Craftsman 580752102, 580752100 Owner’s Manual

Operator'sManual

2780 PSi MAX

2.5 GPff] MAX

_odei No. 580.752100

®

wAReeeG

Before usingthis product, readthis

manualand follow atI Safety Rutes

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, _L 68179 U.S.A.

Visit our Craftsman website: www.craftsman.eom

Part No. 20262166 Draft B(04/24/2007)

Antes de utiiizar el producto, Iea este

manuaiy siga todas Ias Reglasde

Seguridade Instrucciones de Uso.

ADVER'rENCmA

®Safety

®AssembJy

®Operation

,, Maintenance

,, Parts

,, Espa_oi, p. 32

WARRANTY.......................................... 2

SAFETYRULES...................................... 2-5

FEATURESANDCONTROLS.............................. 6

ASSEMBLY......................................... 7-9

OPERATION....................................... 10-13

SPECIFICATIONS..................................... 14

MAINTENANCE.................................... 15-19

If this pressurewasher faiis dueto a defectin materiai or workmanship within one year from the date of purchase,return it to

any Searsstore, other Craftsman outlet, or SearsParts & Repair Centerin the UnitedStates or Canadafor free repair (or

replacementif repair proves impossible).

Ali warranty coverageapplies for only 90 days from dateof purchaseif this pressure washer is ever usedfor commercial or

rentaipurposes.

This warranty gives you specific legal rights, and you mayalso haveother rights which vary from stateto state.

STORAGE........................................... 20

TROUBLESHOOTING.................................. 21

REPLACEMENTPARTS.............................. 22-29

EMISSIONCONTROLWARRANTY..................... 30-31

ESPANOL......................................... 32-55

HOWTOORDERPARTS........................ BACKPAGE

Sears, Roebuck and Ce,, Heffman Estates, JL68179

Sears Canada Jnc,, Terente, 8ntarie, Canada MSB 2B8

Thisis the safety alert symbol, tt is used to alert yea to potential persenaminjary hazards. Obey aH safety messages

that fellow this symbemtoavoid pessiNe injury or death.

_Read this manual carefully and become familiar

..... with your pressurewasher. Knew its applications,

itslimitations, and any hazardsinvolved.

Thesafety alert symboi (,_) is usedwith a signal word

(DAr/GER,CAUTION,WARNING),a pictorial and/or a safety

messageto alert you to hazards.BANGERindicatesa hazard

which, if not avoided, wi/'/resuIt in death or serious injury.

WARNINGindicates a hazard which, if not avoided, cou/d

result in deathor serious injury. CAUTtONindicatesa hazard

which, if not avoided, might resultin minor or moderate

injury. NOTICEindicatesa situation that could result in

equipment damage. Foiiow safety messagesto avoid or

reducethe risk of injury or death.

Hazard $ymhomsand NteanJngs

ToxicFurnes

SlipperySurface

Fire

MovingParts FlyingObiects HotSurface

Kickback ElectricalShock

Fall FluidInjection

Explosion Operator'sManual

© SearsBrands, LLC

WARNING

_'_ Fuet and its vapors are extremely flammable and

explosive.

death.

Fire or explosion can cause severe burns or

Runningenginegivesoffcarbonmonoxide,an

odorless,coioriess,poisongas.

Breathingcarbonmonoxidecancauseheadache,

fatigue,dizziness,vomiting,confusion,seizures,

nausea,faintingordeath.

Somechemicaisordetergentsmaybeharmfulif

inhaledoringested,causingseverenausea,

fainting,orpoisoning.

• OperatepressurewasherONLYoutdoors.

o Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,or otheropenings.

o DONOTstart or runengineindoorsor in anenclosedarea,

evenif windowsanddoorsareopen.

• Usea respiratoror maskwheneverthereis a chancethat

vaporsrnaybeinhaled.

• Readall instructionswith masksoyouarecertainthernaskwill

providethenecessaryprotectionagainstinhalingharmful

vapors.

WARNING

_¢ Risk of electrocution.

• NEVERspray nearpower source

Contact with power source can cause electric

shock or burn.

WHENARRmNG ORBRAINING FUEL

o Turn pressure washer OFFand let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relievepressure

in tank.

o Fill or drain fuel tank outdoors.

• DONOTover% tank. Mow space for fue! expansion.

o If fuel spills, wait until it evaporates before starting engine.

• Keepfuel away frorn sparks, openflames, pilot lights, heat,and

other ignition sources.

• DONOTlight a cigarette or smoke.

WHENSTARTINGEQUmP_'IENT

o Ensure spark plug, muffler, fuel cap, and air cleaner arein

place.

o DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIP_tENT

• DONOTtip engine or equiprnentat anglewhich causes fuel to

spill

o DONOTspray'flamrnable liquids.

WHENTRANSPORTmNGORREPAIRmNGEQNIPI_IENT

o Transport/repair with fuel tank EMPTYor with fuel shutoff valve

OFF.

o Disconnect spark plug wire.

WHENSTORINGFUEL OR EQUIPMENTWiTH FUEL mNTANK

• Store away from furnaces, stoves_water heaters_clothes

dryers, or other appliances that havepilot light or other ignition

source becausethey'can ignite fuel vapors.

WARNING

Starter cord kickback (rapid retraction) can result

in bodily injury. Kickback will pulI hand and arm

toward engine faster than you can Iet go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relieving spray gun

pressure.

o When starting engine pull cord slowly until resistance is felt

andthen pul! rapidly to avoid kickback.

o After eachstarting atternpt where enginefails to run, always

point spray gun in safe direction andsqueezespray gun trigger

to releasehigh pressure. Engagespray gutstrigger lock.

o Firmly grasp spray gun with both hands when using high

pressure spray to avoid iniury when spray gun kicks back.

WARNING

Useof pressure washer cancreate puddles and

slippery surfaces,

Kickbackfrom spray gun cancause you to fall,

* Operatepressure washer frorn a stable surface.

o The cleaningarea should haveadequateslopes and drainageto

reducethe possibility of a fall due to slippery surfaces.

o Be extremelycareful if you rnust usethe pressure washer from

a ladder, scaffolding, or any other similar location.

o Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

pressure stream of water that thi-['s_

equipment produces can cut through skin and its

_ .underlying tissues, ieading to serious injury and

possibie amputation.

_l"_ Spray gun traps h gl water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

DONOTallow CHILDRENto operate pressure washer.

NEVERrepair high pressure hose. Replaceit.

NEVERrepair leakingconnections with sealantof any kind.

Replaceo-ring or seal.

NEVERconnect high pressure hoseto nozzle extension.

Keephigh pressure hose connectedto purnp and spray gun

while system is pressurized.

ALWAYSpoint spray gun in safe direction and squeezespray

gun trigger to releasehigh pressure, every time you stop

engine. Engagetrigger lock when not in use.

NEVERaim spray gutsat people, animals, or plants.

DO NOTsecure spray gun in open position.

DO NOTleavespray gun unattended while rnacbine is running.

NEVERusea spray gun wlsichdoes not have atrigger lock or

trigger guard in place and in working order.

Always be certain spray gun, nozzbs and accessories are

correctly attached.

WARNING

Unintentional sparking can result in fire or

WARNING

Contact with muffler area can result in serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

* DO NOTtouch hot parts and AVOID hot exlsaustgases.

* Allow equipment to cool before touching.

o Keepat least 5 feet (152 crn) of clearanceon all sides of

pressure washer including overhead.

o Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, rnaintainedin

effective working order, complying to USDAForestservice

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states rnay havesimilar laws.

'_¢ electric shock.

WHENADJUSTmNGORMAKING REPAIRSTOYOUR PRESSURE

WASHER

• Disconnectthe sparkplug wire frorn the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTmNGFORENGINESPARK

• Useapproved spark plug tester.

o DONOTcheck for spark with spark plug removed.

WARNING

Starter and other rotating parts canentangie

hands, hair, clothing, or accessories.

• NEVERoperatepressurewasherwithoutprotectivehousingor

covers.

• DONOTwea!looseclothingjewelryor anythingthat maybe

caughtinthestarterorotherrotati_gparts.

o Tieup longhai!andrernovejewelry.

WARNING

IRisk of eyeinjury=

..L..__jSpray cansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentis in use.

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

High pressure spray may damagefragiie items inciuding

lass.

DONOTpointspraygunatglasswhenusingMAX(0°) nozzle.

NEVERaim spraygunatplants.

Improper treatment of pressure washer can damageit and

shorten its iife.

Ifyouhavequestionsaboutintendeduse,askdealerorcontact

Sears.

NEVERoperateunitswith brokenormissingpa!rs,orwithout

protectivehousingor covers.

DONOTby-passanysafetydeviceonthis rnachine.

DONOTtamperwith governedspeed.

DONOToperatepressurewasheraboveratedpressure.

DONOTmodifypressurewasherinanyway.

Beforestartingpressurewasherincoldweathercheckallparts

oftheequiprner_tto besureicehasnot formedthere.

NEVERmovemachinebypullingon hoses.Usehandle

providedon unit.

Checkfuelsystemfor leaksorsignsofdeterioration,suchas

chafedor spongyhose,looseor missingclamps_or damaged

ta!_korcap.Correctalldefectsbeforeoperatingpressure

washer.

Thisequipmentisdesignedto beusedwithSearsauthorized

partsONLY.If equipmentis usedwith partsthatDONOT

complywithminimumspecifications,userassumesall risks

andliabilities.

