Craftsman 580752280 Owner’s Manual

Operator'sManual

2700 PSi MAX

2.3 GPM MAX

Model No. 580.752280

®

CUSTOMERHELPLINE

PRESSUREWASHER

,, Safety

HOURS: Non. - Fri. 8 a.m. to 5 p.m. (CT)

,,Assembly

,, Operation

WARHIHG

Before usingthis product, readthis

manualand follow all Safety Rules

and Operating Instructions.

This pressure washer is rated in accordance to the PressureWasher Manufacture Association

(PWMA) standard PWl01 (Testing and Rating Performance of Pressure Washers).

Esta limpiadora a presi6n est_ clasificadaconforme a la norma PWl01 (comprobaci6n y clasificaciOn de rendimiento de limpiadoras

a presiOn) de la Asociaci6n defabricantes de bombas a presiOn(Pressure Washer Manufacture Association, PWMA).

Sears, RoebuckandCo., HoffmanEstates,IL 60179 U.S.A.

Visit our Craftsman website:www.craftsman.com

Part No. 206016GS Draft B (05/01/2008) 3

Antes de utilizarel producto, leaeste

manualy siga todas las Regiasde

Seguridade Instrucciones de Uso.

ADVERTENCIA

,, Maintenance

,, Parts

,, Espafiol,p. 32

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY........................................ 7-10

OPERATION....................................... 11-15

SPECIFICATIONS..................................... 16

MAINTENANCE.................................... 17-21

STORAGE........................................... 22

TROUBLESHOOTING.................................. 23

REPLACEMENTPARTS.............................. 24-29

EMISSIONCONTROLWARRANTY..................... 30-31

ESPANOL......................................... 32-55

HOWTO ORDERPARTS ........................ BACKPAGE

ONE-YEARFULLWARRAHTYONCRAFTSMAHPRESSUREWASHER

If this pressurewasher fails dueto a defectin materialor workmanship within one year from the date of purchase,return it to

any Searsstore, other Craftsman outlet, or SearsParts & Repair Centerin the UnitedStates or Canadafor free repair (or

replacementif repair proves impossible).

All warranty coverageapplies for only 90 days from dateof purchaseif this pressure washer is ever usedfor commercial or

rentalpurposes.

This warranty gives you specific legal rights, andyou mayalso haveother rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60178

Sears Canada Inc., Toronto, Ontario, Canada M5B 288

,_ Thisisthe safetyalert symbol.It isusedto alert youtopotentialpersonalinjuryhazards.Obeyall safetymessages

thatfollow thissymbolto avoid possibleinjuryor death.

_Read this manualcarefully andbecomefamiliar

with your pressurewasher. Knowits applications,

its limitations, and any hazardsinvolved.

Thesafety alert symbol (,i_) is used with a signal word

(DANGER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert you to hazards.BANGERindicatesa hazard

which, if not avoided, willresult in deathor serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in deathor serious injury. CAUTIONindicates a hazard

which, if not avoided,might result in minor or moderate

injury. NOTlCEindicatesa situation that could result in

equipment damage. Follow safety messagesto avoid or

reducethe risk of injury or death.

Hazard Symbolsand Meaninos

ToxicFumes Kickback

2 5-

SlipperySurface Fall

Fire

MovingParts FlyingObjects

Explosion

ElectricalShock

FluidInjection

Operator'sManual

HotSurface

© SearsBrands, LLC

WARHJNG

Theengineexhaustfromthisproductcontains

chemicalsknownto theState of California to cause

cancer,birthdefects,or otherreproductiveharm.

WARNING

Certain componentsinthis productand relatedaccessories

containchemicalsknownto the State of California to cause

cancer,birthdefects,orotherreproductiveharm.

Washhandsafter handling.

WARNING

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathingcarbon monoxide can cause headache,

_ atigue, dizziness, vomiting, confusion, seizures,

. OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,orotheropenings.

• DONOTstartor runengineindoorsor in anenclosedarea,

evenif windowsanddoorsareopen.

. Usea respiratoror maskwheneverthereisa chancethat

vaporsmaybeinhaled.

• Readall instructionswith masksoyouarecertainthemaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

nausea,fainting or death.

Some chemicals or detergents maybe harmful if

inhaled or ingested, causing severe nausea,

fainting, or poisoning.

WARHIHG

_¢ isk of electrocution.

• NEVERspraynearpowersource.

Contactwith power source can causeelectric

shock or burn.

WARHIHG

Fueland its vapors areextremely flammable and

explosive.

death.

Fireor explosion cancause severeburns or

WHENADDINGOR DRAININGFUEL

• TurnpressurewasherOFFandlet it coolatleast2 minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

• Fillor drainfueltankoutdoors.

. DONOToverfilltank.Allowspaceforfuelexpansion.

• Iffuelspills,waituntilit evaporatesbeforestartingengine.

. Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

. DONOTlighta cigaretteorsmoke.

WHENSTARTINGEQUIPMENT

. Ensuresparkplug,muffler,fuelcap,andair cleanerarein

place.

• DONOTcrankenginewithsparkplugremoved.

WHENOPERATINGEQUIPMENT

• DONOTtip engineor equipmentat anglewhichcausesfuel to

spill.

. DONOTsprayflammableliquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

• Transport/repairwithfueltank EMPTYor withfuelshutoffvalve

OFF.

• Disconnectsparkplugwire.

WHENSTORINGFUELOBEQUIPMENTWITH FUELIN TANK

• Storeawayfromfurnaces,stoves,waterheaters,clothes

dryers,orotherappliancesthathavepilotlightor otherignition

sourcebecausetheycanignitefuelvapors.

WARHJHG

Startercord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

_,_.< toward engine faster than you can let go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spray gun

pressure.

. When starting engine, pull cord slowly until resistanceis felt

andthen pull rapidly to avoidkickback.

• After eachstarting attempt, where enginefails to run, always

point spray gun in safe direction, press red button and squeeze

spray guntrigger to releasehigh pressure.

• Firmly grasp spray gun with both handswhen using high

pressure spray to avoid injury when spray gun kicks back.

WARHIHG

Useof pressure washer cancreate puddles and

slippery surfaces.

Kickbackfrom spray gun can cause you to fall.

%

. Operatepressure washer from a stable surface.

• The cleaning area should haveadequate slopes and drainageto

reducethe possibility of afall dueto slippery surfaces.

. Be extremelycareful if you must usethe pressure washer from

a ladder,scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARHIHG

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

• DONOTallow CHILDRENto operate pressurewasher.

. NEVERrepair high pressure hose. Replaceit.

• NEVERrepair leaking connections with sealantof any kind.

Replaceo-ring or seal.

• NEVERconnect high pressure hoseto nozzle extension.

. Keep high pressure hoseconnectedto pump and spray gun

while system is pressurized.

• ALWAYSpoint spray gun in safe direction, pressred button

and squeezespray gun trigger to releasehigh pressure, every

time you stop engine.

• NEVERaim spray gun at people,animals, or plants.

. DONOTsecure spray gun inopen position.

• DO NOTleavespray gun unattendedwhile machine is running.

. NEVERusea spray gun which does not havea trigger lock or

trigger guard in place and in working order.

. Always be certain spray gun, nozzlesand accessories are

correctly attached.

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

WARHIHG

_ Unintentionalsparking can result infire or

WARHIHG

_ Contact with muffler result in serious

burns.

_ Exhaustheat/gases can ignite combustibles,structures or damagefuel tank causing a fire.

• DO NOTtouch hot parts and AVOID hot exhaust gases.

. Allow equipmentto cool before touching.

• Keepat least 5feet (152 cm) of clearanceon all sides of

pressure washer including overhead.

• Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to havea spark arrester, maintained in

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. Inthe State of California a

spark arrester is required under section 4442 of the California

Public resourcescode. Other states may havesimilar laws.

area can

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOUR

PRESSUREWASHER

. Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

. Use approved sparkplug tester.

• DONOTcheck for sparkwith spark plug removed.

WARHJHG

Starter and other rotating parts canentangle

hands, hair, clothing, or accessories.

* NEVERoperate pressure washer without protective housing or

covers.

* DO NOTwear loose clothing, jewelry or anything that may be

caught in the starter or other rotating parts.

* Tie up long hairand remove jewelry.

WARNING

Risk of eye injury.

" _ JSpray can splash back or propel objects.

Alwayswear safety goggles when using this equipment or in

vicinity of where equipment is in use.

Beforestarting the pressure washer, be sureyou are wearing

adequatesafety goggles.

NEVERsubstitute safetyglasses for safetygoggles.

NOTICE

High pressure spray may damage fragile items including

lass.

DO NOTpoint spray gun at glasswhen using red (0°) nozzle.

NEVERaim spray gun at plants.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

Ifyou havequestions aboutintended use, ask dealer or contact

Sears.

NEVERoperate units with broken or missing parts, or without

protective housingor covers.

DONOT by-pass any safetydevice on this machine.

DONOTtamper with governed speed.

DONOToperate pressure washer above rated pressure.

DONOT modify pressurewasher inany way.

Before starting pressure washer in cold weather, check all parts

of the equipment to besure ice hasnot formed there.

NEVERmove machine by pulling on hoses. Use handle

provided on unit.

Checkfuel system for leaksor signs of deterioration, such as

chafed or spongy hose, loose or missing clamps, or damaged

tank or cap. Correct all defects before operating pressure

washer.

This equipment is designed to be used with Searsauthorized

parts ONLY.If equipment is used with parts that DO NOT

comply with minimum specifications, user assumes all risks

and liabilities.

