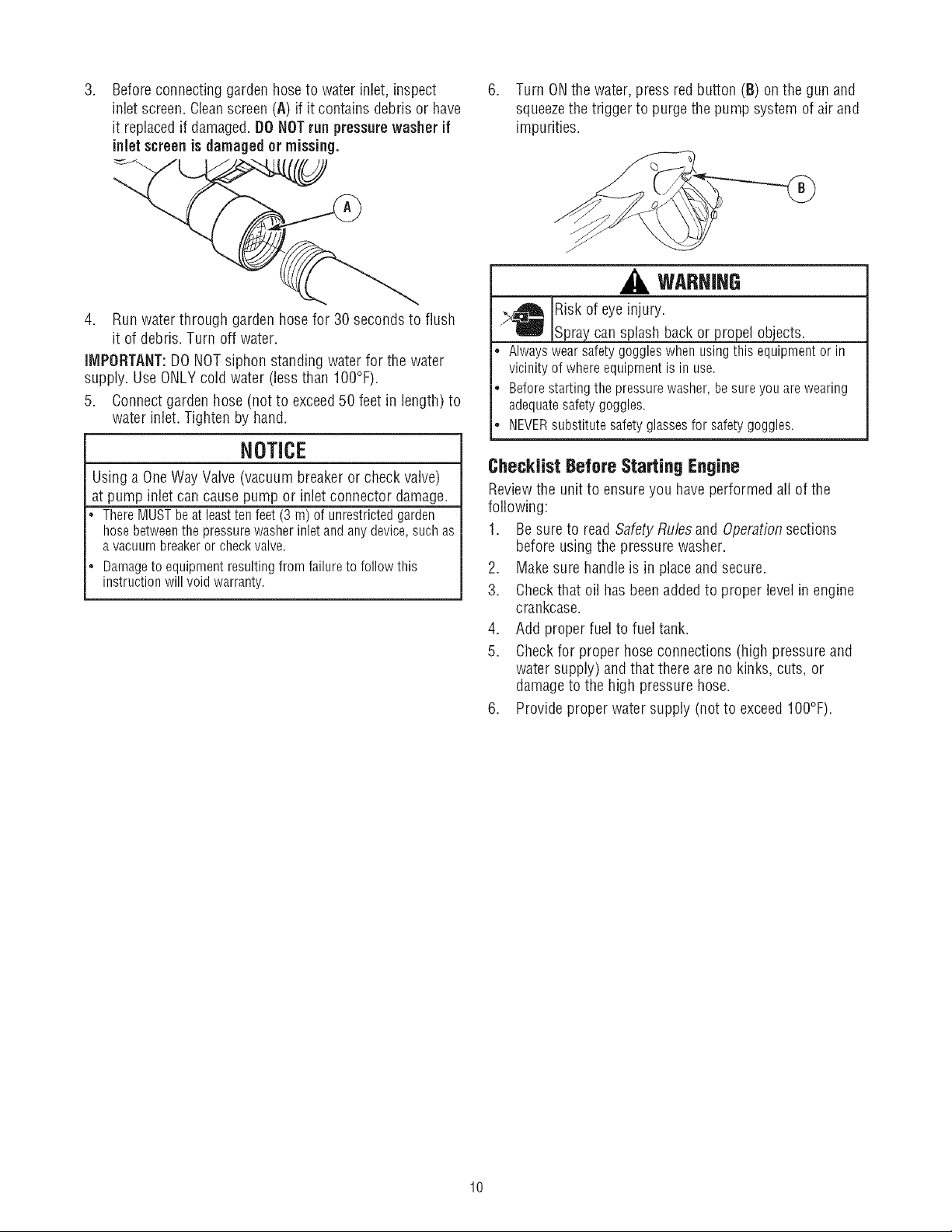

Beforeconnectinggarden hoseto waterinlet, inspect

inlet screen.Cleanscreen (A) if it contains debris or have

it replacedif damaged.DO NOTrun pressurewasherif

inlet screenis damagedor missing.

6. Turn ONthe water,press red button (B) on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

WARHIHG

4. Run water through garden hose for 30 seconds to flush

it of debris. Turn off water.

IMPORTANT:DO NOTsiphon standingwater for the water

supply. UseONLYcold water (less than IO0°F).

5. Connectgarden hose (not to exceed50 feet in length) to

water inlet. Tighten by hand.

NOTICE

Using a OneWay Valve(vacuum breaker or check valve)

at pump inlet can causepump or inlet connector damage.

ThereMUSTbeatleasttenfeet(3m)of unrestrictedgarden

hosebetweenthepressurewasherinletandanydevice,suchas

avacuumbreakerorcheckvalve.

Damagetoequipmentresultingfromfailuretofollowthis

instructionwill voidwarranty.