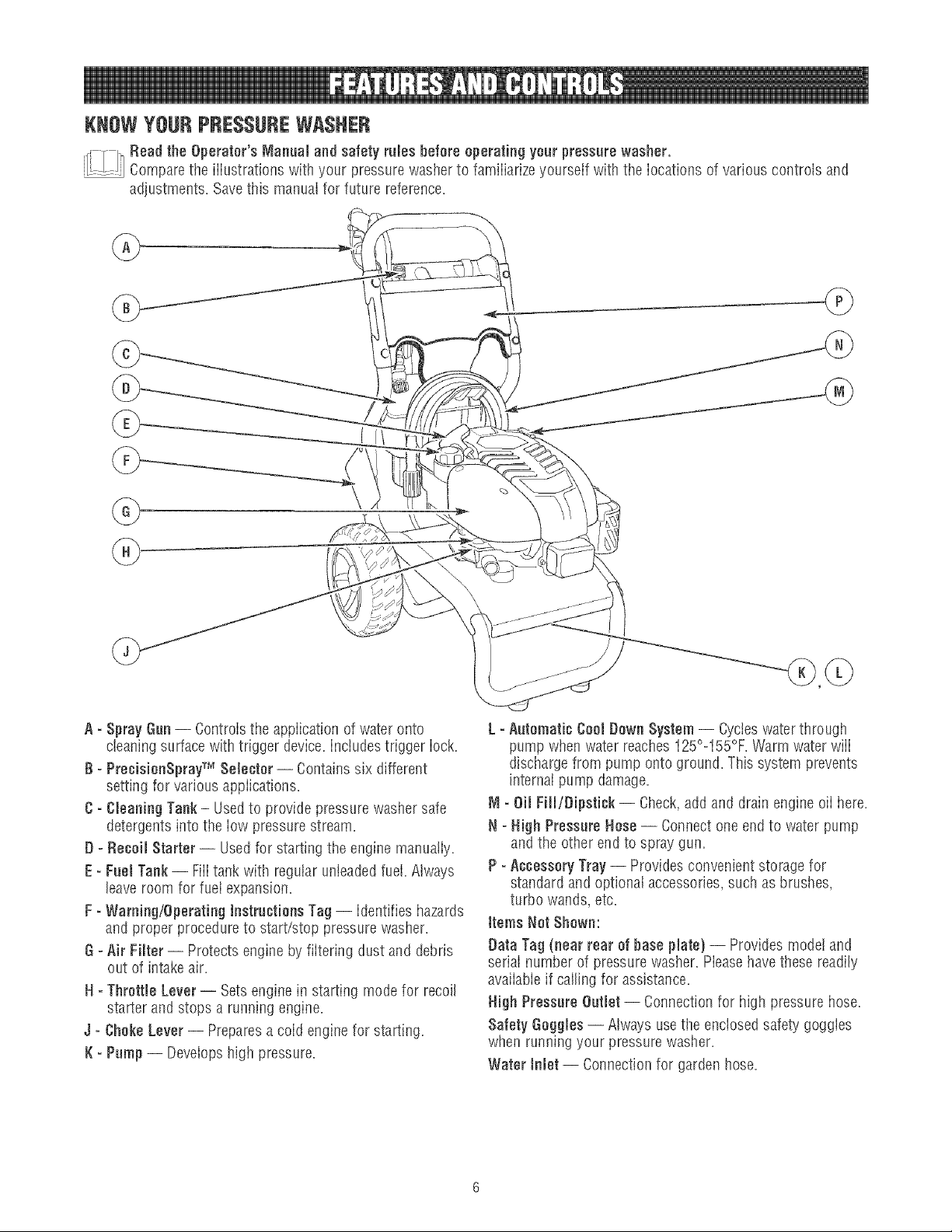

KNOWYOURPRESSUREWASHER

,r' F I-_Read the Operator's ManuaJ and safety ruJesbefore operating your pressurewasher.

.... Comparethe illustrations with your pressurewasher to familiarizeyourself with the locations of various controls and

adjustments. Savethis manualfor future reference.

A =Spray Gun-- Controisthe appiication of wateronto

cleaningsurfacewith trigger device, inctudes trigger iock.

B oPresisieeSprayTM SeJestor-- Containssix different

setting for various appiications.

C- Cleaning Tank - Usedto provide pressure washer safe

detergents into the iow pressure stream.

D -Resoil Starter -- Used for starting the engine manuatiy.

E - Fuel Tank-- FilItank with reguiar unleadedfuel. Aiways

leaveroom for fuei expansion.

F =Warning/Operating instructions Tag-- Identifies hazards

and proper procedureto start/stop pressure washer,

G - Air Filter -- Protectsengine by fiitering dust and debris

out of intake air=

H =ThrottleLever-- Setsenginein starting mode for recoil

starter and stops a running engine.

J =Choke Lever -- Preparesa coid engine for starting.

J(- Pamp -- Developshigh pressure=

L - A[itematic Cool Down System-- Cycleswaterthrough

pump when water reaches 125°=155%.Warm water wiii

discharge from pump ontoground. This system prevents

internal pump damage.

Ni- Oil Fill/Dipstick -- Check,add and drain engine eli here=

N =High Press[ireHose -- Connectone end to water pump

and the other end to spray gun.

P - Accessory Tray -- Provides convenientstorage for

standard and optional accessories,such as brushes,

turbo wands, etc=

items Not Shown:

Data Tag (near rear of base plate) -- Provides model and

serial number of pressure washer. Pieasehavethese readily

avaiiabieif calling for assistance.

High Press[ire O[itJet-- Connectionfor higil pressure hose.

Safety Goggles-- Always usethe enciosedsafety goggies

when running your pressure washer.

Water inlet -- Connectionfor garden hose.

YourcleaningsystemrequiressomeassembIyandisready

foruseonlyafterit hasbeenproperiyservicedwiththe

recommendedoilandfuel.

Jfyou haveany prohbms with the assembly of your

pressurewasher, please call the pressurewasher hempline

at 1o800o222o3136.

UNPACKTHEPRESSUREWASHER

1. Removeeverything from carton exceptpressure washer.

2. Opencarton completely bycutting eachcorner from top

to bottom.

3. Removepressure washer from carton.

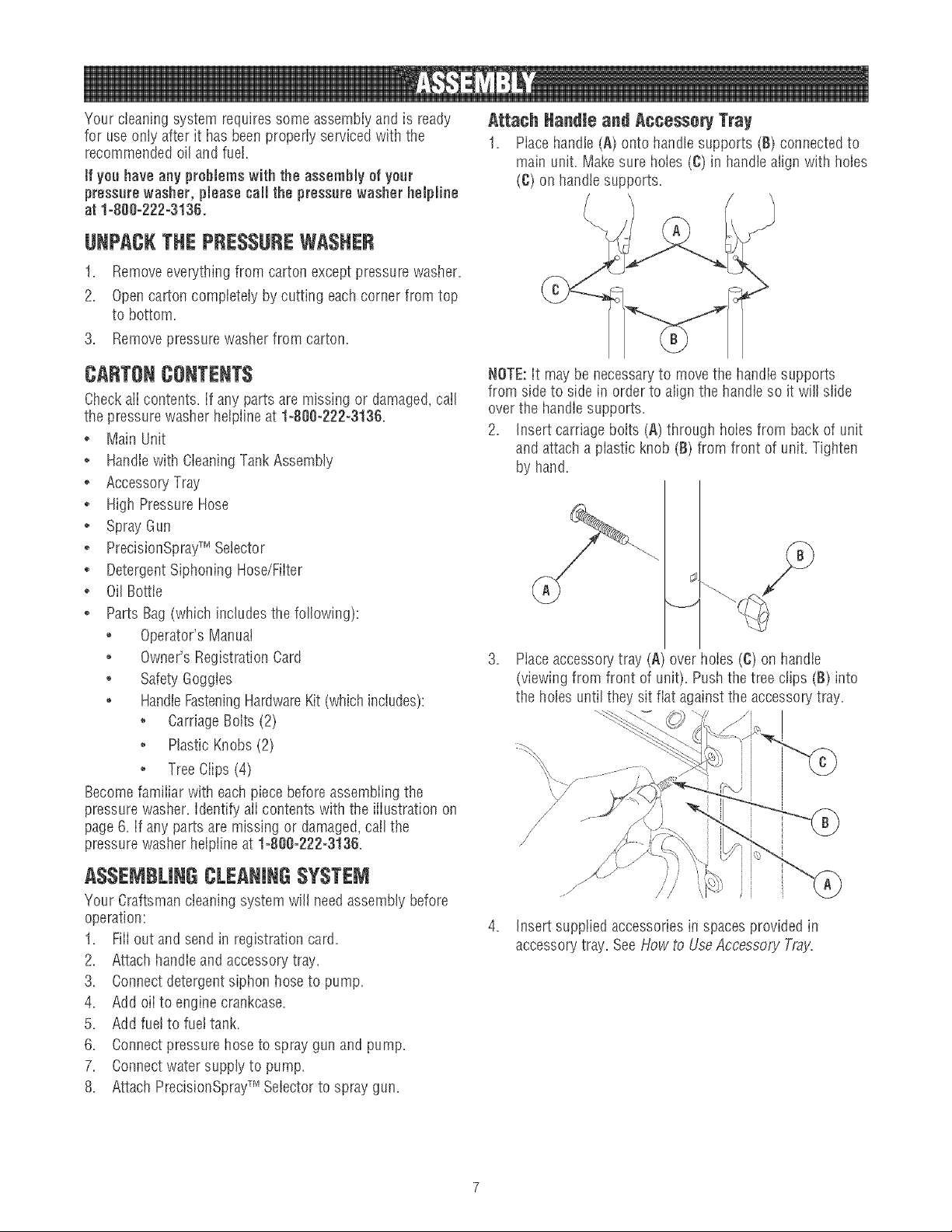

Attach Handle and Accessery Tray

1. Placehandb (A) onto handb supports (8) connected to

main unit. Make sure holes (C) in handb align with holes

(C) on handle supports.

CARTONCONTENTS

Checkali contents, if any parts are missing or damaged,call

the pressure washer hetpline at 1=800=222=3136.

° Main Unit

* Handb with CieaningTankAssembly

, AccessoryTray

° High PressureHose

° Spray Gun

, PrecisionSprayTM Selector

, DetergentSiphoning Hose/Fiiter

* Oil Bottle

, Parts Bag (which includes the following):

. Operator's Manual

, Owner's Registration Card

, SafetyGoggies

, HandieFasteningHardwareKit (whichincludes):

, CarriageBolts (2)

, Plastic Knobs (2)

, Tree6iips (4)

Becomefamiiiar with eachpiecebefore assembiingthe

pressure washer. Identify alIcontents with the illustration on

page 6. if any parts are missing or damaged,call the

pressure washer helptineat 1-808-222-3136.

NOTE:it may be necessaryto move the handle supports

from sideto side in order to align the handle so it wifl slide

overthe handIesupports.

2. Insert carriagebolts (A)through holesfrom backof unit

and attacha plastic knob (8) from front of unit. Tighten

by hand.