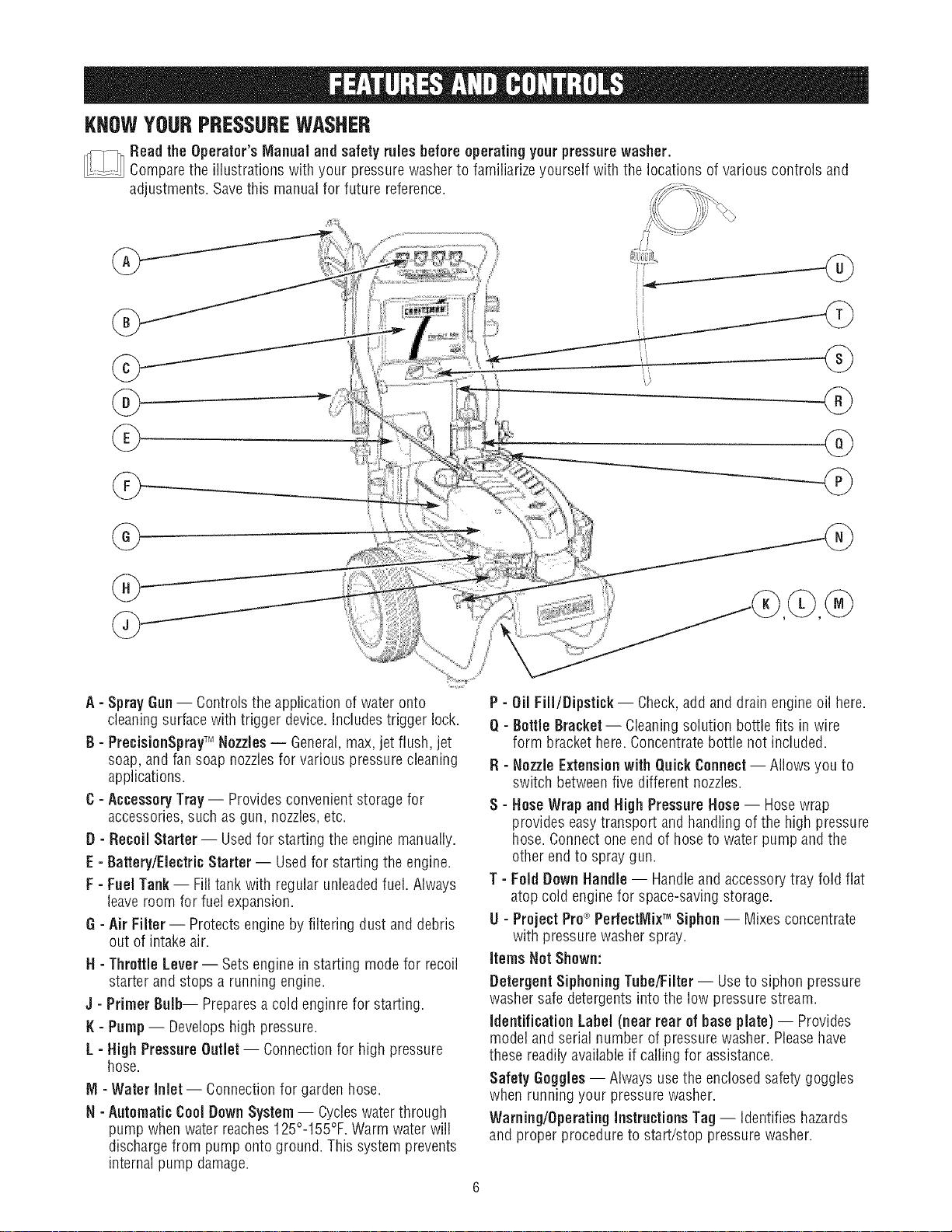

KNOWYOURPRESSUREWASHER

_Read the Operator'sManual andsafety rulesbefore operatingyour pressurewasher.

Comparethe illustrations with your pressurewasher to familiarize yourself with the locations of various controls and

adjustments. Savethis manual for future reference.

!

A - Spray Gun-- Controlsthe application of water onto

cleaningsurfacewith trigger device.Includestrigger lock.

B - PrecisienSprayTM Nozzles-- General,max,jet flush, jet

soap, and fansoap nozzlesfor various pressure cleaning

applications.

C- Accessory Tray-- Providesconvenientstorage for

accessories,such as gun, nozzles,etc.

D - Recoil Starter -- Used for starting the engine manually.

E - Battery/Electric Starter -- Used for starting the engine.

F - Fuel Tank-- Fill tank with regular unleadedfuel. Always

leaveroom for fuel expansion.

G - Air Filter -- Protects engine by filtering dust anddebris

out of intakeair.

H - Throttle Lever-- Setsengine instarting modefor recoil

starter and stops a running engine.

J - Primer Bulb-- Preparesa cold enginre for starting.

I{ - Pump -- Developshigh pressure.

L - High Pressure Outlet-- Connectionfor high pressure

hose.

IVl- Water Inlet -- Connection for garden hose.

N - Automatic Cool DownSystem -- Cycleswater through

pump whenwater reaches125°-155°F.Warm waterwill

dischargefrom pump onto ground. This system prevents

internalpump damage.

P - Oil Fill/Dipstick -- Check,add anddrain engineoil here.

Q - Bottle Bracket -- Cleaningsolution bottle fits in wire

form bracket here.Concentratebottle not included.

R - Nozzle ExtensionwithQuickConnect-- Allows you to

switch betweenfive different nozzles.

S - HoseWrap and HighPressureHose-- Hose wrap

provides easytransport andhandling of the high pressure

hose. Connect one end of hose to water pump andthe

other end to spray gun.

T - Fold DownHandle -- Handleand accessorytray fold flat

atop cold enginefor space-savingstorage.

U - Project Pro_ PerfectlViWMSiphon -- Mixes concentrate

with pressure washerspray.

Items Not Shown:

DetergentSiphoning Tube/Filter-- Useto siphon pressure

washer safe detergentsinto the lowpressure stream.

Identification Label (near rear of baseplate) -- Provides

model and serial number of pressurewasher. Pleasehave

these readily available if calling for assistance.

Safety Goggles-- Always usethe enclosedsafety goggles

when runningyour pressure washer.

Warning/Operating instructionsTag-- Identifies hazards

and proper procedureto start/stop pressurewasher.

Yourpressurewasherrequiressomeassemblyandisready

foruseonlyafterithasbeenproperlyservicedwiththe

recommendedoilandfuel.

If you have any problemswith the assembly of your

pressurewasher, please call the pressurewasher helpline

at 1-800=222=3136.

UHPACi(THEPRESSUREWASHER

1. Removeeverything from carton exceptpressure washer.

2. Opencarton completely bycutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

CARTONCONTENTS

Checkall contents. Ifany parts are missing or damaged,call

the pressure washer helpline at 1-800-222-3136.

• Main Unit

• Handle

• AccessoryTray

• High PressureHose

• Spray Gun

• NozzleExtensionwith Quick ConnectFitting

• Bottle BracketWireform

• Oil Bottle

• StandardSiphoning Hose

• HoseWrap

• Batterywith Key Start

• BatteryCharger

• Parts Bag (which includes the following):

• Operator's Manual

• Owner's RegistrationCard

• SafetyGoggles

• PerfectMixTMSiphoning Unit/Hose

• Bagcontaining 5 PrecisionSprayTM Nozzles

• HandleFasteningHardwareKit (whichincludes):

• Keys (2)

• HandleBolts (2)

• CarriageBolt (2)

• Plastic Knobsfor Handle (2)

• RopeGuide (1)

• Plastic Knob (3)

• TreeClips (4)

Becomefamiliar with eachpiecebefore assemblingthe

pressure washer. Identify allcontents with the illustration on

page 6. If any partsare missing or damaged,callthe

pressure washer helpline at 1-800-222-3136.