_Risk of injury.

ISpray can splash back or propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentisin use.

Beforestartingthe pressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

eye

CheckJistBeforeStartingEngine

Reviewthe unit to ensureyou have performed all of the

following:

1. Besure to readSafetyRules and Operationsections

before usingthe pressure washer.

2. Makesure handle is in placeand secure.

3. Checkthat oil has beenadded to proper levelin engine

crankcase.

4. Add proper fuel to fuel tank.

5. Checkfor proper hoseconnections (high pressure and

water supply) and that there are no kinks, cuts, or

damageto the high pressure hose.

6. Provideproper water supply (not to exceedIO0°F).

10

HOWTOUSEYOURPRESSUREWASHER

If you haveany problems operatingyour pressure washer,

pleasecallthe pressure washer helplineat 1-800-222-3136.

Pressure Washer Location

PressureWasherClearance

,_ WARNING

_ Exhaustheat/gases can ignitecombustibles,

* Keepatleast5ft. (152cm)clearanceonall sidesofpressure

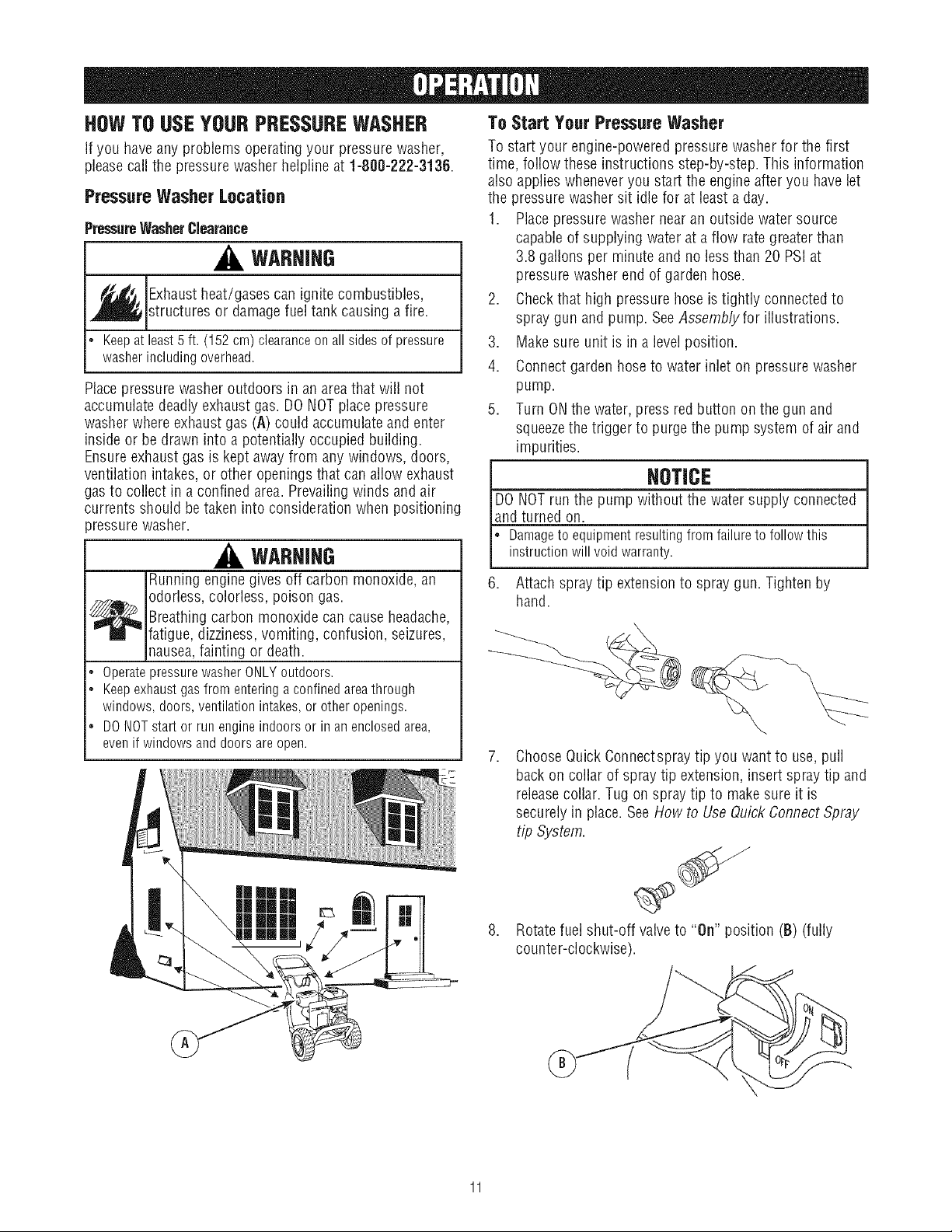

Placepressure washer outdoors in an areathat will not

accumulate deadly exhaustgas. DONOTplacepressure

washer where exhaustgas (A) could accumulateand enter

inside or be drawn into a potentially occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventilation intakes, or other openingsthat can allow exhaust

gasto collect ina confined area. Prevailingwinds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

structures or damagefuel tank causing a fire.

washerincludingoverhead.