3. Placeaccessory tray (A) over holes (g) on handle

(viewing from front of unit). Pushthe tree clips (8) into

the holes until they sit fiat againstthe accessorytray.

/

/

A$$EJ IBLINGCLEANINGSYSTEJ

Your Craftsmancleaningsystem will needassembly before

operation:

1. Fiii out and send in registration card.

2. Attach handieand accessory tray.

3. Connectdetergent siphon hoseto pump.

4. Add eli to engine crankcase.

5. Add fuel to fuel tank.

6. Connectpressure hose to spray gun and pump.

7. Connectwater supply to pump.

8. Attach PrecisionSprayTM Selector to spray gun.

/

Insert supplied accessories in spaces provided in

accessorytray. See How to UseAccessofy Tray.

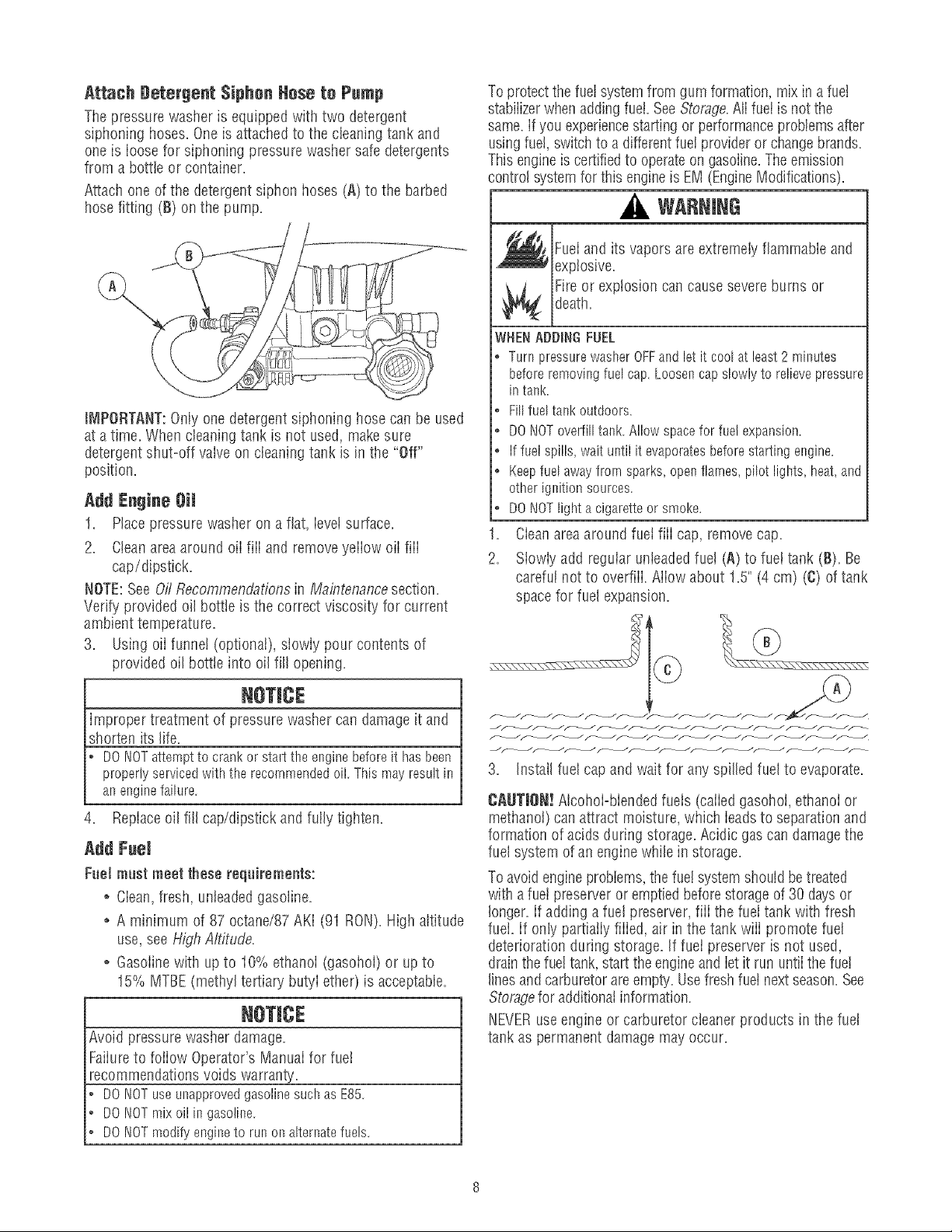

Attach Detergent Siphon Hose te Pemp

Thepressure washer is equipped with two detergent

siphoning hoses. One is attached to the cleaning tank and

one is loosefor siphoning pressure washer safe detergents

from a bottle or container.

Attach one of the detergent siphon hoses (A) to the barbed

hose fitting (B) on the pump.

iMPORTANT:Onlyone detergent siphoning hosecan be used

at a time. When cleaningtank is not used, makesure

detergent shut-off valve on cleaningtank is in the "Off"

position.

Add Engine Oil

1. Placepressure washer on a flat, ievei surface.

2. Cleanarea around oii fiii and remove yeiiow oii fiii

cap/dipstick.

NOTE:See 0i/Recommendations in Maintenancesection.

Verify provided oil bottle is the correct viscosity for current

ambient temperature.

3. Using oiI funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

To protectthefueI systemfrom gum formation, mix in afue!

stabiiizerwhen adding fueLSeeStorage.Ali fueiis not the

same.if you experiencestarting or performanceproblemsafter

usingfue!,switch to a different fuel provideror changebrands.

This engineis certifiedto operateon gasoiine.Theemission

control systemfor this engineis EM(EngineModifications).

WARNING

Fueiand its vapors are extremely flammable and

explosive.

death.

Fireor explosion can causesevere burns or

WHENADEmNGFUEL

• TurnpressurewasherOFFandlet it coolatleast2 minutes

beforeremovingfuelcap.Loosencapslowlyto relievepressure

in tank.

• Fillfueltankoutdoors.

o DONOToverfilltank.Allowspaceforfuel expansion.

• Iffuelspills waituntilit evaporatesbeforestartingengine.

o Keepfuelawayfrornsparks,openflames,pilotlights,heat,and

otherignitionsources.

• DONOTlighta cigaretteorsmoke.

1. Cieanareaaround fuel fiii cap, removecap.

2. Siowiy add regular unleadedfuel (A) to fuet tank (B). Be

carefui not to overfiii. Aiiow about 1.5" (4 cm) (C) oftank

space for fuel expansion.

NOTICE

improper treatment of pressurewasher can damageit and

shorten its life.

DONOTattempttocrankor sta!ttheenginebeforeit hasbeen

properlyservicedwiththerecommendedoil.Thismayresultin

anenginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

Add Fee?

Fuel must meet these requirements:

Clean,fresh, unleadedgasoline.

. A minimum of 87 octane/87AKI (91 RON).Highaltitude

use, see HighAltitude.

° Gasolinewith up to 10% ethanol (gasohoI) or upto

15% MTBE(methyl tertiary butyi ether) is acceptable.

Avoid pressure washer damage.

Faiiumto foliow Operator's Manuai for fuet

recommendations voids warranty.

DONOTuseunapprovedgasolinesuchasE85.

DONOTmixoil in gasoline.

DONOTmodifyengineto runon alternatefuels.

CAUTION! AIcohoI-blendedfuels (caiiedgasohot,ethanol or

methanol) can attract moisture, which leadsto separationand

formation of acids during storage.Acidic gas candamagethe

fuel system ofan engine while in storage.

To avoidengineproblems,the fuel system should betreated

with a fuel preserveror emptiedbefore storageof 30 days or

longer,if adding a fuel preserver, fiii the fuei tank with fresh

fuel. if oniy partiaiiy fiiied, air in the tank wiii promote fuel

deterioration during storage. If fuel preserver is not used,

drainthefueI tank,startthe engineand ietit run untiithe fuel

linesandcarburetorare empty. Usefreshfuel nextseason.See

Storagefor additionalinformation.

NEVERuseengine or carburetor cleaner products in the fuel

tank as permanent damagemay occur.

Ataltitudesover5,000feet(1524meters),aminimum

85octane/ 85 AKI (89 RON)gasoline is acceptable.To

remain emissions compiiant, high attitude adjustment is

required. Operationwithout this adjustment wiii cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seea qualified Searsdealer for high

altitude adjustment information. Operationof the engine at

altitudes below 2,500 feet (762 meters) with the high altitude

kit is not recommended.

Cennect Hese and Water Supply te Pump

NOTE:Remove and discard the shipping caps from the

pump's high pressure outiet and water inlet before attaching

hoses.

1. Uncoii high pressure hose and attach one end of hoseto

baseof spray gun. Tighten by hand.