3. Connectdetergentsiphon hoseto pump.

4. Attach battery/key start.

5. Add oil to enginecrankcase.

6. Add fuel to fuel tank.

7. Connectpressure hose to spray gun and pump.

8. Connectwater supplyto pump.

9. Attach nozzleextension to spray gun.

10. Select/attachquick connect nozzleto nozzleextension.

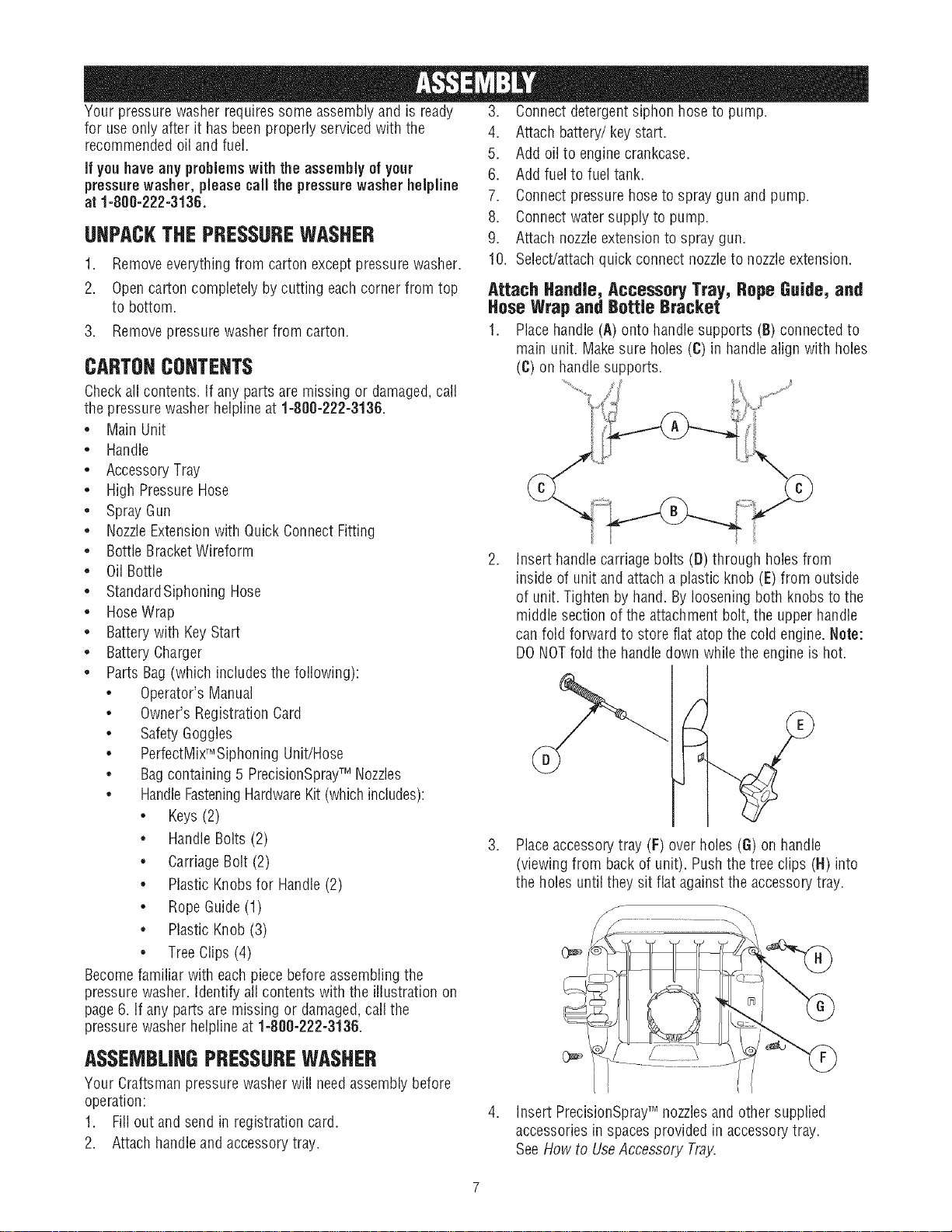

Attach Handle, Accessory Tray, RopeGuide, and

Hose Wrap and Bottle Bracket

1. Placehandle (A)onto handlesupports (B) connectedto

main unit. Make sure holes (C) in handlealign with holes

(C) on handle supports.

Insert handle carriage bolts (8) through holes from

inside of unit andattacha plastic knob (E)from outside

of unit.Tighten by hand. Byloosening both knobs to the

middle section of the attachment bolt, the upper handle

can fold forward to store flat atop the cold engine. Note:

DONOTfold the handledown while the engine is hot.

Placeaccessory tray (F) over holes (6) on handle

(viewing from back of unit). Pushthe tree clips (H) into

the holes until they sit flat againstthe accessorytray.

ASSEMBLINGPRESSUREWASHER

Your Craftsman pressure washer will need assemblybefore

operation:

1. Fill out and send in registration card.

2. Attach handleand accessorytray.

Insert PrecisionSprayTM nozzlesand other supplied

accessories in spaces provided in accessorytray.

SeeHow to UseAccessory Tray.

B,

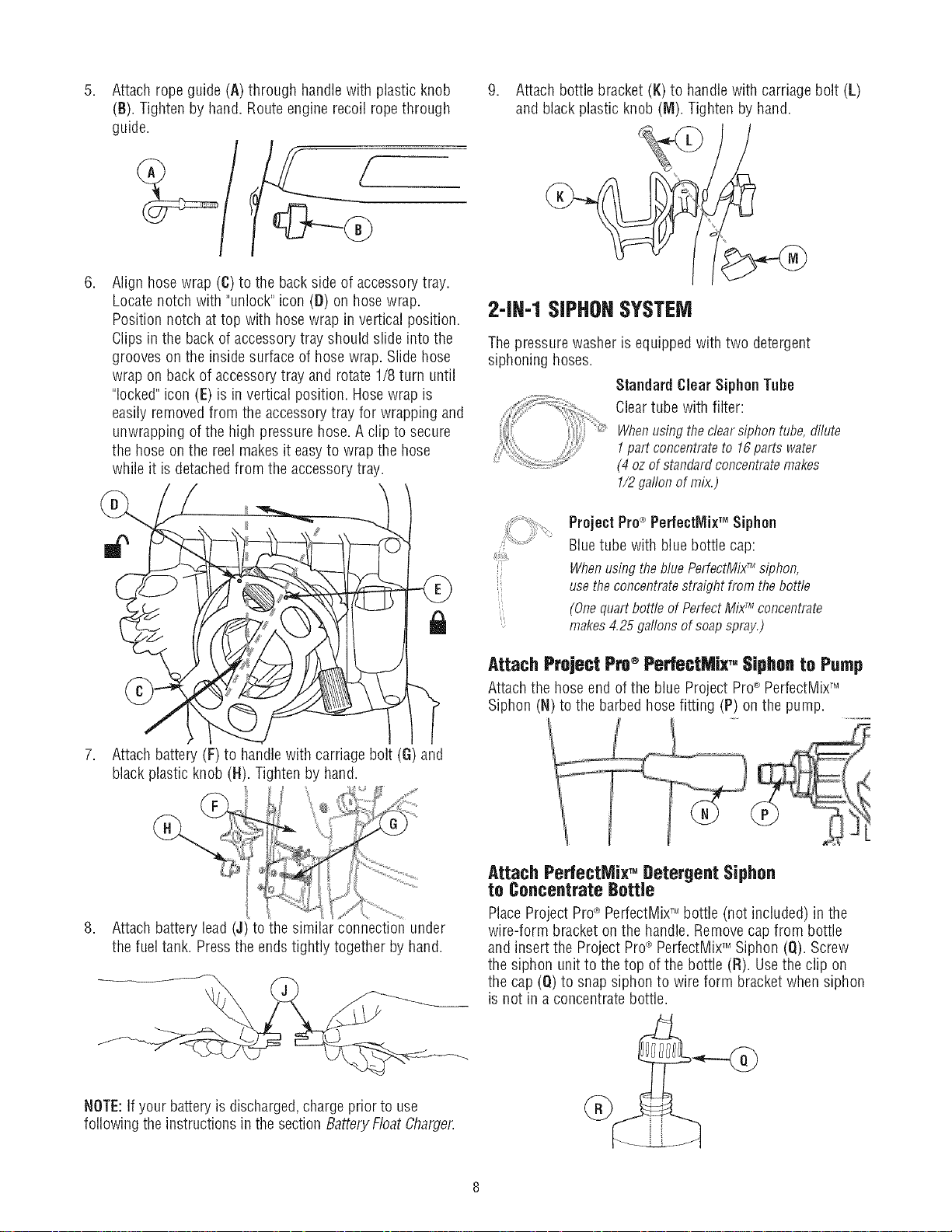

Attach rope guide (A)through handlewith plastic knob

(B). Tighten by hand. Routeengine recoil rope through

guide.

,

Align hose wrap (C)to the back side of accessorytray.

Locate notch with "unlock" icon (8) on hosewrap.

Position notch attop with hosewrap in vertical position.

Clips in the backof accessorytray should slide into the

grooves on the inside surface of hose wrap. Slide hose

wrap on back of accessorytray and rotate1/8 turn until

"locked"icon (E) is invertical position. Hosewrap is

easily removed from the accessorytray for wrapping and

unwrapping ofthe high pressurehose. Aclip to secure

the hose on the reel makesit easyto wrap the hose

while it is detachedfrom the accessorytray.

/

Attach bottlebracket (K) to handlewith carriage bolt (L)

and black plastic knob (M). Tighten by hand.

2-1N-1SIPHONSYSTEM

The pressure washer is equipped with two detergent

siphoning hoses.

Standard Clear SiphonTube

Cleartube with filter:

Whenusingthe dearsiphontube,dilute

1partconcentrateto 16parts water

(4 oz of standardconcentratemakes

1/2gaflonof mix.)

ProjectPro®PerfectMix'_ Siphon

Bluetube with blue bottle cap:

WhenusingthebluePerfectMixTMsiphon,

usetheconcentratestraightfromthebottle

(Onequartbottleof PerfectMixT'_concentrate

makes4.25gaflonsof soapspray.)

7. Attach battery (F) to handlewith carriagebolt (G) and

black plastic knob (H). Tightenby hand.

8. Attach battery lead (J) to the similar connection under

the fuel tank. Pressthe endstightly together by hand.

NOTE:If your batteryis discharged,charge prior to use

following the instructions in the sectionBattery FloatCharger.

Attach Project Pro®PerfectMix TM Siphon to Pump

Attach the hose end of the blue Project Pro®PerfectMix,M

Siphon (N) to the barbed hosefitting (P)on the pump.

Attach PerfectlVlix,. Detergent Siphon

to Concentrate Bottle

PlaceProject Pro®PerfectlY]ix7_bottle (not included) in the

wire-form bracket on the handle.Removecap from bottle

and insert the Project Pro®PerfectMix,MSiphon (Q). Screw

the siphon unit to the top of the bottle (R). Usethe clip on

the cap (Q) to snap siphon to wire form bracket when siphon

is not in a concentrate bottle.