,_ WARHJHG

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

_ reathingcarbon monoxide can causeheadache,

. OperatepressurewasherONLYoutdoors.

. Keepexhaustgasfromenteringaconfinedareathrough

• DONOTstart or runengineindoorsor in anenclosedarea,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

windows,doors,ventilationintakes,or otheropenings.

evenif windowsanddoorsareopen.

To Start Your Pressure Washer

To start your engine-powered pressurewasher for the first

time, follow these instructions step-by-step. This information

also applies wheneveryou start the engine after you have let

the pressure washer sit idle for at leasta day.

1. Placepressure washer nearan outside water source

capableof supplying water at a flow rategreater than

3.8 gallons per minute and no less than 20 PSIat

pressurewasher end of gardenhose.

2. Checkthat high pressure hose istightly connectedto

spray gun and pump. SeeAssemblyfor illustrations.

3. Makesure unit is in a levelposition.

4. Connectgarden hoseto water inlet on pressure washer

pump.

5. Turn ONthe water,press red button on the gun and

squeezethe trigger to purge the pump system of air and

impurities.

[ NOTICE

DONOTrun the pump without the water supply connected

and turned on.

instructionwill void warranty.

L amageto equipmentresultingfromfailureto followthis

6. Attach spray tip extensionto spray gun. Tighten by

hand.

7. ChooseQuick Connectspraytip you want to use,pull

back on collar of spray tip extension, insert spray tip and

releasecollar. Tug on spray tip to make sure it is

securely in place. SeeHow to Use OuickConnect Spray

tip System.

8. Rotate fuel shut-off valveto "On" position (B) (fully

counter-clockwise).

9. Move throttle lever (A) to "Fast" position, shown here as

a rabbit.

10. Move chokelever (B) to "Choke" position.

/

NOTE:For a warm engine, be surethe choke lever is in the

"Run" position.

IMPORTANT:Before starting the pressure washer, be sure

/ou are wearing adequatesafety goggles.

WARNING

>_ Risk of eyeinjury.

_Spray can sp ash back or propel objects.

Alwayswearsafetygoggleswhenusingthisequipmentorin

vicinityofwhereequipmentis in use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesforsafetygoggles.