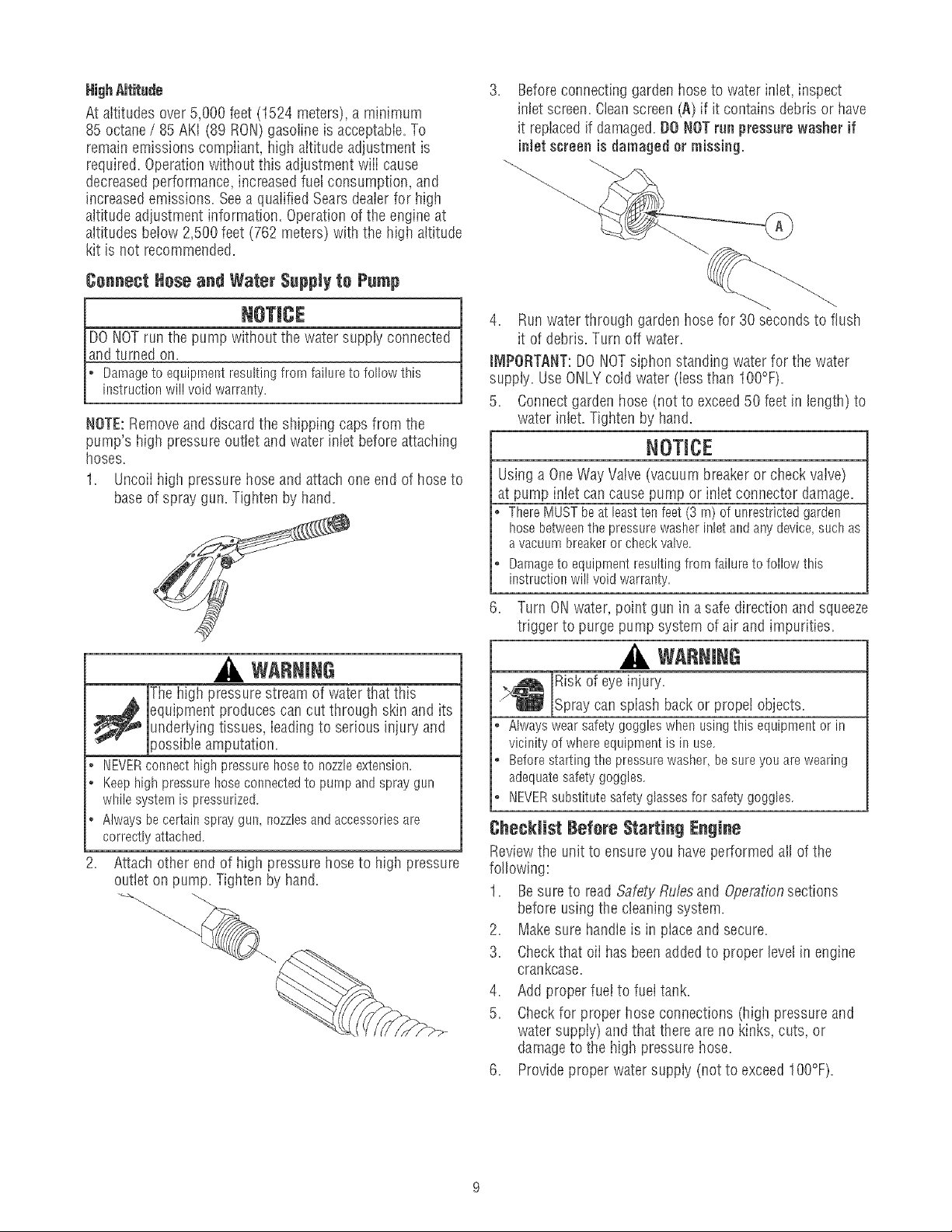

3, Beforeconnecting garden hose to water inlet, inspect

inletscreen. Cleanscreen (A) if it contains debris or have

it replacedif damaged.DONOTrun pressure washer if

inletscreen is damaged or missing,

.

Runwater through garden hosefor 30 secondsto flush

it of debris. Turn off water.

iMPORTANT:DONOTsiphon standing water for the water

supply. Use ONLYcoId water (Iess than 100%).

5. Connectgarden hose (not to exceed50 feet in length) to

water inlet. Tighten by hand.

NOTICE

Using a OneWay Vatve(vacuum breakeror checkvaiv@

at pump inlet can cause pump or iniet connector damage.

ThereMUSTbeatleasttenfeet(3 rn)ofunrestrictedgarden

hosebetweenthepressurewasherinletandanydevice,suchas

avacuumbreakerorcheckvalve.

Darnageto equipmentresultingfromfailuretofollowthis

instructionwillvoidwarranty,

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

underlyingtissues, leadingto serious injury and

)ossibb amputation.

* NEVERconnecthighpressurehoseto nozzbextension.

* Keephighpressurehoseconnectedto purnpandspraygun

whilesysternis pressurized.

. Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

Attach other end of high pressure hoseto high pressure

outlet on pump. Tighten by hand.

6. Turn ONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities.

WARNING

jRiskof eyeinjury.

_Spray cansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthis equipmentor in

vicinityof whereequipmentisin use.

Beforestartingthe pressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesfor safetygoggles.

ChecMJst Befere Starting Engine

Reviewthe unit to ensure you haveperformed all of the

following:

1. Besureto readSafetyRu/'esand Operationsections

before usingthe cleaningsystem.

2. Makesure handle is in placeand secure.

3. Checkthat oii has beenaddedto proper level in engine

crankcase.

4. Add proper fue! to fueI tank.

5. Checkfor proper hose connections (high pressure and

water suppiy) and that there are no kinks, cuts, or

damageto the high pressure hose.

6. Provideproper water supply (not to exceed 100%).

HOWTOUSEYOURCLEANINGSYSTEM

If you haveany probbms operatingyour pressure washer,

pleasecallthe pressure washer heJpfineat 1-800-222-3136,

Pressure Washer Lecation

PressureWasherCJearance

VANNING

Exhaustheat/gases can ignite combustibbs,

structures or damage fuei tank causing a fire.

o Keepatleast5ft. (152crn)clearanceonall sidesof pressure

washerincludingoverhead.

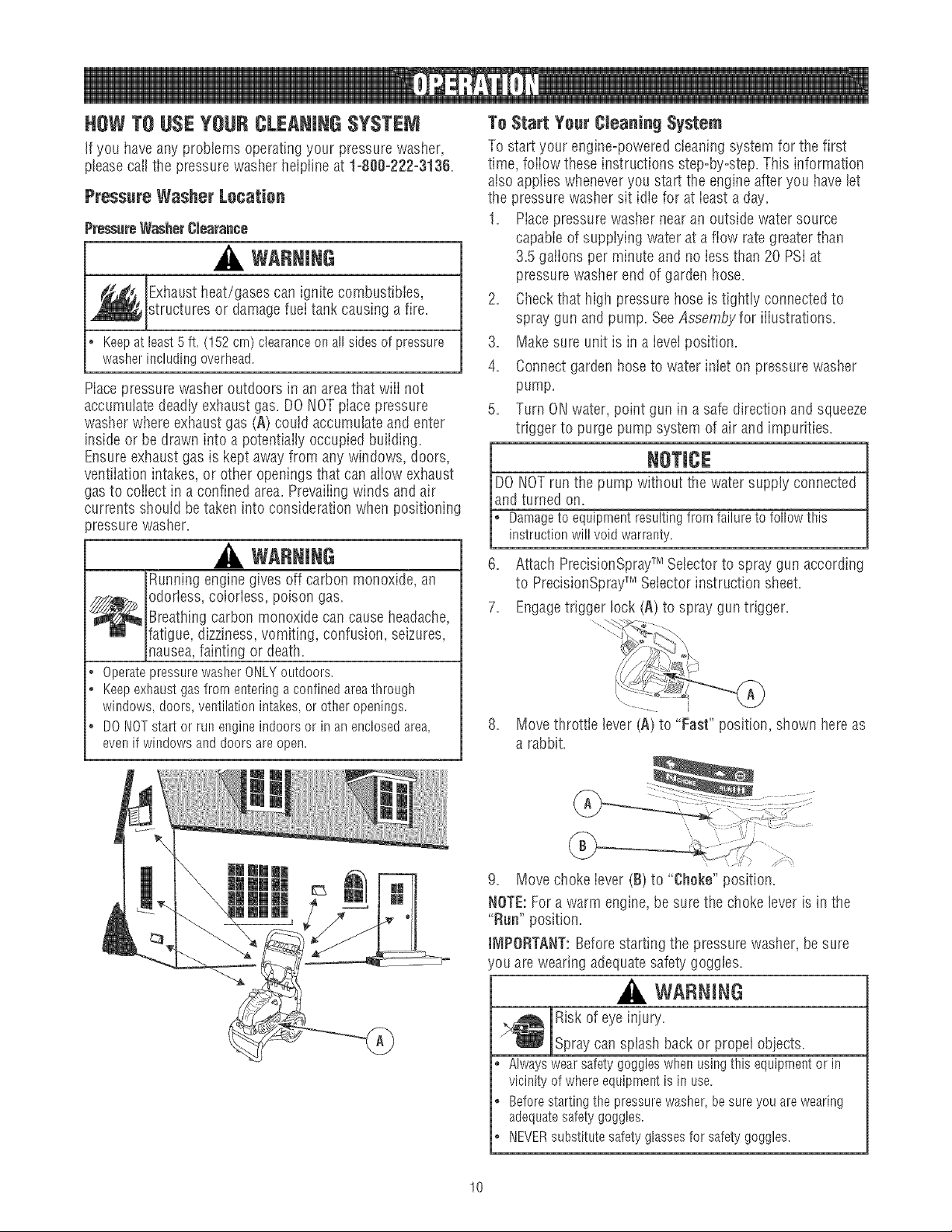

Macepressure washer outdoors in an areathat wiii not

accumulate deadtyexhaustgas. DONOTpiacepressure

washer where exhaustgas (A) could accumulateand enter

inside or be drawn into a potentiaily occupied building.

Ensureexhaust gas is kept awayfrom any windows, doors,

ventiiation intakes, or other openings that can aliow exhaust

gasto coiiect in a confined area. Prevaiiingwinds and air

currents should be taken into considerationwhen positioning

_ressurewasher.

WARNING

Runningengine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathingcarbon monoxide can causeheadache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

° OperatepressurewasherONLYoutdoors.

o Keepexhaustgasfromenteringaconfinedareathrough

windows,doors,ventilationintakes,or otheropenings.

• DONOTstat or runengineindoorsorin anenclosedarea,

evenif windowsanddoorsareopen.

To Start Your CmeaningSystem

To start your engine=poweredcleaning system for the first

time, foiiow these instructions step=by=step.This information

also applies wheneveryou start the engine after you havelet

the pressure washer sit idle for at bast a day.

1= Placepressure washer nearan outside water source

capableof supplying water at a flow rategreater than

3.5 galions per minute and no iess than 20 PSi at

pressurewasher end of garden hose.

2. Checkthat higil pressure hose istightly connectedto

spray gun and pump. SeeAssemby for illustrations.

3. Makesure unit is in a ieveiposition.

4. Connectgarden hose to water intet on pressure washer

pump.

5. Turn ONwater, point gun in a safe direction and squeeze

trigger to purge pump system of air and impurities.

NOTICE

DONOTrun the pump without the water supply connected

and turned on,

t amageto equipmentresultingfrom failureto followthisinstructionwillvoidwarranty.

6. Attach PrecisionSprayTM Selectorto spray gun according

to PrecisionSprayTM Selectorinstruction sheet.