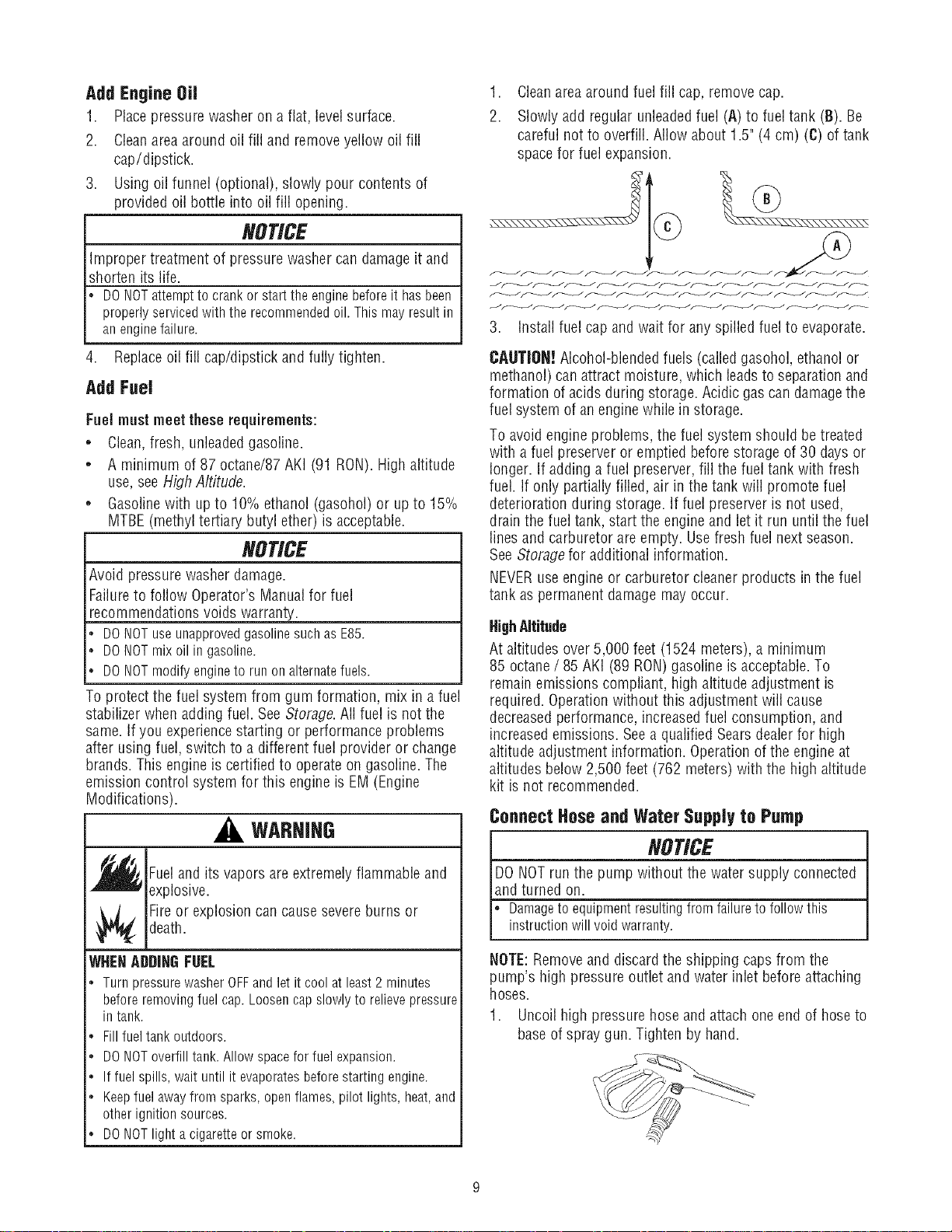

Add Engine 0iJ

1. Placepressure washer on a flat, ]eve]surface.

2. Cleanarea around oil fill and remove yellow oil fill

cap/dipstick.

3. Usingoil funnel (optional), slowly pour contents of

provided oil bottle intooil fill opening.

NOTICE

Improper treatment of pressurewasher can damageit and

shorten its life.

DONOTattempttocrankor starttheenginebeforeit hasbeen

properlyservicedwith therecommendedoil.Thismayresultin

anenginefailure.

1. Cleanareaaround fuel fill cap, removecap.

2. Slowly add regular unleadedfuel (A) to fuel tank (B). Be

careful not to overfill. Allow about 1.5"(4 cm) (C)of tank

space for fuel expansion.

3. Install fuel cap and wait for any spilled fuel to evaporate.

4. Replaceoil fill cap/dipstick and fully tighten.

Add Fuel

Fuel mustmeetthese requirements:

* Clean,fresh, unleadedgasoline.

* A minimum of 87 octane/87 AKI (91 RON).Highaltitude

use, see High Altitude.

* Gasolinewith upto 10% ethanol (gasohoI)or upto 15%

MTBE (methyl tertiary butyl ether) is acceptable.

NOTICE

Avoid pressure washer damage.

Failureto follow Operator's Manual for fuel

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchasE85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

To protect the fuel system from gum formation, mix in a fuel

stabilizer whenadding fuel. SeeStorage.All fuel is not the

same. If you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engineis certified to operateon gasoline.The

emission control system for this engine is EM (Engine

Modifications).

WARHIHG

FueIand its vapors are extremely flammable and

explosive.

CAUTION! Alcohol-blended fuels (calledgasohol, ethanol or

methanol) can attract moisture, which leadsto separation and

formation of acidsduring storage. Acidicgas candamagethe

fuel system of an engine while in storage.

To avoid engine problems, the fuel systemshould be treated

with a fuel preserveror emptied beforestorage of 30 days or

longer. If adding a fuel preserver,fill the fuel tank with fresh

fuel. If only partiallyfilled, air inthe tank will promote fuel

deterioration during storage. Iffuel preserver is not used,

drain the fuel tank, start the engineand let it run until the fuel

linesand carburetor are empty. Usefresh fuel next season.

SeeStoragefor additional information.

NEVERuse engine or carburetorcleaner products in the fuel

tank as permanent damagemay occur.

HighAltitude

At altitudes over5,000 feet (1524 meters), aminimum

85 octane/ 85AKi (89 RON)gasoline isacceptable.To

remainemissions compliant, high altitude adjustment is

required. Operationwithout this adjustment will cause

decreasedperformance, increased fuel consumption, and

increasedemissions. Seea qualified Searsdealerfor high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet(762 meters) with the high altitude

kit is not recommended.

Connect Hose and Water Supply to Pump

[ NOTICE

DONOTrun the pump without the water supply connected

and turned on.

death.

Fireor explosion can causesevere burns or

WHENADDIN6FUEL

* TurnpressurewasherOFFandletit coolat least2minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

. Fillfueltank outdoors.

* DONOToverfilltank.Allowspacefor fuelexpansion.

* If fuelspills,waituntilit evaporatesbeforestartingengine.

* Keepfuelawayfromsparks,openflames,pilotlights,heat,and

otherignitionsources.

. DONOTlighta cigaretteor smoke.

L amageto equipmentresultingfrom failureto followthisinstructionwill voidwarranty.

NOTE:Removeand discardthe shipping caps from the

pump's high pressure outlet and water inlet beforeattaching

hoses.

1. Uncoil high pressurehose and attach oneend of hoseto

baseof spray gun. Tighten by hand.

WARHIHG

The high pressure stream of waterthat this

_ quipment producescan cut through skin and its

* NEVERconnecthighpressurehoseto nozzleextension.

. Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

. Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

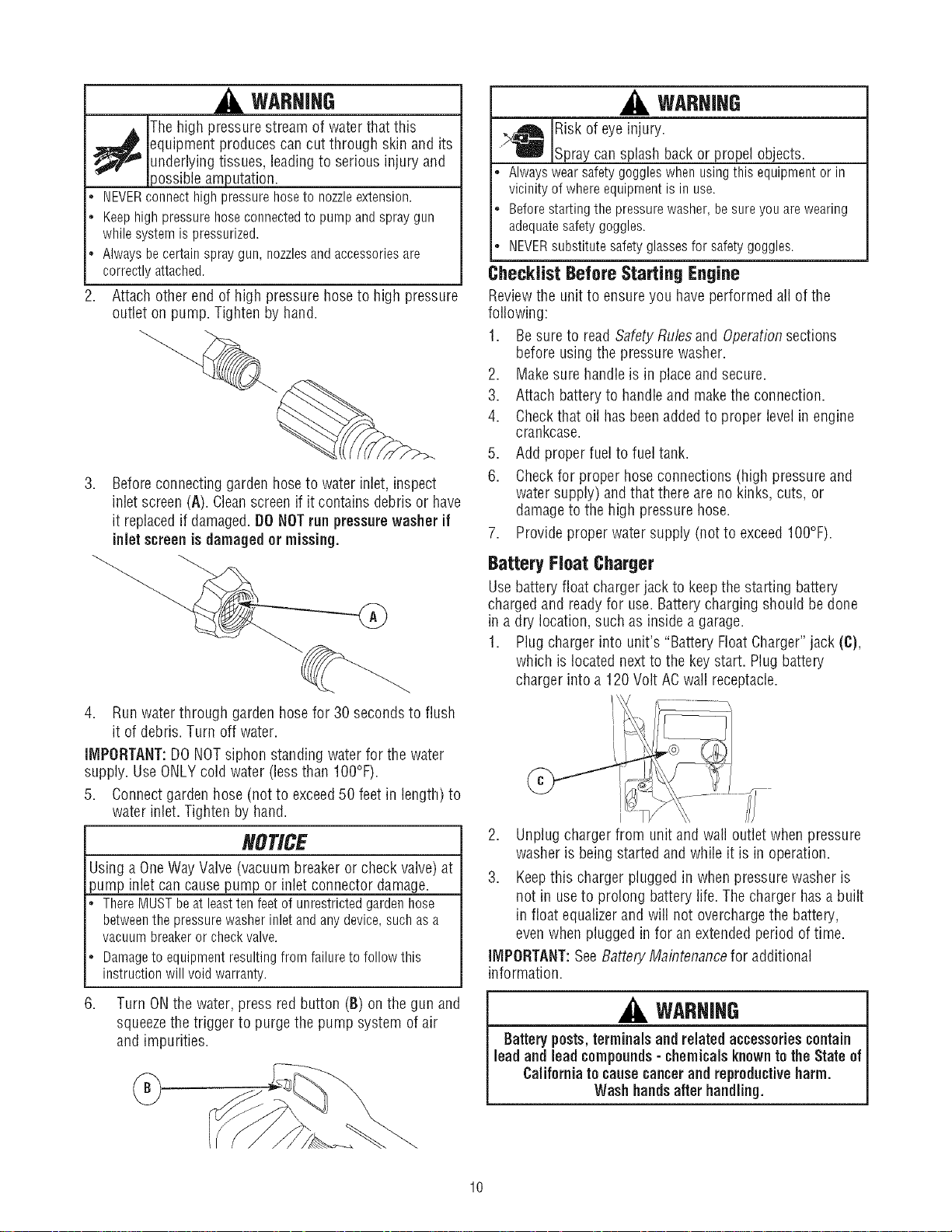

2. Attach other end of high pressurehoseto high pressure

3. Beforeconnectinggarden hose to water inlet, inspect

underlyingtissues, leadingto serious injury and

)ossible amputation.

outlet on pump.Tighten by hand.

inlet screen (A). Cleanscreen if it contains debris or have

it replacedif damaged.DO NOTrun pressurewasher if

inlet screenis damaged or missing.

m

Riskof eyeinjury.

_Spray can splash backor propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentisin use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

WARHIHG

ChecklistBefore StartingE.gi.e

Reviewthe unit to ensureyou have performed all of the

following:

1. Besure to read Safety Rubs and Operationsections

before usingthe pressurewasher.

2. Makesure handle is in placeand secure.

3. Attach batteryto handleand makethe connection.

4. Checkthat oil has beenadded to proper levelin engine

crankcase.

5. Add proper fuelto fuel tank.

6. Checkfor proper hose connections (high pressure and

water supply) andthat there areno kinks, cuts, or

damageto the high pressurehose.

7. Provideproper water supply (not to exceedIO0°F).

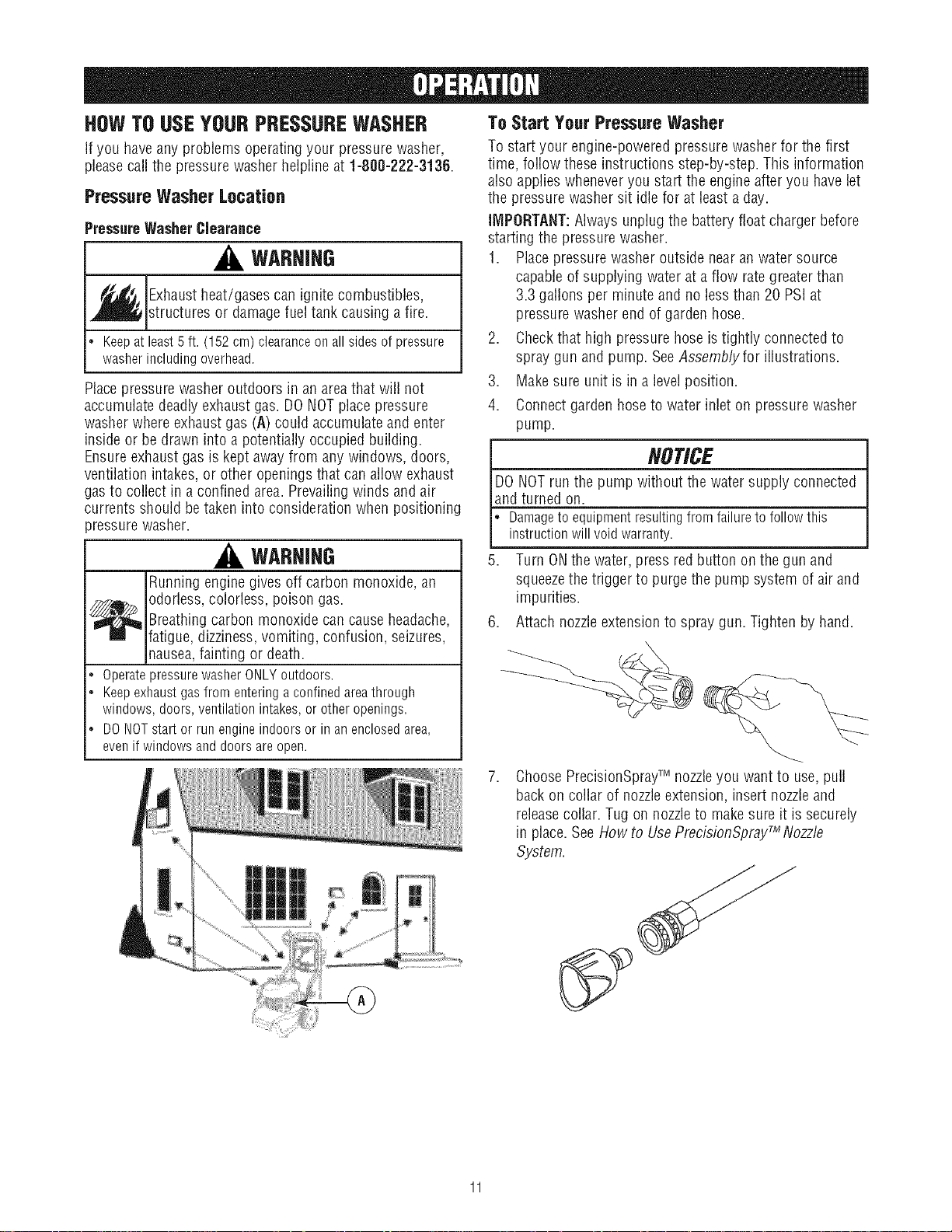

Battery Float Charger

Usebattery float chargerjack to keepthe starting battery

charged and readyfor use. Batterycharging should be done

in a dry location, such as inside a garage.

1. Plug charger into unit's "Battery FloatCharger"jack (C),

which is located nextto the key start. Plug battery

charger into a120 Volt AOwall receptacle.

4. Run water through garden hose for 30 secondsto flush

it of debris. Turn off water.

IMPORTANT:DO NOTsiphon standing water for the water

supply. UseONLYcold water (less than IO0°F).

5. Connectgarden hose (not to exceed50 feet in length) to

water inlet. Tighten by hand.

NOTICE

Using a OneWay Valve(vacuum breakeror check valve)at

pump inlet cancause pump or inlet connector damage.

ThereMUSTbeat leasttenfeetof unrestrictedgardenhose

betweenthe pressurewasherinletandanydevice,suchasa

vacuumbreakerorcheckvalve.

Damageto equipmentresultingfrom failuretofollowthis

instructionwill voidwarranty.

6. Turn ON the water, press redbutton (B) on the gun and

squeezethe trigger to purgethe pump system of air

and impurities.

/ /_ _©

2. Unplugcharger from unit and walloutlet when pressure

washer is beingstarted and whileit is in operation.

3. Keep this charger plugged in when pressure washer is

not in use to prolong battery life. The charger has a built

in float equalizer and will not overcharge the battery,

even when plugged in for an extended period of time.

IMPORTANT:SeeBatteryMaintenancefor additional

information.

WARHIHG

Batteryposts,terminals and relatedaccessories contain

lead and lead compounds- chemicalsknowntothe State of

California to causecancerand reproductiveharm.

Wash handsafter handling.

10

HOWTOUSEYOURPRESSUREWASHER

If you haveany problems operating your pressure washer,

pleasecallthe pressurewasher helplineat 1-808-222-3136.