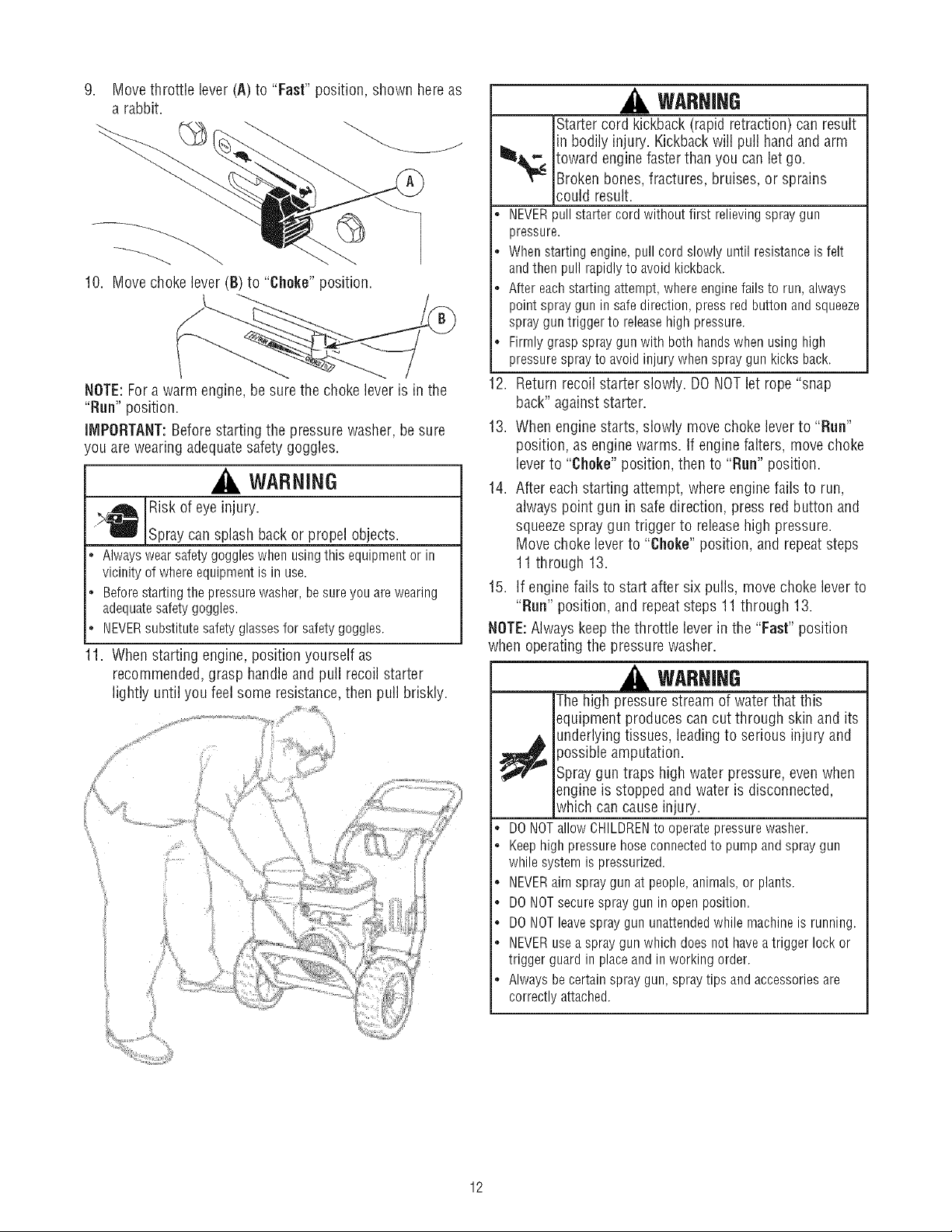

1. When starting engine, position yourself as

recommended, grasp handle and pull recoil starter

lightly until you feel some resistance,then pull briskly.

WARNING

Starter cord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

___ toward enginefaster thanyou can let go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

• Whenstartingengine,pullcord slowlyuntilresistanceisfelt

andthenpullrapidlyto avoidkickback.

, Aftereachstartingattempt,whereenginefailsto run,always

pointspraygunin safedirection,pressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

, Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

12. Return recoil starter slowly. DONOTlet rope "snap

back"against starter.

13. When engine starts, slowly movechoke lever to "Run"

position, as engine warms. If engine falters, move choke

leverto "Choke" position, then to "Run" position.

14. After eachstarting attempt, where enginefails to run,

always point gun in safe direction, press red button and

squeezespray gun trigger to releasehigh pressure.

Move choke leverto "Choke" position, and repeatsteps

11 through 13.

15. If enginefails to start after six pulls, movechoke leverto

"Run" position, and repeatsteps 11 through 13.

NOTE:Always keepthe throttle lever in the "Fast" position

when operatingthe pressure washer.

WARNING

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

, DONOTallowCHILDRENtooperatepressurewasher.

* Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* NEVERaimspraygunatpeople,animals,or plants.

, DONOTsecurespraygun inopenposition.

* DONOTleavespraygununattendedwhile machineis running.

, NEVERusea spraygunwhichdoesnothaveatriggerlockor

triggerguardin placeandinworkingorder.

, Alwaysbecertainspraygun,spraytipsandaccessoriesare

correctlyattached.

12

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

WARHIHG

s_ Contact with muffler result in serious

f_ Exhaustheat/gases can ignite combustibles,

* DONOTtouchhotpartsandAVOIDhot exhaustgases.

* Allowequipmentto coolbeforetouching.

* Codeof FederalRegulation(CFR)Title36Parks,Forests,and

burns.

structures or damagefuel tank causing a fire.

Keepat least5feet (152cm)ofclearanceonall sidesof

pressurewasherincludingoverhead.

PublicPropertyrequireequipmentpoweredbyaninternal

combustionengineto haveasparkarrester,maintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-1Corlaterrevision.IntheStateof Californiaa

sparkarresteris requiredundersection4442of the California

Publicresourcescode.Otherstatesmayhavesimilarlaws.

How to Stop Your Pressure Washer

1. Releasespray gun trigger and letengine idle for two

minutes.

2. Move throttle to SLOWposition, then STOPposition.

area can

WARNING

f_j Backfire,fire or engine damagecould occur.