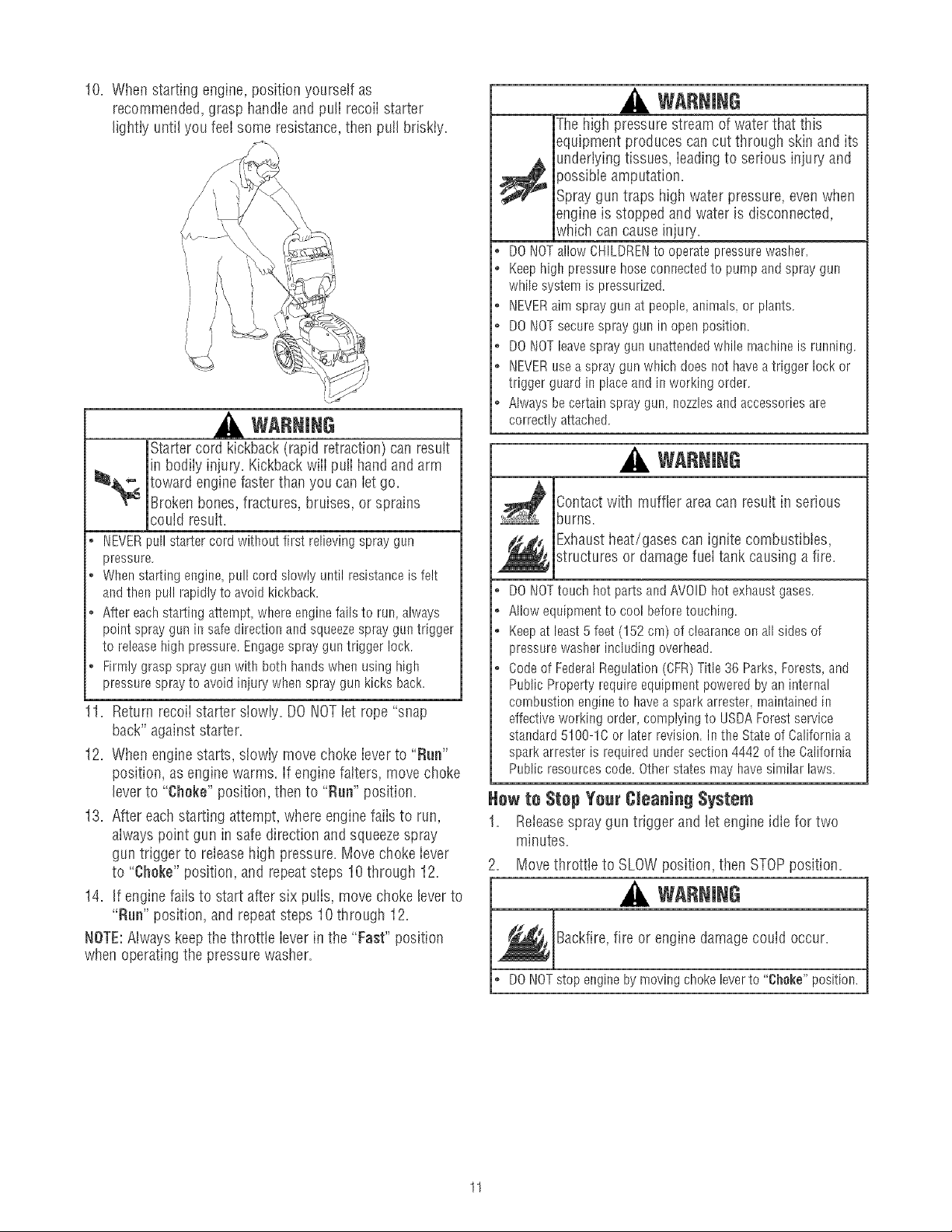

7. Engagetrigger lock (A) to spray gun trigger.

8. Movethrottle lever (A) to "Fast" position, shown hereas

a rabbit.

\

9. Move choke iever (B) to "Choke" position.

NOTE:For a warm engine,be sure the choke leveris in the

"Run" position.

iMPORTANT:Beforestarting the pressurewasher, be sure

ou are wearing adequate safety goggles.

WARNING

>_ iRiskof eYeinjurY.

" |Spraycansplash back or propel objects.

Alwayswearsafetygoggleswhenusingthisequipmentorin

vicinityofwhereequipmentisinuse

Beforestartingthepressurewasher,besureyouarewearing

adequatesafetygoggles.

NEVERsubstitutesafetyglassesforsafetygoggles.

10

lB. Whenstartingengine,positionyourselfas

recommended,grasphandbandpuffrecoiistarter

Jightiyuntilyoufeelsomeresistance,thenpulIbdskiy.

WARNING

Startercord kickback(rapid retraction) can result

in bodily injury. Kickbackwill pulI handand arm

toward enginefaster than youcan iet go.

Brokenbones, fractures, bruises, or sprains

could result.

o NEVERpullstartercordwithoutfirst relievingspraygun

pressure.

• Whenstartingengine_pullcordslowlyuntilresistanceisfelt

andthenpullrapidlyto avoidkickback.

o Aftereachstartingattempt_whereenginefailsto run,always

pointspraygunin safedirectionandsqueezesprayguntrigger

to releasehighpressure.Engagesprayguntriggerlock.

• Firmlygraspspraygunwith bothhandswhenusinghigh

pressuresprayto avoidiniurywhenspraygunkicksback.

1. Return recoii starter slowly. DONOTlet rope "snap

back" against starter.

12. Whenengine starts, slowiy move choke iever to "Run"

position, as engine warms, if engine falters, move choke

leverto "Choke" position, then to "Run" position.

13. After each starting attempt, where engine fails to run,

alwayspoint gun in safe direction and squeezespray

gun trigger to releasehigh pressure. Movechoke lever

to "Choke" position, and repeatsteps 10through 12.

14. If engine faiis to start after six pulis, move choke leverto

"Run" position, and repeatsteps 1Othrough 12.

NOTE:Always keep the throttle ieverin the "Fast" position

when operatingthe pressure washer.

WARNING

Thehigh pressurestream of waterthat thb

equipment produces can cut through skin and its

underlyingtissues, ieadingto serious injury and

)ossible amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

DONOTallowCHILDRENtooperatepressurewasher.

Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

®

NEVERaim spray'gutsatpeople,animals,or plants.

o

DONOTsecurespraygun inopenposition.

®

DONOTleavespraygununattendedwhilernachineis running.

o

NEVERusea spraygunwhichdoesnot haveatriggerlockor

triggerguardin placeandinworkingorder.

Alwaysbecertainspraygun,nozzlesandaccessoriesare

correctlyattached.

WARNING

Contact with muffler area can result in serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

®

DONOTtouchhot partsandAVOIDhotexhaustgases.

o

Allowequipmenttocoolbeforetouching.

o

Keepatleast5 feet(152cm) of clearanceonall sidesof

pressurewasherincludingoverhead.

Codeof FederalRegulation(CFR)Title36 Parks_Forests,and

PublicPropertyrequireequiprnentpoweredby aninternal

combustionengineto haveasparkarrester rnaintainedin

effectiveworkingorder,complyingto USDAForestservice

standard5100-1Cor laterrevision.Inthe Stateof Californiaa

sparkarresteris requiredundersection4442ofthe California

Publicresourcescode.Otherstatesmayhavesimilarlaws.

How te Step Your Cleaning System

1. Reieasespray gun trigger and let engine idle for two

minutes.

2. Movethrottle to SLOWposition, then STOPposition.

WARNING

Backfire,fire or engine damagecould occur.

o DONOTstopenginebymovingchokeleverto "Cheke"position.

11

3. ALWAYSpointsprayguninasafedirectionandsqueeze

sprayguntriggertoreleaseretainedhighwaterpressure.

iMPORTANT:Sprayguntrapshighwaterpressure,even

whenengineisstoppedandwaterisdisconnected.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, ieadingto serious injury and

o Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

• ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressureeverytimeyoustop

engine.Engagetrigger lockwhennotinuse.

4. Engagetrigger lock on spray gun when not in use.

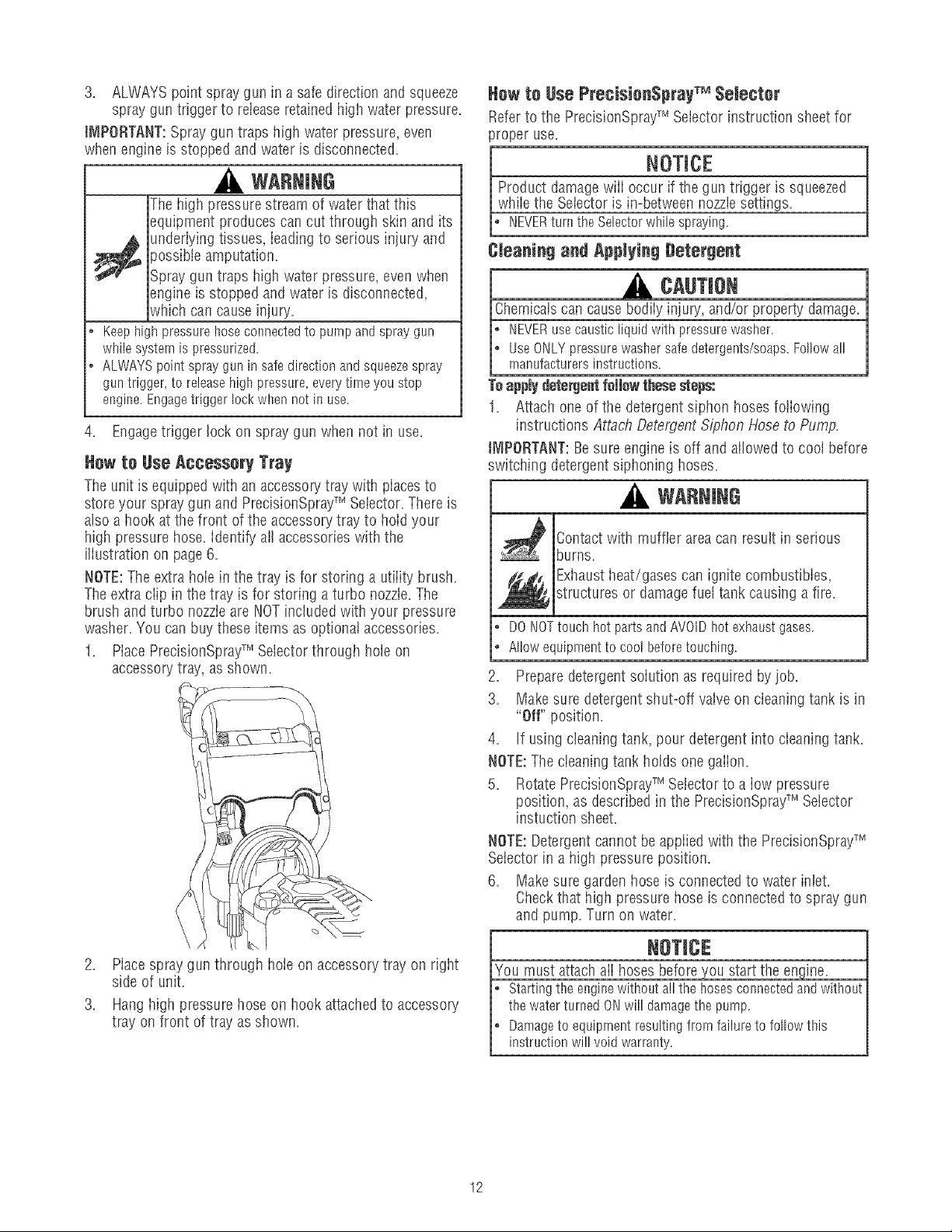

}low te Use Accessory Tray

Theunit is equipped with an accessorytray with placesto

store your spraygun and PrecisionSprayTM Sebctor. Thereis

also a hook at the front of the accessory tray to hoid your

high pressure hose. identify alI accessories with the

iflustration on page 6.