Pressure Washer Location

PressureWasherClearance

WARNING

_ Exhaustheat/gases can ignitecombustibles,

• Keepatleast5ft. (152cm)clearanceonall sidesof pressure

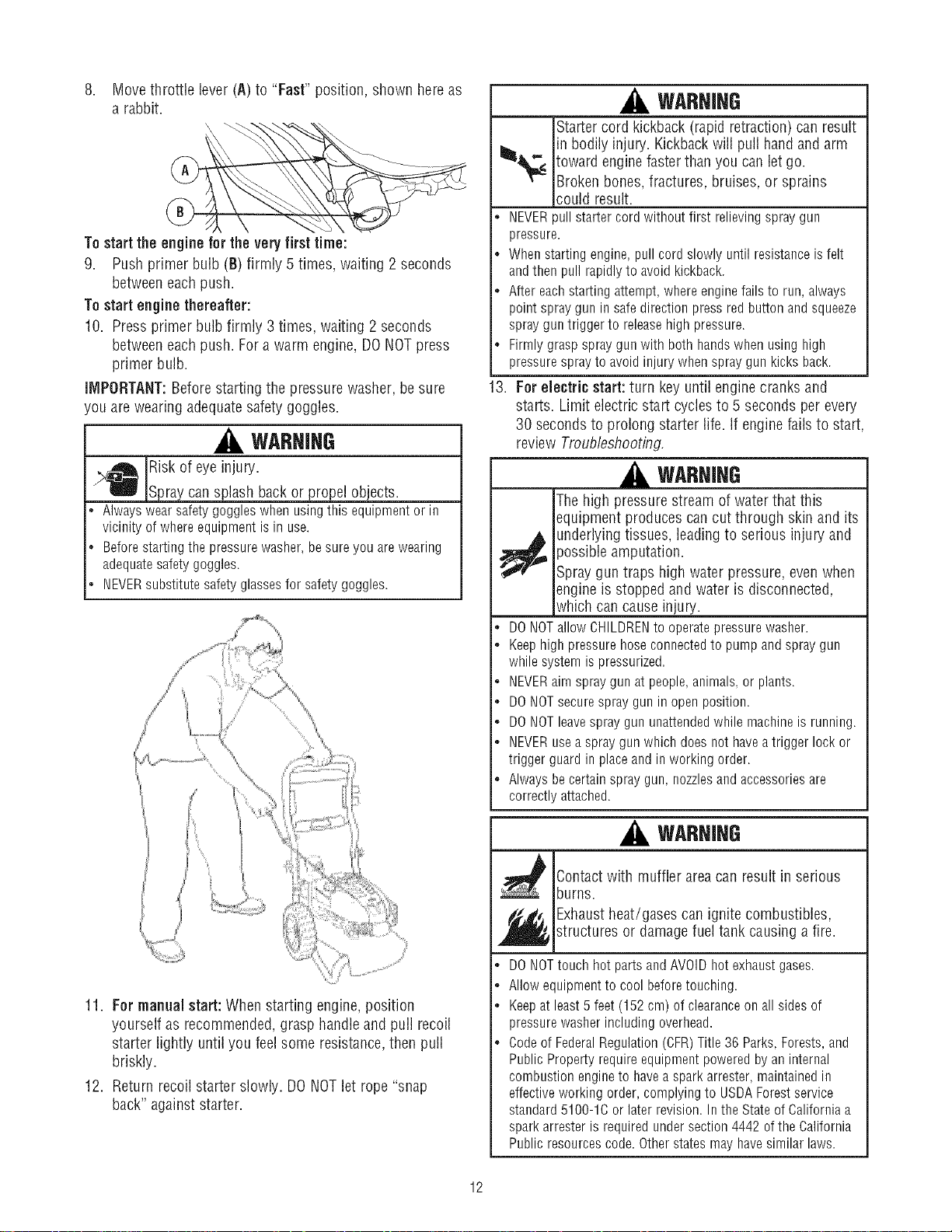

Placepressure washer outdoors in an areathat will not

accumulate deadly exhaust gas. DONOTplacepressure

washer where exhaust gas (A) could accumulateand enter

inside or be drawn into a potentially occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventilation intakes, or other openingsthat can allow exhaust

gasto collect ina confinedarea. Prevailingwinds and air

currents should betaken into considerationwhen positioning

_ressurewasher.

structures or damagefuel tank causing a fire.

washerincludingoverhead.

WARHIHG

Runningengine gives offcarbon monoxide, an

_ dorless, colorless, poison gas.

. OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringaconfinedareathrough

• DONOTstartor runengineindoorsorin anenclosedarea,

Breathingcarbon monoxide can causeheadache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

windows,doors,ventilationintakes,orotheropenings.

evenif windowsanddoorsareopen.

To Start Your Pressure Washer

To start your engine-powered pressurewasher for the first

time, follow these instructions step-by-step. This information

also applies wheneveryou start the engine after you havelet

the pressurewasher sit idle for at leasta day.

IMPORTANT:Always unplug the batteryfloat charger before

starting the pressurewasher.

1. Placepressure washer outside near an water source

capableof supplying water at aflow rate greater than

3.3 gallons perminute andno less than 20 PSI at

pressurewasher endof garden hose.

2. Checkthat high pressure hose istightly connected to

spray gun andpump. SeeAssemblyfor illustrations.

3. Makesure unit is in a levelposition.

4. Connectgarden hose to water inlet on pressure washer

pump.

[ NOTICE

JDONOT the without the connected

and turned on.

L amageto equipmentresultingfrom failureto followthisinstructionwill voidwarranty.

5. Turn ONthe water,press redbutton onthe gun and

6. Attach nozzleextension to spray gun. Tighten by hand.

run

squeezethe trigger to purgethe pump system of air and

impurities.

pump

water

supply

ChoosePrecisionSprayTMnozzleyou wantto use, pull

back on collar of nozzleextension, insert nozzle and

releasecollar. Tug onnozzleto make sure it is securely

in place.See How to UsePrecisionSpraSMNozzle

System.

8. Move throttle lever (A) to "Fast" position, shown hereas

a rabbit.

To start the engine for thevery first time:

9. Push primer bulb (B) firmly 5 times, waiting 2 seconds

betweeneach push.

To start engine thereafter:

10. Press primer bulb firmly 3 times, waiting 2 seconds

betweeneach push. Fora warm engine, DONOTpress

primer bulb.

IMPORTANT:Before starting the pressure washer, besure

/ou arewearing adequatesafety goggles.

WARHIHG

Riskof eyeinjury.

_Spray cansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentis in use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

WARHIHG

Starter cord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pull handand arm

_< toward enginefaster thanyou canlet go.

Brokenbones, fractures, bruises, or sprains

could result.

• NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

• Whenstartingengine,pullcordslowlyuntilresistanceis felt

andthenpullrapidlyto avoidkickback.

• Aftereachstartingattempt,whereenginefailsto run, always

pointspraygunin safedirectionpressredbuttonandsqueeze

sprayguntriggerto releasehighpressure.

• Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

13. For electricstart: turn key until enginecranks and

starts. Limit electric start cycles to 5seconds per every

30 seconds to prolong starter life. If engine fails to start,

review Troubleshooting.

WARHIHG

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

,p_ underlyingtissues, leadingto serious injury and

* DONOTallowCHILDRENtooperatepressurewasher.

, Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

, NEVERaimspraygunat people,animals,or plants.

* DONOTsecuresprayguninopenposition.

, DONOTleavespraygununattendedwhilemachineis running.

* NEVERuseaspraygunwhichdoesnothaveatriggerlockor

triggerguardin placeandinworkingorder.

, Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped andwater is disconnected,

which can cause injury.

11. For manual start: When starting engine, position

yourself as recommended, grasp handleand pull recoil

starter lightly until you feelsome resistance, then pull

briskly.

12. Return recoil starter slowly. DONOTlet rope "snap

back" against starter.

WARHIHG

_ Contact with muffler result in serious

,_ Exhaustheat/gases can ignite combustibles,structures or damagefuel tank causing a fire.

* DONOTtouchhot partsandAVOIDhotexhaustgases.

, Allowequipmenttocoolbeforetouching.

* Keepatleast5 feet(152cm) ofclearanceonall sidesof

, Codeof FederalRegulation(CFR)Title36Parks,Forests,and

12

burns.

pressurewasherincludingoverhead.

PublicPropertyrequireequipmentpoweredbyaninternal

combustionengineto haveasparkarrester,maintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-1Corlaterrevision.IntheStateofCaliforniaa

sparkarresteris requiredundersection4442oftheCalifornia

Publicresourcescode.Otherstatesmayhavesimilarlaws.

area can

14.Aftereachstartingattempt,whereenginefailstorun,

alwayspointguninsafedirection,pressredbuttonand

squeezesprayguntriggertoreleasehighpressure.

WARHIHG

The high pressure stream of waterthat this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntrigger,to releasehighpressure,every

time youstopengine.

NOTE:Always keep the throttle lever in the "Fast" position

when operatingthe pressurewasher.

How to Stop Your Pressure Washer

1. Releasespray gun trigger and letengine idle for two

2. Movethrottle to SLOWposition,then STOPposition.

3. ALWAYSpoint spray gun in asafe direction, push red

iMPORTANT:Spraygun traps high water pressure,even

when engine is stopped and water is disconnected.

_ossibleamputation.

Spray gun traps high water pressure,even when

engine is stopped andwater is disconnected,

which can cause injury.

minutes.

button and squeezespray gun trigger to releaseretained

high water pressure.