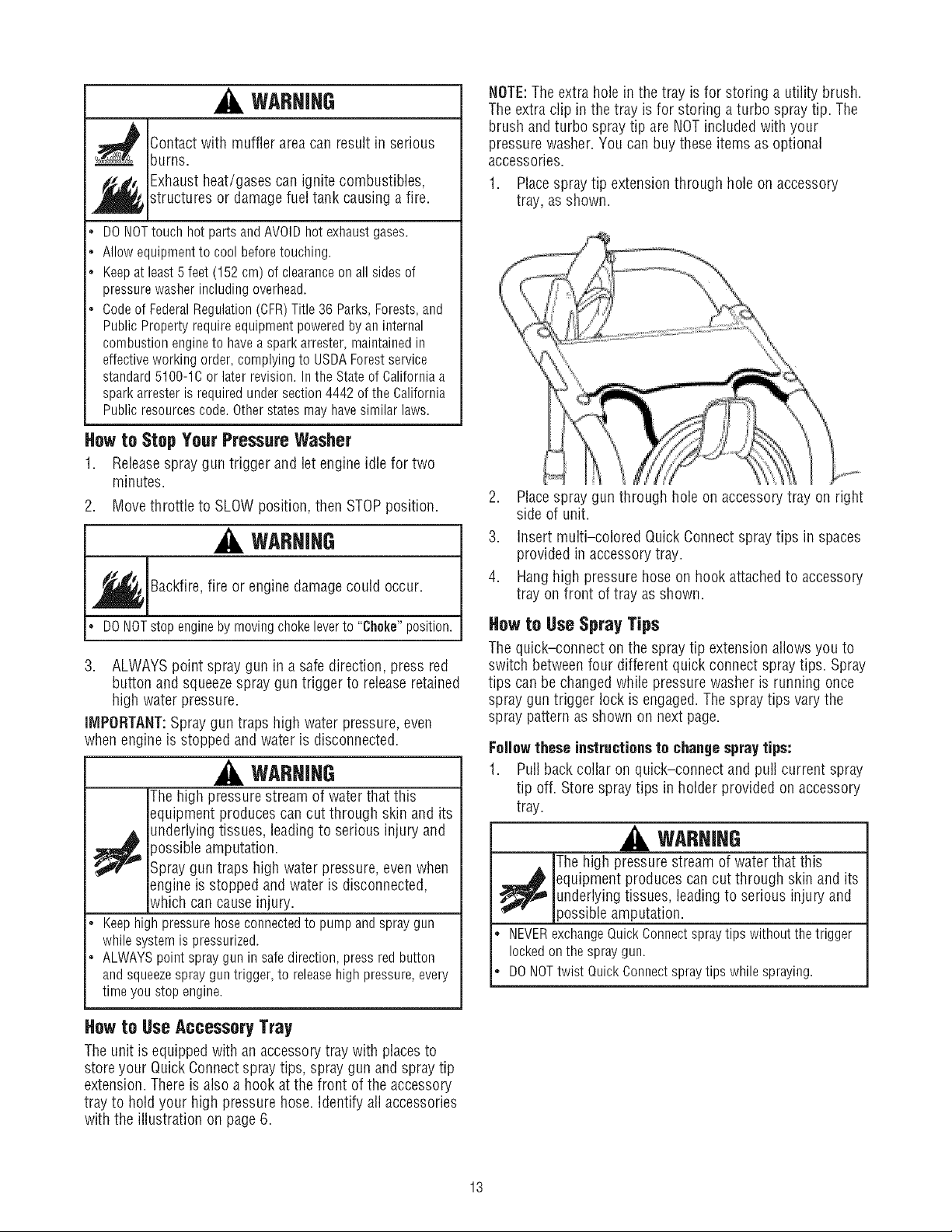

NOTE:The extra hole in the tray is for storing autility brush.

Theextra clip in the tray is for storing a turbo spray tip. The

brush and turbo spray tip are NOTincluded with your

pressure washer. You can buythese items as optional

accessories.

1. Placespray tip extensionthrough hole on accessory

tray, as shown.

,

Placespray gun through holeon accessorytray on right

side of unit.

3.

Insert multi-colored QuickConnectspray tips in spaces

provided in accessorytray.

4.

Hanghigh pressure hose on hook attachedto accessory

tray on front of tray as shown.

DONOTstopenginebymovingchokeleverto "Cheke"position.

3. ALWAYSpoint spraygun in a safedirection, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

IMPORTANT:Spray gun traps high water pressure, even

when engine is stoppedand water is disconnected.

WARHIHG

The high pressurestream of waterthat this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

* ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntrigger,to releasehighpressure,every

time youstopengine.

How to Use Accessory Tray

Theunit is equipped with an accessorytray with placesto

store your QuickConnectspray tips, spray gun and spray tip

extension. There is also a hook at the front of the accessory

tray to hold your high pressure hose. Identify all accessories

with the illustration on page6.

_ossibleamputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

How to Use Spray Tips

Thequick-connect on the spray tip extensionallows you to

switch between four different quick connect spray tips. Spray

tips can bechanged while pressure washer is running once

spray gun trigger lock is engaged. The spraytips vary the

spray pattern as shown on next page.

Followthese instructionsto changespraytips:

1. Puil backcollar on quick-connect and pull current spray

tip off. Storespray tips in holder provided on accessory

tray.