NOTE:The extra hob in the tray is for storing a utiiity brush.

Theextra ciip in thetray is for storing a turbo nozzle.The

brush and turbo nozzieare NOTincludedwith your pressure

washer.You canbuy these items as optional accessories.

1. MacePrecisionSprayTM Selectorthrougll hole on

_ossibteamputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

accessorytray, as shown.

f

How te Use PrecisionSprayTM Selector

Referto the PrecbionSprayTM Selectorinstruction sheet for

proper use.

NOTICE

Product damagewiii occur if the gun trigger is squeezed

while the Seiector is in=behveennozzlesettings.

NEVERturntheSelectorwhilespraying.

Cteaning and Applying Detergent

NEVERusecausticliquidwithpressurewasher.

UseONLYpressurewashersafedetergents/soaps.Followall

rnanufacturersinstructions.

Teapplydetergentfeibw thesesteps:

1. Attach oneof the detergentsiphon hosesfollowing

instructions Attach DetergentSiphon Hoseto Pump.

iMPORTANT:Besure engine is off and allowedto cool before

switching detergent siphoning hoses.

WARNING

Contact with muffler area can result in serious

burns.

Exhaustheat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

• DONOTtouchhotpartsandAVOIDhotexhaustgases.

o Allowequipmentto cool beforetouching.

2. Preparedetergent soiution as required byjob.

3. Makesure detergent shut=off valve on cleaning tank is in

"Off" position.

4. If using cleaning tank, pour detergent into cleaningtank.

NOTE:Thecleaningtank holds one gallon.

5. RotatePrecisionSprayTM Selector to a iow pressure

position, as described in the PrecisionSprayTM Selector

instuction sheet.

NOTE:Detergentcannot be applied with the PrecisionSprayTM

Selector in a higI1pressure position.

6. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

.

Mace spray gun through hoteon accessorytray on rigllt

side of unit.

3.

Hanghigh pressure hose on hook attachedto accessory

tray on front of tray as shown.

You must attach alI hoses before you sta_

Starting the engine without all the hoses connected and without

the water turned ONwill damagethe pump.

Damageto equipment resulting from failure to follow this

instruction will void warranty.

12

7. Engagetriggeriockonspraygunandstartengine

foliowinginstructionsHow to Start Your Pressure

Washe_

8A. If using cleaning tank, rotate detergentshut=off valve on

cbaning tank to ""On"position (A).

/

j/

IMPORTANT:if using detergent siphoning hose, makesure

detergent shut-off valve on cleaningtank is in the "Off"

position.

8B. If using detergentsiphoning hose, piacesmaii fiiter end

of detergentsiphoning tube into detergentcontainer.

NOTICE

Contact with the hot muffler candamagedetergent

siphoning tube.

Wheninee!tingthefilterintoadetergentsolutionbottle,route

thetubeso asto keepit from inadvertentlycontactingthehot

rnuffier.

NOTE:Makesure the filter is fully submerged in detergent

while appiying detergent.

9. Apply detergentto a dry surface,starting at iower

portion of area to be washedand work upward, using

long, even, overiapping strokes.

10. Aliow detergentto "soak in" for 3=5minutes before

washing and rinsing. Re@ptyas neededto prevent

surfacefrom drying. DONOTaiiow detergentto dry on

(prevents streaking).

IMPORTANT:When using the detergentsiphoning hose, you

mustflush the detergentsiphoning system after eachuse by

placingthe fiiter into a bucketof cieanwater, then run the

pressure washer in low pressure for 1=2minutes.

Pressure Washer Rinsing

After detergentis applied, scenrthe _rface andrinseit clean

asfellows:

1. If using cleaning tank, rotate detergentshut-off valve on

cleaningtank to "Off" position.

2. Rotate PrecisionSprayTM Selectorto a high pressure

position, as described in the PrecisionSprayTM Selector

instruction sheet.

3. Keepspray gun a safe distance from spray surface.

WARNING

Kickbackfrom spray gun cancauseyou to fall.

o Operatepressurewasherfrom astablesurface.

o BeextrerneIycarefulifyou mustusethepressurewasherfrom

a ladder,scaffolding,or anyothersimilarlocation.

• Firmlygraspspraygunwithbothhandswhenusinghigh

pressuresprayto avoidinjurywhenspraygunkicksback.

4. Apply a high pressure spray to a small areaand then

check the surface for damage.If no damage,proceedto

step 5.

Start at top of areato be rinsed, working down with

same overiapping strokes usedfor cleaning.

Cteaning Detergent $iphening Tube

If you usedthe detergentsiphoning tube, you must flush it

with cleanwater beforestopping the engine.

1. Engagetrigger iock on spray gun.

2. Piacedetergent siphoning tube/filter in a bucketfull of

ciean water.

RotatePrecisionSprayTM Selector to a iow pressure

position, as described in the PrecisionSprayTM Selector

instruction sheet.

.

Fiushfor 1-2 minutes.

5.

Shut off engine foliowing instructions How to Stop

Pressure Washerand turn off water supply.

6. ALWAYSpoint gun in a safe direction and squeezespray

gun trigger to releaseretained high water pressure.

IMPORTANT:Spraygun traps high water pressure,evenwhen

engineis stoppedand water is disconnected.

WARNING

Thehigh pressurestream of waterthat this

equipment produces can cut through skin and its

_ nderlying tissues, ieadingto serious injury and

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

o ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyou stop

engine.Engagetriggerlockwhennotin use.

}ossibte amputation.

Spray gun traps high water pressure,evenwhen

engine is stopped and water is disconnected,

which can cause injury.

autematic Ceel Dewn System {Thermal lleiief)

If you run the engineon your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reachtemperatures above

125°F.The system engagesto cool the pump by discharging

the warm water onto the grnnnd.

13

ENGINETECHNICALiNFORtViATION

This is a single cylinder, overheadvalve (OHV),air cooled

engine, it is a iow emissions engine.

Inthe Stateof Caiifornia, Model 120000 enginesare certified

by the California Air Resources Boardto meet emissions

standardsfor 125 hours. Such certification does not grant

the purchaser, owner or operator of this engine any

additional warranties with respectto the performance or

operational life of this engine. The engine is warranted soidy

according to the product and emissions warranties stated

elsewherein this manual=

Power Ratings

Thegross power rating for individuaI gas enginemodels is

labeledin accordancewith SAE(Societyof Automotive

Engineers)code J1940 (Small Engine Power & Torque

Rating Procedure),and rating performance has been

obtained andcorrected in accordancewith SAEJ1995

(Revision2002=05).Torque values are derived at3060 RPM;

horsepower values are derivedat 3600 RPM. Actuai gross

engine power wiii be lower and is affected by, among other

things, ambient operating conditions and engine-to-engine

variabiiity. Givenboth the wide array of products on which

enginesare placed and the variety of environmental issues

appiicabb to operatingthe equipment, the gas engine wiii not

developthe rated gross power when used ina given pieceof

power equipment (actual "on-site"or net power). This

difference is due to a variety of factors including, but not

limited to, accessories (air cteaner,exhaust,charging,

cooiing, carburetor, fuel pump, etc.), appiication iimitations,

ambient operating conditions (temperature,humidity,

altitude), and engine-to-engine variabiiity. Due to

manufacturing and capacity iimitations, Briggs & Stratton

maysubstitute an engine of higher ratedpower for this

Seriesengine.

PRODUCTSPECiFiCATiONS

PressureWasherSpecifications

Max Outbt Pressure ....................... 2,700 PSi

Max Ftow Rate............................. 2.5 GPM

DetergentMix ........................ Use as directed

Water SuppiyTemperature .......... Not to exceed 100%

Shipping Weiglst............................. 71 Ibs.

Engine Specifications

Bore ................................. £69 in. (68mm)

Stroke ............................... £04 in. (52ram)

Displacement ........................ 11.57in. (190 cc)

SparkPlug

Type:..................... Briggs & Stratton 491055S

SetGapTo: ...................... O.020inch(O.50mm)

ArrnatureAir Gap: ........... 0.006-0.014in.(O.15-0.36rnm)

Valveclearancewithvalvespringsinstalledand piston1/4in,

(6 turn)pasttopdeadcenter(checkwhenengineiscold),

Intake.................... 0.004°0.006in.(0.10=0.15ram)

Exhaust .................. 0.004-0.008in.(O.10-O.20turn)

FuelCapacity............................... 1.6Quarts

OilCapacity....................... 22 Ounces(0.65liter)

NOTE:For practicai operation, the engine ioad should not

exceed 85% of rated power. Enginepower will decrease

3-I/2% for each 1,000 feet (300 meters) abovesea Ieveiand

1% for each 10° F(5.6° C) above 77° F(25° C). It should

operatesatisfactorily at an angle up to 15°.