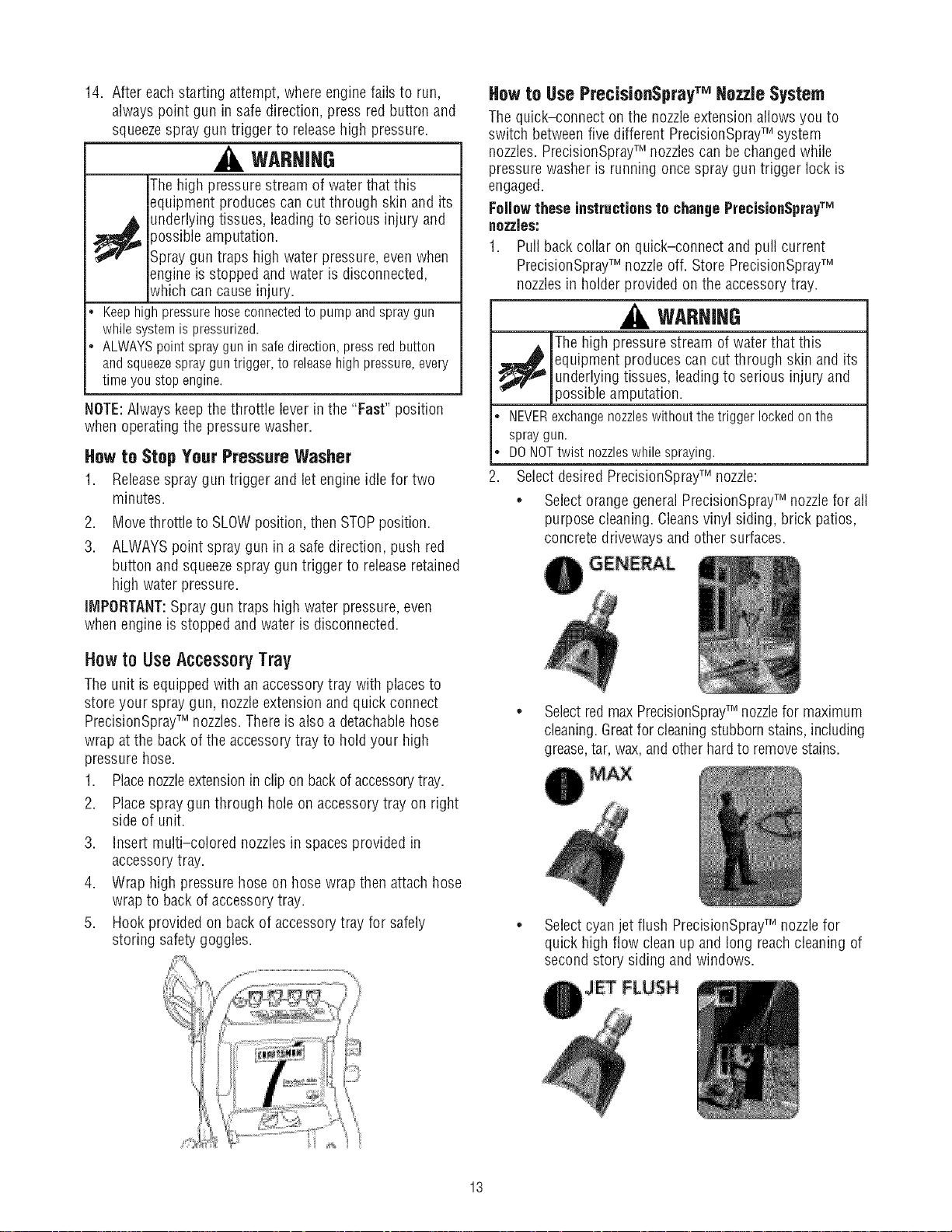

How to Use PrecisionSprayTM Hozzle System

Thequick-connect on the nozzleextension allows you to

switch between five different PrecisionSprayTM system

nozzles. PrecisionSprayTM nozzlescan be changed while

pressure washer is running oncespray guntrigger lock is

engaged.

Foflowthese instructionsto changePrecisionSprayTM

flozzJes:

1. Pull backcollar on quick-connect and pull current

PrecisionSprayTM nozzleoff. Store PrecisionSprayTM

nozzlesin holder provided on the accessory tray.

WARHIHG

Thehigh pressure stream of water that this

_ equipment produces can cut through skin anditsiundery ng tissues, leadingto serious injury and

jpossible amputation.

, NEVERexchangenozzleswithoutthetriggerlockedonthe

spraygun.

, DONOTtwist nozzleswhilespraying.

2. Select desired PrecisionSprayTM nozzle:

• Selectorange generalPrecisionSprayTM nozzlefor all

purpose cleaning. Cleansvinyl siding, brick patios,

concrete driveways and other surfaces.

Howto UseAccessoryTray

The unit is equipped with an accessorytray with placesto

store your spray gun, nozzleextension and quick connect

PrecisionSprayTM nozzles.There is also a detachablehose

wrap at the back of the accessorytray to hold your high

pressure hose.

1. Placenozzleextensionin clip onbackof accessorytray.

2. Placespray gun through hole on accessorytray on right

side of unit.

3. Insert multi-colored nozzlesin spacesprovided in

accessorytray.

4. Wrap high pressure hose on hose wrap then attach hose

wrap to backof accessorytray.

5. Hook provided on backof accessorytray for safely

storing safety goggles.

* Selectred max PrecisionSprayTM nozzlefor maximum

cleaning.Greatfor cleaningstubbornstains, including

grease,tar, wax, and otherhardto removestains.

Selectcyan jet flush PrecisionSprayTM nozzlefor

quick high flow clean up andlong reachcleaning of

second story siding and windows.

JETFLUSH

13

* Selectmagentajet soap PrecisionSprayTM nozzleto

launch soapto secondstory siding and windows.

Select black fan soap PrecisionSprayTM nozzlefor

generalcleaning. Greatfor applying soapto

vehicles, boats, driveways, decks,and patios.

FAN SOAP

3. Pull backon collar,insert new PrecisionSprayTM nozzle

and releasecollar.Tug on nozzleto makesureit is securely

in place.

NOTE:Detergentcannot beapplied with the high pressure

nozzles(Cyan,Orangeor Red).

4. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn onwater.

NOTICE

You must attach all hosesbefore you start the engine.

Startingthe enginewithoutalltile hosesconnectedandwithout

thewaterturnedONwill damagethepump.

Damageto equipmentresultingfrom failureto followthis

instructionwill voidwarranty.

5. Startengine following instructions How to Start Your

Pressure Washer.

6. Placethreadedend of detergent siphoning tube into

detergentcontainer. Tighten by hand.

7. Apply detergentto adry surface, starting at lower

portion of areato bewashed andwork upward, using

long, even, overlapping strokes.

8. Allow detergentto "soakin" for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surface from drying. DONOTallow detergent to dry on

(preventsstreaking).

UsageTips

• Formost effective cleaning, keep PrecisionSprayTM nozzle

from 8 to 24 inches (20 to 61 cm) awayfrom cleaning

surface.

• If you get PrecisionSprayTM nozzletoo close, especially

usinga high pressurenozzle,you maydamage surface

being cleaned.

• DONOTget closer than 6 inches(15 cm) when cleaning

tires.

2-IN-1 SIPHONSYSTEM

Cleaning and Applying Detergent with

the Project Pro®PerfectMix TM Siphon

CAUTIOH

Chemicalscan causebodily injury, and/or property

damage.

NEVERusecausticliquidwith pressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

To apply undiluteddetergent using

the blue PerfectMixTM siphen,

felJow thesesteps:

1. Reviewuse of PrecisionSprayTM nozzles.

2. Attach PerfectMixTM siphon hoseto

pump and PerfectMixTM concentrate

bottle.

3. Make sure fan soap (black) or jet soap

nozzle(magenta)is installed.

Cleaning and Applying Detergent with

the Standard Clear Siphon

To apply diluted detergentusingthe

standard cJearsiphontube,

felJew these steps:

1. Reviewuseof

PrecisionSprayTM nozzles.

2. Attach clear siphon hoseto pump.

3. Mix detergent solution as required by job.

4. Placesmall filter end of clear siphoning tube into

container with diluted solution as described above.

NOTICE

Contact with the hot muffler can damagedetergent

siphoning tube.

Wheninsertingthesiphonintoa detergentsolutionbottle,

routethetubesoasto keepit from inadvertentlycontactingthe

hotmuffler.

NOTE:Makesure the filter is fully submerged in fluid while

applying solution.

5. Makesure fan soap (black) or jet soap nozzle(magenta)

is installed.

NOTE:Detergentcannot beapplied with the high pressure

nozzles(Cyan,Orangeor Red).

6. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn onwater.

7. Start engine following instructions How to Start Your

Pressure Washer.

14

8. Applydetergenttoadrysurface,startingatlower

portionofareatobewashedandworkupward,using

long,even,overlappingstrokes.

9. Allowdetergentto"soakin"for3-5minutesbefore

washingandrinsing.Reapplyasneededtoprevent

surfacefromdrying.DONOTallowdetergenttodryon

(preventsstreaking).

IMPORTANT:Youmustflushthedetergentsiphoningsystem

aftereachusebyplacingthefilterintoabucketofclean

water,thenrunthepressurewasherinlowpressurefor1-2

minutes.

PressureWasherRinsing

ForRinsing:

1. Removesoap nozzlefrom nozzleextension.

2. Selectand install desiredhigh pressure nozzlefollowing

instructions How to Use PrecisionSprayNozzleSystem.

3. Keepthe spray gun a safedistance from the areayou

plan to spray.

WARHIHG

/_ spray gun can cause you

. Operatepressurewasherfrom astablesurface.

• Beextremelycarefulif youmustusethepressurewasherfrom

. Firmlygraspspraygunwith bothhandswhenusinghigh

4. Apply a high pressurespray to asmall area,then check

,

Kickbackfrom to fall.

a ladder,scaffolding,or anyothersimilarlocation.

pressuresprayto avoidinjurywhenspraygunkicksback.

the surfacefor damage.If no damageis found, it is okay

to continue cleaning.

Start at the top of the areato be rinsed, working down

with same overlapping strokes as you usedfor washing

and applying detergent.

Cleaning DetergentSiphoning Tube

If you usedthe clear detergent siphoning tube, you must

flush it with clean water beforestopping the engine.

1. Placedetergent siphoning tube/filter in a bucketfull of

clean water.