WARNING

Thehigh pressurestream of water that this

:_ equipment produces cancut through skin and its

NEVERexchangeQuickConnectspraytips withoutthetrigger

lockedonthespraygun.

DONOTtwist QuickConnectspraytipswhilespraying.

underlyingtissues, leadingto serious injury and

)ossible amputation.

13

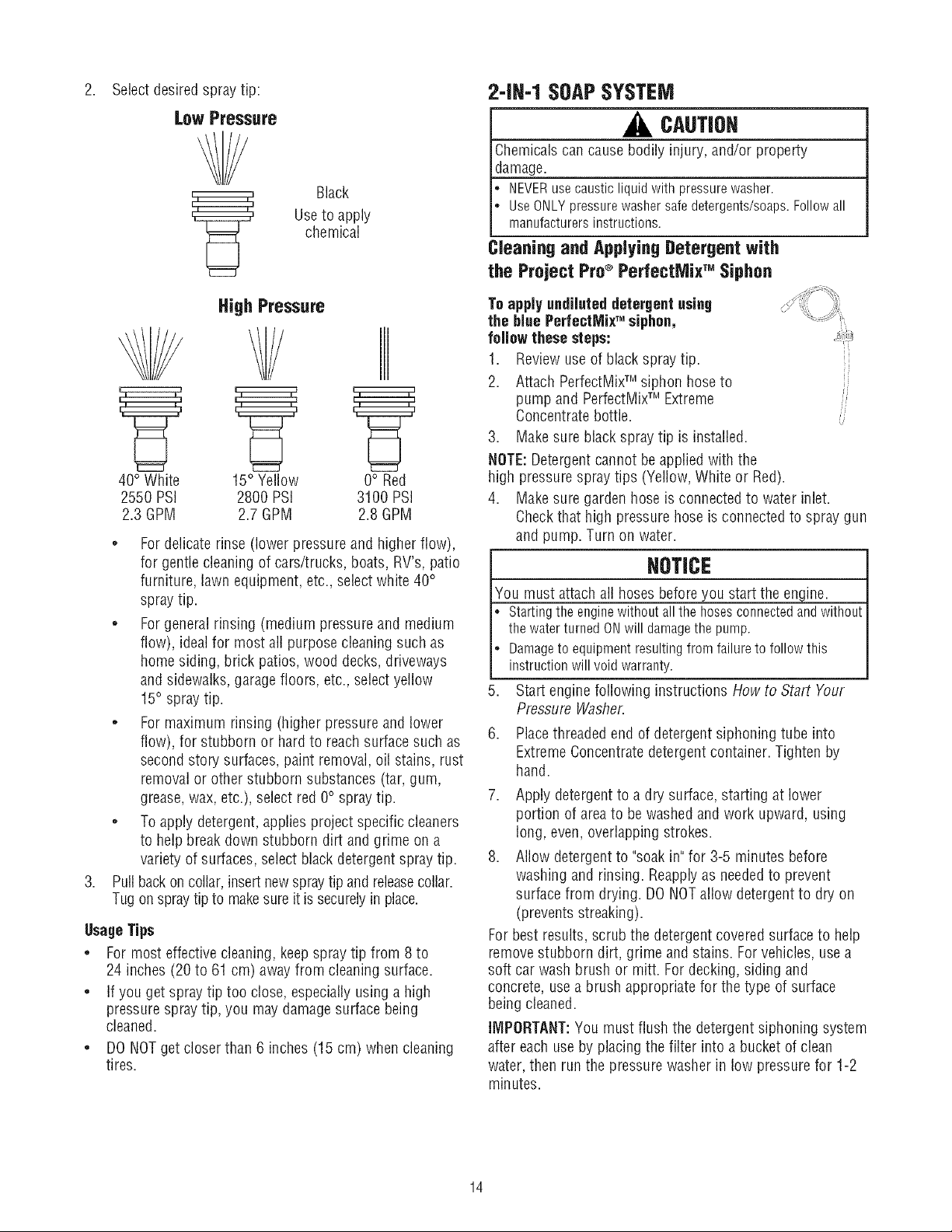

Select desired spraytip:

2. 2-IH-1 SOAPSYSTEM

Low Pressure

Black

Useto apply

chemical

Chemicalscan cause bodily injury, and/or property

damage.

NEVERusecausticliquidwith pressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

CAUTION

Cleaning and Applying Detergent with

the Project Pro®PerfectMix TM Siphon

High Pressure

40° White 15° Yellow 0° Red

2550 PSI 2800 PSI 3100 PSI

2.3 GPM 2.7 GPM 2.8 GPM

* Fordelicate rinse (lower pressure and higher flow),

for gentlecleaning of cars/trucks, boats, RV's,patio

furniture, lawn equipment, etc., select white 40°

spray tip.