14

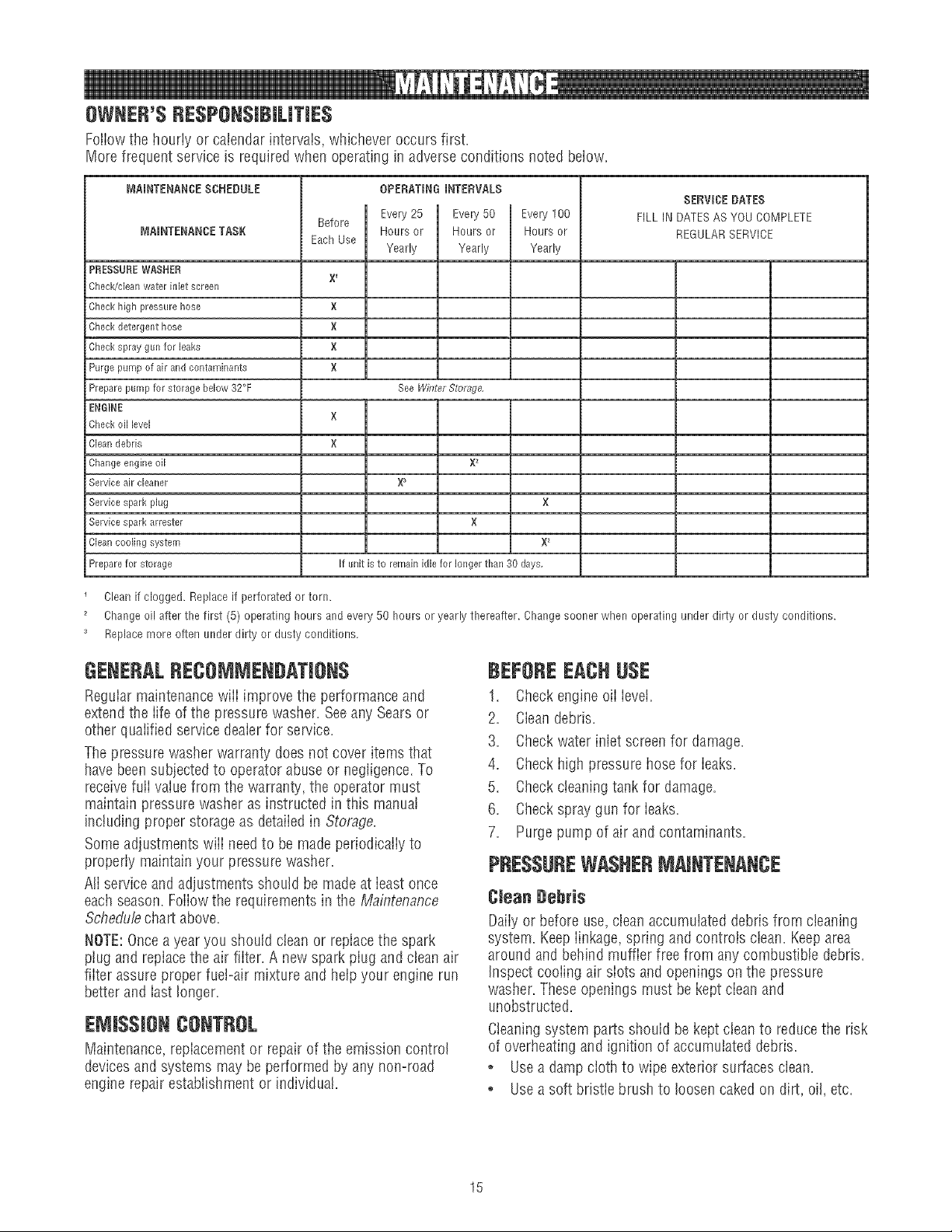

OWNER'SRESPONSiBiLiTIES

Followthe hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MABNTENANCESCHEBULE

_ABNTENANCETASK

PRESSUREWASHER

Chec_dcieanwater inlet screen

Check high pressure hose

Check detergent hose

Checkspray gun for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Check oil level

Clean debris

Changeengine oil

Service air cleaner

Service spark plug

Service spark attester

Clean cooling system

Prepare for storage

Cleanif clogged. Replaceif perforated or torn.

Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

Replacemore often under dirty or dusty conditions,

Before

EachUse

X 1

X

X

X

X

X

X

OPERATINGINTERVALS

Every lO0

Hours or Hours or

Every25 1 Evely 50

Yearly Yearly

See WiRter Storage,

X

If unit is to remain idle for longer than 30 days,

Hours or

Yearly

SERVICEDATES

FILL IN DATESAS YOU COMPLETE

REGULARSERVICE

X

X_

GENERALRECOMMENDATIONS

Reguiarmaintenancewill improve the performanceand

extendthe life of the pressure washer. Seeany Searsor

other qualified service deaierfor service.

Thepressure washer warranty doesnot cover items that

havebeen subjected to operator abuse or negligence.To

receivefuli value from the warranty, the operator must

maintain pressure washer as instructed in this manual

including proper storage as detaiied in Storage.

Someadjustments wili needto be madeperiodicaliy to

properiy maintain your pressure washer.

Ali serviceand adjustments should be madeat ieastonce

eachseason.Foiiow the requirementsin the Maintenance

Schedu/echart above.

NOTE:Oncea year you should clean or replace the spark

ptug and repiacethe air fiiter. A new spark piug and clean air

fiiter assure proper fuel-air mixture and hetpyour engine run

better and iast longer.

EMiSSiONCONTROL

Maintenance,replacementor repair of the emission control

devicesand systems may be performed by any non-road

engine repair establishment or individual.

BEFOREEACHUSE

1. Checkengine oil Ievei.

2. Cleandebris.

3. Checkwater inlet screen for damage.

4. Checkhigh pressure hose for ieaks.

5. Checkcleaning tank for damage.

6. Checkspray gun for ieaks.

7. Purge pump of air and contaminants.

PRESSUREWASHERMAINTENANCE

CmeanDebris

Daily or before use,clean accumuiated debris from cleaning

system. Keeplinkage, spring and controts ctean.Keeparea

around and behind muffler free from any combustible debris.

Inspect cooiing air siots and openings on the pressure

washer. Theseopenings must be kept cleanand

unobstructed.

Cleaningsystem parts should be kept cleanto reducethe risk

of overheating and ignition of accumuiated debris.

o Usea damp cloth to wipe exterior surfaces clean.

, Usea soft bdstie brush to loosencaked on dirt, oil, etc.

15

, Useavacuumcleanerto pickup loose dirt anddebris.

NOTICE

jlmproper treatment of pressurewasher can damageit and

its life.

_horten_ ....

DONOTinsertanyobjectstbroughcoolingslots.

Check and Clean inlet Screen

Examinegarden hose inlet screen. Clean if it is clogged or

replaceif it is torn.

Check High Pressure Hese

High pressure hoses can developleaks from wear, kinking,

or abuse, inspect hose beforeeach use. @eck for cuts,

leaks,abrasions, buiging of cover, or damageor movement

of coupiings. If any of these conditions exist, replacehose

immediately.

WARNING

The high pressure stream of water that this

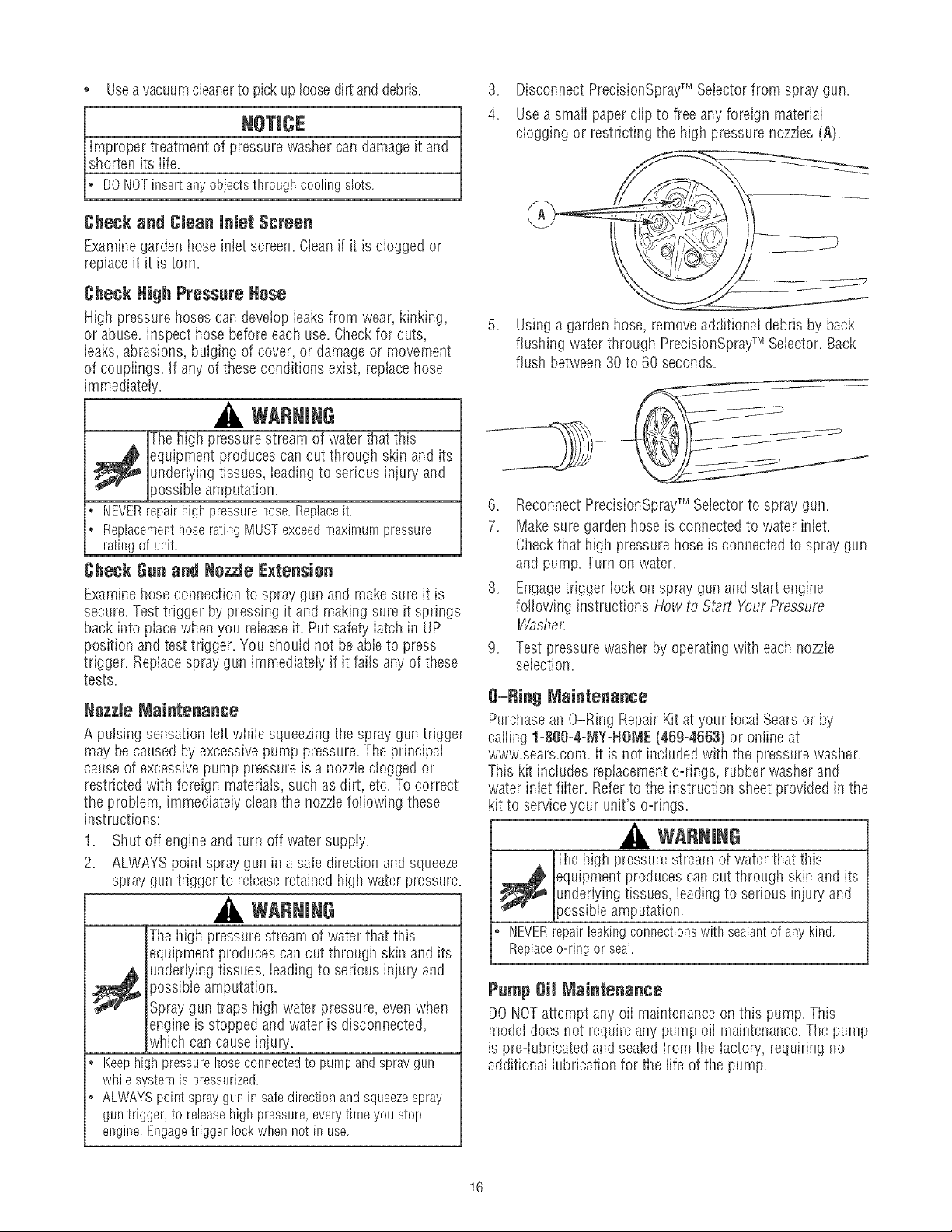

3. Disconnect PrecisionSprayTM Selectorfrom spray gun.

4. Usea smaii paperclip to free any foreign material

clogging or restricting the high pressure nozzies(A).