2. Removehigh pressure nozzlefrom nozzleextension.

3. Selectand install a soap nozzlefollowing instructions

How to Use PrecisionSprayTM NozzleSystem.

4. Flushfor 1-2 minutes.

5. Shut off engine following instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint spray gun ina safedirection, push red

button and squeezespray gun trigger to releaseretained

high water pressure.

WARHIHG

Thehigh pressurestream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leadingto serious injury and

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

. ALWAYSpointspraygunin safedirectionpressred buttonand

squeezesprayguntrigger,to releasehighpressure,everytime

youstopengine.

IMPORTANT:Spraygun traps high water pressure,even

when engine is stopped andwater is disconnected.

Automatic Cool Down System (Thermal Relief)

If you run the engineon your pressure washer for

3-5 minutes without pressing the trigger on the spraygun,

circulating water in the pump can reach temperatures above

125°F.The system engagesto cool the pump by discharging

the warmwater onto the ground.

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped andwater is disconnected,

which can cause injury.

15

EHGINETECHNICALJNFORMATIOH PRODUCTSPECIFICATiOHS

This is a single cylinder, overheadvalve (OHV),air cooled

engine, it is alow emissions engine.

Inthe Stateof California, Model 120000enginesare certified

by the California Air ResourcesBoardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engineany

additional warranties with respectto the performance or

operational life of this engine.Theengine is warrantedsolely

according to the product andemissions warranties stated

elsewherein this manual.

Power Ratings

Thegross power rating for individual gas engine models is

labeledin accordancewith SAE(Societyof Automotive

Engineers)code J1940 (Small Engine Power &Torque

Rating Procedure),and rating performance has been

obtained andcorrected in accordancewith SAEJ1995

(Revision2002-05). Torquevalues are derived at 3060 RPM;

horsepower values are derived at 3600 RPM.Actual gross

engine power will be lower andis affected by, among other

things, ambientoperating conditions and engine-to-engine

variability. Given both the wide array of products on which

enginesare placed and the variety of environmental issues

applicableto operatingthe equipment, the gas engine will not

developthe ratedgross power when used ina given pieceof

power equipment (actual "on-site"or net power). This

difference is due to a variety of factors including, but not

limited to, accessories (aircleaner, exhaust,charging,

cooling, carburetor, fuel pump, etc.),application limitations,

ambient operating conditions (temperature,humidity,

altitude), and engine-to-engine variability. Dueto

manufacturing and capacity limitations, Briggs & Stratton

maysubstitute an engine of higher ratedpower for this

Seriesengine.

This pressurewasher is rated in accordanceto the Pressure

Washer Manufacture Association (PWMA) standard PW101

(Testingand Rating Performanceof PressureWashers).

Pressure Washer Specifications

Max Outlet Pressure ....................... 2,700 PSi

Max Flow Rate............................. 2.3 GPM

DetergentMix ........................ Use as directed

Water Supply Temperature .......... Notto exceed IO0°F

Engine Specifications

Bore ................................. 2.69 in. (68mm)

Stroke ............................... 2.04 in. (52mm)

Displacement ........................ 11.57in. (190 cc)

SparkPlug

Type:..................... Briggs & Stratton 491055S

SetGapTo: ...................... O.020inch(0.50mm)

ArmatureAir Gap: ........... 0.006-0.014in.(O.15-O.36mm)

Valveclearancewithvalvespringsinstalledandpiston1/4in.

(6 ram)pasttopdeadcenter(checkwhenengineiscold).

Intake.................... 0.004-0.006in.(0.10-0.15mm)

Exhaust .................. 0.004-0.008in.(0.10-0.20mm)

FuelCapacity............................... 1.6Quarts

OilCapacity....................... 22 Ounces(0.65 liter)

NOTE:For practical operation, the engine load should not

exceed 85% of rated power. Enginepower will decrease

3-1/2% for each 1,000 feet (300 meters) above sea level and

1% for each 10° F(5.6° C) above 77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

16

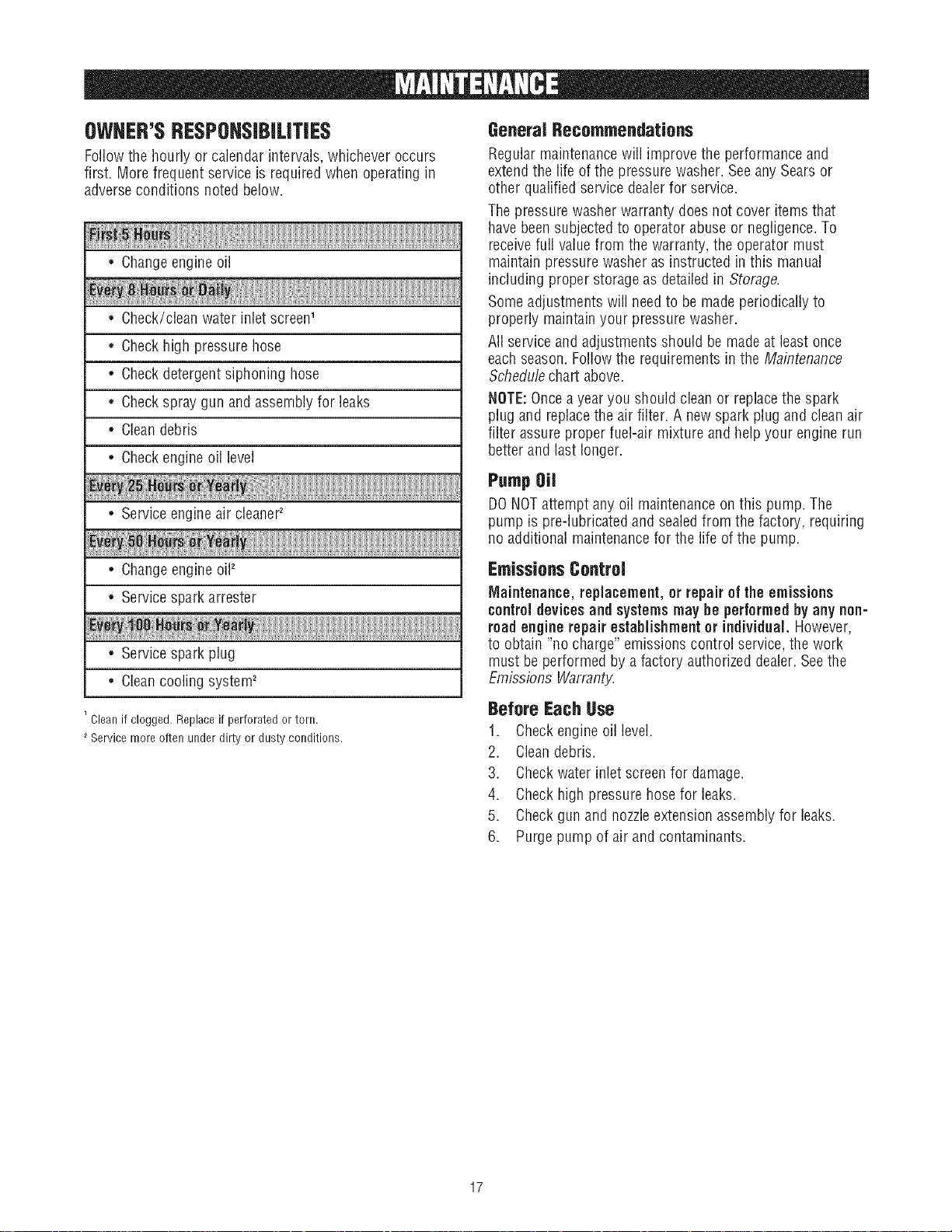

OWHER'SRESPOHSIBILiTIES

Followthe hourly or calendar intervals, whichever occurs

first. More frequent service is requiredwhen operating in

adverseconditions noted below.

• Changeengine oil

• Check/clean water inlet screen1

• Check high pressurehose

• Check detergentsiphoning hose

• Checkspray gun and assembly for leaks

• Clean debris

• Checkengine oil level

• Service engineair cleaner2

General Recommendations

Regularmaintenancewill improve the performanceand

extend the life of the pressure washer. Seeany Searsor

other qualified service dealerfor service.

The pressure washer warranty does not cover items that

havebeensubjectedto operator abuse or negligence. To

receivefull valuefrom the warranty, the operator must

maintain pressure washer as instructed in this manual

including properstorage as detailedin Storage.

Someadjustments will needto be madeperiodically to

properly maintain your pressure washer.

All service and adjustments should bemadeat least once

eachseason. Followthe requirements in the Maintenance

Schedulechart above.

NOTE:Oncea yearyou should clean or replacethe spark

plug and replacethe air filter. A newspark plug andcleanair

filter assure properfuel-air mixture and helpyour engine run

better and last longer.

Pump Oil

DONOTattempt any oil maintenanceon this pump. The

pump is pro-lubricatedand sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

• Changeengine oil2

• Service spark arrester

_ _ LLLLLL

Service spark plug

• Cleancooling system2

' Clean if clogged. Replace if perforated or torn.

Service more often under dirty or dusty conditions.

EmissionsControl

Maintenance, replacement, or repairof the emissions

control devicesand systemsmay be performedby any non-

road engine repair establishmentor individual. However,

to obtain "no charge" emissions control service,the work

must be performed by a factory authorizeddealer.Seethe

Emissions Warranty.

Before Each Use

1. Checkengine oil level.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hose for leaks.

5. Checkgun and nozzleextension assembly for leaks.

6. Purgepump of air and contaminants.

17

Loading...

Loading...