* Forgeneral rinsing (medium pressure and medium

flow), ideal for most all purposecleaning such as

home siding, brick patios, wood decks, driveways

and sidewalks, garagefloors, etc.,select yellow

15° spraytip.

* Formaximum rinsing (higher pressure and lower

flow), for stubborn or hard to reachsurfacesuch as

second story surfaces,paint removal,oil stains, rust

removalor other stubborn substances (tar, gum,

grease,wax, etc.), select red 0° spraytip.

, To apply detergent,applies project specific cleaners

to help breakdown stubborn dirt andgrime ona

variety of surfaces, select black detergentspray tip.

,

Pull backon collar,insert newspraytip and releasecollar.

Tugon spraytip to makesure it is securelyin place.

UsageTips

* Formost effective cleaning, keepspray tip from 8to

24 inches (20 to 61 cm) awayfrom cleaning surface.

, Ifyou get spray tip too close, especiallyusing a high

pressure spray tip, you may damagesurface being

cleaned.

, DONOTget closer than 6 inches (15 cm) when cleaning

tires.

Tn apply undiluteddetergent using

the blue PerfectMix" siphnn,

felJnw these steps:

1. Reviewuseof black spray tip.

2. Attach PerfectMixTM siphon hoseto

pump and PerfectMixTM Extreme

Concentratebottle.

3. Makesure black spray tip is installed.

NOTE:Detergentcannot be appliedwith the

high pressurespray tips (Yellow, White or Red).

4.

Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

NOTICE

You must attachall hosesbefore you start the engine.

Startingthe enginewithoutallthehosesconnectedandwithout

thewaterturnedONwill damagethepump.

Damageto equipmentresultingfrom failureto followthis

instructionwill void warranty.

5. Start engine following instructions How to Start Your

Pressure Washer.

6. Placethreaded end of detergent siphoning tube into

ExtremeConcentratedetergentcontainer. Tighten by

hand.

7. Apply detergentto a dry surface, starting at lower

portion of areato be washed andwork upward, using

long, even, overlappingstrokes.

8. Allow detergentto "soak in"for 3-5 minutes before

washing and rinsing. Reappiyas neededto prevent

surface from drying. DO NOTallow detergent to dry on

(preventsstreaking).

Forbest results, scrub the detergent covered surfaceto help

removestubborn dirt, grime and stains. For vehicles, usea

soft car wash brush or mitt. Fordecking, siding and

concrete, use abrush appropriate for the type of surface

being cleaned.

IMPORTANT:You must flush the detergent siphoning system

after each use by placing the filter into a bucket of clean

water, then run the pressure washer in low pressurefor 1-2

minutes.

14

Cleaning and Applying Detergent with

the Standard Clear Siphon

To apply diluteddetergent usingthe

standardcJearsiphontube,

folJowthesesteps:

1. Reviewuse of black spray tip.

2. Attachclear siphon hose to pump.

3. Mix detergent solution as required byjob.

4. Placesmall filter end of clear siphoning tube into

container with diluted solution as described above.

NOTICE

Contact with the hot muffler can damagedetergent

siphoning tube.

Wheninsertingthesiphonintoa detergentsolutionbottle,

routethetubesoasto keepitfrom inadvertentlycontactingthe

hotmuffler.

NOTE:Makesure the filter is fully submerged in fluid while

applying solution.

5. Make sure black spray tip is installed.

NOTE:Detergentcannot be appliedwith the high pressure

spray tips (Yellow, White or Red).

6. Make sure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

NOTICE

You must attachall hosesbefore you start the engine.

Startingthe enginewithoutallthehosesconnectedandwithout

thewaterturnedONwill damagethepump.

Damageto equipmentresultingfrom failureto followthis

instructionwill void warranty.

7. Start engine following instructions How to Start Your

Pressure Washer.

8. Apply detergentto a dry surface, starting at lower

portion of areato be washed andwork upward, using

long, even, overlappingstrokes.

9. Allow detergentto "soak in"for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surface from drying. DO NOTallow detergent to dry on

(preventsstreaking).

Forbest results, scrub the detergent covered surfaceto help

removestubborn dirt, grime and stains. For vehicles, usea

soft car wash brush or mitt. Fordecking, siding and

concrete, use abrush appropriate for the type of surface

being cleaned.

IMPORTANT:You must flush the detergent siphoning system

after each use by placing the filter into a bucket of clean

water, then run the pressure washer in low pressurefor 1-2

minutes.

15

PressureWasherRinsing

ForRinsing:

1. Removesoapspray tip from spray tip extension.

2. Selectand install desiredhigh pressurespray tip

following instructions How to Use Ouick ConnectSpray

tip System.

3. Keepthe spray gun a safe distance from the areayou

plan to spray.

WARHIHG

Kickbackfrom to fall.