5. Using a garden hose, removeadditional debris by back

flushing water through PrecisionSprayTM Selector. Back

flush between30 to 60 seconds.

_ quipment produces cancut through skin and its

* NEVERrepairhighpressurehose.Replaceit.

* ReplacementhoseratingMUSTexceedmaxh_nurnpressure

ratingof unit.

underiyingtissues, ieadingto serious injury and

)ossibb amputation.

Check Gun and Hezzle Extensien

Examinehose connection to spray gun and makesure it is

secure.Testtrigger by pressing it and making sure it springs

back into piacewhenyou releaseit. Put safety iatch in UP

position and test trigger. You should not beabie to press

trigger. Replacespray gun immediately if it fails any of these

tests.

Hezzle Maintenance

A pulsing sensationfelt while squeezingthe spray gun trigger

may becaused by excessivepump pressure. Theprincipai

cause of excessivepump pressure is a nozzleclogged or

restricted with foreign materials, such asdirt, etc. Tocorrect

the problem, immediately cleanthe nozzlefollowing these

instructions:

1. Shut off engine and turn off water suppiy.

2. ALWAYSpoint spray gun in a safe direction and squeeze

spray gun trigger to releaseretainedhigh water pressure.

WARNING

Thehigh pressure stream of water that this

equipment produces can cut through skin and its

underiying tissues, ieading to serious injury and

possibie amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which cancause injury.

o Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

* ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyou stop

engine.Engagetrigger lockwhennotinuse.

6. ReconnectPrecisionSprayTM Selectorto spray gun.

7. Makesure garden hose is connectedto water iniet.

Checkthat higil pressure hose is connectedto spray gun

and pump. Turn on water.

8. Engagetrigger Iock on spray gun and start engine

following instructions How to Start Your Pressure

Washe,_

9. Test pressure washer by operating with eachnozzie

selection.

g_lling Maintenance

Purchasean O-Ring RepairKit atyour iocaI Searsor by

cailing l o800-4-MYoHOME(469-4663) or ontineat

www.sears.com, it is not inctuded with the pressure washer.

This kit includes replacemento-rings, rubber washer and

water inlet fiiter. Referto the instruction sheet provided in the

kit to serviceyour unit's o-rings.

WARNING

Thehigh pressurestream of waterthat this

_ quipment produces cancut through skin and its

• NEVERrepairleakingconnectionswitbsealantof anykind.

Replaceo-ringor seal.

Pump Oil Maintenance

DONOTattempt any oiI maintenance on this pump. This

model doesnot require any pump oii maintenance.Thepump

is pre°iubricated and seaiedfrom the factory, requiring no

additional lubrication for the life of the pump.

underlyingtissues, ieadingto serious injury and

}ossibte amputation.

16

ENGINEMAINTENANCE

WARNING

Unintentional sparking can result in fire or

_ electric shock.

WHENADJUSTmNGORMAKmNGREPNRSTO YOURPRESSURE

WASHER

* Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGmNESPARK

* Use approved spark plug tester.

o DO NOTcheckfor spark with spark plug rernoved.

Oil

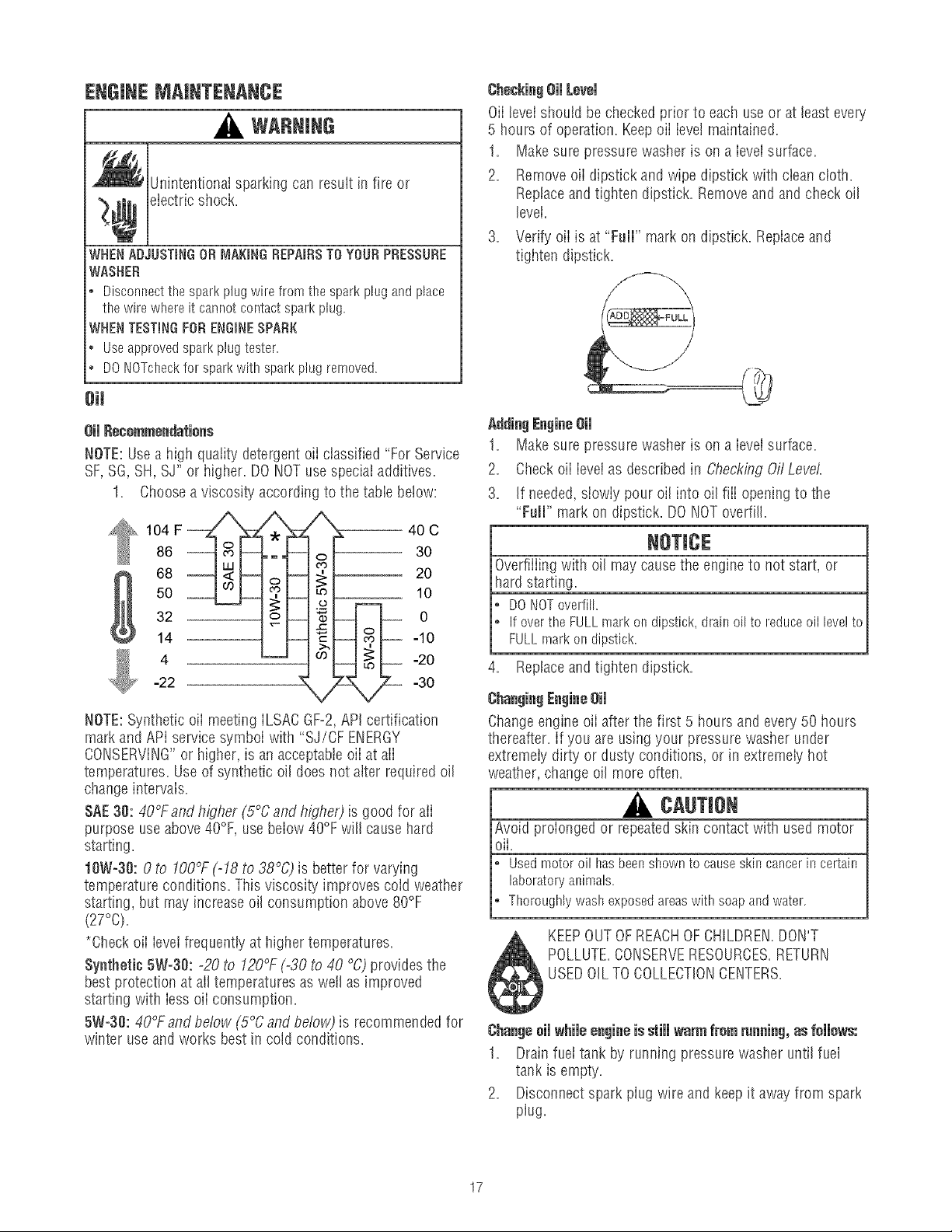

oimRecommendations

NOTE:Usea high quality detergent oiI ciassified "For Service

SF,SG,SH, SJ" or higher. DONOTusespecial additives.

1. Choosea viscosity according to the table below:

CheckingOil Level

OiIlevelshould be checkedprior to each use or at least every

5 hours of operation. Keepoii ievei maintained.

1. Makesure pressure washer is on a ievei surface.

2. Removeoii dipstick and wipe dipstick with clean cioth.

Reptaceandtigilten dipstick. Removeand and check oil

levei.

3. Verify oiI is at "FuIF' mark on dipstick. Replaceand

tighten dipstick.

1. Makesure pressure washer is on a Ieveisurface.

2. Checkoii ievei as described in CheckingOffLevel

3. If needed,siowiy pour oil into oil fiii openingto the

"Full" mark on dipstick. DONOToverfill.

86

68

50

32

104 F

14

4

-22

o 30

20

40 C

10

_ 0

-10

-20

-30

NOTE:Synthetic oii meeting iLSAC GF-2,APIcertification

markand APi service symboi with "SJ/CF ENERGY

CONSERVING"or higher, is anacceptabieoii at aii

temperatures. Useof synthetic oil does not alter required oil

changeintervals.

SAE30: 40°Fand higher (5°C and higher) isgood for aii

purpose useabove40°F, usebelow 40°F will cause hard

starting.

10Wo30:0 to !O0°F(=18to 38°C)is better for varying

temperatureconditions. This viscosity improves coid weather

starting, but may increase oil consumption above80°F

(27%).

*Check oii ievei frequently at higher temperatures,

Synthetic 5w-3g: =20to 120°F(=30to 40 °C) provides the

best protection at all temperatures as well as improved

starting with iess oii consumption,

5W-30: 40°Fand below (5°Cand be/ow) is recommendedfor

winter useand works best in cold conditions.

Overfiiiing with oil may cause the engine to not start, or

hard starting.

DO NOToverfill.

Ifover the FULLmark on dipstick, drain off to reduceoil level to

FULLrnark on dipstick.

4. Replaceand tigllten dipstick.

Changeengine oii after the first 5 hours and every 50 hours

thereafter, if you are usingyour pressure washer under

extremeiy dirty or dusty conditions, or in extremelyhot

weather, changeoil more often.

CAUTION

Avoid proionged or repeatedskin contact with used motor

oil.

Usedmotoroil hasbeenshownto causeskincancerincertain

laboratoryanimals.

Thoroughlywashexposedareaswith soapandwater.

KEEPOUTOFREACHOFCHILDREN.DON'T

POLLUTE.CONSERVERESOURCES.RETURN

USEDOILTOCOLLECTIONCENTERS.

Changeoil whileengineis still warmfromrunning,asfollows:

1. Drainfuel tank by running pressurewasher until fuel

tank is empty.

2. Disconnectspark plug wire and keepit awayfrom spark

plug.

17

Loading...

Loading...