• Operatepressurewasherfrom astablesurface.

, Beextremelycarefulif youmust usethe pressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

, Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

spray gun can cause you

Cleaning DetergentSiphoning Tube

If you usedthe clear detergent siphoning tube, you must

flush it with cleanwater before stopping the engine.

1. Placedetergent siphoning tube/filter in a bucket full of

clean water.

2. Removehigh pressurespray tip from spray tip

extension.

3. Selectand install a soap spray tip following instructions

How to Use Ouick ConnectSpray Tips.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint spray gun in a safe direction push red

button and squeezespray gun trigger to release retained

high water pressure.

WARHIHG

The high pressure stream of water that this

4. Apply a high pressure sprayto asmall area,then check

the surfacefor damage.If no damage is found, it is okay

to continue cleaning.

,

Start at the top of the areato be rinsed, working down

with same overlapping strokes asyou usedfor washing

and applying detergent.

_ equipment produces can cut through skin and its

• Keephigh pressure hoseconnected to pump and spray gun

while system is pressurized.

• ALWAYSpoint spray gun in safe direction, press red button and

squeezespray gun trigger, to releasehigh pressure, everytime

you stop engine.

lunderlying tissues, leading to serious injury and

ipossible amputation.

iMPORTANT:Spraygun traps high water pressure, even

when engine is stopped and water is disconnected.

Automatic Cool Down System (Thermal Relief)

If you run the engine on your pressure washerfor

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach temperatures above

125°F.Thesystem engagesto cool the pump by discharging

the warm water onto the ground.

16

EHGINETECHNICALINFORMATIOH

This is a single cylinder, overheadvalve (OHV),air cooled

engine. It is a low emissions engine.

Inthe Stateof California, Model Series 120000enginesare

certified by the CaliforniaAir ResourcesBoardto meet

emissions standards for 125 hours. Such certification does

not grant the purchaser, owner or operator of this engine any

additional warranties with respectto the performance or

operational life of this engine.Theengine is warranted solely

according to the product and emissions warranties stated

elsewherein this manual.

Power Ratings

Thegross power rating for individual gas engine models is

labeledin accordancewith SAE(Society of Automotive

Engineers)code J1940 (Small Engine Power & Torque

Rating Procedure),and rating performance hasbeen

obtained andcorrected in accordancewith SAEJ1995

(Revision2002-05). Torque values are derived at3060 RPM;

horsepower values are derivedat 3600 RPM. Actual gross

engine power will be lower and is affected by, among other

things, ambient operating conditions and engine-to-engine

variability. Given both the wide array of products on which

enginesare placedand the variety of environmental issues

applicableto operating the equipment, the gas engine will not

developthe rated gross power when used in agiven pieceof

power equipment (actual "on-site" or net power). This

difference is due to a variety of factors including, but not

limited to, accessories (air cleaner, exhaust,charging,

cooling, carburetor, fuel pump, etc.), application limitations,

ambient operating conditions (temperature,humidity,

altitude), and engine-to-engine variability. Dueto

manufacturing and capacity limitations, Briggs & Stratton

maysubstitute anengine of higher ratedpower for this

Seriesengine.

This pressurewasher is rated in accordanceto the Pressure

Washer Manufacture Association (PWMA) standardPW101

(Testingand Rating Performance of PressureWashers).

PRODUCTSPECIFICATJOHS

Pressure Washer Specifications

Max Outlet Pressure ....................... 3,100 PSi

Max How Rate............................. 2.8 GPM

DetergentMix ........................ Use asdirected

Water Supply Temperature .......... Not to exceed IO0°F

Engine Specifications

Bore ................................ 2.672 in.(68mm)

Stroke .............................. 2.204 in.(56mm)

Displacement ........................ 12.48in.(206 cc)

SparkPlug

ResistorType: ............. Briggs & Stratton 491055S

Long Life Platinum: .......... Briggs & Stratton 5066D

SetGapTo: ...................... O.030inch(0.76ram)

ArmatureAir Gap: ........... 0.010-0.014in.(O.25-O.36mm)

Valveclearancewithvalvespringsinstalledandpiston1/4in.

(6 ram)pasttop deadcenter(checkwhenengineiscold).

Intake.................... 0.004-0.006in.(0.10-0.15mm)

Exhaust .................. 0.009-0.011in.(0.23-0.28mm)

FuelCapacity............................... 1.6Quarts

OilCapacity........................ 20 Ounces(0.6 liter)

NOTE:For practical operation, the engine load should not

exceed 85% of rated power. Enginepower will decrease

3-1/2% for each1,000 feet (300 meters) above sea leveland

1% for each 10° F (5.6° C) above 77° F(25° C).It should

operatesatisfactorily at anangle up to 15°.

17

Loading...

Loading...